Page 1

Design Guide

VLT® Flow Drive FC 111

vlt-drives.danfoss.com

Page 2

Page 3

VLT® Flow Drive FC 111

Design Guide

Contents

1

Introduction 10

1.1

Purpose of this Design Guide 10

Additional Resources 10

1.2

Other Resources 10

1.2.1

1.2.2

MCT 10 Set-up Software Support 10

1.3

Document and Software Version 10

1.4

Regulatory Compliance 10

1.4.1

Introduction 10

1.4.2

CE Mark 10

Safety 12

2

Safety Symbols 12

2.1

Qualified Personnel 12

2.2

Contents

Safety Precautions 12

2.3

Product Overview 14

3

3.1

Advantages 14

3.1.1

Why Use a Drive for Controlling Fans and Pumps? 14

3.1.1.1

3.1.1.2

3.1.1.3

3.1.1.4

3.1.1.5

3.1.1.6

3.1.1.7

3.1.1.8

3.1.1.9

3.1.2

Application Examples 20

3.1.2.1

3.1.2.2

The Clear Advantage - Energy Savings 14

Example of Energy Savings 15

Comparison of Energy Savings 15

Example with Varying Flow over 1 Year 17

Better Control 18

Star/Delta Starter or Soft Starter not Required 18

Using a Drive Saves Money 18

Traditional Fan System without a Drive 19

Fan System Controlled by Drives 20

Variable Air Volume 20

Constant Air Volume 21

3.1.2.3

3.1.2.4

3.1.2.5

3.1.2.6

3.1.3

Check Valve Monitoring 26

3.1.4

Dry Pump Detection 26

3.1.5

End of Curve Detection 26

Cooling Tower Fan 22

Condenser Pumps 23

Primary Pumps 24

Secondary Pumps 25

AJ363928382091en-000101/130R0983 | 3Danfoss A/S © 2021.04

Page 4

VLT® Flow Drive FC 111

Design Guide

3.1.6

3.2

Control Structures 26

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.3

Ambient Running Conditions 30

3.3.1

3.3.2

Contents

Time-based Functions 26

Introduction 26

Control Structure Open Loop 27

PM/EC+ Motor Control 27

Local (Hand On) and Remote (Auto On) Control 27

Control Structure Closed Loop 28

Feedback Conversion 28

Reference Handling 28

Tuning the Drive Closed-loop 29

Adjusting the Manual PI 29

Air Humidity 30

Acoustic Noise or Vibration 30

3.3.2.1

3.3.2.2

3.3.3

Aggressive Environments 31

3.4

General Aspects of EMC 31

3.4.1

Overview of EMC Emissions 31

3.4.2

Emission Requirements 32

3.4.3

EMC Emission Test Results 33

3.4.4

Harmonics Emission 34

3.4.4.1

3.4.4.2

3.4.5

Harmonics Emission Requirements 34

3.4.6

Harmonics Test Results (Emission) 36

3.4.7

Immunity Requirements 37

3.5

Galvanic Isolation (PELV) 37

3.6

Ground Leakage Current 38

3.6.1

Using a Residual Current Device (RCD) 40

Acoustic Noise 30

Vibration and Shock 31

Harmonics Emission Requirements 34

Harmonics Test Results (Emission) 35

3.7

Extreme Running Conditions 41

3.7.1

Introduction 41

3.7.2

Motor Thermal Protection (ETR) 42

3.7.3

Thermistor Inputs 42

3.7.3.1

3.7.3.2

Example with Digital Input and 10 V Power Supply 43

Example with Analog Input and 10 V Power Supply 43

AJ363928382091en-000101/130R09834 | Danfoss A/S © 2021.04

Page 5

VLT® Flow Drive FC 111

Design Guide

4

Selection and Ordering 45

Type Code 45

4.1

4.2

Options and Accessories 46

Local Control Panel (LCP) 46

4.2.1

4.2.2

IP21 Enclosure Kit 46

4.2.3

Decoupling Plate 48

4.3

Ordering Numbers 49

4.3.1

Options and Accessories 49

4.3.2

Harmonic Filters 50

4.3.3

External RFI Filter 51

5

Mechanical Installation Considerations 53

5.1

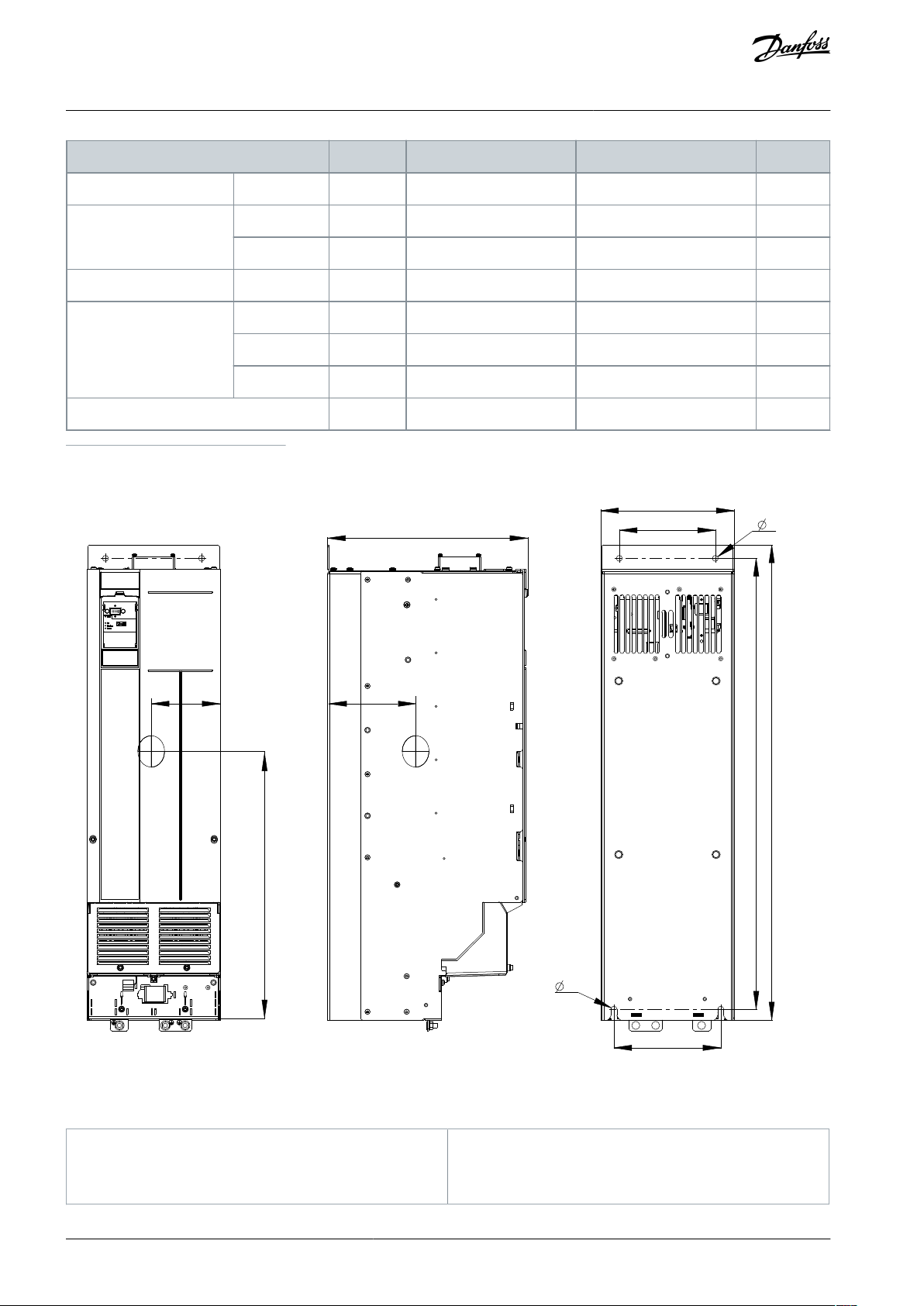

Power Ratings, Weights, and Dimensions 53

5.2

Mechanical Installation H1-H8 55

5.2.1

Side-by-side Installation 55

Contents

5.3

Mechanical Installation H13-H14 56

5.3.1

Tools Needed 56

5.3.2

Installation and Cooling Requirements 56

5.3.3

Lifting the Drive 57

5.3.4

Wall Mounting the Drive 58

5.3.5

Creating Cable Openings 59

5.3.6

Back-channel Cooling 59

5.4

Derating 60

5.4.1

Manual Derating and Automatic Derating 60

5.4.2

Derating for Low-speed Operation 60

5.4.3

Derating for Low Air Pressure and High Altitudes 60

5.4.4

Derating for Ambient Temperature and Switching Frequency 60

6

Electrical Installation Considerations 63

6.1

Safety Instructions 63

6.2

Electrical Wiring 64

6.3

EMC-compliant Electrical Installation 64

6.4

Relays and Terminals 66

6.4.1

Relays and Terminals on Enclosure Sizes H1–H5 66

6.4.2

Relays and Terminals on Enclosure Size H6 67

6.4.3

Relays and Terminals on Enclosure Size H7 67

6.4.4

Relays and Terminals on Enclosure Size H8 68

6.4.5

Relays and Terminals on Enclosure Size H13–H14 69

6.5

View of Control Shelf 69

AJ363928382091en-000101/130R0983 | 5Danfoss A/S © 2021.04

Page 6

VLT® Flow Drive FC 111

Design Guide

6.6

Fastener Tightening Torques 70

6.7

IT Mains 71

6.8

Mains and Motor Connection 72

6.8.1

6.8.2

6.8.3

6.8.4

6.9

Fuses and Circuit Breakers 73

6.9.1

6.9.2

6.9.3

6.9.4

6.9.5

6.10

Control Terminals 75

Contents

Introduction 72

Connecting to the Ground 72

Connecting the Motor 73

Connecting the AC Mains 73

Branch Circuit Protection 73

Short-circuit Protection 73

Overcurrent Protection 74

CE Compliance 74

Recommendation of Fuses and Circuit Breakers 74

6.11

Efficiency 76

6.11.1

Efficiency of the Drive 76

6.11.2

Efficiency of the Motor 77

6.11.3

Efficiency of the System 77

6.12

dU/dt Conditions 77

6.12.1

dU/dt Overview 77

6.12.2

dU/dt Test Results for H1–H8 77

6.12.3

High-power Range 80

6.12.4

dU/dt Test Results for H13–H14 80

7

Programming 81

7.1

Local Control Panel (LCP) 81

7.2

Menus 82

7.2.1

Status Menu 82

7.2.2

Quick Menu 82

7.2.2.1

7.2.2.2

Quick Menu Introduction 82

Setup Wizard Introduction 83

7.2.2.3

7.2.2.4

7.2.2.5

7.2.2.6

7.2.2.7

7.2.2.8

7.2.3

Main Menu 98

Setup Wizard for Open-loop Applications 84

Setup Wizard for Closed-loop Applications 89

Motor Setup 94

Changes Made Function 97

Changing Parameter Settings 98

Accessing All Parameters via the Main Menu 98

AJ363928382091en-000101/130R09836 | Danfoss A/S © 2021.04

Page 7

VLT® Flow Drive FC 111

Design Guide

7.3

Quick Transfer of Parameter Settings between Multiple Drives 98

7.3.1

Transferring Data from the Drive to the LCP 98

7.3.2

Transferring Data from the LCP to the Drive 98

7.4

Readout and Programming of Indexed Parameters 99

7.5

Initialization to Default Settings 99

7.5.1

Recommended Initialization 99

7.5.2

Two-finger Initialization 99

8

RS485 Installation and Set-up 101

8.1

RS485 101

8.1.1

Overview 101

8.1.2

Connecting the Drive to the RS485 Network 102

8.1.3

Hardware Set-up 102

8.1.4

Parameter Settings for Modbus Communication 103

8.1.5

EMC Precautions 103

Contents

8.2

FC Protocol 104

8.2.1

Overview 104

8.2.2

FC with Modbus RTU 104

8.3

Network Configuration 105

8.4

FC Protocol Message Framing Structure 105

8.4.1

Content of a Character (byte) 105

8.4.2

Telegram Structure 105

8.4.3

Telegram Length (LGE) 105

8.4.4

Drive Address (ADR) 106

8.4.5

Data Control Byte (BCC) 106

8.4.6

The Data Field 106

8.4.7

The PKE Field 107

8.4.8

Parameter Number (PNU) 108

8.4.9

Index (IND) 108

8.4.10

Parameter Value (PWE) 108

8.4.11

Data Types Supported by the Drive 109

8.4.12

Conversion 109

8.4.13

Process Words (PCD) 110

8.5

Examples 110

8.5.1

Writing a Parameter Value 110

8.5.2

Reading a Parameter Value 110

8.6

Modbus RTU 111

8.6.1

Prerequisite Knowledge 111

AJ363928382091en-000101/130R0983 | 7Danfoss A/S © 2021.04

Page 8

VLT® Flow Drive FC 111

Design Guide

8.6.2

8.6.3

8.7

Network Configuration 112

8.8

Modbus RTU Message Framing Structure 112

8.8.1

8.8.2

8.8.3

8.8.4

8.8.5

8.8.6

8.8.7

8.8.8

Contents

Modbus RTU Overview 111

Drive with Modbus RTU 111

Modbus RTU Message Byte Format 112

Modbus RTU Telegram Structure 113

Start/Stop Field 113

Address Field 113

Function Field 113

Data Field 113

CRC Check Field 113

Coil Register Addressing 114

8.8.8.1

8.8.8.2

Introduction 114

Coil Register 114

8.8.8.3

8.8.8.4

8.8.8.5

8.8.9

Access via PCD Write/read 116

8.8.10

How to Control the Drive 117

8.8.10.1

8.8.10.2

8.8.10.3

8.9

How to Access Parameters 118

8.9.1

Parameter Handling 118

8.9.2

Storage of Data 118

8.9.3

IND (Index) 119

8.9.4

Text Blocks 119

8.9.5

Conversion Factor 119

8.9.6

Parameter Values 119

8.10

Examples 119

Drive Control Word (FC Profile) 114

Drive Status Word (FC Profile) 115

Address/Registers 115

Introduction 117

Function Codes Supported by Modbus RTU 117

Modbus Exception Codes 118

8.10.1

Introduction 119

8.10.2

Read Coil Status (01 hex) 119

8.10.3

Force/Write Single Coil (05 hex) 120

8.10.4

Force/Write Multiple Coils (0F hex) 121

8.10.5

Read Holding Registers (03 hex) 122

8.10.6

Preset Single Register (06 hex) 122

8.10.7

Preset Multiple Registers (10 hex) 123

8.10.8

Read/Write Multiple Registers (17 hex) 124

AJ363928382091en-000101/130R09838 | Danfoss A/S © 2021.04

Page 9

VLT® Flow Drive FC 111

Design Guide

8.11

Danfoss FC Control Profile 125

8.11.1

Control Word According to FC Profile (8-10 Protocol = FC Profile) 125

8.11.2

Explanation of Each Control Bit 126

8.11.3

Status Word According to FC Profile (STW) 128

8.11.4

Explanation of Each Status Bit 128

8.11.5

Bus Speed Reference Value 130

9

General Specifications 131

9.1

Mains Supply 131

9.1.1

3x380–480 V AC 131

9.2

General Technical Data 133

9.2.1

Protection and Features 133

9.2.2

Mains Supply 133

9.2.3

Motor Output (U, V, W) 133

9.2.4

Cable Length and Cross-section 134

Contents

9.2.5

Digital Inputs 134

9.2.6

Analog Inputs 134

9.2.7

Analog Outputs 135

9.2.8

Digital Output 135

9.2.9

RS485 Serial Communication 135

9.2.10

24 V DC Output 135

9.2.11

Relay Output 135

9.2.12

10 V DC Output 136

9.2.13

Ambient Conditions (H1–H8) 136

9.2.14

Ambient Conditions (H13–H14) 137

10

Appendix 138

10.1

Abbreviations 138

10.2

Definitions 139

10.2.1

AC Drive 139

10.2.2

Input 139

10.2.3

Motor 139

10.2.4

References 141

10.2.5

Miscellaneous 141

AJ363928382091en-000101/130R0983 | 9Danfoss A/S © 2021.04

Page 10

Edition

Remarks

Software version

AJ363928382091, version 0101

First edition.

65.00

VLT® Flow Drive FC 111

Design Guide

Introduction

1 Introduction

1.1 Purpose of this Design Guide

This Design Guide is intended for qualified personnel, such as:

•

Project and systems engineers.

•

Design consultants.

•

Application and product specialists.

The Design Guide provides technical information to understand the capabilities of the VLT® Flow Drive FC 111 for integration into

motor control and monitoring systems. Its purpose is to provide design considerations and planning data for integration of the

drive into a system. It caters for selection of drives and options for a diversity of applications and installations. Reviewing the detailed product information in the design stage enables developing a well-conceived system with optimal functionality and efficiency.

This manual is targeted at a worldwide audience. Therefore, wherever occurring, both SI and imperial units are shown.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Other Resources

Other resources are available to understand advanced drive functions and programming.

•

VLT® Flow Drive FC 111 Operating Guide provides basic information on mechanical dimensions, installation, and programming.

•

VLT® Flow Drive FC 111 Programming Guide provides information on how to program, and includes complete parameter descriptions.

•

Danfoss VLT® Energy Box software. Select PC Software Download at

VLT® Energy Box software allows energy consumption comparisons of HVAC fans and pumps driven by Danfoss drives and alternative methods of flow control. Use this tool to accurately project the costs, savings, and payback of using Danfoss drives on HVAC

fans, pumps, and cooling towers.

Supplementary publications and manuals are available from Danfoss website www.danfoss.com.

www.danfoss.com.

1.2.2 MCT 10 Set-up Software Support

Download the software from the service and support section on www.danfoss.com.

During the installation process of the software, enter access code 81462700 to activate the VLT® Flow Drive FC 111 functionality. A

license key is not required for using the VLT® Flow Drive FC 111 functionality.

The latest software does not always contain the latest updates for drives. Contact the local sales office for the latest drive updates (in

the form of *.OSS files).

