Page 1

Operating Guide

VLT® HVAC Drive FC 131

vlt-drives.danfoss.com

Page 2

Page 3

VLT® HVAC Drive FC 131

Operating Guide

Contents

1

Introduction 6

1.1

Purpose of this Operating Guide 6

Additional Resources 6

1.2

Other Resources 6

1.2.1

1.2.2

MCT 10 Setup Software Support 6

1.3

Document and Software Version 6

1.4

Certificates and Approvals 7

1.5

Disposal 7

Safety 8

2

Safety Symbols 8

2.1

Qualified Personnel 8

2.2

Safety Precautions 8

2.3

Contents

Motor Thermal Protection 9

2.4

Installation 10

3

3.1

Mechanical Installation 10

3.1.1

Side-by-side Installation 10

3.1.2

Drive Dimensions 10

3.2

Electrical Installation 11

3.2.1

Electrical Installation in General 11

3.2.2

IT Mains 11

3.2.3

Mains and Motor Connection 12

3.2.3.1

3.2.3.2

3.2.3.3

3.2.3.4

3.2.3.5

3.2.3.6

3.2.3.7

Introduction 12

Connecting to Mains and Motor 13

Enclosure Size I2 13

Enclosure Size I3 14

Enclosure Size I4 15

IP54 Enclosure Sizes I2, I3, I4 16

Enclosure size I6 16

3.2.3.8

3.2.4

Fuses and Circuit Breakers 18

3.2.4.1

3.2.4.2

3.2.4.3

3.2.4.4

3.2.4.5

Enclosure size I7, I8 18

Branch Circuit Protection 18

Short-circuit Protection 18

Overcurrent Protection 18

UL/Non-UL Compliance 18

Recommendation of Fuses and Circuit Breakers 18

AQ367426199594en-000101/130R0988 | 3Danfoss A/S © 2021.06

Page 4

VLT® HVAC Drive FC 131

Operating Guide

3.2.5

EMC-compliant Electrical Installation 19

3.2.6

Control Terminals 20

3.2.7

Electrical Wiring 22

3.2.8

Acoustic Noise or Vibration 22

4

Programming 23

4.1

Local Control Panel (LCP) 23

4.2

Set-up Wizard 24

4.2.1

Setup Wizard Introduction 24

4.2.2

Setup Wizard for Open-loop Applications 25

4.2.3

Setup Wizard for Closed-loop Applications 31

4.2.4

Motor Setup 36

4.2.5

Changes Made Function 40

4.2.6

Changing Parameter Settings 40

4.2.7

Accessing All Parameters via the Main Menu 40

Contents

5

Warnings and Alarms 41

5.1

List of Warnings and Alarms 41

5.2

LCP Errors Messages 43

6

Specifications 45

6.1

Mains Supply 45

6.1.1

3x380–480 V AC 45

6.2

EMC Emission Test Results 47

6.3

Special Conditions 48

6.3.1

Derating for Ambient Temperature and Switching Frequency 48

6.3.2

Derating for Low Air Pressure and High Altitudes 48

6.4

General Technical Data 48

6.4.1

Protection and Features 48

6.4.2

Mains Supply (L1, L2, L3) 48

6.4.3

Motor Output (U, V, W) 48

6.4.4

Cable Length and Cross-section 48

6.4.5

Digital Inputs 49

6.4.6

Analog Inputs 49

6.4.7

Analog Outputs 49

6.4.8

Digital Output 49

6.4.9

Control Card, RS485 Serial Communication 50

6.4.10

Control Card, 24 V DC Output 50

6.4.11

Relay Output 50

AQ367426199594en-000101/130R09884 | Danfoss A/S © 2021.06

Page 5

VLT® HVAC Drive FC 131

Operating Guide

6.4.12

6.4.13

Contents

Control Card, 10 V DC Output 51

Ambient Conditions 51

AQ367426199594en-000101/130R0988 | 5Danfoss A/S © 2021.06

Page 6

Edition

Remarks

Software version

AQ367426199594, version 0101

First edition.

4.6x

VLT® HVAC Drive FC 131

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Other Resources

Other resources are available to understand advanced drive functions and programming.

•

The VLT® HVAC Drive FC 131 Programming Guide provides information on how to program and includes complete parameter

descriptions.

•

The VLT® HVAC Drive FC 131 Design Guide provides all technical information about the drive. It also lists options and accessories.

The technical documentation is available in electronic form online at

www.danfoss.com.

1.2.2 MCT 10 Setup Software Support

Download the software from the service and support section on www.danfoss.com.

During the installation process of the software, enter access code 81463800 to activate the VLT® HVAC Drive FC 131 functionality. A

license key is not required for using the VLT® HVAC Drive FC 131 functionality.

The latest software does not always contain the latest updates for drives. Contact the local sales office for the latest drive updates (in

the form of *.upd files), or download the drive updates from the service and support section on www.danfoss.com.

1.3 Document and Software Version

The Operating Guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Document and Software Version

AQ367426199594en-000101 / 130R09886 | Danfoss A/S © 2021.06

Page 7

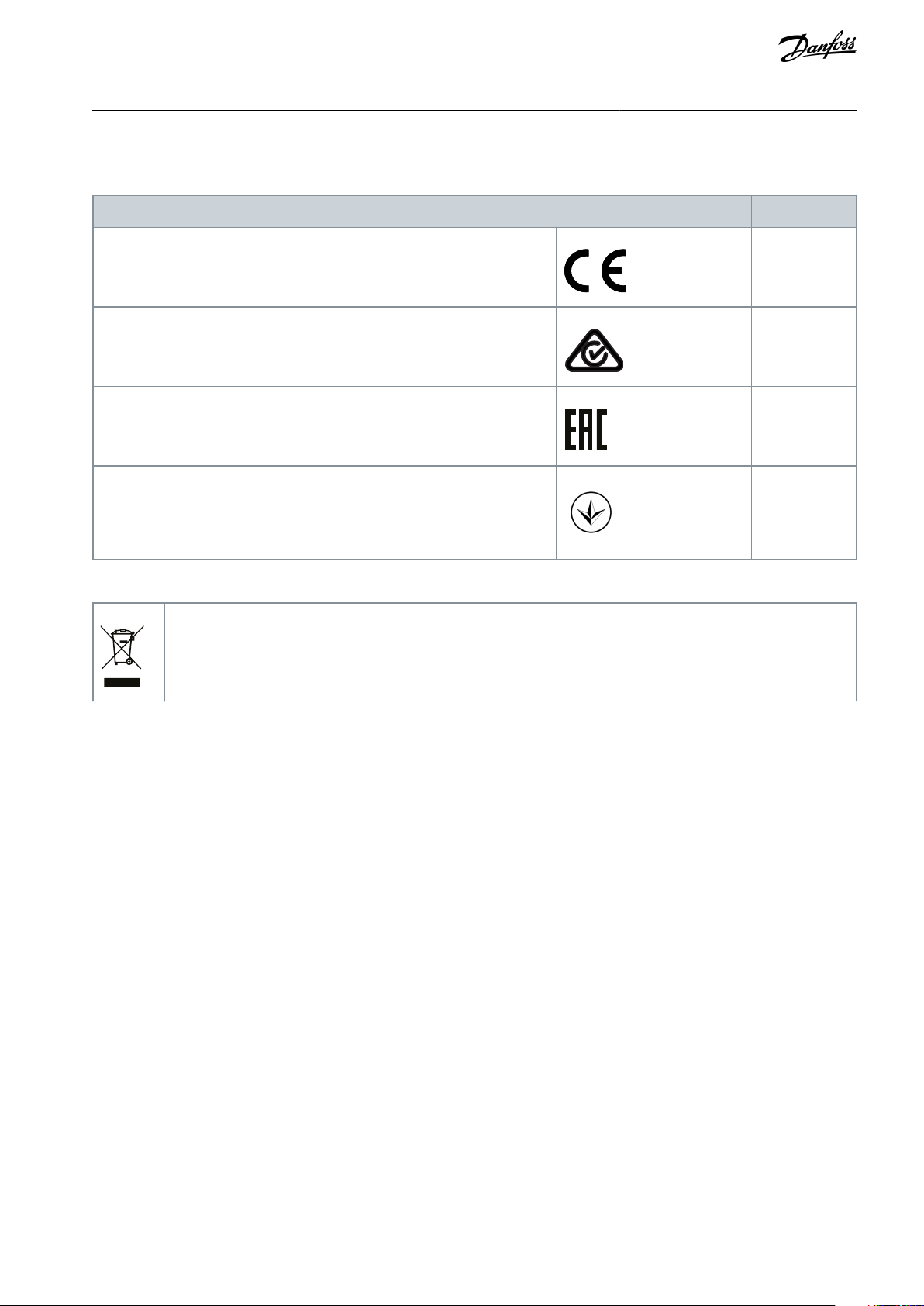

Certification

IP54

EC Declaration of Conformity

✓

RCM✓EAC

✓

UkrSEPRO

089

✓

Do not dispose of equipment containing electrical components together with domestic waste.

Collect it separately in accordance with local and currently valid legislation.

VLT® HVAC Drive FC 131

Operating Guide

1.4 Certificates and Approvals

Table 2: Certificates and Approvals

Introduction

1.5 Disposal

AQ367426199594en-000101 / 130R0988 | 7Danfoss A/S © 2021.06

Page 8

VLT® HVAC Drive FC 131

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HIGH VOLTAGE

AC drives contain high voltage when connected to AC mains input, DC supply, or load sharing. Failure to perform installation,

start-up, and maintenance by qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AQ367426199594en-000101 / 130R09888 | Danfoss A/S © 2021.06

Page 9

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x400

0.75–7.5 (1.0–10)

4

3x400

11–90 (15–125)

15

VLT® HVAC Drive FC 131

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 3: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

2.4 Motor Thermal Protection

Procedure

1.

Set parameter 1-90 Motor Thermal Protection to [4] ETR trip 1 to enable the motor thermal protection function.

AQ367426199594en-000101 / 130R0988 | 9Danfoss A/S © 2021.06

Page 10

Size

IP class

Power [kW (hp)]

Clearance above/below [mm (in)]

I2

IP54

0.75–4.0 (1.0–5.0)

100 (4.0)

I3

IP54

5.5–7.5 (7.5–10)

100 (4.0)

I4

IP54

11–18.5 (15–25)

100 (4.0)

I6

IP54

22–37 (30–50)

200 (7.9)

I7

IP54

45–55 (60–70)

200 (7.9)

I8

IP54

75–90 (100–125)

225 (8.9)

e

f

a

e

e

f

a

d

e

A

a

b

B

C

D

e30bf984.10

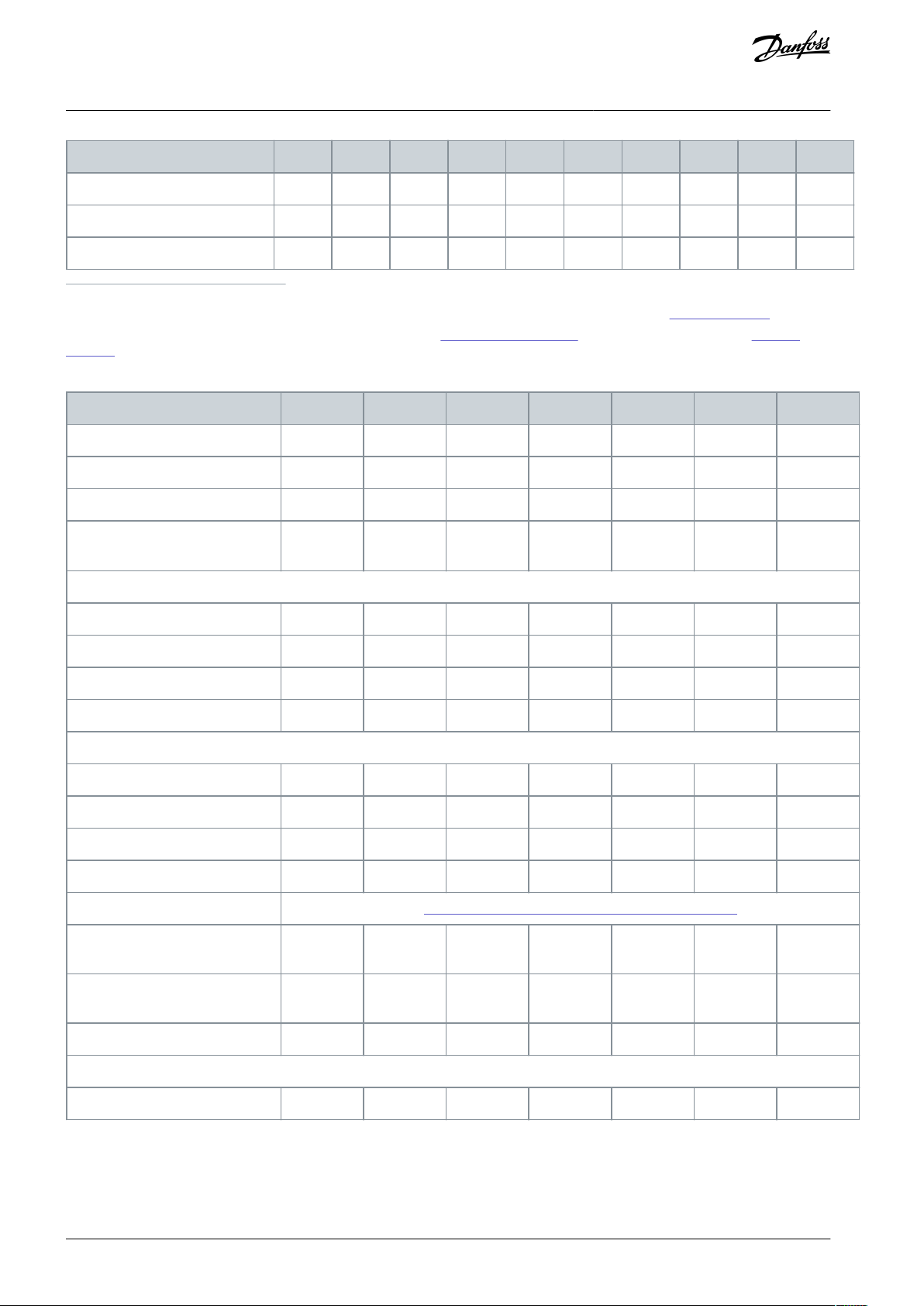

Enclosure Size

I2I3I4I6I7

I8

IP class

IP54

IP54

IP54

IP54

IP54

IP54

Power [kW (hp)]

