Operating Guide

VLT® Midi Drive FC 280

with Functional Safety over Fieldbus

vlt-drives.danfoss.com

VLT® Midi Drive FC 280

Operating Guide

Contents

1

Introduction 9

1.1

Purpose of this Operating Guide 9

Additional Resources 9

1.2

Document and Software Version 9

1.3

1.4

Product Overview 9

1.4.1

Intended Use 9

1.4.2

Block Diagram of the Drive 10

1.4.3

Enclosure Sizes and Power Ratings 11

1.4.4

Safety Functions 11

Approvals and Certifications 11

1.5

Applied Standards and Compliance for Safety Functions 12

1.6

Disposal 12

1.7

Contents

Safety 13

2

2.1

Safety Symbols 13

2.2

Qualified Personnel 13

2.3

Safety Precautions 13

3

Mechanical Installation 16

3.1

Unpacking 16

3.1.1

Items Supplied 16

3.1.2

Identifying the Drive with Ethernet-based Safety Functions 17

3.1.3

Storage 17

3.2

Installation Environment 17

3.3

Mounting 17

3.3.1

Cooling 17

3.3.2

Lifting 17

3.3.3

Mounting 17

3.3.3.1

3.3.3.2

Side-by-side Installation 17

Horizontal Mounting 18

3.3.3.3

3.3.3.4

4

Electrical Installation 21

4.1

Safety Instructions 21

4.2

EMC-compliant Installation 21

4.3

Grounding 22

4.4

Wiring Schematic 23

Bus Decoupling Kit 18

Mounting the Bus Decoupling Kit 18

AQ381425076031en-000101/130R1223 | 3Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

4.5

Control Wiring Access 25

4.6

Examples of Mains, Motor, and Grounding Connection 25

4.7

Connecting the Motor 27

4.7.1

4.8

Connecting AC Mains 28

4.8.1

4.9

Control Wiring 29

4.9.1

4.9.2

4.9.3

4.9.4

4.9.5

4.9.6

Contents

Grounding the Cable Shield 27

Connecting the Drive to Mains 28

Control Terminal Types 29

Wiring to Control Terminals 30

4.9.2.1

Enabling Motor Operation (Terminal 27) 30

Mechanical Brake Control 31

USB Data Communication 32

Serial Communication 32

Wiring 30

4.10

Installation Check List 33

5

Commissioning 35

5.1

Safety Instructions 35

5.1.1

Before Applying Power 35

5.2

Applying Power 35

5.3

Local Control Panel Operation 35

5.3.1

Introduction 35

5.3.2

Numerical Local Control Panel 36

5.3.3

The Right-key Function on NLCP 38

5.3.4

Quick Menu on NLCP 38

5.3.4.1

5.3.4.2

5.3.5

Main Menu on NLCP 39

5.3.5.1

5.3.5.2

5.3.5.3

Operating Quick Menu 38

Quick Menu Structure 39

Operating Main Menu 39

Continuous Parameters 40

Enumerated Parameters 41

5.3.5.4

5.3.6

Graphical Local Control Panel 42

5.3.7

Parameter Settings 45

5.3.8

Changing Parameter Settings with GLCP 45

5.3.8.1

5.3.8.2

5.3.8.3

Array Parameters 42

Introduction 45

Changing Parameter Settings 45

View Changes 45

AQ381425076031en-000101/130R12234 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

5.3.9

5.3.10

5.4

Basic Programming 46

5.4.1

5.4.2

Contents

Backing-up/Downloading Parameters 45

Restoring Default Settings with LCP 46

5.3.10.1

5.3.10.2

5.3.10.3

Asynchronous Motor Set-up 46

5.4.1.1

5.4.1.2

PM Motor Set-up in VVC+ 47

5.4.2.1

5.4.2.2

5.4.2.3

5.4.2.4

Introduction 46

Recommended Initialization 46

Manual Initialization 46

Setting Up Asynchronous Motor 46

Application-specific Adjustment When Running VVC+ 47

Initial Programming Steps 47

Programming Motor Data 47

Testing Motor Operation 48

Parking 48

5.4.3

Automatic Motor Adaptation (AMA) 48

5.4.3.1

5.4.3.2

5.5

Checking Motor Rotation 49

5.6

Checking Encoder Rotation 49

5.7

Testing Local-control 49

5.8

System Start-up 50

5.9

Memory Module 50

5.9.1

Memory Module Overview 50

5.9.2

Synchronizing Drive Data to a New Memory Module (Create Drive Backup) 51

5.9.3

Copying Data to Another Drive 51

5.9.4

Copying Data to Multiple Drives 51

5.9.5

Transferring the Firmware Information 52

5.9.6

Backing Up Parameter Changes to Memory Module 52

5.9.7

Erasing Data 52

5.9.8

Transfer Performance and Indications 52

Introduction 48

Running AMA via LCP 49

6

Safety Functions 54

6.1

Introduction 54

6.2

System Overview 55

6.2.1

Safety Function Architecture 55

6.2.2

Safe State 56

6.2.3

Internal and External Fault 56

6.2.4

Fault Reaction 56

AQ381425076031en-000101/130R1223 | 5Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

6.2.5

6.3

Safety Functions 57

6.3.1

6.3.2

Contents

Recovery from Safe State 56

6.2.5.1

6.2.5.2

Safe Torque Off (STO) 57

6.3.1.1

6.3.1.2

6.3.1.3

6.3.1.4

Safe Stop 1 Time Controlled (SS1-t) 59

6.3.2.1

6.3.2.2

6.3.2.3

6.3.2.4

Recovery from Safe Function Triggered Normally 56

Recovery from Safety Events 57

STO Triggered by DI 58

STO Triggered by Fieldbus 58

Exit STO 59

Restart Behavior 59

SS1-t Triggered by DI 61

SS1-t Triggered by Fieldbus 61

SS1-t Timer Start 62

SS1-t Timing Quit 62

6.3.2.5

6.3.2.6

6.4

Safety Digital Input 62

6.4.1

Valid Voltage 62

6.4.2

Debouncing 62

6.4.3

Discrepancy Tolerance 63

6.5

Safety Fieldbus 63

6.5.1

PROFIsafe 63

6.5.2

PROFIsafe System 64

6.5.2.1

6.5.2.2

6.5.2.3

6.5.2.4

6.5.2.5

6.5.2.5.1

6.5.2.5.2

Safe State of SS1-t 62

Timing Precision 62

The PROFIsafe Frame 64

Parameterization for PROFIsafe 65

PROFIsafe Watchdog Time 66

PROFIsafe Safety Function Response Time (SFRT) 67

PROFIdrive on PROFIsafe 67

PROFIsafe Control Word 67

PROFIsafe Status Word 68

6.6

Installation 69

6.6.1

Safe Input Terminals 69

6.6.2

Jumper for Safety Bypass 69

6.6.3

Connect with Dual-contactor Device 70

6.6.4

Connect with P-M Mode 71

6.6.5

Daisy Chain Connection 72

6.7

Configuration 73

6.7.1

Configuration with MCT 10 73

AQ381425076031en-000101/130R12236 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

6.7.2

6.7.3

6.8

Reset Function 90

6.9

Commissioning and Validation 91

Contents

6.7.1.1

6.7.1.2

6.7.1.3

6.7.1.3.1

6.7.1.4

6.7.1.4.1

6.7.1.4.2

6.7.1.5

6.7.1.6

Configuring PROFIsafe with Siemens TIA Portal 88

6.7.2.1

Programming Safety Functions with Siemens TIA Portal 90

Safety Functions Configuration 73

Commissioning the Safety Option 74

Password Protection 81

Resetting the Password 81

Retrieving Safety Option Status 82

Status Bits for Safety Option Status 82

Status Bits for Safety Option Status 2 83

Copying Safe Parameter Set-up 84

Password Protection LCP Copy and Safe Parameter Mismatch 84

Configuring the Hardware 88

6.9.1

Safety Guidelines 91

6.9.2

Commissioning Requirements 91

6.9.3

Commissioning Test 92

6.9.3.1

6.9.4

Commissioning Test Report 92

6.10

Operation and Maintenance 94

6.10.1

Safe Operation 94

6.10.2

Firmware Update and Modification 94

6.10.3

Troubleshooting 94

6.11

Safety Technical Data 95

6.11.1

Condition and Assumption 95

6.11.2

Safety Technical Data 95

6.12

Safety-related Parameters 97

6.13

Declarations and Certifications 101

7

Application Examples 102

7.1

Introduction 102

Performing the Commissioning Test 92

7.2

Application Examples 102

7.2.1

AMA 102

7.2.2

Speed 103

7.2.3

Start/Stop 104

7.2.4

External Alarm Reset 105

7.2.5

Motor Thermistor 106

7.2.6

SLC 106

AQ381425076031en-000101/130R1223 | 7Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

8

Maintenance, Diagnostics, and Troubleshooting 108

Maintenance and Service 108

8.1

8.2

Warning and Alarm Types 108

Warning and Alarm Displays 108

8.3

8.4

List of Warning and Alarms 109

8.4.1

Warning and Alarm Code List 109

8.4.2

Alarm Words, Warning Words, and Extended Status Words 112

8.5

Troubleshooting 114

9

Specifications 117

9.1

Electrical Data 117

9.2

Mains Supply 120

9.3

Motor Output and Motor Data 120

9.3.1

Motor Output (U, V, W) 120

9.3.2

Torque Characteristics 120

Contents

9.4

Ambient Conditions 121

9.5

Cable Specifications 121

9.6

Control Input/Output and Control Data 122

9.6.1

Digital Inputs 122

9.6.2

Safety Inputs 122

9.6.3

Analog Inputs 122

9.6.4

Pulse Inputs 123

9.6.5

Digital Outputs 123

9.6.6

Control Card, 24 V DC Output 123

9.6.7

Control Card, +10 V DC Output 124

9.6.8

Control Card, RS485 Serial Communication 124

9.6.9

Control Card, USB Serial Communication 124

9.6.10

Relay Outputs 124

9.6.11

Control Card Performance 124

9.6.12

Control Characteristics 124

9.7

Connection Tightening Torques 125

9.8

Fuses and Circuit Breakers 125

9.8.1

Introduction 125

9.8.2

Recommendation of Fuses 125

9.9

Enclosure Sizes, Power Ratings, and Dimensions 127

10

Appendix 131

10.1

Symbols and Abbreviations 131

10.2

Conventions 132

AQ381425076031en-000101/130R12238 | Danfoss A/S © 2022.02

Edition

Remarks

Software version

AQ381425076031, version 0101

First edition.

2.0

VLT® Midi Drive FC 280

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

Other resources are available to understand advanced drive functions, programming and maintenance.

•

The VLT® Midi Drive FC 280 Programming Guide provides information on how to program and includes complete parameter

descriptions.

•

The VLT® Midi Drive FC 280 Design Guide provides detailed information about the design and applications of the drive.

Supplementary publications and manuals are available from the Danfoss website.

1.3 Document and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Document and Software Version

1.4 Product Overview

1.4.1 Intended Use

The drive is an electronic motor controller intended for:

•

Regulation of motor speed in response to system feedback or to remote commands from external controllers. A power drive

system consists of the drive, the motor, and equipment driven by the motor.

•

System and motor status surveillance.

The drive can also be used for motor overload protection.

Depending on the configuration, the drive can be used in standalone applications or form part of a larger appliance or installation.

The drive is allowed for use in residential, industrial, and commercial environments in accordance with local laws and standards.

N O T I C E

In a residential environment, this product can cause radio interference, in which case supplementary mitigation measures can be

required.

Foreseeable misuse

Do not use the drive in applications which are non-compliant with specified operating conditions and environments. Ensure compliance with the conditions specified in chapter Specifications.

