Page 1

Design Guide

VLT® AutomationDrive FC 301/302

0.25–75 kW

Page 2

Page 3

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

Contents

1 Introduction 12

1.1 Purpose of this Design Guide 12

1.2 Trademarks 12

1.3 Additional Resources 12

1.4 Document Version 13

1.5 Conventions 13

2 Safety 14

2.1 Safety 14

2.2 Safety Symbols 14

2.3 Qualified Personnel 14

3 Approvals and Certifications 15

3.1 Regulatory/Compliance Approvals 15

3.2 Typical Product Approvals and Certifications for VLT® Drives 15

3.3 Export Control Regulation 18

3.4 Enclosure Protection Rating 18

4 VLT® Product Family Overview 19

4.1 VLT® Drives 19

4.2 Product Overview of the VLT® AutomationDrive FC 301/302 19

4.3 Power Drive Systems 23

4.3.1 Ecodesign for Power Drive Systems 23

4.3.1.1 Losses in Mains Cabling 25

4.3.1.2 Input Filters: Line Reactors and Harmonic Filters 25

4.3.1.3 Drive, Input Side 26

4.3.1.4 DC Link 27

4.3.1.5 Drive, Output Side 28

4.3.1.6 Motor Cables and Motor 29

5 Product Overview 30

5.1 Overview of Drives Systems 30

5.1.1 Filter Options 30

5.1.1.1 Protection of Motor Insulation 31

5.1.1.2 Reduction of Motor Acoustic Noise 31

5.1.1.3 Reduction of High-frequency Electromagnetic Noise in Motor Cables 31

5.1.1.4 Bearing Currents and Shaft Voltage 31

5.1.2 Supported Motor Types 32

5.1.3 Bearing Currents 33

5.2 Integrated Motion Controller 36

AJ286655760917en-000101 / | 3Danfoss A/S © 2019.10

Page 4

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

5.2.1 Positioning, Homing, and Synchronization 36

5.2.1.1 Positioning 36

5.2.1.2 Homing 37

5.2.1.3 Synchronization 37

5.2.1.4 Fieldbus References 38

5.2.2 Control 39

5.2.2.1 Control Loops 39

5.2.2.2 Control and Status Signals 40

5.3 Functional Safety 42

5.3.1 Protection of Personnel and Equipment 42

5.3.2 VLT® Safety Option MCB 150 and MCB 151 42

5.3.3 VLT® Sensorless Safety MCB 159 43

5.3.4 VLT® Safety Option MCB 152 43

5.3.5 Safety Functions 43

5.4 Danfoss VLT® FlexConcept® 45

5.5 Torque Sharing/Droop 46

5.6 Power Limit Function 47

5.7 Service Log 49

5.8 Maintenance Functions 49

6 Product Features 52

6.1 Automated Operational Features 52

6.1.1 Short-circuit Protection 52

6.1.2 Overvoltage Protection 52

6.1.3 Missing Motor Phase Detection 53

6.1.4 Mains Phase Imbalance Detection 53

6.1.5 Switching on the Output 53

6.1.6 Overload Protection 54

6.1.7 Locked Rotor Protection 54

6.1.8 Automatic Derating 54

6.1.8.1 Overview of Automatic Derating 55

6.1.8.2 Sine-wave Filter Fixed Mode 56

6.1.8.3 Overview Table 57

6.1.8.4 High Motor Load 58

6.1.8.5 High Voltage on the DC link 58

6.1.8.6 Low Motor Speed 58

6.1.8.7 High Internal Temperature 59

6.1.8.8 Current 60

6.1.9 Automatic Energy Optimization 60

6.1.10 Automatic Switching Frequency Modulation 61

6.1.11 Automatic Derating for High Switching Frequency 61

6.1.12 Power Fluctuation Performance 61

AJ286655760917en-000101 /4 | Danfoss A/S © 2019.10

Page 5

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

6.1.13 Resonance Damping 61

6.1.14 Temperature-controlled Fans 61

6.1.15 EMC Compliance 61

6.1.16 Galvanic Isolation of Control Terminals 62

6.2 Custom Application Features 62

6.2.1 Automatic Motor Adaptation (AMA) 62

6.2.2 Motor Thermal Protection 62

6.2.3 Motor Thermal Protection for Ex-e or Ex-n Motors 63

6.2.4 Mains Dropout 65

6.2.5 Built-in PID Controller 65

6.2.6 Automatic Restart 65

6.2.7 Flying Start 65

6.2.8 Full Torque at Reduced Speed 65

6.2.9 Frequency Bypass 66

6.2.10 Motor Preheat 66

6.2.11 Programmable Set-ups 66

6.2.12 Smart Logic Controller 66

6.2.13 Safe Torque Off 68

6.3 Dynamic Braking Overview 68

6.4 Mechanical Holding Brake Overview 69

6.4.1 Open-loop Mechanical Brake Control 69

6.4.2 Closed-loop Mechanical Brake Control/Hoist Mechanical Brake 70

6.5 Load Sharing Overview 71

6.5.1 Preconditions and Special Conditions 72

6.5.2 Combinations of Enclosure Sizes 73

6.6 Regen Overview 74

7 Options and Accessories Overview 76

7.1 Introduction 76

7.2 VLT® FC Series Options Concept 76

7.3 VLT® Fieldbus Options 77

7.4 VLT® Functional Extensions 78

7.5 VLT® Programmable Controllers 78

7.6 VLT® Power Options 79

7.6.1 VLT® Harmonic Filters 79

7.6.2 VLT® Sine-wave Filters 79

7.6.3 VLT® dU/dt Filters 80

7.6.4 VLT® Common-mode Filters 80

7.6.5 VLT® Brake Resistors 80

7.6.6 VLT® Line Reactors 81

7.7 Kits and Accessories 81

7.7.1 Panel Through Mounting Kits for VLT® FC Series Enclosure Sizes A, B, and C 81

AJ286655760917en-000101 / | 5Danfoss A/S © 2019.10

Page 6

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

7.7.2 IP21/NEMA Type 1 Enclosure Kits for VLT® FC Series Enclosure Sizes A, B, and C 82

7.7.3 Mounting Brackets for VLT® FC Series Enclosure Sizes A5, B1, B2, C1, and C2 86

7.7.4 Remote Mounting Kits for LCP 88

7.7.4.1 Remote Mounting Kit for LCP 102 and LCP 103 with Cover for Outdoor Mounting 88

7.7.4.2 Panel Mounting Kit for LCP 102, LCP 101, and LCP 103 89

7.7.5 VLT® Wireless Communication Panel LCP 103 and MyDrive® Connect 91

8 Specifications 92

8.1 Enclosure Size by Power Rating 92

8.2 Electrical Data 94

8.2.1 Mains Supply 3x200–240 V AC, T2 94

8.2.2 Mains Supply 3x380–480 V AC, FC 301 T4 and 3x380–500 V AC, FC 302 T5 97

8.2.3 Mains Supply 3x525–600 V AC, T6 101

8.2.4 Mains Supply 3x525–690 V AC, T7 105

8.2.5 Power Cable Cross-sections 108

8.3 Mains Supply 109

8.4 Motor Output and Motor Data 109

8.4.1 Motor Output (U, V, W) 109

8.4.2 Torque Characteristics 110

8.5 Ambient Conditions 110

8.6 Cable Specifications 111

8.6.1 Cable Lengths and Cross-sections for Control Cables 111

8.7 Control Input/Output and Control Data 111

8.7.1 Digital Inputs 111

8.7.2 STO Terminal 37 111

8.7.3 Analog Inputs 112

8.7.4 Pulse/Encoder Inputs 112

8.7.5 Digital Outputs 113

8.7.6 Analog Output 113

8.7.7 Control Card, 24 V DC Output 114

8.7.8 Control Card, +10 V DC Output 114

8.7.9 Control Card, RS485 Serial Communication 114

8.7.10 Control Card, USB Serial Communication 114

8.7.11 Relay Outputs 114

8.7.12 Control Card Performance 115

8.7.13 Control Characteristics 115

8.8 Connection Tightening Torques 116

8.9 Power Ratings, Weight, and Dimensions 117

9 Mechanical Installation Considerations 122

9.1 Storage 122

9.2 Operating Environment 122

AJ286655760917en-000101 /6 | Danfoss A/S © 2019.10

Page 7

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

9.2.1 Gases 122

9.2.2 Dust 123

9.2.3 Outdoor Installation in freezing Temperature Environments 124

9.2.4 Potentially Explosive Atmospheres 125

9.2.5 Vibration and Shock 126

9.2.6 Maintenance 126

9.3 Mounting Configurations 126

9.3.1 Side-by-side Mounting 126

9.3.2 Wall Mounting 128

9.4 Derating 129

9.4.1 Derating for Running at Low Speed 129

9.4.2 Derating for Low Air Pressure 130

9.4.3 Derating for Ambient Temperature and Switching Frequency 131

9.4.3.1 Derating for Ambient Temperature, Enclosure Size A 131

9.4.3.2 Derating for Ambient Temperature, Enclosure Size B 132

9.4.3.3 Derating for Ambient Temperature, Enclosure Size C 137

10 Electrical Installation Considerations 141

10.1 Safety Instructions 141

10.2 Wiring Schematic 143

10.3 Connections 144

10.3.1 Power Connections 144

10.3.2 IT Grid Connection 145

10.3.3 DC Bus Connection 146

10.3.4 Load Sharing Connection 146

10.3.5 Brake Cable Connection 147

10.3.6 Grounding 147

10.3.7 Safety Ground Connection 147

10.4 Cables 147

10.4.1 EMC-correct Cables 147

10.4.2 Preparing Cable Entry Holes 149

10.4.3 Specifications of Entry Holes 149

10.4.3.1 Entry Holes, Enclosure Size A2, IP21 149

10.4.3.2 Entry Holes, Enclosure Size A3, IP21 150

10.4.3.3 Entry Holes, Enclosure Size A4, IP55 150

10.4.3.4 Entry Holes, Enclosure Size A4, IP55 Threaded Gland Holes 151

10.4.3.5 Entry Holes, Enclosure Size A5, IP55 151

10.4.3.6 Entry Holes, Enclosure Size A5, IP55 Threaded Gland Holes 152

10.4.3.7 Entry Holes, Enclosure Size B1, IP21 152

10.4.3.8 Entry Holes, Enclosure Size B1, IP55 153

10.4.3.9 Entry Holes, Enclosure Size B1, IP55 Threaded Gland Holes 153

10.4.3.10 Entry Holes, Enclosure Size B2, IP21 154

AJ286655760917en-000101 / | 7Danfoss A/S © 2019.10

Page 8

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

10.4.3.11 Entry Holes, Enclosure Size B2, IP55 155

10.4.3.12 Entry Holes, Enclosure Size B2, IP55 Threaded Gland Holes 155

10.4.3.13 Entry Holes, Enclosure Size B3, IP21 156

10.4.3.14 Entry Holes, Enclosure Size C1, IP21 156

10.4.3.15 Entry Holes, Enclosure Size C2, IP21 157

10.4.4 Tightening Torques for Cover 157

10.5 Control Wiring and Terminals 158

10.5.1 Shielded Control Cables 158

10.5.2 Wiring to Control Terminals 159

10.5.3 Control Terminal Types 160

10.5.4 Terminal Descriptions 161

10.6 Fuses and Circuit Breakers 162

10.6.1 Fuse Recommendations 162

10.6.2 CE Compliance 163

10.6.3 UL Compliance 166

10.7 Relays 168

10.7.1 Overview of Relay Terminals 170

10.8 Disconnects and Contactors 171

10.9 Motor 173

10.9.1 Motor Thermal Protection 174

10.9.2 Parallel Connection of Motors 174

10.9.3 Motor Insulation 175

10.9.4 Motor Bearing Currents 176

10.10 Braking 176

10.10.1 Selection of Brake Resistor 176

10.10.2 Control with Brake Function 179

10.11 Residual Current Device 180

10.12 Leakage Current 180

10.12.1 Using a Residual Current Device (RCD) 182

10.13 Efficiency 183

10.14 Acoustic Noise and Airflow 184

10.15 dU/dt Conditions 185

10.15.1 dU/dt Values, 200–240 V (T2) 186

10.15.1.1 dU/dt Values for P5K5T2, 200–240 V 186

10.15.1.2 dU/dt Values for P7K5T2, 200–240 V 186

10.15.1.3 dU/dt Values for P11KT2, 200–240 V 186

10.15.1.4 dU/dt Values for P15KT2, 200–240 V 187

10.15.1.5 dU/dt Values for P18KT2, 200–240 V 187