3x380–480 V

0.75–4.0

(1.0–5.0)

5.5–7.5

(7.5–10)

11–18.5

(15–25)

22–37

(30–50)

45–55

(60–70)

75–90

(100–125)

Height [mm (in)]

A

332 (13.1)

368 (14.5)

476 (18.7)

650 (25.6)

680 (26.8)

770 (30)

a

318.5 (12.53)

354 (13.9)

460 (18.1)

624 (24.6)

648 (25.5)

739 (29.1)

Width [mm (in)]

B

115 (4.5)

135 (5.3)

180 (7.0)

242 (9.5)

308 (12.1)

370 (14.6)

b

74 (2.9)

89 (3.5)

133 (5.2)

210 (8.3)

272 (10.7)

334 (13.2)

VLT® HVAC Drive FC 131

Operating Guide

3 Installation

3.1 Mechanical Installation

3.1.1 Side-by-side Installation

The drive can be mounted side by side but requires the clearance above and below for cooling.

Table 4: Clearance Required for Cooling

Installation

The drives are not suitable for outdoor mounting.

3.1.2 Drive Dimensions

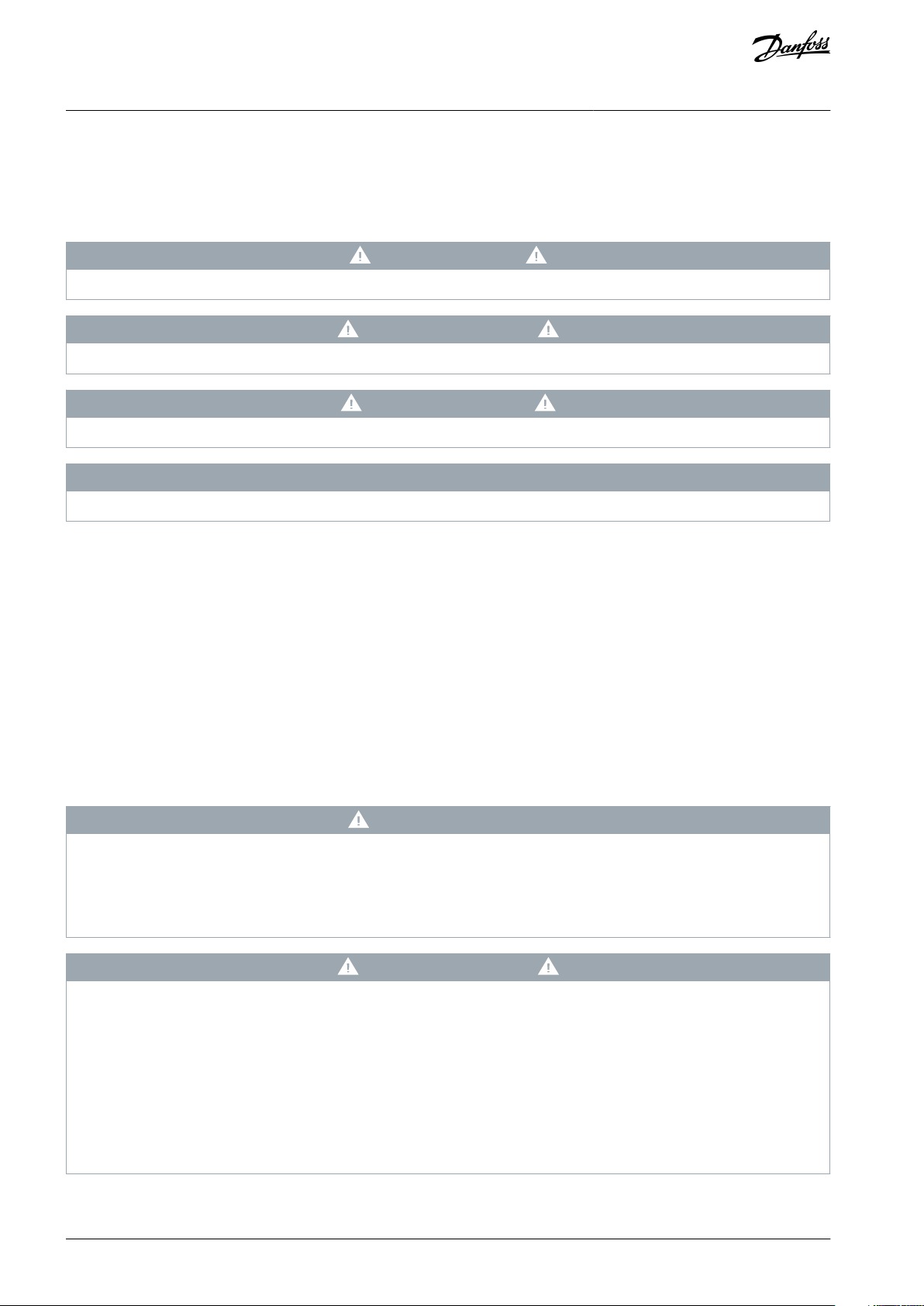

Illustration 1: Dimensions

Table 5: Dimensions, Enclosure Sizes I2–I8

N O T I C E

AQ367426199594en-000101 / 130R098810 | Danfoss A/S © 2021.06

Page 11

Enclosure Size

I2I3I4I6I7

I8

Depth [mm (in)]

C

225 (8.9)

237 (9.3)

290 (11.4)

260 (10.2)

310 (12.2)

335 (13.2)

Mounting hole [mm (in)]

d

11 (0.43)

12 (0.47)

12 (0.47)

19 (0.75)

19 (0.75)

19 (0.75)

e

5.5 (0.22)

6.5 (0.26)

6.5 (0.26)

9 (0.35)

9 (0.35)

9 (0.35)

f

9 (0.35)

9.5 (0.37)

9.5 (0.37)

9 (0.35)

9.8 (0.39)

9.8 (0.39)

Maximum weight kg (lb)

5.3 (11.7)

7.2 (15.9)

13.8 (30.42)

27 (59.5)

45 (99.2)

65 (143.3)

Power [kW (hp)]

Torque [Nm (in-lb)]

Enclosure

size

IP class

3x380–480 V

Mains

Motor

DC connection

Control terminals

Ground

Relay

I2

IP54

0.75–4.0 (1.0–5.0)

0.8 (7.0)

0.8 (7.0)

0.8 (7.0)

0.5 (4.0)

0.8 (7.0)

0.5 (4.0)

I3

IP54

5.5–7.5 (7.5–10)

0.8 (7.0)

0.8 (7.0)

0.8 (7.0)

0.5 (4.0)

0.8 (7.0)

0.5 (4.0)

I4

IP54

11–18.5 (15–25)

1.2 (11)

1.2 (11)

0.8 (7.0)

0.5 (4.0)

0.8 (7.0)

0.5 (4.0)

I6

IP54

22–37 (30–50)

4.5 (40)

4.5 (40)

–

0.5 (4.0)

3 (27)

0.6 (5.0)

I7

IP54

45–55 (60–70)

10 (89)

10 (89)

–

0.5 (4.0)

3 (27)

0.6 (5.0)

I8

IP54

75–90 (100–125)

14 (124)/24

(212)

(1)

14 (124)/24

(212)

(1)

–

0.5 (4.0)

3 (27)

0.6 (5.0)

VLT® HVAC Drive FC 131

Operating Guide

The dimensions are only for the physical units. When installing in an application, allow space above and below the units for cooling.

The amount of space for free air passage is listed in 3.1.1 Side-by-side Installation.

Installation

3.2 Electrical Installation

3.2.1 Electrical Installation in General

All cabling must comply with national and local regulations on cable cross-sections and ambient temperature. Copper conductors

are required. 75 °C (167 °F) is recommended.

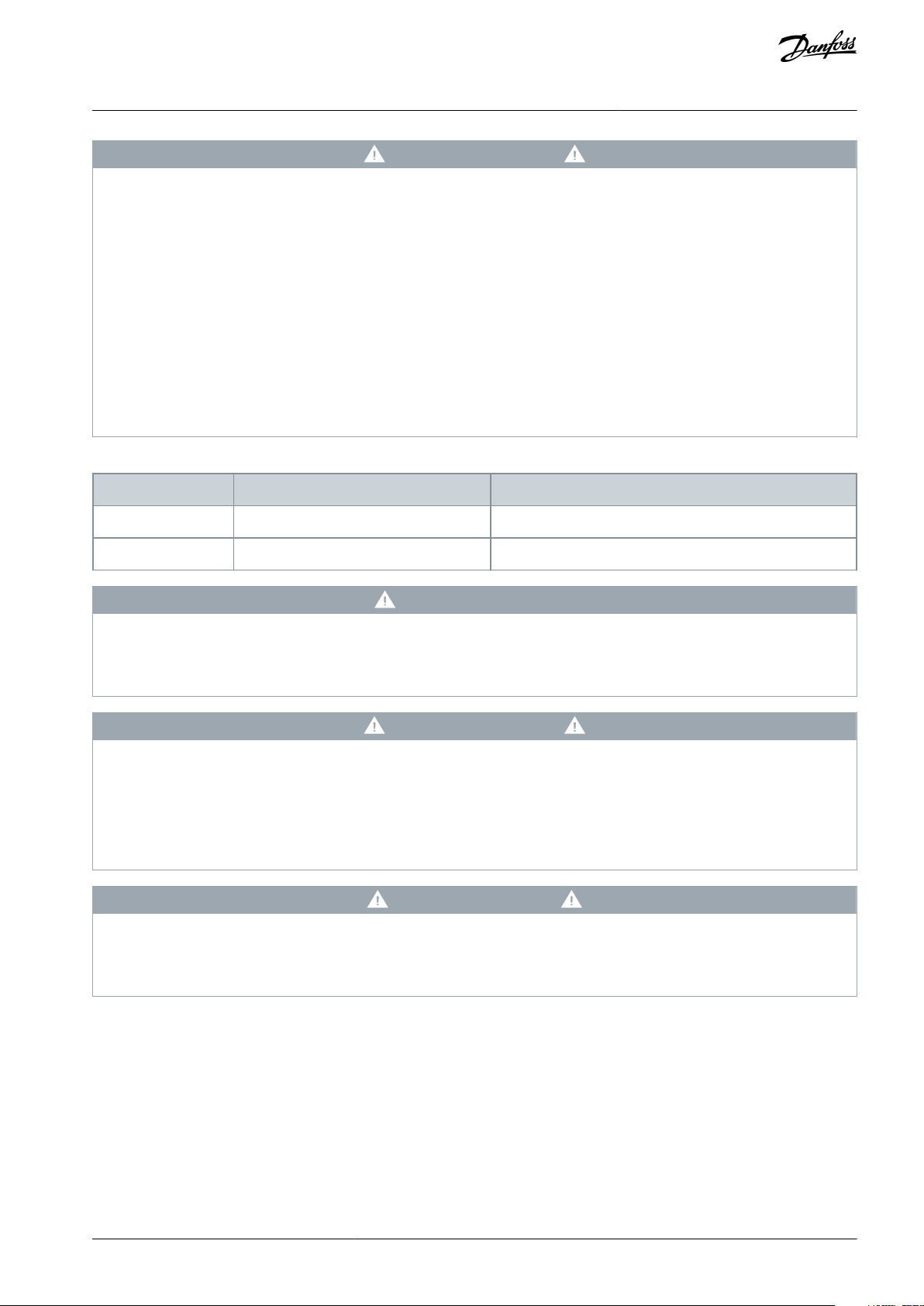

Table 6: Tightening Torques for Enclosure Sizes I2–I8

1

Cable dimensions ≤95 mm2.

