Page 1

User Guide

drives.danfoss.com

Danfoss DriveManager Plug-in for TwinCAT

VLT® AutomationDrive FC 301/FC 302, VLT® Decentral Drive FCD 302

Page 2

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Contents

1

Introduction 3

1.1

Purpose of the User Guide 3

1.2

Qualied Personnel 3

1.3

Additional Resources 3

1.4

Document and TwinCAT® Version 3

Product Overview 3

1.5

1.5.1

Purpose of the Plug-in 3

1.5.2

Preconditions 4

Supported Drive Series 4

1.5.3

1.5.3.1

Limitations 4

1.5.4

2

Installation and Deinstallation 5

Supported Data Types 4

Contents

Installing the Danfoss DriveManager Plug-in for TwinCAT® 5

2.1

2.2

Deinstallation, Danfoss DriveManager Plug-in for TwinCAT® and VLT® Motion Control Tool MCT 10 6

User Interface 7

3

3.1

Description of the Danfoss DriveManager for TwinCAT® User Interface 7

4

Using the Danfoss DriveManager Plug-in for TwinCAT® 9

4.1

Scanning Devices 9

Modifying the Startup List with Danfoss DriveManager Plug-in for TwinCAT® 13

4.2

4.2.1

Grid Colors 15

4.2.2

Removing a Parameter from the Startup List 15

4.2.3

Adding a Default Value to the Startup List 16

4.2.4

Activating the Conguration 16

4.3

Working with an Online Drive 17

4.4

Modifying the Online Drive Parameters with Danfoss DriveManager Plug-in for TwinCAT® 17

4.4.1

Restricted Modication 18

4.5

Use Cases for Manual Drive Identication 20

4.5.1

Drive Identied but not Created in Danfoss DriveManager Plug-in 20

4.5.1.1

4.5.2

The Drive is Created, but Has Been Changed Externally 21

Identifying the Device 21

BC319549253561en-000301/130R0913 2 | Danfoss A/S © 2020.06

Page 3

Revision

Remarks

TwinCAT® version

Danfoss DriveManager

version

BC319549253561, version 0301

Update to Danfoss DriveManager software

version.

3.1

1.47

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Introduction

1 Introduction

1.1 Purpose of the User Guide

This User Guide provides:

•

Step-by-step instructions on how to install the Danfoss DriveManager Plug-in for TwinCAT®.

•

Description of the Danfoss DriveManager user interface.

•

Use case examples of working with the Danfoss DriveManager.

The user guide is intended for use by qualied personnel.

VLT® is a registered trademark for Danfoss A/S.

TwinCAT® is a registered trademark of Beckho Automation GmbH. Other designations used in this publication may be trademarks

whose use by 3rd parties for their own purposes could violate the rights of the owners.

1.2 Qualied Personnel

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation

of the drive. Only qualied personnel are allowed to install and operate this equipment.

Qualied personnel are dened as trained sta, who are authorized to install, commission, and maintain equipment, systems, and

circuits in accordance with pertinent laws and regulations. Also, the qualied personnel must be familiar with the instructions and

safety measures described in this manual.

1.3 Additional Resources

Resources available for the TwinCAT® software and for the drives in which the software can be installed:

•

The Operating Guide of the relevant drive provides the necessary information for getting the drive up and running.

•

The Design Guide of the relevant drive provides detailed information about capabilities and functionality to design motor control systems.

•

The Programming Guide of the relevant drive provides greater detail on working with parameters.

•

The Function Blocks with TwinCAT® User Guide provides instructions on how to integrate a Danfoss drive into a Beckho TwinCAT® 3 system.

1.4 Document and TwinCAT® Version

This User Guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

N O T I C E

This manual contains images from previous versions. The purpose of these images is merely showing and understanding how to

use the software.

Table 1: Document and TwinCAT® Version

1.5 Product Overview

1.5.1 Purpose of the Plug-in

The Danfoss Drive Manager Plug-in for TwinCAT simplies the complete commissioning of Danfoss drives without using VLT® Motion Control Tool MCT 10.