10.15.1.6 dU/dt Values for P22KT2, 200–240 V 187

10.15.1.7 dU/dt Values for P30KT2, 200–240 V 187

10.15.1.8 dU/dt Values for P37KT2, 200–240 V 187

10.15.2 dU/dt Values, 380–480 V (T4) 188

AJ286655760917en-000101 /8 | Danfoss A/S © 2019.10

Page 9

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

10.15.2.1 dU/dt Values for P1K5T4, 380–480 V 188

10.15.2.2 dU/dt Values for P4K0T4, 380–480 V 188

10.15.2.3 dU/dt Values for P7K5T4, 380–480 V 188

10.15.2.4 dU/dt Values for P11KT4, 380–480 V 188

10.15.2.5 dU/dt Values for P15KT4, 380–400 V 189

10.15.2.6 dU/dt Values for P18KT4, 380–480 V 189

10.15.2.7 dU/dt Values for P22KT4, 380–480 V 189

10.15.2.8 dU/dt Values for P30KT4, 380–480 V 189

10.15.2.9 dU/dt Value for P37KT4, 380–480 V 190

10.15.2.10dU/dt Values for P45KT4, 380–480 V 190

10.15.3 dU/dt Values, 380–500 V (T5) 190

10.15.3.1 dU/dt Values for P55KT5, 380–500 V 190

10.15.3.2 dU/dt Values for P75KT5, 380–500 V 190

10.15.4 dU/dt Values, 600 V (T6) 190

10.15.4.1 dU/dt Values for P15KT6, 600 V 191

10.15.4.2 dU/dt Values for P30KT6, 600 V 191

10.15.4.3 dU/dt Values for P75KT6, 600 V 191

10.15.5 dU/dt Values, 525–690 V (T7) 191

10.15.5.1 dU/dt Values for P7K5T7, 525–690 V 191

10.15.5.2 dU/dt Values for P45KT7, 525–690 V 192

10.16 Electromagnetic Compatibility (EMC) Overview 192

10.16.1 EMC Test Results 192

10.16.2 Emission Requirements 193

10.16.3 Immunity Requirements 194

10.16.4 EMC Compatibility 196

10.17 EMC-compliant Installation 197

10.18 Harmonics Overview 200

10.18.1 Harmonics Analysis 200

10.18.2 Effect of Harmonics in a Power Distribution System 201

10.18.3 IEC Harmonic Standards 202

10.18.4 Harmonic Results (Emission) 203

10.18.5 Harmonic Mitigation 204

10.18.6 Harmonic Calculation 205

10.18.7 Line Reactors 205

11 Basic Operating Principles 206

11.1 Introduction 206

11.2 Drive Controls 206

11.2.1 Control Principle 206

11.2.2 Local (Hand On) and Remote (Auto On) Control 207

11.3 Reference Limits 209

11.4 PID Control 211

AJ286655760917en-000101 / | 9Danfoss A/S © 2019.10

Page 10

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

11.4.1 Speed PID Control 211

11.4.2 Tuning PID Speed Control 212

11.4.3 Process PID Control 212

11.4.4 Advanced PID Control 213

11.5 More Operating Principles 213

11.5.1 FC 301 versus FC 302 Control Principle 214

11.5.2 Control Structure in VVC+ 215

11.5.3 Control Structure in Flux Sensorless 216

11.5.4 Control Structure in Flux with Motor Feedback 217

12 How to Order a Drive 218

12.1 Drive Configurator 218

12.1.1 Type Code 218

12.1.2 Language Packages 221

12.2 Order Numbers for Options and Accessories 222

12.2.1 Order Numbers for Options for Slot A 222

12.2.2 Order Numbers for Options for Slot B 222

12.2.3 Order Numbers for Options for Slot C 223

12.2.4 Order Numbers for Options for Slot D 223

12.2.6 Order Numbers for Miscellaneous Hardware 224

12.2.7 Order Numbers for Local Control Panel Options 225

12.2.8 Order Numbers for PC Software 226

12.2.9 Ordering of VLT® Brake Resistors MCE 101 226

12.2.9.1 Order Numbers for Brake Resistors FC 301, T2, Horizontal Braking 10% Duty Cycle 227

12.2.9.2 Order Numbers for Brake Resistors FC 301, T2, Vertical Braking 40% Duty Cycle 228

12.2.9.3 Order Numbers for Brake Resistors FC 301, T2, Flat-pack for Horizontal Conveyors 229

12.2.9.4 Order Numbers for Brake Resistors FC 301, T4, Horizontal Braking 10% Duty Cycle 229

12.2.9.5 Order Numbers for Brake Resistors FC 301, T4, Vertical Braking 40% Duty Cycle 231

12.2.9.6 Order Numbers for Brake Resistors FC 301, T4, Flat-pack for Horizontal Conveyors 232

12.2.9.7 Order Numbers for Brake Resistors FC 302, T2, Horizontal Braking 10% Duty Cycle 232

12.2.9.8 Order Numbers for Brake Resistors FC 302, T2, Vertical Braking 40% Duty Cycle 233

12.2.9.9 Order Numbers for Brake Resistors FC 302, T2, Flat-pack for Horizontal Conveyors 234

12.2.9.10 Order Numbers for Brake Resistors FC 302, T5, Horizontal Braking 10% Duty Cycle 235

12.2.9.11 Order Numbers for Brake Resistors FC 302, T5, Vertical Braking 40% Duty Cycle 236

12.2.9.12 Order Numbers for Brake Resistors FC 302, T5, Flat-pack for Horizontal Conveyors 237

12.2.9.13 Order Numbers for Brake Resistors FC 302, T6, Horizontal Braking 10% Duty Cycle 237

12.2.9.14 Order Numbers for Brake Resistors FC 302, T6, Vertical Braking 40% Duty Cycle 239

12.2.9.15 Order Numbers for Brake Resistors FC 302, T7, Vertical Braking 40% Duty Cycle 240

12.2.10 Order Numbers for Accessory Bags 241

12.2.11 Ordering of Harmonic Filters 241

12.2.11.1 Order Numbers for Harmonic Filters, 380–415 V, 50 Hz 242

12.2.11.2 Order Numbers for Harmonic Filters, 380–415 V, 60 Hz 243

AJ286655760917en-000101 /10 | Danfoss A/S © 2019.10

Page 11

ContentsDesign Guide | VLT® AutomationDrive FC 301/302

12.2.11.3 Order Numbers for Harmonic Filters, 440–480 V, 60 Hz 245

12.2.11.4 Order Numbers for Harmonic Filters, 600 V, 60 Hz 246

12.2.11.5 Order Numbers for Harmonic Filters, 500–690 V, 50 Hz 248

12.2.12 Order Numbers for VLT® Sine-wave Filters MCC 101 249

12.2.13 Order Numbers for VLT® dU/dt Filters MCC 102 250

12.2.15 Spare Parts 252

13 Appendix 253

13.1 Symbols and Abbreviations 253

AJ286655760917en-000101 / | 11Danfoss A/S © 2019.10

Page 12

Design Guide | VLT® AutomationDrive FC 301/302

Introduction

1 Introduction

1.1 Purpose of this Design Guide

This Design Guide is intended for qualified personnel, such as:

• Project and systems engineers.

• Design consultants.

• Application and product specialists.

The Design Guide provides technical information to understand the capabilities of the VLT® AutomationDrive FC 301/FC 302 for

integration into motor control and monitoring systems. Its purpose is to provide design considerations and planning data for

integration of the drive into a system. It caters for selection of drives and options for a diversity of applications and installations.

Reviewing the detailed product information in the design stage enables developing a well-conceived system with optimal

functionality and efficiency.

This manual is targeted at a worldwide audience. Therefore, wherever occurring, both SI and imperial units are shown.

1.2 Trademarks

VLT® is a registered trademark for Danfoss A/S.

1.3 Additional Resources

Various resources are available to understand advanced drive operation, programming, and directives compliance.

• The VLT® AutomationDrive FC 301/302 Operating Guide provides detailed information for the installation and start-up of the

drive.

• The VLT® AutomationDrive FC 301/302 Programming Guide provides greater detail on how to work with parameters. It also

contains application examples.

• The VLT® Condition-based Monitoring Programming Guide provides information on working with condition-based monitoring

parameters on the VLT® FC series AC drives.

• The VLT® Integrated Motion Control Application Guide provides information on working with the Integrated Motion Controller

(IMC) feature. The guide shows application examples, and presents the functionalities while showing required parameter settings

and connections.

• The VLT® Safe Torque Off Operating Guide describes how to use Danfoss VLT® drives in functional safety applications. This

manual is supplied with the drive when the Safe Torque Off option is present.

• The VLT® Brake Resistor MCE 101 Design Guide describes how to select the optimal brake resistor.

• The VLT® Advanced Harmonic Filters AHF 005/AHF 010 Design Guide describes harmonics, various mitigation methods, and

the operation principle of the advanced harmonic filter. This guide also describes how to select the correct advanced harmonics

filter for a particular application.

• The Output Filter Design Guide explains why it is necessary to use output filters for certain applications and how to select the

optimal dU/dt or sine-wave filter.

• Supplemental publications, drawings, EPLAN macros, and manuals are available at

Optional equipment is available that may change some of the information described in these publications. Be sure to follow the

instructions supplied with the options for specific requirements.

www.danfoss.com.

Contact a Danfoss supplier or visit www.danfoss.com for more information.

12 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 13

Design Guide | VLT® AutomationDrive FC 301/302

1.4 Document Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

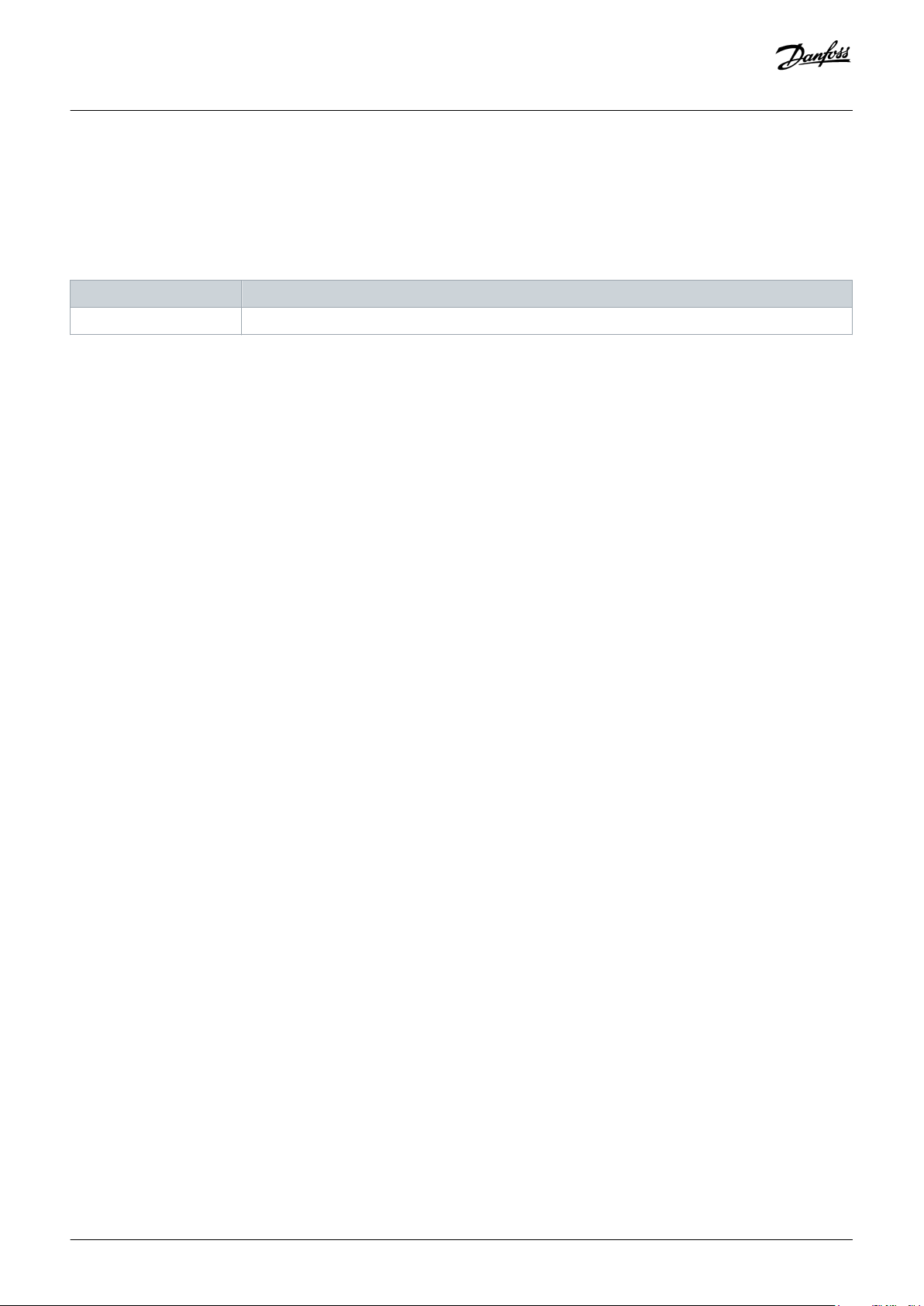

Table 1: Document Version

Edition Remarks

MG33BGxx New document structure. All chapters updated.

1.5 Conventions

• Numbered lists indicate procedures.

• Bulleted and dashed lists indicate listings of other information where the order of the information is not relevant.

• Bolded text indicates highlighting and section headings.

• Italicized text indicates the following:

- Cross-reference.

- Link.

- Footnote.

- Parameter name.

- Parameter option.

- Parameter group name.

- Alarms/warnings.

• All dimensions in drawings are in metric values (imperial values in brackets).

• An asterisk (*) indicates the default setting of a parameter.

Introduction

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 13

Page 14

Design Guide | VLT® AutomationDrive FC 301/302

Safety

2 Safety

2.1 Safety

When designing AC drives, some residual dangers cannot be avoided constructively. One example is the discharge time, which is very

important to observe to avoid potential death or serious injury. For the Danfoss VLT® drives, the discharge time is from 4–40 minutes

depending on the drive size.

For further information on safety precautions, refer to the product-specific Operating Guide.