1.3 Document and Software Version

This guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

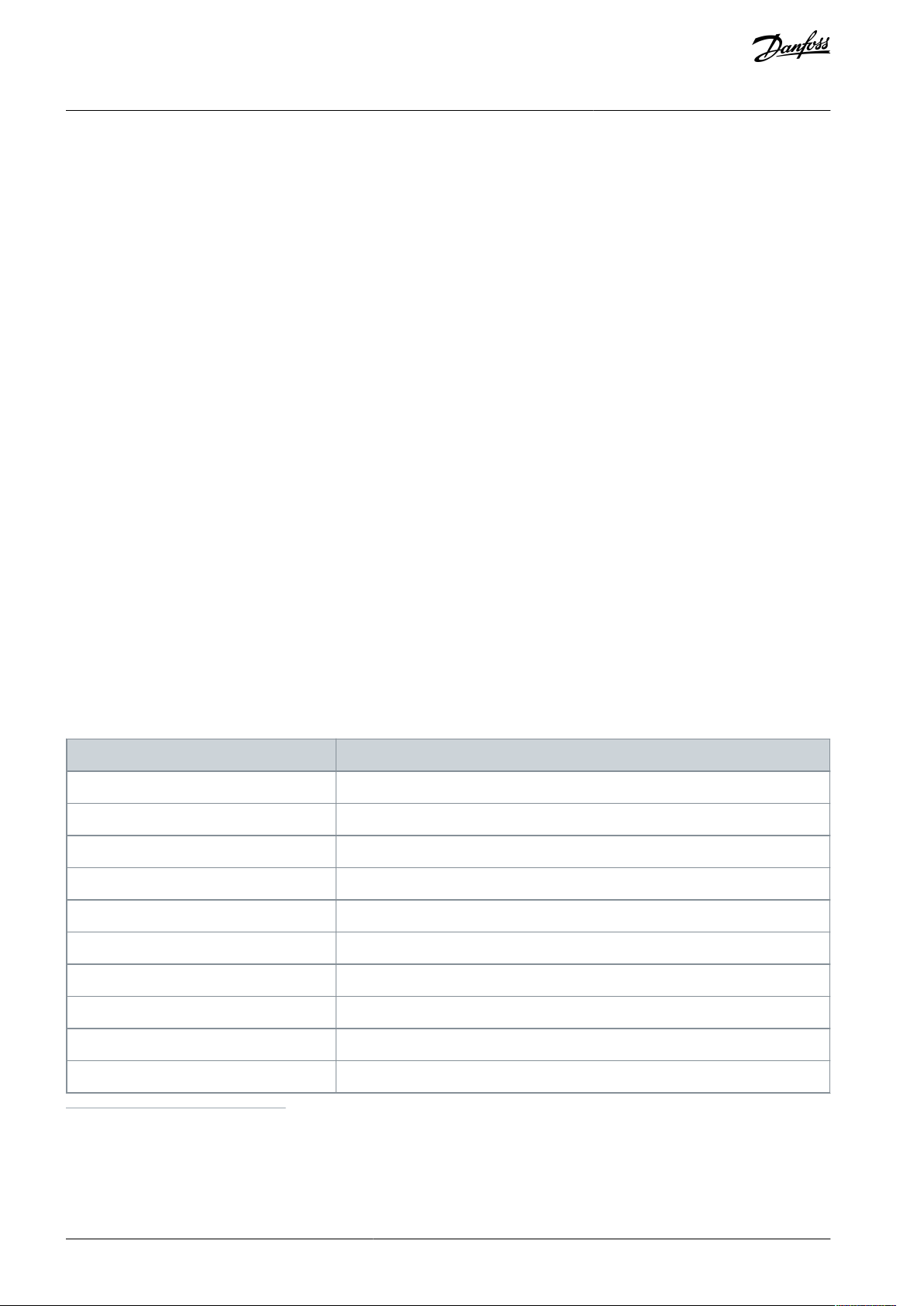

Table 1: Document and Software Version

1.4 Regulatory Compliance

1.4.1 Introduction

AC drives are designed in compliance with the directives described in this section.

1.4.2 CE Mark

The CE mark (Communauté Européenne) indicates that the product manufacturer conforms to all applicable EU directives. The EU

directives applicable to the design and manufacture of drives are listed in the following table.

AJ363928382091en-000101 / 130R098310 | Danfoss A/S © 2021.04

Page 11

EU directive

Version

Low Voltage Directive

2014/35/EU

EMC Directive

2014/30/EU

ErP Directive

VLT® Flow Drive FC 111

Design Guide

Introduction

N O T I C E

The CE mark does not regulate the quality of the product. Technical specifications cannot be deduced from the CE mark.

N O T I C E

Drives with an integrated safety function must comply with the machinery directive.

Table 2: EU Directives Applicable to Drives

Declarations of conformity are available on request.

1.4.2.1 Low Voltage Directive

The aim of the Low Voltage Directive is to protect persons, domestic animals and property against dangers caused by the electrical

equipment, when operating electrical equipment that is installed and maintained correctly, in its intended application. The directive

applies to all electrical equipment in the 50–1000 V AC and the 75–1500 V DC voltage ranges.

1.4.2.2 EMC Directive

The purpose of the EMC (electromagnetic compatibility) Directive is to reduce electromagnetic interference and enhance immunity

of electrical equipment and installations. The basic protection requirement of the EMC Directive states that devices that generate

electromagnetic interference (EMI), or whose operation could be affected by EMI, must be designed to limit the generation of electromagnetic interference and shall have a suitable degree of immunity to EMI when properly installed, maintained, and used as

intended. Electrical equipment devices used alone or as part of a system must bear the CE mark. Systems do not require the CE

mark, but must comply with the basic protection requirements of the EMC Directive.

1.4.2.3 ErP Directive

The ErP Directive is the European Ecodesign Directive for energy-related products. The directive sets ecodesign requirements for

energy-related products, including drives, and aims at reducing the energy consumption and environmental impact of products by

establishing minimum energy-efficiency standards.

AJ363928382091en-000101 / 130R0983 | 11Danfoss A/S © 2021.04

Page 12

VLT® Flow Drive FC 111

Design Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AJ363928382091en-000101 / 130R098312 | Danfoss A/S © 2021.04

Page 13

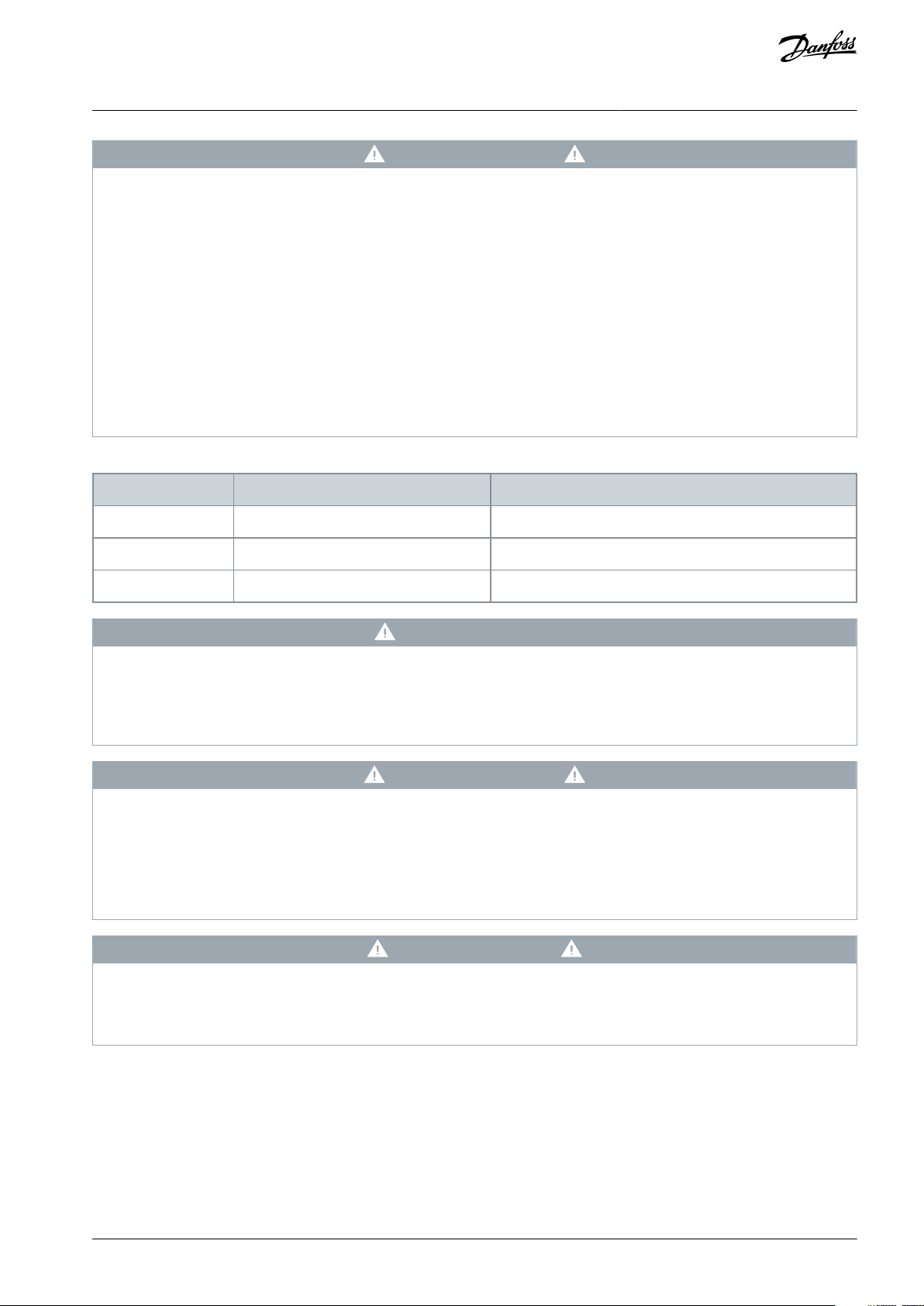

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x400

0.37–7.5 (0.5–10)

4

3x400

11–90 (15–125)

15

3x400

110–315 (150–450)

20

VLT® Flow Drive FC 111

Design Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 3: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AJ363928382091en-000101 / 130R0983 | 13Danfoss A/S © 2021.04

Page 14

e30ba780.11

SYSTEM CURVE

FAN CURVE

PRESSURE%

A

B

C

0

20

40

60

80

100

120

20

40

60 80 100 120 140 160 180

VOLUME%

120

100

80

60

40

20

0

20

40

60

80 100 120 140 160 180

120

100

80

60

40

20

0

20

40

60 80 100 120 140 160 180

Volume %

Volume %

INPUT POWER % PRESSURE %

SYSTEM CURVE

FAN CURVE

A

B

C

e30ba781.11

ENERGY

CONSUMED

VLT® Flow Drive FC 111

Design Guide

Product Overview

3 Product Overview

3.1 Advantages

3.1.1 Why Use a Drive for Controlling Fans and Pumps?

A drive takes advantage of the fact that centrifugal fans and pumps follow the laws of proportionality for such fans and pumps. For

further information, see 3.1.1.2 Example of Energy Savings.

