Operating Guide

VLT® Flow Drive FC 111

vlt-drives.danfoss.com

VLT® Flow Drive FC 111

Operating Guide

Contents

1

Introduction 6

1.1

Purpose of this Operating Guide 6

Additional Resources 6

1.2

Other Resources 6

1.2.1

1.2.2

MCT 10 Set-up Software Support 6

1.3

Document and Software Version 6

1.4

Disposal 6

Safety 7

2

Safety Symbols 7

2.1

Qualified Personnel 7

2.2

Safety Precautions 7

2.3

Motor Thermal Protection 8

2.4

Contents

Product Overview 9

3

Intended Use 9

3.1

3.2

Power Ratings, Weights, and Dimensions 9

3.3

Check Valve Monitoring 12

3.4

Dry Pump Detection 12

3.5

End of Curve Detection 12

3.6

Time-based Functions 12

3.7

Relays and Terminals 13

3.7.1

Relays and Terminals on Enclosure Sizes H1–H5 13

3.7.2

Relays and Terminals on Enclosure Size H11 14

3.7.3

Relays and Terminals on Enclosure Size H12 14

3.7.4

Relays and Terminals on Enclosure Size H13–H14 15

3.8

View of Control Shelf 16

4

Mechanical Installation 18

4.1

Storage and Operating Environment 18

4.2

Side-by-side Installation 19

4.3

Tools Needed 20

4.4

Installation and Cooling Requirements 20

4.5

Lifting the Drive 22

4.6

Wall Mounting the Drive 22

4.7

Creating Cable Openings 23

AQ304735638503en-000301/130R0265 | 3Danfoss A/S © 2021.10

VLT® Flow Drive FC 111

Operating Guide

5

Electrical Installation 25

Safety Instructions 25

5.1

5.2

EMC-compliant Electrical Installation 25

Electrical Wiring 26

5.3

5.4

Fastener Tightening Torques 27

5.5

IT Mains 28

5.6

Mains and Motor Connection 29

5.6.1

Introduction 29

5.6.2

Connecting to the Ground 29

5.6.3

Connecting the Motor 30

5.6.4

Connecting the AC Mains 31

5.7

Fuses and Circuit Breakers 32

5.7.1

Branch Circuit Protection 32

5.7.2

Short-circuit Protection 32

Contents

Overcurrent Protection 32

5.7.3

5.7.4

CE Compliance 32

5.7.5

Recommendation of Fuses 32

5.8

Control Terminals 33

5.9

Acoustic Noise or Vibration 34

6

Programming 35

6.1

Local Control Panel (LCP) 35

6.2

Set-up Wizard 36

6.2.1

Setup Wizard Introduction 36

6.2.2

Setup Wizard for Open-loop Applications 37

6.2.3

Setup Wizard for Closed-loop Applications 42

6.2.4

Motor Setup 47

6.2.5

Changes Made Function 51

6.2.6

Changing Parameter Settings 51

6.2.7

Accessing All Parameters via the Main Menu 51

7

Applications 52

7.1

Application Selections 52

7.1.1

Open Loop 52

7.1.2

Process Closed Loop 53

7.1.3

Constant Pressure Water Supply 55

7.1.4

Multiple Pump Control 57

AQ304735638503en-000301/130R02654 | Danfoss A/S © 2021.10

VLT® Flow Drive FC 111

Operating Guide

8

Cascade Controller 60

Introduction 60

8.1

8.1.1

Cascade Controller 60

Fixed Lead Pump 60

8.1.2

8.1.3

Lead Pump Alternation 60

8.1.4

Bandwidth Management 60

8.2

System Status and Operation 61

8.3

Start/Stop Conditions 61

8.4

Cascade Controller Wizard 62

8.5

Cascade Controller Connection 63

8.5.1

1 Pump, 1 Relay Mode 63

8.5.2

1 Pump, 2 Relay Mode 63

9

Warnings and Alarms 65

9.1

List of Warnings and Alarms 65

Contents

9.2

LCP Errors Messages 67

10

Specifications 69

10.1

Mains Supply 69

10.1.1

3x380–480 V AC 69

10.2

EMC Emission Test Results 71

10.3

Special Conditions 72

10.3.1

Dusty or Humid Environment 72

10.3.2

Derating for Ambient Temperature and Switching Frequency 72

10.3.3

Derating for Low Air Pressure and High Altitudes 72

10.4

General Technical Data 72

10.4.1

Protection and Features 72

10.4.2

Mains Supply 72

10.4.3

Motor Output (U, V, W) 73

10.4.4

Cable Length and Cross-section 73

10.4.5

Digital Inputs 73

10.4.6

Analog Inputs 74

10.4.7

Analog Outputs 74

10.4.8

Digital Output 74

10.4.9

RS485 Serial Communication 75

10.4.10

24 V DC Output 75

10.4.11

Relay Output 75

10.4.12

10 V DC Output 75

10.4.13

Ambient Conditions 75

AQ304735638503en-000301/130R0265 | 5Danfoss A/S © 2021.10

Edition

Remarks

Software version

AQ304735638503, version 0301

Update the manual for 30–90 kW

(40–125 hp) drives.

75.02 for 30–90 kW (40–125 hp); 65.02 for other power

sizes of the drive.

Do not dispose of equipment containing electrical components together with domestic waste.

Collect it separately in accordance with local and currently valid legislation.

VLT® Flow Drive FC 111

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Other Resources

Other resources are available to understand advanced drive functions and programming.

•

The VLT® Flow Drive FC 111 Programming Guide provides information on how to program and includes complete parameter

descriptions.

•

The VLT® Flow Drive FC 111 Design Guide provides all technical information about the drive. It also lists options and accessories.

The technical documentation is available in electronic form online at

1.2.2 MCT 10 Set-up Software Support

Download the software from the service and support section on www.danfoss.com.

During the installation process of the software, enter access code 81462700 to activate the VLT® Flow Drive FC 111 functionality. A

license key is not required for using the VLT® Flow Drive FC 111 functionality.

The latest software does not always contain the latest updates for drives. Contact the local sales office for the latest drive updates (in

the form of *.OSS files).

www.danfoss.com.

1.3 Document and Software Version

The Operating Guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Document and Software Version

1.4 Disposal

AQ304735638503en-000301 / 130R02656 | Danfoss A/S © 2021.10

VLT® Flow Drive FC 111

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AQ304735638503en-000301 / 130R0265 | 7Danfoss A/S © 2021.10

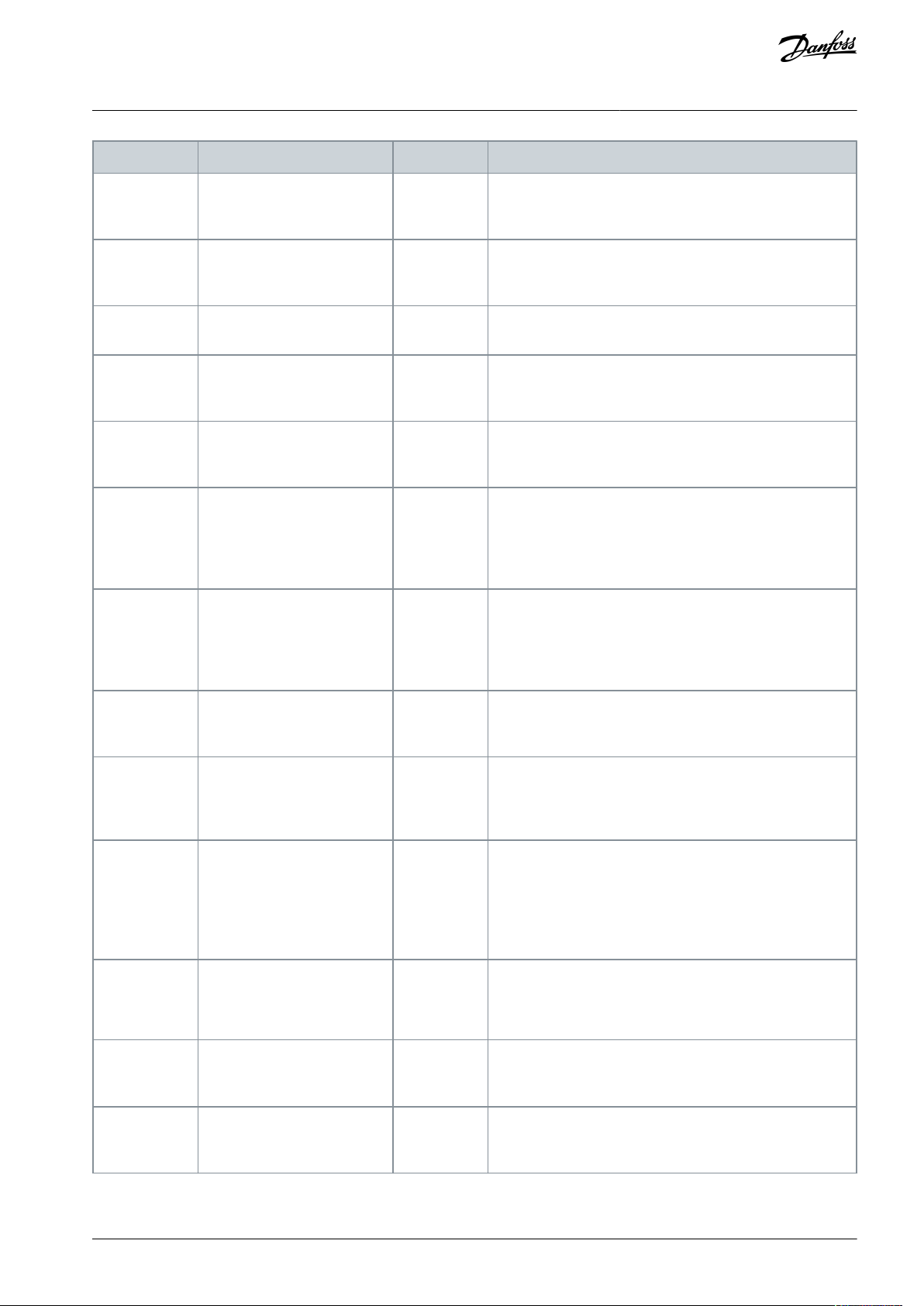

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x400

0.37–7.5 (0.5–10)

4

3x400

11–90 (15–125)

15

3x400

110–315 (150–450)

20

VLT® Flow Drive FC 111

Operating Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

2.4 Motor Thermal Protection

Procedure

1.

Set parameter 1-90 Motor Thermal Protection to [4] ETR trip 1 to enable the motor thermal protection function.

AQ304735638503en-000301 / 130R02658 | Danfoss A/S © 2021.10

e

f

a

e

e

f

a

d

e

A

a

b

B

C

D

e30bf984.10

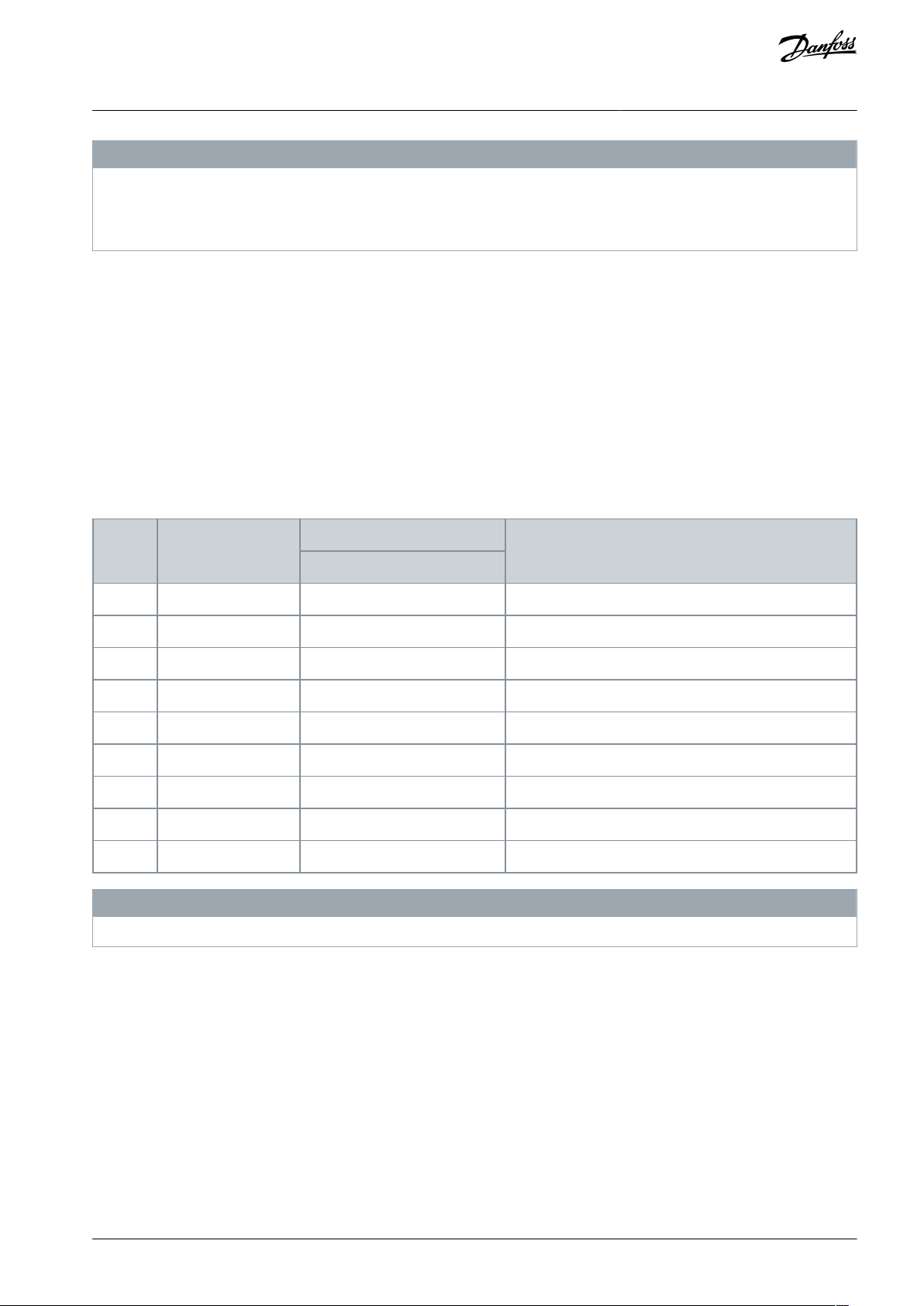

Enclosure Size

H1H2H3H4H5

IP class

IP20

IP20

IP20

IP20

IP20

Power [kW (hp)]

3x380–480 V

0.37–1.5

(0.5–2.0)

2.2–4.0

(3.0–5.0)

5.5–7.5

(7.5–10)

11–15

(15–20)

18.5–22

(25–30)

Height [mm (in)]

A

195 (7.7)

227 (8.9)

255 (10.0)

296 (11.7)

334 (13.1)

A

(1)

273 (10.7)

303 (11.9)

329 (13.0)

359 (14.1)

402 (15.8)

a

183 (7.2)

212 (8.3)

240 (9.4)

275 (10.8)

314 (12.4)

Width [mm (in)]

B

75 (3.0)

90 (3.5)

100 (3.9)

135 (5.3)

150 (5.9)

b

56 (2.2)

65 (2.6)

74 (2.9)

105 (4.1)

120 (4.7)

Depth [mm (in)]

C

168 (6.6)

190 (7.5)

206 (8.1)

241 (9.5)

255 (10)

VLT® Flow Drive FC 111

Operating Guide

Product Overview

3 Product Overview

3.1 Intended Use

The drive is an electronic motor controller that converts AC mains input into a variable AC waveform output. The frequency and

voltage of the output are regulated to control the motor speed or torque. The drive is designed to:

•

Regulate motor speed in response to system feedback or remote commands from external controllers.

•

Monitor system and motor status.

•

Provide motor overload protection.

The drive is designed for industrial and commercial environments in accordance with local laws and standards. Depending on configuration, the drive can be used in standalone applications or form part of a larger system or installation.

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

Foreseeable misuse

Do not use the drive in applications which are non-compliant with specified operating conditions and environments. Ensure compliance with the conditions specified in chapter Specifications.

