Danfoss FC 202 Operating guide

MAKING MODERN LIVING POSSIBLE

Operating Instructions VLT® AQUA Drive FC 202

110–1400 kW

www.danfoss.com/drives

Contents |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

Contents

1 How to Read these Operating Instructions |

4 |

2 Safety |

6 |

2.1 Safety Note |

6 |

2.1.1 General Warning |

6 |

2.1.2 Before Commencing Repair Work |

7 |

2.1.3 Special Conditions |

7 |

2.1.4 Avoid Unintended Start |

7 |

2.1.5 Safe Torque Off (STO) |

7 |

2.1.6 IT Mains |

8 |

3 How to Install |

9 |

3.1 How to Get Started |

9 |

3.2 Pre-installation |

9 |

3.2.1 Planning the Installation Site |

9 |

3.2.2 Receiving the Frequency Converter |

10 |

3.2.3 Transportation and Unpacking |

10 |

3.2.4 Lifting |

10 |

3.2.5 Mechanical Dimensions |

12 |

3.2.6 Rated Power |

18 |

3.3 Mechanical Installation |

20 |

3.3.1 Tools Needed |

20 |

3.3.2 General Considerations |

20 |

3.3.3 Terminal Locations - Enclosure Type D |

21 |

3.3.4 Terminal Locations - E Enclosures |

24 |

3.3.5 Terminal Locations - Enclosure type F |

29 |

3.3.6 Cooling and Airflow |

33 |

3.3.7 Installation on the Wall - IP21 (NEMA 1) and IP54 (NEMA 12) Units |

35 |

3.3.8 Gland/Conduit Entry - IP21 (NEMA 1) and IP54 (NEMA12) |

35 |

3.3.9 IP21 Drip Shield Installation (Enclosure Types D1 and D2) |

37 |

3.4 Field Installation of Options |

37 |

3.4.1 Installation of Duct Cooling Kit in Rittal Enclosures |

37 |

3.4.2 Outside Installation/NEMA 3R Kit for Rittal Enclosures |

38 |

3.4.3 Installation on Pedestal |

39 |

3.4.4 Installation of Input Plate Options |

40 |

3.4.5 Installation of Mains Shield for Frequency Converters |

41 |

3.5 Enclsoure Type F Panel Options |

41 |

3.5.1 Enclsoure Type F Options |

41 |

3.6 Electrical Installation |

42 |

3.6.1 Power Connections |

42 |

MG20P402 - Rev. 2013-12-16 |

1 |

Contents |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

3.6.2 Grounding |

53 |

3.6.3 Extra Protection (RCD) |

53 |

3.6.4 RFI Switch |

53 |

3.6.5 Torque |

53 |

3.6.6 Shielded Cables |

54 |

3.6.7 Motor Cable |

54 |

3.6.8 Brake Cable for Frequency Converters with Factory Installed Brake Chopper Op- |

|

tion |

55 |

3.6.9 Brake Resistor Temperature Switch |

55 |

3.6.10 Load Sharing |

55 |

3.6.11 Shielding against Electrical Noise |

55 |

3.6.12 Mains Connection |

56 |

3.6.13 External Fan Supply |

56 |

3.6.14 Fuses |

56 |

3.6.15 Mains Disconnectors |

59 |

3.6.16 F Enclosure Circuit Breakers |

59 |

3.6.17 F Enclosure Mains Contactors |

60 |

3.6.18 Motor Insulation |

60 |

3.6.19 Motor Bearing Currents |

60 |

3.6.20 Control Cable Routing |

60 |

3.6.21 Access to Control Terminals |

62 |

3.6.22 Electrical Installation, Control Terminals |

62 |

3.6.23 Electrical Installation, Control Cables |

63 |

3.6.24 Switches S201, S202, and S801 |

65 |

3.7 Connection Examples |

66 |

3.7.1 Start/Stop |

66 |

3.7.2 Pulse Start/Stop |

66 |

3.8 Final Set-up and Test |

67 |

3.9 Additional Connections |

68 |

3.9.1 Mechanical Brake Control |

68 |

3.9.2 Parallel Connection of Motors |

68 |

3.9.3 Motor Thermal Protection |

69 |

4 How to operate the frequency converter |

70 |

4.1 Ways of Operation |

70 |

4.1.1 How to operate graphical LCP (GLCP) |

70 |

4.1.2 How to Operate Numeric LCP (NLCP) |

73 |

4.1.3 Changing Data |

75 |

4.1.4 Changing a Text Value |

75 |

4.1.5 Changing a Group of Numeric Data Values |

75 |

4.1.6 Changing of Data Value, Step-by-Step |

76 |

2 |

MG20P402 - Rev. 2013-12-16 |

Contents |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

4.1.7 Read-out and Programming of Indexed Parameters |

76 |

4.1.8 Tips and Tricks |

76 |

5 How to programme the frequency converter |

79 |

5.1 How to programme |

79 |

5.2 Commonly Used Parameters - Explanations |

84 |

5.3 Parameter Menu Structure |

112 |

6 General Specifications |

117 |

7 Troubleshooting |

130 |

Index |

142 |

MG20P402 - Rev. 2013-12-16 |

3 |

How to Read these Operating... VLT AQUA Drive FC 202 Operation Instructions

1 |

1 |

1 How to Read these Operating Instructions |

|

|

VLT AQUA Drive

FC 200 Series

Software version: 2.1x

This guide can be used with all FC 202 frequency converters with software

version 2.1x or later. The actual software version number can be read from

15-43 Software Version.

This publication contains information proprietary to Danfoss. By accepting and using this manual the user agrees that the information contained herein is used solely for operating equipment from Danfoss or equipment from other vendors if such equipment is intended for communication with Danfoss equipment over a serial communication link. This publication is protected under the Copyright laws of Denmark and most other countries.

Danfoss does not warrant that a software program produced according to the guidelines provided in this manual functions properly in every physical, hardware or software environment.

Although Danfoss has tested and reviewed the documentation within this manual, Danfoss makes no warranty or representation, neither expressed nor implied, with respect to this documentation, including its quality, performance, or fitness for a particular purpose.

In no event shall Danfoss be liable for direct, indirect, special, incidental, or consequential damages arising out of the use, or the inability to use information contained in this manual, even if advised of the possibility of such damages. In particular, Danfoss is not responsible for any costs, including but not limited to those incurred as a result of lost profits or revenue, loss or damage of equipment, loss of computer programs, loss of data, the costs to substitute these, or any claims by third parties.

Danfoss reserves the right to revise this publication at any time and to make changes to its contents without prior

notice or any obligation to notify former or present users of such revisions or changes.

1.1.1 Available Literature

•VLT® AQUA Drive FC 202 Operating Instructions provide the neccessary information for getting the frequency converter up and running.

•VLT® AQUA Drive FC 202, 110-1400 kW Operating Instructions provide the neccessary information for getting the high power frequency converter up and running.

•VLT® AQUA Drive FC 202 Design Guide entails all technical information about the frequency converter and customer design and applications.

•VLT® AQUA Drive FC 202 Programming Guide provides information on how to programme and includes complete parameter descriptions.

•VLT® AQUA Drive FC 202 Profibus

•VLT® AQUA Drive FC 202 DeviceNet

•Output Filters Design Guide

•VLT® AQUA Drive FC 202 Cascade Controller

•Application Note MN20A: Submersible Pump Application

•Application Note MN20: Master/Follower Operation Application

•Application Note MN20F: Drive Closed Loop and Sleep Mode

•Installation Instruction for Mounting Brackets Enclosure type A5, B1, B2, C1 and C2 IP21, IP55 or IP66

•Instruction for Analog I/O Option MCB109

•Instruction for Panel through mount kit

•VLT® Active Filter Operating Instruction

Danfoss technical literature is also available online at www.danfoss.com/BusinessAreas/DrivesSolutions/ Documentations/Technical+Documentation.htm.