3.2.2 IT Mains

IT MAINS

Installation on isolated mains source, that is, IT mains.

Ensure that the supply voltage does not exceed 440 V (3x380–480 V units) when connected to mains.

-

For IP54, 400 V, 0.75–18.5 kW (1.0–25 hp) units, open the RFI switch by removing the EMC screw inside the drive when at IT grid. The

EMC screw is shown in the the following illustration.

C A U T I O N

AQ367426199594en-000101 / 130R0988 | 11Danfoss A/S © 2021.06

Page 12

e30bc251.10

1

EMC screw

VLT® HVAC Drive FC 131

Operating Guide

Installation

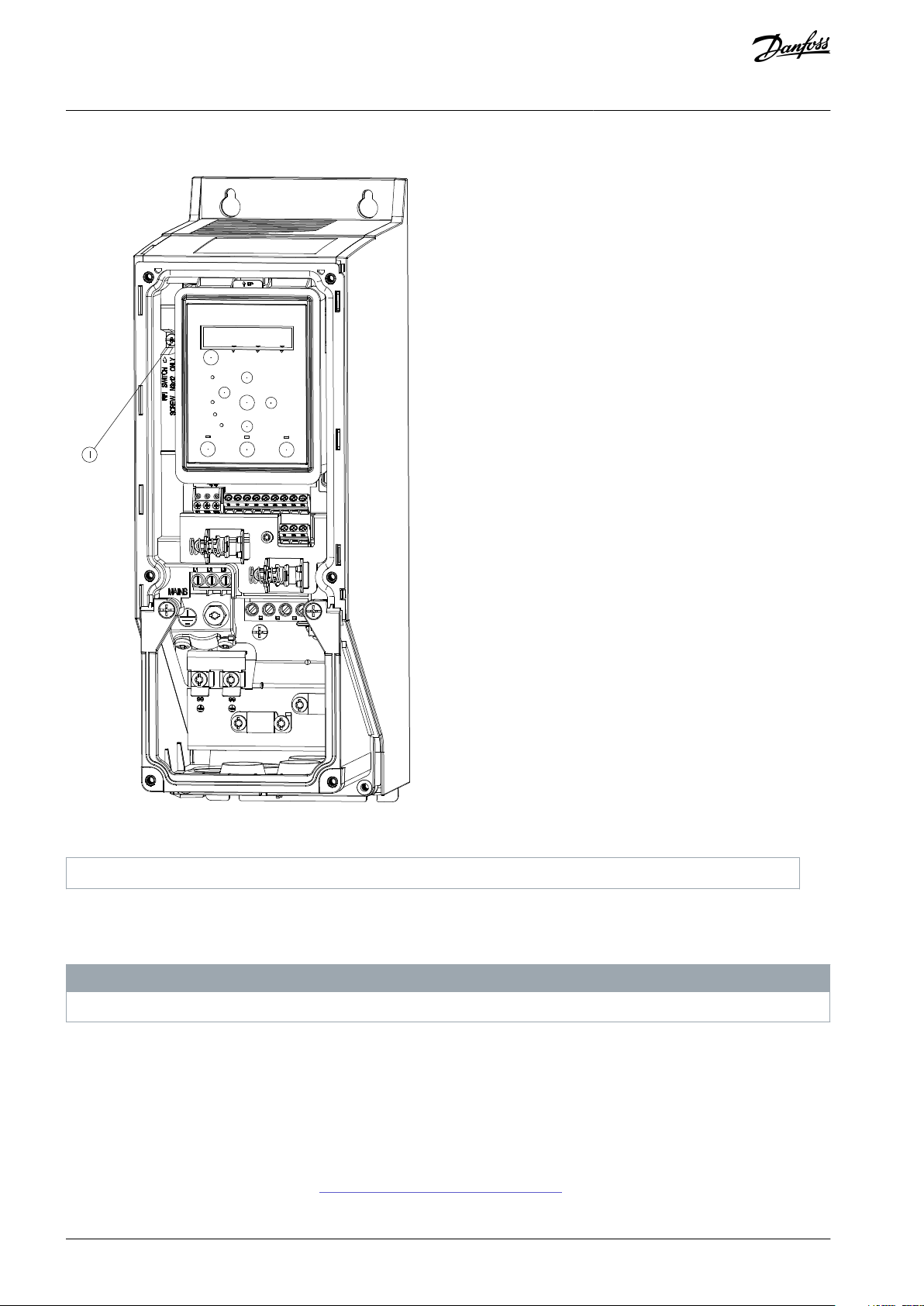

Illustration 2: IP54, 400 V, 0.75–18.5 kW (1–25 hp)

For IP54, 400 V, 22-90 kW (30–125 hp) units, the RFI switch can be opened in parameter 14-50 RFI Filter. Select [1] On to turn the RFI

filter on. The RFI filter ensures that the drive complies with EMC standards. Select [0] Off only when the drive is connected to IT

mains.

N O T I C E

If reinserted, use only M3x12 screw.

3.2.3 Mains and Motor Connection

3.2.3.1 Introduction

The drive is designed to operate all standard 3-phase induction motors.

•

Use a shielded/armored motor cable to comply with EMC emission specifications and connect this cable to the motor.

•

Keep the motor cable as short as possible to reduce the noise level and leakage currents.

•

Also see EMC-Correct Installation in the 3.2.5 EMC-compliant Electrical Installation.

AQ367426199594en-000101 / 130R098812 | Danfoss A/S © 2021.06

Page 13

e30bc299.10

7

3

2

5

1

8

4

6

1

RS485

2

Mains

3

Ground

4

Cable clamps

5

Motor

6

UDC7Relays

8

I/O

VLT® HVAC Drive FC 131

Operating Guide

3.2.3.2 Connecting to Mains and Motor

1.

Mount the ground cables to the ground terminal.

2.

Connect the motor to terminals U, V, and W, and then tighten the screws according to the torques.

3.

Connect the mains supply to terminals L1, L2, and L3, and then tighten the screws according to the torques described in

3.2.1 Electrical Installation in General.

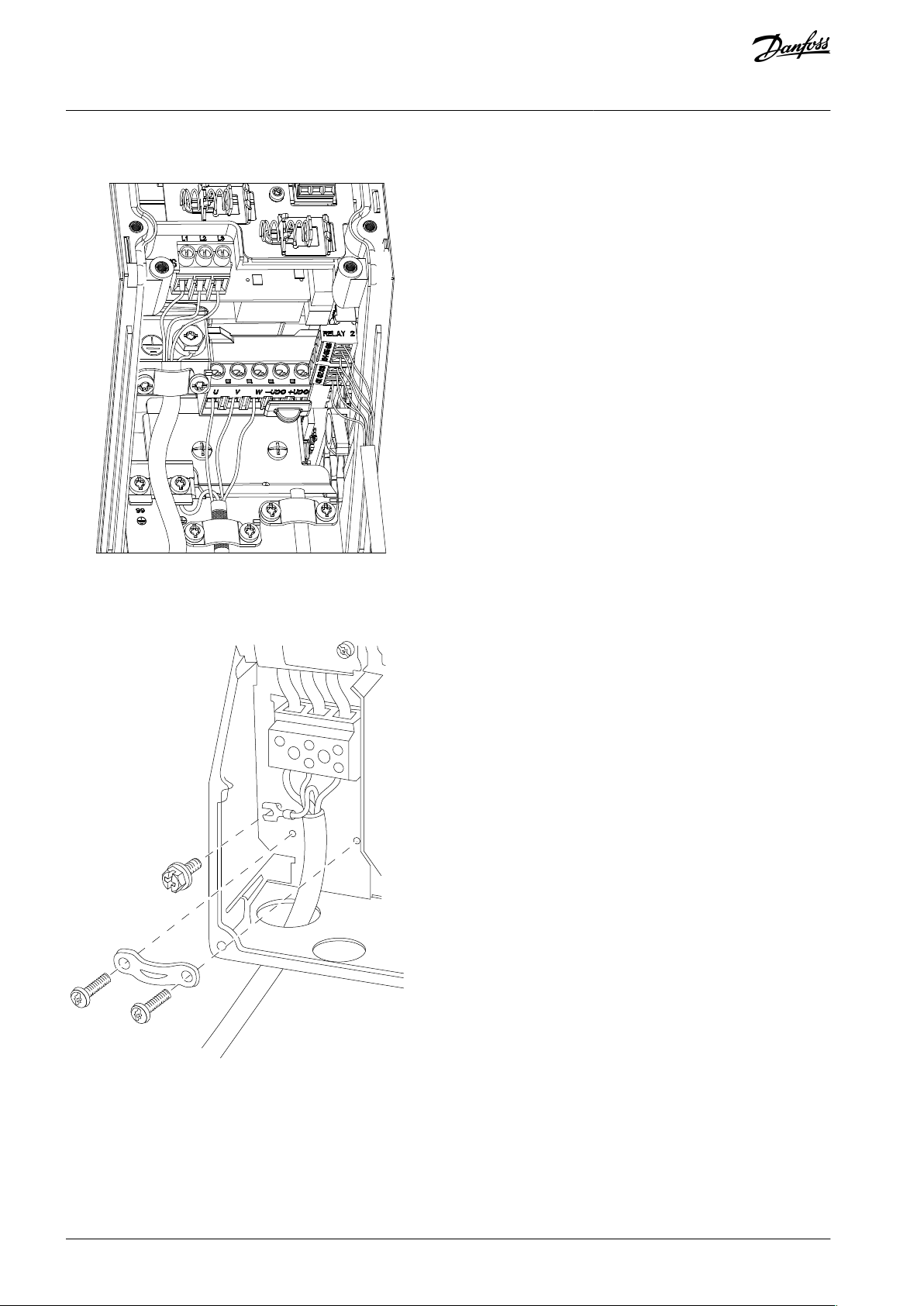

3.2.3.3 Enclosure Size I2

Installation

Illustration 3: Enclosure Size I2, IP54, 380–480 V, 0.75–4.0 kW (1.0–5.0 hp)

