Page 1

FC 300 DeviceNet and Allen Bradley Control logix 5550

Introduction ................................................................. 2

FC 300 DeviceNet card ............................................ 2

Creation of an EDS file ............................................. 4

Configuring the FC 300 with RS Networx ......... 7

I/O communication with RS Logix 5000 ....... 1 0

Explicit messages with RS Logix 5000........... 1 2

MN.33.B1.02 - VLT is a registered Danfoss trademark

1

Page 2

FC 300 DeviceNet and Allen Bradley Control logix 5550

Introduction

This application note describes how to set

up DeviceNet communication between a

Danfoss FC 300 frequency converter and

1756-DNB DeviceNet Scanner from Allen

Bradley. It is assumed that you have some

knowledge of RS Logix, the DeviceNet

Scanners and ladder logic.

This note describes:

z FC 300 DeviceNet card

z Configuration of the FC 300 with RS

Networx

z ADR - Auto Device Recovery

z I/O communication with RS Logix 5000

z Explicit messages with RS Logix 5000

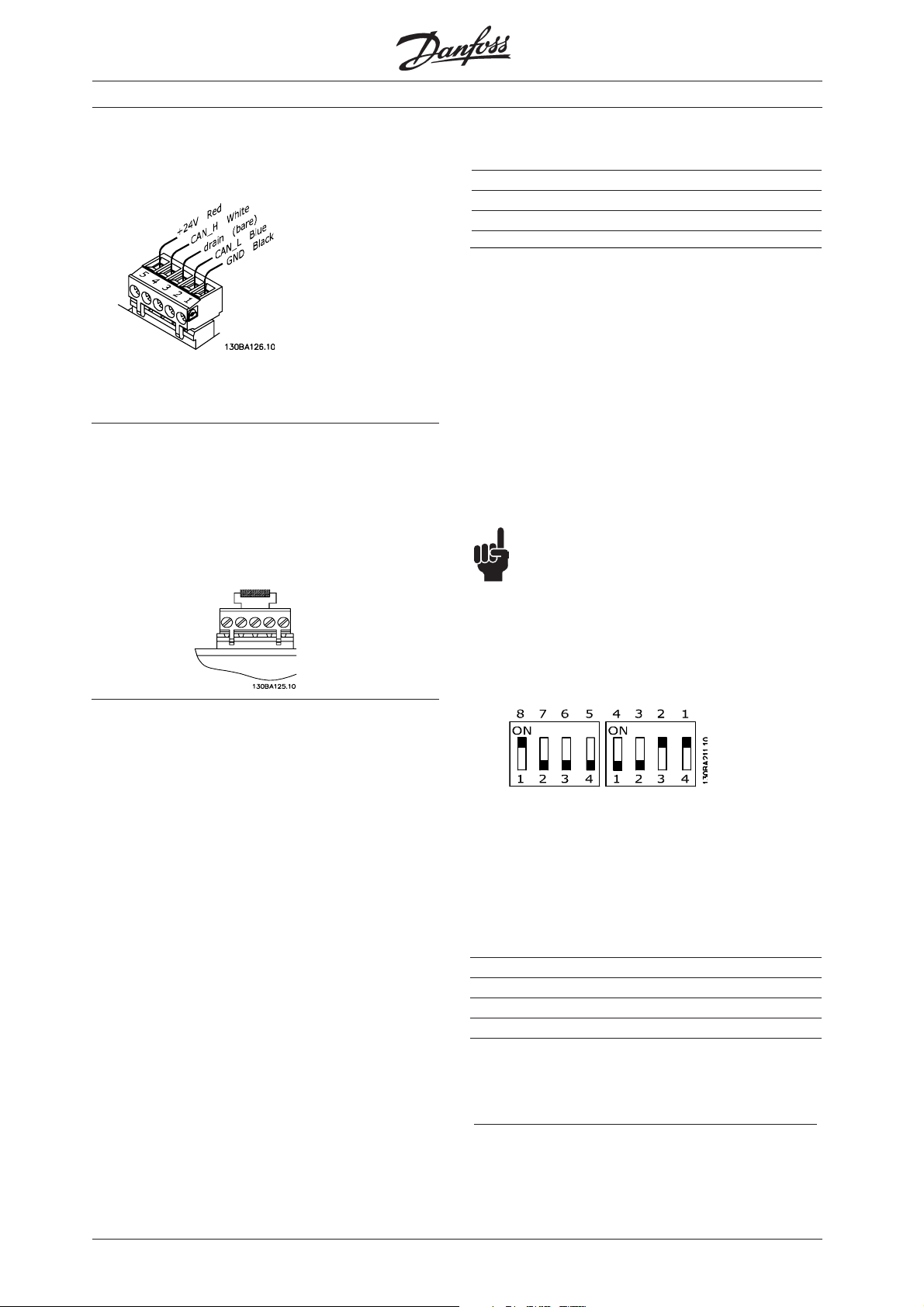

FC 300 DeviceNet card

The photo shows the DeviceNet card

which can be installed in FC 300 Series.

NOTE!:

The examples do not describe all the

functions needed for a real application, for

example error handling.

The examples are based upon that a RS

Logix5000 project has been created, and

the 1756-DNB has been added to the I/O

configuration.

Details of some of the components/

software:

FC 300 with DeviceNet version 2.5.

1756-DNB Series A Firmware Revision 6.002

RS Networx version 5.11.00

RS Logix 5000 version 13.00.00

MS Module status LED

NS Network status LED

NS Network status LED

MS Module status LED

Address switch and

baud rate setting

2

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 3

FC 300 DeviceNet and Allen Bradley Control logix 5550

DeviceNet connection

DeviceNet termination

Termination resistors should be installed at

each end of the bus line.

The resistors must be mounted between

terminal 2 CAN_L and terminal 4 CAN_H and

should have the following specification:

121 Ohm, 1 % Metal film and 1/4 Watt

Cable length

Baud rate Max. total cable length [m]

