Page 1

Fact Sheet

VLT® AutomationDrive FC 302 with integrated motion controller

– for positioning and synchronization applications

hardware. With sensorless control (no

motor feedback) best performance is

achieved with a PM motor. The performance of sensorless control of induction motors is however sufficient for

less-demanding applications.

With IMC you save time and cost:

No advanced programming and

fewer components means fewer

hours needed for engineering,

installation and commissioning

Save further cost for a feedback

Discover precision positioning and

synchronization control in modern dance

Perform high-precision positioning

and synchronization, simply using an

AC drive. With the Integrated Motion

Controller (IMC) functionality, the

VLT® AutomationDrive FC 302

replaces more complex positioning

and synchronization controllers, to save

time and cost.

Positioning and synchronization

operations are typically performed

using a servo drive or a motion

controller. However, many of these

applications do not actually require

the dynamic performance available

from a servo drive.

Encoderfree

to save costs and

reduce complexity

Therefore the FC 302 with IMC is a costeffective, high-performance alternative

to servo in single-axis positioning and

synchronizing applications.

Use IMC for many applications that

have been solved with servo drives

until now, such as:

Rotary tables

Cutting machines

Packaging machines

Use FC 302 to run an induction or PM

motor with or without motor feed-

back – with no need for additional

Feature Benefit

Motion control functionality

integrated into the AC drive

No encoder and no encoder wiring required

No servo drive required

Configuration via parameters

Home synchronizing

– Renewal of calibration on every cycle

Homing on torque limit

– No sensor required

device, cabling and installation by

using sensorless control

To save cost for a home sensor and

cabling, use the “homing on torque

limit” function

The IMC solution provides

easy and safe set-up:

Configuration via parameters, with

no advanced programming required.