4 |

MG20P402 - Rev. 2013-12-16 |

How to Read these Operating... |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

1 |

1 |

|

The frequency converter complies with UL508C thermal |

|||

memory retention requirements. For more information, refer to the section Motor Thermal Protection in the Design Guide.

NOTICE

Imposed limitations on the output frequency (due to export control regulations):

From software version 6.72 the output frequency of the frequency converter is limited to 590 Hz. Software versions 6x.xx also limit the maximum output frequency to 590 Hz, but these versions cannot be flashed, i.e. neither downgraded nor upgraded.

The following symbols are used in this document:

WARNING

WARNING

Indicates a potentially hazardous situation which could result in death or serious injury.

CAUTION

CAUTION

Indicates a potentially hazardous situation which could result in minor or moderate injury. It may also be used to alert against unsafe practices.

NOTICE

Indicates important information, including situations that may result in damage to equipment or property.

MG20P402 - Rev. 2013-12-16 |

5 |

Safety |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

2 Safety

2 2

2.1 Safety Note

WARNING

WARNING

The voltage of the frequency converter is dangerous whenever connected to mains. Incorrect installation of the motor, frequency converter or fieldbus may cause damage to the equipment, serious personal injury or death. Consequently, the instructions in this manual, as well as national and local rules and safety regulations, must be complied with.

Safety Regulations

1.The frequency converter must be disconnected from mains if repair work is to be carried out. Check that the mains supply has been disconnected and that the necessary time has passed before removing motor and mains plugs.

2.The [STOP/RESET] key on the control panel of the frequency converter does not disconnect the equipment from mains and is thus not to be used as a safety switch.

3.Correct protective earthing of the equipment must be established, the user must be protected against supply voltage, and the motor must be protected against overload in accordance with applicable national and local regulations.

4.The earth leakage currents are higher than 3.5 mA.

5.Protection against motor overload is set by par. 1-90 Motor Thermal Protection. If this function is desired, set par. 1-90 to data value [ETR trip] (default value) or data value [ETR warning]. Note: The function is initialised at 1.16 x rated motor current and rated motor frequency. For the North American market: The ETR functions provide class 20 motor overload protection in accordance with NEC.

6.Do not remove the plugs for the motor and mains supply while the frequency converter is connected to mains. Check that the mains supply has been disconnected and that the necessary time has passed before removing motor and mains plugs.

7.Note that the frequency converter has voltage inputs other than L1, L2 and L3, when load sharing (linking of DC intermediate circuit) and external 24 V DC have been installed. Check that all voltage inputs have been disconnected and that the necessary time has passed before commencing repair work.

NOTICE

Installation at high altitude:

380 - 480 V: At altitudes above 3,000 m, contact Danfoss regarding PELV.

525 - 690 V: At altitudes above 2,000 m, contact Danfoss regarding PELV.

Warning against Unintended Start

1.The motor can be stopped with digital commands, bus commands, references or a local stop, while the frequency converter is connected to mains. To avoid personal injury, these stop functions are not sufficient to ensure that no unintended start occurs.

2.While parameters are being changed, the motor may start. Consequently, always press [RESET]; following which data can be modified.

3.A motor that has been stopped may start if faults occur in the electronics of the frequency converter, or if a temporary overload or a fault in the supply mains or the motor connection ceases.

WARNING

WARNING

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as external 24 V DC, load sharing (linkage of DC intermediate circuit), as well as the motor connection for kinetic back-up.

2.1.1 General Warning

WARNING

WARNING

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains. Also make sure that other voltage inputs have been

disconnected, (linkage of DC intermediate circuit), as well as the motor connection for kinetic back-up.

Before touching any potentially live parts of the frequency converter, wait at least as follows: Be aware that there may be high voltage on the DC link even when the Control Card LEDs are turned off. A red LED is mounted on a circuit board inside the frequency converter to indicate the DC bus voltage. The red LED stays lit until the DC link is 50 V DC or lower.

6 |

MG20P402 - Rev. 2013-12-16 |

Safety |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

WARNING

WARNING

Leakage Current

The earth leakage current from the frequency converter exceeds 3.5 mA. According to IEC 61800-5-1 a reinforced Protective Earth connection must be ensured by means of: a min. 10mm² Cu or 16mm² Al PE-wire or an addtional PE wire - with the same cable cross section as the Mains wiring - must be terminated separately. Residual Current Device

This product can cause a D.C. current in the protective conductor. Where a residual current device (RCD) is used for extra protection, only an RCD of Type B (time delayed) shall be used on the supply side of this product. See also RCD Application Note MN.90.GX.02. Protective earthing of the frequency converter and the use of RCD's must always follow national and local regulations.

2.1.2 Before Commencing Repair Work

1.Disconnect the frequency converter from mains.

2.Disconnect DC bus terminals 88 and 89.

3.Wait at least the time mentioned in chapter 2.1.1 General Warning.

2.1.3 Special Conditions

Electrical ratings

The rating indicated on the nameplate of the frequency converter is based on a typical 3-phase mains power supply, within the specified voltage, current and temperature range, which is expected to be used in most applications.

The frequency converters also support other special applications, which affect the electrical ratings of the frequency converter. Special conditions which affect the electrical ratings might be:

•Single phase applications

•High temperature applications which require derating of the electrical ratings

•Marine applications with more severe environmental conditions.

Consult the relevant clauses in these instructions and in the Design Guide for information about the electrical ratings.

Installation requirements

The overall electrical safety of the frequency converter requires special installation considerations regarding:

•Fuses and circuit breakers for over-current and short-circuit protection

•Selection of power cables (mains, motor, brake, loadsharing and relay)

• |

Grid configuration (IT,TN, grounded leg, etc.) |

|

• |

Safety of low-voltage ports (PELV conditions) |

2 |

|

2 |

Consult the relevant clauses in these instructions and in the Design Guide for information about the installation requirements.

WARNING

WARNING

The frequency converter's DC link capacitors remain charged after power has been disconnected. To avoid an electrical shock hazard, disconnect the frequency converter from the mains before carrying out maintenance. Before doing service on the frequency converter, wait at least the amount of time indicated below:

Voltage |

Power size |

Min. Waiting Time |

|

|

|

|

|

380 - 480 V |

110 - 250 kW |

20 minutes |

|

|

|

|

|

|

315 |

- 1000 kW |

40 minutes |

|

|

|

|

525 - 690 V |

45 |

- 400 kW |

20 minutes |

|

|

|

|

|

4501400 kW |

30 minutes |

|

|

|

|

|

Be aware that there may be high voltage on the DC link even when the LEDs are turned off.

Table 2.1 Discharge Time

2.1.4 Avoid Unintended Start

WARNING

WARNING

While the frequency converter is connected to mains, the motor can be started/stopped using digital commands, bus commands, references or via the Local Control Panel.

•Disconnect the frequency converter from mains whenever personal safety considerations make it necessary to avoid unintended start.

•To avoid unintended start, always activate the [Off] key before changing parameters.

•Unless terminal 37 is turned off, an electronic fault, temporary overload, a fault in the mains supply, or lost motor connection may cause a stopped motor to start.