125 kBaud 500

250 kBaud 250

500 kBaud 100

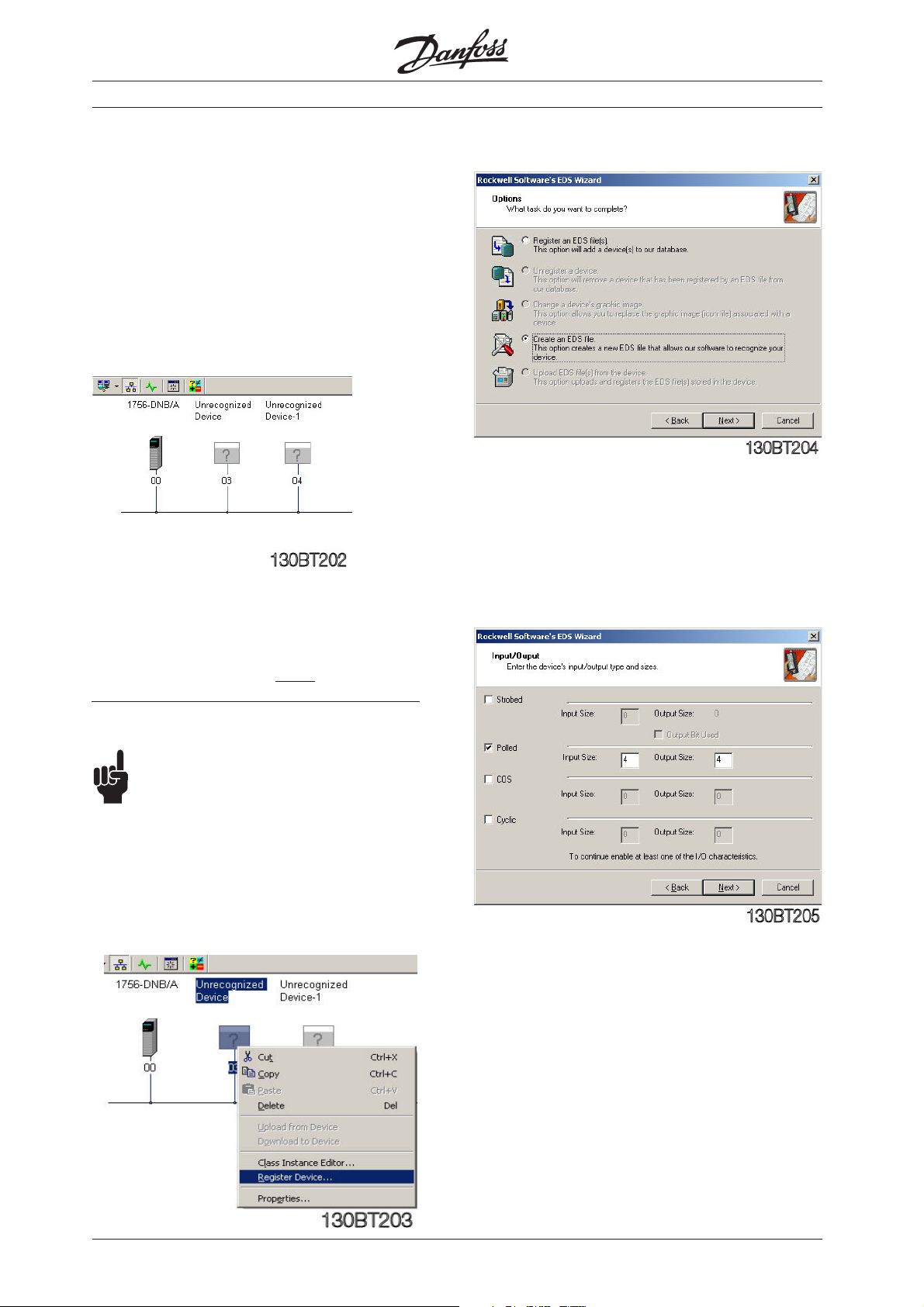

Address and baud rate setting

Dip switch 1-6 set the DeviceNet address/

Mac ID and 7-8 the baud rate.

Switch 6 is the Most Significant Bit (MSB)

and Switch 1 is the Least Significant Bit

(LSB).

When setting the address/Mac ID you must

ensure that each device on the network has

a unique address. The Baud rate can be

read in parameter 10-01 Baud rate Select

and the address/Mac ID can be read in

parameter 10-02 Mac ID.

NOTE!:

Switch off the power supply before

changing the hardware switches.

LEDs

For the Module Status LED:

1 . When the LED is off, no power is applied

to the option.

2. When the LED is green, the device is

operational

3. When the LED is flashing green, the

device is in standby

4. When the LED is flashing red, the device

detects a minor fault

5. When the LED is red, the device detects

an unrecoverable fault

6. When the LED is flashing red/green, the

device is self testing

For the Network Status LED:

1. When the LED is off, the network is nonpowered/not online

2. When the LED is flashing green, the

network is online but not connected

3. When the LED is green, the network is

online and connected

4. When the LED is flashing red, the

network has a connection time-out

5. When the LED is red, the network has a

critical link failure.

MN.33.B1.02 - VLT is a registered Danfoss trademark

If the address is to be set to 3 and the Baud

rate to 500 k Baud, the dip switches should

be set as follow:

ON = 1

OFF = 0

Switch Settings for DeviceNet Module Baud

rate:

