ENGINEERING TOMORROW

Design Guide

VLT® Midi Drive FC 280

vlt-drives.danfoss.com

Contents Design Guide

Contents

1 Introduction

1.1 Purpose of the Design Guide

1.2 Additional Resources

1.3 Denitions

1.4 Document and Software Version

1.5 Approvals and Certications

1.6 Safety

2 Product Overview

2.1 Enclosure Size Overview

2.2 Electrical Installation

2.2.1 Motor Connection 14

2.2.2 AC Mains Connection 15

2.2.3 Control Terminal Types 16

2.2.4 Wiring to Control Terminals 17

2.3 Control Structures

2.3.1 Control Modes 18

2.3.2 Control Principle 19

2.3.3 Control Structure in VVC

5

5

5

5

8

8

9

10

10

12

18

+

19

2.3.4 Internal Current Control in VVC+ Mode 21

2.3.5 Local (Hand On) and Remote (Auto On) Control 21

2.4 Reference Handling

2.4.1 Reference Limits 23

2.4.2 Scaling of Preset References and Bus References 24

2.4.3 Scaling of Analog and Pulse References and Feedback 24

2.4.4 Dead Band Around Zero 25

2.5 PID Control

2.5.1 Speed PID Control 28

2.5.2 Process PID Control 31

2.5.3 Process Control Relevant Parameters 32

2.5.4 Example of Process PID Control 33

2.5.5 Process Controller Optimization 35

2.5.6 Ziegler Nichols Tuning Method 36

2.6 EMC Emission and Immunity

2.6.1 General Aspects of EMC Emission 36

2.6.2 EMC Emission 38

22

28

36

2.6.3 EMC Immunity 40

2.7 Galvanic Isolation

2.8 Ground Leakage Current

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 1

41

41

Contents

VLT® Midi Drive FC 280

2.9 Brake Functions

2.9.1 Mechanical Holding Brake 42

2.9.2 Dynamic Braking 43

2.9.3 Brake Resistor Selection 43

2.10 Motor Insulation

2.10.1 Sine-wave Filters 44

2.10.2 dU/dt Filters 45

2.11 Smart Logic Controller

2.12 Extreme Running Conditions

2.12.1 Motor Thermal Protection 46

3 Application Examples

3.1 Introduction

3.1.1 Encoder Connection 48

3.1.2 Encoder Direction 48

3.1.3 Closed-loop Drive System 48

3.2 Application Examples

3.2.1 AMA 49

42

44

45

46

48

48

49

3.2.2 Speed 49

3.2.3 Start/Stop 50

3.2.4 External Alarm Reset 51

3.2.5 Motor Thermistor 51

3.2.6 SLC 51

4 Safe Torque O (STO)

5 RS485 Installation and Set-up

5.1 Introduction

5.1.1 Overview 53

5.1.2 Network Connection 53

5.1.3 Hardware Set-up 54

5.1.4 Parameter Settings for Modbus Communication 54

5.1.5 EMC Precautions 54

5.2 FC Protocol

5.2.1 Overview 54

5.2.2 FC with Modbus RTU 55

52

53

53

54

5.3 Network Conguration

5.4 FC Protocol Message Framing Structure

5.4.1 Content of a Character (byte) 55

5.4.2 Telegram Structure 55

5.4.3 Telegram Length (LGE) 55

2 Danfoss A/S © 05/2017 All rights reserved. MG07B302

55

55

Contents Design Guide

5.4.4 Frequency Converter Address (ADR) 56

5.4.5 Data Control Byte (BCC) 56

5.4.6 The Data Field 56

5.4.7 The PKE Field 56

5.4.8 Parameter Number (PNU) 57

5.4.9 Index (IND) 57

5.4.10 Parameter Value (PWE) 57

5.4.11 Data Types Supported by the Frequency Converter 57

5.4.12 Conversion 57

5.4.13 Process Words (PCD) 58

5.5 Examples

5.5.1 Writing a Parameter Value 58

5.5.2 Reading a Parameter Value 58

5.6 Modbus RTU

5.6.1 Prerequisite Knowledge 59

5.6.2 Overview 59

5.6.3 Frequency Converter with Modbus RTU 59

5.7 Network Conguration

5.8 Modbus RTU Message Framing Structure

5.8.1 Introduction 60

5.8.2 Modbus RTU Telegram Structure 60

5.8.3 Start/Stop Field 60

5.8.4 Address Field 60

5.8.5 Function Field 60

5.8.6 Data Field 61

5.8.7 CRC Check Field 61

5.8.8 Coil Register Addressing 61

58

59

59

60

5.8.9 How to Control the Frequency Converter 63

5.8.10 Function Codes Supported by Modbus RTU 63

5.8.11 Modbus Exception Codes 63

5.9 How to Access Parameters

5.9.1 Parameter Handling 63

5.9.2 Storage of Data 64

5.9.3 IND (Index) 64

5.9.4 Text Blocks 64

5.9.5 Conversion Factor 64

5.9.6 Parameter Values 64

5.10 Examples

5.10.1 Read Coil Status (01 hex) 64

5.10.2 Force/Write Single Coil (05 hex) 65

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 3

63

64

Contents

VLT® Midi Drive FC 280

5.10.3 Force/Write Multiple Coils (0F hex) 65

5.10.4 Read Holding Registers (03 hex) 65

5.10.5 Preset Single Register (06 hex) 66

5.10.6 Preset Multiple Registers (10 hex) 66

5.11 Danfoss FC Control Prole

5.11.1 Control Word According to FC Prole (8-10 Protocol = FC Prole) 67

5.11.2 Status Word According to FC Prole (STW) 68

5.11.3 Bus Speed Reference Value 70

6 Type Code and Selection

6.1 Type Code

6.2 Ordering Numbers: Options, Accessories, and Spare Parts

6.3 Ordering Numbers: Brake Resistors

6.3.1 Ordering Numbers: Brake Resistors 10% 73

6.3.2 Ordering Numbers: Brake Resistors 40% 75

6.4 Ordering Numbers: Sine-wave Filters

6.5 Ordering Numbers: dU/dt Filters

6.6 Ordering Numbers: External EMC Filters

7 Specications

7.1 Electrical Data

7.2 Mains Supply

67

71

71

71

73

76

77

77

80

80

83

7.3 Motor Output and Motor Data

7.4 Ambient Conditions

7.5 Cable Specications

7.6 Control Input/Output and Control Data

7.7 Connection Tightening Torques

7.8 Fuses and Circuit Breakers

7.9 Eciency

7.10 Acoustic Noise

7.11 dU/dt Conditions

7.12 Special Conditions

7.12.1 Manual Derating 93

7.12.2 Automatic Derating 95

7.13 Enclosure Sizes, Power Ratings, and Dimensions

Index

83

84

84

85

88

89

90

91

91

92

96

99

4 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Introduction Design Guide

1 Introduction

1.1 Purpose of the Design Guide

This design guide is intended for project and systems

engineers, design consultants, and application and product

specialists. Technical information is provided to understand

the capabilities of the frequency converter for integration

into motor control and monitoring systems. Details

concerning operation, requirements, and recommendations

for system integration are described. Information is

provided for input power characteristics, output for motor

control, and ambient operating conditions for the

frequency converter.

Also included are:

Safety features.

•

Fault condition monitoring.

•

Operational status reporting.

•

Serial communication capabilities.

•

Programmable options and features.

•

Design details such as site requirements, cables, fuses,

control wiring, the size and weight of units, and other

critical information necessary to plan for system integration

are also provided.

Reviewing the detailed product information in the design

stage enables developing a well-conceived system with

optimal functionality and

VLT® is a registered trademark.

Additional Resources

1.2

eciency.

Denitions

1.3

1.3.1 Frequency Converter

Coast

The motor shaft is in free mode. No torque on the motor.

I

VLT,MAX

Maximum output current.

I

VLT,N

Rated output current supplied by the frequency converter.

U

VLT,MAX

Maximum output voltage.

1.3.2 Input

Control commands

Start and stop the connected motor with LCP and digital

inputs.

Functions are divided into 2 groups.

Functions in group 1 have higher priority than functions in

group 2.

Group 1 Precise stop, coast and reset stop, precise stop

and coast stop, quick stop, DC braking, stop, and

[OFF].

Group 2 Start, pulse start, reversing, start reversing, jog,

and freeze output.

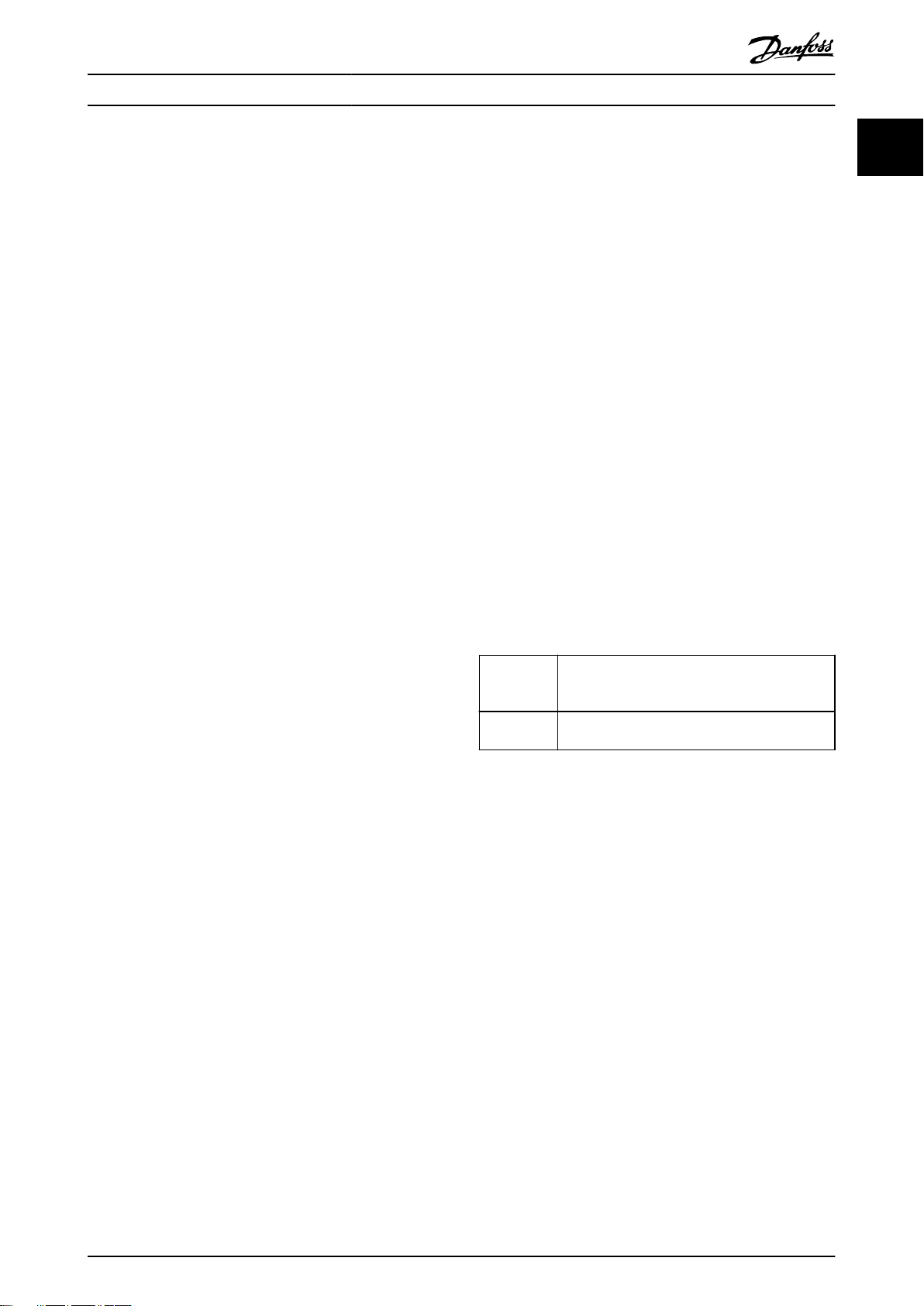

Table 1.1 Function Groups

1.3.3 Motor

1 1

Resources available to understand operations and

programming of the frequency converter:

VLT® Midi Drive FC 280 Operating Guide, provides

•

information about the installation, commissioning,

application, and maintenance of the frequency

converter.

VLT® Midi Drive FC 280 Programming Guide,

•

provides information on how to program and

includes complete parameter descriptions.

Supplementary publications and manuals are available

from Danfoss. See drives.danfoss.com/knowledge-center/

technical-documentation/ for listings.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 5

Motor running

Torque generated on the output shaft and speed from

0 RPM to maximum speed on the motor.

f

JOG

Motor frequency when the jog function is activated (via

digital terminals or bus).

f

M

Motor frequency.

f

MAX

Maximum motor frequency.

f

MIN

Minimum motor frequency.

f

M,N

Rated motor frequency (nameplate data).

I

M

Motor current (actual).

I

M,N

Nominal motor current (nameplate data).

175ZA078.10

Pull-out

RPM

Torque

Introduction

VLT® Midi Drive FC 280

11

n

M,N

Nominal motor speed (nameplate data).

n

s

Synchronous motor speed.

2 × Parameter 1−23 × 60s

ns=

n

slip

Parameter 1−39

Motor slip.

P

M,N

Rated motor power (nameplate data in kW or hp).

T

M,N

Rated torque (motor).

U

M

Instantaneous motor voltage.

U

M,N

Rated motor voltage (nameplate data).

Break-away torque

Preset reference

A dened preset reference to be set from -100% to +100%

of the reference range. Selection of 8 preset references via

the digital terminals. Selection of 4 preset references via

the bus.

Pulse reference

A pulse frequency signal transmitted to the digital inputs

(terminal 29 or 33).

Ref

MAX

Determines the relationship between the reference input at

100% full scale value (typically 10 V, 20 mA) and the

resulting reference. The maximum reference value is set in

parameter 3-03 Maximum Reference.

Ref

MIN

Determines the relationship between the reference input at

0% value (typically 0 V, 0 mA, 4 mA) and the resulting

reference. The minimum reference value is set in

parameter 3-02 Minimum Reference.

1.3.5 Miscellaneous

Analog inputs

The analog inputs are used for controlling various

functions of the frequency converter.

There are 2 types of analog inputs:

Current input: 0–20 mA and 4–20 mA.

•

Voltage input: 0–10 V DC.

•

Analog outputs

The analog outputs can supply a signal of 0–20 mA, or 4–

20 mA.

Automatic motor adaptation, AMA

Illustration 1.1 Break-away Torque

η

VLT

The eciency of the frequency converter is dened as the

ratio between the power output and the power input.

Start-disable command

A start-disable command belonging to the control

commands in group 1. See Table 1.1 for more details.

Stop command

A stop command belonging to the control commands in

group 1. See Table 1.1 for more details.

1.3.4 References

Analog reference

A signal transmitted to the analog inputs 53 or 54 can be

voltage or current.

Binary reference

A signal transmitted via the serial communication port.

The AMA algorithm determines the electrical parameters

for the connected motor at standstill.

Brake resistor

The brake resistor is a module capable of absorbing the

brake power generated in regenerative braking. This

regenerative brake power increases the DC-link voltage,

and a brake chopper ensures that the power is transmitted

to the brake resistor.

CT characteristics

Constant torque characteristics used for all applications

such as conveyor belts, displacement pumps, and cranes.

Digital inputs

The digital inputs can be used for controlling various

functions of the frequency converter.

Digital outputs

The frequency converter features 2 solid-state outputs that

can supply a 24 V DC (maximum 40 mA) signal.

DSP

Digital signal processor.

6 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Introduction Design Guide

ETR

Electronic thermal relay is a thermal load calculation based

on present load and time. Its purpose is to estimate the

motor temperature.

FC standard bus

Includes RS485 bus with FC protocol or MC protocol. See

parameter 8-30 Protocol.

Initializing

If initializing is carried out (parameter 14-22 Operation

Mode), the frequency converter returns to the default

setting.

Intermittent duty cycle

An intermittent duty rating refers to a sequence of duty

cycles. Each cycle consists of an on-load and an o-load

period. The operation can be either periodic duty or nonperiodic duty.

LCP

The local control panel makes up a complete interface for

control and programming of the frequency converter. The

LCP is detachable. With the installation kit option, the LCP

can be installed up to 3 m (9.8 ft) from the frequency

converter in a front panel.

NLCP

The numerical local control panel interface for control and

programming of the frequency converter. The display is

numerical and the panel is used to show process values.

The NLCP has storing and copy functions.

GLCP

The graphic local control panel interface for control and

programming of the frequency converter. The display is

graphic and the panel is used to show process values. The

GLCP has storing and copy functions.

lsb

Least signicant bit.

msb

Most signicant bit.

MCM

Short for mille circular mil, an American measuring unit for

cable cross-section. 1 MCM = 0.5067 mm2.

On-line/o-line parameters

Changes to on-line parameters are activated immediately

after the data value is changed. To activate changes to o-

line parameters, press [OK].

Process PID

The PID control maintains speed, pressure, and

temperature by adjusting the output frequency to match

the varying load.

PCD

Process control data.

PFC

Power factor correction.

Power cycle

Switch o the mains until the display (LCP) is dark, then

turn power on again.

Power factor

The power factor is the relation between I1 and I

Power factor =

For FC 280 frequency converters,

Power factor =

3xUxI1cosϕ1

3xUxI

I1xcosϕ1

I

RMS

RMS

=

I

RMS

cosϕ

I

1

1 = 1, therefore:

RMS

.

The power factor indicates to which extent the frequency

converter imposes a load on the mains supply.

The lower the power factor, the higher the I

RMS

for the

same kW performance.

I

RMS

=

I

+ I

1

5

+ I

2

+ .. + I

7

2

n

2

2

In addition, a high power factor indicates that the dierent

harmonic currents are low.

The built-in DC coils (T2/T4) and PFC (S2) produce a high

power factor, minimizing the imposed load on the mains

supply.

Pulse input/incremental encoder

An external, digital pulse transmitter used for feeding back

information on motor speed. The encoder is used in

applications where great accuracy in speed control is

required.

RCD

Residual current device.

Set-up

Save parameter settings in 4 set-ups. Change among the 4

parameter set-ups and edit 1 set-up while this set-up is

inactive.