BC319549253561en-000301 / 130R0913 | 3 Danfoss A/S © 2020.06

Page 4

Danfoss DriveManager Plug-in for TwinCAT

User Guide

1.5.2 Preconditions

•

Operating system: Windows 7 or later.

•

TwinCAT 3.1 must be installed in the default folder C:\TwinCAT.

N O T I C E

It is not necessary to install Danfoss ESI les separately as they are installed with the plug-in.

1.5.3 Supported Drive Series

The Danfoss DriveManager Plug-in for TwinCAT® supports the following drive series:

•

VLT® AutomationDrive FC 301

•

VLT® AutomationDrive FC 302

•

VLT® Decentral Drive FCD 302

1.5.3.1 Supported Data Types

The Danfoss DriveManager plug-in for TwinCAT® supports the following data types:

•

INTEGER8

•

INTEGER16

•

INTEGER32

•

UNSIGNED8

•

UNSIGNED16

•

UNSIGNED32

•

VISIBLE_STRING

•

4 byte BYTE_STRING

•

NORMAL_VALUE_N2

•

BIT_SEQUENCE

•

TIME_DIFFERENCE_WITH_DATE_INDICATION

•

TIME_DIFFERENCE_WITHOUT_DATE_INDICATION

Introduction

1.5.4 Limitations

The limitations listed apply to Danfoss DriveManager Plug-in for TwinCAT® version 1.47.

The plug-in does not support the following:

•

Certain drive-specic data types:

-

TIMEOFDAY

-

TIMEOFDAY_WITHOUT_DATE

•

Parameters in parameter group 19-** User-dened Parameters.

•

Running automatic motor adaptation (AMA).

•

Parameters in parameter group 12-2* Process Data.

•

Conguring more than 1 out of 4 drive setups at a time via the plug-in.