Baud Switch Switch

Rate Setting Setting

87

125 kBPS 0 0

250 kBPS 0 1

500 kBPS 1 0

125 kBPS 1 1

3

Page 4

FC 300 DeviceNet and Allen Bradley Control logix 5550

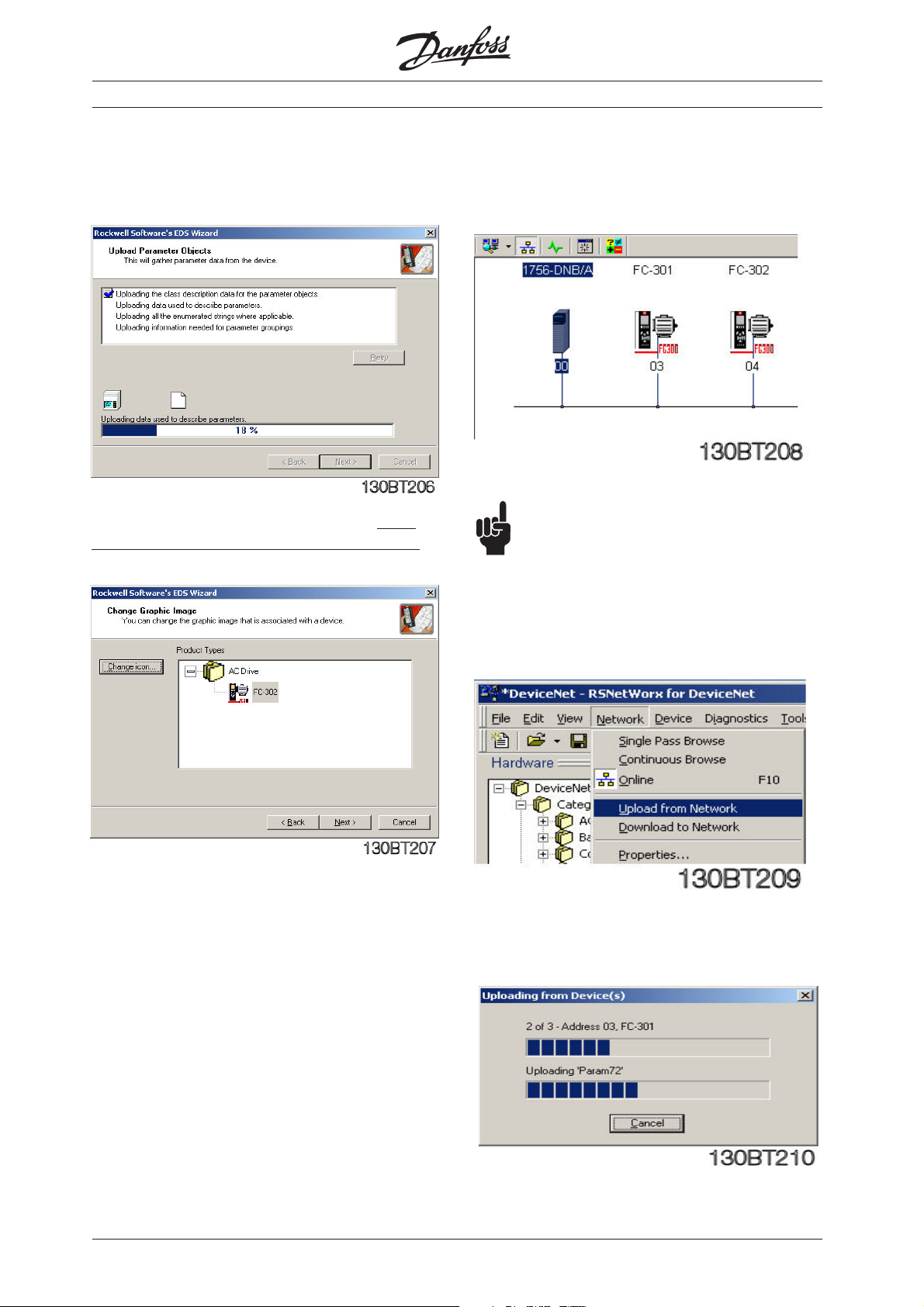

Creation of an EDS file

In this example the DeviceNet network consists of a

FC 301 set up to address 3, a FC 302 set up to

address 4 and the Master (1756-DNB) set up to

address 0.

Start RS Networx and a new project.

Go online and browse the Network via RS Linx. If

RS Networx does not have an EDS (Electronic Data

Sheet) installed the Device will be shown as an

Unrecognized Device.

The EDS Wizard is started and click on Next.

Choose Create an EDS file and click on Next.

By Input/Output choose a type and a size. Note

that Strobed is not supported FC 301 and 302.