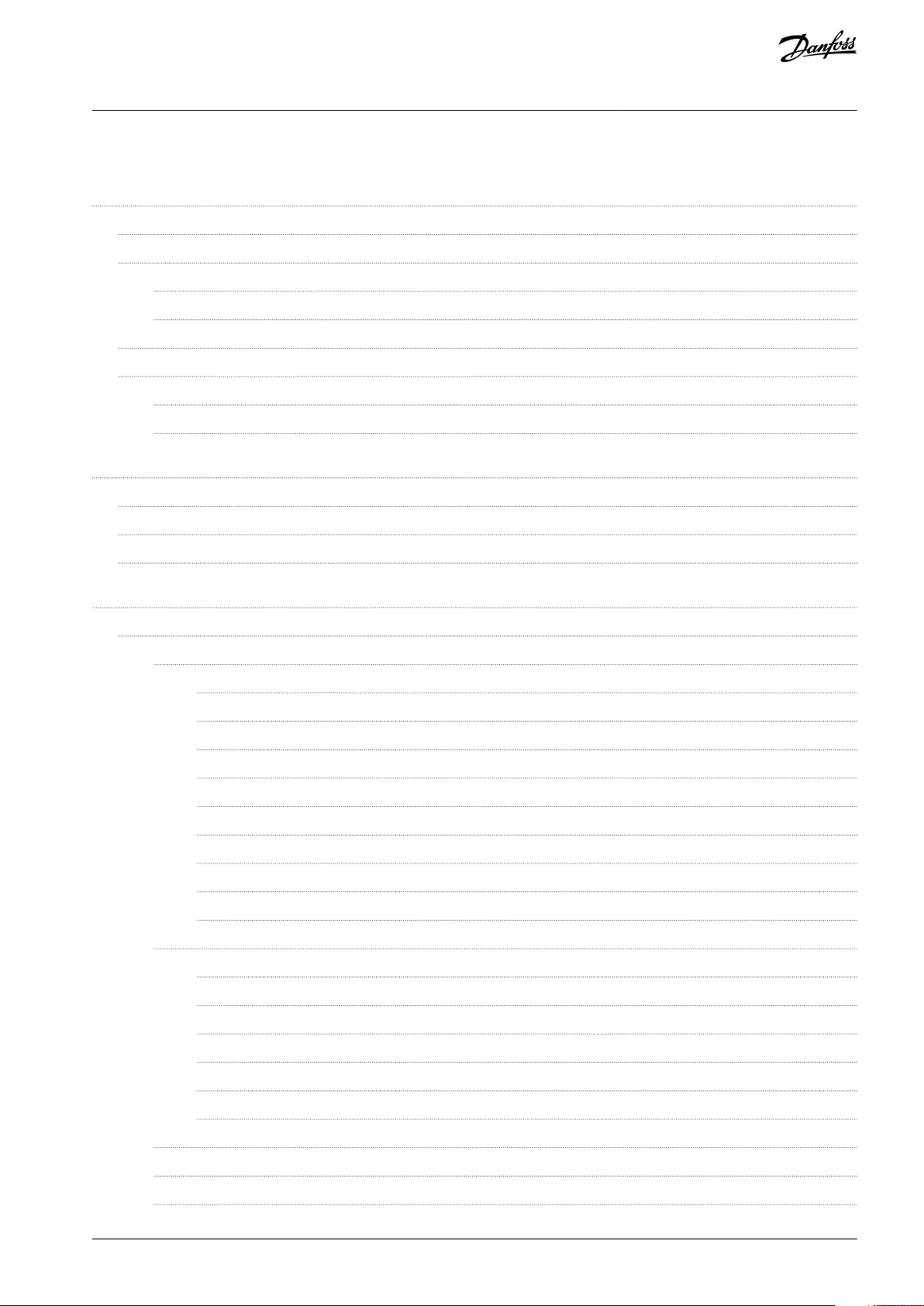

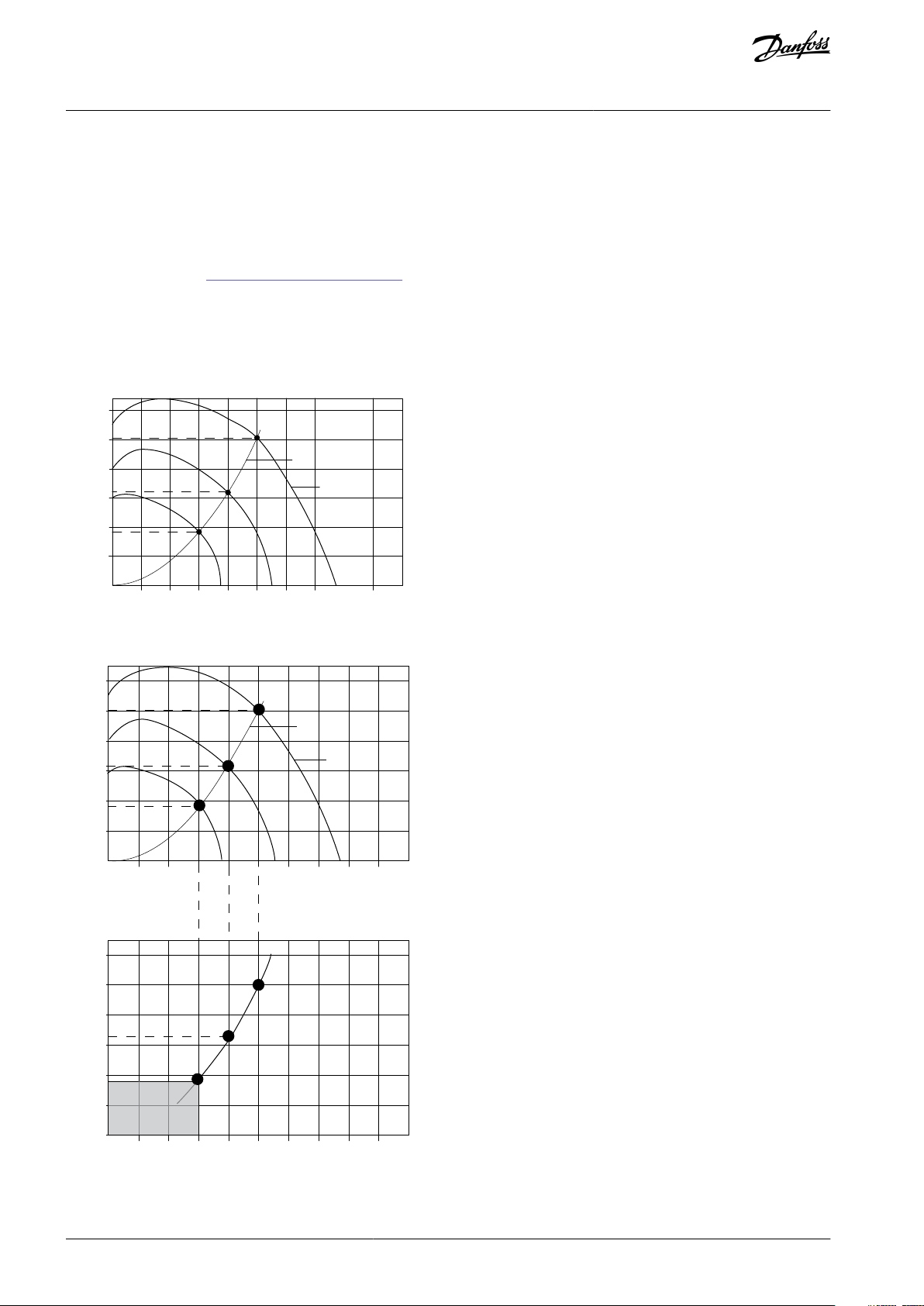

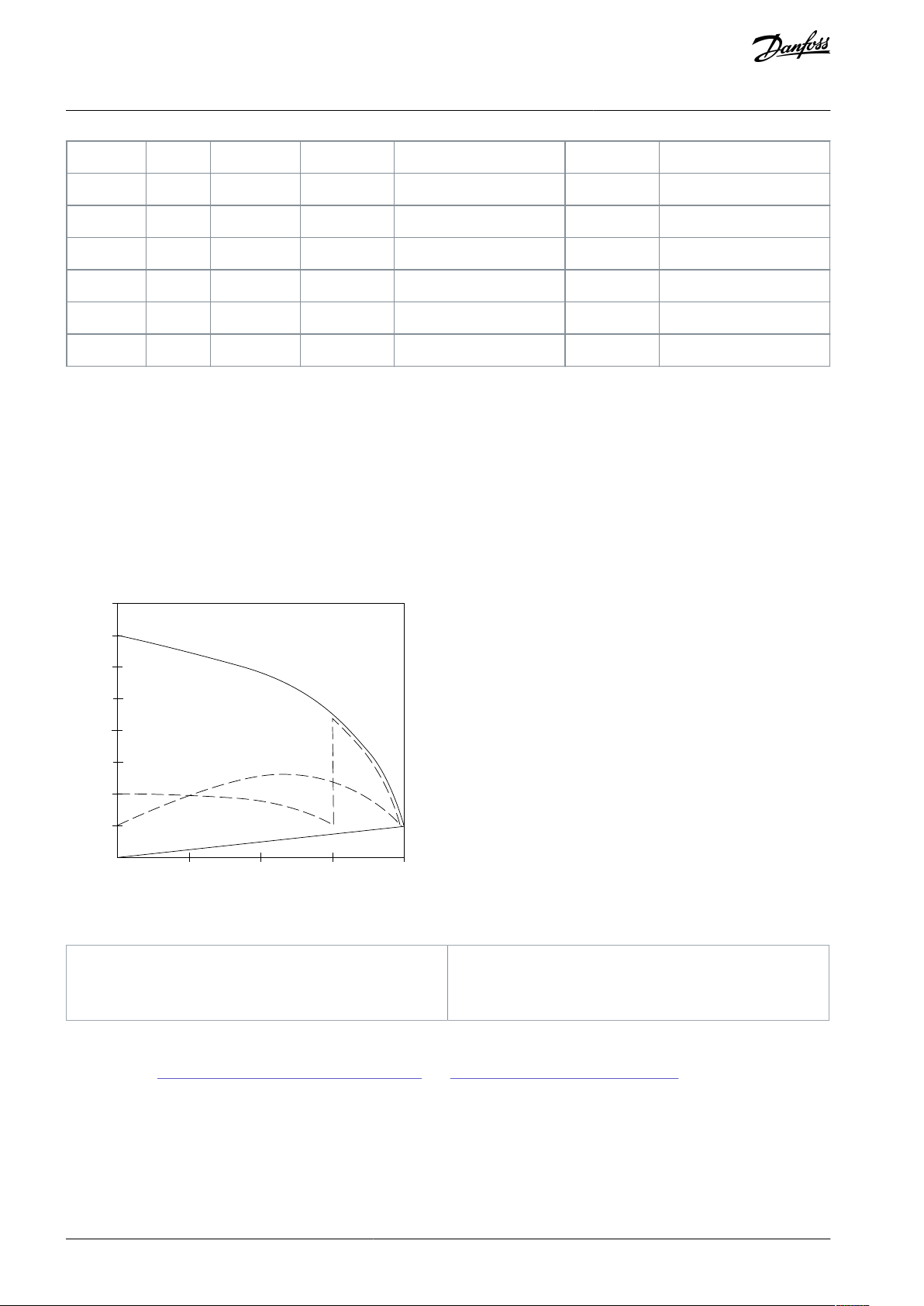

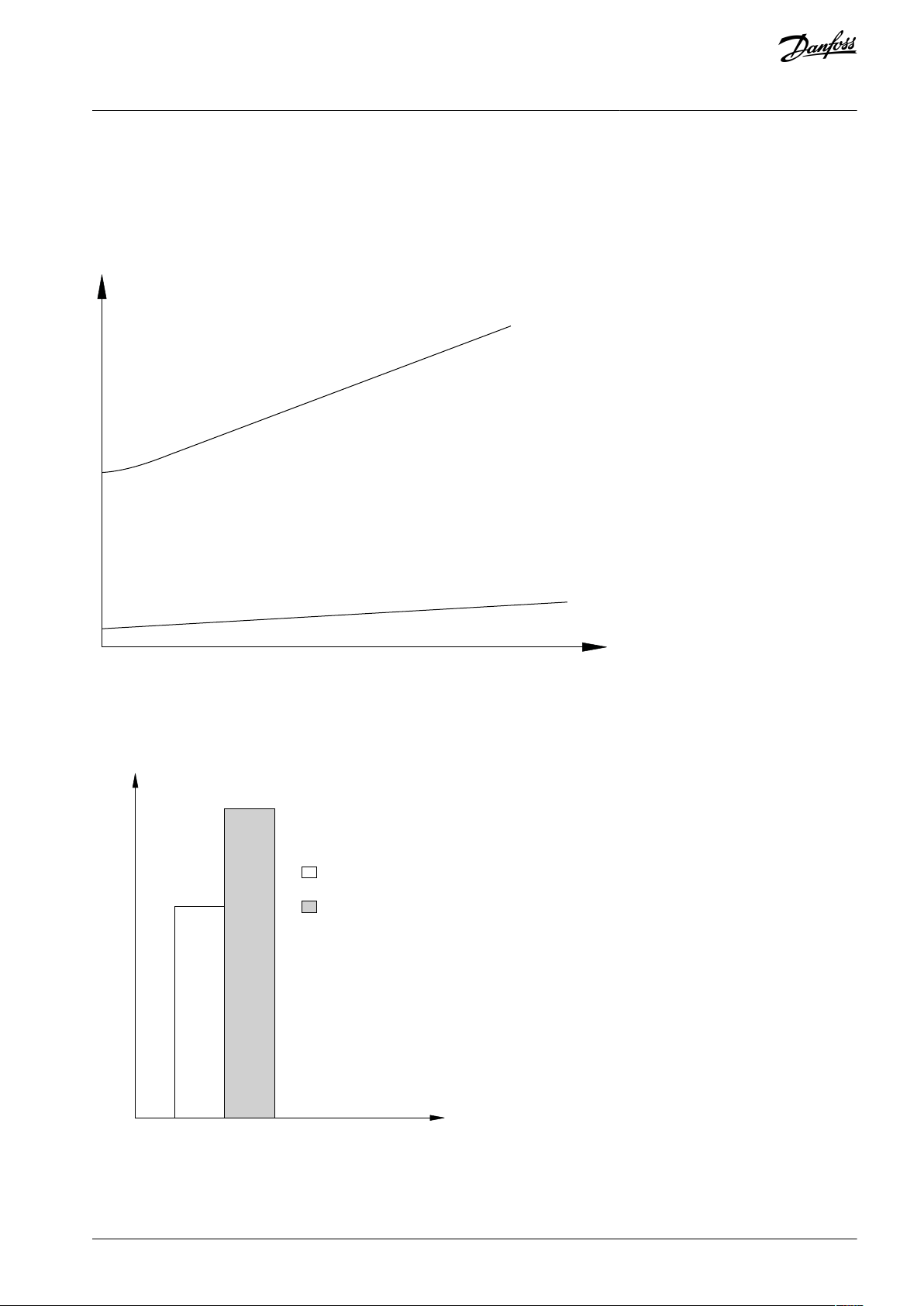

3.1.1.1 The Clear Advantage - Energy Savings

The clear advantage of using a drive for controlling the speed of fans or pumps lies in the electricity savings.

When comparing with alternative control systems and technologies, a drive is the optimum energy control system for controlling

fan and pump systems.

Illustration 1: Fan Curves (A, B, and C) for Reduced Fan Volumes

Illustration 2: Energy Savings with Drive Solution

AJ363928382091en-000101 / 130R098314 | Danfoss A/S © 2021.04

Page 15

n

100%

50%

25%

12,5%

50% 100%

80%

80%

e75ha208.10

P o w er ~n

3

P r essur e ~n

2

Fl o w ~n

Q = Flow

P = Power

Q1 = Rated flow

P1 = Rated power

Q2 = Reduced flow

P2 = Reduced power

H = Pressure

n = Speed control

H1 = Rated pressure

n1 = Rated speed

H2 = Reduced pressure

n2 = Reduced speed

VLT® Flow Drive FC 111

Design Guide

Product Overview

When using a drive to reduce fan capacity to 60% - more than 50% energy savings may be obtained in typical applications.

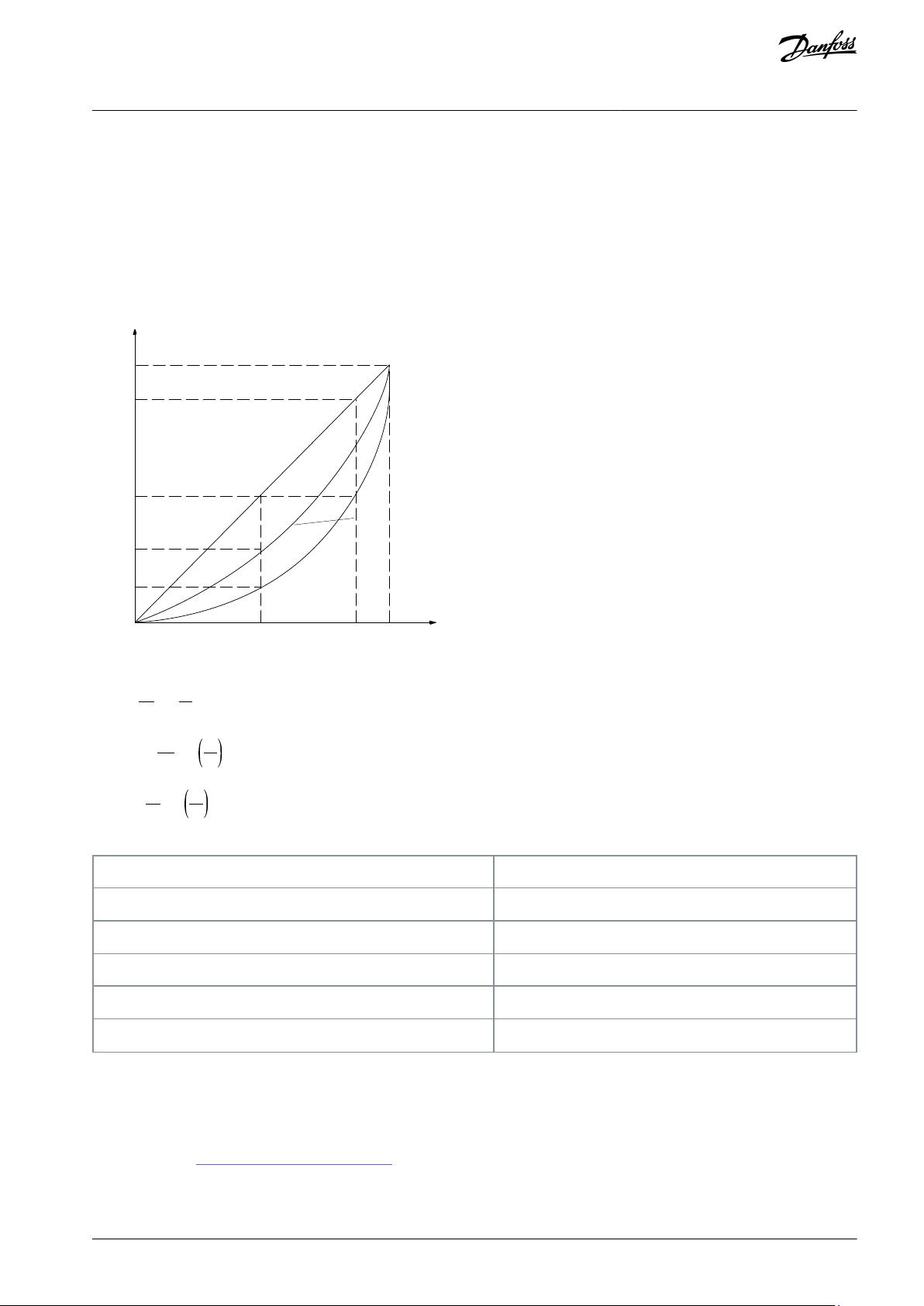

3.1.1.2 Example of Energy Savings

As shown in the following illustration, the flow is controlled by changing the RPM. By reducing the speed by only 20% from the

rated speed, the flow is also reduced by 20%. This is because the flow is directly proportional to the RPM. The consumption of electricity, however, is reduced by 50%.

If the system in question only needs to be able to supply a flow that corresponds to 100% a few days in a year, while the average is

below 80% of the rated flow for the remainder of the year, the amount of energy saved is even more than 50%.

The following illustration describes the dependence of flow, pressure, and power consumption on RPM.

Illustration 3: Laws of Proportionally

Q

n

1

1

Flow:

Pressure:

Power:

Table 4: The Laws of Proportionality

=

Q

n

2

2

H

1

=

H

2

P

1

=

P

2

2

n

1

n

2

3

n

1

n

2

3.1.1.3 Comparison of Energy Savings

The Danfoss drive solution offers major savings compared with traditional energy saving solutions such as discharge damper solution and inlet guide vanes (IGV) solution. This is because the drive is able to control fan speed according to thermal load on the

system, and the drive has a built-in facility that enables the drive to function as a building management system, BMS.

The illustration in 3.1.1.2 Example of Energy Savings shows typical energy savings obtainable with 3 well-known solutions when fan

volume is reduced to 60%. As the graph shows, more than 50% energy savings can be achieved in typical applications.

AJ363928382091en-000101 / 130R0983 | 15Danfoss A/S © 2021.04

Page 16

e30ba782.10

1

2

3

4

5

1

Discharge damper

2

Less energy savings

3

Maximum energy savings

4

IGV5Costlier installation

e30ba779.12

0 60 0 60 0 60

0

20

40

60

80

100

Discharge Damper Solution

IGV Solution

VLT Solution

Energy consumed

Energy consumed

Energy consumed

Input power %

Volume %

VLT® Flow Drive FC 111

Design Guide

Product Overview

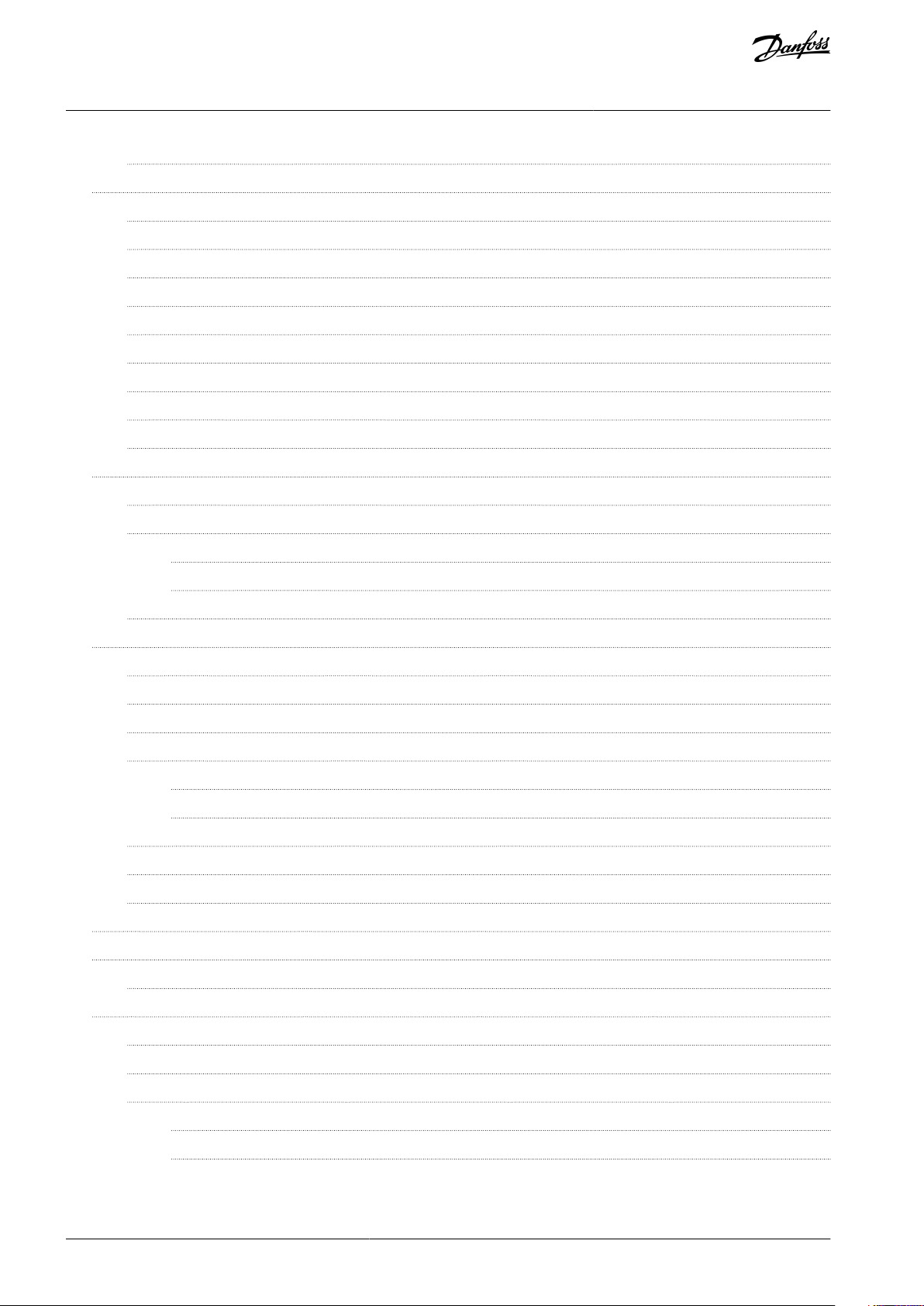

Illustration 4: The 3 Common Energy Saving Systems

Illustration 5: Energy Savings

Discharge dampers reduce power consumption. Inlet guide vanes offer a 40% reduction, but are expensive to install. The Danfoss

drive solution reduces energy consumption with more than 50% and is easy to install. It also reduces noise, mechanical stress, and

wear-and-tear, and extends the life span of the entire application.

