Fact Sheet

VLT® AutomationDrive FC 300

Ambient temperature and derating charts

Products

VLT® AutomationDrive FC 301/302 0.25 kW to 37 kW @ 200 – 240 V AC

VLT® AutomationDrive FC 301/302 0.37 kW to 75 kW @ 380-480/500 V AC

VLT® AutomationDrive FC 301/302 1.1 kW to 75 kW @ 525-690 V AC

VLT® AutomationDrive FC 302 90 kW to 500 kW @ 380-500 V AC

VLT® AutomationDrive FC 302 55 kW to 710 kW @ 525-690 V AC

Ambient temperature – general terms

Designed for variable speed control of

all induction motors and permanent

magnet motors, on any industrial

machine or production line, a VLT®

AutomationDrive FC 300 helps its

owner save energy, increase flexibility,

and optimize processes.

98%

energy efficiency

with flexible robust

operation in a wide

temperature range

n The definition of ambient and

cooling temperature is according to

EN50178, and IEC721-3-3 class 3K3.

n The drive can operate at elevated

ambient temperatures up to +55 °C,

however, the rated current must be

de-rated (please refer to the

derating chart below).

n Do not operate in environments

where the ambient temperature

exceeds 55 °C (131 °F). If the

temperature exceeds ambient

temperature limits, extra air

conditioning of the cabinet or

installation site is required.

Ambient temperature for operation and derating

n All products listed are able to work

at the below given ambient

temperature without any condition

/influence on the fulfillment of

specifications”

n Ambient temperature:

-10 °C to +45 °C

n Ambient temperature:

+45 °C to 55 °C with derating

(refer derating table)

n The drive can operate at

temperatures down to -10 °C (14 °F).

However, proper operation at rated

load is only guaranteed at 0 °C

(32 °F) or higher.

n Temperature range during storage /

transport is -25 to 65/70 °C

(-13 °F- 149/158 °F).

n Avoiding extreme ambient

temperatures prolongs the life of

the equipment and maximizes

overall system reliability.

n As a rule of thumb, the lifetime of

electronic components decreases

by 50% for every 10 °C when

operated above its design

temperature.

n All products listed are able to work

at ambient temperatures up to

50 °C without derating if certain

conditions are met/followed:.

n Applicable for EEF2 Class motors

n Reduce Switching frequency

(refer derating chart)

n Change switching mode to

“60 AVM” from “SFAVM”

drives.danfoss.com

Derating table for different power sizes and switching mode

2

4 6 8 10 12 14 16

0

2

4 6 8 10 12 14 16

e30ba402.10

0

I

(%)

2

4 6 8 10 12 14 16

0

I

(%)

e30ba401.11

n Derate the output current at high

temperatures. This calculation takes

place after the calculations for

derating the switching frequency.

n The result is an attempt to lower the

temperatures by first lowering the

switching frequency, and then

lowering the output current.

n Current derating only takes place if

the user has programmed the unit

to derate in overtemperature

situations. If the user has selected a

trip function for overtemperature

situations, the current derate factor

is not lowered.