BC319549253561en-000301 / 130R0913 4 | Danfoss A/S © | 2020.06

Page 5

e30bh687.12

e30bh688.12

Danfoss DriveManager Plug-in for TwinCAT

User Guide

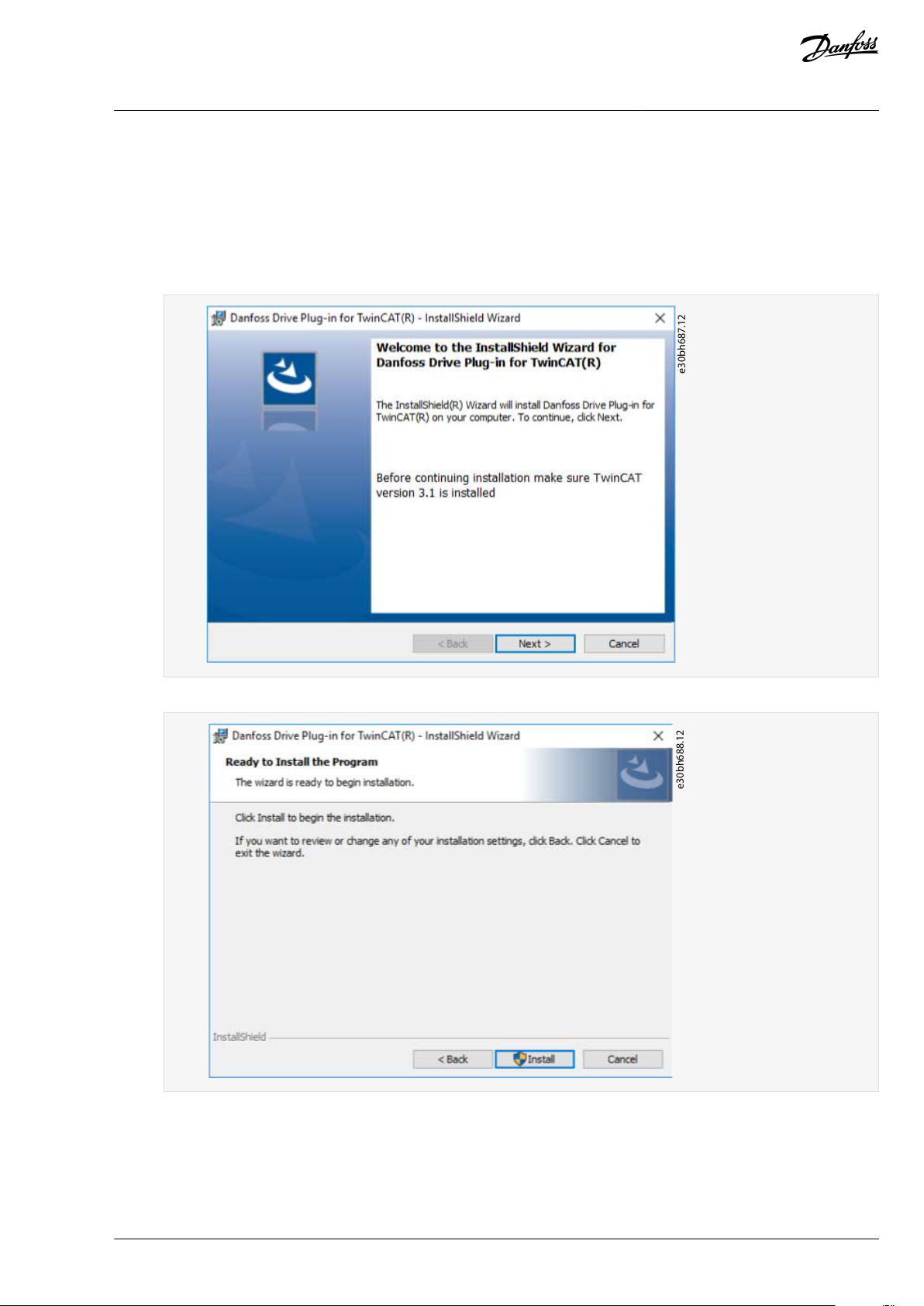

2 Installation and Deinstallation

2.1 Installing the Danfoss DriveManager Plug-in for TwinCAT®

Follow the on-screen instructions for installing the plug-in.

Procedure

1.

Double-click the Danfoss DriveManager Plugin for TwinCAT le to start the Installshield Wizard.

Installation and Deinstallation

2.

Click Next.

3.

Click Install.

