Operating Guide

VLT® AQUA Drive FC 202

110-800 kW, D9h-D10h and E5h-E6h Enclosed Drives

drives.danfoss.com

VLT® AQUA Drive FC 202

Operating Guide

Contents

1

Introduction 8

1.1

Purpose of this Operating Guide 8

Additional Resources 8

1.2

Manual Version 8

1.3

1.4

Approvals and Certifications 8

1.5

Finding the Declaration of Conformity Certificate 9

1.6

Declaration of Conformity Certificate 10

Safety 14

2

Safety Symbols 14

2.1

Qualified Personnel 14

2.2

Safety Precautions 15

2.3

3

Product Overview 17

Contents

3.1

Intended Use 17

3.2

What is an Enclosed Drive? 17

3.3

Location of Options within an Enclosed Drive 20

3.4

Drive Identification 22

3.4.1

Identifying the Drive and Its Options 22

3.4.2

Enclosure Size Identification 23

3.4.3

Type Code Identification 24

3.5

Power Ratings, Weight, and Dimensions 31

3.6

Control Compartment and Local Control Panel 33

3.6.1

Control Compartment Overview 33

3.6.2

Control Compartment Door 34

3.6.3

Local Control Panel (LCP) 35

3.6.4

LCP Menu 37

4

Mechanical Installation 39

4.1

Items Supplied 39

4.2

Split Shipment 39

4.3

Tools Needed 40

4.4

Storing the Drive 40

4.5

Operating Environment 40

4.5.1

Overview 40

4.5.2

Gases 40

4.5.3

Dust 40

4.5.4

Potentially Explosive Atmospheres 41

AQ262141056213en-000201/130R0882 | 3Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

4.6

Installation Requirements 41

4.7

Cooling Requirements 42

4.8

Airflow Rates 42

4.9

Lifting the Drive 44

4.10

Combining Multiple Cabinets from a Split Shipment 44

4.11

Installing the Enclosed Drive 46

4.11.1

Creating an Entry for Cables 46

4.11.2

Installing the Drive with Back-channel Cooling Option 46

4.11.3

Securing the Cabinet(s) to the Floor 47

5

Electrical Installation 49

5.1

Safety Instructions 49

5.2

EMC-compliant Installation 49

5.3

Wiring Overview for D9h and D10h Enclosed Drives 53

5.4

Wiring Overview for E5h and E6h Enclosed Drives 54

Contents

5.5

Control Terminal Wiring Diagram Cross-reference 55

5.6

Split Shipment Wiring Harnesses 56

5.6.1

Connecting Wiring Harnesses 56

5.6.2

Cable Routing 57

5.6.3

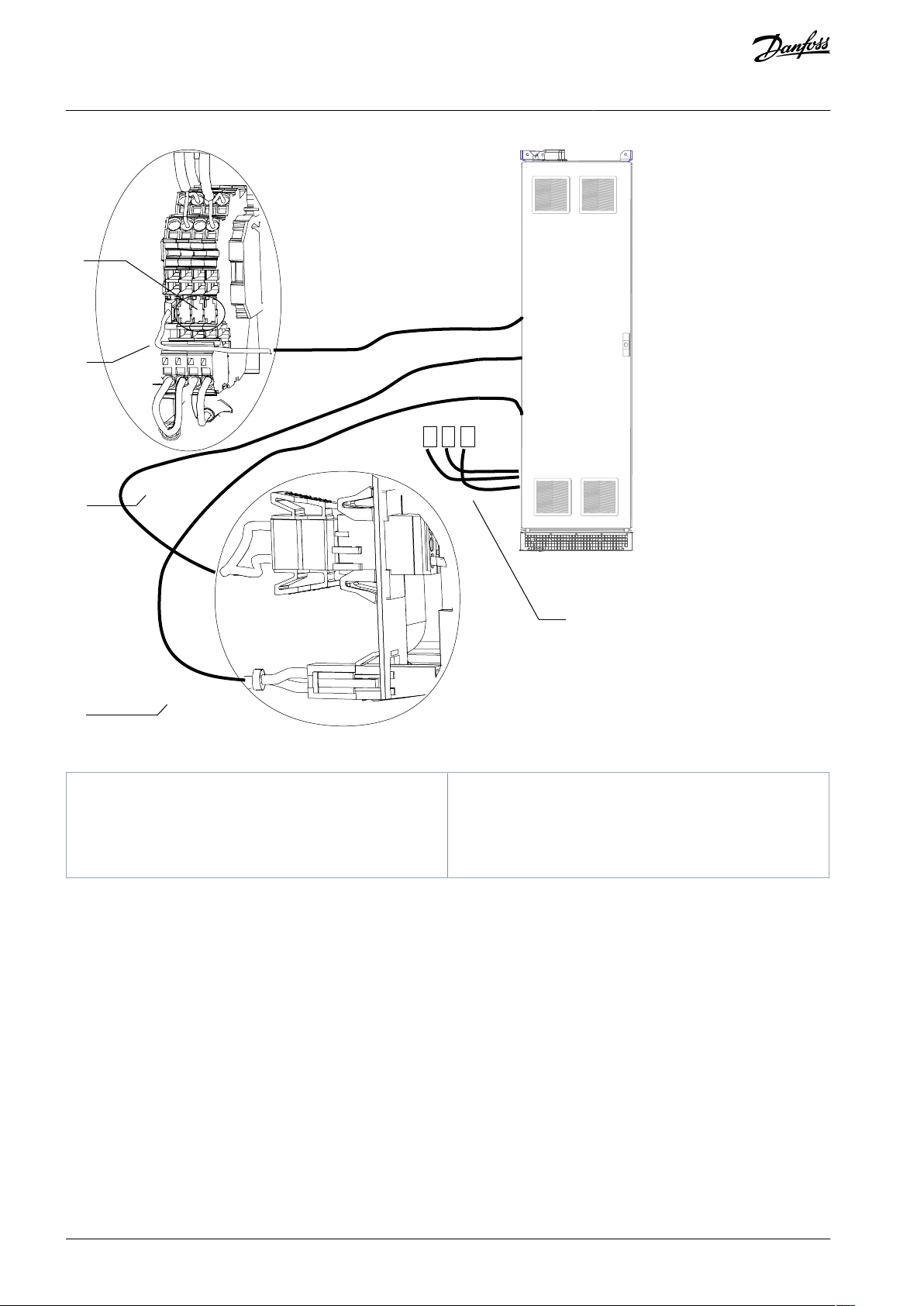

D10h Wiring Harness 65

5.6.4

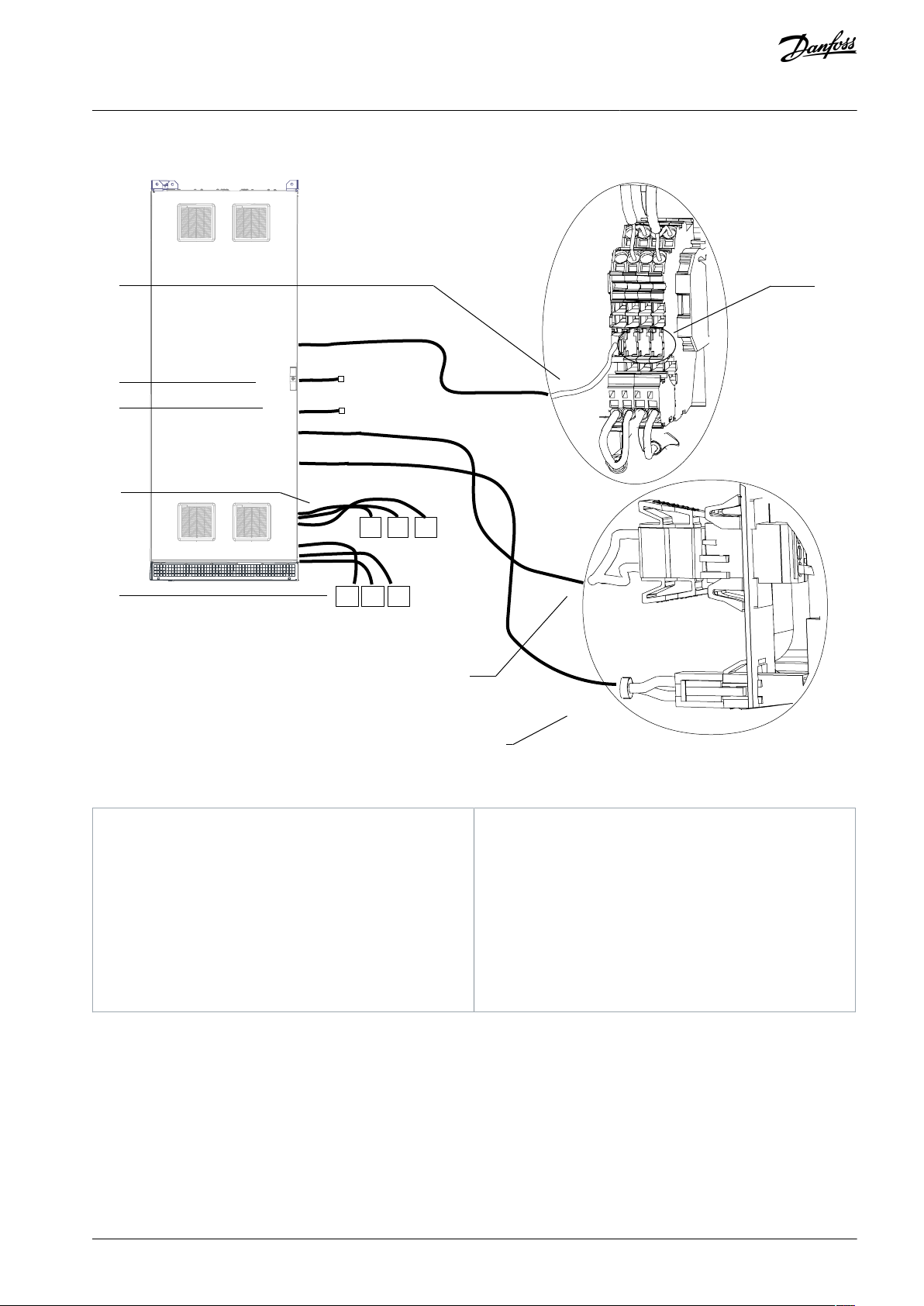

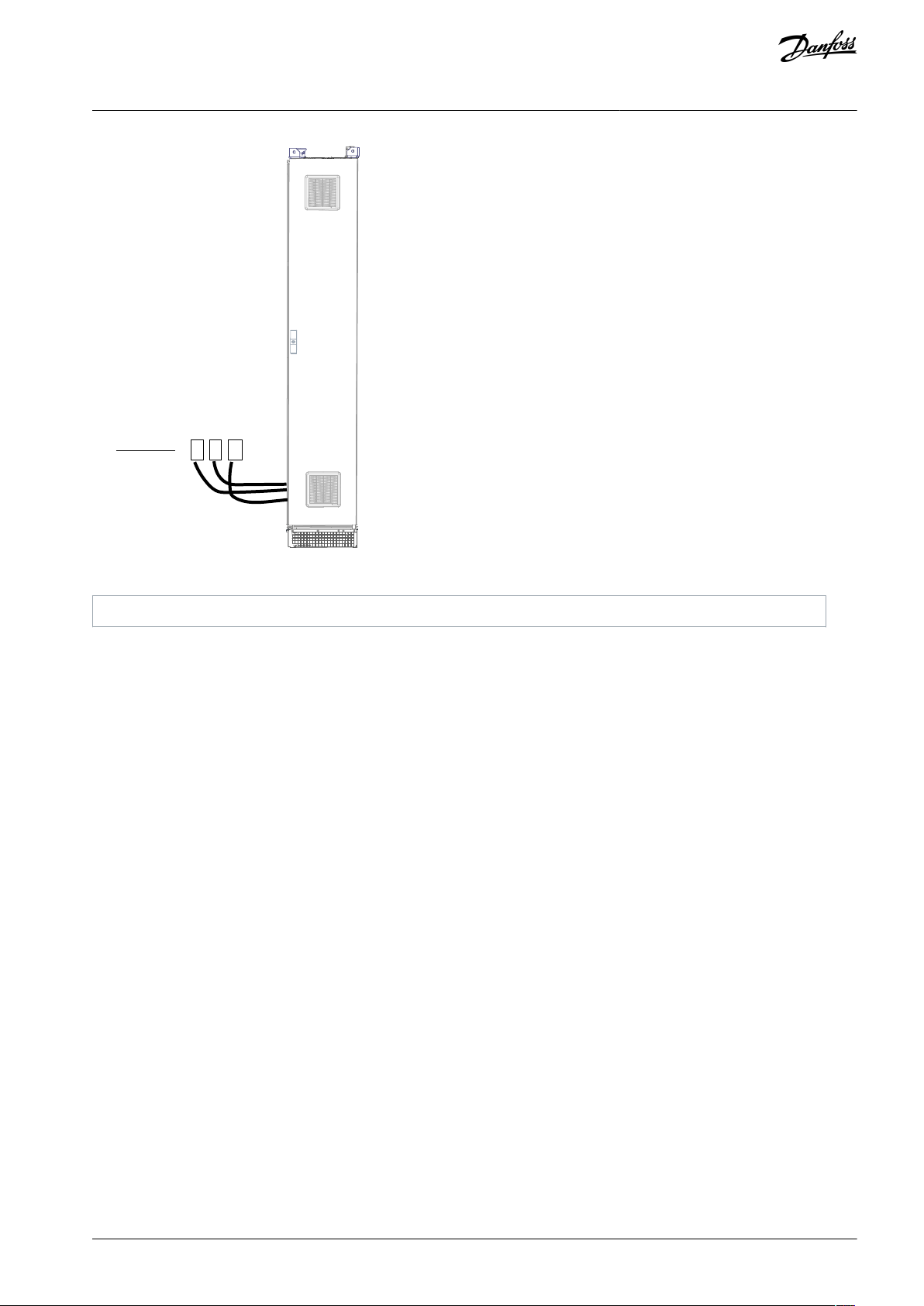

E5h Wiring Harness 69

5.6.5

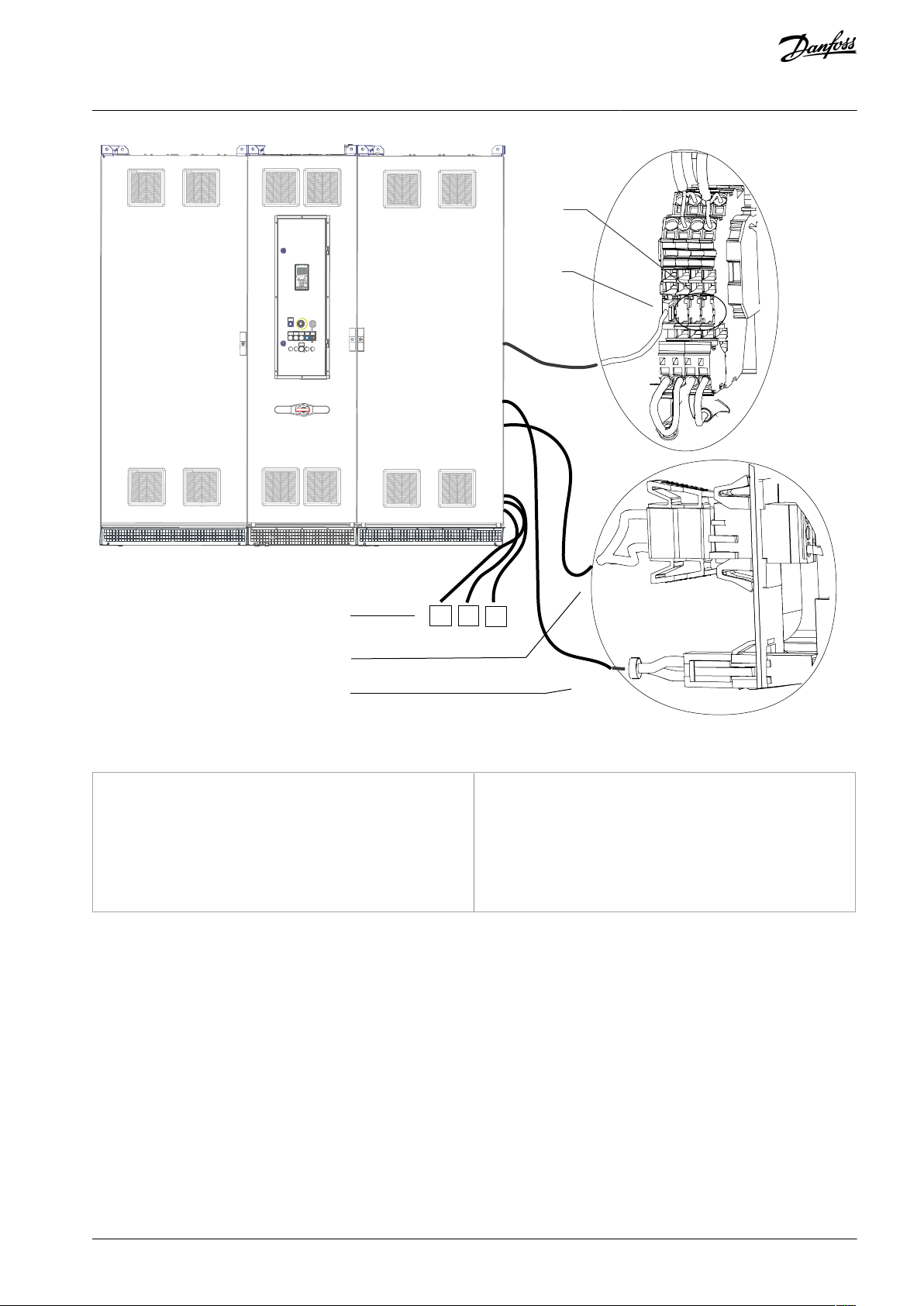

E6h Wiring Harness 75

5.7

Control Compartment Wiring 81

5.7.1

Safety Precautions 81

5.7.2

Control Compartment Interior View 82

5.7.3

Control Terminals 83

5.7.4

Relay Terminals 84

5.7.5

Option Card Terminals 84

5.7.6

Control Compartment Options 88

5.8

Connecting Motor, Mains, and Ground Cables 95

5.8.1

Power Cabling and Grounding Considerations 95

5.8.2

Connecting to the Mains 96

5.8.3

Connecting the Drive Module to the Motor 98

5.8.4

Connecting the Sine-wave Filter to the Motor 100

5.8.5

Connecting the dU/dt Filter to the Motor 101

5.8.6

Connecting to Ground 103

5.9

Installing Upstream Fuses 104

5.9.1

Upstream Fuse Considerations 104

AQ262141056213en-000201/130R08824 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

5.9.2

Recommended Fuse Ratings for IEC Installation 104

5.9.3

Recommended Fuse Ratings for UL Installation 105

5.10

Enabling Motor Operation 106

5.11

Selecting the Voltage/Current Input Signal 106

5.12

Setting Up RS485 Serial Communication 107

5.13

Configuring the Passive Harmonic Filter (PHF) 108

5.14

Configuring the dU/dt Filter 108

5.15

Configuring the Sine-wave Filter 108

5.16

MCCB Configuration 108

5.17

Safe Torque Off (STO) Wiring 109

6

Pre-start Check 110

7

Commissioning 112

7.1

Applying Power to the Drive 112

Contents

7.2

Programming the Drive 112

7.2.1

Parameter Overview 112

7.2.2

Parameter Navigation 113

7.2.3

Programming Example for an Open-loop Application 113

7.2.4

Entering System Information 114

7.2.5

Configuring Automatic Energy Optimization 115

7.2.6

Configuring Automatic Motor Adaptation 115

7.3

Testing Before System Start-up 115

7.3.1

Testing Motor Rotation 115

7.3.2

Testing Encoder Rotation 115

7.4

Starting Up the Drive for the First Time 116

7.5

Parameter Settings 116

7.5.1

Parameter Setting Overview 116

7.5.2

Uploading and Downloading Parameter Settings 116

7.5.3

Restoring Factory Default Settings Using the Recommended Initialization 117

7.5.4

Restoring Factory Default Settings Using Manual Initialization 117

8

Wiring Configuration Examples 118

8.1

Application Examples 118

8.1.1

Wiring Configuration for Automatic Motor Adaptation (AMA) 118

8.1.2

Wiring Configuration for Automatic Motor Adaptation (AMA) without T27 118

8.1.3

Wiring Configuration: Speed 119

8.1.4

Wiring Configuration: Feedback 121

8.1.5

Wiring Configuration: Run/Stop 122

AQ262141056213en-000201/130R0882 | 5Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

8.1.6

Wiring Configuration: Start/Stop 124

8.1.7

Wiring Configuration: External Alarm Reset 126

8.1.8

Wiring Configuration: RS485 126

8.1.9

Wiring Configuration: Motor Thermistor 127

8.1.10

Wiring for Regeneration 127

8.1.11

Wiring Configuration for a Relay Set-up with Smart Logic Control 128

8.1.12

Wiring Configuration for a Submersible Pump 128

8.1.13

Wiring Configuration for a Cascade Controller 130

8.1.14

Wiring Configuration for a Fixed Variable Speed Pump 131

8.1.15

Wiring Configuration for Lead Pump Alternation 132

9

Maintenance, Diagnostics, and Troubleshooting 133

9.1

Maintenance and Service 133

9.2

Disposal 133

9.3

Status Messages 133

Contents

9.4

Warnings and Alarms 137

9.5

Troubleshooting 153

10

Specifications 156

10.1

Electrical Data 156

10.1.1

Electrical Data, 380–480 V AC 156

10.1.2

Electrical Data, 525–690 V AC 161

10.2

Mains Supply 166

10.3

Motor Output and Motor Data 166

10.3.1

Motor Output (U, V, W) 166

10.3.2

Torque Characteristics 167

10.4

Ambient Conditions 167

10.5

Motor and Control Cables 167

10.6

Control Input/Output and Control Data 168

10.6.1

Control Card, USB Serial Communication 168

10.6.2

STO Terminal XD2.19 (Terminal XD2.19 is Fixed PNP Logic) 168

10.6.3

Control Card, 24 V DC Output 168

10.6.4

Control Card, 10 V DC Output 168

10.6.5

Digital Outputs 169

10.6.6

Digital Inputs 169

10.6.7

Pulse/Encoder Inputs 169

10.6.8

Control Characteristics 170

10.6.9

Relay Outputs 170

10.6.10

Analog Output 171

AQ262141056213en-000201/130R08826 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

10.6.11

10.6.12

10.6.13

10.7

Filter Specifications 172

10.7.1

10.7.2

10.7.3

10.7.4

10.8

Fuses, Circuit Breakers, and Switches 174

10.8.1

10.8.2

10.8.3

10.8.4

10.8.5

Contents

Analog Inputs 171

Control Card, RS485 Serial Communication 171

Control Card Performance 171

Passive Harmonic Filter Specifications 172

Line Reactor Specifications 172

dU/dt Filter Specifications 173

Sine-wave Filter Specifications 173

Panel Fuses 175

Contactor Switches 176

Fusible Disconnect Switches 177

Non-fusible Disconnect Switches 178

Molded-case Circuit Breakers 179

10.9

Enclosure Dimensions 180

10.9.1

Pedestal Dimensions 180

10.9.2

D9h Enclosed Drive Exterior Dimensions 180

10.9.3

D10h Enclosed Drive Exterior Dimensions 181

10.9.4

E5h Enclosed Drive Exterior Dimensions 182

10.9.5

E6h Enclosed Drive Exterior Dimensions 183

10.10

Enclosure Airflow 184

10.11

Fastener Torque Ratings 184

11

Appendix 185

11.1

Conventions 185

11.2

Abbreviations 185

11.3

International/North American Default Parameter Settings 187

11.4

Required Parameter Settings for Drive Options 188

11.5

Block Diagrams 189

11.6

Input Power Option Losses 192

11.6.1

Contactor Losses 192

11.6.2

Fusible Disconnect Losses 193

11.6.3

Non-fusible Disconnect Losses 194

11.6.4

Molded-case Circuit Breaker (MCCB) Losses 195

11.6.5

Passive Harmonic Filter Losses 196

11.6.6

Line Reactor Losses 197

11.6.7

dU/dt Filter Losses 198

11.6.8

Sine-wave Filter Losses 199

AQ262141056213en-000201/130R0882 | 7Danfoss A/S © 2021.11

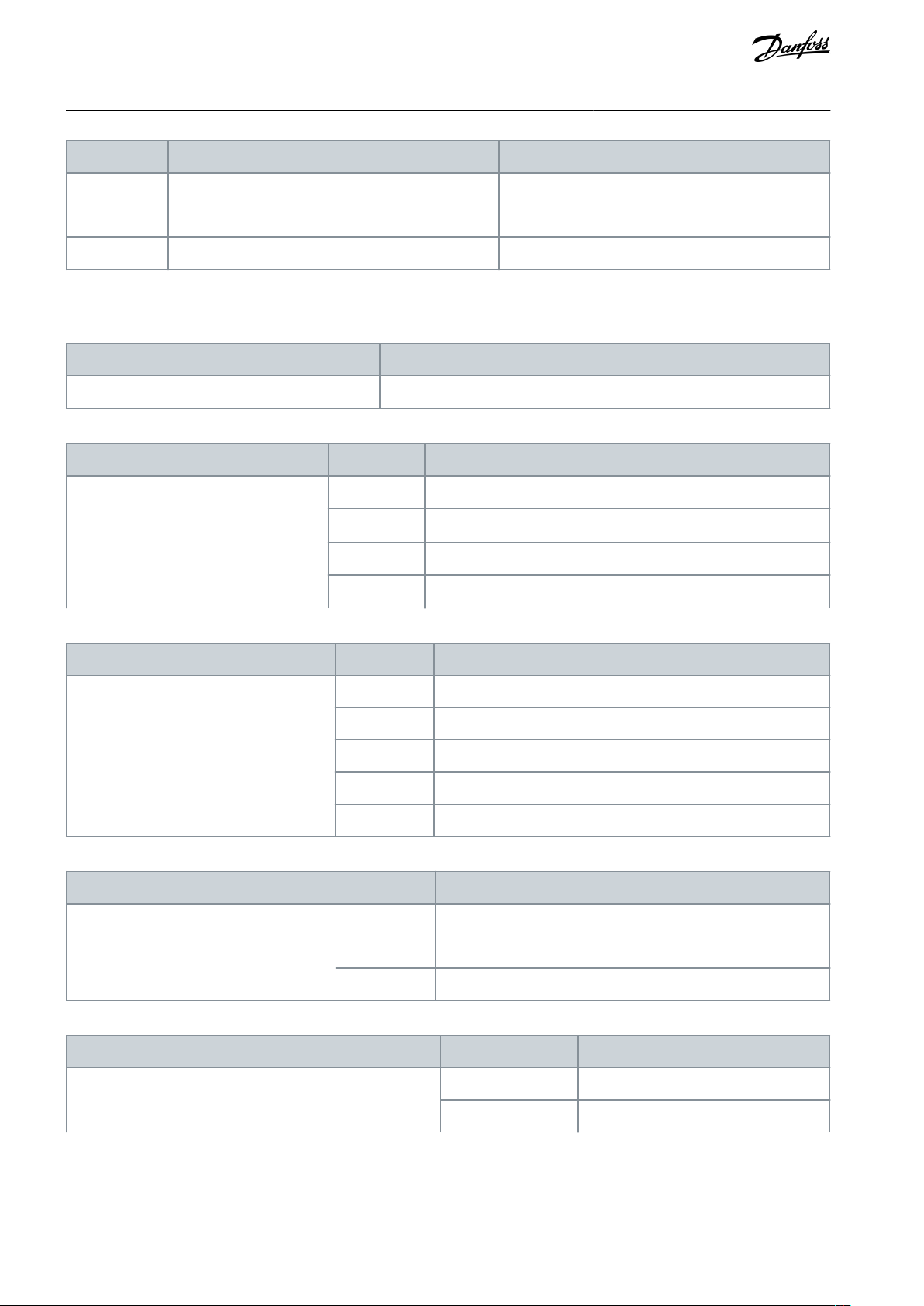

Version

Remarks

Software version

AQ262141056213 - 0201

Updated illustrations and power loss tables.