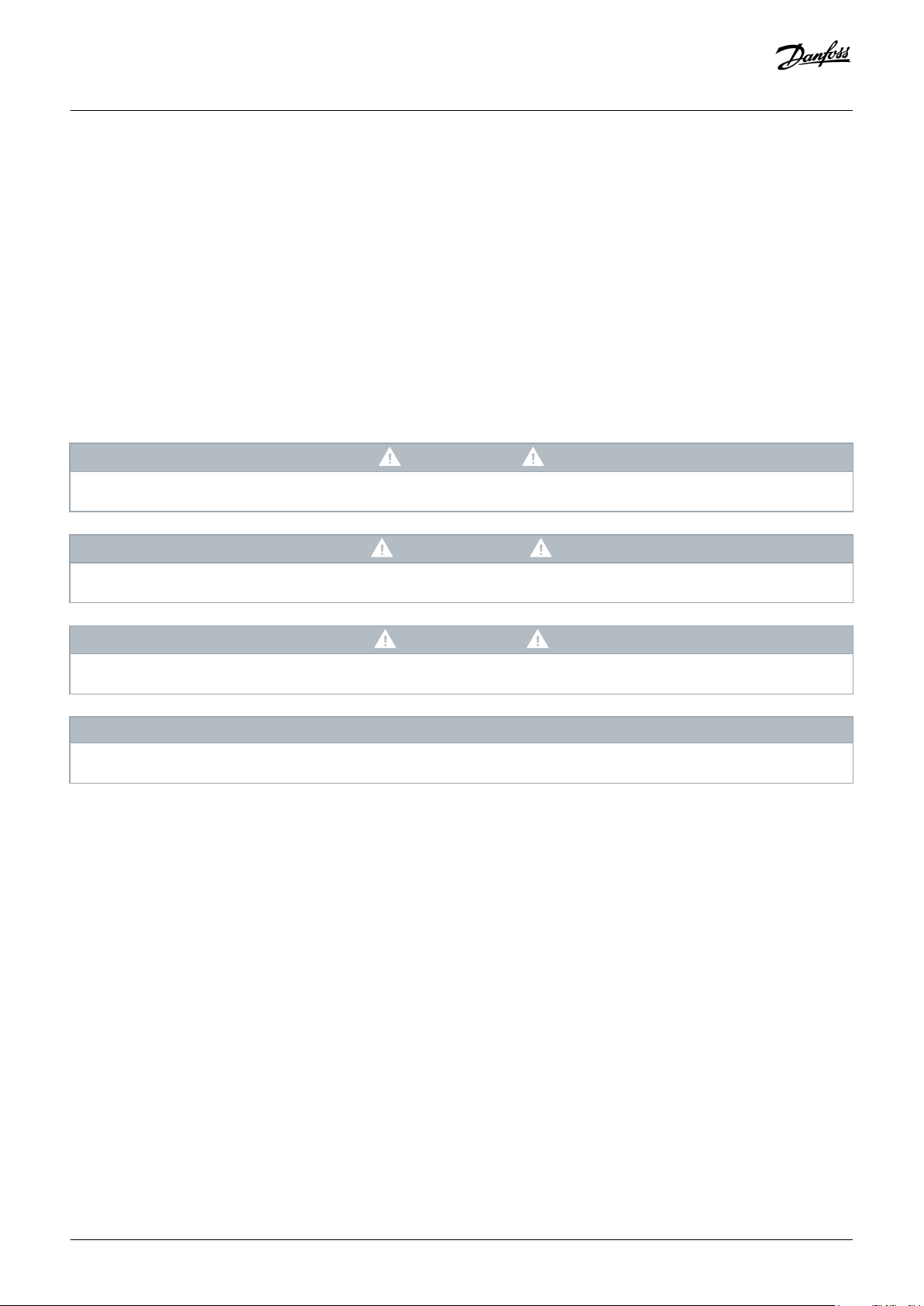

2.2 Safety Symbols

The following symbols are used in this manual:

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

2.3 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store,

assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

• Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

• Are familiar with the basic regulations concerning health and safety/accident prevention.

• Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in the

Operating Guide.

• Have good knowledge of the generic and specialist standards applicable to the specific application.

14 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 15

Design Guide | VLT® AutomationDrive FC 301/302

Approvals and Certifications

3 Approvals and Certifications

3.1 Regulatory/Compliance Approvals

This section provides a brief description of the various approvals and certifications that are on Danfoss VLT® drives. Not all approvals

are on all drives.

NOTICE

IMPOSED LIMITATIONS ON THE OUTPUT FREQUENCY

From software version 6.72 onwards, the output frequency of the drive is limited to 590 Hz due to export control regulations.

Software versions 6.xx also limit the maximum output frequency to 590 Hz, but these versions cannot be flashed, that is,

neither downgraded nor upgraded.

3.2 Typical Product Approvals and Certifications for VLT® Drives

The VLT® AutomationDrive product series complies with a wide scope of required standards and directives. Information on the specific

product certifications can be found on the product nameplate.

3.2.1 CE Mark

The drive complies with relevant directives and their related standards for the extended Single Market in the European Economic Area.

Table 2: EU directives applicable to drives

EU Directive Version

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

Machinery Directive

(1)

ErP Directive 2009/125/EU

ATEX Directive 2014/34/EU

RoHS Directive

Radio Equipment Directive

(2)

(3)

REACH Directive 1907/2006/EC

1

Machinery Directive conformance is only required for drives with an integrated safety function.

2

For China RoHS, contact Danfoss application support to get the certificate.

3

Radio Equipment Directive is only required for interfaces supporting wireless communication.

2014/42/EU

2011/65/EU

2014/53/EU

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 15

Page 16

Design Guide | VLT® AutomationDrive FC 301/302

Approvals and Certifications

3.2.2 Low Voltage Directive

The aim of the Low Voltage Directive is to protect persons, domestic animals and property against dangers caused by the electrical

equipment, when operating electrical equipment that is installed and maintained correctly, in its intended application. The directive

applies to all electrical equipment in the 50–1000 V AC and the 75–1500 V DC voltage ranges.

3.2.3 EMC Directive

The purpose of the EMC (electromagnetic compatibility) Directive is to reduce electromagnetic interference and enhance immunity of

electrical equipment and installations. The basic protection requirement of the EMC Directive states that devices that generate

electromagnetic interference (EMI), or whose operation could be affected by EMI, must be designed to limit the generation of

electromagnetic interference and shall have a suitable degree of immunity to EMI when properly installed, maintained, and used as

intended. Electrical equipment devices used alone or as part of a system must bear the CE mark. Systems do not require the CE mark,

but must comply with the basic protection requirements of the EMC Directive.

3.2.4 Machinery Directive

The aim of the Machinery Directive is to ensure personal safety and avoid property damage to mechanical equipment used in its

intended application. The Machinery Directive applies to a machine consisting of an aggregate of interconnected components or

devices of which at least 1 is capable of mechanical movement. Drives with an integrated functional safety function must comply with

the Machinery Directive. Drives without a functional safety function do not fall under the Machinery Directive. If a drive is integrated

into a machinery system, Danfoss can provide information on safety aspects relating to the drive. When drives are used in machines

with at least 1 moving part, the machine manufacturer must provide a declaration stating compliance with all relevant statutes and

safety measures.

3.2.5 ErP Directive

The ErP directive is the European Ecodesign Directive for energy-related products. The directive sets ecodesign requirements for

energy-related products, including drives, and aims at reducing the energy consumption and environmental impact of products by

establishing minimum energy-efficiency standards.

3.2.6 ATEX Directive

Illustration 1: ATEX Logo

3.2.7 Radio Equipment Directive

Devices that emit or receive radio waves as part of radio communication are required to comply with the Radio Equipment Directive.

The drive itself does not contain a radio device, and hence compliance to the directive is not relevant. However, user interfaces

containing active radio devices, such as the integrated control panel with wireless communication capabilities, comply with the

directive.

16 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 17

089

Design Guide | VLT® AutomationDrive FC 301/302

Approvals and Certifications

3.2.8 UL Listing

3.2.9 CSA/cUL

3.2.10 TÜV

TÜV is a European safety organization which certifies the functional safety of the drive in accordance to EN/IEC 61800-5-2. The TÜV

both tests products and monitors their production to ensure that companies stay compliant with their regulations.

3.2.11 EAC

Illustration 2: EAC Mark

The EAC logo must be both on the product label and on the packaging label. All products used within the EAC area, must be bought at

Danfoss inside the EAC area.

3.2.12 UkrSEPRO

Illustration 3: UkrSEPRO Mark

3.2.13 RCM Mark Compliance

Illustration 4: RCM Mark

3.2.14 Marine Type Approvals

VLT® AutomationDrive drives have several marine type approvals. For a list of the approvals and certifications, see the FC 301/FC 302

product page at www.danfoss.com.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 17

Page 18

Design Guide | VLT® AutomationDrive FC 301/302

Approvals and Certifications

3.2.15 Moroccan Conformity Mark

Illustration 5: Morocco CMIM Mark

The drive complies with relevant directives and their related standards for the Morocco market.

3.3 Export Control Regulation

AC drives can be subject to regional and/or national export control regulations. Both the EU and USA have regulations for so-called

dual-use products (products for both military and non-military use), which currently includes AC drives with a capacity to operate 600–

2000 Hz. These products can still be sold, but it requires a set of measures, for example a license, or an end-user statement.

An ECCN number is used to classify all AC drives that are subject to export control regulations. The ECCN number is provided in the

documentation accompanying the AC drive. If the AC drive is re-exported, it is the responsibility of the exporter to ensure compliance

with the relevant export control regulations.

For further information, contact Danfoss Drives Global or the local sales office.

3.4 Enclosure Protection Rating

The VLT® drive series are available in various enclosure protection ratings to accommodate the needs of the application. Enclosure

protection ratings are provided based on 2 international standards:

• UL type validates that the enclosures meet NEMA (National Electrical Manufacturers Association) standards. The construction and

testing requirements for enclosures are provided in NEMA Standards Publication 250-2003 and UL 50, 11th edition.

• IP (Ingress Protection) ratings outlined by the IEC (International Electrotechnical Commission) in the rest of the world. The standard

Danfoss VLT® drive series are available in various enclosure protections to meet the requirements of IP00 (Chassis), IP20 (Protected

chassis), IP21 (NEMA Type 1), or IP54 (NEMA Type 12). In this manual, NEMA Type is written as Type, for example, IP21/Type 1.

18 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 19

Design Guide | VLT® AutomationDrive FC 301/302

VLT® Product Family Overview

4 VLT® Product Family Overview

4.1 VLT® Drives

Danfoss offers 3 types of AC drives in different-sized enclosures for a wide range of applications, with power ratings from 0.25–1200 kW

(0.34–1350 hp).

Standalone drives (frequency converters)

The Danfoss standalone drives are so robust that they can be mounted outside of cabinets virtually anywhere, even right beside the

motor. Equipped for the toughest of environment, they suit any application.

More uncompromising features:

• Enclosure sizes with protection ratings up to IP54/UL Type 12.

• Full EMC compliance according to international standards.

• Ruggedized and coated PCBs.

• Wide temperature range, operating from -25 to +40 °C (-13 to 104 °F) without derating.

• Motor cable lengths up to 150 m (492 ft) for shielded cables and 300 m (984 ft) for unshielded cables.

Enclosed drives

Danfoss enclosed drives are designed with the installer and operator in mind to save time on installation, commissioning, and

maintenance. The enclosed drives are designed for full access from the front. After opening the cabinet door, all components can be

reached without removing the drive, even when mounted side by side. Several cooling options, including back-channel cooling,

provide optimum adaption to the installation location and application.

More time-saving features:

• An intuitive user interface with an award-winning local control panel (LCP) and common control platform that streamlines start-up

and operating procedures.

• Robust design and advanced controls make Danfoss drives virtually maintenance free.

System modules

The compact design of the system modules makes them easy to fit even in small spaces. Integrated filters, input fuses, options, and

accessories provide extra capabilities and protection without increasing the enclosure size.

More space-saving features:

• Built-in DC-link reactors for harmonic suppression eliminate the need for higher loss external AC line reactors.

• Optional built-in RFI filters are available throughout the power range.

• Regen terminals are available within the standard enclosures (for enclosure sizes D, E, and F).

• In addition to the many valuable features that the Danfoss drives offers as standard, there are several other control, monitoring,

and power options available in pre-engineered factory configurations.

For more details on the enclosure types, the modularity, and the applications, see the product-specific Selection Guides on

www.danfoss.com.

4.2 Product Overview of the VLT® AutomationDrive FC 301/302

The VLT® AutomationDrive FC 301/FC 302 is a drive for controlling

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 19

Page 20

Design Guide | VLT® AutomationDrive FC 301/302

• Asynchronous AC induction motors,

• Permanent magnet synchronous motors,

• AC induction servomotors, and

• Synchronous reluctance motors (SynRM motors).

As other Danfoss AC drives, the VLT® AutomationDrive is motor independent, meaning that the drive can be connected to any brand of

motor, thus providing great flexibility when designing an installation.

The FC 301/FC 302 is built on a modular concept design and is equipped with a wide range of features enabling optimal process

control and high-quality output. With the many features, the drive meets the requirements of many industrial, chemical, and marine

applications, for example:

• Operating pumps.

• Conveyors.

• Material handling equipment.

• Hoists.

• Steering gear.

• Extruders.

• Palletizers.

In typical installations, the drive forms part of a bigger system and can be supplied with extra equipment, for example brakes, kits, and

various filters.

VLT® Product Family Overview

Adding to the flexibility are the different ways of connectivity, and as the drive supports all leading industry fieldbusses, it is

independent of the fieldbus system being used. The drive can be controlled:

• Directly from the local LCP.

• Local digital I/O or via industrial network connection.

• Wireless via the VLT® Wireless Control Panel LCP 103. The LCP 103 connects to the MyDrive® Connect app and enables control from

a mobile device.

Easy installation and commissioning

The FC 301/FC 302 comes with pluggable and spring-loaded I/O terminals making wiring and installation easy. During commissioning,

the FC 301/FC 302 offers time-saving application-dependent functions, such as:

• Droop for load sharing.