By the FC 300 series the EDS file can be created

from the Drive via RS Networx. It is also possible to

download the EDS file from

www.danfoss.com/BusinessAreas/DrivesSolutions

NOTE!:

The EDS file does not contain all

parameters but a selected, limited number

of parameters. Note that an EDS file needs

to be created for both FC 301 and 302.

To create an EDS file right click on the

"Unrecognized Device" and choose Register

Device.

http://

Creation of an EDS file

Click on Next and the EDS file will start to be

created from the FC 300 Drive.

4

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 5

FC 300 DeviceNet and Allen Bradley Control logix 5550

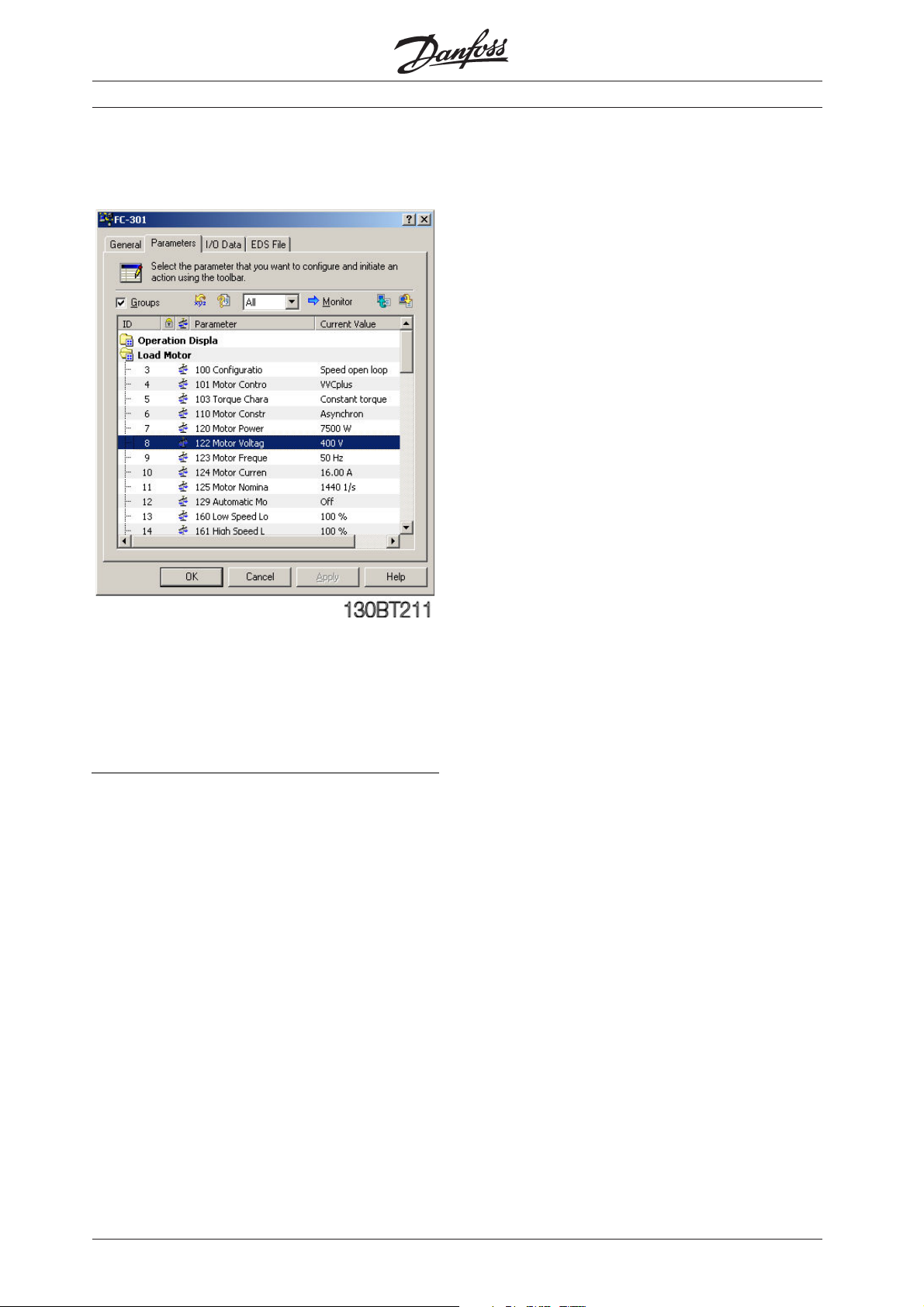

After the Parameter Objects that is used to create

the EDS file have been uploaded an Icon can be

linked to the FC 300 EDS file.

