Application Guide

Multi-Master Cascade Control

VLT® AQUA Drive FC 202

drives.danfoss.com

Multi-Master Cascade Control

Application Guide

Contents

1

Before You Begin 5

1.1

Version History 5

Purpose of the Guide 5

1.2

Additional Resources 5

1.3

Introduction to Multi-Master Cascade Control 6

2

An Overview 6

2.1

System Requirements and Compatibility 7

2.2

Identifying Control Card 7

2.2.1

Ordering Multi-Master Cascade Control 7

2.3

Ordering from Factory 7

2.3.1

Ordering Retrofit on Existing VLT® Product 7

2.3.2

Identifying License Key for Cascade Control 8

2.3.3

Contents

Loading new software to AC drives 8

2.4

Installing Modbus Multi-Master Cascade Control 9

3

3.1

Wiring the Daisy Chain Module 9

4

Multi-Master Cascade Control Parameter Setup 10

4.1

Multi-Master Cascade Control Parameter Setup 10

4.2

Assigning Correct Addresses for Modbus Multi-Master Cascade Control System 10

4.3

Maintenance and Replacement Scenario 10

4.4

Parameter Setup for Master Drive(s) – Basic Setup 11

4.5

Parameter Setup for Followers (Basic Setup) 12

4.6

Copy settings 13

5

Staging Parameter Setup 14

5.1

Staging Parameter Setup 14

5.2

Stage-On Speed 14

5.3

Stage-Off Speed 14

5.4

General Staging Parameters 15

6

Sleep Mode Parameter Overview 16

6.1

Sleep Mode Parameter Setup 16

6.2

Entering Sleep Mode 16

6.3

Activating Drives from Sleep Mode 16

7

Cascading Operation and Settings 17

7.1

Cascading Operation 17

AB389040992368en-000101/130R1229 | 3Danfoss A/S © 2021.12

Multi-Master Cascade Control

Application Guide

7.2

Local Control Panel (LCP) Readings 18

8

Maintenance Scenarios 20

8.1

Service on Primary Master (Address 1) 20

8.2

Service on Backup Master running as a Follower 20

8.3

Service on Follower 21

9

Alarms, Warnings, and Defects 22

9.1

System Setups and Actions to Alarms, Warnings 22

Water Features with Multi-Master Cascade 24

10

Water Features 24

10.1

Check Valve Ramp 24

10.2

Sleep Mode 24

10.3

Deragging 25

10.4

10.5

Dry Pump 25

Contents

10.6

End of Curve Detection 26

10.7

Flow Compensation 26

10.8

Pipefill 27

10.9

Flow Confirmation 27

AB389040992368en-000101/130R12294 | Danfoss A/S © 2021.12

Manual Version

Remarks

M00342, doc version 01

Information in this version of the manual corresponds to software version 4.11

Multi-Master Cascade Control

Application Guide

Before You Begin

1 Before You Begin

1.1 Version History

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is in English.

1.2 Purpose of the Guide

This Application Guide is intended for qualified personnel such as

•

Automation engineers

•

Configurators who has experience operating with parameters and basic knowledge of AC drives

The Application Guide provides information on the functions and features of the Multi-Master Control using the built-in Modbus

RTU for communication between multiple FC 202 drives. The guide covers information on ordering, installation, parameter setups

and maintenance use cases.

1.3 Additional Resources

Additional resources are available with related information.

•

VLT® AQUA Drive FC 202 Programming Guide.

•

VLT® AQUA Drive Cascade Controller Options MCO 101/102 Operating guide offers more information on advanced and flexible

options.

Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation when not avoided, results in death or serious injury.

W A R N I N G

Indicates a hazardous situation when not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation when not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

AB389040992368en-000101 / 130R1229 | 5Danfoss A/S © 2021.12

1

1 2 3 4

2 3 4

Line supply

LXX1 LXX1

68 69 68 68 6869 69 69

100% 100% 100% 100%

1

1 2 3 4

2 3 4

Line supply

LXX1 LXX1

68 69 68 68 6869 69 69

100% 100% 100% 100%

e30bi493.10

Multi-Master Cascade Control

Introduction to Multi-Master

Application Guide

Cascade Control

2 Introduction to Multi-Master Cascade Control

2.1 An Overview

Benefits of Multi-Master Cascade Control setup

•

Easy installation using daisy-chain Modbus connection terminal 68/69

•

Easy commissioning using dialog based Smart Start

•

True multi-master functionality for cascade redundancy

•

Improved system performance

Significant reduced wiring complexity as the drive communication is daisy-chain using the on-board RS485 communication terminals. The communication protocol is Modbus RTU and requires an absolute minimum setup of parameters. The dialog-based Smart

Start makes configuration easy and trouble-free.

The automatic drive detection supports hot-swap providing a rigid system setup against loose connection or cable failure. In case of

master drive failure, the system automatically reallocates the master functionality.

In water distribution systems, it is usually the requirement that the cascade system has a redundant master functionality, this functionality is now an integrated solution in the drives. Multi-Master Cascade comes with improved functionalities and system performance, as the master knows the status and performance of the individual drives and pumps.

Example

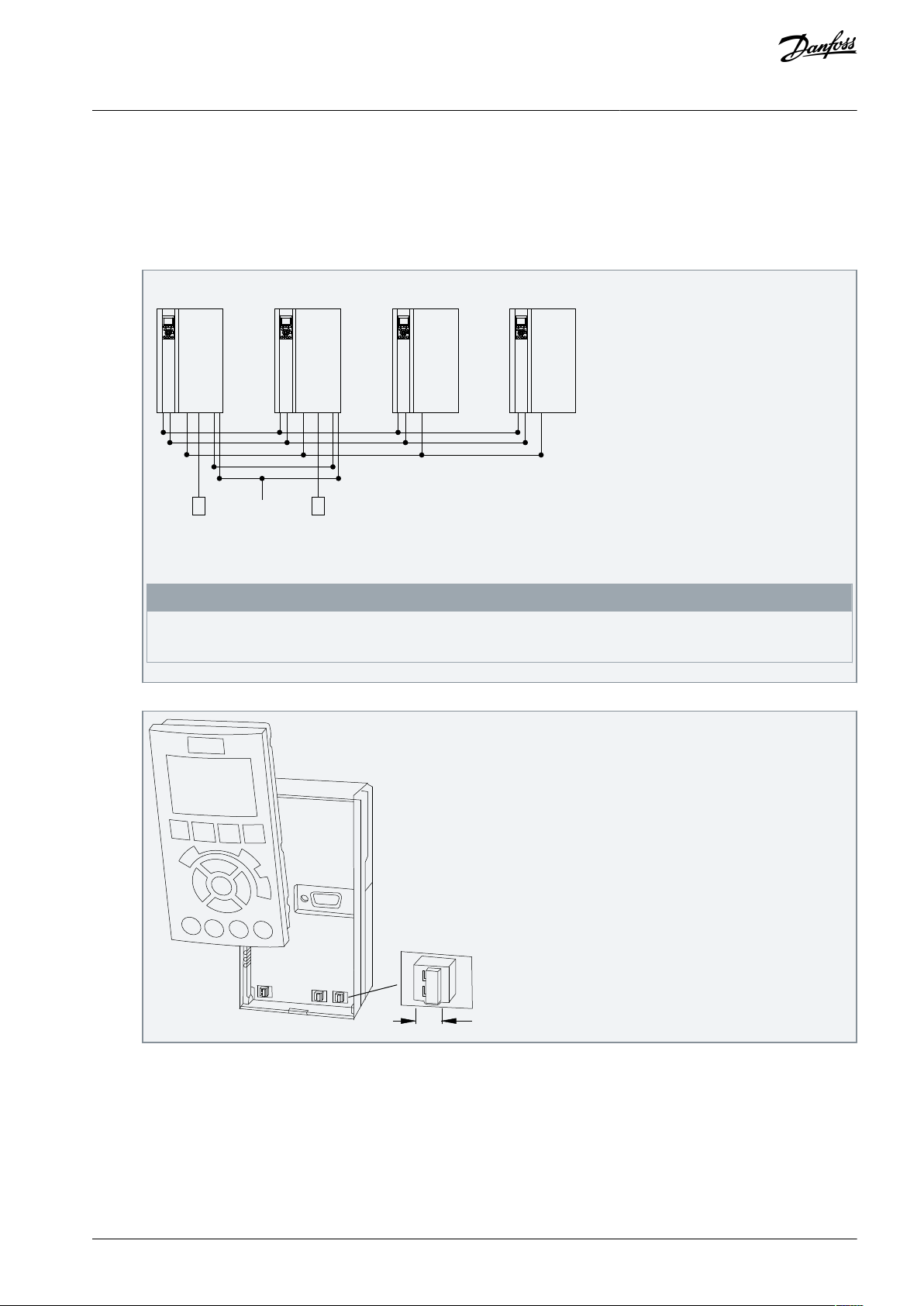

The illustration shows a system with 4 AC Drives, where 2 are allocated Master recognized by License Code LXX1. In case of defect

on Master Drive ID 1, the master automatically changes to ID 2 for full functionality until replaced on site. This example is considered

to explain the different phases such as installation, commissioning, and troubleshooting.