AQ381425076031en-000101 / 130R1223 | 9Danfoss A/S © 2022.02

•••

•

•

•

•••

•

•

•

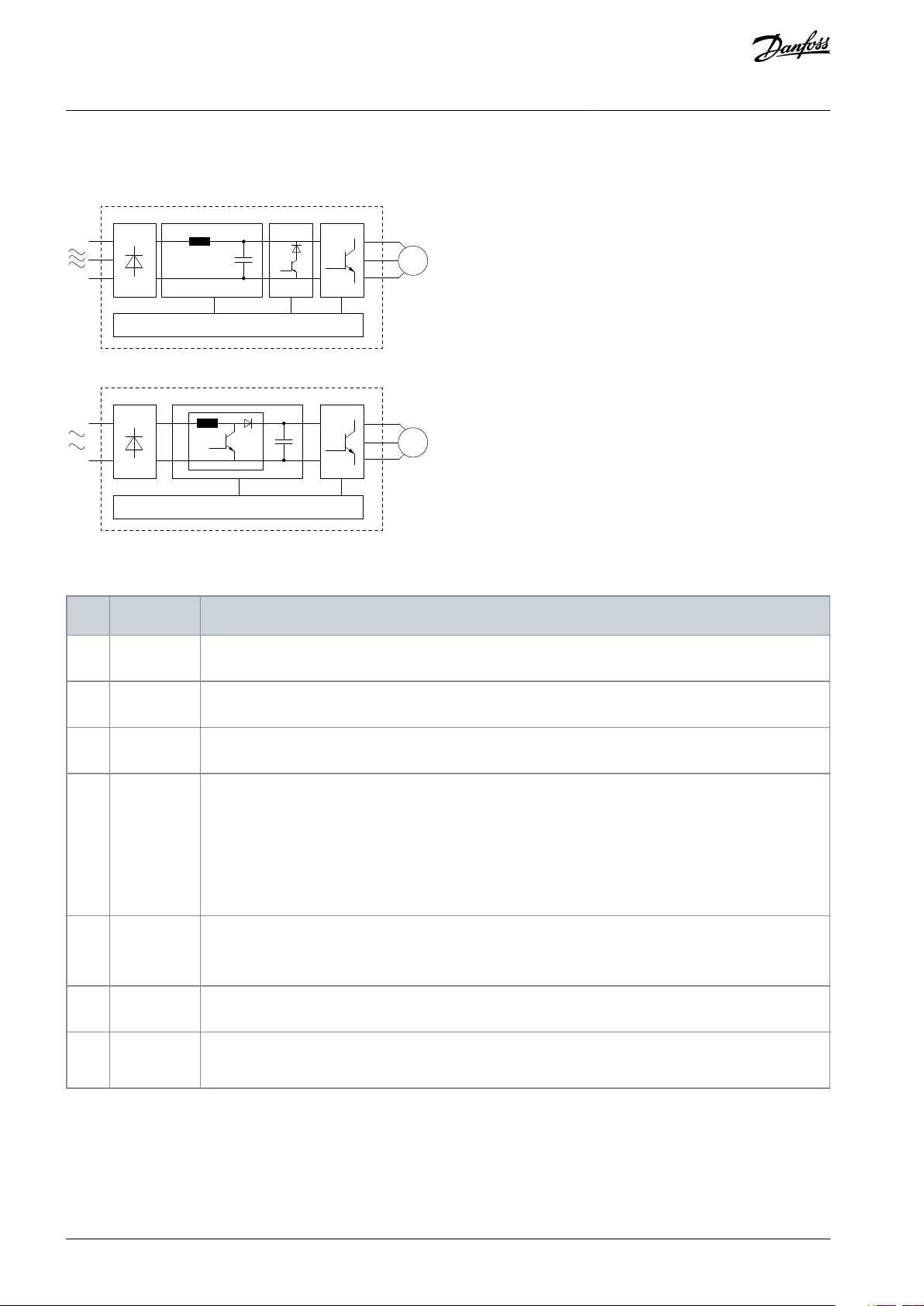

M

7

63

4

5

2

1

8

10

e30be200.12

M

7

63

4

5

2

1

8

9

T2/T4

S2

Area

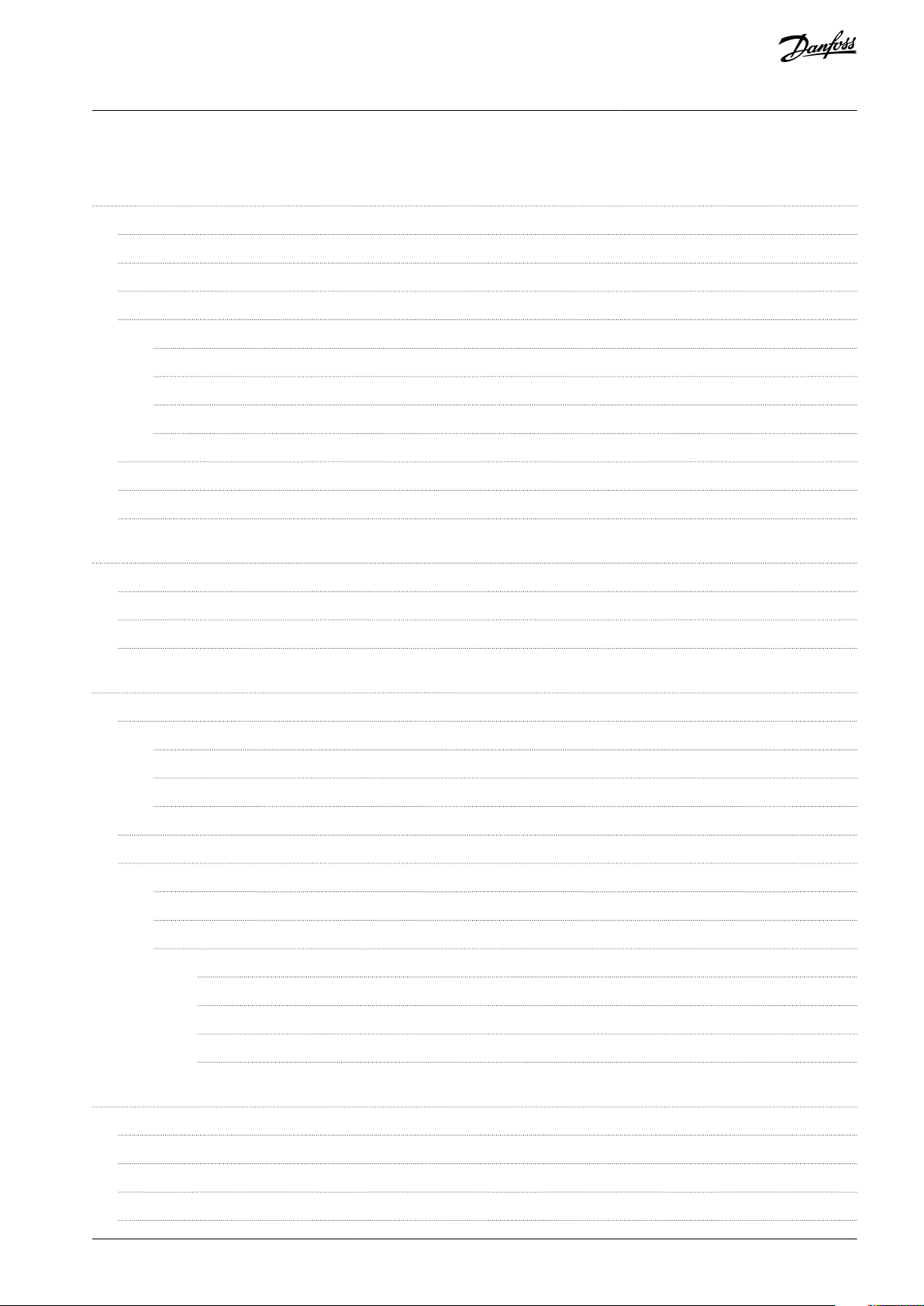

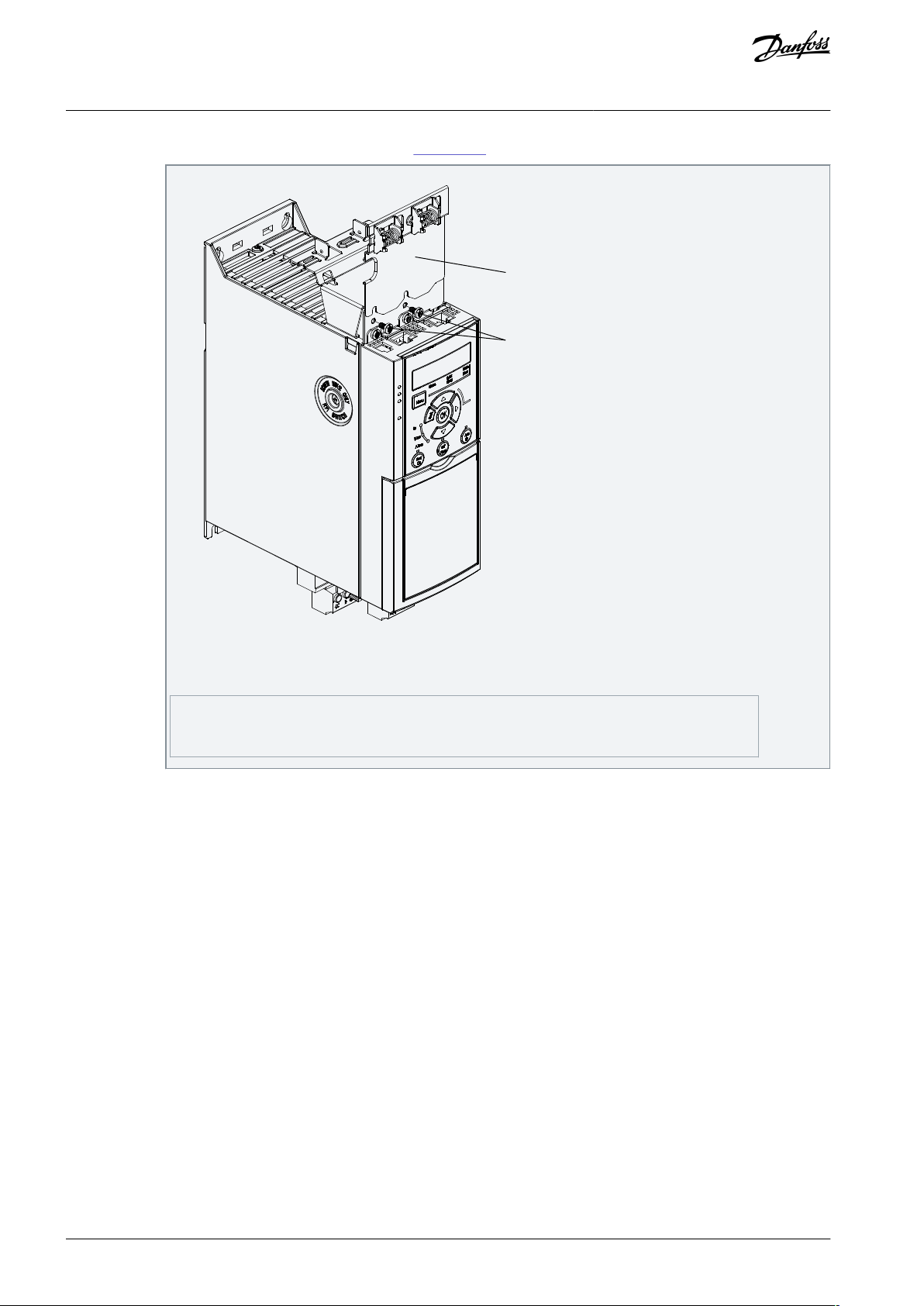

Component

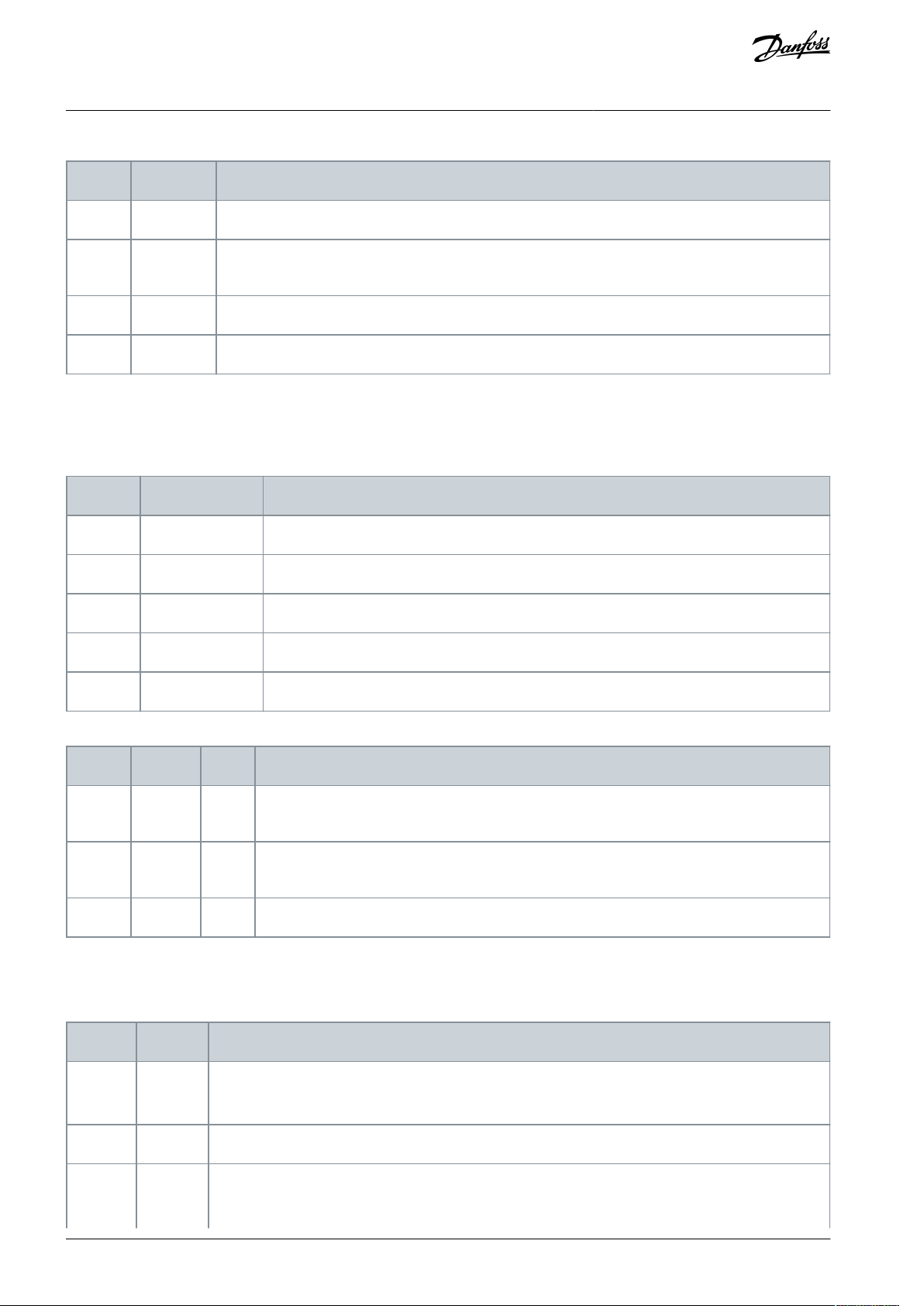

Functions

1

Mains input

AC mains supply to the drive.

2

Rectifier

The rectifier bridge converts the AC input to DC current to supply inverter power.

3

DC bus

Intermediate DC-bus circuit handles the DC current.

4

DC reactor

Filters the intermediate DC circuit current.

Provides mains transient protection.

Reduces the root mean square (RMS) current.

Raises the power factor reflected back to the line.

Reduces harmonics on the AC input.

5

Capacitor

bank

Stores the DC power.

Provides ride-through protection for short power losses.

6

Inverter

Converts the DC into a controlled PWM AC waveform for a controlled variable output to the motor.

7

Output to

motor

Regulated 3-phase output power to the motor.

VLT® Midi Drive FC 280

Operating Guide

1.4.2 Block Diagram of the Drive

Introduction

Illustration 1: Block Diagram of the Drive

Table 2: Functions of Each Component

AQ381425076031en-000101 / 130R122310 | Danfoss A/S © 2022.02

•

•

•

•

•

Area

Component

Functions

8

Control circuitry

Input power, internal processing, output, and motor current are monitored to provide efficient operation and control.

User interface and external commands are monitored and performed.

Status output and control can be provided.

9

PFC

Power factor correction changes the waveform of current which is drawn by the drive to improve the

power factor.

10

Brake chopper

Brake chopper is used in the DC intermediate circuit to control DC voltage when the load feeds energy back.

089

VLT® Midi Drive FC 280

Operating Guide

Introduction

1.4.3 Enclosure Sizes and Power Ratings

For enclosure sizes and power ratings of the drives, refer to 9.9 Enclosure Sizes, Power Ratings, and Dimensions.

1.4.4 Safety Functions

The following safety functions are integrated in this drive according to EN IEC 61800-5-2:

•

Safe Torque Off (STO).

•

Safe Stop 1 time controlled (SS1-t).

See Chapter 6 Safety Functions for details about the installation, configuration, commissioning, maintenance, and technical data.

1.5 Approvals and Certifications

For compliance with the European Agreement concerning International Carriage of Dangerous Goods by Inland Waterways (ADN),

refer to the chapter ADN-compliant Installation in the VLT® Midi Drive FC 280 Design Guide.

The drive complies with UL 508C thermal memory retention requirements. For more information, refer to the chapter Motor Thermal Protection in the VLT® Midi Drive FC 280 Design Guide.

AQ381425076031en-000101 / 130R1223 | 11Danfoss A/S © 2022.02

Do not dispose of equipment containing electrical components together with domestic waste.

Collect it separately in accordance with local and currently valid legislation.

VLT® Midi Drive FC 280

Operating Guide

1.6 Applied Standards and Compliance for Safety Functions

Safe Torque Off (STO)

The STO function is designed and approved according to the following standards:

•

EN IEC 61508, SIL3

•

EN IEC 61800-5-2, SIL3

•

EN IEC 62061, SILCL of SIL3

•

EN ISO 13849-1, Category 3, PL e

Safe Stop 1 time controlled (SS1-t)

The SS1-t function is designed and approved according to the following standards:

•

EN IEC 61508, SIL3

•

EN IEC 61800-5-2, SIL3

•

EN IEC 62061, SILCL of SIL3

•

EN ISO 13849-1, Category 3, PL e

1.7 Disposal

Introduction

AQ381425076031en-000101 / 130R122312 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this guide:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation

of the drive. Only qualified personnel are allowed to install and operate this equipment.

Qualified personnel are defined as trained staff, who are authorized to install, commission, and maintain equipment, systems, and

circuits in accordance with pertinent laws and regulations. Also, the qualified personnel must be familiar with the instructions and

safety measures described in this manual.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AQ381425076031en-000101 / 130R1223 | 13Danfoss A/S © 2022.02

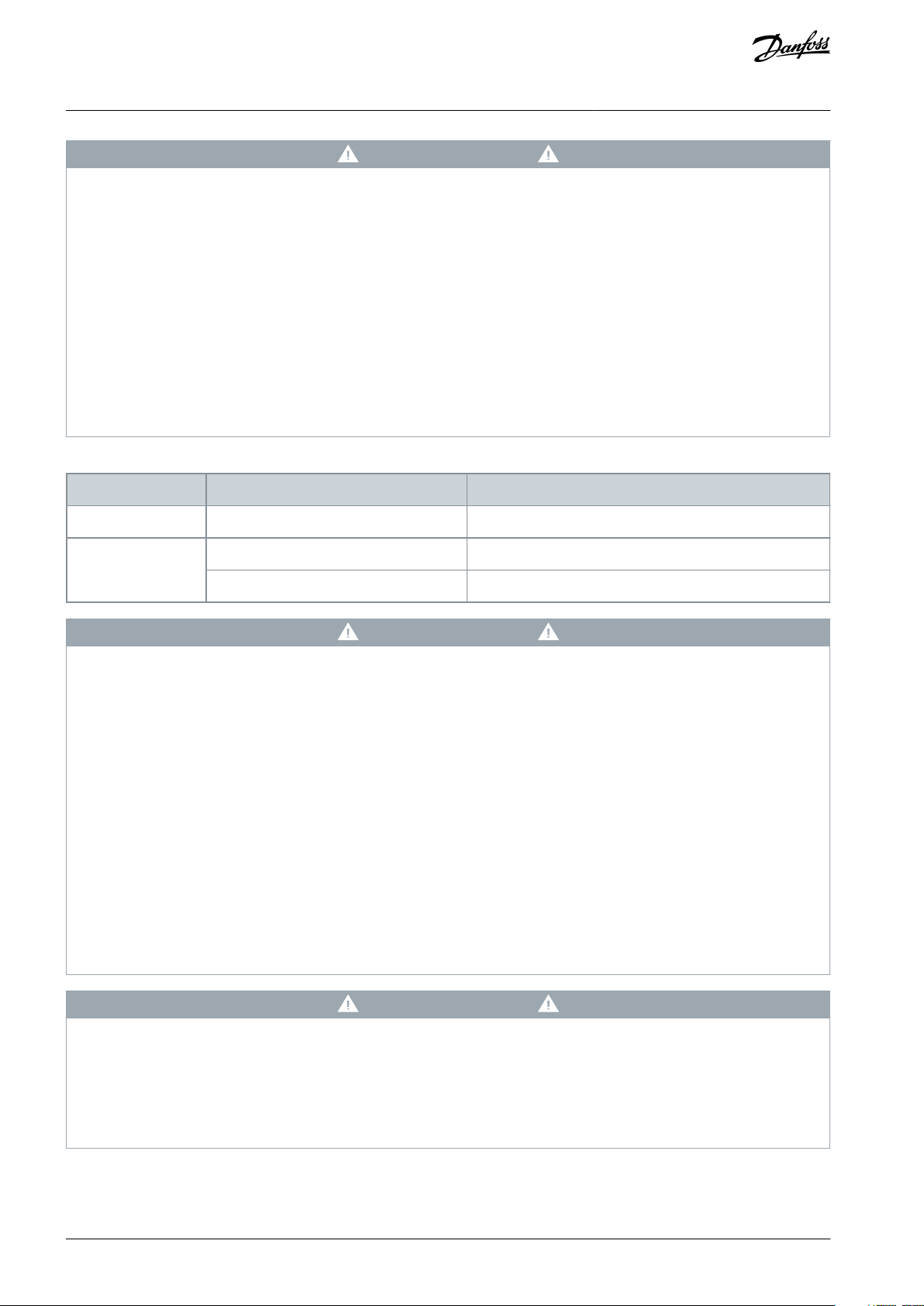

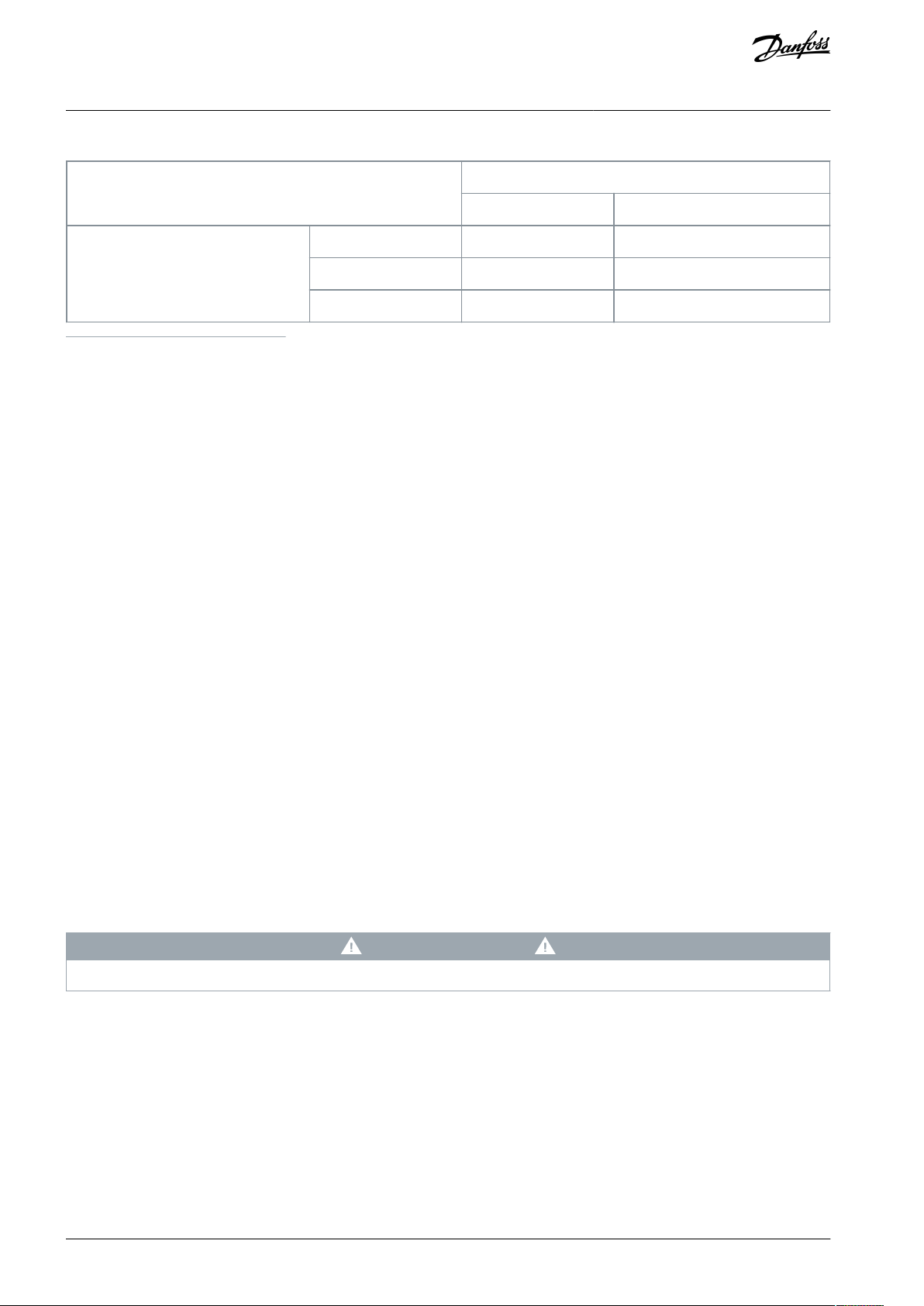

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

200–240

0.37–3.7 kW (0.5–5 hp)

4

380–480

0.37–7.5 kW (0.5–10 hp)

4

11–22 kW (15–30 hp)

15

VLT® Midi Drive FC 280

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 3: Discharge Time

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious injury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

-

tions for high touch current equipment. The reinforced protective earthing of the drive can be done with:

a PE conductor with a cross-section of at least 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al.

