Programming Guide

VLT® Flow Drive FC 111

vlt-drives.danfoss.com

VLT® Flow Drive FC 111

Programming Guide

Contents

1

Introduction 5

1.1

Purpose of this Programming Guide 5

Additional Resources 5

1.2

Other Resources 5

1.2.1

1.2.2

MCT 10 Set-up Software Support 5

1.3

Document and Software Version 5

1.4

Electrical Wiring 5

Safety 7

2

Safety Symbols 7

2.1

Qualified Personnel 7

2.2

Safety Precautions 7

2.3

3

Programming 9

Contents

3.1

Local Control Panel (LCP) 9

3.2

Menus 10

3.2.1

Status Menu 10

3.2.2

Quick Menu 10

3.2.2.1

3.2.2.2

3.2.2.3

3.2.2.4

3.2.2.5

3.2.2.6

3.2.2.7

3.2.2.8

3.2.3

Main Menu 26

3.3

Quick Transfer of Parameter Settings between Multiple Drives 26

3.3.1

Transferring Data from the Drive to the LCP 26

3.3.2

Transferring Data from the LCP to the Drive 26

Quick Menu Introduction 10

Setup Wizard Introduction 11

Setup Wizard for Open-loop Applications 12

Setup Wizard for Closed-loop Applications 17

Motor Setup 22

Changes Made Function 26

Changing Parameter Settings 26

Accessing All Parameters via the Main Menu 26

3.4

Readout and Programming of Indexed Parameters 26

3.5

Initialization to Default Settings 27

3.5.1

Recommended Initialization 27

3.5.2

Two-finger Initialization 27

4

Parameters 29

4.1

Parameter List 29

4.2

Parameter Group 0-** Operation / Display 32

AU363928304090en-000101/130R0982 | 3Danfoss A/S © 2021.07

VLT® Flow Drive FC 111

Programming Guide

4.3

Parameter Group 1-** Load and Motor 40

4.4

Parameter Group 2-** Brakes 57

4.5

Parameter Group 3-** Reference/Ramps 59

4.6

Parameter Group 4-** Limits/Warnings 64

4.7

Parameter Group 5-** Digital In/Out 68

4.8

Parameter Group 6-** Analog In/Out 91

4.9

Parameter Group 8-** Comm. and Options 103

4.10

Parameter Group 13-** Smart Logic 115

4.11

Parameter Group 14-** Special Functions 129

4.12

Parameter Group 15-** Drive Information 138

4.13

Parameter Group 16-** Data Readouts 144

4.14

Parameter Group 18-** Info & Readouts 156

4.15

Parameter Group 20-** Drive Closed Loop 157

4.16

Parameter Group 22-** Appl. Functions 164

Contents

4.17

Parameter Group 23-** Time-based Functions 177

4.18

Parameter Group 24-** Appl. Functions 2 178

4.19

Parameter Group 25-** Cascade Controller 183

4.20

Parameter Group 30-** Special Features 189

5

Troubleshooting 191

5.1

Warning and Alarm Messages 191

5.2

Alarm Words 193

5.3

Warning Words 194

5.4

Extended Status Words 195

5.5

Descriptions of Warnings and Alarms 196

5.6

LCP Errors Messages 203

6

Appendix 205

6.1

Abbreviations 205

6.2

Definitions 206

6.2.1

AC Drive 206

6.2.2

Input 206

6.2.3

Motor 206

6.2.4

References 207

6.2.5

Miscellaneous 208

AU363928304090en-000101/130R09824 | Danfoss A/S © 2021.07

Edition

Remarks

Software version

AU363928304090, version 0101

First edition.

6x.xx

VLT® Flow Drive FC 111

Programming Guide

Introduction

1 Introduction

1.1 Purpose of this Programming Guide

This Programming Guide provides information on working with parameters on the VLT® Flow Drive FC 111 drive.

It provides information on how to programme the drive, and a list and description of all parameters.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

1.2.1 Other Resources

Other resources are available to understand advanced drive functions and programming.

•

VLT® Flow Drive FC 111 Operating Guide provides basic information on mechanical dimensions, installation, and programming.

•

VLT® Flow Drive FC 111 Design Guide provides information on how to design motor control systems.

•

Danfoss VLT® Energy Box software. Select PC Software Download at

VLT® Energy Box software allows energy consumption comparisons of HVAC fans and pumps driven by Danfoss drives and alternative methods of flow control. Use this tool to accurately project the costs, savings, and payback of using Danfoss drives on HVAC

fans, pumps, and cooling towers.

Supplementary publications and manuals are available from Danfoss website.

www.danfoss.com.

1.2.2 MCT 10 Set-up Software Support

Download the software from the service and support section on www.danfoss.com.

During the installation process of the software, enter access code 81462700 to activate the VLT® Flow Drive FC 111 functionality. A

license key is not required for using the VLT® Flow Drive FC 111 functionality.

The latest software does not always contain the latest updates for drives. Contact the local sales office for the latest drive updates (in

the form of *.OSS files).

