Page 1

MAKING MODERN LIVING POSSIBLE

Output Filters Design Guide

VLT® AutomationDrive FC 300

VLT® AQUA Drive FC 200

VLT® HVAC Drive FC 100

Page 2

Contents Output Filters Design Guide

Contents

1 How to Read this Design Guide

1.1.2 Abbreviations 3

2 Safety and Conformity

2.1 Safety Precautions

2.1.1 CE Conformity and Labelling 4

3 Introduction to Output Filters

3.1 Why use Output Filters

3.2 Protection of Motor Insulation

3.2.1 The Output Voltage 5

3.3 Reduction of Motor Acoustic Noise

3.4 Reduction of High Frequency Electromagnetic Noise in the Motor Cable

3.5 What are Bearing Currents and Shaft Voltages?

3.5.1 Mitigation of Premature Bearing Wear-Out 9

3.5.2 Measuring Electric Discharges in the Motor Bearings 10

3.6 Which Filter for which Purpose

3.6.1 dU/dt Filters 12

3

4

4

5

5

5

7

8

9

12

3.6.2 Sine-wave Filters 14

3.6.3 High-Frequency Common-Mode Core Kits 16

4 Selection of Output Filters

4.1 How to Select the Correct Output Filter

4.1.1 Product Overview 17

4.1.2 HF-CM Selection 19

4.2 Electrical Data - dU/dt Filters

4.3 Electrical Data - Sine-wave Filters

4.3.1 Spare Parts/Accessories 27

4.3.2 Cable Glands for Floor Standing Filters 27

4.3.3 Terminal Kits 28

4.4 Sine-Wave Filters

4.4.1 dU/dt Filters 30

4.4.2 Sine-Wave Foot Print Filter 31

5 How to Install

5.1 Mechanical Mounting

17

17

20

22

29

32

32

5.1.1 Safety Requirements for Mechanical Installation 32

5.1.2 Mounting 32

5.1.3 Mechanical Installation of HF-CM 32

5.1.4 Earthing of Sine-wave and dU/dt Filters 33

MG.90.N5.02 - VLT® is a registered Danfoss trademark 1

Page 3

Contents Output Filters Design Guide

5.1.5 Screening 33

5.2 Mechanical Dimensions

5.2.1 Sketches 34

6 How to Programme the Frequency Converter

6.1.1 Parameter Settings for Operation with Sine-wave Filter 43

Index

34

43

44

2 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 4

How to Read this Design Gui... Output Filters Design Guide

1 How to Read this Design Guide

This Design Guide will introduce all aspects of output filters

for your frequency converter; from choosing the right output

filter for the application to instructions about how to install it

and how to program the frequency converter.

Danfoss technical literature is also available online at

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.

1.1.1 Symbols

Symbols used in this manual

NOTE

Indicates something to be noted by the reader.

CAUTION

Indicates a general warning.

WARNING

Indicates a high-voltage warning.

Indicates default setting

✮

1.1.2 Abbreviations

Alternating current AC

American wire gauge AWG

Ampere/AMP A

Automatic Motor Adaptation AMA

Current limit I

Degrees Celsius °C

Direct current DC

Drive Dependent D-TYPE

Electro Magnetic Compatibility EMC

Electronic Thermal Relay ETR

Drive FC

Gram g

Hertz Hz

Kilohertz kHz

Local Control Panel LCP

Meter m

Millihenry Inductance mH

Milliampere mA

Millisecond ms

Minute min

Motion Control Tool MCT

Nanofarad nF

Newton Meters Nm

Nominal motor current I

Nominal motor frequency f

Nominal motor power P

Nominal motor voltage U

Parameter par.

Protective Extra Low Voltage PELV

Rated Inverter Output Current I

Revolutions Per Minute RPM

Second sec.

Synchronous Motor Speed n

Torque limit T

Volts V

I

VLT,MAX

I

VLT,N

LIM

M,N

M,N

M,N

M,N

INV

s

LIM

The maximum output current.

The rated output current

supplied by the frequency

converter.

1 1

MG.90.N5.02 - VLT® is a registered Danfoss trademark 3

Page 5

Safety and Conformity Output Filters Design Guide

2 Safety and Conformity

22

NOTE

2.1 Safety Precautions

Never attempt to repair a defect filter.

Equipment containing electrical components

may not be disposed of together with domestic

waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

MCC 101/102

Design Guide

2.1.1 CE Conformity and Labelling

What is CE Conformity and Labelling?

The purpose of CE labelling is to avoid technical trade

obstacles within EFTA and the EU. The EU has introduced the

CE label as a simple way of showing whether a product

complies with the relevant EU directives. The CE label says

nothing about the specifications or quality of the product.

The low-voltage directive (73/23/EEC)

Frequency converters must be CE labelled in accordance

with the low-voltage directive of January 1, 1997. The

directive applies to all electrical equipment and appliances

used in the 50 - 1000V AC and the 75 - 1500V DC voltage

ranges. Danfoss CE-labels in accordance with the directive

and issues a declaration of conformity upon request.

NOTE

The filters presented in this design guide are specially

designed and tested for Danfoss frequency converters (FC

102/202/301 and 302). Danfoss takes no resposibility for the

use of third party output filters.

NOTE

The phased out LC-filters that were developed for the

VLT5000 series and are not compatible with the VLT FC

100/200/300.

However, the new filters are compatible with both FC-series

and VLT 5000-series

NOTE

690V applications:

For motors not specially designed for frequency converter

operation or without double insulation, Danfoss highly

recommend the use of either dU/dt or Sine-Wave filters.

NOTE

Sine-wave filters can be used at switching frequencies higher

than the nominal switching frequency, but should never be

used at switching frequencies with less than 20% lower than

the nominal switching frequency.

NOTE

dU/dt filters, unlike Sine-wave filters, can be used at lower

switching frequency than the nominal switching frequency,

but higher switching frequency will cause overheating of the

filter and should be avoided.

Warnings

CAUTION

When in use the filter surface temperature rises. DO NOT

touch the filter during operation.

WARNING

Never work on a filter in operation. Touching the electrical

parts may be fatal - even after the equipment has been

disconnected from the frequency converter or motor.

WARNING

Before servicing the filter, wait at least the voltage discharge

time stated in the Design Guide for the corresponding

frequency converter to avoid electrical shock hazard.

4 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 6

Introduction to Output Filt... Output Filters Design Guide

3 Introduction to Output Filters

3.1 Why use Output Filters

This chapter describes why and when to use Output Filters

with Danfoss frequency converters. It is divided into 4

sections:

Protection of Motor Insulation

•

Reduction of Motor Acoustic Noise

•

Reduction of High Frequency Electromagnetic

•

Noise in Motor Cable

Bearing currents and shaft voltage

•

3.2 Protection of Motor Insulation

3.2.1 The Output Voltage

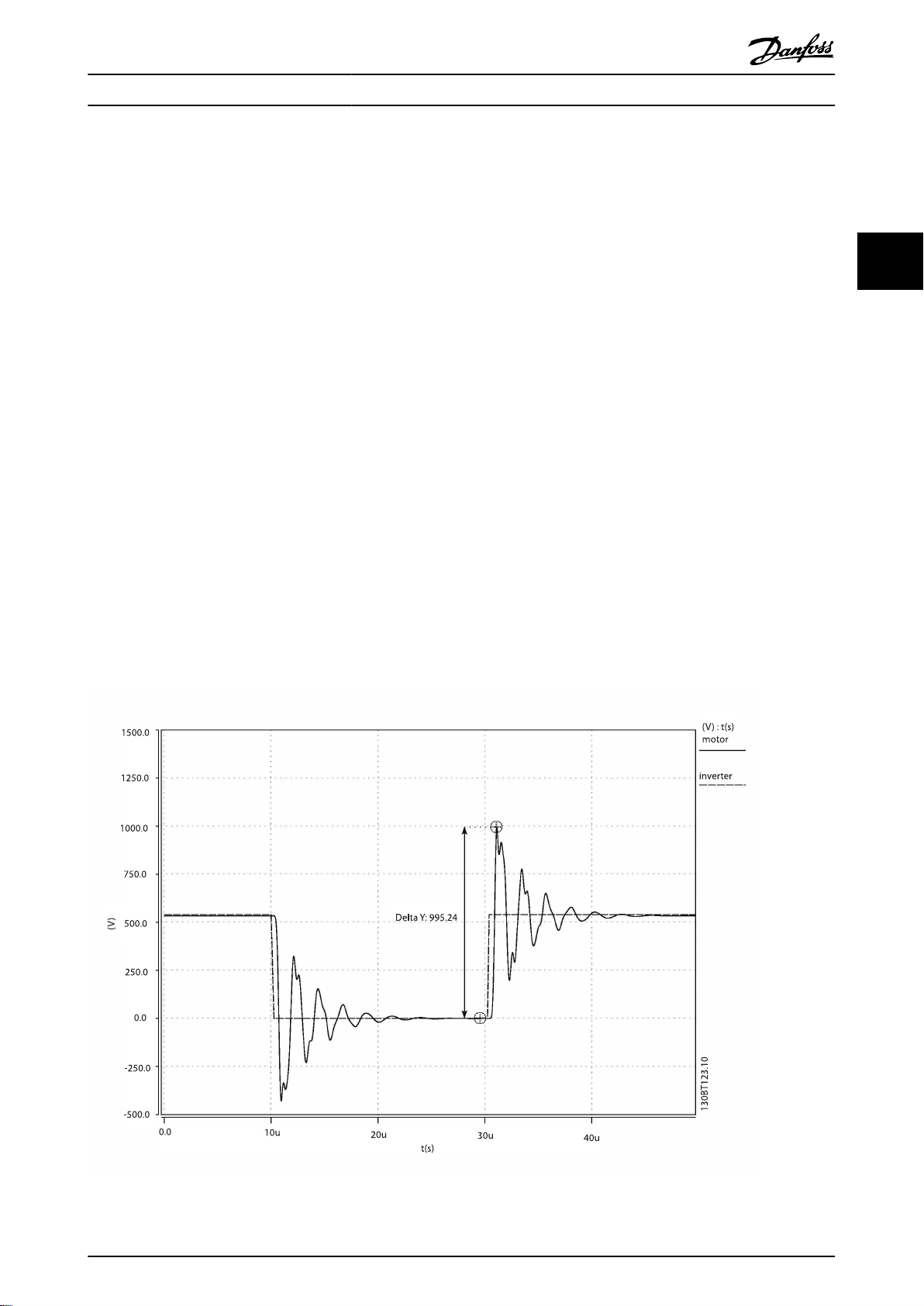

The output voltage of the frequency converter is a series of

trapezoidal pulses with a variable width (pulse width

modulation) characterized by a pulse rise-time tr.

When a transistor in the inverter switches, the voltage across

the motor terminal increases by a dU/dt ratio that depends

on:

the motor cable (type, cross-section, length,

•

screened or unscreened, inductance and

capacitance)

the high frequency surge impendance of the motor

•

Because of the impedance mismatch between the cable

characteristic impedance and the motor surge impedance a

wave reflection occurs, causing a ringing voltage overshoot

at the motor terminals - see Illustration 3.1. The motor surge

impedance decreases with the increase of motor size

resulting in reduced mismatch with the cable impedance.

The lower reflection coefficient (Γ) reduces the wave

reflection and thereby the voltage overshoot. Typical values

are given in Table 3.1.

In the case of parallel cables the cable characteristic

impedance is reduced, resulting in a higher reflection

coefficient higher overshoot. For more information please

see IEC 61800-8.

3

3

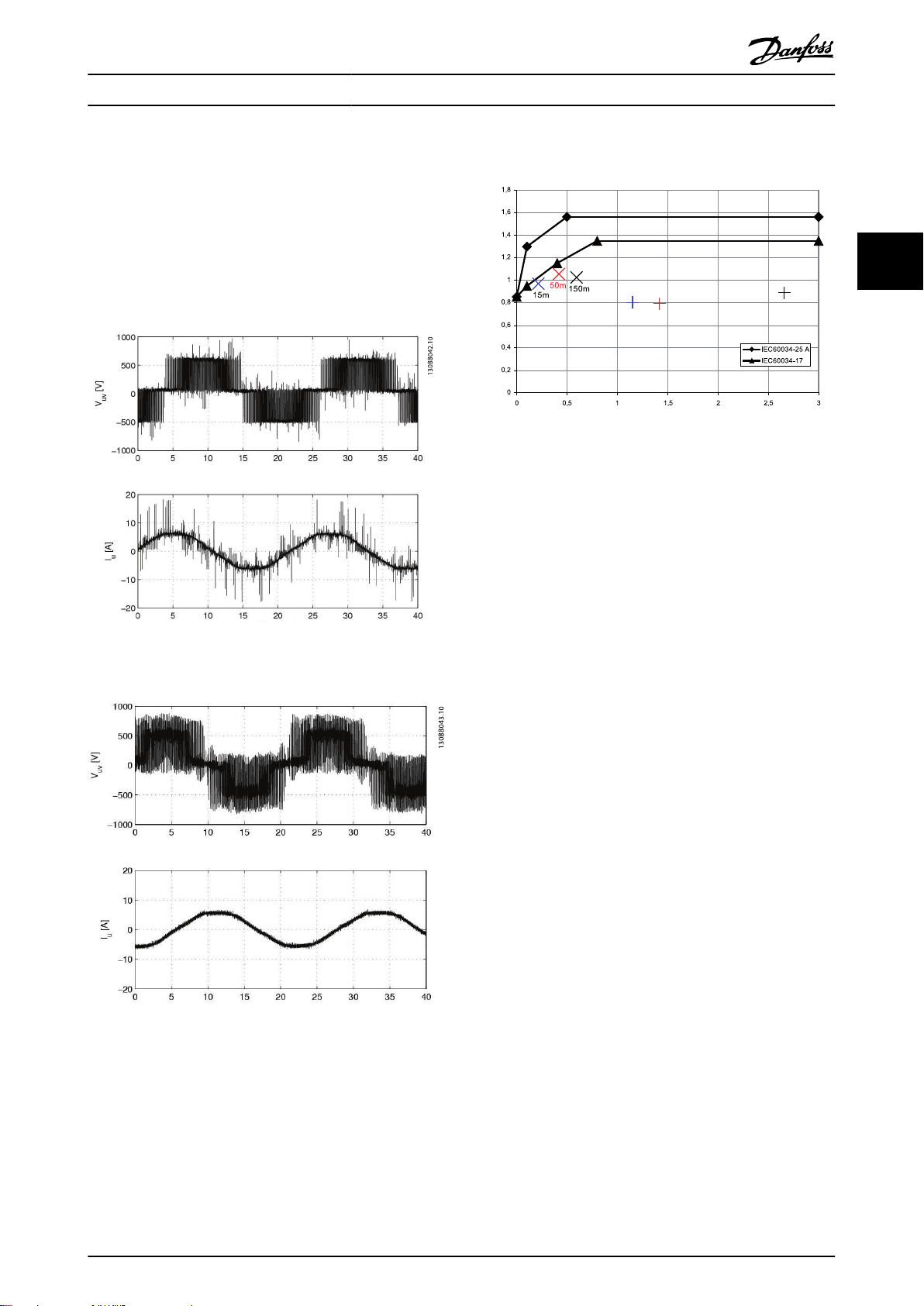

Illustration 3.1 Example of Converter Output Voltage (dotted line) and Motor Terminal Voltage After 200m of Cable (solid line)