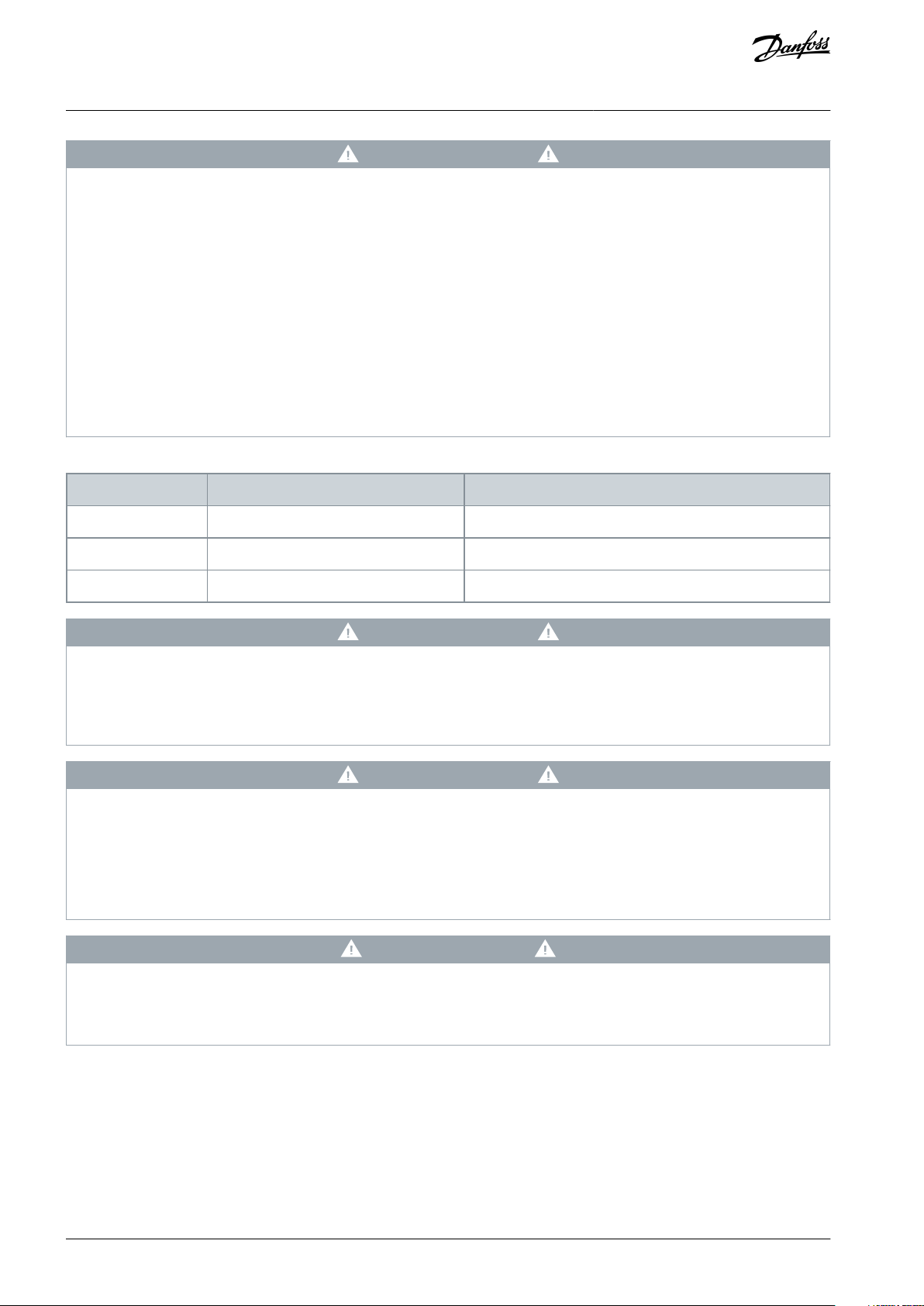

3.2 Power Ratings, Weights, and Dimensions

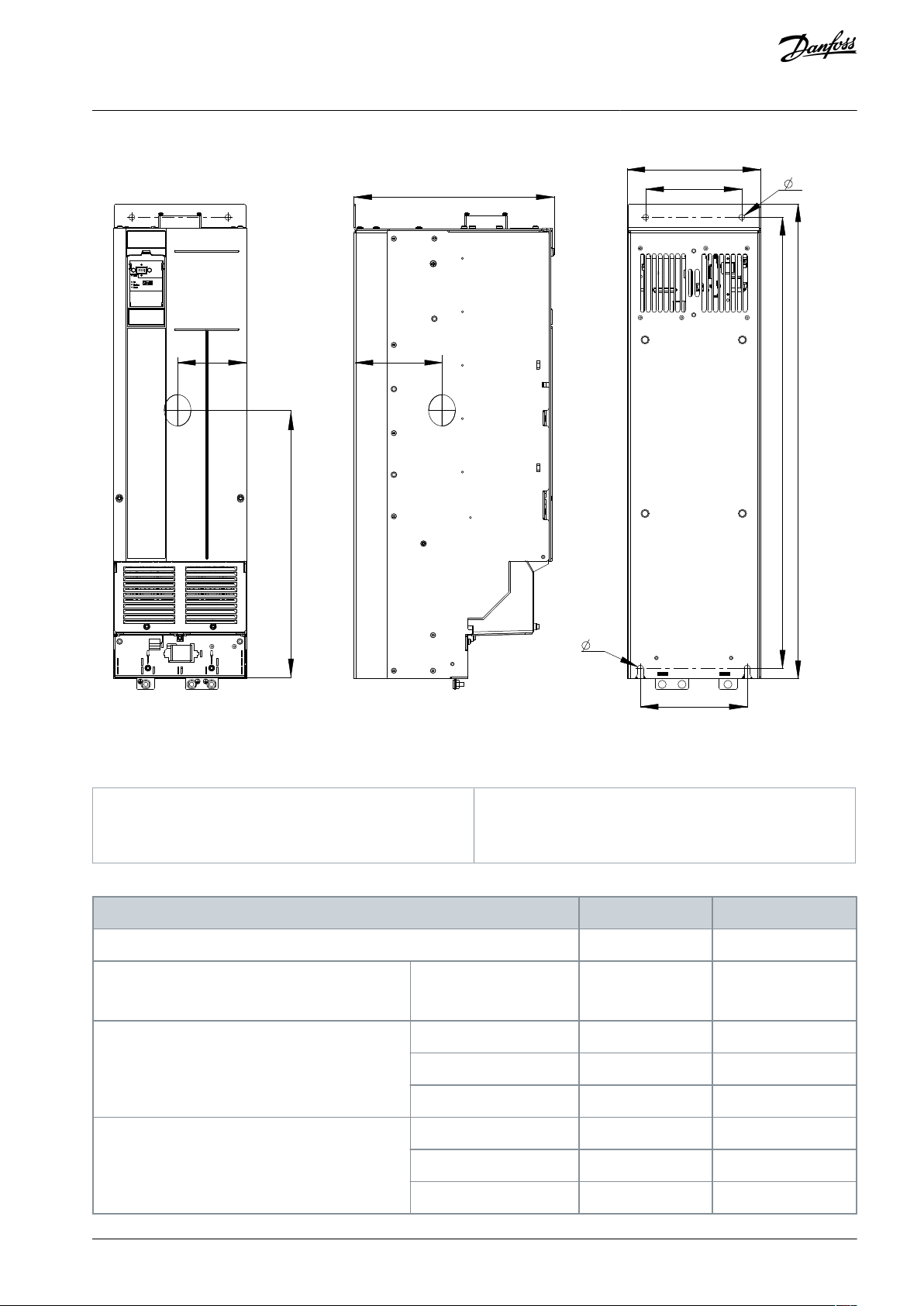

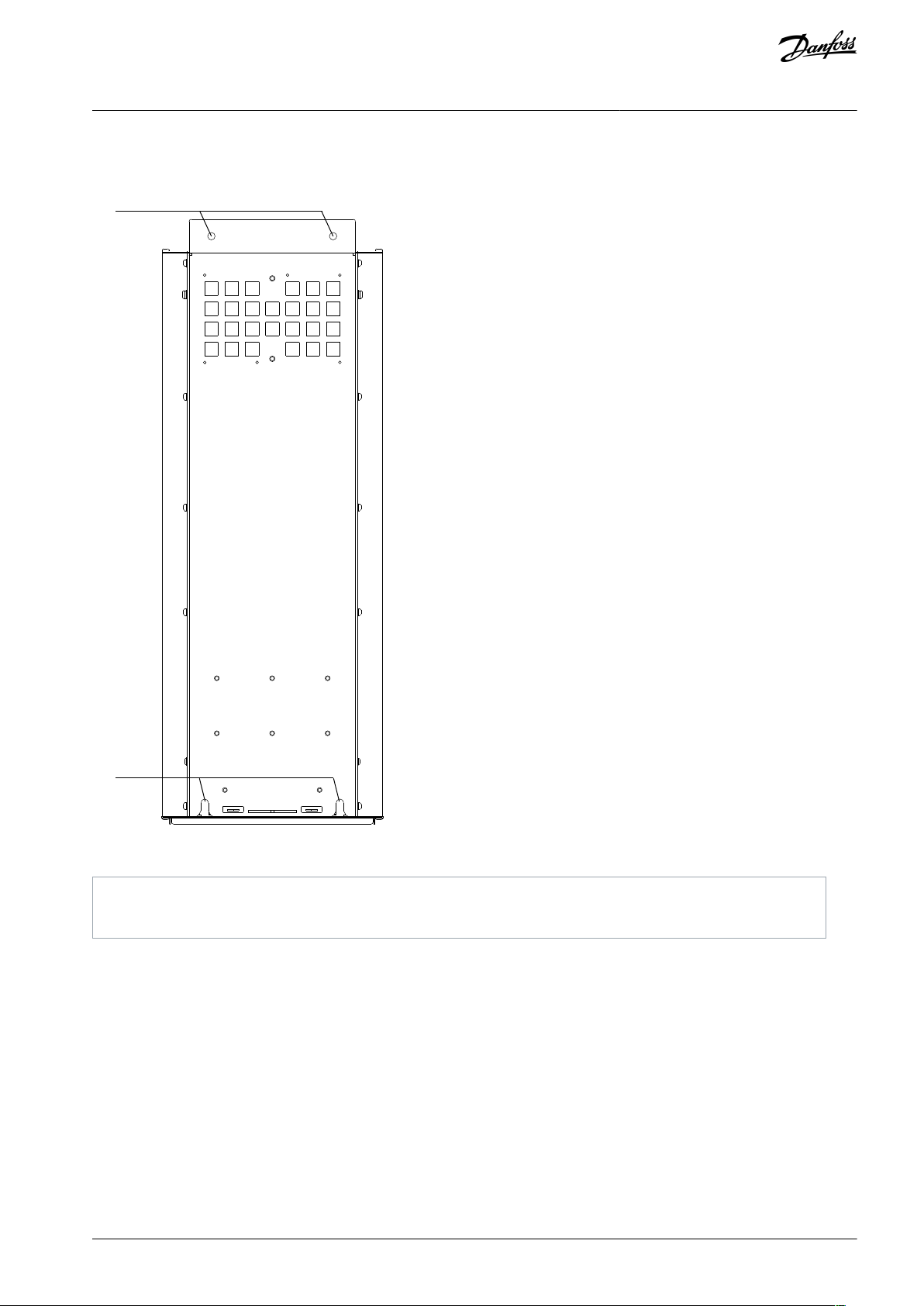

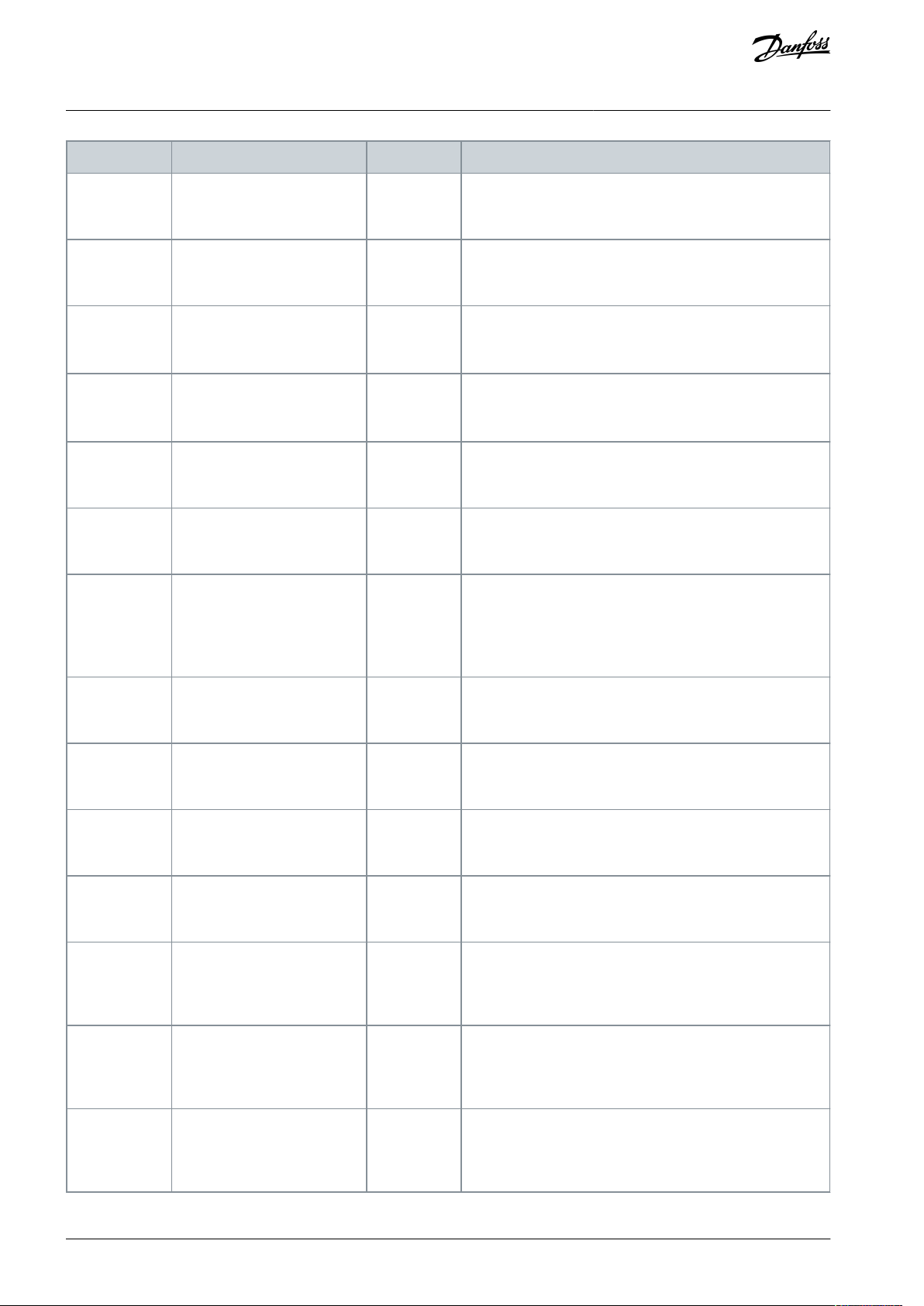

Illustration 1: Dimensions, Enclosure Sizes H1–H5 & H11–H12

Table 3: Power Ratings, Weights, and Dimensions, Enclosure Sizes H1–H5

AQ304735638503en-000301 / 130R0265 | 9Danfoss A/S © 2021.10

Enclosure Size

H1H2H3H4H5

Mounting hole [mm (in)]

d

9 (0.35)

11 (0.43)

11 (0.43)

12.6 (0.50)

12.6 (0.50)

e

4.5 (0.18)

5.5 (0.22)

5.5 (0.22)

7 (0.28)

7 (0.28)

f

5.3 (0.21)

7.4 (0.29)

8.1 (0.32)

8.4 (0.33)

8.5 (0.33)

Maximum weight [kg (lb)]

2.1 (4.6)

3.4 (7.5)

4.5 (9.9)

7.9 (17.4)

9.5 (20.9)