Illustration 1: Illustration Example

Application setups supported by Modbus Multi-Master Cascade

Following are the six setups supported by Modbus Multi-Master Cascade

•

Supports only Master Follower cascade.

•

Equal sized pumps.

•

A maximum of 8 pumps in cascade system.

•

A master drive requires a license code (LXX1 or LX11) to unlock the master functionality and Parameter Group 27-*.

•

A minimum of 1 master for Modbus Cascade.

•

A minimum of 2 masters for accomplishing Multi-Master Cascade.

Setup 3 and Setup 4 are not available in Modbus Multi-Master Cascade in software versions 3.91 or older versions. Setups 1 and 2

are assigned for Multi-Master. Flexibility in assigning different setups for different scenarios is limited.

For use of digital cascade without multi-master and available in setup 3 and 4, use parameter 8–30[22] Modbus Cascade Master in

software version 3.40.

N O T I C E

N O T I C E

AB389040992368en-000101 / 130R12296 | Danfoss A/S © 2021.12

•

•

•

•

•

•

VLT® Product

Minimum Software Compatibility Version

VLT® AQUA Drive FC 202

Software version 4.11 and higher on all drives in cascade system.

Control Card Version

Identification of Control Card Version

Production Identification

MKII

White USB

CW18 Y2018 or later.

Scenario

Control

Card

Parameter 15–

43

Action

1

MKII

3.91

Order license code. See 2.3 Ordering Multi-Master Cascade Control Flash software version 4.11 or

newer.

2

MKII

3.80 or

older

Flash software version 4.11 or newer.

Order license code for master drive(s). See 2.3 Ordering Multi-Master Cascade Control.

3

MKI

Order new control card.

Order license Code for master drive(s). See 2.3 Ordering Multi-Master Cascade Control.

Replace old control card with new Mk II control card. Ensure to upgrade to software version

4.11.

Enable license code for master drive(s).

Note: It is not possible to order an MKII control card with pre-initialized license code activated.

Activation must take place on site.

Multi-Master Cascade Control

Introduction to Multi-Master

Application Guide

Cascade Control

2.2 System Requirements and Compatibility

VLT® products and software compatibility for Multi-Master Cacade Control

To enable and effective functioning of Multi-Master Cascade Control, verify the following software compatibility and system-requirements.

Table 1: VLT® Product and Software Compatibility for Multi-Master Cascade Control

Table 2: Control Card Compatibility for Multi-Master Cascade Control

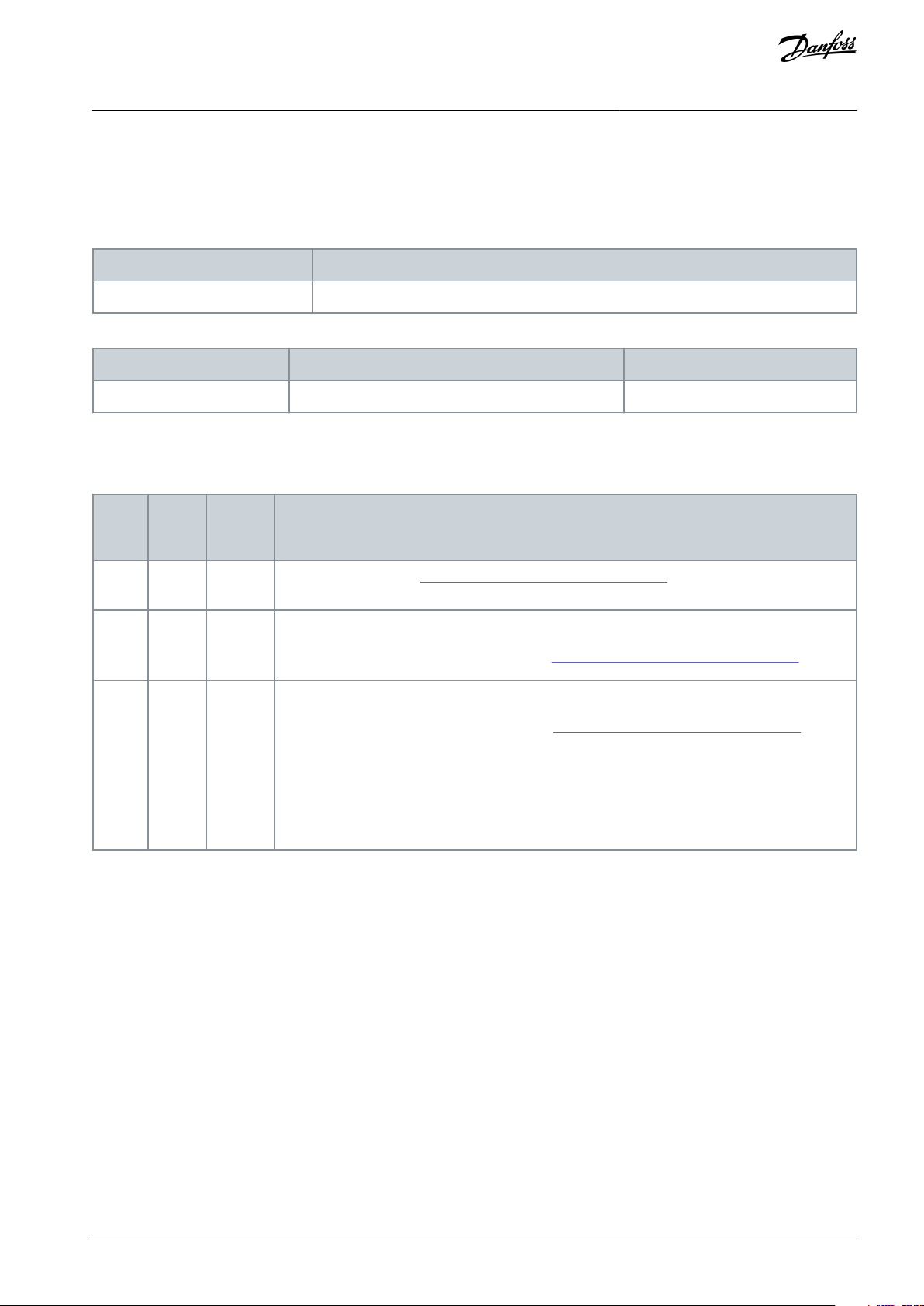

Retrofit existing VLT® AQUA Drive FC 202

Following are the 3 scenarios and actions to retrofit an existing drive.

Table 3: Retrofit Existing VLT® AQUA Drive FC 202

2.2.1 Identifying Control Card

2.3 Ordering Multi-Master Cascade Control

Modbus multi-master is enabled with license codes. The license codes can be installed from the factory or retrofit to an existing

VLT® AQUA Drive FC 202.

2.3.1 Ordering from Factory

Procedure

1.

Select the license code character [12]. For example, LXX1 replaces SXXX.

2.3.2 Ordering Retrofit on Existing VLT® Product

To proceed with creation of unique license code, it is required to obtain the S/N number of each VLT® AQUA Drive FC 202 which is

intended as master. After generating unique license code(s), the list is shared for activating the feature in the drives.