• Integrated brake control for safe operation of hoists.

• Integrated process controller for demand-based pumping.

• Power limit function for limiting the motor power distributed to the motor when required.

Commissioning can be made effectively via the VLT® Motion Control Tool MCT 10, which is a PC tool designed especially for drive

commissioning. The tool contains many features, and it is also possible to create Smart Assisted Start-up wizards, define initial

parameter values, and much more.

To ensure optimal control of the motor, the VLT® AutomationDrive offers a built-in algorithm, automatic motor adaptation (AMA). At

commissioning, program the function via the parameters to fine-tune the drive to match the motor.

Power sizes, voltage ranges, and enclosure protection classes

The VLT® AutomationDrive FC 301/FC 302 is available in many power sizes, voltage ranges, and enclosure protection classes, which

makes it easy to find the perfect drive for a given application.

20 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 21

e30ba870.11

e30ba809.11

e30ba810.11

e30bb458.11

e30ba811.11

Design Guide | VLT® AutomationDrive FC 301/302

Table 3: Voltage Ranges and Power Ranges

VLT® Product Family Overview

Voltage ranges [V] Power ranges [kW (hp)]

3 x 200–240 0.25–37 (0.34–50)

3 x 380–480/500 0.37–800 (0.5–1075)

3 x 525–600 0.75–75 (1.0–100)

3 x 525–690 1.1–1200 (1.5–1600)

Enclosure protection ratings:

• IP20/Chassis

• IP21/Type 1

• IP54/Type 12

• IP55/Type 12

• IP66/Type 4X

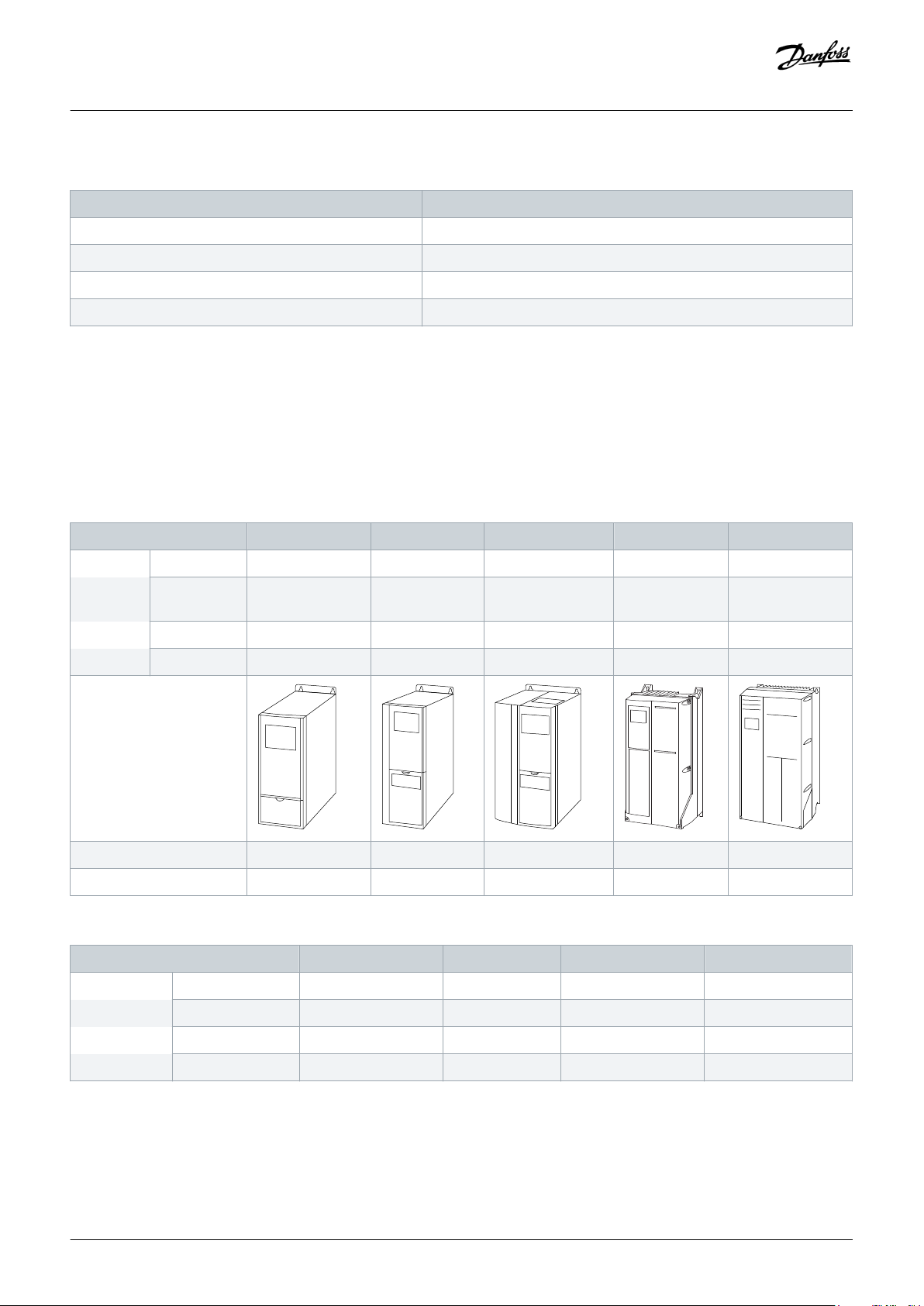

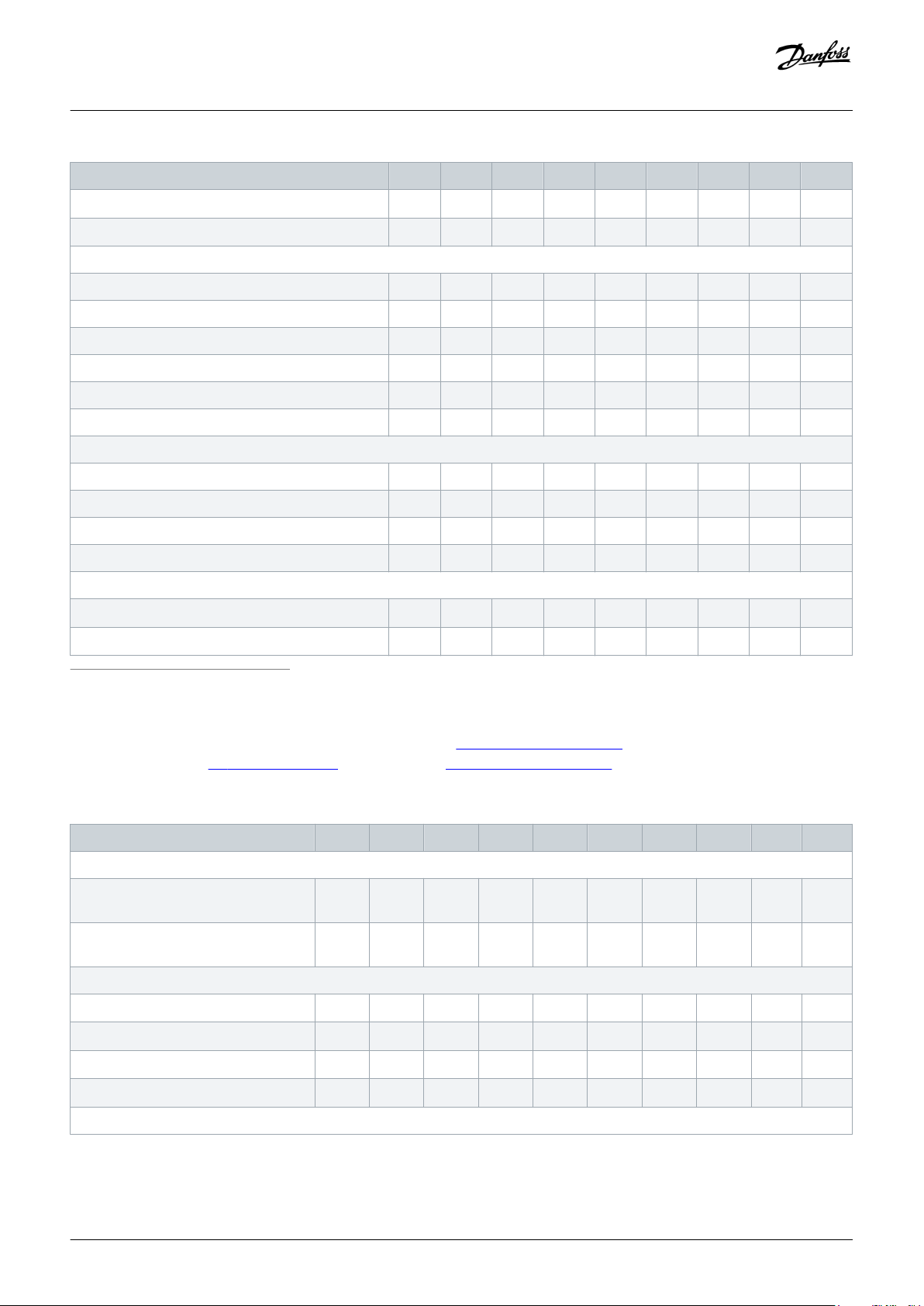

Table 4: Enclosures A1–A5: Power Sizes, Voltage Ranges, and Protection Rating

Enclosure A1 A2 A3 A4 A5

Power

[kW]

200–240 V 0.25–1.5 0.25–2.2 3–3.7 0.25–2.2 0.25–3.7

380–480/500V0.37–1.5 0.37–4 5.5–7.5 0.37–4 0.37–7.5

525–600 V – – 0.75–7.5 – 0.75–7.5

525–690 V – – 1.1–7.5 – –

IP 20 20/21 20/21 55/66 55/66

NEMA Chassis Chassis/Type 1 Chassis/Type 1 Type 12/4X Type 12/4X

Table 5: Enclosures B1–B4: Power Sizes, Voltage Ranges, and Protection Rating

Enclosure B1 B2 B3 B4

Power [kW] 200–240 V 5.5–7.5 11 5.5–7.5 11–15

Danfoss A/S © 2019.10

380–480/500 V 11–15 18.5–22 11–15 18.5–30

525–600 V 11–15 18.5–22 11–15 18.5–30

525–690 V – 11–22 – 11–30

AJ286655760917en-000101 / 130R0301| 21

Page 22

e30ba812.11

e30ba813.11

e30ba826.11

e30ba827.11

e30ba814.11

e30ba815.11

e30ba828.11

e30ba829.11

e30bu371.10

Design Guide | VLT® AutomationDrive FC 301/302

VLT® Product Family Overview

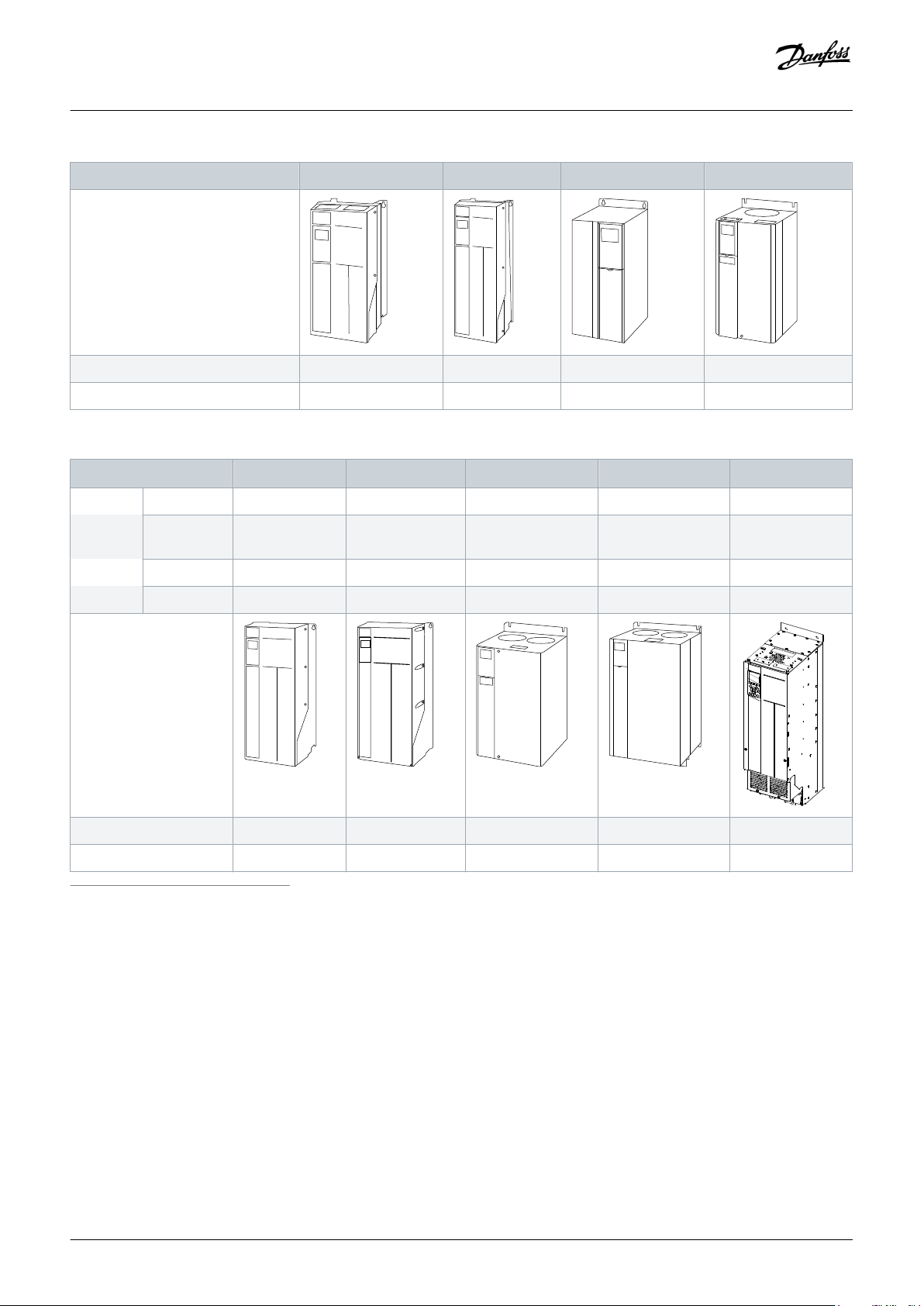

Enclosure B1 B2 B3 B4

IP 21/55/66 21/55/66 20 55

NEMA Type 1/12/4X Type 1/12/4X Chassis Chassis

Table 6: Enclosures C1–C4/D3h: Power Sizes, Voltage Ranges, and Protection Rating

Enclosure C1 C2 C3 C4

Power

[kW]

200–240 V 5.5–7.5 11 5.5–7.5 11–15 –

380–

11–15 18.5–22 11–15 18.5–30 –

D3h

480/500 V

525–600 V 11–15 18.5–22 11–15 18.5–30 –

525–690 V – 11–22 – 11–30 55–75

IP 21/55/66 21/55/66 20 55 20

NEMA Type 1/12/4X Type 1/12/4X Chassis Chassis Chassis

1

Details, see separate design guide VLT® AutomationDrive FC 302 90–710 kW

(1)

Standalone drives and enclosed drives

Based on the selected protection rating, select either a standalone drive or an enclosed drive.

