Fact Sheet

VLT® Midi Drive FC 280

Flexible. Communicative. Easy to use.

Access your true high-efficiency

potential with the VLT® Midi Drive

FC 280, the evolution of the popular

VLT® 2800 drive. Profit from new savings, with a wide range of features

designed to make installing, using,

and maintaining the drive as simple

and as easy as possible – just set and

forget.

This AC drive delivers precise and

efficient motor control for machine

builders in the food and beverage,

material handling, and processing

industries. It is strong on control performance, functional safety, and flexible

fieldbus communication.

It’s also an easy retrofit for the

VLT® 2800 in established plant or

machinery concepts.

Active power factor

correction for singlephase units reduces

harmonics to less

than

8% THDi

The right mix of features ensures the

AC drive suits your task, whether for

conveyor systems, mixers, and packag-

Integrated features free you from

finding space and budget to install

extra components:

ing systems or driving pumps, fans, and

compressors.

VLT® Midi Drive saves installation time,

with all pluggable connectors, and USB

n Harmonic mitigation

n RFI filter

n Dual-channel Safe Torque Off (STO)

n Brake chopper

port for convenient PC connection. For

easy and intelligent commissioning,

transfer, or programming of factory

settings, use the handy VLT® Memory

Module.

Product range

3 x 380-480 V ...................................0.37-22 kW

3 x 200-240 V ..................................0.37-3.7 kW

1 x 200-240 V ..................................0.37-2.2 kW

Set-up wizards simplify commissioning

for common applications.

Feature Benefit

Integrated harmonics and EMC design

Integrated DC choke or active power factor

correction (PFC)

Integrated EMC filter

RFI switch – Operates safely on IT mains

Easy to install and set up

Pluggable terminals – Fast installation and unit exchange

USB port

Application set-up wizards – Easy commissioning

Enhanced numerical LCP (option) – Cost effective user interface

Graphical LCP supporting various languages,

including adapter (option)

Memory module (option)

Memory module reader (option)

Strategic design for applications, safety, and motor control

Integrated Safe Torque Off (STO), dual channel

Control algorithm runs both

induction and PM motors

Integrated brake chopper for 3-phase drives in all

power sizes up to 22 kW

Side-by-side or horizontal mounting, without

derating and clearance

Operates at up to 45 °C without derating and

clearance

– Saves installation time and panel space

requirements

– Improves power supply quality

– Reduces effective input current/VA rating

– Avoids malfunction and improves reliability

of surrounding components

– Saves installation time and panel space

requirements

– Proven compliance to Cat. C2/EN 61800-3

(Class A1/EN 55011)

– Easy PC connection for troubleshooting

or commissioning

– No need for adapter or PC-USB driver

– Easy set-up in one of seven main languages

– Fast troubleshooting

– Convenient transfer of parameter set-up

– Easy firmware updates

– Easy and fast commissioning

– Convenient transfer files to and from the

VLT® Memory Module MCM 102 via PC

– Eliminates external components

– Enables reliable functional safety

– Freedom to choose the best

high-efficiency motor for the task

– No cost for external braking chopper

– Allows flexible mounting and saves cabinet

space and cost

– Saves cost for external cooling and reduces

downtime for overtemperature failures

drives.danfoss.com

Integrated harmonic mitigation

In compliance with IEC/EN 61000-3-2/

61000-3-12, the integrated DC chokes

for all 3-phase units reduce harmonics

to less than 48% THDi.

For single-phase units the harmonics

are less than 8% thanks to the

integrated active PFC.

Integrated RFI lter

Built-in filters not only save space, but

also eliminate extra costs for fitting,

wiring and material.

Dual-channel Safe Torque O

The Safe Torque Off (STO) function is a

component in a safety control system.

STO prevents the unit from generating

the energy that is required to rotate the

motor, which ensures safe conditions in

emergency situations.

PM motor compatibility

The VLT® Midi Drive provides highly

efficient permanent magnet (PM)

motor control in open loop under

V VC+ in the whole power range.

Your choice of eldbus

n PROFINET with dual port

n POWERLINK with dual port

n EtherNet/IP™ with dual port

n PROFIBUS

n CANopen

n Modbus RTU and FC Protocol are

integrated as standard

The optional 24 V DC back-up

power supply keeps the fieldbus

communication on, while disconnected

from mains.

Specifications

Mains supply (L1, L2, L3)

Supply voltage

Supply frequency 50/60 Hz

Displacement power factor (cos φ) Near unity (> 0.98)

Switching frequency on input supply L1, L2, L3 Switching maximum 2 times/minute

Output data (U, V, W)

Output voltage 0-100% of supply voltage

Switching on output Unlimited

Ramp times 0.01-3600 s

Frequency range 0-500 Hz

Programmable digital inputs and outputs

Digital inputs / digital outputs* 6 (7) / 1

Logic PNP or NPN

Voltage level 0-24 V DC

One of 6 digital inputs can be configured as digital output or pulse output. One of analog inputs can be configured as an extra digital input, thereby bring the quantity of digital inputs to 7.

Pulse and encoder inputs

Pulse inputs / encoder inputs** 2/2

Voltage level 0-24 V DC

**Note: Two digital inputs can be configured as pulse inputs.

One pair of inputs can be configured as encoder inputs.