-

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

-

minimum cross-sectional area of 2.5 mm2 (14 AWG) (mechanical protected) or 4 mm2 (12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

-

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm2 (14 AWG)

-

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

-

reinforced protective earthing conductor is 10 mA leakage current.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this guide.

-

AQ381425076031en-000101 / 130R122314 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

Safety

AQ381425076031en-000101 / 130R1223 | 15Danfoss A/S © 2022.02

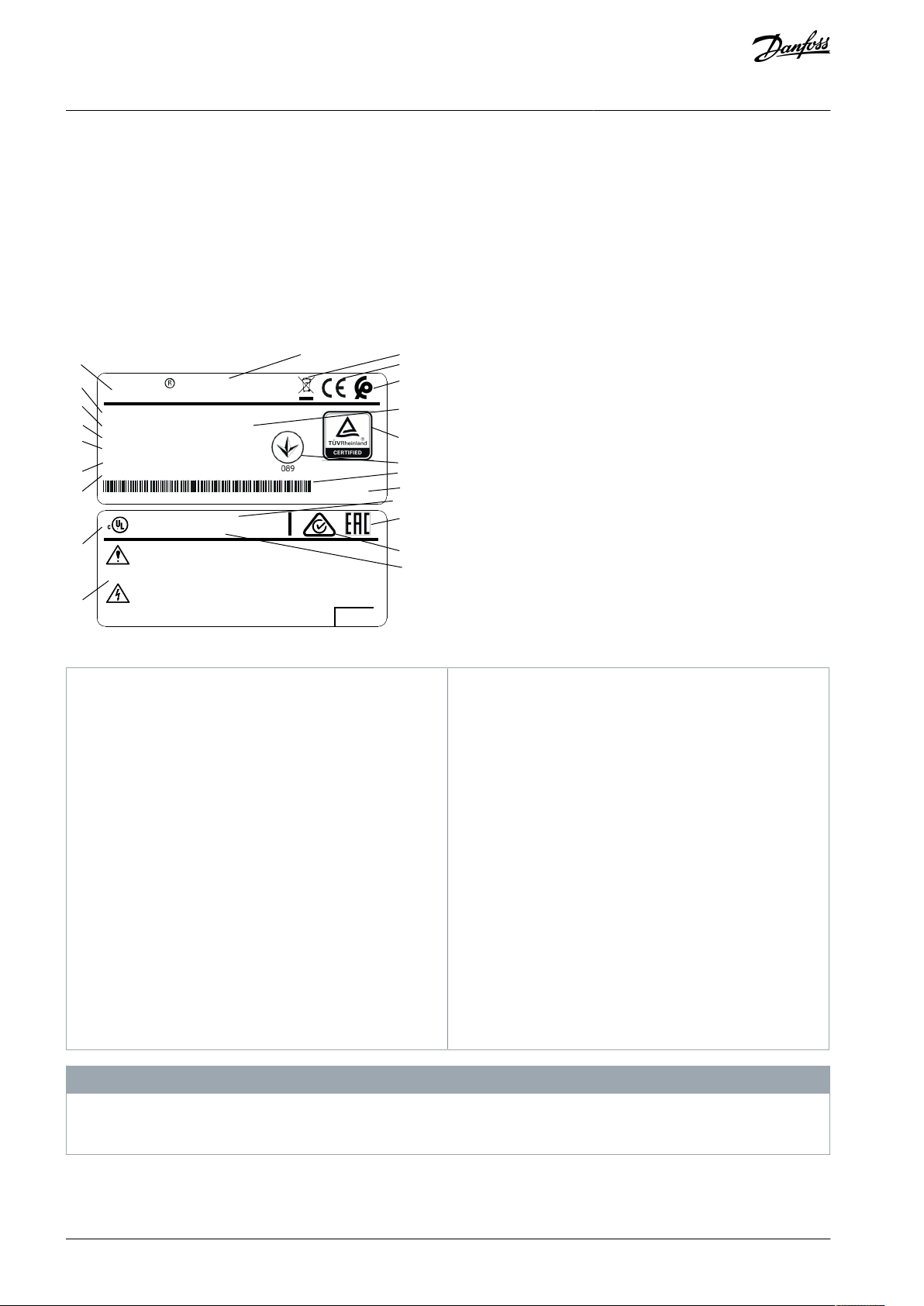

e30be616.15

VLT

MADE IN

DENMARK

T/C: FC-280PK37T4E20H1BXCXXXSXXXXAX

0.37kW 0.5HP

IN: 3x380-480V 50/60Hz, 1.2/1.0A

OUT: 3x0-Vin 0-500Hz, 1.2/1.1A

IP20 SIL3 PL.e

P/N: 134U2184 S/N: 000000G000

Midi Drive

www.danfoss.com

CAUTION / ATTENTION:

WARNING / AVERTISSEMENT:

See manual for special condition/mains fuse

Voir manual de conditions speciales/fusibles

Stored charge, wait 4 min.

Charge résiduelle, attendez 4 min.

21

1

2

4

3

5

11

20

19

18

16

15

13

10

8

9

6

17

R

US LISTED

www.tuv.com

ID 0600000000

Danfoss A/S, 6430 Nordborg, Denmark

12

7

SIL3

E358 502

See manual for mains fuse

IND.CON.EQ

5AF3

14

22

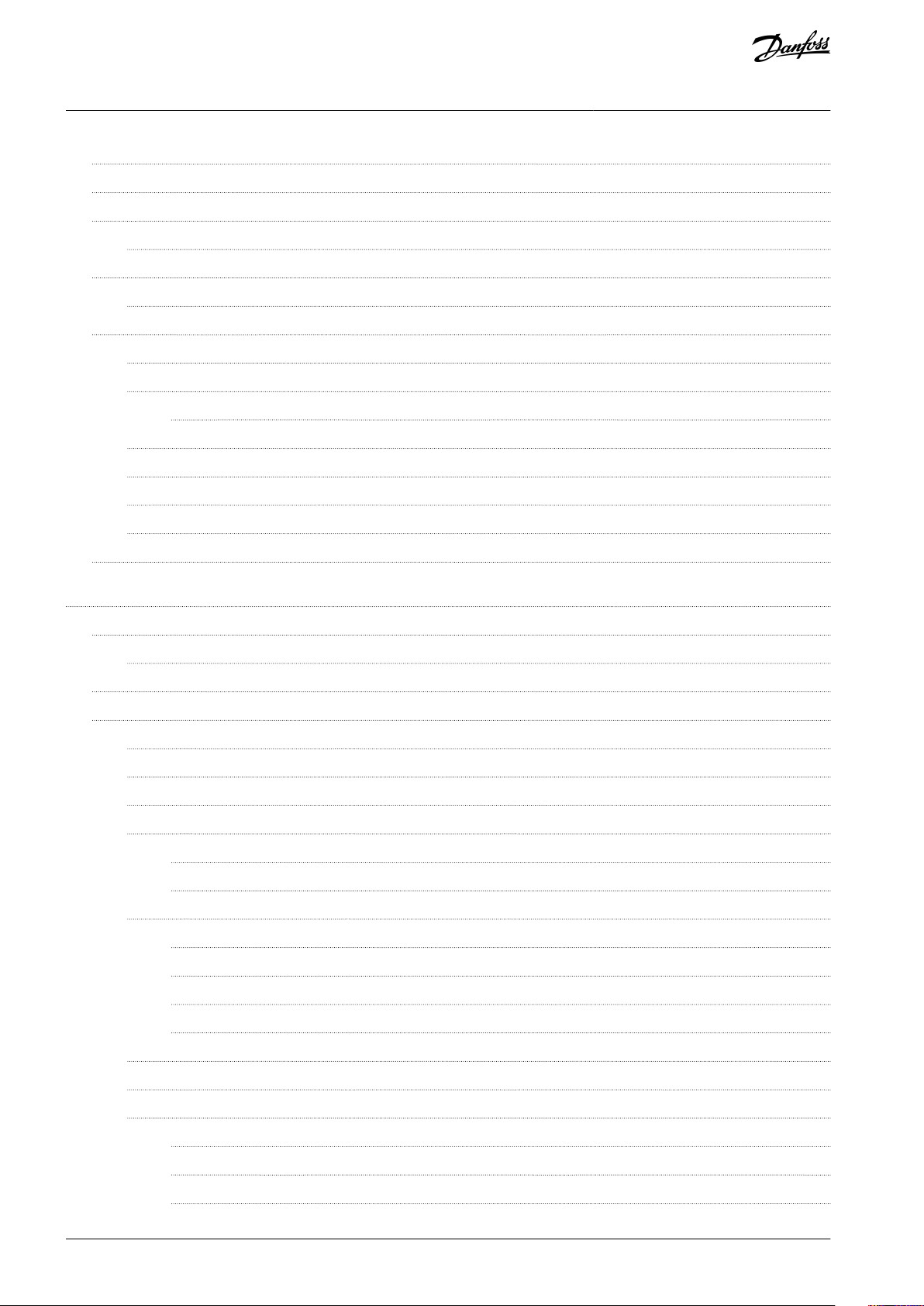

1

Product logo

2

Product name

3

Disposal

4

CE mark

5

Morocco

6

Serial number

7

TÜV logo

8

UkrSEPRO logo

9

Barcode

10

Country of origin

11

UL reference

12

EAC logo

13

RCM logo

14

Reference to enclosure type

15

Warning specifications

16

UL logo

17

IP rating

18

Output voltage, frequency, and current (at low/high

voltages)

19

Input voltage, frequency, and current (at low/high

voltages)

20

Power rating

21

Ordering number

22

Type code

VLT® Midi Drive FC 280

Operating Guide

Mechanical Installation

3 Mechanical Installation

3.1 Unpacking

3.1.1 Items Supplied

Items supplied vary according to product configuration.

•

Make sure that the items supplied and the information on the nameplate correspond to the order confirmation.

•

Check the packaging and the drive visually for damage caused by inappropriate handling during shipment. File any claim for

damage with the carrier. Retain damaged parts for clarification.

Illustration 2: Product Nameplate (Example)

Do not remove the nameplate from the drive (loss of warranty).

For more information of the type code, refer to the chapter Type Code in the VLT® Midi DriveFC 280 Design Guide.

-

N O T I C E

AQ381425076031en-000101 / 130R122316 | Danfoss A/S © 2022.02

- P

4

e30bu891.10

B C A X X X X

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 30 22 21 23 27 25 24 26 28 29

F0 C 2 1 X L

Pos.

S

FS1

H

0

E

T

K

3

7

8

2

VLT® Midi Drive FC 280

Operating Guide

Mechanical Installation

3.1.2 Identifying the Drive with Ethernet-based Safety Functions

To identify whether the drive is equipped with the Ethernet-based safety functions, check the following:

•

The drive's type code on the product label contains “SFS1” at bits 24~27, for example:

Illustration 3: Type Code Example for Drive with Ethernet-based Safety Functions

•

The drive has terminal 39.

3.1.3 Storage

Ensure that the requirements for storage are fulfilled. Refer to 9.4 Ambient Conditions for further details.

3.2 Installation Environment

N O T I C E

REDUCED LIFETIME

In environments with airborne liquids, particles, or corrosive gases, ensure that the IP/Type rating of the equipment matches the

installation environment. Failure to meet requirements for ambient conditions can reduce lifetime of the drive.

Ensure that requirements for air humidity, temperature, and altitude are met.

-

Vibration and shock

The drive complies with requirements for units mounted on the walls and floors of production premises, and in panels bolted to

walls or floors. For detailed ambient conditions, refer to 9.4 Ambient Conditions.

3.3 Mounting

3.3.1 Cooling

N O T I C E

Improper mounting can result in overheating and reduced performance.

•

Ensure 100 mm (3.9 in) of top and bottom clearance for air cooling.

3.3.2 Lifting

•

To determine a safe lifting method, check the weight of the unit, see 9.9 Enclosure Sizes, Power Ratings, and Dimensions.

•

Ensure that the lifting device is suitable for the task.

•

If necessary, plan for a hoist, crane, or forklift with the appropriate rating to move the unit.

•

For lifting, use hoist rings on the unit, when provided.

3.3.3 Mounting

Procedure

1.

Ensure that the strength of the mounting location supports the unit weight.

2.

Place the unit as near to the motor as possible. Keep the motor cables as short as possible.

3.

Mount the unit vertically on a solid flat surface.

4.

Use the slotted mounting holes on the unit for wall mount, when provided. For dimensions of mounting holes, see 9.9

Enclosure Sizes, Power Ratings, and Dimensions.