The standalone drives have a protection rating of at least IP21/Type 1. These drives can be mounted both outside and inside in dusty

and damp environments without any further protection.

The enclosed drives have a protection rating of IP20/Chassis and must be built into cabinets for protection against dust and moisture.

The enclosed drives are not suitable for outdoor installation.

Both standalone drives and enclosed drives come in different enclosure sizes depending on the selected power size, voltage range,

and enclosure protection rating.

22 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 23

Design Guide | VLT® AutomationDrive FC 301/302

For low-power applications (0.25–75 kW), select between enclosure sizes A, B, C, and D3h.

For high-power applications (90–1200 kW), select between enclosure sizes Dxh, Exh, and F.

For more information about available enclosure sizes, refer to 8.1 Enclosure Size by Power Rating.

Functionalities

The VLT® AutomationDrive offers various customizable functionalities such as:

• Power hardware with varying voltage ratings, current ratings, protection ratings, and EMC performance ratings.

• Control hardware with various control cards with, for example, Integrated Motion Controller for high-precision positioning and

synchronization applications.

• Added functional extensions for extending the functionalities of the drive, for example, easy PLC integration.

• License packages, including condition-based monitoring and other extra software functionalities.

Safety functions

As standard, the drive is delivered with the Safe Torque Off (STO) function, which protects both operators and equipment if a failure

occurs. Furthermore, the built-in STO function is cost-saving as it makes separate safety modules unnecessary. Furthermore, 6 different

safety options are available:

• VLT® Safety PLC Interface MCB 108

• VLT® PTC Thermistor Card MCB 112 (for example, for ATEX applications).

• VLT® Safety Option MCB 150.

• VLT® Safety Option MCB 151.

• VLT® Safety Option MCB 152.

• VLT® Sensorless Safety MCB 159.

VLT® Product Family Overview

Troubleshooting and Maintenance

Troubleshooting and maintenance of the VLT® AutomationDrive FC 301/FC 302 are made easier and more precise with the increased

digitalization.

The sensors in the FC 301/FC 302 record and store real-time information about warnings and alarms. By adding the VLT® Real-time

Clock MCB 117 option, it is even possible to have the stored events time and date stamped.

Regarding maintenance, the FC 301/FC 302 features functions for preventive maintenance and condition-based monitoring.

The preventive maintenance functions are programmed in the drive and can be used to schedule maintenance alerts based on

running time of the drive.

Using the condition-based monitoring functions turns the drive into a sensor that continuously monitors the condition of the motor

and application. Using the DrivePro® services with the drive, the collected data can be shared with maintenance personnel and other

service providers.

4.3 Power Drive Systems

4.3.1 Ecodesign for Power Drive Systems

The Ecodesign Directive is the legislative framework that sets requirements on all energy-related products in the domestic,

commercial, and industrial sectors throughout Europe.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 23

Page 24

Mains &

cabling

Transmis-

sion

Load-

Machine

Driven Equipment

Extended Product

Motor System

Vollständiges Antriebsgerät (CDM)

Motor Starter

(Contactor, Softstarter,…)

Motor control equipment = CDM or starter

Feeding

section

Auxiliaries

Basic

Drive

Module

(BDM)

Complete Drive Module (CDM)

Power Drive System (PDS)

e30bu372.10

Relative torque

producing current

Relative

motor stator

frequency

100 %

50 %

25 %

0 %

0 % 50 % 90 %

e30bu372.10

Design Guide | VLT® AutomationDrive FC 301/302

VLT® Product Family Overview

The Ecodesign requirements are only mandatory within the European Union. These requirements are like the legislative requirements

for energy-related products which apply in North America and Australia.

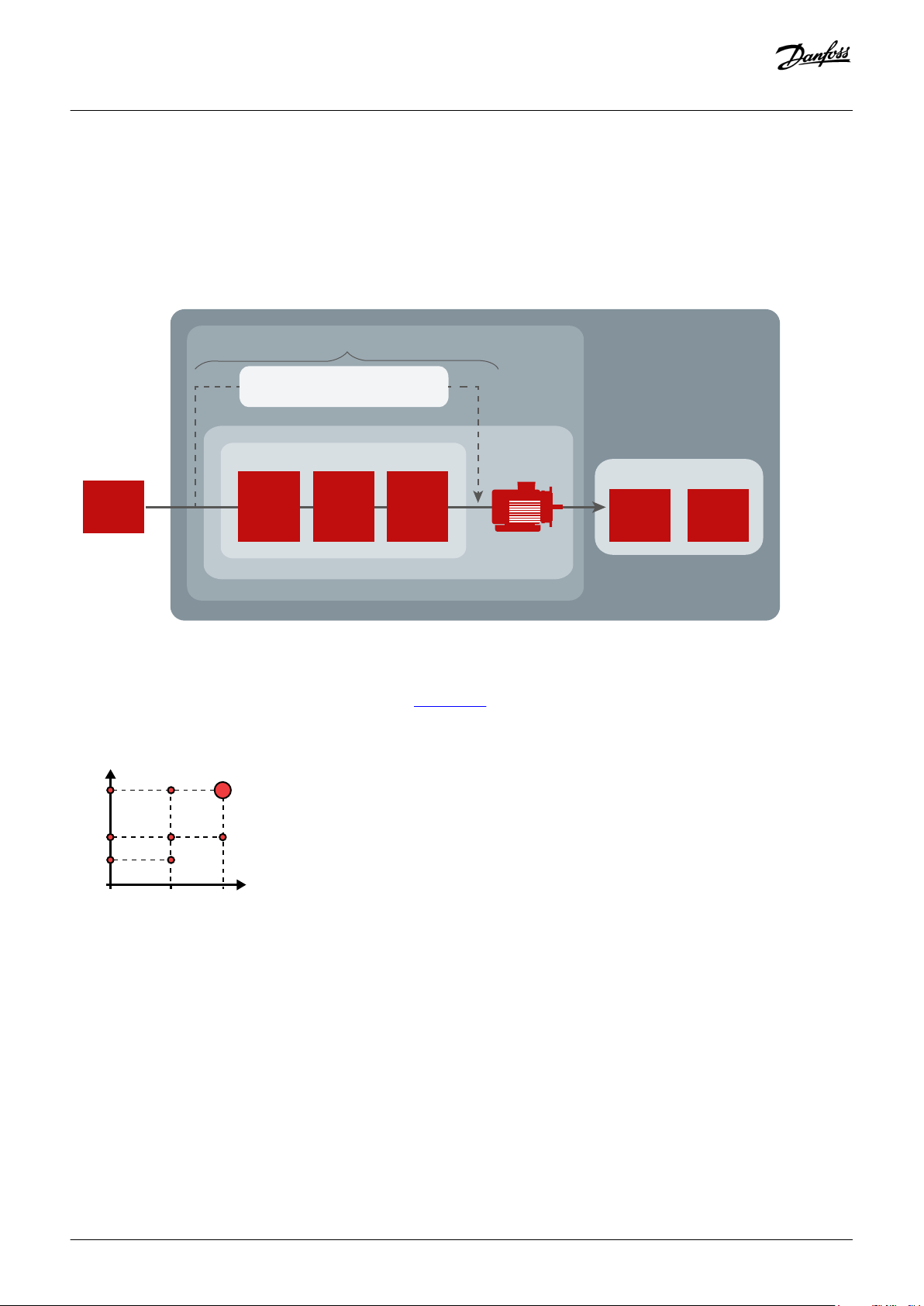

Terms like Complete Drive Module (CDM) and Power Drive Systems (PDS) are used to define the elements in the design. The objective

is to make more efficient and fewer energy consuming designs.

The CDM contains the drive controller as well as auxiliary devices and input components.