AQ367426199594en-000101 / 130R0988 | 13Danfoss A/S © 2021.06

Page 14

e30bc201.10

1

RS485

2

Mains

3

Ground

4

Cable clamps

5

Motor

6

UDC7Relays

8

I/O

VLT® HVAC Drive FC 131

Operating Guide

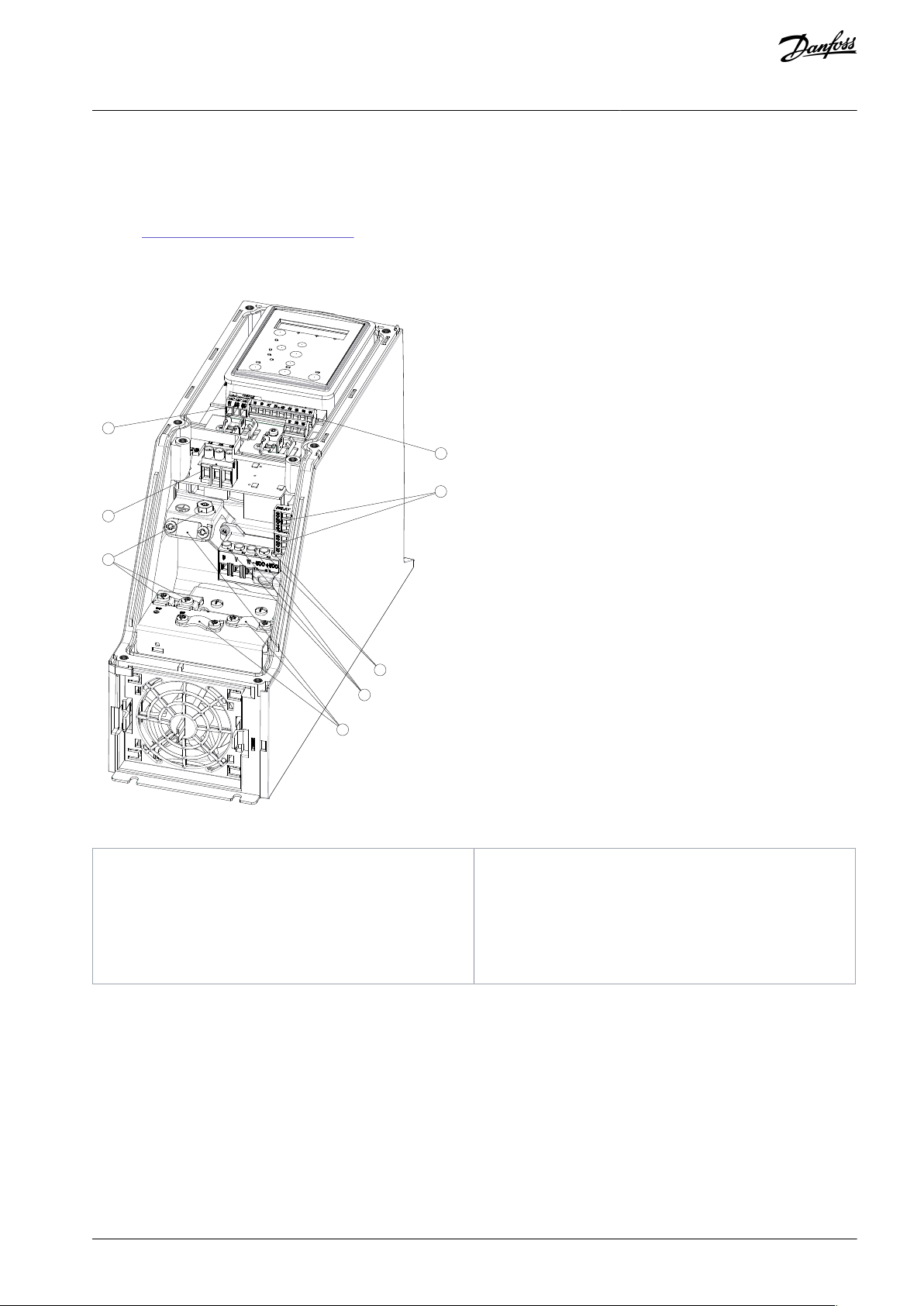

3.2.3.4 Enclosure Size I3

Installation

Illustration 4: Enclosure Size I3, IP54, 380–480 V, 5.5–7.5 kW (7.5–10 hp)

AQ367426199594en-000101 / 130R098814 | Danfoss A/S © 2021.06

Page 15

e30bd011.10

1

RS485

2

Mains

3

Ground

4

Cable clamps

5

Motor

6

UDC7Relays

8

I/O

VLT® HVAC Drive FC 131

Operating Guide

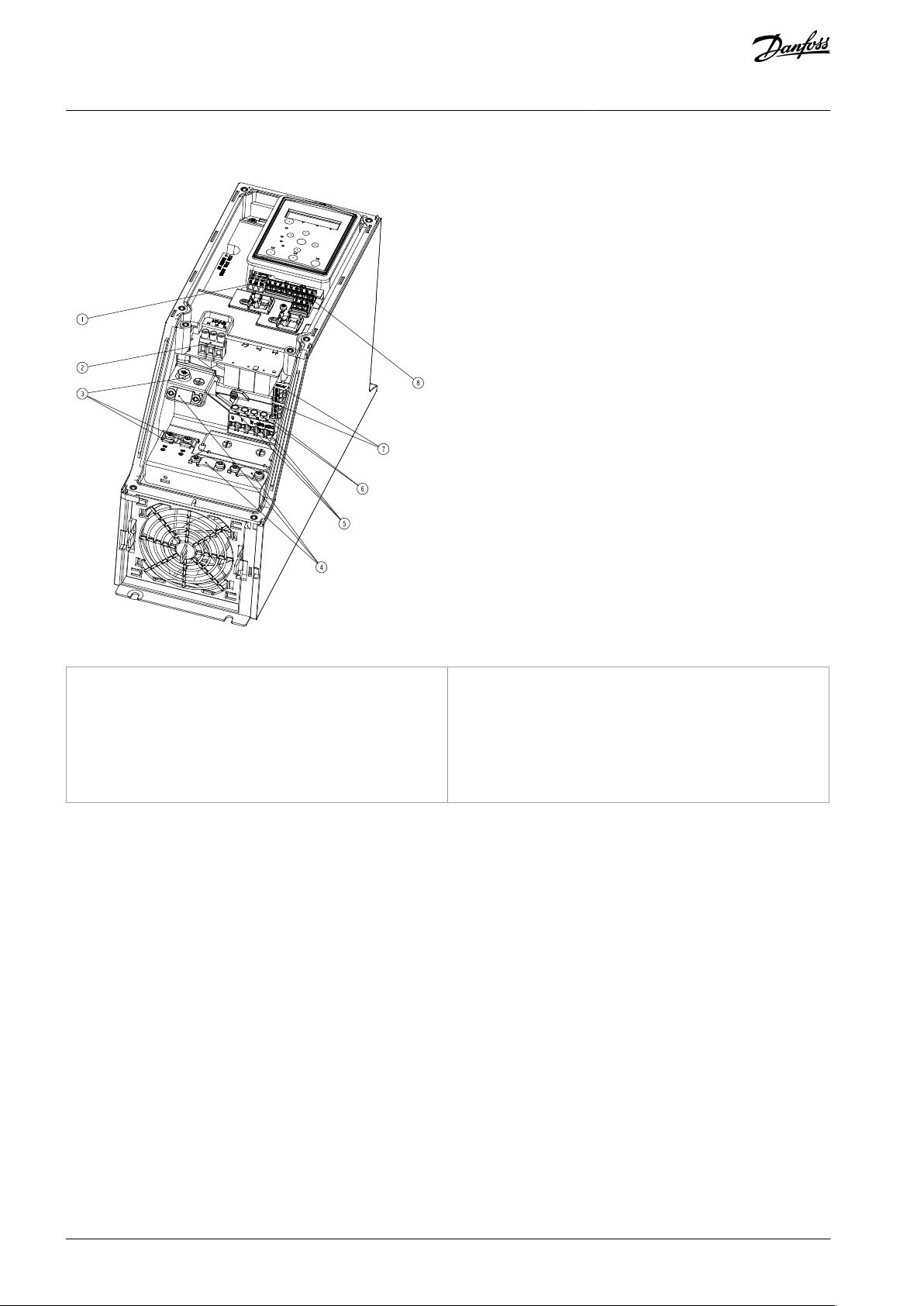

3.2.3.5 Enclosure Size I4

Installation

Illustration 5: Enclosure Size I4, IP54, 380–480 V, 11–18.5 kW (15–25 hp)

AQ367426199594en-000101 / 130R0988 | 15Danfoss A/S © 2021.06

Page 16

e30bc203.10

e30bt326.10

VLT® HVAC Drive FC 131

Operating Guide

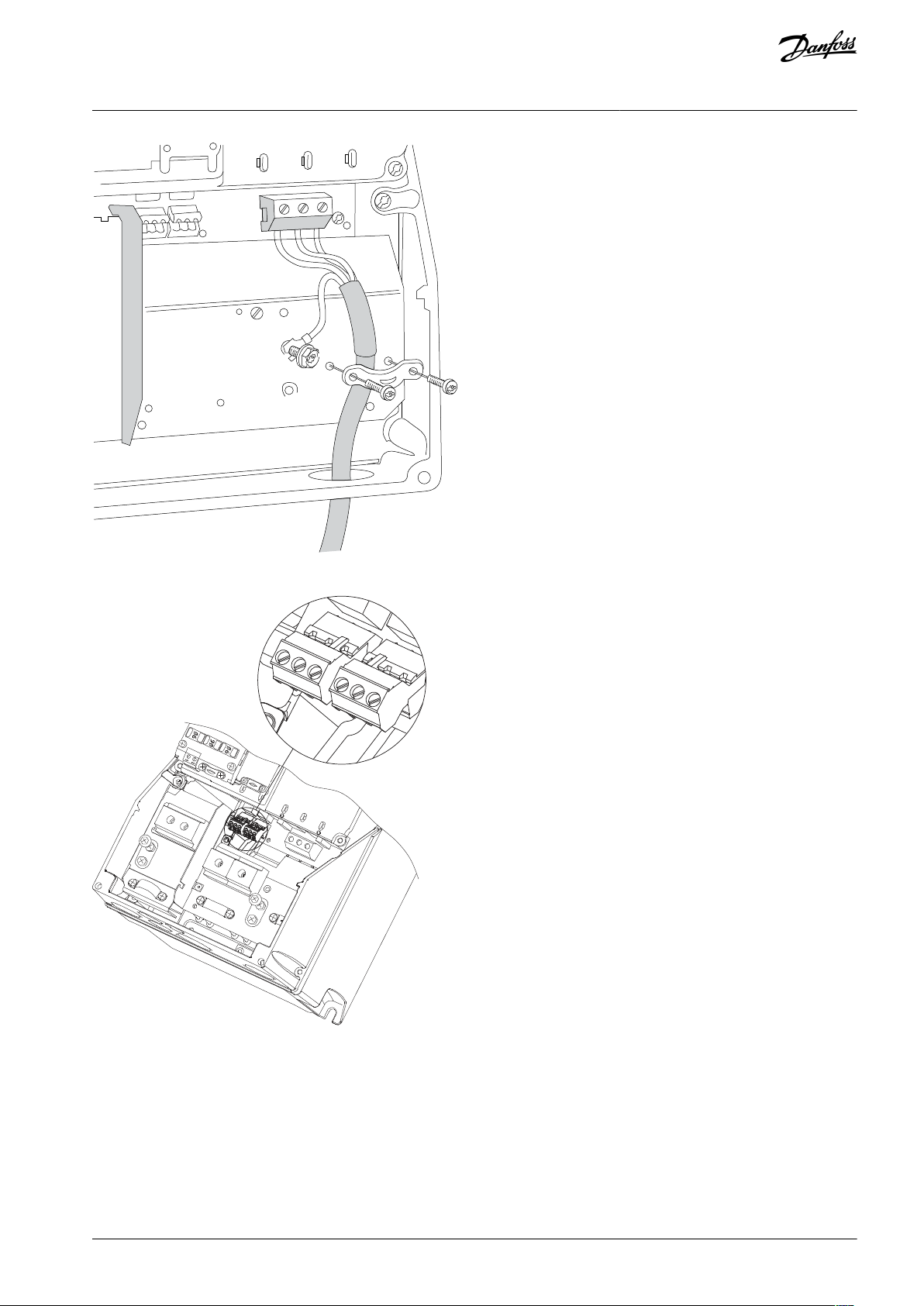

3.2.3.6 IP54 Enclosure Sizes I2, I3, I4

Installation

Illustration 6: IP54 Enclosure Sizes I2, I3, I4

3.2.3.7 Enclosure size I6

Illustration 7: Connecting to Mains for Enclosure Size I6, IP54, 380–480 V, 22–37 kW (30–50 hp)