SFAVM

Acronym describing the switching pattern stator uxoriented asynchronous vector modulation.

Slip compensation

The frequency converter compensates for the motor slip by

giving the frequency a supplement that follows the

measured motor load, keeping the motor speed almost

constant.

Smart logic control (SLC)

The SLC is a sequence of user-dened actions executed

when the smart logic controller evaluates the associated

user-dened events as true (Parameter group 13-** Smart

Logic Control).

STW

Status word.

THD

Total harmonic distortion states the total contribution of

harmonic distortion.

Thermistor

A temperature-dependent resistor placed where the

temperature is monitored (frequency converter or motor).

1 1

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 7

Introduction

VLT® Midi Drive FC 280

11

Trip

Trip is a state entered in fault situations. Examples of fault

situations:

The frequency converter is subject to an over

•

voltage.

The frequency converter protects the motor,

•

process, or mechanism.

Restart is prevented until the cause of the fault has

disappeared, and the trip state is canceled by activating

reset or, in some cases, by being programmed to reset

automatically. Do not use trip for personal safety.

Trip lock

Trip lock is a state entered in fault situations when the

frequency converter is protecting itself and requiring

physical intervention. For example, a short circuit on the

output triggers a trip lock. A locked trip can only be

canceled by cutting o mains, removing the cause of the

fault, and reconnecting the frequency converter. Restart is

prevented until the trip state is canceled by activating

reset or, sometimes, by being programmed to reset

automatically. Do not use trip lock for personal safety.

VT characteristics

Variable torque characteristics used for pumps and fans.

+

VVC

If compared with standard voltage/frequency ratio control,

voltage vector control (VVC+) improves the dynamics and

stability, both when the speed reference is changed and in

relation to the load torque.

60° AVM

Refer to the switching pattern 60° asynchronous vector

modulation.

Document and Software Version

1.4

1.5.1 CE Mark

The CE mark (Communauté européenne) indicates that the

product manufacturer conforms to all applicable EU

directives.

The EU directives applicable to the design and

manufacture of frequency converters are:

The Low Voltage Directive.

•

The EMC Directive.

•

The Machinery Directive (for units with an

•

integrated safety function).

The CE mark is intended to eliminate technical barriers to

free trade between the EC and EFTA states inside the ECU.

The CE mark does not regulate the quality of the product.

Technical specications cannot be deduced from the CE

mark.

1.5.2 Low Voltage Directive

Frequency converters are classied as electronic

components and must be CE labeled in accordance with

the Low Voltage Directive. The directive applies to all

electrical equipment in the 50–1000 V AC and the 75–

1500 V DC voltage ranges.

The directive mandates that the equipment design must

ensure the safety and health of people and livestock, and

the preservation of material by ensuring the equipment is

properly installed, maintained, and used as intended.

Danfoss CE labels comply with the Low Voltage Directive,

and Danfoss provides a declaration of conformity at

request.

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.2 shows

the document version and the corresponding software

version.

Edition Remarks

MG07B3

1.5

Frequency converters are designed in compliance with the

directives described in this section.

8 Danfoss A/S © 05/2017 All rights reserved. MG07B302

More information for POWERLINK and

software update.

Table 1.2 Document and Software Version

Approvals and Certications

Software

version

1.3

1.5.3 EMC Directive

Electromagnetic compatibility (EMC) means that electromagnetic interference between pieces of equipment does

not hinder their performance. The basic protection

requirement of the EMC Directive 2014/30/EU states that

devices that generate electromagnetic interference (EMI) or

whose operation could be aected by EMI must be

designed to limit the generation of electromagnetic

interference and shall have a suitable degree of immunity

to EMI when properly installed, maintained, and used as

intended.

A frequency converter can be used as standalone device or

as part of a more complex installation. Devices in either of

these cases must bear the CE mark. Systems must not be

CE marked but must comply with the basic protection

requirements of the EMC directive.

Introduction Design Guide

1.5.4 UL Compliance

UL-listed

Illustration 1.2 UL

Applied standards and compliance for STO

Using STO on terminals 37 and 38 requires fulllment of all

provisions for safety including relevant laws, regulations,

and guidelines. The integrated STO function complies with

the following standards:

IEC/EN 61508:2010, SIL2

•

IEC/EN 61800-5-2:2007, SIL2

•

IEC/EN 62061:2015, SILCL of SIL2

•

EN ISO 13849-1:2015, Category 3 PL d

•

Frequency converters can be subject to regional and/or

national export control regulations.

An ECCN number is used to classify all frequency

converters that are subject to export control regulations.

1 1

The ECCN number is provided in the documents

accompanying the frequency converter.

In case of re-export, it is the responsibility of the exporter

to ensure compliance with the relevant export control

regulations.

Safety

1.6

Frequency converters contain high-voltage components

and have the potential for fatal injury if handled

improperly. Only qualied personnel are allowed to install

and operate the equipment. Do not attempt repair work

without rst removing power from the frequency converter

and waiting the designated duration of time for stored

electrical energy to dissipate.

Refer to the operating instructions shipped with the unit,

and available online for:

Discharge time.

•

Detailed safety instructions and warnings.

•

Strict adherence to safety precautions and notices is

mandatory for safe operation of the frequency converter.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 9

130BA870.10

130BA809.10

130BA810.10

130BA810.10

130BA810.10

Product Overview

VLT® Midi Drive FC 280

2 Product Overview

22

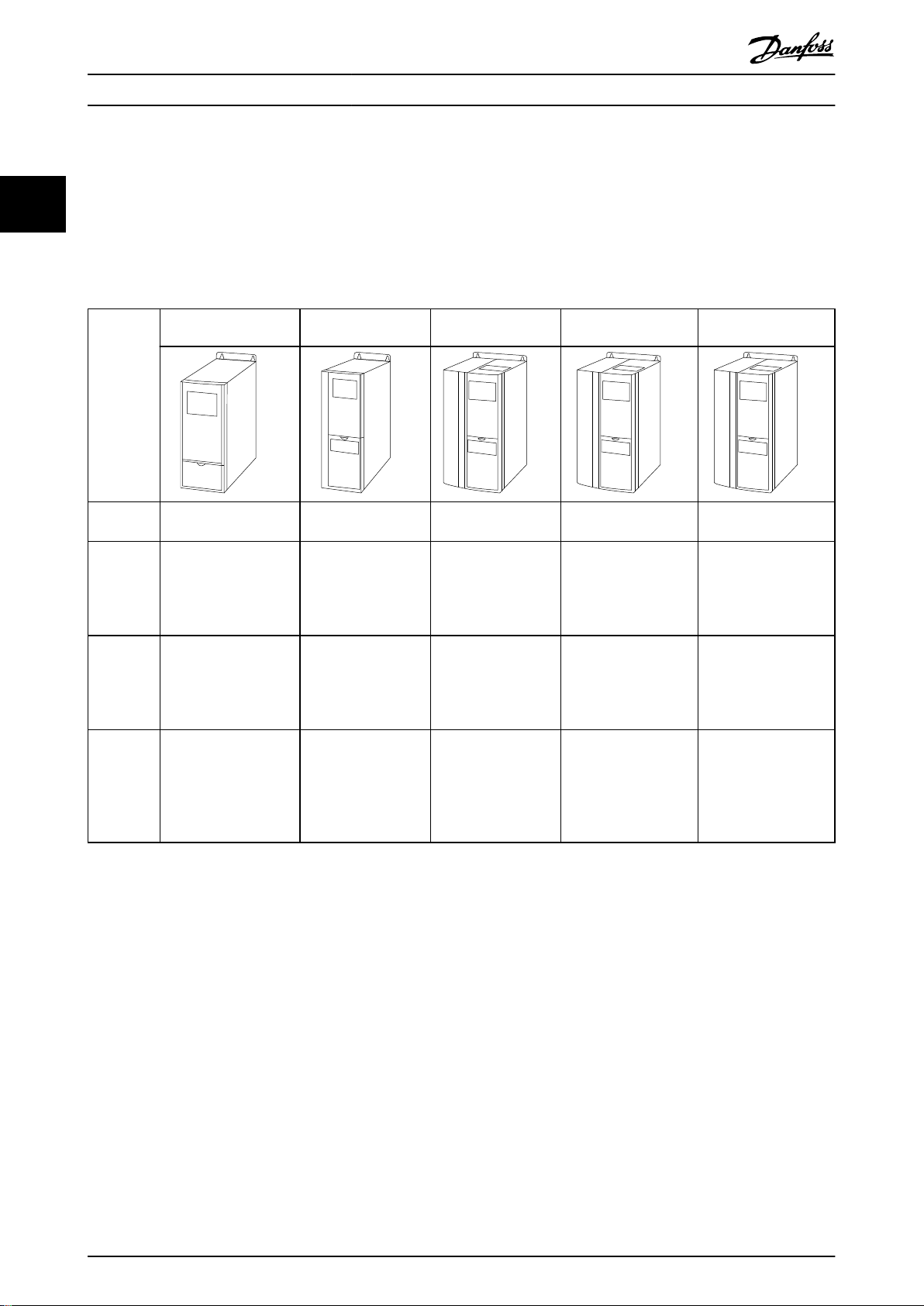

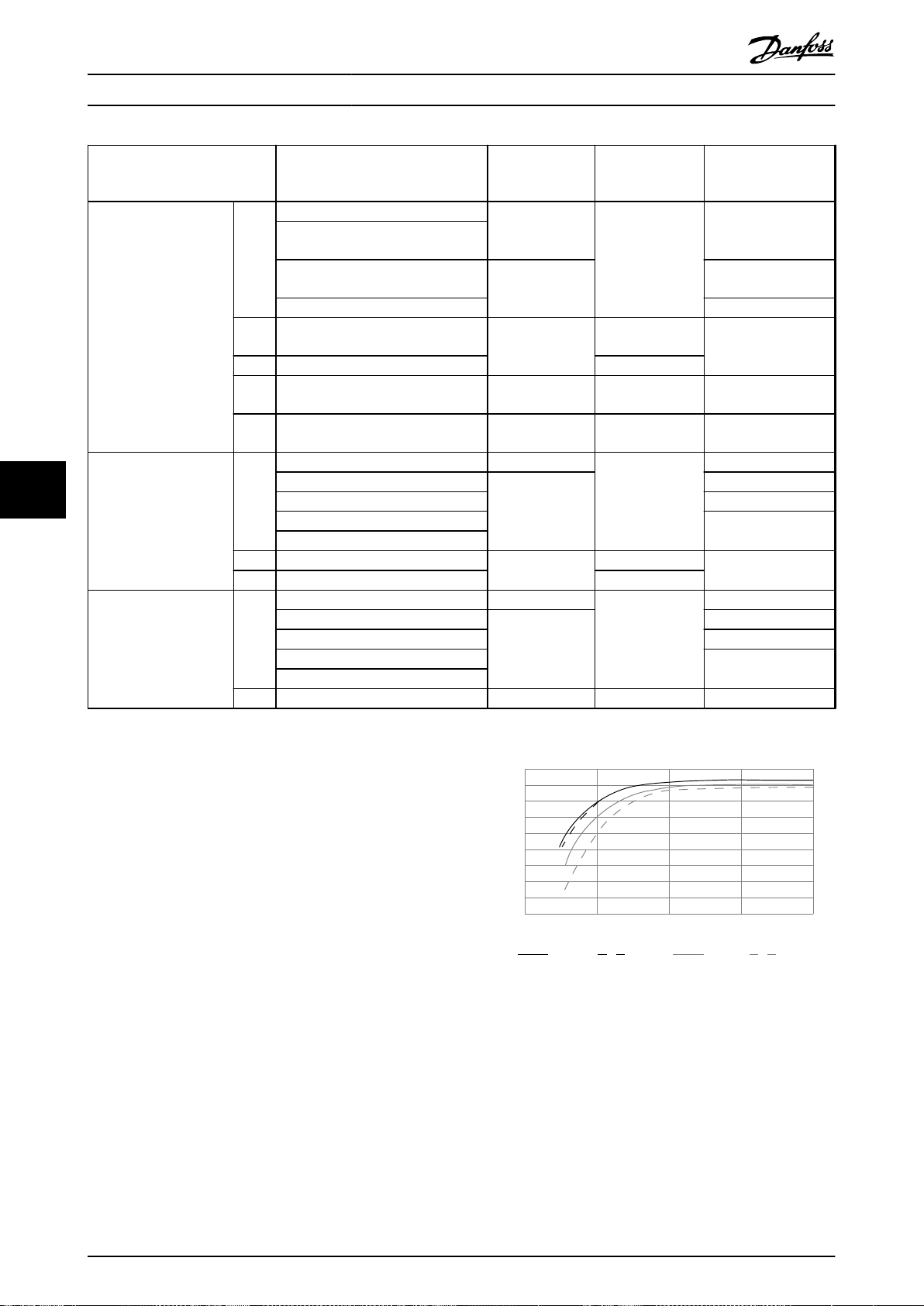

2.1 Enclosure Size Overview

Enclosure size depends on power range. For details about dimensions, refer to chapter 7.13 Enclosure Sizes, Power Ratings,

and Dimensions.

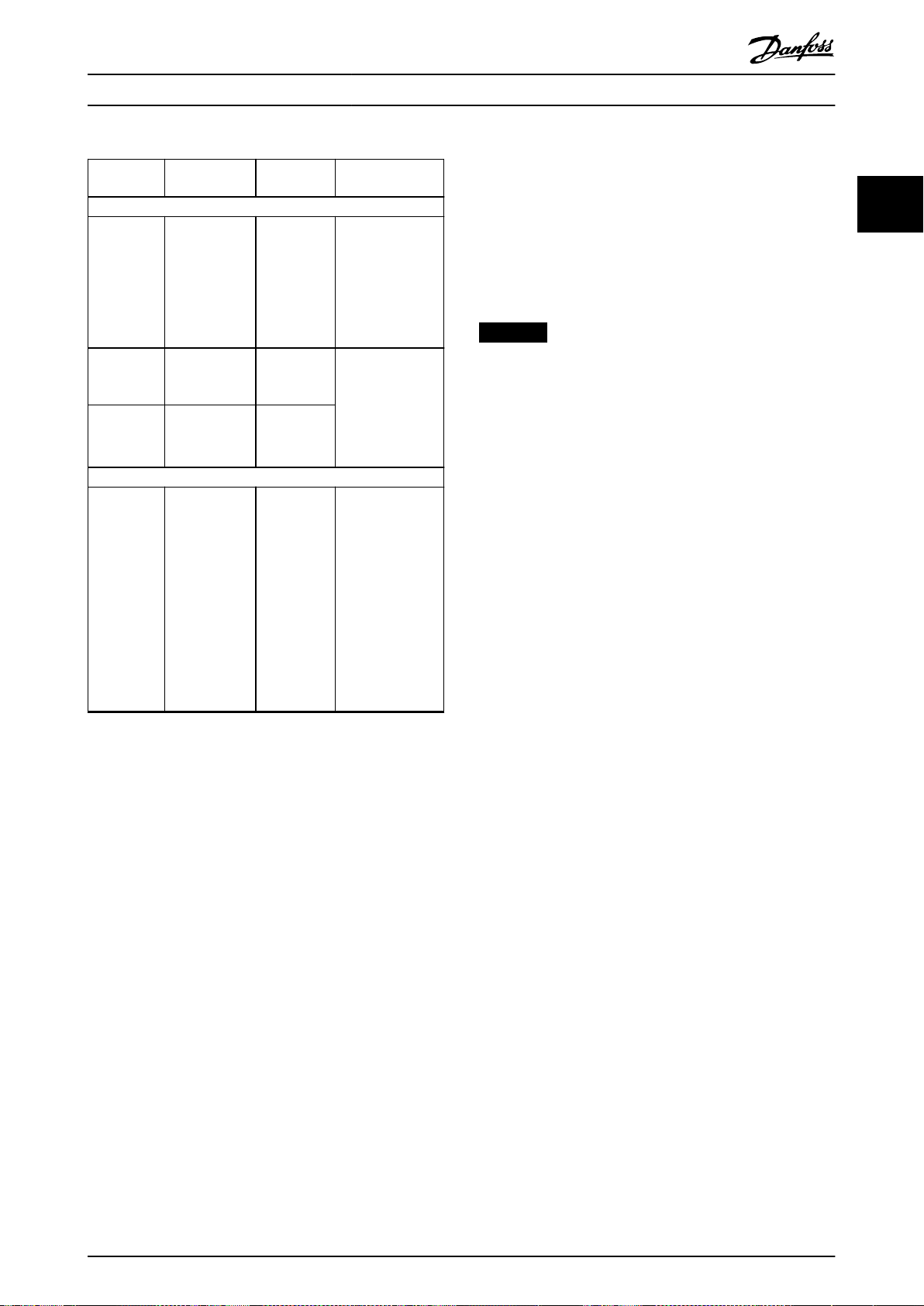

Enclosure

size

Enclosure

protection

Power

range

[kW (hp)]

3-phase

380–480 V

Power

range

[kW (hp)]

3-phase

200–240 V

Power

range

[kW (hp)]

single-

phase

200–240 V

K1 K2 K3 K4 K5

1)

IP20 IP20 IP20 IP20 IP20

0.37–2.2 (0.5–3.0) 3.0–5.5 (5.0–7.5) 7.5 (10) 11–15 (15–20) 18.5–22 (25–30)

0.37–1.5 (0.5–2.0) 2.2 (3.0) 3.7 (5.0) – –

0.37–1.5 (0.5–2.0) 2.2 (3.0) – – –

Table 2.1 Enclosure Sizes

1) IP21 is available for some variants of VLT® Midi Drive FC 280. With IP21 kit options mounted, all power sizes can be IP21.

Enclosure size is used throughout this guide whenever procedures or components dier between frequency converters

based on physical size.