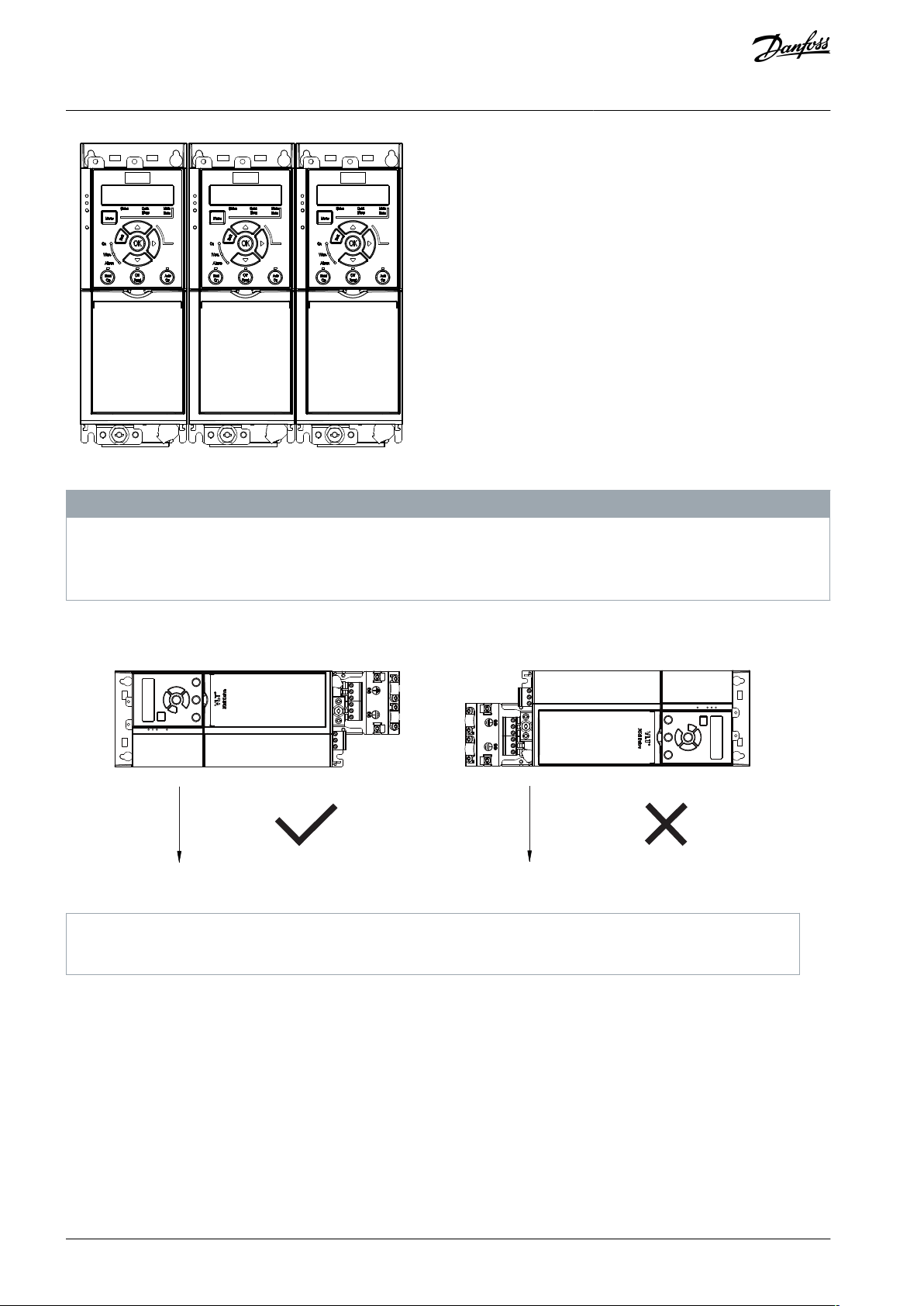

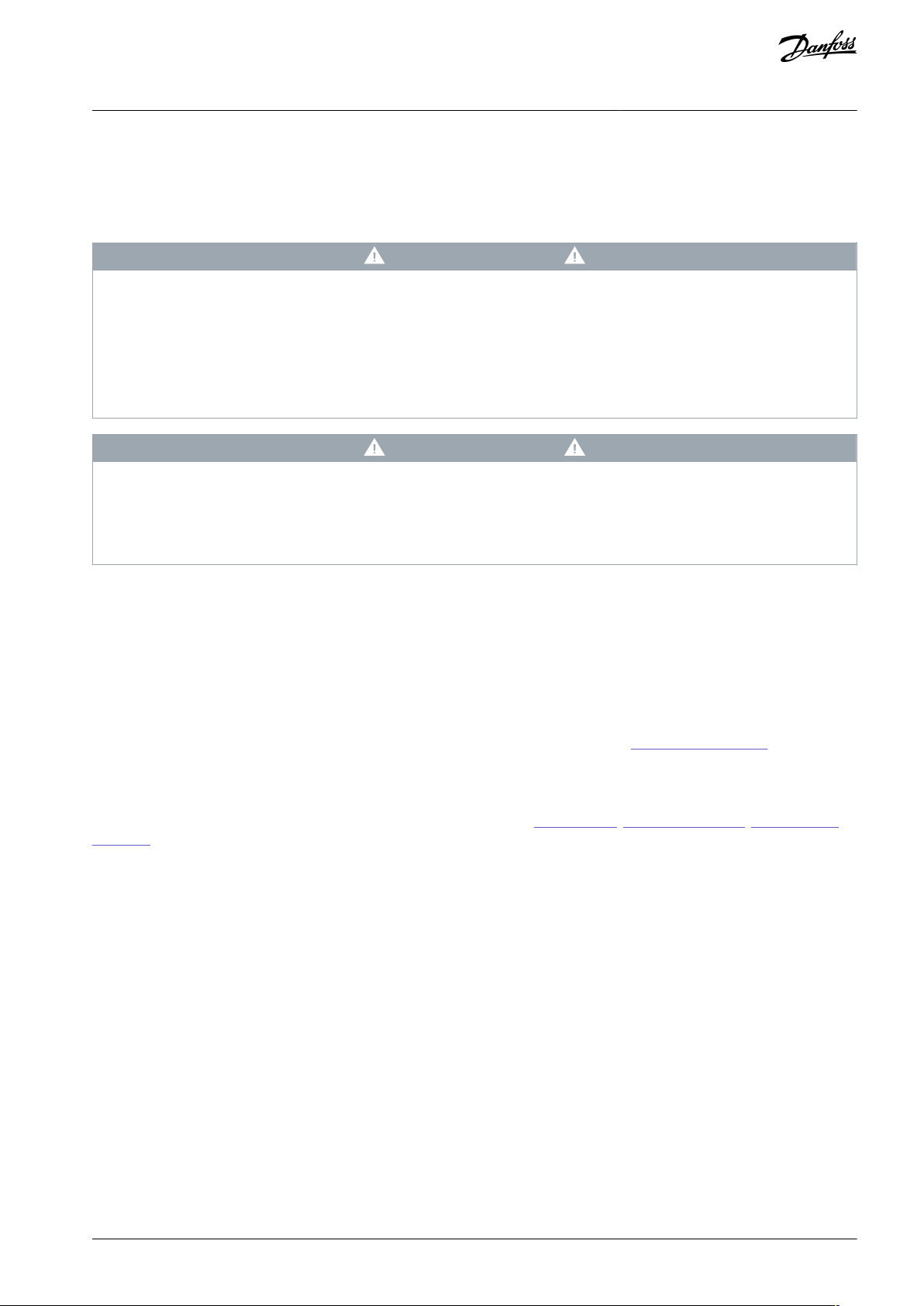

3.3.3.1 Side-by-side Installation

All VLT® Midi Drive FC 280 units can be installed side by side in vertical or horizontal position. The units do not require extra ventilation on the side.

AQ381425076031en-000101 / 130R1223 | 17Danfoss A/S © 2022.02

e30be615.12

e30bf642.10

G

G

(1)

(2)

1

Correct horizontal mounting (left side downwards)

2

Incorrect horizontal mounting (right side downwards)

VLT® Midi Drive FC 280

Operating Guide

Illustration 4: Side-by-side Installation

Mechanical Installation

N O T I C E

RISK OF OVERHEATING

If IP21 conversion kit is used, mounting the units side by side could lead to overheating and damage to the unit.

At least 30 mm (1.2 in) is required between the top cover edges of IP21 conversion kit.

-

3.3.3.2 Horizontal Mounting

Illustration 5: Horizontal Mounting

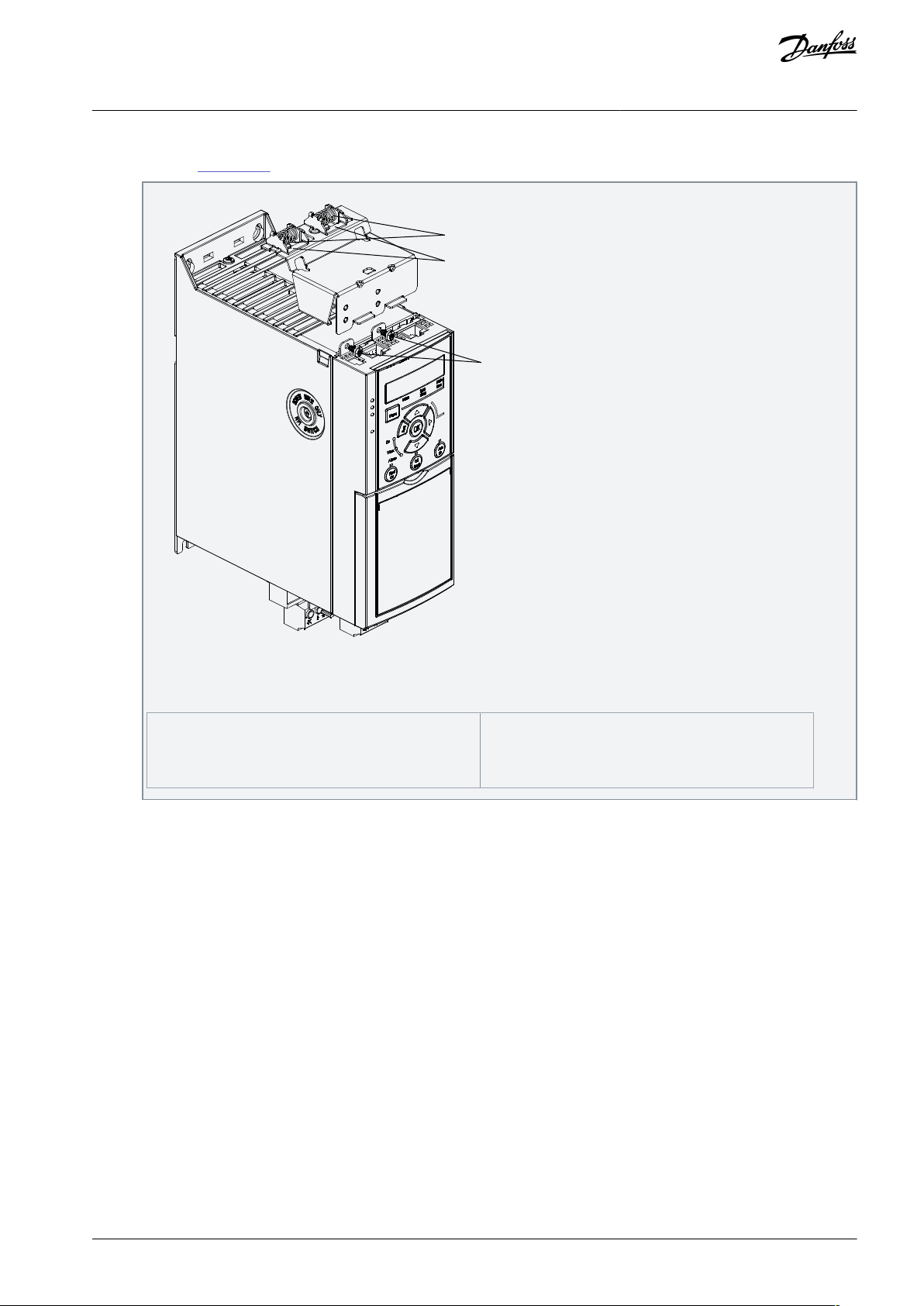

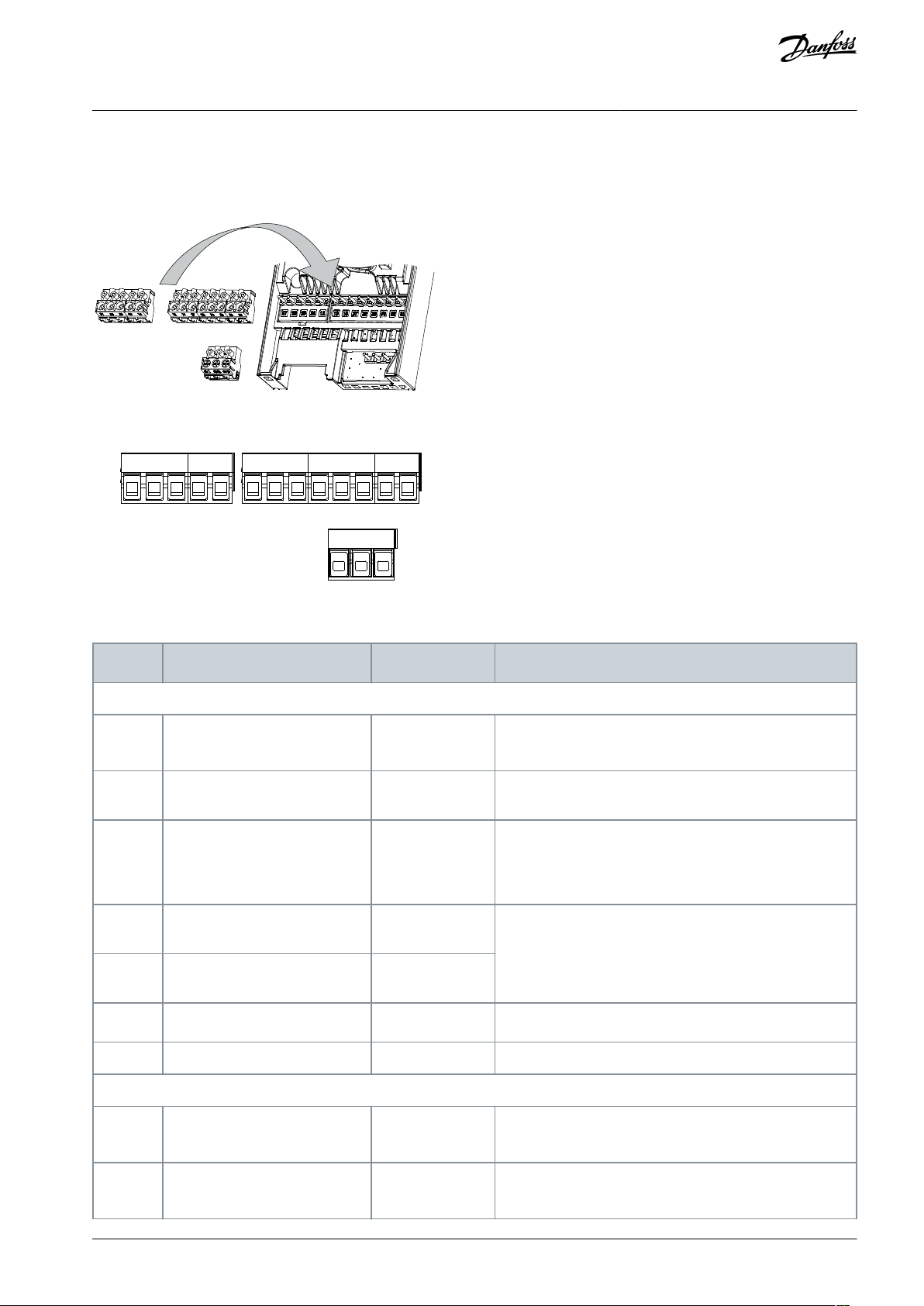

3.3.3.3 Bus Decoupling Kit

The bus decoupling kit ensures mechanical fixation and electrical shielding of cables for the control cassettes with PROFINET/PROFISAFE.

Each bus decoupling kit contains 1 horizontal decoupling plate and 1 vertical decoupling plate. Mounting the vertical decoupling

plate is optional. The vertical decoupling plate provides better mechanical support for Ethernet connectors and cables.

3.3.3.4 Mounting the Bus Decoupling Kit

Procedure

AQ381425076031en-000101 / 130R122318 | Danfoss A/S © 2022.02

1

2

3

e30be480.10

1

Mechanical springs

2

Metal clamps

3

Screws

VLT® Midi Drive FC 280

Operating Guide

1.

Place the horizontal decoupling plate on the control cassette mounted on the drive and fasten the plate using 2 screws as

shown in Illustration 6. Tightening torque is 0.7–1.0 Nm (6.2–8.9 in-lb).

Mechanical Installation

Illustration 6: Fasten the Horizontal Decoupling Plate with Screws

The illustration shows Ethernet-based connectors (RJ45). The actual connector type depends on the selected fieldbus variant of the drive.

2.

Optional: Mount the vertical decoupling plate as follows:

a.

Remove the 2 mechanical springs and 2 metal clamps from the horizontal plate.

b.

Mount the mechanical springs and metal clamps on the vertical plate.

AQ381425076031en-000101 / 130R1223 | 19Danfoss A/S © 2022.02

e30be481.10

1

2

1

Vertical decoupling plate

2

Screws

VLT® Midi Drive FC 280

Operating Guide

c.

Mechanical Installation

Fasten the plate with 2 screws as shown in Illustration 7. Tightening torque is 0.7–1.0 Nm (6.2–8.9 in-lb).

Illustration 7: Fasten the Vertical Decoupling Plate with Screws

The illustration shows Ethernet-based connectors (RJ45). The actual connector type depends on the selected

fieldbus variant of the drive.

3.

Push the Ethernet cable connectors (RJ45) into the sockets in the control cassette.

4.

Place the Ethernet cables between the springloaded metal clamps to establish mechanical fixation between the cables and

the clamps.

AQ381425076031en-000101 / 130R122320 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

4 Electrical Installation

4.1 Safety Instructions

See chapter Safety for general safety instructions.

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment turned

off and locked out/tagged out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out/tag out all the drives.

-

W A R N I N G

ELECTRICAL SHOCK AND FIRE HAZARD – RCD COMPLIANCE

The drive can cause a DC fault current in the PE conductor. Failure to use a Type B residual current-operated protective device

(RCD) can lead to the RCD not providing the intended protection and therefore can result in death, fire, or other serious hazard.

When an RCD is used for protection against electrical shock or against fire, only a Type B device is allowed on the supply side.

-

Overcurrent protection

•

Extra protective equipment, such as short-circuit protection or motor thermal protection between drive and motor, is required

for applications with multiple motors.

•

Input fusing is required to provide short-circuit and overcurrent protection. If not factory-supplied, the installer must provide

fuses. See maximum fuse ratings in chapter Fuses and Circuit Breakers.

Wire type and ratings

All wiring must comply with local and national regulations regarding cross-section and ambient temperature requirements.

•

Power connection wire recommendation: Minimum 75 °C (167 °F) rated copper wire. See

•

mended wire sizes and types.

9.5 Cable Specifications for recom-

4.2 EMC-compliant Installation

To obtain an EMC-compliant installation, follow the instructions provided in 4.3 Grounding, 4.4 Wiring Schematic, 4.7 Connecting

the Motor, and chapter Control Wiring.

AQ381425076031en-000101 / 130R1223 | 21Danfoss A/S © 2022.02

e30bc500.12

FC 1

FC 1

FC 2

FC 2

FC 3

FC 3

PE

PE

A

B

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

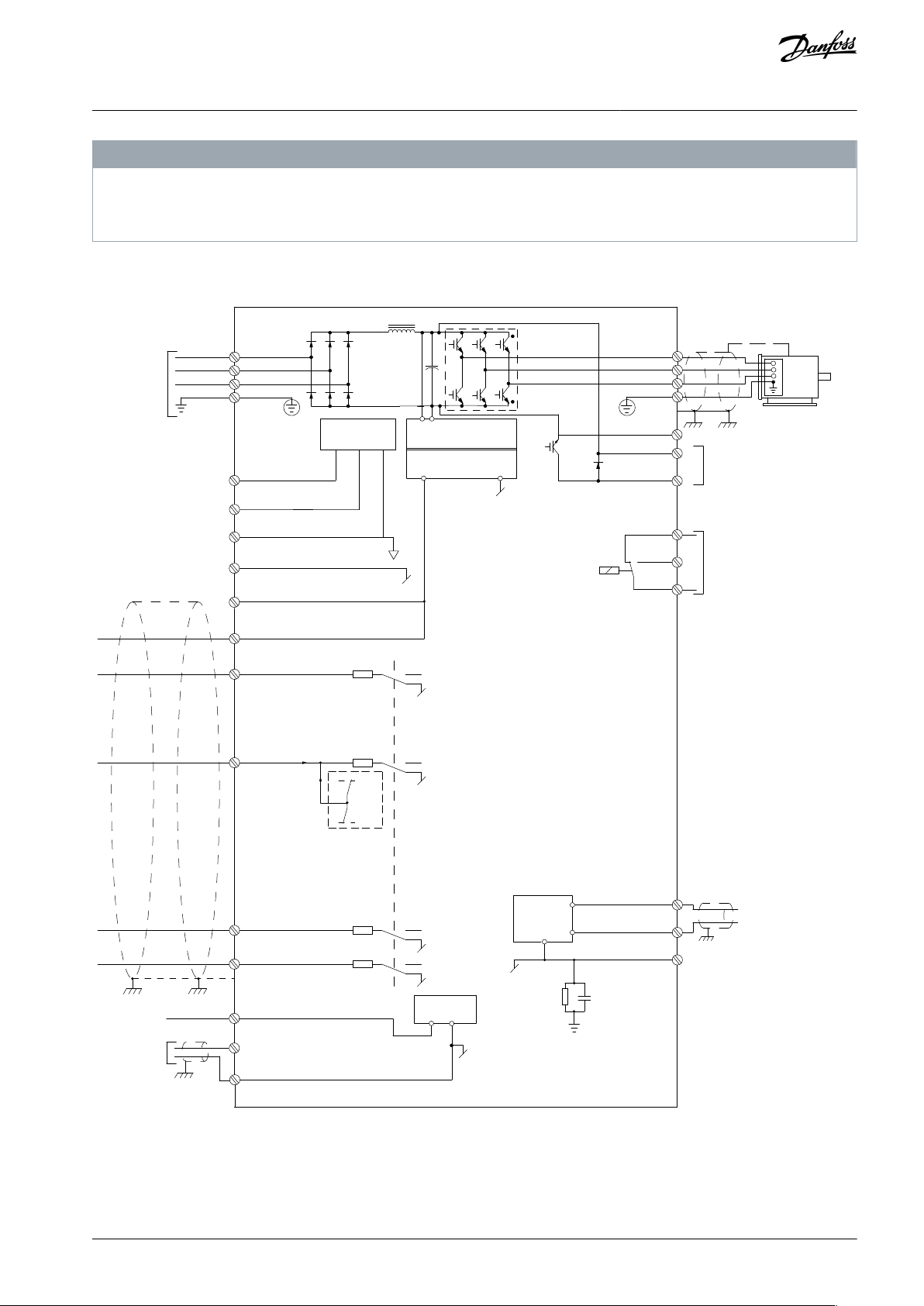

4.3 Grounding

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious injury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

-

tions for high touch current equipment. The reinforced protective earthing of the drive can be done with:

a PE conductor with a cross-section of at least 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al.