3.40

MG80H1xx

First version

3.31

089

VLT® AQUA Drive FC 202

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

Other resources are available to understand advanced drive functions and programming.

•

The Programming Guide provides detailed information on the LCP, menu system, parameters, and troubleshooting with alarms

and warnings.

•

The Design Guide provides detailed information about capabilities and functionality to design motor control systems.

•

The Safe Torque Off Operating Guide provides detailed specifications, requirements, and installation instructions for the Safe

Torque Off function.

•

Supplementary publications and manuals are available from Danfoss, see

1.3 Manual Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

www.danfoss.com.

Table 1: Manual and Software Version

1.4 Approvals and Certifications

The following list is a selection of possible type approvals and certifications for Danfoss drives:

The specific approvals and certification for the enclosed drive or drive module are on the nameplate of the drive. For more information, contact the local Danfoss office or partner.

AQ262141056213en-000201 / 130R08828 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Introduction

Thermal memory retention requirement

The enclosed drive is UL listed per UL508A and CSA 14 standards. The drive module in the enclosed drive system complies with UL

508C or UL 61800-5-1 thermal memory retention requirements. For more information on UL 508C thermal memory retention requirements, refer to the Motor Thermal Protection section in the product-specific Design Guide.

N O T I C E

OUTPUT FREQUENCY LIMIT

Due to export control regulations, the output frequency of the enclosed drive (with no output filters) is limited to 590 Hz. For

demands exceeding 590 Hz, contact Danfoss. For enclosed drives with output filters, the maximum output frequency is limited to

60 Hz without derating and to 100/120 Hz with derating.

ADN-compliance

For more information on compliance with the European Agreement concerning International Carriage of Dangerous Goods by Inland Waterways (ADN), refer to section ADN-compliant Installation in the product-specific Design Guide.

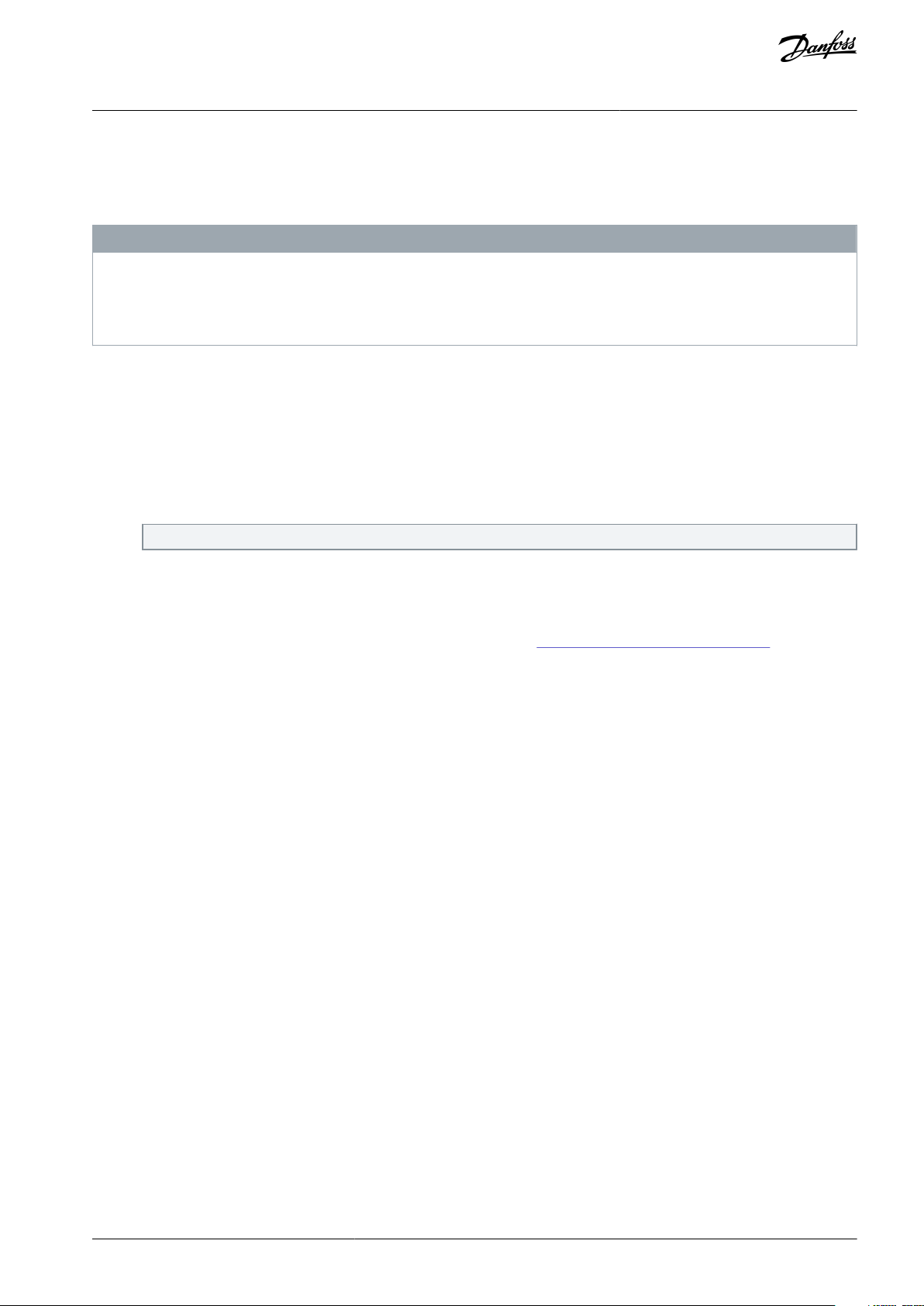

1.5 Finding the Declaration of Conformity Certificate

1.

Open a web browser and enter https://www.danfoss.com/en/service-and-support/documentation/.

2.

Click Certificates & declarations.

3.

Use the Search field to search for PLV*.

The system provides a list of the search results.

Filter the search results be entering the following criteria.

4.

a.

Business unit = Drives

b.

Documents/Document types = Certificate

5.

Scroll down until you find the PLV XXX titled certificate for the specific product segment, such as PLV 202 EU Declaration.

Double click the link to the open the certificate. For an example, see

1.6 Declaration of Conformity Certificate.

AQ262141056213en-000201 / 130R0882 | 9Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

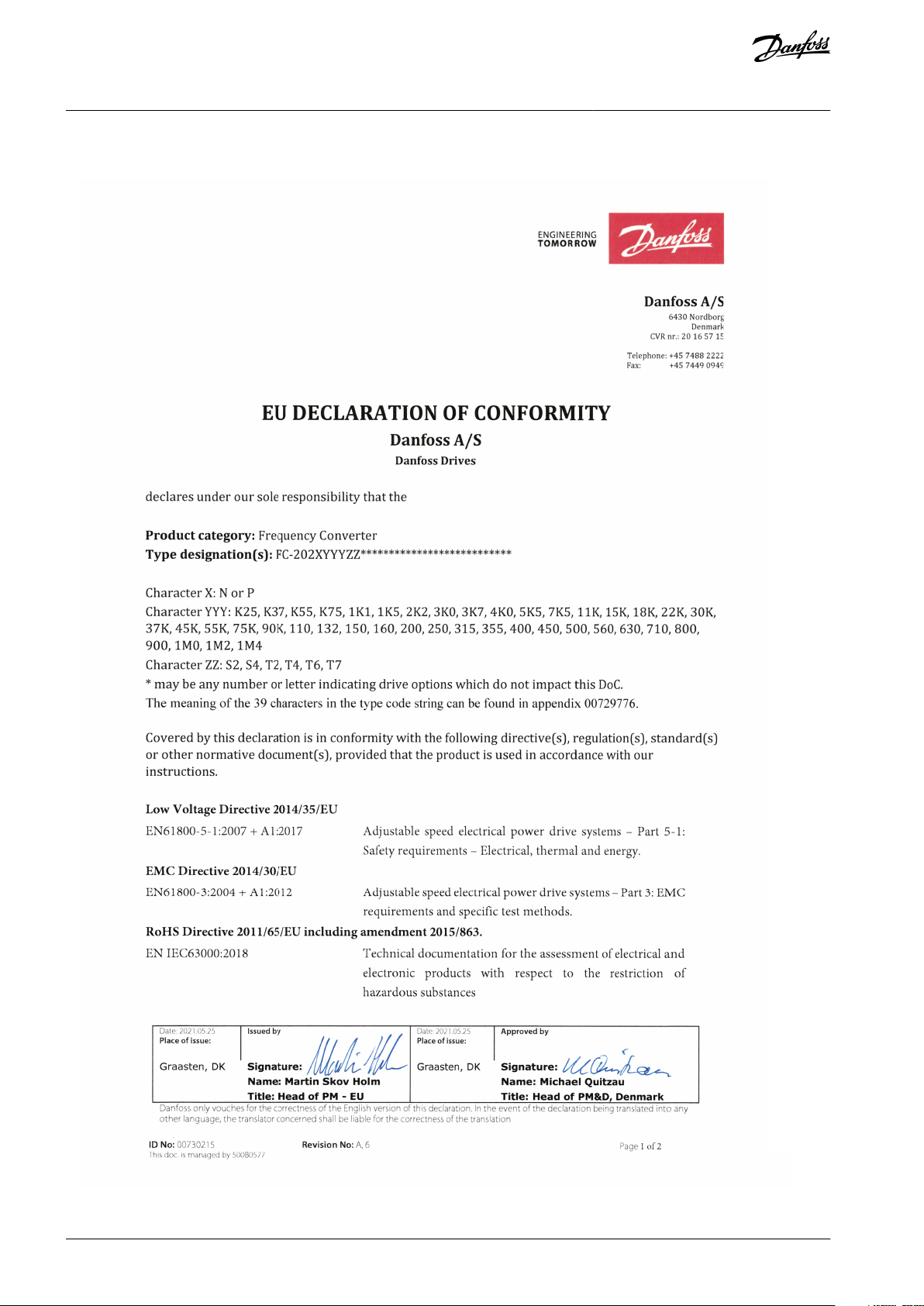

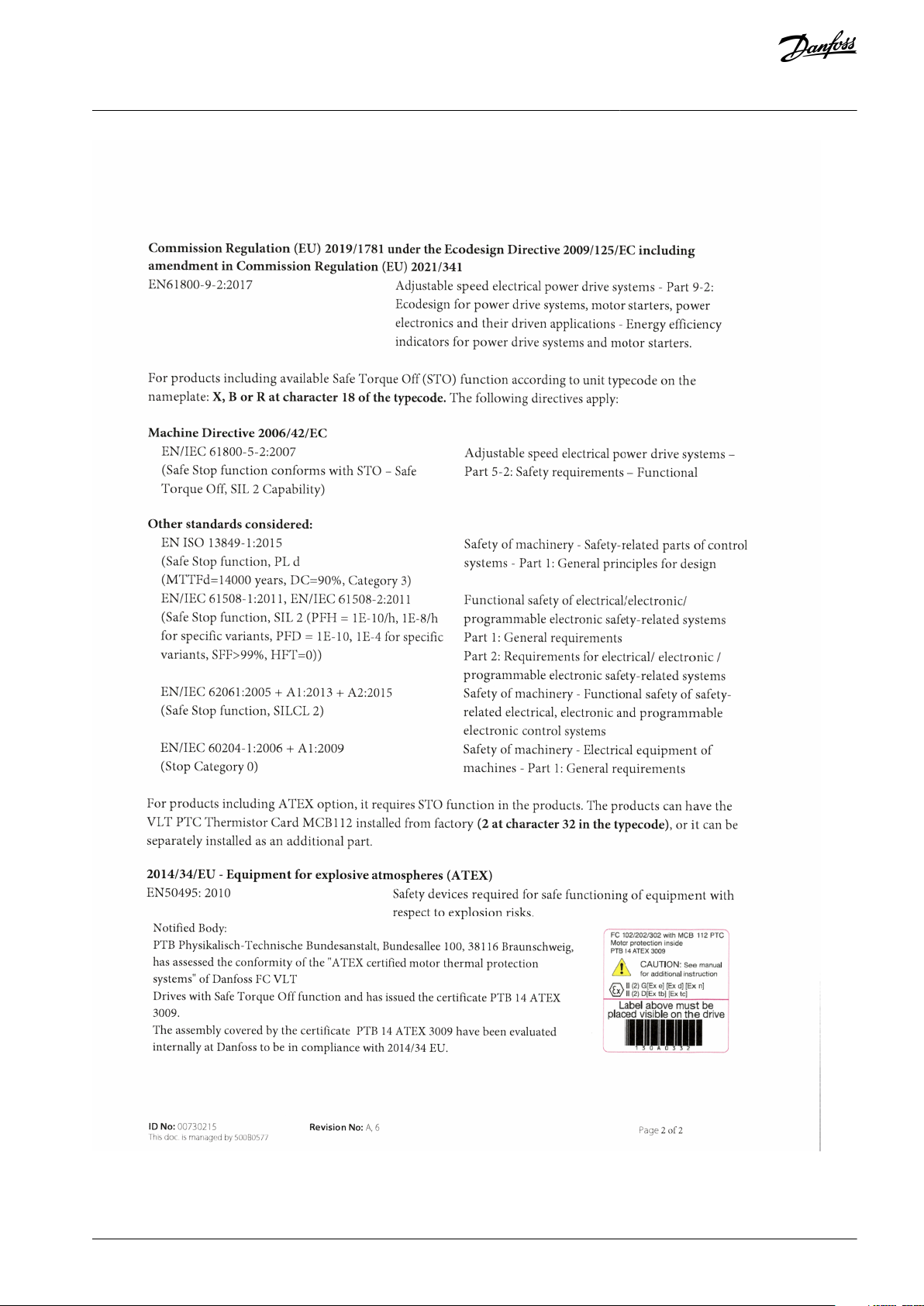

1.6 Declaration of Conformity Certificate

Introduction

AQ262141056213en-000201 / 130R088210 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Introduction

AQ262141056213en-000201 / 130R0882 | 11Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Introduction

AQ262141056213en-000201 / 130R088212 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Introduction

AQ262141056213en-000201 / 130R0882 | 13Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

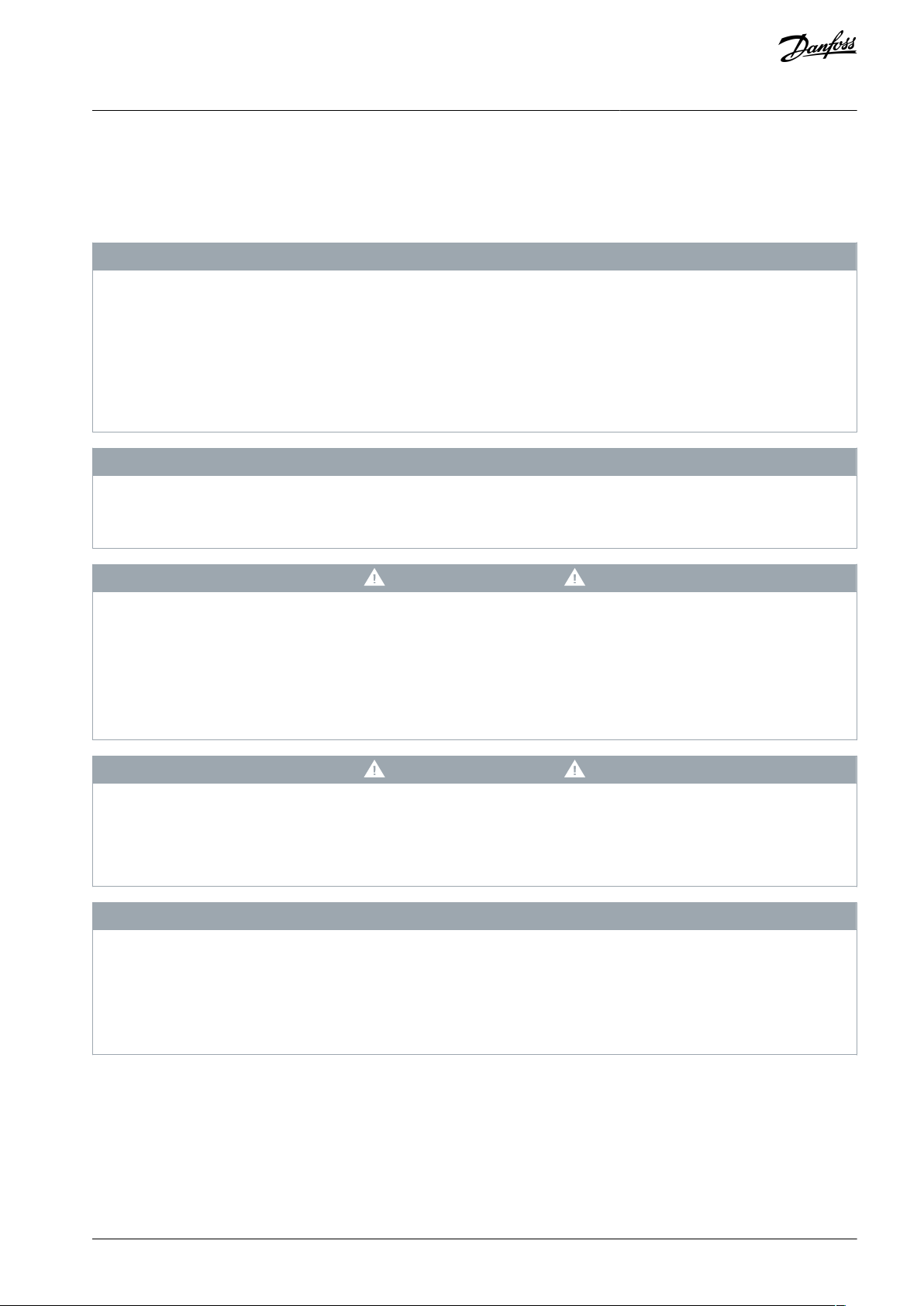

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

AQ262141056213en-000201 / 130R088214 | Danfoss A/S © 2021.11

Drive model

Minimum waiting time

D9h/D10h

20 minutes

E5h/E6h

40 minutes

VLT® AQUA Drive FC 202

Operating Guide

Safety

2.3 Safety Precautions

W A R N I N G

LACK OF SAFETY AWARENESS

This document gives important information on how to prevent injury and damage to the equipment or the system. Ignoring

them can lead to death, serious injury, or severe damage to the equipment.

Make sure to fully understand the dangers and safety measures incurred in the application.

-

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors and, if input filter options are present, extra capacitors and inductors. These components

can remain charged even when the drive is not powered. High voltage can be present even when the warning indicator lights are

off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified both in the Discharge Time table and on the

-

nameplate on top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

HIGH VOLTAGE

AC drives contain high voltage when connected to AC mains input. Failure to perform installation , start-up, and maintenance by

qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to the AC mains, DC supply, or load sharing, the motor may start at any time, causing risk of death,

serious injury, and equipment or property damage. The motor may start by activation of an external switch, a fieldbus command,

an input reference signal from the LCP or LOP, via remote operation using MCT 10 Set-up software, or after a cleared fault condi-

tion.

Press [Off] on the LCP before programming parameters.

-

Disconnect the drive from the mains whenever personal safety considerations make it necessary to avoid unintended motor

-

start.

Check that the drive, motor, and any driven equipment are in operational readiness.

-

AQ262141056213en-000201 / 130R0882 | 15Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

W A R N I N G

ROTATING SHAFTS

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this guide.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

Safety

AQ262141056213en-000201 / 130R088216 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

3 Product Overview

3.1 Intended Use

N O T I C E

OUTPUT FREQUENCY LIMIT

Due to export control regulations, the output frequency of the drive is limited to 590 Hz. For demands exceeding 590 Hz, contact

Danfoss.

The enclosed drive is an electronic motor controller that converts AC mains input into a variable AC waveform output. The frequency and voltage of the output are regulated to control the motor speed or torque. Depending on the configuration, the drive can be

used in standalone applications or form part of a larger system or installation. The enclosed drive is designed to:

•

Regulate motor speed in response to system feedback or remote commands from external controllers.

•

Provide motor overload protection.

•

Monitor system and motor status.

•

Reduce harmonics and increase the power factor using the optional passive harmonic filter or line reactor.

•

Reduce motor acoustic noise and protect motor insulation with the optional output filters.

•

Reduce bearing current and shaft voltage with the optional common-mode filter.

•

Reduce high-frequency, electromagnetic noise in the motor cables with the optional dU/dt filter.

•

Provide sinusoidal output with optional sine-wave filter.

The enclosed drive is designed for residential, industrial, and commercial environments in accordance with local laws and standards. Do not use this drive in applications that are non-compliant with specified operating conditions and environments.

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

3.2 What is an Enclosed Drive?

The enclosed drive is an IP21/54 (NEMA 1/12) enclosure surrounding an IP20 (Protected Chassis) drive to form the basis of the system. There are 4 enclosed drive models with varying power ratings.

•

D9h model: 110–160 kW (125–250 hp)

•

D10h model: 200–400 kW (250–450 hp)

•

E5h model: 355–630 kW (450–650 hp)

•

E6h model: 500–800 kW (650–950 hp)

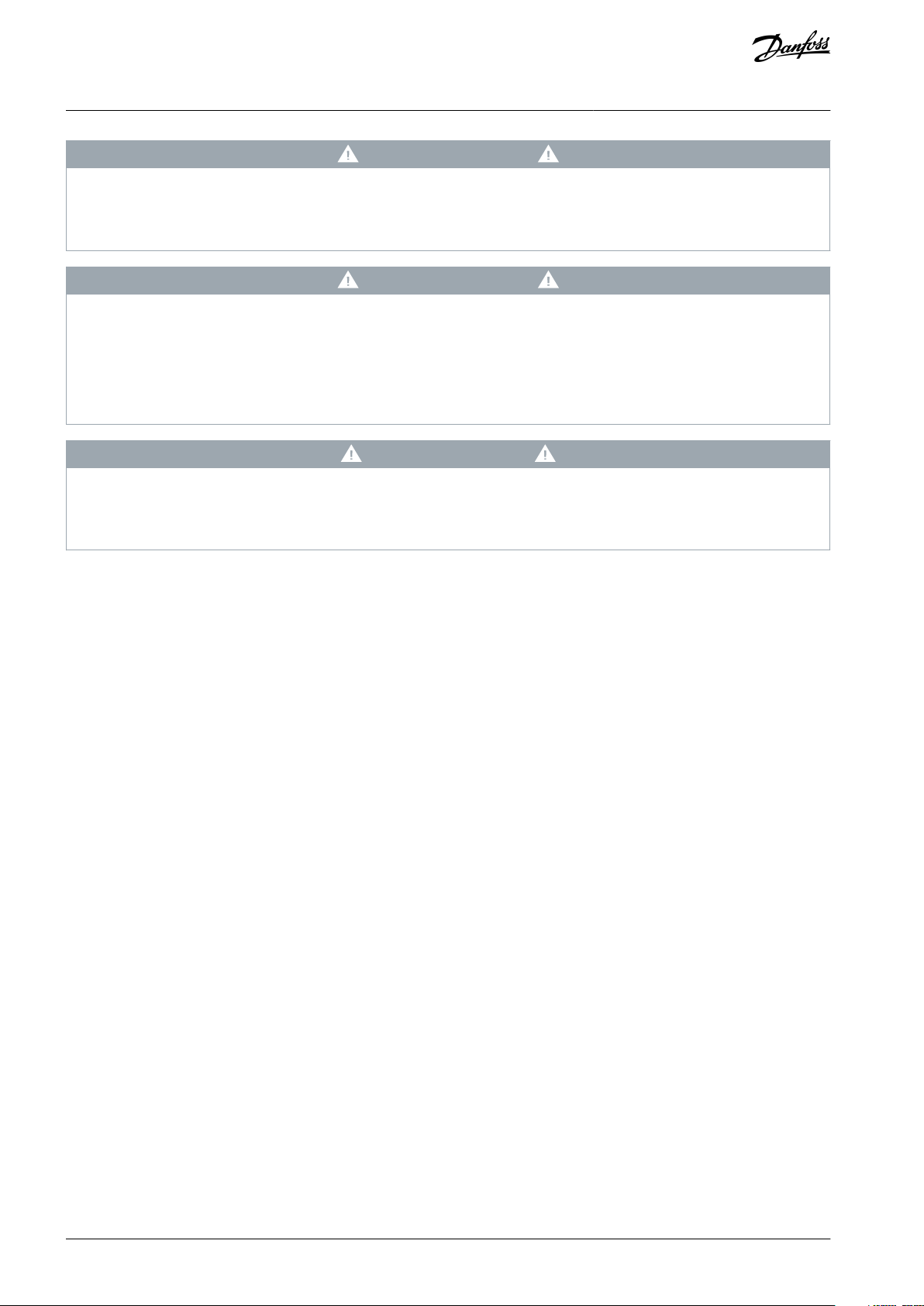

The enclosed drive is available with various power options and input and output filters to create a factory-built, custom drive. Some

options and filters result in extra cabinets attached to the left or right side of the drive cabinet. These optional cabinets are shown

with dotted lines, while the drive cabinet is shaded.