Find the enclosure size using the following steps:

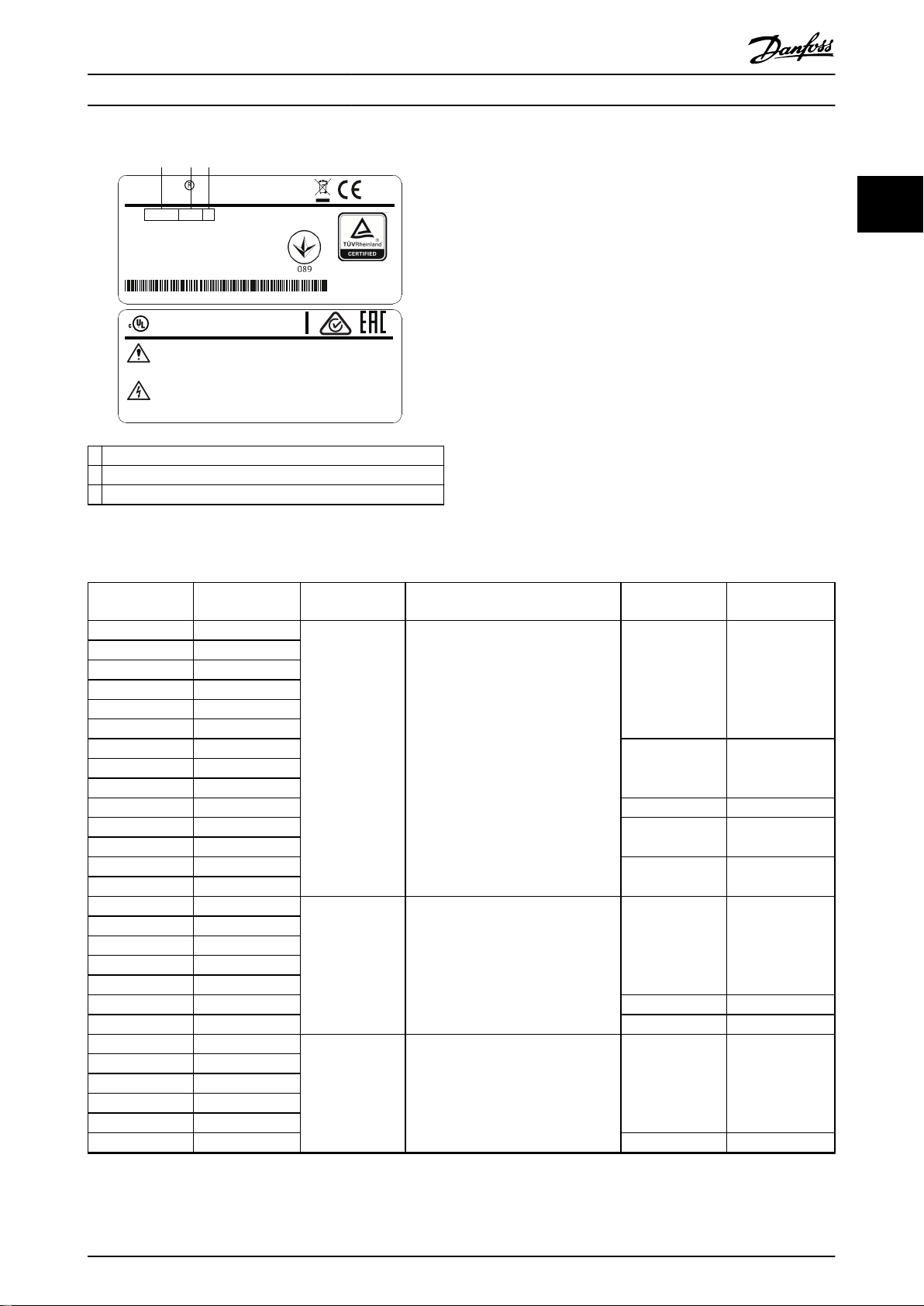

1. Obtain the following information from the type code on the nameplate. Refer to Illustration 2.1.

1a Product group and frequency converter series (characters 1–6), for example FC 280.

1b Power rating (characters 7–10), for example PK37.

1c Voltage rating (phases and mains) (characters 11–12), for example T4.

2. Within Table 2.2,

10 Danfoss A/S © 05/2017 All rights reserved. MG07B302

nd the power rating and voltage rating, and look up the enclosure size of FC 280.

130BF709.10

VLT

MADE IN

DENMARK

T/C: FC-280PK37T4E20H1BXCXXXSXXXXAX

0.37kW 0.5HP

IN: 3x380-480V 50/60Hz, 1.2/1.0A

OUT: 3x0-Vin 0-500Hz, 1.2/1.1A

IP20

P/N: 134U2184 S/N: 000000G000

Midi Drive

www.danfoss.com

CAUTION / ATTENTION:

WARNING / AVERTISSEMENT:

See manual for special condition/mains fuse

Voir manual de conditions speciales/fusibles

Enclosure: See manual

5AF3 E358502 IND.CONT.EQ.

Stored charge, wait 4 min.

Charge r

é

siduelle, attendez 4 min.

R

US LISTED

www.tuv.com

ID 0600000000

Danfoss A/S, 6430 Nordborg, Denmark

1 2 3

Product Overview Design Guide

1 Product group and frequency converter series

2 Power rating

3 Voltage rating (phases and mains)

Illustration 2.1 Using the Nameplate to Find the Enclosure Size

2 2

Power rating in

nameplate

[kW (hp)]

PK37 0.37 (0.5)

PK55 0.55 (0.75)

PK75 0.75 (1.0)

P1K1 1.1 (1.5)

P1K5 1.5 (2.0)

P2K2 2.2 (3.0)

P3K0 3 (4.0)

P4K0 4 (5.0)

P5K5 5.5 (7.5)

P7K5 7.5 (10) K3 K3T4

P11K 11 (15)

P15K 15 (20)

P18K 18.5 (25)

P22K 22 (30)

PK37 0.37 (0.5)

PK55 0.55 (0.75)

PK75 0.75 (1.0)

P1K1 1.1 (1.5)

P1K5 1.5 (2.0)

P2K2 2.2 (3.0) K2 K2T2

P3K7 3.7 (5.0) K3 K3T2

PK37 0.37 (0.5)

PK55 0.55 (0.75)

PK75 0.75 (1.0)

P1K1 1.1 (1.5)

P1K5 1.5 (2.0)

P2K2 2.2 (3.0) K2 K2S2

Table 2.2 Enclosure Size of FC 280

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 11

Power

Voltage rating in

nameplate

Phases and mains voltage Enclosure size

T4 3-phase 380–480 V

T2 3-phase 200–240 V

S2 Single phase 200–240 V

Frequency

converter

K1 K1T4

K2 K2T4

K4 K4T4

K5 K5T4

K1 K1T2

K1 K1S2

Power

input

Switch mode

power supply

Motor

Analog output

interface

(PNP) = Source

(NPN) = Sink

ON = Terminated

OFF = Open

Brake

resistor

91 (L1/N)

92 (L2/L)

93 (L3)

PE

50 (+10 V OUT)

53 (A IN)

2)

54 (A IN)

55 (COM digital/analog I/O)

0/4−20 mA

12 (+24 V OUT)

13 (+24 V OUT)

18 (D IN)

10 V DC

15 mA 100 mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(A OUT) 42

(P RS485) 68

(N RS485) 69

(COM RS485) 61

0 V

5 V

S801

0/4−20 mA

RS485

RS485

03

+10 V DC

0−10 V DC

24 V DC

02

01

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

19 (D IN)

24 V (NPN)

0 V (PNP)

27 (D IN/OUT)

24 V

0 V

0 V (PNP)

24 V (NPN)

29 (D IN)

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

38 (STO2)

4)

37 (STO1)

4)

95

P 5-00

21

ON

(+DC/R+) 89

(R-) 81

0−10 V DC

(-DC) 88

RFI

0 V

250 V AC, 3 A

Relay 1

1)

3)

5)

5)

130BE202.18

Product Overview

VLT® Midi Drive FC 280

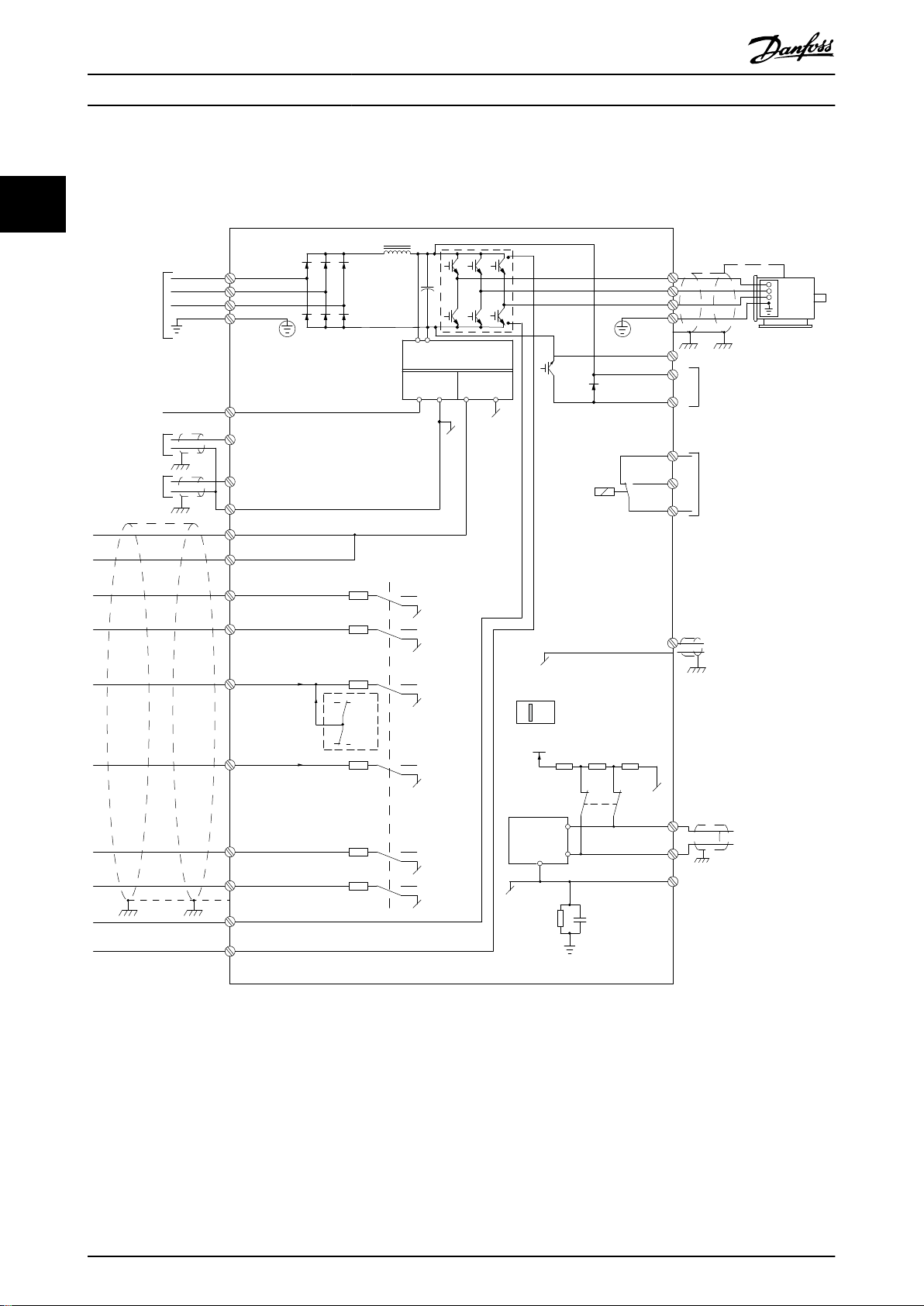

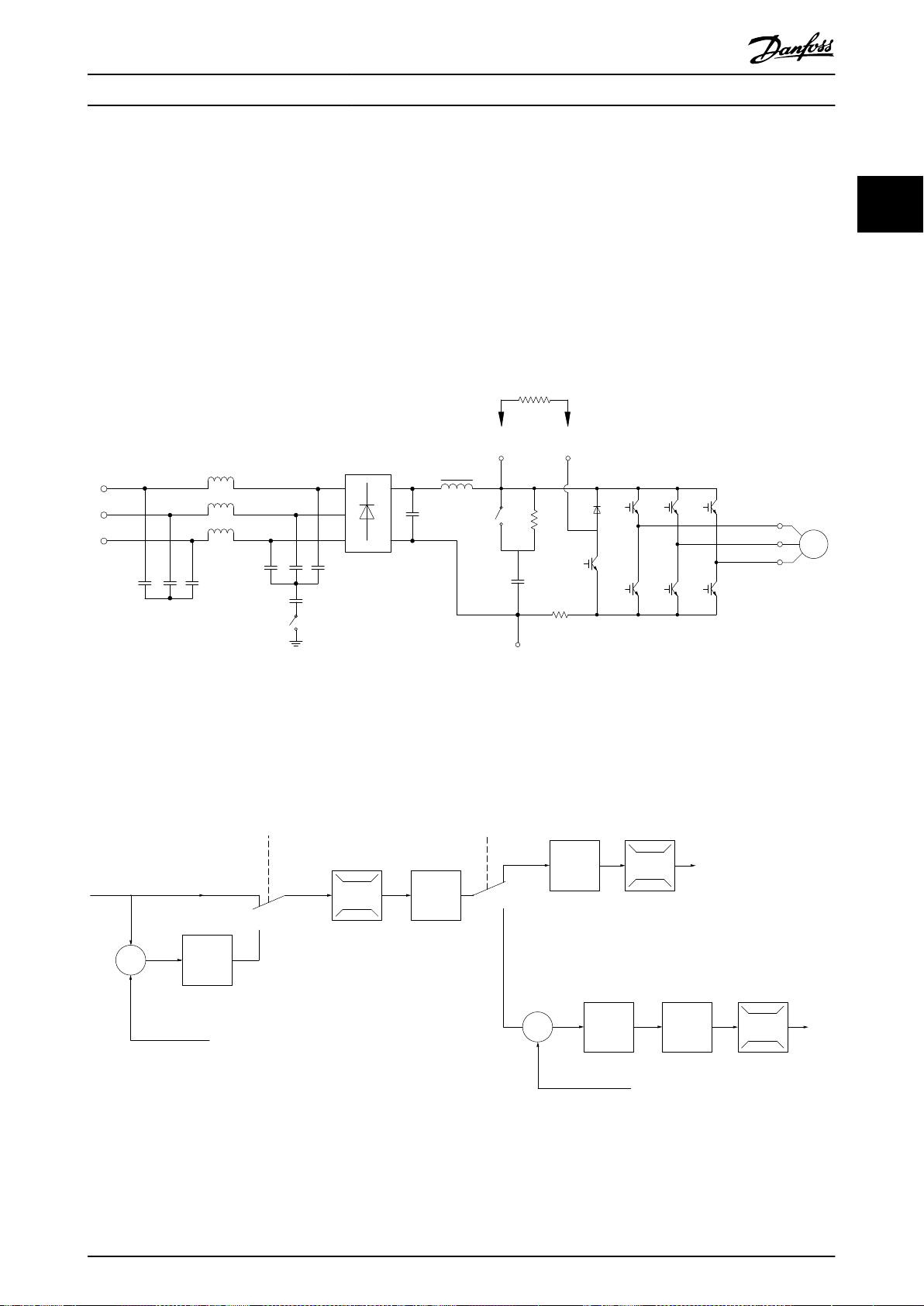

2.2 Electrical Installation

This section describes how to wire the frequency converter.

22

Illustration 2.2 Basic Wiring Schematic Drawing

A = Analog, D = Digital

1) Built-in brake chopper is only available on 3-phase units.

2) Terminal 53 can also be used as digital input.

3) Switch S801 (bus terminal) can be used to enable termination on the RS485 port (terminals 68 and 69).

4) Refer to chapter 4 Safe Torque O (STO) for the correct STO wiring.

5) The S2 (single-phase 200–240 V) frequency converter does not support load sharing application.

12 Danfoss A/S © 05/2017 All rights reserved. MG07B302

130BF228.10

L1

L2

L3

PE

PE

u

v

w

2

1

3

5

16

17

18

14

12

8

7

10

9

4

11

13

4

4

6

15

90

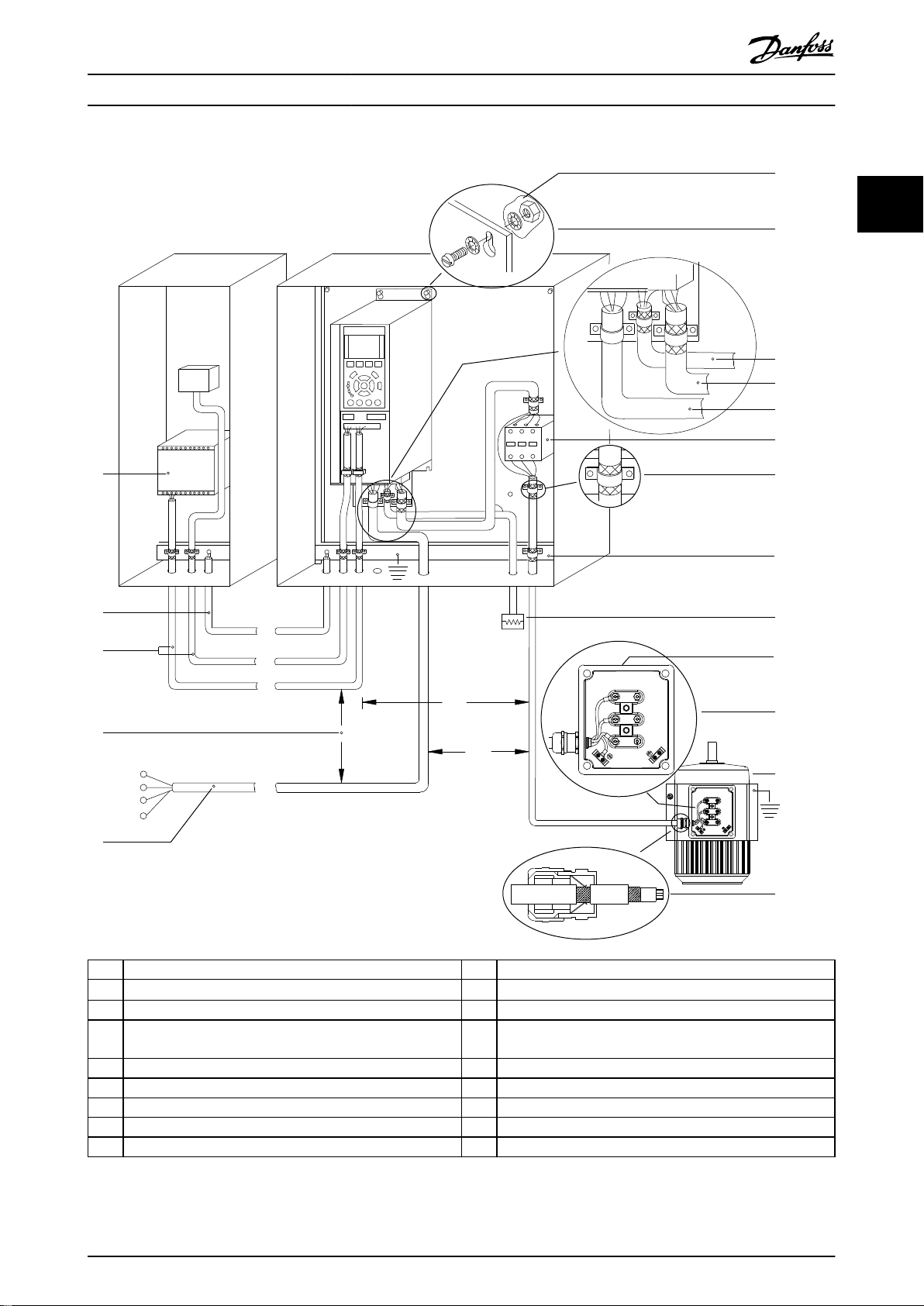

Product Overview Design Guide

2 2

1 PLC 10 Mains cable (unshielded)

2

Minimum 16 mm2 (6 AWG) equalizing cable

3 Control cables 12 Cable insulation stripped

4 Minimum 200 mm (656 ft) between control cables, motor

cables, and mains cables.