MG.90.N5.02 - VLT® is a registered Danfoss trademark 5

Page 7

Introduction to Output Filt... Output Filters Design Guide

3

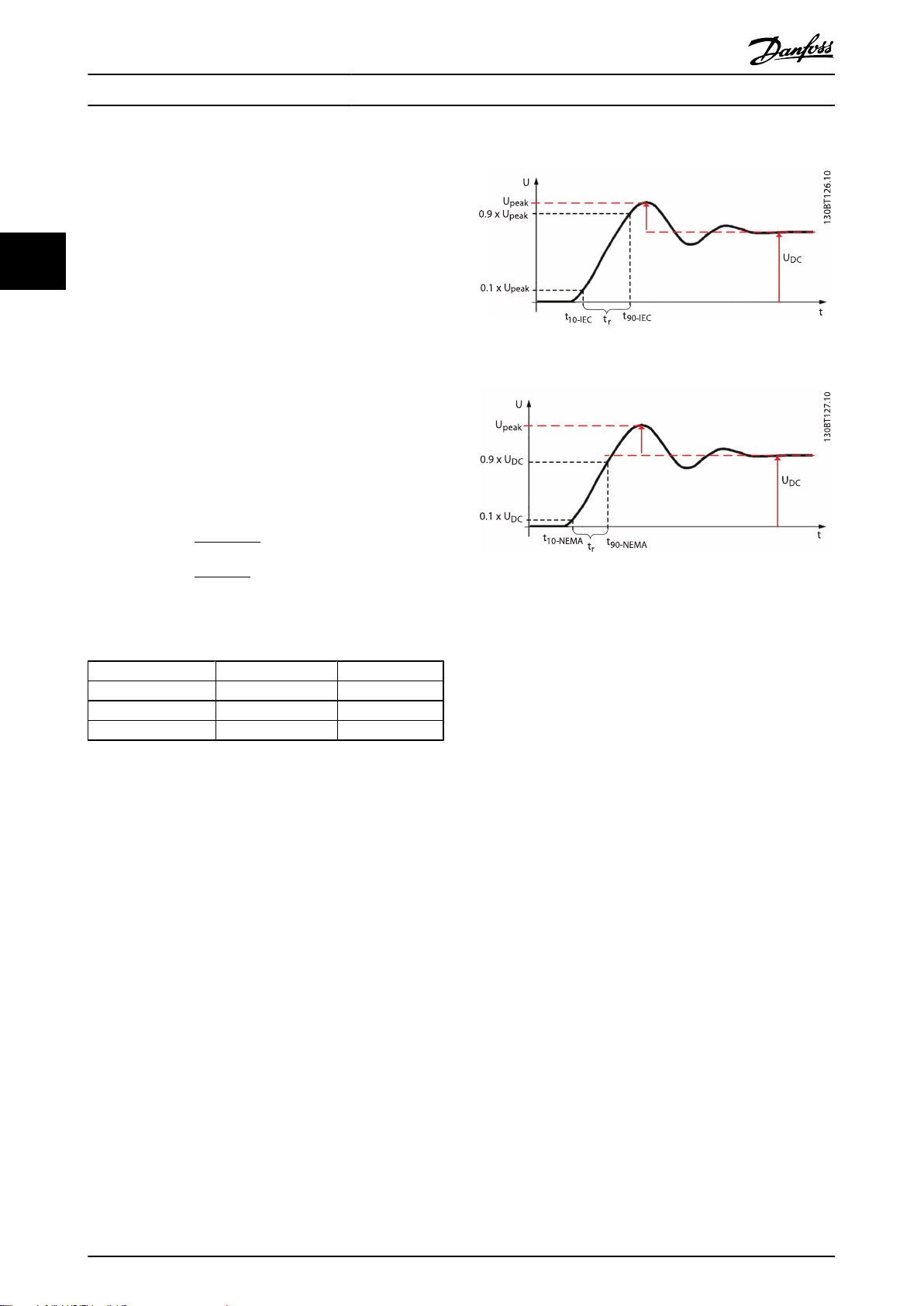

Typical values for the rise time and peak voltage U

PEAK

are

measured on the motor terminals between two phases.

Two different definitions for the risetime tr are used in

practice. The international IEC standards define the rise-time

as the time between 10% to 90% of the peak voltage U

peak

The US National Electrical Manufacturers Association (NEMA)

defines the rise-time as the time between 10% and 90% of

the final, settled voltage, that is equal to the DC link voltage

UDC. See Illustration 3.2 and Illustration 3.3.

To obtain approximate values for cable lengths and voltages

not mentioned below, use the following rules of thumb:

1. Rise time increases with cable length.

2.

U

= DC link voltage x (1+Γ); Γ represents the

PEAK

reflection coefficient and typical values can be

found in table below

(DC link voltage = Mains voltage x 1.35).

0.8 ×

0.8 ×

t

(

NEMA

r

U

PEAK

(IEC)

t

r

U

DC

(NEMA)

)

values at different cable lengths

peak

3.

dU/dt =

dU/dt

=

(For dU/dt, rise time, U

please consult the drive Design Guide)

Motor power [kW]

<3.7 2000 - 5000 0.95

90 800 0.82

355 400 0.6

Table 3.1 Typical Values for Reflection Coefficients (IEC 61800-8).

Zm [Ω]

Γ

The IEC and NEMA Definitions of Risetime t

r

.

Illustration 3.2 IEC

Illustration 3.3 NEMA

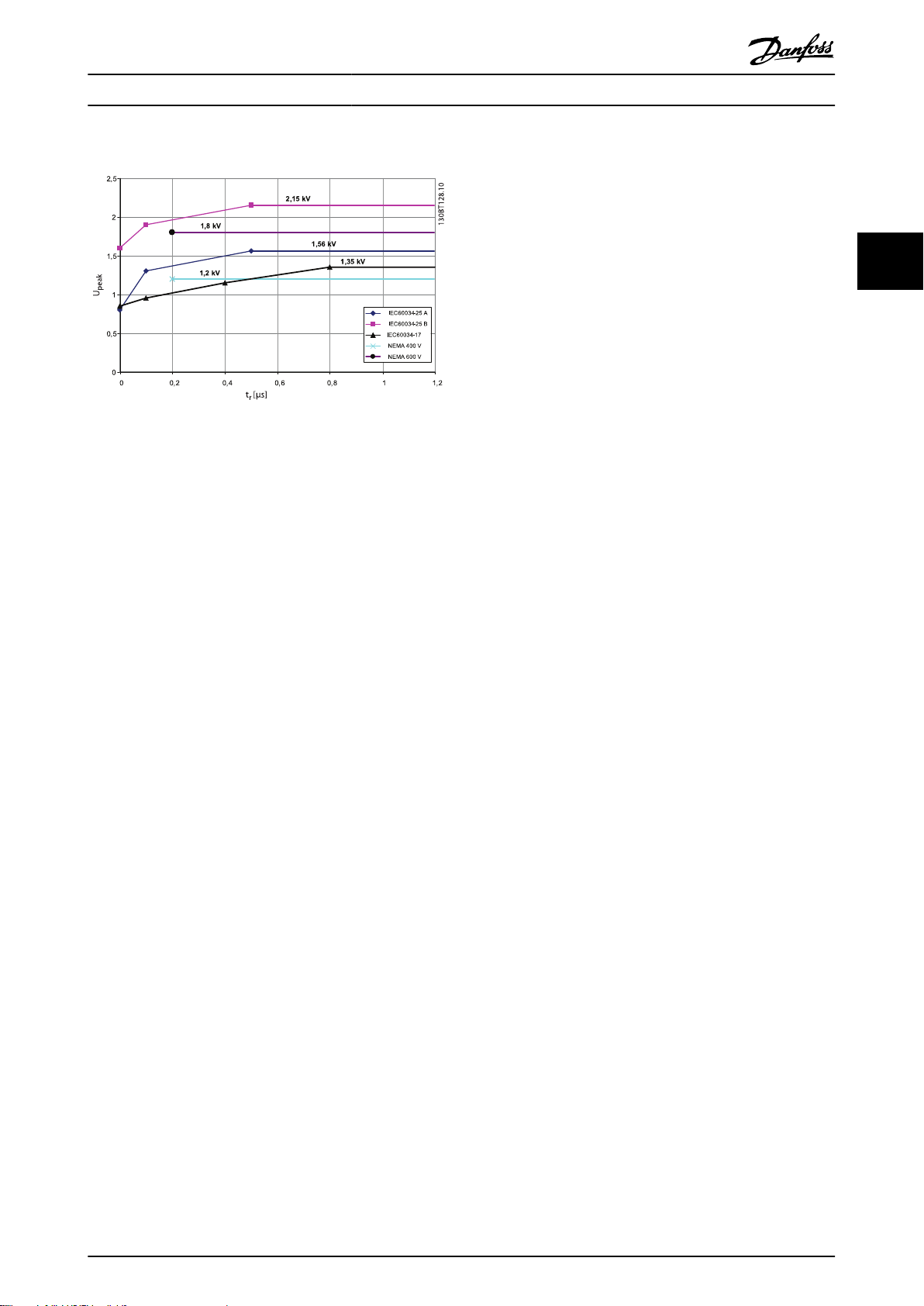

Various standards and technical specifications present limits

of the admissible U

and tr for different motor types. Some

peak

of the most used limit lines are shown in Illustration 3.4

IEC 60034-17 – limit line for general purpose

•

motors when fed by frequency converters, 500V

motors.

IEC 60034-25 – limit for converter rated motors:

•

curve A is for 500V motors and curve B is for 690V

motors.

NEMA MG1 – Definite purpose Inverter Fed Motors.

•

If, in your application, the resulting U

and tr exceed the

peak

limits that apply for the motor used, an output filter should

be used for protecting the motor insulation.

6 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 8

Introduction to Output Filt... Output Filters Design Guide

3

3

Illustration 3.4 Limit Lines for U

and Risetime tr.

peak

3.3 Reduction of Motor Acoustic Noise

The acoustic noise generated by motors has three main

sources.

1. The magnetic noise produced by the motor core,

through magnetostriction

2. The noise produced by the motor bearings

3. The noise produced by the motor ventilation

When a motor is fed by a frequency converter, the

pulsewidth modulated (PWM) voltage applied to the motor

causes additional magnetic noise at the switching frequency

and harmonics of the switching frequency (mainly the

double of the switching frequency). In some applications this

is not acceptable. In order to eliminate this additional

switching noise, a sine-wave filter should be used. This will

filter the pulse shaped voltage from the frequency converter

and provide a sinusoidal phase-to-phase voltage at the

motor terminals.