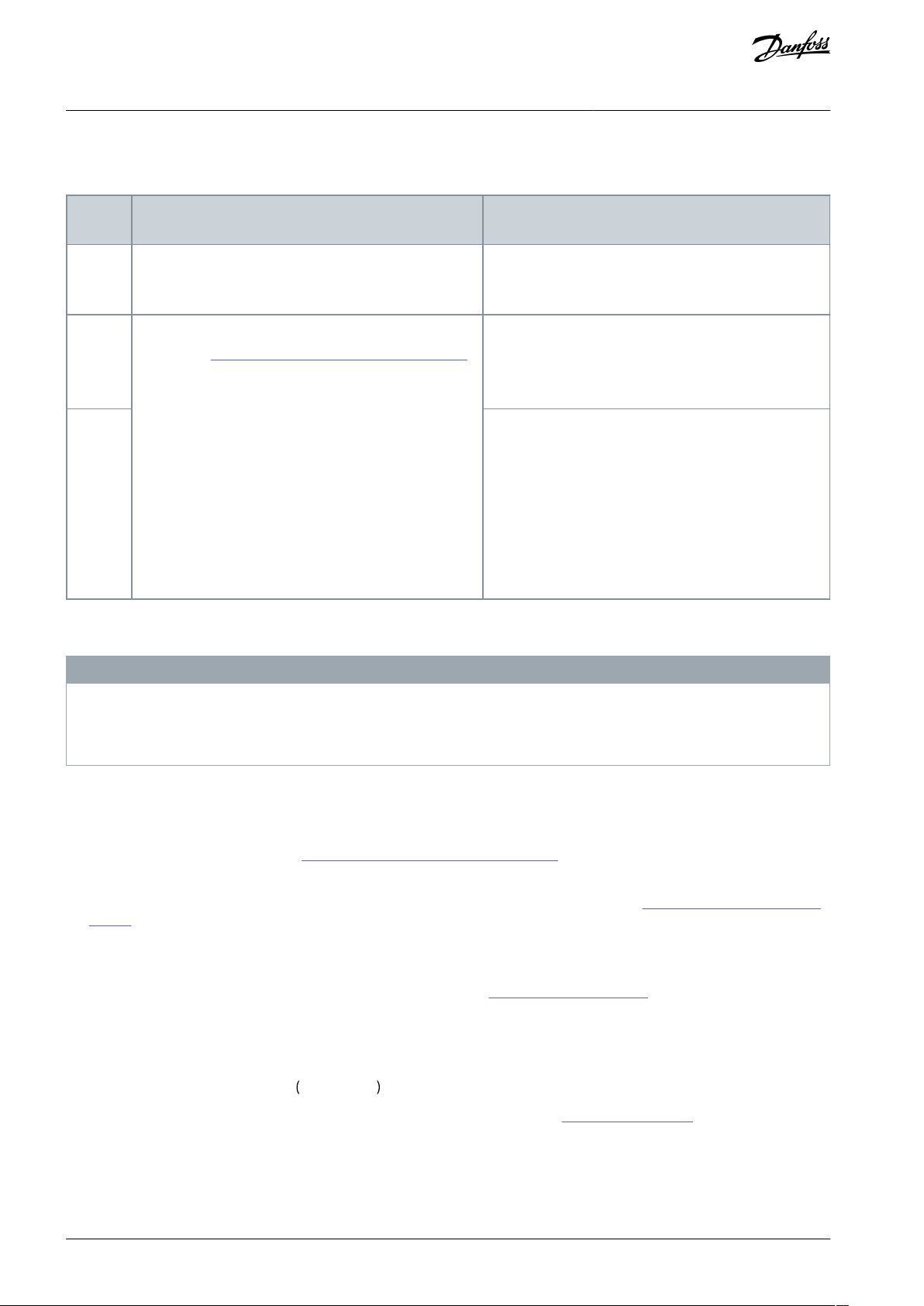

Enclosure Size

H11

H12

IP class

IP20

IP20

(1)

Power [kW (hp)]

3x380–480 V

30–45

(40–60)

55–90

(70–125)

Height [mm (in)]

A

515 (20.3)

550 (21.7)

A

(2)

545 (21.5)

610.5 (24)

a

495 (19.5)

521 (20.5)

Width [mm (in)]

B

233 (9.2)

308 (12.1)

b

200 (7.9)

270 (10.6)

Depth [mm (in)]

C

241 (9.5)

323 (12.7)

Mounting hole [mm (in)]

d

–

–e8.5 (0.33)

8.5 (0.33)

f

13 (0.5)

17 (0.67)

Maximum weight [kg (lb)]

22.6 (49.8)

40.7 (89.7)

e30bv016.10

VLT® Flow Drive FC 111

Operating Guide

1

Including decoupling plate.

Table 4: Power Ratings, Weights, and Dimensions H11–H12

Product Overview

1

Install the protective cover on the mains and motor terminals after connecting the stripped wire. See Illustration 2.

2

Including decoupling plate.