5 Mains supply 14 Brake resistor

6 Bare (unpainted) surface 15 Metal box

7 Star washers 16 Connection to motor

8 Brake cable (shielded) 17 Motor

9 Motor cable (shielded) 18 EMC cable gland

Illustration 2.3 Typical Electrical Connection

11 Output contactor, and so on.

13 Common ground busbar. Follow local and national

requirements for cabinet grounding.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 13

130BD531.10

U

V

W

96

97

98

Product Overview

2.2.1 Motor Connection

VLT® Midi Drive FC 280

22

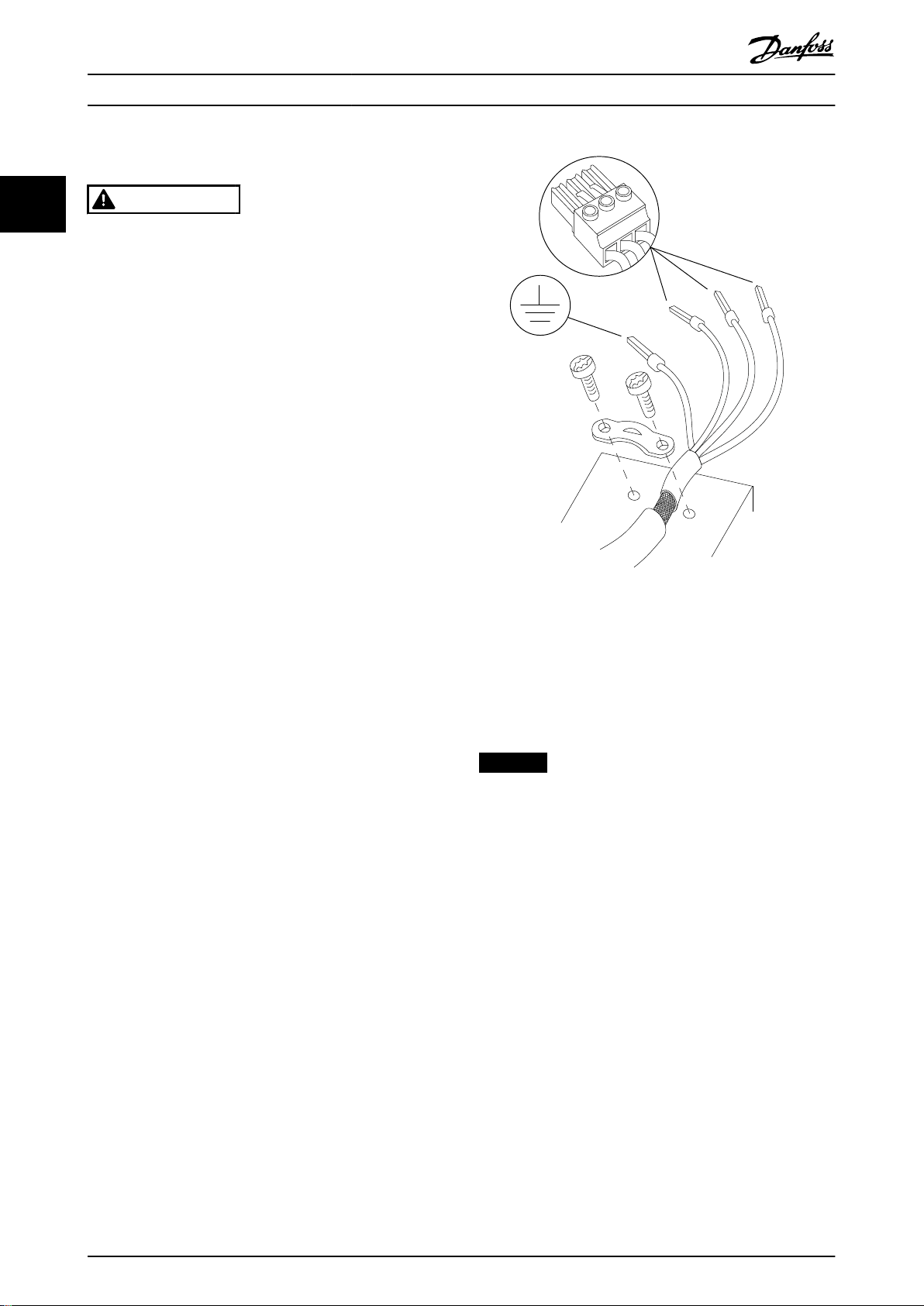

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables that run

together can charge equipment capacitors, even when

the equipment is turned o and locked out. Failure to

run output motor cables separately or use shielded

cables could result in death or serious injury.

Run output motor cables separately.

•

Use shielded cables.

•

Comply with local and national electrical codes

•

for cable sizes. For maximum cable sizes, see

chapter 7.1 Electrical Data.

Follow motor manufacturer wiring requirements.

•

Motor wiring knockouts or access panels are

•

provided at the base of IP21 (NEMA type 1) units.

Do not wire a starting or pole-changing device

•

(for example Dahlander motor or slip ring

induction motor) between the frequency

converter and the motor.

Procedure

1. Strip a section of the outer cable insulation.

Recommended length is 10–15 mm (0.4–0.6 in).

2. Position the stripped cable under the cable clamp

to establish mechanical xation and electrical

contact between the cable shield and ground.

3. Connect the ground cable to the nearest

grounding terminal in accordance with the

grounding instructions provided in chapter

Grounding in the VLT® Midi Drive FC 280 Operating

Guide. See Illustration 2.4.

4. Connect the 3-phase motor wiring to terminals

96 (U), 97 (V), and 98 (W), as shown in

Illustration 2.4.

5. Tighten the terminals in accordance with the

information provided in chapter 7.7 Connection

Tightening Torques.

Illustration 2.4 Motor Connection

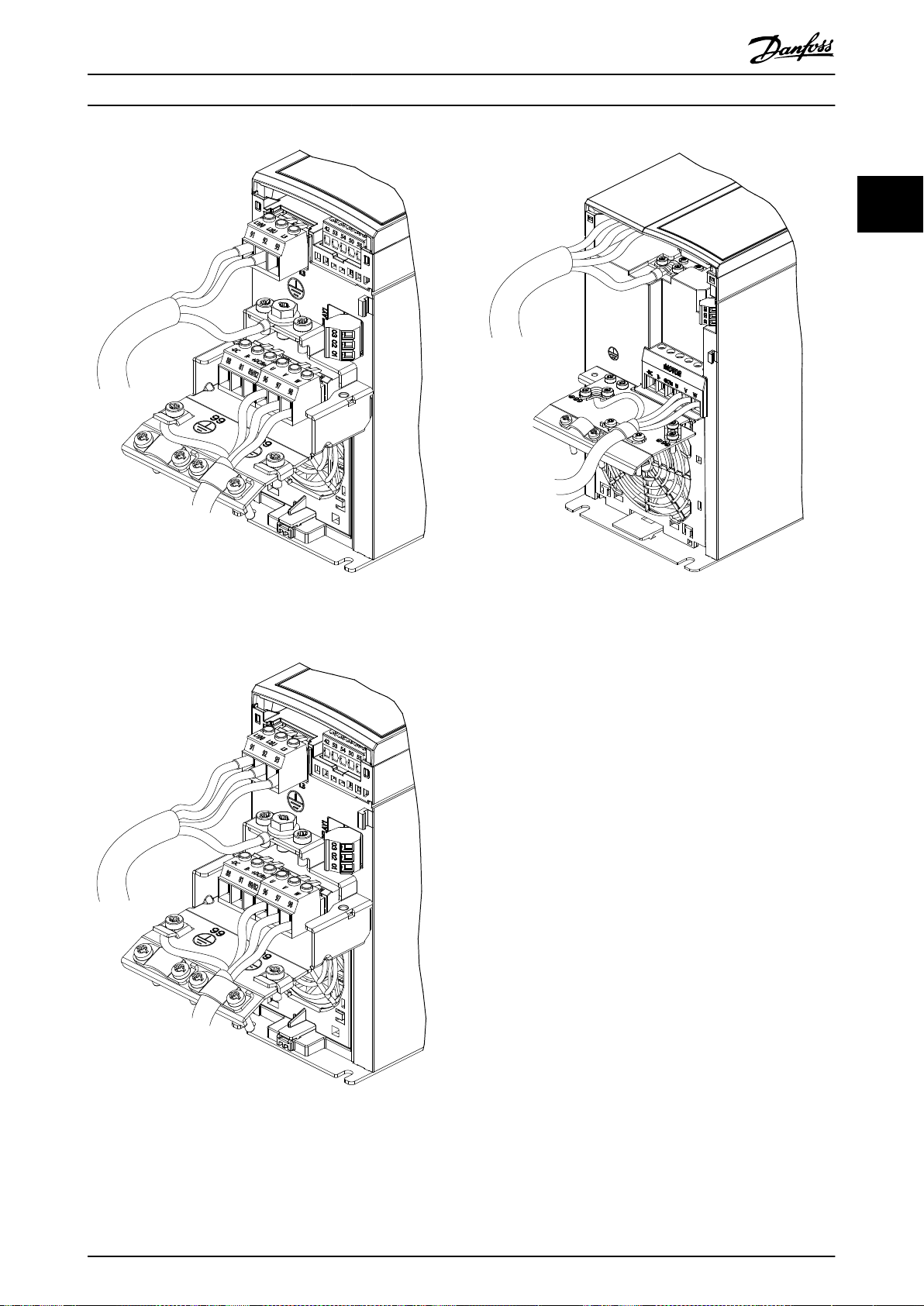

The mains, motor, and grounding connection for singlephase and 3-phase frequency converters are shown in

Illustration 2.5, Illustration 2.6, and Illustration 2.7, respectively. Actual congurations vary with unit types and

optional equipment.

NOTICE

In motors without phase insulation, paper, or other

insulation reinforcement suitable for operation with

voltage supply, use a sine-wave lter on the output of

the frequency converter.

14 Danfoss A/S © 05/2017 All rights reserved. MG07B302

130BE232.11

130BE231.11

130BE804.10

Product Overview Design Guide

2 2

Illustration 2.5 Mains, Motor, and Grounding Connection for

Single-phase Units (K1, K2)

Illustration 2.6 Mains, Motor, and Grounding Connection for 3-

phase Units (K1, K2, K3)

Illustration 2.7 Mains, Motor, and Grounding Connection for 3-

phase Units (K4, K5)

2.2.2 AC Mains Connection

Size the wiring based on the input current of the

•

frequency converter. For maximum wire sizes, see

chapter 7.1 Electrical Data.

Comply with local and national electrical codes

•

for cable sizes.

Procedure

1. Connect the AC input power cables to terminals

N and L for single-phase units (see

Illustration 2.5), or to terminals L1, L2, and L3 for

3-phase units (see Illustration 2.6 and

Illustration 2.7).

2. Depending on the conguration of the

equipment, connect the input power to the

mains input terminals or the input disconnect.

3. Ground the cable in accordance with the

grounding instructions in chapter Grounding in

®

the VLT

4. When supplied from an isolated mains source (IT

mains or oating delta) or TT/TN-S mains with a

grounded leg (grounded delta), ensure that the

RFI lter screw is removed. Removing the RFI

screw prevents damage to the DC link and

reduces ground capacity currents in accordance

with IEC 61800-3 (see Illustration 7.13, the RFI

screw locates on the side of the frequency

converter).

Midi Drive FC 280 Operating Guide.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 15

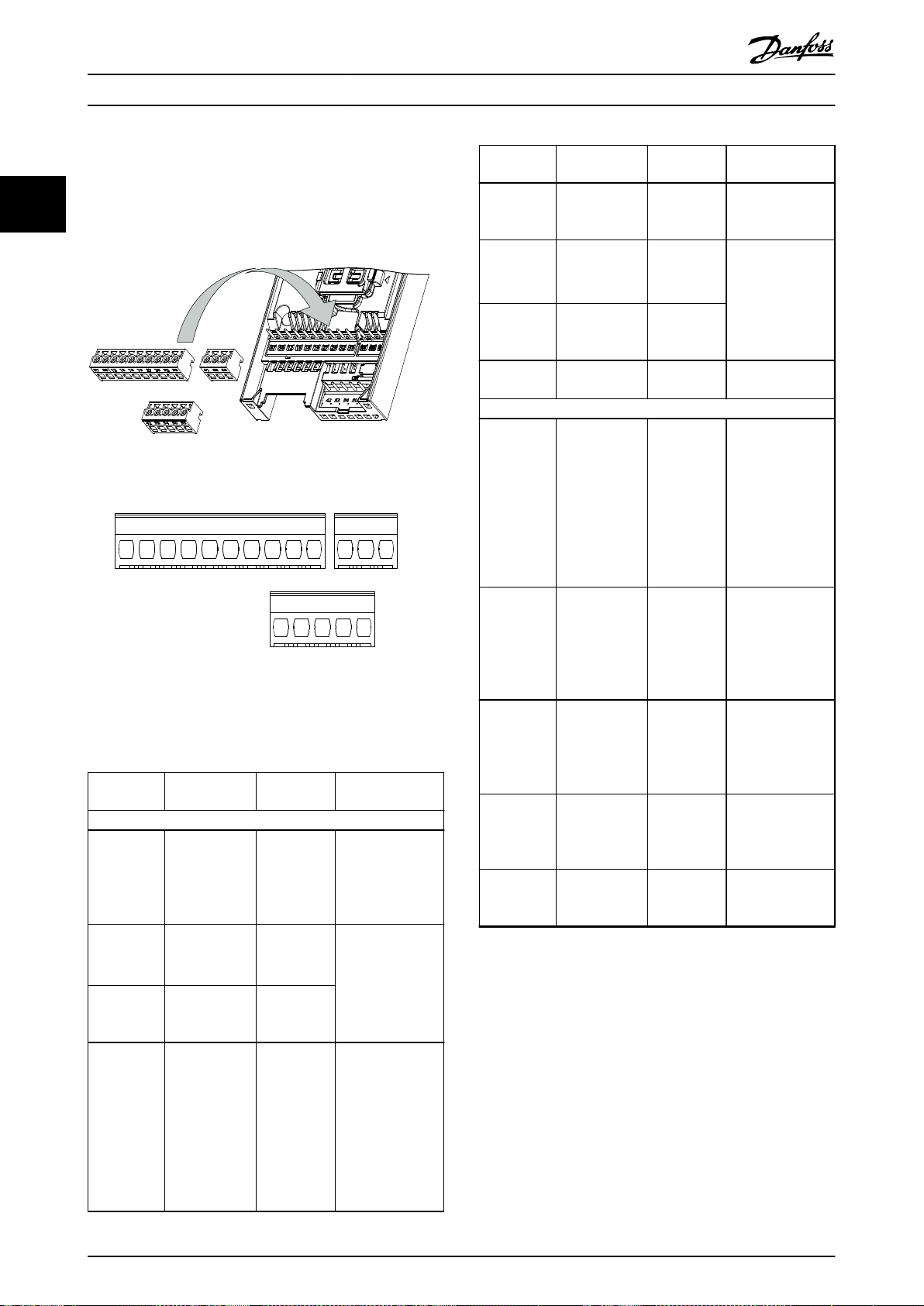

130BE212.10

1 2

3

130BE214.10

37 38 12 13 18 19 27 29 32 33 61

42 53 54 50 55

68 69

1

3

2

Product Overview

VLT® Midi Drive FC 280

2.2.3 Control Terminal Types

22

Illustration 2.8 shows the removable frequency converter

connectors. Terminal functions and default settings are

summarized in Table 2.3 and Table 2.4.

Illustration 2.8 Control Terminal Locations

Illustration 2.9 Terminal Numbers

See chapter 7.6 Control Input/Output and Control Data for

terminal ratings details.

Terminal Parameter

Digital I/O, pulse I/O, encoder

12, 13 – +24 V DC

Parameter 5-10

18

19

27

Terminal 18

Digital Input

Parameter 5-11

Terminal 19

Digital Input

Parameter 5-01

Terminal 27

Mode

Parameter 5-12

Terminal 27

Digital Input

Parameter 5-30

Terminal 27

Digital Output

Default

setting

[8] Start

[10] Reversing

DI [2] Coast

inverse

DO [0] No

operation

Description

24 V DC supply

voltage. Maximum

output current is

100 mA for all

24 V loads.

Digital inputs.

Selectable for

either digital

input, digital

output, or pulse

output. The

default setting is

digital input.