MG.90.N5.02 - VLT® is a registered Danfoss trademark 7

Page 9

3

Introduction to Output Filt... Output Filters Design Guide

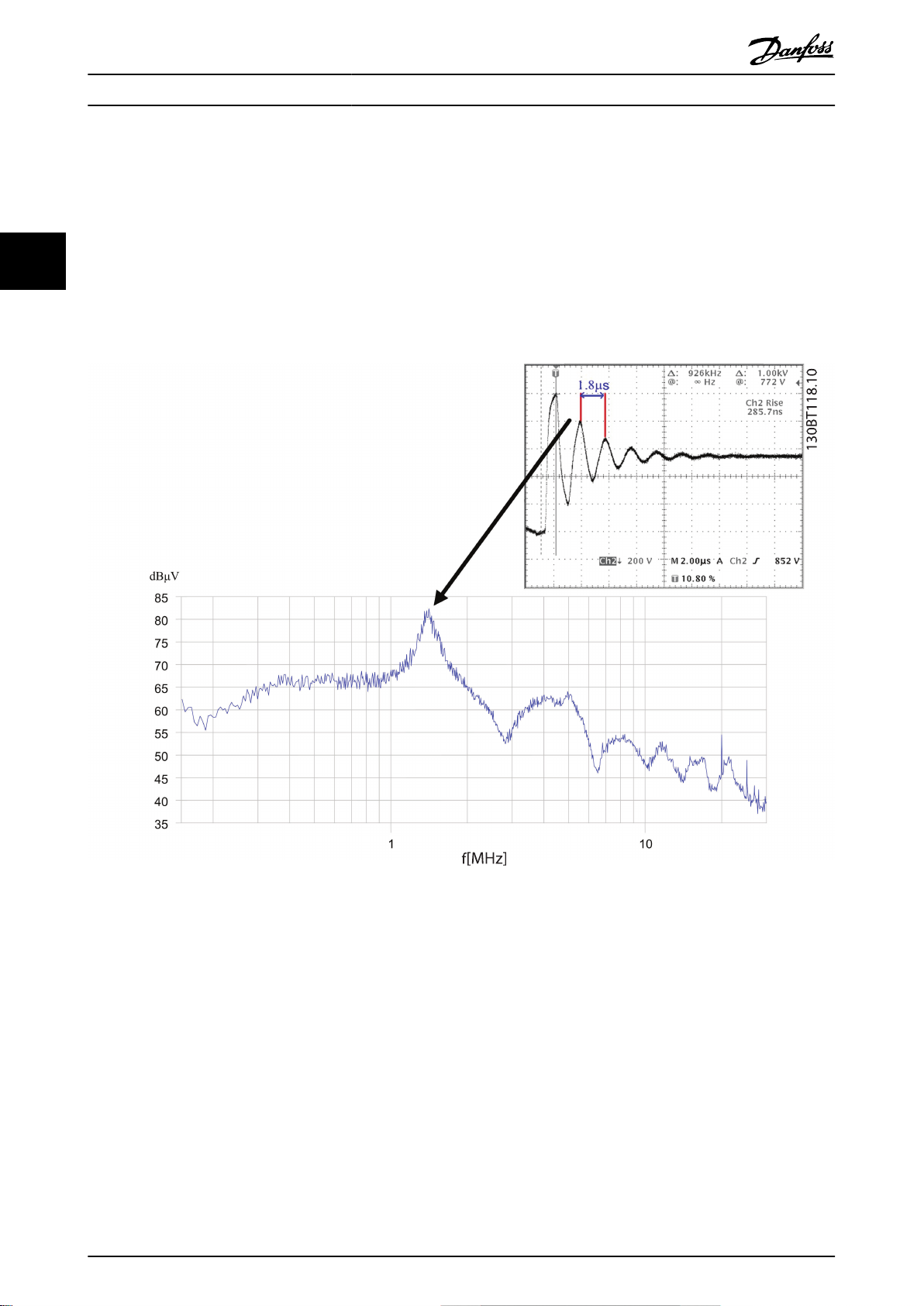

3.4 Reduction of High Frequency Electromagnetic Noise in the Motor Cable

When no filters are used, the ringing voltage overshoot that occurs at the motor terminals is the main high-frequency noise

source. Illustration 3.5 shows the correlation between the frequency of the voltage ringing at the motor terminals and the

spectrum of the high-frequency conducted interference in the motor cable.

Besides this noise component, there are also other noise components such as:

The common-mode voltage between phases and ground at the switching frequency and its harmonics - high

•

amplitude but low frequency.

High-frequency noise (above 10MHz) caused by the switching of semiconductors - high frequency but low amplitude.

•

Illustration 3.5 Correlation Between the Frequency of the Ringing Voltage Overshoot and the Spectrum of Noise Emissions.

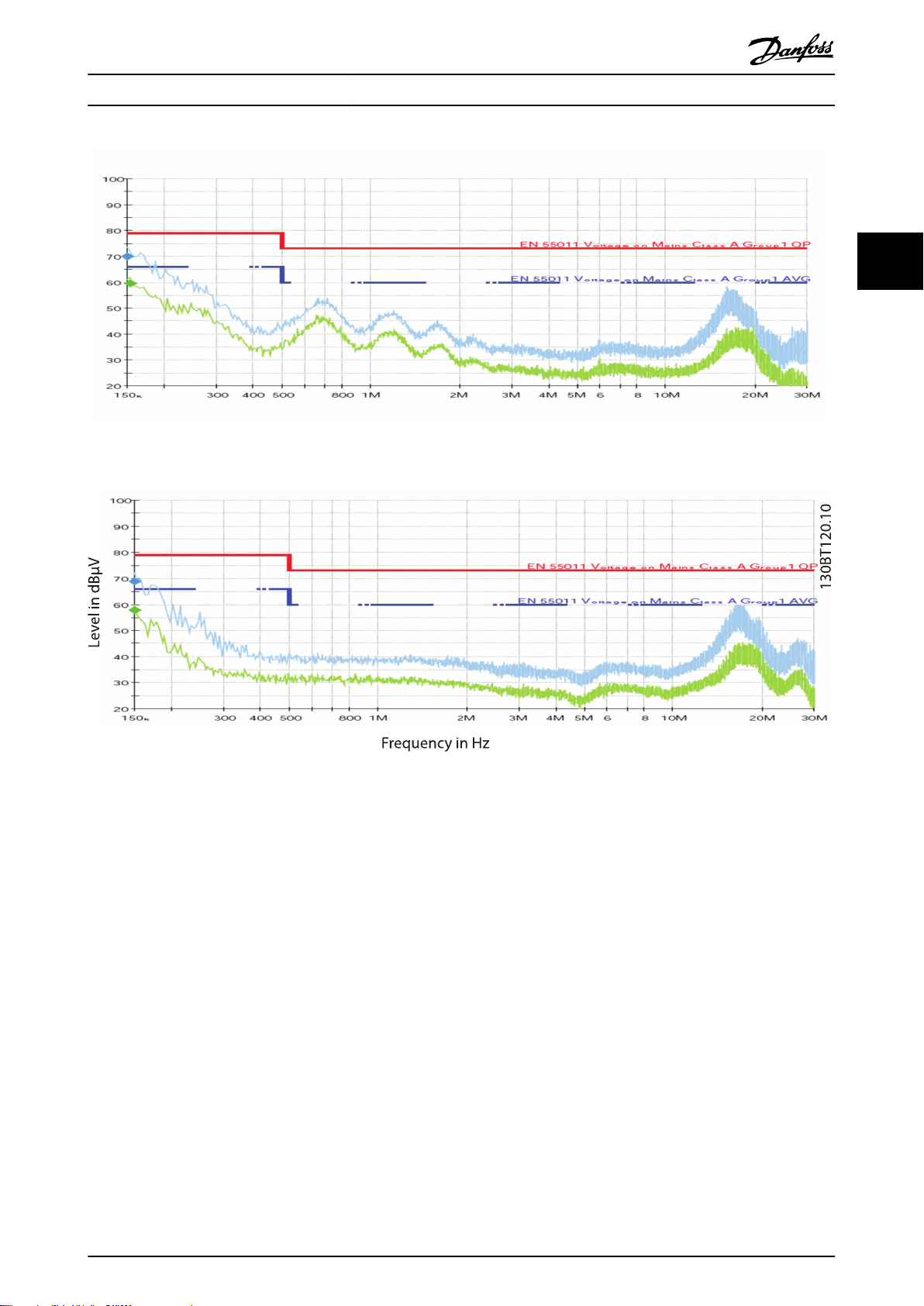

When an output filter is installed following effect is achieved:

In the case of dU/dt filters the frequency of the ringing oscillation is reduced below 150kHz.

•

In the case of sine-wave filters the ringing oscillation is completely eliminated and the motor is fed by a sinusoidal

•

phase-to-phase voltage.

Remember, that the other two noise components are still present. This is illustrated in the conducted emission measurements

shown in Illustration 3.7 and Illustration 3.8. The use of unshielded motor cables is possible, but the layout of the installation

should prevent noise coupling between the unshielded motor cable and the mains line or other sensitive cables (sensors,

communication, etc.). This can be achieved by cable segregation and placement of the motor cable in a separate, continuous

and grounded cable tray.

8 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 10

Introduction to Output Filt... Output Filters Design Guide

3.5 What are Bearing Currents and Shaft

Voltages?

Fast switching transistors in the frequency converter

combined with an inherent common-mode voltage (voltage

between phases and ground) generate high-frequency

bearing currents and shaft voltages. While bearing currents

and shaft voltages can also occur in direct-on-line motors,

these phenomena are accentuated when the motor is fed

from a frequency converter. The majority of bearing

damages in motors fed by frequency converters are because

of vibrations, misalignment, excessive axial or radial loading,

improper lubrication, impurities in the grease. In some cases,

bearing damages are caused by bearing currents and shaft

voltages. The mechanism that causes bearing currents and

shaft voltages is quite intricate and beyond the scope of this

Design Guide. Basically, two main mechanisms can be

identified:

Capacitive coupling: the voltage across the bearing

•

is generated by parasitic capacitances in the motor.

Inductive coupling: caused by circulating currents

•

in the motor.

The grease film of a running bearing behaves like isolation.

The voltage across the bearing can cause a breakdown of the

grease film and produce a small electric discharge (a spark)

between the bearing balls and the running track. This

discharge produces a microscopic melting of the bearing ball

and running track metal and in time it causes the premature

wear-out of the bearing. This mechanism is called Electrical

Discharge Machining or EDM.

Measures that isolate the motor shaft from the load

Use isolated bearings (or at least one isolated

•

bearing at the non-driving end NDE).

Prevent shaft ground current by using isolated

•

couplings.

Mechanical measures

Make sure that the motor and load are properly

•

aligned.

Make sure the loading of the bearing (axial and

•

radial) is within the specifications.

Check the vibration level in the bearing.

•

Check the grease in the bearing and make sure the

•

bearing is correctly lubricated for the given

operating conditions.

One of the mitigation measures is to use filters. This can be

used in combination with other measures, such as those

presented above. High-frequency common-mode (HF-CM)

filters (core kits) are specially designed for reducing bearing

stress. Sine-wave filters also have a good effect. dU/dt filters

have less effect and it is recommended to use them in

combination with HF-CM cores.

3

3

Mitigation of Premature Bearing Wear-

3.5.1

Out

There are a number of measures that can be taken for

preventing premature wearing and damage of the bearings

(not all of them are applicable in all cases – combinations

can be used). These measures aim either to provide a lowimpedance return path to the high-frequency currents or to

electrically isolate the motor shaft for preventing currents

through the bearings. Besides, there are also mechanical

related measures.

Measures to provide a low-impedance return path

Follow EMC installation rules strictly. A good high-

•

frequency return path should be provided between

motor and frequency converter, for example by

using shielded cables.

Make sure that the motor is properly grounded and

•

the grounding has a low-impedance for highfrequency currents.

Provide a good high-frequency ground connection

•

between motor chassis and load.

Use shaft grounding brushes.

•

MG.90.N5.02 - VLT® is a registered Danfoss trademark 9

Page 11

129

50 - 200

MHz

130BB729.10

130B8000

3

Introduction to Output Filt... Output Filters Design Guide

3.5.2 Measuring Electric Discharges in the

Motor Bearings

The occurrence of electric discharges in the motor bearings

can be measured using an oscilloscope and a brush to pick

up the shaft voltage. This method is difficult and the

interpretation of the measured waveforms requires a deep

understanding of the bearing current phenomena. An easy

alternative is to use an electrical discharge detector

(130B8000), as shown in Illustration 3.6. Such a device

consists of a loop antenna that receives signals in the

frequency range of 50MHz – 200MHz and a counter. Each

electric discharge produces an electromagnetic wave that is

detected by the instrument and the counter is incremented.

If the counter displays a high number of discharges it means

that there are many discharges occurring in the bearing and

mitigation measures have to be taken to prevent the early

wear out of the bearing. This instrument can be used for

experimentally determining the exact number of cores

needed to reduce bearing currents. Start with a set of 2

cores. If the discharges are not eliminated, or drastically

reduced, add more cores. The number of cores presented in

the table above is a guiding value that should cover most

applications with a generous safety margin. If the cores are

installed on the drive terminals and you experiment core

saturation because of long motor cables (the cores have no

effect on bearing currents), check the correctness of the

installation. If cores keep saturating after the installation is

made according to EMC best practice, consider moving the

cores to the motor terminals.

Illustration 3.6 Electrical Discharge Detector

10 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 12

Level in dBµV

Frequency in Hz

130BT119.10

Introduction to Output Filt... Output Filters Design Guide

Illustration 3.7 Mains Line Conducted Noise, No Filter

3

3

Illustration 3.8 Mains Line Conducted Noise, Sine-wave Filter

MG.90.N5.02 - VLT® is a registered Danfoss trademark 11

Page 13

3

Introduction to Output Filt... Output Filters Design Guide

3.6 Which Filter for which Purpose

Table 3.2 shows a comparison of dU/dt, Sine-wave filter, and HF-CMperformance. It can be used to determine which filter to use

with your application.