AJ363928382091en-000101 / 130R098316 | Danfoss A/S © 2021.04

Page 17

500

[h]

t

1000

1500

2000

200100

300

[m3 /h]

400

Q

e75ha210.11

e75ha209.11

60

50

40

30

20

10

H

s

0

100

200 300 400

(m w g)

B

C

A

750r pm

1050r pm

1350r pm

1650r pm

0

10

20

30

(kW

)

40

50

60

200

100

300 ( m 3 /h )

( m

3

/h )

400

750r

pm

1050r pm

1350r pm

1650r pm

P

shaf

t

C

1

B

1

A

1

m3/h

Distribution

Valve regulation

Drive control

%

Hours

Power

Consumption

Power

Consumption

A1 - B

1

kWh

A1 - C

1

kWh

VLT® Flow Drive FC 111

Design Guide

Product Overview

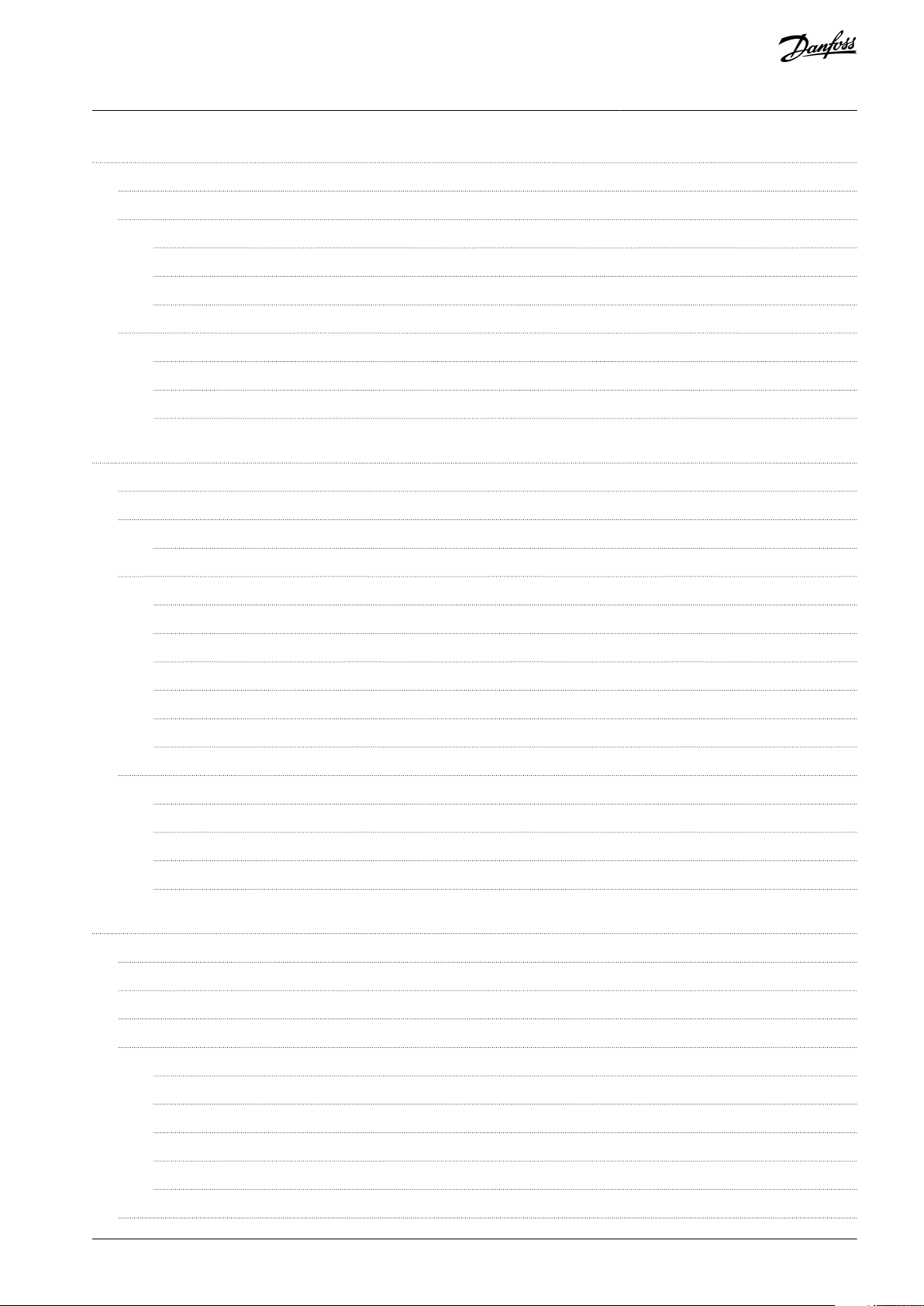

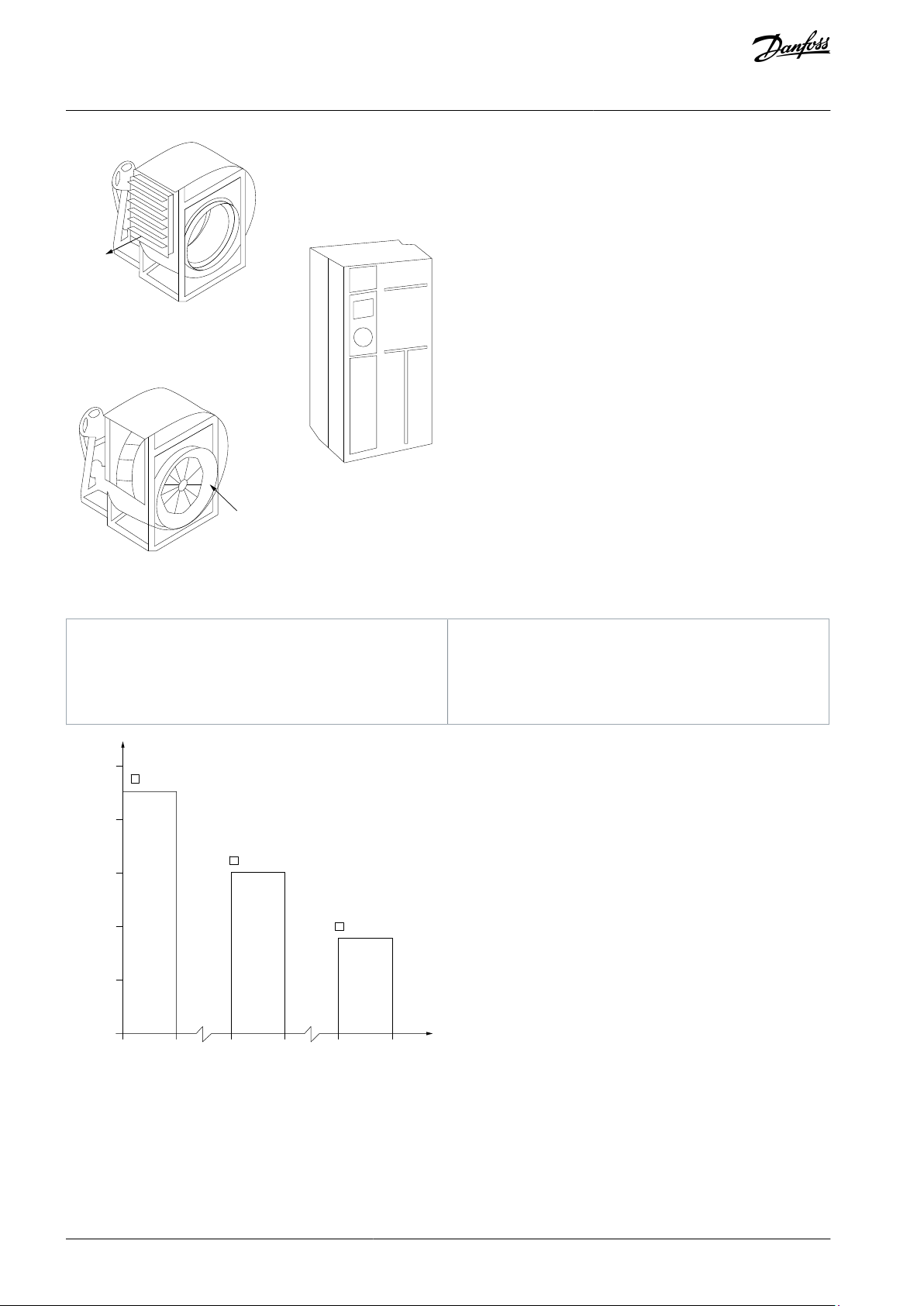

3.1.1.4 Example with Varying Flow over 1 Year

This example is calculated based on pump characteristics obtained from a pump datasheet. The result obtained shows energy savings of more than 50% at the given flow distribution over a year. The payback period depends on the price per kWh and the price of

drive. In this example, it is less than a year when compared with valves and constant speed.

Energy savings

P

= P

shaft

shaft output

Illustration 6: Flow Distribution over 1 Year

Illustration 7: Energy

Table 5: Result

AJ363928382091en-000101 / 130R0983 | 17Danfoss A/S © 2021.04

Page 18

3505438

42.5

18.615

42.5

18.615

300151314

38.5

50.589

29.0

38.106

250201752

35.0

61.320

18.5

32.412

200201752

31.5

55.188

11.5

20.148

150201752

28.0

49.056

6.5

11.388

100201752

23.0

40.296

3.5

6.132

Σ

100

8760–275.064

–

26.801

F ull load

% F ull load cur r en t

& speed

500

100

0

0

12,5 25 37,5 50H z

200

300

400

600

700

800

4

3

2

1

e75ha227.10

1

VLT® Flow Drive FC 111

2

Star/delta starter

3

Soft starter

4

Start directly on mains

VLT® Flow Drive FC 111

Design Guide

Product Overview

3.1.1.5 Better Control

If a drive is used for controlling the flow or pressure of a system, improved control is obtained.

A drive can vary the speed of the fan or pump, obtaining variable control of flow and pressure. Furthermore, a drive can quickly

adapt the speed of the fan or pump to new flow or pressure conditions in the system.

Simple control of process (flow, level, or pressure) utilizing the built-in PI control.

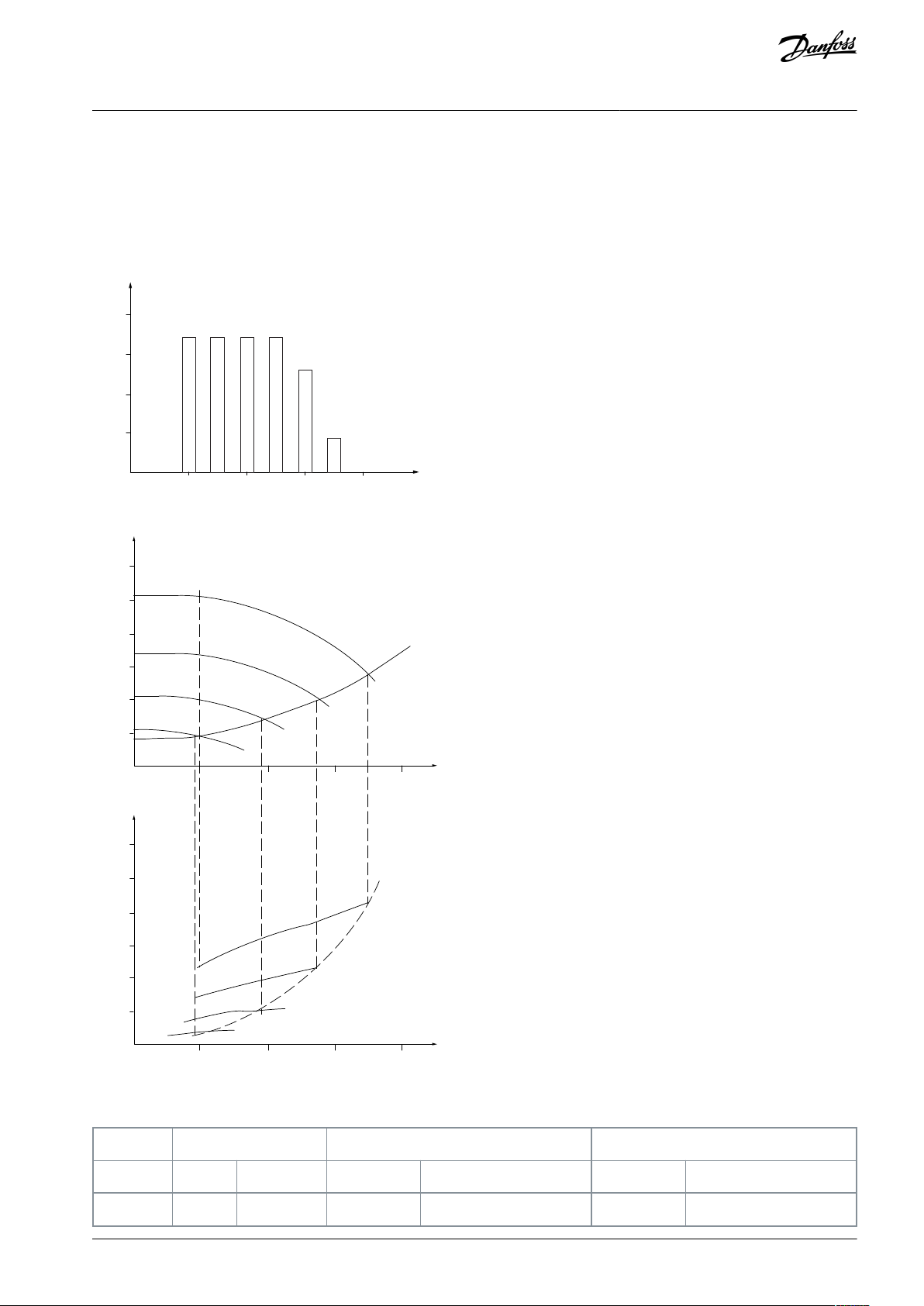

3.1.1.6 Star/Delta Starter or Soft Starter not Required

When larger motors are started, it is necessary in many countries to use equipment that limits the start-up current. In more traditional systems, a star/delta starter or soft starter is widely used. Such motor starters are not required if a drive is used.

As shown in the following illustration, a drive does not consume more than rated current.

Illustration 8: Start-up Current

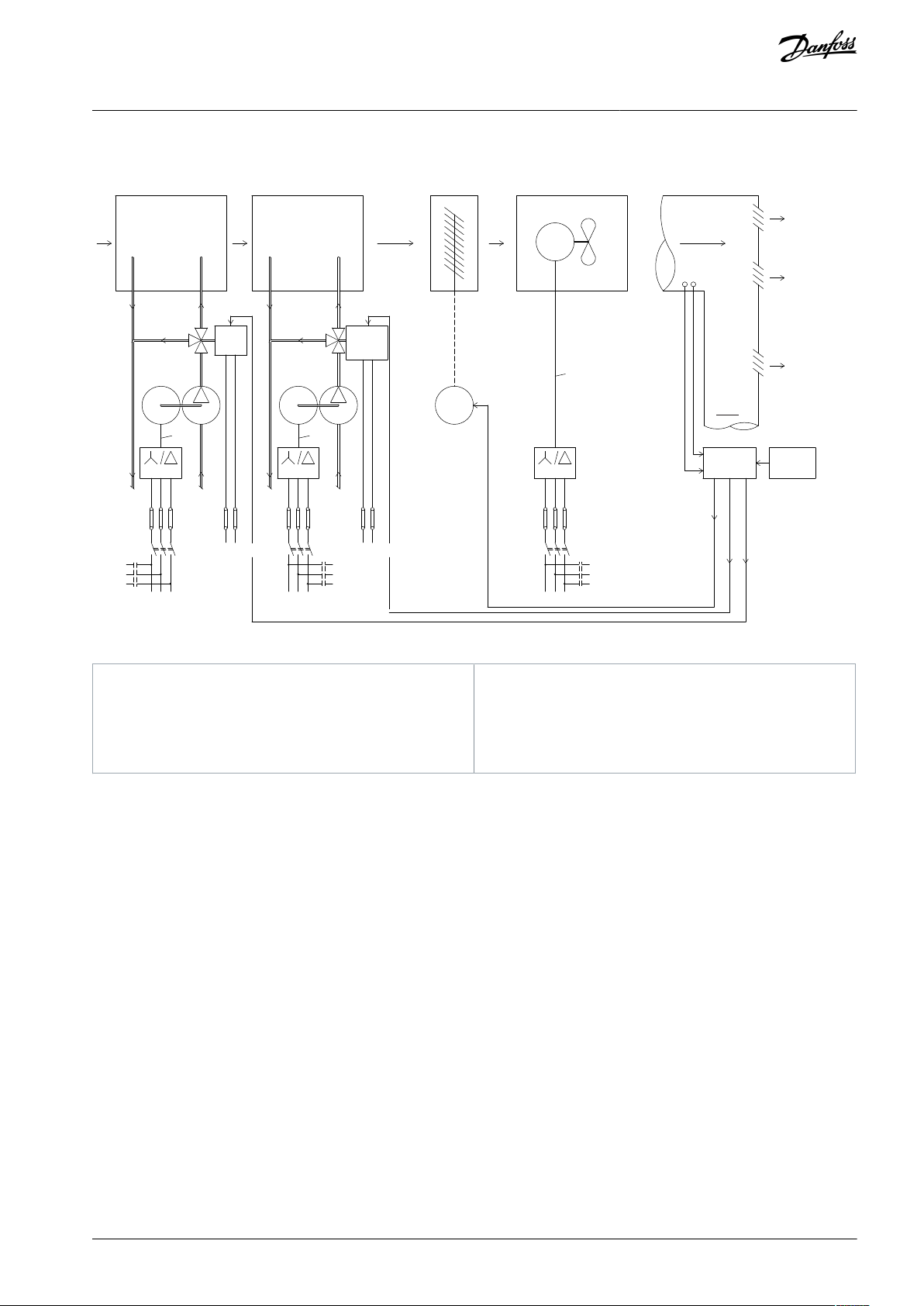

3.1.1.7 Using a Drive Saves Money

The example in 3.1.1.8 Traditional Fan System without a Drive and 3.1.1.9 Fan System Controlled by Drives shows that a drive replaces other equipment. It is possible to calculate the cost of installing the 2 different systems. In the example, the 2 systems can be

established at roughly the same price.

Use the VLT® Energy Box software that is introduced in chapter Additional Resources to calculate the cost savings that can be achieved by using a drive.

AJ363928382091en-000101 / 130R098318 | Danfoss A/S © 2021.04

Page 19

M

- +

M

M

x6 x6

x6

e75ha205.12

Valve

position

Starter

Fuses

LV

supply

P.F.C

Flow

3-Port

valve

Bypass

Return

Control

Supply

air

V.A.V

outlets

Duct

P.F.C

Mains

Fuses

Starter

Bypass

supply

LV

Return

valve

3-Port

Flow

Control

Valve

position

Starter

Power

Factor

Correction

Mains

IGV

Mechanical

linkage

and vanes

Fan

Motor

or

actuator

Main

B.M.S

Local

D.D.C.

control

Sensors

PT

Pressure

control

signal

0/10V

Temperature

control

signal

0/10V

Control

Mains

Cooling section Heating section

Fan sectionInlet guide vane

Pump Pump

D.D.C.

Direct digital control

E.M.S.

Energy management system

V.A.V.