Reduced complexity will minimize

the risk of errors

To add more functionality, use the

Smart Logic Controller (SLC), which

is fully compatible with IMC

To realign the home position

during operation, use the “home

synchronizing” function

– Save cost and time for extra components

– Lower purchase cost due to fewer components

– More robust installation

– Reduced electrical and mechanical

installation time

– Easier and faster set-up

– No advanced programming required

– Lower purchase cost

– Achieve a safe result

– Save time

– Avoid complexity

– Minimize risk of errors associated

with advanced programming

High level of accuracy maintained continuously

–

in systems with slip

– Save purchase, installation and maintenance

cost of extra equipment

www.danfoss.com/imc

Page 2

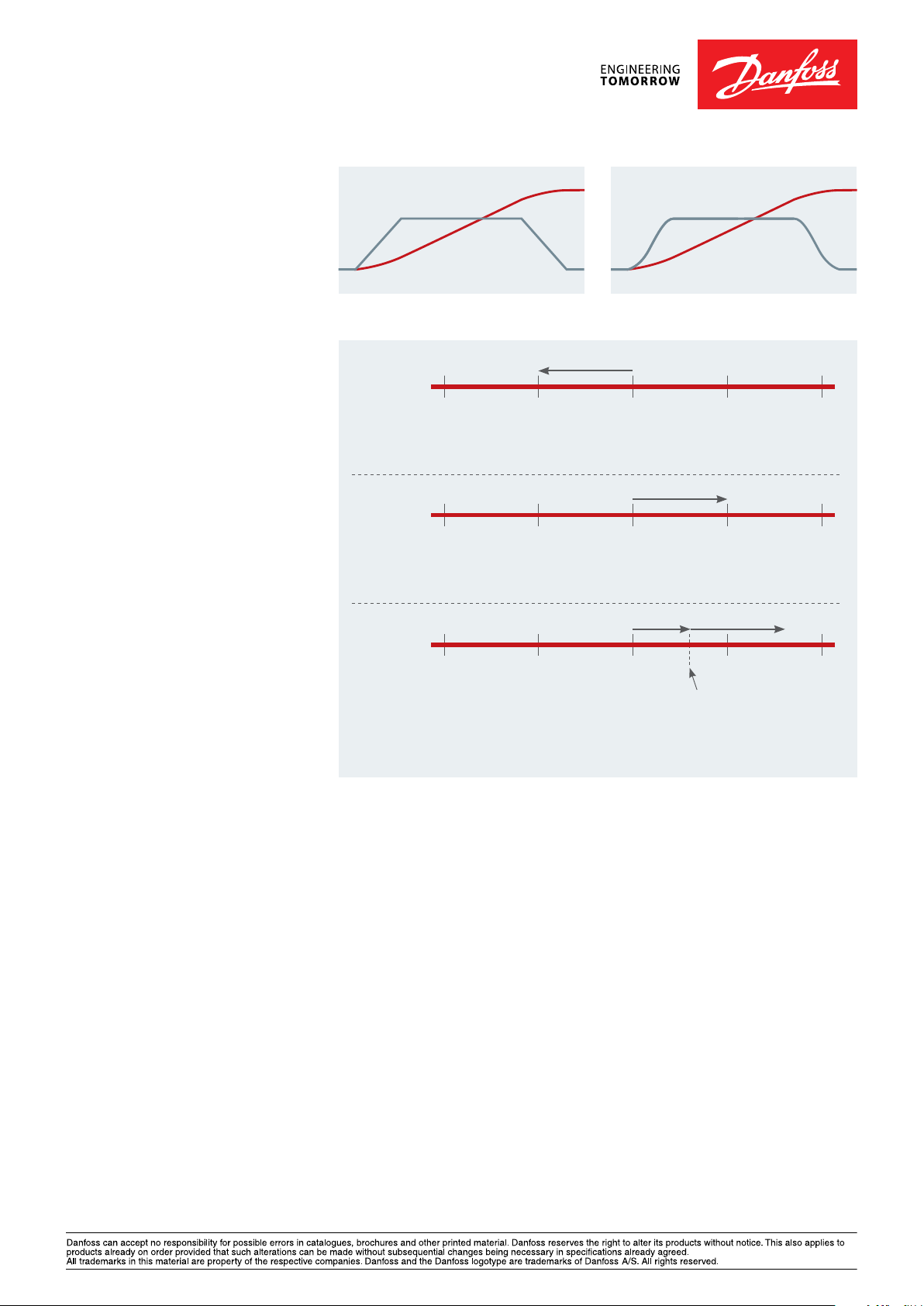

Positioning

In positioning mode, the drive controls

movement over a specific distance

(relative positioning) or to a specific

target (absolute positioning). The drive

calculates the motion profile based on

target position, speed reference and

ramp settings (see the examples in Fig. 1

and Fig. 2 on the right).

There are 3 positioning types using different references for defining the target

position:

Absolute positioning

Target position is relative to the

defined zero point of the machine.

Relative positioning

Target position is relative to

the actual position of the machine.

Touch probe positioning

Target position is relative to a signal

on a digital input

This illustration (Fig. 3) shows the

different resulting target with a set

target position (reference) of 1000 and

starting position of 2000 for each of the

positioning types.

Synchronizing

In synchronizing mode the drive follows the position of a master, multiple

drives can follow the same master. The

master signal can be an external signal

e.g. from an encoder, a virtual master

signal generated by a drive or master

positions transferred by fieldbus. Gear

ratio and position offset is adjustable by

parameter.

Homing

With sensorless control and closed

loop control with an incremental

encoder homing is required to create

a reference for the physical position of

PositionPosition

Speed Speed

Fig. 1. Motion profile with linear ramps Fig. 2. Motion profile with S-ramps

Absolute

0 1000 2000 3000 4000

With absolute positioning, the drive moves backwards from the starting position

of 2000 to the absolute position of 1000 related to 0.

Relative

0 1000 2000 3000 4000

With relative positioning, the drive moves a distance of 1000 forward from

the starting position of 2000 ending at position 3000.

Touch probe

0 1000 2000 3000 4000

Touch probe sensor

With touch probe positioning, the drive starts moving forward from the starting

position of 2000, detects the touch probe sensor and moves a distance of 1000

forward from the position of the touch probe sensor.

Fig. 3. IMC supports 3 positioning modes

the machine after power up. There are

several home functions with and without sensor to choose from. The home

synchronizing function can be used to

continuously realign the home position

during operation when there is some

sort of slip in the system. For example

in case of sensorless control with an

induction motor or in case of slip in the

mechanical transmission.

DKDD.PFF.300.A5.02 © Copyright Danfoss Drives | 2020.09

Loading...

Loading...