Procedure

1.

Order a retrofit license key via local Danfoss sales office contact.

AB389040992368en-000101 / 130R1229 | 7Danfoss A/S © 2021.12

Parameter Number

Factory delivered license code

Retrofit license code

15–44 Ordered Typecode String

LXX1

SXXX

15-45 Actual Typecode String

LXX1

LXX1

50-00 License Installed

Cascade 2.0

Cascade 2.0

Multi-Master Cascade Control

Application Guide

2.

Obtain the S/N number of each VLT® AQUA Drive FC 202 which is intended as master. Send the S/N information to the local

Danfoss contact.

S/N can be obtained in different ways:

•

On invoice with specific drive

•

Value is identified in parameter 15-51 using LCP or MCT-10

•

Product label

3.

Enter the license key in parameter 50-01.

After the drive accepts the license key, parameter 50-01 displays 0000-0000-0000-0000.

Power cycle the drive.

4.

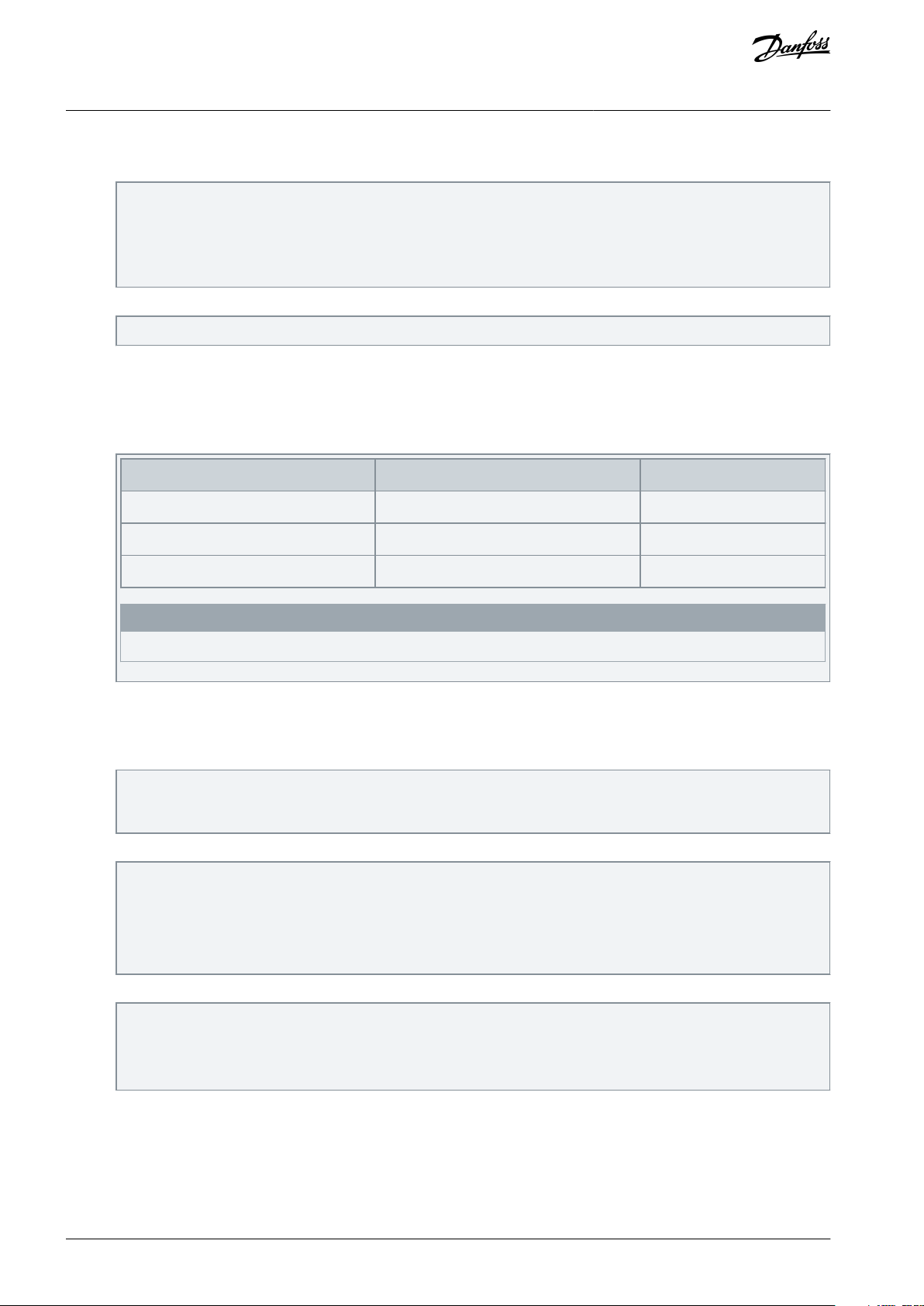

2.3.3 Identifying License Key for Cascade Control

Procedure

To identify license key for cascade control, verify the typecode using the following parameters.

1.

Introduction to Multi-Master

Cascade Control

The ordered type code string is not changed when activating a retrofit license in the drive.

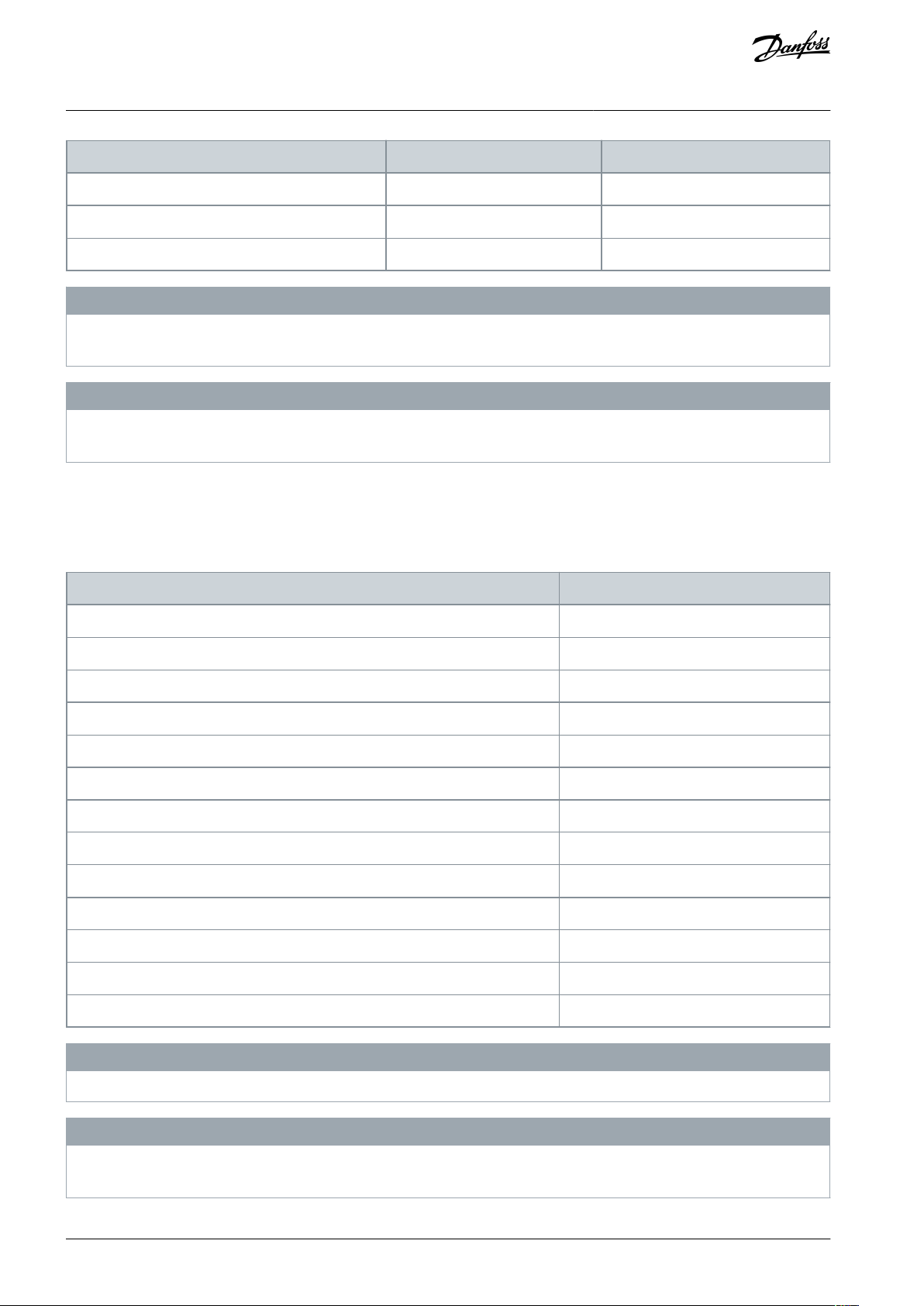

2.4 Loading new software to AC drives

Procedure

1.