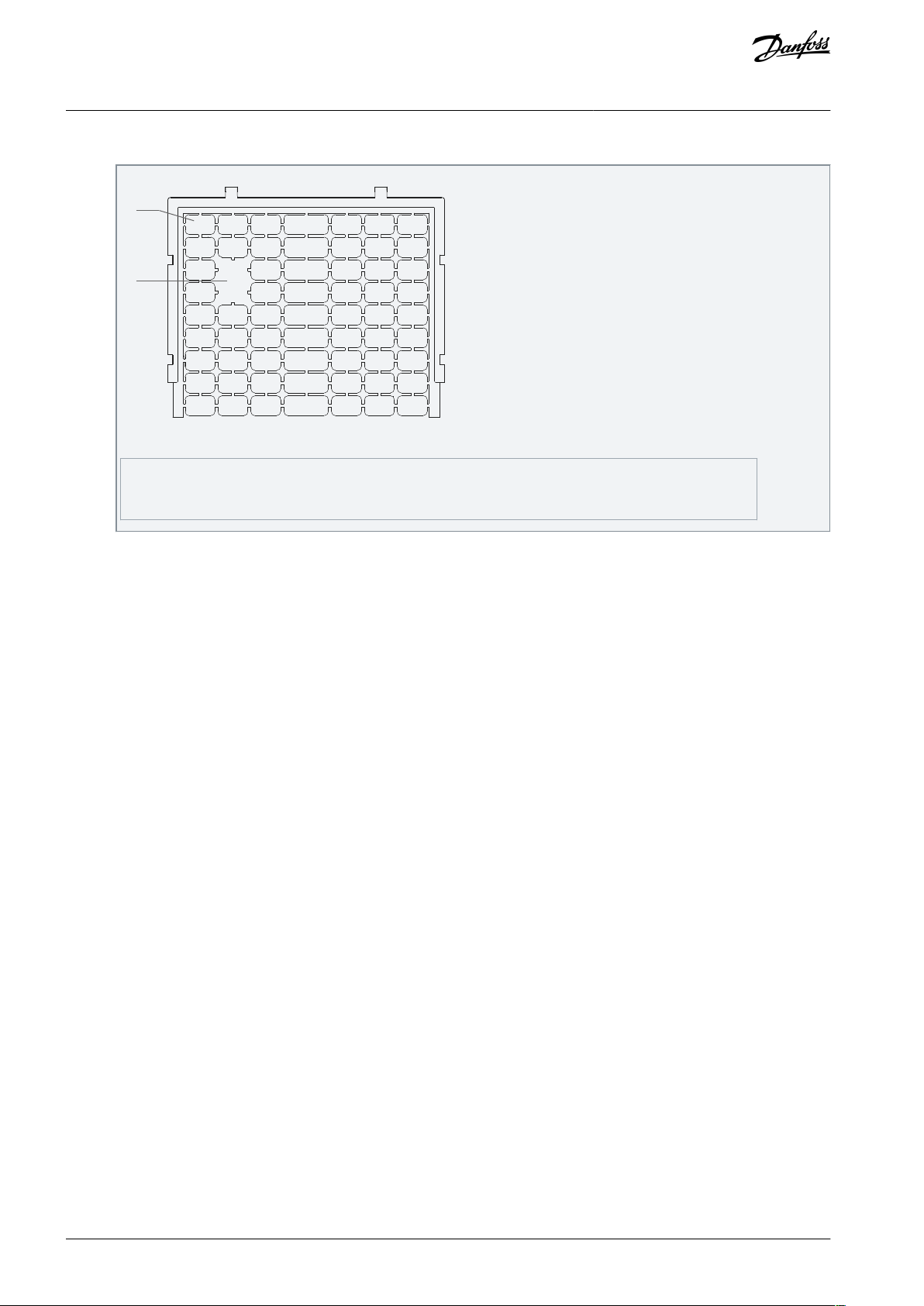

Illustration 2: Protective Cover

AQ304735638503en-000301 / 130R026510 | Danfoss A/S © 2021.10

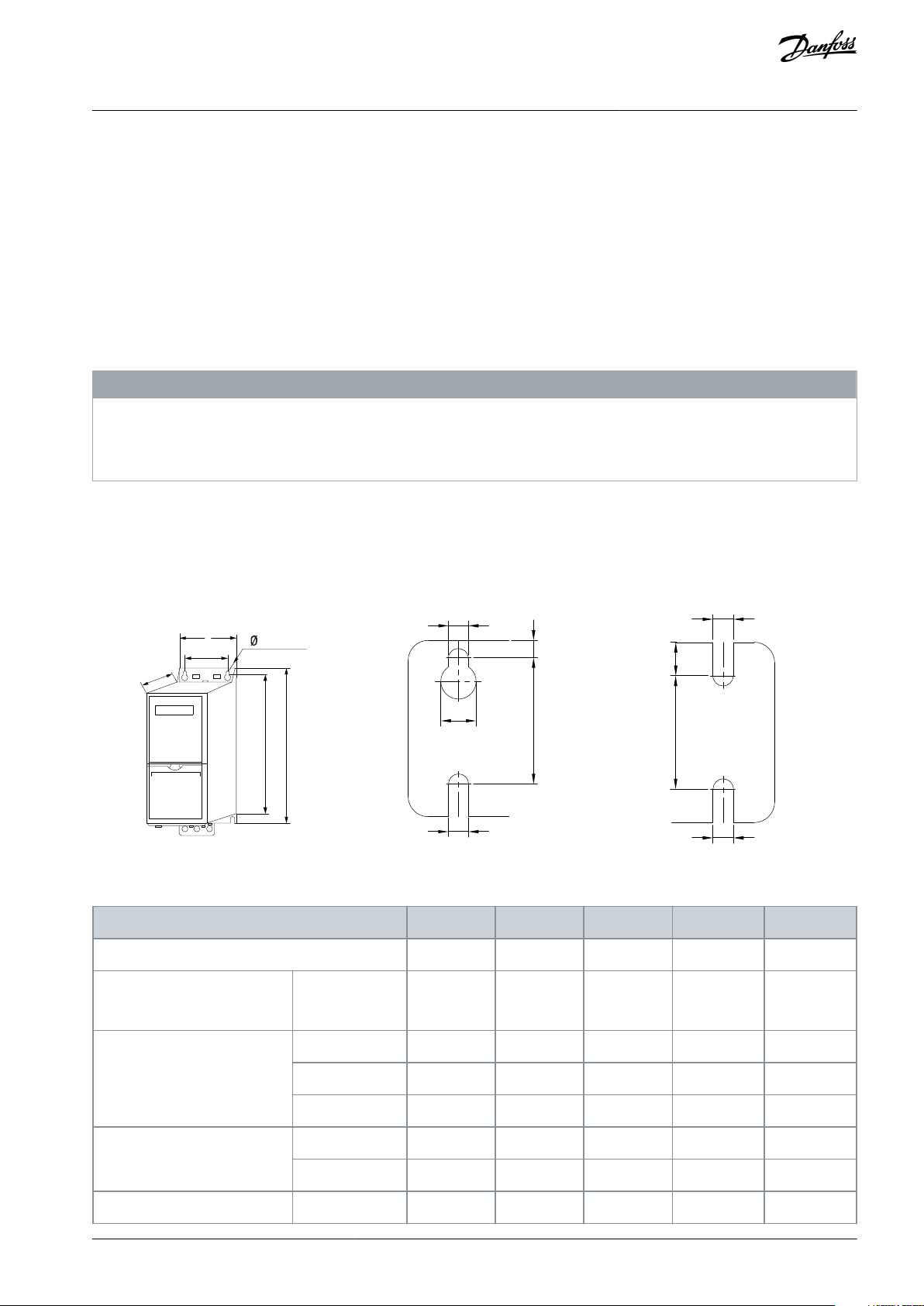

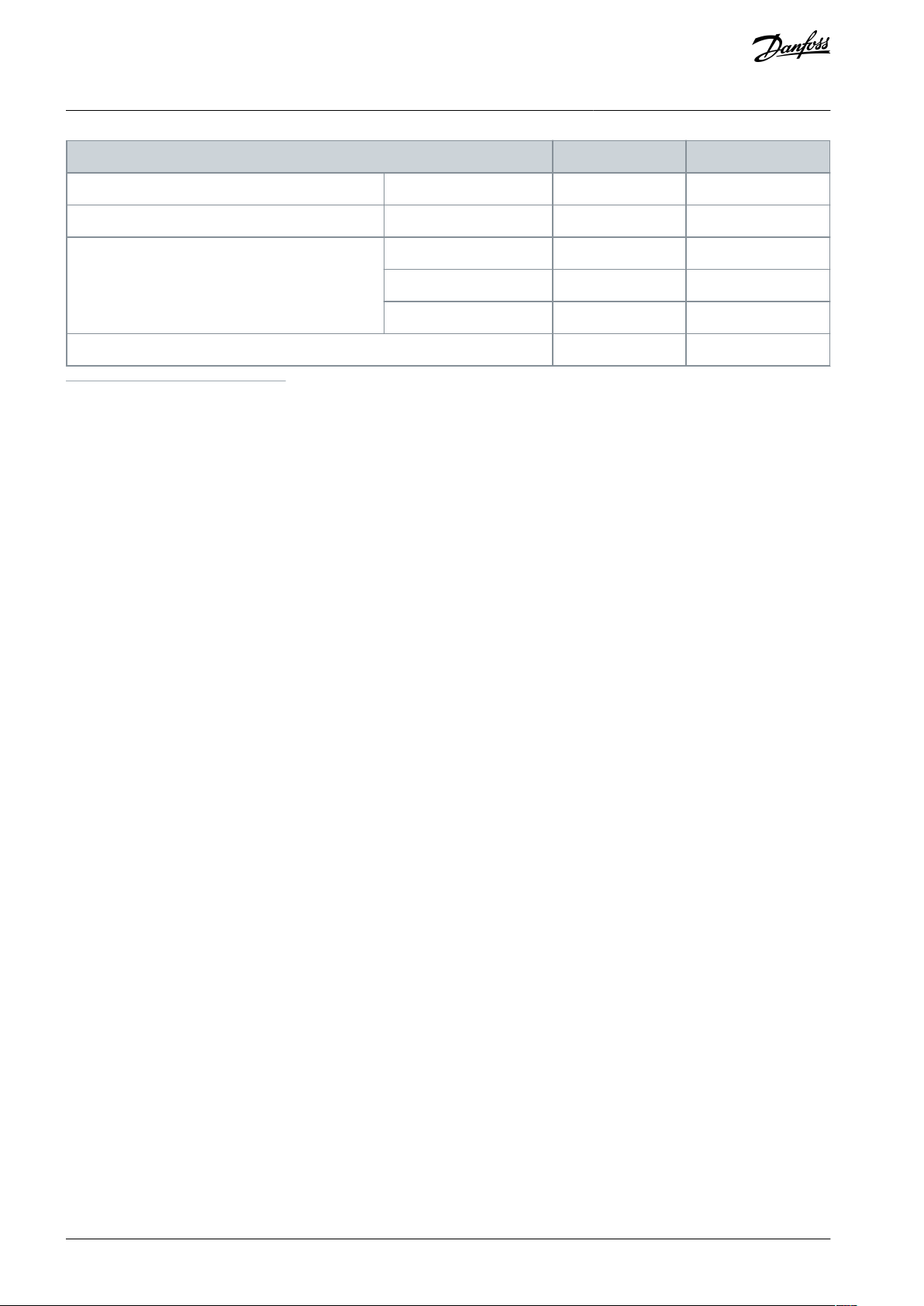

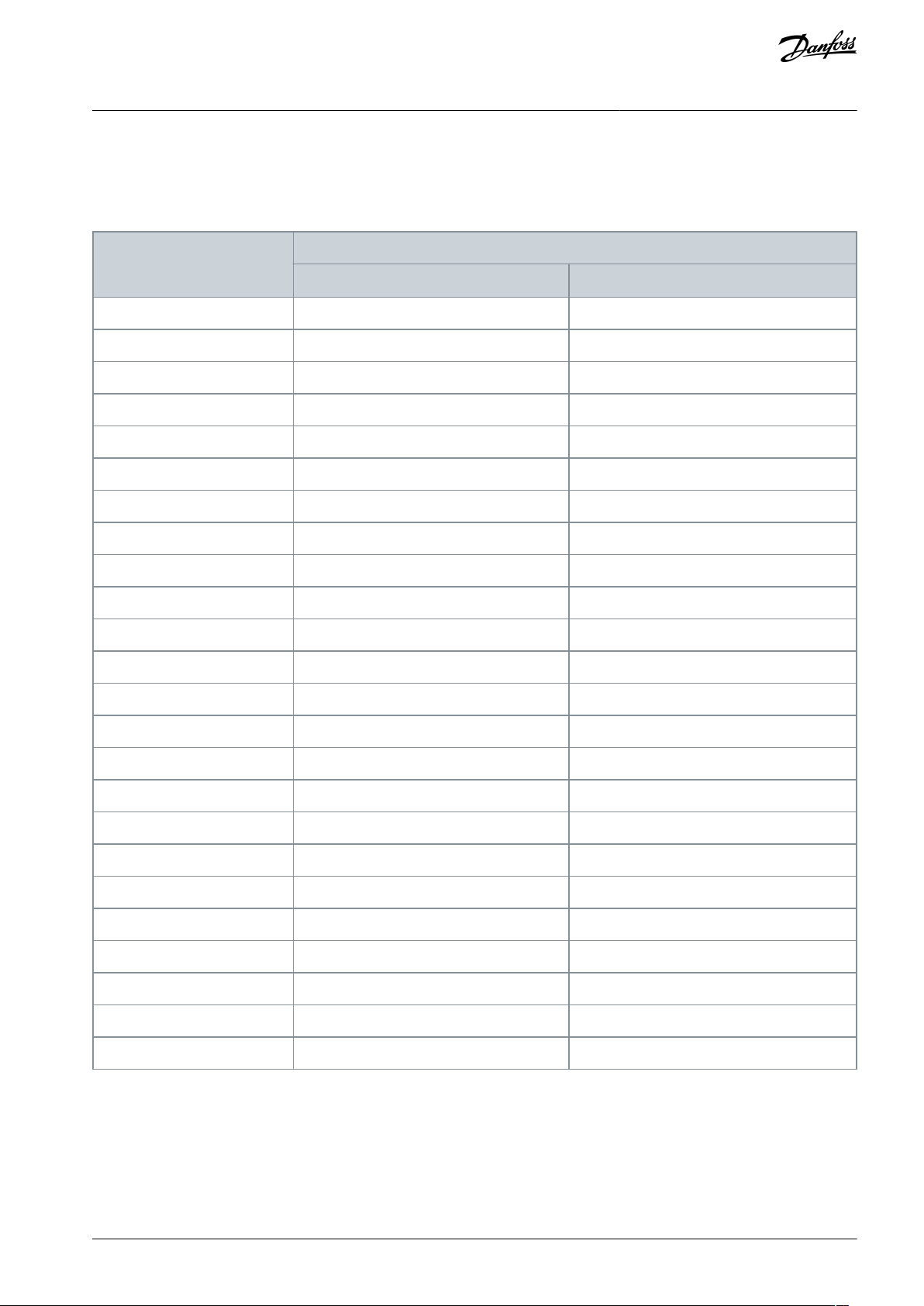

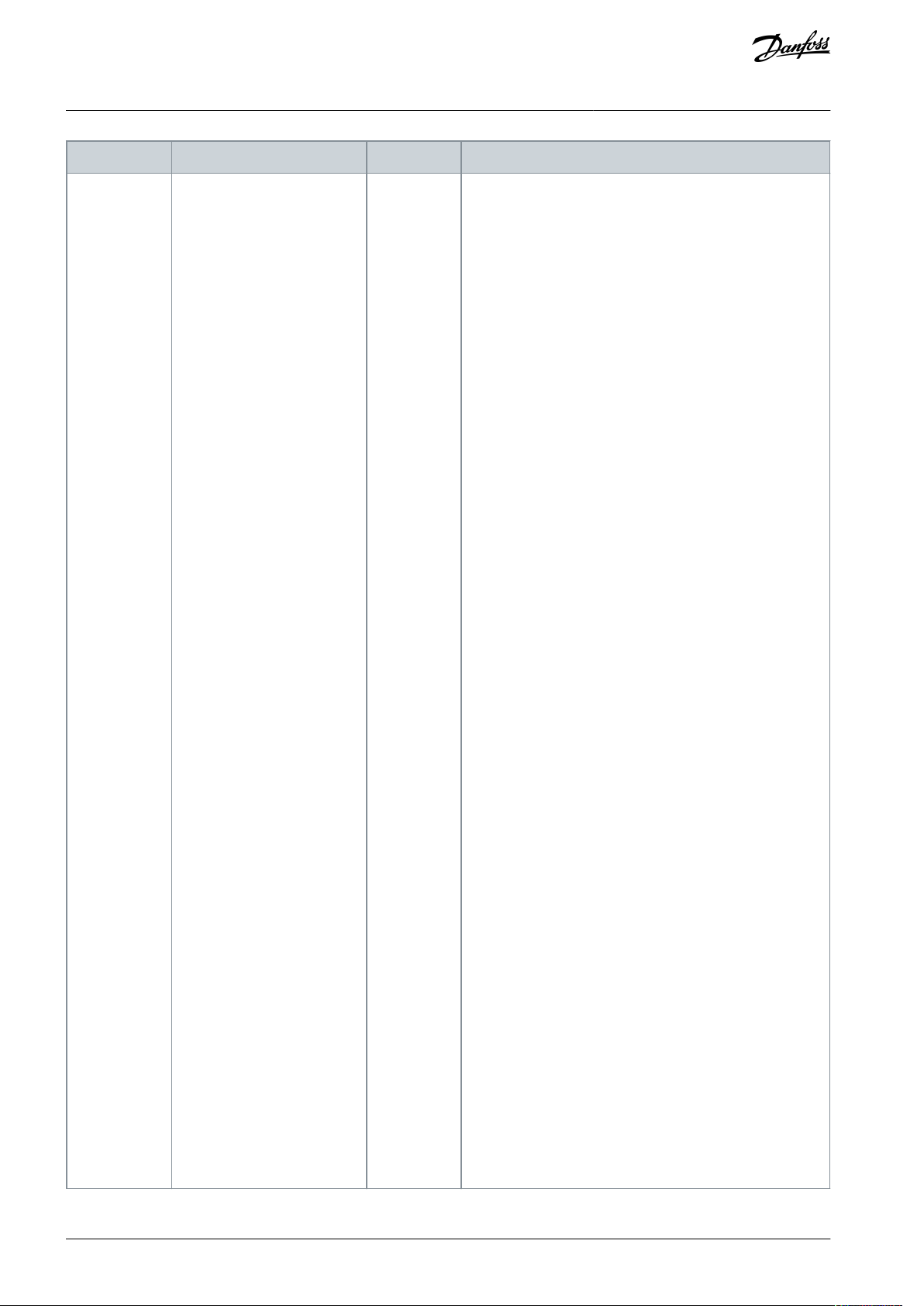

e30bu775.10

C

D

b1

B

b D

A

a

E

F

G

(1) (2)

(3)

1

Front view

2

Side view

3

Back view

Enclosure Size

H13

H14

IP class

IP20

IP20

Power [kW (hp)]

3x380–480 V

110–160

(150–250)

200–315

(300–450)

Height [mm (in)]

A

889 (35.0)

1096 (43.1)

A

(1)

909 (35.8)

1122 (44.2)

a

844 (33.2)

1051 (41.4)

Width [mm (in)]

B

250 (9.8)

350 (13.8)

b

180 (7.1)

280 (11.0)

b1

200 (7.9)

271 (10.7)

VLT® Flow Drive FC 111

Operating Guide

Product Overview

Illustration 3: Dimensions, Enclosure Sizes H13–H14

Table 5: Power Ratings, Weights, and Dimensions H13–H14

AQ304735638503en-000301 / 130R0265 | 11Danfoss A/S © 2021.10

Enclosure Size

H13

H14

Depth [mm (in)]

C

375 (14.8)

375 (14.8)

Mounting hole [mm (in)]

D

11 (0.4)

11 (0.4)

Center of gravity [mm (in)]

E

128 (5.0)

176 (6.9)

F

495 (19.5)

611 (24.1)

G

148 (5.8)

148 (5.8)

Maximum weight [kg (lb)]

98 (216)

164 (362)

VLT® Flow Drive FC 111

Operating Guide

1

Including decoupling plate.

The dimensions are only for the physical units.

Product Overview

3.3 Check Valve Monitoring

In the pump application system, a damaged check valve is hard to detect, which therefore causes low efficiency of the whole system. VLT® Flow Drive FC 111 can monitor the status of check valves in the system. After enabling the check valve monitoring function via setting parameter 22-04 Check Valve Monitor to [1] Enabled, the drive trips warning 159, Check Valve Failure if a damaged

check valve is detected.

3.4 Dry Pump Detection

In the pump application system, the drive monitors the operation status of the system to detect whether there is water on the

pump's suction side. If the pump runs at maximum speed and consumes little power, then it can be assumed that there is no water

on the pump's suction side. Via setting parameter 22-26 Dry Pump Function to warning or alarm, the drive trips warning/alarm 93, dry

pump if the dry-pump condition is detected.

3.5 End of Curve Detection

In the pump application system, the drive monitors the operation status of the system to detect whether the pressure side of pump

is subject to a major leakage. If the pump runs at maximum speed for a defined time period, but the pressure is below the set point,

then it can be considered to reflect the end-of-curve situation. Via setting parameter 22-50 End of Curve Function to warning or

alarm, the drive trips warning/alarm 94, end of curve if the end-of-curve condition is detected.

3.6 Time-based Functions

In some application scenarios, there are requirements to control the motor running for a specific time, in a specific direction and a

specific speed within a specific time interval. For example, checking the motor status in fire mode or exercising pumps, fans, and

compressors.

For detailed parameter settings, refer to the parameter group 23-** Time-based Functions in the drive's Programming Guide.

AQ304735638503en-000301 / 130R026512 | Danfoss A/S © 2021.10

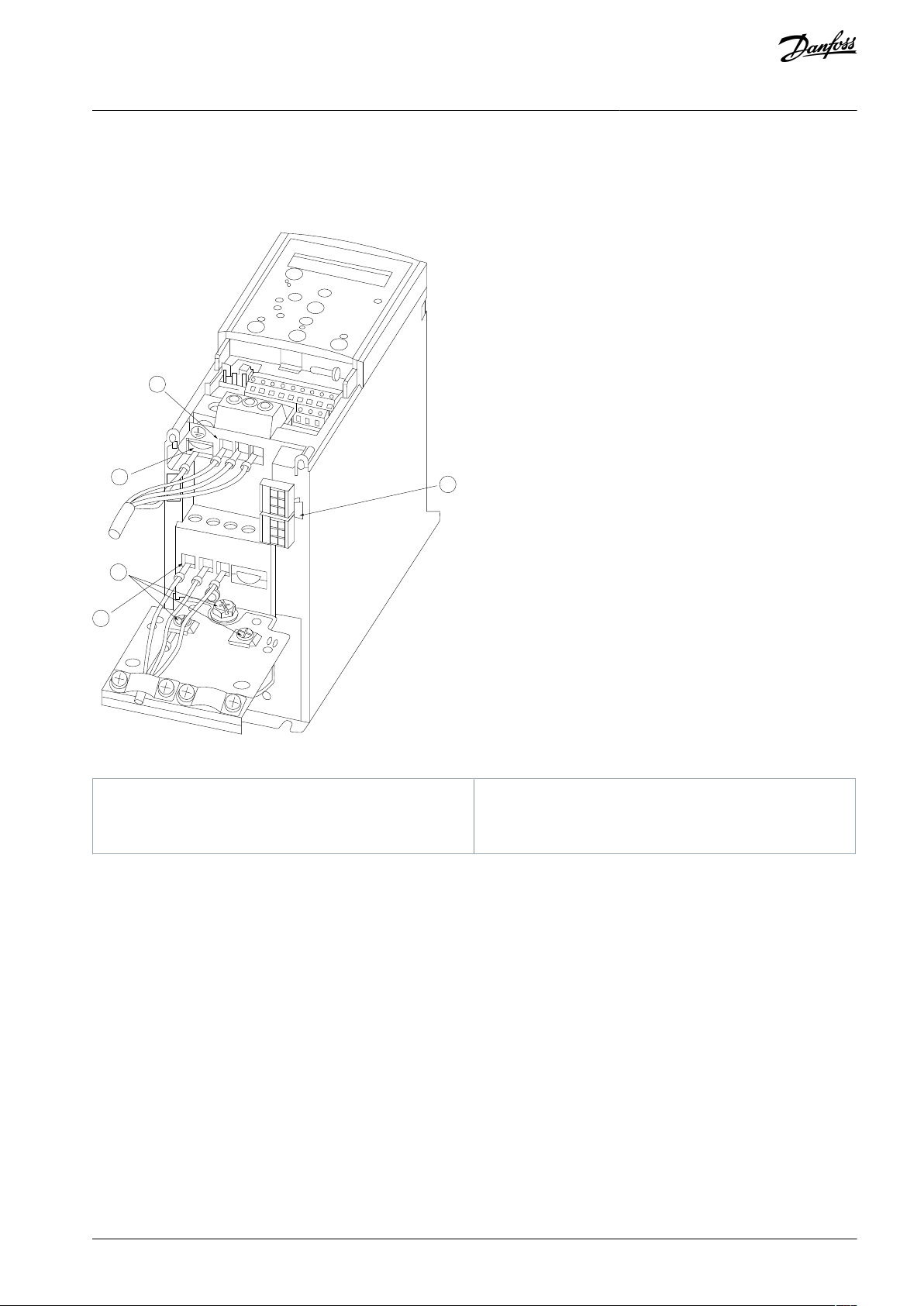

e30bb634.10

1

2

2

3

4

M

ot

or

U

V

W

-DC

+DC

M

AINS

1

Mains

2

Ground

3

Motor

4

Relays

VLT® Flow Drive FC 111

Operating Guide

3.7 Relays and Terminals

3.7.1 Relays and Terminals on Enclosure Sizes H1–H5

Product Overview

Illustration 4: Enclosure Sizes H1–H5 IP20, 380–480 V, 0.37–22 kW (0.5–30 hp)