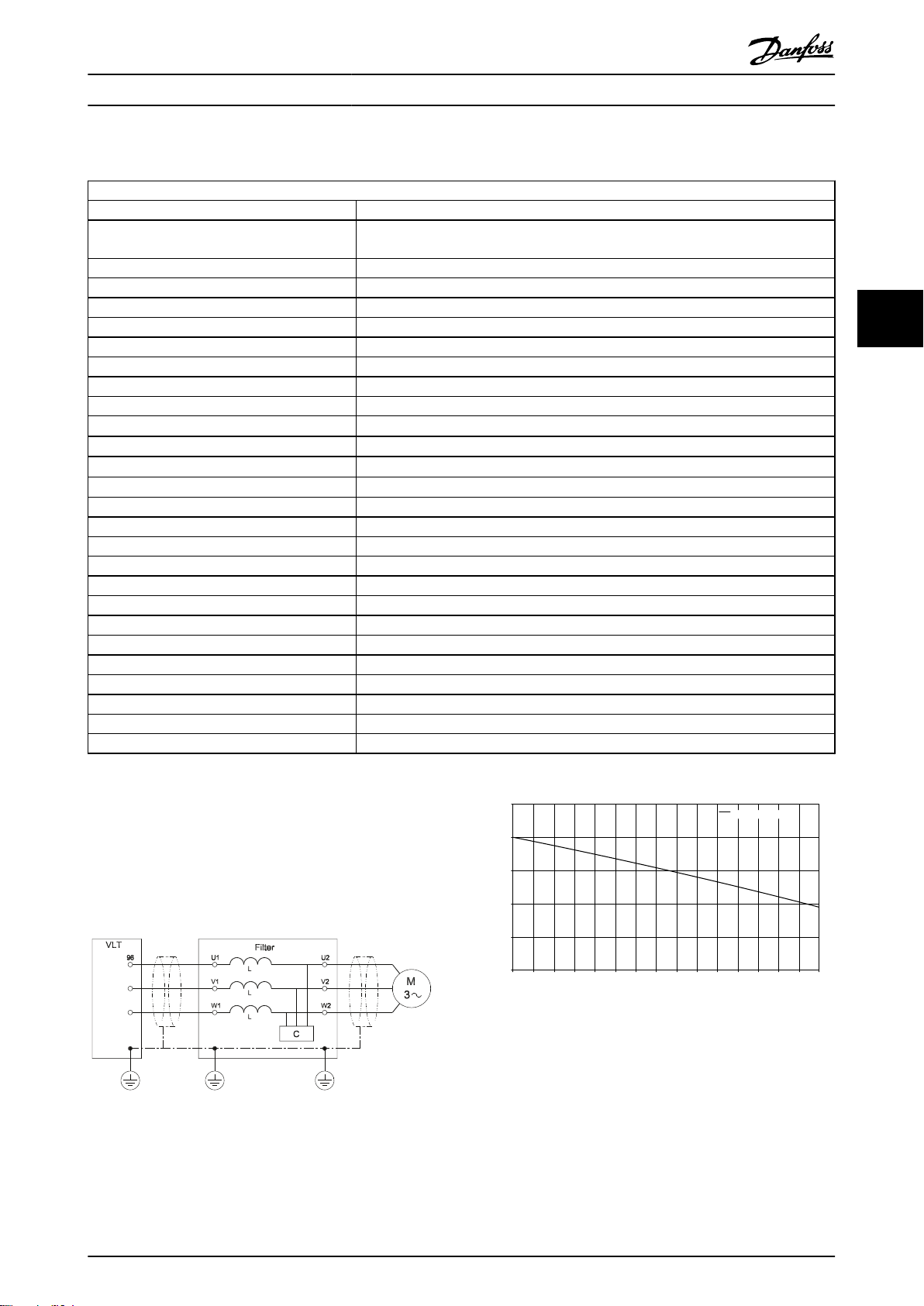

Performance criteria dU/dt filters Sine-wave filters High-frequency common-mode filters

Motor insulation

stress

Motor bearing stress Slightly reduced, only in high-

EMC performance Eliminates motor cable ringing.

Max. motor cable

length

Acoustic motor

switching noise

Relative size 15-50% (depending on power size) 100% 5 - 15%

Voltage drop

Up to 150m cable (screened/

unscreened) complies with the

requirements of IEC 60034-17

(general purpose motors). Above

this cable length the risk of “double

pulsing” (two time mains network

voltage) increases.

power motors.

Does not change the emission class.

Does not allow longer motor cables

as specified for the frequency

converter’s built-in RFI filter.

100m ... 150m

With guaranteed EMC performance:

150m screened.

Without guaranteed EMC

performance: 150m unscreened.

Does not eliminate acoustic

switching noise.

0.5% 4-10% none

Provides a sinusoidal phase-to-phase

motor terminal voltage. Complies with

1

IEC 60034-17 1 and NEMA-MG1

requirements for general purpose

motors with cables up to 500m (1km for

VLT frame size D and above).

Reduces bearing currents caused by

circulating currents. Does not reduce

common-mode currents (shaft

currents).

Eliminates motor cable ringing. Does

not change the emission class. Does not

allow longer motor cables as specified

for the frequency converter’s built-in

RFI filter.

With guaranteed EMC performance:

150m screened and 300m unscreened.

Without guaranteed EMC performance:

up to 500m (1km for VLT frame size D

and above)

Eliminates acoustic switching noise

from the motor caused by magnetostriction.

Does not reduce motor insulation stress

Reduces bearing stress by limiting

common-mode high-frequency

currents

Reduces high-frequency emissions

(above 1MHz). Does not change the

emission class of the RFI filter. Does not

allow longer motor cables as specified

for the frequency converter.

150m screened (frame size A, B, C), 300

m screened (frame size D, E, F), 300 m

unscreened

Does not eliminate acoustic switching

noise.

Table 3.2 Comparison of dU/dt and Sine-wave Filters

1) Not 690V.

2) See general specification for formula.

3.6.1 dU/dt Filters

The dU/dt filters consist of inductors and capacitors in a low

pass filter arrangement and their cut off frequency is above

the nominal switching frequency of the frequency converter.

The inductance (L) and capacitance (C) values are shown in

the tables in 4.2 Electrical Data - dU/dt Filters. Compared to

Sine-wave filters they have lower L and C values, thus they

are cheaper and smaller. With a dU/dt filter the voltage wave

form is still pulse shaped but the current is sinusoidal - see

following illustrations.

Features and benefits

dU/dt filters reduce the voltage peaks and dU/dt of the

pulses at the motor terminals. The dU/dt filters reduce dU/dt

to approx. 500V/μs.

Advantages

Protects the motor against high dU/dt values and

•

voltage peaks, hence prolongs the lifetime of the

motor

Allows the use of motors which are not specifically

•

designed for converter operation, for example in

retrofit applications

Application areas

Danfoss recommends the use of dU/dt filters in the following

applications:

Applications with frequent regenerative braking

•

Motors that are not rated for frequency converter

•

operation and not complying with IEC 600034-25

Motors placed in aggressive environments or

•

running at high temperatures

Applications with risk of flash over

•

12 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 14

130BB113.11

Upeak [kV]

15m dv/dt filter

rise time [µs]

150m dv/dt filter

50m dv/dt filter

Introduction to Output Filt... Output Filters Design Guide

Installations using old motors (retrofit) or general

•

purpose motors not complying with IEC 600034-17

Applications with short motor cables (less than

•

15m)

690V applications

•

Voltage and current with and without dU/dt filter:

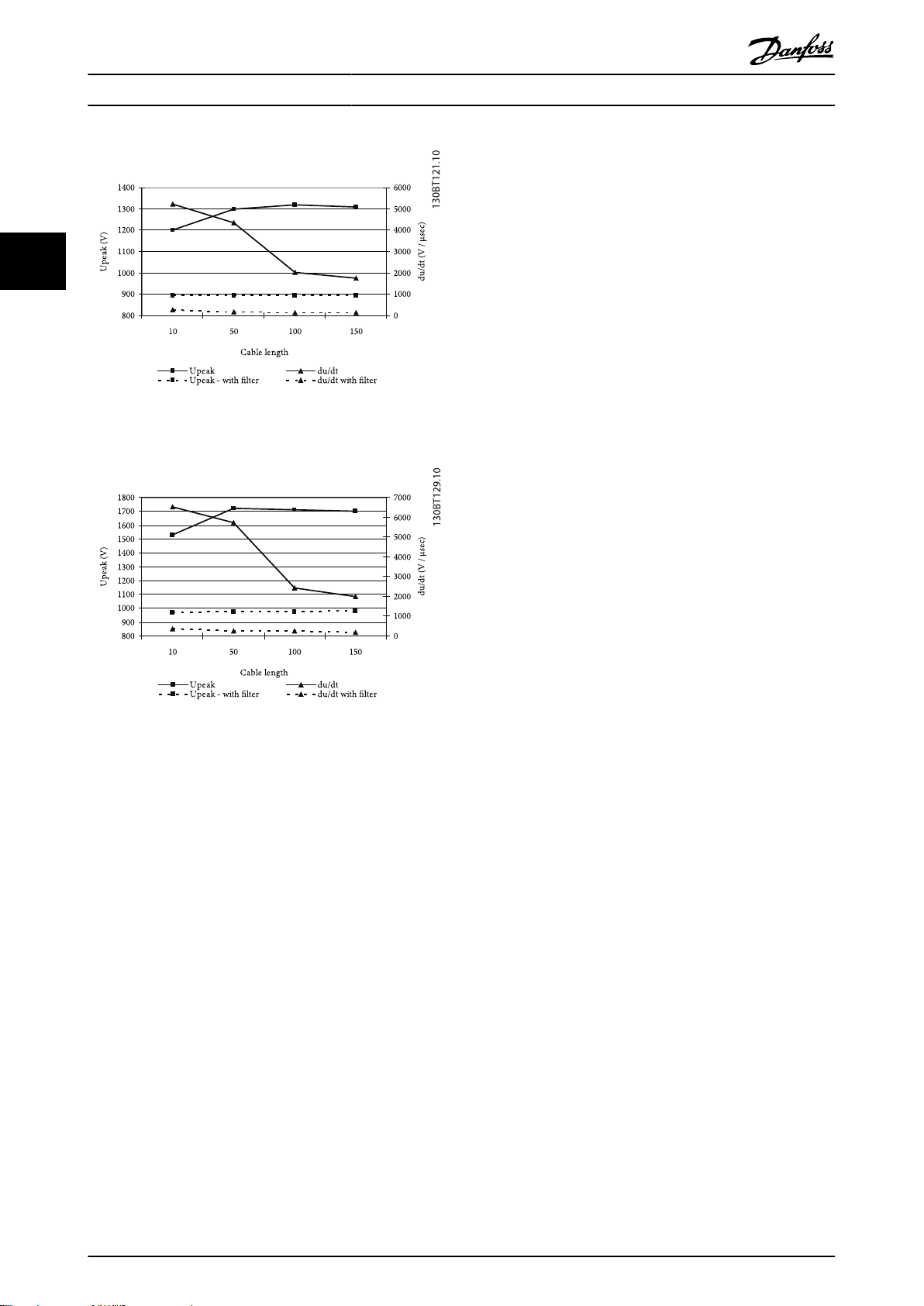

Illustration 3.11 Measured dU/dt values (rise time and peak

voltages) with and without dU/dt filter using 15m, 50m and 150m

cable lengths on a 400V, 37kW induction motor.

The dU/dt value decreases with the motor cable length

whereas the peak voltage increases (see Illustration 3.11). The

U

peak

and as Udc increases during motor braking (generative) U

can increase to values above the limits of IEC 60034-17 and

thereby stress the motor insulation. Danfoss therefore

Illustration 3.9 Without Filter

recommends dU/dt filters in applications with frequent

braking. Furthermore the illustration above shows how the

U

peak

increases, the cable capacitance rises and the cable behaves

like a low-pass filter. That means longer rise-time tr for longer

cables. Therefore it is recommended to use dU/dt filters only

in applications with cable lengths up to 150m. Above 150m

dU/dt filters have no effect. If further reduction is needed,

use a sine-wave filter.

value depends on the Udc from the frequency converter

peak

increases with the cable length. As the cable length

3

3

Illustration 3.10 With dU/dt Filter

Filter features

IP00 and IP20/23/54 enclosure in the entire power

•

range

Side by side mounting with the drive

•

Reduced size, weight and price compared to the

•

sine-wave filters

Possibility of connecting screened cables with

•

included decoupling plate

Compatible with all control principles including

•

flux and VVC

Filters wall mounted up to 177A and floor mounted

MG.90.N5.02 - VLT® is a registered Danfoss trademark 13

•

above that size

PLUS

Page 15

3

Introduction to Output Filt... Output Filters Design Guide

3.6.2

Sine-wave filters are designed to let only low frequencies

pass. High frequencies are consequently shunted away

which results in a sinusoidal phase to phase voltage

waveform and sinusoidal current waveforms. With the

sinusoidal waveforms the use of special frequency converter

motors with reinforced insulation is no longer needed. The

acoustic noise from the motor is also damped as a

consequence of the sinusoidal wave condition. The sinewave filter also reduces insulation stress and bearing

currents in the motor, thus leading to prolonged motor

lifetime and longer periods between services. Sine-wave

Illustration 3.12 525V - With and Without dU/dt Filter

filters enable use of longer motor cables in applications

where the motor is installed far from the frequency

converter. As the filter does not act between motor phases

and ground, it does not reduce leakage currents in the

cables. Therefore the motor cable length is limited - see

Table 3.2.

The Danfoss Sine-wave filters are designed to operate with

the VLT® FC 100/200/300. They replace the LC-filter product

range and are backwards compatible with the VLT

5000-8000 Series Drives. They consist of inductors and

capacitors in a low-pass filter arrangement. The inductance

(L) and capacitance (C) values are shown in tables in

4.3 Electrical Data - Sine-wave Filters.

Sine-wave Filters

Illustration 3.13 690V - With and Without dU/dt Filter

Source: Test of 690V 30kW VLT FC 302 with MCC 102 dU/dt

filter

Illustration 3.12 and Illustration 3.13 show how U

time behaves as a function of the motor cable length. In

installations with short motor cables (below 5-10m) the rise

time is short which causes high dU/dt values. The high dU/dt

can cause a damaging high potential difference between the

windings in the motor which can lead to breakdown of the

insulation and flash-over. Danfoss therefore recommends

dU/dt filters in applications with motor cable lengths shorter

than 15m.

peak

and rise

Features and benefits

As described above, Sine-wave filters reduce motor

insulation stress and eliminate switching acoustic noise from

the motor. The motor losses are reduced because the motor

is fed with a sinusoidal voltage, as shown in Illustration 3.12.