Create a back-up of the parameters.

•

Copy parameters to project in MCT-10.

•

Save project.

2.

Load the software into AC drives.

•

Remove the Modbus Connector (plug 61, 68, 69) before loading the software via the USB port.

•

After connecting the USB port, right-click on the USB 1 in the software tray on the PC.

•

Click Drive Software Upgrader. (requires Service Level 1 access). Contact Danfoss if needed.

•

Locate the required file and click Start Upgrade.

3.

After uploading the software to the drive, perform the following:

•

Connect Modbus Connector (plug 6, 68, 69) again.

•

Write parameters from the project back to AC drive.

•

Power cycle AC drive.

N O T I C E

AB389040992368en-000101 / 130R12298 | Danfoss A/S © 2021.12

68 696120

1 2 3 4

18 68 68 6869 69 69

6161

20 18

LXX1 LXX1

Pressure

transmitter

Pressure

transmitter

Start signal

e30bi494.10

e30bf146.10

BUS TER.

OFF-ON

A53 A54

U- I U- I

1

2

N O

1

2

N O

1

2

N O

1

2

N O

Multi-Master Cascade Control

Installing Modbus Multi-Master

Application Guide

3 Installing Modbus Multi-Master Cascade Control

3.1 Wiring the Daisy Chain Module

Ensure to install the drive using the instructions provided in VLT® AQUA Drive FC 202 Operating Guide.

Procedure

1.

Wire Modbus in Daisy Chain Terminal 68 and Terminal 69, and Terminal 61.

Cascade Control

Illustration 2: Wiring Daisy Chain Modbus

N O T I C E

Each assigned master requires a start signal and feedback. For example, pressure transmitter and PID must be set up

and tuned.

2.

Terminate first and last drive by S801 ON.

AB389040992368en-000101 / 130R1229 | 9Danfoss A/S © 2021.12

1

1 2 3 4

2 3 4

Line supply

LXX1 LXX1

68 69 68 68 6869 69 69

100% 100% 100% 100%

e30bi492.10

Parameter 8–31

SW

Priority

Set the value as 1

LXX1

Primary Master (setup 1 and 2)

Set the value as 2

LXX1

Back-up Master (setup 1 and 2)

Set the value as 3

SXXX

Follower (setup 1)

Set the value as 4

SXXX

Follower (setup 1)

Multi-Master Cascade Control

Multi-Master Cascade Control

Application Guide

Parameter Setup

4 Multi-Master Cascade Control Parameter Setup

4.1 Multi-Master Cascade Control Parameter Setup

A typical multi-master cascade parameter setup has the following:

•

Parameter 8–30[23] is set as Modbus Multi-Master on master drives.

•

A minimum of 2 master drives is required to obtain multi-master functionality. A maximum of 8 masters are allowed.

•

For masters, use 2 setups and must be configured in setup 1 and setup 2.

•

For followers, use 1 setup.

•

Ensure parameter 8–32 Baud Rate is identical in all drives (masters and followers).

4.2 Assigning Correct Addresses for Modbus Multi-Master Cascade Control System

If there are multiple masters the consisting of primary master and backup masters, the master status is determined by parameter 8–

31 Address, where the lowest assigned is Primary Master. All back-up masters power up as assigned follower as they do not have the

lowest address.

For example, Drive ID 1 is primary master as the assigned address 1 is the lowest. The system setup is shown in the figure.

Illustration 3: System Setup Example

For the system setup shown in the figure, the parameter setup and priority is as follows:

Considerations when assigning parameter 8–31:

•

The drive ID must be in the order from 1–8.

•

Drive IDs should be sequential. This means that a setup from 1, 3, 4, 5 is not allowed as 2 is missing.

•

Masters must be assigned lowest IDs. For example, when there are 4 master drives, these drives are assigned IDs from 1–4.

•

Follower drives must be assigned IDs following the master node addresses. Consider 4 masters and 4 followers, the followers

must be assigned 5,6,7,8.

4.3 Maintenance and Replacement Scenario

If an assigned master is failing or being powered off due to maintenance, the next lowest address is assigned to the master drive

automatically.

If a drive with lower address is reinserted into the system, the lowest address reinserts into the system as a follower. Assignment of

master functionality to the lowest address in the system happens automatically.

AB389040992368en-000101 / 130R122910 | Danfoss A/S © 2021.12

Parameter

Set-up 1 (Master Mode)

Set-up 2 (Follower Mode)

Parameter 0-02 Motor Speed Unit

[1] Hz**

[1] Hz**

Parameter 0-10 Active Setup

[9] Multi Set-up

[9] Multi Set-up

Parameter 0-12 This Set-up Linked to

[2] Set-up*

[1] Set-up 1*

Parameter 0-21 Display Line 1.2 Small

[1652] Feedback[Unit]**

[0] None**

Parameter 0-23 Display Line 2 Large

[2794] Cascade System Status

[39] Display Text 3

Parameter 0-24 Display Line 3 Large

[2793] Cascade Option Status

[38] Display Text 2

Parameter 0-38 Display Text 2

Follower **

Follower **

Parameter 0-39 Display Text 3

Backup Master **

Backup Master **

Parameter 1-00 Configuration mode

[3] Closed Loop *

[0] Open Loop*

Parameter 3-03 Maximum Reference

[100] Application Specific**

= Par. 4-13 RPM / Par. 4-14 Hz*

Parameter 3-15 Reference 1 Source

[0] No function *

[0] No function *

Parameter 3-41 Ramp 1 Ramp Up Time

A

A

Parameter 3-42 Ramp 1 Ramp Down Time

B

B

Parameter 4-12 Motor Speed Low Limit [Hz]

C

C

Parameter 4-14 Motor Speed High Limit [Hz]

DDParameter 5-10 Terminal 18 Digital Input

[8] Start*

[0] No Operation *

Parameter 6-01 Live Zero Timeout Function

[30] Warning only *

[30] Warning only *

Parameter 6-22 Terminal 54 Low Current

Application specific

Ignore

Parameter 6-23 Terminal 54 High Current

Application specific

Ignore

Parameter 6-24 Term 54 Low Ref. / Feedb. Val

Application specific

Ignore

Parameter 6-25 Term 54 High Ref. / Feedb. val

Application specific

Ignore

Parameter 8-01 Control Site

[0] Digital and ctrl.word **

[2] Control word only

Parameter 8-02 Control Source

[0] None or [3] Option A *

[1] FC Port *

Parameter 8-04 Control Timeout Function

Application specific

[0] Off *

Parameter 8-30 Protocol

[23] Modbus Multi Master *

[23] Modbus Multi Master *

Parameter 8-31 Address

1-x

1-x

Multi-Master Cascade Control

Multi-Master Cascade Control

Application Guide

Parameter Setup

4.4 Parameter Setup for Master Drive(s) – Basic Setup

Parameters for the master drive must be configured in setup 1 and setup 2.

•

Setup 1 (Master Mode): The drive receives commands from digital input or A-option. Speed reference is obtained from PID.

•

Setup 2 (Follower Mode): The drive receives commands from the assigned master drive, in the system, ignoring digital and

analogue input and A options input. Speed reference in set-up must be scaled equal to the master drive in set-up 1.