-

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

-

minimum cross-sectional area of 2.5 mm2 (14 AWG) (mechanical protected) or 4 mm2 (12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

-

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm2 (14 AWG)

-

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

-

reinforced protective earthing conductor is 10 mA leakage current.

For electrical safety

Ground the drive in accordance with applicable standards and directives.

•

Use a dedicated ground wire for input power, motor power, and control wiring.

•

Do not ground 1 drive to another in a daisy chain fashion (see

•

•

Keep the ground wire connections as short as possible.

•

Follow motor manufacturer wiring requirements.

•

Minimum cable cross-section for the ground wires: 10 mm2 (7 AWG).

•

Separately terminate individual ground wires, both complying with the dimension requirements.

Illustration 8).

Illustration 8: Grounding Principle

For EMC-compliant installation

•

Establish electrical contact between the cable shield and the drive enclosure by using metal cable glands or by using the clamps

provided on the equipment.

•

Use high-strand wire to reduce burst transient.

•

Do not use pigtails.

AQ381425076031en-000101 / 130R122322 | Danfoss A/S © 2022.02

Power

input

Switch mode

power supply

Motor

interface

(PNP) = Source

(NPN) = Sink

Brake

resistor

91 (L1/N)

92 (L2/L)

93 (L3)

PE

13 (+24 V OUT)

18 (D IN)

100 mA

+

-

(U) 96

(V) 97

(W) 98

(PE) 99

(P RS485) 68

(N RS485) 69

(COM RS485) 61

RS485

RS485

03

+10 V DC

0−10 V DC

24 V DC

02

01

24 V (NPN)

0 V (PNP)

24 V (NPN)

0 V (PNP)

17 V

0 V

24 V (NPN)

0 V (PNP)

0 V (PNP)

24 V (NPN)

33 (D IN)

32 (D IN)

38 (SI B)

1)

37 (SI A)

1)

95

P 5-00

(+DC/R+) 89

(R-) 81

(-DC) 88

RFI

0 V

250 V AC, 3 A

Relay 1

2)

3)

3)

e30bu940.10

27 (D IN/OUT)

4)

50 (+10 V OUT)

53 (A IN)

5)

55 (COM digital/analog I/O)

10 V DC

15 mA

+ -

Safety input

interface

39 (Safe GND)

20

12

COM safe input

6)

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

N O T I C E

POTENTIAL EQUALIZATION

Risk of burst transient when the ground potential between the drive and the control system is different. Install equalizing cables

between the system components. Recommended cable cross-section: 16 mm2 (6 AWG).

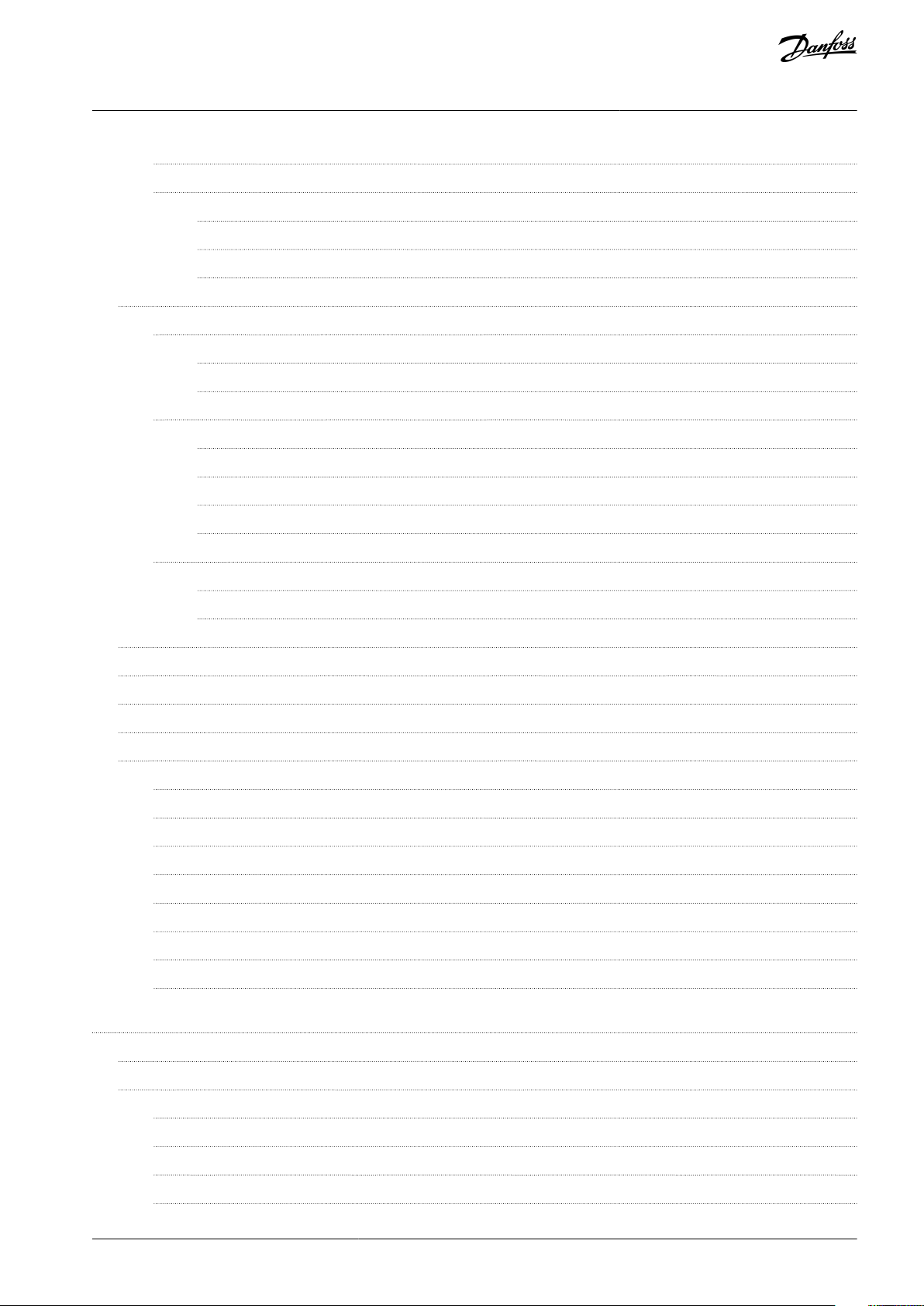

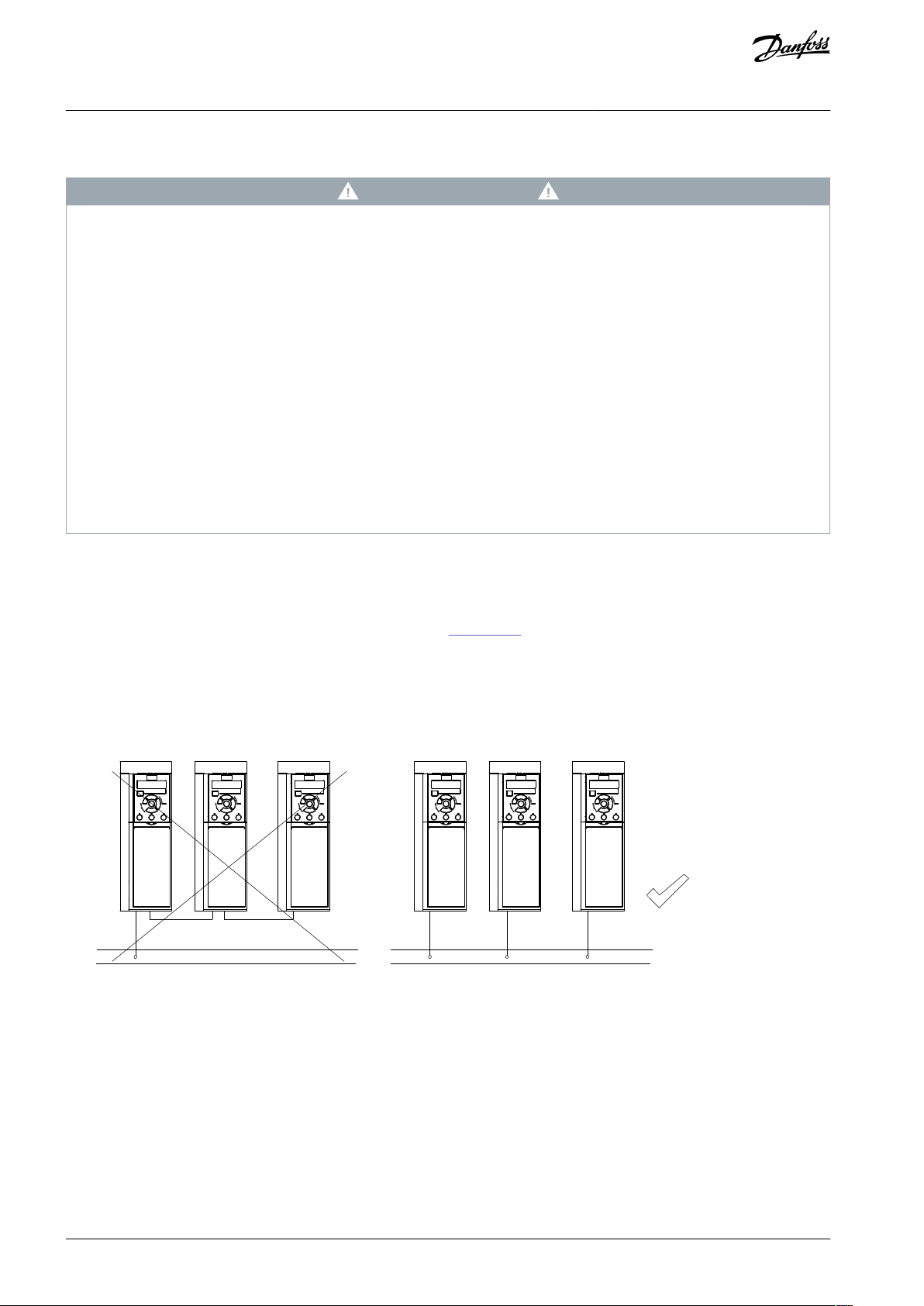

4.4 Wiring Schematic

Illustration 9: Basic Wiring Schematic

AQ381425076031en-000101 / 130R1223 | 23Danfoss A/S © 2022.02

A

Analog

D

Digital

1

Refer to chapter 6 Safety Functions for the correct

safety functions wiring.

2

Built-in brake chopper is only available on 3-phase

units.

3

The S2 (single-phase 200–240 V) drive does not support load sharing application.

4

The maximum voltage is 17 V for terminal 27 as analog output.

5

Terminal 53 can also be used as digital input.

6

Terminal 61 is internally connected to terminal 20

and 55.

L1

L2L3PEL1L2L3PEPEu

v

w

2

1

3

5

IEC 60309

16

17

18

14

12

8

7

10

9

4

11

13

446

15

90

+DC

BR-

B

M

AINS

L1 L2 L3

91 92 93

RELA

Y 1 RELA

Y 2

99

- L

C -

UV

W

MO

T

OR

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

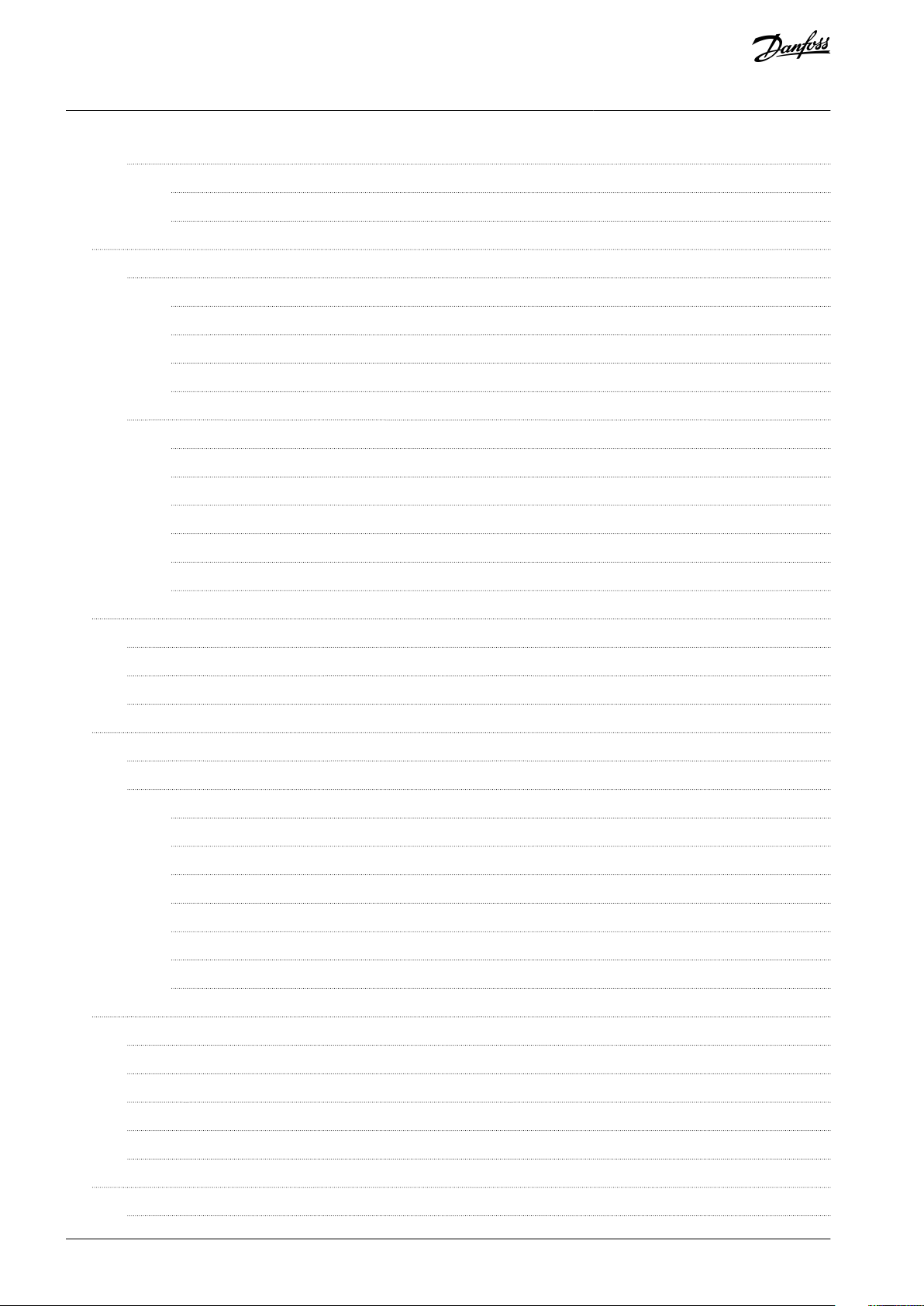

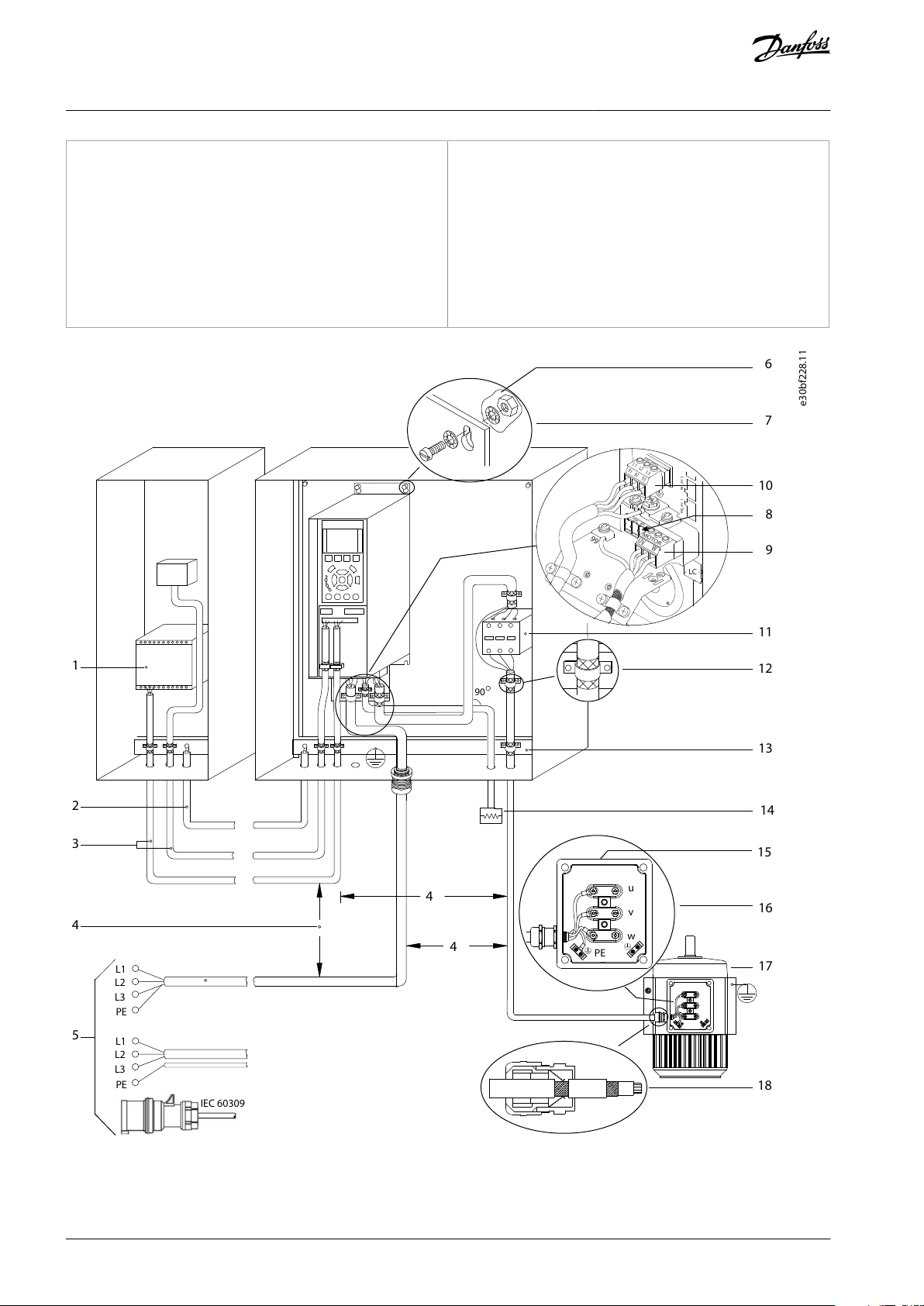

Illustration 10: Typical Electrical Connection

AQ381425076031en-000101 / 130R122324 | Danfoss A/S © 2022.02

1

PLC

2

Minimum 16 mm2 (6 AWG) equalizing cable

3

Control cables

4

Minimum 200 mm (7.87 in) between control cables,

motor cables, and mains cables.