Moreover, the filter eliminates the pulse reflections in the

motor cable thus reducing the losses in the frequency

converter.

Advantages

Protects the motor against voltage peaks hence

•

prolongs the lifetime

Reduces the losses in the motor

•

Eliminates acoustic switching noise from the motor

•

Reduces semiconductor losses in the drive with

•

long motor cables

Decreases electromagnetic emissions from motor

•

cables by eliminating high frequency ringing in the

cable

Reduces electromagnetic interference from

•

unscreened motor cables

Reduces the bearing current thus prolonging the

•

lifetime of the motor

14 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 16

Introduction to Output Filt... Output Filters Design Guide

Voltage and current with and without Sine-wave filter

Illustration 3.14 Without Filter

Applications with motor cables above 150m up to

•

300m (with both screened and unscreened cable).

The use of motor cables longer than 300m

depends on the specific application

Applications where the service interval on the

•

motor has to be increased

690V applications with general purpose motors

•

Step up applications or other applications where

•

the frequency converter feeds a transformer

Example of relative motor sound pressure level

measurements with and without Sine-wave filter

3

3

Illustration 3.15 With Sine-wave Filter

Application areas

Danfoss recommends the use of Sine-wave filters in the

following applications.

Applications where the acoustic switching noise

•

from the motor has to be eliminated

Retrofit installations with old motors with poor

•

insulation

Applications with frequent regenerative braking

•

and motors that do not comply with IEC 60034-17

Applications where the motor is placed in

•

aggressive environments or running at high

temperatures

MG.90.N5.02 - VLT® is a registered Danfoss trademark 15

Features

•

•

•

•

•

•

IP00 and IP20 enclosure in the entire power range

(IP23 for floor standing filters)

Compatible with all control principle including flux

and VVC

Side by side mount with the frequency converter

up to 75A

Filter enclosure matching the frequency converter

enclosure

Possibility of connecting unscreened and screened

cables with included decoupling plate

Filters wall mounted up to 75A and floor mount

above

PLUS

Page 17

Introduction to Output Filt... Output Filters Design Guide

Parallel filter installation is possible with

•

applications in the high power range

3.6.3 High-Frequency Common-Mode Core

Kits

3

High-frequency common-mode (HF-CM) core kits are one of

the mitigation measures to reduce bearing wear. However,

they should not be used as the sole mitigation measure.

Even when HF-CM cores are used, the EMC-correct installation rules must be followed. The HF-CM cores work by

reducing the high-frequency common-mode currents that

are associated with the electric discharges in the bearing.

They also reduce the high-frequency emissions from the

motor cable which can be used, for example, in applications

with unshielded motor cables.

16 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 18

Selection of Output Filters Output Filters Design Guide

4 Selection of Output Filters

4.1 How to Select the Correct Output Filter

An output filter is selected based on the nominal motor current. All filters are rated for 160% overload for 1 minute, every 10

minutes.

4.1.1 Product Overview

To simplify the Filter Selection Table 4.1 shows which Sine-wave filter to use with a specific frequency converter. This is based on

the 160% overload for 1 minute every 10 minutes and is to be considered guideline.

Mains supply 3 x 240 to 500V

Rated filter

current at 50Hz

2.5 5 120 130B2439 130B2404 PK25 - PK37 PK37 - PK75 PK37 - PK75

4.5 5 120 130B2441 130B2406 PK55 P1K1 - P1K5 P1K1 - P1K5

8 5 120 130B2443 130B2408 PK75 - P1K5 P2K2 - P3K0 P2K2 - P3K0

10 5 120 130B2444 130B2409 P4K0 P4K0

17 5 120 130B2446 130B2411 P2K2 - P4K0 P5K5 - P7K5 P5K5 - P7K5

24 4 100 130B2447 130B2412 P5K5 P11K P11K

38 4 100 130B2448 130B2413 P7K5 P15K - P18K P15K - P18K

48 4 100 130B2307 130B2281 P11K P22K P22K

62 3 100 130B2308 130B2282 P15K P30K P30K

75 3 100 130B2309 130B2283 P18K P37K P37K

115 3 100 130B3181 130B3179 P22K - P30K P45K - P55K P55K - P75K

180 3 100 130B3183 130B3182 P37K - P45K P75K - P90K P90K - P110

260 3 100 130B3185 130B3184 P110 - P132 P132

410 3 100 130B3187 130B3186 P160 - P200 P160 - P200

510 3 100 130B3189 130B3188 P250 P250

660 2 70 130B3192 130B3191 P315 - P355 P315 - P355

800 2 70 130B3194 130B3193 P400 P400 - P450

1020 2 70 2 x 130B3189 2 x 130B3188 P450 - P500 P500 - P560

1320 2 70 2 x 130B3192 2 x 130B3191 P560 - P630 P630 - P710

1530 2 70 3 x 130B3189 3 x 130B3188 P710 - P800 P800

1980 2 70 3 x 130B9192 3 x 130B3191 P1M0

Minimum

switching

frequency [kHz]

Maximum output

frequency [Hz] With

derating

Code number

IP20

Code number

IP00

Frequency converter size

200-240V 380-440V 441-500V

4 4

Table 4.1 Filter Selection

MG.90.N5.02 - VLT® is a registered Danfoss trademark 17

Page 19

Selection of Output Filters Output Filters Design Guide

Mains supply 3 x 525 to 600/690V

Rated filter

current at 50Hz

13 2 70 130B3196 130B3195 PK75 - P7K5

28 2 100 130B4113 130B4112 P11K - P18K

45 2 100 130B4115 130B4114 P22K - P30K P37K

76 2 100 130B4117 130B4116 P37K - P45K P45K - P55K

44

115 2 100 130B4119 130B4118 P55K - P75K P75K - P90K

165 2 70 130B4124 130B4121 P110 - P132

260 2 100 130B4126 130B4125 P160 - P200

303 2 70 130B4151 130B4129 P250

430 1.5 60 130B4153 130B4152 P315 - P400

530 1.5 100 130B4155 130B4154 P500

660 1.5 100 130B4157 130B4156 P560 - P630

868 1.5 60 2 x 130B4153 2 x 130B4152 P710

1060 1.5 100 2 x 130B4155 2 x 130B4154 P800 - P900

1590 1.5 60 3 x 130B4155 3 x 130B4154 P1M0

Table 4.2 Filter Selection

Minimum

switching

frequency [kHz]

Maximum output

frequency [Hz] With

derating

Code number

IP20

Code number

IP00

Frequency converter size

525-600V 525-690V

Generally the output filters are designed for the nominal

switching frequency of the frequency converter.

NOTE

Sine-wave filters can be used at switching frequencies higher

than the nominal switching frequency, but should never be

used at switching frequencies with less than 20% lower than

the nominal switching frequency.

NOTE

dU/dt filters, unlike Sine-wave filters, can be used at lower

switching frequency than the nominal switching frequency,

but higher switching frequency will cause the overheating of

the filter and should be avoided.

18 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 20

W

w

H

h

d

130BB728.10

Selection of Output Filters Output Filters Design Guide

4.1.2 HF-CM Selection

The cores can be installed at the frequency converter’s

output terminals (U, V, W) or in the motor terminal box.

When installed at the frequency converter’s terminals the

HF-CM kit reduces both bearing stress and high-frequency

electromagnetic interference from the motor cable. The

number of cores depends on the motor cable length and

frequency converter voltage and a selection table is shown

below.

Cable

length

[m]

100 4 4 2 4 4 4 2 4

150 4 6 4 4 4 4 4 4

300 4 6 4 4 4 6 4 4

When installed in the motor terminal box the HF-CM kit

reduces only bearing stress and has no effect on the electromagnetic interference from the motor cable. Two cores are

sufficient in most cases, independent of the motor cable

length.

Danfoss provides the HF-CM cores in kits of two pieces/kit.

The cores are oval shaped for the ease of installation and are

available in four sizes: for A and B frames, for C frames, for D

frames, for E and F frames. For F frame frequency converters,

one core kit shall be installed at each inverter module

terminals. Mechanical mounting can be made with cable ties.

There are no special requirements regarding mechanical

mounting.

A- and B

frame

T5 T7 T5 T7 T5 T7 T5 T7

50 2 4 2 2 2 4 2 2

C frame D frame E- F frame

CAUTION

Check the core temperature during commissioning. A

temperature above 70°C indicates saturation of the cores. If

this happens add more cores. If the cores still saturate it

means that the cable capacitance is too large because of: too

long cable, too many parallel cables, cable type with high

capacitance.

Applications with parallel cables

When parallel cables are used the total cable length has to

be considered. For example 2 x 100m cables are equivalent

with one 200m cable. If many paralleled motors are used a

separate core kit should be installed for each individual

motor.

The ordering numbers for the core kits (2 cores/package) are

given in the following table.

VLT

frame

size

A and B 130B3257 60 43 40 25 22 0.25 130x100x70

C 130B3258 102 69 61 28 37 1.6 190x100x70

D 130B3259 189 143 126 80 37 2.45 235x190x

E and F 130B3260 305 249 147 95 37 4.55 290x260x

Danfoss

part no.

Core dimension [mm] Weight Packaging

dimension

W w H h d [kg] [mm]

140

110

4 4

In normal operation the temperature is below 70°C.

However, if the cores are saturated they can get hot, with

temperatures above 70°C. Therefore it is important to use

the correct number of cores to avoid saturation. Saturation

can occur if the motor cable is too long, motor cables are

paralleled or high capacitance motor cables, not suitable for

frequency converter operation, are used. Always avoid motor

cables with sector-shaped cores. Use only cables with roundshaped cores.

MG.90.N5.02 - VLT® is a registered Danfoss trademark 19

Page 21

Selection of Output Filters Output Filters Design Guide

4.2 Electrical Data - dU/dt Filters

C

Filter

data

μH

44

filter losses

525 - 550V 551 - 690V

75 83

315 429 400 410

500V

380 - 440V 441 -

VLT power and current rating Maximum

200 -

690V

240v

@ 50HzkW

5.5 24.2 11 24 11 21 7.5 14 11 13 37 150 10

7.5 30.8 15 32 15 27 11 19 15 18

18.5 37.5 18.5 34 15 23 18.5 22

22 44 22 40 18.5 28 22 27

11 46.2 30 61 30 52 30 43 30 34 130 110 13.6

15 59.4 37 73 37 65 37 54 37 41

18.5 74.8 45 90 55 80 45 65 45 52

55 106 75 105 55 87 55 62 145 95 15

22 88

30 115 75 147 90 130 75 113 90 108 205 111 15

110 212 132 190 110 162 110 131 315 50 20

132 260 160 240 132 201 132 155

160 315 200 303 160 192

37 143 90 177 110 160 90 137

45 170

200 395 250 361 160 253 200 242 398 30 43

250 480 315 443 200 303 250 290

315 600 355 540 250 360 315 344 550 17 66

355 658 400 590 300 395 355 380

400 745 450 678 400 523 500 500 850 13 99

450 800 500 730 450 596 560 570

500 880 560 780 500 659 630 630

575/600V

@ 60Hz

3)

460/480V @

60Hz and

500/525V @

50Hz

2)

[A]

Filter current rating at given voltage and motor frequency

Code number IP00

20 MG.90.N5.02 - VLT® is a registered Danfoss trademark

1)

4

IP20/IP23

IP54

380V @ 60Hz

and

200/440V @

kW A kW A kW A kW A kW A W uH nF

50Hz

44 40 32 27

IP00

IP20

IP54

130B2835

130B2836

130B2837

90 80 58 54

IP00

IP20

IP54

130B2838

130B2839

130B2840

106 105 94 86

IP00

IP20

IP54

130B2841

130B2842

130B2843

177 160 131 108

IP00

IP20

IP54

130B2844

130B2845

130B2846

315 303 242 192

IP00

IP23

130B2847

130B2848

480 443 344 290

IP00

IP23

130B2849

130B2850

IP00

130B2851

658 590 500 450

IP23

130B2852

880 780 630 630

IP00

IP23

130B2853

130B2854

The filter enclosure is IP20 for wall-mounted filters and IP23 for floor-mounted filters2) For derating with motor frequency consider 60Hz rating=0.94 x 50Hz rating and 100Hz rating= 0.75 x 50Hz rating3) 525V operation requires a T7 drive

1)

Table 4.3 dU/dt Filter 3x200-690V IP00/IP20/IP23/IP54

IP54 is available up to 177A

4

Page 22

Selection of Output Filters Output Filters Design Guide

nF

Filter

data

μH

filter losses

VLT power and current size Maximum

380 - 440V 441 - 500V 525 - 550V 551 - 690V L C

690V

kW A kW A kW A kW A W

@ 50Hz

4 4

900 945

710 1260 800 1160 750 988or

575/600V

460/480V @

2

[A]

Filter current rating at given voltage and motor frequency

1

IP20/IP23

Code number IP00

380V @

@ 60Hz

60Hz and

60Hz and

500/525V @

200/440V @

3

50Hz

50Hz

For F frame drives, parallel filters shall be used, one filter for each

IP00

IP23

2 x 1302852

2 x 130B2851

inverter module.