The following table describes the basic setup for master drives. In the table, * indicates mandatory settings and ** indicates recommended settings.

Table 4: Basic setup for master drives

AB389040992368en-000101 / 130R1229 | 11Danfoss A/S © 2021.12

Parameter

Set-up 1 (Master Mode)

Set-up 2 (Follower Mode)

Parameter 20-00 Feedback 1 Source

[2] Analog Input 54 *

Ignore

Parameter 27-10 Cascade Controller

[1] Master/Follower *

[1] Master/Follower *

Parameter 27-11 Number Of Drives

E (max 8)

E (max 8)

Parameter

Setup Follower

Parameter 0-02 Motor Speed Unit

[1] Hz **

Parameter 0–24 Display Line 3 Large

[38] Display Text 2 **

Parameter 0–38 Display Text 2

Follower **

Parameter 1-00 Configuration mode

[0] Open Loop *

Parameter 3-03 Maximum reference

= Par. 4–12 (Hz) *

Parameter 3–15 Reference 1 Source

[0] No function *

Parameter 4–14 Motor Speed High Limit [Hz]

D *

Parameter 8-01 Control Site

[2] Control word only**

Parameter 8-02 Control Source

[1] FC Port *

Parameter 8-03 Control Timeout

15.00 s**

Parameter 8-04 Control Timeout Function

[2] Stop**

Parameter 8–30 Protocol

[2] Modbus RTU *

Parameter 8–31 Address

2-x *

Multi-Master Cascade Control

Multi-Master Cascade Control

Application Guide

Parameter Setup

N O T I C E

Ensure the values in parameter numbers 3–41 Ramp 1 Ramp Up Time, 3–42 Ramp 1 Ramp Down Time, 4–12 Motor Speed Low Limit

[Hz], 4–14 Motor Speed High Limit [Hz], 8–31 Address, 27–11 Number Of Drives are identical in setup 1 and setup 2.

N O T I C E

Ensure that parameter 8-04 Control Word Timeout Function is only configured when parameter 8-02 Control Word Source is set as A

option. If parameter 8-02 Control Word Source is set as 0, do not set any values in parameter 8-04 Control Word Timeout Function.

4.5 Parameter Setup for Followers (Basic Setup)

A follower utilizes set-up 1 only and follows the commands send by the primary master. The following table details the basic setup

for followers.

Table 5: Recommended Settings for Follower Setup

Ensure parameter 8-01 Control Site is not set to [1] Digital only.

A control timeout is recommended when the master drive is not active. On setting parameter 8-04 Control Word Timeout to [2]

Stop, the follower drive resumes when a master drive is reactivated.

N O T I C E

N O T I C E

AB389040992368en-000101 / 130R122912 | Danfoss A/S © 2021.12

Multi-Master Cascade Control

Application Guide

4.6 Copy settings

Typically, it is recommended to copy settings to all drives in the system.

Copy Settings to all drives in the system

Copying settings is achieved by using the parameter 0–50 LCP Copy [1] All to LCP or MCT10.

Copying from (Master to Master) or (Follower to Follower)

Ensure to change the parameter 8–31 Address so that no drives should have the same address.

Copying from Master to Follower

It is not recommended to copy settings from master to follower.

Multi-Master Cascade Control

Parameter Setup

AB389040992368en-000101 / 130R1229 | 13Danfoss A/S © 2021.12

1

1 2 3 4

2 3 4

Line supply

LXX1 LXX1

68 69 68 68 6869 69 69

100% 100% 100% 100%

e30bi492.10

Parameter

Setup 1 (Master Mode)

Example Setting

Setup 2 (Follower Mode)

Parameter 27-32.0 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.1 Stage On Speed [Hz]

Pump 2 staging speed

48.5

Ignore

Parameter 27-32.2 Stage On Speed [Hz]

Pump 3 staging speed

48.5

Ignore

Parameter 27-32.3 Stage On Speed [Hz]

Pump 4 staging speed

48.5

Ignore

Parameter 27-32.4 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.5 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.6 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.7 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.8 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.9 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter 27-32.10 Stage On Speed [Hz]

Ignore

48.5

Ignore

Parameter

Setup 1 (Master Mode)

Example Setting

Setup 2 (Follower Mode)

Parameter 27-34.0 Stage Off Speed [Hz]

Ignore

0

Ignore

Parameter 27-34. Stage Off Speed [Hz]

Pump 1 off**

30.5

Ignore

Multi-Master Cascade Control

Application Guide

Staging Parameter Setup

5 Staging Parameter Setup

5.1 Staging Parameter Setup

Consider the example with 4 drives in a setup. Ensure that staging parameters are set for assigned masters in setup 1. Setup 2 can

be disregarded. Followers do not require configuration of staging parameters. Staging speeds and de-staging speeds are application specific.

In the following sections, recommendation settings for the stage-on speed, stage-off speed, and general staging parameters.

5.2 Stage-On Speed

Table 6: Stage-On Speed Parameters

The highest index speed in parameter 27–32.X must be set to motor speed high limit in parameter 4–13 Motor Speed High Limit [RPM]

or parameter 4–14 Motor Speed High Limit [Hz].

5.3 Stage-Off Speed

Table 7: Stage-off Speed Parameters

AB389040992368en-000101 / 130R122914 | Danfoss A/S © 2021.12

Parameter

Setup 1 (Master Mode)

Example Setting

Setup 2 (Follower Mode)

Parameter 27-34.2 Stage Off Speed [Hz]

Pump 2 de-staging

32

Ignore

Parameter 27-34.3 Stage Off Speed [Hz]

Pump 3 de-staging

34

Ignore

Parameter 27-34.4 Stage Off Speed [Hz]

Pump 4 de-staging

36

Ignore

Parameter 27-34.5 Stage Off Speed [Hz]

Ignore

37.5

Ignore

Parameter 27-34.6 Stage Off Speed [Hz]

Ignore

39.2

Ignore

Parameter 27-34.7 Stage Off Speed [Hz]

Ignore

40.4

Ignore

Parameter 27-34.8 Stage Off Speed [Hz]

Ignore

41.3

Ignore

Parameter 27-34.9 Stage Off Speed [Hz]

Ignore

42

Ignore

Parameter 27-34.10 Stage Off Speed [Hz]