BC319549253561en-000301 / 130R0913 | 5 Danfoss A/S © 2020.06

Page 6

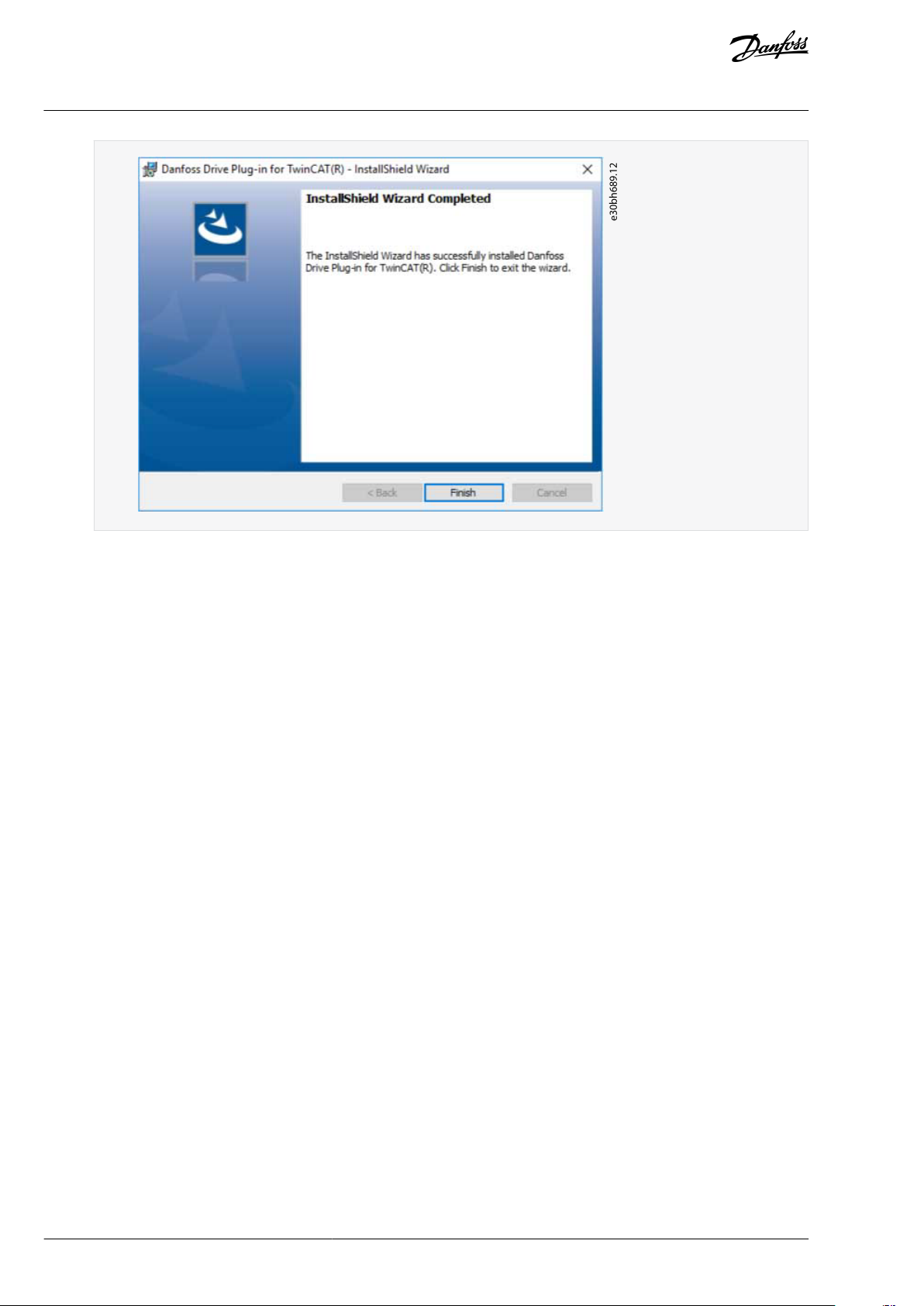

e30bh689.12

Danfoss DriveManager Plug-in for TwinCAT

User Guide

4.

Click Finish.

Installation and Deinstallation

2.2 Deinstallation, Danfoss DriveManager Plug-in for TwinCAT® and VLT® Motion Control Tool MCT

10

If both the Danfoss DriveManager Plug-in for TwinCAT® and the VLT® Motion Control Tool MCT 10 are installed, they share a database.

Uninstalling either program aects the operation of the other.

After uninstalling 1 of the programs, reinstall the other to continue normal operation.