AQ304735638503en-000301 / 130R0265 | 13Danfoss A/S © 2021.10

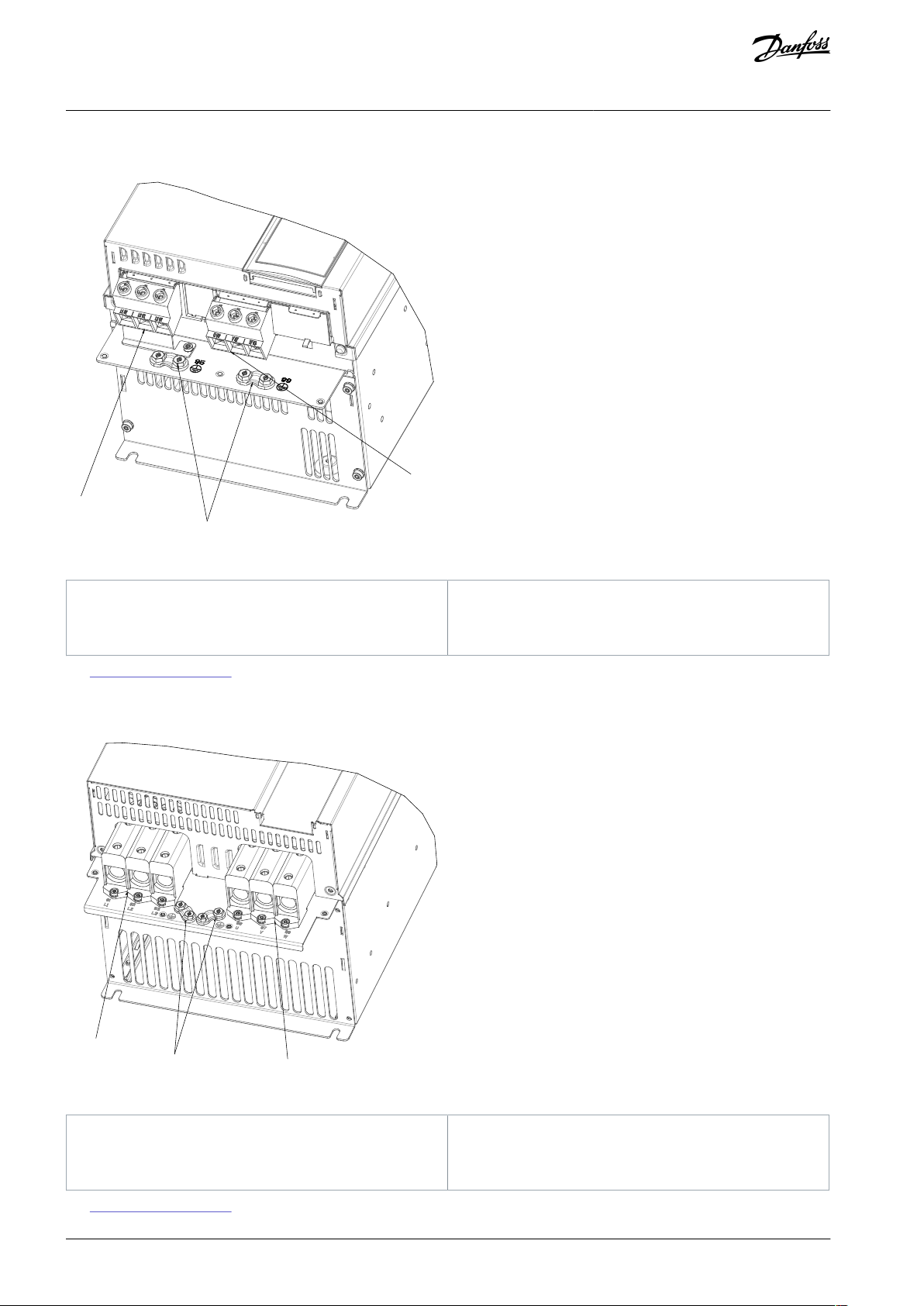

1

2

3

e30bu937.10

1

Mains

2

Ground

3

Motor

1

2

3

e30bu938.10

1

Mains

2

Ground

3

Motor

VLT® Flow Drive FC 111

Operating Guide

3.7.2 Relays and Terminals on Enclosure Size H11

Product Overview

Illustration 5: Enclosure Size H11 IP20, 380–480 V, 30–45 kW (40–60 hp)

See 3.8 View of Control Shelf for the relay terminals of H11 drives.

3.7.3 Relays and Terminals on Enclosure Size H12

Illustration 6: Enclosure Size H12 IP20, 380–480 V, 55–90 kW (75–125 hp)

See 3.8 View of Control Shelf for the relay terminals of H12 drives.

AQ304735638503en-000301 / 130R026514 | Danfoss A/S © 2021.10

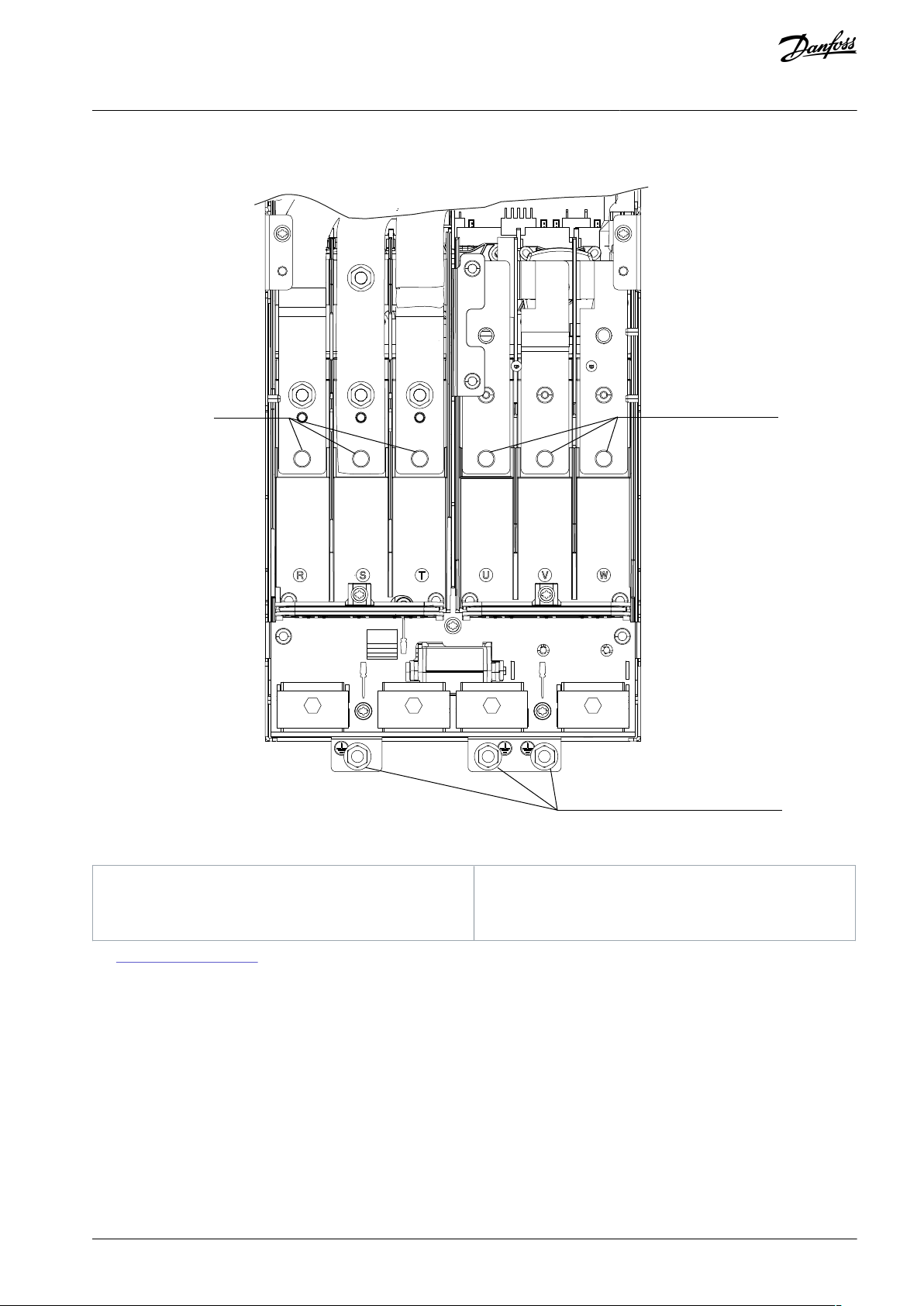

e30bu777 .10

1

2

3

1

Mains

2

Motor

3

Ground

VLT® Flow Drive FC 111

Operating Guide

3.7.4 Relays and Terminals on Enclosure Size H13–H14

Product Overview

Illustration 7: Enclosure Size H13–H14 IP20, 380–480 V, 110–315 kW (150–450 hp)

See 3.8 View of Control Shelf for the relay terminals of H13–H14 drives.

AQ304735638503en-000301 / 130R0265 | 15Danfoss A/S © 2021.10

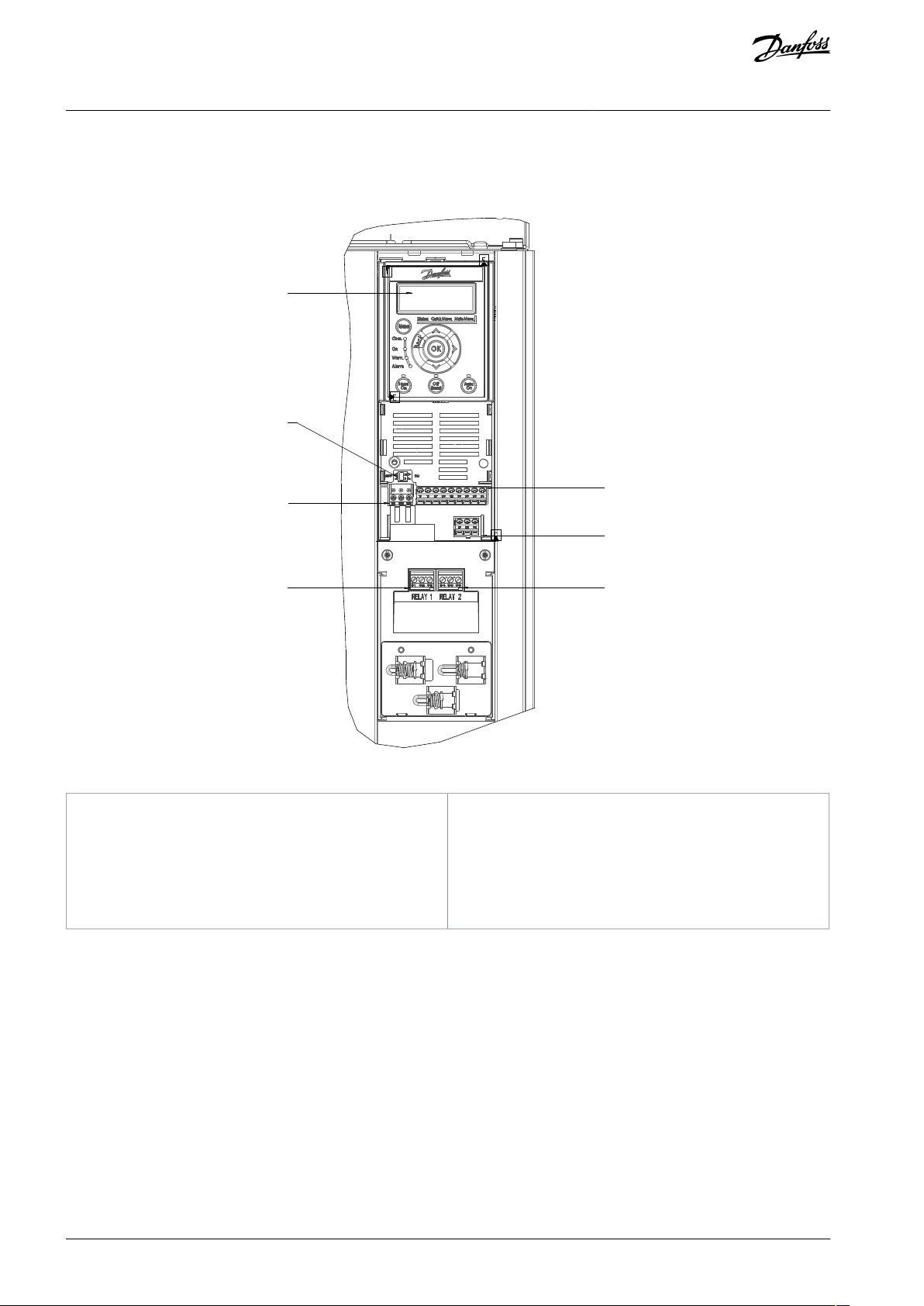

e30bu939.10

1

2

3

4

5

6

7

1

LCP2RS485 termination switch

3

RS485 fieldbus connector

4

Relay 1 on power card

5

Digital I/O and 24 V supply

6

Analog I/O connector

7

Relay 2 on power card

VLT® Flow Drive FC 111

Operating Guide

Product Overview

3.8 View of Control Shelf

The control shelf of H11-H14 drives holds the keypad, known as the local control panel or LCP. The control shelf also includes the

control terminals, relays, and various connectors.

Illustration 8: View of Control Shelf in H11–H12

AQ304735638503en-000301 / 130R026516 | Danfoss A/S © 2021.10

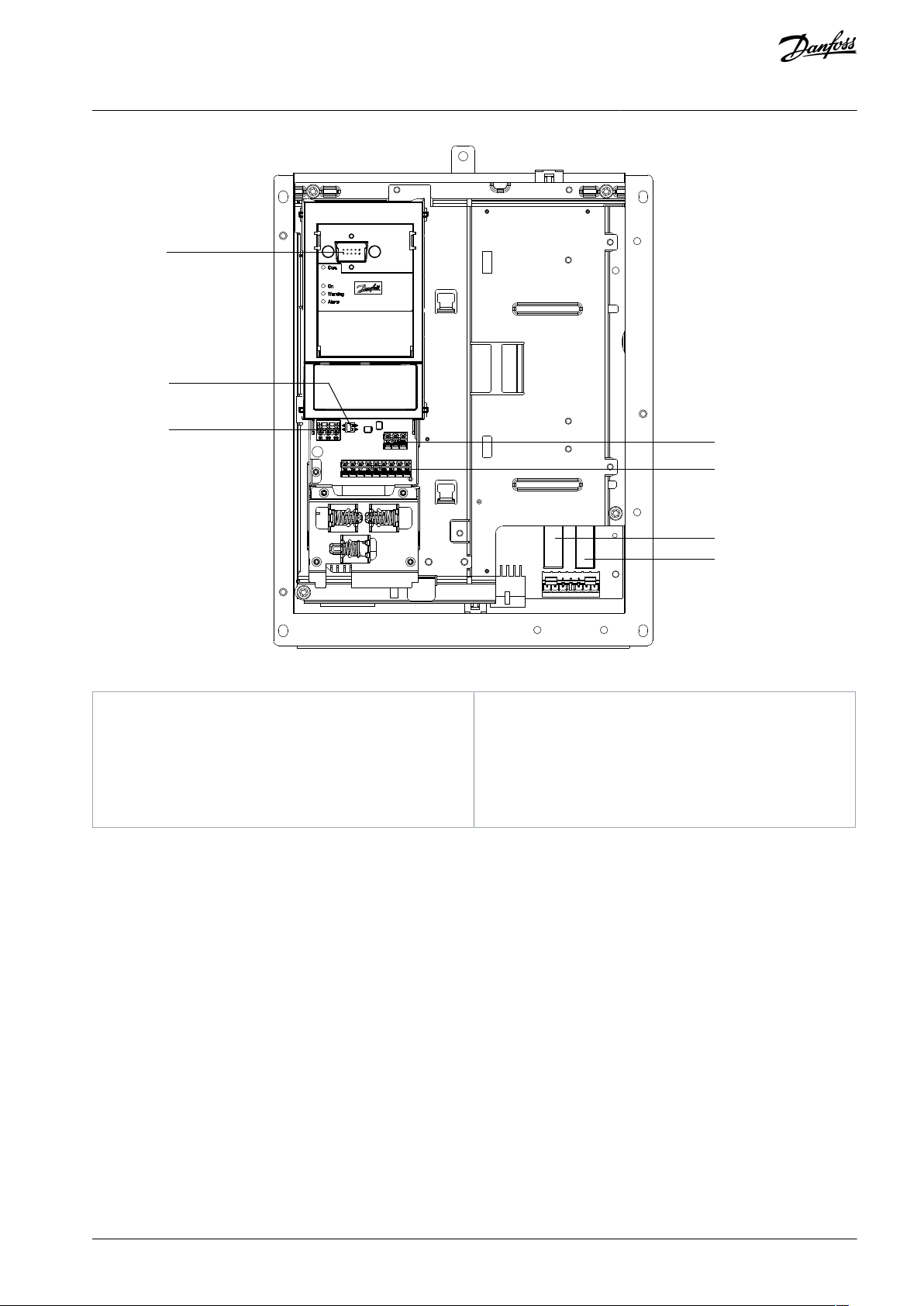

e30bu776.10

1

2

3

4

5

6

7

1

LCP connector

2

RS485 termination switch

3

RS485 fieldbus connector

4

Analog I/O connector

5

Digital I/O and 24 V supply

6

Relay 1 on power card

7

Relay 2 on power card

VLT® Flow Drive FC 111

Operating Guide

Product Overview

Illustration 9: View of Control Shelf in H13–H14

AQ304735638503en-000301 / 130R0265 | 17Danfoss A/S © 2021.10

Voltage [V]

Altitude restrictions

380–480

At altitudes above 3000 m (9842 ft), contact Danfoss regarding PELV.

VLT® Flow Drive FC 111

Operating Guide

Mechanical Installation

4 Mechanical Installation

4.1 Storage and Operating Environment

Storage

Store the drive in a dry location. Keep the equipment sealed in its packaging until installation. Refer to the Ambient Conditions

section for recommended ambient temperature.