AQ262141056213en-000201 / 130R0882 | 17Danfoss A/S © 2021.11

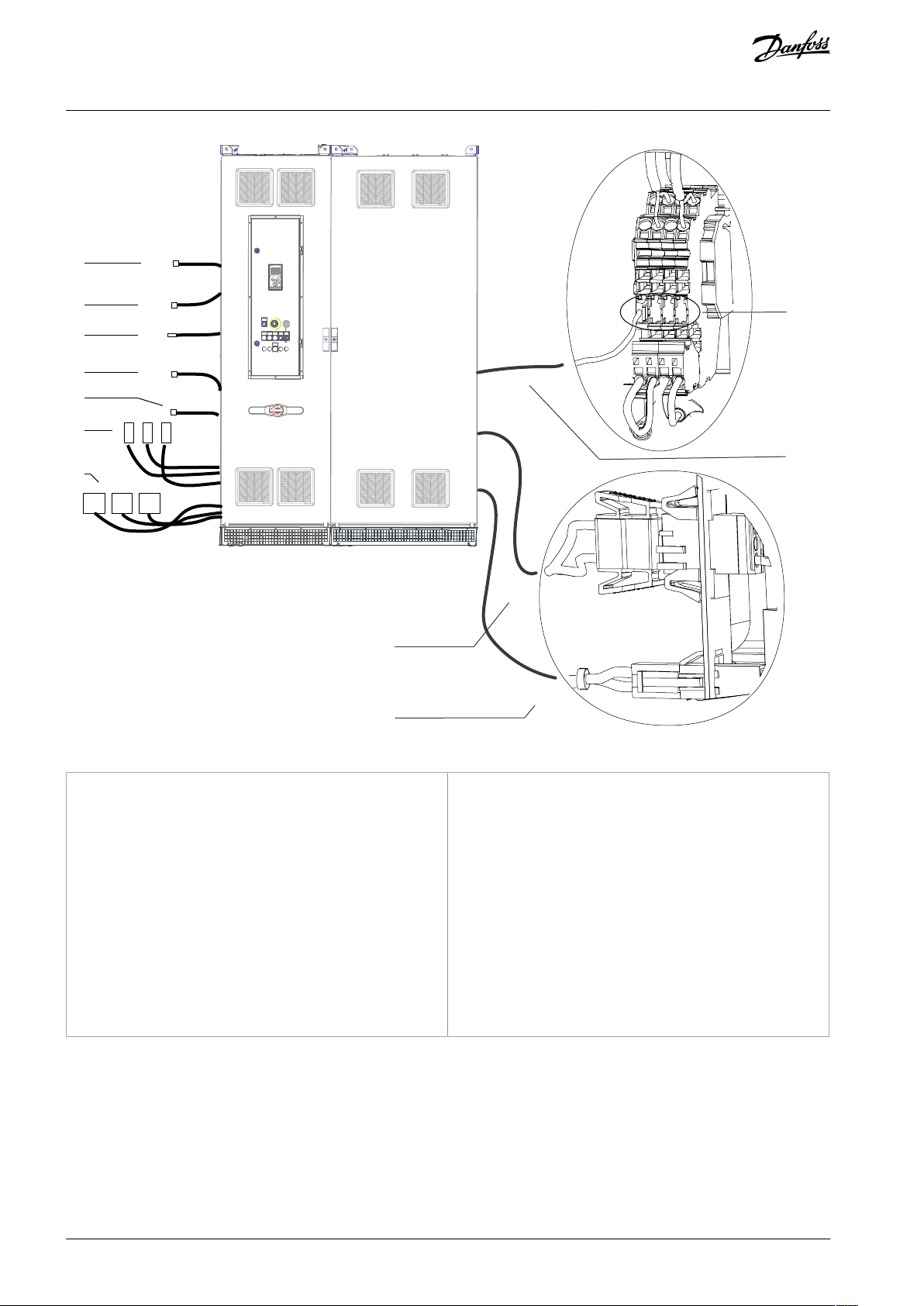

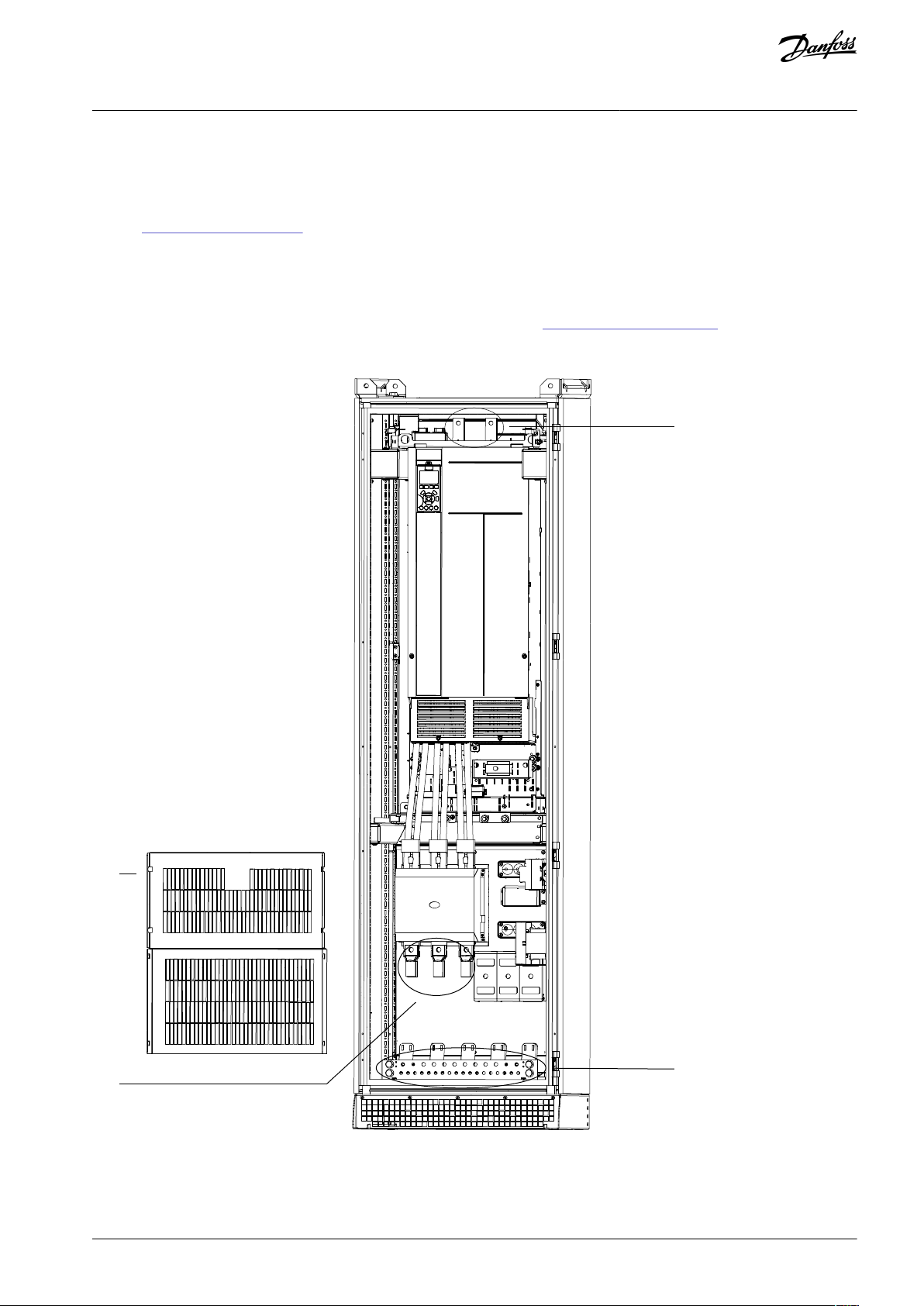

e30bu152.10

1

3

2

4

5

1

Input filter cabinet (passive harmonic filter or line reactor)

2

Drives cabinet

3

Sine-wave cabinet

4

Control compartment

5

Input power options

(1)

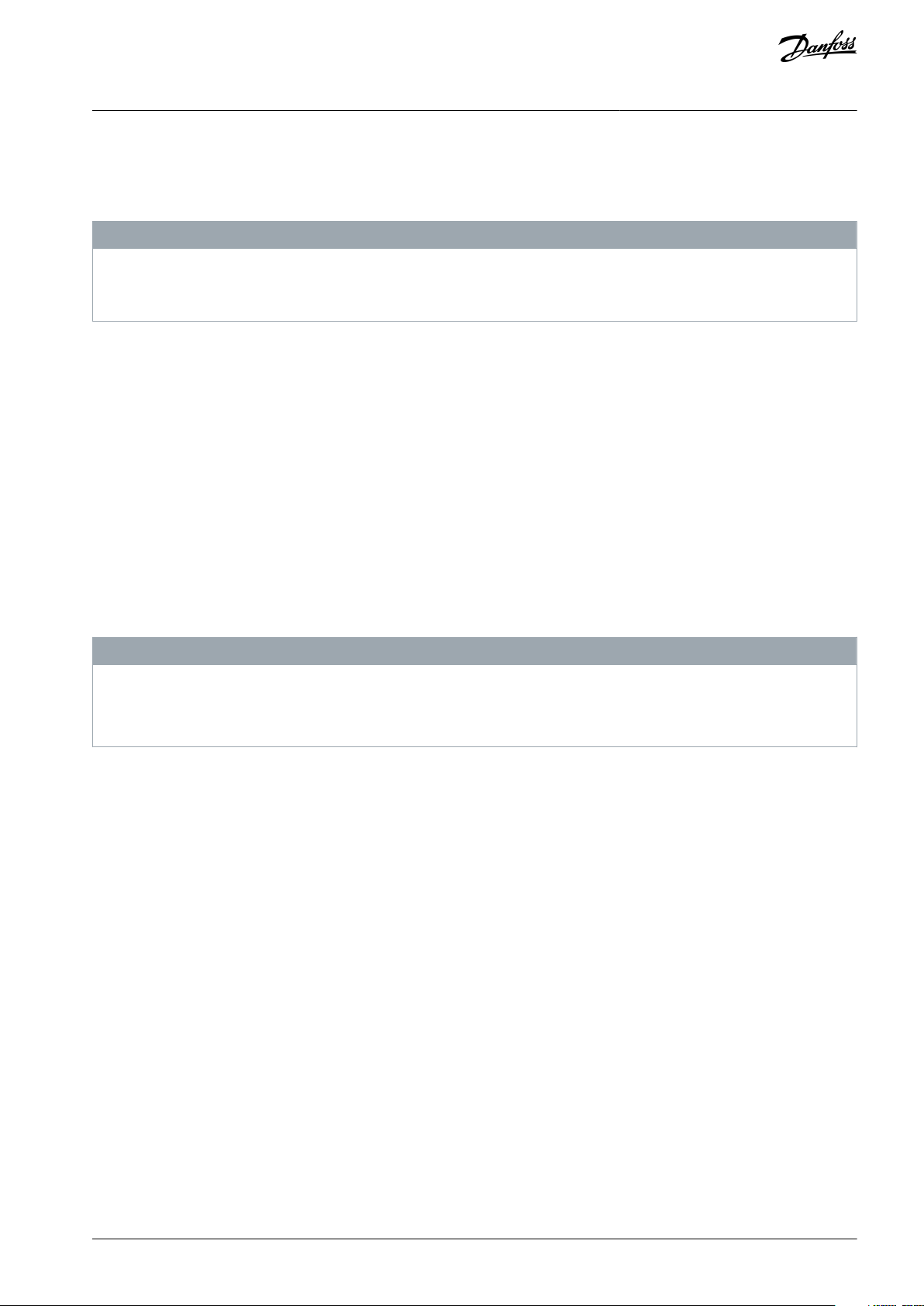

e30bu067.10

1

2

4

5

3

1

Input filter cabinet (passive harmonic filter or line reactor)

2

Input power options cabinet

(1)

3

Drive cabinet

4

Sine-wave filter cabinet

5

Control compartment

VLT® AQUA Drive FC 202

Operating Guide

Illustration 1: Possible Configurations for a D9h Enclosed Drive

Product Overview

1

The D9h enclosure does not require an input power options cabinet – the input power options are placed in the drive cabinet.

Illustration 2: Possible Configurations for a D10h Enclosed Drive

1

If more than 1 input power option is ordered, the D10h enclosed drive requires an input power options cabinet. Otherwise the single input power

option is placed below the control compartment in the drive cabinet.

AQ262141056213en-000201 / 130R088218 | Danfoss A/S © 2021.11

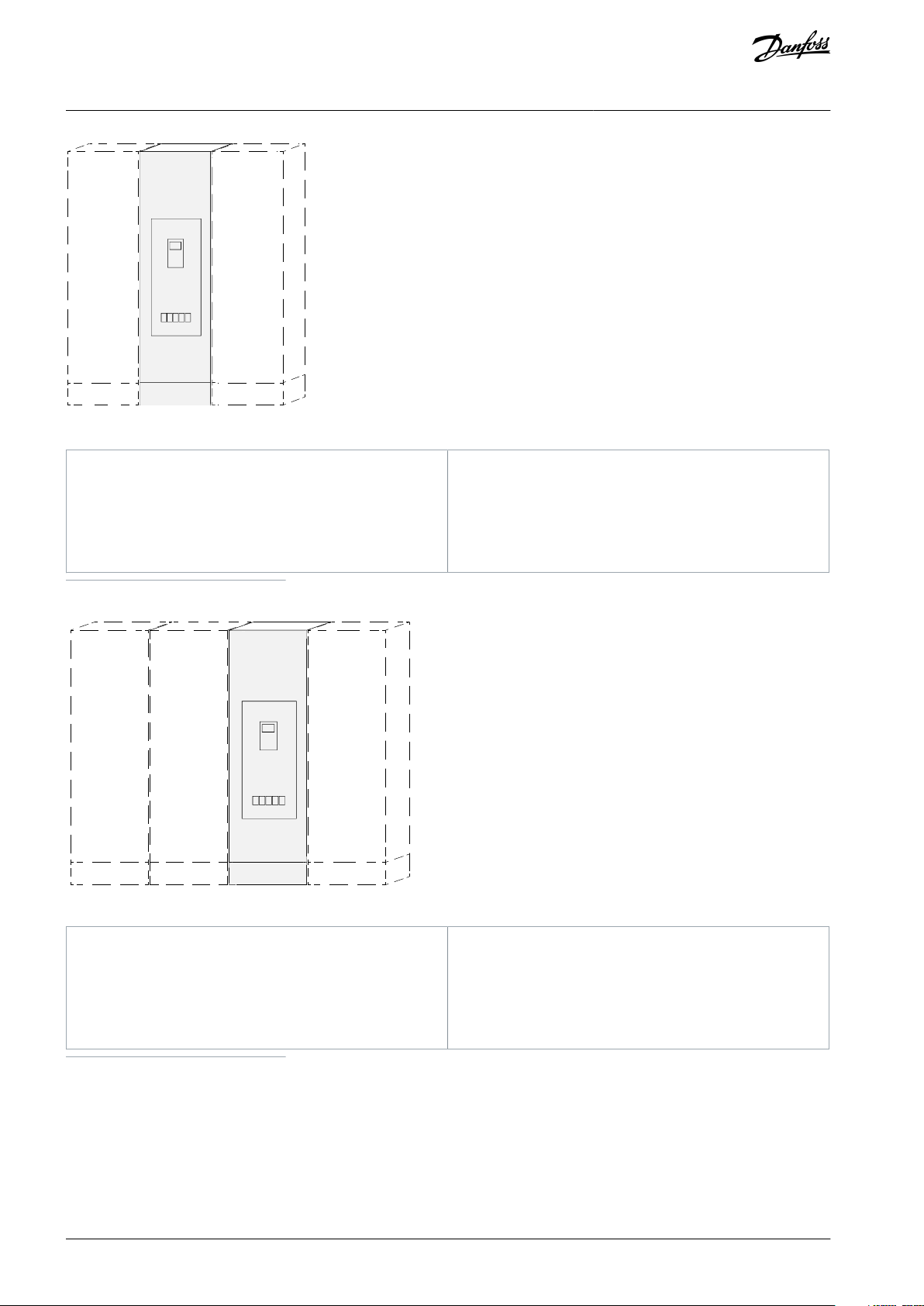

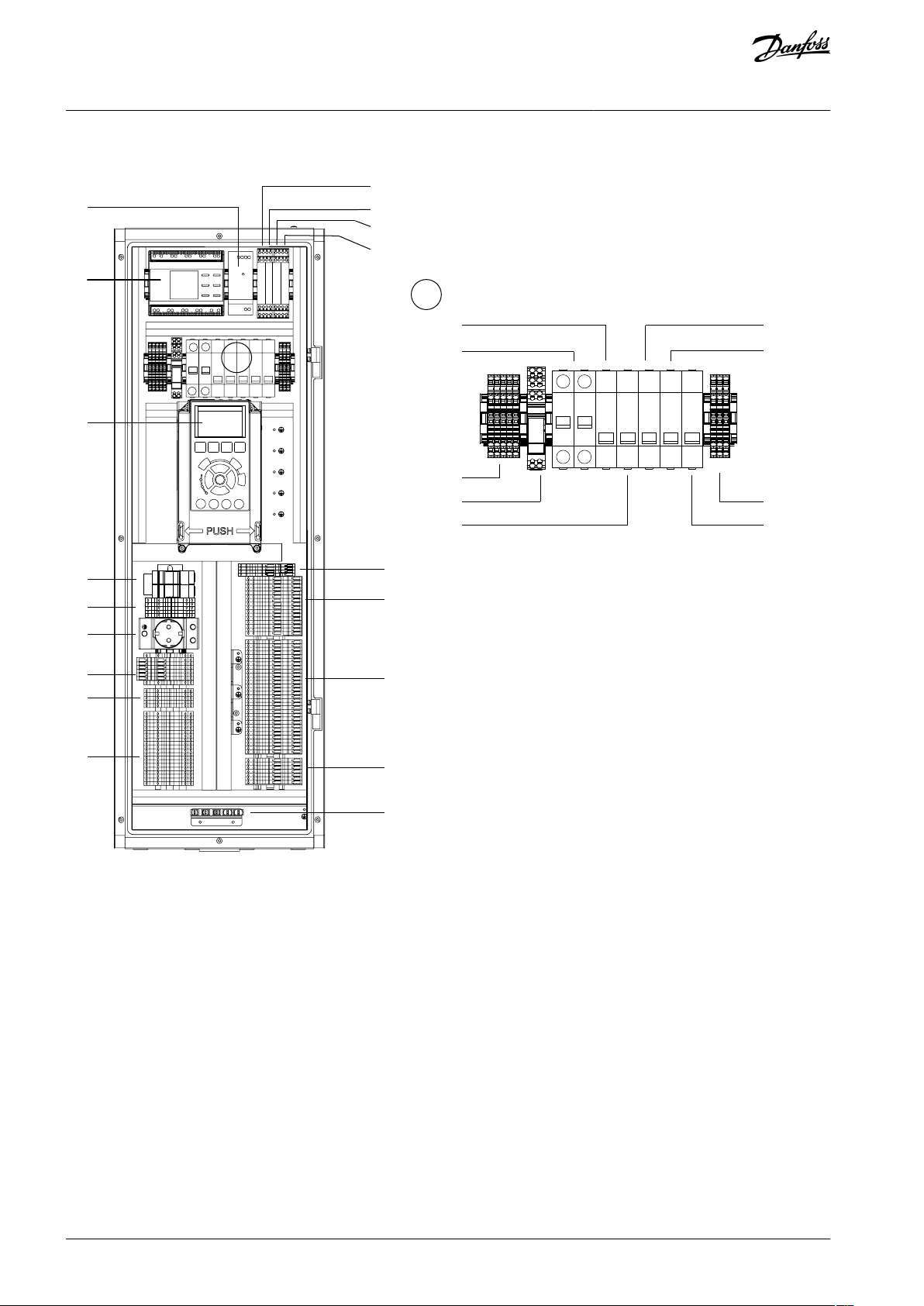

e30bu068.10

1

2

4

3

6

5

3

1

Input filter cabinet (passive harmonic filter or line reactor)