The FC 300 Icon can be downloaded from http://

www.danfoss.com/BusinessAreas/DrivesSolutions

After the EDS files for FC 301 and 302 have

been created you can browse the Network

again and the Drives will be shown.

NOTE!:

As the EDS files for FC 301 and 302 will

cover all motor and voltage sizes it is necessary to

upload the factory setting by the first

commissioning. This will secure that the correct

motor parameters are used in the EDS file.

Click on Network and Upload from Network.

MN.33.B1.02 - VLT is a registered Danfoss trademark

Now all Devices on the DeviceNet will be

read.

5

Page 6

FC 300 DeviceNet and Allen Bradley Control logix 5550

Creation of an EDS file

Double click on one of the FC 300 and the

parameters can be changed and downloaded.

Parameter written from RS Networx via the EDS file

is from the factory stored in RAM. To store the data

in non-volatile memory parameter 10-31 Store Data

Values or parameter 10-33 Store Always can be

used.

6

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 7

FC 300 DeviceNet and Allen Bradley Control logix 5550

Configuring the FC 300 with RS Networx

Double click on the 1756-DNB Scanner.

Click on Scanlist and add the two Devices

from Available Devices to the Scanlist.

Click on one of the FC 300 and on Edit I/O

Parameters.

The Polled input/output byte size needs to match

the actual instance type in parameter 10-10

Process Data Type Selection according to the table

below.

Click on Input and if you click on AutoMap

the I/O area of the FC 300 Devices will be

added to the first free area, here I 0.0.

Note that the I/O area of the Control logix Scanner

is organised as 32 bits (double word). This may vary

by other Scanner types.

This means that the FC 301 (address 3) Status word

will be read from the I/O area I:0.0 to I:0.15 and the

Main Actual Value from I:0.16 to I:0.32.

Parameter Polled size Polled size

10-10 input output

Instance 20/70 4 bytes 4 bytes

Instance 21/71 4 bytes 4 bytes

Instance 100/150 4 bytes 4 bytes

Instance 101/151 8 bytes 8 bytes

In this example FC 301 (address 3) is setup to Polled

I/O with 4 bytes using instance 100/150 and FC 302

(address 4) is setup to Polled I/O with 8 bytes using

instance 101/151.

The last four bytes of Instance 101/151 can be

configured in parameter 10-11 Process Data Write

and 10-12 Process Data Read.

Do the same with the Output to map Control word

and reference.

MN.33.B1.02 - VLT is a registered Danfoss trademark

7

Page 8

FC 300 DeviceNet and Allen Bradley Control logix 5550

Configuring the FC 300 with RS Networx

Auto-Device Replacement, or ADR, is a feature that

automatic replaces a failed device on a DeviceNet

network and returns it to the original setup without

having to use a software tool. It consists of two

features:

z Configuration Recovery, CR.

With this feature the Scanner will download the stored configuration (EDS file) to

the FC 300 before it begins to exchange

I/O data with that device. Notice this will

happen by each power up of the Master,

so this will expand the power up time.

z Auto Address Recovery, AAR.

With this feature the scanner (master)

will change the device node address from

63 (the default address) to the original

address.

Example: The connection between the

Scanner and FC 301 at node address #3

is broken and the FC 301 needs to be

replaced. In this situation the Scanner

will continually query for a new FC 301 at

node address #63. When a new FC 301 is

power up with the factory settings and if

the Electronic Key of the device that the

scanner lost at node address #3

matches, it will change the node address

from #63 to #3.

After Auto Address Recovery the EDS file

will be downloaded the node address #3.

The FC 300 can now be seen as an available device

for ADR.