IP00

IP23

3 x 130B2849

3 x 130B3850

IP00

IP23

or

2 x 130B2853

2 x 130B2854

IP00

IP23

IP00 800 1460 1000 1380 850 1108 1000 1060

3 x 130B2851

3 x 130B2852

3 x 130B2853

IP23 1000 1700 1100 1530 1000 1317 1200 1260

IP00 450 800 500 730 500 659

IP23 500 880 560 780

3 x 130B2854

2 x 130B2849

2 x 130B2852

The filter enclosure is IP20 for wall-mounted filters and IP23 for floor-mounted filters2) For derating with motor frequency consider 60Hz rating=0.94 x 50Hz rating and 100Hz rating= 0.75 x 50Hz rating3) 525V operation requires a T7 drive

1)

MG.90.N5.02 - VLT® is a registered Danfoss trademark 21

Page 23

Selection of Output Filters Output Filters Design Guide

4.3 Electrical Data - Sine-wave Filters

1

μF

-Value

y

C

29 10.25 1.8 0.55 1.8 0.55 1.6 50 50 50

L-value

13 2.2

6.9 4.71.1 6.6 2.2 5.6 2.2 4.8 75 70 70

3.1 103 12.5 5.5 13 5.5 11 100 110 100

1.6 10

44

470 0.51 15

650 0.33 25

850 0.34 25

VLT Power and Current Ratings Filter Losses

Switching

Frequency

@ 100Hz @ 200-240V @ 380-440V @ 441-500V @ 200-240V @ 380-440V @ 441-500V

@

Filter Current Rating

@ 50Hz

IP00

IP20

Code

60Hz

A A A kHz kW A kW A kW A W W W mH

2

(IP23)

Number

0.37 1.3 0.37 1.1 45 45

2.5 2.5 2* 5

IP00

IP20

130B2404

130B2439

1.1 3 1.1 3 60 60

0.37 2.4 0.75 2.4 0.75 2.1 60 60 60

IP00

130B2406

0.55 3.5 1.5 4.1 1.5 3.4 65 70 65

0.75 4.6 65

4.5 4 3.5* 5

IP20

130B2441

1.5 7.5 3 7.2 3 6.3 80 80 80

8 7.5 5* 5

IP00

IP20

130B2408

130B2443

2.2 10.6 90

10 9.5 7.5* 5 4 10 4 8.2 95 90 5.2 6.8

IP00

IP20

130B2409

130B2444

3.7 16.7 7.5 16 7.5 14.5 125 125 115

17 156 13 5

IP00

IP20

130B2411

130B2446

15 32 15 27 170 160

24 23 18 4 5.5 24.2 11 24 11 21 150 150 150 2.4 10

IP00

IP20

IP00

130B2412

130B2447

130B2413

7.5 30.8 18.5 37.5 18.5 34 160 180 170

38 36 28.5 4

IP20

IP00

130B2448

130B2281

48 45.5 36 4 11 46.2 22 44 22 40 270 270 260 1.1 14.7

IP20

IP00

130B2307

130B2282

62 59 46.5 3 15 59.4 30 61 30 52 300 310 280 0.85 30

IP20

IP00

130B2308

130B2283

22 88 45 90 55 80

75 71 56 3 18.5 74.8 37 73 37 65 350 350 330 0.75 30

IP20

IP00

130B2309

130B3179

30 115 55 106 75 105

37 143 75 147 90 130

115 109 86 3

IP23

IP00

130B3181

130B3182

110 212 132 190

45 170 90 177 110 160

180 170 135 3

IP23

IP00

130B3183

130B3184

132 260 160 240

260 246 195 3

IP23

130B3185

*) 120Hz

Equivalent STAR-connection value2IP23 - All floor mounted filters

1

Table 4.4 Sine-wave Filter 3x380-500 V IP00/IP20/IP23

22 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 24

Selection of Output Filters Output Filters Design Guide

1

μF

-Value

y

C

L-value

4 4

VLT Power and Current Ratings Filter Losses

160 315 200 303

1150 0.25 33

200 395 250 361

315 600 355 540

2000 0.15 106

355 658 400 590

450 800 500 730

2900

500 880 560 780

560 990 630 890

4000

630 1120 710 1050

4350

710 1260 800 1160

800 1460 1000 1380

Switching

Frequency

@ 100Hz @ 200-240V @ 380-440V @ 441-500V @ 200-240V @ 380-440V @ 441-500V

@

@

Filter Current Rating

IP00

IP20

Code

60Hz

A A A kHz kW A kW A kW A W W W mH

50Hz

2

(IP23)

Number

410 390 308 3

IP00

IP23

IP00

130B3186

130B3187

130B3188

510 456 360 3 250 480 315 443 1450 0.14 66

IP23

IP00

130B3189

130B3191

660 627 495 3

800 712 562 2 400 745 450 678 3000 0.1 153

1020 912 720 2

1320 1254 990 2

1530 1368 1080 2

1980 1881 1485 2 1000 1700 1100 1530 6000

IP23

IP00

IP23

IP00

IP23

IP00

IP23

IP00

IP23

IP00

IP23

130B3192

130B3193

130B3194

2 x 130B3188

2 x 130B3189

2 x 130B3191

2 x 130B3192

3 x 130B3188

3 x 130B3189

3 x 130B3191

MG.90.N5.02 - VLT® is a registered Danfoss trademark 23

Equivalent STAR-connection value2IP23 - All floor mounted filters

3 x 130B3192

*) 120Hz

1

Table 4.5 Sine-wave Filter 3x380-500V IP00/IP20/IP23

Page 25

Selection of Output Filters Output Filters Design Guide

1

-

y

C

Value

L-value

μF

44

VLT Power and Current Ratings Filter losses

@ 525-550V @ 525-600V @ 690V @ 525-550V @ 525-600V @ 690V

0.75 1.7

1.1 2.4

1.5 2.7

2.2 4.1

115 8.1 4.7

3 5.2

4 6.4

5.5 9.5

7.5 11.5

11 13

11 18 15 18

150 5 10

15 22 18.5 22

18.5 27 22 27

22 34 30 34

250 2.5 15

30 41 30 46 37 46

37 52 37 56 45 54

475 1.6 33

45 62 45 76 55 73

55 83 55 90 75 86

750 0.91 33

75 100 75 113 90 108

90 131 90 137 110 131

1100 0.765 66

110 155 110 162 132 155

150 192 132 201 160 192

1300 0.48 66

180 242 160 253 200 242

220 290 200 303 250 290

1800 0.42 66

260 344 315 344 250 360

450 596 560 570

3000 0.19 153

480 630 630 630 500 596

Switching

Frequency

@

100Hz

@

60Hz

@ 50Hz

2

IP00

Code

A A A kHz kW A kW A kW A W W W mH

IP20(IP23)

Number

Filter Current Rating

24 MG.90.N5.02 - VLT® is a registered Danfoss trademark

13 12 9 2

IP00

IP20

130B3195

130B3196

28 26 21 2

IP00

IP23

130B4112

130B4113

45 42 33 2

IP00

IP23

IP00

130B4114

130B4115

130B4116

76 72 57 2

IP23

IP00

130B4117

130B4118

115 109 86 2

IP23

IP00

130B4119

130B4121

165 156 124 2

IP23

IP00

130B4124

130B4125

260 246 195 2

IP23

130B4126

360 314 270 2

IP00

IP23

IP00

130B4129

130B4151

130B4152

430 407 323 1.5 300 429 400 410 315 429 2150 0.285 99

IP23

IP00

130B4153

130B4154

530 502 398 1.5 375 523 500 500 400 523 2400 0.215 120

IP23

IP00

130B4155

130B4156

660 625 496 1.5

IP23

130B4157

1

Equivalent STAR-connection value2IP23 - All floor mounted filters

Table 4.6 Sine-wave Filter 3x525-690V IP00/IP20/IP23

Page 26

Selection of Output Filters Output Filters Design Guide

1

μF

-Value

y

C

4300

4800

7200

4 4

Filter Current Rating Switching Frequency VLT Power and Current Ratings Filter losses L-value

@ 50Hz @ 60Hz @ 100Hz @ 525-550V @ 525-600V @ 690V @ 525-550V @ 525-600V @ 690V

2

IP00

IP20(IP23)

A A A kHz kW A kW A kW A W W W mH

970 1260 1200 1260 1000 1317

860 814 646 1.5

IP23

670 898 800 850 630 763

1060 1004 796 1.5

IP23

820 1060 1000 1060 800 1108

1590 1506 1194 1.5

IP23

Code

Number

2 x 130B4142 IP00

2 x 130B4153 560 730 710 730 460 630

2 x 130B4154 IP00

3 x 130B4154 IP00

3 x 130B4155 970 1260 1200 1260 1000 1317

Equivalent STAR-connection value2IP23 - All floor mounted filters

1

MG.90.N5.02 - VLT® is a registered Danfoss trademark 25

2 x 130B4155 900 945 710 939

Page 27

Selection of Output Filters Output Filters Design Guide

1

μF

-Value

y

C

44

VLT Power and Current Rating Filter losses L-value

Frequency

Filter Current Rating Switching

A A A kHz kW A kW A kW A W W W mH

@ 50Hz @ 60Hz @ 100Hz @ 200-240V @ 380-440V @ 441-500V @ 200-240V @ 380-440V @ 441-500V

Code

Number

130B2542 10 10 8 5 2.2 10.6 4 10 4 8.2 60 60 5.3 1.36

3 12.5 5.5 13 5.5 11 100 100 100 3.1 2.04

130B2543 17 17 13.6 5

3.7 16.7 7.5 16 7.5 14.5 100 100 100 3.1 2.04

Table 4.7 Sine-wave Foot Print Filter 3x200-500V IP20

26 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 28

130BB880.10

Selection of Output Filters Output Filters Design Guide

4.3.1 Spare Parts/Accessories

Protective earth (PE) grounding plate for IP00 and IP20 wall

mounted filters. The accessory bag also includes all

necessary screws and cable fixations.

Wall mounted Sine-wave filters

IP00 IP20

130B2404 130B2439

130B2406 130B2441

130B2408 130B2443

130B2409 130B2444

130B2411 130B2446

130B2412 130B2447

130B2413 130B2448

130B2341 130B2321

130B2281 130B2307

130B2282 130B2308

130B2283 130B2309

130B2835 130B2836 130B4175

130B2838 130B2839 130B4176

130B2841 130B2842 130B4177

Nom. filter current rating

(200-380/460/600/690V)

[A]

44/40/32/27 130B2835

90/80/58/54 130B2838

106/105/94/86 130B2841

177/160/131/108 130B2844

Filter code number Accessory bag

130B2836

130B2839

130B2842

130B2845

Accessories - L-shapes

Accessory bag

130B0385

130B0386

130B0387

130B4175

130B4176

130B4176

130B4127

Danfoss part

Voltage Current IP

13 00 130B3195 --13 20 130B3196 --28 00 130B4112 --28 20 130B4113 --45 00 130B4114 --45 20 130B4115 --76 00 130B4116 ---

76 23 130B4117 --115 00 130B4118 --115 23 130B4119 ---

690

165 00 130B4121 130B3137

165 23 130B4124 130B3137

260 00 130B4125 130B3137

260 23 130B4126 130B3137

360 00 130B4129 130B3138

360 23 130B4151 130B3138

430 00 130B4152 130B3138

430 23 130B4153 130B3138

530 00 130B4154 130B3138

530 23 130B4155 130B3138

660 00 130B4156 130B3139

660 23 130B4157 130B3139

no. L-shape

4.3.2 Cable Glands for Floor Standing Filters

Nom. filter current rating

(200-380/460/600/690V)

[A]

315/303/242/192 130B2848

480/443/344/290 130B2850

658/590/500/450 130B2852

880/780/630/630 130B2854

Filter code number Spare part no.

130B4178

4 4

Voltage Current IP

115 00 130B3179 --115 23 130B3181 --180 00 130B3182 --180 23 130B3183 --260 00 130B3184 130B3137

260 23 130B3185 130B3137

500

410 00 130B3186 130B3138

410 23 130B3187 130B3138

510 00 130B3188 130B3138

510 23 130B3189 130B3138

660 00 130B3191 130B3139

660 23 130B3192 130B3139

800 00 130B3193 130B3139

800 23 130B3194 130B3139

Danfoss part

no. L-shape

MG.90.N5.02 - VLT® is a registered Danfoss trademark 27

Page 29

Selection of Output Filters Output Filters Design Guide

4.3.3 Terminal Kits

Danfoss

Voltage Current IP

115 00 130B3179 115 23 130B3181 130B4178

180 00 130B3182 180 23 130B3183 130B4178

44

500

690

260 00 130B3184 260 23 130B3185 130B4178

410 00 130B3186 410 23 130B3187 130B4178

510 00 130B3188 510 23 130B3189 130B4178

660 00 130B3191 660 23 130B3192 130B4178

800 00 130B3193 800 23 130B3194 130B4178

13 00 130B3195 130B4175

13 20 130B3196 130B4175

28 00 130B4112 130B4175

28 20 130B4113 130B4175

45 00 130B4114 130B4176

45 20 130B4115 130B4176

76 00 130B4116 -

76 23 130B4117 130B4178

115 00 130B4118 115 23 130B4119 130B4178

165 00 130B4121 165 23 130B4124 130B4178

260 00 130B4125 260 23 130B4126 130B4178

360 00 130B4129 360 23 130B4151 130B4178

430 00 130B4152 430 23 130B4153 130B4178

530 00 130B4154 530 23 130B4155 130B4178

660 00 130B4156 660 23 130B4157 130B4178

part no. Spare parts

28 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 30

97

98

99

130BB109.11

T emper a tur e der a ting cur v e lout[%]

110%

100%

90%

80%

70%

60%

45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

Ambien t t emper a tur e [ º C]

cur r en t der a ting

130BB068.11

Selection of Output Filters Output Filters Design Guide

4.4 Sine-Wave Filters

Technical Specifications

Voltage rating 3 x 200-500V and 500-690V AC

up to 800A (500V) and 660A (690V). F frame current ratings are achieved by filter

Nominal current @ 50Hz

Motor frequency derating

50Hz Inominal

60Hz 0.94 x Inominal

100Hz 0.75 x Inominal

Minimum switching frequency nominal switching frequency of the respective FC 102, 202 or 302 x 0.80

Maximum switching frequency 8kHz

Overload capacity 160% for 60 seconds, every 10 minutes.