2

Input power options cabinet

3

Drive cabinet

4

Sine-wave filter cabinet

5

Control compartment

6

dU/dt filter cabinet

VLT® AQUA Drive FC 202

Operating Guide

Illustration 3: Possible Configurations for an E5h or E6h Enclosed Drive

Product Overview

AQ262141056213en-000201 / 130R0882 | 19Danfoss A/S © 2021.11

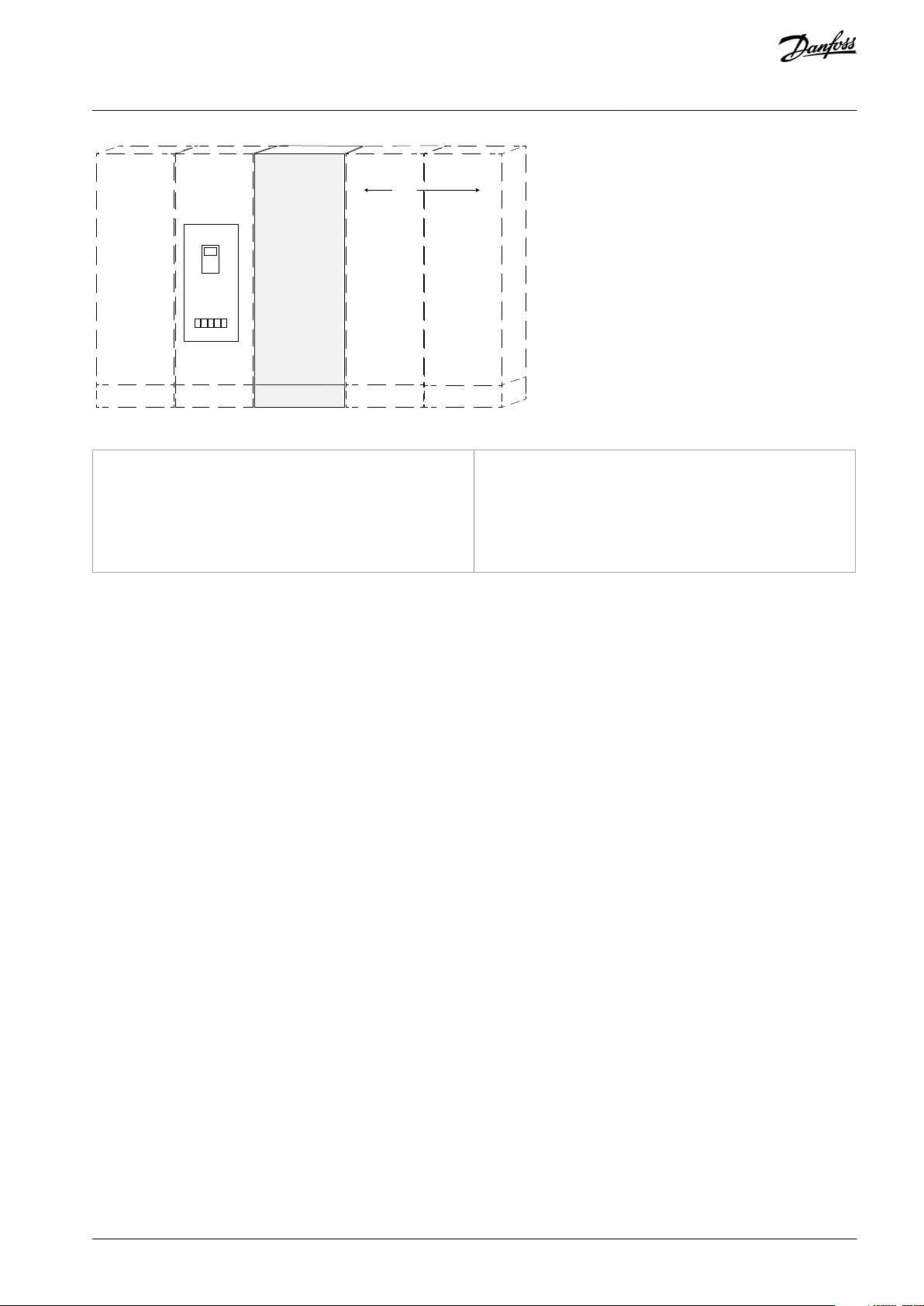

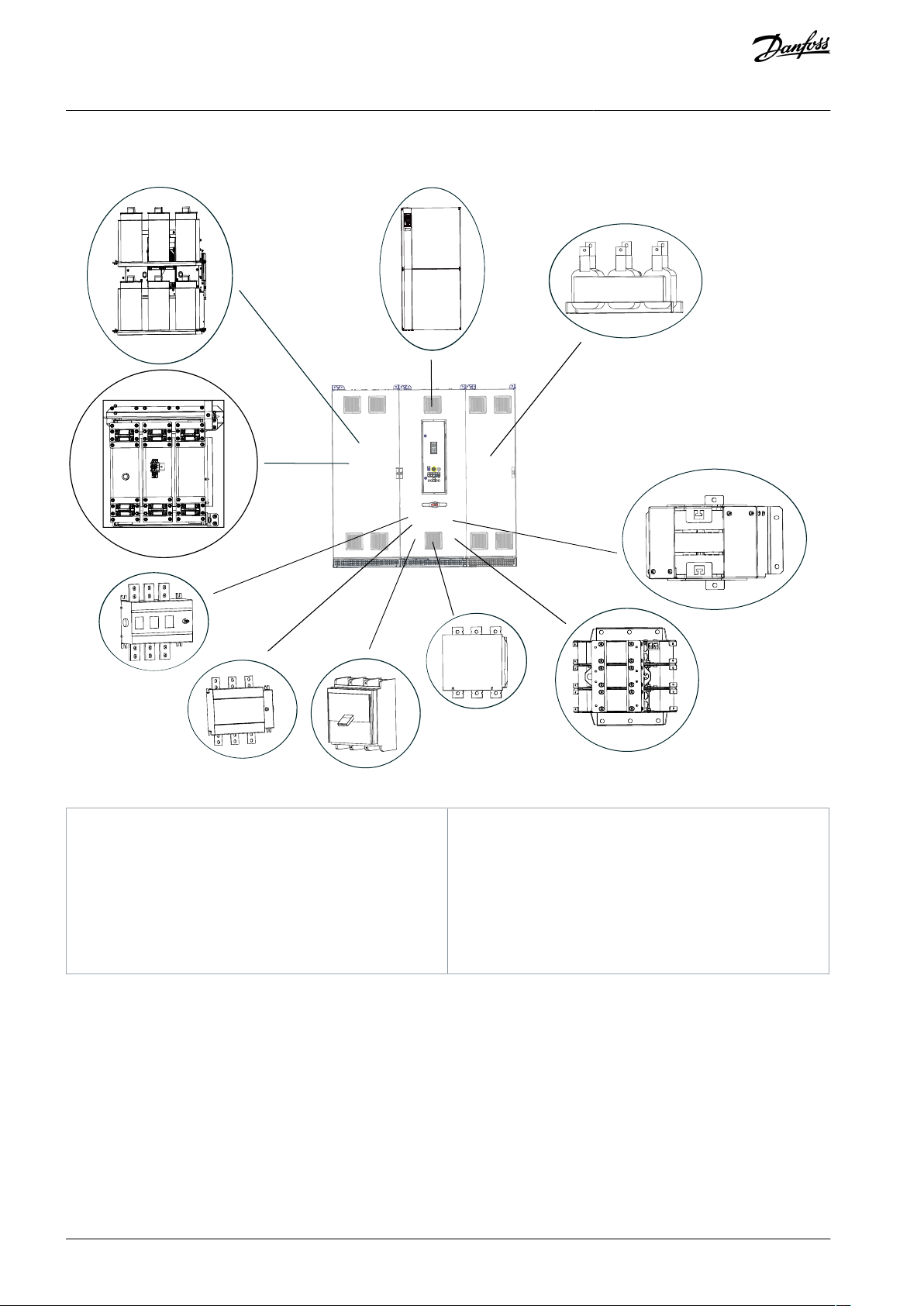

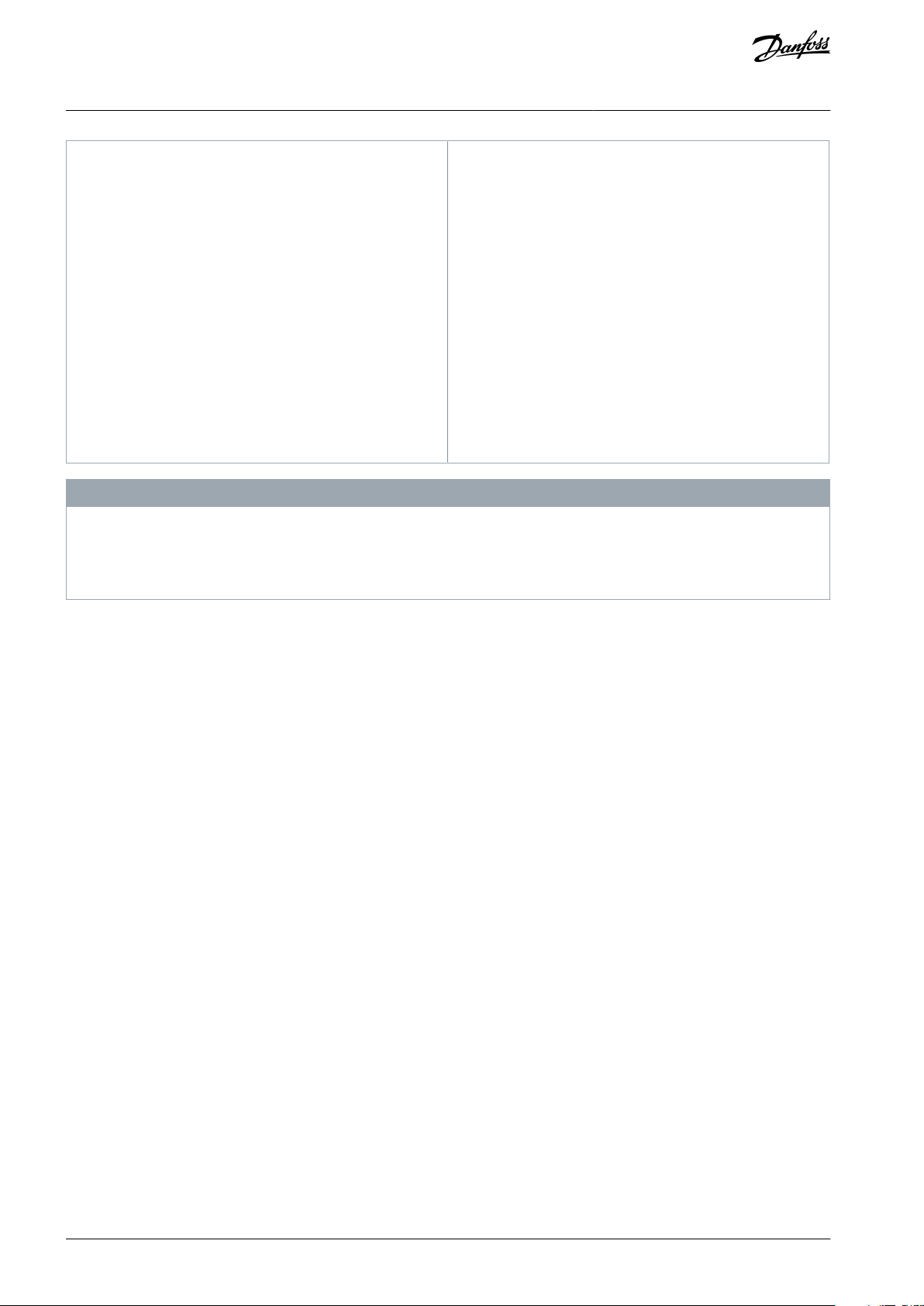

e30bu177.11

1

2

3

4

5

6

7

8

9

10

1

Passive harmonic filter (PHF)

2

Line reactor

3

Non-fusible disconnect

4

Fusible disconnect

5

Molded-case circuit breaker (MCCB)

6

Mains contactor

7

dU/dt filter

8

Common-mode filter

9

Sine-wave filter

10

Drive module (varies in power rating)

VLT® AQUA Drive FC 202

Operating Guide

3.3 Location of Options within an Enclosed Drive

Product Overview

Illustration 4: Visual Representation of a D9h Enclosure and the Locations of Available Options

AQ262141056213en-000201 / 130R088220 | Danfoss A/S © 2021.11

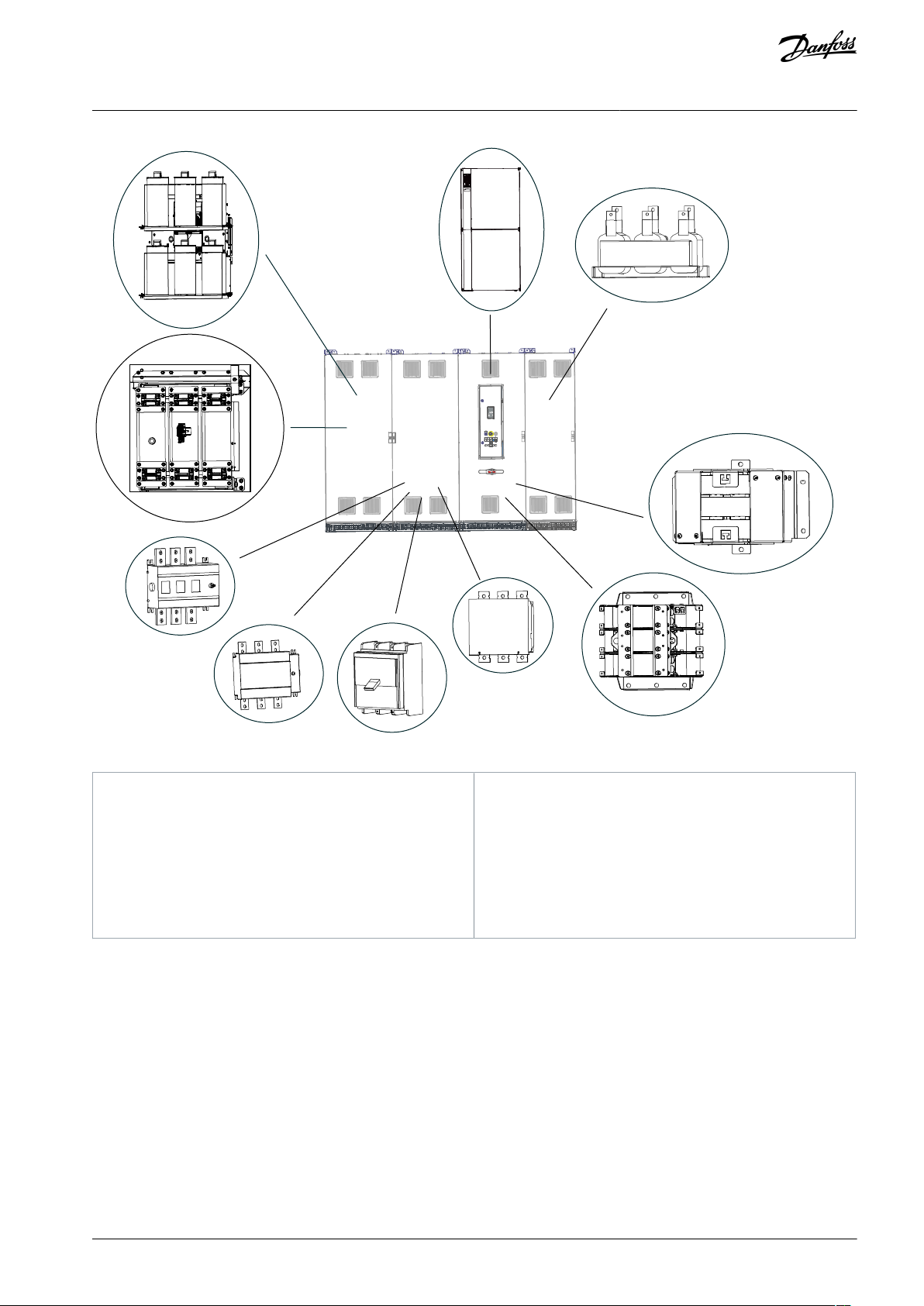

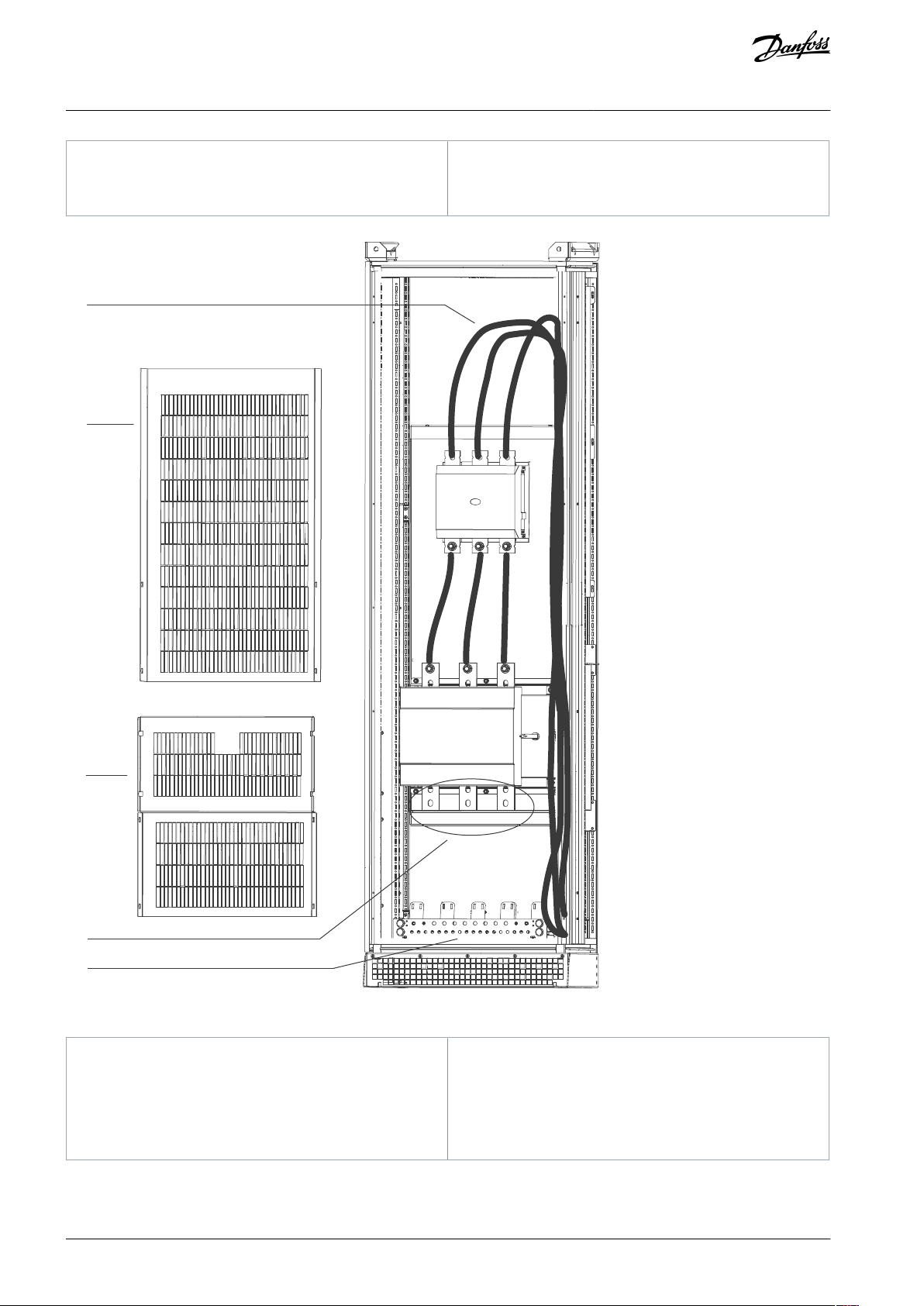

e30bu178.12

1

2

3

4

5

6

7

8

9

10

1

Passive harmonic filter (PHF)

2

Line reactor

3

Non-fusible disconnect

4

Fusible disconnect

5

Molded-case circuit breaker (MCCB)

6

Mains contactor

7

dU/dt filter

8

Common-mode filter

9

Sine-wave filter

10

Drive module (varies in power rating)

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

Illustration 5: Visual Representation of a D10h Enclosure and the Locations of Available Options

AQ262141056213en-000201 / 130R0882 | 21Danfoss A/S © 2021.11

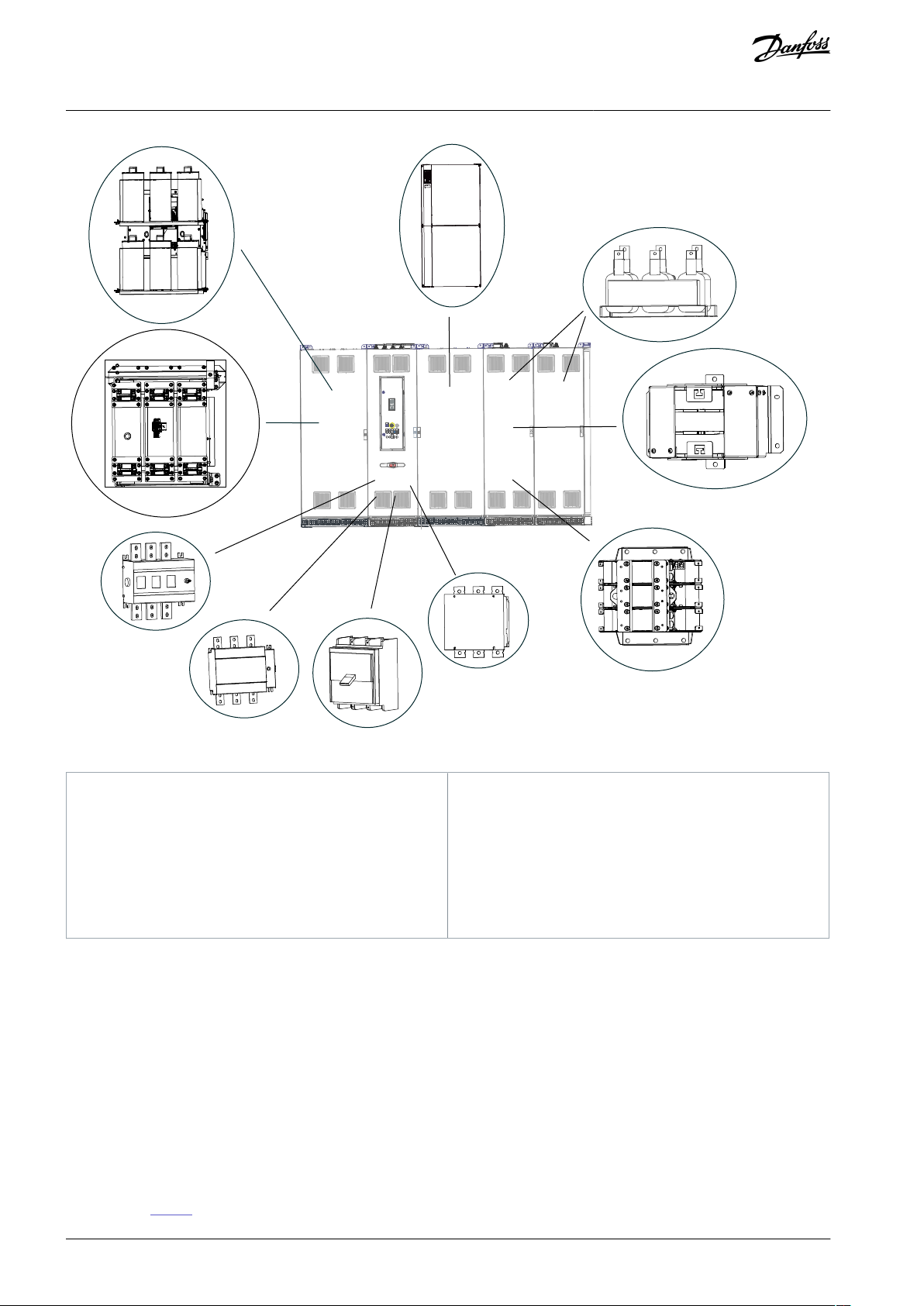

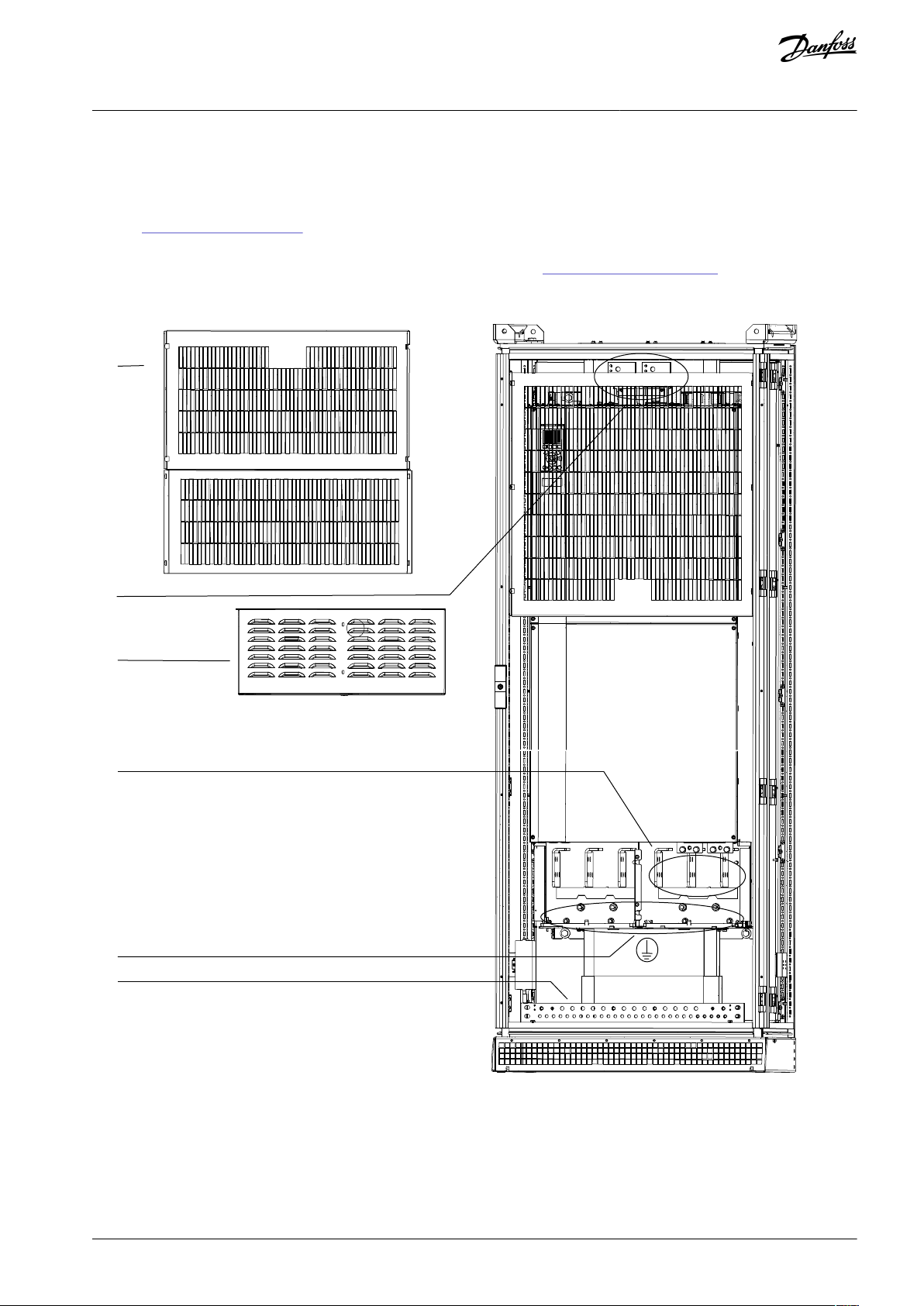

e30bu141.12

1

2

3

4

5

6

7

8

9

10

1

Passive harmonic filter (PHF)

2

Line reactor

3

Non-fusible disconnect

4

Fusible disconnect

5

Molded-case circuit breaker (MCCB)

6

Mains contactor

7

dU/dt filter

8

Common-mode filter

9

Sine-wave filter

10

Drive module (varies in power rating)

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

Illustration 6: Visual Representation of a E5h/E6h Enclosure and the Locations of Available Options

3.4 Drive Identification

3.4.1 Identifying the Drive and Its Options

Enclosure size and specific options are used throughout this guide whenever procedures or components differ based on the drive

and its options. Use the following steps to identify the enclosed drive:

Procedure

1.

Locate the type code (T/C) on the nameplate. The nameplate is found on the exterior of the drive by the bottom grill and

on the control compartment door.

2.

Determine the type of enclosure by obtaining the following information from the type code:

a.

Product group and drive series (characters 1–6).

b.

Voltage rating (character 8).

c.

Model/power rating (characters 10–12).

3.

Go to Table 3 and use the model number and voltage rating to find the enclosure size.

AQ262141056213en-000201 / 130R088222 | Danfoss A/S © 2021.11

•

•

•

•

•

•

•

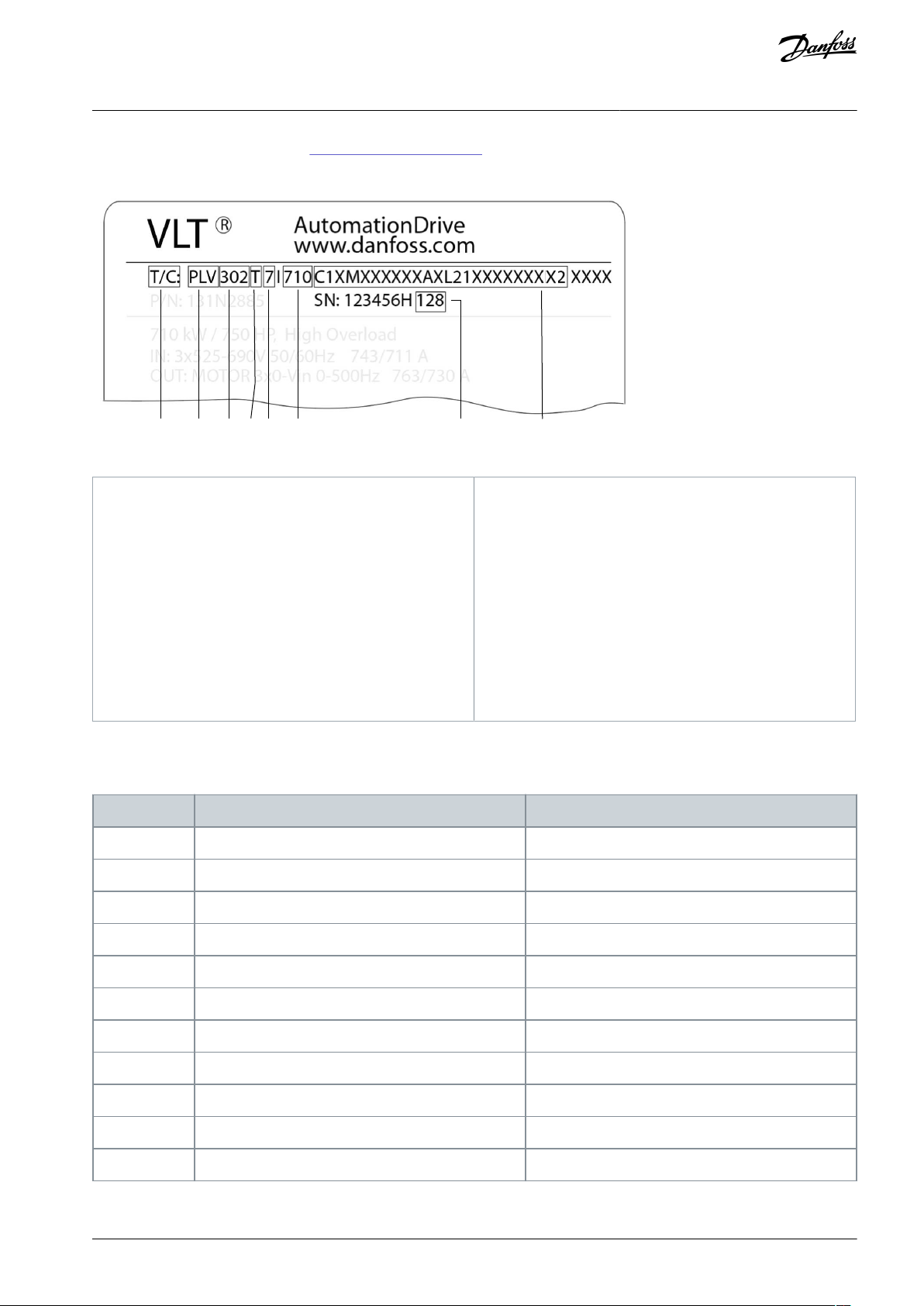

e30bu139.11

1 2 3 4 5 6 7 8

1

Type code

2

Product group (PLV = enclosed drive)

3

Drive series

102 = VLT® HVAC Drive

103 = VLT® Refrigeration Drive

202 = VLT® AQUA Drive

302 = VLT® AutomationDrive

4

Low harmonic filter option (if any)

5

Mains voltage

4 = 380–480 V

5 = 380–500 V

7 = 525–690 V

6

Model/power rating

7

Build date (wwy, where ww = the week and y = the

last digit of the year)

8

Option codes

Model

Enclosure size (380–480 V)

Enclosure size (525–690 V)

N110

D9h

D9h

N132

D9h

D9h

N160

D9h

D9h

N200

D10h

D10h

N250

D10h

D10h

N315

D10h

D10h

N355

E5h–N400

E5h

D10h

N450

E5h

E5h

N500

E6h

E5h

N560

E6h

E5h

VLT® AQUA Drive FC 202

Operating Guide

4.