Ignore

42.5

Ignore

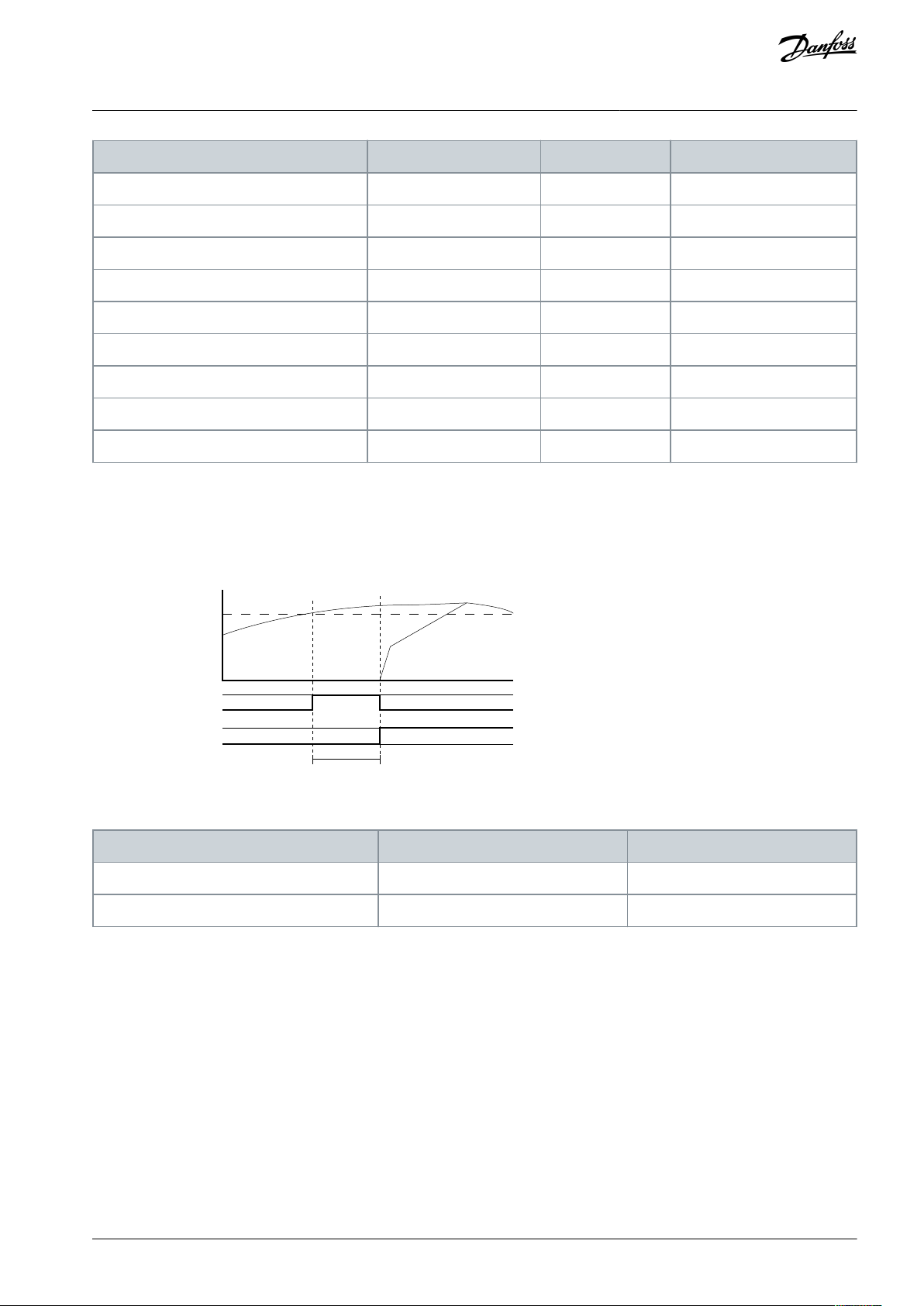

15 Sec

Par. 27-32.X

Stage On Speed [Hz]

ONPar. 27-23

Staging Delay (sec)

OFF

Par. 27-32.1

DI Terminal 18 [start signal]

Frequency

Pump 1 speed

Pump 2 speed

Time

e30bi491.10

Parameter ID

Setup 1 (Master Mode)

Setup 2 (Follower Mode)

Parameter 27-23 Staging Delay

15 seconds (recommended)

Ignore

Parameter 27-24 Destaging Delay

15 seconds (recommended)

Ignore

Multi-Master Cascade Control

Application Guide

Staging Parameter Setup

** Lowest index speed in parameter 27-34.1 must be equal or greater than motor speed low limit specified in parameter 4-11 Motor

Speed Low Limit [RPM] or parameter 4-12 Motor Speed Low Limit [Hz].

5.4 General Staging Parameters

This section provides an overview of the parameters for general staging.

Illustration 4: General Staging Parameters

Table 8: General Staging Parameters

AB389040992368en-000101 / 130R1229 | 15Danfoss A/S © 2021.12

Parameter

Setup 1 (Master Mode)

Setup 2 (Follower Mode)

Parameter 27–21 Override Limit

10%

Ignore

Parameter 20-21Setpoint 1

Application specific [80]

Ignore

Parameter

Setup 1 (Master Mode)

Setup 2 (Follower Mode)

Parameter 3-03 Maximum Reference

100

= Parameter 4-14 Motor Speed High Limit [Hz] (D)

Parameter 27–21 Override Limit

10%

Ignore

Parameter 20–2 Setpoint 1

80

Ignore

Multi-Master Cascade Control

Application Guide

Sleep Mode Parameter Overview

6 Sleep Mode Parameter Overview

6.1 Sleep Mode Parameter Setup

When the last pump which is operating drops below parameter 27–34.1, sleep mode is activated. The de-stage speed for the duration set in parameter 27–24 De-staging Delay.

6.2 Entering Sleep Mode

Sleep mode occurs when the actual speed is less than the value configured in parameter 27–34.1 Stage Off Speed for the time in

seconds configured in parameter 27–24 De-staging Delay.

To enable sleep mode, make sure the parameter 27–34.1 Stage Off Speed is higher than parameter 4–11 Motor Speed Low Limit [RPM]

or parameter 4–12 Motor Speed Low Limit [Hz].

If the value in parameter 27–34.01 is equal or less than the value specified in parameter 4–11 Motor Speed Low Limit [RPM] or parame-

ter 4–12 Motor Speed Low Limit [Hz], the system continues to operate at minimum speed. For example, if setting parameter 4–11

Motor Speed Low Limit [RPM] or parameter 4–12 Motor Speed Low Limit [Hz] is set to 0, sleep mode is disabled and continues to oper-

ate at minimum speed.

6.3 Activating Drives from Sleep Mode

Table 9: Recommended Parameter Settings

Following is an example of activating drives from sleep mode.

Table 10: Example of Recommended Parameters

Multi-Master Control activates during sleep mode when parameter 27–21 Override Limit is reached. Override Limit is a % of parameter 3-03 Maximum Reference.

How to calculate:

Drive start < Setpoint in parameter 20–21 Setpoint 1 – (Parameter 27–21 Override Limit x Parameter 3-03 Maximum Reference) )

Drive start < 80 – (10% x 100) = 70

AB389040992368en-000101 / 130R122916 | Danfoss A/S © 2021.12

1

1 2 3 4

2 3 4

Line supply

LXX1 LXX1

68 69 68 68 6869 69 69

100% 100% 100% 100%

e30bi492.10

Frequency

Pump 4 Pump 2 Pump 3

Time

15 Sec 15 Sec

OFF

DI Terminal 18 [start signal]

Par. 27-32.2

Par. 27-32.1

OFF

ON

Par. 27-32.X

Stage On Speed [Hz]

Par. 4-12

Motor Speed Low Limit [Hz]

Staging Delay (sec)