Enclosure degree IP00, IP20 for wall-mounted, IP23 for floor mounted.

Ambient temperature -10° to +45°C

Storage temperature -25° to +60°C

Transport temperature -25° to +70°C

Maximum ambient temperature (with derating) 55°C

Maximum altitude without derating 1000m

Maximum altitude with derating 4000m

Derating with altitude 5%/1000m

MTBF 1481842 h

FIT 1.5 106/h

Tolerance of the inductance

Degree of pollution EN 61800-5-1 II

Overvoltage category EN 61800-5-1 III

Environmental Conditions Load 3K3

Environmental Conditions Storage 1K3

Environmental Conditions Transport 2K3

Noise level < frequency converter

Approvals CE (EN 61558, VDE 0570), RoHS, cULus file E219022 (pending)

paralleling, one filter per inverter module.

± 10%

4 4

The voltage drop across the inductor can be calculated using

this formula:

ud

= 2 × π ×

f

× L ×

m

I

fm = output frequency

L = filter inductions

I = current

Illustration 4.1 Filter Diagram

MG.90.N5.02 - VLT® is a registered Danfoss trademark 29

Page 31

Selection of Output Filters Output Filters Design Guide

4.4.1 dU/dt Filters

Technical Specifications

Voltage rating 3 x 200-690V

Nominal current @ 50Hz up to 880A. F frame current ratings are achieved by filter paralleling, one filter per inverter module.

Motor frequency derating

50Hz Inominal

60Hz 0.94 x Inominal

44

Minimum switching frequency no limit

Maximum switching frequency nominal switching frequency of the respective FC 102, 202 or 302

Overload capacity 160% for 60 seconds, every 10 minutes.

Enclosure degree IP00, IP 20 for wall-mounted, IP23 for floor mounted. IP21/NEMA 1 available for wall-mounted using

Ambient temperature

Storage temperature

Transport temperature

Maximum ambient temperature (with

derating) Maximum altitude without

derating

Maximum altitude without derating 1000m

Maximum altitude with derating 4000m

Derating with altitude 5%/1000m

MTBF 1481842 h

FIT

Tolerance of the inductance

Degree of pollution EN 61800-5-1 II

Overvoltage category EN 61800-5-1 III

Environmental Conditions Load 3K3

Environmental Conditions Storage 1K3

Environmental Conditions Transport 2K3

Noise level < frequency converter

Approvals CE (EN61558, VDE 0570), RoHS, cULus file E219022 (pending)

100Hz 0.75 x Inominal

separate kits.

-10° to +45°C

-25° to +60°C

-25° to +70°C

55°C

1.5 106 / h

± 10%

30 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 32

Selection of Output Filters Output Filters Design Guide

4.4.2 Sine-Wave Foot Print Filter

Technical Specification

Voltage rating 3 x 200-500V AC

Nominal current I¬N @ 50Hz 10 – 17A

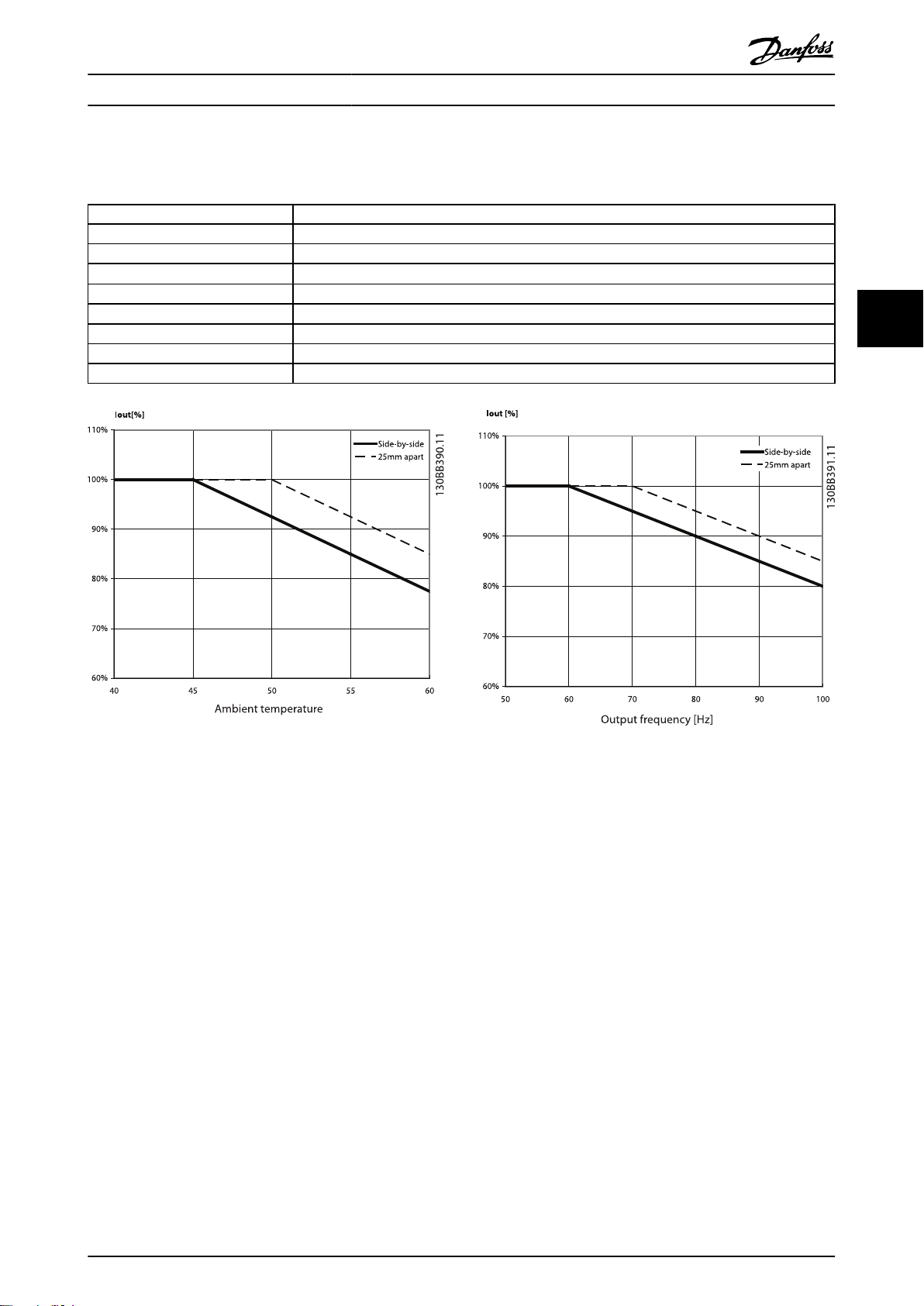

Motor frequency 0-60Hz without derating. 100/120Hz with derating (see derating curves below)

Ambient temperature

Min. switching frequency f

Max. switching frequency f

Overload capacity 160% for 60 sec. every 10 minutes.

Enclosure degree IP20

Approval CE, RoHS

-25° to 45°C side by side mount, without derating (see derating curves below)

5kHz

min

16kHz

max

4 4

Illustration 4.2 Temperature Derating

Illustration 4.3 Output Frequency Derating

MG.90.N5.02 - VLT® is a registered Danfoss trademark 31

Page 33

PE

U

V W

130BB726.10

PE U V W

130BB727.10

How to Install Output Filters Design Guide

5 How to Install

5.1 Mechanical Mounting

5.1.1 Safety Requirements for Mechanical

Installation

WARNING

55

Pay attention to the requirements that apply to integration

and field mounting kit. Observe the information in the list to

avoid serious damage or injury, especially when installing

large units.

The filter is cooled by natural convection.

To protect the unit from overheating it must be ensured that

the ambient temperature does not exceed the maximum

temperature stated for the filter. Locate the maximum

temperature in the paragraph Derating for Ambient

Temperature.

If the ambient temperature is in the range of 45°C - 55°C,

derating of the filter will become relevant.

Illustration 5.1 Correct Installation

Mounting

5.1.2

All wall mounted filters must be mounted vertically

•

with the terminals at the bottom.

Do not mount the filter close to other heating

•

elements or heat sensitive material (such as wood)

The filter can be side-mounted with the frequency

•

converter. There is no requirement for spacing

between the filter and frequency converter.

Top and bottom clearance is minimum 100mm

•

(200mm for foot print filters).

The surface temperature of IP20/23 units does not

•

exceed 70°C.

The surface temperature of IP00 filters can exceed

•

70°C and a hot surface warning label is placed on

the filter.

Mechanical Installation of HF-CM

5.1.3

The HF-CM cores have an oval shape to allow easier installation. They should be placed around the three motor phases

(U, V and W). It is important to put all three motor phases

through the core, else the core will saturate. It is also

important not to put the PE or any grounding wires through

the core, else the core will loose its effect. In most

applications several cores have to be stacked.

Illustration 5.2 Wrong Installation. The PE should not go through

the core.

The cores can vibrate due to the alternating magnetic field.

When close to the cable’s isolation or other parts, it is

possible that the vibration causes the wearing of the core or

cable isolation material. Use cable ties to secure the cores

and cable.

32 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 34

How to Install Output Filters Design Guide

5.1.4 Earthing of Sine-wave and dU/dt Filters

WARNING

The filter must be earthed before switching the power on

(high leakage currents).

Common mode interferences are kept small by ensuring that

the current return path to the frequency converter has the

lowest possible impedance.

Choose the best earthing possibility (e.g. cabinet

•

mounting panel)

Use the enclosed (in accessory bag) protective

•

earth terminal to ensure the best possible earthing

Remove any paint present to ensure good electrical

•

contact

Ensure that the filter and frequency converter make

•

solid electrical contact (high frequency earthing)

The filter must be earthed before switching the

•

power on (high leakage currents)

Screening

5.1.5

unscreened cables are employed it should be

ensured that the installation minimizes the

possibility of cross-couplings with other cables

carrying sensitive signals. This can be achieved by

measures such as cable segregation and mounting

in earthed cable trays.

The cable screen must be solidly connected at both

•

ends to the chassis (e.g. housing of filter and

motor).

If IP00 filters are installed in cabinets and screened

•

cables are used, the screen of the motor cable

should be terminated at the cabinet cable entry

point.

All screen connections must exhibit the smallest

•

possible impedance, i.e. solid, large area

connections, both ends of screened cable.

Maximum cable length between frequency

•

converter and output filter:

Below 7.5kW: 2m

Between 7.5 - 90kW: 5-10m

Above 90kW: 10-15m

NOTE

The cable between frequency converter and filter should be

kept as short as possible

5 5

It is recommended to use screened cables to reduce the

radiation of electromagnetic noise into the environment and

prevent malfunctions in the installation.

Cable between the frequency converter output (U,

•

V, W) and filter input (U1, V1, W1) to be screened or

twisted.

Use preferably screened cables between the filter

•

output (U2, V2, W2) and the motor. When

Illustration 5.3 Wiring Diagram

For F frame frequency converters parallel filters shall be used, one filter for each inverter module.

The cables or bus bars between inverter and filter should have the same length for each module.

The paralleling connection should be after the dU/dt filter/sine-wave filter, either at the filters' terminals or at the motor

terminals.

NOTE

More than 10m is possible but Danfoss strongly discourge

such installations, due to the risk of increased EMI and

voltage spikes on the filter terminals.