1.3 Document and Software Version

This guide is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

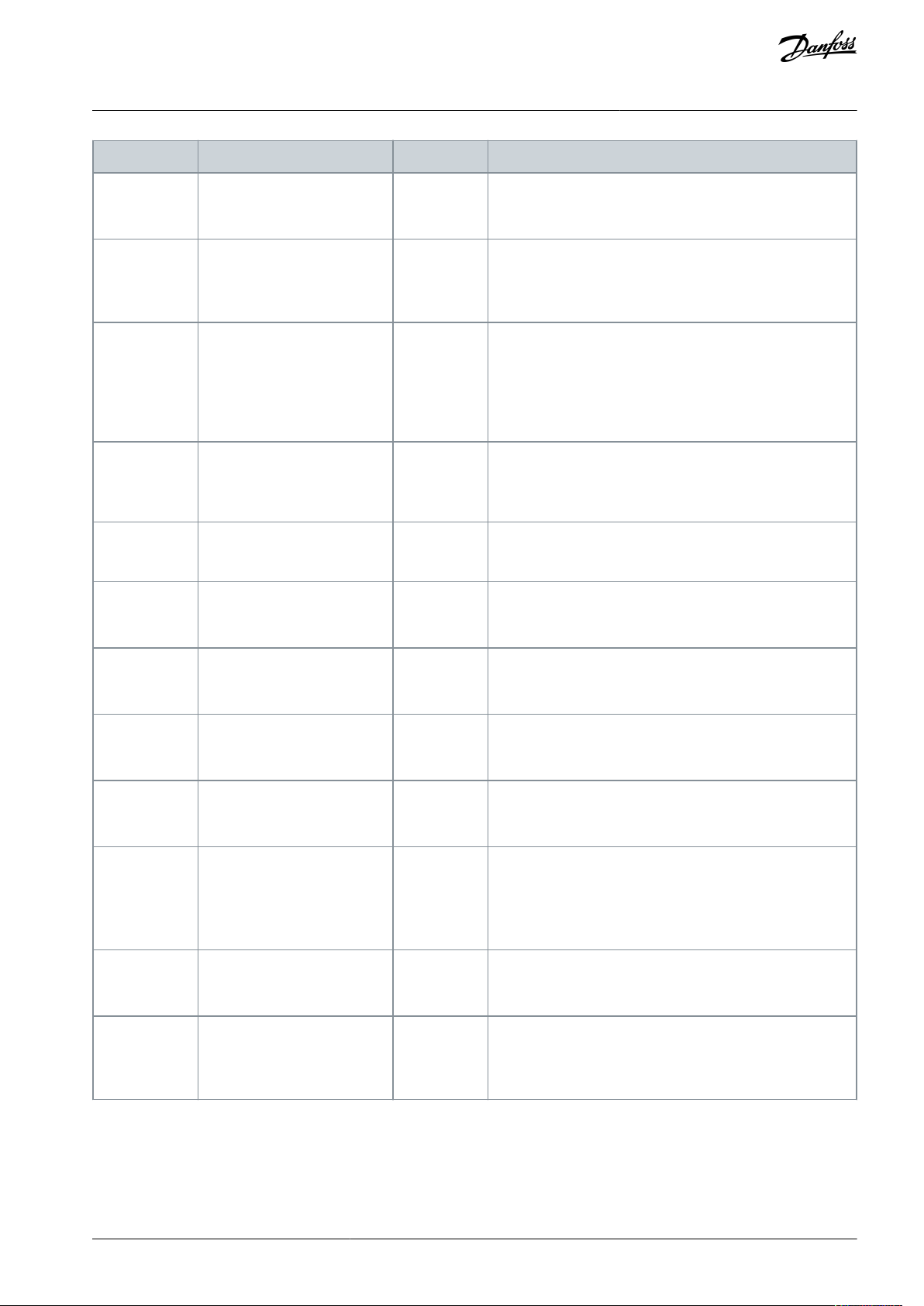

Table 1: Document and Software Version

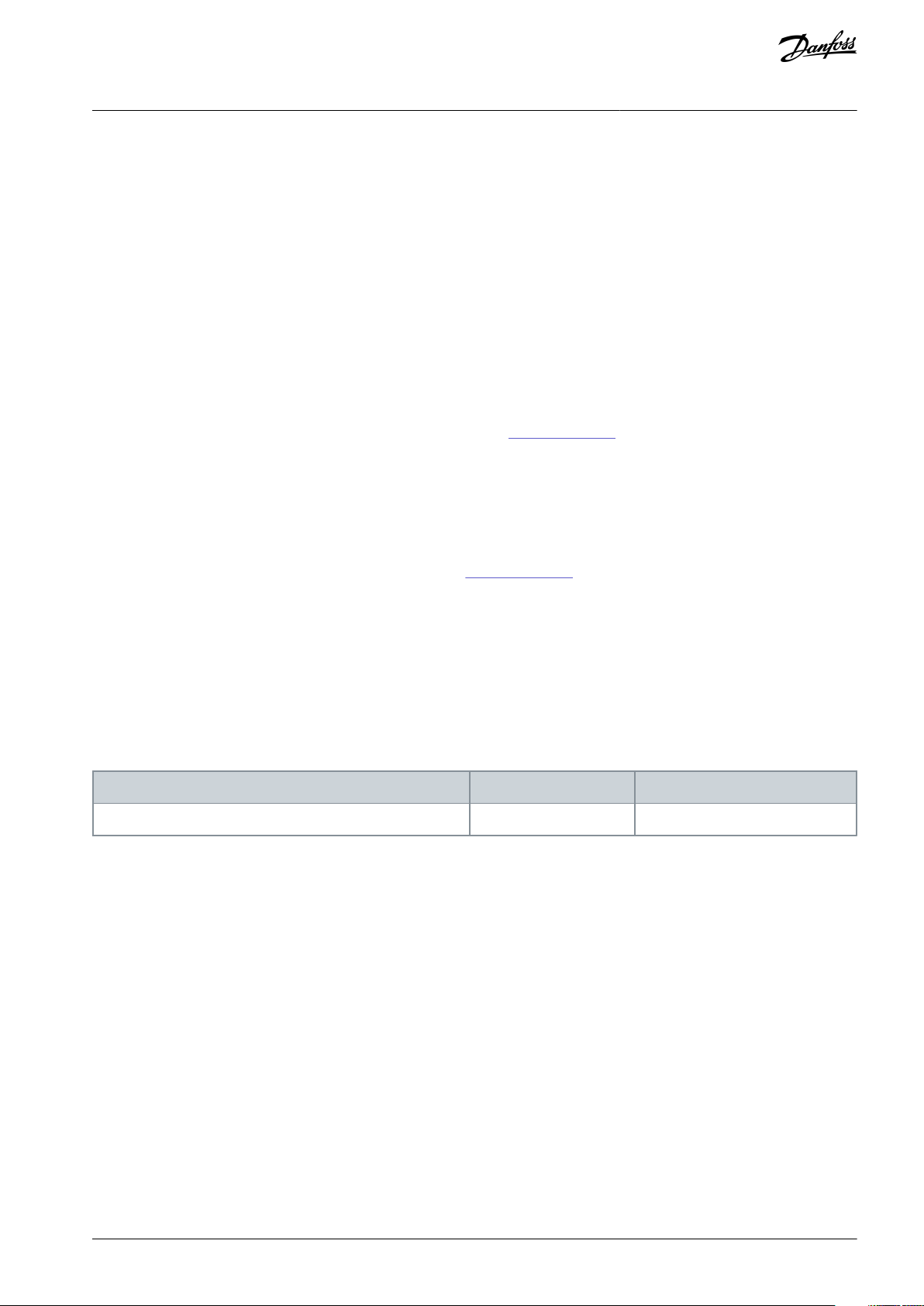

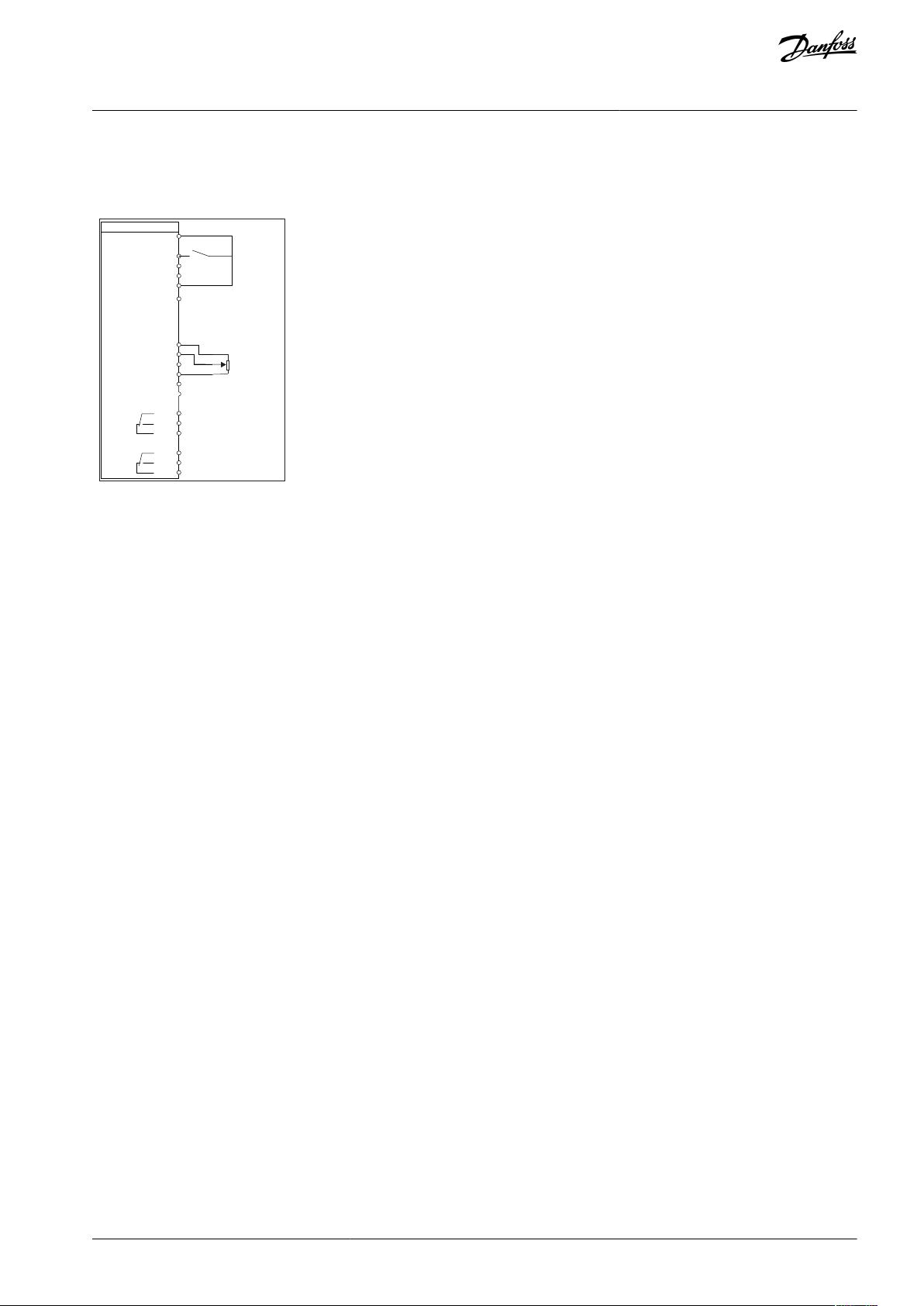

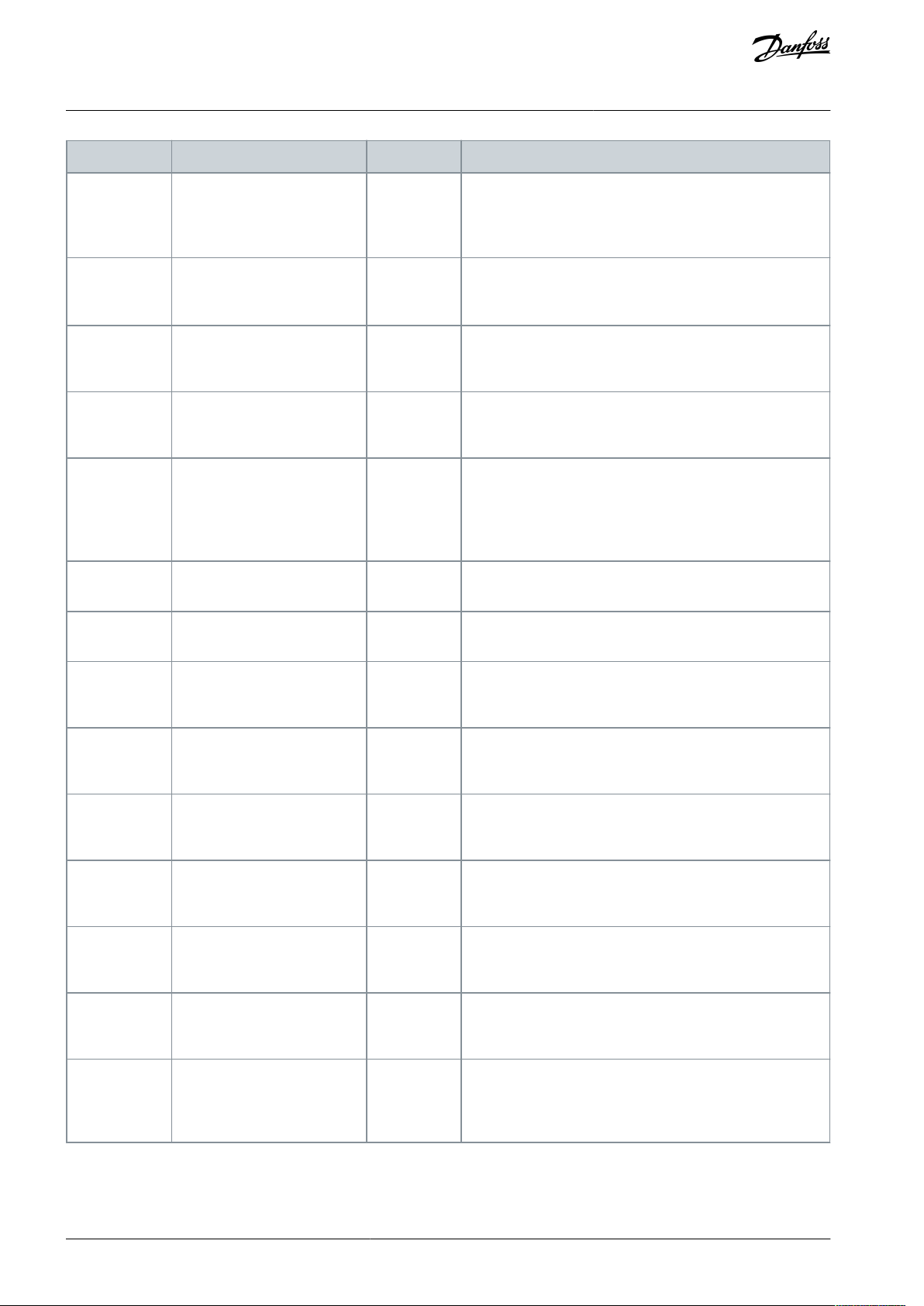

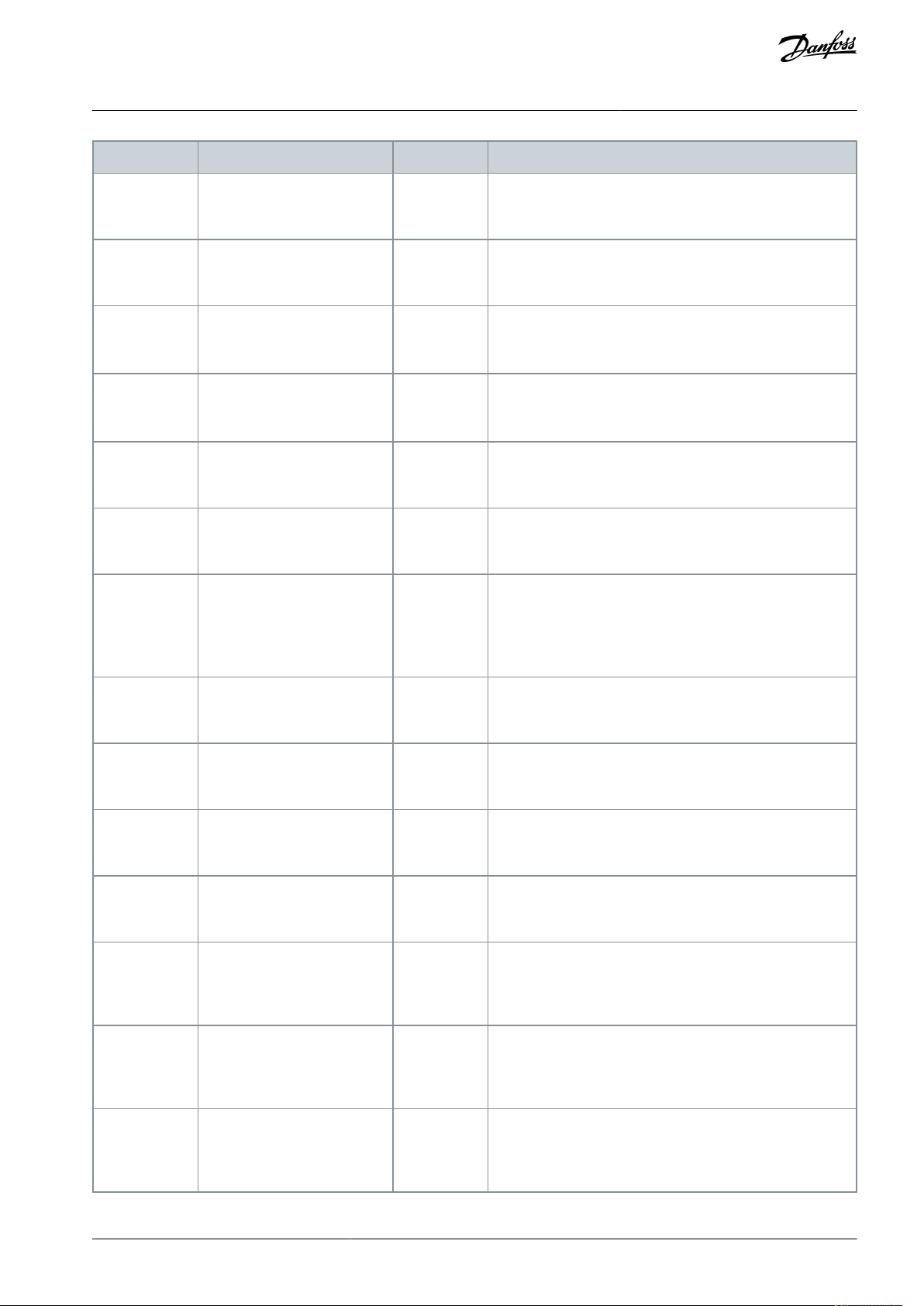

1.4 Electrical Wiring

AU363928304090en-000101 / 130R0982 | 5Danfoss A/S © 2021.07

L1

L2

L3

3-phase

power

input

PE

PE

+10 V DC

0-10 V DC-

0-10 V DC-

50 (+10 V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20 mA A OUT / D OUT

45 0/4-20 mA A OUT / D OUT

18 (D IN)

19 (D IN)

27 (D IN/OUT)

29 (D IN/OUT)

12 (+24 V OUT)

24 V (NPN)

20 (COM D IN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

24 V (NPN)

O V (PNP)

Bus ter.

Bus ter.

RS485

Interface

RS485

(N RS485) 69

(P RS485) 68

(Com RS485 ) 61

(PNP)-Source

(NPN)-Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240 V AC 3 A

Not present on all power sizes

Do not connect shield to 61

01

02

03

relay 1

relay 2

UDC+

UDC-

Motor

U

V

W

e30bd467.12

06

05

04

240 V AC 3 A

VLT® Flow Drive FC 111

Programming Guide

Introduction

Illustration 1: Basic Wiring Schematic Drawing

There is no access to UDC- and UDC+ on the following units:

IP20, 380–480 V, 30–315 kW (40–450 hp)

-

N O T I C E

AU363928304090en-000101 / 130R09826 | Danfoss A/S © 2021.07

VLT® Flow Drive FC 111

Programming Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals provided with the unit, especially the instructions given in

the Operating Guide.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

2.3 Safety Precautions

W A R N I N G

HAZARDOUS VOLTAGE

AC drives contain hazardous voltage when connected to the AC mains or connected on the DC terminals. Failure to perform

installation, start-up, and maintenance by skilled personnel can result in death or serious injury.

Only skilled personnel must perform installation, start-up, and maintenance.

-

W A R N I N G

UNINTENDED START

When the drive is connected to AC mains, DC supply, or load sharing, the motor may start at any time. Unintended start during

programming, service, or repair work can result in death, serious injury, or property damage. Start the motor with an external

switch, a fieldbus command, an input reference signal from the local control panel (LCP), via remote operation using MCT 10

software, or after a cleared fault condition.

Disconnect the drive from the mains.

-

Press [Off/Reset] on the LCP before programming parameters.

-

Ensure that the drive is fully wired and assembled when it is connected to AC mains, DC supply, or load sharing.

-

AU363928304090en-000101 / 130R0982 | 7Danfoss A/S © 2021.07

Voltage [V]

Power range [kW (hp)]

Minimum waiting time (minutes)

3x400

0.37–7.5 (0.5–10)

4

3x400

11–90 (15–125)

15

3x400

110–315 (150–450)

20

VLT® Flow Drive FC 111

Programming Guide

Safety

W A R N I N G

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death or

serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in the table Discharge time and is also visible

-

on the nameplate on the top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Table 2: Discharge Time

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure that the minimum size of the ground conductor complies with the local safety regulations for high touch current

-

equipment.

W A R N I N G

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this manual.