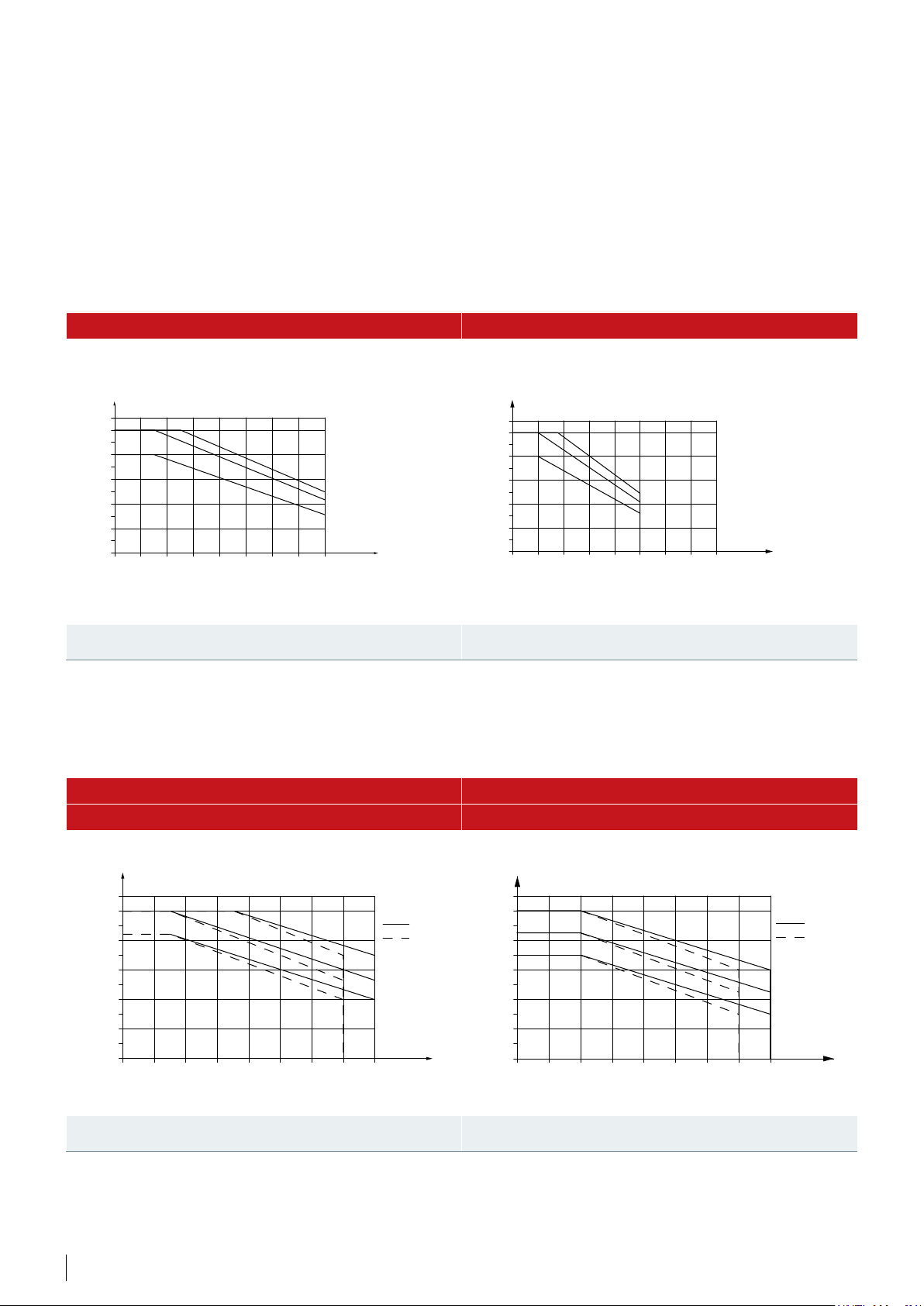

Derating for Ambient Temperature – Enclosure Size A (up to 7.5 kW @ 380-480/500 V)

60 ° AVM - Pulse width modulation SFAVM - Stator frequency induction vector modulation

I

110%

100%

80%

60%

40%

20%

(%)

out

e30ba393.10

A1-A3 45°C, A5 40°C

A1-A3 50°C, A5 45°C

A1-A3 55°C, A5 50°C

0

2

0

4 6 8 10 12 14 16

fsw (kHz)

110%

100%

80%

60%

40%

20%

I

(%)

out

A1-A3 45°C, A4-A5 40°C

A1-A3 50°C, A4-A5 45°C

A1-A3 55°C, A4-A5 50°C

0

e30bd639.10

fsw (kHz)

Illustration 62: Derating of I

Enclosure Size A, using 60° AVM

for Different T

out

AMB,MAX

for

Illustration 63: Derating of I

Enclosure Size A, using SFAVM

out

for Different T

AMB,MAX

for

Derating for Ambient Temperature – Enclosure Size B (up to 30 kW (IP20) and 22 kW (IP21/55 @ 380-480/500 V)

B1 & B2 – 60° AVM – High Overload B1 & B2 – 60° AVM - Normal Overload

60° AVM - Pulse width modulation, high overload (160%) 60° AVM - Pulse width modulation, normal overload (110%)

80%

60%

40%

20%

out

NO

45°C

50°C

55°C

f

0

sw

110%

100%

80%

60%

40%

20%

out

HO

B1

B2

45°C

50°C

55°C

f

(kHz)