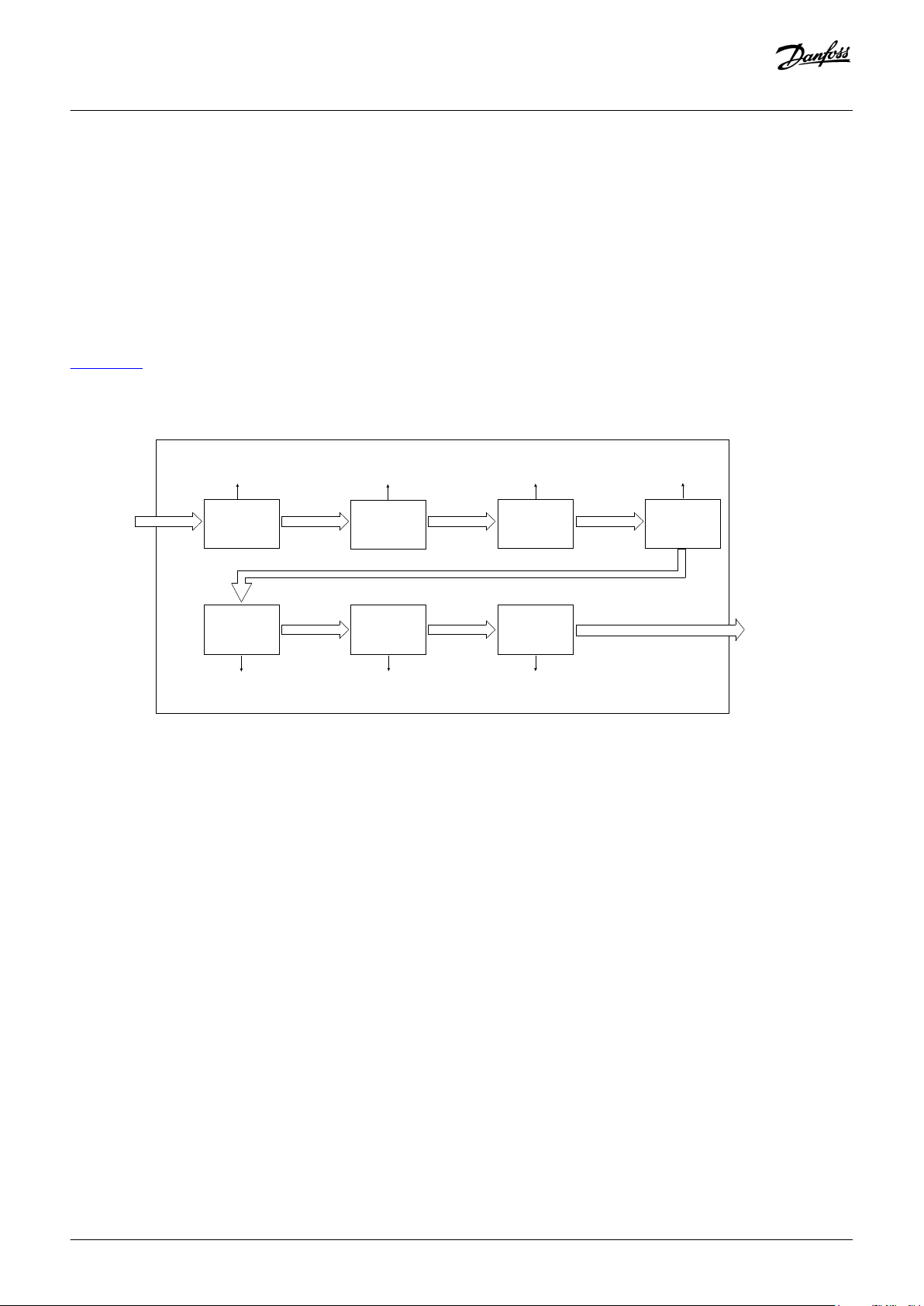

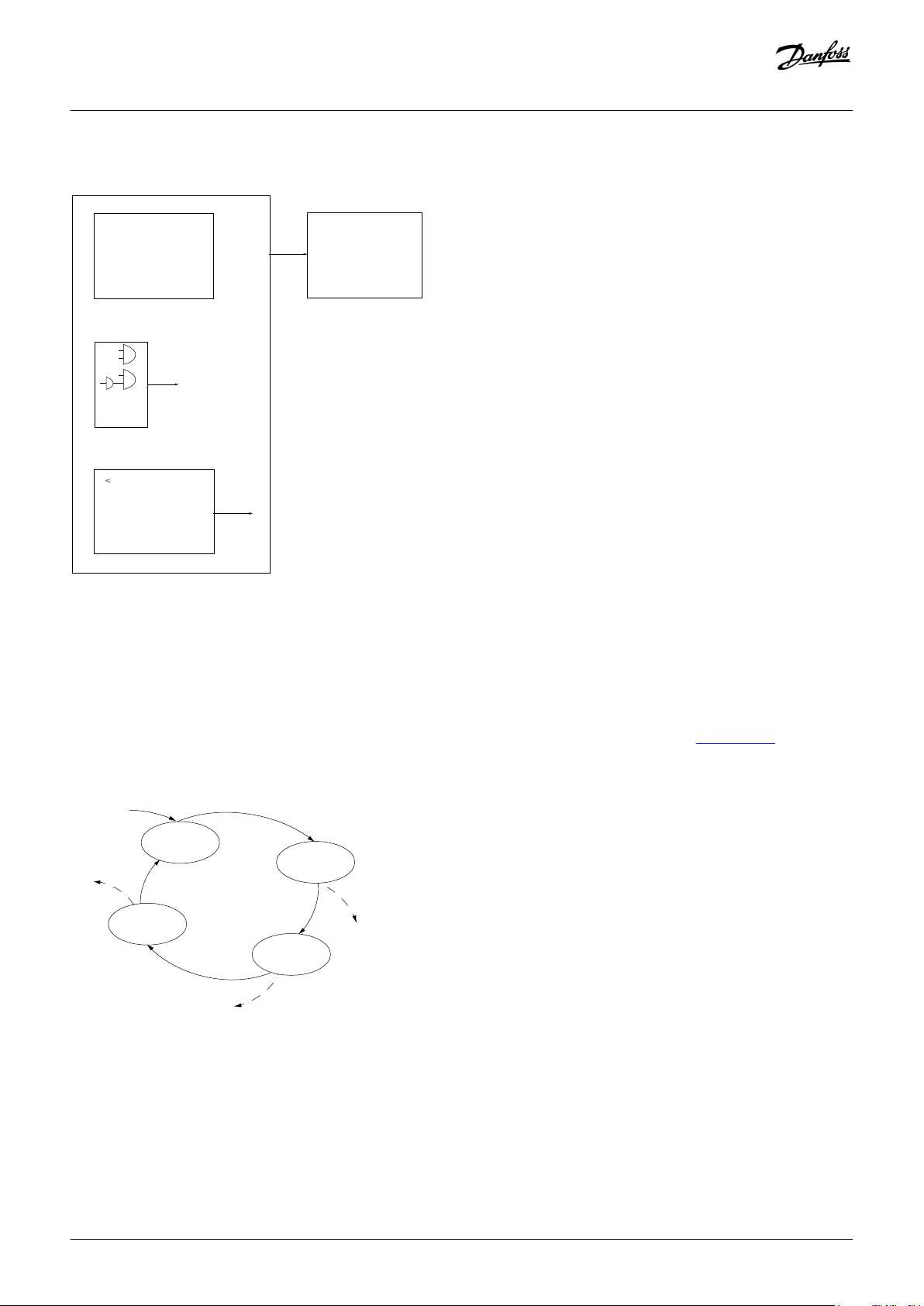

Illustration 6: Drive System Design

The efficiency classes IE0 to IE2 of the drive controller as specified in IEC 61800-9-2 (EN 50598-2) refer to the 90/100 operating point, i.e.

90 % motor stator frequency and 100% torque current (see illustration 7).

Illustration 7: Operating Point according to IEC 61800-9-2 (EN 50598)

Since in the future all component manufacturers will disclose their loss data according to this new standard, optimized applications

can be designed with a wide range of different components. The new Standard allows an accurate preliminary calculation of the power

losses, so that the ROI (Return of Investment) can be reliably determined. Up to now the overall efficiency of speed-regulated electric

motors was estimated with the aid of approximate energy consumption calculations.

It is now possible to determine the total losses of a system for the 8 operating points defined in the standard, including the part load

operation, via a simple addition of power losses. Danfoss helps its customers to avoid having to rely on system solution providers, to

ensure that their systems will retain a competitive advantage also in the future.

EC 61800-9-2 (EN 50598-2) shifts the focus from the individual component to the efficiency of the whole drive system. The new

efficiency classes (International Efficiency for Systems, IES)

24 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 25

Input power

e30bh443.10

Output power

Mains cabeling Input filters

Drive input

DC link

Drive output Output filters

Motor cables

and motor

Losses

Losses

Losses

Losses

Losses Losses Losses

Design Guide | VLT® AutomationDrive FC 301/302

VLT® Product Family Overview

allow a simple determination of the total losses for a whole drive system (PDS).

Danfoss offers the MyDrive® ecoSmart™ tool, which is available online or as a Smartphone app to assist with the efficiency calculation.

Use MyDrive® ecoSmart™ to:

• Look up part load data as defined in IEC 61800-9-2, for VLT® and VACON® drives

• Calculate efficiency class and part load efficiency for drives and power drive systems

• Create a report documenting part load loss data and IE or IES efficiency class.

For more information, refer to http://ecosmart.danfoss.com.

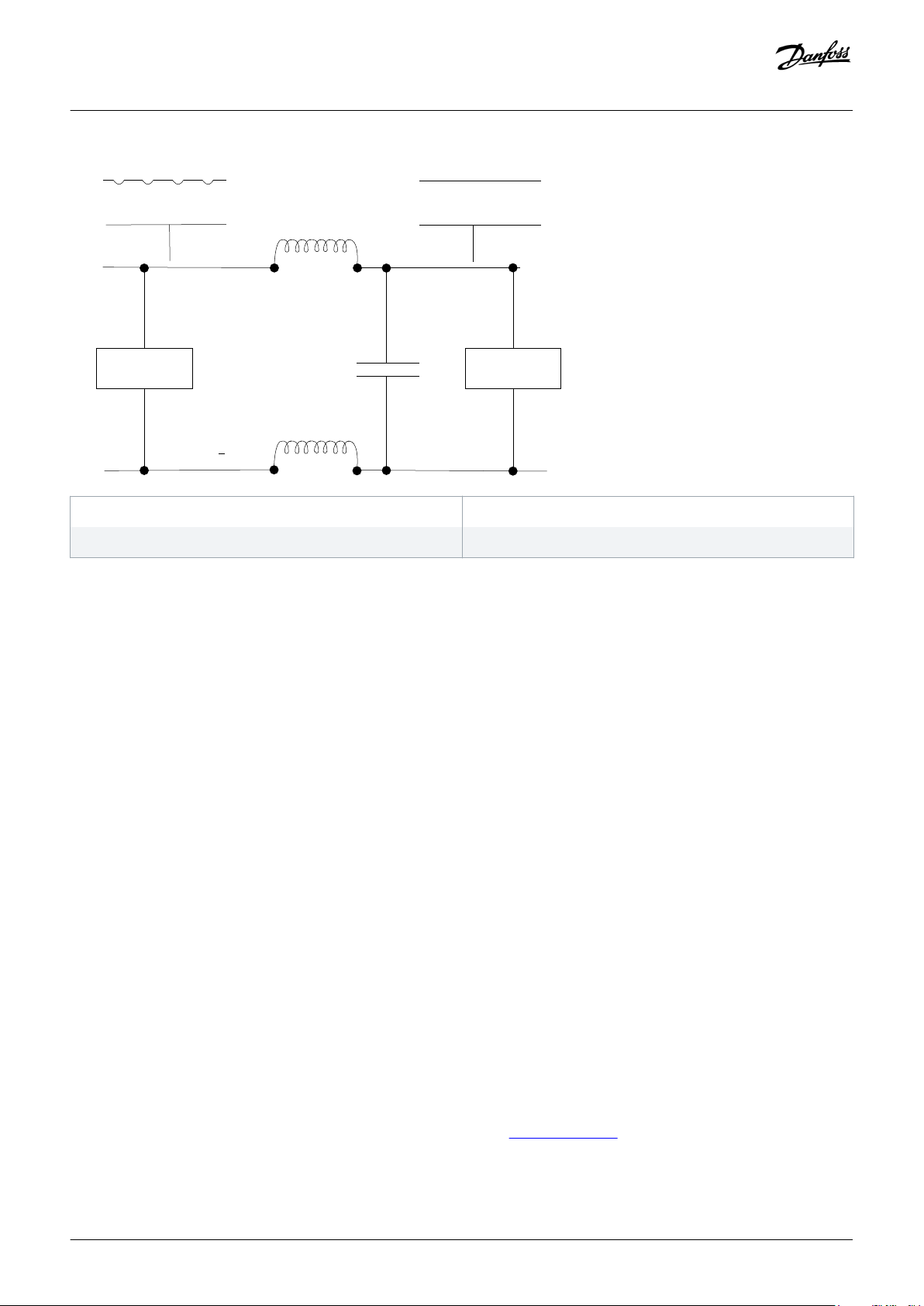

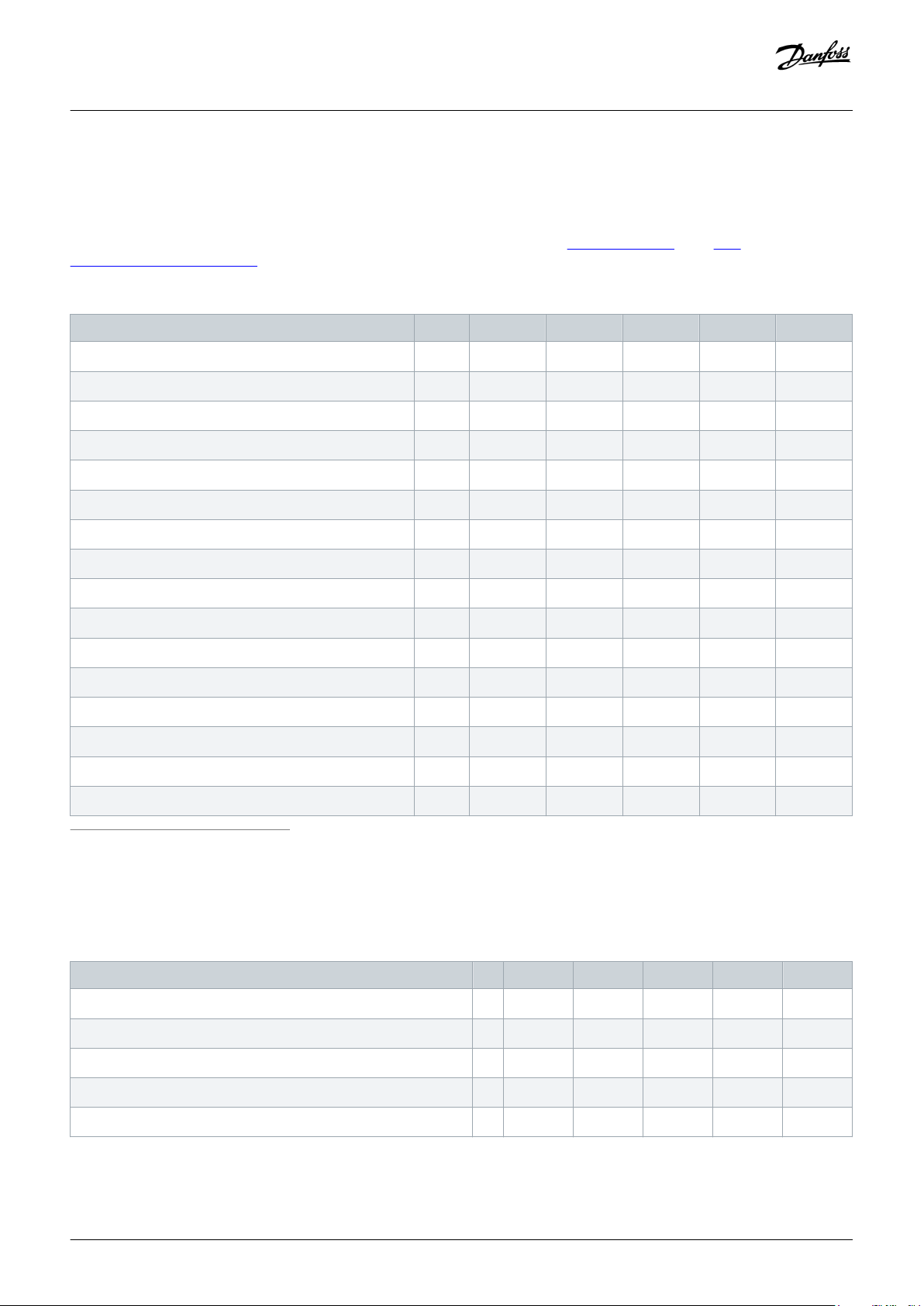

illustration 8 shows the components in the PDS which contribute to losses in the design. Mains cables and the load machine are not a

part of the PDS, even though their losses can be significant and could be a part of the evaluation of the overall energy efficiency of the

installation.

Illustration 8: Losses in a Power Drive System

4.3.1.1 Losses in Mains Cabling

The cabling from the supply must be considered, as the selection of suitable cables is often a problem, especially when dedicated

feeding transformers are installed. From the impedance of the cables, the energy losses are created in the ohmic part. Calculate the

active power losses for a 3-phase system with a star point groundingas follows:

P

L,mains

= 3 x R x I

2

L1

Because the load, when using drives and motors, also include reactive power and harmonic currents, these parameters also contribute

to losses. The ratio between active and apparent power is normally called the power factor. Having a PDS with a power factor close to 1

result in the lowest losses in the mains. Using filters on the input side of the drive can lower the power factor.