Variable air volume

Sensor

P

Pressure

Sensor

T

Temperature

VLT® Flow Drive FC 111

Design Guide

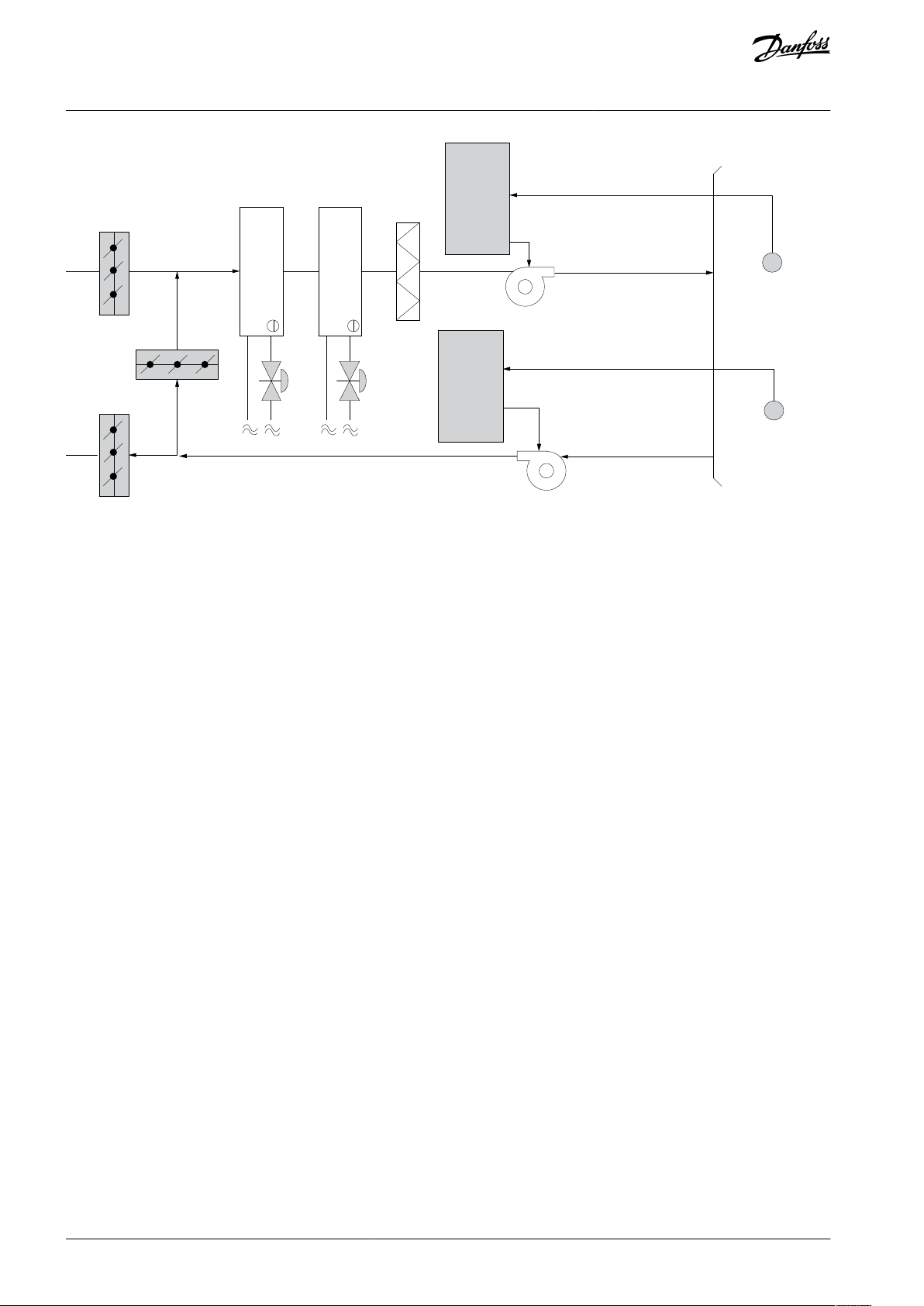

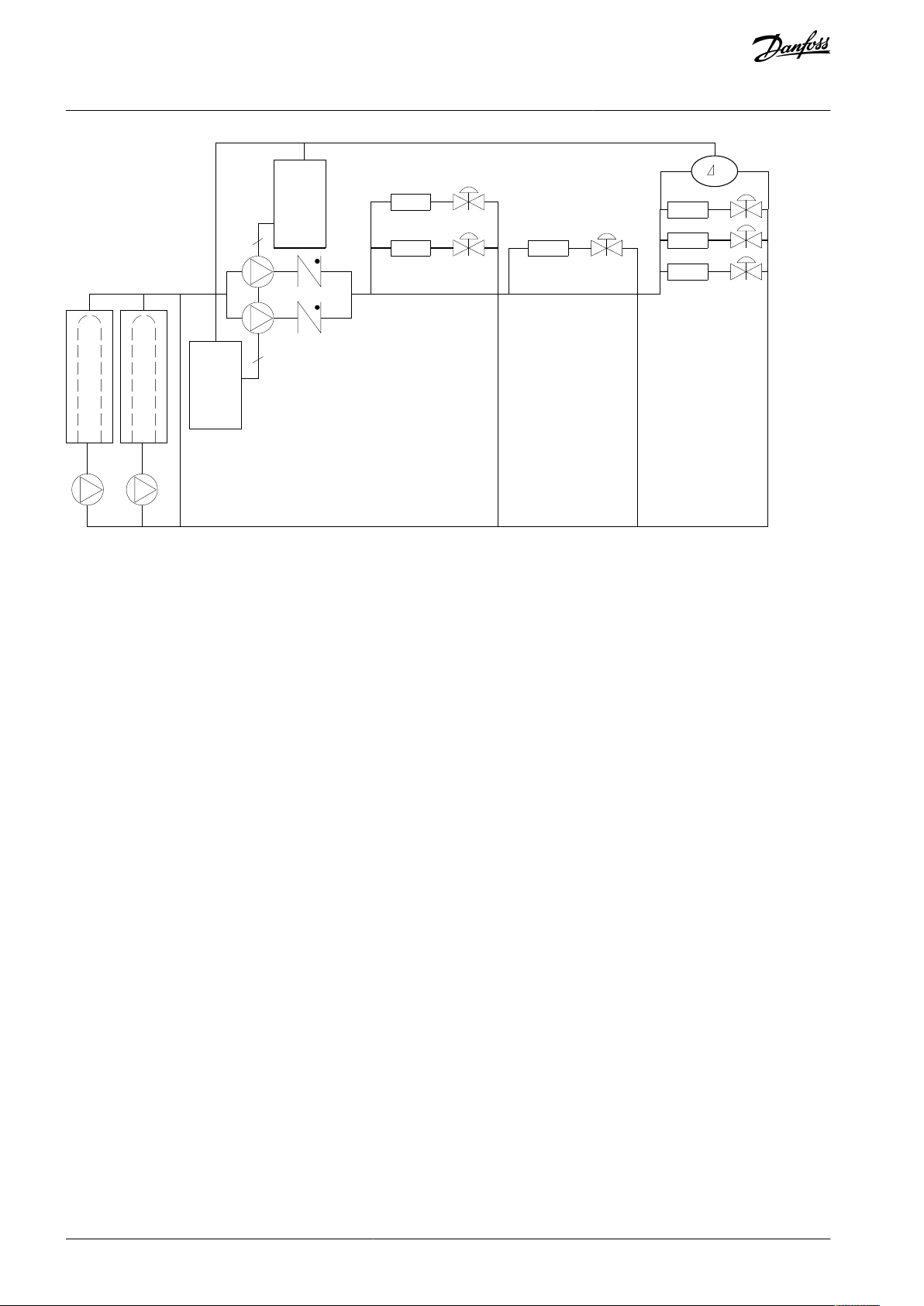

3.1.1.8 Traditional Fan System without a Drive

Product Overview

Illustration 9: Traditional Fan System without a Drive

AJ363928382091en-000101 / 130R0983 | 19Danfoss A/S © 2021.04

Page 20

e75ha206.11

Pump

Flow

Return

Supply

air

V.A.V

outlets

Duct

Mains

Pump

Return

Flow

Mains

Fan

Main

B.M.S

Local

D.D.C.

control

Sensors

Mains

Cooling section

Heating section

Fan section

Pressure

control

0-10V

or

0/4-20mA

Control

temperature

0-10V

or

0/4-20mA

Control

temperature

0-10V

or

0/4-20mA

VLT

M

- +

VLT

M

M

PT

VLT

x3 x3

x3

D.D.C.

Direct digital control

E.M.S.

Energy management system

V.A.V.

Variable air volume

Sensor

P

Pressure

Sensor

T

Temperature

VLT® Flow Drive FC 111

Design Guide

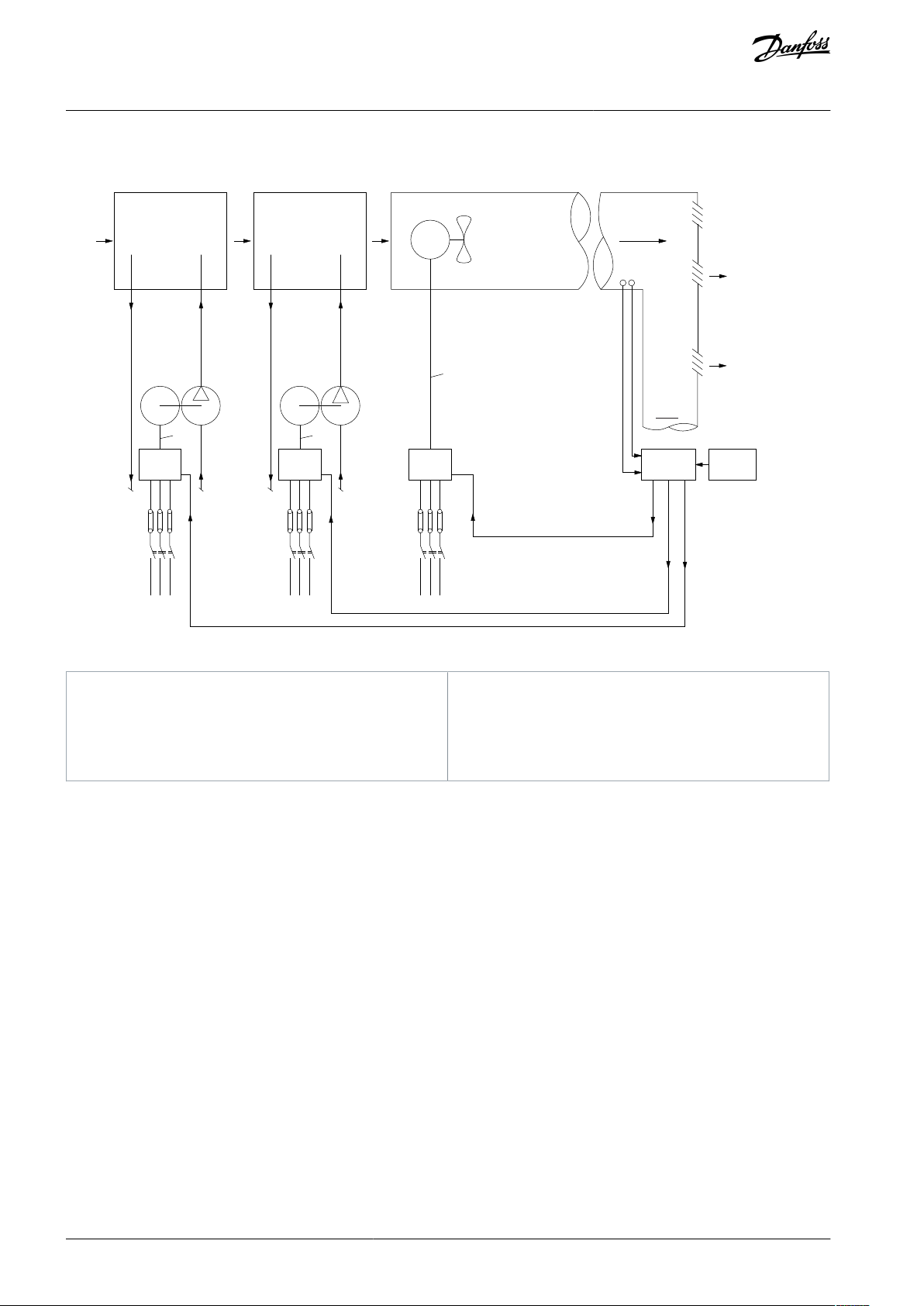

3.1.1.9 Fan System Controlled by Drives

Product Overview

Illustration 10: Fan System Controlled by Drives

3.1.2 Application Examples

The following sections give typical examples of applications.

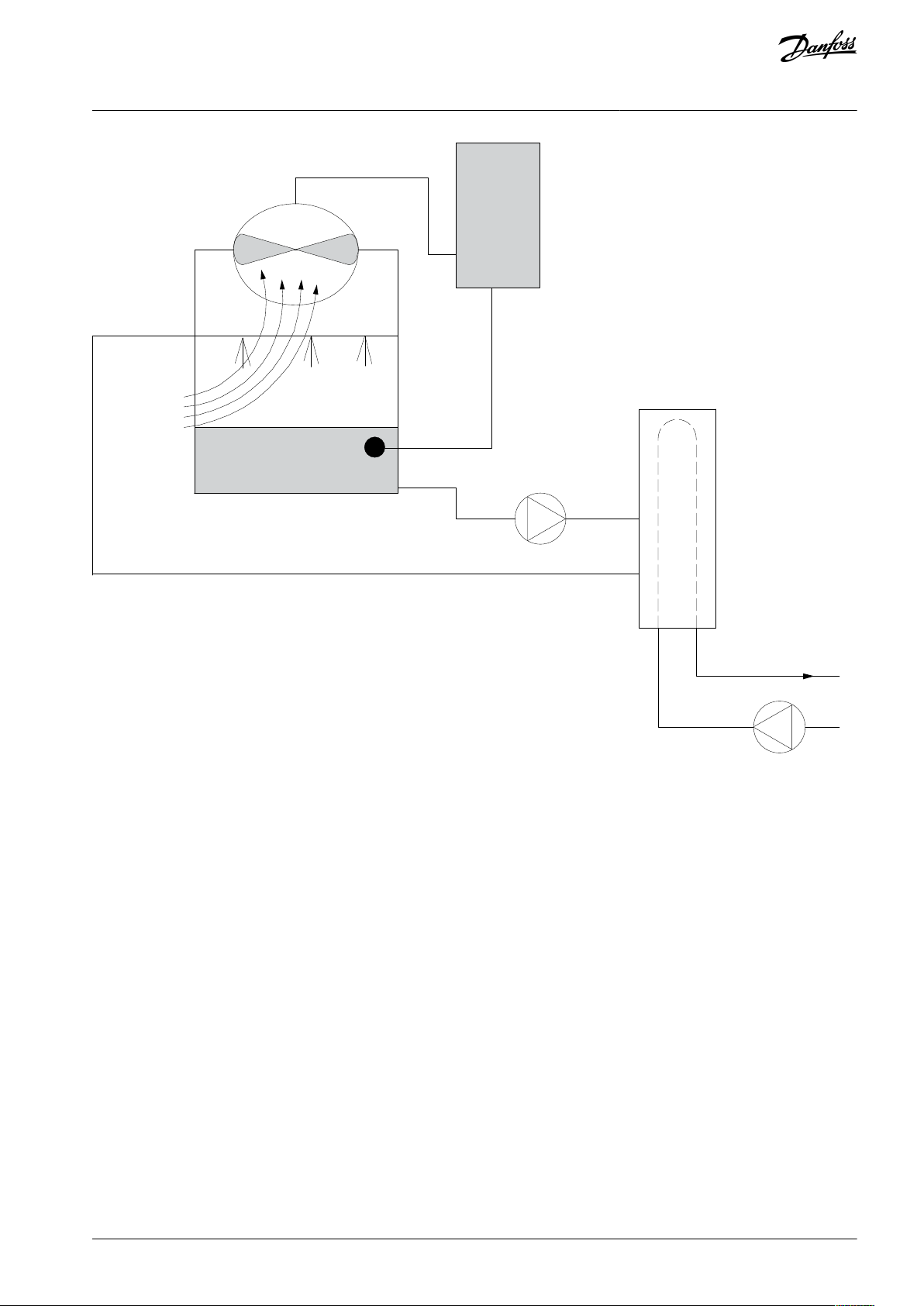

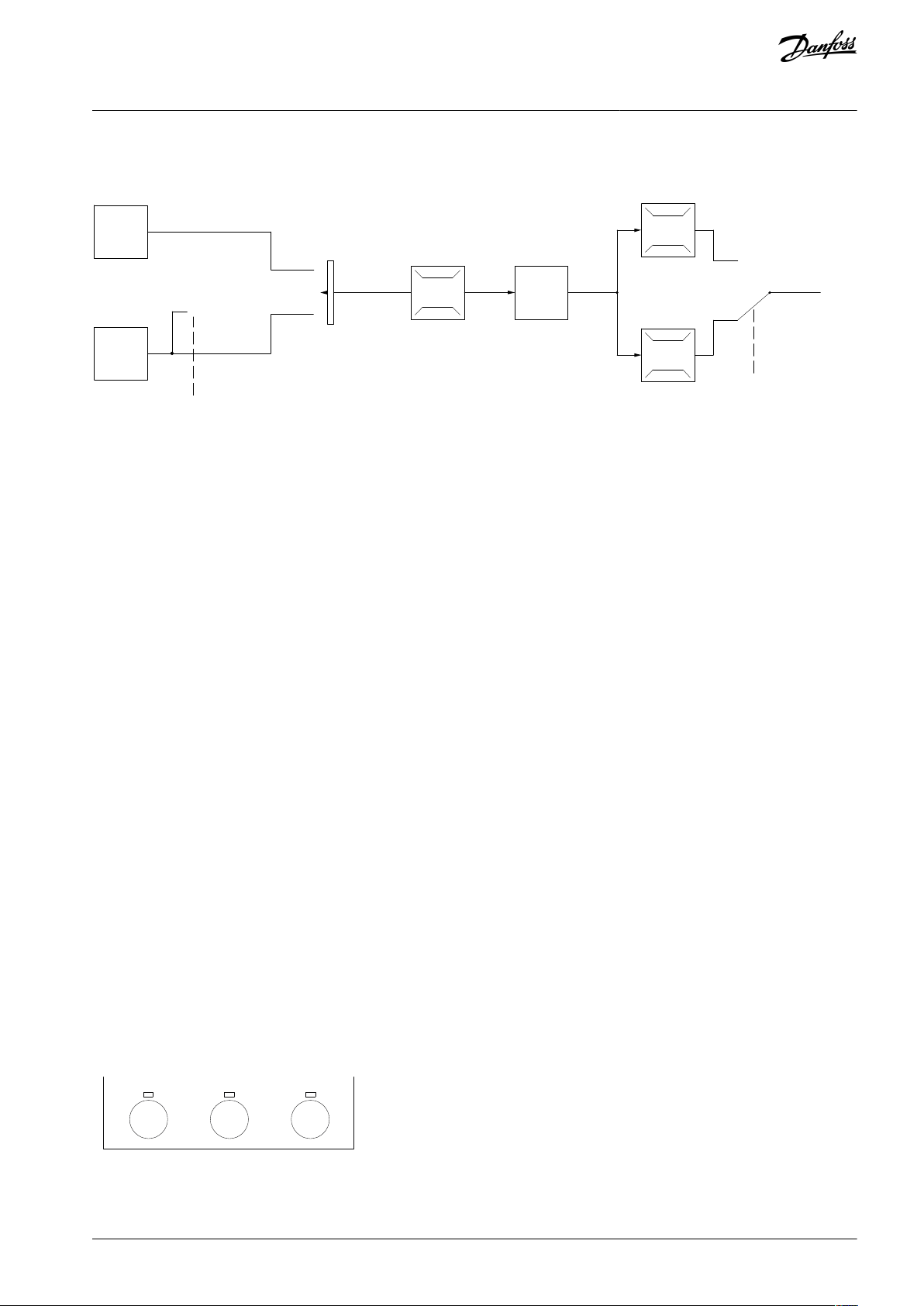

3.1.2.1 Variable Air Volume

VAV or variable air volume systems, control both the ventilation and temperature to satisfy the requirements of a building. Central

VAV systems are considered to be the most energy efficient method to air condition buildings. By designing central systems instead

of distributed systems, a greater efficiency can be obtained.

The efficiency comes from utilizing larger fans and larger chillers which have much higher efficiencies than small motors and distributed air-cooled chillers. Savings are also seen from the decreased maintenance requirements.

The VLT Solution

While dampers and IGVs work to maintain a constant pressure in the ductwork, a drive solution saves much more energy and reduces the complexity of the installation. Instead of creating an artificial pressure drop or causing a decrease in fan efficiency, the

drive decreases the speed of the fan to provide the flow and pressure required by the system.

Centrifugal devices such as fans behave according to the centrifugal laws. This means that the fans decrease the pressure and flow

they produce as their speed is reduced. Their power consumption is thereby significantly reduced. The PI controller of the drive can

be used to eliminate the need for additional controllers.