BC319549253561en-000301 / 130R0913 6 | Danfoss A/S © | 2020.06

Page 7

e30bh690.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

User Interface

3 User Interface

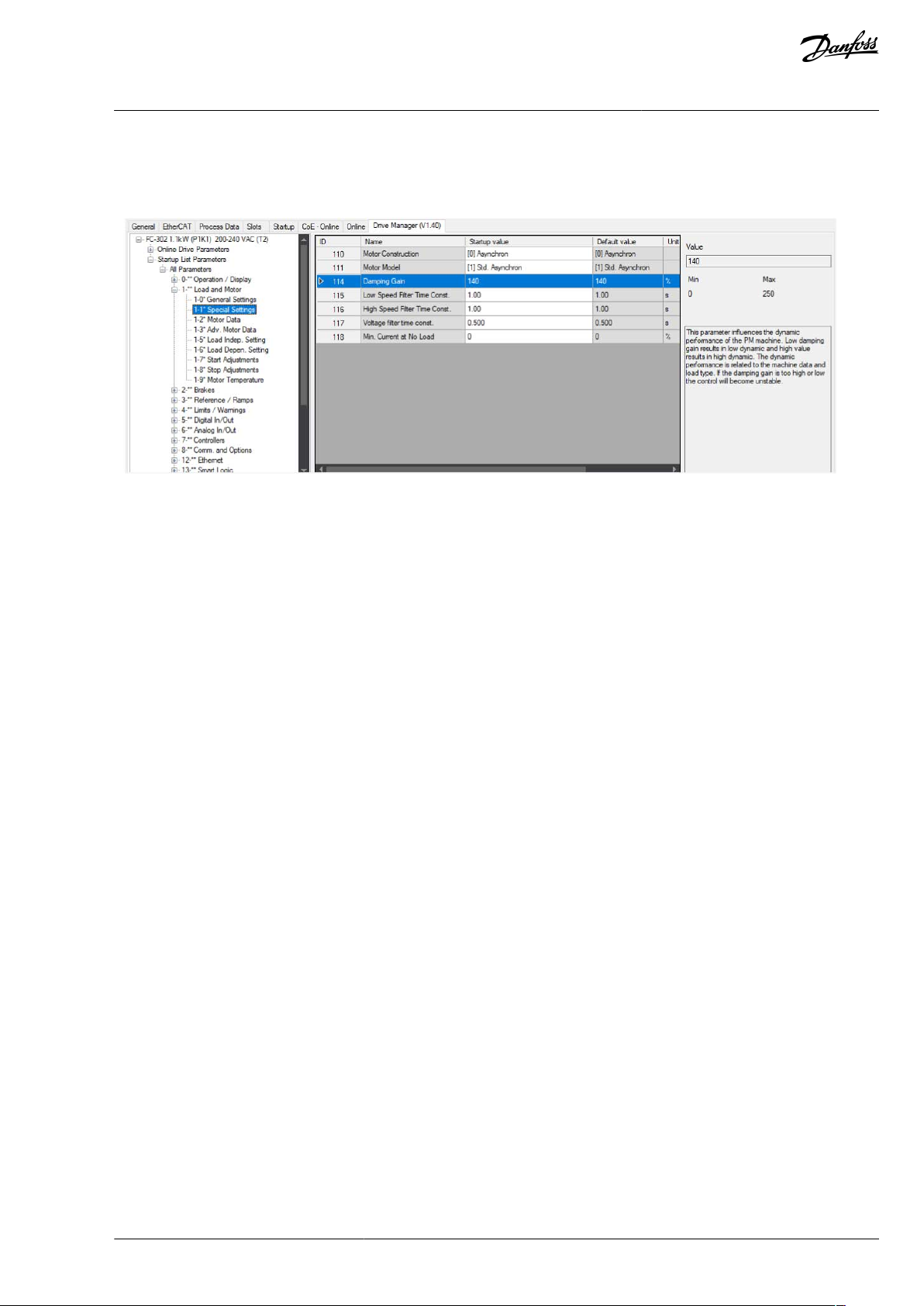

3.1 Description of the Danfoss DriveManager for TwinCAT® User Interface

The interface is split into 3 views:

•

The left view contains parameter groups and subgroups.

•

The middle view contains the following parameter information:

-

ID (parameter number)

-

Name

-

Value

-

Default value

-

Unit

-

Data type

-

Index - start-up list index

•

The right view contains parameter values, its minimum and maximum values, and the description.

Parameter values are modied via the Edit Parameter dialog, which can be called through a mouse double-click, or by pressing ei-

ther the spacebar or the Enter key.

BC319549253561en-000301 / 130R0913 | 7 Danfoss A/S © 2020.06

Page 8

e30bh824.10

Danfoss DriveManager Plug-in for TwinCAT

User Guide

User Interface

Illustration 1: Edit Parameter Dialog

BC319549253561en-000301 / 130R0913 8 | Danfoss A/S © | 2020.06

Page 9

e30bh691.11

e30bh692.11

e30bh963.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

4 Using the Danfoss DriveManager Plug-in for TwinCAT®

4.1 Scanning Devices

This procedure is a use case for scanning devices.