2.1.5 Safe Torque Off (STO)

To run Safe Torque Off, additional wiring for the frequency converter is required, refer to Safe Torque Off Operating Instructions for Danfoss VLT® Frequency Converters for further information.

MG20P402 - Rev. 2013-12-16 |

7 |

Safety |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

2.1.6 IT Mains

2 2

WARNING

WARNING

IT mains

Do not connect frequency converters with RFI-filters to mains supplies with a voltage between phase and earth of more than 440 V for 400 V converters and 760 V for 690 V converters.

For 400 V IT mains and delta earth (grounded leg), mains voltage may exceed 440 V between phase and earth. For 690 V IT mains and delta earth (grounded leg), mains voltage may exceed 760 V between phase and earth. Failure to follow recommendations could result in death or serious injury.

14-50 RFI Filter can be used to disconnect the internal RFI capacitors from the RFI filter to ground.

2.1.7 Disposal Instruction

Equipment containing electrical components must not be disposed of together with domestic waste.

It must be separately collected with electrical and electronic waste according to local and currently valid legislation.

8 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

3 How to Install

3.1 How to Get Started

This chapter covers mechanical and electrical installations to and from power terminals and control card terminals. Electrical installation of options is described in the relevant

Operating Instructions and Design Guide.

The frequency converter is designed to achieve a quick and EMC-correct installation by following the steps described below.

WARNING

WARNING

Read the safety instructions before installing the unit. Failure to follow recommendations could result in death or serious injury.

Mechanical Installation

•Mechanical mounting

Electrical Installation

•Connection to Mains and Protecting Earth

•Motor connection and cables

•Fuses and circuit breakers

•Control terminals - cables

Quick Setup

•Local Control Panel, LCP

•Automatic Motor Adaptation, AMA

•Programming

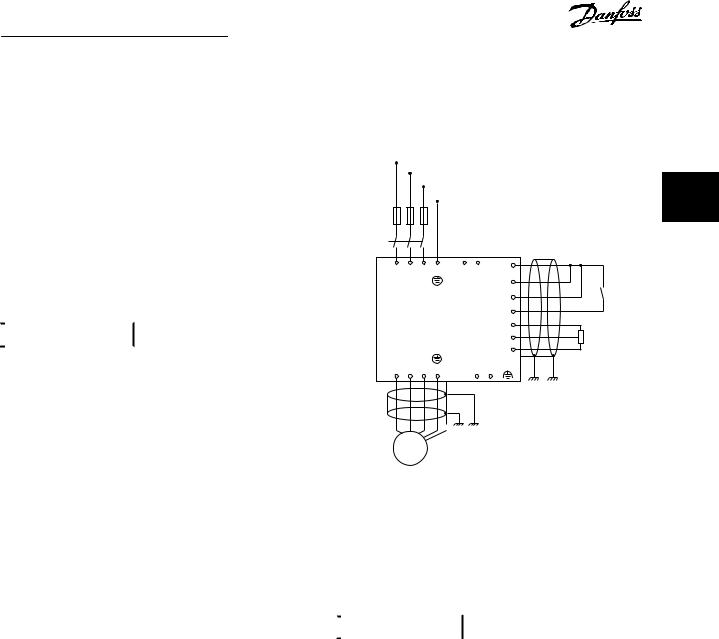

Frame size is depending on enclosure type, power range and mains voltage

L1 |

|

<![if ! IE]> <![endif]>130BA015.13 |

|

||

L2 |

|

|

|

|

|

L3 |

|

|

|

|

|

PE |

|

|

|

|

F1

91 |

92 |

93 |

95 |

88 |

89 |

|

12 |

|

|

||||||

|

|

|

|

DC- |

DC+ |

27 |

|

L1 |

L2 |

L3 |

PE |

|

|

|

1 |

|

|

|

37 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

|

|

|

|

|

50 |

|

|

|

|

|

|

|

53 |

U |

V |

W |

PE |

|

|

|

55 |

|

|

|

|

|

R- |

R+ |

|

96 |

97 |

98 |

99 |

|

81 |

82 |

|

M

3

Illustration 3.1 Diagram showing basic installation including mains, motor, start/stop key, and potentiometer for speed adjustment.

3.2 Pre-installation

3.2.1 Planning the Installation Site

CAUTION

CAUTION

Before performing the installation it is important to plan the installation of the frequency converter. Neglecting this may result in extra work during and after installation.

Select the best possible operation site by considering the following (see details on the following pages, and the respective Design Guides)

•Ambient operating temperature

•Installation method

•How to cool the unit

•Position of the frequency converter

•Cable routing

•Ensure the power source supplies the correct voltage and necessary current

•Ensure that the motor current rating is within the maximum current from the frequency converter

•If the frequency converter is without built-in fuses, ensure that the external fuses are rated correctly.

3 3

MG20P402 - Rev. 2013-12-16 |

9 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

3.2.2 Receiving the Frequency Converter

When receiving the frequency converter, make sure that the packaging is intact, and be aware of any damage that might have occurred to the unit during transport. In case

3 3 damage has occurred, contact immediately the shipping company to claim the damage.

3.2.3 Transportation and Unpacking

Before unpacking the frequency converter it is recommended that it is located as close as possible to the final installation site.

Remove the box and handle the frequency converter on the pallet, as long as possible.

3.2.4 Lifting

Always lift the frequency converter in the dedicated lifting eyes. For all D and E2 (IP00) enclosures, use a bar to avoid bending the lifting holes of the frequency converter.

<![if ! IE]><![endif]>176FA245.10

Illustration 3.2 Recommended Lifting Method, Enclosure Types

D and E

WARNING

WARNING

The lifting bar must be able to handle the weight of the frequency converter. See Mechanical Dimensions for the weight of the different enclosure type. Maximum diameter for bar is 2.5 cm (1 inch). The angle from the top of the frequency converter to the lifting cable should be 60° or greater.

<![endif]>130BA832.11

Illustration 3.3 Recommended Lifting Method, Enclsoure Type

F1 (460 V, 600 to 900 HP, 575/690 V, 900 to 1150 HP)

<![if ! IE]><![endif]>130BA834.11

Illustration 3.4 Recommended Lifting Method, Enclosure Type F2 (460 V, 1000 to 1200 HP, 575/690 V, 1250 to 1350 HP)

10 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

<![endif]>130BA833.11

Illustration 3.5 Recommended Lifting Method, Enclosure Type F3 (460 V, 600 to 900 HP, 575/690 V, 900 to 1150 HP)

<![if ! IE]><![endif]>130BA835.11

Illustration 3.6 Recommended Lifting Method, Enclosure Type F4 (460 V, 1000 to 1200 HP, 575/690 V, 1250 to 1350 HP)

<![if ! IE]><![endif]>130BB753.10

<![endif]>130BB688.10

3 3

Illustration 3.8 Recommended lifting method, Enclosure Type F9/F10

<![if ! IE]><![endif]>130BB689.10

Illustration 3.9 Recommended lifting method, Enclosure Type

F11/F12/F13/F14

Illustration 3.7 Recommended lifting method, Enclosure Type

F8

MG20P402 - Rev. 2013-12-16 |

11 |

How to Install VLT AQUA Drive FC 202 Operation Instructions

NOTICE

The plinth is provided in the same packaging as the frequency converter but is not attached to enclosure types F1-F4 during shipment. The plinth is required to allow airflow to the frequency converter to provide proper cooling. The F enclosures should be positioned on top of the plinth in the final installation location. The angle from the top of the frequency converter to the lifting cable should be 60° or greater.

3 3 In addition to the drawings above a spreader bar is an acceptable way to lift the F enclosures.