AQ367426199594en-000101 / 130R098816 | Danfoss A/S © 2021.06

Page 17

e30bt325.10

311

e30ba215.10

RELA

Y 1

RELA

Y 2

03 02 01

90

05 04

VLT® HVAC Drive FC 131

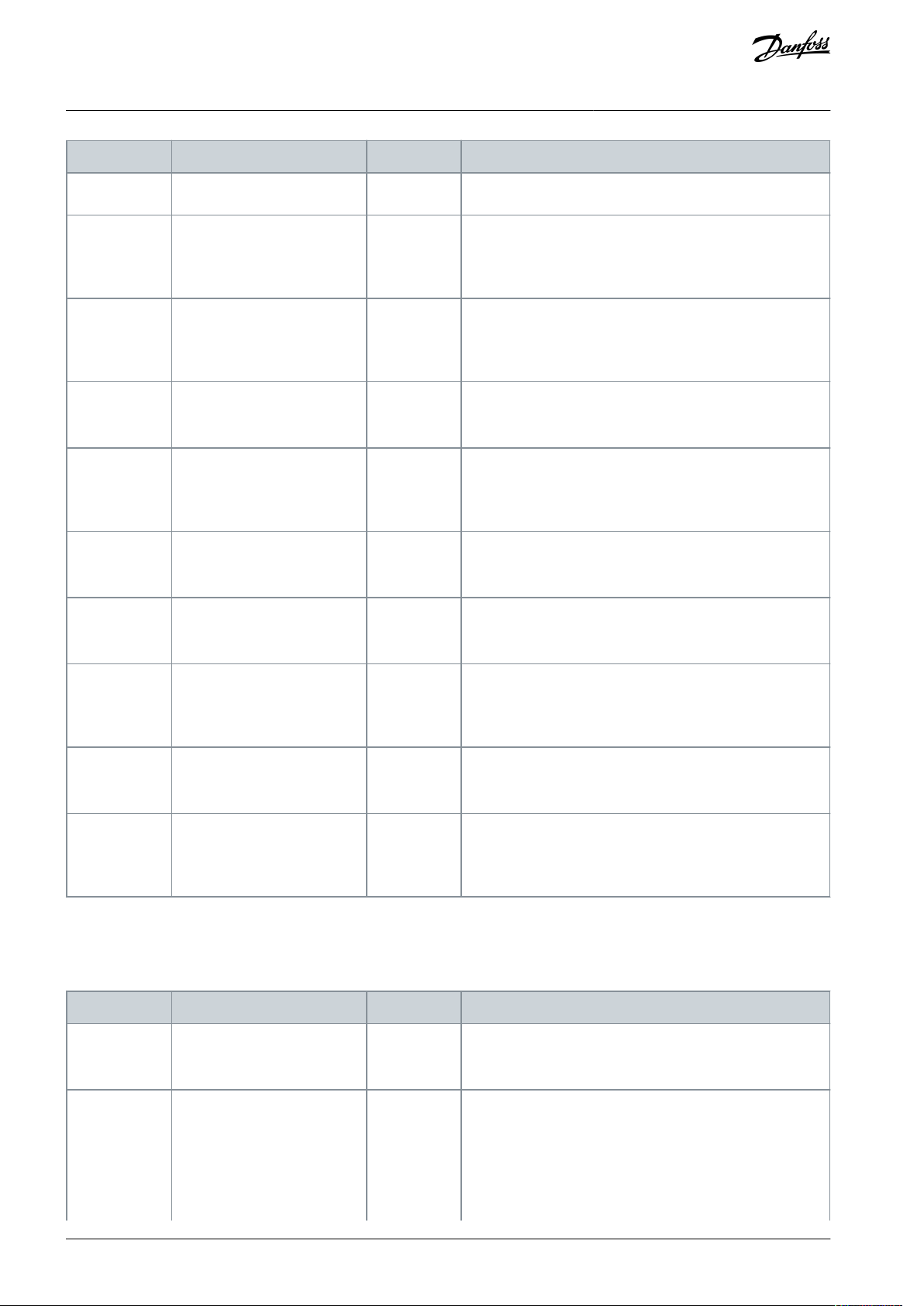

Operating Guide

Installation

Illustration 8: Connecting to Motor for Enclosure Size I6, IP54, 380–480 V, 22–37 kW (30–50 hp)

Illustration 9: Relays on Enclosure Size I6, IP54, 380–480 V, 22–37 kW (30–50 hp)

AQ367426199594en-000101 / 130R0988 | 17Danfoss A/S © 2021.06

Page 18

91

L1

92

L2

93

L3

96

U

97

V

98

W

88

DC-

99

95

e30bc248.10

Circuit breaker

Fuse

UL

Non-ULULNon-UL

Bussmann

Bussmann

Bussmann

Bussmann

Maximum fuse

Power [kW (hp)]

Type RK5

Type RK1

Type J

Type T

Type G

VLT® HVAC Drive FC 131

Operating Guide

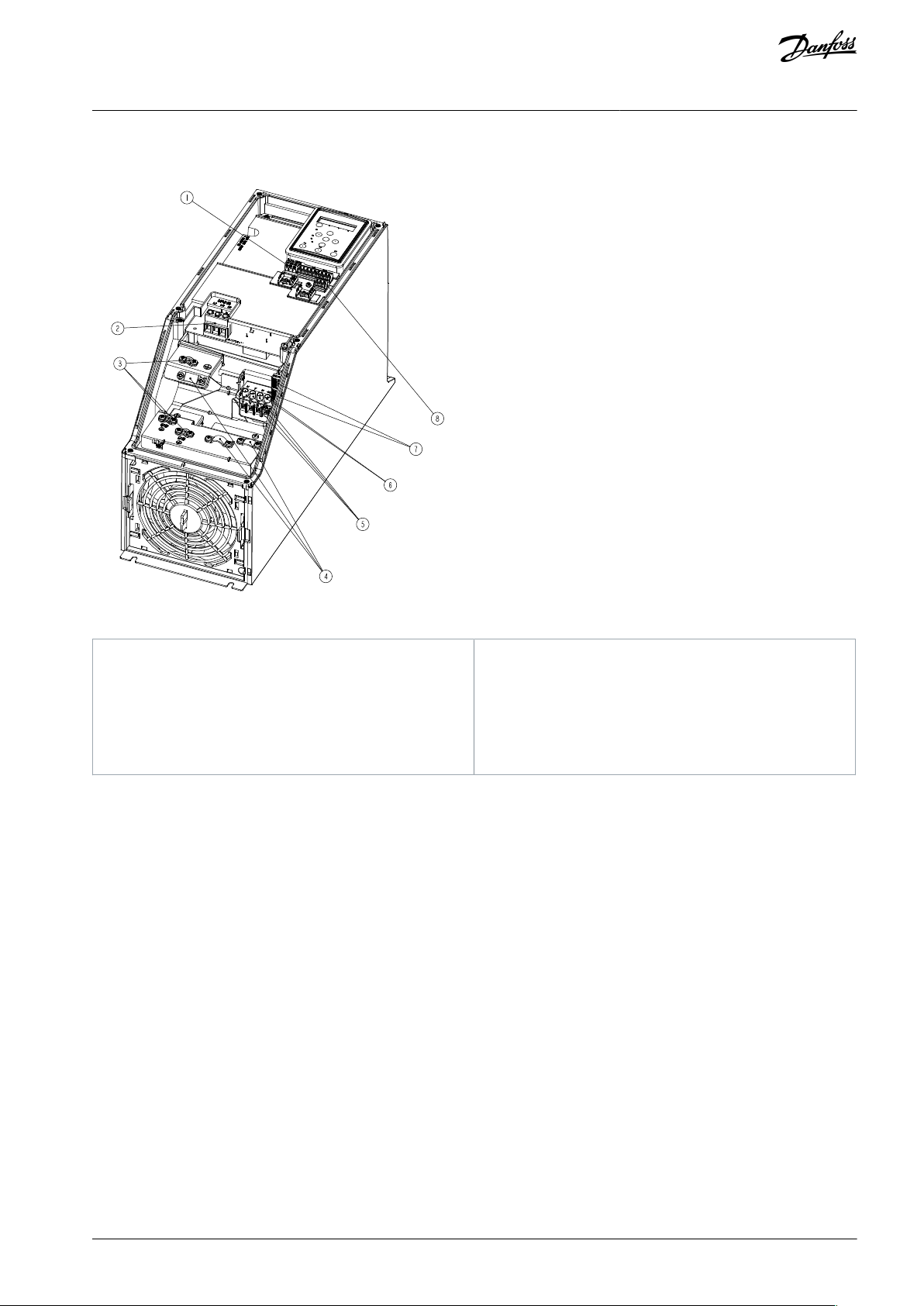

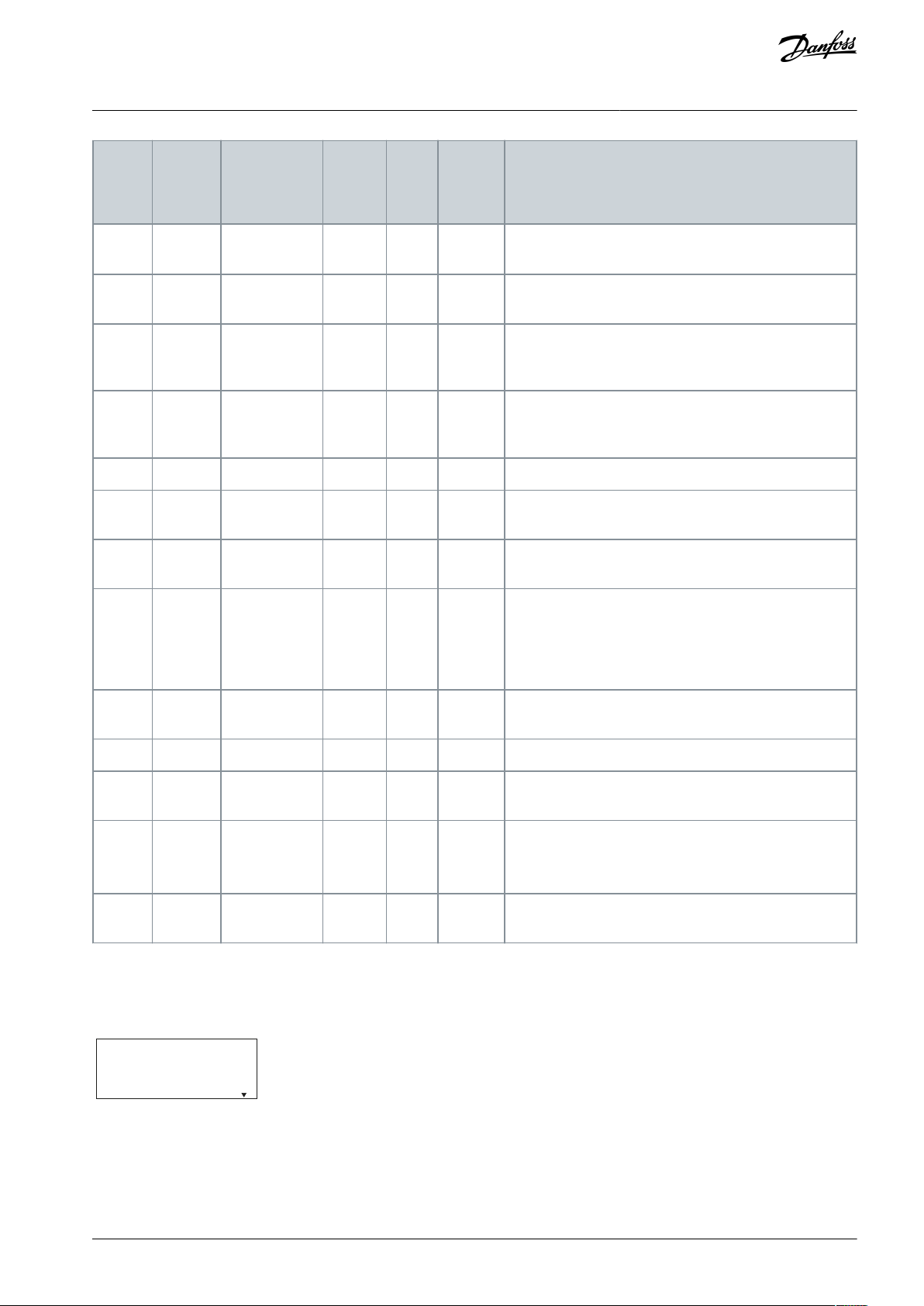

3.2.3.8 Enclosure size I7, I8

Illustration 10: Enclosure Sizes I7, I8, IP54, 380–480 V, 45–55 kW (60–70 hp), IP54, 380–480 V, 75–90 kW (100–125 hp)

Installation

3.2.4 Fuses and Circuit Breakers

3.2.4.1 Branch Circuit Protection

To prevent fire hazards, protect the branch circuits in an installation - switch gear, machines, and so on - against short circuits and

overcurrent. Follow national and local regulations.

3.2.4.2 Short-circuit Protection

Danfoss recommends using the fuses and circuit breakers listed in this chapter to protect service personnel or other equipment in

case of an internal failure in the unit or a short circuit on the DC link. The drive provides full short-circuit protection in case of a short

circuit on the motor.

3.2.4.3 Overcurrent Protection

Provide overload protection to avoid overheating of the cables in the installation. Overcurrent protection must always be carried

out according to local and national regulations. Design circuit breakers and fuses for protection in a circuit capable of supplying a

maximum of 100000 A

(symmetrical), 480 V maximum.

rms

3.2.4.4 UL/Non-UL Compliance

To ensure compliance with UL or IEC 61800-5-1, use the circuit breakers or fuses listed in this chapter. Circuit breakers must be

designed for protection in a circuit capable of supplying a maximum of 10000 A

(symmetrical), 480 V maximum.

rms

3.2.4.5 Recommendation of Fuses and Circuit Breakers

N O T I C E

If a malfunction occurs, failure to follow the protection recommendation may result in damage to the drive.