Terminal Parameter

Parameter 5-13

29

32

33

37, 38 – STO

42

50 – +10 V DC

53

54

55 – –

Table 2.3 Terminal Descriptions - Digital Inputs/Outputs,

Analog Inputs/Outputs

Terminal 29

Digital Input

Parameter 5-14

Terminal 32

Digital Input

Parameter 5-15

Terminal 33

Digital Input

Analog inputs/outputs

Parameter 6-91

Terminal 42

Analog Output

Parameter

group 6-1*

Analog input 53

Parameter

group 6-2*

Analog input 54

Default

setting

[14] Jog Digital input.

[0] No

operation

[0] No

operation

[0] No

operation

–

–

Description

Digital input, 24 V

encoder. Terminal

33 can be used for

pulse input.

Functional safety

inputs.

Programmable

analog output. The

analog signal is 0–

20 mA or 4–

20 mA at a

maximum of

500 Ω. Can also

be congured as

digital outputs.

10 V DC analog

supply voltage.

15 mA maximum

commonly used

for potentiometer

or thermistor.

Analog input. Only

voltage mode is

supported. It can

also be used as

digital input.

Analog input.

Selectable

between voltage

or current mode.

Common for

digital and analog

inputs.

16 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Product Overview Design Guide

Terminal Parameter

Serial communication

61 – –

Parameter

68 (+)

69 (-)

01, 02, 03

group 8-3* FC

port settings

Parameter

group 8-3* FC

port settings

Parameter 5-40

Function Relay

Default

setting

Relays

[1] Control

Ready

–

–

Description

Integrated RC lter

for cable shield.

ONLY for

connecting the

shield when

experiencing EMC

problems.

RS485 interface. A

control card switch

is provided for

termination

resistance.

Form C relay

output. These

relays are in

various locations

depending on the

frequency

converter congu-

ration and size.

Usable for AC or

DC voltage and

resistive or

inductive loads.

2.2.4 Wiring to Control Terminals

Control terminal connectors can be unplugged from the

frequency converter for ease of installation, as shown in

Illustration 2.8.

For details about STO wiring, refer to chapter 4 Safe Torque

O (STO).

NOTICE

Keep control cables as short as possible and separate

them from high-power cables to minimize interference.

1. Loosen the screws for the terminals.

2. Insert sleeved control cables into the slots.

3. Fasten the screws for the terminals.

4. Ensure that the contact is rmly established and

not loose. Loose control wiring can be the source

of equipment faults or less than optimal

operation.

See chapter 7.5 Cable Specications for control terminal

cable sizes and chapter 3 Application Examples for typical

control cable connections.

2 2

Table 2.4 Terminal Descriptions - Serial Communication

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 17

Product Overview

VLT® Midi Drive FC 280

2.3 Control Structures

A frequency converter recties AC voltage from mains into

22

DC voltage. Then the DC voltage is converted into an AC

current with a variable amplitude and frequency.

The motor is supplied with variable voltage/current and

frequency, enabling

phased standard AC motors and permanent magnet

synchronous motors.

innitely variable speed control of 3-

Speed/torque reference

The reference to these controls can be either a single

reference or the sum of various references including

relatively scaled references. Reference handling is explained

in detail in chapter 2.4 Reference Handling.

Process control

There are 2 types of process control:

2.3.1 Control Modes

The frequency converter controls either the speed or the

torque on the motor shaft. The frequency converter also

controls the process for some applications which use

process data as reference or feedback, for example,

temperature and pressure. Setting parameter 1-00 Congu-

ration Mode determines the type of control.

Speed control

There are 2 types of speed control:

Speed open-loop control, which does not require

•

any feedback from the motor (sensorless).

Speed closed-loop PID control, which requires a

•

speed feedback to an input. A properly optimized

speed closed-loop control has higher accuracy

than a speed open-loop control.

Select which input to use as speed PID feedback in

parameter 7-00 Speed PID Feedback Source.

Torque control

The torque control function is used in applications where

the torque on motor output shaft controls the application

as tension control. Select [2] Torque closed loop or [4]

Torque open loop in parameter 1-00 Conguration Mode.

Torque setting is done by setting an analog, digital, or buscontrolled reference. When running torque control, it is

recommended to run a full AMA procedure, because

correct motor data is important in achieving optimal

performance.

works for 2 directions. The torque is calculated

from the internal current measurement in the

frequency converter.

Process closed-loop control, which runs speed

•

open-loop to control the motor internally, is a

basic process PID controller.

Extended PID speed open-loop control, which

•

also runs speed open-loop to control the motor

internally, extends the function of the basic

process PID controller by adding more functions.

For example, feed forward control, clamping,

reference/feedback lter, and gain scaling.

Closed loop in VVC+ mode. This function is used

•

in applications with low to medium dynamic

variation of shaft and oers excellent

performance in all 4 quadrants and at all motor

speeds. The speed feedback signal is mandatory.

Ensure that the encoder resolution is at least

1024 PPR, and the shield cable of the encoder is

properly grounded, because the accuracy of the

speed feedback signal is important. Tune

parameter 7-06 Speed PID Lowpass Filter Time to

get the best speed feedback signal.

Open loop in VVC+ mode. The function is used in

•

mechanically robust applications, but the

accuracy is limited. Open-loop torque function

18 Danfoss A/S © 05/2017 All rights reserved. MG07B302

130BD974.10

L2 92

L1 91

L3 93

M

U 96

V 97

W 98

RFI switch

Inrush

R+

82

Load sharing -

88(-)

R81

Brake resistor

Load sharing +

89(+)

+

_

+

_

S

S

Cong. mode

Ref.

Process

P 1-00

High

+f max.

Low

-f max.

P 4-12

Motor speed

low limit (Hz)

P 4-14

Motor speed

high limit (Hz)

Motor

controller

Ramp

Speed

PID

P 7-20 Process feedback

1 source

P 7-22 Process feedback

2 source

P 7-00 Speed PID

feedback source

P 1-00

Cong. mode

P 4-19

Max. output freq.

-f max.

Motor

controller

P 4-19

Max. output freq.

+f max.

P 3-**

P 7-0*

130BD371.10

Product Overview Design Guide

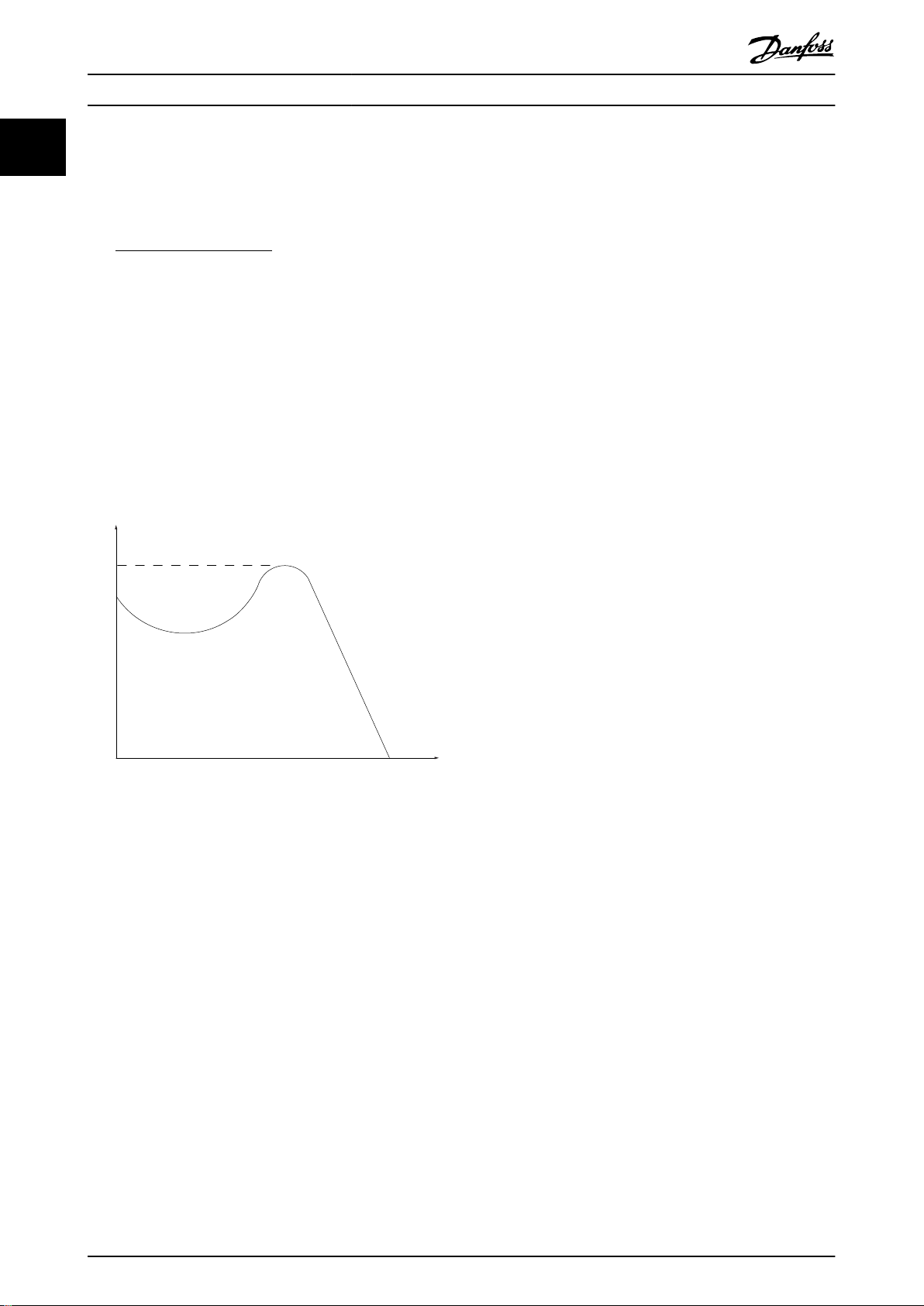

2.3.2 Control Principle

VLT® Midi Drive FC 280 is a general-purpose frequency converter for variable speed applications. The control principle is

based on VVC+.

FC 280 frequency converters can handle asynchronous motors and permanent magnet synchronous motors up to 22 kW

(30 hp).

The current-sensing principle in FC 280 frequency converters is based on the current measurement by a resistor in the DC

link. The ground fault protection and short circuit behavior are handled by the same resistor.

2 2

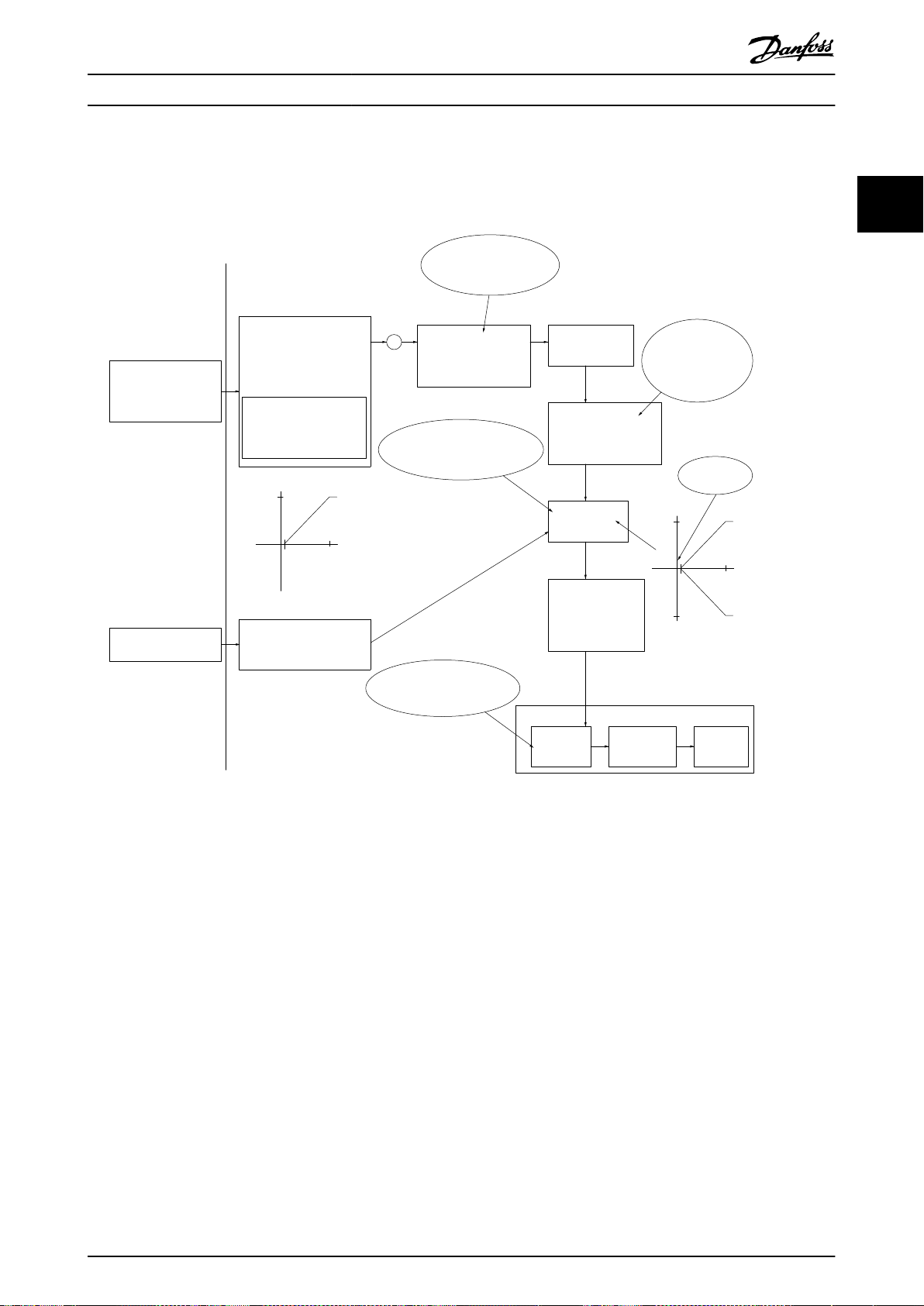

Illustration 2.10 Control Diagram

2.3.3

Control Structure in VVC

Illustration 2.11 Control Structure in VVC+ Open-loop Congurations and Closed-loop Congurations

In the conguration shown in Illustration 2.11, parameter 1-01 Motor Control Principle is set to [1] VVC+ and

parameter 1-00 Conguration Mode is set to [0] Speed open loop. The resulting reference from the reference handling system

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 19

+

Product Overview

is received and fed through the ramp limitation and speed limitation before being sent to the motor control. The output of

the motor control is then limited by the maximum frequency limit.

VLT® Midi Drive FC 280

22

If parameter 1-00 Conguration Mode is set to [1] Speed closed loop, the resulting reference is passed from the ramp

limitation and speed limitation into a speed PID control. The speed PID control parameters are in parameter group 7-0*

Speed PID Ctrl. The resulting reference from the speed PID control is sent to the motor control limited by the frequency limit.

Select [3] Process in parameter 1-00

pressure in the controlled application. The process PID parameters are in parameter groups 7-2* Process Ctrl. Feedb and 7-3*

Process PID Ctrl.

Conguration Mode to use the process PID control for closed-loop control of speed or

20 Danfoss A/S © 05/2017 All rights reserved. MG07B302

130BP046.10

Hand

on

O

Auto

on

Reset

Hand

On

Off

Reset

Auto

On

130BB893.10

Product Overview Design Guide

2.3.4

Internal Current Control in VVC

+

Mode

The frequency converter features an integral current limit

control. This feature is activated when the motor current,

and thus the torque, is higher than the torque limits set in

parameter 4-16 Torque Limit Motor Mode,

parameter 4-17 Torque Limit Generator Mode, and

parameter 4-18 Current Limit.

When the frequency converter is at the current limit during

motor operation or regenerative operation, the frequency

converter tries to get below the preset torque limits as

quickly as possible without losing control of the motor.

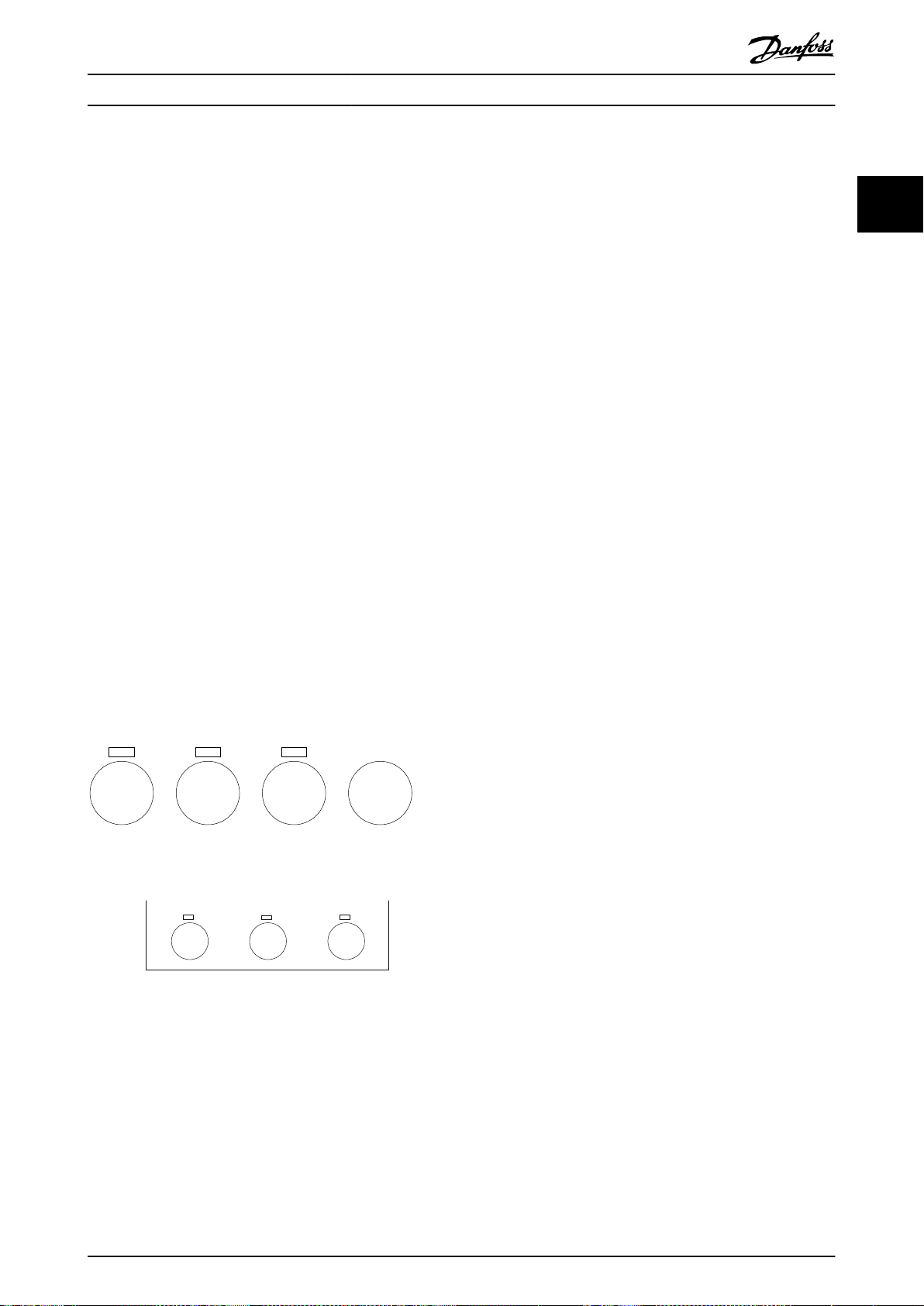

2.3.5 Local (Hand On) and Remote (Auto

On) Control

Operate the frequency converter manually via the local

control panel (graphic LCP or numerical LCP) or remotely

via analog/digital inputs or eldbus.