-

C A U T I O N

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

AU363928304090en-000101 / 130R09828 | Danfoss A/S © 2021.07

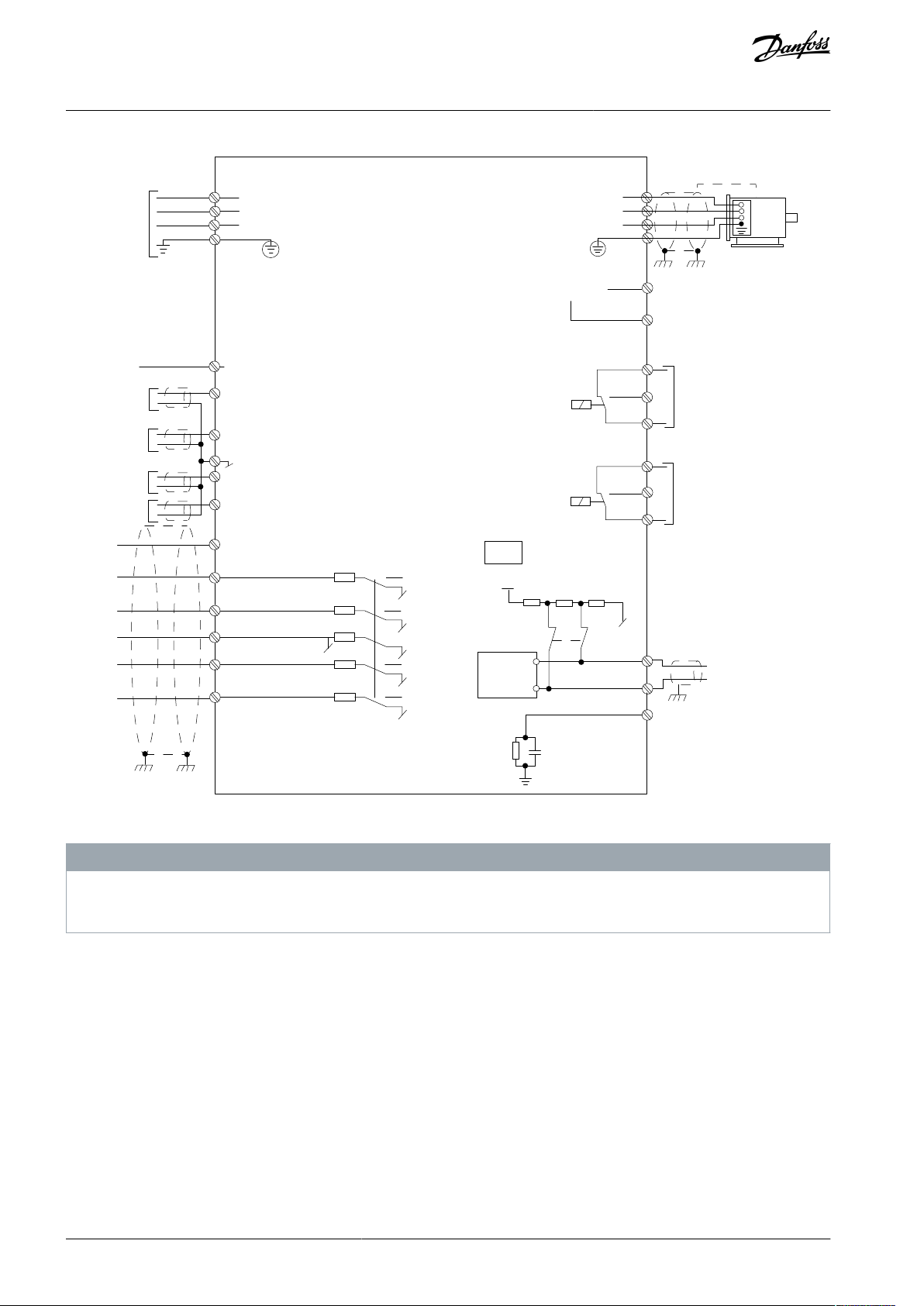

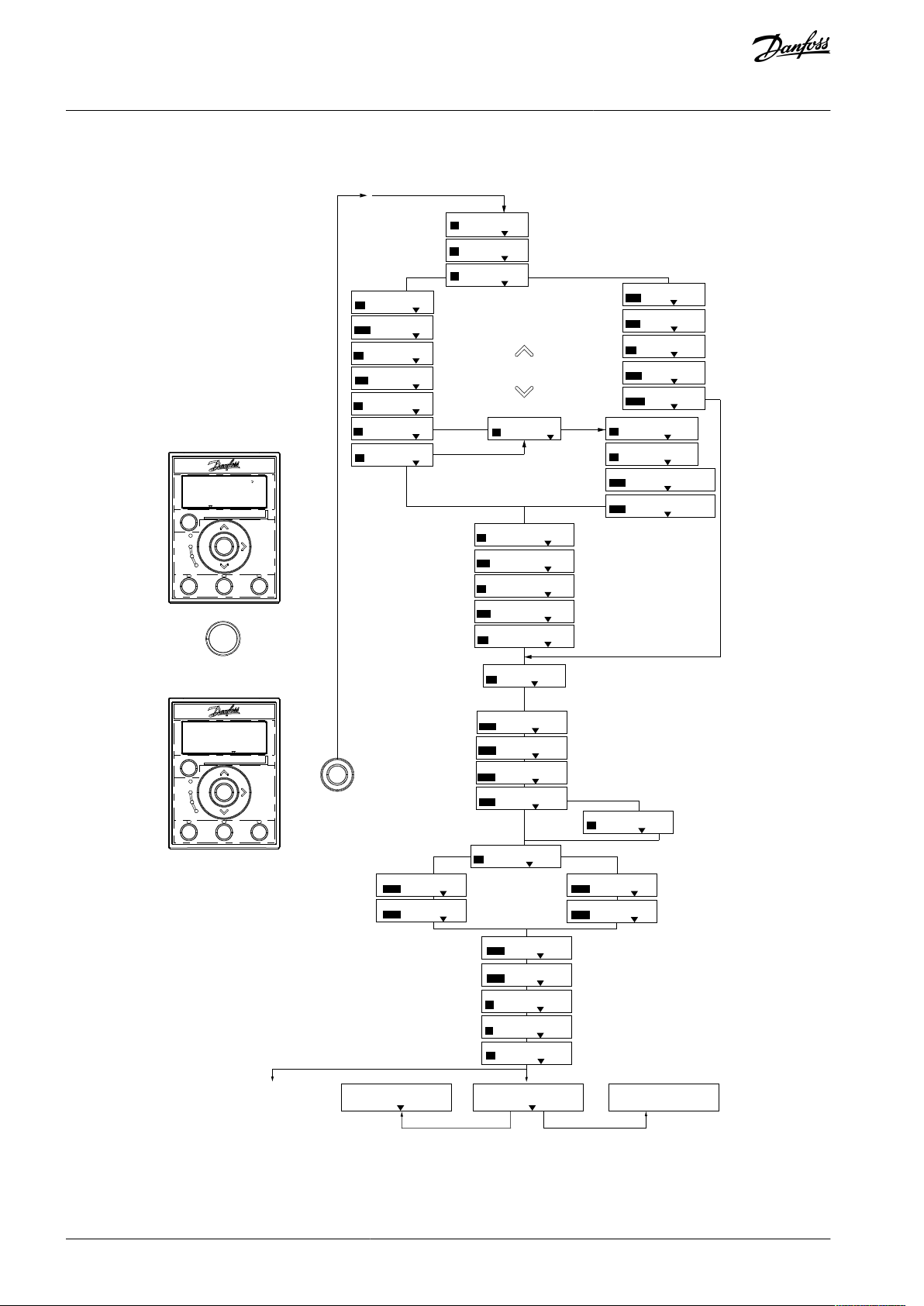

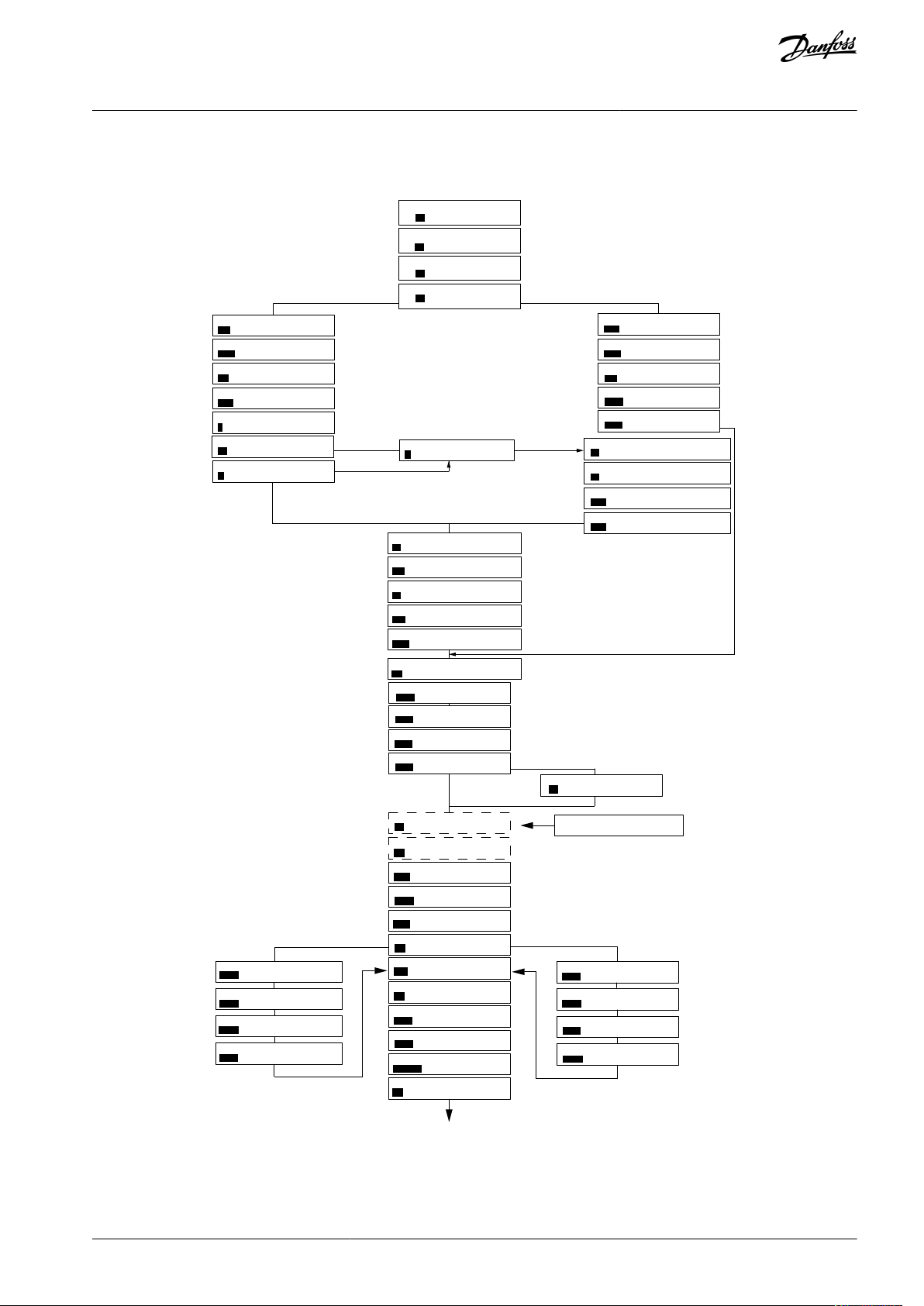

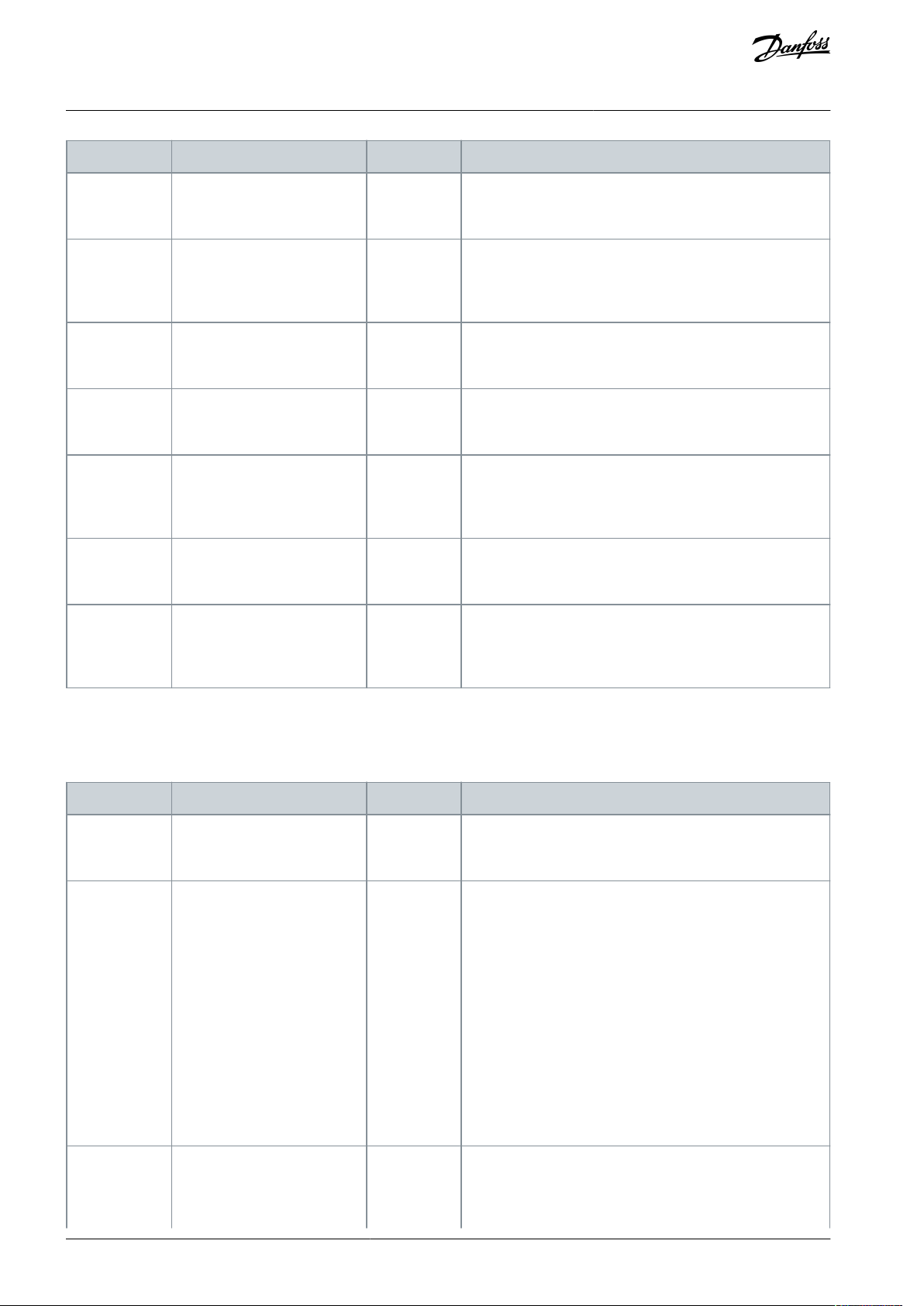

e30bu792.11

B

a

c

k

Com.

4-10 Motor Speed Direction

[2] Both directions

Setup 1

A

B

1

12

13 14 15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

Off

Reset

Auto

On

Alarm

Warn.

On

11

B

C

D

A

13 14 15

12

11

11

5

4

10

6

7

8

9

1

2

11

LCP 32 LCP 31

4-10 Motor Speed Dir

ection

[2] Both directions

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

1

Parameter number and name.

2

Parameter value.

3

The setup number shows the active setup and the edit setup.

For LCP 32, the setup number only shows in Status menu, the number outside brackets is active setup, and the number inside

brackets is edit setup. For example, 1(2) means 1 is the active setup, and 2 is the edit setup.

For LCP 31, if the same setup acts as both active and edit setup, only that setup number is shown (factory setting). When the

active and the edit setup differ, both numbers are shown in the display (setup 12). The number flashing indicates the edit

setup.