Table 7: Fuses and Circuit Breakers

AQ367426199594en-000101 / 130R098818 | Danfoss A/S © 2021.06

Page 19

3x380–480 V IP54

0.75 (1.0)

–

PKZM0-16

FRS-R-10

KTS-R-10

JKS-10

JJS-10161.5 (2.0)

PKZM0-16

FRS-R-10

KTS-R-10

JKS-10

JJS-10162.2 (3.0)

PKZM0-16

FRS-R-15

KTS-R-15

JKS-15

JJS-15163.0 (4.0)

PKZM0-16

FRS-R-15

KTS-R-15

JKS-15

JJS-15164.0 (5.0)

PKZM0-16

FRS-R-15

KTS-R-15

JKS-15

JJS-15165.5 (7.5)

PKZM0-25

FRS-R-25

KTS-R-25

JKS-25

JJS-25257.5 (10)

PKZM0-25

FRS-R-25

KTS-R-25

JKS-25

JJS-252511 (15)

PKZM4-63

FRS-R-50

KTS-R-50

JKS-50

JJS-506315 (20)

PKZM4-63

FRS-R-50

KTS-R-50

JKS-50

JJS-506318.5 (25)

PKZM4-63

FRS-R-80

KTS-R-80

JKS-80

JJS-806322 (30)

Moeller NZMB1-A125

–

FRS-R-80

KTS-R-80

JKS-80

JJS-80

125

30 (40)

FRS-R-125

KTS-R-125

JKS-125

JJS-125

125

37 (50)

FRS-R-125

KTS-R-125

JKS-125

JJS-125

125

45 (60)

Moeller NZMB2-A160

–

FRS-R-125

KTS-R-125

JKS-125

JJS-125

160

55 (70)

FRS-R-200

KTS-R-200

JKS-200

JJS-200

160

75 (100)

Moeller NZMB2-A250

–

FRS-R-200

KTS-R-200

JKS-200

JJS-200

200

90 (125)

FRS-R-250

KTS-R-250

JKS-200

JJS-200

200

VLT® HVAC Drive FC 131

Operating Guide

Installation

3.2.5 EMC-compliant Electrical Installation

To ensure EMC-correct electrical installation, observe the following:

•

Use only shielded/armored motor cables and shielded/armored control cables.

•

Ground the shield at both ends.

•

Avoid installation with twisted shield ends (pigtails), because it reduces the shielding effect at high frequencies. Use the cable

clamps provided.

•

Ensure the same potential between the drive and the ground potential of PLC.

•

Use star washers and galvanically conductive installation plates.

AQ367426199594en-000101 / 130R0988 | 19Danfoss A/S © 2021.06

Page 20

B

a

c

k

OK

Com.

On

Warn.

Alarm

Hand

On

Reset

Auto

On

Menu

Status Quick

Menu

Main

Menu

L1

L2

L3

PE

Minimum 16 mm

2

equalizing cable

Control cables

All cable entries in

one side of the panel

Grounding rail

Cable insulation stripped

Output contactor

Motor cable

Motor, 3 phases and

PLC

Panel

Mains-supply

Minimum 200 mm (7.87 in)

between control

cable, mains cable,

and between mains

motor cable

PLC

protective earth

Reinforced protective earth

e30bb761.13

(6 AWG)

VLT® HVAC Drive FC 131

Operating Guide

Installation

Illustration 11: EMC-compliant Installation

3.2.6 Control Terminals

Remove the terminal cover to access the control terminals.

Use a flat-edged screwdriver to push down the lock lever of the terminal cover under the LCP, then remove the terminal cover as

shown in the following illustration.

For IP54 units, control terminals can be accessed after removing the front cover.

AQ367426199594en-000101 / 130R098820 | Danfoss A/S © 2021.06

Page 21

e30bd331.10

e30bf892.10

12 20 55

181927 29 42 54

45 50 53

DIGI IN

61 68 69

N

P

COMM. GND

+24 V

GND

GND

10 V OUT

10 V/20 mA IN

0/4-20 mA A OUT/DIG OUT

BUS TER.

OFF ON

DIGI IN

DIGI IN

DIGI IN

0/4-20 mA A OUT/DIG OUT

10 V/20 mA IN

VLT® HVAC Drive FC 131

Operating Guide

Installation

Illustration 12: Removing the Terminal Cover

The following illustration shows all the drive control terminals. Applying start (terminal 18), connection between terminals 12-27,

and an analog reference (terminal 53 or 54, and 55) make the drive run.

The digital input mode of terminal 18, 19, and 27 is set in parameter 5-00 Digital Input Mode (PNP is default value). Digital input 29

mode is set in parameter 5-03 Digital Input 29 Mode (PNP is default value).

Illustration 13: Control Terminals

AQ367426199594en-000101 / 130R0988 | 21Danfoss A/S © 2021.06

Page 22

L1

L2

L3

3-phase

power

input

PE

PE

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN/OUT)

29 (D IN/OUT)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bd467.13

06

05

04

240 V AC 3 A

VLT® HVAC Drive FC 131

Operating Guide

3.2.7 Electrical Wiring

Installation

Illustration 14: Basic Wiring Schematic Drawing

N O T I C E

There is no access to UDC- and UDC+ on the following units:

IP54, 380–480 V, 22–90 kW (30–125 hp)

-

3.2.8 Acoustic Noise or Vibration

If the motor or the equipment driven by the motor - for example, a fan - is making noise or vibrations at certain frequencies, configure the following parameters or parameter groups to reduce or eliminate the noise or vibrations:

•

Parameter group 4-6* Speed Bypass.

•

Set parameter 14-03 Overmodulation to [0] Off.

•

Switching pattern and switching frequency parameter group 14-0* Inverter Switching.

•

Parameter 1-64 Resonance Dampening.

AQ367426199594en-000101 / 130R098822 | Danfoss A/S © 2021.06

Page 23

e30bu820.10

B

C

D

A

13 14 15

12

11

11

5

4

10

6

7

8

9

1

2

11

1 (2)

3

1

Parameter number and name.

2

Parameter value.

3

Setup number shows the active setup and the edit setup (only in Status menu). The number outside brackets is active setup,

and the number inside brackets is edit setup. For example, 1(2) means 1 is the active setup, and 2 is the edit setup.

4

Motor direction is shown to the bottom left of the display – indicated by a small arrow pointing either clockwise or counterclockwise.

5

The triangle indicates if the LCP is in Status, Quick Menu, or Main Menu.

VLT® HVAC Drive FC 131

Operating Guide

4 Programming

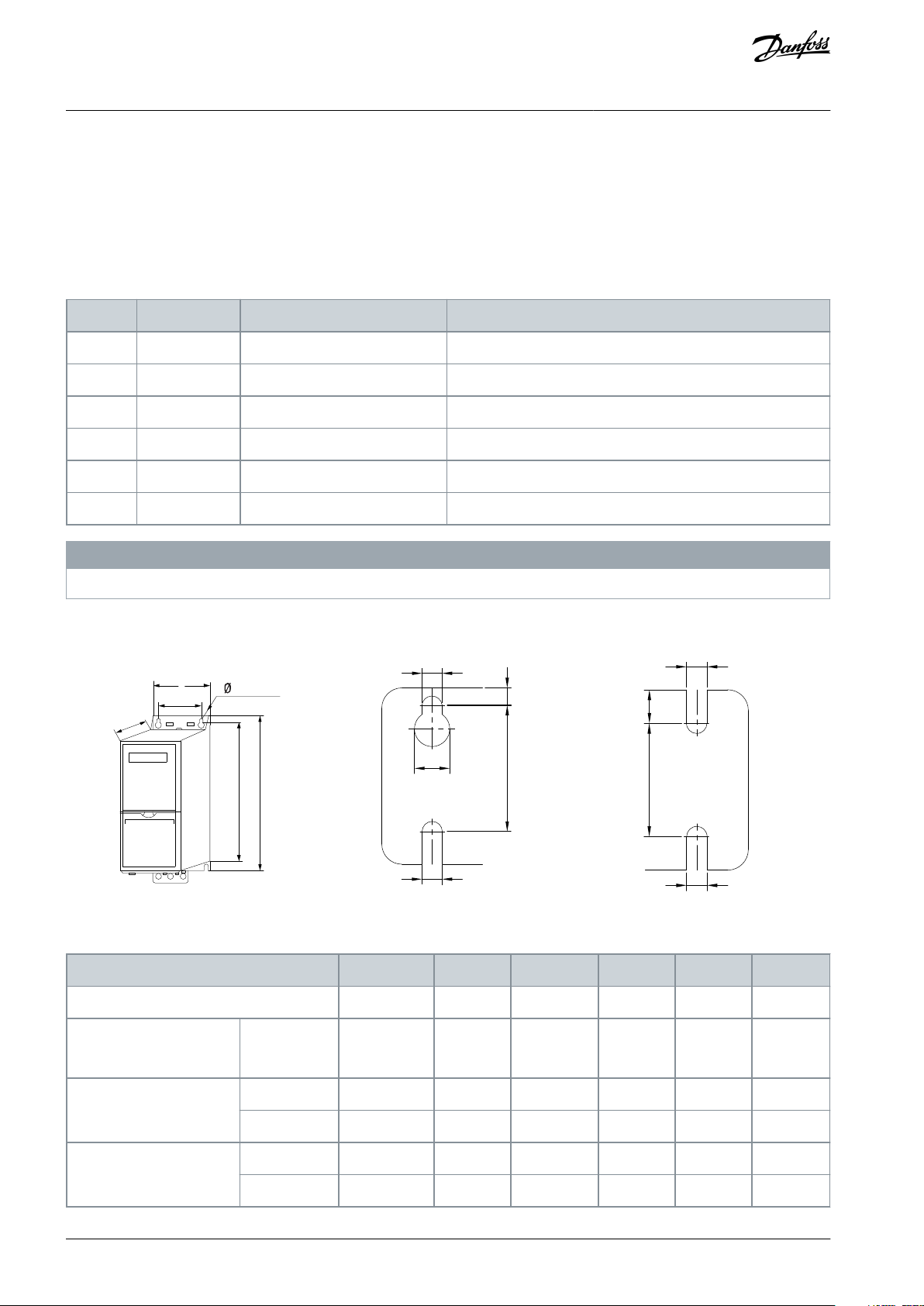

4.1 Local Control Panel (LCP)

The LCP is divided into 4 functional sections.

•

A. Display

•

B. Menu key

•

C. Navigation keys and indicator lights

•

D. Operation keys and indicator lights

Programming

Illustration 15: Local Control Panel (LCP 32)

A. Display

The graphical LCD-display is illuminated with clear white backlight and can show either 3 full lines (in programming mode) or 2 full

& 2 ½ lines (in status mode). The following table describes the information that can be read from the display.

Table 8: Legend to Section A, Illustration 3

B. Menu key

Press [Menu] to select among Status, Quick Menu, or Main Menu.

AQ367426199594en-000101 / 130R0988 | 23Danfoss A/S © 2021.06

Page 24

6

Com. (yellow indicator): Flashes during bus communication.

7

On (green indicator): Shows the power on status.

8

Warn. (yellow indicator): Indicates a warning.

9

Alarm (red indicator): Indicates an alarm.

10

[Back]: For moving to the previous step or layer in the navigation structure.

11

Up arrow key, down arrow key, and right arrow key: For navigating among parameter groups and parameters, and within

parameters. They can also be used for setting local reference.

12

[OK]: For selecting a parameter and for accepting changes to parameter settings.

13

[Hand On]: Starts the motor and enables control of the drive via the LCP.

N O T I C E

[2] Coast inverse is the default option for parameter 5-12 Terminal 27 Digital Input. If there is no 24 V supply to terminal 27,

[Hand On] does not start the motor. Connect terminal 12 to terminal 27.

14

[Off/Reset]: Stops the compressor (Off). If in alarm mode, the alarm is reset.

15

[Auto On]: The drive is controlled either via control terminals or serial communication.

FC

+24 V (OUT)

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

+

0–10 V

Start

+10 V (OUT)

A IN

A IN

COM IN/OUT

45

Reference

e30bb674.11

VLT® HVAC Drive FC 131

Operating Guide

C. Navigation keys and indicator lights

Table 9: Legend to Section C, Illustration 3

D. Operation keys and indicator lights

Table 10: Legend to Section D, Illustration 3

Programming

4.2 Set-up Wizard

4.2.1 Setup Wizard Introduction

The built-in wizard menu guides the installer through the setup of the drive in a clear and structured manner for open-loop and

closed-loop applications, and for quick motor settings.

Illustration 16: Drive Wiring

The wizard can always be accessed again through the quick menu. Press [OK] to start the wizard. Press [Back] to return to the status

view.