Periodic forming (capacitor charging) is not necessary during storage unless storage exceeds 12 months.

Operating Environment

N O T I C E

OPERATING ENVIRONMENT

In environments with airborne liquids, particles, or corrosive gases, failure to meet requirements for ambient conditions can re-

duce the lifetime of the drive.

Ensure that the IP/Type rating of the equipment matches the installation environment.

-

Ensure that requirements for air humidity, temperature, and altitude are met.

-

Table 6: Installation at High Altitudes

N O T I C E

CONDENSATION

Moisture can condense on the electronic components and cause short circuits.

Avoid installation in areas subject to frost.

-

Install an optional space heater when the drive is colder than the ambient air.

-

Operating in standby mode reduces the risk of condensation as long as the power dissipation keeps the circuitry free of

-

moisture.

N O T I C E

EXTREME AMBIENT CONDITIONS

Hot or cold temperatures compromise unit performance and longevity.

Do not operate in environments where the ambient temperature exceeds 55 °C (131 °F).

-

The drive can operate at temperatures down to -15 °C (5 °F). However, proper operation at rated load is only guaranteed at

-

0 °C (32 °F) or higher.

Extra air conditioning of the cabinet or installation site is required if temperature exceeds ambient temperature limits.

-

W A R N I N G

EXPLOSIVE ATMOSPHERE

Do not install the drive in a potentially explosive atmosphere.

Install the unit in a cabinet outside of this area.

-

Failure to follow this guideline increases risk of death or serious injury.

-

AQ304735638503en-000301 / 130R026518 | Danfoss A/S © 2021.10

Size

IP class

Power [kW (hp)]

Clearance above/below [mm (in)]

3x380–480 V

H1

IP20

0.37–1.5 (0.5–2.0)

100 (4)

H2

IP20

2.2–4.0 (3.0–5.4)

100 (4)

H3

IP20

5.5–7.5 (7.5–10)

100 (4)

H4

IP20

11–15 (15–20)

100 (4)

H5

IP20

18.5–22 (25–30)

100 (4)

H11

IP20

30–45 (40–60)

200 (7.9)

H12

IP20

55–90 (70–125)

200 (7.9)

H13

IP20/Chassis

110–160 (150–250)

225 (9)

H14

IP20/Chassis

200–315 (300–450)

225 (9)

VLT® Flow Drive FC 111

Operating Guide

Mechanical Installation

N O T I C E

GASES

Aggressive gases, such as hydrogen sulfide, chlorine, or ammonia can damage the electrical and mechanical components.

The unit uses conformal-coated circuit boards to reduce the effects of aggressive gases.

-

When installing the drive in dusty environments, pay attention to the following:

Periodic maintenance

When dust accumulates on electronic components, it acts as a layer of insulation. This layer reduces the cooling capacity of the

components, and the components become warmer. The hotter environment decreases the life of the electronic components. Keep

the heat sink and fans free from dust build-up.

Cooling fans

Fans provide airflow to cool the drive. When fans are exposed to dusty environments, the dust can damage the fan bearings and

cause premature fan failure. Also, dust can accumulate on fan blades causing an imbalance which prevents the fans from properly

cooling the unit.

4.2 Side-by-side Installation

The drive can be mounted side by side but requires the clearance above and below for cooling.

Table 7: Clearance Required for Cooling

With IP21 option kit mounted (available for H1–H5 & H11–H12), a distance of 50 mm (2 in) between the units is required.

N O T I C E

AQ304735638503en-000301 / 130R0265 | 19Danfoss A/S © 2021.10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Tools

Needed

Receiving/unloading

Installation

H1–H5

–

3 mm flat-edged screwdriver for terminals.

T20 torx head screwdriver for M5 grounding screw.

H11–

H12

I-beam and hooks rated to lift the weight of the drive.

Refer to 3.2 Power Ratings, Weights, and Dimensions.

Crane or other lifting aid to place the unit into position.

Allen key 6# (for M8).

T30 torx head screwdriver for terminals.

T25 torx head screwdriver for M6 grounding screw.

H13–

H14

Drill with a 12 mm (1/2 in) drill bit.

Tape measurer.

Phillips and flat bladed screwdrivers.

Wrench with 7–17 mm metric sockets.

Wrench extensions.

T25 and T50 torx drives.

Sheet metal punch and/or pliers for cable entry plate.

VLT® Flow Drive FC 111

Operating Guide

4.3 Tools Needed

Table 8: Tools Needed

Mechanical Installation

4.4 Installation and Cooling Requirements

OVERHEATING

Improper mounting can result in overheating and reduced performance.

Install the drive according to the installation and cooling requirements.

-

Installation requirements

•

Ensure drive stability by mounting the drive vertically to a solid flat surface.

•

Ensure that the strength of the mounting location supports the drive weight. Ensure that the mounting location allows access

to open the enclosure door. Refer to 3.2 Power Ratings, Weights, and Dimensions.

•

Ensure that there is enough space around the drive for cooling airflow.

•

Place the drive as near to the motor as possible. Keep the motor cables as short as possible. See 10.4.4 Cable Length and Cross-

section.

•

Ensure the location allows for cable entry at the bottom of the drive.

Cooling and airflow requirements

•

Ensure that top and bottom clearance for air cooling is provided, see 4.2 Side-by-side Installation.

•

Consider derating for temperatures starting between 40 °C (104 °F) and 55 °C (131 °F) and elevation 1000 m (3300 ft) above sea

level. See chapter Derating in the Design Guide for detailed information.

•

The drive's maximum heating value could be estimated via the following equation:

Maximumheatingvalue ≈ Power × 1 − Efficiency

For example, the heating value of 110 kW (150 hp) drive could be 2.2 kW. Refer to 10.1.1 3x380–480 V AC for the drive's efficiency at rated load.

•

If multiple drives are installed in 1 cabinet at the same time, the heating value and ventilation volume shall be accumulated.

N O T I C E

AQ304735638503en-000301 / 130R026520 | Danfoss A/S © 2021.10

Power [kW (hp)]

Ventilation volume reference value of the cabinet

CFM

m3/hr

0.37 (0.5)

240.75 (1.0)

471.5 (2.0)

8142.2 (3.0)

9153 (4.0)

13224 (5.0)

19325.5 (7.5)

22377.5 (10)

406811 (15)

73

125

15 (20)

100

170

18.5 (25)

135

229

22 (30)

160

272

30 (40)

178

303

37 (50)

220

374

45 (60)

240

408

55 (70)

257

436

75 (100)

350

595

90 (125)

370

629

110 (150)

414

704

132 (175)

499

849

160 (250)

605

1029

200 (300)

757

1286

250 (350)

887

1507

315 (450)

1118

1900

VLT® Flow Drive FC 111

Operating Guide

••If there are other heating devices, increase the ventilation according to the instructions.

If the dust screen needs to be installed, the air volume needs to be appropriately increased according to the wind resistance

coefficient of the dust screen. For the wind resistance coefficient of dust screen, contact the dust screen supplier.

Table 9: Ventilation Volume Reference Value of the Cabinet

Mechanical Installation

AQ304735638503en-000301 / 130R0265 | 21Danfoss A/S © 2021.10

e30bg512.11

65° min

VLT® Flow Drive FC 111

Operating Guide

Mechanical Installation

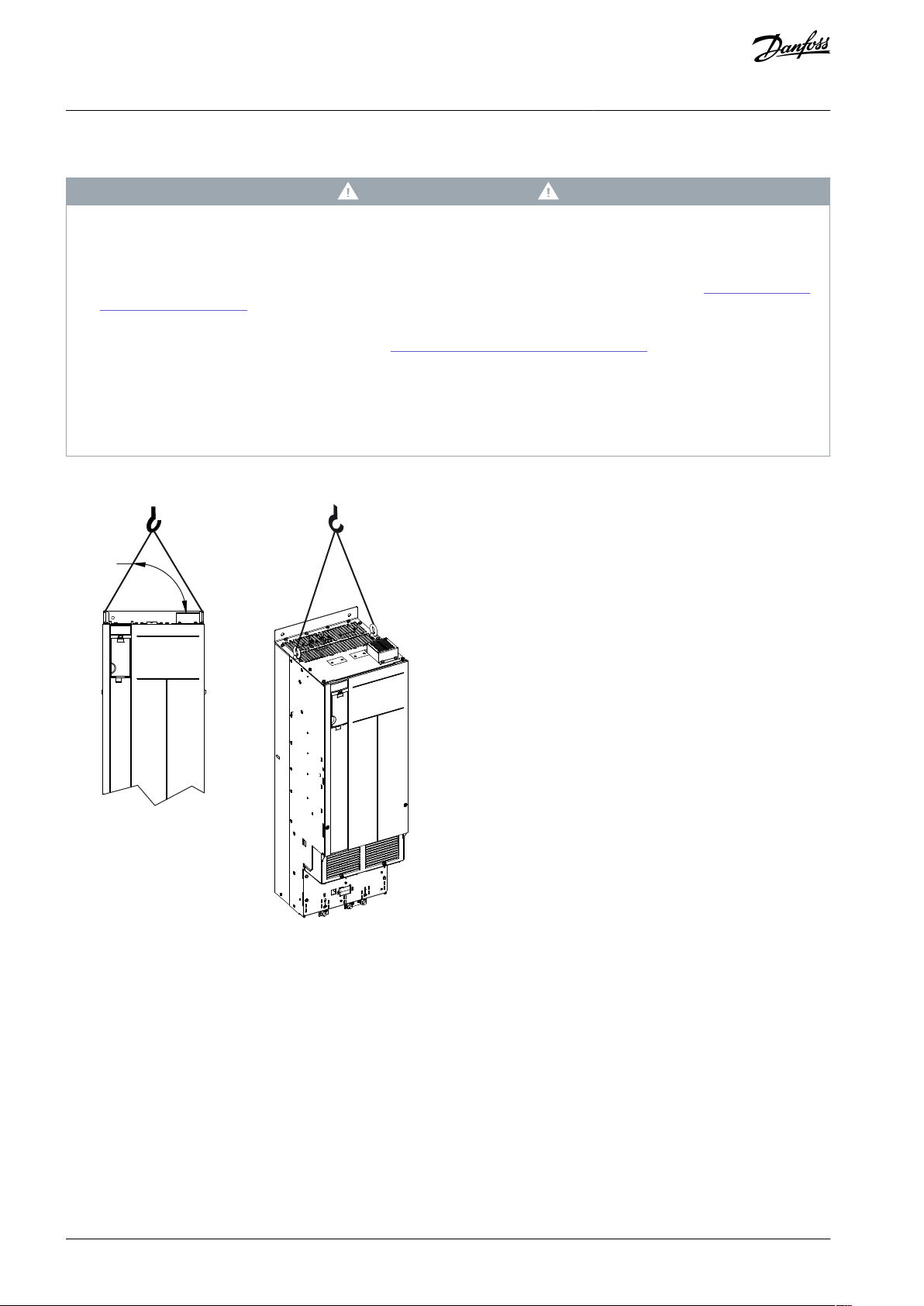

4.5 Lifting the Drive

W A R N I N G

HEAVY LOAD

Unbalanced loads can fall or tip over. Failure to take proper lifting precautions increases risk of death, serious injury, or equip-

ment damage.

Move the unit using a hoist, crane, forklift, or other lifting device with the appropriate weight rating. See 3.2 Power Ratings,

-

Weights, and Dimensions for the weight of the drive.

Failure to locate the center of gravity and correctly position the load can cause unexpected shifting during lifting and trans-

-

port. For measurements and center of gravity, see 3.2 Power Ratings, Weights, and Dimensions.

The angle from the top of the drive module to the lifting cables affects the maximum load force on the cable. This angle

-

must be 65° or greater. Refer to the following illustration. Attach and dimension the lifting cables properly.

Never walk under suspended loads.

-

To guard against injury, wear personal protective equipment such as gloves, safety glasses, and safety shoes.

-

Always lift the drive using the dedicated eye bolts at the top of the drive. See the following illustration.

Illustration 10: Lifting the Drive

4.6 Wall Mounting the Drive

H13 and H14 are chassis drives intended to be mounted on a wall or on a mounting plate within an enclosure. To wall mount the

drive, use the following steps.

Procedure

1.

Fasten 2 M10 bolts in the wall to align with the fastener slots at the bottom of drive.

2.

Slide the lower fastener slots in the drive over the M10 bolts.

AQ304735638503en-000301 / 130R026522 | Danfoss A/S © 2021.10

1

2

e30bg288.10

1

Top mounting holes

2

Lower fastener slots

VLT® Flow Drive FC 111

Operating Guide

3. Tip the drive against the wall, and secure the top with 2 M10 bolts in the mounting holes.

Example

Mechanical Installation

Illustration 11: Drive-to-wall Mounting Holes

4.7 Creating Cable Openings

After installing H13-H14 drive, create cable openings in the gland plate to accommodate the mains and motor cables. The gland

plate is required to maintain the drive protection rating.

Procedure

AQ304735638503en-000301 / 130R0265 | 23Danfoss A/S © 2021.10

1

e30bf662.10

2

1

Plastic tabs

2

Tabs removed for cable access

VLT® Flow Drive FC 111

Operating Guide

1. Punch out plastic tabs to accommodate the cables.

Illustration 12: Cable Openings in Plastic Gland Plate

Mechanical Installation

AQ304735638503en-000301 / 130R026524 | Danfoss A/S © 2021.10

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

5 Electrical Installation

5.1 Safety Instructions

See chapter Safety for general safety instructions.

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables from different drives that are run together can charge equipment capacitors even

with the equipment turned off and locked out. Failure to run output motor cables separately or use shielded cables could result

in death or serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out all the drives.

-

W A R N I N G

SHOCK HAZARD

The drive can cause a DC current in the ground conductor and thus result in death or serious injury. Failure to follow the recom-

mendation means that the residual current-operated protective device (RCD) cannot provide the intended protection.

When a residual current-operated protective device (RCD) is used for protection against electrical shock, only an RCD of Type

-

B is allowed on the supply side.

Overcurrent protection

•

Additional protective equipment such as short-circuit protection or motor thermal protection between drive and motor is required for applications with multiple motors.

•

Input fusing is required to provide short circuit and overcurrent protection. If fuses are not factory-supplied, the installer must

provide them. See maximum fuse ratings in chapter Fuses and Circuit Breakers.

Wire type and ratings

•

All wiring must comply with local and national regulations regarding cross-section and ambient temperature requirements.

•

Power connection wire recommendation: Minimum 75 °C (167 °F) rated copper wire.

See 10.4.4 Cable Length and Cross-section for recommended wire sizes and types.