4

Motor direction is shown to the bottom left of the display – indicated by a small arrow pointing either clockwise or counterclockwise.

5

The triangle indicates if the LCP is in Status, Quick Menu, or Main Menu.

VLT® Flow Drive FC 111

Programming Guide

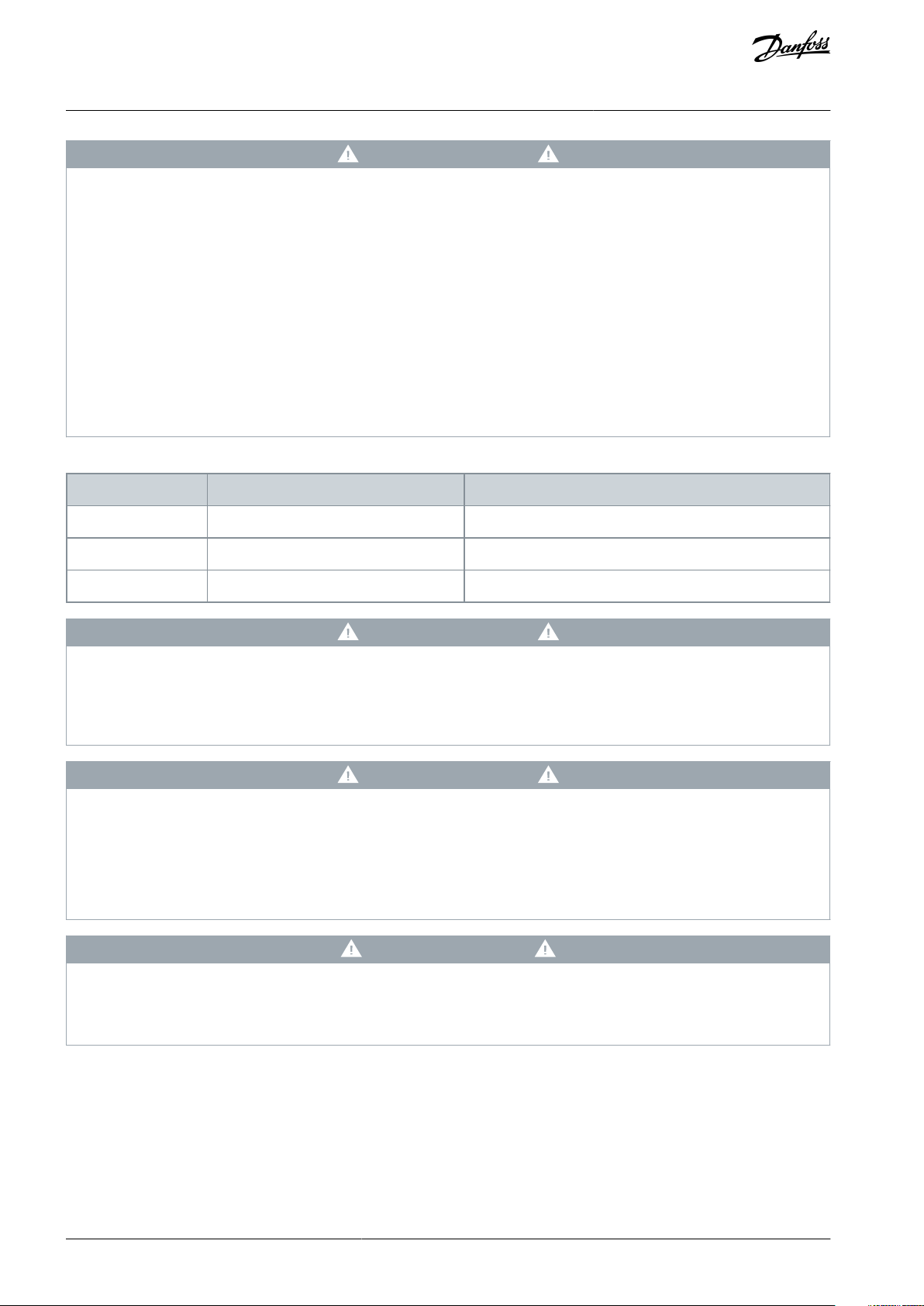

3 Programming

3.1 Local Control Panel (LCP)

The LCP is divided into 4 functional sections.

•

A. Display

•

B. Menu key

•

C. Navigation keys and indicator lights

•

D. Operation keys and indicator lights

Programming

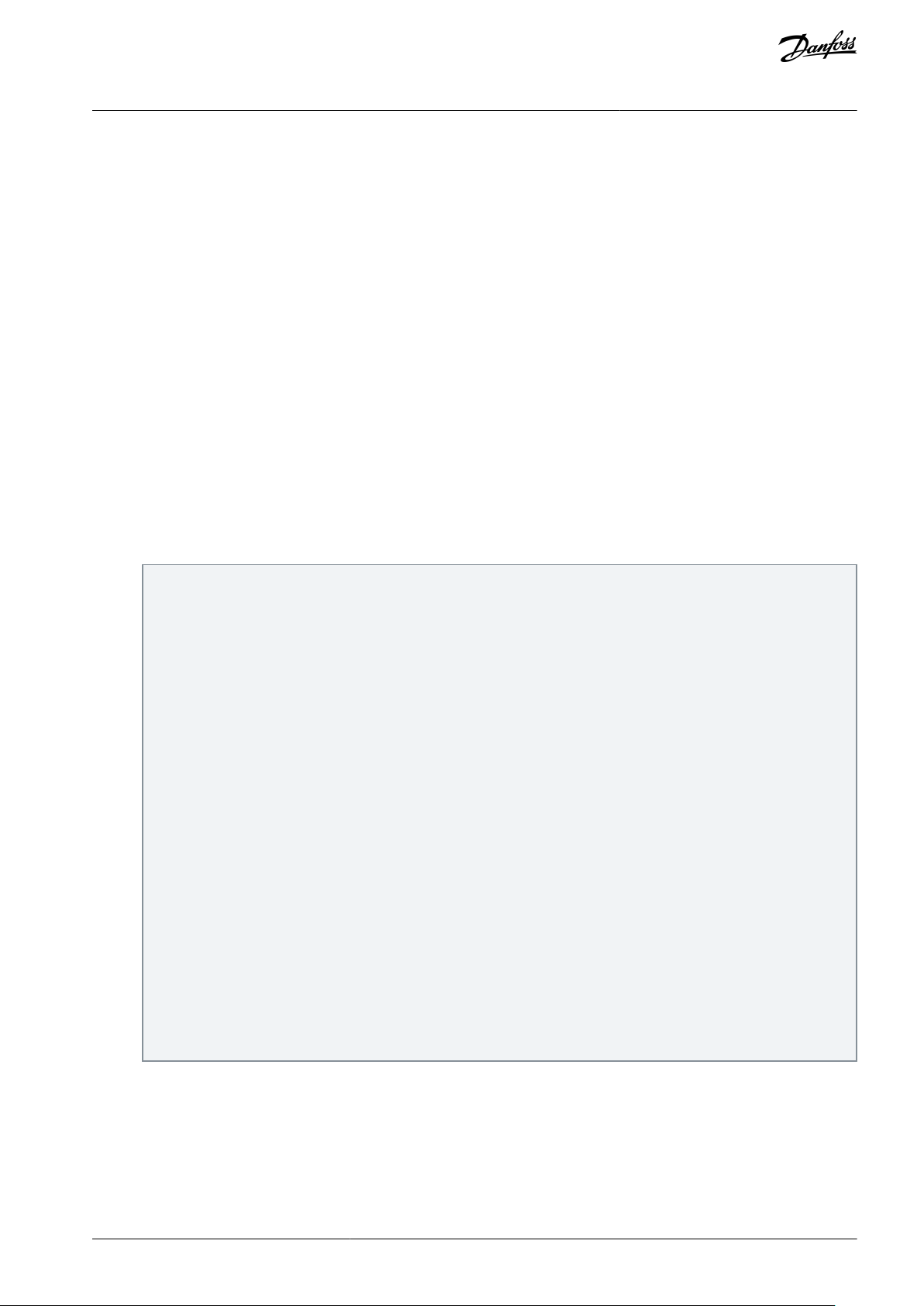

Illustration 2: Local Control Panel (LCP)

A. Display

The LCD-display of LCP 32 is illuminated with 3 alphanumeric lines, while the LCD-display of LCP 31 is illuminated with 2 alphanumeric lines. All data is shown on the LCP. The Table 3 describes the information that can be read from the display.

Table 3: Legend to Section A, Illustration 3

B. Menu key

Press [Menu] to select among Status, Quick Menu, or Main Menu.

C. Navigation keys and indicator lights

AU363928304090en-000101 / 130R0982 | 9Danfoss A/S © 2021.07

6

Com. (yellow indicator): Flashes during bus communication.

7

On (green indicator): Shows the power-on status.

8

Warn. (yellow indicator): Indicates a warning.

9

Alarm (red indicator): Indicates an alarm.

10

[Back]: For moving to the previous step or layer in the navigation structure.

11

Up arrow key, down arrow key, and right arrow key: For navigating among parameter groups and parameters, and within

parameters. They can also be used for setting local reference.

12

[OK]: For selecting a parameter and for accepting changes to parameter settings.

13

[Hand On]: Starts the motor and enables control of the drive via the LCP.

N O T I C E

[2] Coast inverse is the default option for parameter 5-12 Terminal 27 Digital Input. If there is no 24 V supply to terminal 27,

[Hand On] does not start the motor. Connect terminal 12 to terminal 27.

14

[Off/Reset]: Stops the compressor (Off). If in alarm mode, the alarm is reset.

15

[Auto On]: The drive is controlled either via control terminals or serial communication.

VLT® Flow Drive FC 111

Programming Guide

Table 4: Legend to Section C, Illustration 3

D. Operation keys and indicator lights

Table 5: Legend to Section D, Illustration 3

Programming

3.2 Menus

3.2.1 Status Menu

In the Status menu, the selection options are:

•

Motor frequency [Hz], parameter 16-13 Frequency.

•

Motor current [A], parameter 16-14 Motor current.

•

Motor speed reference in percentage [%], parameter 16-02 Reference [%].

•

Feedback, parameter 16-52 Feedback [Unit].

•

Motor power parameter 16-10 Power [kW] for kW, parameter 16-11 Power [hp] for hp. If parameter 0-03 Regional Settings is set to

[1] North America, motor power is shown in hp instead of kW.

•

Custom readout, parameter 16-09 Custom Readout.

•

Motor Speed [RPM], parameter 16-17 Speed [RPM].

3.2.2 Quick Menu

3.2.2.1 Quick Menu Introduction

Use the Quick Menu to program the most common functions. The Quick Menu consists of:

Wizard for open-loop applications.

•

Wizard for closed-loop applications.

•

Motor set-up.

•

Changes made.