AQ367426199594en-000101 / 130R098824 | Danfoss A/S © 2021.06

Page 25

Power kW/50 H z

Motor Power

Motor Voltage

Motor Frequency

Motor Current

Motor nominal speed

if

Select Regional Settings

... the Wizard starts

200-240V/50Hz/Delta

Grid Type

Induction motor

Asynchronous

Motor Type

Motor current

Motor nominal speed

Motor Cont. Rated Torque

Stator resistance

Motor poles

Back EMF at 1000 rpm

Motor type = IPM

Motor type = SPM

d-axis Inductance Sat. (LdSat)

[0]

[0]

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

Start Mode

Rotor Detection

[0]

Position Detection Gain

%

Off

100

Locked Rotor Detection

[0]

s

Locked Rotor Detection Time[s]

0.10

57

V

5

mH

q-axis Inductance (Lq)

5

mH

1.10

kW

400

V

50

Hz

Max Output Frequency

65

Hz

Motor Cable Length

50

m

4.66

A

1420

RPM

[0]

PM motor

Set Motor Speed low Limit

Hz

Set Motor Speed high Limit

Hz

Set Ramp 1 ramp-up time

s

Set Ramp 1 ramp-down Time

s

Active Flying start ?

Disable

Set T53 low Voltage

V

Set T53 high Voltage

V

Set T53 Low Current

A

Set T53 High Current

A

Voltage

AMA Failed

AMA Failed

Automatic Motor Adaption

Auto Motor Adapt OK

Press OK

Select Function of Relay 2

No function

Off

Select Function of Relay 1

[0] No function

Set Max Reference

Hz

Hz

Set Min Reference

AMA running

-----

Do AMA

(Do not AMA)

AMA OK

[0]

[0]

[0]

Select T53 Mode

Current

Current

Motor type = Induction

Motor type = PM motor

0000

0050

0010

0010

[0]

[0]

04.66

13.30

0050

0220

0000

0050

The next screen is

the Wizard screen.

Power-up Screen

e30bu808.11

q-axis Inductance Sat. (LqSat)

5

mH

Current at Min Inductance for d-axis

100

%

Current at Min Inductance for q-axis

100

%

d-axis Inductance (Lq)

5

mH

... the Wizard starts

1 (1)

0.0 Hz

0.000 kW

Auto On

0-**: FC-xxx Wizard

1-**: Closed Loop Set

2-**: Motor Setup

Or

VLT® HVAC Drive FC 131

Operating Guide

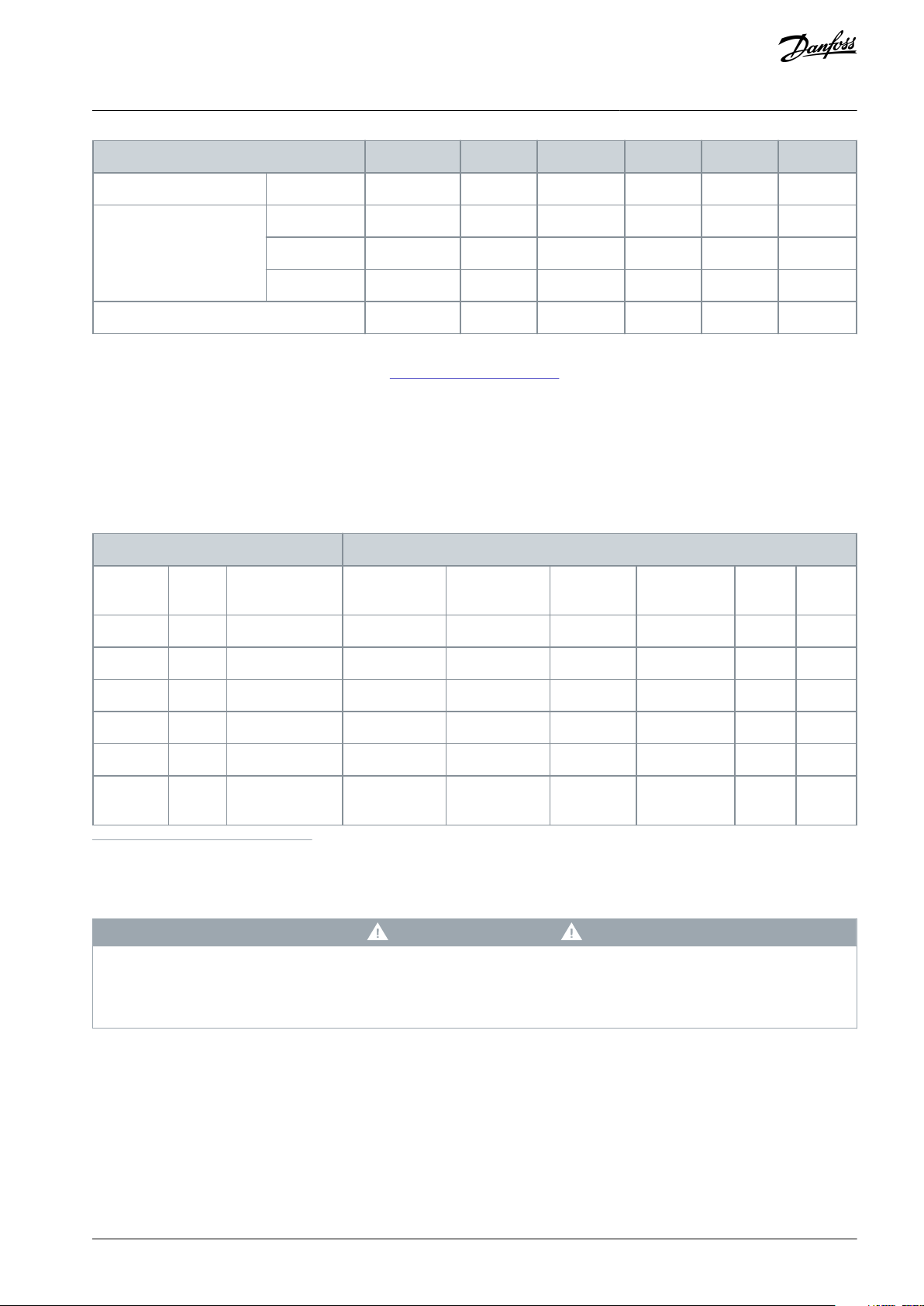

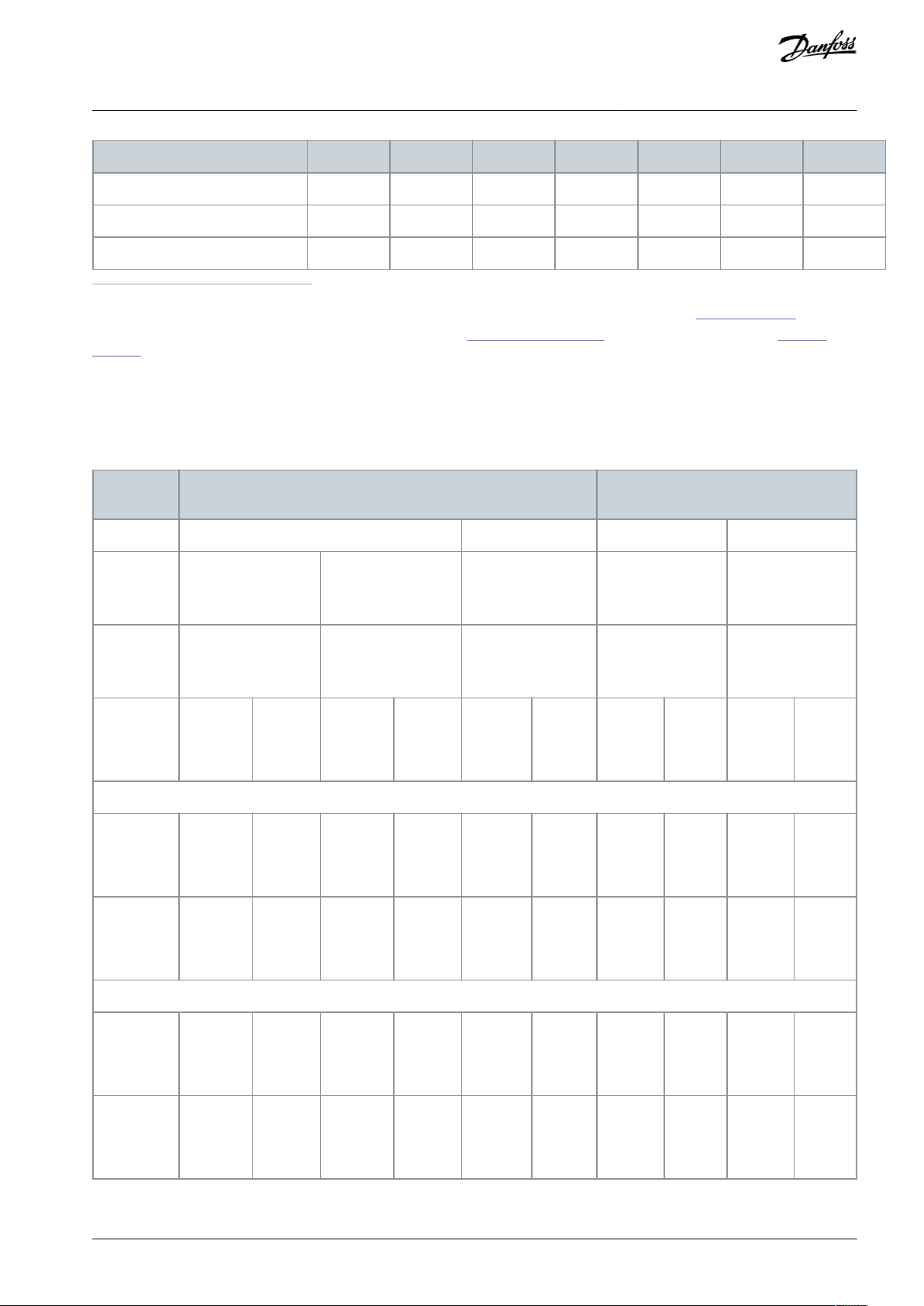

4.2.2 Setup Wizard for Open-loop Applications

Programming

Illustration 17: Setup Wizard for Open-loop Applications

AQ367426199594en-000101 / 130R0988 | 25Danfoss A/S © 2021.06

Page 26

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[0] 200–240 V/50 Hz/IT-grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[30] 525–600 V/50 Hz/IT-grid

[31] 525–600 V/50 Hz/Delta

[32] 525–600 V/50 Hz

[100] 200–240 V/60 Hz/IT-grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

[130] 525–600 V/60 Hz/IT-grid

[131] 525–600 V/60 Hz/Delta

[132] 525–600 V/60 Hz

Size related

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

VLT® HVAC Drive FC 131

Operating Guide

Table 11: Setup Wizard for Open-loop Applications

Programming

AQ367426199594en-000101 / 130R098826 | Danfoss A/S © 2021.06

Page 27

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–1000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–9999 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–1000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 27Danfoss A/S © 2021.06

Page 28

Parameter

Option/range

Default

Usage

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-29

Automatic Motor Adaption

(AMA)

See parameter 1-29 Automatic

Motor Adaption (AMA).

Off

Performing an AMA optimizes motor performance.

Parameter 1-30

Stator Resistance (Rs)

0.000–99.990 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R098828 | Danfoss A/S © 2021.06

Page 29

Parameter

Option/range

Default

Usage

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a motor spinning due to mains drop-out. Select [0] Disabled if this function is not required. When this parameter is set to [1] Ena-

bled, parameter 1-71 Start Delay and parameter 1-72 Start

Function are not functional. Parameter 1-73 Flying Start is ac-

tive in VVC+ mode only.

Parameter 3-02

Minimum Reference

-4999.000–4999.000

0

The minimum reference is the lowest value obtainable by

summing all references.

Parameter 3-03

Maximum Reference

-4999.000–4999.000

50

The maximum reference is the lowest obtainable by summing all references.

Parameter 3-41

Ramp 1 Ramp

Up Time

0.01–3600.00 s

Size related

If asynchronous motor is selected, the ramp-up time is from

0 to rated parameter 1-23 Motor Frequency. If PM motor is selected, the ramp-up time is from 0 to parameter 1-25 Motor

Nominal Speed.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.01–3600.00 s

Size related

For asynchronous motors, the ramp-down time is from rated

parameter 1-23 Motor Frequency to 0. For PM motors, the

ramp-down time is from parameter 1-25 Motor Nominal

Speed to 0.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100 Hz

Enter the maximum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[9] Alarm

Select the function to control output relay 1.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[5] Drive running

Select the function to control output relay 2.

Parameter 6-10

Terminal 53

Low Voltage

0.00–10.00 V

0.07 V

Enter the voltage that corresponds to the low reference value.

Parameter 6-11

Terminal 53

High Voltage

0.00–10.00 V

10 V

Enter the voltage that corresponds to the high reference value.