0

sw

110%

100%

B1

B2

(kHz)

Illustration 66: Derating of I

Enclosure Sizes B1 and B2, using 60° AVM

for Different T

out

2 Danfoss Drives · DKDD.PFF.304.A1.02

AMB,MAX

for

Illustration 67: Derating of I

Enclosure Sizes B1 and B2, using 60° AVM

for Different T

out

AMB,MAX

for

B1 & B2 – SFAVM – High Overload B1 & B2 – SFAVM – Normal Overload

SFAVM - Stator frequency induction vector modulation,

high overload (160%)

(%)

I

out

80%

60%

40%

20%

HO

0

2

0

4 6 8 10 12 14 16

110%

100%

45°C

50°C

55°C

f

sw

B1

B2

(kHz)

SFAVM - Stator frequency induction vector modulation,

normal overload (110%)

I

(%)

out

NO

110%

100%

e30ba404.10

80%

60%

40%

20%

0

2

0

4 6 8 10 12 14 16

45°C

50°C

55°C

f

sw

B1

B2

(kHz)

e30ba403.11

Illustration 70: Derating of I

Enclosure Sizes B1 and B2, using SFAVM

for Different T

out

AMB,MAX

for

Illustration 71: Derating of I

Enclosure Sizes B1 and B2, using SFAVM

for Different T

out

B3 & B4 – 60° AVM- High Overload B3 & B4 – 60° AVM- Normal Overload

(%)

l

110%

100%

90%

80%

60%

40%

20%

out

HO

110%

e30bb830.10

B3 & B4

o

45 C

o

50 C

f

sw

0

0

2 4

6 8

10

12 14

(kHz)

16

100%

90%

80%

60%

40%

20%

(%)

l

out

NO

0

0

2 4

6 8

10

AMB,MAX

12 14

for

16

45 C

50 C

55 C

f

sw

e30bb828.10

B3

B4

o

o

o

(kHz)