Programmable analog inputs

Analog inputs 2

Modes

Voltage level 0 V to +10 V (scaleable)

Current level 0/4 to 20 mA (scaleable)

Programmable analog outputs

Analog outputs 1

Current range at analog output 0/4 to 20 mA

Programmable relay outputs

Relay outputs 1

Approvals

Approvals CE, UL listed, cUL, TÛV, RCM (C-Tick), EAC

Easy connectivity

For convenient PC connection during

commissioning or service, use the

integrated USB port.

200-240 V (-15%/+10%)

380-480 V (-15%/+10%)

1 voltage or current /

1 voltage or DI

b

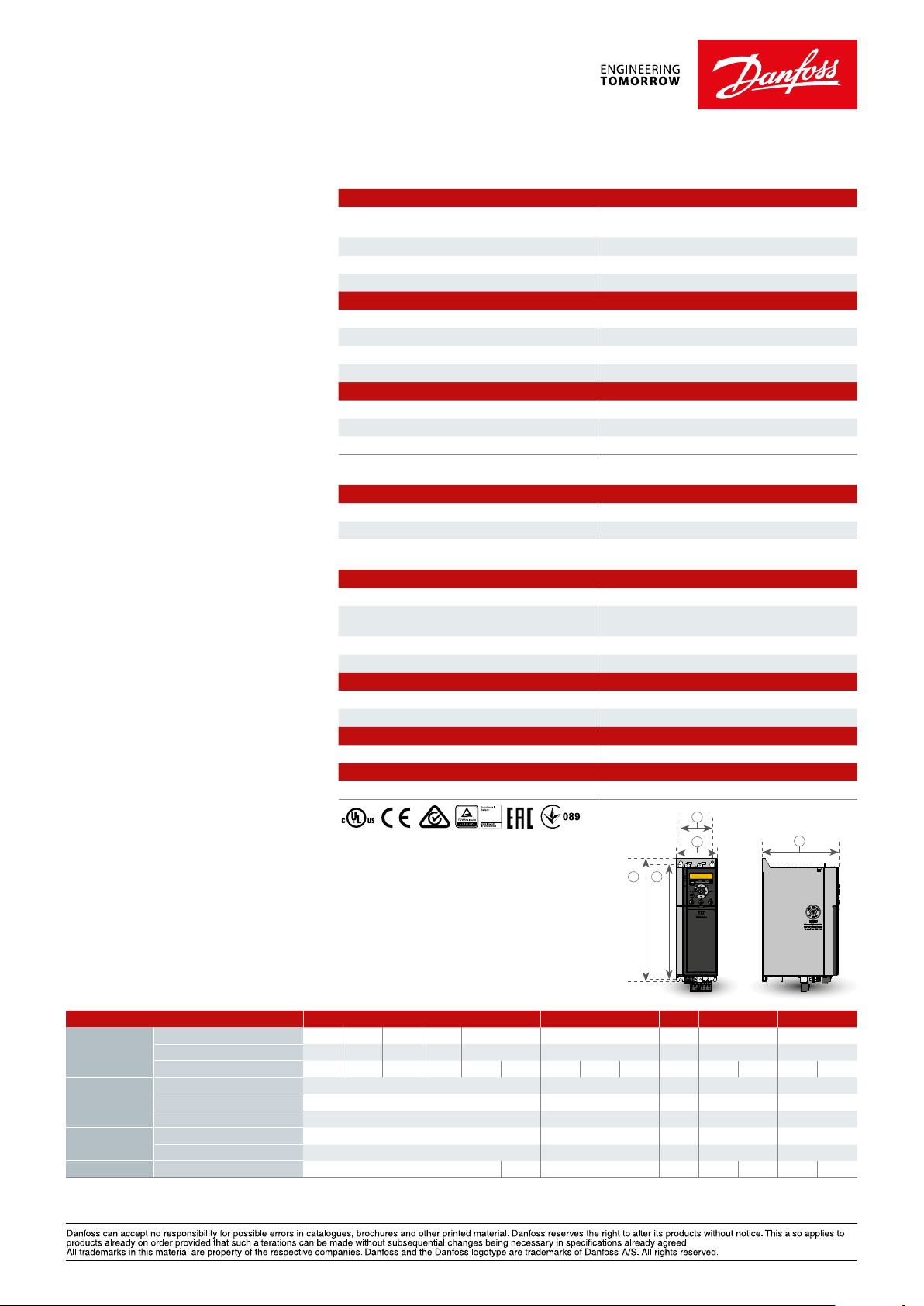

B

A a

C

Dimensions and weights

Enclosure IP20 K1 K2 K3 K4 K5

Power size

[kW]

Dimensions

[mm]

Mounting

holes

Weight [kg] IP20

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, drives.danfoss.com, E-mail: info@danfoss.com

DKDD.PFP.820.A7.02 © Copyright Danfoss Drives | 2017.06

Single-phase 200-240 V

3-phase 200-240 V 0.37 0.55 0.75 1.1 1.5 2.2 3.7

3-phase 380-480 V 0.37 0.55 0.75 1.1 1.5 2.2 3 4 5.5 7.5 11 15 18.5 22

Height A 210 272.5 272.5 320 410

Width B 75 90 115 135 150

Depth C 168 168 168 245 245

a 198 260 260 297.5 390

b 60 70 90 105 120

0.37 0.55 0.75 1.1 1.5 2.2

2.3 2.5 3.6 4.1 9.4 9.5 12.3 12.5

EtherNet/IP™ and DeviceNet™ are trademarks of ODVA, Inc.

Loading...

Loading...