Parameter 6-12

Terminal 53

Low Current

0.00–20.00 mA

4 mA

Enter the current that corresponds to the low reference value.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 29Danfoss A/S © 2021.06

Page 30

Parameter

Option/range

Default

Usage

Parameter 6-13

Terminal 53

High Current

0.00–20.00 mA

20 mA

Enter the current that corresponds to the high reference value.

Parameter 6-19

Terminal 53

mode

[0] Current

[1] Voltage

[1] Voltage

Select if terminal 53 is used for current or voltage input.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1 s

0.10 s

–

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R098830 | Danfoss A/S © 2021.06

Page 31

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Induction motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

400

V

1-24 Motor Current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0010

s

3-42 Ramp1 ramp-down time

0010

s

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-14 Motor speed high limit

0050

Hz

e30bc402.16

1-20 Motor Power

1.10

kW

1-23 Motor Frequency

50

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

Off

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Configuration Mode

[3]

Closed Loop

0-03 Regional Settings

[0]

Power kW/50 Hz

3-16 Reference Source 2

[0]

No Operation

1-10 Motor Type

[0]

Asynchronous

[0]

200-240V/50Hz/Delta

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-38 q-axis inductance(Lq)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 RPM

57

V

PM motor

1-39 Motor Poles

8

%

04.66

Hz

Motor type = Induction

Motor type = PM motor

Motor type = IPM

Motor type = SPM

1-44 d-axis Inductance Sat. (LdSat)

(1-70) Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

Off

100

30-22 Locked Rotor Detection

[0]

s

30-23 Locked Rotor Detection Time[s]

0.10

5

mH

1-42 Motor Cable Length

50

m

(1-45) q-axis Inductance Sat. (LqSat)

5

mH

(1-48) Current at Min Inductanc e for d-axis

100

%

1-49 Current at Min Inductanc e for q-axis

100

%

1-37 d-axis inductance(Lq)

5

mH

... the Wizard starts

... the Wizard starts

VLT® HVAC Drive FC 131

Operating Guide

4.2.3 Setup Wizard for Closed-loop Applications

Programming

Illustration 18: Setup Wizard for Closed-loop Applications

AQ367426199594en-000101 / 130R0988 | 31Danfoss A/S © 2021.06

Page 32

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[0] 200–240 V/50 Hz/IT-grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[30] 525–600 V/50 Hz/IT-grid

[31] 525–600 V/50 Hz/Delta

[32] 525–600 V/50 Hz

[100] 200–240 V/60 Hz/IT-grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

[130] 525–600 V/60 Hz/IT-grid

[131] 525–600 V/60 Hz/Delta

[132] 525–600 V/60 Hz

Size selected

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

Parameter 1-00

Configuration

Mode

[0] Open loop

[3] Closed loop

[0] Open loop

Select [3] Closed loop.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

VLT® HVAC Drive FC 131

Operating Guide

Table 12: Setup Wizard for Closed-loop Applications

Programming

AQ367426199594en-000101 / 130R098832 | Danfoss A/S © 2021.06

Page 33

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–1000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–60000 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–10000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 33Danfoss A/S © 2021.06

Page 34

Parameter

Option/range

Default

Usage

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-29

Automatic Motor Adaption

(AMA)

–

Off

Performing an AMA optimizes motor performance.

Parameter 1-30

Stator Resistance (Rs)

0.000–9999.000 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R098834 | Danfoss A/S © 2021.06

Page 35

Parameter

Option/range

Default

Usage

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a spinning motor in, for example, fan applications. When PM is selected,

this parameter is enabled.

Parameter 3-02

Minimum Reference

-4999.000–4999.000

0

The minimum reference is the lowest value obtainable by

summing all references.

Parameter 3-03

Maximum Reference

-4999.000–4999.000

50

The maximum reference is the highest value obtainable by

summing all references.

Parameter 3-10

Preset Reference

-100–100%

0

Enter the setpoint.

Parameter 3-41

Ramp 1 Ramp

Up Time

0.05–3600.0 s

Size related

Ramp-up time from 0 to rated parameter 1-23 Motor Frequen-

cy for asynchronous motors. Ramp-up time from 0 to parameter 1-25 Motor Nominal Speed for PM motors.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.05–3600.0 s

Size related

Ramp-down time from rated parameter 1-23 Motor Frequency

to 0 for asynchronous motors. Ramp-down time from param-

eter 1-25 Motor Nominal Speed to 0 for PM motors.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0.0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100 Hz

Enter the minimum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter 6-20

Terminal 54

Low Voltage

0.00–10.00 V

0.07 V

Enter the voltage that corresponds to the low reference value.

Parameter 6-21

Terminal 54

High Voltage

0.00–10.00 V

10.00 V

Enter the voltage that corresponds to the high reference value.

Parameter 6-22

Terminal 54

Low Current

0.00–20.00 mA

4.00 mA

Enter the current that corresponds to the low reference value.

Parameter 6-23

Terminal 54

High Current

0.00–20.00 mA

20.00 mA

Enter the current that corresponds to the high reference value.

Parameter 6-24

Terminal 54

-4999–4999

0

Enter the feedback value that corresponds to the voltage or

current set in parameter 6-20 Terminal 54 Low Voltage/param-

eter 6-22 Terminal 54 Low Current.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 35Danfoss A/S © 2021.06

Page 36

Parameter

Option/range

Default

Usage

Low Ref./Feedb.

Value

Parameter 6-25

Terminal 54

High Ref./

Feedb. Value

-4999–4999

50

Enter the feedback value that corresponds to the voltage or

current set in parameter 6-21 Terminal 54 High Voltage/pa-

rameter 6-23 Terminal 54 High Current.

Parameter 6-26

Terminal 54 Filter Time Constant

0.00–10.00 s

0.01

Enter the filter time constant.

Parameter 6-29

Terminal 54

mode

[0] Current

[1] Voltage

[1] Voltage

Select if terminal 54 is used for current or voltage input.

Parameter

20-81 PI Normal/Inverse

Control

[0] Normal

[1] Inverse

[0] Normal

Select [0] Normal to set the process control to increase the

output speed when the process error is positive. Select [1] In-

verse to reduce the output speed.

Parameter

20-83 PI Start

Speed [Hz]

0–200 Hz

0 Hz

Enter the motor speed to be attained as a start signal for

commencement of PI control.

Parameter

20-93 PI Proportional Gain

0.00–10.00

0.01

Enter the process controller proportional gain. Quick control

is obtained at high amplification. However, if amplification is

too high, the process may become unstable.

Parameter

20-94 PI Integral Time

0.1–999.0 s

999.0 s

Enter the process controller integral time. Obtain quick control through a short integral time, though if the integral time

is too short, the process becomes unstable. An excessively

long integral time disables the integral action.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1.00 s

0.10 s

–

Parameter

Option/range

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[0] 200–240 V/50 Hz/IT-grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

Size selected

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

VLT® HVAC Drive FC 131

Operating Guide

Programming

4.2.4 Motor Setup

The motor setup wizard guides users through the needed motor parameters.

Table 13: Motor Setup Wizard Settings

AQ367426199594en-000101 / 130R098836 | Danfoss A/S © 2021.06

Page 37

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[30] 525–600 V/50 Hz/IT-grid

[31] 525–600 V/50 Hz/Delta

[32] 525–600 V/50 Hz

[100] 200–240 V/60 Hz/IT-grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

[130] 525–600 V/60 Hz/IT-grid

[131] 525–600 V/60 Hz/Delta

[132] 525–600 V/60 Hz

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 37Danfoss A/S © 2021.06

Page 38

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option/range

Default

Usage

Parameter 1-66 Min. Current at Low Speed.

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–10000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–9999 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–1000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-30

Stator Resistance (Rs)

0–99.990 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R098838 | Danfoss A/S © 2021.06

Page 39

Parameter

Option/range

Default

Usage

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a spinning motor.

Parameter 3-41

Ramp 1 Ramp

Up Time

0.05–3600.0 s

Size related

Ramp-up time from 0 to rated parameter 1-23 Motor Frequen-

cy.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.05–3600.0 s

Size related

Ramp-down time from rated parameter 1-23 Motor Frequency

to 0.

VLT® HVAC Drive FC 131

Operating Guide

Programming

AQ367426199594en-000101 / 130R0988 | 39Danfoss A/S © 2021.06

Page 40

Parameter

Option/range

Default

Usage

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0.0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100.0 Hz

Enter the maximum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100.0 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1.00 s

0.10 s

–

VLT® HVAC Drive FC 131

Operating Guide

Programming

4.2.5 Changes Made Function

The changes made function lists all parameters changed from default settings.

•

The list shows only parameters that have been changed in the current edit setup.

•

Parameters that have been reset to default values are not listed.

•

The message Empty indicates that no parameters have been changed.

4.2.6 Changing Parameter Settings

Procedure

1.

To enter the Quick Menu, press the [Menu] key until the indicator in the display is placed above Quick Menu.

2.

Press [▵] [▿] to select the wizard, closed-loop setup, motor setup, or changes made.

3.

Press [OK].

4.

Press [▵] [▿] to browse through the parameters in the Quick Menu.

5.

Press [OK] to select a parameter.

6.

Press [▵] [▿] to change the value of a parameter setting.

7.

Press [OK] to accept the change.

8.

Press either [Back] twice to enter Status, or press [Menu] once to enter the Main Menu.

4.2.7 Accessing All Parameters via the Main Menu

Procedure

1.

Press the [Menu] key until the indicator in the display is placed above Main Menu.

2.

Press [▵] [▿] to browse through the parameter groups.

3.

Press [OK] to select a parameter group.

4.

Press [▵] [▿] to browse through the parameters in the specific group.

5.

Press [OK] to select the parameter.

6.

Press [▵] [▿] to set/change the parameter value.

7.

Press [OK] to accept the change.

AQ367426199594en-000101 / 130R098840 | Danfoss A/S © 2021.06

Page 41

Fault

num-

ber

Alarm/

warning

bit num-

ber

Fault text

Warn-

ing

Alarm

Trip

locked

Cause of problem

216Live zero error

XX–

Signal on terminal 53 or 54 is less than 50% of the value

set in parameter 6-10 Terminal 53 Low Voltage, parameter

6-12 Terminal 53 Low Current, parameter 6-20 Terminal 54

Low Voltage, or parameter 6-22 Terminal 54 Low Current.

See also parameter group 6-0* Analog I/O Mode.

3–No motor

X––

No motor is connected to the output of the drive.

414Mains ph. loss

XXX

Missing phase on the supply side or too high voltage imbalance. Check the supply voltage. See parameter 14-12

Function at Mains Imbalance.

711DC over volt

XX–

DC-link voltage exceeds the limit.

810DC under volt

XX–

DC-link voltage drops below voltage warning low-limit.

99Inverter over-

load

XX–

More than 100% load for a long time.

108Motor ETR

over

XX–

Motor is too hot due to more than 100% load for a long

time. See parameter 1-90 Motor Thermal Protection.

117Motor th over

XX–

Thermistor or thermistor connection is disconnected. See

parameter 1-90 Motor Thermal Protection.

135Over current

XXX

Inverter peak current limit is exceeded.

142Earth fault

–XX

Discharge from output phases to ground.

1612Short circuit

–XX

Short circuit in motor or on motor terminals.

174Ctrl. word TO

XX–

No communication to drive. See parameter group 8-0*

General Settings.

2450Fan fault

XX–

The heat sink cooling fan is not working (only on 400 V,

30–90 kW (40–125 hp) units).

3019U phase loss

–XX

Motor phase U is missing. Check the phase. See parameter

4-58 Missing Motor Phase Function.

3120V phase loss

–XX

Motor phase V is missing. Check the phase. See parameter

4-58 Missing Motor Phase Function.

3221W phase loss

–XX

Motor phase W is missing. Check the phase. See parame-

ter 4-58 Missing Motor Phase Function.

3817Internal fault

–XX

Contact the local Danfoss supplier.

4428Earth fault

–XX

Discharge from output phases to ground, using the value

of parameter 15-31 Alarm Log Value if possible.

4633Control volt-

age fault

–XX

Control voltage is low. Contact the local Danfoss supplier.

VLT® HVAC Drive FC 131

Operating Guide

5 Warnings and Alarms

5.1 List of Warnings and Alarms

Table 14: Warnings and Alarms

Warnings and Alarms

AQ367426199594en-000101 / 130R0988 | 41Danfoss A/S © 2021.06

Page 42

Fault

num-

ber

Alarm/

warning

bit num-

ber

Fault text

Warn-

ing

Alarm

Trip

locked

Cause of problem

472324 V supply

low

XXX

24 V DC supply may be overloaded.

5115AMA U

nom

,

I

nom

–X–