Using the type code, refer to 3.4.3 Type Code Identification to identify the installed options.

Example

Illustration 7: Using the Nameplate to Find the Enclosure Size and Installed Options

Product Overview

3.4.2 Enclosure Size Identification

Table 3: Model by Drive Voltage

AQ262141056213en-000201 / 130R0882 | 23Danfoss A/S © 2021.11

Model

Enclosure size (380–480 V)

Enclosure size (525–690 V)

N630–E5h

N710–E6h

N800–E6h

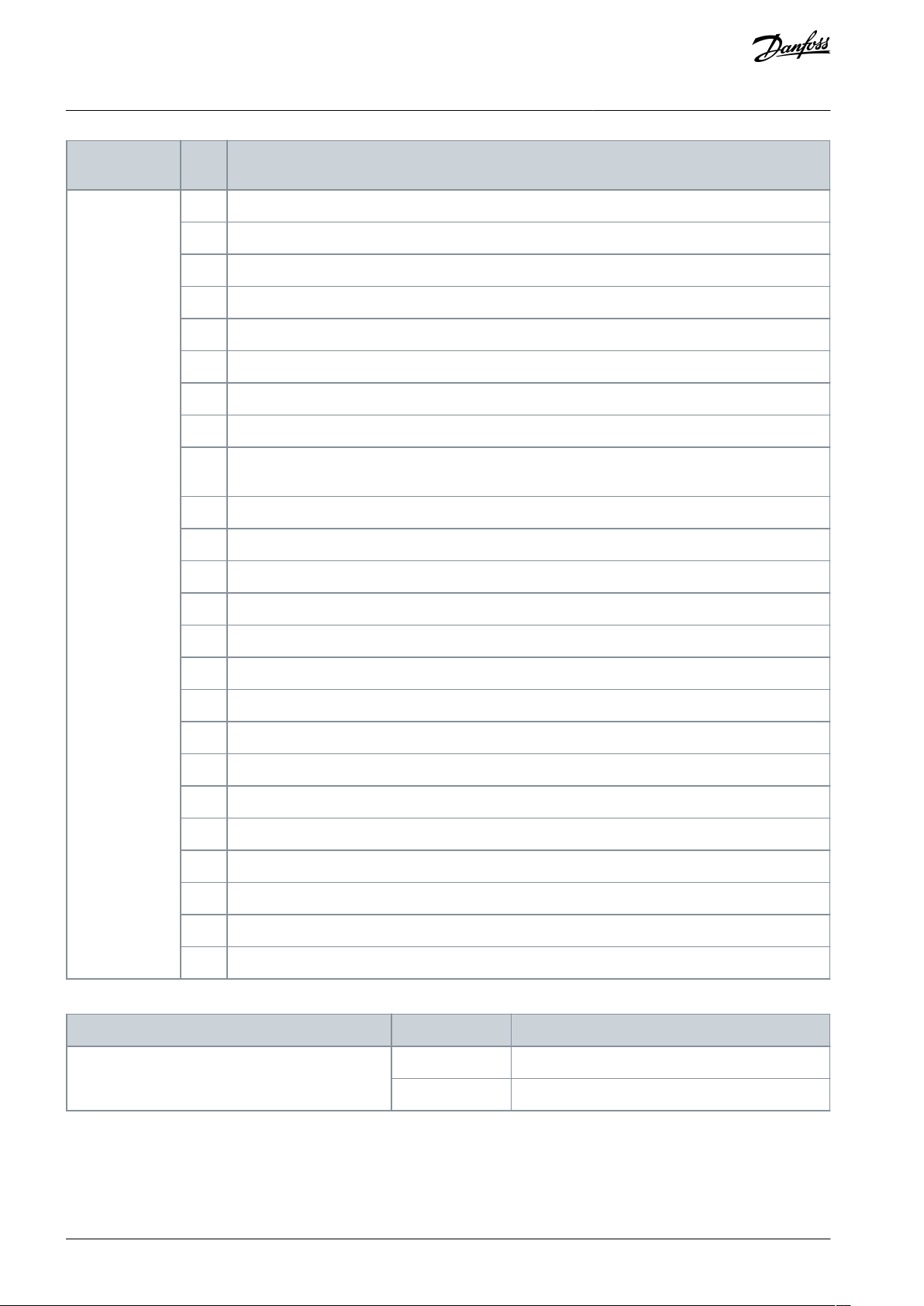

Character position

Code

Description

1–3

PLV

VLT® Enclosed Drives

Character position

Code

Description

4–6

102

VLT® HVAC Drive FC 102

103

VLT® Refrigeration Drive FC 103

202

VLT® AQUA Drive FC 202

302

VLT® AutomationDrive FC 302

Character position

Code

Description

7

T

None

P

Passive filter, THDi=5%, 50 Hz

H

Passive filter, THDi=8%, 50 Hz

L

Passive filter, THDi=5%, 60 Hz

U

Passive filter, THDi=8%, 60 Hz

Character position

Code

Description

8

4

380–480 V

5

380–500 V

7

525–690 V (525–600 V for UL)

Character position

Code

Description

9

I

IECUUL

VLT® AQUA Drive FC 202

Operating Guide

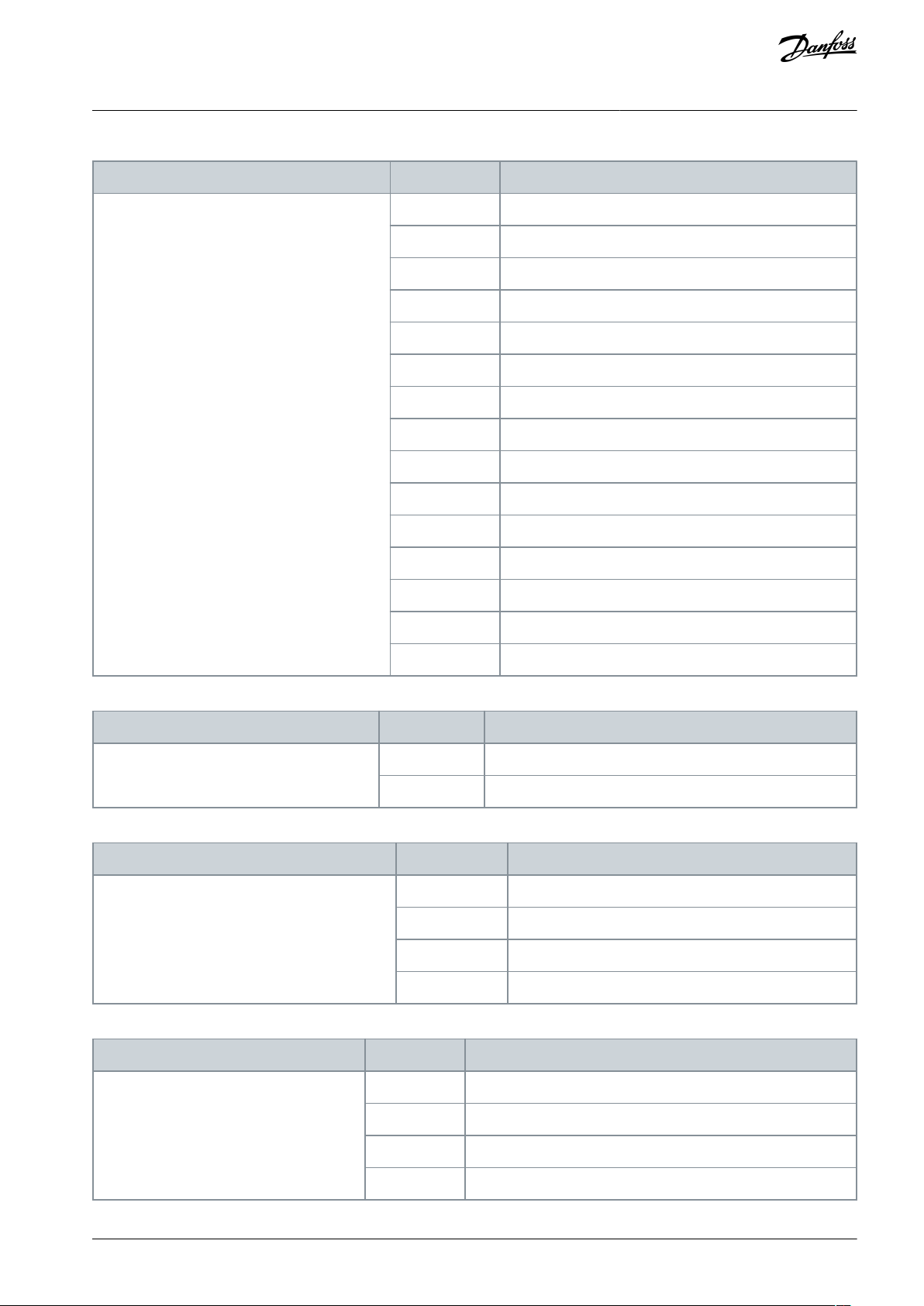

3.4.3 Type Code Identification

Table 4: Product Group Code

Table 5: Drive Series Codes

Product Overview

Table 6: Low-harmonic Filter Codes

Table 7: Mains Voltage Codes

Table 8: Norms and Standards Codes

AQ262141056213en-000201 / 130R088224 | Danfoss A/S © 2021.11

Character position

Code

Description

10–12

90K

(N90K) 90 kW/125 hp

110

(N110) 110 kW/150 hp

132

(N132) 132 kW/200 hp

160

(N160) 160 kW/250 hp

200

(N200) 200 kW/300 hp

250

(N250) 250 kW/350 hp

315

(N315) 315 kW/450 hp

355

(N355) 355 kW/500 hp

400

(N400) 400 kW/550 hp

450

(N450) 450 kW/600 hp

500

(N500) 500 kW/650 hp

560

(N560) 560 kW/750 hp

630

(N639) 630 kW/900 hp

710

(N710) 710 kW/1000 hp

800

(N800) 800 kW/1200 hp

Character position

Code

Description

13

C

Coated PCB

R

Coated PCB + ruggedized

Character position

Code

Description

14

1

100 mm high pedestal

2

200 mm high pedestal

4

400 mm high pedestal

5

Marine pedestal

Character position

Code

Description

15

X

No brake IGBT

B

Brake IGBT

T

Safe Torque Off

U

Brake IGBT + Safe Torque Off

VLT® AQUA Drive FC 202

Operating Guide

Table 9: Power Rating Codes

Product Overview

Table 10: Drive Module PCB Coating Codes

Table 11: Plinth (Pedestal) Codes

Table 12: Drive Module Braking and Safety Codes

AQ262141056213en-000201 / 130R0882 | 25Danfoss A/S © 2021.11

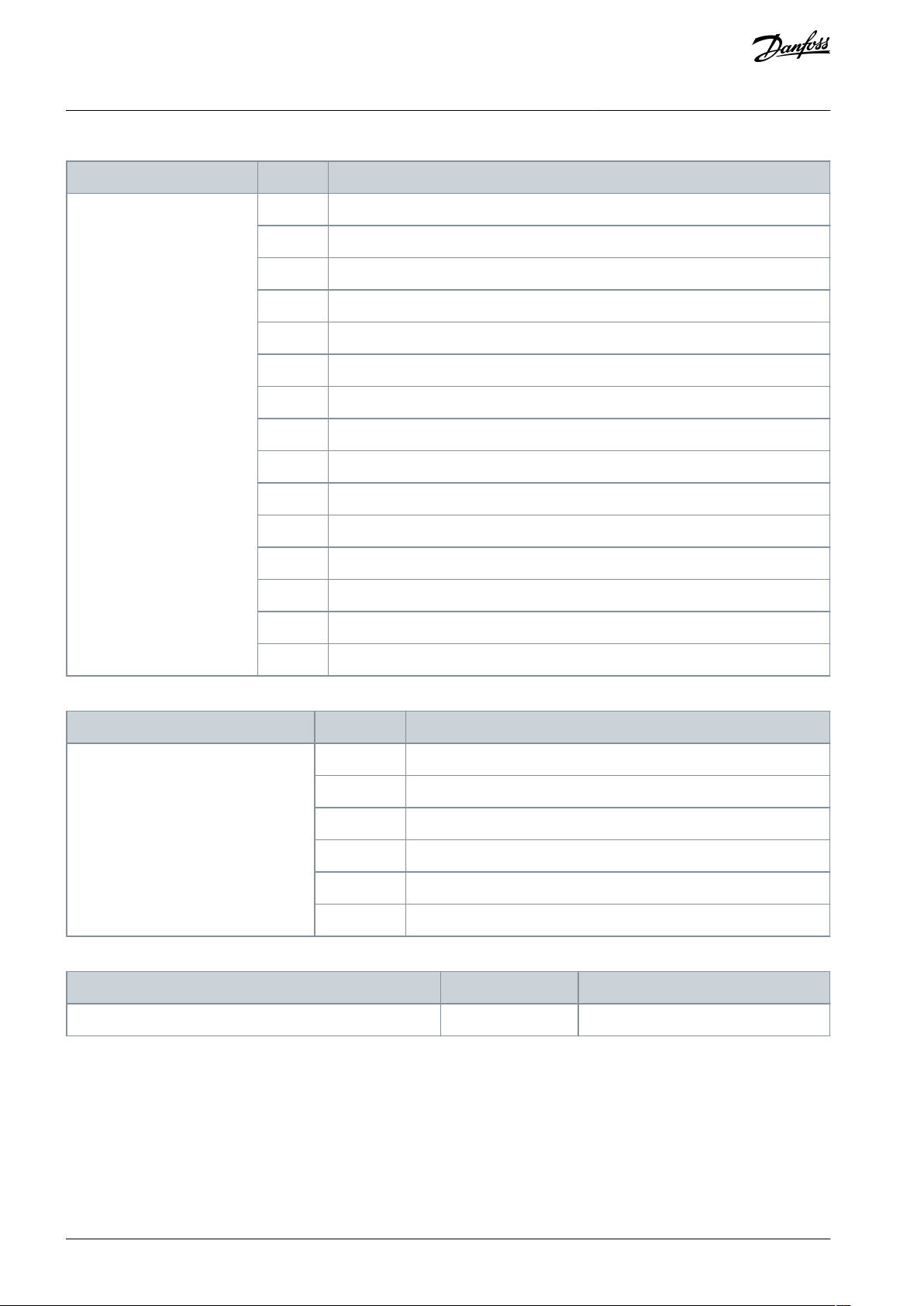

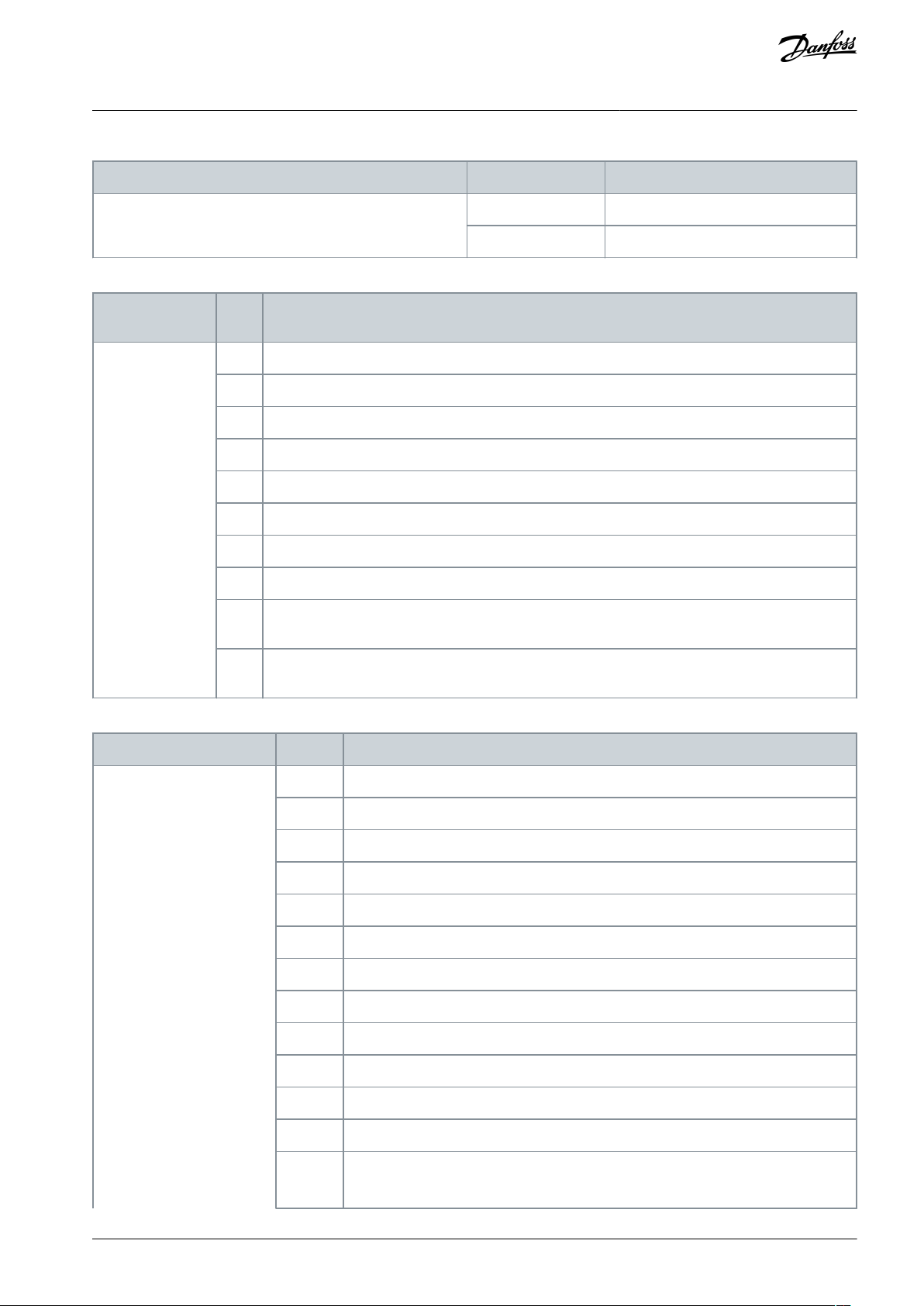

Character position

Code

Description

16–17

MX

None

M1

Fusible disconnect

M2

Non-fusible disconnect

M3

Circuit breaker (MCCB)

M4

Mains contactor

M5

AC reactor

M6

Fuses

MA

Fusible disconnect + mains contactor

MB

Non-fusible disconnect + mains contactor

MC

AC reactor + fusible disconnect

MD

AC reactor + fusible disconnect + mains contactor

ME

AC reactor + non-fusible disconnect

MF

AC reactor + circuit breaker (MCCB)