Start and stop the frequency converter by pressing the

[Hand On] and [Reset] keys on the LCP. Set-up is required

via the following parameters:

2 2

Parameter 0-40 [Hand on] Key on LCP.

•

Parameter 0-44 [O/Reset] Key on LCP.

•

Parameter 0-42 [Auto on] Key on LCP.

•

Reset alarms via the [Reset] key or via a digital input, when

the terminal is programmed to Reset.

Illustration 2.12 GLCP Control Keys

Illustration 2.13 NLCP Control Keys

Local reference forces the

loop, independent of the setting in parameter 1-00 Congu-

ration Mode.

conguration mode to open

Local reference is restored when the frequency converter

powers down.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 21

No function

Analog ref.

Pulse ref.

Local bus ref.

Preset relative ref.

Preset ref.

Local bus ref.

No function

Analog ref.

Pulse ref.

Analog ref.

Pulse ref.

Local bus ref.

No function

Local bus ref.

Pulse ref.

No function

Analog ref.

Input command:

Catch up/ slow down

Catchup Slowdown

value

Freeze ref./Freeze output

Speed up/ speed down

ref.

Remote

Ref. in %

-max ref./

+max ref.

Scale to

Hz

Scale to

Nm

Scale to

process

unit

Relative

X+X*Y

/100

DigiPot

DigiPot

DigiPot

max ref.

min ref.

DigiPot

D1

P 5-1x(15)

Preset '1'

External '0'

Process

Torque

Speed

open/closed loop

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(0)

(0)

(1)

Relative scaling ref.

P 3-18

Ref.resource 1

P 3-15

Ref. resource 2

P 3-16

Ref. resource 3

P 3-17

200%

-200%

Y

X

-100%

100%

%

%

Ref./feedback range

P 3-00

Conguration mode

P 1-00

P 3-14

±100%

130BD374.10

P 16-01

P 16-02

P 3-12

P 5-1x(21)/P 5-1x(22)

P 5-1x(28)/P 5-1x(29)

P 5-1x(19)/P 5-1x(20)

P 3-04

Freeze ref.

&

increase/

decrease

ref.

Catch up/

slow

down

P 3-10

Product Overview

VLT® Midi Drive FC 280

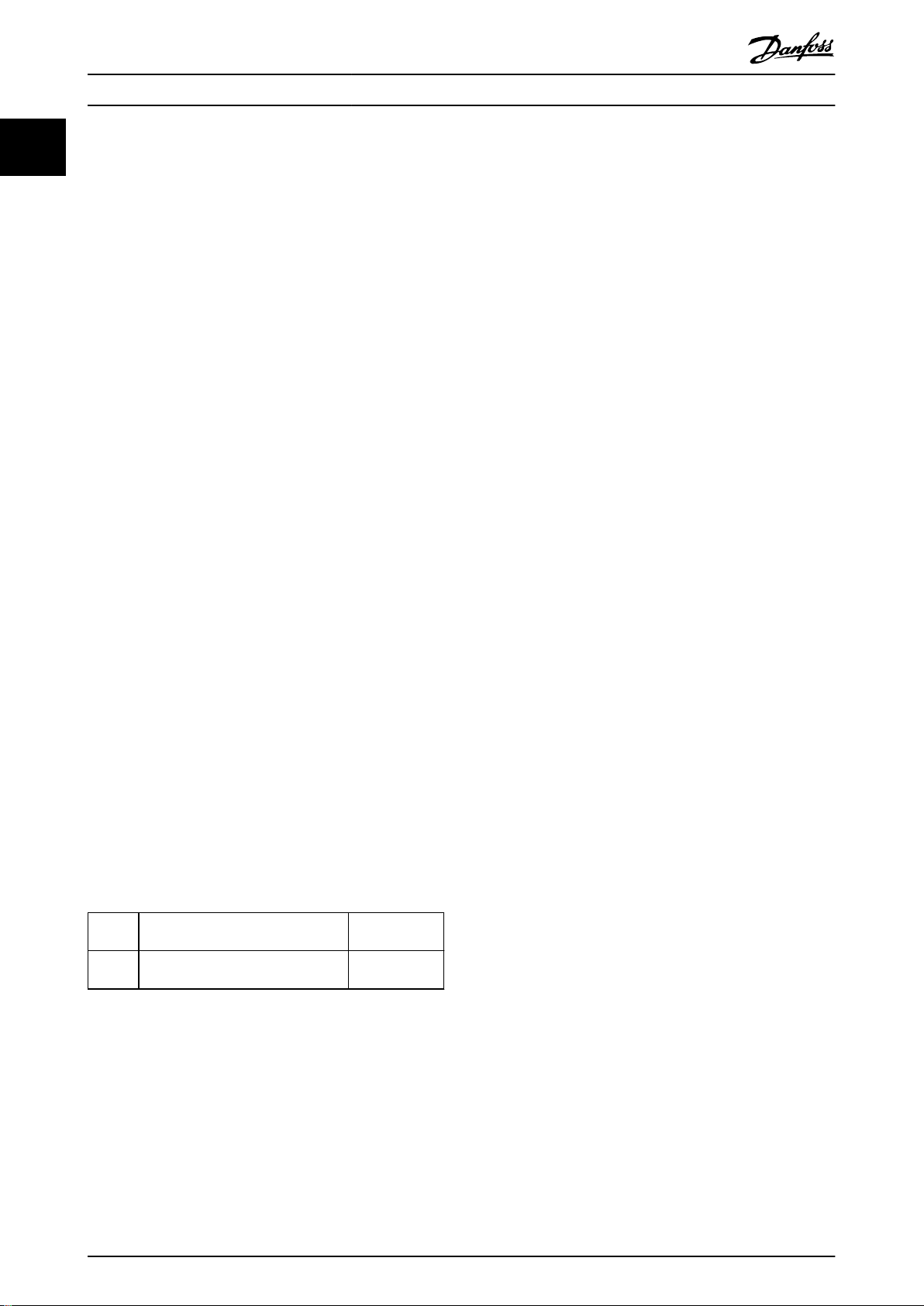

2.4 Reference Handling

Local reference

22

The local reference is active when the frequency converter is operated with [Hand On] active. Adjust the reference by [▲]/[▼]

and [◄/[►].

Remote reference

The reference handling system for calculating the remote reference is shown in Illustration 2.14.

Illustration 2.14 Remote Reference

22 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Resulting reference

Sum of all

references

Forward

Reverse

P 3-00 Reference Range= [0] Min-Max

130BA184.10

-P 3-03

P 3-03

P 3-02

-P 3-02

P 3-00 Reference Range =[1]-Max-Max

Resulting reference

Sum of all

references

-P 3-03

P 3-03

130BA185.10

Product Overview Design Guide

The remote reference is calculated once in every scan

interval and initially consists of 2 types of reference

inputs:

1. X (the external reference): A sum (see

parameter 3-04 Reference Function) of up to 4

externally selected references, comprising any

combination (determined by the setting of

parameter 3-15 Reference 1 Source,

parameter 3-16 Reference 2 Source, and

parameter 3-17 Reference 3 Source) of a xed

preset reference (parameter 3-10 Preset Reference),

variable analog references, variable digital pulse

references, and various eldbus references in any

unit the frequency converter is monitoring ([Hz],

[RPM], [Nm], and so on).

2. Y (the relative reference): A sum of 1 xed preset

reference (parameter 3-14 Preset Relative Reference)

and 1 variable analog reference

(parameter 3-18 Relative Scaling Reference

Resource) in [%].

The 2 types of reference inputs are combined in the

following formula:

Remote reference=X+X*Y/100%.

If relative reference is not used, set parameter 3-18 Relative

Scaling Reference Resource to [0] No function and

parameter 3-14 Preset Relative Reference to 0%. The digital

inputs on the frequency converter can activate both the

catch up/slow down function and the freeze reference

function. The functions and parameters are described in

the VLT® Midi Drive FC 280 Programming Guide.

The scaling of analog references is described in parameter

groups 6-1* Analog Input 53 and 6-2* Analog Input 54, and

the scaling of digital pulse references is described in

parameter group 5-5* Pulse Input.

Reference limits and ranges are set in parameter group 3-0*

Reference Limits.

2.4.1 Reference Limits

Parameter 3-00 Reference Range, parameter 3-02 Minimum

Reference, and parameter 3-03 Maximum Reference dene

the allowed range of the sum of all references. The sum of

all references is clamped when necessary. The relation

between the resulting reference (after clamping) and the

sum of all references are shown in Illustration 2.15 and

Illustration 2.16.

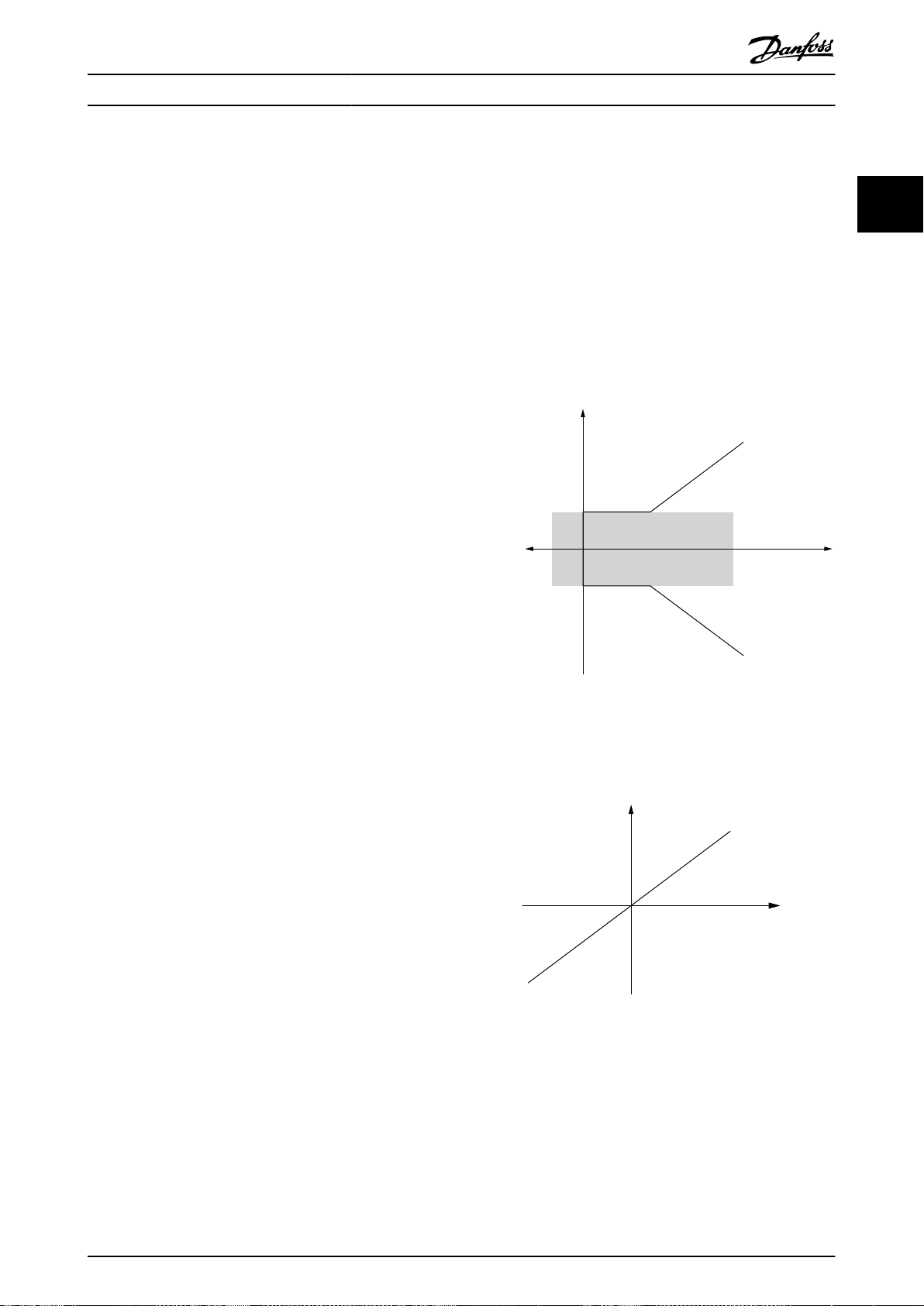

Illustration 2.15 Sum of All References When Reference Range

is Set to 0

2 2

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 23

Illustration 2.16 Sum of All References When Reference Range

is Set to 1

The value of parameter 3-02 Minimum Reference cannot be

set to less than 0, unless parameter 1-00 Conguration

Mode is set to [3] Process. In that case, the following

relations between the resulting reference (after clamping)

and the sum of all references are as shown in

Illustration 2.17.

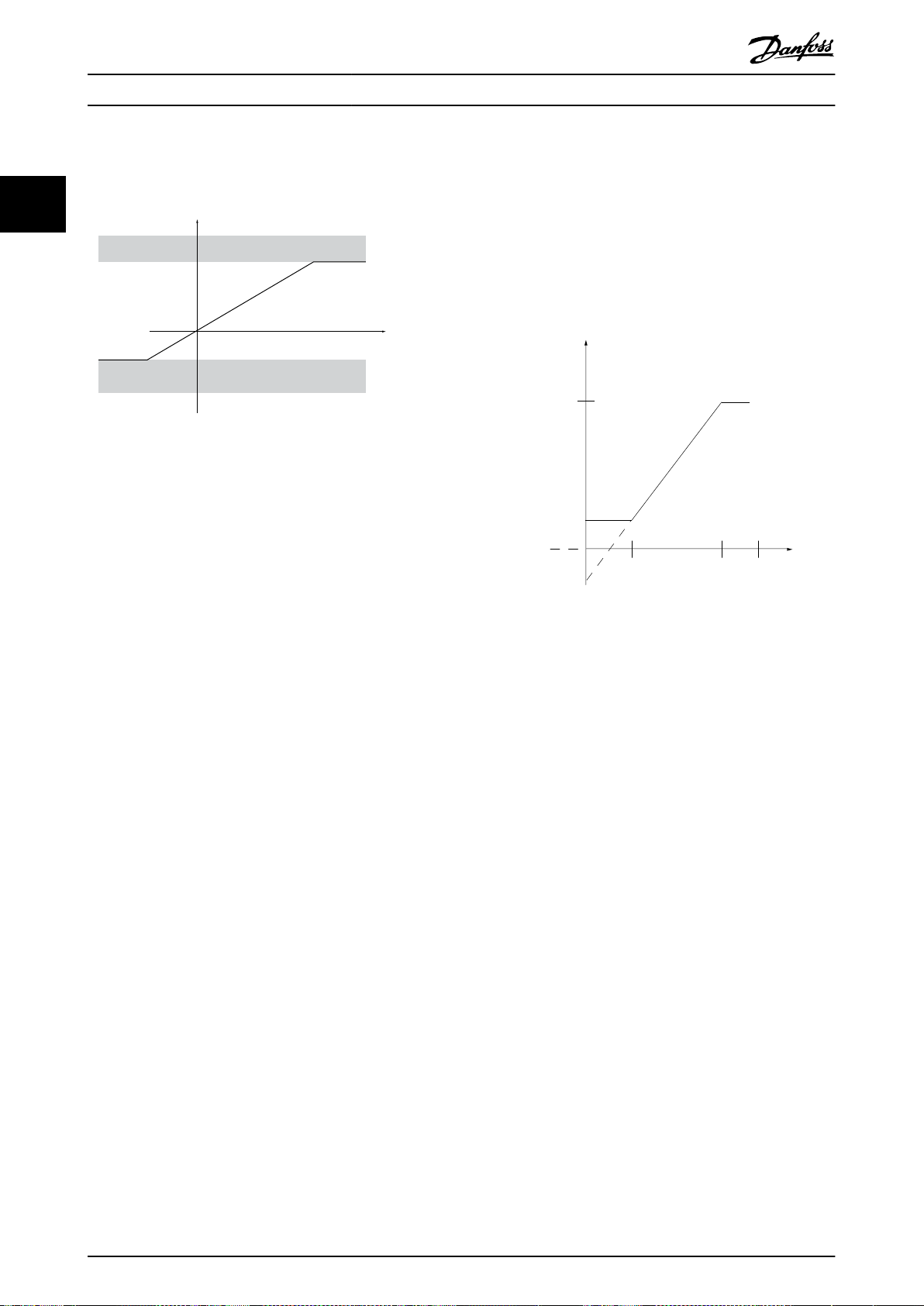

130BA186.11

P 3-03

P 3-02

Sum of all

references

P 3-00 Reference Range= [0] Min to Max

Resulting reference

Resource output

[Hz]

Resource input

Terminal X

high

High reference/

feedback value

130BD431.10

8

[V]

50

10

P1

P2

10

Low reference/

feedback value

Product Overview

VLT® Midi Drive FC 280

2.4.3 Scaling of Analog and Pulse

References and Feedback

22

References and feedback are scaled from analog and pulse

inputs in the same way. The only dierence is that a

reference above or below the specied minimum and

maximum endpoints (P1 and P2 in Illustration 2.18) are

clamped while feedbacks above or below are not.