5

Mains supply

6

Bare (unpainted) surface

7

Star washers

8

Brake cable (shielded)

9

Motor cable (shielded)

10

Mains cable (unshielded)

11

Output contactor, and more.

12

Cable insulation stripped

13

Common ground busbar. Follow local and national

requirements for cabinet grounding.

14

Brake resistor

15

Metal box

16

Connection to motor

17

Motor

18

EMC cable gland

e30bc504.11

VLT® Midi Drive FC 280

Operating Guide

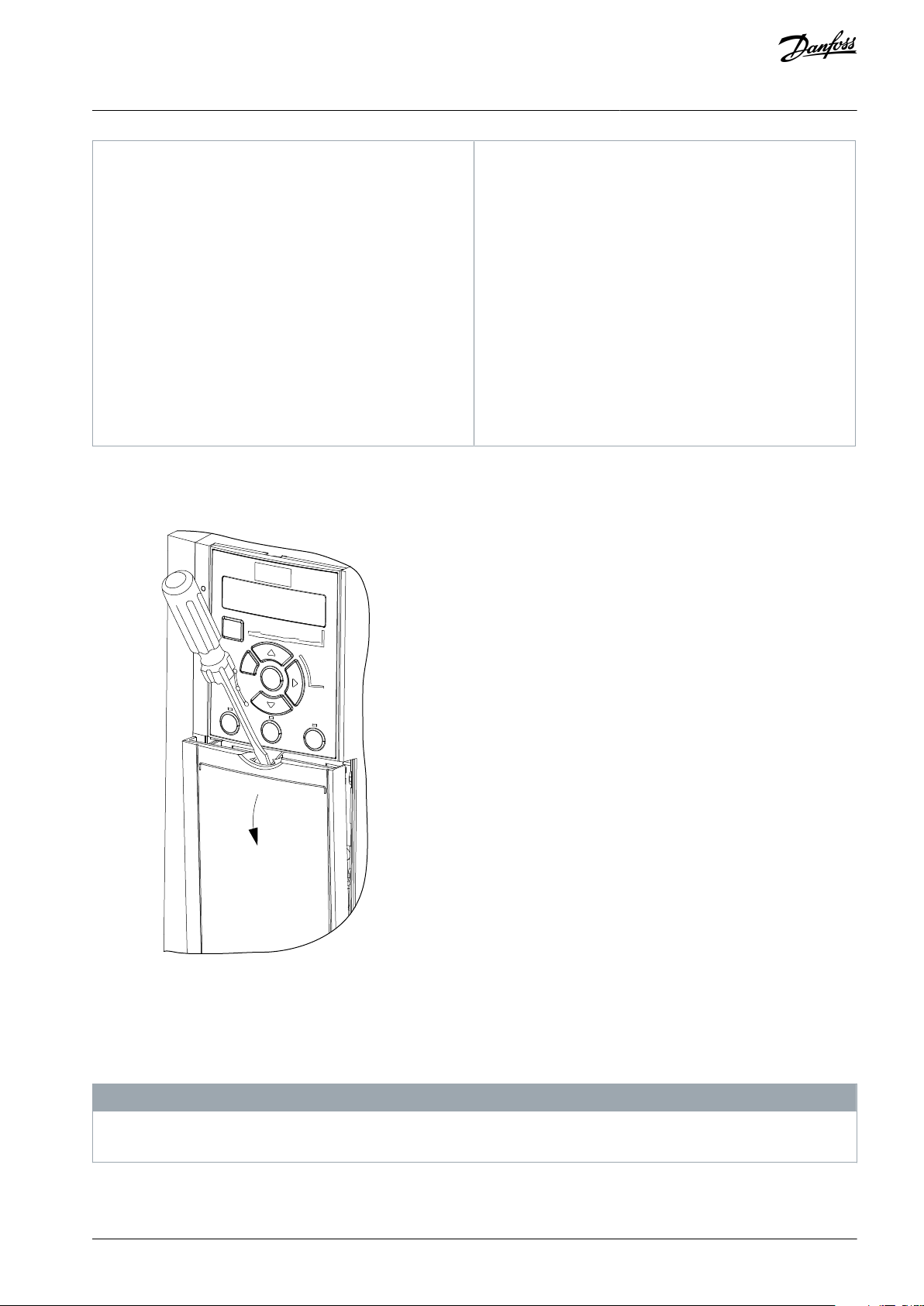

4.5 Control Wiring Access

•

Remove the cover plate with a screwdriver. See the following illustration.

Electrical Installation

Illustration 11: Control Wiring Access

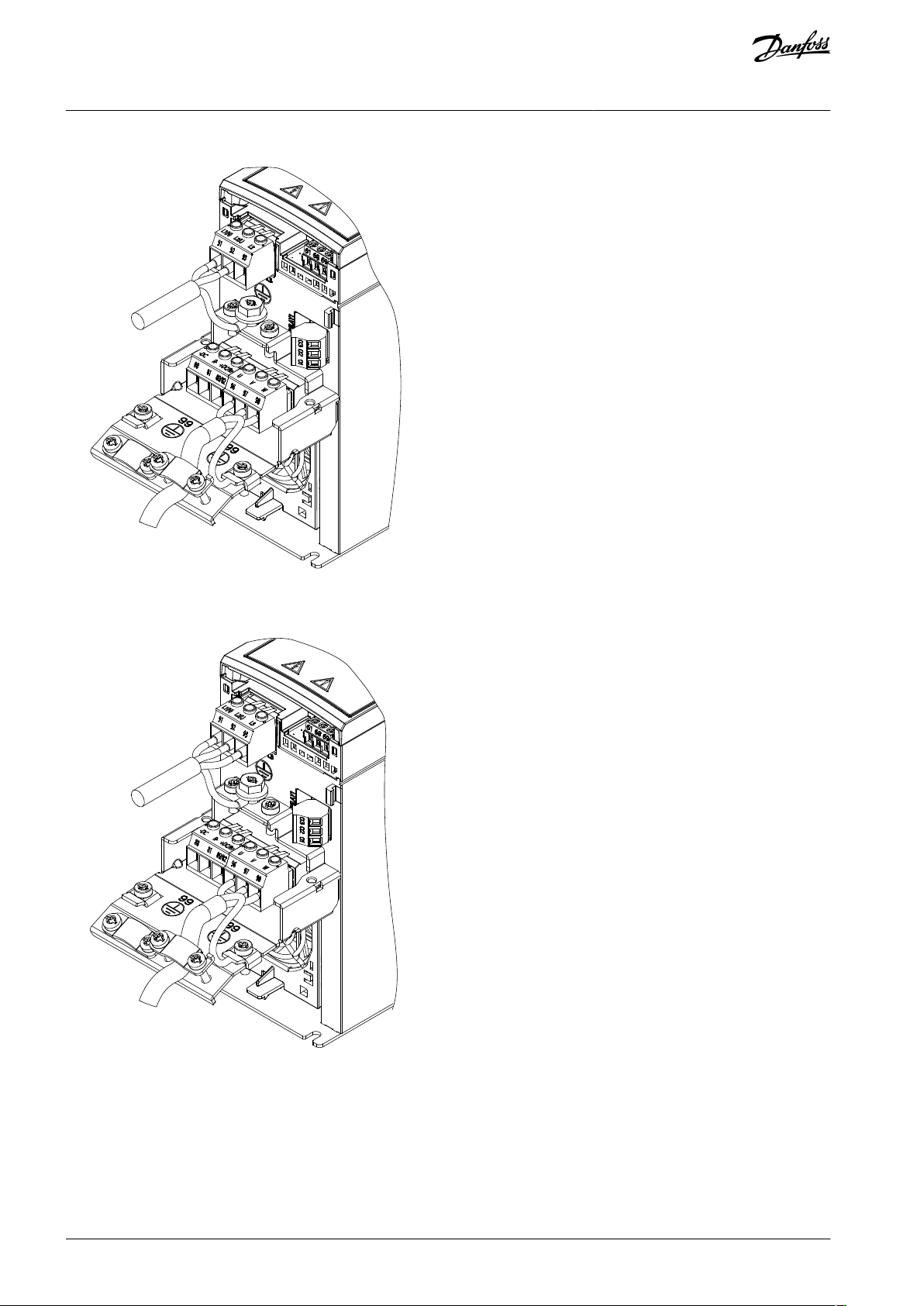

4.6 Examples of Mains, Motor, and Grounding Connection

The mains, motor, and grounding connection for single-phase and 3-phase drives are shown in the following illustrations respectively. Actual configurations vary with unit types and optional equipment.

In motors without phase insulation, paper, or other insulation reinforcement suitable for operation with voltage supply, use a

sine-wave filter on the output of the drive.

N O T I C E

AQ381425076031en-000101 / 130R1223 | 25Danfoss A/S © 2022.02

e30bu973.10

e30bu974.10

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

Illustration 12: Example of Mains, Motor, and Grounding Connection for Single-phase Units (K1, K2)

Illustration 13: Example of Mains, Motor, and Grounding Connection for 3-phase Units (K1, K2, K3)

AQ381425076031en-000101 / 130R122326 | Danfoss A/S © 2022.02

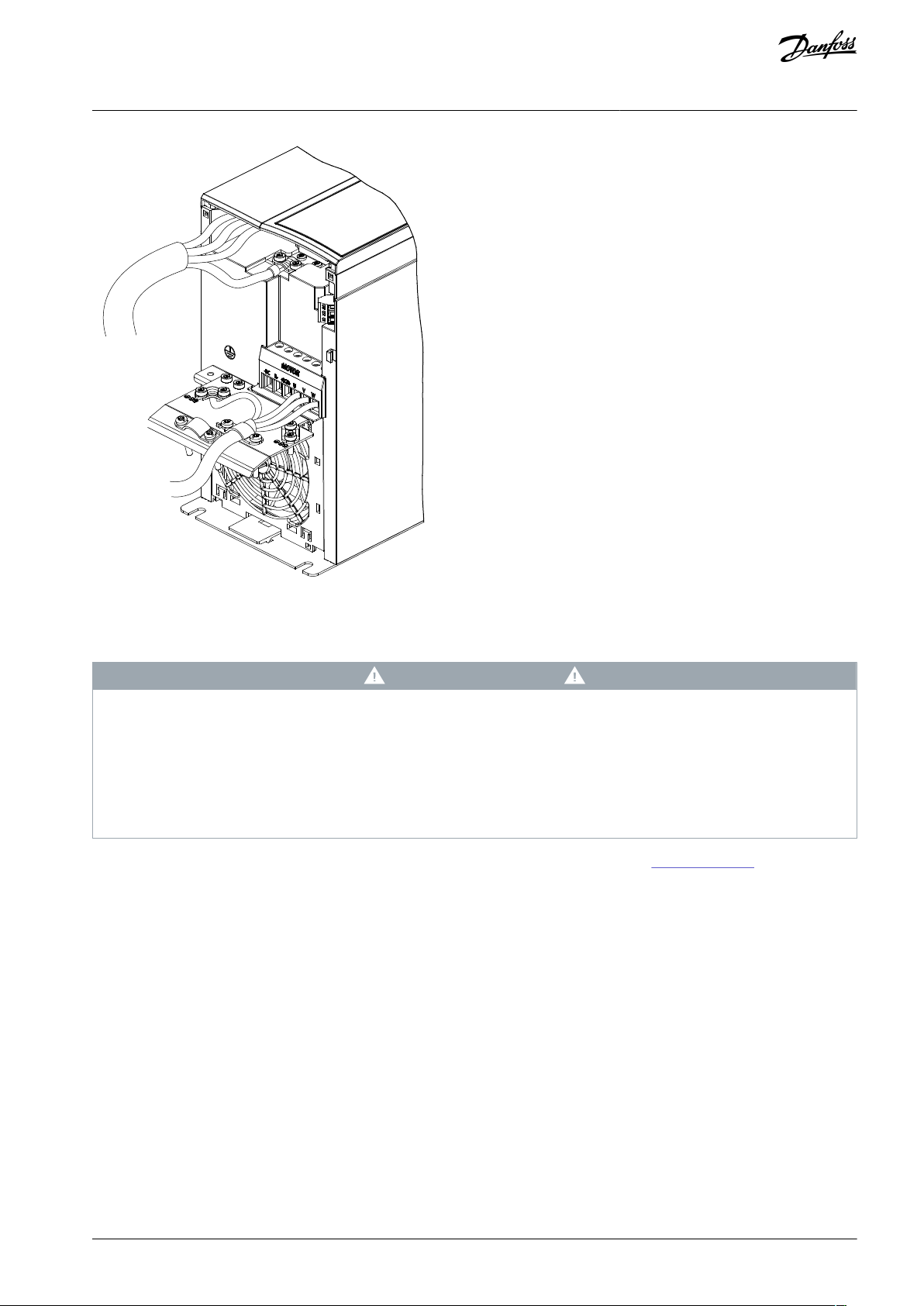

e30be804.10

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

Illustration 14: Example of Mains, Motor, and Grounding Connection for 3-phase Units (K4, K5)

4.7 Connecting the Motor

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment turned

off and locked out/tagged out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out/tag out all the drives.

-

•

Comply with local and national electrical codes for cable sizes. For maximum cable sizes, see 9.1 Electrical Data.

•

Follow motor manufacturer wiring requirements.

•

Motor wiring knockouts or access panels are provided at the base of IP21/Type 1 units.

•

Do not wire a starting or pole-changing device (for example, Dahlander motor or slip ring induction motor) between the drive

and the motor.

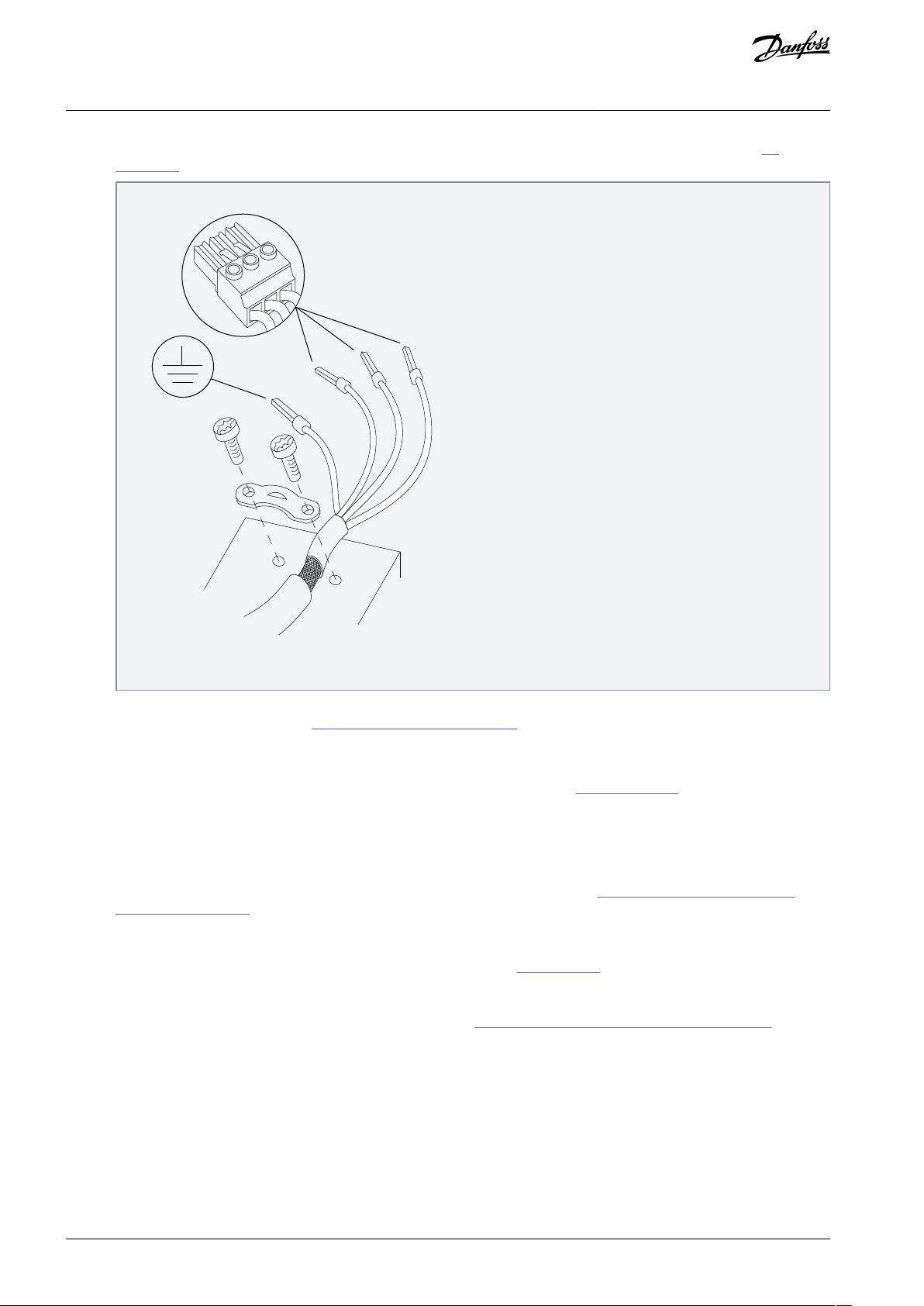

4.7.1 Grounding the Cable Shield

Procedure

1.