Ensure that the hardware setup is correct.

Procedure

1.

Open TwinCAT®.

2.

Create a new TwinCAT project.

Using the Danfoss DriveManager

Plug-in for TwinCAT®

3.

On the TwinCAT Project tab in the middle view, click Choose Target.

4.

Select the target system and click OK.

If the active solution platform is not TwinCAT RT (x64), it has to be changed.

5.

Click Yes to change the solution platform.

6.

Select the tab TwinCAT.

7.

Select Reset TwinCAT (Cong Mode).

BC319549253561en-000301 / 130R0913 | 9 Danfoss A/S © 2020.06

Page 10

e30bh694.10

e30bh695.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Using the Danfoss DriveManager

Plug-in for TwinCAT®

8.

Click OK.

9.

In the Solution Explorer window, right-click Devices and select Scan.

BC319549253561en-000301 / 130R0913 10 | Danfoss A/S © | 2020.06

Page 11

e30bh696.11

e30bh697.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Using the Danfoss DriveManager

Plug-in for TwinCAT®

10.

Click OK.

BC319549253561en-000301 / 130R0913 | 11 Danfoss A/S © 2020.06

Page 12

e30bh698.11

e30bh699.11

e30bh700.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

11.

Click OK.

Using the Danfoss DriveManager

Plug-in for TwinCAT®

12.

Click Yes.

If the network was set up correctly, all drives are found and identied, and the Danfoss DriveManager Plug-in for TwinCAT® is ready

to be used.

N O T I C E

If the drive software version is not supported (for example, if it is a new software version), the project drive can be created man-

ually.

BC319549253561en-000301 / 130R0913 12 | Danfoss A/S © | 2020.06

Page 13

e30bh701.11

e30bh702.12

e30bh703.10

Danfoss DriveManager Plug-in for TwinCAT

Using the Danfoss DriveManager

User Guide

If the software version is not supported, contact Danfoss help desk to nd the most compatible software version from the list of

supported rmware, or to receive software support.

Plug-in for TwinCAT®

4.2 Modifying the Startup List with Danfoss DriveManager Plug-in for TwinCAT®

The startup list may already contain values that were congured by the system manager based on the ESI specications. More application-specic entries can be created.

To edit the start-up list parameters, use either the Startup tab or the Drive Manager tab.

BC319549253561en-000301 / 130R0913 | 13 Danfoss A/S © 2020.06

Page 14

e30bh704.10

e30bh705.11

e30bh706.11

e30bh707.11

Danfoss DriveManager Plug-in for TwinCAT

Using the Danfoss DriveManager

User Guide

The Danfoss DriveManager Plug-in makes easy to work with parameters. The parameters are easily found, selections can be made

from dropdown lists, and values can be entered directly.

Example

Example of selecting an option in a parameter via the Danfoss DriveManager:

Illustration 2: Parameter Selected in Startup List

Plug-in for TwinCAT®

Illustration 3: Option Selected for Parameter in Danfoss DriveManager

Example

Example of setting a value for a parameter via the Danfoss DriveManager:

Illustration 4: Parameter Selected in Startup List

Illustration 5: Parameter Value Added in DriveManager

BC319549253561en-000301 / 130R0913 14 | Danfoss A/S © | 2020.06

Page 15

e30bh708.11

Color

Description

White

The parameter has the default value and is not in the startup list.

Golden

If the parameter value is dierent from the default value, this parameter value, and all other parameters depending on that one, are added to the startup list and marked with a golden color.

Orange

By right-clicking, the parameter is added to the startup list whether it has a default value or not.

Gainsboro

(dark gray)

The parameter is read-only.

Red

Occurs if an error takes place and a parameter value cannot be read from the drive.