Click on each node and click on „Load Device

Config“. Click also on Configuration Recovery and

Auto-Address Recovery by ADR Settings if these

functions are require.

Click on ADR to set up the ADR menu.

8

This indicates the size of the Device

configuration (EDS file).

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 9

FC 300 DeviceNet and Allen Bradley Control logix 5550

Configuring the FC 300 with RS Networx

Click on Enable Auto-Address Recovery and

a Warning will appear. Click Yes to this

Warning and set the PLC in Stop (Program).

Download the configuration to the Scanner

and turn the key on the Scanner to Run to

start to communicate with the slaves.

MN.33.B1.02 - VLT is a registered Danfoss trademark

9

Page 10

FC 300 DeviceNet and Allen Bradley Control logix 5550

I/O communication with RS Logix 5000

Start RS Logix 5000 and a new project.

Make the I/O configuration and click on

Controller tags.

Click on Local data for the DeviceNet

module. Now you can see the full input area

of the DeviceNet system.

Device Address Input PCD 1 PCD 2 PCD 3 PCD 4

Status Word Main Actual Motor Motor

FC 301 3 Local:2:I.Data[0] 0607 Hex 0000 Hex - FC 302 4 Local:2:I.Data[1] 0F07 Hex 2000 Hex - FC 302 4 Local:2:I.Data[2] - - A1 Hex= FB Hex=

Choose to see the format in Hex.

See a detailed description of the status word in the

FC 300 DeviceNet Operating Instructions

(MG33DXYY).

In this example Local:2:I.Data indicates the

following:

Value current frequency

1.61 A 25.1 Hz

Example on status words from FC 301/302

(par. 1010 Process Data Type Selection =

Instance 100/150 or 101/151):

0607 Hex: Stand by

0F07 Hex: Speed = ref. VLT running

0E07 Hex: Speed ≠ ref. i.e. ramping.

VLT running

0F87 Hex: Warning

10

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 11

FC 300 DeviceNet and Allen Bradley Control logix 5550

I/O communication with RS Logix 5000

Click on the Local output data. Now you

can see the full Output area of the

DeviceNet system.

Choose to see the format in Hex.

See a detailed description of the control word in the

FC 300 DeviceNet Operating Instructions

(MG33AXYY).

To start the FC 300 when using Instance

100/150 or 101/151 the start command

should be 047C Hex. The Reference goes

from 0 – 4000 Hex, corresponding to 0 –100

%.

Device Address Output PCD 1 PCD 2 PCD 3 PCD 4

Control Word Reference Ramp 1 Ramp 1

FC 301 3 Local:2:O.Data[0] 043C Hex 1000 Hex - FC 302 4 Local:2:O.Data[1] 047C Hex 2000 Hex - FC 302 4 Local:2:O.Data[2] - - 64 Hex= 12C Hex=

In this example Local:2:O.Data[0] indicates

the following:

0-4000 hex up P.341 down P.342

1.00 sec 3.00 sec

Example on Control words to the FC 300

(par. 512 Telegram profile = FC Drive [1]):

047C Hex: Start via ramp time 1

043C Hex: Stop via ramp time 1

0474 Hex: Coast

046C Hex: Quick Stop via Ouick Stop ramp

time

847C Hex: Reversing and start

MN.33.B1.02 - VLT is a registered Danfoss trademark

Example on reference to the FC 300 (par.

303 Max. reference = 1500 rpm):

1000 Hex ~ 25 % reference = 12.5 Hz

2000 Hex ~ 50 % reference = 25.0 Hz

4000 Hex ~ 100 % reference = 50.0 Hz

11

Page 12

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

Explicit messages is used to read or write from the

PLC to FC 300 parameters.

In this example an explicit message will be set up to

read parameter 16-13 Frequency and an explicit

message to write to parameter 341 Ramp up time

1.

Click on Controller Tags and add a new tag

called MESSAGE.

Click on box next to DINT and in Select

Data type choose MESSAGE.

12

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 13

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

Add a new tag called Motor_frequency.

Click on box next to INT and in Select Data type

choose INT with an Array of 0.