MG

AC reactor + mains contactor

MH

AC reactor + non-fusible disconnect + mains contactor

Character position

Code

Description

18

X

None

D

dU/dt filter

S

Sine-wave filter

C

Common-mode filter

1

Common-mode + dU/dt filters

2

Common-mode + sine-wave filters

Character position

Code

Description

19XNone

VLT® AQUA Drive FC 202

Operating Guide

Table 13: Mains Option Codes

Product Overview

Table 14: Output Filter Codes

Table 15: Reserved Code

AQ262141056213en-000201 / 130R088226 | Danfoss A/S © 2021.11

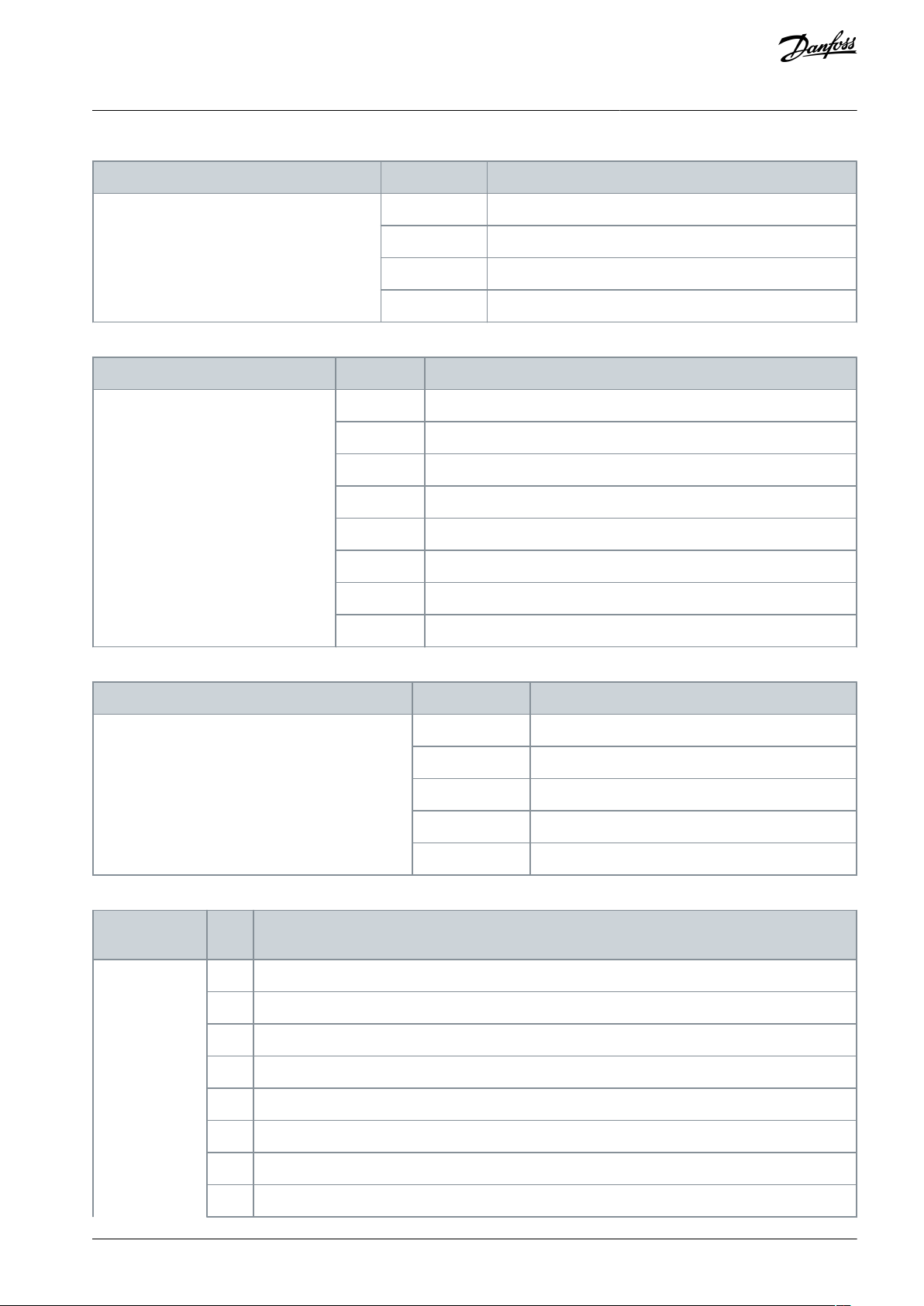

Character position

Code

Description

20

X

Bottom

T

TopLMains top, motor bottom

M

Mains bottom, motor top

Character position

Code

Description

21

1

230 V AC external

2

230 V AC internal

4

230 V AC internal + 24 V DC internal

5

230 V AC external + 24 V DC internal

6

120 V AC external

7

120 V AC internal

8

120 V AC internal + 24 V DC internal

9

120 V AC external + 24 V DC internal

Character position

Code

Description

22

X

Bottom in, top out

1

Back in, back out

C

Back in, top out

D

Bottom in, back out

N

None

Character position

Code

Description

23–24

AX

No auxiliary options

A1

AC socket+cabinet light

A2

Extended I/O terminals

A3

Cabinet heater

A4

Motor heater control

A5

Insulation monitor

AA

AC socket + cabinet light + extended I/O terminals

AB

AC socket + cabinet light + cabinet heater

VLT® AQUA Drive FC 202

Operating Guide

Table 16: Cable Infeed Codes

Table 17: Auxiliary Power Supply Codes

Product Overview

Table 18: Back-channel Cooling Codes

Table 19: Auxiliary Function Codes

AQ262141056213en-000201 / 130R0882 | 27Danfoss A/S © 2021.11

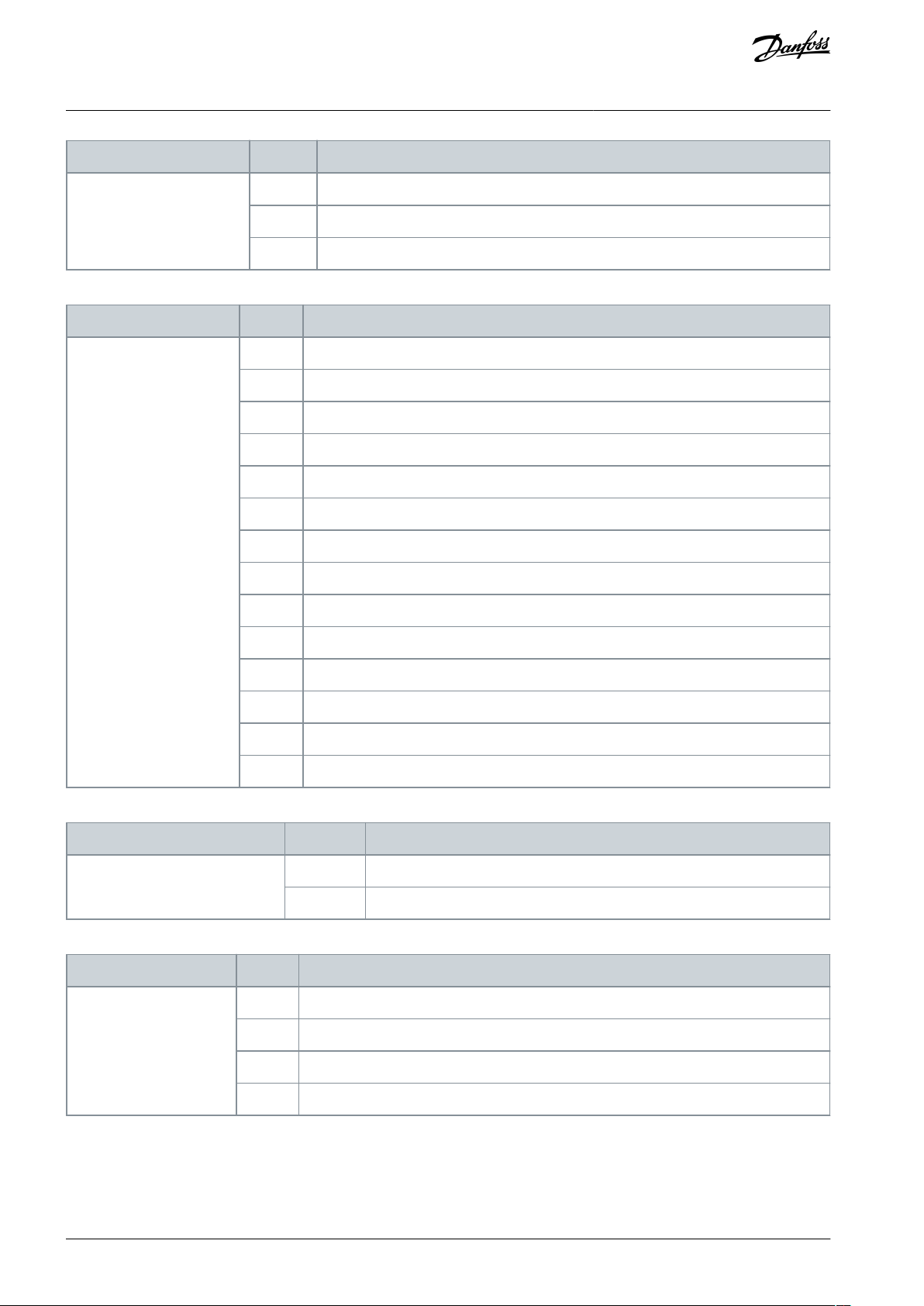

Character position

Code

Description

AC

AC socket + cabinet light + motor heater control

AD

AC socket + cabinet light + insulation monitor

AE

AC socket + cabinet light + extended I/O terminals + cabinet heater

AF

AC socket + cabinet light + extended I/O terminals + motor heater control

AG

AC socket + cabinet light + extended I/O terminals + insulation monitor

AH

AC socket + cabinet light + extended I/O terminals + cabinet heater + motor heater control

AI

AC socket + cabinet light + extended I/O terminals + cabinet heater + insulation monitor

AJ

AC socket + cabinet light + extended I/O terminals + motor heater control + insulation monitor

AK

AC socket + cabinet light + extended I/O terminals + cabinet heater + motor heater control + insulation monitor

AL

AC socket + cabinet light + cabinet heater + motor heater control

AM

AC socket + cabinet light + cabinet heater + insulation monitor

AN

AC socket + cabinet light + cabinet heater + motor heater control + insulation monitor

AO

AC socket + cabinet light + motor heater control + insulation monitor

AP

Extended I/O terminals + cabinet heater

AQ

Extended I/O terminals + motor heater control

AR

Extended I/O terminals + insulation monitor

AS

Extended I/O terminals + cabinet heater + motor heater control

AT

Extended I/O terminals + cabinet heater + insulation monitor

AU

Extended I/O terminals + cabinet heater + motor heater control + insulation monitor

AV

Extended I/O terminals + motor heater control + insulation monitor

AW

Cabinet heater + motor heater control

A8

Cabinet heater + insulation monitor

AY

Cabinet heater + motor heater control + insulation monitor

AZ

Motor heater control + insulation monitor

Character position

Code

Description

25

L

LCP in the door

N

No LCP in the door

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

Table 20: LCP Mounting Codes

AQ262141056213en-000201 / 130R088228 | Danfoss A/S © 2021.11

Character position

Code

Description

26–27

21

IP2154IP54

Character position

Code

Description

28–29

XX

None

D1

Signal lights and reset button

D2

Emergency switch off + emergency push-button

D3

STO with emergency push-button (basic functional safety)

D4

STO/SS1 with emergency push-button + safely limited speed (TTL encoder)

D5

STO/SS1 with emergency push-button + safely limited speed (HTL encoder)

DA

Indicator lights and reset button + emergency switch off and emergency push-button

DB

Indicator lights and reset button + STO with emergency push-button (basic functional safety)

DC

Indicator lights and reset button + STO/SS1 with emergency push-button + safely limited speed

(TTL encoder)

DE

Indicator lights and reset button + STO/SS1 with emergency push-button + safely limited speed

(HTL encoder)

Character position

Code

Description

30

X

No A option

0

VLT® PROFIBUS DP-V1 MCA 101

4

VLT® DeviceNet MCA 104 (FC 102/FC 202/FC 302 only)

6

VLT® CANopen MCA 105 (FC 302 only)

8

VLT® EtherCAT MCA 124 (FC 302 only)

G

VLT® LonWorks MCA 108 (FC 102 only)

J

VLT® BACnet MCA 109 (FC 102 only)

K

VLT® BACnet/IP MCA 125 (FC 102 only)

L

VLT® PROFINET MCA 120

N

VLT® EtherNet/IP MCA 121 (FC 102/FC 202/FC 302 only)

Q

VLT® Modbus TCP MCA 122 (FC 102/FC 202/FC 302 only)

T

VLT® PROFIBUS Converter VLT 3000 MCA 113 (FC 302 only)

U

VLT® PROFIBUS Converter VLT 5000 MCA 114 (FC 302 only)

VLT® AQUA Drive FC 202

Operating Guide

Table 21: Protection Rating Codes

Table 22: Door-mounted Codes

Product Overview

Table 23: A Option Codes

AQ262141056213en-000201 / 130R0882 | 29Danfoss A/S © 2021.11

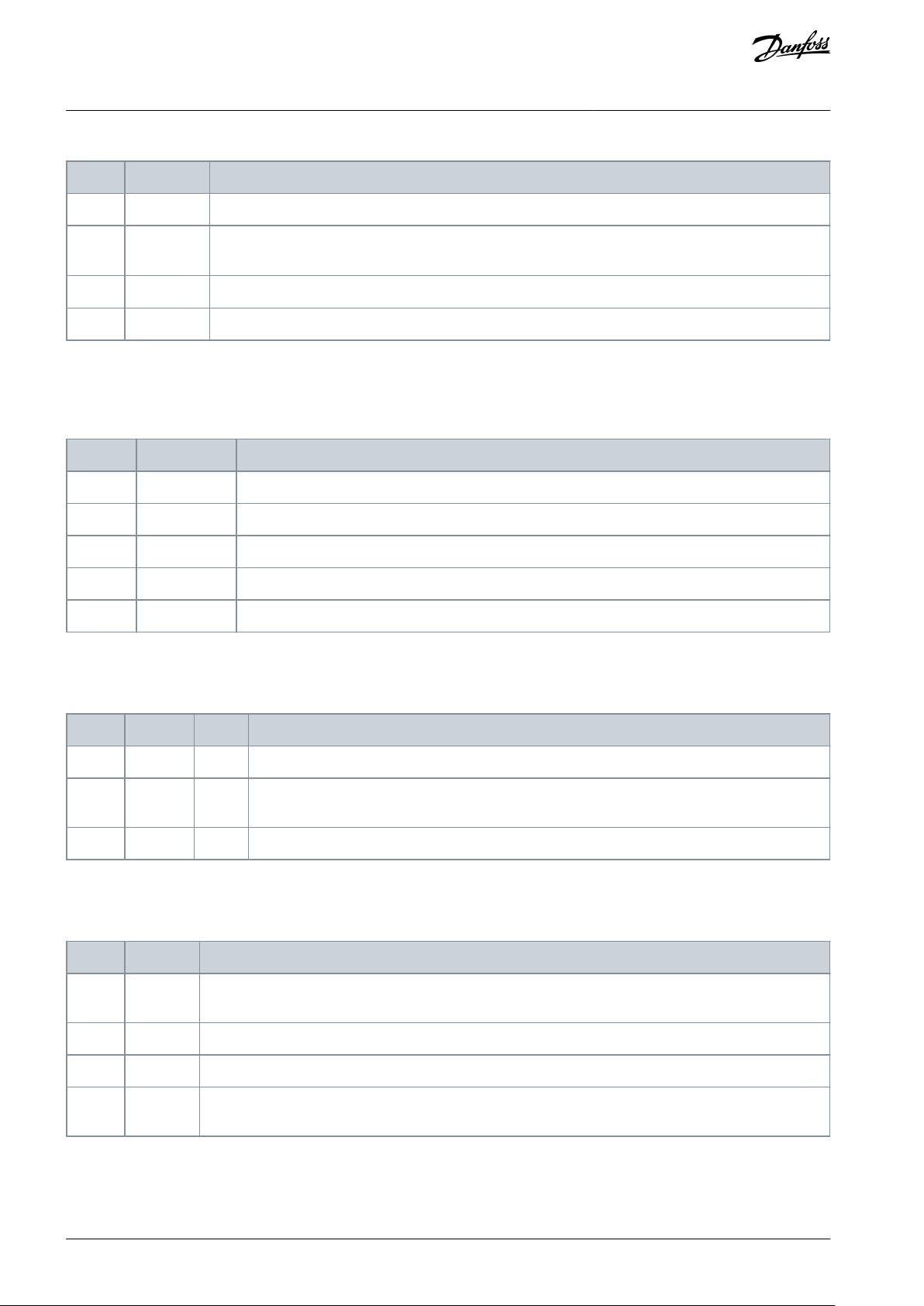

Character position

Code

Description

Y

VLT® POWERLINK MCA 123 (FC 302 only)

W

VLT® DeviceNet Converter MCA 194 (FC 302 only)

Z

VLT® AK-LonWorks MCA 107 (FC 103 only)

Character position

Code

Description

31

X

No B option

0

VLT® Analog I/O MCB 109 (FC 102/FC 103/FC 202 only)

2

VLT® PTC Thermistor Card MCB 112 (FC 102/FC 202/FC 302 only)

4

VLT® Sensor Input MCB 114 (FC 102/FC 202/FC 302 only)

K

VLT® General Purpose I/O Option MCB 101

P

VLT® Relay Option MCB 105

Y

VLT® Extended Cascade Controller MCO 101 (FC 202 only)

R

VLT® Encoder Option MCB 102 (FC 302 only)

U

VLT® Resolver Option MCB 103 (FC 302 only)

Z

VLT® Safety PLC Interface MCB 108 (FC 302 only)

5

VLT® Programmable I/O MCB 115

6

VLT® Safe Option TTL MCB 150 (FC 302 only)

7

VLT® Safe Option HTL MCB 151 (FC 302 only)

8

VLT® Safety Option MCB 152 (FC 302 only)

Character position

Code

Description

32

X

No C option software

4

VLT® Motion Control MCO 305 (FC 302 only)

Character position

Code

Description

33

X

No C1 option

5

VLT® Advanced Cascade Controller MCO 102 (FC 202/FC 302 only)

7

VLT® Sensorless Safety MCB 159 (FC 302 only)

R

VLT® Extended Relay Card MCB 113 (FC 302 only)

VLT® AQUA Drive FC 202

Operating Guide

Table 24: B Option Codes

Product Overview

Table 25: C0 Option MCO Codes

Table 26: C1 Option Codes

AQ262141056213en-000201 / 130R088230 | Danfoss A/S © 2021.11

Character position

Code

Description

34

X

No software option

0

VLT® Synchronizing Controller MCO 350 (FC 302 only)

1

VLT® Positioning Controller MCO 351 (FC 302 only)

Character position

Code

Description

35

X

No D option

0

VLT® 24 V DC Supply MCB 107

1

VLT® Real time clock option MCB 117

Character position

Code

Description

36

2

(H2) RFI class A2 (C3)

4

(H4) RFI class A1 (C2)

Character position

Code

Description

37–39

X

None

Character position

Code

Description

40

X

English, no 2nd language

G

English + German

F

English + French

Enclosed drive

D9h

D10h

E5h

E6h

Rated power at 380–480 V [kW

(hp)]

110–160 (150–250)

200–315 (300–450)

355–450 (500–600)

500–560 (650–750)

Rated power at 525–690 V [kW

(hp)]

110–160 (125–200)

200–400 (250–400)

450–630 (450–650)

710–800 (750–950)

Protection rating

IP21 (NEMA 1)/

IP54 (NEMA 12)

IP21 (NEMA 1)/IP54

(NEMA 12)

IP21 (NEMA 1)/IP54

(NEMA 12)

IP21 (NEMA 1)/IP54

(NEMA 12)

Drive cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

2100 (82.7)

2100 (82.7)

2100 (82.7)

2100 (82.7)

Width [mm (in)]

(2)

400 (15.8)

600 (23.6)

600 (23.6)

800 (31.5)

VLT® AQUA Drive FC 202

Operating Guide

Table 27: C Option Software Codes

Table 28: D Option Codes

Table 29: EMC Filter Codes

Product Overview

Table 30: Reserved Code

Table 31: Documentation Language Codes

3.5 Power Ratings, Weight, and Dimensions

Table 32: Power Ratings and Dimensions for D9h–D10h and E5h–E6h Enclosures (Standard Configurations)

AQ262141056213en-000201 / 130R0882 | 31Danfoss A/S © 2021.11

Enclosed drive

D9h

D10h

E5h

E6h

Depth [mm (in)]

600 (23.6)

600 (23.6)

600 (23.6)

600 (23.6)

Weight [kg (lb)]

(2)

280 (617)

355 (783)

400 (882)

431 (950)

Input filter cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

2100 (82.7)

2100 (82.7)

2100 (82.7)

2100 (82.7)

Width [mm (in)]

400 (15.8)/600

(23.6)

400 (15.8)/600

(23.6)

600 (23.6)/800 (31.5)

600 (23.6)/800 (31.5)

Depth [mm (in)]

600 (23.6)

600 (23.6)

600 (23.6)

600 (23.6)

Weight [kg (lb)]

410 (904)

410 (904)/530

(1168)

530 (1168)

530 (1168)/955

(2105)

Input power options cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

–

2100 (82.7)

2100 (82.7)

2100 (82.7)

Width [mm (in)]

–

600 (23.6)

600 (23.6)

600 (23.6)

Depth [mm (in)]

–

600 (23.6)

600 (23.6)

600 (23.6)

Weight [kg (lb)]

–

380 (838)

380 (838)

380 (838)

Sine-wave filter cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

2100 (82.7)

2100 (82.7)

2100 (82.7)

2100 (82.7)

Width [mm (in)]

600 (23.6)

600 (23.6)

1200 (47.2)

1200 (47.2)

Depth [mm (in)]

600 (23.6)

600 (23.6)

600 (23.6)

600 (23.6)

Weight [kg (lb)]

384 (847)

384 (847)

768 (1693)

768 (1693)

dU/dt filter cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

––2100 (82.7)

2100 (82.7)

Width [mm (in)]

(3)

––400 (15.8)

400 (15.8)

Depth [mm (in)]

––600 (23.6)

600 (23.6)

Weight [kg (lb)]

––240 (529)

240 (529)

Top entry/exit cabinet

D9h

D10h

E5h

E6h

Height [mm (in)]

(1)

2100 (82.7)

2100 (82.7)

2100 (82.7)

2100 (82.7)

Width [mm (in)]

(3)

400 (15.8)

400 (15.8)

400 (15.8)

400 (15.8)

Depth [mm (in)]

600 (23.6)

600 (23.6)

600 (23.6)

600 (23.6)

Weight [kg (lb)]

164 (362)

164 (362)

164 (362)

164 (362)

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

1

Cabinet height includes standard 100 mm (3.9 in) pedestal. A 200 mm (7.9 in) or 400 mm (15.8 in) pedestal is optional.

2

Without options.

3

The E5h and E6h enclosures contain 2 sine-wave cabinets. The provided width is the total of both cabinets.

AQ262141056213en-000201 / 130R088232 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

3.6 Control Compartment and Local Control Panel

3.6.1 Control Compartment Overview

The control compartment is a self-contained space that can be accessed without opening the drive enclosure. The control compartment contains the following:

•

Control terminals.

•

Relay terminals.

•

Terminals for option cards.

•

Optional components:

-

Auxiliary supply terminals.

-

Auxiliary voltage transformer connections.

-

+24 V DC external supply.

-

AC customer socket.

-

Extended I/O terminals.

-

Cabinet heater connections.

-

Motor heater control connections.

-

Thermal trip indicator relays.

-

Insulation monitor.

-

Magnetic cabinet light.

•

Buttons and indicator lights (on the exterior door).

•

Local control panel (LCP).

•

Product nameplate.

AQ262141056213en-000201 / 130R0882 | 33Danfoss A/S © 2021.11

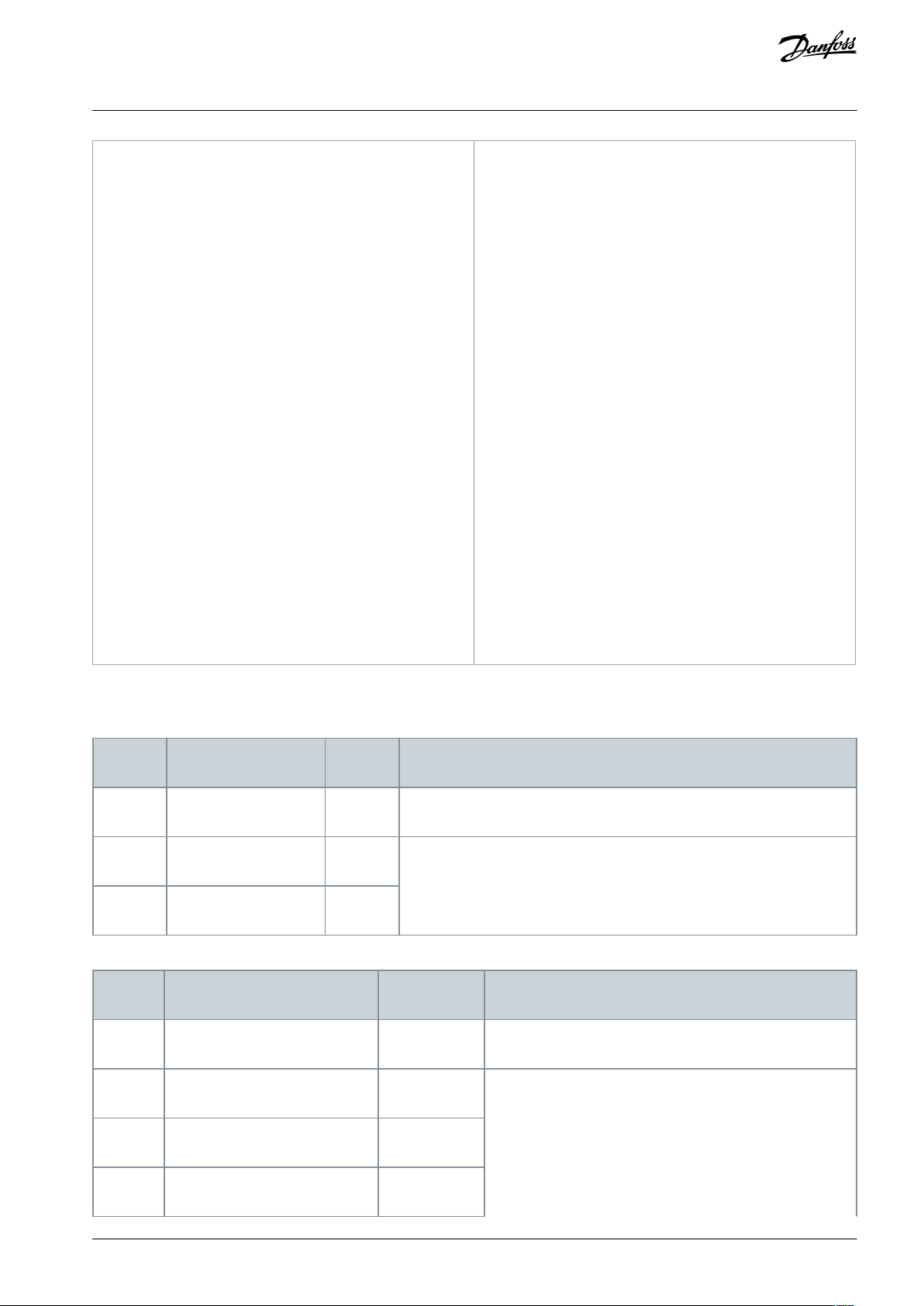

e30bu142.11

4

6

7

8

5

3

2

1

9

1

Local control panel (LCP)

2

Emergency push-button

3

Fault indicator light

4

Run indicator light

5

Insulation fault indicator light

6

USB slot

7

0–1 Start switch

8

Reset button

9

Nameplate

VLT® AQUA Drive FC 202

Operating Guide

3.6.2 Control Compartment Door

Product Overview

Illustration 8: Exterior Door of Control Compartment (Shown with All Options)

AQ262141056213en-000201 / 130R088234 | Danfoss A/S © 2021.11

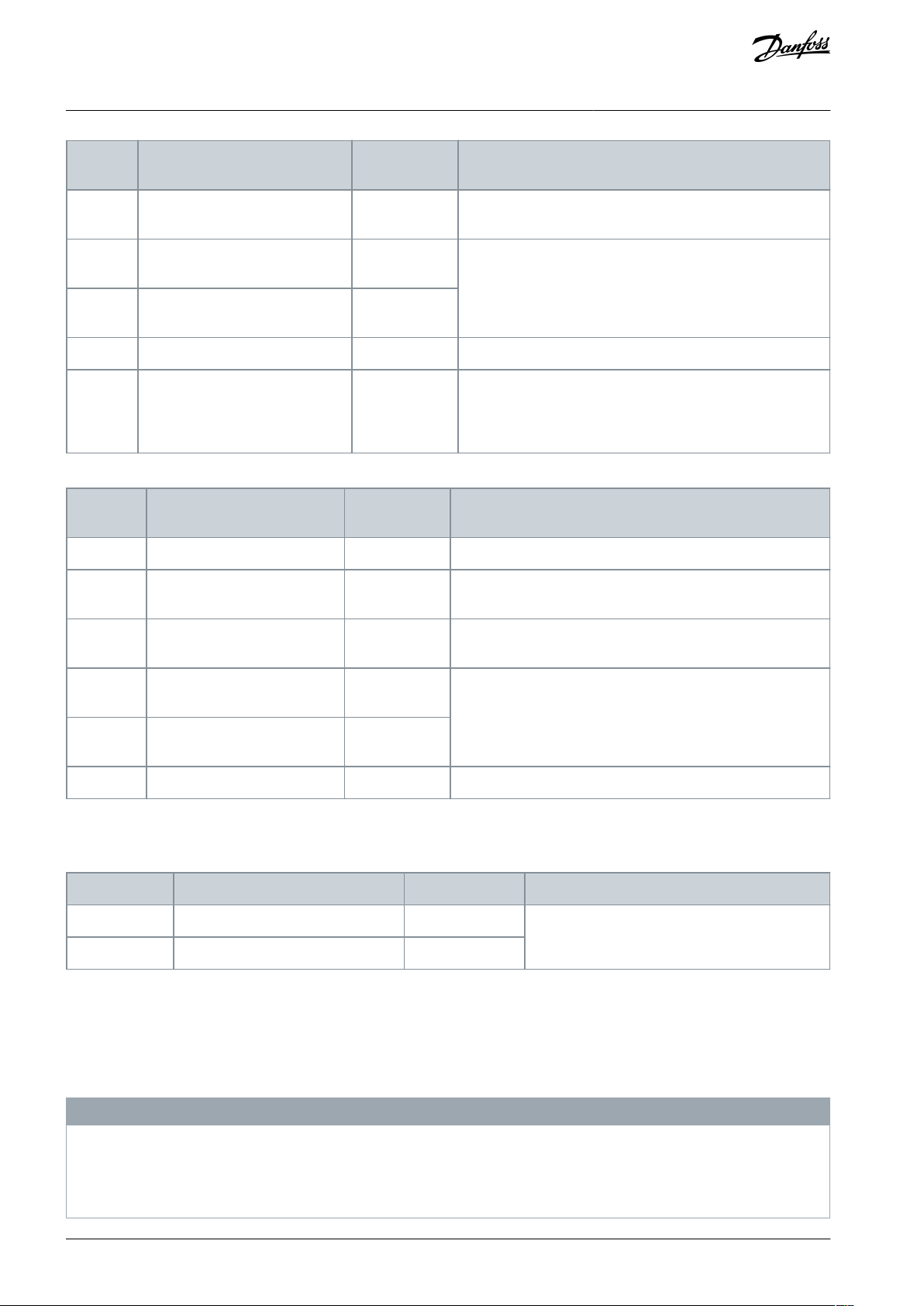

e30bf155.10

Auto

On

Reset

Hand

On

Off

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(1)

0.00 kW

Off Remote Stop

0.0 Hz

On

Alarm

Warn.