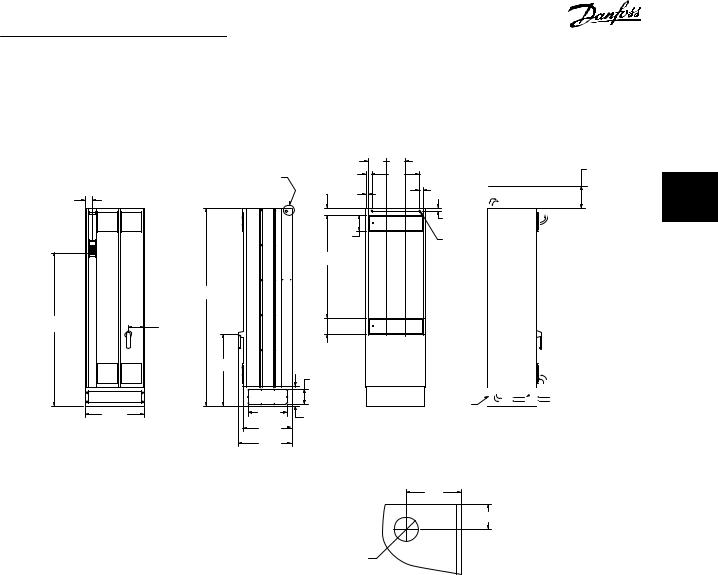

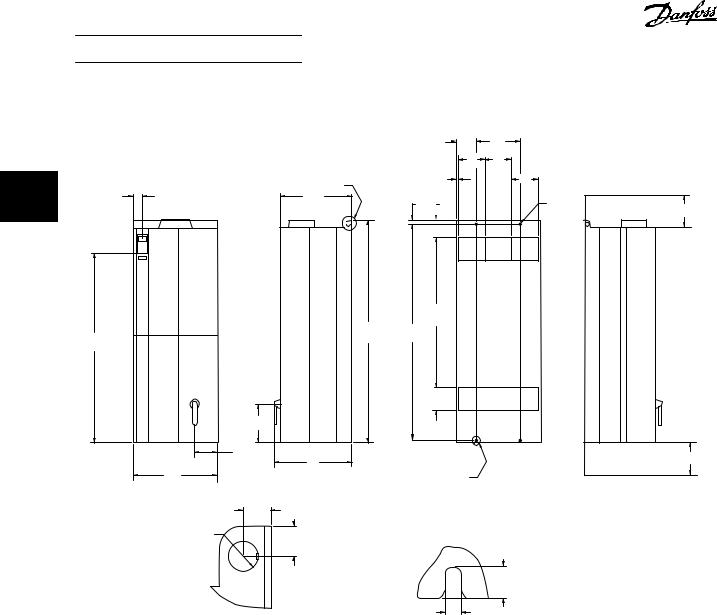

3.2.5 Mechanical Dimensions

|

IP21 AND IP54 / UL AND NEMA TYPE 1 AND 12 |

|

|||

|

D1 |

|

|

|

|

|

A |

|

B |

|

|

74 |

|

|

304 |

25 |

|

|

|

(1.0) |

225 |

||

(2.9) |

|

|

(12.0) |

||

|

|

|

(8.9) |

||

|

|

|

|

|

|

|

|

120 |

|

|

|

|

|

(4.7) |

|

|

|

|

|

|

|

160.0 |

|

|

|

|

|

(6.3) |

|

|

|

|

|

|

1362 |

|

|

849 |

|

|

(53.6) |

|

1166 |

(33.4) |

|

1154 |

|

|

1209 |

|

|

||

981 |

(45.9) |

(47.6) |

|

(45.4) |

|

|

|

|

|

|

|

(38.6) |

|

|

|

|

|

|

310 |

160.0 |

|

|

|

|

(12.2) |

(6.3) |

|

|

|

163 |

380 |

|

177.0 |

|

225 |

(6.4) |

(15.0) |

|

(7.0) |

|

|

|

|

|

|

|

(8.9) |

420 |

417 |

C |

354.0 |

|

|

(16.5) |

(16.4) |

|

(13.9) |

|

|

Illustration 3.10 |

|

|

|

|

|

|

D2 |

72 |

|

(2.8) |

|

|

120 |

|

(4.7) |

|

977 |

|

(38.5) |

1547 |

1589 |

(60.9) |

(62.6) |

|

160.0 |

|

(6.3) |

423 |

|

(16.6) |

|

157 |

380 |

(6.2) |

(15.0) |

420 |

417 |

(16.5) |

(16.4) |

304 |

25 |

|

(12.0) |

||

(1.0) |

||

|

||

|

160.0 |

|

|

(6.3) |

|

|

1535 |

|

|

(60.4) |

|

184.5 |

|

|

(7.3) |

|

|

369.0 |

|

|

(14.5) |

|

225.0 |

<![if ! IE]> <![endif]>130BA443.11 |

(8.9) |

|

225.0 |

|

(8.9) |

|

* Note airflow directions

|

|

D3 |

|

IP00 / CHASSIS |

|

|

|

|

|

|

|

|

|

66 |

298 |

|

|

A |

B |

|

|

( 2.6) |

( 11.7) |

|

|

|

|

|

|

||

|

66 |

298 |

304 |

25 |

|

|

|

|

(1.0) |

225 |

|

|

|||

|

( 2.6) |

(11.7) |

(12.0) |

|

|

||

|

|

|

|

|

(8.9) |

|

|

|

|

120 |

|

|

|

|

|

|

|

( 4.7) |

|

|

|

|

|

|

|

|

|

160.0 |

|

|

|

|

|

|

|

( 6.30) |

|

|

|

|

|

696 |

|

|

|

|

1280 |

|

|

( 27.4) |

|

1001 |

|

1099 |

|

|

|

|

|

(50.4) |

|||

|

997 |

1046 |

|

( 39.4) |

|

(43.3) |

|

818 |

( 41.2) |

|

|

|

|

|

|

( 39.3) |

|

|

|

|

|

|

|

( 32.2) |

|

|

|

|

|

|

|

|

|

160 |

|

|

|

|

|

|

147 |

( 6.3) |

|

|

|

|

161 |

|

( 5.8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

( 6.3) |

|

157 |

375 |

177 |

|

225 |

151 |

375 |

|

( 6.2) |

(14.8) |

(7.0) |

C |

(8.9) |

(5.9) |

( 14.8) |

|

408 |

417 |

354 |

|

|

417 |

|

|

|

|

408 |

||||

|

(16.1) |

(16.4) |

(13.9) |

|

|

( 16.1) |

( 16.4) |

D4

120 ( 4.7)

1327

(52.2)

977 ( 38.5)

160 ( 6.3)

304 |

25 |

( 12.0) |

( 1.0) |

|

160.0 |

|

( 6.30 ) |

|

1282 |

|

( 50.5) |

185 |

|

( 7.3 ) |

|

369 |

|

( 14.5) |

|

225.0 |

<![if ! IE]> <![endif]>138BA442.10 |

( 8.9) |

|

225.0 |

|

(8.9) |

|

|

|

|

|

IP00/IP21/IP54 - ALL SIZES |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