4.3.1.2 Input Filters: Line Reactors and Harmonic Filters

Line reactor

A line reactor is an inductor which is wired in series between a power source and a load. Line reactors, also called input AC reactors, are

typically used in motor drive applications.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 25

Page 26

Design Guide | VLT® AutomationDrive FC 301/302

The main function of the line reactor lies into its current limiting characteristics. Line reactors also reduce the main harmonics, limit the

inrush currents, and protect drives and motors. An overall improvement of the true power factor and the quality of the input current

waveform can be achieved.

When to use line reactors

It is important to consider the installation environment for the drives. In some situations, distortion from the grid can damage the drive

and precautions must be taken.

A simple menas of prevention is to ensure a minimum of impedance in front of the drive.

• The installation site has switched power factor correction capacitors.

• The installation site has lightening strikes or voltage spikes.

• The installation site has power interruptions or voltage dips.

VLT® Product Family Overview

Danfoss offers the line reactor program VLT® Line Reactor MCC 103, see

Harmonic filters

The purpose of using harmonic filters is to reduce the distortion on the mains. The distortion is generated by the drives when

switching the voltage to generate a frequency on the output. The harmonics should be limited both seen from energy consumption

perspective and disturbance of other users in the grid.

There are 2 categories of harmonic solutions:

• Passive.

• Active.

Passive solutions consist of capacitors, inductors, or a combination of both in different arrangements. The simplest solution is to add

inductors/reactors of typically 3–5% in front of the drive. This added inductance reduces the number of harmonic currents produced

by the drive. More advanced passive solutions combine capacitors and inductors in trap arrangement specially tuned to eliminate

harmonics starting from, for example, the 5th harmonic.

For more details on the Danfoss passive solutions, refer to VLT® Advanced Harmonic Filters AHF 005/AHF 010 Design Guide.

The active solutions determine the exact current that cancels the harmonics present in the circuit and synthesizes and injects that

current into the system. Thus, the active solution mitigates the real-time harmonic disturbances, which makes these solutions effective

at any load profile.

For more details on the Danfoss active solutions, refer to VLT® Low Harmonic Drive Operating Instructions, and VLT® Advanced Active

Filter AAF 006 Operating Instructions.

Danfoss.com.

4.3.1.3 Drive, Input Side

RFI (radio frequency interference)

Drives generate radio frequency interference (RFI) due to their variable-width current pulses. Drives and motor cables radiate these

components and conduct them into the mains system.

RFI filters are used to reduce this interference on the mains according to IEC 61800-3 in order not to disturb radio services. Maximum

allowed emission depends on the environment where the PDS is used.

The need for reducing the interferences and the losses created by the coils is a trade-off that is hard to influence in the use of drives.

Even though the losses exist, it is important to fulfill the legislation demands for the installation environment.

26 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 27

Design Guide | VLT® AutomationDrive FC 301/302

RFI filter on IT grid

If the drive is supplied from an isolated mains source (IT mains, floating delta) or TT/TN-S mains with grounded leg (grounded delta),

the RFI filter must be turned off.

In the OFF position, the internal capacitors between the chassis (ground), the input RFI filter, and the DC link are cut off. As the RFI

switch is turned off, the drive is not able to meet optimum EMC performance.

By opening the RFI filter switch, the ground leakage currents are also reduced, but not the high-frequency leakage currents caused by

the switching frequency of the drive. It is important to use isolation monitors that are designed for use with power electronics (IEC

61557-8). For example, Deif type SIMQ, Bender type IRDH 275/375, or similar.

The Danfoss VLT® drives can be ordered with different types of RFI filters. See more details on RFI, the use of RFI filters, and EMC

compliance in 10.16 Electromagnetic Compatibility (EMC) Overview.

Passive diode rectifier input

The use of diode rectifiers on the input side of the drives are the most cost-effective design. The energy flow goes from the mains to

the load and have low losses. On the other hand, diodes create harmonics in the mains when rectifying and thereby create losses.

These harmonics can be reduced by having DC-link coils, which are used in the Danfoss VLT® drives.

An energy flow from the drive back to the grid is not possible with this design as the energy is generated back from the application to

the DC link. Use a DC chopper and a connected resistor to absorb the energy. This reduces the energy efficiency significantly. If more

drives are installed, an improvement can be gained via load sharing by connecting the DC links, see

For information about the use of brake resistors for drives ordered with built-in brake choppers, refer to 10.10.1 Selection of Brake

Resistor and 10.10.2 Control with Brake Function.

VLT® Product Family Overview

10.3.4 Load Sharing Connection.

Active front end

In contrast to the diode rectifier, the active front end can generate excessive energy from the DC link back to the mains. In regenerative

applications, this design provides a significant improvement of the energy efficiency. This technology also has advantages in relation

to harmonics compensation and a more stable DC-link voltage. The design has similar functions on the input as on the output,

controlling IGBTs. There are also losses generated by switching of the IGBTs, which influence the energy efficiency. Due to the extra

IGBTs, this solution can be more expensive and is not used as often as the passive diode rectifier.

4.3.1.4 DC Link

The DC link is a power storage facility for the output section of the drive. There are 2 major components to the DC-link section:

• Capacitors

• Coils

In illustration 9 only 1 capacitor is shown, but it is always a series of capacitors.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 27

Page 28

1

3

+

+

2 4

e30bh114.10

Design Guide | VLT® AutomationDrive FC 301/302

VLT® Product Family Overview

1 Direct current (AC ripple)

3 Direct current

Illustration 9: Wiring Diagram of the DC Link

2 Rectifier

4 Inverter

With Danfoss VLT® drives, this intermediate section always uses DC coils, also known as DC line reactors or DC chokes. For cost

considerations, most other drive manufacturers do not offer these DC line reactors as standard equipment. Danfoss regards these coils

as essential for 2 main reasons:

• The ability to reduce harmonic noise (interference) by 40%.

• The ability to ride through a temporary loss of power. This allows the drive to avoid numerous unplanned shutdowns.

4.3.1.5 Drive, Output Side

The output side of the drive contains IGBTs used for generating a variable AC voltage with variable frequency. If no filters are used,

overvoltage spikes, due to reflection of the voltage waveform, can be measured on the motor connection. This situation is often linked

with long motor cables used in the installation and can reach values up to twice the level of the DC-link voltage.

From a user perspective, losses on the output side of the drive can be influenced by using a lower switching frequency, but this also

contributes to higher losses in the motor and filters installed. To optimize energy efficiency, a compromise must be found when

selecting the components used, for example, filters, motor type, and others. Often, output filters are used with the purpose of reducing

stress on the insulation.

In the following sections, the aspect of different filter types is discussed in perspective of energy efficiency versus function.

Common-mode filters

Common-mode HF filters are placed between the drive and the motor. They are nanocrystaline cores that mitigate high-frequency

noise in the motor cable (shielded or unshielded) and eliminate bearing currents, and hence Electro Discharge Machining (EDM) or

bearing etching in the motor. Bearing currents caused by drives are also referred to as common-mode currents.

Since the common-mode filters mitigate high frequency, these filters absorb energy and contribute also to losses. Here, the trade-off is

the advantage described compared with the losses.

More information on VLT® Common Mode Filters MCC 105 can be found on www.Danfoss.com.

28 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 29

Design Guide | VLT® AutomationDrive FC 301/302

dU/dt filters

At the IGBTs on the output switch, the voltage is not a clean sinus curve. It contains fast changes in voltage levels over a very short

time. The use of dU/dt filters increases the raise time of the motor voltage to reduce the stress on the motor insulation. If not avoided,

the problem will typically not show at once, but after some time, the insulation breaks and creates problems.

The switching frequency influences the losses in the dU/dt filters. These losses can be up to 1% of the rated power. Here, the trade-off

is the possible damage of the motor over time compared with the cost of energy losses.

Danfoss offers the VLT® dU/dt Filter MCC 102 as a possible solution. Find more information on www.Danfoss.com.

Sine-wave filters

A more advanced, but also more costly solution, is using sine-wave filters.

The VLT® Sine-Wave Filter MCC 101 is a differential-mode low-pass filter that suppresses the switching frequency component coming

from the drive and smoothes out the phase-to-phase voltage of the drive to become sinusoidal. This reduces the motor insulation

stress and bearing currents. By supplying the motor with a sinusoidal voltage waveform, the switching acoustic noise from the motor is

also eliminated.

For more detailed information, see the VLT® Sine-Wave Filter MCC 101 factsheet.

VLT® Product Family Overview

However, this type of filter also produces a voltage drop and there may be a reduction in the available control bandwidth. This can

sometimes make it impossible to use this filter type. Again, as for the dU/dt filter, losses are linked to the switching frequency.

For more detailed information, see the

VLT® Output Filters Design Guide.

4.3.1.6 Motor Cables and Motor

Motor cables

Motor cables introduce mainly ohmic losses: the longer the cables, the more resistance. In general, when correctly selected, the losses

in cables shorter than 25 m (82 ft) can be neglected. In single-wire cables with individual shielding, current causes losses in the cable

shielding. These losses can be neglected when using 3-wire cables.

Motor

There are many different types of motors that can be operated with a drive. The solution for dealing with losses in motors is therefore

depending on the individual motor type and installation. In standard IEC 61800-9-2:2017 annex D, a discussion on motor load and

losses is found.

A method to evaluate the losses generated in the motor operated with a drive can be found in the standards IEC 60034-2-1 and IEC TS

60034-2-4.

For the drive dealt with in this manual, find more information on supported motor types in 5.1.2 Supported Motor Types.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 29

Page 30

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

5 Product Overview

5.1 Overview of Drives Systems

Danfoss offers drives in different enclosure types for a wide range of applications.

Standalone AC drives

The Danfoss standalone AC drives are so robust that they can be mounted outside of cabinets virtually anywhere, even right beside the

motor. Equipped for the toughest of environment, they suit any application.

More uncompromising features:

• Enclosure sizes with protection ratings up to IP66/UL Type 4X.

• Full EMC compliance according to international standards.

• Ruggedized and coated PCBs.

• Wide temperature range, operating from -25 °C to +50 °C (-13 °F to 122 °F) without derating.

• Motor cable lengths up to 150 m (492 ft) shielded / 300 m (984 ft) unshielded as standard with uncompromised performance.

Enclosed drives

Danfoss drives are designed with the installer and operator in mind to save time on installation, commissioning, and maintenance.

VLT® enclosed drives are designed for full access from the front. After opening the cabinet door, all components can be reached

without removing the drive, even when mounted side by side.

Several cooling options, including back-channel cooling, provide optimum adaption to the installation location and application.

More time-saving features:

• An intuitive user interface with an award-winning local control panel (LCP) and common control platform that streamlines start-up

and operating procedures.

• Robust design and advanced controls make Danfoss drives virtually maintenance-free.

Modules

The compact design of the VLT® high-power drive modules makes them easy to fit even in small spaces. Integrated filters, options, and

accessories provide extra capabilities and protection without increasing the enclosure size.

More space-saving features:

• Built-in DC-link reactors for harmonic suppression eliminate the need for higher loss external AC line reactors.

• Optional built-in RFI filters are available throughout the power range.

• Optional input fuses and load share terminals are available within the standard enclosures.

• In addition to the many valuable features that the Danfoss drives offer as standard, there are several other control, monitoring, and

power options available in pre-engineered factory configurations.

For more details on the enclosure types, the modularity, and the applications, see the product-specific selection guides on

www.danfoss.com.

5.1.1 Filter Options

Filters are often extra components that must be planned for when designing the power drive system. It is important to understand

why and when to use output filters with Danfoss drives.

30 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 31

Design Guide | VLT® AutomationDrive FC 301/302

For more details on output filters, refer to Output Filters Design Guide.

Product Overview

5.1.1.1 Protection of Motor Insulation

The output voltage of the drive is a series of trapezoidal pulses with a variable width (pulse width modulation) characterized by a pulse

rise time, tr. When a transistor in the inverter switches, the voltage across the motor terminal increases by a dU/dt ration depending on:

• The motor cable (type, cross-section, length, shielded or unshielded, inductance, and capacitance).

• The high-frequency surge impedance of the motor.

Because of the impedance mismatch between the cable characteristic impedance and the motor surge impedance, a wave reflection

occurs, causing a ringing voltage overshoot at the motor terminals

5.1.1.2 Reduction of Motor Acoustic Noise

There are 3 main sources for generation of acoustic noise in the motor:

• The magnetic noise produced by the motor core through magnetostriction.

• The noise produced by motor bearings.

• The noise produced by motor ventilation.

When a motor is fed by a drive, the pulse-width-modulated (PWM) voltage applied to the motor causes extra magnetic noise at the

switching frequency and harmonics of the switching frequency (mainly the double of the switching frequency). In some applications,

this is not acceptable. To eliminate this additional switching noise, use a sine-wave filter. This filter filters the pulse-shaped voltage

from the drive and provides a sinusoidal phase-to-phase voltage at the motor terminals.

5.1.1.3 Reduction of High-frequency Electromagnetic Noise in Motor Cables

Using filters reduces noise generated in the motor cables.

When no filters are used, the ringing voltage overshoot that occurs at the motor terminals is the main high-frequency noise source. The

noise can be explained by the correlation between the frequency of the voltage ringing at the motor terminals and the spectrum of

the high-frequency conducted interference in the motor cable. Besides this noise component, there are also other noise components

such as:

• The common-mode voltage between phases and ground at the switching frequency and its harmonics - high amplitude but low

frequency.

• High-frequency noise (above 10 MHz) caused by the switching of semiconductors - high frequency but low amplitude.