•

AU363928304090en-000101 / 130R098210 | Danfoss A/S © 2021.07

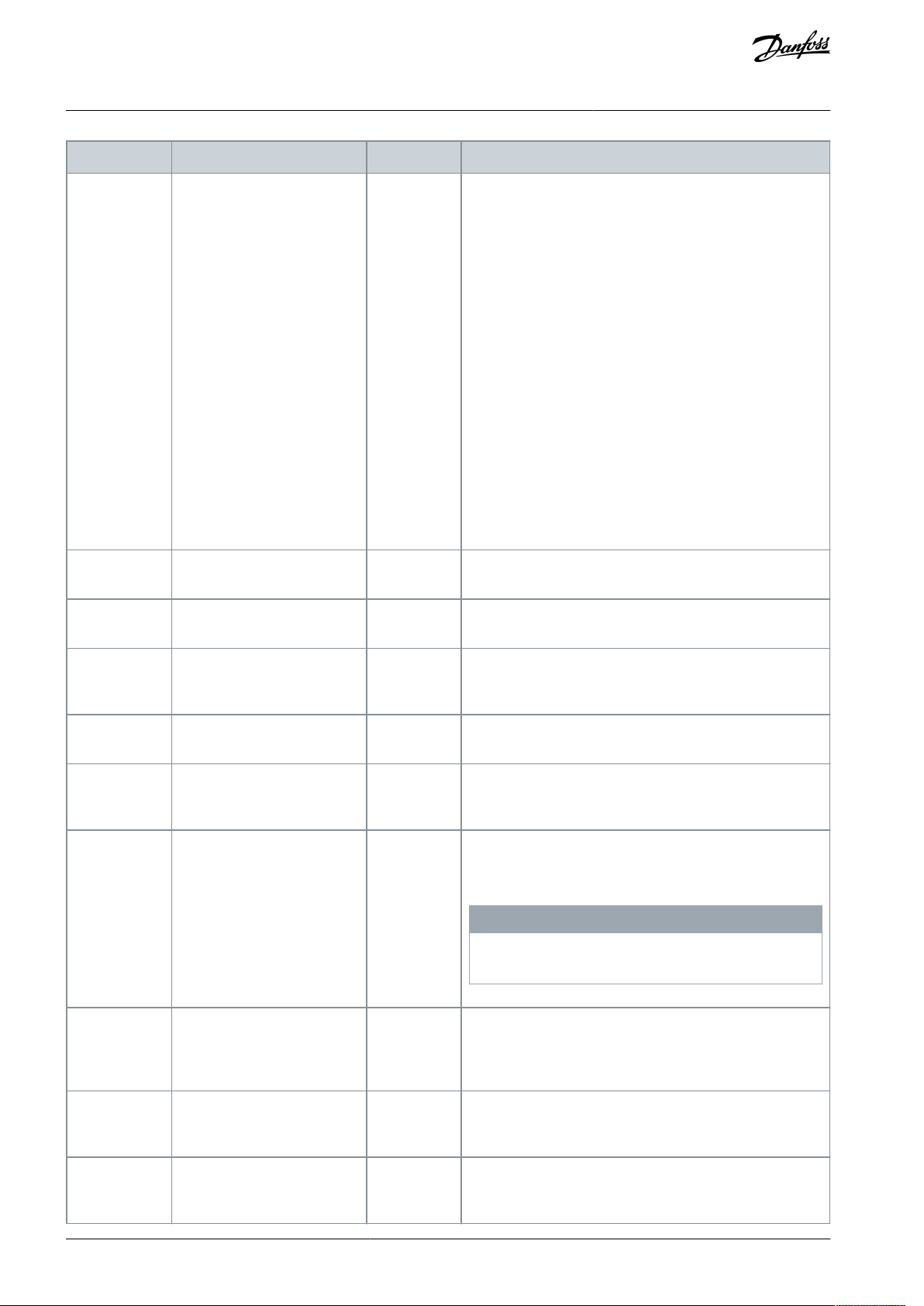

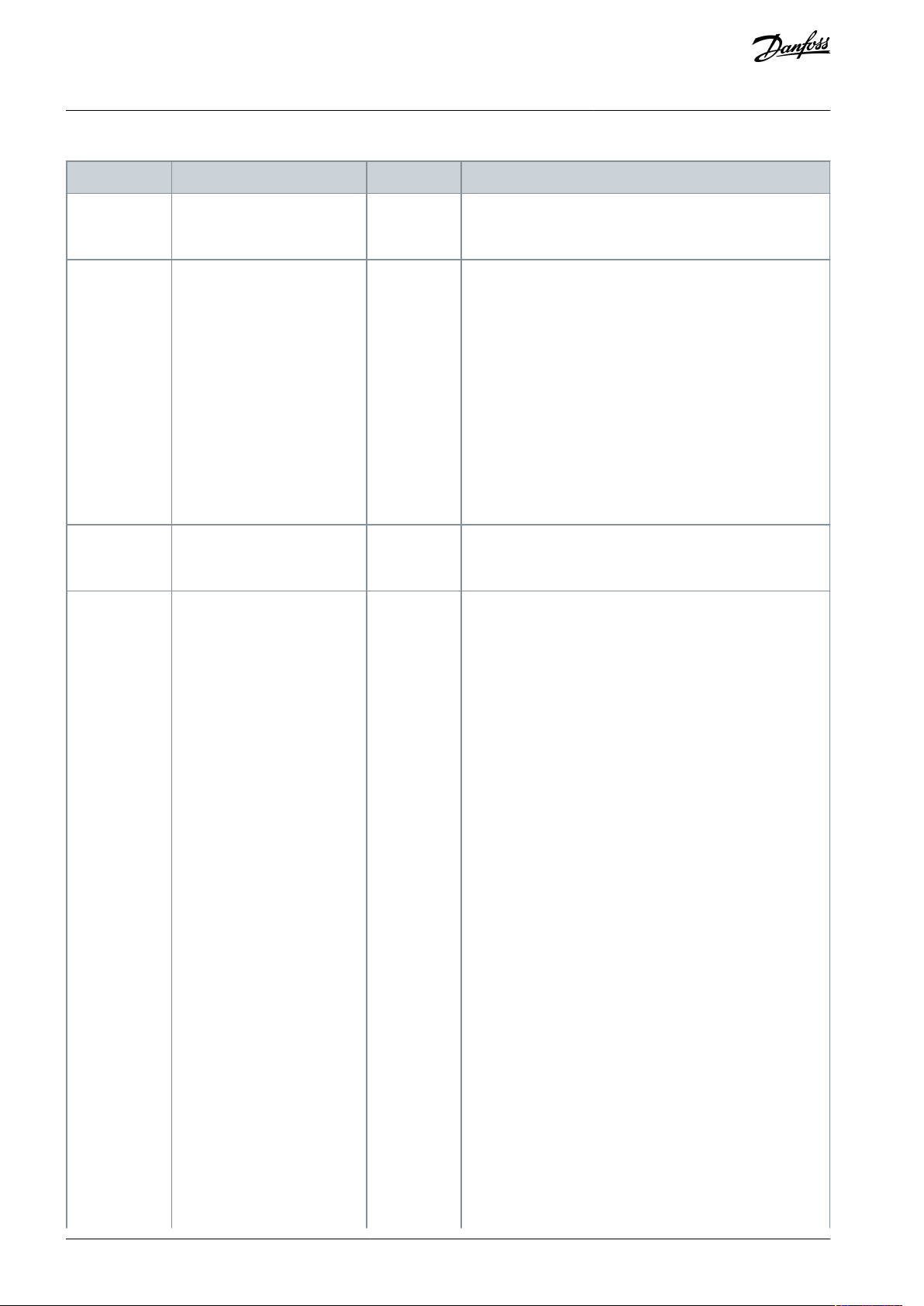

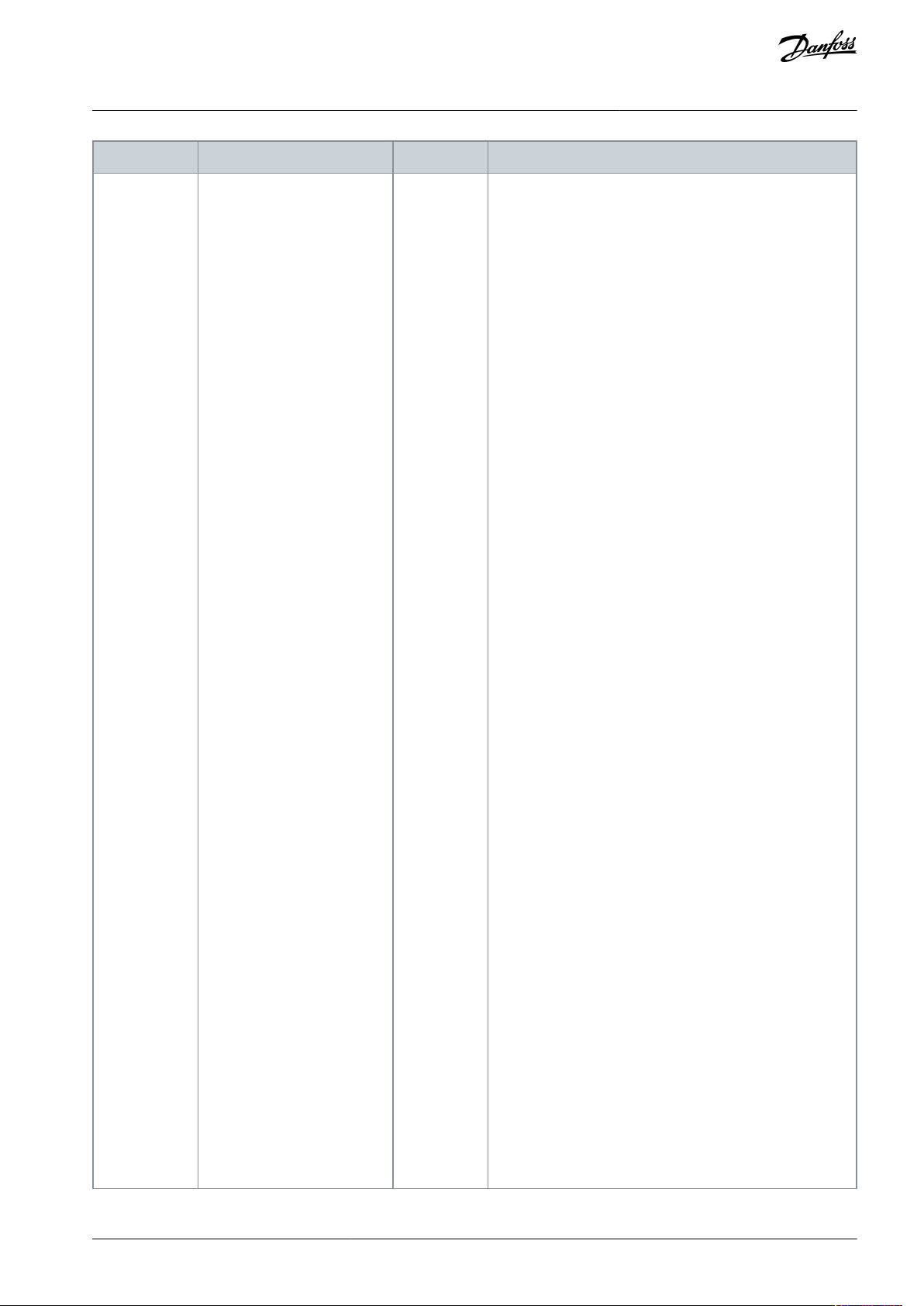

FC

+24 V (OUT)

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

+

0–10 V

Start

+10 V (OUT)

A IN

A IN

COM IN/OUT

45

Reference

e30bb674.11

VLT® Flow Drive FC 111

Programming Guide

Programming

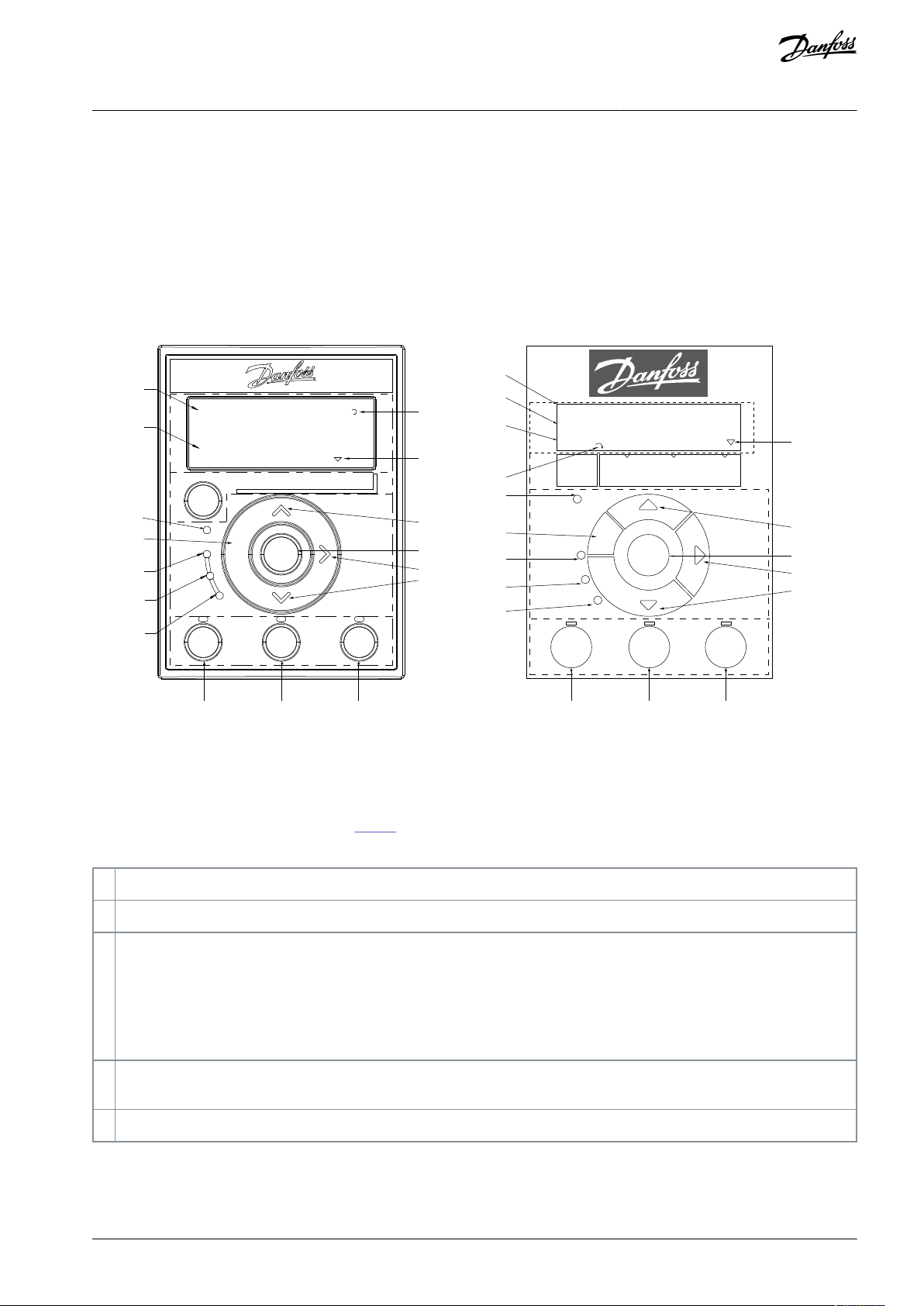

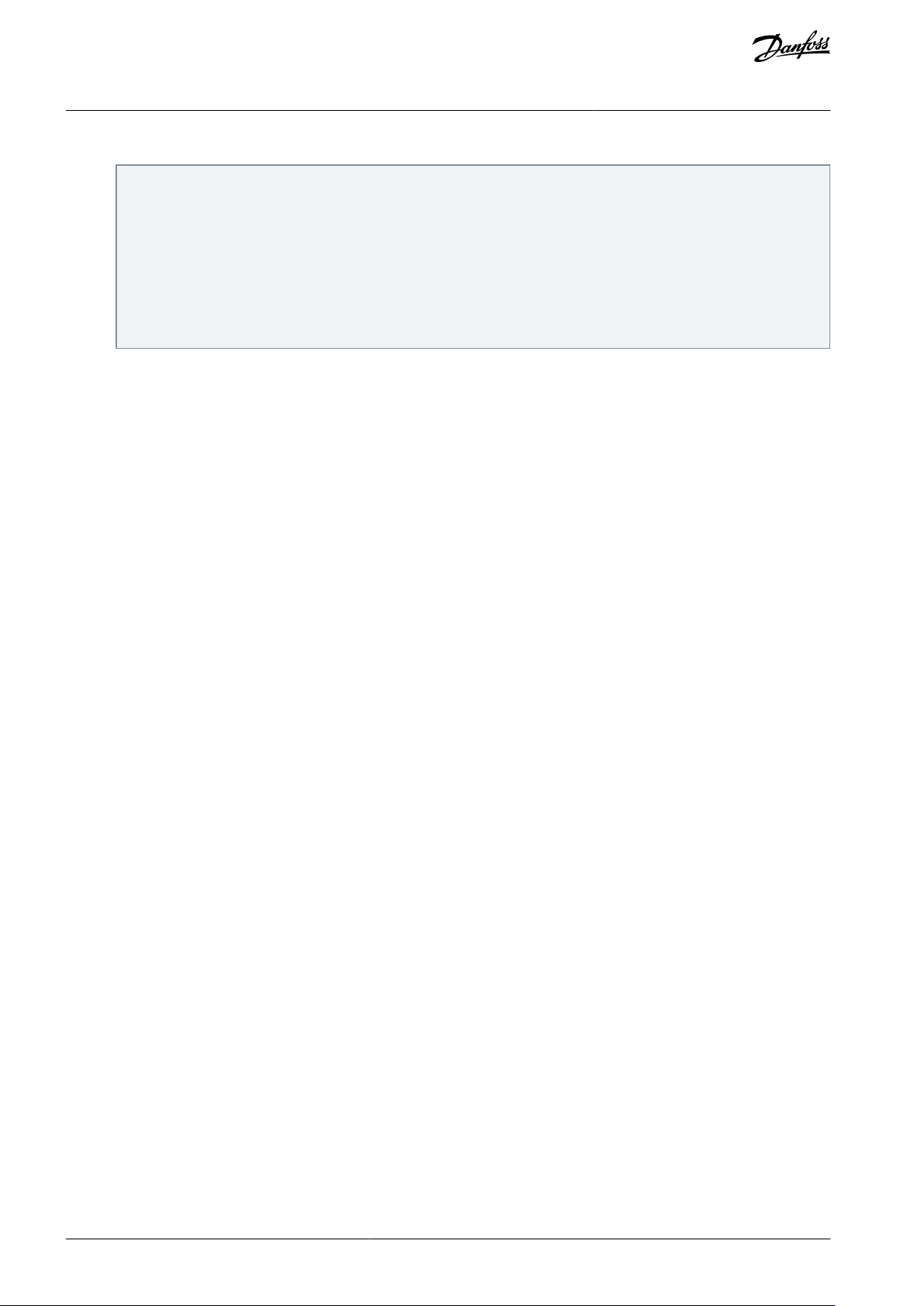

3.2.2.2 Setup Wizard Introduction

The built-in wizard menu guides the installer through the setup of the drive in a clear and structured manner for open-loop and

closed-loop applications, and for quick motor settings.