51 |

||||||

A |

|

B |

|

|

49 |

|

Ø 11 |

C |

11 |

|

|

|

|

|

( 2.0) |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

( 1.9 ) |

( .4) |

( 0.4) |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

|

( 1.0) |

25 |

10 |

|

(0.4) |

|

|

( 1.0 ) |

|

|

20.0 |

|

|

|

|

|

|

(0.8) |

|

|

22 |

22 |

|

(0.9) |

(0.9) |

|

|

Illustration 3.11

12 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

* Note airflow directions

E1 |

IP21 AND IP54 / UL AND NEMA TYPE 1 AND 12 |

|||

|

|

|

185 |

185 |

|

F |

|

( 7.3 ) ( 7.3 ) |

|

|

|

58 |

484 |

|

|

|

|

( 2.3 ) |

(19.1) |

|

|

|

23 |

185 |

72 |

|

72 |

( 7.3 ) |

|

|

( 2.8 ) |

(0.9) |

|

|

( 2.8 ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

27 |

|

|

|

|

( 1.1 ) |

|

|

|

160 |

2X13 |

|

|

|

( 6.3 ) |

|

|

|

|

(0.5) |

|

|

|

|

|

|

|

|

1043 |

|

|

|

|

( 41.1 ) |

|

|

|

2000 |

|

|

|

|

(78.74) |

|

|

|

1551 |

164 |

|

|

|

( 61.1 ) |

|

|

|

|

|

( 6.5 ) |

|

|

|

|

|

160 |

|

|

|

|

( 6.3 ) |

|

|

|

727 |

|

|

|

|

( 28.6 ) |

|

|

|

|

|

145 |

|

|

|

|

( 5.7 ) |

|

|

600 |

392 |

198 |

|

CABLE BASE |

(23.62) |

( 15.4 ) |

|

|

|

|

494 |

( 7.8 ) |

|

|

|

( 19.4 ) |

|

|

|

|

538 |

|

|

|

|

( 21.2 ) |

|

|

|

225 |

<![if ! IE]> <![endif]>130BA444.10 |

( 8.86 ) |

|

SIDE CABLE ENTRY

KNOCK-OFF PLATE

KNOCK-OFF PLATE

BOTTOM CABLE ENTRY

BOTTOM CABLE ENTRY

F |

56 |

|

( 2.2 ) |

|

25 |

|

(1.0) |

Ø 25 |

|

( 1.0 ) |

|

Illustration 3.12

* Note airflow directions

3 3

MG20P402 - Rev. 2013-12-16 |

13 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

E2 |

|

IP00 / CHASSIS |

|

|

|

|

|

|

|

|

139 |

304 |

|

|

|

|

|

|

(5.5) |

(12.0) |

|

|

|

|

|

|

184 |

184 |

|

|

|

|

|

|

(7.3) |

(7.3) |

|

|

|

|

D |

|

14 |

184 |

3 |

3 |

|

|

|

(1.5) |

|

|

64 |

|

498 |

25 |

120 |

2X13 |

||

(2.5) |

|

(19.5) |

|||||

|

(1.0) |

(4.7) |

(0.5) |

||||

|

|

|

|||||

|

|

|

|

|

1043 |

|

|

|

|

|

|

1547 |

(41.1) |

|

|

|

|

1320 |

|

1502 |

|

|

|

|

|

|

(60.9) |

(59.1) |

|

|

|

|

|

(52.0) |

|

|

|

|

|

|

|

|

|

|

160 |

|

|

|

|

|

|

|

(6.3) |

|

|

|

|

|

269 |

|

|

|

|

|

|

|

(10.6) |

|

|

|

|

|

|

|

156 |

|

|

|

|

|

|

|

(6.2) |

539 |

|

|

|

|

|

585 |

|

(21.2) |

|

E |

|

|

|

|

|

|

|

||

|

|

(23.0) |

|

|

|

|

|

|

|

D |

23 |

|

|

|

|

|

|

(0.9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25 |

|

25 |

|

E |

|

|

|

(1.0) |

|

|

|

||

|

|

|

|

(1.0) |

|

|

|

|

|

|

|

|

|

|

27 |

|

|

|

|

|

|

|

(1.0) |

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

(0.5) |

|

Illustration 3.13

* Note airflow directions

<![endif]>130BA445.10

225

(8.9)

225

(8.9)

14 |

MG20P402 - Rev. 2013-12-16 |

|

F1 |

|

|

|

IP 21/54 - NEMA 1/12 |

F3 |

|

|

IP 21/54 - NEMA 1/12 |

<![if ! IE]> <![endif]>How |

|

|

|

|

1 |

|

<![if ! IE]> <![endif]>130BB027.10 |

|

|

|

|

|

<![if ! IE]> <![endif]>Install to |

|

1400.0 |

ø29.0 |

|

225.0 |

|

|

|

|

|

||

|

(55.12) |

|

(8.85) |

|

|

|

|

|

|||

|

(1.14) |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

1 |

|

<![if ! IE]> <![endif]>130BB029.10 |

|

|

|

|

|

|

|

1997 |

|

|

225.0 |

|

|

|

|

|

|

|

|

ø29 |

|

(8.85) |

|

||

|

|

|

|

|

|

(78.6) |

|

|

|||

|

|

|

|

|

|

|

( 1.1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2281.4 |

|

|

|

|

|

|

|

|

|

|

|

(89.82) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2280 |

|

|

|

|

<![if ! IE]> <![endif]>VLT |

|

2206.4 |

|

|

|

|

(89.7) |

|

|

|

|

|

|

|

|

|

|

2205 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

| <![if ! IE]> <![endif]>.Rev - MG20P402 |

(86.87) |

|

|

|

|

(86.8) |

|

|

|

|

<![if ! IE]> <![endif]>FC Drive AQUA |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1497 |

|

|

|

|

||

|

|

|

|

|

(58.9) |

|

|

|

|

||

1499.2 |

|

|

|

|

|

|

|

|

|

||

(59.02) |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

| <![if ! IE]> <![endif]>16-12-2013 |

|

|

|

|

|

|

|

|

|

607 |

<![if ! IE]> <![endif]>Operation 202 |

|

|

|

|

|

|

|

|

|

(23.9) |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

607.0 |

|

|

|

|

|

<![if ! IE]> <![endif]>Instructions |

|

|

|

|

|

(23.9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1) Minimum clearance from ceiling

Table 3.1

<![if ! IE]><![endif]>15

<![if ! IE]><![endif]>3

<![endif]>3

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

|

<![if ! IE]> <![endif]>NEMA 1/12 |

|

|

10.130BB030 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>604 |

<![if ! IE]> <![endif]>(23.8) |

|

|

|

|

<![if ! IE]> <![endif]>- |

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

3 |

<![if ! IE]> <![endif]>IP 21/54 |

|

|

|

<![if ! IE]> <![endif]>225.0 (8.85) |

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>1 |

<![if ! IE]> <![endif]>Ø29 (1.1) |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

<![if ! IE]> <![endif]>2401 (94.5) |

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>F4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>2280 |

<![if ! IE]> <![endif]>(89.7) |

<![if ! IE]> <![endif]>2205 |

<![if ! IE]> <![endif]>(86.8) |

<![if ! IE]> <![endif]>1497 |

<![if ! IE]> <![endif]>(58.9) |

|

|

|

|

|

<![if ! IE]> <![endif]>IP 21/54 - NEMA 1/12 |

10.130BB028 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>(23.8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>606 |

|

|

|

|

<![if ! IE]> <![endif]>225.0 |

|

<![if ! IE]> <![endif]>(8.85) |

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>Ø29 |

<![if ! IE]> <![endif]>(1.1) |

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>ceiling |

|

|

|

<![if ! IE]> <![endif]>F2 |

<![if ! IE]> <![endif]>1804 |

<![if ! IE]> <![endif]>(71.0) |

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>1) Minimum clearance from |