MG.90.N5.02 - VLT® is a registered Danfoss trademark 33

Page 35

C

B

a

A

b

f

e

130BB526.10

130BB879.10

How to Install Output Filters Design Guide

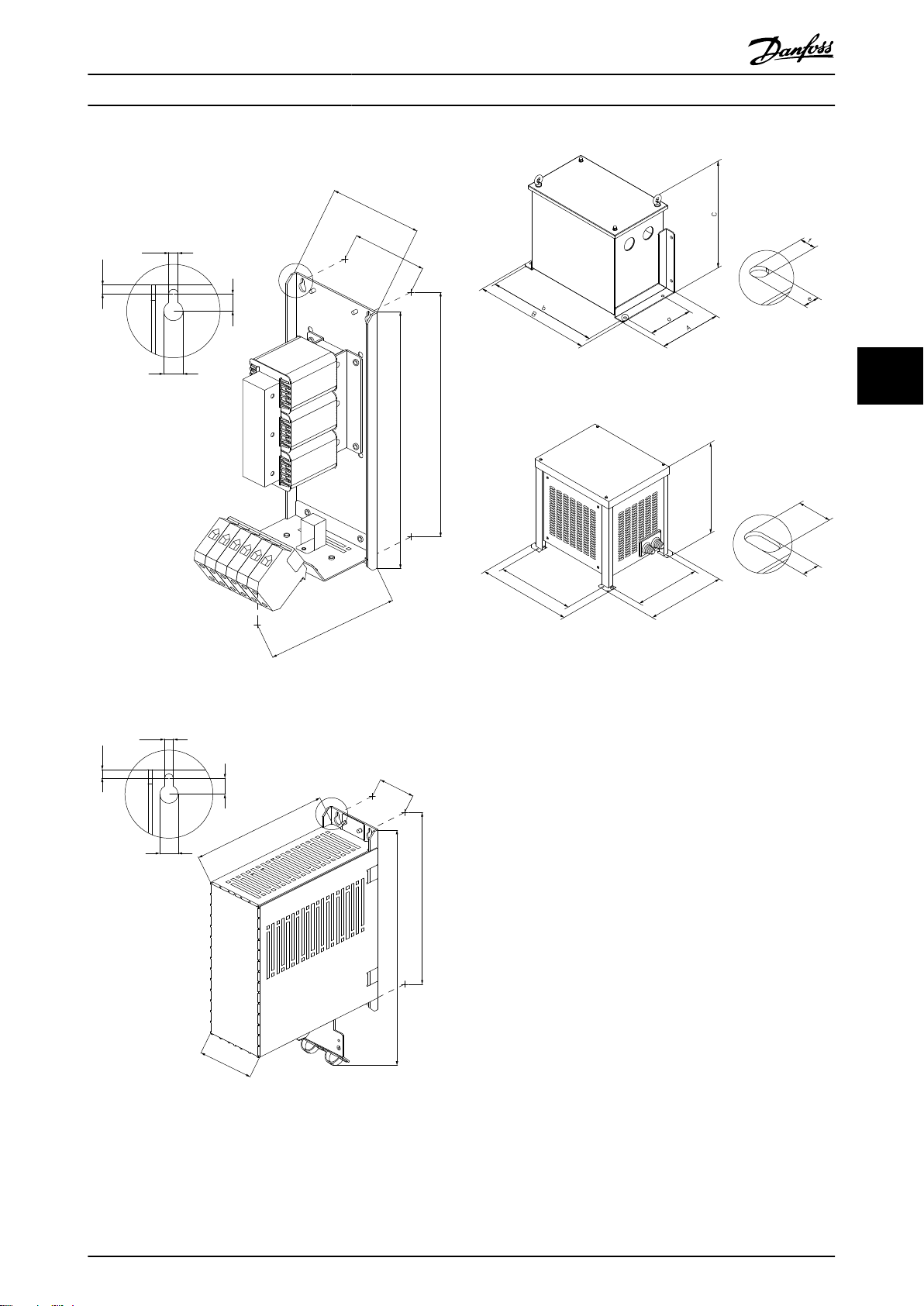

5.2 Mechanical Dimensions

5.2.1 Sketches

Floor Mounted Sine-wave filters

Wall Mounted Sine-wave filters

55

Illustration 5.6 IP23 Floor Mounted

Illustration 5.4 IP00 Wall Mounted

Illustration 5.5 IP20 Wall Mounted

Illustration 5.7 IP00 Floor Mounted

Illustration 5.8 IP20 Wall Mounted Foot Print Filters

34 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 36

a

b

A

C

B

c

e

d

f

A

A

130BB523.10

b

a

A

C

B

e

f

A

d

c

A

130BB524.10

130BB875.10

C

B

a

A

b

f

e

130BB526.10

How to Install Output Filters Design Guide

Wall mounted dU/du filters

Illustration 5.9 IP00 Wall Mounted

Illustration 5.11 IP54 Floor/Wall Mounted

Illustration 5.12 IP23 Floor Mounted

5 5

Illustration 5.10 IP20 Wall Mounted

MG.90.N5.02 - VLT® is a registered Danfoss trademark 35

Page 37

b

B

a

A

e

f

C

A

A

130BB525.10

C

B

a

A

b

f

e

130BB526.10

30

88

5 1635

15

10.5

15

130BB527.10

18

88

5 1834

18

17.5

45

34

34

13

70

130BB528.10

23 24

18

34

8

ø13

88

80

25

12.5

23 34

62.5

130BB529.10

How to Install Output Filters Design Guide

Floor mounted dU/du filters

55

Illustration 5.13 IP00 Floor Mounted

Illustration 5.16 L-shaped Terminal Kit 130B3138

Illustration 5.14 IP23 Floor Mounted

Illustration 5.17 L-shaped Terminal Kit 130B3139

Illustration 5.15 L-shaped Terminal Kit 130B3137

36 MG.90.N5.02 - VLT® is a registered Danfoss trademark

Page 38

How to Install Output Filters Design Guide

5.2.2 Physical Dimensions

1)

L-shaped

terminal

kit

screw

torque

AWG Nm/ft-Ib Part no.

2

mm

c d e f kg

5 5

Enclosure Dimensions [mm] Weight Mounting Wire cross section Terminal

Code

number

b C

a B

A

(depth)

(width)

(height)

130B2835 IP00 295 279 115 85 170 11.5 13 6.2 6 4.6 wall 16 6 4/3 N/A

130B2836 IP20 370 279 118 85 242 11.5 13 6.2 6 6.3 wall 16 6 4/3 N/A

Table 5.1 200-690V dU/dt Filters - Physical Dimensions

130B2838 IP00 395 379 155 125 220 11.5 13 6.2 6 12.7 wall 50 1 6/4.5 N/A

130B2839 IP20 475 379 157 125 248 11.5 13 6.2 6 16.2 wall 50 1 6/4.5 N/A

130B2841 IP00 395 379 155 125 220 11.5 13 6.2 6 22 wall 50 1 6/4.5 N/A

130B2842 IP20 475 379 158 125 248 11.5 13 6.2 6 25.5 wall 50 1 6/4.5 N/A

130B2844 IP00 445 429 185 155 235 11.5 13 6.2 6 27 wall 95 3/0 12/9 N/A

130B2845 IP20 525 429 188 155 335 11.5 13 6.2 6 30 wall 95 3/0 12/9 N/A

130B2847 IP00 300 275 190 100 235 11 22 33 floor M10 18/13.3 130B3137

130B2848 IP23 425 325 700 660 620 13 17 64.5 floor M10 18/13.3 130B3137

130B2849 IP00 300 275 250 125 235 11 22 36 floor 2 x M10 30/22.1 130B3138

130B3850 IP23 425 325 700 660 620 13 17 67.5 floor 2 x M10 30/22.1 130B3138

130B2851 IP00 350 325 250 123 270 11 22 47 floor 2 x M10 30/22.1 130B3138

130B2852 IP23 425 325 700 660 620 13 17 78.5 floor 2 x M10 30/22.1 130B3138

MG.90.N5.02 - VLT® is a registered Danfoss trademark 37

For floor mounted filters, an optional terminal connection kit is available for the ease of installation. Please see the L-shaped terminal kit sketches.

130B2853 IP00 400 375 290 159 283 11 22 72 floor 4 x M10 30/22.1 130B3139

130B2854 IP23 792 660.5 940 779 918 11 22 182 floor 4 x M10 30/22.1 130B3139

1)

The kit is not included in the filter delivery and should be ordered separately.

Page 39

How to Install Output Filters Design Guide

1)

L-shaped

terminal kit

Terminal

screw torque

floor N/A

130B3137

floor

floor 130B3138

floor 130B3138

floor 130B3139

Max. wire cross section

direction

AWG Nm/ft-lb Part no.

2

mm

c d e f kg Wall/Floor

C

(depth)

b

2.5

wall 4 24 - 10 0.6/0.44 N/A

3.3

wall 4 24 - 10 0.6/0.44 N/A

4.6

205

wall 4 24 - 10 0.6/0.44 N/A

8 11 6.5 6.5

6.1

wall 4 24 - 10 0.6/0.44 N/A

7.8

wall 4 24 - 10 0.6/0.44 N/A

14.4

wall 16 20 - 4 2/1.5 N/A

17.7

260

wall 16 20 - 4 2/1.5 N/A

12 19 9 9

34

258

wall 50 6 - 1/0 8/5.9 N/A

12 19 9 20

36

wall 50 6 - 1/0 8/5.9 N/A

50

wall 50 6 - 1/0 15/11.1 N/A

floor 2.0-6.0 N/A

55

Mounting

B

(width)

a

A

Code number Enslosure Measurements / Dimensions Weight

38 MG.90.N5.02 - VLT® is a registered Danfoss trademark

(height

130B2404 IP00

200 190 75 60 205 7 8 4.5 5

200 190 75 60 205 7 8 4.5 5

268 257 90 70

268 257 90 70 205 8 11 6.5 6.5

268 257 130 90 205 8 11 6.5 6.5

330 312 150 120 260 12 19 9 9

430 412 150 120

530 500 170 125

610 580 170 125 260 12 19 9 20

610 580 170 135 260 12 19 9 20

130B2439 IP20 3.3

130B2406 IP00

130B2441 IP20 4.2

130B2408 IP00

130B2443 IP20 206 5.8

130B2409 IP00

130B2444 IP20 7.1

130B2411 IP00

130B2446 IP20 9.1

130B2412 IP00

130B2447 IP20 16.9

130B2413 IP00

130B2448 IP20 259 19.9

130B2281 IP00

130B2307 IP20 260 39

130B2282 IP00

130B2308 IP20 41

130B2283 IP00

130B2309 IP20 54

130B3179 IP00 520 - 470 400 334 175 13 26 95

130B3181 IP23 918 898 904 779 792 661 11 22 205

130B3182 IP00 580 - 470 400 311 150 13 26 127

130B3183 IP23 918 898 904 779 792 661 11 22 237

130B3184 IP00 520 - 500 450 350 200 13 26 197

130B3185 IP23 918 898 904 779 792 661 11 22 307

130B3186 IP00 520 - 500 450 400 250 13 26 260

130B3187 IP23 918 898 904 779 792 661 11 22 370

130B3188 IP00 520 - 500 450 400 250 13 26 265

130B3189 IP23 1161 1141 1260 1099 991 860 11 22 425

130B3191 IP00 620 - 620 575 583 250 13 26 410

130B3192 IP23 1161 1141 1260 1099 991 860 11 22 570

For floor mounted filters, an optional terminal connection kit is available for the ease of installation. Please see the L-shaped terminal kit sketches.

1)

Table 5.2 500V Sine-wave Filter - Physical dimensions

The kit is not included in the filter delivery and should be ordered separately.

Page 40

How to Install Output Filters Design Guide

1)

L-shaped

terminal kit

Terminal

screw torque

Max. wire cross section

direction

Mounting

AWG Nm/ft-lb Part no.

2

mm

N/A

floor 130B3139

N/A

N/A

N/A

5 5

Code number Enclosure Measurements / Dimensions Weight

c d e f kg Wall/Floor

C

(depth)

b

B

(width)

a

A

(height)

130B3193 IP00 620 - 620 575 583 250 13 26 410

130B3194 IP23 1161 1141 1260 1099 991 860 11 22 610

2 x 130B3188 IP00

2 x 130B3189 IP23

2 x 130B3191 IP00

2 x 130B3192 IP23

3 x 130B3188 IP00

3 x 130B3189 IP23

For floor mounted filters, an optional terminal connection kit is available for the ease of installation. Please see the L-shaped terminal kit sketches.

3 x 130B3191 IP00

3 x 130b3192 IP23

1)

Table 5.3 500V Sine-wave Filter - Physical Dimensions

The kit is not included in the filter delivery and should be ordered separately.

MG.90.N5.02 - VLT® is a registered Danfoss trademark 39

Page 41

How to Install Output Filters Design Guide

1)

L-shaped

terminal kit

torque

Terminal screw

55

Max. wire cross section

Mounting

Weigh

2

direction

t

C

AWG Nm/ft-lb Part no.

mm

c d e f kg wall/floor

)

depth

wall 16 20 - 8 2/1.5 N/A

floor 16 20 - 8 15/11.1 N/A

floor 50 8 - 6 15/11.1 N/A

floor 95 6 - 4 15/11.1 N/A

floor 95 4 - 2 15/11.1 N/A

floor Ø10.5 2 - 1/0 15/11.1 130B3137

floor Ø10.5 2/0 - 4/0 18/13.3 130B3137

floor 2 x Ø13 2/0 - 4/0 18/13.3 130B3138

floor 2 x Ø13 4/0 - 5/0 18/13.3 130B3138

floor 2 x Ø13 4/0 - 5/0 30/22.1 130B3138

floor 4 x Ø13 5/0 30/22.1 130B3139

5/0 - 6/0 30/22.1 N/A

6/0 30/22.1 N/A

6/0 30/22.1 N/A

b

B

width)

a

A

(height)

130B3195 IP00 465 449 115 85 270 225 13 6.2 6.5 18

130B3196 IP20 465 449 118 85 243 - 13 6.2 6.5 21

130B4112 IP00 505 489 155 125 270 225 13 6.2 6.5 27

130B4113 IP23 505 489 158 125 310 - 13 6.2 6.5 31

130B4114 IP00 625 609 155 125 370 300 13 6.2 6.5 43

130B4115 IP23 625 609 158 125 310 - 13 6.2 6.5 49

130B4116 IP00 520 - 470 400 332 175 13 26 107

130B4117 IP23 715 699 798 676 620 502 11 22 142

130B4118 IP00 520 - 470 400 332 175 13 26 123

130B4119 IP23 715 699 798 676 620 502 11 22 160

130B4121 IP00 470 - 500 450 400 200 13 26 160

130B4124 IP23 918 898 940 779 792 661 11 22 270

130B4125 IP00 535 - 660 575 460 250 13 26 315

130B4126 IP23 1161 1141 1260 1099 991 860 11 22 475

130B4129 IP00 660 - 800 750 610 275 13 26 513

130B4151 IP23 1161 1141 1260 1099 991 860 11 22 673

130B4152 IP00 660 - 800 750 610 275 13 26 485

130B4153 IP23 1161 1141 1260 1099 991 860 11 22 645

130B4154 IP00 660 - 800 750 684 350 13 26 600

Code number Enclosure Measurements / Dimensions

40 MG.90.N5.02 - VLT® is a registered Danfoss trademark

130B4155 IP23 1161 1141 1260 1099 991 860 11 22 760

130B4156 IP00 490 - 800 750 713 375 13 26 745

130B4157 IP23 1161 1141 1260 1099 991 860 11 22 905

2 x 130B4152 IP00

2 x 130B4153 IP23

For floor mounted filters, an optional terminal connection kit is available for the ease of installation. Please see the L-shaped terminal kit sketches.

2 x 130B4154 IP00

3 x 1304155 IP23

2 x 130B4155 IP23

3 x 130B4154 IP00