Illustration 3: Drive Wiring

The wizard can always be accessed again through the quick menu. Press [OK] to start the wizard. Press [Back] to return to the status

view.

AU363928304090en-000101 / 130R0982 | 11Danfoss A/S © 2021.07

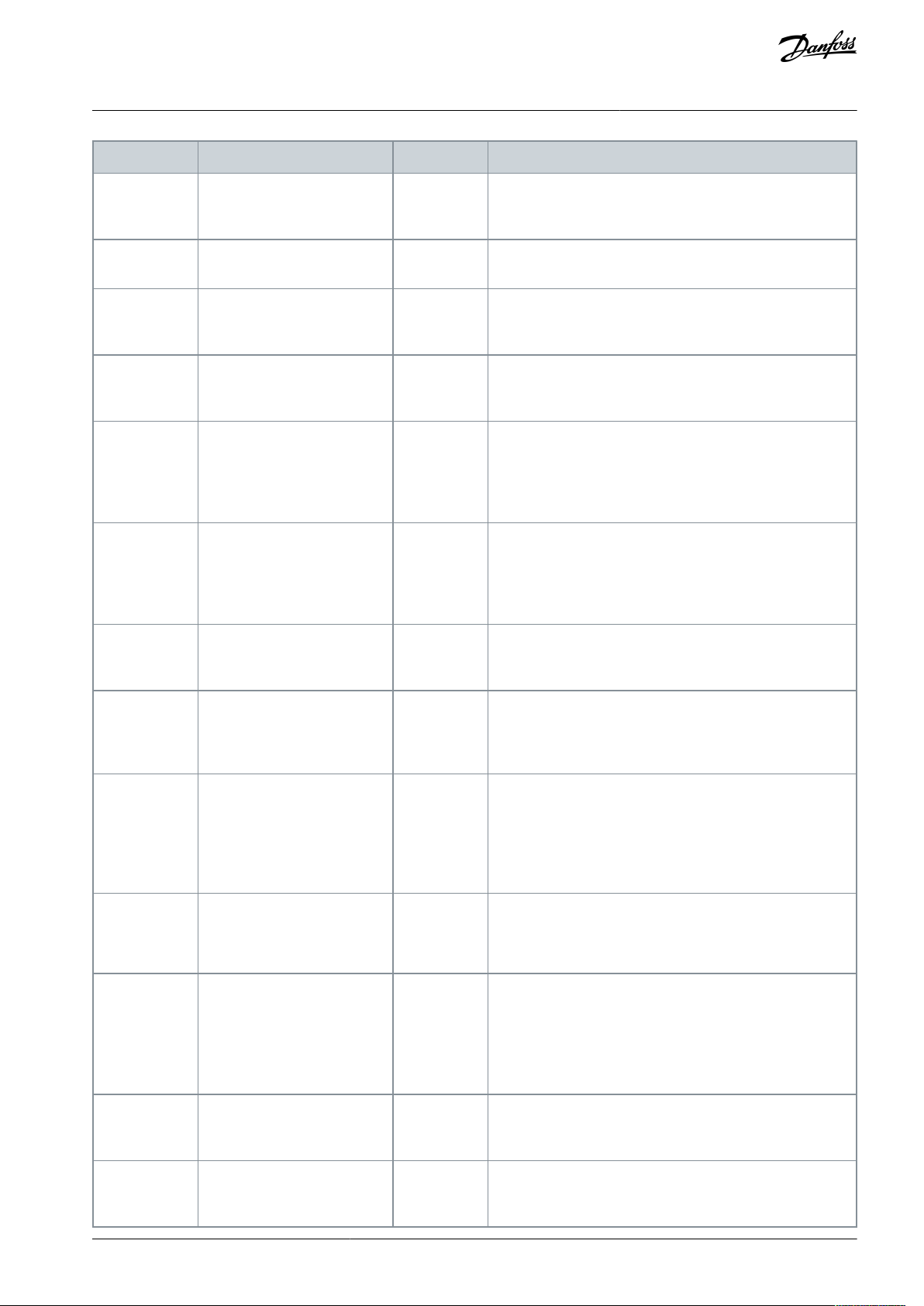

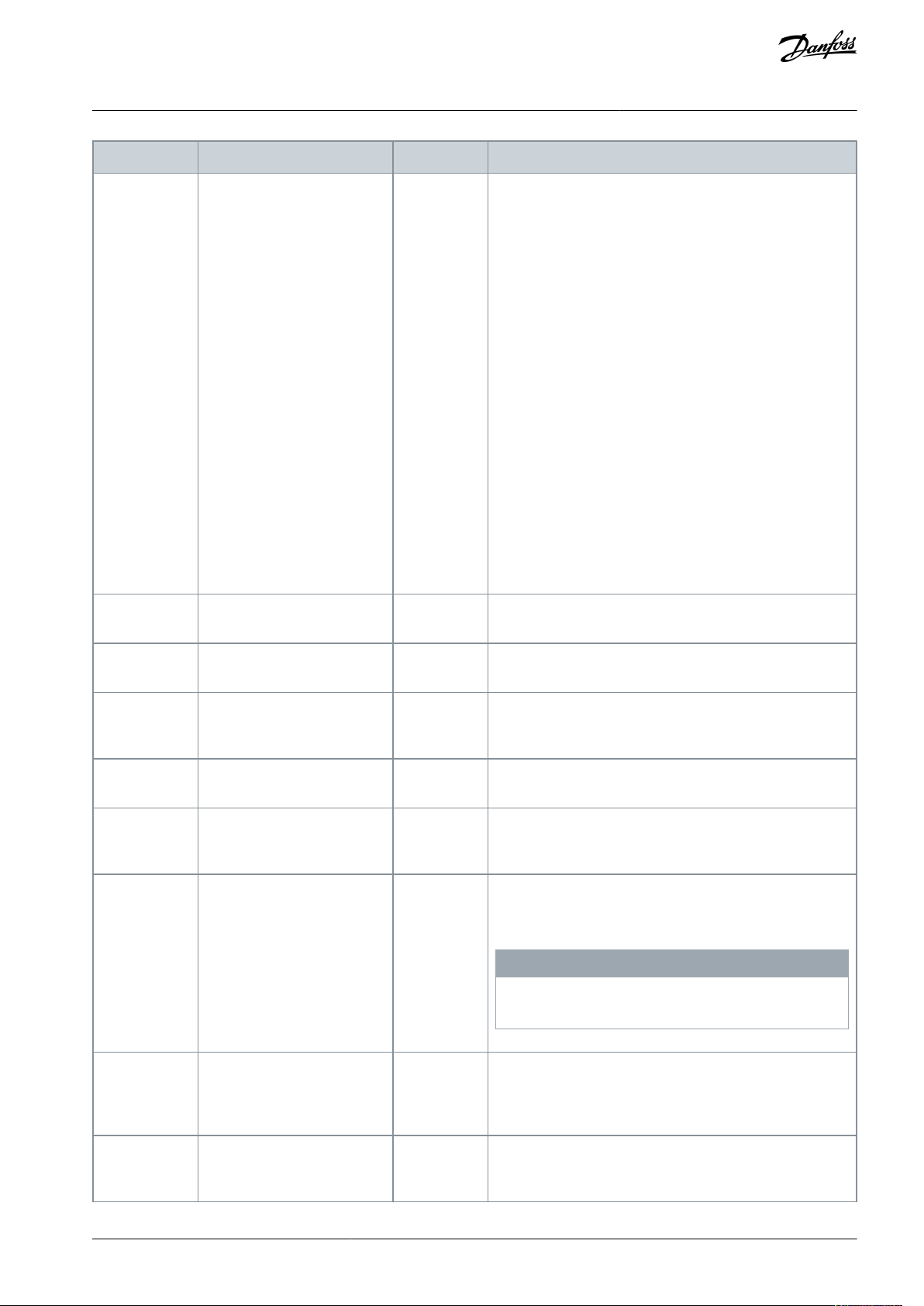

Power kW/50 H z

Motor Power

Motor Voltage

Motor Frequency

Motor Current

Motor nominal speed

if

Select Regional Settings

... the Wizard starts

200-240V/50Hz/Delta

Grid Type

Induction motor

Asynchronous

Motor Type

Motor current

Motor nominal speed

Motor Cont. Rated Torque

Stator resistance

Motor poles

Back EMF at 1000 rpm

Motor type = IPM

Motor type = SPM

d-axis Inductance Sat. (LdSat)

[0]

[0]

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

Start Mode

Rotor Detection

[0]

Position Detection Gain

%

Off

100

Locked Rotor Detection

[0]

s

Locked Rotor Detection Time[s]

0.10

57

V

5

mH

q-axis Inductance (Lq)

5

mH

1.10

kW

400

V

50

Hz

Max Output Frequency

65

Hz

Motor Cable Length

50

m

4.66

A

1420

RPM

[0]

PM motor

Set Motor Speed low Limit

Hz

Set Motor Speed high Limit

Hz

Set Ramp 1 ramp-up time

s

Set Ramp 1 ramp-down Time

s

Active Flying start ?

Disable

Set T53 low Voltage

V

Set T53 high Voltage

V

Set T53 Low Current

A

Set T53 High Current

A

Voltage

AMA Failed

AMA Failed

Automatic Motor Adaption

Auto Motor Adapt OK

Press OK

Select Function of Relay 2

No function

Off

Select Function of Relay 1

[0] No function

Set Max Reference

Hz

Hz

Set Min Reference

AMA running

-----

Do AMA

(Do not AMA)

AMA OK

[0]

[0]

[0]

Select T53 Mode

Current

Current

Motor type = Induction

Motor type = PM motor

0000

0050

0010

0010

[0]

[0]

04.66

13.30

0050

0220

0000

0050

The next screen is

the Wizard screen.

Power-up Screen

e30bu808.12

q-axis Inductance Sat. (LqSat)

5

mH

Current at Min Inductance for d-axis

100

%

Current at Min Inductance for q-axis

100

%

d-axis Inductance (Lq)

5

mH

... the Wizard starts

Or

0-** FC-xxx Wizard

2-** Motor Setup

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

1-** Closed Loop Set

0.0 Hz

Auto On

Status

Quick

Menu

Main

Menu

Menu

OK

Com.

On

Warn.

Alarm

Hand

On

Off

Reset

Auto

On

Back

0.000 kW

1 (1)

Menu

OK

VLT® Flow Drive FC 111

Programming Guide

3.2.2.3 Setup Wizard for Open-loop Applications

Programming

Illustration 4: Setup Wizard for Open-loop Applications

AU363928304090en-000101 / 130R098212 | Danfoss A/S © 2021.07

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size related

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

N O T I C E

Compared to 380–440 V groups, when selecting 440–

480 V groups, the rated current decreases accordingly.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

VLT® Flow Drive FC 111

Programming Guide

Table 6: Setup Wizard for Open-loop Applications

Programming

AU363928304090en-000101 / 130R0982 | 13Danfoss A/S © 2021.07

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Option

Default

Usage

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–1000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–9999 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–1000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-29

Automatic Motor Adaption

(AMA)

See parameter 1-29 Automatic

Motor Adaption (AMA).

Off

Performing an AMA optimizes motor performance.

Parameter 1-30

Stator Resistance (Rs)

0.000–99.990 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R098214 | Danfoss A/S © 2021.07

Parameter

Option

Default

Usage

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a motor spinning due to mains drop-out. Select [0] Disabled if this function is not required. When this parameter is set to [1] Ena-

bled, parameter 1-71 Start Delay and parameter 1-72 Start

Function are not functional. Parameter 1-73 Flying Start is ac-

tive in VVC+ mode only.

Parameter 3-02

Minimum Reference

-4999.000–4999.000

0

The minimum reference is the lowest value obtainable by

summing all references.

Parameter 3-03

Maximum Reference

-4999.000–4999.000

50

The maximum reference is the lowest obtainable by summing all references.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R0982 | 15Danfoss A/S © 2021.07

Parameter

Option

Default

Usage

Parameter 3-41

Ramp 1 Ramp

Up Time

0.01–3600.00 s

Size related

If induction motor is selected, the ramp-up time is from 0 to

rated parameter 1-23 Motor Frequency. If PM motor is selected, the ramp-up time is from 0 to parameter 1-25 Motor

Nominal Speed.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.01–3600.00 s

Size related

For induction motors, the ramp-down time is from rated pa-

rameter 1-23 Motor Frequency to 0. For PM motors, the rampdown time is from parameter 1-25 Motor Nominal Speed to 0.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100 Hz

Enter the maximum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[9] Alarm

Select the function to control output relay 1.

Parameter 5-40

Function Relay

See parameter 5-40 Function

Relay.

[5] Drive running

Select the function to control output relay 2.

Parameter 6-10

Terminal 53

Low Voltage

0.00–10.00 V

0.07 V

Enter the voltage that corresponds to the low reference value.

Parameter 6-11

Terminal 53

High Voltage

0.00–10.00 V

10 V

Enter the voltage that corresponds to the high reference value.