Illustration 2.17 Sum of All References When Minimum

Reference is Set to a Minus Value

2.4.2 Scaling of Preset References and Bus

References

Preset references are scaled according to the following

rules:

When parameter 3-00 Reference Range is set to [0]

•

Min–Max, 0% reference equals 0 [unit] where unit

can be any unit, for example RPM, m/s, and bar.

100% reference equals the maximum (absolute

value of parameter 3-03 Maximum Reference,

absolute value of parameter 3-02 Minimum

Reference).

When parameter 3-00 Reference Range is set to [1]

•

-Max–+Max, 0% reference equals 0 [unit], and

100% reference equals maximum reference.

Bus references are scaled according to the following

rules:

When parameter 3-00 Reference Range is set to [0]

•

Min–Max, 0% reference equals minimum

reference and 100% reference equals maximum

reference.

When parameter 3-00 Reference Range is set to [1]

•

-Max–+Max, -100% reference equals -maximum

reference, and 100% reference equals maximum

reference.

Illustration 2.18 Minimum and Maximum Endpoints

24 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Resource output

[Hz] or “No unit”

Resource input

[mA]

Quadrant 2

Quadrant 3

Quadrant 1

Quadrant 4

Terminal X high

Low reference/feedback

value

High reference/feedback

value

1

-50

165020

P1

P2

0

130BD446.10

forward

reverse

Terminal low

Product Overview Design Guide

The endpoints P1 and P2 are dened in Table 2.5 depending on the choice of input.

Input Analog 53

voltage mode

P1=(Minimum input value, minimum reference value)

Minimum reference value Parameter 6-14 Te

rminal 53 Low

Ref./Feedb. Value

Minimum input value Parameter 6-10 Te

rminal 53 Low

Voltage [V]

P2=(Maximum input value, maximum reference value)

Maximum reference value Parameter 6-15 Te

rminal 53 High

Ref./Feedb. Value

Maximum input value Parameter 6-11 Te

rminal 53 High

Voltage [V]

Table 2.5 P1 and P2 Endpoints

Analog 54

voltage mode

Parameter 6-24 Te

rminal 54 Low

Ref./Feedb. Value

Parameter 6-20 Te

rminal 54 Low

Voltage [V]

Parameter 6-25 Te

rminal 54 High

Ref./Feedb. Value

Parameter 6-21 Te

rminal 54 High

Voltage [V]

Analog 54

current mode

Parameter 6-24 Ter

minal 54 Low Ref./

Feedb. Value

Parameter 6-22 Ter

minal 54 Low

Current [mA]

Parameter 6-25 Ter

minal 54 High Ref./

Feedb. Value

Parameter 6-23 Ter

minal 54 High

Current [mA]

Pulse input 29 Pulse input 33

Parameter 5-52 Ter

m. 29 Low Ref./

Feedb. Value

Parameter 5-50 Ter

m. 29 Low

Frequency [Hz]

Parameter 5-53 Ter

m. 29 High Ref./

Feedb. Value

Parameter 5-51 Ter

m. 29 High

Frequency [Hz]

Parameter 5-57 Term. 33

Low Ref./Feedb. Value

Parameter 5-55 Term. 33

Low Frequency [Hz]

Parameter 5-58 Term. 33

High Ref./Feedb. Value

Parameter 5-56 Term. 33

High Frequency [Hz]

2.4.4 Dead Band Around Zero

Sometimes, the reference (in rare cases also the feedback) should have a dead band around 0 to ensure that the machine is

stopped when the reference is near 0.

2 2

To make the dead band active and to set the amount of dead band, do the following:

P1 or P2

Set either the minimum reference value (see Table 2.5 for relevant parameter) or maximum reference value at 0. In

•

other words, either P1 or P2 must be on the X-axis in Illustration 2.19.

Ensure that both points dening the scaling graph are in the same quadrant.

•

denes the size of the dead band as shown in Illustration 2.19.

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 25

Illustration 2.19 Size of Dead Band

20

1

10

V

V

20

1

10

-20

130BD454.10

+

Analog input 53

Low reference 0 Hz

High reference 20 Hz

Low voltage 1 V

High voltage 10 V

Ext. source 1

Range:

0.0% (0 Hz)

100.0% (20 Hz)

100.0% (20 Hz)

Ext. reference

Range:

0.0% (0 Hz)

20 Hz 10V

Ext. Reference

Absolute

0 Hz 1 V

Reference

algorithm

Reference

100.0% (20 Hz)

0.0% (0 Hz)

Range:

Limited to:

0%- +100%

(0 Hz- +20 Hz)

Limited to: -200%- +200%

(-40 Hz- +40 Hz)

Reference is scaled

according to min

max reference giving a

speed.!!!

Scale to

speed

+20 Hz

-20 Hz

Range:

Speed

setpoint

Motor

control

Range:

-8 Hz

+8 Hz

Motor

Digital input 19

Low No reversing

High Reversing

Limits Speed Setpoint

according to min max speed.!!!

Motor PID

Hz

Hz

Dead band

Digital input

General Reference

parameters:

Reference Range: Min - Max

Minimum Reference: 0 Hz (0,0%)

Maximum Reference: 20 Hz (100,0%)

General Motor

parameters:

Motor speed direction:Both directions

Motor speed Low limit: 0 Hz

Motor speed high limit: 8 Hz

Product Overview

VLT® Midi Drive FC 280

Case 1: Positive reference with dead band, digital input to trigger reverse, part I

Illustration 2.20 shows how reference input with limits inside minimum to maximum limits clamps.

22

Illustration 2.20 Clamping of Reference Input with Limits inside Minimum to Maximum

26 Danfoss A/S © 05/2017 All rights reserved. MG07B302

+

30 Hz

1

10

20 Hz

1

10

130BD433.11

-20 Hz

V

V

Analog input 53

Low reference 0 Hz

High reference 20 Hz

Low voltage 1 V

High voltage 10 V

Ext. source 1

Range:

0.0% (0 Hz)

150.0% (30 Hz)

150.0% (30 Hz)

Ext. reference

Range:

0.0% (0 Hz)

30 Hz 10 V

Ext. Reference

Absolute

0 Hz 1 V

Reference

algorithm

Reference

100.0% (20 Hz)

0.0% (0 Hz)

Range:

Limited to:

-100%- +100%

(-20 Hz- +20 Hz)

Limited to: -200%- +200%

(-40 Hz- +40 Hz)

Reference is scaled

according to

max reference giving a

speed.!!!

Scale to

speed

+20 Hz

-20 Hz

Range:

Speed

setpoint

Motor

control

Range:

–10 Hz

+10 Hz

Motor

Digital input 19

Low No reversing

High Reversing

Limits Speed Setpoint

according to min max speed.!!!

Motor PID

Dead band

Digital input

General Reference

parameters:

Reference Range: -Max - Max

Minimum Reference: Don't care

Maximum Reference: 20 Hz (100.0%)

General Motor

parameters:

Motor speed direction: Both directions

Motor speed Low limit: 0 Hz

Motor speed high limit: 10 Hz

Product Overview Design Guide

Case 2: Positive reference with dead band, digital input to trigger reverse, part II

Illustration 2.21 shows how reference input with limits outside -maximum to +maximum limits clamps to the input low and

high limits before adding to external reference, and how the external reference is clamped to -maximum to +maximum by

the reference algorithm.

2 2

Illustration 2.21 Clamping of Reference Input with Limits outside -Maximum to +Maximum

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 27

Product Overview

VLT® Midi Drive FC 280

2.5 PID Control

2.5.1 Speed PID Control

22

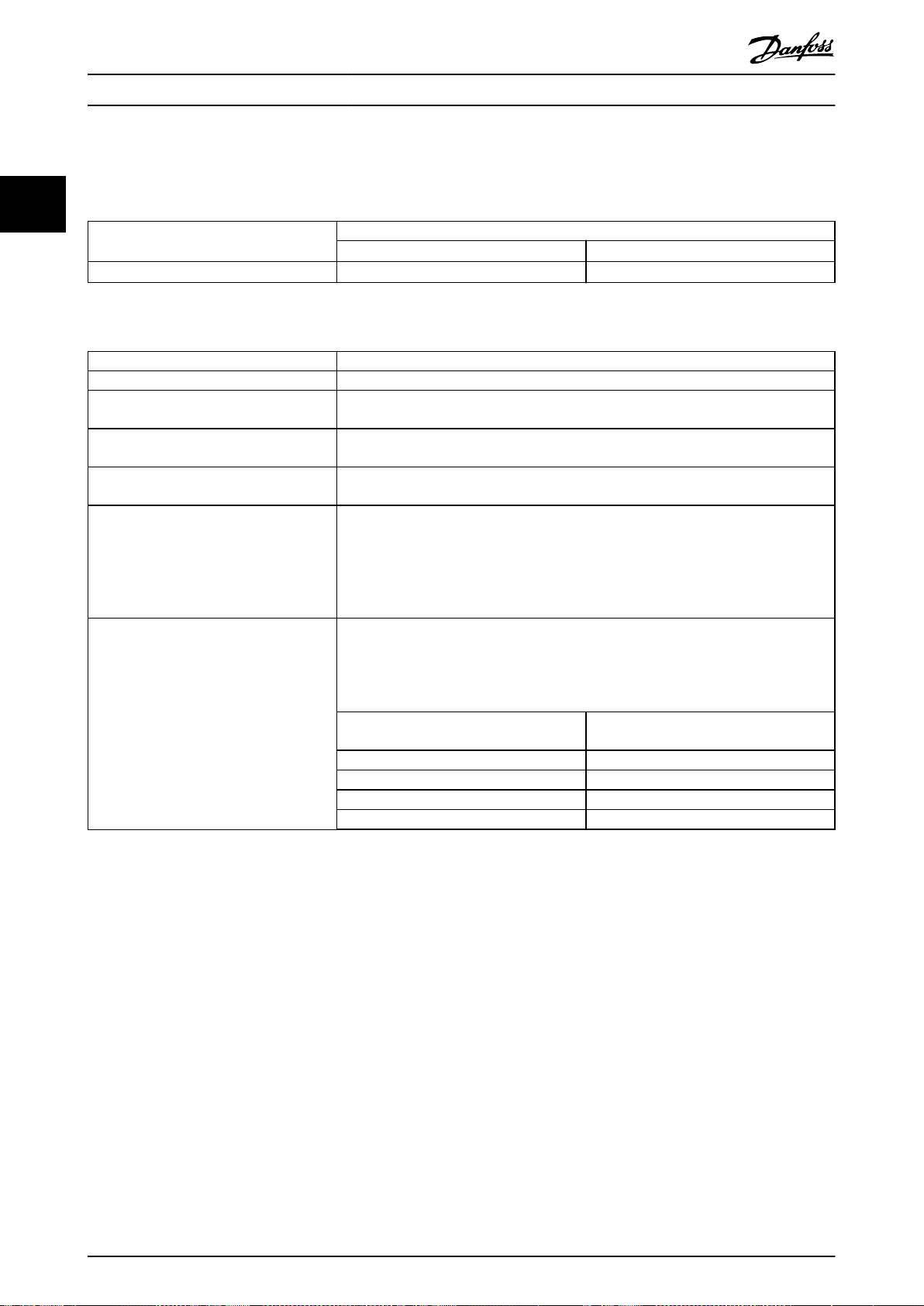

Parameter 1-00 Conguration Mode

[1] Speed closed loop

Table 2.6 Control Congurations, Active Speed Control

1) Not available indicates that the

Parameter Description of function

Parameter 7-00 Speed PID Feedback Source Select from which input the speed PID gets its feedback.

Parameter 7-02 Speed PID Proportional Gain The higher the value, the quicker the control. However, too high a value may lead to

Parameter 7-03 Speed PID Integral Time Eliminates steady state speed error. Lower values mean quicker reaction. However, too low

Parameter 7-04 Speed PID Dierentiation Time Provides a gain proportional to the rate of change of the feedback. A setting of 0 disables

Parameter 7-05 Speed PID Di. Gain Limit If there are quick changes in reference or feedback in a given application, which means

Parameter 7-06 Speed PID Lowpass Filter Time A low-pass lter that dampens oscillations on the feedback signal and improves steady

specic mode is not available at all.

Parameter 1-01 Motor Control Principle

U/f

Not available

oscillations.

a value may lead to oscillations.

the dierentiator.

that the error changes swiftly, the dierentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

dierentiator gain is. The dierentiator gain can thus be limited to allow setting of the

reasonable dierentiation time for slow changes and a suitably quick gain for quick

changes.

state performance. However, too long a lter time deteriorates the dynamic performance of

the speed PID control.

Practical settings of parameter 7-06 Speed PID Lowpass Filter Time taken from the number of

pulses per revolution on from encoder (PPR):

Encoder PPR Parameter 7-06 Speed PID Lowpass Filter

512 10 ms

1024 5 ms

2048 2 ms

4096 1 ms

1)

VVC

Active

Time

+

Table 2.7 Speed Control Parameters

28 Danfoss A/S © 05/2017 All rights reserved. MG07B302

M

3

96 97 9998

91 92 93 95

50

12

L1 L2L1PEL3

W PEVU

F1

L2

L3

N

PE

18

53

27

55

32

33

24 Vdc

130BD372.11

Product Overview Design Guide

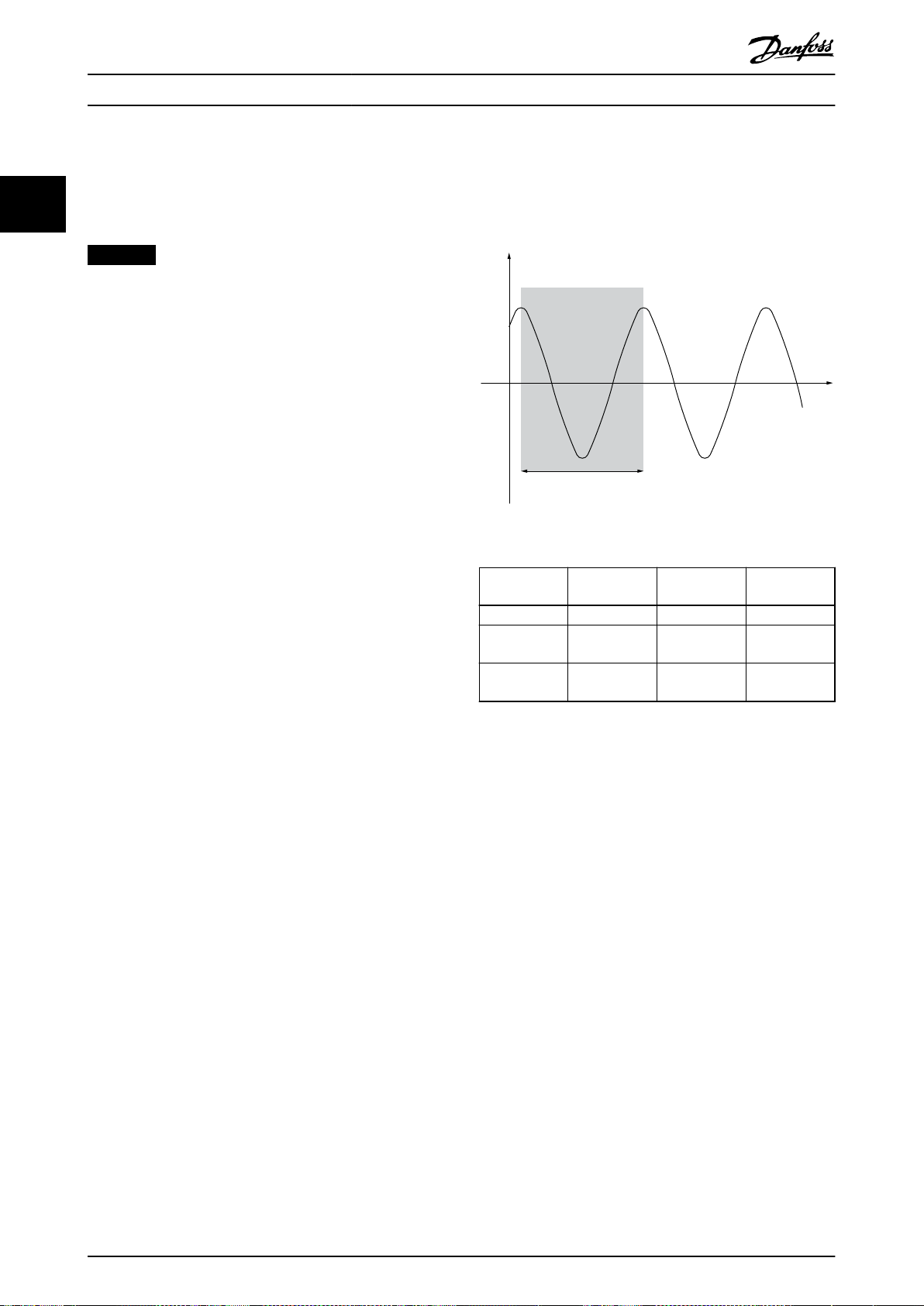

Example of programming the speed control

In this example, the speed PID control is used to maintain a constant motor speed regardless of the changing load on the

motor. The required motor speed is set via a potentiometer connected to terminal 53. The speed range is 0–1500 RPM

corresponding to 0–10 V over the potentiometer. A switch connected to terminal 18 controls starting and stopping. The

speed PID monitors the actual RPM of the motor by using a 24 V (HTL) incremental encoder as feedback. The feedback

sensor is an encoder (1024 pulses per revolution) connected to terminals 32 and 33. The pulse frequency range to terminals

32 and 33 is 4 Hz–32 kHz.

2 2

Illustration 2.22 Speed Control Programming

Follow the steps in Table 2.8 to program the speed control (see explanation of settings in the programming guide)

In Table 2.8, it is assumed that all other parameters and switches remain at their default setting.