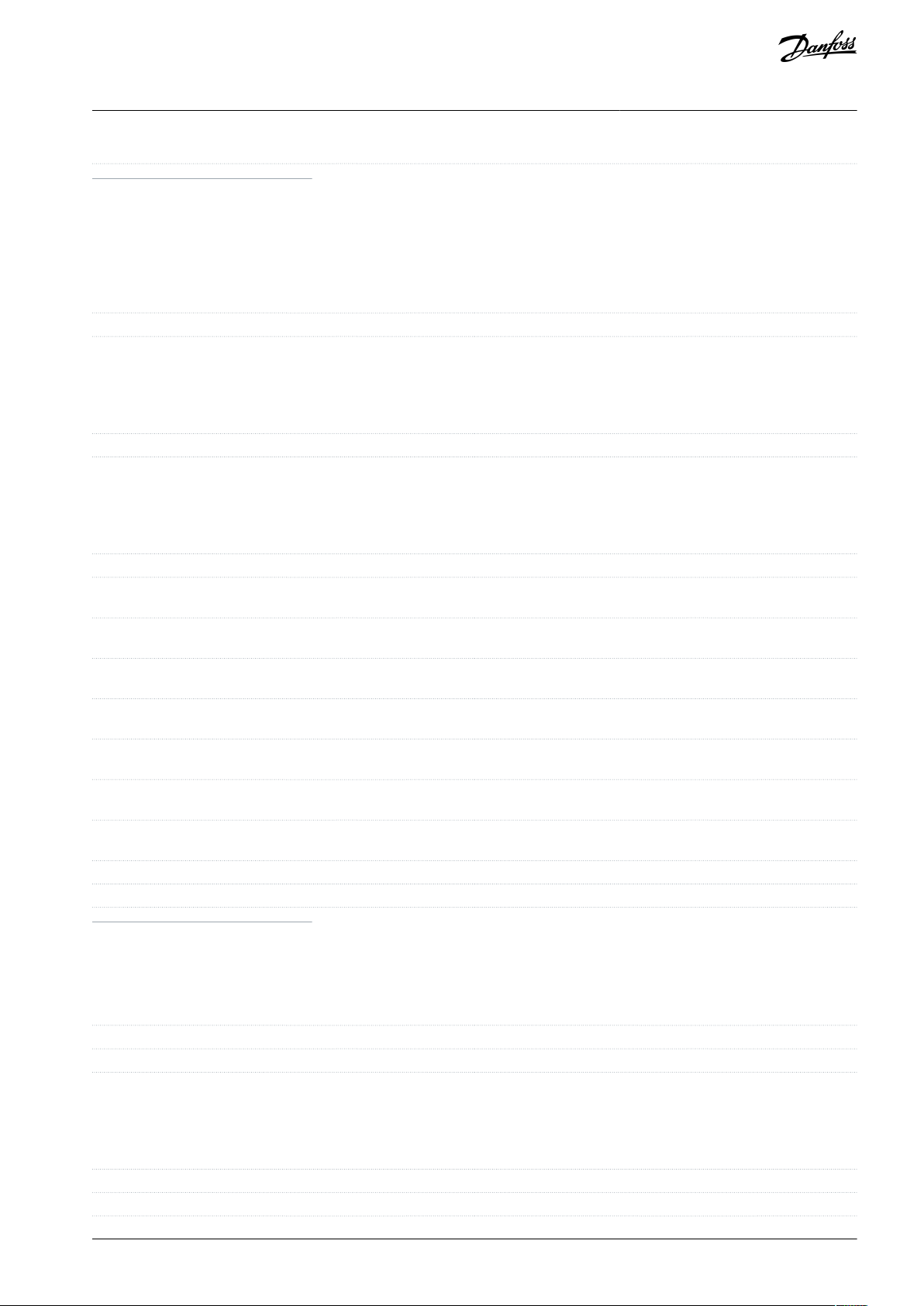

5.2 EMC-compliant Electrical Installation

To ensure EMC-correct electrical installation, observe the following:

•

Use only shielded/armored motor cables and shielded/armored control cables.

•

Ground the shield at both ends.

•

Avoid installation with twisted shield ends (pigtails), because it reduces the shielding effect at high frequencies. Use the cable

clamps provided.

•

Ensure the same potential between the drive and the ground potential of PLC.

•

Use star washers and galvanically conductive installation plates.

AQ304735638503en-000301 / 130R0265 | 25Danfoss A/S © 2021.10

B

a

c

k

OK

Com.

On

Warn.

Alarm

Hand

On

Reset

Auto

On

Menu

Status Quick

Menu

Main

Menu

L1

L2

L3

PE

Minimum 16 mm

2

equalizing cable

Control cables

All cable entries in

one side of the panel

Grounding rail

Cable insulation stripped

Output contactor

Motor cable

Motor, 3 phases and

PLC

Panel

Mains-supply

Minimum 200 mm (7.87 in)

between control

cable, mains cable,

and between mains

motor cable

PLC

protective earth

Reinforced protective earth

e30bb761.13

(6 AWG)

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

Illustration 13: EMC-compliant Installation

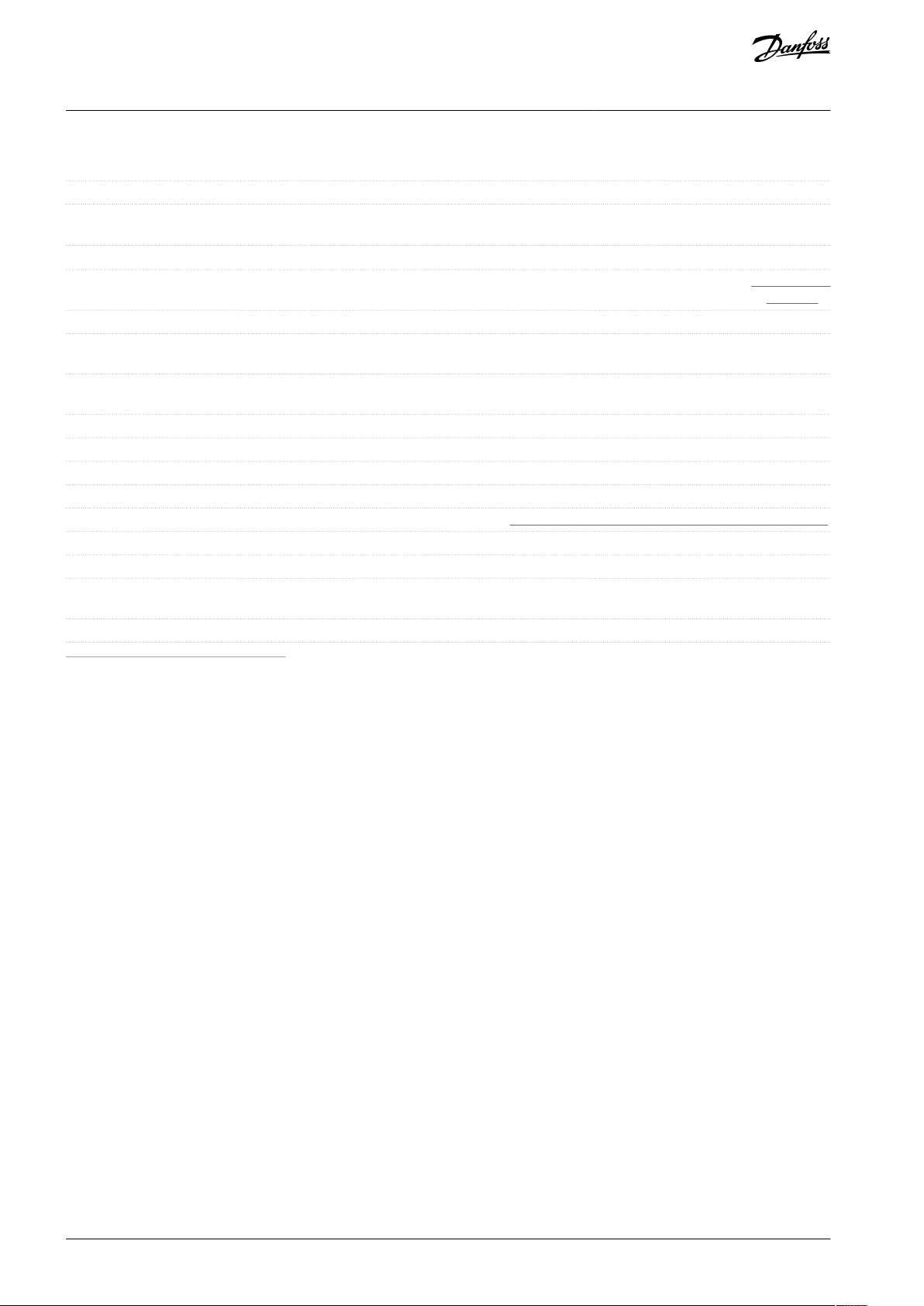

5.3 Electrical Wiring

AQ304735638503en-000301 / 130R026526 | Danfoss A/S © 2021.10

L1

L2

L3

3-phase

power

input

PE

PE

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN/OUT)

29 (D IN/OUT)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bd467.12

06

05

04

240 V AC 3 A

Power [kW (hp)]

Torque [Nm (in-lb)]

Enclosure size

IP class

3x380–480 V

Mains

Motor

DC connection

Control terminals

Ground

Relay

H1

IP20

0.37–1.5 (0.5–2.0)

0.8 (7)

0.8 (7)

0.8 (7)

0.5 (4)

0.8 (7)

0.5 (4)

H2

IP20

2.2–4.0 (3.0–5.4)

0.8 (7)

0.8 (7)

0.8 (7)

0.5 (4)

0.8 (7)

0.5 (4)

H3

IP20

5.5–7.5 (7.5–10)

0.8 (7)

0.8 (7)

0.8 (7)

0.5 (4)

0.8 (7)

0.5 (4)

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

Illustration 14: Basic Wiring Schematic Drawing

There is no access to UDC- and UDC+ on the following units:

-

5.4 Fastener Tightening Torques

Apply the correct torque when tightening fasteners in the locations that are listed in the following tables. Too low or too high torque when fastening an electrical connection results in a bad electrical connection. To ensure correct torque, use a torque wrench.

Table 10: Tightening Torques for Enclosure Sizes H1–H5 & H11–H12, 3x380–480 V

IP20, 380–480 V, 30–315 kW (40–450 hp)

N O T I C E

AQ304735638503en-000301 / 130R0265 | 27Danfoss A/S © 2021.10

Power [kW (hp)]

Torque [Nm (in-lb)]

Enclosure size

IP class

3x380–480 V

Mains

Motor

DC connection

Control terminals

Ground

Relay

H4

IP20

11–15 (15–20)

1.2 (11)

1.2 (11)

1.2 (11)

0.5 (4)

0.8 (7)

0.5 (4)

H5

IP20

18.5–22 (25–30)

1.2 (11)

1.2 (11)

1.2 (11)

0.5 (4)

0.8 (7)

0.5 (4)

H11

IP20

30–45 (40–60)

4.5 (40)

4.5 (40)

–

0.5 (4)

3 (27)

0.5 (4)

H12

IP20

55 (70)

10 (89)

10 (89)

–

0.5 (4)

3 (27)

0.5 (4)

H12

IP20

75 (100)

14 (124)

14 (124)

–

0.5 (4)

3 (27)

0.5 (4)

H12

IP20

90 (125)

24 (212)

(1)

24 (212)

(1)

–

0.5 (4)

3 (27)

0.5 (4)

Location

Bolt size

Torque [Nm (in-lb)]

Mains terminals

M10/M12

19 (168)/37 (335)

Motor terminals

M10/M12

19 (168)/37 (335)

Ground terminals

M8/M10

9.6 (84)/19.1 (169)

Relay terminals

–

0.5 (4)

Door/panel cover

M5

2.3 (20)

Gland plate

M5

2.3 (20)

e30bb612.10

1

1

EMC screw

VLT® Flow Drive FC 111

Operating Guide

1

Cable dimensions >95 mm2.

Table 11: Tightening Torques for Enclosure Sizes H13–H14, 3x380–480 V

Electrical Installation

5.5 IT Mains

C A U T I O N

IT MAINS

Installation on isolated mains source, that is, IT mains.

Ensure that the supply voltage does not exceed 440 V (3x380–480 V units) when connected to mains.

-

For 380–480 V, IP20, 0.37–22 kW (0.5–30 hp) units, open the RFI switch by removing the screw on the side of the drive when at IT

grid.

Illustration 15: IP20, 0.37–22 kW (0.5–30 hp), 380–480 V

AQ304735638503en-000301 / 130R026528 | Danfoss A/S © 2021.10

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

N O T I C E

If reinserted, use only M3x12 screw.

For 380–480 V, 30–90 kW (40–125 hp) units, set parameter 14-50 RFI Filter to [0] Off when operating in IT mains.

For 380–480 V, 110–315 kW (150–450 hp) units, if the drive is supplied from an isolated mains source (IT mains, floating delta, or

grounded delta) or TT/TN-S mains with grounded leg, the RFI switch is recommended to be turned off via parameter 14-50 RFI Filter

on the drive and parameter 14-50 RFI Filter on the filter. For more details, see IEC 364-3. In the [Off] position, the filter capacitors

between the chassis and the DC link are cut off to avoid damage to the DC link and to reduce the ground capacity currents, according to IEC 61800-3.

If optimum EMC performance is needed, or parallel motors are connected, or the motor cable length is above 25 m (82 ft), Danfoss

recommends setting parameter 14-50 RFI Filter to [On]. It is important to use isolation monitors that are rated for use together with

power electronics (IEC 61557-8).

5.6 Mains and Motor Connection

5.6.1 Introduction

The drive is designed to operate all standard 3-phase asynchronous motors.

Use a shielded/armored motor cable to comply with EMC emission specifications and connect this cable to both the decoupling

•

plate and the motor.

•

Keep the motor cable as short as possible to reduce the noise level and leakage currents.

For further details on mounting the decoupling plate, see the relevant Decoupling Plate Installation Guide.

•

Also see EMC-Correct Installation in the

•

5.2 EMC-compliant Electrical Installation.

5.6.2 Connecting to the Ground

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

For electrical safety:

•

Ground the drive in accordance with applicable standards and directives.

•

Use a dedicated ground wire for input power, motor power, and control wiring.

•

Do not ground 1 drive to another in a daisy chain fashion.

•

Keep the ground wire connections as short as possible.

•

Follow motor manufacturer wiring requirements.

•

Minimum cable cross-section: 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al (or 2 rated ground wires terminated separately).

•

Tighten the terminals in accordance with the information provided in 5.4 Fastener Tightening Torques.

For EMC-compliant installation

•

Establish electrical contact between the cable shield and the drive enclosure by using metal cable glands or by using the clamps

provided on the equipment.

•

Reduce burst transient by using high-strand wire.

•

Do not use twisted shield ends (pigtails).

AQ304735638503en-000301 / 130R0265 | 29Danfoss A/S © 2021.10

e30bv020.10

1

2

1

Ferrule without plastic sleeve

2

Ferrule with plastic sleeve

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

N O T I C E

POTENTIAL EQUALIZATION

There is a risk of burst transient when the ground potential between the drive and the control system is different.

Install equalizing cables between the system components. Recommended cable cross-section: 16 mm2 (6 AWG).

-

5.6.3 Connecting the Motor

W A R N I N G

INDUCED VOLTAGE

Induced voltage from output motor cables that run together can charge equipment capacitors, even with the equipment turned

off and locked out/tagged out. Failure to run output motor cables separately or to use shielded cables could result in death or

serious injury.

Run output motor cables separately or use shielded cables.

-

Simultaneously lock out/tag out all the drives.

-

•

Comply with local and national electrical codes for cable sizes. For maximum wire sizes, see 10.4.4 Cable Length and Cross-

section.

•

Follow motor manufacturer wiring requirements.

•

Motor wiring knockouts or access panels are provided at the base of IP21 and higher units.

•

Do not wire a starting or pole-changing device (for example, Dahlander motor or slip ring asynchronous motor) between the

drive and the motor.

Procedure

1.

For H12 drives, remove the protective covers using a screwdriver before connecting the stripped wire.

2.

For H1–H5 and H13–H14 drives, strip a section of the outer cable insulation.

3.

For H11-H12 drives:

a.

If ferrule without plastic sleeve is used, strip 16–17 mm (0.63–0.67 in) section of the outer cable insulation.

b.

If ferrule with plastic sleeve is used, strip a section of the outer cable insulation.

Illustration 16: Ferrule with/without Plastic Sleeve

AQ304735638503en-000301 / 130R026530 | Danfoss A/S © 2021.10

e30bv021.10

1

2

3

1

Terminal locating slot

2

Cover positioning pins

3

Cable block slice

VLT® Flow Drive FC 111

Operating Guide

4.

Position the stripped wire under the cable clamp, establishing mechanical fixation and electrical contact between the cable

shield and ground.

5.

Connect the ground wire to the nearest grounding terminal in accordance with the grounding instructions provided in

5.6.2 Connecting to the Ground.

6.

Connect the 3-phase motor wiring to terminals U, V, and W.

7.

Tighten the terminals in accordance with the information provided in 5.4 Fastener Tightening Torques.

8.

For H12 drives, install the protective cover on the terminals.

a.

Cut the cable block slice according to the wire size.

b.

Put the positioning pin to the terminal locating slot.

Electrical Installation

Illustration 17: Installing Protective Covers, H12

5.6.4 Connecting the AC Mains

•

Size the wiring according to the input current of the drive. For maximum wire sizes, see 10.1.1 3x380–480 V AC.

•

Comply with local and national electrical codes for cable sizes.

Procedure

1.

For H12 drives, remove the protective covers using a screwdriver before connecting the stripped wire.

2.

For H1–H5 and H13–H14 drives, strip a section of the outer cable insulation.

3.

For H11-H12 drives, see the Illustration Ferrule with/without Plastic Sleeve in

a.

If ferrule without plastic sleeve is used, strip 16–17 mm (0.63–0.67 in) section of the outer cable insulation.

b.

If ferrule with plastic sleeve is used, strip a section of the outer cable insulation.

4.

Position the stripped wire under the cable clamp, establishing mechanical fixation and electrical contact between the cable

shield and ground.