Yellow

Occurs if a parameter value cannot be applied because the parameter depends on the values of other parameters.

e30bh709.11

e30bh710.11

Danfoss DriveManager Plug-in for TwinCAT

Using the Danfoss DriveManager

User Guide

Plug-in for TwinCAT®

4.2.1 Grid Colors

In the DriveManager view, the values of the parameters are color-coded depending on whether they are default or non-default values, or if they have been added to the startup list with or without a default value.

Illustration 6: Example of Color-coded Values in the DriveManager View

Table 2: Grid Color Legend

4.2.2 Removing a Parameter from the Startup List

When removing a parameter, the context menu depends on whether the parameter value is default or not. If the parameter value is

not default, the parameter is reset to default before it is removed from the startup list.

Procedure

1.

Right-click the parameter to be removed from the startup list.

2.

Click the context menu.

Illustration 7: Example of Parameter with Default Value

Illustration 8: Example of Parameter with Non-default Value

BC319549253561en-000301 / 130R0913 | 15 Danfoss A/S © 2020.06

Page 16

e30bh711.11

e30bh712.11

e30bh713.11

Danfoss DriveManager Plug-in for TwinCAT

User Guide

4.2.3 Adding a Default Value to the Startup List

To initialize drives, the parameters must have default values.

Procedure

1.

Right-click the parameter to be added to the startup list.

2.

Select the parameter appearing in the context menu.

4.2.4 Activating the Conguration

To apply the startup list to the PLC, activate the conguration as described in this procedure.

N O T I C E

The startup list must be applied to the drive RAM. After a power cycle, reapply the list to the RAM.

Using the Danfoss DriveManager

Plug-in for TwinCAT®

N O T I C E

To ensure that the correct values are applied to the startup list, initialize the drive before using it.

Procedure

1.

Select the TwinCAT tab.

2.

Select Activate Conguration.

3.

Click OK.

BC319549253561en-000301 / 130R0913 16 | Danfoss A/S © | 2020.06

Page 17

e30bh714.11

e30bh825.10

Danfoss DriveManager Plug-in for TwinCAT

User Guide

4.

Click OK.

4.3 Working with an Online Drive

This procedure is a use case for working with online drives.

Using the Danfoss DriveManager

Plug-in for TwinCAT®

Ensure that the proper hardware setup is in place.

Procedure

1.

Scan for devices (see 4.1 Scanning Devices).

2.

Select the scanned device and go to the DriveManager tab.

3.

Select a parameter group under Online Drive Parameters.

Illustration 9: Example of Parameters Read From the Online Drive

4.4 Modifying the Online Drive Parameters with Danfoss DriveManager Plug-in for TwinCAT®

Parameters under Online Drive Parameters allow interaction with an online drive in a more convenient way so that the parameters in

the parameter grid show the actual values read from the drive. Parameter values of an online drive can be edited in the same way as

the parameters under Startup List Parameters.

BC319549253561en-000301 / 130R0913 | 17 Danfoss A/S © 2020.06

Page 18

e30bh826.10

e30bh827.10

Danfoss DriveManager Plug-in for TwinCAT

Using the Danfoss DriveManager

User Guide

Illustration 10: Example of a Parameter Modication From the Online Drive

4.4.1 Restricted Modication

Restrictions on the modication of online drive parameters often occur in the following situations:

•

The parameter is read-only.

Plug-in for TwinCAT®

Illustration 11: Examples of Read-only Parameters with Corresponding Label Shown in the Right View

•

The parameter is not editable while the motor is running. An example of such a parameter is shown in Illustration 9. The corresponding label is shown in the right view.

•

The parameter value is not read. Parameter polling is not instant and performed starting from the top row so that if a parameter

is yet to be read, its value is shown as "????????".

BC319549253561en-000301 / 130R0913 18 | Danfoss A/S © | 2020.06

Page 19

e30bh828.10

e30bh829.10

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Using the Danfoss DriveManager

Plug-in for TwinCAT®

Illustration 12: Example of Read and Unread Parameters in the Grid

•

The parameter value cannot be read. Typically, such an issue occurs if there are network problems. A corresponding message is

shown in the parameter grid indicating the exact cause for the issue.