AJ363928382091en-000101 / 130R098320 | Danfoss A/S © 2021.04

Page 21

D1

D2

D3

C

ooling c oil

Hea ting c oil

F

ilt

er

P r essur e

sig nal

Supply fan

V A V bo x es

Fl o w

Fl o w

P r essur e

tr ansmitt er

R etur n fan

3

3

T

e30bb455.10

Drive

Drive

VLT® Flow Drive FC 111

Design Guide

Illustration 11: Variable Air Volume

Product Overview

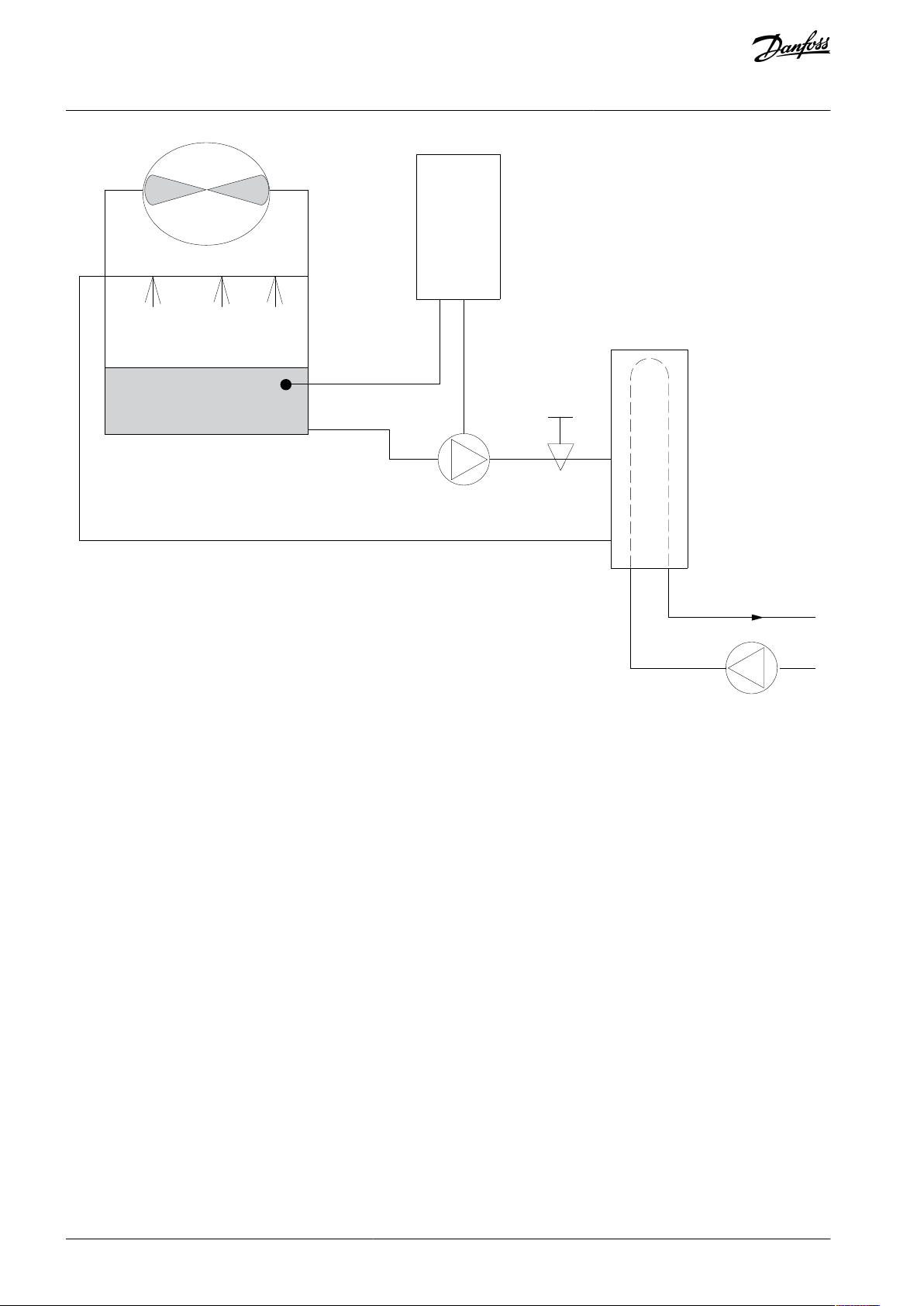

3.1.2.2 Constant Air Volume

CAV, or constant air volume systems, are central ventilation systems usually used to supply large common zones with the minimum

amounts of fresh tempered air. They preceded VAV systems and are therefore found in older multi-zoned commercial buildings as

well. These systems preheat amounts of fresh air utilizing air handling units (AHUs) with a heating coil, and many are also used to air

condition buildings and have a cooling coil. Fan coil units are frequently used to assist in the heating and cooling requirements in

the individual zones.

The VLT Solution

With a drive, significant energy savings can be obtained while maintaining decent control of the building. Temperature sensors or

CO2 sensors can be used as feedback signals to drives. Whether controlling temperature, air quality, or both, a CAV system can be

controlled to operate based on actual building conditions. As the number of people in the controlled area decreases, the need for

fresh air decreases. The CO2 sensor detects lower levels and decreases the supply fans speed. The return fan modulates to maintain

a static pressure setpoint or fixed difference between the supply and return airflows.

With temperature control, especially used in air conditioning systems, as the outside temperature varies as well as the number of

people in the controlled zone changes, different cooling requirements exist. As the temperature decreases below the setpoint, the

supply fan can decrease its speed. The return fan modulates to maintain a static pressure setpoint. By decreasing the air flow, energy used to heat or cool the fresh air is also reduced, adding further savings.

Several features of the Danfoss dedicated drive can be utilized to improve the performance of the CAV system. One concern of

controlling a ventilation system is poor air quality. The programmable minimum frequency can be set to maintain a minimum

amount of supply air regardless of the feedback or reference signal. The drive also includes a PI controller, which allows monitoring

both temperature and air quality. Even if the temperature requirement is fulfilled, the drive maintains enough supply air to satisfy

the air quality sensor. The controller is capable of monitoring and comparing 2 feedback signals to control the return fan by maintaining a fixed differential airflow between the supply and return ducts as well.

AJ363928382091en-000101 / 130R0983 | 21Danfoss A/S © 2021.04

Page 22

P r essur e

sig nal

C ooling c oil

Hea ting c oil

D1

D2

D3

F ilt er

P r essur e

tr ansmitt er

Supply fan

R etur n fan

T emper a tur e

sig nal

T emper a tur e

tr ansmitt er

e30bb451.10

Drive

Drive

VLT® Flow Drive FC 111

Design Guide

Illustration 12: Constant Air Volume

Product Overview

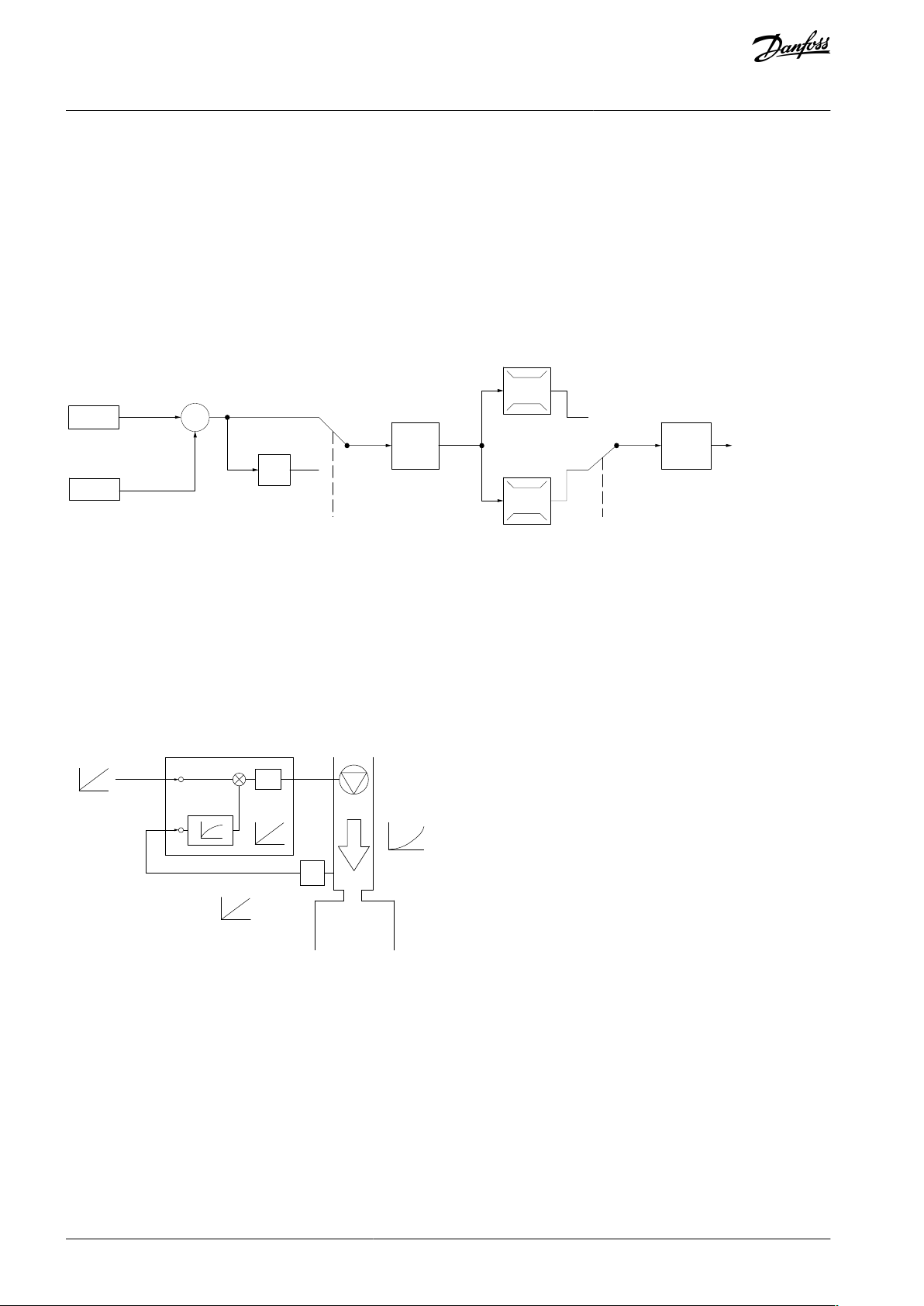

3.1.2.3 Cooling Tower Fan

Cooling tower fans cool condenser-water in water-cooled chiller systems. Water-cooled chillers provide the most efficient means of

creating chilled water. They are as much as 20% more efficient than air cooled chillers. Depending on climate, cooling towers are

often the most energy efficient method of cooling the condenser-water from chillers.

They cool the condenser water by evaporation. The condenser water is sprayed into the cooling tower until the cooling towers fill to

increase its surface area. The tower fan blows air through the fill and sprayed water to aid in the evaporation. Evaporation removes

energy from the water dropping its temperature. The cooled water collects in the cooling towers basin where it is pumped back

into the chillers condenser and the cycle is repeated.

The VLT Solution

With a drive, the cooling towers fans can be controlled to the required speed to maintain the condenser-water temperature. The

drives can also be used to turn the fan on and off as needed.

Several features of the Danfoss dedicated drive can be utilized to improve the performance of cooling tower fans applications. As

the cooling tower fans drop below a certain speed, the effect the fan has on cooling the water becomes small. Also, when utilizing a

gearbox to frequency control the tower fan, a minimum speed of 40–50% is required.

The customer programmable minimum frequency setting is available to maintain this minimum frequency even as the feedback or

speed reference calls for lower speeds.

Also as a standard feature, the drive can be programmed to enter a sleep mode and stop the fan until a higher speed is required.

Additionally, some cooling tower fans have undesirable frequencies that may cause vibrations. These frequencies can easily be avoided by programming the bypass frequency ranges in the drive.

AJ363928382091en-000101 / 130R098322 | Danfoss A/S © 2021.04

Page 23

W a t er I nlet

W a t er Outlet

CHILLER

T emper a tur e

S ensor

BASIN

C onderser

W a t er pump

Supply

e30bb453.10

Drive

VLT® Flow Drive FC 111

Design Guide

Product Overview

Illustration 13: Cooling Tower Fan

3.1.2.4 Condenser Pumps

Condenser water pumps are primarily used to circulate water through the condenser section of water cooled chillers and their associated cooling tower. The condenser water absorbs the heat from the chiller's condenser section and releases it into the atmosphere

in the cooling tower. These systems are used to provide the most efficient means of creating chilled water, they are as much as 20%

more efficient than air cooled chillers.

The VLT Solution

Drives can be added to condenser water pumps instead of balancing the pumps with a throttling valve or trimming the pump impeller.

Using a drive instead of a throttling valve simply saves the energy that would have been absorbed by the valve. This can amount to

savings of 15–20% or more. Trimming the pump impeller is irreversible, thus if the conditions change and higher flow is required

the impeller must be replaced.

AJ363928382091en-000101 / 130R0983 | 23Danfoss A/S © 2021.04

Page 24

Wa t e

r

I

nlet

Wa

t e

r

Outlet

BASIN

F

lo w or pr essur

e sensor

C ondenser

W a t er pump

T hr ottling

v alv e

Supply

CHILLER

e30bb452.10

Drive

VLT® Flow Drive FC 111

Design Guide

Product Overview

Illustration 14: Condenser Pumps

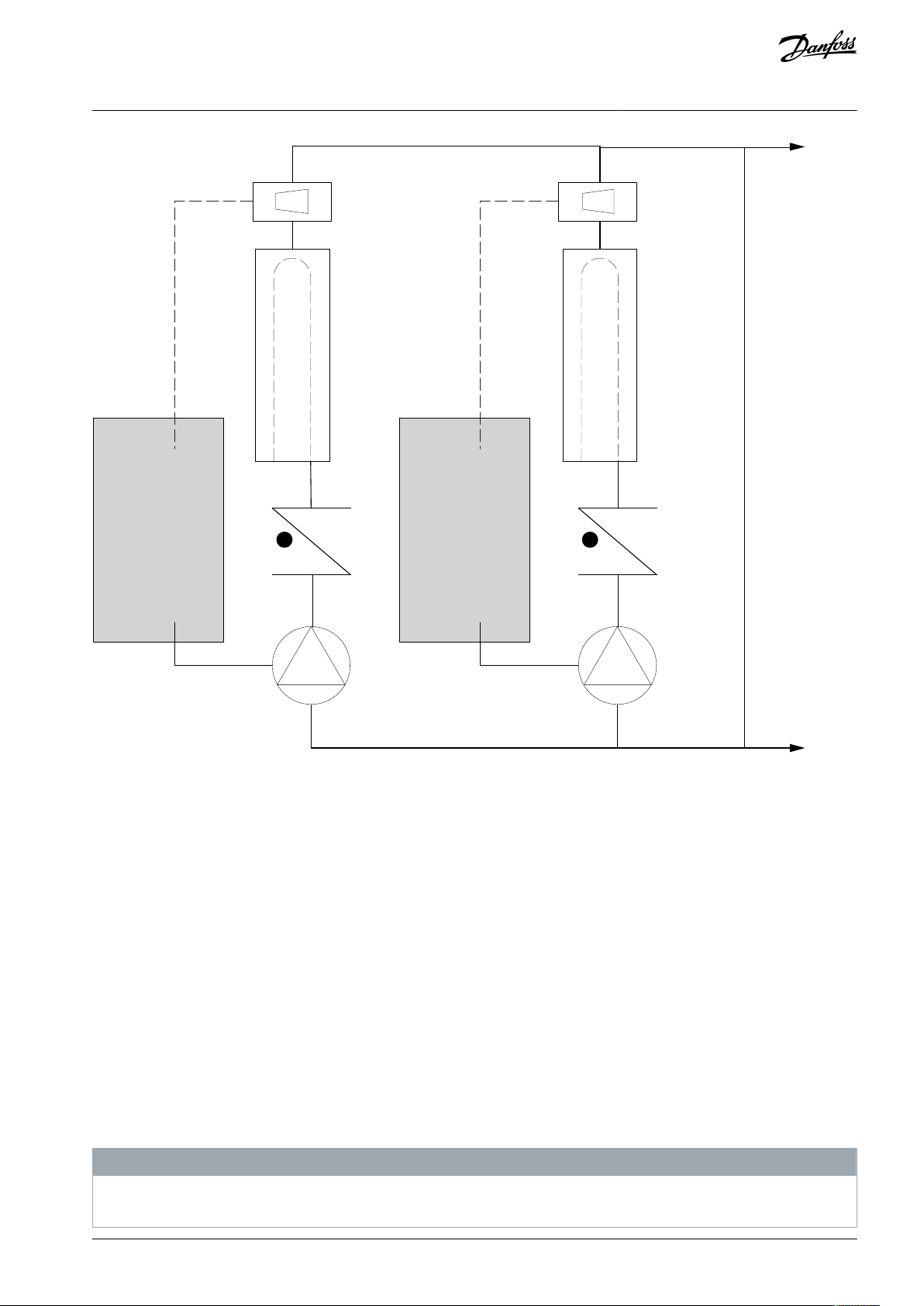

3.1.2.5 Primary Pumps

Primary pumps in a primary/secondary pumping system can be used to maintain a constant flow through devices that encounter

operation or control difficulties when exposed to variable flow. The primary/secondary pumping technique decouples the primary

production loop from the secondary distribution loop. This allows devices such as chillers to obtain constant design flow and operate properly while allowing the rest of the system to vary in flow.

As the evaporator flow rate decreases in a chiller, the chilled water begins to become overchilled. As this happens, the chiller attempts to decrease its cooling capacity. If the flow rate drops far enough, or too quickly, the chiller cannot shed its load sufficiently

and the chiller’s safety trips the chiller requiring a manual reset. This situation is common in large installations especially when 2 or

more chillers in parallel are installed if primary/ secondary pumping is not utilized.

The VLT Solution

Depending on the size of the system and the size of the primary loop, the energy consumption of the primary loop can become

substantial.

A drive can be added to the primary system to replace the throttling valve and/or trimming of the impellers, leading to reduced

operating expenses. 2 control methods are common:

Flow meter

Because the desired flow rate is known and is constant, a flow meter installed at the discharge of each chiller, can be used to control

the pump directly. Using the built-in PI controller, the drive always maintains the appropriate flow rate, even compensating for the

changing resistance in the primary piping loop as chillers and their pumps are staged on and off.

Local speed determination

The operator simply decreases the output frequency until the design flow rate is achieved.

Using a drive to decrease the pump speed is very similar to trimming the pump impeller, except it does not require any labor, and

the pump efficiency remains higher. The balancing contractor simply decreases the speed of the pump until the proper flow rate is

achieved and leaves the speed fixed. The pump operates at this speed any time the chiller is staged on. Because the primary loop

does not have control valves or other devices that can cause the system curve to change, and the variance due to staging pumps

and chillers on and off is usually small, this fixed speed remains appropriate. If the flow rate needs to be increased later in the system’s life, the drive can simply increase the pump speed instead of requiring a new pump impeller.