Par. 27-23

e30bi490.10

Multi-Master Cascade Control

Application Guide

Cascading Operation and Settings

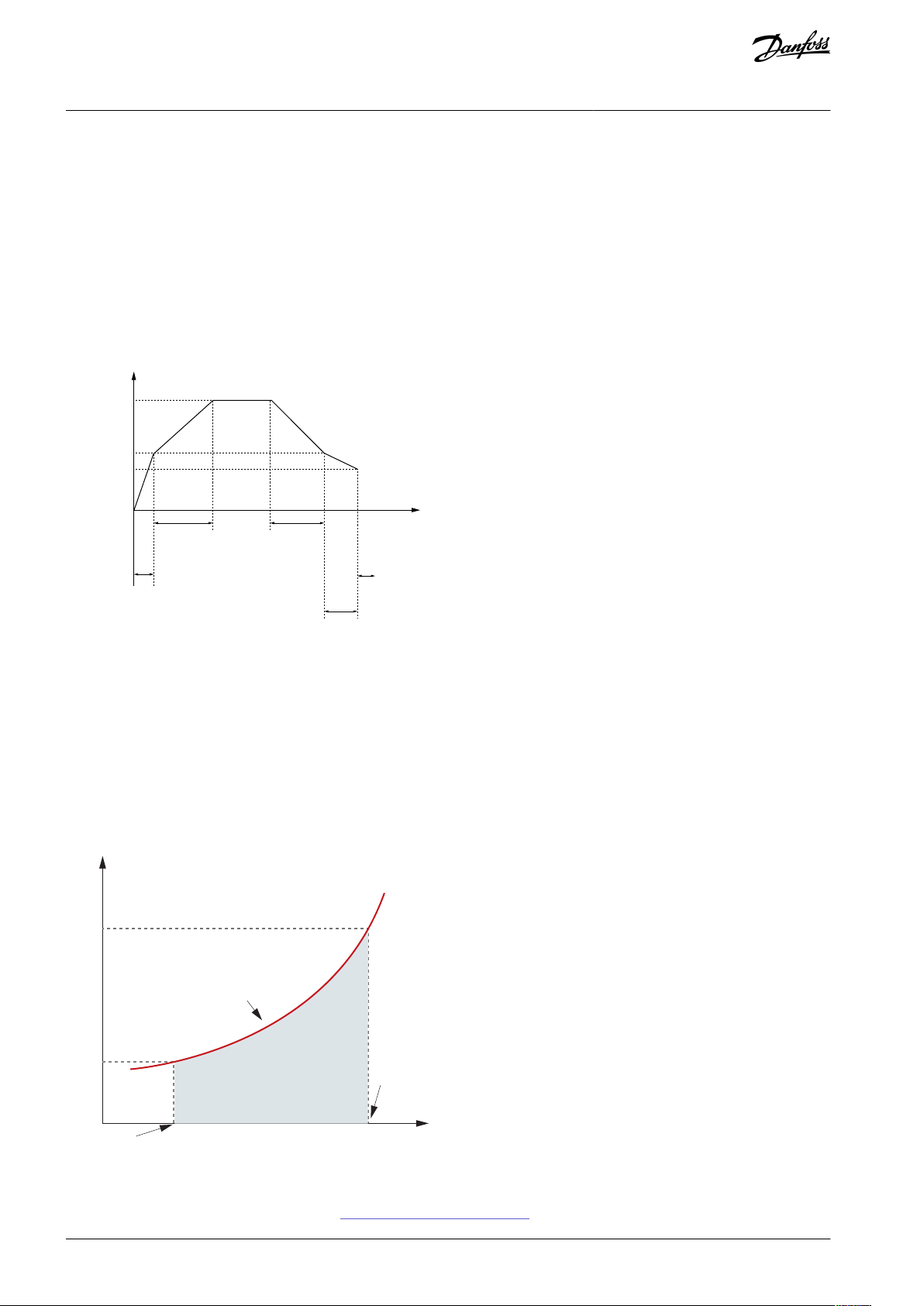

7 Cascading Operation and Settings

7.1 Cascading Operation

Consider the scenario when the system is activated with Start signal.

Illustration 5: Scenario Illustration

Start signal is started via Digital Input on Terminal 18.

Pump 4 is activated first as it has least running hours. If the frequency rises above parameter 27-32.X during the duration specified in

parameter 27-23 , the subsequent pump with the second least running hours begins. In this case, pump 2 is staged. If the frequency

is still above parameter 27-32.X for the duration specified in parameter 27-23, the pump with third least running hours begins. In this

case, pump 3 is staged on. This continues as the last pump is staged on.

Illustration 6: Cascading Operation

On the contrary, when the frequency is below parameter 27-34.X stage off for duration of parameter 27-24 De-stage Delay, the drive

with the highest running hours stops. This continues until 1 pump is running at a frequency below the value specified in Parameter

27-34.1 Stage Off, and higher than parameter 4-12 Motor Speed Low Limit for the duration specified in parameter 27-24 De-stage Delay.

The last drive stops and the system goes into sleep mode

AB389040992368en-000101 / 130R1229 | 17Danfoss A/S © 2021.12

LCP

view

and

notes

For 3 drives

For 8 drives

LCP

view

e30bj394.10

e30bj395.10

Notes

Off is the current state of the unit viewed.

Notice: Off is viewed in 2 places. The meaning for both is the

same.

Colon is used in-between, for example, M:o

Off is the current state of the unit viewed.

Notice: Off is only viewed in 1 place due to lack of space.

No colon is used, for example, Mo.

Drive

Options

Description

Master (M)

o

The master drive is online but idle (not running), Mo indicates that the master drive is online but idle.

Follower (F)

D

The follower drive is online and running. FD indicates that the follower drive is online and running.

Follower (F)

x

The drive is not reachable by network. This is possible when parameter 27–11 is set to 3 and only 2

drives are connected.

Fx indicates that the follower drive cannot be reached by network.

MXInterlock, trip, Drive not ready, Drive coast, Drive trip lock status of the master drive.

MX indicates Master interlock.

Option

Description

Off

System is stopped

Running

System is running with 1 or more pump.

Multi-Master Cascade Control

Application Guide

Cascading Operation and Settings

N O T I C E

If the parameter 4-12 Motor Speed Low Limit is higher than the value specified in parameter 27-31.1 Stage Off Speed, the last drive

continues to operate in minimum speed until the stop signal is started.

7.2 Local Control Panel (LCP) Readings

The following table describes LCP readings for the parameter settings.

•

Parameter 0–23 Display Line 2 Large as [2794] Cascade System Status

•

Parameter 0–24 Display Line 3 Large as [2793] Cascade Option Status

To set the number of drives, go to parameter 27–11 Number of drives and set as required.

Table 11: LCP view

Table 12: Options and Description for Display Large [2794] as Cascade System Status

Table 13: Options and Description for Display Large as [2793] Cascade Option Status

AB389040992368en-000101 / 130R122918 | Danfoss A/S © 2021.12

Option

Description

Stg

A pump is staged in.

dstg

A pump is de-staged.

Alt

Alternation is occurring.

Multi-Master Cascade Control

Application Guide

Cascading Operation and Settings

AB389040992368en-000101 / 130R1229 | 19Danfoss A/S © 2021.12

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi486.10

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi487.10

Multi-Master Cascade Control

Application Guide

8 Maintenance Scenarios

8.1 Service on Primary Master (Address 1)

Consider the scenario to stop only the primary master without stopping the drive.

N O T I C E

It is recommended to use DI (Digital Input)

Maintenance Scenarios

It is recommended to use DI (Digital Input) [130] Pump 1 interlock.

An example of actions to stop the master drive and keep the system running are as follows:

•

Wire DI 33

•

Program parameter 5-15 as [130] Pump 1 interlock

The following actions will stop the complete system:

•

[Hand On] or [Off] mode on LCP keypad will stop all follower drives.

•

Using DI for external interlock parameter 5-* [7]. External interlock stops the complete system.

8.2 Service on Backup Master running as a Follower

Consider the scenario to service on backup master running as a follower.

Illustration 7: Service on Backup Master drive which runs as a Follower Drive

[Off] mode on Drive 2 LCP keypad, stops pump 2.

It is recommended to use pump interlock DI using [131] Pump 2 interlock on Master Drive, as drive 2 is the backup master and

potentially becomes the master drive in cases of primary master drive break-down. The wiring should be to both primary and secondary master drive.

See wiring example.

AB389040992368en-000101 / 130R122920 | Danfoss A/S © 2021.12

68 696120

1

19

27

29

32

2 3 4

18 68 68 6869 69 69

6161

20 18

LXX1 LXX1

Pump interlock 1

Pump interlock 2

Pump interlock 3

Pump interlock 4

Pressure

transmitter

Pressure

transmitter

Start signal

e30bi489.10

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi488.10

Multi-Master Cascade Control

Application Guide

Maintenance Scenarios

Illustration 8: Wiring Example

8.3 Service on Follower

Consider the scenario when the follower drive on pump 3 fails. Any actions performed affects only the specific drive.

Illustration 9: Service on Follower Drive

AB389040992368en-000101 / 130R1229 | 21Danfoss A/S © 2021.12

•

•

•

•

•

•

•

•

•

•

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi486.10

System setup

System Action

Primary

Master (Address 1)

Change the master, when the following occurs on the primary master:

Supply power is turned off.

Control card defect.

Warning, Live Zero error. This is only shown if parameter 6-01 Live Zero Timeout Function is configured to [30]

Warning Only.

The system stops when primary master detects the following:

Alarm 68, Safe Stop Activated.

Alarm 94, End of Curve.

Alarm 92, No Flow Alarm.

Alarm 93, Dry Pump Alarm.

Alarm 60, External Interlock.

Followers are operating, when the primary master stops:

Any other alarm/fault.

LCP status: M:X F:D F:D F:D

Multi-Master Cascade Control

Application Guide

Alarms, Warnings, and Defects

9 Alarms, Warnings, and Defects

9.1 System Setups and Actions to Alarms, Warnings

This section explains behaviors which are triggered by alarms, warnings, and defects. Following are three examples.