Illustration 13: Example of a Situation Where a Parameter Cannot be Read

•

The parameter has a dependency. It could be that a parameter depends on the values of other parameters that have not been

read yet. In this case, the cell will be highlighted in yellow, and the mouse hover will trigger a tooltip message.

BC319549253561en-000301 / 130R0913 | 19 Danfoss A/S © 2020.06

Page 20

e30bh831.10

Danfoss DriveManager Plug-in for TwinCAT

Using the Danfoss DriveManager

User Guide

Illustration 14: Example of a Situation Where a Parameter Cannot be Stored due to Being Dependent on Other Parameters

To handle restricted parameters, manually read the parameters of the drive.

Plug-in for TwinCAT®

4.5 Use Cases for Manual Drive Identication

4.5.1 Drive Identied but not Created in Danfoss DriveManager Plug-in

The problem in this use case is that, even though the devices are identied and created at the scanning, they may be unvisited after

saving and closing the project. This can occur if, for example, many devices are connected. In these cases, the previously unvisited

devices in the solution explorer do not have the project drives created automatically the next time the project is opened.

Illustration 15: Resulting View of a Device Being Previously Identied, but not Created in the Danfoss DriveManager Plug-in

Solution

Try to identify the drive by clicking the Try to identify the Drive button. On a successful drive identication, the drive is created auto-

matically as shown in

Illustration 16. If the identication fails, a corresponding error message is shown with hints to troubleshooting.

BC319549253561en-000301 / 130R0913 20 | Danfoss A/S © | 2020.06

Page 21

e30bh832.10

e30bh833.10

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Illustration 16: Device Created Successfully via the Manual Drive Identication Feature

4.5.1.1 Identifying the Device

Procedure

Scan for devices.

1.

2.

Select the scanned device and go to the DriveManager tab.

3.

Click the Try to identify the Drive button.

Using the Danfoss DriveManager

Plug-in for TwinCAT®

4.5.2 The Drive is Created, but Has Been Changed Externally

The problem in this use case is that, while the project is open with previously scanned devices, some of the devices may have been

changed externally. For example, a software version has been updated by VLT® Motion Control Tool MCT 10, which causes the drive

information in the plug-in to stay outdated.

Solution

Try to identify the drive by clicking the Try to identify the Drive button on the drive information panel. The identication result is

shown at the bottom of the panel. There are 4 possible outcomes:

The conguration is identical. The project is up-to-date and no changes to the projects are done.

•

The conguration is dierent.

•

-

The project update is possible. In such case, the Danfoss DriveManager updates the project to the up-to-date state. To see an

example where the updated information text appears in green, refer to

-

The project update is not possible. No changes to the project are done and an error message is shown.

•

Identication has failed. No changes to the projects are done and an error message is shown.

Illustration 17.

Illustration 17: Drive Information has been Successfully Identied and Updated

BC319549253561en-000301 / 130R0913 | 21 Danfoss A/S © 2020.06

Page 22

Danfoss DriveManager Plug-in for TwinCAT

User Guide

Index

A

Activate conguration................................................................................16

Active solution platform...............................................................................9

Additional resources......................................................................................3

Apply startup list to PLC.............................................................................16

C

Color code.......................................................................................................15

E

ESI les...................................................................................................................

L

Limitations of the Danfoss DriveManager.............................................4

N

New project.......................................................................................................9

O

Online drive....................................................................................................17

Index

P

Preconditions................................................................................................... 4

Q

Qualied personnel........................................................................................3

S

Scanning............................................................................................................ 9

Startup list.......................................................................................................13

T

Target system................................................................................................... 9

U

User interface................................................................................................... 7

BC319549253561en-000301/130R0913 22 | Danfoss A/S © 2020.06

Page 23

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice.

This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All

trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

130R0913

© Danfoss A/S 2020.06

BC319549253561en-000301/130R0913

M0011501

Loading...

Loading...