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>(86.9) |

<![if ! IE]> <![endif]>1499 |

<![if ! IE]> <![endif]>(59.0) |

|

<![if ! IE]> <![endif]>Table 3.2 |

|

|

|

|

|

|

<![if ! IE]> <![endif]>2281 |

<![if ! IE]> <![endif]>(89.8) |

|

<![if ! IE]> <![endif]>2206 |

|

|

|

|||

|

|

16 |

|

|

|

|

|

|

|

|

|

MG20P402 - Rev. 2013-12-16 |

|

||

How to Install |

|

|

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enclosure type Size |

|

D1 |

|

D2 |

D3 |

D4 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 - 250 kW |

|

|

|

|

|

|

|

|

110-132 kW at 400 V |

160-250 kW at 400 V |

110-132 kW at 400 V |

at 400 V |

|

|

|

|

|

||||

|

|

|

(380-480 V) |

|

(380-480 V) |

(380-480 V) |

(380-480 V) |

|

|

|

|

|

|||

|

|

|

45-160 kW at 690 V |

200-400 kW at 690 V |

45-160 kW at 690 V |

200-400 kW |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||||||

|

|

|

(525-690 V) |

|

(525-690 V) |

(525-690 V) |

at 690 V |

|

|

3 |

|

3 |

|||

|

|

|

|

|

|

|

|

|

|

(525-690 V) |

|

|

|||

IP |

|

|

21 |

|

54 |

21 |

|

54 |

00 |

00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

NEMA |

|

|

Type 1 |

|

Type 12 |

Type 1 |

|

Type 12 |

Chassis |

Chassis |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shipping |

|

Height |

|

|

|

|

|

|

|

|

|

|

|

|

|

dimensions |

|

|

650 |

|

650 |

650 |

|

650 |

650 |

650 |

|

|

|

|

|

[mm] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width |

1730 |

|

1730 |

1730 |

|

1730 |

1220 |

1490 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depth |

570 |

|

570 |

570 |

|

570 |

570 |

570 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

converter |

|

Height |

1209 |

|

1209 |

1589 |

|

1589 |

104 |

1327 |

|

|

|

|

|

dimensions |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[mm] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width |

420 |

|

420 |

420 |

|

420 |

408 |

408 |

|

|

|

|

|

|

|

Depth |

380 |

|

380 |

380 |

|

380 |

375 |

375 |

|

|

|

|

|

|

|

Max |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

weight |

104 |

|

104 |

151 |

|

151 |

91 |

138 |

|

|

|

|

|

|

|

[kg] |

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 3.3 |

Mechanical dimensions, Enclosure type D |

|

|

|

|

|

|

|

|

|

|

||||

MG20P402 - Rev. 2013-12-16 |

17 |

|

|

|

|

How to Install |

|

VLT AQUA Drive FC 202 Operation Instructions |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enclosure Type Size |

E1 |

E2 |

|

F1 |

F2 |

|

F3 |

F4 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

315-450 kW at |

315-450 kW at |

|

500-710 kW at |

800-1000 kW at |

|

500-710 kW at |

800-1000 kW at |

|

|

|

|

|

|

|

400 V |

400 V |

|

400 V |

400 V |

|

400 V |

400 V |

|

|

|

|

|

|

|

(380-480 V) |

(380-480 V) |

|

(380-480 V) |

(380-480 V) |

|

(380-480 V) |

(380-480 V) |

|

|

|

|

|

|

|

450-630 kW at |

450-630 kW at |

|

710-900 kW at |

1000-1200 kW at |

|

710-900 kW at |

1000-1400 kW at |

|

|

|

|

|

|

|

|

|

||||||

3 |

|

3 |

|

|

|

|

690 V |

690 V |

|

690 V |

690 V |

|

690 V |

690 V |

|

|

|

|

|

(525-690 V) |

(525-690 V) |

|

(525-690 V) |

(525-690 V) |

|

(525-690 V) |

(525-690 V) |

||

|

|

|

|

IP |

|

|

21, 54 |

00 |

|

21, 54 |

21, 54 |

|

21, 54 |

21, 54 |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

NEMA |

|

|

Type 1/ Type 12 |

Chassis |

|

Type 1/Type 12 |

Type 1/Type 12 |

|

Type 1/Type 12 |

Type 1/Type 12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shipping |

|

Height |

|

|

|

|

|

|

|

|

|

|

|

|

dimensions |

|

|

840 |

831 |

|

2324 |

2324 |

|

2324 |

2324 |

|

|

|

|

[mm] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width |

2197 |

1705 |

|

1569 |

1962 |

|

2159 |

2559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depth |

736 |

736 |

|

1130 |

1130 |

|

1130 |

1130 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

converter |

|

Height |

2000 |

1547 |

|

2204 |

2204 |

|

2204 |

2204 |

|

|

|

|

dimensions |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[mm] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Width |