LCP status: M:X F:D F:D F:D

Illustration 10: System Setup - Primary Master (Address 1)

Table 14: System Actions

AB389040992368en-000101 / 130R122922 | Danfoss A/S © 2021.12

•

•

•

•

•

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi487.10

System setup

System Action

Backup Master (Runs as Followers)

During this alarm, the drive continues to operate.

The LCP status is M:D F:X F:D F:D.

1

1 2 3 4

2 3 4

Line supply

!

LXX1 LXX1

68 69 68 68 6869 69 69

e30bi488.10

System setup

System Action

Follower

The follower stops.

The system continues.

The LCP status is displayed as M:D F:D F:X F:D.

Multi-Master Cascade Control

Application Guide

LCP status: M:D F:X F:D F:D

Illustration 11: System Setup - Backup Master

Table 15: System Actions

Alarms, Warnings, and Defects

LCP status: M:D F:D F:X F:D

Illustration 12: System Setup - Follower Drive

Table 16: System Actions

AB389040992368en-000101 / 130R1229 | 23Danfoss A/S © 2021.12

Time

Final ramp

down time

Check valve

ramp down

time

Normal

ramp

Initial

ramp time

Normal

ramp down

time

Check valve

end speed

Motor speed

low limit

Motor speed

high limit

Speed

e30bj392.10

Power

Frequency

Low speed

High

speed

power

Low

speed

power

No/low flow

power curve

High

speed

No/low flow detection

e30bi482.10

No/Low flow detection

Multi-Master Cascade Control

Water Features with Multi-Master

Application Guide

Cascade

10 Water Features with Multi-Master Cascade

10.1 Water Features

This section provides an overview of water related features which are enabled when using the Multi-Master Cascade Control. This

section briefs on the compatibility with the multi-master setup and the parameters to configure to enable the feature..

10.2 Check Valve Ramp

Feature compatible with Multi-Master Setup

Yes, the feature can work with multi-master cascade setup of drives.

How does Check Valve Ramp work?

Illustration 13: Check Valve Ramp

Parameters to configure the feature

•

Parameter 3–85 is application specific.

•

Parameter 3-86/Parameter 3–87 is application specific.

10.3 Sleep Mode

Feature compatibility with Multi-Master Cascade Setup

This feature is supported by the multi-master cascade setup.

How does the feature work?

Illustration 14: Sleep Mode

Parameter to configure the feature:

For more information on how to configure, see 6.1 Sleep Mode Parameter Setup

AB389040992368en-000101 / 130R122924 | Danfoss A/S © 2021.12

Speed

Derag function

activated

Derag off delay:

Par. 29-15

Time

Deragging run time: Par. 29-12

1 cycle

Number of cycles: Par. 29-10

+/- derag

speed:

Par. 29-13

Par. 29-14

0 Hz/RPM

e30bi483.10

Power

Frequency

Low speed

High

speed

power

Low

speed

power

No/low flow

power curve

High

speed

No/low flow detection

e30bi482.10

No/Low flow detection

Multi-Master Cascade Control

Application Guide

10.4 Deragging

Feature compatibility with Multi-Master Control Set up

No, this feature does not work with multi-master control set up of drives.

How does the feature work?

Water Features with Multi-Master

Cascade

Illustration 15: Deragging

10.5 Dry Pump

Feature compatibility with Multi-Master Control Setup

The feature work with conditions on Multi-Master control setup of drives. The feature can be used if primary master drive has priority 1 and all back-up master and follower drives have priority 2 or spare pump which is specified in parameter 27–16.

N O T I C E

This type of setting means that the primary master drive always operates when a demand is available and is not part of normal

runtime balancing to even out the running hours of the pumps.

How does the feature work?

Illustration 16: Dry Pump

AB389040992368en-000101 / 130R1229 | 25Danfoss A/S © 2021.12

Pressure

Pump curve

System curve

Flow

e30bi480.10

Pressure

Flow

Flow

compensation

Constant pressure

operation

Energy saved

e30bi481.10

Multi-Master Cascade Control

Water Features with Multi-Master

Application Guide

Cascade

10.6 End of Curve Detection

Feature Compatibility with Multi Master Cascade Setup

The feature work with conditions on Multi-Master Cascade set up of drives. The feature can be used if primary master drive has

priority 1 and all back-up master and follower drives have priority 2 or spare pump which is specified in parameter 27–16.

N O T I C E

This type of setting means that the primary master drive always operates when a demand is available and is not part of normal

runtime balancing to even out the running hours of the pumps.

How does the feature work?

Illustration 17: End of Curve Detection

10.7 Flow Compensation

Feature Compatibility with Multi Master Cascade Setup

The feature works with Multi-Master Cascade set up of drives.

How does the feature work?

Illustration 18: Flow Compensation

How to configure the feature?

Configure the following parameters:

AB389040992368en-000101 / 130R122926 | Danfoss A/S © 2021.12

Time

Final ramp

down time

Check valve

ramp down

time

Normal

ramp

Initial

ramp time

Normal

ramp down

time

Check valve

end speed

Motor speed

low limit

Motor speed

high limit

Speed

e30bj392.10

Multi-Master Cascade Control

Application Guide

•

Parameter 22–80 as [1] Enabled

•

Parameter 22–87 to application specific settings

•

Parameter 20–21 to application specific settings

10.8 Pipefill

Feature Compatibility with Multi Master Cascade Setup

The feature works with Multi-Master Cascade setup of drives.

How does the feature work?

Water Features with Multi-Master

Cascade

Illustration 19: Pipefill

How to configure the feature?

•

Set parameter 29-01 as [1] Enabled.

•

Use speed or pressure.

See VLT® FC 202 Programming guide for information on parameters.

10.9 Flow Confirmation

Feature Compatibility with Multi-Master Cascade Set up

The feature work with conditions on Multi-Master Cascade set up of drives. Can be used if primary master drive has priority 1 and all

back-up master and follower drives have priority 2 or spare pump which is specified in parameter 27-16

N O T I C E

This type of setting means the primary master drive always operates when a demand is available and isnot part of normal run-

time balancing to even out the running hours of the pumps.

AB389040992368en-000101 / 130R1229 | 27Danfoss A/S © 2021.12

Speed

Start command

Verifying flow

Ext. digital signal

(eg. from valve)

Time

t0 t2<t1

ON

ON

ON

OFF

OFF

OFF

Max.

speed

Min.

speed

e30bj393.10

Multi-Master Cascade Control

Water Features with Multi-Master

Application Guide

Cascade

N O T I C E

Flow confirmation for each pump with flow switch can be enabled in Multi-Master with programming of smart logic control. Con-

tact local sales office for support.

How does the feature work?

Illustration 20: Flow Confirmation

AB389040992368en-000101 / 130R122928 | Danfoss A/S © 2021.12

Multi-Master Cascade Control

Application Guide

Index

A

Application Setups.........................................................................................6

C

Cascading Operation.................................................................................. 17

Control Card Compatibility......................................................................... 7

I

Identify license key.........................................................................................8

Installing Modbus Multi-Master Cascade...............................................9

L

Loading new software.................................................................................. 8

M

Maintenance on backup master............................................................. 20

Maintenance on follower.......................................................................... 21

Maintenance on primary master............................................................ 20

Multi-Master Cascade Control....................................................................6

Index

Multi-Master Cascade Control Parameter Setup.............................. 10

O

Ordering Multi-Master Cascade Control................................................ 7

R

Retrofit existing VLT® AQUA FC 202 Drive............................................. 7

S

Sleep mode parameter...............................................................................16

Software Compatibility.................................................................................7

Staging Parameter Setup.......................................................................... 14

T

Troubleshooting...........................................................................................22

W

Water Features with Multi-Master Cascade Control........................24

AB389040992368en-000101/130R1229 | 29Danfoss A/S © 2021.12

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogs, brochures, and other printed material. Danfoss reserves the right to alter its products without notice. This

also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All

trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

*130R1229*

Danfoss A/S © 2021.12

AB389040992368en-000101 / 130R1229

*M0034201*

Loading...

Loading...