Strip a section of the outer cable insulation.

2.

Position the stripped wire under the cable clamp to establish mechanical fixation and electrical contact between the cable

shield and ground.

AQ381425076031en-000101 / 130R1223 | 27Danfoss A/S © 2022.02

e30bd531.11

U

V

W

96

97

98

VLT® Midi Drive FC 280

Operating Guide

3.

Connect the ground wire to the nearest grounding terminal in accordance with the grounding instructions, see 4.3

Grounding.

Electrical Installation

Illustration 15: Motor Connection

4.

Connect the 3-phase motor wiring to terminals 96 (U), 97 (V), and 98 (W).

5.

Torque-tighten the terminals, see 9.7 Connection Tightening Torques.

4.8 Connecting AC Mains

•

Size the wiring based on the input current of the drive. For maximum wire sizes, see 9.1 Electrical Data.

•

Comply with local and national electrical codes for cable sizes.

4.8.1 Connecting the Drive to Mains

Procedure

1.

Connect the AC input power cables to terminals N and L for single-phase units (see 4.6 Examples of Mains, Motor, and

Grounding Connection).

2.

3.

4.

Depending on the configuration of the equipment, connect the input power to the mains input terminals or the input disconnect.

Ground the cable in accordance with the grounding instructions, see 4.3 Grounding.

When supplied from an isolated mains source (IT mains or floating delta) or TT/TN-S mains with a grounded leg (grounded

delta), ensure that the RFI filter screw is removed. Removing the RFI screw prevents damage to the DC link and reduces

ground capacity currents in accordance with IEC 61800-3 (see 9.9 Enclosure Sizes, Power Ratings, and Dimensions, the RFI

screw is on the side of the drive).

AQ381425076031en-000101 / 130R122328 | Danfoss A/S © 2022.02

e30bu975.10

1

2

3

e30bu976.10

1 2

3

37

38 39 20 12

13

18 27

32

33 50 53

55

61 68 69

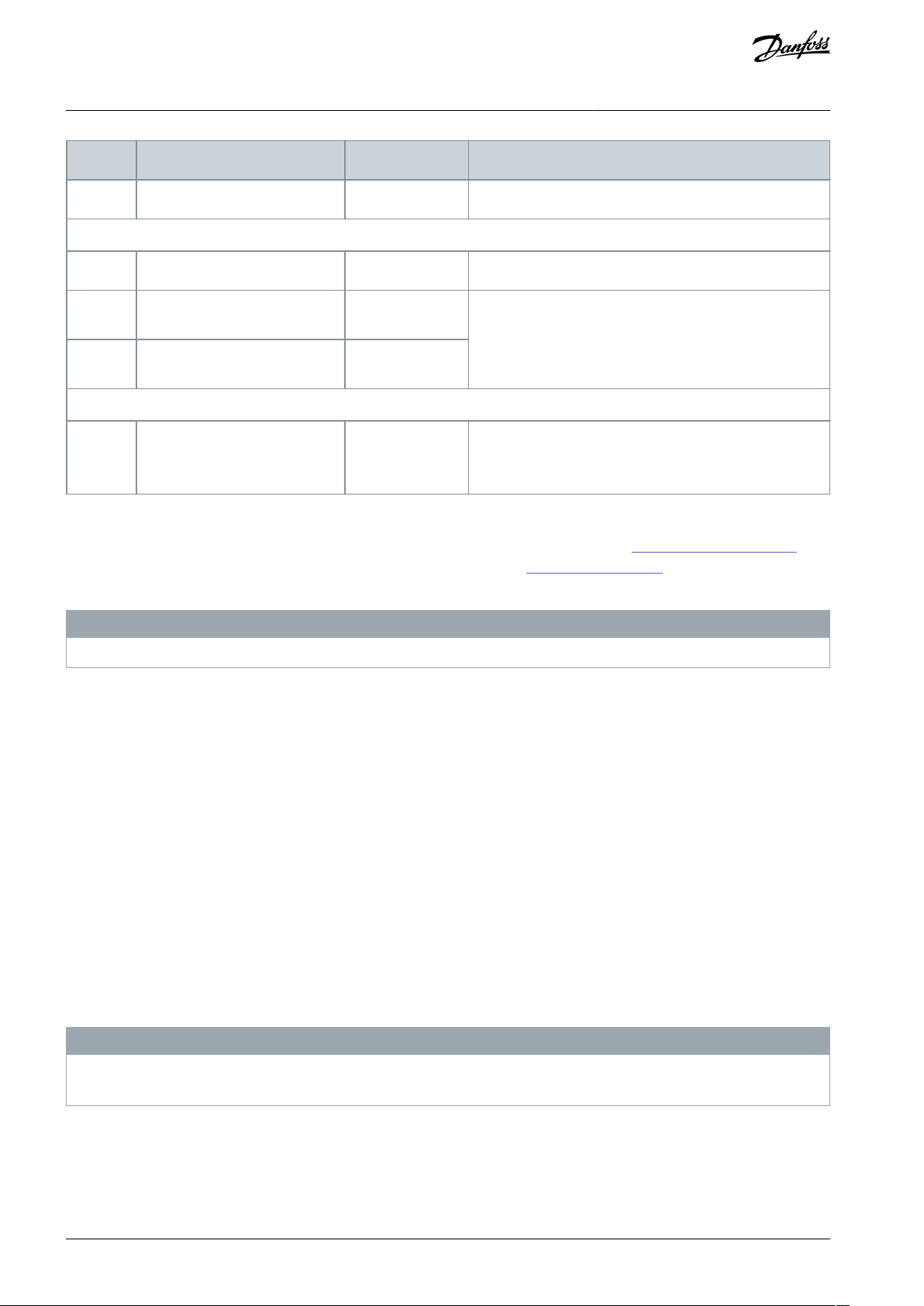

Terminal

Parameter

Default setting

Description

Digital I/O, pulse I/O, encoder

12, 13

–

+24 V DC

24 V DC supply voltage. Maximum output current is 100

mA for all 24 V loads.

18

Parameter 5-10 Terminal 18 Digital Input

[8] Start

Digital inputs.

27

Parameter 5-01 Terminal 27 Mode,

parameter 5-12 Terminal 27 Digital Input, parameter 5-30 Terminal

27 Digital Output

DI [2] Coast inverse

DO [0] No opera-

tion

Selectable for either digital input, digital output, or pulse

output. The default setting is digital input.

32

Parameter 5-14 Terminal 32 Digital Input

[0] No operation

Digital input, 24 V encoder. Terminal 33 can be used for

pulse input.

33

Parameter 5-15 Terminal 33 Digital Input

[0] No operation

37, 38

Parameter 42-20 Safe Function

[5] Disable

Functional safety inputs.

39––

Function safety COM ground.

Analog inputs/outputs

50

–

+10 V DC

10 V DC analog supply voltage. 15 mA maximum commonly used for potentiometer or thermistor.

53

Parameter group 6-1* Analog Input 53

–

Analog input. Only voltage mode is supported. It can also

be used as digital input.

VLT® Midi Drive FC 280

Operating Guide

4.9 Control Wiring

4.9.1 Control Terminal Types

Illustration 16: Control Terminal Locations

Electrical Installation

Illustration 17: Terminal Numbers

Table 4: Terminal Descriptions

AQ381425076031en-000101 / 130R1223 | 29Danfoss A/S © 2022.02

Terminal

Parameter

Default setting

Description

55, 20

––Common for digital and analog inputs.

Serial communication

61––

Connected to digital/analog ground internally.

68 (+)

Parameter group 8-3* FC Port Settings

–

RS485 interface. A control card switch is provided for termination resistance.

69 (-)

Parameter group 8-3* FC Port Settings–Relays

01, 02, 03

Parameter 5-40 Function Relay

[1] Control Ready

Form C relay output. These relays are in various locations

depending on the drive configuration and size. Usable for

AC or DC voltage and resistive or inductive loads.

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

4.9.2 Wiring to Control Terminals

Control terminal connectors can be unplugged from the drive for ease of installation, as shown in 4.9.1 Control Terminal Types.

For details about safety functions wiring, refer to chapter 6 Safety Functions. See 9.5 Cable Specifications for control terminal cable

sizes and chapter Application Examples for typical control cable connections.

N O T I C E

Keep control cables as short as possible and separate them from high-power cables to minimize interference.

4.9.2.1 Wiring

Procedure

1.

Loosen the screws for the terminals.

2.

Insert sleeved control cables into the slots.

3.

Fasten the screws for the terminals.

4.

Ensure that the contact is firmly established and not loose. Loose control wiring can be the source of equipment faults or

less than optimal operation.

4.9.3 Enabling Motor Operation (Terminal 27)

A jumper wire is required between terminal 12 (or 13) and terminal 27 for the drive to operate when using factory default programming values.

•

Digital input terminal 27 is designed to receive 24 V DC external interlock command.

•

When no interlock device is used, wire a jumper between control terminal 12 (recommended) or 13 to terminal 27. The jumper

provides an internal 24 V signal on terminal 27.

•

Only for GLCP: When the status line at the bottom of the LCP reads AUTO REMOTE COAST, it indicates that the unit is ready to

operate but is missing an input signal on terminal 27.

N O T I C E

UNABLE TO START

The drive cannot operate without a signal on terminal 27, unless terminal 27 is reprogrammed.

AQ381425076031en-000101 / 130R122330 | Danfoss A/S © 2022.02

Start Current

2)

Only support in some products.

1)

DC injection current during “Active Brake Delay” after MAV reduced to “0” . Only support in some products.

Off

On

Off

Relay / DO Status

Active Brake Delay

Active Brake Delay

MAV

Start Speed

Active Brake Speed

0

t

Start Delay

Off

On

Off

Start Command

Released

Activated

Reaction time of

mech. brake

Reaction time of

mech. brake

Mech . Brake Status

Release Brake Current

Output Current

DC Injection Current

1)

0

t

e30bf687.10

Activated

Note:

2)

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

4.9.4 Mechanical Brake Control

In hoisting/lowering applications, it is necessary to control an electro-mechanical brake.

•

Control the brake using any relay output or digital output (terminal 27).

•

Keep the output closed (voltage-free) as long as the drive is unable to keep the motor at standstill, for example due to the load

being too heavy.

•

Select [32] Mechanical brake control in parameter group 5-4* Relays for applications with an electro-mechanical brake.

•

The brake is released when the motor current exceeds the preset value in parameter 2-20 Release Brake Current.

•

The brake is engaged when the output frequency is less than the frequency set in parameter 2-22 Activate Brake Speed [Hz], and

only if the drive carries out a stop command.

If the drive is in 1 of the following situations, the mechanical brake immediately closes.

In alarm mode.

•

In an overvoltage situation.

•

STO is activated.

•

Coast command is given.

•

Illustration 18: Mechanical Brake

The drive is not a safety device. It is the responsibility of the system designer to integrate safety devices according to relevant national crane/lift regulations.

AQ381425076031en-000101 / 130R1223 | 31Danfoss A/S © 2022.02

e30be201.12

L1(N) L2(L) L3

U V W

02 01

A1

A2

Drive

Output

relay

Command circuit

220 V AC

Mechanical

brake

ShaftMotor

Freewheeling

diode

Brake power circuit

380 V AC

Output

contactor

input

e30bt623.12

VLT® Midi Drive FC 280

Operating Guide

Illustration 19: Connecting the Mechanical Brake to the Drive

Electrical Installation

4.9.5 USB Data Communication

Illustration 20: Network Bus List

When the USB cable is disconnected, the drive connected via the USB port is removed from the Network bus list.

N O T I C E

CONNECT 1 DRIVE VIA USB TO PC

A USB bus has no address-setting capacity and no bus name to configure. If connecting more than 1 drive through USB, the bus

name is auto-incremented in the MCT 10 Set-up Software Network bus list.

Connecting more than 1 drive through a USB cable often causes computers installed with Windows to throw an exception and

crash.

-

4.9.6 Serial Communication

Connect RS485 serial communication wiring to terminals (+) 68 and (-) 69.

•

•

Only connect 1 drive via USB to the PC.

Shielded serial communication cable is recommended.

See 4.3 Grounding for proper grounding.

AQ381425076031en-000101 / 130R122332 | Danfoss A/S © 2022.02

•

•

•

•

•

•

•

•

•

61

68

69

+

e30bb489.10

RS485

Inspect for

Description

✓

Auxiliary equipment

Look for auxiliary equipment, switches, disconnects, or input fuses/circuit breakers, residing on the

input power side of the drive, or output side to the motor. Ensure that they are ready for full-speed

operation.

Check the function and installation of any sensors used for feedback to the drive.

Remove any power factor correction capacitors on the motor.

Adjust any power factor correction capacitors on the mains side and ensure that they are dampened.

Cable routing

Ensure that the motor wiring and control wiring are separated, shielded, or in 3 separate metallic conduits for high frequency interference isolation.

Control wiring

Check for broken or damaged wires and loose connections.

Check that the control wiring is isolated from power and motor wiring for noise immunity.

Check the voltage source of the signals, if necessary.

The use of shielded cable or twisted pair is recommended. Ensure that the shield is terminated correctly.

Cooling clearance

Ensure that the top and bottom clearance is adequate to ensure proper airflow for cooling, see chap-

ter Mounting.

VLT® Midi Drive FC 280

Operating Guide

Illustration 21: Serial Communication Wiring Diagram

Electrical Installation

For basic serial communication set-up, select the following:

•

Protocol type in parameter 8-30 Protocol.

•

Drive address in parameter 8-31 Address.

•

Baud rate in parameter 8-32 Baud Rate.

Two communication protocols are internal to the drive.

Danfoss FC

•

Modbus RTU

•

Follow motor manufacturer wiring requirements.

Functions can be programmed remotely using the protocol software and RS485 connection, or in parameter group 8-** Communica-

tions and Options.

Selecting a specific communication protocol changes various default parameter settings to match the specifications of the protocol

and makes extra protocol-specific parameters available.

4.10 Installation Check List

Before completing installation of the unit, inspect the entire installation as detailed in

completed.

Table 5: Installation Check List

Table 5. Check and mark the items when

AQ381425076031en-000101 / 130R1223 | 33Danfoss A/S © 2022.02

•

•••

•••••

•••

Inspect for

Description

✓

Ambient conditions

Check that requirements for ambient conditions are met.

Fusing and circuit breakers

Check for proper fusing or circuit breakers.

Check that all fuses are inserted firmly and are in operational condition, and that all circuit breakers

are in the open position.

Grounding

Check for sufficient ground connections and ensure that those connections are tight and free of oxidation.

Grounding to conduit, or mounting the back panel to a metal surface, is not a suitable grounding.

Input and output power wiring

Check for loose connections.

Check that the motor and mains cables are in separate conduit or separated shielded cables.

Panel interior

Inspect that the unit interior is free of dirt, metal chips, moisture, and corrosion.

Check that the unit is mounted on an unpainted metal surface.

Switches

Ensure that all switch and disconnect settings are in the proper positions.

Vibration

Check that the unit is mounted solidly, or that shock mounts are used, as necessary.

Check for an unusual amount of vibration.

VLT® Midi Drive FC 280

Operating Guide

Electrical Installation

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AQ381425076031en-000101 / 130R122334 | Danfoss A/S © 2022.02

VLT® Midi Drive FC 280

Operating Guide

Commissioning

5 Commissioning

5.1 Safety Instructions

See chapter Safety for general safety instructions.

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

N O T I C E

The front covers with warning signs are an integrated part of the drive and considered safety covers. The covers must be in place

before applying power and at all times.

5.1.1 Before Applying Power

Procedure

1.

Close the safety cover properly.

2.

Check that all cable glands are firmly tightened.

3.

Ensure that input power to the unit is off and locked out. Do not rely on the drive disconnect switches for input power

isolation.

4.

Verify that there is no voltage on input terminals L1 (91), L2 (92), and L3 (93), phase-to-phase, and phase-to-ground.

5.

Verify that there is no voltage on output terminals 96 (U), 97 (V), and 98 (W), phase-to-phase, and phase-to-ground.

6.

Confirm continuity of the motor by measuring Ω values on U–V (96–97), V–W (97–98), and W–U (98–96).

7.

Check for proper grounding of the drive and the motor.

8.

Inspect the drive for loose connections on the terminals.

9.

Confirm that the supply voltage matches the voltage of the drive and the motor.

5.2 Applying Power

Procedure

1.

Confirm that the input voltage is balanced within 3%. If not, correct the input voltage imbalance before proceeding. Repeat

this procedure after the voltage correction.

2.

Ensure that any optional equipment wiring matches the installation application.

3.

Ensure that all operator devices are in the OFF position. Panel doors must be closed and covers securely fastened.

4.

Apply power to the unit. Do not start the drive now. For units with a disconnect switch, turn it to the ON position to apply

power to the drive.

5.3 Local Control Panel Operation

5.3.1 Introduction

The drive supports numerical local control panel (NLCP), graphic local control panel (GLCP), and blind cover. This section describes

the operations with NLCP and GLCP.

N O T I C E

The drive can also be programmed from the MCT-10 Set-up Software on PC via RS485 com-port. This software can be or-

-

dered using code number 130B1000 or downloaded from the Danfoss website: www.danfoss.com/en/service-and-support/

downloads/dds/vlt-motion-control-tool-mct-10/#tab-downloads.

AQ381425076031en-000101 / 130R1223 | 35Danfoss A/S © 2022.02

e30bc506.10

Setup 1

A

B

C

D

5

12

13

14

15

10

11

10

9

6

7

8

4

1

2

3

Menu

Sta

tus

Quick

Menu

Main

Menu

Hand

On

Off

Reset

Auto

On

Back

OK

On

Warn

Alarm

Number

Function

1

The set-up number shows the active set-up and the edit set-up. If the same set-up acts as both active and edit set-up,

only that set-up number is shown (factory setting). When active and edit set-ups differ, both numbers are shown in

the display (set-up 12). The number flashing indicates the edit set-up.

2

Parameter number.

3

Parameter value.

4

Motor direction is shown at the bottom left of the display. A small arrow indicates the direction.

5

The triangle indicates whether the LCP is in Status, Quick Menu, or Main Menu.