600 |

585 |

|

1400 |

1800 |

|

2000 |

2400 |

|

|

|

|

|

|

Depth |

494 |

498 |

|

606 |

606 |

|

606 |

606 |

|

|

|

|

|

|

Max |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

weight |

313 |

277 |

|

1004 |

1246 |

|

1299 |

1541 |

|

|

|

|

|

|

[kg] |

|

|

|

|

|

|

|

|

|

|

|

|

Table 3.4 |

Mechanical dimensions, Enclosure Types E and F |

|

|

|

|

|

||||

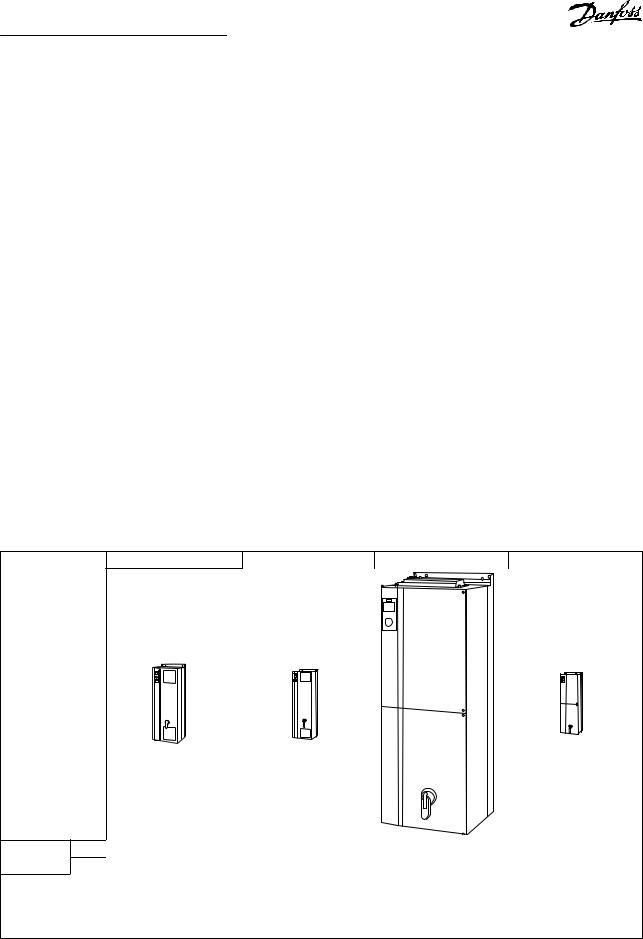

3.2.6 Rated Power

Enclosure type |

D1 |

D2 |

D3 |

D4 |

||

|

|

|

|

|

<![if ! IE]> <![endif]>130BA819.10 |

|

|

|

<![if ! IE]> <![endif]>130BA816.10 |

<![if ! IE]> <![endif]>130BA817.10 |

|

<![if ! IE]> <![endif]>130BA820.10 |

|

Enclosure |

IP |

21/54 |

21/54 |

00 |

00 |

|

protection |

NEMA |

Type 1/Type 12 |

Type 1/Type 12 |

Chassis |

Chassis |

|

Normal overload |

110 - 132 kW at 400 V |

150 - 250 kW at 400 V |

110 - 132 kW at 400 V |

150 - 250 kW at 400 V |

||

(380 - 480 V) |

(380 - 480 V) |

(380 - 480 V) |

(380 - 480 V) |

|||

rated power - 110% |

||||||

45 - 160 kW at 690 V |

200 - 400 kW at 690 V |

45 - 160 kW at 690 V |

200 - 400 kW at 690 V |

|||

overload torque |

||||||

(525-690 V) |

(525-690 V) |

(525-690 V) |

(525-690 V) |

|||

|

|

|||||

Table 3.5

18 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

Enclosure type |

E1 |

E2 |

|

F1/F3 |

|

F2/F4 |

|

|

|

|

<![if ! IE]> <![endif]>130BA818.10 |

<![if ! IE]> <![endif]>130BA821.10 |

F3 F1 |

<![if ! IE]> <![endif]>130BA959.10 |

F4 F2 |

<![if ! IE]> <![endif]>130BB092.11 |

|

|

|

|

|

|||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

3 |

3 |

Enclosure |

IP |

21/54 |

00 |

|

21/54 |

|

21/54 |

|

protection |

NEMA |

Type 1/Type 12 |

Chassis |

Type 1/Type 12 |

Type 1/Type 12 |

|

||

Normal overload |

315 - 450 kW at 400 V |

315 - 450 kW at 400 V |

500 - 710 kW at 400 V |

800 - 1000 kW at 400 V |

rated power - |

(380 - 480 V) |

(380 - 480 V) |

(380 - 480 V) |

(380 - 480 V) |

110% overload |

450 - 630 kW at 690 V |

450 - 630 kW at 690 V |

710 - 900 kW at 690 V |

1000 - 1400 kW at 690 V |

torque |

(525-690 V) |

(525-690 V) |

(525-690 V) |

(525-690 V) |

Table 3.6

NOTICE

The F enclosures are available in 4 different sizes, F1, F2, F3 and F4 The F1 and F2 consist of an inverter cabinet on the right and rectifier cabinet on the left. The F3 and F4 have an additional options cabinet left of the rectifier cabinet. The F3 is an F1 with an additional options cabinet. The F4 is an F2 with an additional options cabinet.

MG20P402 - Rev. 2013-12-16 |

19 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

3.3 Mechanical Installation

Preparation of the mechanical installation of the frequency converter must be done carefully to ensure a proper result and to avoid additional work during installation. Start taking a close look at the mechanical drawings at the end

3 3 of this instruction to become familiar with the space demands.

3.3.1 Tools Needed

To perform the mechanical installation the following tools are needed:

•Drill with 10 or 12 mm drill

•Tape measure

•Wrench with relevant metric sockets (7-17mm)

•Extensions to wrench

•Sheet metal punch for conduits or cable glands in IP21/Nema 1 and IP54 units

•Lifting bar to lift the unit (rod or tube max. Ø 5 mm (1 inch), able to lift minimum 400 kg (880 lbs).

•Crane or other lifting aid to place the frequency converter in position

•A Torx T50 tool is needed to install the E1 in IP21 and IP54 enclosure types.

<![endif]>176FA235.11

399 |

(15.7) |

526 |

(20.7) |

<105,0° |

Illustration 3.14 Space in Front of IP21/IP54 Rated Enclosure Types D1 and D2

<![if ! IE]><![endif]>176FA276.12

579

(22.8)

748

(29.5) ≤105,0°

Illustration 3.15 Space in Front of IP21/IP54 Rated Enclosure Type E1

3.3.2 General Considerations

Wire access

Ensure that proper cable access is present including necessary bending allowance. As the IP00 enclosure is open to the bottom cables must be fixed to the back panel of the enclosure where the frequency converter is mounted, i.e. by using cable clamps.

CAUTION

CAUTION

All cable lugs/shoes must mount within the width of the terminal bus bar.

Space

Ensure proper space above and below the frequency converter to allow airflow and cable access. In addition space in front of the unit must be considered to enable opening of the door of the panel.

578 |

776 |

<![if ! IE]> <![endif]>130BB003.13 |

(22.8) |

(30.6) |

|

Illustration 3.16 Space in Front of IP21/IP54 Rated Enclosure Type F1

2X578 |

776 |

<![if ! IE]> <![endif]>130BB004.13 |

[22.8] |

|

|

|

[30.6] |

|

Illustration 3.17 Space in Front of IP21/IP54 Rated Enclosure Type F3

624 |

579 |

<![if ! IE]> <![endif]>130BB005.13 |

578 |

|

|

[22.8] |

[22.8] |

|

[24.6] |

|

|

Illustration 3.18 Space in Front of IP21/IP54 Rated Enclosure Type F2

20 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

2x579

(22.8)

624 (24.6)

624 (24.6)

578 (22.8)

578 (22.8)

<![endif]>130BB006.10

Illustration 3.19 Space in Front of IP21/IP54 Rated Enclosure |

|

|

|

3 |

|

3 |

|

Type F4 |

|

||

|

|

|

|

|

|

|

|

3.3.3 Terminal Locations - Enclosure Type D

Consider the following terminal positions when designing for cables access.

|

R/12 91 |

|

S/L2 92 |

T/L3 93 |

|

|

||

A |

|

|

|

|

|

|

|

|

|

-DC 88 |

+DC 89 |

|

|

|

|

||

B |

|

|

|

|

|

|

|

|

-R |

81 |

+R |

|

82 |

U/T1 96 |

V/T2 97 |

W/T3 98 |

D |

|

|

|

|

|

||||

C |

|

|

|

|

|

|

|

0, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(0,) |

E |

J |

L |

|

F K M G |

N H |

I |

0, |

|

|

|

|

|

|

|

|

|

(0,) |

Illustration 3.20 Position of Power Connections, Enclosure Types D3 and D4

|

|

|

<![if ! IE]> <![endif]>176FA238.10 |

O |

P |

Q |

0, |

|

|

|

(0,) |

MG20P402 - Rev. 2013-12-16 |

21 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

|

|

R/L1 |

91 |

S/L2 |

92 T/L3 |

93 |

|

|

<![if ! IE]> <![endif]>176FA239.10 |

|

|

|

|

|

|

|||||

|

|

R |

-DC |

+DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

3 |

3 |

-R |

81 |

+R |

82 |

U/T1 96 |

V/T2 97 |

W/T398 |

|

|

|

|

|

|

|

||||||

|

|

0, |

|

|

|

|

|

|

|

|

|

|

(0,) |

|

|

|

|

|

|

|

|

|

|

|

S |

|

T |

|

U |

0, |

V |

0, |

|

|

|

|

|

|

|

|

(0,) |

|

(0,) |

Illustration 3.21 Position of Power Connections with Disconnect Switch, Enclosure Types D1 and D2

Be aware that the power cables are heavy and hard to bend. Consider the optimum position of the frequency converter for ensuring easy installation of the cables.