Parameter 6-12

Terminal 53

Low Current

0.00–20.00 mA

4 mA

Enter the current that corresponds to the low reference value.

Parameter 6-13

Terminal 53

High Current

0.00–20.00 mA

20 mA

Enter the current that corresponds to the high reference value.

Parameter 6-19

Terminal 53

mode

[0] Current

[1] Voltage

[1] Voltage

Select if terminal 53 is used for current or voltage input.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1 s

0.10 s

–

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R098216 | Danfoss A/S © 2021.07

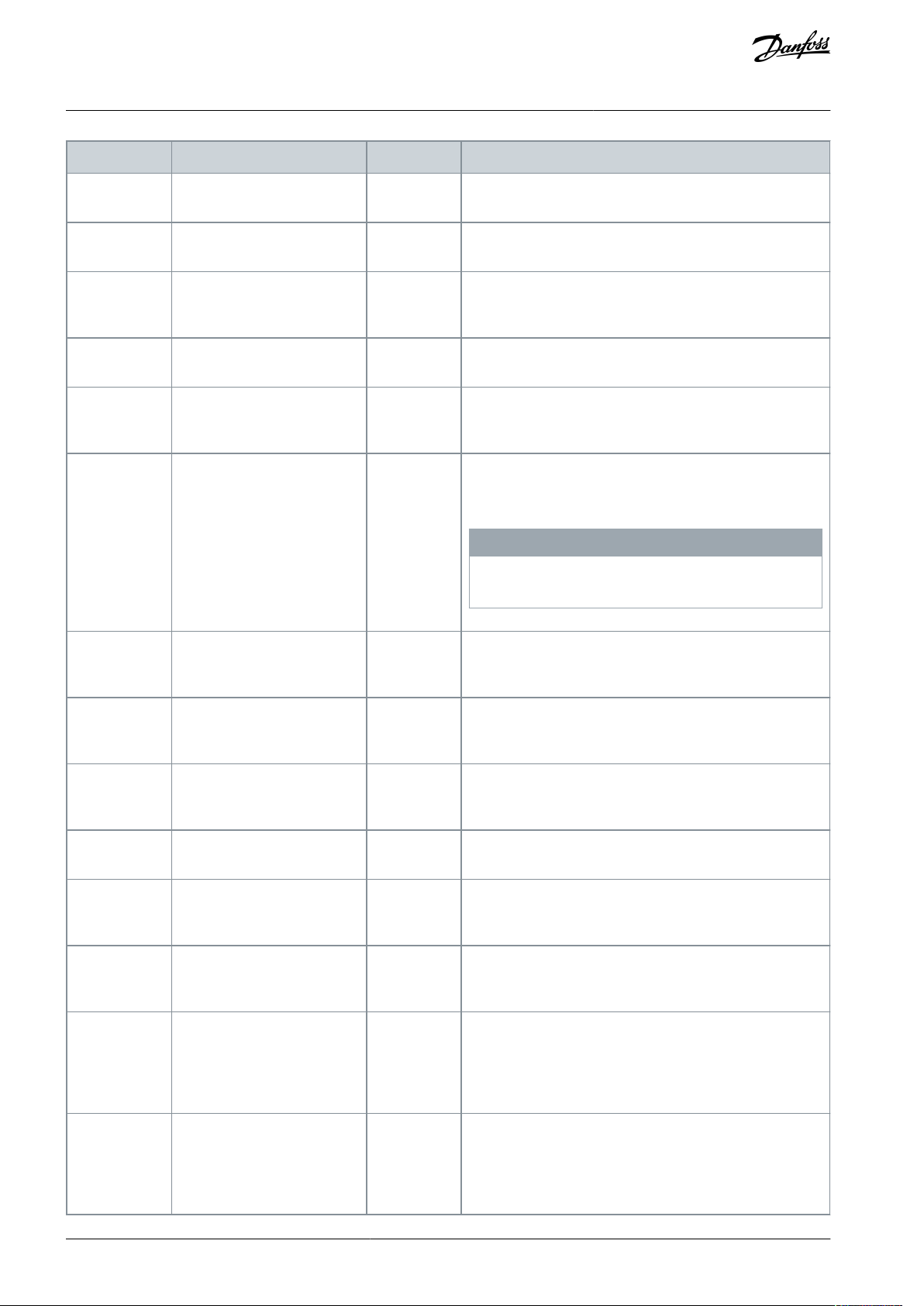

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Induction motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

400

V

1-24 Motor Current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0010

s

3-42 Ramp1 ramp-down time

0010

s

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-14 Motor speed high limit

0050

Hz

e30bc402.16

1-20 Motor Power

1.10

kW

1-23 Motor Frequency

50

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

Off

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Configuration Mode

[3]

Closed Loop

0-03 Regional Settings

[0]

Power kW/50 Hz

3-16 Reference Source 2

[0]

No Operation

1-10 Motor Type

[0]

Asynchronous

[0]

200-240V/50Hz/Delta

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-38 q-axis inductance(Lq)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 RPM

57

V

PM motor

1-39 Motor Poles

8

%

04.66

Hz

Motor type = Induction

Motor type = PM motor

Motor type = IPM

Motor type = SPM

1-44 d-axis Inductance Sat. (LdSat)

(1-70) Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

Off

100

30-22 Locked Rotor Detection

[0]

s

30-23 Locked Rotor Detection Time[s]

0.10

5

mH

1-42 Motor Cable Length

50

m

(1-45) q-axis Inductance Sat. (LqSat)

5

mH

(1-48) Current at Min Inductanc e for d-axis

100

%

1-49 Current at Min Inductanc e for q-axis

100

%

1-37 d-axis inductance(Lq)

5

mH

... the Wizard starts

... the Wizard starts

VLT® Flow Drive FC 111

Programming Guide

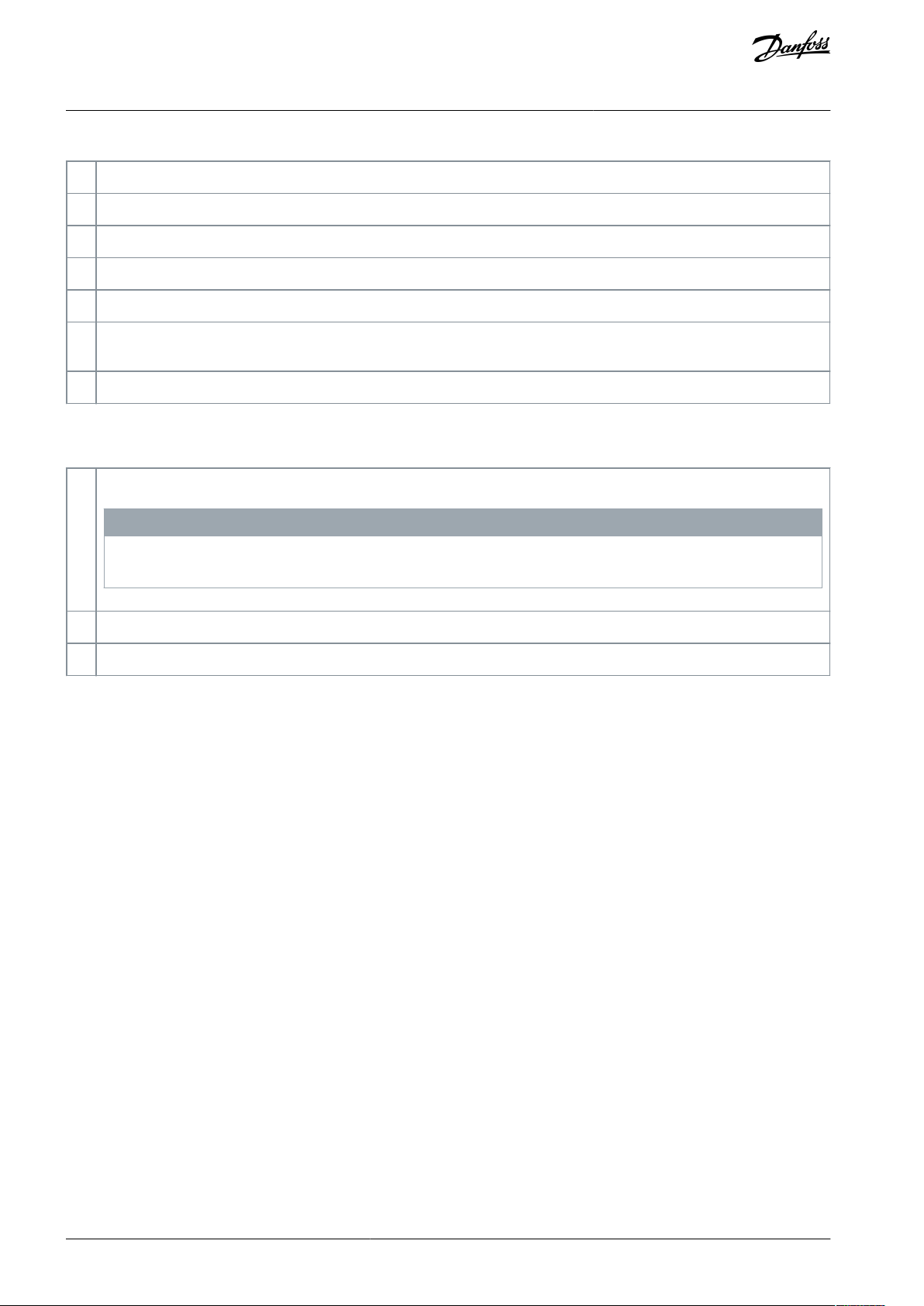

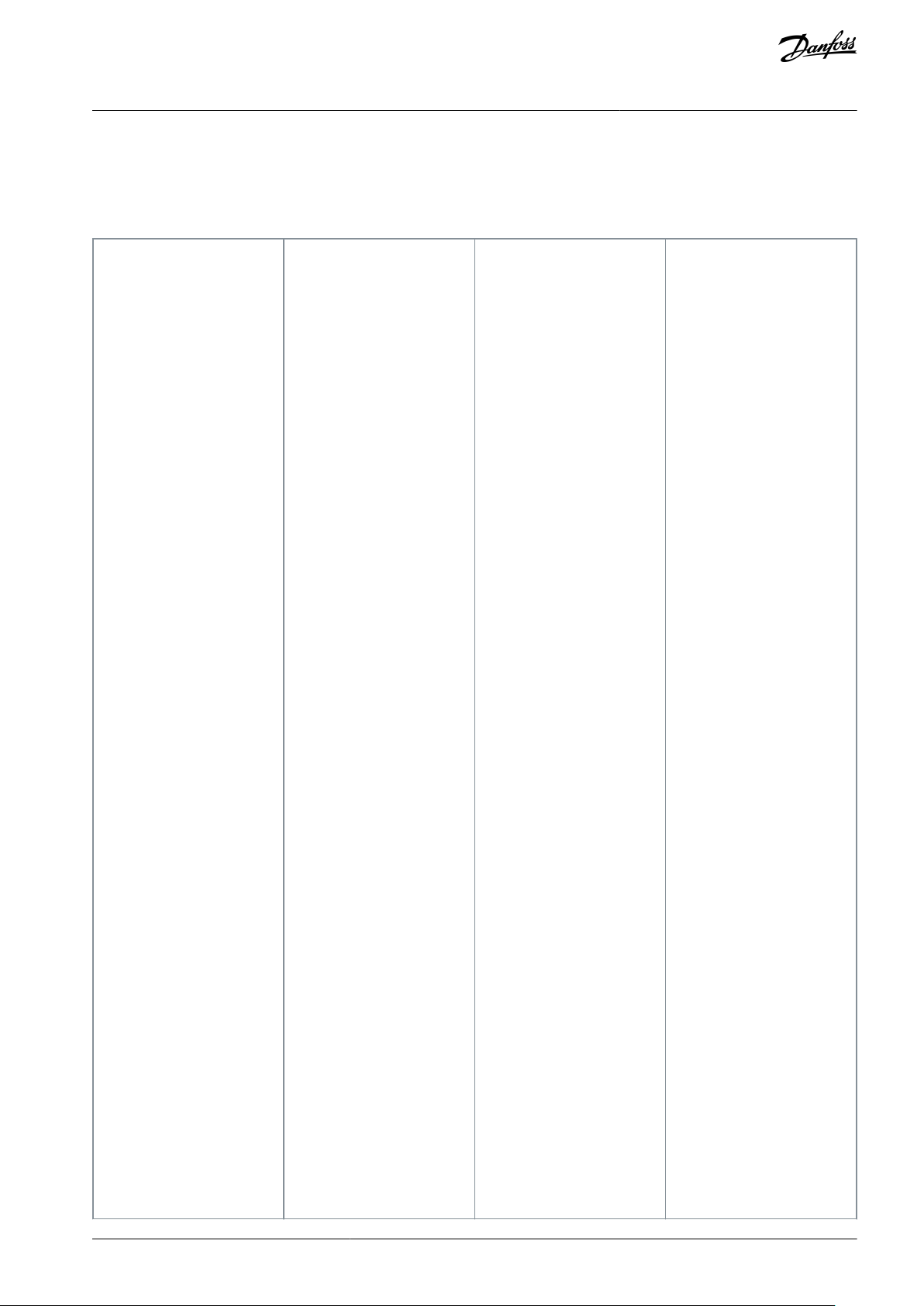

3.2.2.4 Setup Wizard for Closed-loop Applications

Programming

Illustration 5: Setup Wizard for Closed-loop Applications

AU363928304090en-000101 / 130R0982 | 17Danfoss A/S © 2021.07

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Range

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size selected

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

Parameter 1-00

Configuration

Mode

[0] Open loop

[3] Closed loop

[0] Open loop

Select [3] Closed loop.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

VLT® Flow Drive FC 111

Programming Guide

Table 7: Setup Wizard for Closed-loop Applications

Programming

AU363928304090en-000101 / 130R098218 | Danfoss A/S © 2021.07

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Range

Default

Usage

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–1000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–60000 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–10000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-29

Automatic Motor Adaption

(AMA)

–

Off

Performing an AMA optimizes motor performance.

Parameter 1-30

Stator Resistance (Rs)

0.000–9999.000 Ω

Size related

Set the stator resistance value.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R0982 | 19Danfoss A/S © 2021.07

Parameter

Range

Default

Usage

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a spinning motor in, for example, fan applications. When PM is selected,

this parameter is enabled.