Function Parameter number Setting

1) Make sure that the motor runs properly. Do the following:

Set the motor parameters using the data on the

nameplate.

Perform an AMA. Parameter 1-29 Automatic

2) Check that the motor is running and that the encoder is attached properly. Do the following:

Press [Hand On]. Check that the motor is running and note

the rotation direction (referred to as the positive direction).

3) Make sure that the frequency converter limits are set to safe values:

Set acceptable limits for the references. Parameter 3-02 Minimum

Check that the ramp settings are within frequency

converter capabilities and allowed application operating

specications.

Parameter group 1-2*

As specied by motor nameplate.

Motor Data

[1] Enable complete AMA

Motor Adaption (AMA)

Set a positive reference.

0

Reference

Parameter 3-03 Maximum

50

Reference

Parameter 3-41 Ramp 1

Default setting

Ramp Up Time

Parameter 3-42 Ramp 1

Default setting

Ramp Down Time

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 29

Product Overview

VLT® Midi Drive FC 280

Set acceptable limits for the motor speed and frequency. Parameter 4-12 Motor

Speed Low Limit [Hz]

Parameter 4-14 Motor

22

4) Congure the speed control and select the motor control principle:

Activation of speed control Parameter 1-00 Congu-

Selection of motor control principle Parameter 1-01 Motor

5) Congure and scale the reference to the speed control:

Set up analog input 53 as a reference source. Parameter 3-15 Reference 1

Scale analog input 53 0 Hz (0 V) to 50 Hz (10 V) Parameter group 6-1*

6) Congure the 24 V HTL encoder signal as feedback for the motor control and the speed control:

Set up digital input 32 and 33 as encoder inputs. Parameter 5-14 Terminal

Select terminal 32/33 as speed PID feedback. Parameter 7-00 Speed PID

7) Tune the speed control PID parameters:

Use the tuning guidelines when relevant or tune manually. Parameter group 7-0*

8) Finish:

Save the parameter setting to the LCP for safe keeping. Parameter 0-50 LCP Copy [1] All to LCP

Speed High Limit [Hz]

Parameter 4-19 Max

Output Frequency

ration Mode

Control Principle

Source

Analog Input 1

32 Digital Input

Parameter 5-15 Terminal

33 Digital Input

Feedback Source

Speed PID Ctrl.

0 Hz

50 Hz

60 Hz

[1] Speed closed loop

+

[1] VVC

Not necessary (default)

Not necessary (default)

[82] Encoder input B

[83] Encoder input A

[1] 24 V Encoder

Table 2.8 Programming Order for Speed PID Control

30 Danfoss A/S © 05/2017 All rights reserved. MG07B302

P 7-30

normal/inverse

PID

P 7-38

*(-1)

Feed forward

Reference

Handling

Feedback

Handling

% [unit]

% [unit]

%

[unit]

%

[speed]

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

Process PID

130BA178.10

_

+

0%

-100%

100%

0%

-100%

100%

Product Overview Design Guide

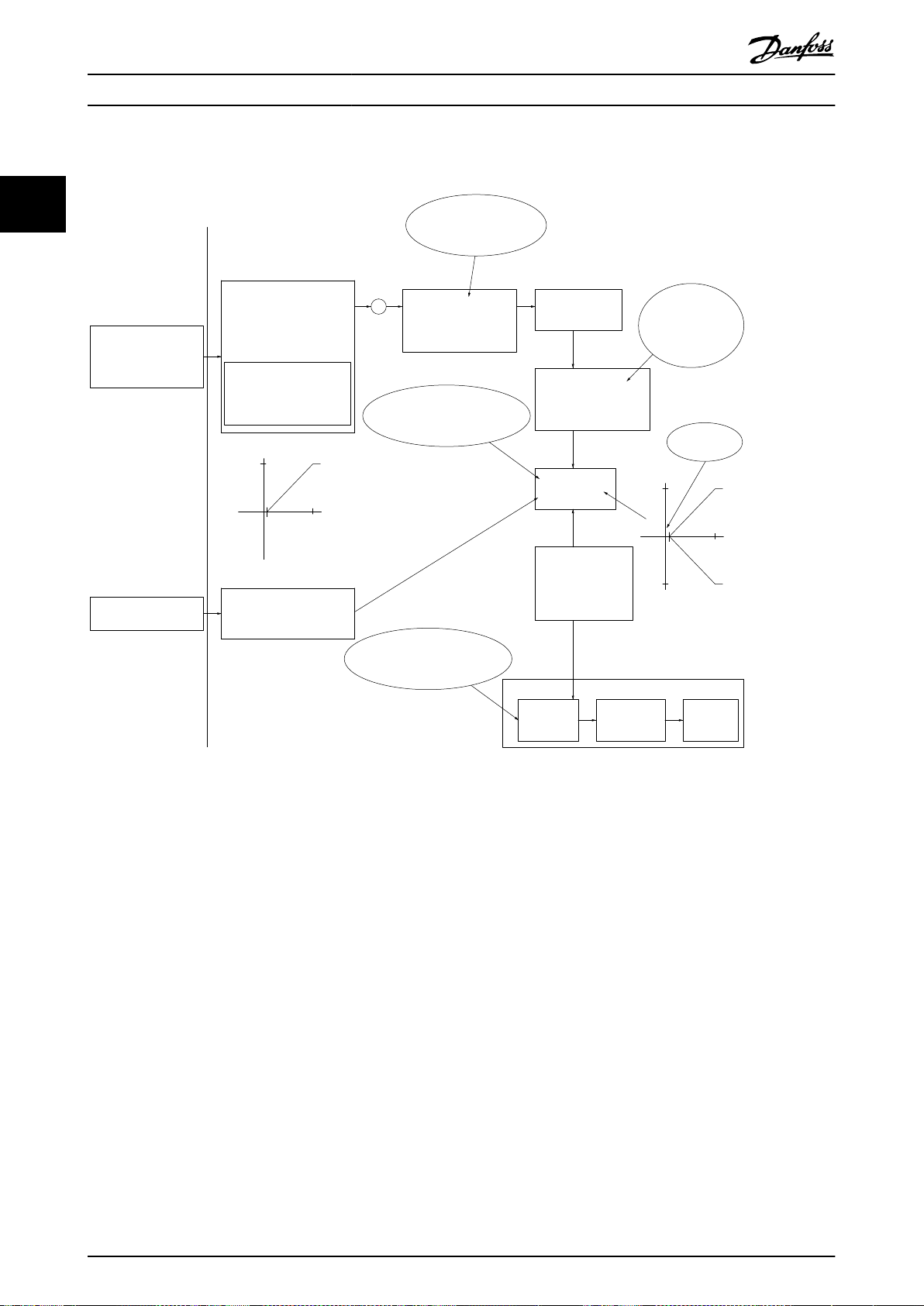

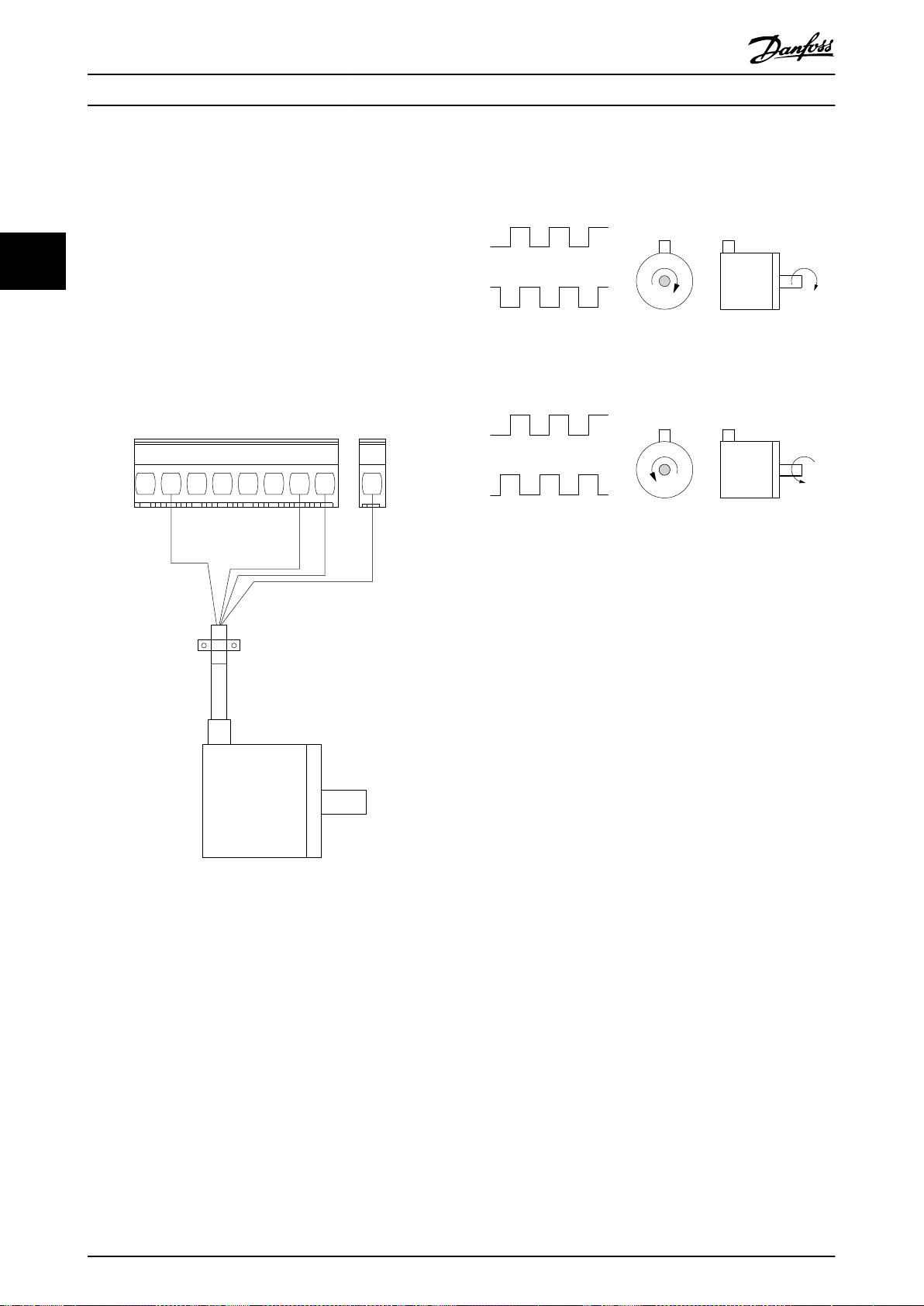

2.5.2 Process PID Control

The process PID control can be used to control application parameters that can be measured by a sensor (for example

pressure, temperature, ow) and aected by the connected motor through a pump, fan, or other connected devices.

Table 2.9 shows the control congurations in which the process control is possible. Refer to chapter 2.3 Control Structures to

see where the speed control is active.

Parameter 1-00 Conguration Mode Parameter 1-01 Motor Control Principle

U/f

VVC

+

[3] Process Process Process

Table 2.9 Control Conguration

NOTICE

The process control PID works under the default parameter setting, but tuning the parameters is recommended to

optimize the application control performance.

2 2

Illustration 2.23 Process PID Control Diagram

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 31

Product Overview

VLT® Midi Drive FC 280

2.5.3 Process Control Relevant Parameters

22

Parameter Description of function

Parameter 7-20 Process CL Feedback 1 Resource Select from which source (analog or pulse input) the process PID gets its feedback.

Parameter 7-22 Process CL Feedback 2 Resource Optional: Determine if (and from where) the process PID gets an additional feedback

signal. If an additional feedback source is selected, the 2 feedback signals are added

before being used in the process PID control.

Parameter 7-30 Process PID Normal/ Inverse

Control

Parameter 7-31 Process PID Anti Windup The anti-windup function ensures that when either a frequency limit or a torque limit is

Parameter 7-32 Process PID Start Speed In some applications, reaching the required speed/setpoint can take a long time. In such

Parameter 7-33 Process PID Proportional Gain The higher the value, the quicker the control. However, too large a value may lead to

Parameter 7-34 Process PID Integral Time Eliminates steady state speed error. A lower value means a quicker reaction. However, too

Parameter 7-35 Process PID Dierentiation Time Provides a gain proportional to the rate of feedback change. A setting of 0 disables the

Parameter 7-36 Process PID Di. Gain Limit If there are quick changes in reference or feedback in a given application (which means

Parameter 7-38 Process PID Feed Forward

Factor

Parameter 5-54 Pulse Filter Time Constant

•

#29 (Pulse term. 29)

Parameter 5-59 Pulse Filter Time Constant

•

#33 (Pulse term. 33)

Parameter 6-16 Terminal 53 Filter Time

•

Constant (Analog term 53)

Parameter 6-26 Terminal 54 Filter Time

•

Constant (Analog term. 54)

Under [0] Normal operation, the process control responds with an increase of the motor

speed if the feedback is lower than the reference. Under [1] Inverse operation, the process

control responds with a decreasing motor speed instead.

reached, the integrator is set to a gain that corresponds to the actual frequency. This

avoids integrating on an error that cannot be compensated for by a speed change. Press

[0] O to disable this function.

applications, it may be an advantage to set a xed motor speed from the frequency

converter before the process control is activated. Set a xed motor speed by setting a

process PID start value (speed) in parameter 7-32 Process PID Start Speed.

oscillations.

small a value may lead to oscillations.

dierentiator.

that the error changes swiftly), the dierentiator may soon become too dominant. This is

because it reacts to changes in the error. The quicker the error changes, the stronger the

dierentiator gain is. The dierentiator gain can thus be limited to allow setting of the

reasonable dierentiation time for slow changes.

In applications where there is a good (and approximately linear) correlation between the

process reference and the motor speed necessary for obtaining that reference, use the

feed forward factor to achieve better dynamic performance of the process PID control.

If there are oscillations of the current/voltage feedback signal, use a low-pass lter to

dampen these oscillations. The pulse lter time constant represents the speed limit of the

ripples occurring on the feedback signal.

Example: If the low-pass lter has been set to 0.1 s, the limit speed is 10 RAD/s (the

reciprocal of 0.1 s), corresponding to (10/(2 x π))=1.6 Hz. This means that the lter

dampens all currents/voltages that vary by more than 1.6 oscillations per second. The

control is only carried out on a feedback signal that varies by a frequency (speed) of less

than 1.6 Hz.

The low-pass lter improves steady state performance, but selecting a too long lter time

deteriorates the dynamic performance of the process PID control.

Table 2.10 Process Control Parameters

32 Danfoss A/S © 05/2017 All rights reserved. MG07B302

Temperature

Fan speed

Temperature

transmitter

Heat

Heat

generating

process

Cold air

130BA218.10

100kW

n °CW

Transmitter

96 97 9998

91 92 93 95

50

13

L1 L2

L1

PEL3

W PEVU

F1

L2

L3

N

PE

130BF102.10

18

53

27

55

54

M

3

Product Overview Design Guide

2.5.4 Example of Process PID Control

Illustration 2.24 is an example of a process PID control used

in a ventilation system:

Illustration 2.24 Process PID Control in a Ventilation System

In a ventilation system, the temperature can be set from -5

to +35 °C (23–95 °F) with a potentiometer of 0–10 V. To

keep the set temperature constant, use the process control.

Illustration 2.25 2-wire Transmitter

The control is inverse, which means that when the

temperature increases, the ventilation speed is increased as

well to generate more air. When the temperature drops,

the speed is reduced. The transmitter used is a

temperature sensor with a working range of -10 to +40 °C

(14–104 °F), 4–20 mA.

1. Start/stop via the switch connected to terminal

18.

2. Temperature reference via potentiometer (-5 to

+35 °C (23–95 °F), 0–10 V DC) connected to

terminal 53.

3. Temperature feedback via transmitter (-10 to

+40 °C (14–104 °F), 4–20 mA) connected to

terminal 54.

Function Parameter

number

Initialize the frequency converter. Parameter 14-2

2 Operation

Mode

1) Set motor parameters:

Set the motor parameters according to nameplate

data.

Parameter

group 1-2*

Motor Data

Perform a full AMA. Parameter 1-29

Automatic

Motor

Adaption

2) Check that motor is running in the correct direction.

When the motor is connected to the frequency converter with straight forward phase order as U-U; V-V; W-W, the motor shaft usually

turns clockwise seen into shaft end.

Press [Hand On]. Check the shaft direction by

applying a manual reference.

(AMA)

Setting

[2] Initialisation - make a power cycling - press reset.

As stated on motor nameplate.

[1] Enable complete AMA.

2 2

MG07B302 Danfoss A/S © 05/2017 All rights reserved. 33

Product Overview

VLT® Midi Drive FC 280

Function Parameter

number

If the motor turns opposite of required direction:

22

1. Change motor direction in

parameter 4-10 Motor Speed Direction.

2. Turn o mains, and wait for DC link to

discharge.

3. Switch 2 of the motor phases.

Set conguration mode. Parameter 1-00

3) Set reference conguration, that is the range for reference handling. Set scaling of analog input in parameter group 6-** Analog In/Out.

Set reference/feedback units.

Set minimum reference (10 °C (50 °F)).

Set maximum reference (80 °C (176 °F)).

If the set value is determined from a preset value

(array parameter), set other reference sources to [0]

No Function.

4) Adjust limits for the frequency converter:

Set ramp times to an appropriate value as 20 s. Parameter 3-41

Set minimum speed limits.

Set motor speed maximum limit.

Set maximum output frequency.

Set parameter 6-19 Terminal 53 mode and parameter 6-29 Terminal 54 mode to voltage or current mode.

5) Scale analog inputs used for reference and feedback:

Parameter 4-10

Motor Speed

Direction

Conguration

Mode

Parameter 3-01

Reference/

Feedback Unit

Parameter 3-02

Minimum

Reference

Parameter 3-03

Maximum

Reference

Parameter 3-10

Preset

Reference

Ramp 1 Ramp

Up Time

Parameter 3-42

Ramp 1 Ramp

Down Time

Parameter 4-12

Motor Speed

Low Limit [Hz]

Parameter 4-14

Motor Speed

High Limit [Hz]

Parameter 4-19

Max Output