22 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

NOTICE

All D enclosures are available with standard input terminals or disconnect switch. All terminal dimensions can be found in Table 3.7.

|

IP21 (NEMA 1)/IP54 (NEMA 12) |

|

IP00/Chassis |

|

3 |

|

3 |

|||||

|

D1 |

|

D2 |

|

D3 |

|

D4 |

|

|

|

||

|

|

|

|

|

|

|

|

|

||||

A |

277 |

(10.9) |

379 |

(14.9) |

119 |

(4.7) |

122 |

(4.8) |

|

|

|

|

B |

227 |

(8.9) |

326 |

(12.8) |

68 (2.7) |

68 (2.7) |

|

|

|

|

||

C |

173 |

(6.8) |

273 |

(10.8) |

15 (0.6) |

16 (0.6) |

|

|

|

|

||

D |

179 |

(7.0) |

279 |

(11.0) |

20.7 (0.8) |

22 (0.8) |

|

|

|

|

||

E |

370 |

(14.6) |

370 |

(14.6) |

363 |

(14.3) |

363 |

(14.3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

300 |

(11.8) |

300 |

(11.8) |

293 |

(11.5) |

293 |

(11.5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

222 |

(8.7) |

226 |

(8.9) |

215 |

(8.4) |

218 |

(8.6) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

139 |

(5.4) |

142 |

(5.6) |

131 |

(5.2) |

135 |

(5.3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

I |

55 (2.2) |

59 (2.3) |

48 (1.9) |

51 (2.0) |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

J |

354 |

(13.9) |

361 |

(14.2) |

347 |

(13.6) |

354 |

(13.9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

284 |

(11.2) |

277 |

(10.9) |

277 |

(10.9) |

270 |

(10.6) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

334 |

(13.1) |

334 |

(13.1) |

326 |

(12.8) |

326 |

(12.8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M |

250 |

(9.8) |

250 |

(9.8) |

243 |

(9.6) |

243 |

(9.6) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

167 |

(6.6) |

167 |

(6.6) |

159 |

(6.3) |

159 |

(6.3) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

261 |

(10.3) |

260 |

(10.3) |

261 |

(10.3) |

261 |

(10.3) |

|

|

|

|

P |

170 |

(6.7) |

169 |

(6.7) |

170 |

(6.7) |

170 |

(6.7) |

|

|

|

|

Q |

120 |

(4.7) |

120 |

(4.7) |

120 |

(4.7) |

120 |

(4.7) |

|

|

|

|

R |

256 |

(10.1) |

350 |

(13.8) |

98 (3.8) |

93 (3.7) |

|

|

|

|

||

S |

308 |

(12.1) |

332 |

(13.0) |

301 |

(11.8) |

324 |

(12.8) |

|

|

|

|

T |

252 |

(9.9) |

262 |

(10.3) |

245 |

(9.6) |

255 |

(10.0) |

|

|

|

|

U |

196 |

(7.7) |

192 |

(7.6) |

189 |

(7.4) |

185 |

(7.3) |

|

|

|

|

V |

260 |

(10.2) |

273 |

(10.7) |

260 |

(10.2) |

273 |

(10.7) |

|

|

|

|

Table 3.7 Cable Positions Dimensions in mm (inch)

MG20P402 - Rev. 2013-12-16 |

23 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

3.3.4 Terminal Locations - E Enclosures

Terminal Locations - E1

Take the following position of the terminals into consideration when designing the cable access.

3 |

3 |

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>176FA278.10 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

492[19.4] |

|

|

|

|

|

|

|

|

|

|

|

|

|

323[12.7] |

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0[0.0] |

|

|

|

|

|

|

195[7.7] |

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>600[23.6] |

<![if ! IE]> <![endif]>525[20.7] |

<![if ! IE]> <![endif]>412[16.2] |

<![if ! IE]> <![endif]>300[11.8] |

<![if ! IE]> <![endif]>188[7.4] |

<![if ! IE]> <![endif]>75[3.0] |

<![if ! IE]> <![endif]>0[0.0] |

<![if ! IE]> <![endif]>409[16.1] |

<![if ! IE]> <![endif]>371[14.6] |

<![if ! IE]> <![endif]>280[11.0] |

<![if ! IE]> <![endif]>193[7.6] |

<![if ! IE]> <![endif]>155[6.1] |

<![if ! IE]> <![endif]>0[0.0] |

|

Illustration 3.22 IP21 (NEMA Type 1) and IP54 (NEMA Type 12) Enclosure Power Connection Positions |

|

|

|

|

||||||||

24 |

MG20P402 - Rev. 2013-12-16 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

B |

|

|

|

|

<![if ! IE]> <![endif]>176FA272.10 |

|

|

|

|

|

|

|

|

||

-R |

81 |

|

|

9 |

3 |

3 |

|

A |

A |

A |

A |

||||

19 Nm [14 FTa |

|

|

|||||

|

|

|

|

|

|

||

453[17.8] |

|

|

|

|

|

|

0[0.0]

| <![if ! IE]> <![endif]>0[0.0] |

<![if ! IE]> <![endif]>55[2.2] |

<![if ! IE]> <![endif]>91[3.6] |

<![if ! IE]> <![endif]>139[5.5] |

<![if ! IE]> <![endif]>175[6.9] |

Illustration 3.23 IP21 (NEMA type 1) and IP54 (NEMA type 12)

Enclosure Power Connection Positions (Detail B)

MG20P402 - Rev. 2013-12-16 |

25 |

How to Install |

VLT AQUA Drive FC 202 Operation Instructions |

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>176FA279.11 |

3 |

3 |

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

[ 0.0 |

] |

|

|

|

|

|

|

|

|

|

|

28 |

[ 1.1 |

] |

|

|

|

|

|

|

|

|

|

167 |

[ 6.6 |

] |

|

|

|

|

|

|

|

|

|

195 |

[ 7.7 |

] |

|

|

|

|

|

<![if ! IE]> <![endif]>D |

<![if ! IE]> <![endif]>C |

<![if ! IE]> <![endif]>B |

<![if ! IE]> <![endif]>[ 0.0 ] |

|

|

<![if ! IE]> <![endif]>17.4 ] A |

<![if ! IE]> <![endif]>10.5 ] |

<![if ! IE]> <![endif]>[ 8.9 ] |

<![if ! IE]> <![endif]>[ 2.0 ] |

<![if ! IE]> <![endif]>[ 0.0 ] |

|

|

|

|

<![if ! IE]> <![endif]>0 |

|

|

<![if ! IE]> <![endif]>[ |

<![if ! IE]> <![endif]>[ |

<![if ! IE]> <![endif]>226 |

<![if ! IE]> <![endif]>51 |

<![if ! IE]> <![endif]>0 |

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>441 |

<![if ! IE]> <![endif]>266 |

Illustration 3.24 IP21 (NEMA type 1) and IP54 (NEMA type 12) Enclosure Power Connection Position of Disconnect Switch

Enclosure |

|

Unit type |

|

|

|

Dimensions [mm]/(inch) |

|

|

|

|||

types |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IP54/IP21 UL AND NEMA1/NEMA12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E1 |

|

250/315 kW (400 V) AND 355/450-500/630 |

396 |

(15.6) |

267 (10.5) |

332 |

(13.1) |

397 |

(15.6) |

528 |

(20.8) |

N/A |

|

KW (690 V) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

315/355-400/450 kW (400 V) |

408 |

(16.1) |

246 (9.7) |

326 |

(12.8) |

406 |

(16.0) |

419 |

(16.5) |

459 (18.1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 3.8 |

Dimensions for Disconnect Terminal |

|

|

|

|

|

|

|

|

|

|

|

26 |

MG20P402 - Rev. 2013-12-16 |

Loading...

Loading...