VLT® Midi Drive FC 280

Operating Guide

5.3.2 Numerical Local Control Panel

The numerical local control panel is divided into 4 functional sections.

•

A. Numeric display.

•

B. Menu key.

•

C. Navigation keys and indicator lights (LEDs).

•

D. Operation keys and indicator lights (LEDs).

Commissioning

Illustration 22: View of the NLCP

A. Numeric display

The LCD display is backlit with 1 numeric line. All data is shown in the LCP.

Table 6: Legend to Section A

AQ381425076031en-000101 / 130R122336 | Danfoss A/S © 2022.02

•

•

e30bd135.10

Setup 1234

INDEX

AHP

VkW

srpm

Hz%

n2n1

n3

p5

p4

p3

p2 p1

Number

Indicator

Light

Function

6OnGreen

ON turns on when the drive receives power from the mains voltage, a DC bus terminal, or a 24 V

external supply.

7

Warn

Yellow

When warning conditions are met, the yellow WARN LED turns on, and text appears in the display area identifying the problem.

8

Alarm

Red

A fault condition causes the red alarm LED to flash and an alarm text is shown.

Number

Key

Function

9

Back

For moving to the previous step or layer in the navigation structure.

10

[▵][▿]

For switching between parameter groups, parameters, and within parameters, or increasing/decreasing parameter values. Arrows can also be used for setting local reference.

11

[OK]

Press to access parameter groups or to enable a selection.

12

[▹]

Press to move from left to right within the parameter value to change each digit individually.

Number

Key

Function

13

Hand On

Starts the drive in local control.

An external stop signal by control input or serial communication overrides the local hand on.

14

Off/Reset

Stops the motor but does not remove power to the drive, or resets the drive manually after a fault has

been cleared. If in alarm mode, the alarm is reset if the alarm condition is removed.

15

Auto On

Puts the system in remote operational mode.

Responds to an external start command by control terminals or bus communication.

VLT® Midi Drive FC 280

Operating Guide

Illustration 23: Display Information

B. Menu key

To select between Status, Quick Menu, or Main Menu, press [Menu].

C. Indicator lights (LEDs) and navigation keys

Table 7: Legend to Section C, Indicator Lights (LEDs)

Commissioning

Table 8: Legend to Section C, Navigation Keys

D. Operation keys and indicator lights (LEDs)

Table 9: Legend to Section D

AQ381425076031en-000101 / 130R1223 | 37Danfoss A/S © 2022.02

e30bc440.10

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

VLT® Midi Drive FC 280

Operating Guide

Commissioning

W A R N I N G

ELECTRICAL HAZARD

Even after pressing the [Off/Reset] key, voltage is present at the terminals of the drive. Pressing the [Off/Reset] key does not disconnect the drive from mains. Touching live parts can result in death or serious injury.

Do not touch any live parts.

-

5.3.3 The Right-key Function on NLCP

Press [▹] to edit any of the 4 digits on the display individually. When pressing [▹] once, the cursor moves to the first digit and the

digit starts flashing as shown in Illustration 24. Press the [▵] [▿] to change the value. Pressing [▹] does not change the value of the

digits or move the decimal point.

Illustration 24: Right-key Function

[▹] can also be used for moving between parameter groups. When in Main Menu, press [▹] to move to the first parameter in the next

parameter group (for example, move from parameter 0-03 Regional Settings [0] International to parameter 1-00 Configuration

Mode [0] Open loop).

5.3.4 Quick Menu on NLCP

5.3.4.1 Operating Quick Menu

The Quick Menu gives easy access to the most frequently used parameters.

Procedure

1.

To enter Quick Menu, press [Menu] until the indicator in display is placed above Quick Menu.

AQ381425076031en-000101 / 130R122338 | Danfoss A/S © 2022.02

e30bc445.13

1-22 XXXX V

Motor

nominal

speed

QM 1

0-01

[0]

1-10 [0]

1-24 XXXX A

Language

Motor Type

1-20 XXXX kW

Motor power

Motor voltage

1-26 XXXX 1-23 XXXX

Stator

Motor frequency

1-25 XXXX

1-30 XXXX

1-39 XXXX

1-40 XXXX

1-37 XXXX

1-25 XXXX

1-24 XXXX

A

3-02 XXXX

3-03 XXXX

3-41 XXXX S

3-42 XXXX S

5-12

[2]

1-29 [1] AMA

Back EMF at

1000 RPM

d-axis

QM 2

BMS

AMS

ES

5-70 XXXX

5-71

[0]

1-30 XXXX

1-39 XXXX

1-90

[0]

2-10 [0]

4-16 XXXX %

4-17 XXXX %

4-18 XXXX %

1-00 [0]

1-01 [1]

1-10 [0]

1-24 XXXX A 1-20 XXXX kW

1-22 XXXX V

Motor

nominal

speed

Motor power

Motor voltage

1-26 XXXX 1-23 XXXX

Motor frequency

1-25 XXXX

1-30 XXXX

1-40 XXXX

1-37 XXXX

1-25 XXXX

1-24 XXXX

A

Back EMF at

1000 RPM

d-axis

1-39 XXXX

4-14 XXXX

4-19 XXXX

Stator

QM 3

QM 4 QM 5

L10C

SFS

TBD

Motor

nominal

speed

Motor

nominal

speed

Motor current

Motor cont.

rated torque

Resistance (Rs)

Motor poles

inductance (Ld)

Asynchronous motor

Motor current

Minimum reference

Maximum reference

Ramp 1 ramp-up time

Ramp 1 ramp-down time

Terminal 27 digital input

Basic motor set-up

mode

Motor control

principle

Motor type

PM motor

PM motor

Motor

current

Motor cont.

rated torque

Stator

Resistance (Rs)

Motor poles

inductance (Ld)

Motor speed high limit [Hz]

Maximum output frequency

Asynchronous motor

Motor current

RPM

RPM

RPM

Hz

RPM

Hz

Hz

Hz

Hz

Hz

Adv. motor set-up

Resistance (Rs)

Motor poles

Motor thermal

protection

Brake function

Torque limit motor mode

Torque limit generator mode

Current limit

Encoder set-up

Terminal 32/33

pulses per revolution

Terminal 32/33

encoder direction

Changes made

Last 10 changes Since factory setting

Alarm log

VLT® Midi Drive FC 280

Operating Guide

2.

Press [▵] [▿] to select either QM1 or QM2, then press [OK].

3.

Press [▵] [▿] to browse through the parameters in Quick Menu.

Press [OK] to select a parameter.

4.

Press [▵] [▿] to change the value of a parameter setting.

5.

Press [OK] to accept the change.

6.

7.

To exit, press either [Back] twice (or 3 times if in QM2 and QM3) to enter Status, or press [Menu] once to enter Main Menu.

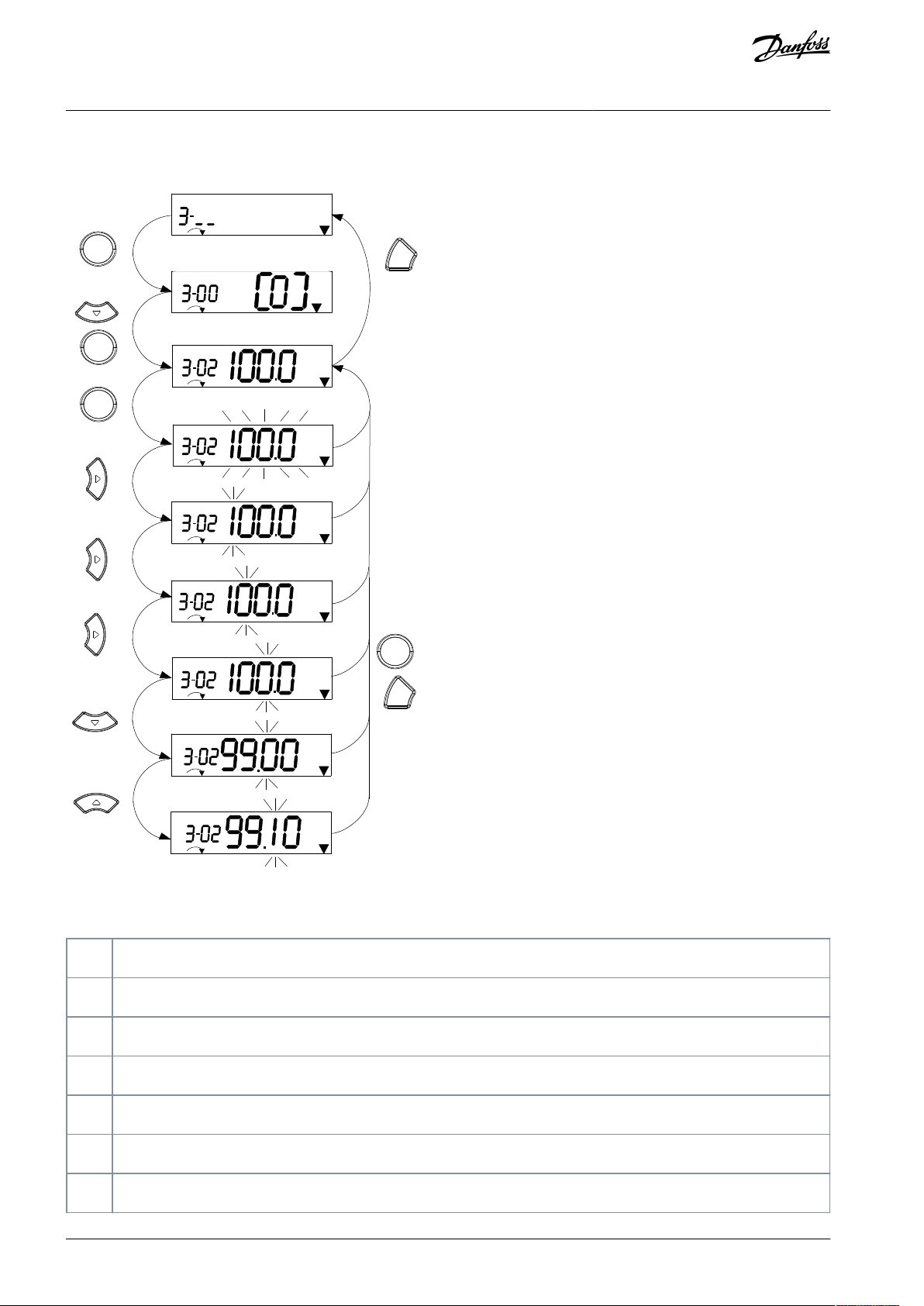

5.3.4.2 Quick Menu Structure

Commissioning

Illustration 25: Quick Menu Structure

5.3.5 Main Menu on NLCP

5.3.5.1 Operating Main Menu

The Main Menu gives access to all parameters.

Procedure

AQ381425076031en-000101 / 130R1223 | 39Danfoss A/S © 2022.02

1.

To enter Main Menu, press [Menu] until the indicator in the display is placed above Main Menu.

2.

[▵] [▿]: Browse through the parameter groups.

3.

Press [OK] to select a parameter group.

4.

[▵] [▿]: Browse through the parameters in the specific group.

5.

Press [OK] to select the parameter.

6.

[▹] and [▵] [▿]: Set/change the parameter value.

7.

Press [OK] to accept the value.

8.

To exit, press either [Back] twice (or 3 times for array parameters) to enter Main Menu, or press [Menu] once to enter Status.

e30bc446.10

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

1

2

3

4

5

6

7

10

11

12

OK

OK

Back

8

Back

Setup 1

2 x

+

OK

9

OK

1

[OK]: The first parameter in the group is shown.

2

Press [▿] repeatedly to move down to the parameter.

3

Press [OK] to start editing.

4

[▹]: First digit flashing (can be edited).

5

[▹]: Second digit flashing (can be edited).

6

[▹]: Third digit flashing (can be edited).

7

[▿]: Decreases the parameter value, the decimal point changes automatically.

VLT® Midi Drive FC 280

Operating Guide

5.3.5.2 Continuous Parameters

Commissioning

Illustration 26: Main Menu Interactions - Continuous Parameters

Table 10: Changing Values in Continuous Parameters

AQ381425076031en-000101 / 130R122340 | Danfoss A/S © 2022.02

8

[▵]: Increases the parameter value.

9

[Back]: Cancel changes, return to 2.

[OK]: Accept changes, return to 2.

10

[▵][▿]: Select parameter within the group.

11

[Back]: Removes the value and shows the parameter group.

12

[▵][▿]: Select group.

e30bc447.11

Setup 1

Setup 1

Setup 1

1

2

3

4

5

6

OK

OK

Back

7

OK

Back

1

[OK]: The first parameter in the group is shown.

2

Press [OK] to start editing.

3

[▵][▿]: Change parameter value (flashing).

4

Press [Back] to cancel changes or [OK] to accept changes (return to screen 2).

5

[▵][▿]: Select a parameter within the group.

6

[Back]: Removes the value and shows the parameter group.

7

[▵][▿]: Select a group.

VLT® Midi Drive FC 280

Operating Guide

Commissioning

5.3.5.3 Enumerated Parameters

For enumerated parameters, the interaction is similar, but the parameter value is shown in brackets because of the digits limitation

(4 large digits) on the NLCP, and the enum can be greater than 99. When the enum value is greater than 99, the LCP can only show

the first part of the bracket.

Illustration 27: Main Menu Interactions - Enumerated Parameters

Table 11: Changing Values in Enumerated Parameters

AQ381425076031en-000101 / 130R1223 | 41Danfoss A/S © 2022.02

e30bc448.10

1

2

4

5

6

7

8

9

10

OK

Back

Back

Back

5 x

Setup 1

Setup 1

Setup 1

Setup 1

%

INDEX

%

INDEX

%

INDEX

Setup 1

INDEX

%

OK

OK

OK

1

[OK]: Shows parameter numbers and the value in the first index.

2

[OK]: Index can be selected.

3

[▵][▿]: Select index.

4

[OK]: Value can be edited.

5

[▵][▿]: Change parameter value (flashing).

6

[Back]: Cancels changes.

[OK]: Accepts changes.

7

[Back]: Cancels editing index, selects a new parameter.

8

[▵][▿]: Select parameter within the group.

9

[Back]: Removes parameter index value and shows the parameter group.

10

[▵][▿]: Select group.

VLT® Midi Drive FC 280

Operating Guide

5.3.5.4 Array Parameters

Commissioning

Illustration 28: Main Menu Interactions - Array Parameters

Table 12: Changing Values in Array Parameters

5.3.6 Graphical Local Control Panel

The GLCP is divided into 4 functional groups.

•

A. Display area.

•

B. Display menu keys.

•

C. Navigation keys and indicator lights (LEDs).

•

D. Operation keys and reset.

AQ381425076031en-000101 / 130R122342 | Danfoss A/S © 2022.02

e30bd598.10

Auto

On

Reset

Hand

On

Off

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(1)

36.4 kW

Auto Remote Ramping

0.000

On

Alarm

Warn.

A

7.83 A

799 RPM

B

C

D

53.2 %

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 20 21

Display

Parameter number

Default setting

1

0-20

[1602] Reference [%]

2

0-21

[1614] Motor Current

3

0-22

[1610] Power [kW]

4

0-23

[1613] Frequency

5

0-24

[1502] kWh Counter

VLT® Midi Drive FC 280

Operating Guide

Commissioning

Illustration 29: Graphic Local Control Panel (GLCP)

A. Display area

The display area is activated when the drive receives power from the mains voltage, a DC bus terminal or a 24 V DC external supply.

The information shown on the LCP can be customized for user applications. Select options in the Quick Menu Q3-13 Display Settings.

Table 13: Legend to Section A

B. Display menu keys

Menu keys are used for menu access for parameter set-up, toggling through status display modes during normal operation, and

viewing fault log data.

AQ381425076031en-000101 / 130R1223 | 43Danfoss A/S © 2022.02

•

Number

Key

Function

6

Status

Shows operational information.

7

Quick Menu

Allows access to programming parameters for initial set-up instructions and many detailed application

instructions.

8

Main Menu

Allows access to all programming parameters.

9

Alarm Log

Shows a list of current warnings, the last 10 alarms, and the maintenance log.

Number

Key

Function

10

Back

Reverts to the previous step or list in the menu structure.

11

Cancel

Cancels the last change or command as long as the display mode has not changed.

12

Info

Press for a definition of the function being shown.

13

Navigation keys

To move between items in the menu, use the 4 navigation keys.

14OKPress to access parameter groups or to enable a selection.

Number

Indicator

Light

Function

15OnGreen

ON turns on when the drive receives power from the mains voltage, a DC bus terminal or a 24 V

DC external supply.

16

Warn

Yellow

When warning conditions are met, the yellow WARN LED turns on, and text appears in the display area identifying the problem.

17

Alarm

Red

A fault condition causes the red alarm LED to flash, and an alarm text is shown.

Number

Key

Function

18

Hand On

Starts the drive in hand-on mode.

An external stop signal by control input or serial communication overrides the local hand on.

19

Off

Stops the motor but does not remove power to the drive.

20

Auto On

Puts the system in remote operational mode.

VLT® Midi Drive FC 280

Operating Guide

Table 14: Legend to Section B

Commissioning

C. Navigation keys and indicator lights (LEDs)

Navigation keys are used for programming functions and moving the display cursor. The navigation keys also provide speed control

in local operation. There are also 3 drive status indicator lights in this area.

Table 15: Legend to Section C, Navigation Keys

Table 16: Legend to Section C, Indicator Lights (LEDs)

D. Operation keys and reset

Operation keys are at the bottom of the LCP.

Table 17: Legend to Section D

AQ381425076031en-000101 / 130R122344 | Danfoss A/S © 2022.02

•

Number

Key

Function

Responds to an external start command by control terminals or serial communication.

21

Reset

Resets the drive manually after a fault has been cleared.

VLT® Midi Drive FC 280

Operating Guide

Commissioning

N O T I C E

To adjust the display contrast, press [Status] and the [▵]/[▿] keys.

5.3.7 Parameter Settings

Establishing the correct programming for applications often requires setting functions in several related parameters.

Programming data is stored internally in the drive.

•

For back-up, upload data into the LCP memory.

•

To download data to another drive, connect the LCP to that unit and download the stored settings.

•

Restoring factory default settings does not change data stored in the LCP memory.

5.3.8 Changing Parameter Settings with GLCP

5.3.8.1 Introduction

Access and change parameter settings from the Quick Menu or from the Main Menu. The Quick Menu only gives access to a limited

number of parameters.

5.3.8.2 Changing Parameter Settings

Procedure

1.