Now all the Tags are created to read the Motor

frequency parameter 16-13 on address number 3.

By I/O configuration double click on 1756DNB Scanner.

Give the Scanner a name, for example Dnet

and click on OK.

MN.33.B1.02 - VLT is a registered Danfoss trademark

13

Page 14

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

Click on Main routine and add a new rung.

Click on the Input/Output tag and drag and

drop a MSG block to the rung.

Click on blue ? and choose the MESSAGE

tag from the list.

Click on box next to MESSAGE to configure

the read command of parameter 16-13 Motor

frequency.

Add an input (Examine Off) to the Message

block and set it to MESSAGE.EN.

In this example the Scanner always reads the Motor

frequency.

Set the Message Configuration to the following:

Message Type: CIP Generic

Service Type: Get Attribute Single (Read command)

Class: 74 Hex (116 dec). This is the Class ID for Group 1600.

See page 17.

Instance: 1 Hex. Set always this to 1.

Attribute: 71 Hex (113 dec). The attribute is the last two digits of the

parameternumber + 100.

Set the Destination to the Motor_frequency tag and the message is now set up to read par. 16-13 Motor

frequency.

14

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 15

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

Click on Communication and create a path

to the FC 301 at address 3.

Dnet is the name of 1756-DNB Scanner and

2 is a fixed number and 3 is the address of

FC 301. Click Apply and OK.

Save the program and download it to the scanner.

Click on controller tags and give the FC 301 a start

signal.

By Motor_frequency the actual frequency is

shown. 250 means that the actual frequency is 25.0 Hz due to the conversion

index of -1.

MN.33.B1.02 - VLT is a registered Danfoss trademark

15

Page 16

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

If you want to write to a parameter you

must use the Service type Set Attribute

Single and create a source element where

the parameter value can be defined.

The Source Length should match the Data

type size of the parameter. The Data type

can be seen by the factory settings in the

Operating Instruction.

16

MN.33.B1.02 - VLT is a registered Danfoss trademark

Page 17

FC 300 DeviceNet and Allen Bradley Control logix 5550

Explicit messages with RS Logix 5000

Parameter range: Class:

Group 0-00 - 0-99 Operation & Display Class 100 (64 Hex)

Group 1-00 - 1-99 Load & Motor Class 101 (65 Hex)

Group 2-00 - 2-99 Brakes Class 102 (66 Hex)

Group 3-00 - 3-99 Reference / Ramps Class 103 (67 Hex)

Group 4-00 - 4-99 Limits / Warnings Class 104 (68 Hex)

Group 5-00 - 5-99 Digital In / Out Class 105 (69 Hex)

Group 6-00 - 6-99 Analog In / Out Class 106 (6A Hex)

Group 7-00 - 7-99 Controls Class 107 (6B Hex)

Group 8-00 - 8-99 Comm. and Options Class 108 (6C Hex)

Group 10-00 - 10-99 Can Fieldbus Class 110 (6E Hex)

Group 13-00 - 13-99 Smart Logic Class 113 (71 Hex)

Group 14-00 - 14-99 Special Functions Class 114 (72 Hex)

Group 15-00 - 15-99 Drive Information Class 115 (73 Hex)

Group 16-00 - 16-99 Data Readouts Class 116 (74 Hex)

Group 17-00 - 17-99 Motor Feedback Option Class 117 (75 Hex)

Instance Description:

In the Danfoss FC 300 Series we only

handle Instance 1, so always leave this at

the value of 1.

Attribute Description:

The attribute for the FC 300 parameters are the 2

(two) last digits of the Parameter + 100.

By following this structure all 1 dimensional

parameters can be accessed by Explicit

Message.

As example for Parameter 1662,

FC 300 Parameter FC 300 Parameter

FC 300 Parameter

FC 300 Parameter FC 300 Parameter

16-62 116 1 162

ClassClass

Class

ClassClass

InstanceInstance

Instance

InstanceInstance

AttributeAttribute

Attribute

AttributeAttribute

MN.33.B1.02 - VLT is a registered Danfoss trademark

17

Loading...

Loading...