Illustration 68: Derating of I

Enclosure Sizes B3 and B4, using 60° AVM

for Different T

out

AMB,MAX

for

Illustration 69: Derating of I

Enclosure Sizes B3 and B4, using 60° AVM

for Different T

out

AMB,MAX

for

3Danfoss Drives · DKDD.PFF.304.A1.02

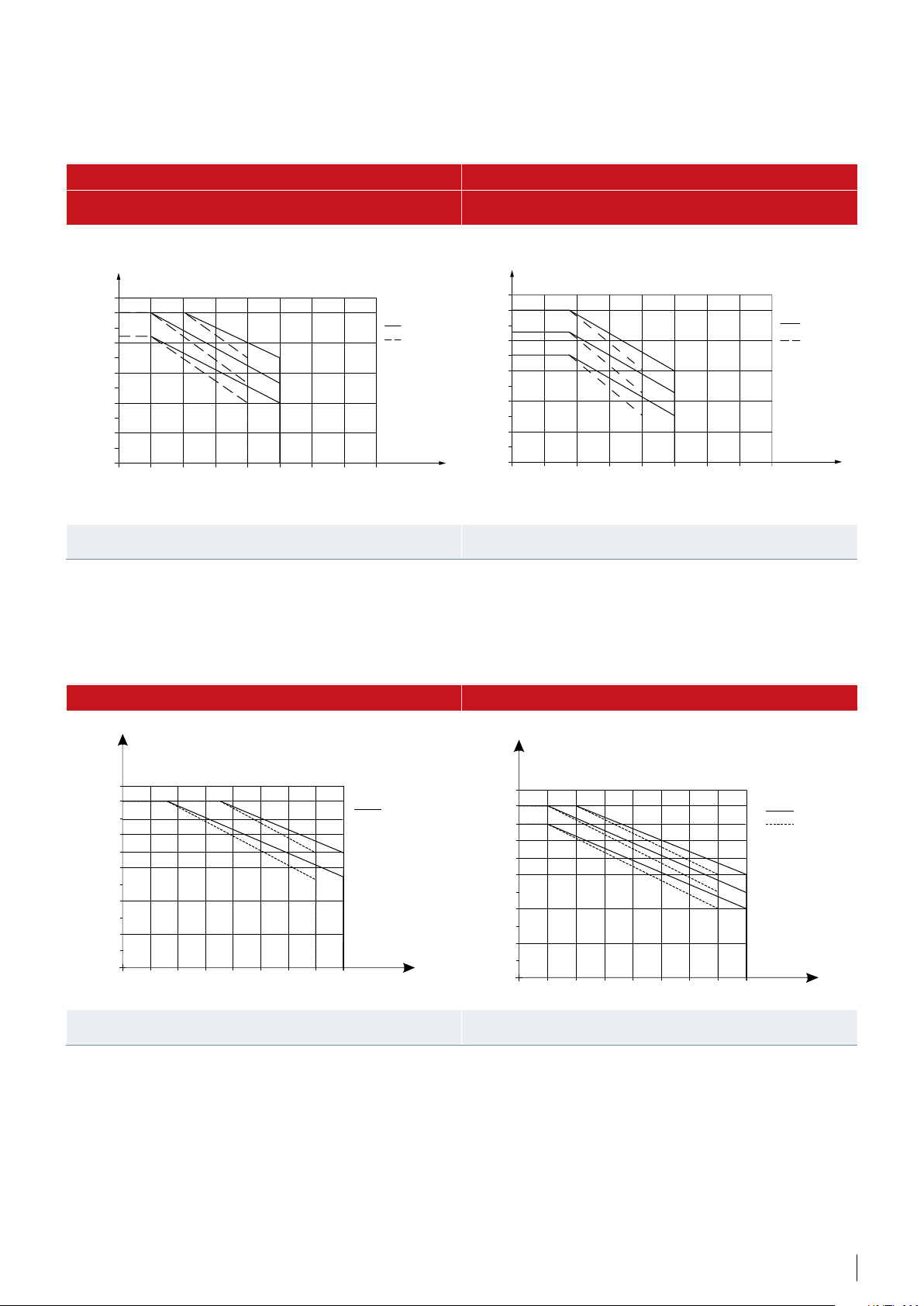

B3 & B4 – SFAVM – High Overload B3 & B4 – SFAVM – Normal Overload

(%)

l

110%

100%

90%

80%

60%

40%

l

HO

(%)

out

e30bb834.10

B3

B4

o

45 C

o

50 C

110%

100%

90%

80%

60%

40%

out

NO

45 C

50 C

e30bb832.10

B3

B4

o

o

20%

0

0

2 4

Illustration 72: Derating of I

Enclosure Sizes B3 and B4, using SFAVM

6 8

out

10

12 14

for Different T

16

AMB,MAX

f

sw

(kHz)

for

20%

0

0

2 4

Illustration 73: Derating of I

Enclosure Sizes B3 and B4, using SFAVM

6 8

for Different T

out

10

12 14

AMB,MAX

16

for

f

sw

Derating for Ambient Temperature – Enclosure Size C (upto 75 kW 380/500 V)

C1 & C2 – 60° AVM – High Overload C1 & C2 – 60° AVM – Normal Overload

60° AVM - Pulse width modulation, high overload (160%) 60° AVM - Pulse width modulation, normal overload (110%)

(%)

I

110%

100%

80%

60%

40%

20%

out

HO

C1 & C2

e30ba398.10

45°C

50°C

55°C

(kHz)

f

0

2

0

4 6 8 10 12 14 16

sw

110%

100%

80%

60%

40%

20%

I

(%)

out

NO

0

0

2

4 6 8 10 12 14 16

(kHz)

45°C

50°C

55°C

f

sw

C1 & C2

(kHz)

e30ba397.10

Illustration 80: Derating of I

Enclosure Sizes C1 and C2, using 60° AVM

for Different T

out

4 Danfoss Drives · DKDD.PFF.304.A1.02

AMB,MAX

for

Illustration 81: Derating of I

Enclosure Sizes C1 and C2, using 60° AVM

for Different T

out

AMB,MAX

for

C1 & C2 – SFAVM – High Overload C1 & C2 – SFAVM – Normal Overload

SFAVM - Stator frequency induction vector modulation,

high overload (160%)

(%)

I

out

HO

110%

100%

80%

60%

40%

20%

0

2

0

4 6 8 10 12 14 16

45°C

50°C

55°C

f

sw

C1 & C2

(kHz)

SFAVM - Stator frequency induction vector modulation,

normal overload (110%)

(%)