Installing an output filter gives the following advantages:

• dU/dt filters reduce the frequency of the ringing oscillation to a level below 150 kHz.

• Sine-wave filters eliminate the ringing oscillation and the motor receives a sinusoidal phase-to-phase voltage.

5.1.1.4 Bearing Currents and Shaft Voltage

Fast switching transistors in the drive combined with an inherent common-mode voltage (voltage between phases and ground)

generate high-frequency bearing currents and shaft voltages. While bearing currents and shaft voltages can also occur in direct-on-line

motors, these phenomena are accentuated when the motor is fed from a drive.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 31

Page 32

Design Guide | VLT® AutomationDrive FC 301/302

Most bearing damage in motors fed by drives is caused by vibrations, misalignment, excessive axial or radial loading, improper

lubrication, and impurities in the grease. Sometimes, bearing damage is caused by bearing currents and shaft voltages. The

mechanism that causes bearing currents and shaft voltages is complicated to explain, but it is important to know that it exists. Two

main mechanisms can be identified:

• Capacitive coupling: The voltage across the bearing is generated by parasitic capacitances in the motor.

• Inductive coupling: Caused by circulating currents in the motor.

The grease film of a running bearing behaves like isolation. The voltage across the bearing can cause a breakdown of the grease film

and produce a small electric discharge (a spark) between the bearing balls and the running track. This discharge produces a

microscopic melting of the bearing ball and running track metal and over time it causes the premature wear-out of the bearing. This

mechanism is called electrical discharge machining (EDM).

Product Overview

5.1.2 Supported Motor Types

Today, the drive-controlled, 3-phase motor is a standard element in all automated applications. High-efficiency induction motors, but

also motor designs such as permanent magnet motors, EC motors, and synchronous reluctance motors, need regulation with AC

drives. Many motors cannot be operated directly from the 3-phase standard power supply.

The Danfoss VLT® drives can control multiple motor technologies. The most advanced is the VLT® AutomationDrive FC 302. This drive is

compatible with virtually all types of common AC motor technologies on the market:

• Induction motors (IM).

• Surface permanent magnet motors (SPM).

• Interior permanent magnet motors (IPM).

• Synchronous reluctance motors (SynRM).

• Permanent magnet assisted synchronous reluctance motors (PMaSynRM).

Induction motors, synchronous motors, and induction servo motors are all supported as standard without the need for extra software.

The FC 302 can control the motors in either open loop or closed loop through its high precision motor control platform, VVC+ or flux

control.

Standard IEC line motors (IEC 60034-30-1)

The standard IEC 60034-30-1 of March 2014 replaces the standard 60034-30:2008, which has defined 3 efficiency levels for 3-phase

induction motors. The updated standard IEC 60034-30-1 now includes the 4th efficiency level, IE4. Furthermore, 8-pole motors and an

extended power range are now included in the standard.

Efficiency classes:

In the IEC 60034-30-1, the following efficiency classes are defined for induction motors:

• IE1 (Standard efficiency).

• IE2 (High efficiency).

• IE3 (Premium efficiency).

• IE4 (Super premium efficiency).

IE = Internation efficiency.

These motor types can all be operated with Danfoss VLT® drives.

More information on this topic can be found in the publication Motor Technologies for Higher Efficiency in Applications. This

document can be downloaded from

www.danfoss.com.

32 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 33

e30bh117.10

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

5.1.3 Bearing Currents

Protecting the motor insulation and bearings

The drive employs modern IGBT inverter technology. Regardless of the frequency, the drive output comprises pulses of approximately

the drive DC bus voltage with a very short rise time. The pulse voltage can almost double at the motor terminals, depending on the

attenuation and reflection properties of the motor cable and the terminals. This can cause extra stress on the motor and motor cable

insulation. Modern AC drives with their fast-rising voltage pulses and high-switching frequencies can generate current pulses that flow

through the motor bearings. Gradually, these current pulses can erode the bearing races and rolling elements. Optional dU/dt filters

protect the motor insulation system and reduce bearing currents. Optional common-mode filters mainly reduce bearing currents.

Insulated N-end (non-drive end) bearings protect the motor bearings.

Practical tips

Usually, the shielding surface of the motor cable is connected to the frame of the terminal box and not to the motor stator frame.

However, the motor terminal box on some motors can be mounted to the stator housing with a considerable change of the highfrequency currents and impedance. Typically, there is a gasket between the terminal box and the stator frame, and the box is attached

to the motor frame with 4 small screws. Conducted measurements on these motors showed that screws did not provide a low

impedance from the terminal box to the stator and therefore, the common-mode currents were oscillated with a noticeable

magnitude.

Applying high-frequency bonding straps between the motor terminal box and the stator frame helps providing low impedance for

high-frequency currents and therefore eliminating the common-mode current oscillations in the installation.

Illustration 10: Installation of EMC straps from the Terminal Box to the Motor Frame

Sometimes, so called NYCWY cables are used to connect the motor to the drive inverter. The symmetry of the PE conductor in these

cables is achieved by a conductor surrounding all the phase leads. These cables, however, prevent common-mode currents at the

fundamental frequency only.

To avoid common-mode currents at fundamental and high frequencies at the same time, use multicore symmetric motor cables with 3

ground conductors with a shield.

Applying common-mode cores

Common-mode cores across motor cable conductors effectively reduce high-frequency motor bearing currents. On motors with a

power rating of approximately 100 kW and onwards, the result of reduction of bearing currents is most evident.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 33

Page 34

PE U V W

e30bd839.10

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

High-frequency common-mode cores may have an oval or round shape and they are easy-to-install components.

Install common-mode cores in a way that only unshielded power cores of the motor cable are wired through the core. The PE and

shielding wires must be placed outside of the core. It is also important that all 3 motor phase wires are wired through the same core.

Otherwise, the cores do not provide the required functionality.

Illustration 11: Installing Common-mode Cores

Depending on the power rating of the drive installation and the quantity of motor cables connected in parallel, several same-size

common-mode cores might be used. In dedicated product manuals, preselection tables advise on the required minimal quantity of

single common-mode cores to install. The number of cores depend on the power rating, the nominal voltage of the drive installation,

and the length of the applied motor cables.

Applying common-mode cores on motor cables connected in parallel

If many motor cables connected in parallel are used and the power wires of all cables cannot be fitted through the common-mode

cores, place the required number of cores on each individual motor cable. This ensures the saturation of the core due to likely unequal

current sharing between cables. Wire all 3-phase conductors of each cable through 1 set of cores.

34 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 35

Ferrite rings

Metallic

cabinet wall

Shield connected

to ground

Motor cable

PE

Mains cable

High-frequency

grounding

Motor cable

Ferrite rings

Metallic

cabinet wall

Shield connected

to ground

e30bg998.11

e30bh118.10

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

Illustration 12: Installation of CM Cores on Cables Connected in Parallel

As losses of common-mode cores are low, the expected temperature of the core is below 60 °C (140 °F) under normal circumstances.

Thus common-mode cores can also be accommodated inside the motor terminal box. If cores cannot be fitted inside the drive housing

or the motor terminal box, they can be placed in an external cabinet close to the motor.

Illustration 13: Mounting of CM Cores Inside the Motor Terminal Box

To ensure minimal bearing currents in the motor, Danfoss recommends ordering the drive with output motor filters as a power option.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 35

Page 36

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

5.2 Integrated Motion Controller

NOTICE

The integrated motion control is only available with special IMC software version 48.XX. To order the drive with the IMC

software, use the type code with software release version S067.

The integrated motion controller (IMC) enables position control with all motor control principles and motor types with and without

feedback.

To activate the IMC functionality, select [9] Positioning or [10] Synchronization in parameter 1-00 Configuration Mode. IMC enables the

following functions:

• Positioning: Absolute, relative, and touch probe.

• Homing.

• Position synchronization.

• Virtual master.

Position control in both positioning and synchronization modes can be either sensorless or with feedback. In the sensorless control

principle, the motor angle calculated by the motor controller is used as feedback. In the closed-loop control principle, VLT®

AutomationDrive FC 302 supports most standard incremental encoders, absolute encoders, and resolvers. The position controller can

handle both linear and rotary systems. The controller can scale positions to any relevant physical unit such as mm or degrees.

5.2.1 Positioning, Homing, and Synchronization

5.2.1.1 Positioning

The drive supports relative positioning and absolute positioning. A positioning command requires 3 inputs:

• Target position.

• Speed reference.

• Ramp times.

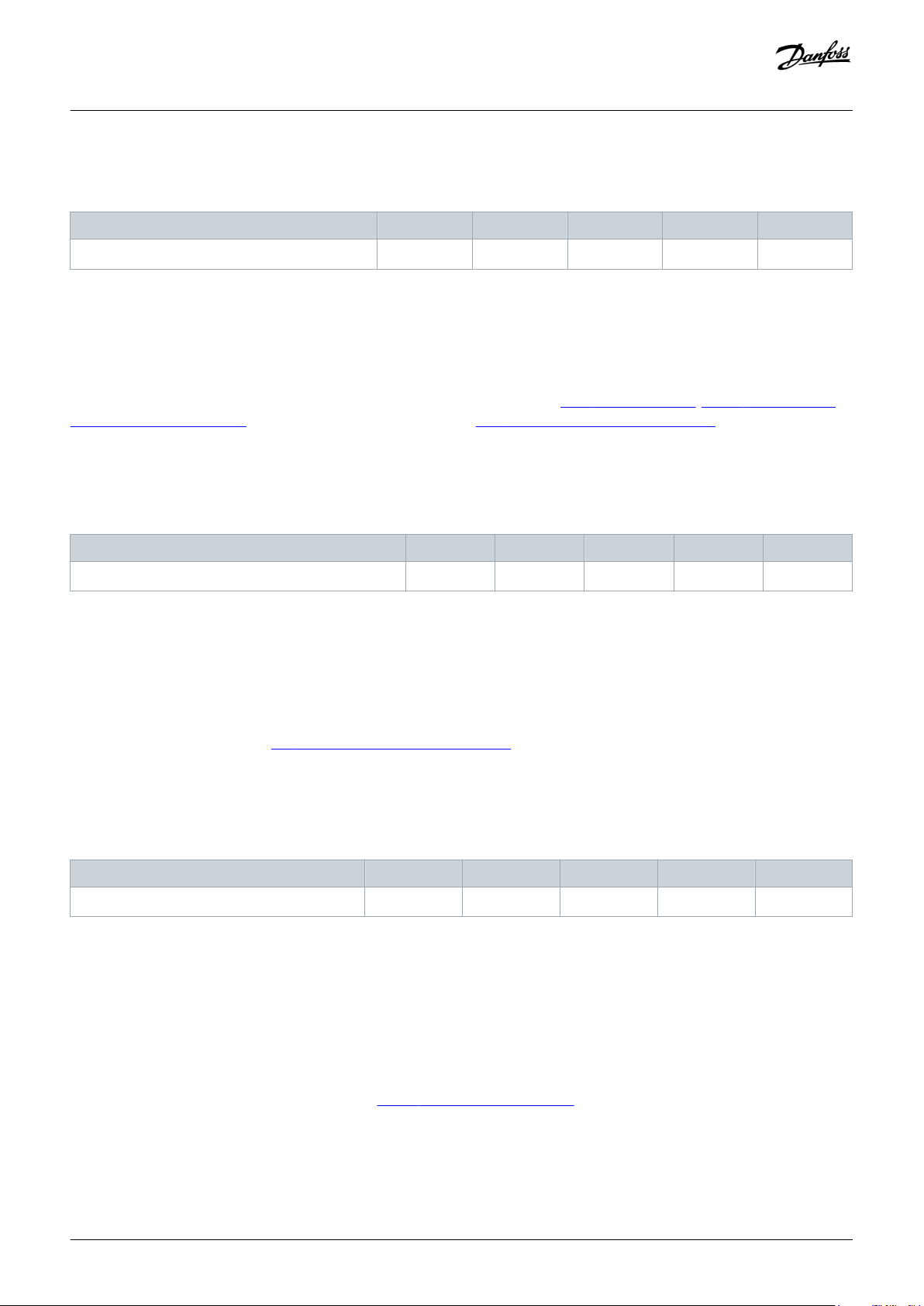

The 3 inputs can come from various sources, see illustration 14.

36 | Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301

Page 37

+

e30be774.11

Par. 3-20 Preset target positions

Fieldbus reference 1 or pos. REF

Par. 3-16 Reference resource 2

Par. 3-17 Reference resource 3

Par. 3-03 Default speed

Fieldbus reference 1

Par. 3-15 Reference resource 1

Ramp settings:

Parameter groups 3-4* – 3-7*

Target position

Speed ref.

Acceleration/Deceleration

Profile generator

Commanded position

Speed

Acceleration

Design Guide | VLT® AutomationDrive FC 301/302

Product Overview

Illustration 14: Positioning References

In each control cycle (1 ms), the profile generator calculates position, speed, and acceleration required to do the specified movement.

The outputs from the profile generator are used for the position and speed controller.

5.2.1.2 Homing

Homing is required for creating a reference to the physical machine position in closed-loop control principle with incremental encoder

or in sensorless control principle. IMC supports various homing functions with or without a homing sensor. Select the homing function

in parameter 17-80 Homing Function. After selecting a homing function, complete homing before executing absolute positioning.

5.2.1.3 Synchronization

In synchronization mode, the drive follows the position of a master signal. The master signal and the offset between the master and

the slave are handled as shown in illustration 15.

Danfoss A/S © 2019.10

AJ286655760917en-000101 / 130R0301| 37

Page 38

Position ref.

Acceleration/Deceleration

Speed ref.

Fieldbus Sync. REF

Master position

Par. 3-16 Reference Resource 2