0.00 A

0 RPM

0.0 %

A1.1

A1.2

A1.3

A2

A3

B1

B2

B4

B3

C1

C2

C3

C4

C5

D1

D2

D3

E1

E2

E3

E4

Callout

Parameter

Default setting

A1.1

Parameter 0-20 Display Line 1.1 Small

Reference [Unit]

A1.2

Parameter 0-21 Display Line 1.2 Small

Analog input 53 [V]

A1.3

Parameter 0-22 Display Line 1.3 Small

Motor current [A]

A2

Parameter 0-23 Display Line 2 Large

Frequency [Hz]

A3

Parameter 0-24 Display Line 3 Large

Feedback [Unit]

VLT® AQUA Drive FC 202

Operating Guide

3.6.3 Local Control Panel (LCP)

Product Overview

Illustration 9: Graphical Local Control Panel (LCP)

The local control panel (LCP) is the combined display and keypad on the front of the drive. The LCP is used to:

•

Control the drive and motor.

•

Access drive parameters and program the drive.

•

Show operational data, drive status, and warnings.

A numeric local control panel (NLCP) is available as an option. The NLCP operates in a manner similar to the LCP, but there are

differences. For details on how to use the NLCP, see the product-specific Programming Guide.

A. Display area

Each display readout has a parameter associated with it. The information shown on the LCP can be customized for specific applications. Refer to My Personal Menu in the LCP Menu section.

Table 33: LCP Display Area

B. Menu keys

Menu keys are used to access the menu for setting up parameters, toggling through status display modes during normal operation,

and viewing fault log data.

AQ262141056213en-000201 / 130R0882 | 35Danfoss A/S © 2021.11

Callout

Key

Function

B1

Status

Shows operational information.

B2

Quick Menu

Allows access to parameters for initial set-up instructions. Also provides detailed application steps. Refer

to Quick Menu mode in the LCP Menu section.

B3

Main Menu

Allows access to all parameters. Refer to Main Menu mode in the LCP Menu section.

B4

Alarm Log

Shows a list of current warnings and the last 10 alarms.

Callout

Key

Function

C1

Back

Reverts to the previous step or list in the menu structure.

C2

Cancel

Cancels the last change or command as long as the display mode has not changed.

C3

Info

Shows a definition of the function being shown.

C4OKAccesses parameter groups or enables an option.

C5

[▵][▹] [▿] [◃]

Moves between items in the menu.

Callout

Indicator

LED

Function

D1OnGreen

Activates when the drive receives power from the mains voltage or a 24 V external supply.

D2

Warn.

Yellow

Activates when warning conditions are active. Text appears in the display area identifying the

problem.

D3

Alarm

Red

Activates during a fault condition. Text appears in the display area identifying the problem.

Callout

Key

Function

E1

[Hand On]

Starts the drive in local control. An external stop signal by control input or serial communication overrides

the local [Hand On].

E2

Off

Stops the motor but does not remove power to the drive.

E3

Reset

Resets the drive manually after a fault has been cleared.

E4

Auto On

Puts the system in remote operational mode so it can respond to an external start command by control

terminals or serial communication.

VLT® AQUA Drive FC 202

Operating Guide

Table 34: LCP Menu Keys

Product Overview

C. Navigation keys

Navigation keys are used for programming functions and moving the display cursor. The navigation keys also provide speed control

in local (hand) operation. The display brightness can be adjusted by pressing [Status] and [▵]/[▿] keys.

Table 35: LCP Navigation Keys

D. Indicator lights

Indicator lights identify the drive status and provide a visual notification of warning or fault conditions.

Table 36: LCP Indicator Lights

E. Operation keys and reset

The operation keys are found toward the bottom of the local control panel.

Table 37: LCP Operation Keys and Reset

AQ262141056213en-000201 / 130R088236 | Danfoss A/S © 2021.11

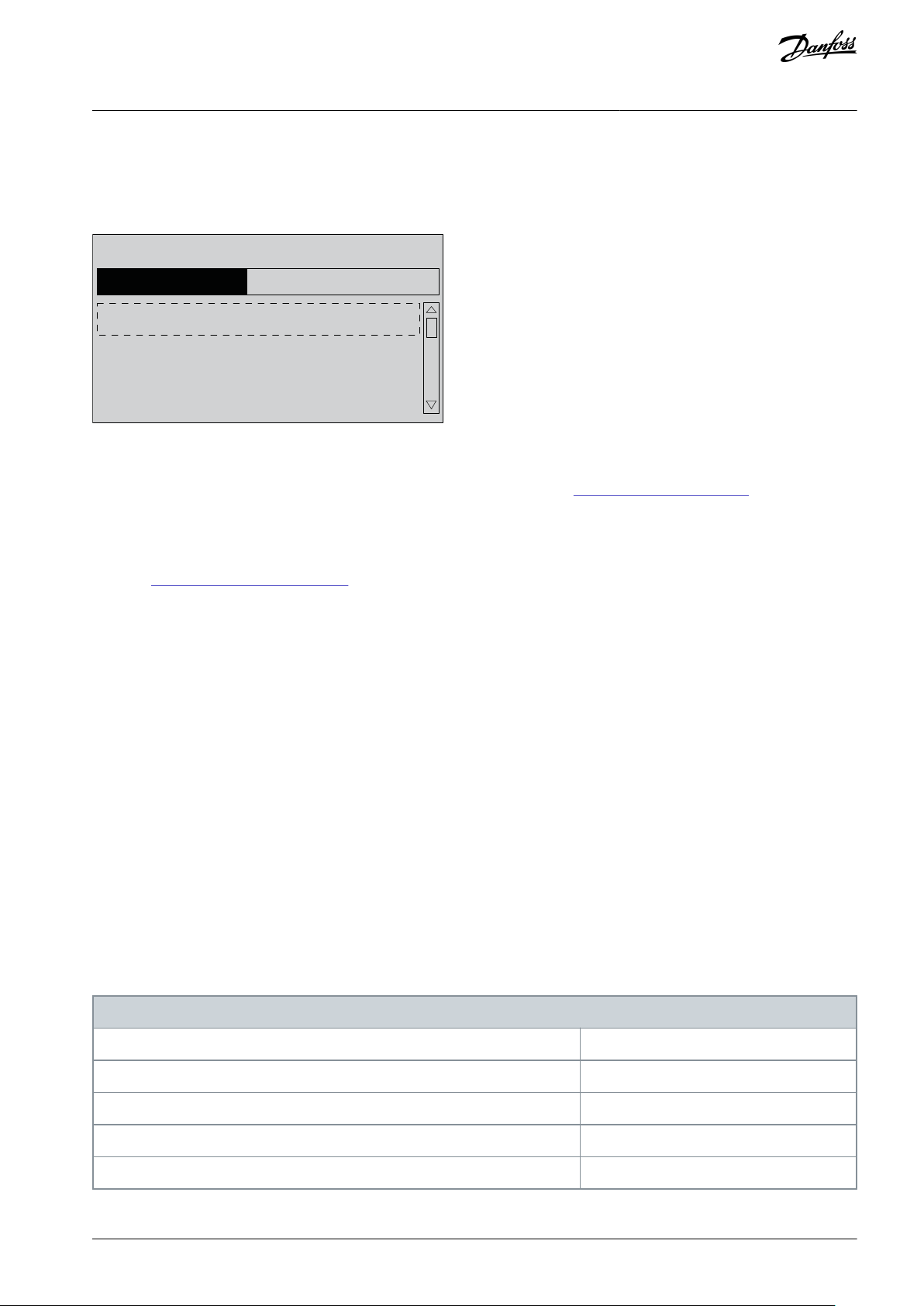

e30bf242.10

Q1 My Personal Menu

Q2 Quick Setup

Q3 Function Setups

Q5 Changes Made

0.0% 0.00

Quick Menus

1(1)

Q6 Loggings

Parameter 0-20 Display Line 1.1 Small

Reference [Unit]

Parameter 0-21 Display Line 1.2 Small

Analog input 53 [V]

Parameter 0-22 Display Line 1.3 Small

Motor current [A]

Parameter 0-23 Display Line 2 Large

Frequency [Hz]

Parameter 0-24 Display Line 3 Large

Feedback [Unit]

VLT® AQUA Drive FC 202

Operating Guide

Product Overview

3.6.4 LCP Menu

Quick Menus

The Quick Menus mode provides a list of menus used to configure and operate the drive. Select the Quick Menus mode by pressing

the [Quick Menu] key. The resulting readout appears on the LCP display.

Illustration 10: Quick Menu View

Q1 My Personal Menu

The Personal Menu is used to determine what is shown in the display area. Refer to 3.6.3 Local Control Panel (LCP). This menu can

also show up to 50 pre-programmed parameters. These 50 parameters are manually entered using parameter 0-25 My Personal

Menu.

Q2 Quick Setup

The parameters found in the Q2 Quick Setup contain basic system and motor data that are always necessary for configuring the

drive. See

Q3 Function Setups

The parameters found in the Q3 Function Setups contain data for fan, compressor, and pump functions. This menu also includes

parameters for LCP display, digital preset speeds, scaling of analog references, closed-loop single-zone, and multizone applications.

Q4 Smart Setup

Q4 Smart Setup guides the user through typical parameter settings used to configure 1 of the following 4 applications:

•

•

•

•

The [Info] key can be used to see help information for various selections, settings, and messages.

Q5 Changes Made

Select Q5 Changes Made for information about:

•

•

Q6 Loggings

Use Q6 Loggings for fault finding. To get information about the display line readout, select Loggings. The information is shown as

graphs. Only parameters selected in parameter 0-20 Display Line 1.1 Small through parameter 0-24 Display Line 3 Large can be viewed.

It is possible to store up to 120 samples in the memory for later reference.

7.2.4 Entering System Information for the set-up procedures.

Single pump/motor.

Motor alternation.

Master/follower.

Basic cascade.

The 10 most recent changes.

Changes made from default setting.

Table 38: Logging Parameter Examples

AQ262141056213en-000201 / 130R0882 | 37Danfoss A/S © 2021.11

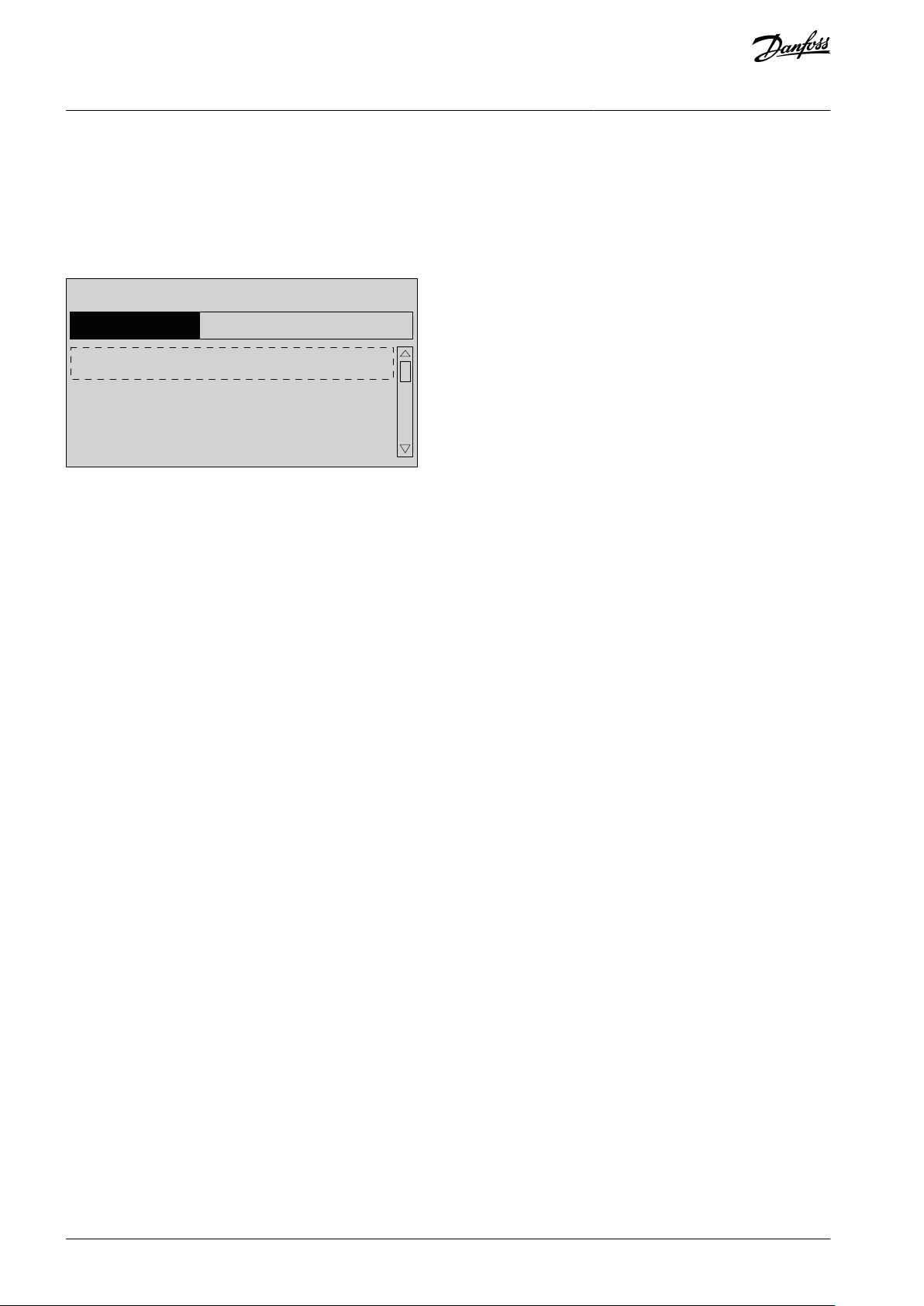

e30bf204.10

O-** Operation / Display

1-** Load and Motor

2-** Brakes

3-** Reference / Ramps

0.0% 0.00 A

Main Menu

1(1)

VLT® AQUA Drive FC 202

Operating Guide

Q7 Water and Pumps

The parameters found in the Q7 Water and Pumps contain basic data that is necessary for configuring water pump applications.

Main Menu

The Main Menu mode is used to:

•

List the parameter groups available to the drive and drive options.

•

Change parameter values.

Illustration 11: Main Menu View

Product Overview

AQ262141056213en-000201 / 130R088238 | Danfoss A/S © 2021.11

e30bu138.11

1

2

3

4

5

6

e30bu764.11

1

Type code

2

Part number and serial number

3

Power rating

4

Input voltage, frequency, and current (at low/high

voltages)

5

Output voltage, frequency, and current (at low/high

voltages)

6

Discharge time

VLT® AQUA Drive FC 202

Operating Guide

Mechanical Installation

4 Mechanical Installation

4.1 Items Supplied

Items supplied can vary according to product configuration.

•

Make sure that the items supplied and the information on the nameplate correspond to the order confirmation.

•

Visually check the packaging and the drive for damage caused by inappropriate handling during shipment. File any claim for

damage with the carrier. Retain damaged parts for clarification.

Illustration 12: Example of a Product Nameplate for E6h Enclosure (IEC Version on Left, UL Version on Right)

WARRANTY

Removing the nameplate from the drive results in loss of warranty.

N O T I C E

4.2 Split Shipment

Depending on what options are ordered with an enclosed drive, the drive can consist of 5 cabinets and measure 3400 mm (134 in)

in width, which can be difficult to transport and handle. In cases where an enclosed drive exceeds 1800 mm (71 in) in width, the

cabinets are separated and shipped in multiple boxes. All necessary fasteners needed for reassembly are provided in the delivery.

To reassemble a split shipment, refer to 4.10 Combining Multiple Cabinets from a Split Shipment and 5.6.1 Connecting Wiring Har-

nesses.

AQ262141056213en-000201 / 130R0882 | 39Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Mechanical Installation

4.3 Tools Needed

•

I-beam and hooks rated to lift the weight of the drive.

•

Crane or other lifting aid to place the unit into position.

•

Drill with a 12 mm (1/2 in) drill bit.

•

Tape measurer.

•

Phillips and flat-bladed screwdrivers.

•

Wrench with 7–17 mm metric sockets.

•

Wrench extensions.

•

T25 and T50 Torx drives.

•

Sheet metal punch and/or pliers for cable entry plate.

4.4 Storing the Drive

Store the drive in a dry location. Keep the equipment sealed in its packaging until installation. Refer to the Ambient Conditions

section for recommended ambient temperature.

Periodic forming (capacitor charging) is not necessary during storage unless storage exceeds 12 months.

4.5 Operating Environment

4.5.1 Overview

In environments with airborne liquids, particles, or corrosive gases, ensure that the IP/NEMA protection rating of the equipment

matches the installation environment. Refer to the Ambient Conditions section.

N O T I C E

CONDENSATION

Moisture can condense on the electronic components and cause short circuits.

Avoid installation in areas subject to frost.

-

Install an optional space heater when the unit is colder than the ambient air.

-

Operating in standby mode reduces the risk of condensation as long as the power dissipation keeps the circuitry free of

-

moisture.

N O T I C E

EXTREME AMBIENT CONDITIONS

Hot or cold temperatures compromise unit performance and longevity.

Do not operate in environments where the ambient temperature exceeds 50 °C (122 °F) for units rated at 400–500 V and

-

45 °C (113 °F) for units rated at 525–690 V unless the drive is derated. Refer to the Derating section in the design guide.

The unit can operate at temperatures down to -10 °C (14 °F). However, proper operation at rated load is only guaranteed at

-

0 °C (32 °F) or higher. Also, temperature feedback is not shown when temperatures are below 0 °C (32 °F).

Provide extra air conditioning for the cabinet or installation site when the temperature exceeds ambient temperature limits.

-

4.5.2 Gases

Aggressive gases, such as hydrogen sulphide, chlorine, or ammonia can damage the electrical and mechanical components. The

unit uses conformal-coated circuit boards to reduce the effects of aggressive gases.

For conformal coating class specifications and ratings, see the Ambient Conditions section.

4.5.3 Dust

When installing the unit in a dusty environment, keep the following free from dust buildup:

•

Electronic components.

•

Heat sink.

•

Fans.

AQ262141056213en-000201 / 130R088240 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Keep the heat sink and fans free from dust buildup. When dust accumulates on electronic components, it acts as a layer of insulation. This layer reduces the cooling capacity of the components, and the components become warmer. The hotter environment

decreases the life of the electronic components. Dust can also accumulate on fan blades, causing an imbalance which prevents the

fan from properly cooling the unit. Dust buildup can also damage fan bearings and cause premature fan failure.

For more information, refer to the Maintenance and Service section.

Mechanical Installation

4.5.4 Potentially Explosive Atmospheres

W A R N I N G

EXPLOSIVE ATMOSPHERE

Installing the drive in a potentially explosive atmosphere can lead to death, personal injury, or property damage.

Install the unit in a cabinet outside of the potentially explosive area.

-

Use a motor with an appropriate ATEX protection class.

-

Install a PTC temperature sensor to monitor the motor temperature.

-

Install short motor cables.

-

Use sine-wave output filters when shielded motor cables are not used.

-

As required by the EU Directive 2014/34/EU, any electrical or electronic device intended for use in an environment with a potentially

explosive mixture of air, flammable gas, or dust must be ATEX-certified. Systems operated in this environment must fulfill the following special conditions to comply with the ATEX protection class:

•

Class d specifies that if a spark occurs, it is contained in a protected area.

•

Class e prohibits any occurrence of a spark.

Motors with class d protection

Does not require approval. Special wiring and containment are required.

Motors with class e or class n protection

When combined with an ATEX-approved PTC monitoring device like the VLT® PTC Thermistor Card MCB 112, installation does not

need an individual approval from an approbated organization.

Motors with class d/e protection

The motor itself has an e ignition protection class, while the motor cabling and connection environment are in compliance with the

d classification. To attenuate the high peak voltage, use a sine-wave filter at the drive output.

N O T I C E

MOTOR THERMISTOR SENSOR MONITORING

Units with the VLT® PTC Thermistor Card MCB 112 option are PTB-certified for potentially explosive atmospheres.

4.6 Installation Requirements

N O T I C E

OVERHEATING

Improper mounting can result in overheating and reduced performance.

Install the drive according to the installation and cooling requirements.

-

•

Locate the unit as near to the motor as possible. For the maximum motor cable length, see 10.5 Motor and Control Cables.

•

Ensure unit stability by mounting the unit to a solid surface.

•

Ensure that the strength of the mounting location supports the unit weight.

•

Ensure that there is enough space around the unit for proper cooling. Refer to 10.10 Enclosure Airflow.

•

Ensure enough access to open the door.

•

Ensure cable entry from the bottom.

AQ262141056213en-000201 / 130R0882 | 41Danfoss A/S © 2021.11

Cabinet

Back-channel fan [m3/hr (cfm)]

Drive module top fan [m3/hr (cfm)]

Cabinet door fan [m3/hr (cfm)]

PHF/line reactor

450 (265)

––Drive

420 (250)

102 (60)

150 (90)

dU/dt

–––

Sine-wave

900 (530)

––Top entry/top exit

–––

Cabinet

Back-channel fan [m3/hr (cfm)]

Drive module top fan [m3/hr (cfm)]

Cabinet door fan [m3/hr (cfm)]

PHF/line reactor

515 (303)

––Input options

––510 (310)

Drive

840 (500)

204 (120)

315 (185)

dU/dt

–––

Sine-wave

900 (530)

––Top entry/top exit

–––

Cabinet

Back-channel fan [m3/hr (cfm)]

Drive module top fan [m3/hr (cfm)]

Cabinet door fan [m3/hr (cfm)]

PHF/line reactor

765 (450)

––Input options

––510 (310)

Drive

994 (585)

595 (350)

335 (200)

VLT® AQUA Drive FC 202

Operating Guide

Mechanical Installation

4.7 Cooling Requirements

N O T I C E

OVERHEATING

Improper mounting can result in overheating and reduced performance.

Install the drive following the installation and cooling requirements.

-

•

Ensure that top and bottom clearance for air cooling is provided. Clearance requirement: 225 mm (9 in).

•

Provide sufficient airflow flow rate. See 4.8 Airflow Rates.

•

Consider derating for temperatures starting between 45 °C (113 °F) and 50 °C (122 °F) and elevation 1000 m (3300 ft) above sea

level.

The enclosed drive, excluding the input power options cabinet, utilizes a back-channel cooling concept that removes the air used to

cool the heat sink. The heat sink cooling air carries approximately 90% of the heat out of the back channel of the drive. Different

back-channel cooling kits are available to redirect the airflow based on individual needs.

4.8 Airflow Rates

Table 39: Airflow Rates for D9h Enclosure

Table 40: Airflow Rates for D10h Enclosure

Table 41: Airflow Rates for E5h Enclosure

AQ262141056213en-000201 / 130R088242 | Danfoss A/S © 2021.11

Cabinet

Back-channel fan [m3/hr (cfm)]

Drive module top fan [m3/hr (cfm)]

Cabinet door fan [m3/hr (cfm)]

dU/dt

665 (392)

––Sine-wave

2x900 (530)

––Top entry/top exit

–––

Cabinet

Back-channel fan [m3/hr (cfm)]

Drive module top fan [m3/hr (cfm)]

Cabinet door fan [m3/hr (cfm)]

PHF/line reactor

1285 (755)

––Input options

––510 (310)

Drive

1053–1206 (620–710)

629 (370)

430 (255)

dU/dt

665 (392)

––Sine-wave

2x900 (530)

––Top entry/top exit

–––

VLT® AQUA Drive FC 202

Operating Guide

Table 42: Airflow Rates for E6h Enclosure

Mechanical Installation

AQ262141056213en-000201 / 130R0882 | 43Danfoss A/S © 2021.11

>60

>60

e30bu146.11

VLT® AQUA Drive FC 202

Operating Guide

Mechanical Installation

4.9 Lifting the Drive

W A R N I N G

HEAVY WEIGHT

The drive is heavy. Failure to follow local safety regulations for lifting heavy weights may cause death, personal injury, or property

damage.

Ensure that the lifting equipment is in proper working condition.

-

Check the weight of the drive and verify that the lifting equipment can safely lift the weight.

-

Ensure that the angle from the top of the drive to the lifting cable is 65° or greater.

-

Test lift the drive approximately 610 mm (24 in) to verify the proper center of gravity lift point. Reposition the lifting point if

-

the unit is not level.

Never walk under suspended loads.