I

out

NO

110%

100%

e30ba400.10

80%

60%

40%

20%

0

0

2

4 6 8 10 12 14 16

45°C

50°C

55°C

f

sw

C1 & C2

(kHz)

e30ba399.10

Illustration 84: Derating of I

Enclosure Sizes C1 and C2, using SFAVM

for Different T

out

AMB,MAX

for

Illustration 85: Derating of I

Enclosure Sizes C1 and C2, using SFAVM

for Different T

out

C3 & C4 – 60° AVM – High Overload C3 & C4 – 60° AVM – Normal Overload

110%

100%

90%

80%

60%

40%

20%

l

HO

out

(%)

2 4

6 8

110%

e30bb831.10

C3 & C4

o

45 C

o

50 C

f

sw

(kHz)

10

12 14

16

100%

90%

80%

60%

40%

20%

(%)

l

out

NO

0

0

2 4

6 8

10

o

45 C

o

50 C

o

55 C

12 14

AMB,MAX

for

C3 & C4

f

sw

(kHz)

16

e30bb829.10

Illustration 82: Derating of I

Enclosure Sizes C3 and C4, using 60° AVM

for Different T

out

AMB,MAX

for

Illustration 83: Derating of I

Enclosure Sizes C3 and C4, using 60° AVM

for Different T

out

AMB,MAX

for

5Danfoss Drives · DKDD.PFF.304.A1.02

C3 & C4 – SFAVM – High Overload C3 & C4 – SFAVM – Normal Overload

e30bb835.10

Iout [%]

fsw [kHz]

(%)

l

out

HO

110%

100%

90%

80%

o

60%

40%

20%

0

0

2 4

Illustration 86: Derating of I

Enclosure Sizes C3 and C4, using SFAVM

45 C

50 C

6 8

for Different T

out

o

10

12 14

AMB,MAX

16

for

110%

100%

C3 & C4

f

sw

(kHz)

90%

80%

60%

40%

20%

Illustration 87: Derating of I

Enclosure Sizes C3 and C4, using SFAVM

(%)

l

out

NO

0

0

2 4

Derating for Ambient Temperature – Enclosure Size D(N90 to N250 kW 380-500 V)

6 8

for Different T

out

45 C

50 C

e30bb833.10

C3 & C4

o

o

f

sw

(kHz)

10

12 14

AMB,MAX

16

for

D1 to D8h – 60° AVM – High Overload D1 to D8h – 60° AVM – Normal Overload

High overload HO, 150% Normal overload NO, 110%

110

100

90

80

70

60

130BX473.11

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

1

0

2 3 4 5 6 7 8

9

110

100

90

80

Iout [%]

70

60

50

1

2 3 4 5 6 7 8 90

fsw

[kHz]

130BX474.11

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

6 Danfoss Drives · DKDD.PFF.304.A1.02

D1 to D8h – SFAVM – High Overload D1 to D8h – SFAVM – Normal Overload

130BX475.11

Iout [%]

130BX477.11

Iout [%]

Iout [%]

110

110

100

90

80

70

60

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

2 4 60

31 5

[kHz]

fsw

100

90

80

Iout [%]

70

60

50

1

2 4

fsw

3

[kHz]

40 ˚C (104 ˚F)

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

5

130BX476.11

60

Derating for Ambient Temperature – Enclosure Size E (N315 to N500 kW 380-500 V)

E1 to E4h – 60° AVM – High Overload E1 to E4h – 60° AVM – Normal Overload

110

100

90

80

70

60

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

1

2 3 4 5 6 70

fsw

[kHz]

110

100

90

80

70

60

50

2 3 4 5 6 70

1

fsw

130BX478.11

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

50 ˚C (131 ˚F)

[kHz]

7Danfoss Drives · DKDD.PFF.304.A1.02

E1 to E4h – SFAVM – High Overload E1 to E4h – SFAVM – Normal Overload

110

100

90

Iout [%]

80

70

60

110

130BX479.11

100

130BX480.11

90

80

Iout [%]

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

1

2 3 4 50

[kHz]

fsw

70

60

40 ˚C (104 ˚F)

45 ˚C (113 ˚F)

50 ˚C (122 ˚F)

55 ˚C (131 ˚F)

DKDD.PFF.304.A1.02 © Copyright Danfoss Drives | 2020.02

Loading...

Loading...