5.

Connect the ground wire to the nearest grounding terminal in accordance with the grounding instructions provided in

5.6.2 Connecting to the Ground.

6.

For H1-H5 & H11-H12 drives, connect the 3-phase AC input power wiring to terminals L1, L2, and L3.

7.

For H13-H14 drives, connect the 3-phase AC input power wiring to terminals R, S, and T.

8.

When supplied from an isolated mains source (IT mains or floating delta) or TT/TN-S mains with a grounded leg (grounded

delta), ensure that parameter 14-50 RFI Filter is set to [0] Off to avoid damage to the DC link and to reduce ground capacity

currents.

9.

Tighten the terminals in accordance with the information provided in 5.4 Fastener Tightening Torques.

10.

For H12 drives, install the protective cover on the terminals, see the Illustration Installing Protective Covers, H12 in 5.6.3 Con-

necting the Motor.

a.

Cut the cable block slice according to the wire size.

b.

Put the positioning pin to the terminal locating slot.

5.6.3 Connecting the Motor.

AQ304735638503en-000301 / 130R0265 | 31Danfoss A/S © 2021.10

3x380–480 V IP20 [kW (hp)]

Maximum fuse

0.37 (0.5)

gG-10

0.75 (1.0)

gG-10

1.5 (2.0)

gG-10

2.2 (3.0)

gG-16

3.0 (4.0)

gG-16

4.0 (5.4)

gG-16

5.5 (7.5)

gG-25

7.5 (10)

gG-25

11 (15)

gG-50

15 (20)

gG-50

18.5 (25)

gG-63

22 (30)

gG-63

30 (40)

gG-125

37 (50)

gG-125

45 (60)

gG-125

55 (70)

aR-250

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

5.7 Fuses and Circuit Breakers

5.7.1 Branch Circuit Protection

To prevent fire hazards, protect the branch circuits in an installation, switch gear, machines, and so on, against short circuits and

overcurrent. Follow national and local regulations.

5.7.2 Short-circuit Protection

Danfoss recommends using the fuses and circuit breakers listed in this chapter to protect service personnel or other equipment in

case of an internal failure in the unit or a short circuit on the DC link. The drive provides full short-circuit protection in case of a short

circuit on the motor.

5.7.3 Overcurrent Protection

Provide overload protection to avoid overheating of the cables in the installation. Overcurrent protection must always be carried

out according to local and national regulations. Design circuit breakers and fuses for protection in a circuit capable of supplying a

maximum of 100000 A

(symmetrical), 480 V maximum.

rms

5.7.4 CE Compliance

To ensure compliance with IEC 61800-5-1, use the circuit breakers or fuses listed in this chapter. Circuit breakers must be designed

for protection in a circuit capable of supplying a maximum of 10000 A

(symmetrical), 480 V maximum.

rms

5.7.5 Recommendation of Fuses

N O T I C E

In the event of malfunction, failure to follow the protection recommendation may result in damage to the drive.

Table 12: Recommendation of Fuses

AQ304735638503en-000301 / 130R026532 | Danfoss A/S © 2021.10

75 (100)

aR-250

90 (125)

aR-250

110 (150)

aR-315

132 (175)

aR-350

160 (250)

aR-400

200 (300)

aR-500

250 (350)

aR-630

315 (450)

aR-800

Model

Fuse Options

Bussman

Littelfuse

Littelfuse

Bussman

Siba

Ferraz-Shawmut

Ferraz-Shawmut(Europe)

P110

170M2619

LA50QS300-4

L50S-300

FWH-300A

20 189 20.315

A50QS300-4

6,9URD31D08A0315

P132

170M2620

LA50QS350-4

L50S-350

FWH-350A

20 189 20.350

A50QS350-4

6,9URD31D08A0350

P160

170M2621

LA50QS400-4

L50S-400

FWH-400A

20 189 20.400

A50QS400-4

6,9URD31D08A0400

P200

170M4015

LA50QS500-4

L50S-500

FWH-500A

20 189 20.550

A50QS500-4

6,9URD31D08A0550

P250

170M4016

LA50QS600-4

L50S-600

FWH-600A

20 189 20.630

A50QS600-4

6,9URD31D08A0630

P315

170M4017

LA50QS800-4

L50S-800

FWH-800A

20 189 20.800

A50QS800-4

6,9URD32D08A0800

e30bd331.11

VLT® Flow Drive FC 111

Operating Guide

Table 13: H13–H14 Power/semiconductor Fuse Options, 380–480 V

Electrical Installation

5.8 Control Terminals

Remove the terminal cover (H1-H5 & H11-H12) or the cradle cover (H13-H14) to access the control terminals.

H1-H5 & H11-H12

Use a flat-edged screwdriver to push down the lock lever of the terminal cover under the LCP, then remove the terminal cover as

shown in Illustration 18.

Illustration 18: Removing the Terminal Cover

H13-H14

Press the tips of the cradle cover inwards as shown in Illustration 19, and then lift the cradle cover up.

AQ304735638503en-000301 / 130R0265 | 33Danfoss A/S © 2021.10

e30bu793.10

e30bv024.10

12 20 55

181927 29 42 54

45 50 53

DIGI IN

616869

N

P

COMM. GND

+24 V

GND

GND

10 V OUT

10 V/20 mA IN

0/4-20 mA A OUT/DIG OUT

BUS TER.

OFF

ON

DIGI IN

DIGI IN/OUT

DIGI IN/OUT

0/4-20 mA A OUT/DIG OUT

10 V/20 mA IN

VLT® Flow Drive FC 111

Operating Guide

Electrical Installation

Illustration 19: Removing the Cradle Cover

All the drive control terminals are shown in Illustration 20. Applying start (terminal 18), connection between terminals 12-27, and an

analog reference (terminal 53 or 54, and 55) make the drive run.

The digital input mode of terminal 18, 19, and 27 is set in parameter 5-00 Digital Input Mode (PNP is default value). Digital input 29

mode is set in parameter 5-03 Digital Input 29 Mode (PNP is default value).

Illustration 20: Control Terminals

5.9 Acoustic Noise or Vibration

If the motor or the equipment driven by the motor, for example, a fan, is making noise or vibrations at certain frequencies, configure

the following parameters or parameter groups to reduce or eliminate the noise or vibrations:

•

Parameter group 4-6* Speed Bypass.

•

Set parameter 14-03 Overmodulation to [0] Off.

•

Switching pattern and switching frequency parameter group 14-0* Inverter Switching.

•

Parameter 1-64 Resonance Dampening.

AQ304735638503en-000301 / 130R026534 | Danfoss A/S © 2021.10

e30bu792.11

B

a

c

k

Com.

4-10 Motor Speed Direction

[2] Both directions

Setup 1

A

B

1

12

13 14 15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

Off

Reset

Auto

On

Alarm

Warn.

On

11

B

C

D

A

13 14 15

12

11

11

5

4

10

6

7

8

9

1

2

11

LCP 32 LCP 31

4-10 Motor Speed Dir

ection

[2] Both directions

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

1

Parameter number and name.

2

Parameter value.

3

The setup number shows the active setup and the edit setup.

For LCP 32, the setup number only shows in Status menu, the number outside the brackets is active setup, and the number

inside the brackets is edit setup. For example, 1(2) means 1 is the active setup, and 2 is the edit setup.

For LCP 31, if the same setup acts as both active and edit setup, only that setup number is shown (factory setting). When the

active and the edit setup differ, both numbers are shown in the display (setup 12). The number flashing indicates the edit

setup.

4

Motor direction is shown to the bottom left of the display – indicated by a small arrow pointing either clockwise or counterclockwise.

5

The triangle indicates if the LCP is in Status, Quick Menu, or Main Menu.

VLT® Flow Drive FC 111

Operating Guide

6 Programming

6.1 Local Control Panel (LCP)

The LCP is divided into 4 functional sections.

•

A. Display

•

B. Menu key

•

C. Navigation keys and indicator lights

•

D. Operation keys and indicator lights

Programming

Illustration 21: Local Control Panel (LCP)

A. Display

The LCD-display of LCP 32 is illuminated with 3 alphanumeric lines, while the LCD-display of LCP 31 is illuminated with 2 alphanumeric lines. All data is shown on the LCP. The Table 14 describes the information that can be read from the display.

Table 14: Legend to Section A, Illustration 3

B. Menu key

Press [Menu] to select among Status, Quick Menu, or Main Menu.

C. Navigation keys and indicator lights

AQ304735638503en-000301 / 130R0265 | 35Danfoss A/S © 2021.10

6

Com. (yellow indicator): Flashes during bus communication.

7

On (green indicator): Shows the power-on status.

8

Warn. (yellow indicator): Indicates a warning.

9

Alarm (red indicator): Indicates an alarm.

10

[Back]: For moving to the previous step or layer in the navigation structure.

11

[▵], [▿], and [▹]: For navigating among parameter groups and parameters, and within parameters. They can also be used for

setting local reference.

12

[OK]: For selecting a parameter and for accepting changes to parameter settings.

13

[Hand On]: Starts the motor and enables control of the drive via the LCP.

N O T I C E

[2] Coast inverse is the default option for parameter 5-12 Terminal 27 Digital Input. If there is no 24 V supply to terminal 27,

[Hand On] does not start the motor. Connect terminal 12 to terminal 27.

14

[Off/Reset]: Stops the compressor (Off). If in alarm mode, the alarm is reset.

15

[Auto On]: The drive is controlled either via control terminals or serial communication.

FC

+24 V (OUT)

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

+

0–10 V

Start

+10 V (OUT)

A IN

A IN

COM IN/OUT

45

Reference

e30bb674.11

VLT® Flow Drive FC 111

Operating Guide

Table 15: Legend to Section C, Illustration 3

D. Operation keys and indicator lights

Table 16: Legend to Section D, Illustration 3

Programming

6.2 Set-up Wizard

6.2.1 Setup Wizard Introduction

The built-in wizard menu guides the installer through the setup of the drive in a clear and structured manner for open-loop and

closed-loop applications, and for quick motor settings.

Illustration 22: Drive Wiring

The wizard can always be accessed again through the quick menu. Press [OK] to start the wizard. Press [Back] to return to the status

view.

AQ304735638503en-000301 / 130R026536 | Danfoss A/S © 2021.10

Power kW/50 H z

Motor Power

Motor Voltage

Motor Frequency

Motor Current

Motor nominal speed

if

Select Regional Settings

... the Wizard starts

200-240V/50Hz/Delta

Grid Type

Induction motor

Asynchronous

Motor Type

Motor current

Motor nominal speed

Motor Cont. Rated Torque

Stator resistance

Motor poles

Back EMF at 1000 rpm

Motor type = IPM

Motor type = SPM

d-axis Inductance Sat. (LdSat)

[0]

[0]

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

Start Mode

Rotor Detection

[0]

Position Detection Gain

%

Off

100

Locked Rotor Detection

[0]

s

Locked Rotor Detection Time[s]

0.10

57

V

5

mH

q-axis Inductance (Lq)

5

mH

1.10

kW

400

V

50

Hz

Max Output Frequency

65

Hz

Motor Cable Length

50

m

4.66

A

1420

RPM

[0]

PM motor

Set Motor Speed low Limit

Hz

Set Motor Speed high Limit

Hz

Set Ramp 1 ramp-up time

s

Set Ramp 1 ramp-down Time

s

Active Flying start ?

Disable

Set T53 low Voltage

V

Set T53 high Voltage

V

Set T53 Low Current

A

Set T53 High Current

A

Voltage

AMA Failed

AMA Failed

Automatic Motor Adaption

Auto Motor Adapt OK

Press OK

Select Function of Relay 2

No function

Off

Select Function of Relay 1

[0] No function

Set Max Reference

Hz

Hz

Set Min Reference

AMA running

-----

Do AMA

(Do not AMA)

AMA OK

[0]

[0]

[0]

Select T53 Mode

Current

Current

Motor type = Induction

Motor type = PM motor

0000

0050

0010

0010

[0]

[0]

04.66

13.30

0050

0220

0000

0050

The next screen is

the Wizard screen.

Power-up Screen

e30bu808.12

q-axis Inductance Sat. (LqSat)

5

mH

Current at Min Inductance for d-axis

100

%

Current at Min Inductance for q-axis

100

%

d-axis Inductance (Lq)

5

mH

... the Wizard starts

Or

0-** FC-xxx Wizard

2-** Motor Setup

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

1-** Closed Loop Set

0.0 Hz

Auto On

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

0.000 kW

1 (1)

Menu

OK

VLT® Flow Drive FC 111

Operating Guide

6.2.2 Setup Wizard for Open-loop Applications

Programming

Illustration 23: Setup Wizard for Open-loop Applications

AQ304735638503en-000301 / 130R0265 | 37Danfoss A/S © 2021.10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size related

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

N O T I C E

Compared to 380–440 V groups, when selecting 440–

480 V groups, the rated current decreases accordingly.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

VLT® Flow Drive FC 111

Operating Guide

Table 17: Setup Wizard for Open-loop Applications

Programming

AQ304735638503en-000301 / 130R026538 | Danfoss A/S © 2021.10

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option

Default

Usage

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–1000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–9999 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–1000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-29

Automatic Motor Adaption

(AMA)

See parameter 1-29 Automatic

Motor Adaption (AMA).

Off

Performing an AMA optimizes motor performance.

Parameter 1-30

Stator Resistance (Rs)

0.000–99.990 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

VLT® Flow Drive FC 111

Operating Guide

Programming

AQ304735638503en-000301 / 130R0265 | 39Danfoss A/S © 2021.10

Parameter

Option

Default

Usage

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a motor spinning due to mains drop-out. Select [0] Disabled if this function is not required. When this parameter is set to [1] Ena-

bled, parameter 1-71 Start Delay and parameter 1-72 Start

Function are not functional. Parameter 1-73 Flying Start is ac-

tive in VVC+ mode only.

Parameter 3-02

Minimum Reference

-4999.000–4999.000

0

The minimum reference is the lowest value obtainable by

summing all references.

Parameter 3-03

Maximum Reference

-4999.000–4999.000

50

The maximum reference is the lowest obtainable by summing all references.

VLT® Flow Drive FC 111

Operating Guide

Programming

AQ304735638503en-000301 / 130R026540 | Danfoss A/S © 2021.10

Parameter

Option

Default

Usage

Parameter 3-41

Ramp 1 Ramp

Up Time

0.01–3600.00 s

Size related

If induction motor is selected, the ramp-up time is from 0 to

rated parameter 1-23 Motor Frequency. If PM motor is selected, the ramp-up time is from 0 to parameter 1-25 Motor

Nominal Speed.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.01–3600.00 s

Size related

For induction motors, the ramp-down time is from rated pa-

rameter 1-23 Motor Frequency to 0. For PM motors, the rampdown time is from parameter 1-25 Motor Nominal Speed to 0.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100 Hz

Enter the maximum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[9] Alarm

Select the function to control output relay 1.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[5] Drive running

Select the function to control output relay 2.

Parameter 6-10

Terminal 53

Low Voltage

0.00–10.00 V

0.07 V

Enter the voltage that corresponds to the low reference value.

Parameter 6-11

Terminal 53

High Voltage

0.00–10.00 V

10 V

Enter the voltage that corresponds to the high reference value.

Parameter 6-12

Terminal 53

Low Current

0.00–20.00 mA

4 mA

Enter the current that corresponds to the low reference value.

Parameter 6-13

Terminal 53

High Current

0.00–20.00 mA

20 mA

Enter the current that corresponds to the high reference value.

Parameter 6-19

Terminal 53

mode

[0] Current

[1] Voltage

[1] Voltage

Select if terminal 53 is used for current or voltage input.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1 s

0.10 s

–

VLT® Flow Drive FC 111

Operating Guide

Programming

AQ304735638503en-000301 / 130R0265 | 41Danfoss A/S © 2021.10

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Induction motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

400

V

1-24 Motor Current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0010

s

3-42 Ramp1 ramp-down time

0010

s

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-14 Motor speed high limit

0050

Hz

e30bc402.16

1-20 Motor Power

1.10

kW

1-23 Motor Frequency

50

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

Off

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Configuration Mode

[3]

Closed Loop

0-03 Regional Settings

[0]

Power kW/50 Hz

3-16 Reference Source 2

[0]

No Operation

1-10 Motor Type

[0]

Asynchronous

[0]

200-240V/50Hz/Delta

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current