-

Illustration 13: Recommended Lifting Method

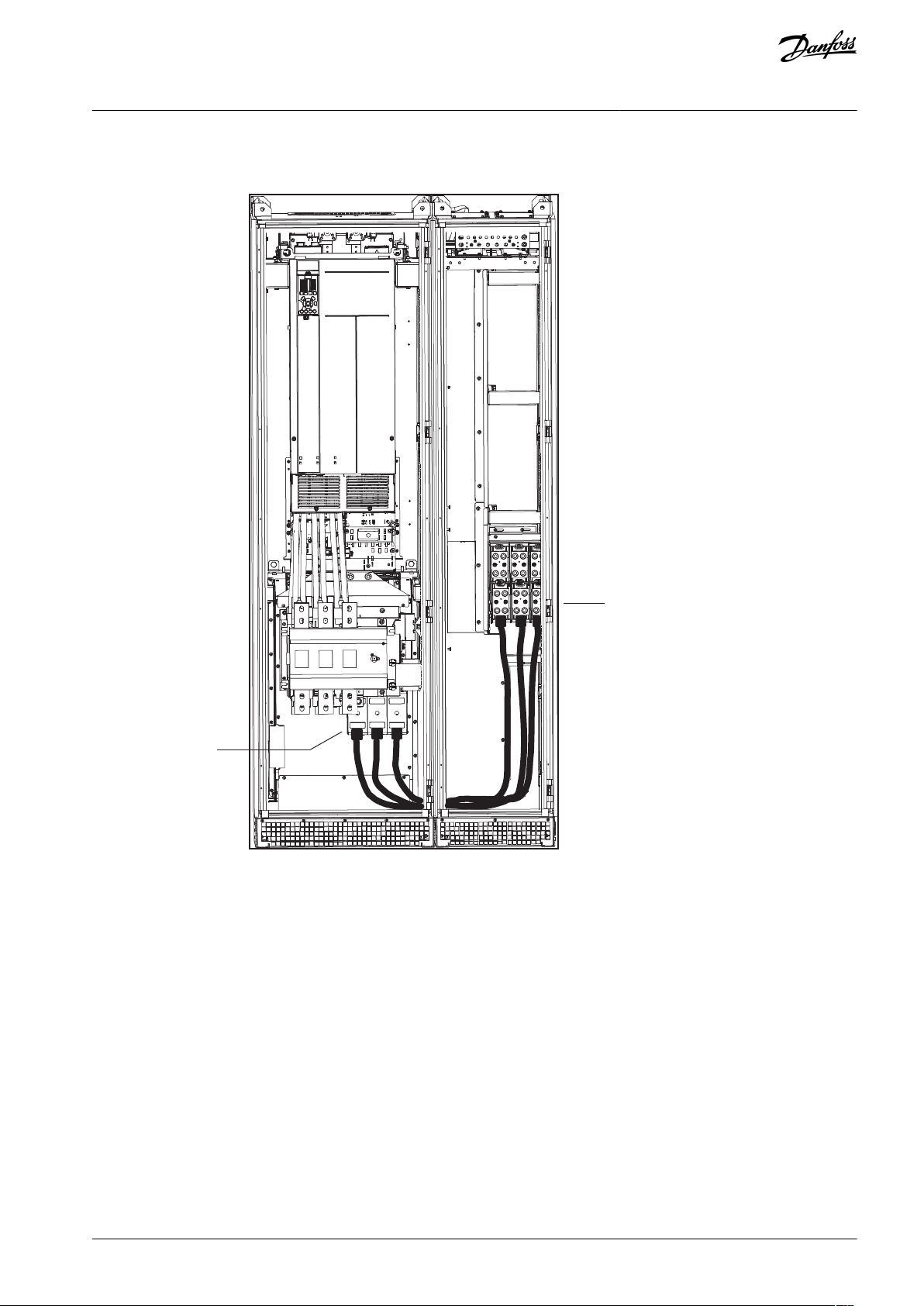

4.10 Combining Multiple Cabinets from a Split Shipment

Procedure

1.

Make sure the cabinets are in the right order and place them side by side. For the proper order, refer to 3.2 What is an

Enclosed Drive?.

2.

Attach the cabinets to one another:

a.

Remove the Rittal back cover from each cabinet.

b.

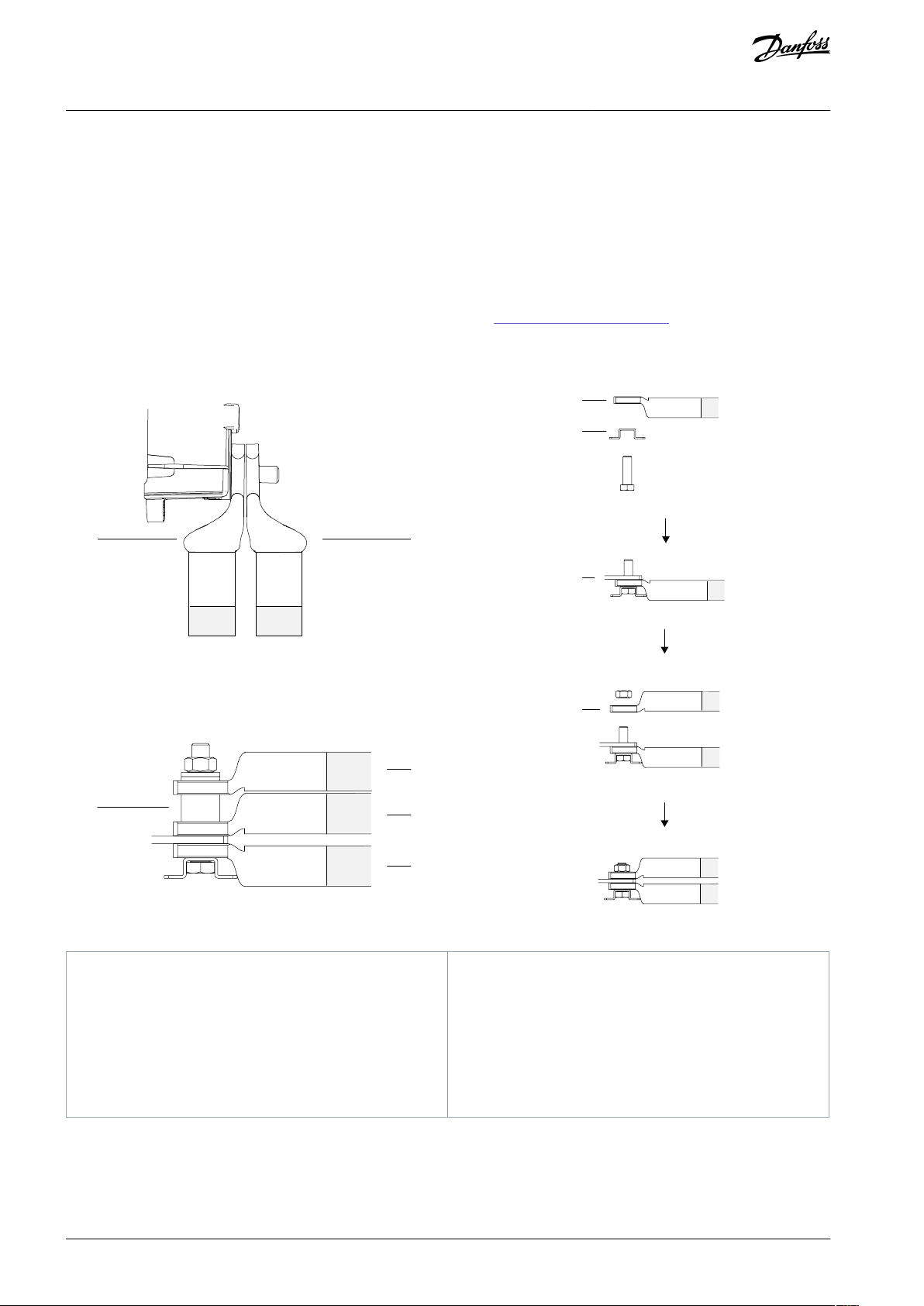

Secure the back side of the cabinets to one another using the back brackets. See Illustration 14.

c.

Secure the front side of the cabinets to one another using the front brackets. See Illustration 14.

AQ262141056213en-000201 / 130R088244 | Danfoss A/S © 2021.11

e30bu125.10

1

2

1

Front brackets

2

Back brackets

e30bu133.10

VLT® AQUA Drive FC 202

Operating Guide

d.e.Secure the lifting eyelets to the top of the cabinets. See Illustration 15.

Join the grounding bars using the connector piece (see the shaded piece in Illustration 16).

Example

Mechanical Installation

Illustration 14: Bracket Mounting Points for Cabinets

Illustration 15: Connecting the Lifting Eyelet Between Cabinets

AQ262141056213en-000201 / 130R0882 | 45Danfoss A/S © 2021.11

e30bu134.10

VLT® AQUA Drive FC 202

Operating Guide

Illustration 16: Connecting the Grounding Bar Between Cabinets

4.11 Installing the Enclosed Drive

Mechanical Installation

4.11.1 Creating an Entry for Cables

Procedure

1.

Locate the cabinets that contain the motor and mains terminals.

2.

Open the cabinet doors and remove any protective covers placed over the terminals.

3.

Cut or drill openings in the cable entry plate and fit with appropriate Type-rated IEC/UL conduits, according to the mains

and motor cable sizes.

4.

Terminate the shields properly.

4.11.2 Installing the Drive with Back-channel Cooling Option

Procedure

1.

Select an area in which to install the enclosure. Do not install the enclosure in an airtight space. The drive receives approximately 5–10% of intake air from the front of the cabinet.

2.

Measure the duct openings in the back of the cabinets and create corresponding openings in the wall where the enclosure

will be located.

3.

If the enclosed drive is configured with a cabinet heater, connect the cabinet heater supply cable to the correct terminals in

the control compartment. Refer to 5.7.2 Control Compartment Interior View.

4.

Move the enclosure near the wall, lining up the enclosure ducts with the openings in the wall.

AQ262141056213en-000201 / 130R088246 | Danfoss A/S © 2021.11

e30bu169.10

VLT® AQUA Drive FC 202

Operating Guide

5.

Make sure to provide an airtight seal for between the duct and wall opening.

Example

Mechanical Installation

Illustration 17: Cabinet Airflow with the Back-channel Option (Duct Adapter Flanges not Provided with Option)

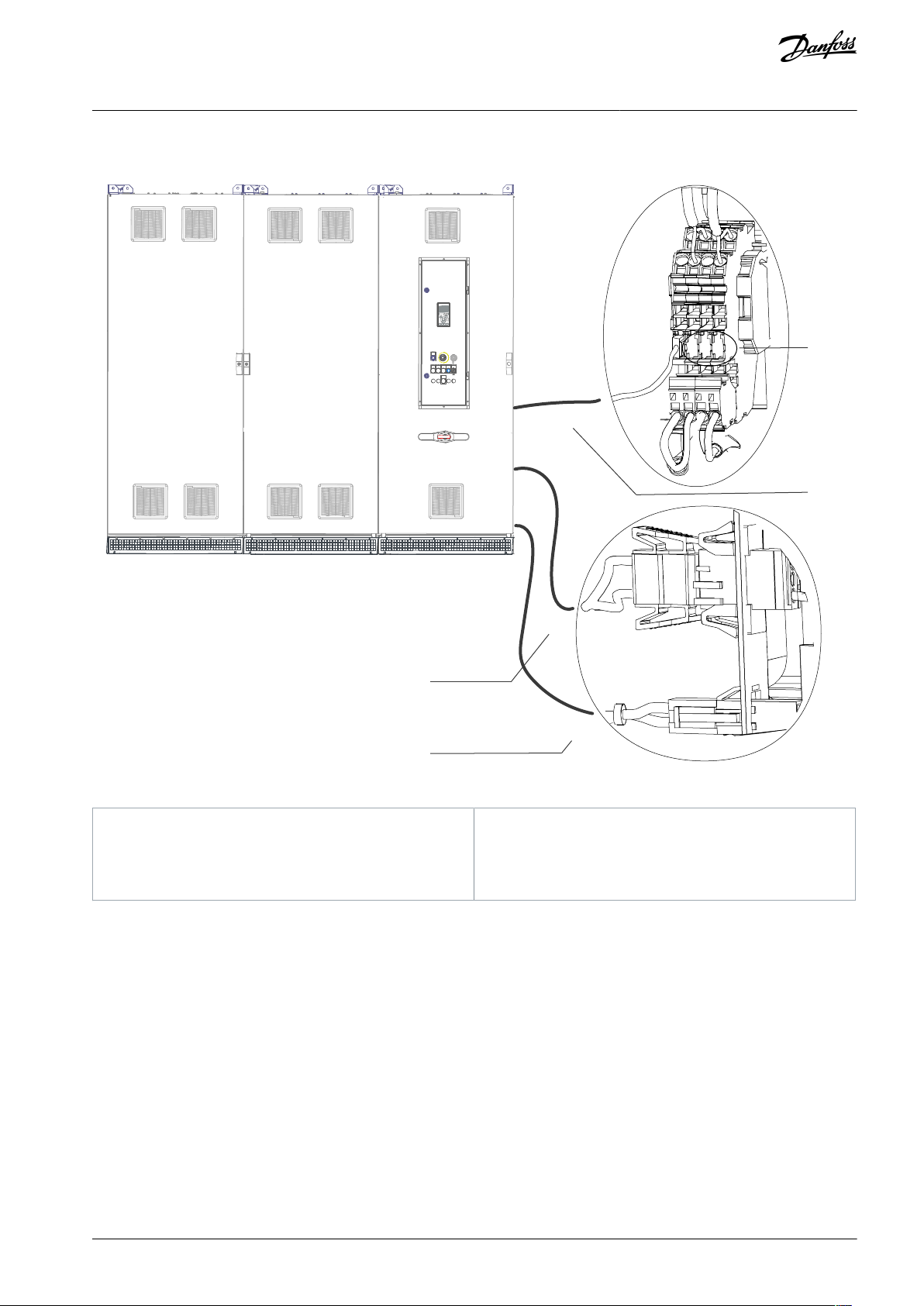

4.11.3 Securing the Cabinet(s) to the Floor

There are 3 methods to secure the cabinet to the floor:

•

Use the 4 mounting points at the base of the pedestal.

•

Use the 2 mounting points at the front base of the pedestal and the 2 mounting points at the upper back of the cabinet.

•

Use the 2 mounting points in the mounting bracket and the 2 mounting points at the front base of the pedestal.

To use the mounting bracket, first attach it to the floor by sliding the edge of the cabinet pedestal under the mounting bracket.

Then secure the 2 mounting holes to the front base of the pedestal.

AQ262141056213en-000201 / 130R0882 | 47Danfoss A/S © 2021.11

e30bu147.11

A

The 4 mounting points at the base of the pedestal

B

The 2 mounting points at the front base of the pedestal

C

The 2 mounting points at the upper back of the cabinetDThe 2 mounting points in the mounting bracket

VLT® AQUA Drive FC 202

Operating Guide

Example

Mechanical Installation

Illustration 18: Cabinet Mounting Points

AQ262141056213en-000201 / 130R088248 | Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

Electrical Installation

5 Electrical Installation

5.1 Safety Instructions

See the Safety Precautions section for general safety warnings.

N O T I C E

EXCESSIVE HEAT AND PROPERTY DAMAGE

Overcurrent can generate excessive heat within the drive. Failure to provide overcurrent protection can result in risk of fire and

property damage.

Additional protective equipment such as short-circuit protection or motor thermal protection between drive and motor is

-

required for applications with multiple motors.

Input fusing is required to provide short circuit and overcurrent protection. If fuses are not factory-supplied, the installer

-

must provide them. See maximum fuse ratings in the Specifications chapter.

N O T I C E

WIRE TYPE AND RATINGS

All wiring must comply with local and national regulations regarding cross-section and ambient temperature requirements. For

power connections, minimum 75 °C (167 °F) rated copper wire is recommended. Refer to the the Specifications chapter.

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables from different drives that are run together can charge equipment capacitors even

with the equipment turned off and locked out. Failure to run output motor cables separately or use shielded cables could result

in death or serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out all the drives.

-

W A R N I N G

SHOCK HAZARD

The drive can cause a DC current in the PE conductor. Failure to use a Type B residual current-operated protective device (RCD)

may lead to the RCD not providing the intended protection and therefore may result in death or serious injury.

When an RCD is used for protection against electrical shock, only a Type B device is allowed on the supply side.

-

N O T I C E

PROPERTY DAMAGE

Protection against motor overload is not included in the default setting. For the North American market, the ETR function pro-

vides class 20 motor overload protection in accordance with NEC. Failure to set the ETR function means that motor overload pro-

tection is not provided and property damage can occur if the motor overheats.

Enable the ETR function by setting parameter 1-90 Motor Thermal Protection to [ETR trip] or [ETR warning].

-

5.2 EMC-compliant Installation

To obtain an EMC-compliant installation, be sure to follow all electrical installation instructions.

Also, remember to practice the following:

AQ262141056213en-000201 / 130R0882 | 49Danfoss A/S © 2021.11

VLT® AQUA Drive FC 202

Operating Guide

•

When using relays, control cables, a signal interface, fieldbus, or brake, connect the shield to the enclosure at both ends. If the

ground path has high impedance, is noisy, or is carrying current, break the shield connection on 1 end to avoid ground current

loops.

•

Convey the currents back to the unit using a metal mounting plate. Ensure good electrical contact from the mounting plate by

securely fastening the mounting screws to the drive chassis.

•

Use shielded cables for motor output cables. An alternative is unshielded motor cables within metal conduit.

•

Ensure that motor and brake cables are as short as possible to reduce the interference level from the entire system.

•

Avoid placing cables with a sensitive signal level alongside motor and brake cables.

•

For communication and command/control lines, follow the particular communication protocol standards. For example, USB

must use shielded cables, but RS485/ethernet can use shielded UTP or unshielded UTP cables.

•

Ensure that all control terminal connections are rated protective extra low voltage (PELV).

Electrical Installation

N O T I C E

TWISTED SHIELD ENDS (PIGTAILS)

Twisted shield ends increase the shield impedance at higher frequencies, which reduces the shield effect and increases the leak-

age current.

Use integrated shield clamps instead of twisted shield ends.

-

N O T I C E

SHIELDED CABLES

If shielded cables or metal conduits are not used, the unit and the installation do not meet regulatory limits on radio frequency

(RF) emission levels.

N O T I C E

EMC INTERFERENCE

Failure to isolate power, motor, and control cables can result in unintended behavior or reduced performance.

Use shielded cables for motor and control wiring.

-

Provide a minimum 200 mm (7.9 in) separation between mains input, motor cables, and control cables.

-

N O T I C E

INSTALLATION AT HIGH ALTITUDE

There is a risk for overvoltage. Isolation between components and critical parts could be insufficient and may not comply with

PELV requirements.

Use external protective devices or galvanic isolation. For installations above 2000 m (6500 ft) altitude, contact Danfoss re-

-

garding protective extra low voltage (PELV) compliance.

N O T I C E

PROTECTIVE EXTRA LOW VOLTAGE (PELV) COMPLIANCE

Prevent electric shock by using PELV electrical supply and complying with local and national PELV regulations.

AQ262141056213en-000201 / 130R088250 | Danfoss A/S © 2021.11

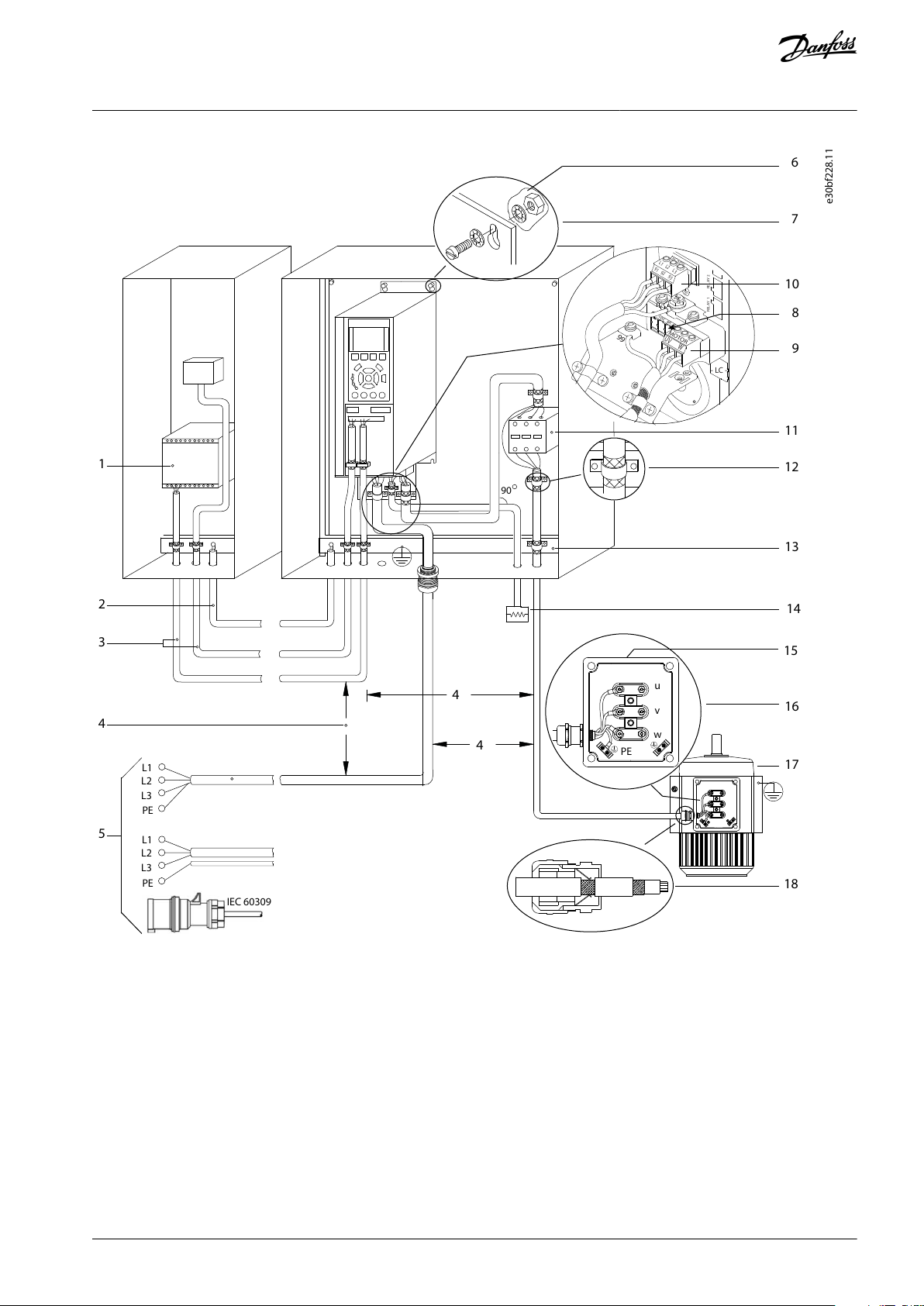

L1

L2L3PEL1L2L3PEPEu

v

w

2

1

3

5

IEC 60309

16

17

18

14

12

8

7

10

9

4

11

13

446

15

90

+DC

BR-

B

M

AINS

L1 L2 L3

91 92 93

RELA

Y 1 RELA

Y 2

99

- L

C -

UV

W

MO

T

OR

VLT® AQUA Drive FC 202

Operating Guide

Electrical Installation

Illustration 19: Example of Proper EMC Installation

AQ262141056213en-000201 / 130R0882 | 51Danfoss A/S © 2021.11

1

Programmable logic controller (PLC)

2

Minimum 16 mm2 (6 AWG) equalizing cable

3

Control cables

4

Minimum 200 mm (7.9 in) between control cables,

motor cables, and mains cables

5

Mains supply options, see IEC/EN 61800-5-1

6

Bare (unpainted) surface

7

Star washers

8

Brake cable (shielded) – not shown, but same

gounding principle applies as for motor cable

9

Motor cable (shielded)

10

Mains cable (unshielded)

11

Output contactor, and so on

12

Cable insulation stripped

13

Common ground busbar. Follow local and national

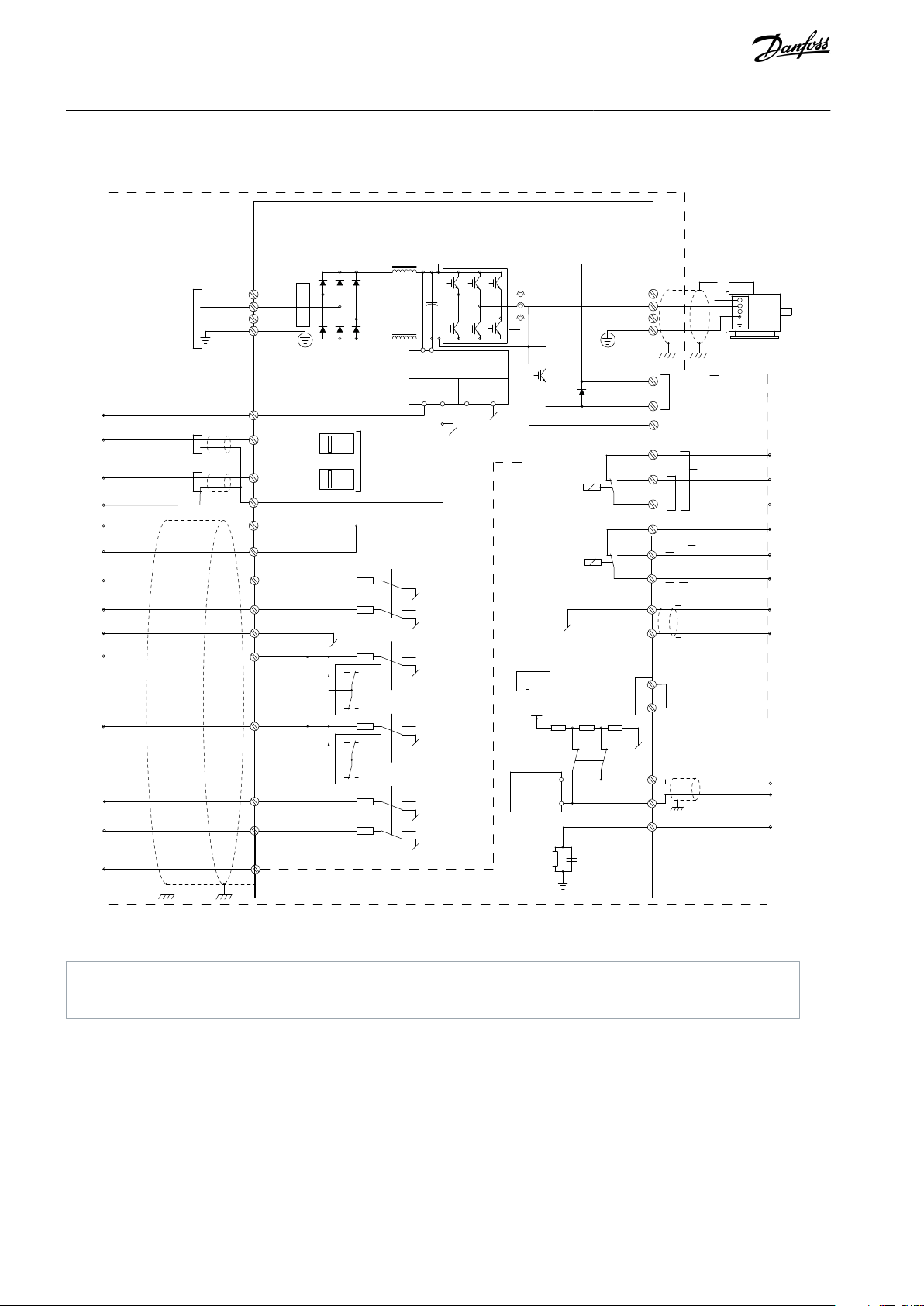

requirements for cabinet grounding