AJ363928382091en-000101 / 130R098324 | Danfoss A/S © 2021.04

Page 25

CHILLER

CHILLER

F

lo

wmet er

F lo wmet er

F F

e30bb456.10

Drive

Drive

VLT® Flow Drive FC 111

Design Guide

Product Overview

Illustration 15: Primary Pumps

3.1.2.6 Secondary Pumps

Secondary pumps in a primary/secondary chilled water pumping system distribute the chilled water to the loads from the primary

production loop. The primary/secondary pumping system is used to hydronically de-couple 1 piping loop from another. In this case,

the primary pump is used to maintain a constant flow through the chillers while allowing the secondary pumps to vary in flow,

increase control and save energy.

If the primary/secondary concept is not used in the design of a variable volume system when the flow rate drops far enough or too

quickly, the chiller cannot shed its load properly. The chiller’s low evaporator temperature safety then trips the chiller requiring a

manual reset. This situation is common in large installations especially when 2 or more chillers in parallel are installed.

The VLT Solution

While the primary-secondary system with 2-way valves improves energy savings and eases system control problems, the true energy savings and control potential is realized by adding drives.

With the proper sensor location, the addition of drives allows the pumps to vary their speed to follow the system curve instead of

the pump curve. This results in the elimination of wasted energy and eliminates most of the overpressurization that 2-way valves

can be subjected to.

As the monitored loads are reached, the 2-way valves close down. This increases the differential pressure measured across the load

and the 2-way valve. As this differential pressure starts to rise, the pump is slowed to maintain the control head also called setpoint

value. This setpoint value is calculated by summing the pressure drop of the load and the 2-way valve together under design conditions.

N O T I C E

When running multiple pumps in parallel, they must run at the same speed to maximize energy savings, either with individual

dedicated drives or 1 drive running multiple pumps in parallel.

AJ363928382091en-000101 / 130R0983 | 25Danfoss A/S © 2021.04

Page 26

CHILLER

CHILLER

3

3

P

e30bb454.10

Drive

Drive

VLT® Flow Drive FC 111

Design Guide

Product Overview

Illustration 16: Secondary Pumps

3.1.3 Check Valve Monitoring

In the pump application system, a damaged check valve is hard to detect, which therefore causes low efficiency of the whole system. VLT® Flow Drive FC 111 has the ability to monitor the status of check valves in the system. After enabling the check valve monitoring function via setting the parameter 22-04 Check Valve Monitor to [1] Enabled, once a damaged check valve is detected, the

drive trips warning 159, Check Valve Failure.

3.1.4 Dry Pump Detection

In the pump application system, the drive monitors the operation status of the system to detect whether there is water on pump's

suction side. If the pump runs at maximum speed and consumes little power, then it can be assumed that there is no water on the

pump's suction side. Via setting the parameter 22-26 Dry Pump Function to warning or alarm, once the dry pump condition is detected, the drive trips warning/alarm 93, dry pump.

3.1.5 End of Curve Detection

In the pump application system, the drive monitors the operation status of the system to detect whether the pressure side of pump

is subject to a major leakage. If the pump runs at maximum speed for a defined time period, but the pressure is below the set point,

then it can be considered to reflect the end of curve situation. Via setting the parameter 22-50 End of Curve Function to warning or

alarm, once the end of curve condition is detected, the drive trips warning/alarm 94, end of curve.

3.1.6 Time-based Functions

In some application scenarios, there are requirements to control the motor running for a specific time, in a specific direction and a

specific speed within a specific time interval. For example, checking the motor status in fire mode or exercising pumps, fans, and

compressors.

For detailed parameter settings, refer to the parameter group 23-** Time-based Functions in the drive's Programming Guide.

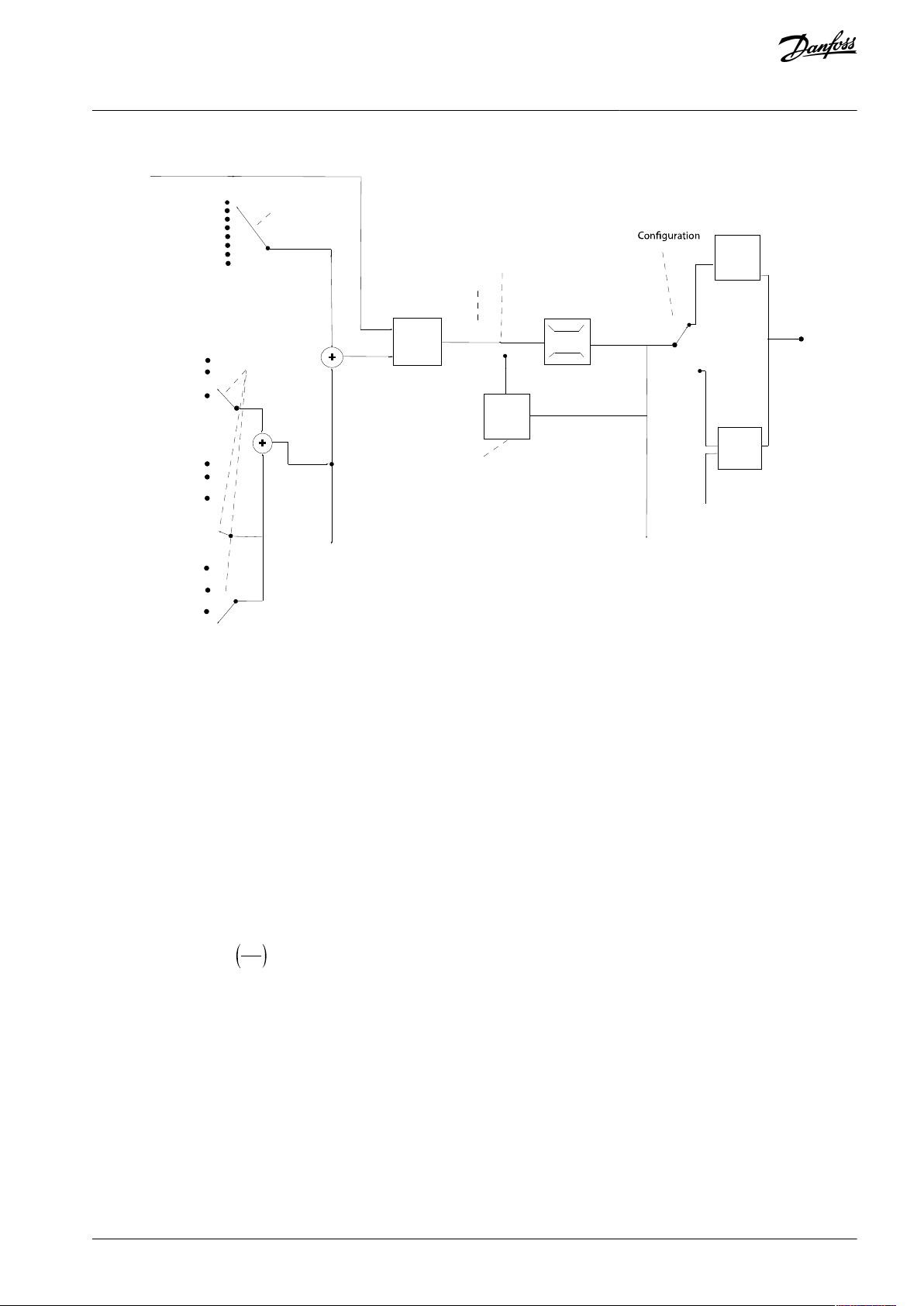

3.2 Control Structures

3.2.1 Introduction

There are two control modes for the drive:

Open loop.

•

Closed loop.

•

Select [0] Open loop or [1] Closed loop in parameter 1-00 Configuration Mode.

AJ363928382091en-000101 / 130R098326 | Danfoss A/S © 2021.04

Page 27

100%

0%

-100%

100%

A ut o mode

Hand mode

L ocal

P 4-10

M ot or speed

dir ec tion

P 4-14

M ot or speed

high limit [H z]

P 4-12

M ot or speed

lo w limit [H z]

Reference

handling

Remote

reference

Local

reference

scaled to

Hz

LCP Hand on,

off and auto

on keys

Remote

Reference

P 3-4* Ramp 1

P 3-5* Ramp 2

Ramp

To motor

control

e30bb892.11

Hand

On

On

e30bb893.11

Off Auto

Reset

VLT® Flow Drive FC 111

Design Guide

Product Overview

3.2.2 Control Structure Open Loop

Illustration 17: Open-loop Structure

In the configuration shown in the above illustration, parameter 1-00 Configuration Mode is set to [0] Open loop. The resulting reference from the reference handling system or the local reference is received and fed through the ramp limitation and speed limitation

before being sent to the motor control. The output from the motor control is then limited by the maximum frequency limit.

3.2.3 PM/EC+ Motor Control

The Danfoss EC+ concept provides the possibility for using high-efficient PM motors (permanent magnet motors) in IEC standard

enclosure sizes operated by Danfoss drives.

The commissioning procedure is comparable to the existing one for asynchronous (induction) motors by utilizing the Danfoss VVC

PM control strategy.

Customer advantages:

•

Free choice of motor technology (permanent magnet or induction motor).

•

Installation and operation as know on induction motors.

•

Manufacturer independent when selecting system components (for example, motors).

•

Best system efficiency by selecting best components.

•

Possible retrofit of existing installations.

•

Power range: 0.37–90 kW (0.5–121 hp) (400 V) for induction motors and 0.37–22 kW (0.5–30 hp) (400 V) for PM motors.

Current limitations for PM motors:

•

Currently only supported up to 22 kW (30 hp).

•

LC filters are not supported with PM motors.

•

Kinetic back-up algorithm is not supported with PM motors.

•

Support only complete AMA of the stator resistance Rs in the system.

•

No stall detection (supported from software version 62.80).

3.2.4 Local (Hand On) and Remote (Auto On) Control

The drive can be operated manually via the local control panel (LCP) or remotely via analog/digital inputs or serial bus. If allowed in

parameter 0-40 [Hand on] Key on LCP, parameter 0-44 [Off/Reset] Key on LCP, and parameter 0-42 [Auto on] Key on LCP, it is possible to

start and stop the drive via LCP by pressing [Hand On] and [Off/Reset]. Alarms can be reset via the [Off/Reset] key.

+

Illustration 18: LCP Keys

Local reference forces the configuration mode to open loop, independent on the setting of parameter 1-00 Configuration Mode.

AJ363928382091en-000101 / 130R0983 | 27Danfoss A/S © 2021.04

Page 28

7-30 PI

Nor mal/I n v erse

C on tr ol

PI

F eedback

P 4-10

M ot or speed

dir ec tion

T o mot or

c on tr ol

e30bb894.11

S

100%

0%

-100%

100%

*[-1]

_

+

Reference

Scale to

speed

e30bb895.10

+

-

PI

P

P

P

Ref.

signal

Desired

flow

FB conversion

Ref.

FB

Flow

FB

signal

Flow

P 20-01

VLT® Flow Drive FC 111

Design Guide

Product Overview

Local reference is restored at power-down.

3.2.5 Control Structure Closed Loop

The internal controller allows the drive to become a part of the controlled system. The drive receives a feedback signal from a sensor

in the system. It then compares this feedback to a setpoint reference value and determines the error, if any, between these 2 signals.

It then adjusts the speed of the motor to correct this error.

For example, consider a compressor application where the speed of the compressor is to be controlled to ensure a constant suction

pressure in an evaporator. The suction pressure value is supplied to the drive as the setpoint reference. A pressure sensor measures

the actual suction pressure in the evaporator and supplies the data to the drive as a feedback signal. If the feedback signal is greater

than the setpoint reference, the drive speeds up the compressor to reduce the pressure. In a similar way, if the suction pressure is

lower than the setpoint reference, the drive automatically slows down the compressor to increase the pressure.

Illustration 19: Control Structure Closed Loop

While the default values for the closed-loop controller of the drive often provide satisfactory performance, the control of the system

can often be optimized by adjusting parameters.

3.2.6 Feedback Conversion

In some applications, it may be useful to convert the feedback signal. One example of this is using a pressure signal to provide flow

feedback. Since the square root of pressure is proportional to flow, the square root of the pressure signal yields a value proportional

to the flow. See the following illustration.

Illustration 20: Feedback Signal Conversion

3.2.7 Reference Handling

Details for open-loop and closed-loop operation.

AJ363928382091en-000101 / 130R098328 | Danfoss A/S © 2021.04

Page 29

Speed open

loop

mode

Input command:

freeze reference

Process

control

Scale to

Hz

Scale to

process

unit

Remote

reference/

setpoint

±200%

Feedback

handling

Remote

reference in %

maxRefPCT

minRefPct

min-max ref

Freeze

reference &

increase/

decrease

reference

±100%

Input commands:

Speed up/speed down

±200%

Relative

reference

=

X+X*Y/100

±200%

External reference in %

±200%

Parameter choise:

Reference resource 1,2,3

±100%

Preset reference

Input command:

preset ref bit0, bit1, bit2

+

+

Relative scalling reference

Intern resource

Preset relative reference

±100%

Preset reference 0 ±100%

Preset reference 1 ±100%

Preset reference 2 ±100%

Preset reference 3 ±100%

Preset reference 4 ±100%

Preset reference 5 ±100%

Preset reference 6 ±100%

Preset reference 7 ±100%

External resource 1

No function

Analog reference

±200 %

Local bus reference

±200 %

Pulse input reference

±200 %

Pulse input reference

±200 %

Pulse input reference

±200 %

External resource 2

No function

Analog reference

±200 %

Local bus reference

±200 %

External resource 3

No function

Analog reference

±200 %

Local bus reference

±200 %

Y

X

e30be842.10

VLT® Flow Drive FC 111

Design Guide

Product Overview

Illustration 21: Block Diagram Showing Remote Reference

The remote reference consists of:

•

Preset references.

•

External references (analog inputs and serial communication bus references).

•

The preset relative reference.

•

Feedback-controlled setpoint.

Up to 8 preset references can be programmed in the drive. The active preset reference can be selected using digital inputs or the

serial communications bus. The reference can also be supplied externally, most commonly from an analog input. This external

source is selected by 1 of the 3 reference source parameters (parameter 3-15 Reference 1 Source, parameter 3-16 Reference 2 Source,

and parameter 3-17 Reference 3 Source). All reference resources and the bus reference are added to produce the total external reference. The external reference, the preset reference, or the sum of the 2 can be selected to be the active reference. Finally, this reference can by be scaled using parameter 3-14 Preset Relative Reference.

The scaled reference is calculated as follows:

Reference = X + X ×

Where X is the external reference, the preset reference or the sum of these and Y is parameter 3-14 Preset Relative Reference in [%].

If Y, parameter 3-14 Preset Relative Reference, is set to 0%, the reference is not affected by the scaling.

3.2.8 Tuning the Drive Closed-loop

Once the drive's closed-loop controller has been set up, test the performance of the controller. Often, its performance may be acceptable using the default values of parameter 20-93 PI Proportional Gain and parameter 20-94 PI Integral Time. However, sometimes

it may be helpful to optimize these parameter values to provide faster system response while still controlling speed overshoot.

3.2.9 Adjusting the Manual PI

Procedure

1.

Start the motor.

100

Y

AJ363928382091en-000101 / 130R0983 | 29Danfoss A/S © 2021.04

Page 30

Enclosure size

Level [dBA]

(1)

H1

43.6H250.2H353.8H464H563.7H671.5H767.5 (75 kW (100 hp) 71.5 dB)

H8

73.5

H1373H14

75

VLT® Flow Drive FC 111

Design Guide

2.

Set parameter 20-93 PI Proportional Gain to 0.3 and increase it until the feedback signal begins to oscillate. If necessary, start

and stop the drive or make step changes in the setpoint reference to attempt to cause oscillation.

3.

Reduce the PI proportional gain until the feedback signal stabilizes.

4.

Reduce the proportional gain by 40–60%.

5.

Set parameter 20-94 PI Integral Time to 20 s and reduce it until the feedback signal begins to oscillate. If necessary, start and

stop the drive or make step changes in the setpoint reference to attempt to cause oscillation.

Increase the PI integral time until the feedback signal stabilizes.

6.

Increase the integral time by 15–50%.

7.

Product Overview

3.3 Ambient Running Conditions

3.3.1 Air Humidity

The drive has been designed to meet the IEC/EN 60068-2-3 standard, EN 50178 9.4.2.2 at 50 °C (122 °F).

3.3.2 Acoustic Noise or Vibration

If the motor or the equipment driven by the motor - for example, a fan - makes noise or vibrations at certain frequencies, configure

the following parameters or parameter groups to reduce or eliminate the noise or vibrations:

•

Parameter group 4-6* Speed Bypass.

•

Set parameter 14-03 Overmodulation to [0] Off.

•

Switching pattern and switching frequency parameter group 14-0* Inverter Switching.

•

Parameter 1-64 Resonance Dampening.

3.3.2.1 Acoustic Noise

The acoustic noise from the drive comes from 3 sources:

DC-link coils.

•

Integral fan.

•

RFI filter choke.

•

Table 6: Typical Values Measured at a Distance of 1 m (3.28 ft) from the Unit

1

The values are measured under the background of 35 dBA noise and the fan running with full speed.

AJ363928382091en-000101 / 130R098330 | Danfoss A/S © 2021.04

Page 31

VLT® Flow Drive FC 111

Design Guide

Product Overview

3.3.2.2 Vibration and Shock

The drive has been tested according to the following standards:

•

IEC/EN 60068-2-6: Vibration (sinusoidal) - 1970

•

IEC/EN 60068-2-64: Vibration, broad-band random

The drive complies with the requirements that exist for units mounted on the walls and floors of production premises, and in panels

bolted to walls or floors.

3.3.3 Aggressive Environments

A drive contains many mechanical and electronic components. All are to some extent vulnerable to environmental effects.

C A U T I O N

INSTALLATION ENVIRONMENTS

Failure to take necessary protective measures increases the risk of stoppages, potentially causing equipment damage and per-

sonnel injury.

Do not install the drive in environments with airborne liquids, particles, or gases that may affect or damage the electronic

-

components.

Liquids can be carried through the air and condense in the drive and may cause corrosion of components and metal parts. Steam,

oil, and salt water may cause corrosion of components and metal parts. As an extra protection, coated printed circuit boards can be

ordered as an option (standard on some power sizes).

Airborne particles such as dust may cause mechanical, electrical, or thermal failure in the drive. A typical indicator of excessive levels

of airborne particles is dust particles around the drive fan. In dusty environments, use a cabinet for IP20/TYPE 1 equipment.

In environments with high temperatures and humidity, corrosive gases such as sulphur, nitrogen, and chlorine compounds cause

chemical processes on the drive components.

Such chemical reactions rapidly affect and damage the electronic components. In such environments, mount the equipment in a

cabinet with fresh air ventilation, keeping aggressive gases away from the drive. An extra protection in such areas is a coating of the

printed circuit boards, which can be ordered as an option.

Before installing the drive, check the ambient air for liquids, particles, and gases. This is done by observing existing installations in

this environment. Typical indicators of harmful airborne liquids are water or oil on metal parts, or corrosion of metal parts.

Excessive dust particle levels are often found on installation cabinets and existing electrical installations. One indicator of aggressive

airborne gases is blackening of copper rails and cable ends on existing installations.

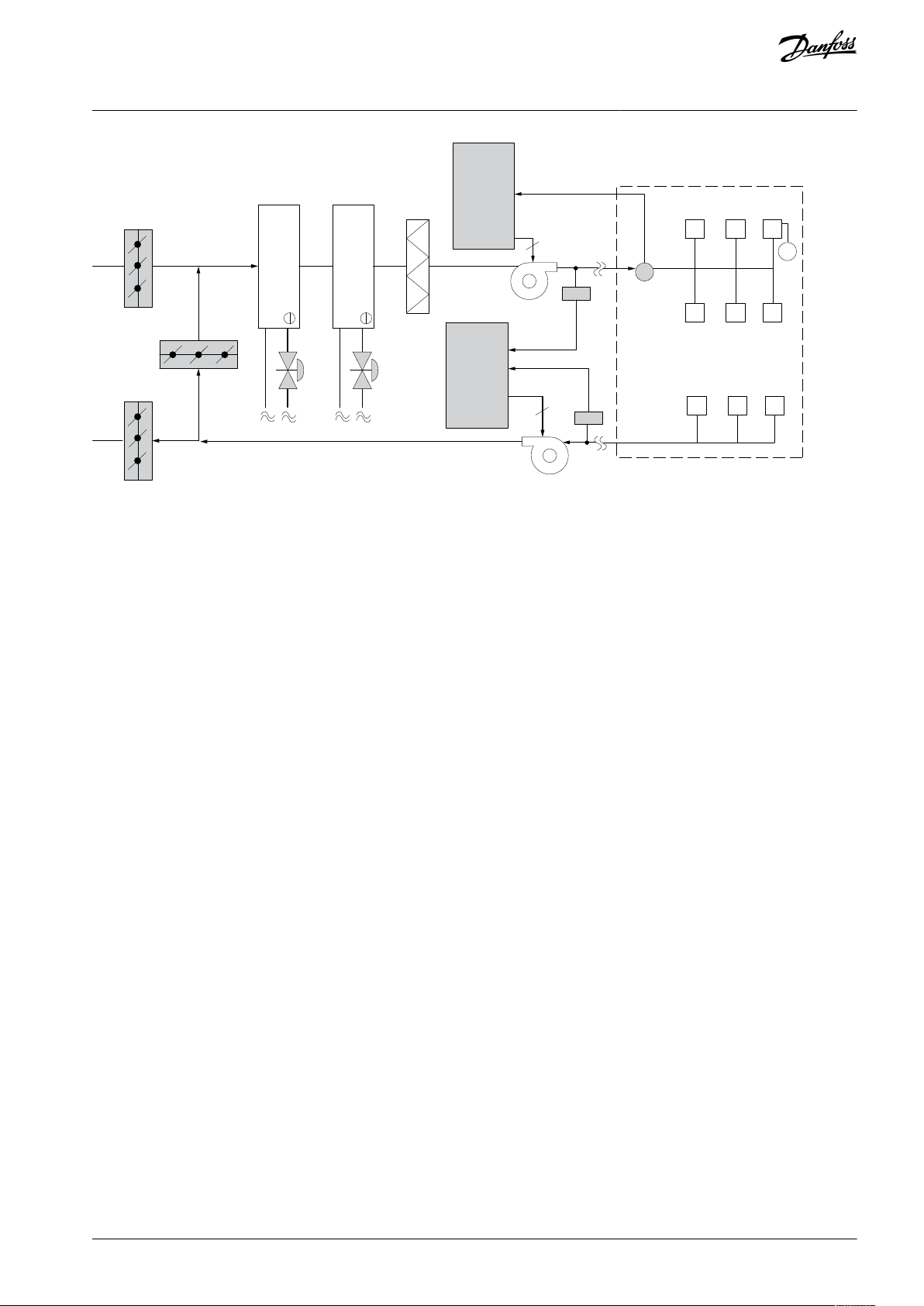

3.4 General Aspects of EMC

3.4.1 Overview of EMC Emissions

Drives (and other electrical devices) generate electronic or magnetic fields that may interfere with their environment. The electromagnetic compatibility (EMC) of these effects depends on the power and the harmonic characteristics of the devices.

Uncontrolled interaction between electrical devices in a system can degrade compatibility and impair reliable operation. Interference may take the form of mains harmonics distortion, electrostatic discharges, rapid voltage fluctuations, or high-frequency interference. Electrical devices generate interference along with being affected by interference from other generated sources.

Electrical interference usually occur at frequencies in the range 150 kHz to 30 MHz. Airborne interference from the drive system in

the range 30 MHz to 1 GHz is generated from the inverter, the motor cable, and the motor.

Capacitive currents in the motor cable coupled with a high dU/dt from the motor voltage generate leakage currents, as shown in

the following illustration.

The use of a shielded motor cable increases the leakage current (see the following illustration) because shielded cables have higher

capacitance to ground than unshielded cables. If the leakage current is not filtered, it causes greater interference on the mains in

the radio frequency range below approximately 5 MHz. Since the leakage current (I1) is carried back to the unit through the shield

(I3), there is only a small electromagnetic field (I4) from the shielded motor cable according to the following illustration.

AJ363928382091en-000101 / 130R0983 | 31Danfoss A/S © 2021.04

Page 32

1

2

z

z

z

L1

L2

L3

PE

U

V

W

C

S

I

2

I

1

I

3

I

4

C

S

C

S

C

S

C

S

I

4

C

S

z

PE

3

4

5

6

e75za062.12

1

Ground wire

2

Shield

3

AC mains supply

4

Drive5Shielded motor cable

6

Motor

EN/IEC

61800-3 Category

Definition

Equivalent emission class in EN

55011

C1

Drives installed in the first environment (home and office) with a supply voltage less than

1000 V.

Class B

C2

Drives installed in the first environment (home and office) with a supply voltage less than

1000 V, which are neither plug-in nor movable and are intended to be installed and commissioned by a professional.

Class A Group 1

C3

Drives installed in the second environment (industrial) with a supply voltage lower than

1000 V.

Class A Group 2

C4

Drives installed in the second environment with a supply voltage equal to or above 1000

V or rated current equal to or above 400 A or intended for use in complex systems.

No limit line. Make

an EMC plan.

VLT® Flow Drive FC 111

Design Guide

Illustration 22: Generation of Leakage Currents

Product Overview

The shield reduces the radiated interference, but increases the low-frequency interference on the mains. Connect the motor cable

shield to the drive enclosure and on the motor enclosure. This is best done by using integrated shield clamps to avoid twisted shield

ends (pigtails). Pigtails increase the shield impedance at higher frequencies, which reduces the shield effect and increases the leakage current (I4).

If a shielded cable is used for relay, control cable, signal interface, and brake, mount the shield on the enclosure at both ends. In

some situations, however, it is necessary to break the shield to avoid current loops.

If the shield is to be placed on a mounting plate for the drive, the mounting plate must be made of metal, to convey the shield

currents back to the unit. Moreover, ensure good electrical contact from the mounting plate through the mounting screws to the

drive chassis.

When using unshielded cables, some emission requirements are not complied with, although most immunity requirements are observed.

To reduce the interference level from the entire system (unit+installation), make motor and brake cables as short as possible. Avoid

placing cables with a sensitive signal level alongside motor and brake cables. Radio interference higher than 50 MHz (airborne) is

especially generated by the control electronics.

3.4.2 Emission Requirements

The EMC product standard for drives defines 4 categories (C1, C2, C3, and C4) with specified requirements for emission and immunity. The following table states the definition of the 4 categories and the equivalent classification from EN 55011.

Table 7: Correlation between IEC 61800-3 and EN 55011

AJ363928382091en-000101 / 130R098332 | Danfoss A/S © 2021.04

Page 33

Environment

Generic emission standard

Equivalent emission

class in EN 55011

First environment (home and office)

EN/IEC 61000-6-3 Emission standard for residential, commercial

and light industrial environments.

Class B

Second environment (industrial environment)

EN/IEC 61000-6-4 Emission standard for industrial environments.

Class A Group 1

RFI filter

type

Conduct emission. Maximum shielded cable length [m (ft)]

Radiated emission

Industrial environment

EN 55011

Class A Group 2

Industrial environment

Class A Group 1

Industrial environment

Class B

Housing, trades and

light industries

Class A Group 1

Industrial environment

Class B

Housing, trades

and light industries

EN/IEC

61800-3

Category C3

Second environment

industrial

Category C2

First environment

home and office

Category C1

First environment

home and office

Category C2

First environment

home and office

Category C1

First environment

home and office

Without

external

filter

With external

filter

Without

external

filter

With external

filter

Without

external

filter

With external

filter

Without

external

filter

With

external filter

Without

external

filter

With

external filter

H4 RFI filter (EN55011 A1, EN/IEC61800-3 C2)

0.37–22 kW

(0.5–30 hp)

3x380–480

V IP20

––25 (82)

50 (164)

–

20 (66)

Yes

Yes–No

H2 RFI filter (EN 55011 A2, EN/IEC 61800-3 C3)

30–90 kW

(40–125

hp) 3x380–

480 V IP20

25 (82)

–––––No–No–

H3 RFI filter (EN55011 A1/B, EN/IEC 61800-3 C2/C1)

30–90 kW

(40–125

hp) 3x380–

480 V IP20

––50 (164)

–

20 (66)

–

Yes–No

–

VLT® Flow Drive FC 111

Design Guide

When the generic (conducted) emission standards are used, the drives are required to comply with the limits in the following table.

Table 8: Correlation between Generic Emission Standards and EN 55011

Product Overview

3.4.3 EMC Emission Test Results

The following test results have been obtained using a system with a drive, a shielded control cable, a control box with potentiometer, and a shielded motor cable.

Table 9: EMC Emission Test Results, H1–H8

AJ363928382091en-000101 / 130R0983 | 33Danfoss A/S © 2021.04

Page 34

RFI filter type

Conduct emission. Maximum shielded cable length [m

(ft)]

Radiated emission

EN 55011

Class B Housing,

trades and light

industries

Class A Group 1

Industrial environment

Class A Group 2

Industrial environment

Class B Housing, trades

and light industries

Class A Group

1 Industrial

environment

Class A Group

2 Industrial

environment

EN/IEC

61800-3

Category C1

First environment home and

office

Category C2

First environment home and

office

Category C3

Second environment industrial

Category C1

First environment home

and office

Category C2

First environment home

and office

Category C3

First environment home

and office

H2 RFI filter (EN 55011 A2, EN/IEC 61800-3 C3)

110–315 kW

(150– 450 hp)

3x380–480 V

IP20

NoNo150 m (492 ft)

NoNoYes

I1I5I

7

Hz50250

350

e75ha034.10

VLT® Flow Drive FC 111

Design Guide

Table 10: EMC Emission Test Results, H13–H14

Product Overview

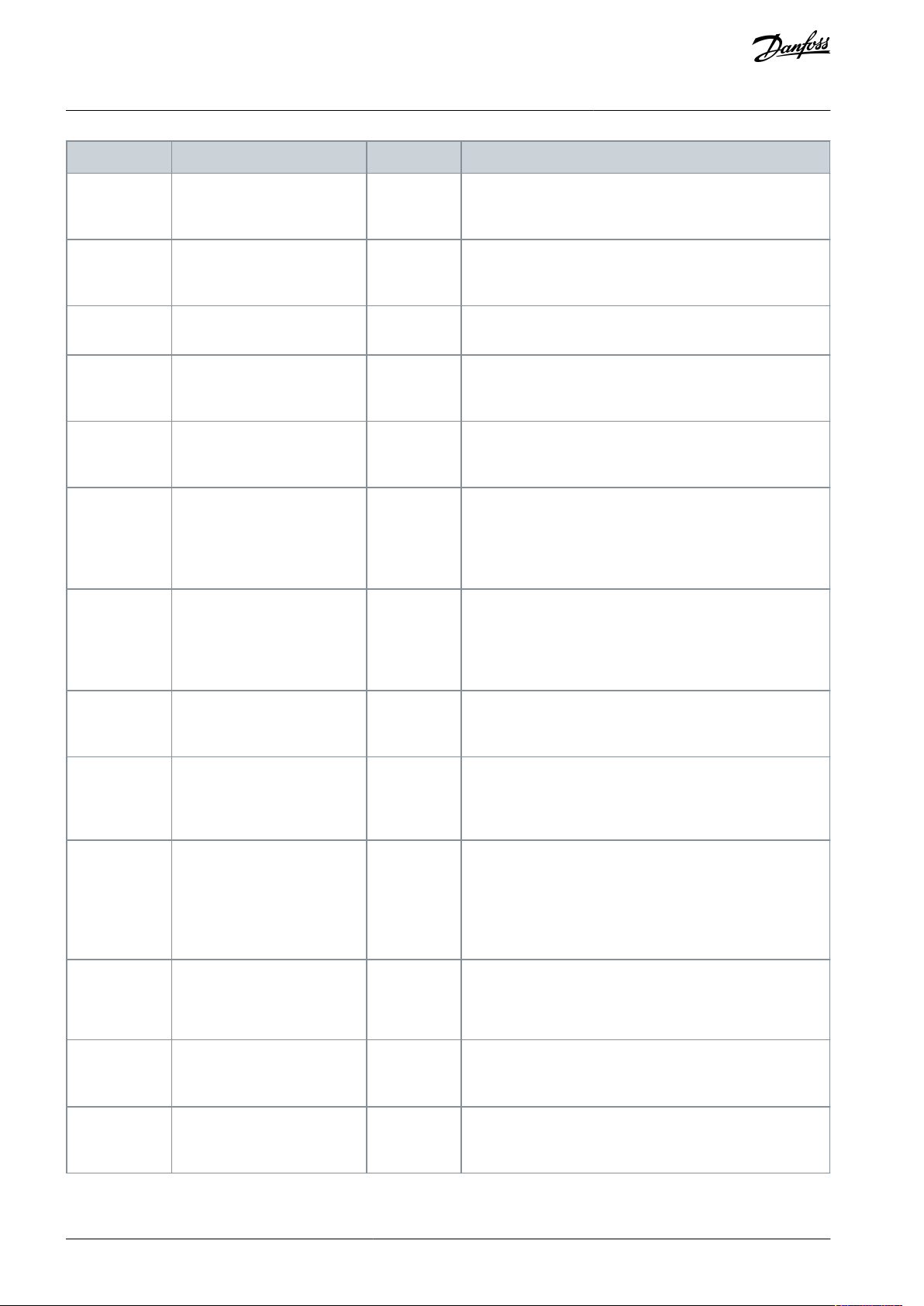

3.4.4 Harmonics Emission

A drive takes up a non-sinusoidal current from mains, which increases the input current I

formed with a Fourier analysis and split into sine-wave currents with different frequencies, that is, different harmonic currents I

with 50 Hz basic frequency:

. A non-sinusoidal current is trans-

RMS

n

Table 11: Harmonic Currents

The harmonics do not affect the power consumption directly, but increase the heat losses in the installation (transformer, cables).

So, in plants with a high percentage of rectifier load, maintain harmonic currents at a low level to avoid overload of the transformer

and high temperature in the cables.

Illustration 23: DC-link Coils

N O T I C E

Some of the harmonic currents might disturb communication equipment connected to the same transformer or cause resonance

with power factor correction batteries.

To ensure low harmonic currents, the drive is equipped with DC-link coils as standard. This normally reduces the input current I

by 40%.

The voltage distortion on the mains supply voltage depends on the size of the harmonic currents multiplied by the mains impedance for the frequency in question. The total voltage distortion THDv is calculated based on the individual voltage harmonics using this formula:

RMS

THD% = U

+ U

5

2

+ ... + U

7

2

N

2

(UN% of U)

3.4.4.1 Harmonics Emission Requirements

Equipment is connected to the public supply network.

AJ363928382091en-000101 / 130R098334 | Danfoss A/S © 2021.04

Page 35

Options

Definition

1

IEC/EN 61000-3-2 Class A for 3-phase balanced equipment (for professional equipment only up to 1 kW (1.3 hp) total

power).

2

IEC/EN 61000-3-12 Equipment 16–75 A and professional equipment as from 1 kW (1.3 hp) up to 16 A phase current.

Individual harmonic current In/I1 (%)

I5I7I11I

13

Actual 6.0–10 kW (8.0–15 hp), IP20, 200 V (typical)

32.6

16.6

8.0

6.0

Limit for R

sce

≥120

402515

10

Harmonic current distortion factor (%)

THDi

PWHD

Actual 6.0–10 kW (8.0–15 hp), 200 V (typical)

39

41.4

Limit for R

sce

≥120

48

46

Individual harmonic current In/I1 (%)

I5I7I11I

13

Actual 6.0–22 kW (8.0–30 hp), IP20, 380–480 V (typical)

36.7

20.8

7.6

6.4

Limit for R

sce

≥120

402515

10

Harmonic current distortion factor (%)

THDi

PWHD

Actual 6.0–22 kW (8.0–30 hp), 380–480 V (typical)

44.4

40.8

Limit for R

sce

≥120

48

46

Individual harmonic current In/I1 (%)

I5I7I11I

13

Actual 30 kW (40 hp), IP20, 380–480 V (typical)

36.7

13.8

6.9

4.2

Limit for R

sce

≥120

402515

10

Harmonic current distortion factor (%)

THDi

PWHD

Actual 30 kW (40 hp), 380–480 V (typical)

40.6

28.8

VLT® Flow Drive FC 111

Design Guide

Table 12: Connected Equipment

Product Overview

3.4.4.2 Harmonics Test Results (Emission)

Power sizes up to 10 kW (15 hp) [200–240 V AC] comply with IEC/EN 61000-3-12, Table 4. Power sizes up to 30 kW (40 hp) [380–

480 V AC] comply with IEC/EN 61000-3-2 Class A and IEC/EN 61000-3-12, Table 4.

Table 13: Harmonic Current 6.0–10 kW (8.0–15 hp), 200 V

Table 14: Harmonic Current 6.0–22 kW (8.0–30 hp), 380–480 V

Table 15: Harmonic Current 30 kW (40 hp), 380–480 V

AJ363928382091en-000101 / 130R0983 | 35Danfoss A/S © 2021.04

Page 36

Limit for R

sce

≥120

48

46

Options

Definition

1

IEC/EN 61000-3-2 Class A for 3-phase balanced equipment (for professional equipment only up to 1 kW (1.3 hp) total

power).

2

IEC/EN 61000-3-12 Equipment 16–75 A and professional equipment as from 1 kW (1.3 hp) up to 16 A phase current.

Individual harmonic current In/I1 (%)

I5I7I11I

13

Actual 0.37–22 kW (0.5–30 hp), IP20, 380-480 V (typical)

36.7

20.8

7.6

6.4

Limit for R

sce

≥120

402515

10

Harmonic current distortion factor (%)

THDi

PWHD

Actual 0.37–22 kW (0.5–30 hp), 380-480 V (typical)

44.4

40.8

Limit for R