Parameter 3-02

Minimum Reference

-4999.000–4999.000

0

The minimum reference is the lowest value obtainable by

summing all references.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R098220 | Danfoss A/S © 2021.07

Parameter

Range

Default

Usage

Parameter 3-03

Maximum Reference

-4999.000–4999.000

50

The maximum reference is the highest value obtainable by

summing all references.

Parameter 3-10

Preset Reference

-100–100%

0

Enter the setpoint.

Parameter 3-41

Ramp 1 Ramp

Up Time

0.05–3600.0 s

Size related

Ramp-up time from 0 to rated parameter 1-23 Motor Frequen-

cy for induction motors. Ramp-up time from 0 to parameter

1-25 Motor Nominal Speed for PM motors.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.05–3600.0 s

Size related

Ramp-down time from rated parameter 1-23 Motor Frequency

to 0 for induction motors. Ramp-down time from parameter

1-25 Motor Nominal Speed to 0 for PM motors.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0.0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100 Hz

Enter the minimum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter 6-20

Terminal 54

Low Voltage

0.00–10.00 V

0.07 V

Enter the voltage that corresponds to the low reference value.

Parameter 6-21

Terminal 54

High Voltage

0.00–10.00 V

10.00 V

Enter the voltage that corresponds to the high reference value.

Parameter 6-22

Terminal 54

Low Current

0.00–20.00 mA

4.00 mA

Enter the current that corresponds to the low reference value.

Parameter 6-23

Terminal 54

High Current

0.00–20.00 mA

20.00 mA

Enter the current that corresponds to the high reference value.

Parameter 6-24

Terminal 54

Low Ref./Feedb.

Value

-4999–4999

0

Enter the feedback value that corresponds to the voltage or

current set in parameter 6-20 Terminal 54 Low Voltage/param-

eter 6-22 Terminal 54 Low Current.

Parameter 6-25

Terminal 54

High Ref./

Feedb. Value

-4999–4999

50

Enter the feedback value that corresponds to the voltage or

current set in parameter 6-21 Terminal 54 High Voltage/pa-

rameter 6-23 Terminal 54 High Current.

Parameter 6-26

Terminal 54 Filter Time Constant

0.00–10.00 s

0.01

Enter the filter time constant.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R0982 | 21Danfoss A/S © 2021.07

Parameter

Range

Default

Usage

Parameter 6-29

Terminal 54

mode

[0] Current

[1] Voltage

[1] Voltage

Select if terminal 54 is used for current or voltage input.

Parameter

20-81 PI Normal/Inverse

Control

[0] Normal

[1] Inverse

[0] Normal

Select [0] Normal to set the process control to increase the

output speed when the process error is positive. Select [1] In-

verse to reduce the output speed.

Parameter

20-83 PI Start

Speed [Hz]

0–200 Hz

0 Hz

Enter the motor speed to be attained as a start signal for

commencement of PI control.

Parameter

20-93 PI Proportional Gain

0.00–10.00

0.01

Enter the process controller proportional gain. Quick control

is obtained at high amplification. However, if amplification is

too high, the process may become unstable.

Parameter

20-94 PI Integral Time

0.1–999.0 s

999.0 s

Enter the process controller integral time. Obtain quick control through a short integral time, though if the integral time

is too short, the process becomes unstable. An excessively

long integral time disables the integral action.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1.00 s

0.10 s

–

Parameter

Range

Default

Usage

Parameter 0-03

Regional Settings

[0] International

[1] US

[0] International

–

Parameter 0-06

GridType

[10] 380–440 V/50 Hz/IT-grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT-grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[110] 380–440 V/60 Hz/IT-grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT-grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

Size selected

Select the operating mode for restart after reconnection of

the drive to mains voltage after power down.

Parameter 1-10

Motor Construction

*[0] Asynchron

[1] PM, non-salient SPM

[3] PM, salient IPM

[0] Asynchron

Setting the parameter value might change these parameters:

VLT® Flow Drive FC 111

Programming Guide

Programming

3.2.2.5 Motor Setup

The motor setup wizard guides users through the needed motor parameters.

Table 8: Motor Setup Wizard Settings

AU363928304090en-000101 / 130R098222 | Danfoss A/S © 2021.07

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Parameter

Range

Default

Usage

Parameter 1-01 Motor Control Principle.

Parameter 1-03 Torque Characteristics.

Parameter 1-08 Motor Control Bandwidth.

Parameter 1-14 Damping Gain.

Parameter 1-15 Low Speed Filter Time Const.

Parameter 1-16 High Speed Filter Time Const.

Parameter 1-17 Voltage Filter Time Const.

Parameter 1-20 Motor Power.

Parameter 1-22 Motor Voltage.

Parameter 1-23 Motor Frequency.

Parameter 1-24 Motor Current.

Parameter 1-25 Motor Nominal Speed.

Parameter 1-26 Motor Cont. Rated Torque.

Parameter 1-30 Stator Resistance (Rs).

Parameter 1-33 Stator Leakage Reactance (X1).

Parameter 1-35 Main Reactance (Xh).

Parameter 1-37 d-axis Inductance (Ld).

Parameter 1-38 q-axis Inductance (Lq).

Parameter 1-39 Motor Poles.

Parameter 1-40 Back EMF at 1000 RPM.

Parameter 1-44 d-axis Inductance Sat. (LdSat).

Parameter 1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-46 Position Detection Gain.

Parameter 1-48 Current at Min Inductance for d-axis.

Parameter 1-49 Current at Min Inductance for q-axis.

Parameter 1-66 Min. Current at Low Speed.

Parameter 1-70 PM Start Mode.

Parameter 1-72 Start Function.

Parameter 1-73 Flying Start.

Parameter 1-80 Function at Stop.

Parameter 1-82 Min Speed for Function at Stop [Hz].

Parameter 1-90 Motor Thermal Protection.

Parameter 2-00 DC Hold/Motor Preheat Current.

Parameter 2-01 DC Brake Current.

Parameter 2-02 DC Braking Time.

Parameter 2-04 DC Brake Cut In Speed.

Parameter 2-10 Brake Function.

Parameter 4-14 Motor Speed High Limit [Hz].

Parameter 4-19 Max Output Frequency.

Parameter 4-58 Missing Motor Phase Function.

Parameter 14-65 Speed Derate Dead Time Compensation.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R0982 | 23Danfoss A/S © 2021.07

Parameter

Range

Default

Usage

Parameter 1-20

Motor Power

0.18–110 kW/0.25–150 hp

Size related

Enter the motor power from the nameplate data.

Parameter 1-22

Motor Voltage

50–1000 V

Size related

Enter the motor voltage from the nameplate data.

Parameter 1-23

Motor Frequency

20–400 Hz

Size related

Enter the motor frequency from the nameplate data.

Parameter 1-24

Motor Current

0.01–10000.00 A

Size related

Enter the motor current from the nameplate data.

Parameter 1-25

Motor Nominal

Speed

50–9999 RPM

Size related

Enter the motor nominal speed from the nameplate data.

Parameter 1-26

Motor Cont.

Rated Torque

0.1–1000.0 Nm

Size related

This parameter is available when parameter 1-10 Motor Con-

struction is set to options that enable permanent motor

mode.

N O T I C E

Changing this parameter affects the settings of other pa-

rameters.

Parameter 1-30

Stator Resistance (Rs)

0–99.990 Ω

Size related

Set the stator resistance value.

Parameter 1-37

d-axis Inductance (Ld)

0.000–1000.000 mH

Size related

Enter the value of the d-axis inductance. Obtain the value

from the permanent magnet motor datasheet.

Parameter 1-38

q-axis Inductance (Lq)

0.000–1000.000 mH

Size related

Enter the value of the q-axis inductance.

Parameter 1-39

Motor Poles

2–100

4

Enter the number of motor poles.

Parameter 1-40

Back EMF at

1000 RPM

10–9000 V

Size related

Line-line RMS back EMF voltage at 1000 RPM.

Parameter 1-42

Motor Cable

Length

0–100 m

50 m

Enter the motor cable length.

Parameter 1-44

d-axis Inductance Sat.

(LdSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Ld. Ideally, this parameter has the same value as parameter

1-37 d-axis Inductance (Ld). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

Parameter 1-45

q-axis Inductance Sat.

(LqSat)

0.000–1000.000 mH

Size related

This parameter corresponds to the inductance saturation of

Lq. Ideally, this parameter has the same value as parameter

1-38 q-axis Inductance (Lq). However, if the motor supplier

provides an induction curve, enter the induction value,

which is 200% of the nominal current.

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R098224 | Danfoss A/S © 2021.07

Parameter

Range

Default

Usage

Parameter 1-46

Position Detection Gain

20–200%

100%

Adjusts the height of the test pulse during position detection at start.

Parameter 1-48

Current at Min

Inductance for

d-axis

20–200%

100%

Enter the inductance saturation point.

Parameter 1-49

Current at Min

Inductance for

q-axis

20–200%

100%

This parameter specifies the saturation curve of the d- and qinductance values. From 20–100% of this parameter, the inductances are linearly approximated due to parameter 1-37

d-axis Inductance (Ld), parameter 1-38 q-axis Inductance (Lq),

parameter 1-44 d-axis Inductance Sat. (LdSat), and parameter

1-45 q-axis Inductance Sat. (LqSat).

Parameter 1-70

PM Start Mode

[0] Rotor Detection

[1] Parking

[3] Rotor Last Position

[1] Parking

Select the PM motor start mode.

Parameter 1-73

Flying Start

[0] Disabled

[1] Enabled

[0] Disabled

Select [1] Enabled to enable the drive to catch a spinning motor.

Parameter 3-41

Ramp 1 Ramp

Up Time

0.05–3600.0 s

Size related

Ramp-up time from 0 to rated parameter 1-23 Motor Frequen-

cy.

Parameter 3-42

Ramp 1 Ramp

Down Time

0.05–3600.0 s

Size related

Ramp-down time from rated parameter 1-23 Motor Frequency

to 0.

Parameter 4-12

Motor Speed

Low Limit [Hz]

0.0–400.0 Hz

0.0 Hz

Enter the minimum limit for low speed.

Parameter 4-14

Motor Speed

High Limit [Hz]

0.0–400.0 Hz

100.0 Hz

Enter the maximum limit for high speed.

Parameter 4-19

Max Output

Frequency

0.0–400.0 Hz

100.0 Hz

Enter the maximum output frequency value. If parameter

4-19 Max Output Frequency is set lower than parameter 4-14

Motor Speed High Limit [Hz], parameter 4-14 Motor Speed High

Limit [Hz] is set equal to parameter 4-19 Max Output Frequency automatically.

Parameter

30-22 Locked

Rotor Detection

[0] Off

[1] On

[0] Off

–

Parameter

30-23 Locked

Rotor Detection

Time [s]

0.05–1.00 s

0.10 s

–

VLT® Flow Drive FC 111

Programming Guide

Programming

AU363928304090en-000101 / 130R0982 | 25Danfoss A/S © 2021.07

VLT® Flow Drive FC 111

Programming Guide

3.2.2.6 Changes Made Function

The changes made function lists all parameters changed from default settings.

•

The list shows only parameters that have been changed in the current edit setup.

•

Parameters that have been reset to default values are not listed.

•

The message Empty indicates that no parameters have been changed.

3.2.2.7 Changing Parameter Settings

Procedure

1.

To enter the Quick Menu, press the [Menu] key until the indicator in the display is placed above Quick Menu.

2.

Press [▵] [▿] to select the wizard, closed-loop setup, motor setup, or changes made.

3.

Press [OK].

4.

Press [▵] [▿] to browse through the parameters in the Quick Menu.

5.

Press [OK] to select a parameter.

6.

Press [▵] [▿] to change the value of a parameter setting.

7.

Press [OK] to accept the change.

8.

Press either [Back] twice to enter Status, or press [Menu] once to enter the Main Menu.

3.2.2.8 Accessing All Parameters via the Main Menu

Procedure

1.

Press the [Menu] key until the indicator in the display is placed above Main Menu.

2.

Press [▵] [▿] to browse through the parameter groups.

3.

Press [OK] to select a parameter group.

4.

Press [▵] [▿] to browse through the parameters in the specific group.

5.

Press [OK] to select the parameter.

6.

Press [▵] [▿] to set/change the parameter value.

7.

Press [OK] to accept the change.

Programming

3.2.3 Main Menu

Press [Menu] to access the main menu and program all parameters. The main menu parameters can be accessed readily unless a

password has been created via parameter 0-60 Main Menu Password.

For most applications, it is not necessary to access the main menu parameters. The quick menu provides the simplest and quickest

access to the typical required parameters.

3.3 Quick Transfer of Parameter Settings between Multiple Drives

When the set-up of a drive is completed, store the data in the LCP. Then connect the LCP to another drive and copy the parameter

settings to the new drive.

3.3.1 Transferring Data from the Drive to the LCP

Procedure

1.

Go to parameter 0-50 LCP Copy.

Press [OK].

2.

3.

Select [1] All to LCP.

Press [OK].

4.

3.3.2 Transferring Data from the LCP to the Drive

Procedure

1.

Go to parameter 0-50 LCP Copy.

Press [OK].

2.

3.

Select [2] All from LCP.

Press [OK].

4.

3.4 Readout and Programming of Indexed Parameters

Procedure

AU363928304090en-000101 / 130R098226 | Danfoss A/S © 2021.07

VLT® Flow Drive FC 111

Programming Guide

1.

Select the parameter and press [OK].

2.

Press [▵]/[▿] to scroll through the indexed values.

3.

To change the parameter value, select the indexed value and press [OK].

4.

Change the value by pressing [▵]/[▿].

5.

Press [OK] or [Cancel] to accept or abort the new setting.

6.

Press [Back] to leave the parameter.

3.5 Initialization to Default Settings

There are 2 ways to initialize the drive to the default settings.

•

Recommended initialization

•

Two-finger initialization

Initialization of parameters is confirmed by alarm 80, Drive initialised in the display after the power cycle.

3.5.1 Recommended Initialization

Procedure

1.

Select parameter 14-22 Operation Mode.

Press [OK].

2.

3.

Select [2] Initialisation and press [OK].

Power off the drive and wait until the display turns off.

4.

Reconnect the mains supply. The drive is now reset, except for the following parameters.

5.

Programming

•

Parameter 1-06 Clockwise Direction

•

Parameter 8-30 Protocol

•

Parameter 8-31 Address

•

Parameter 8-32 Baud Rate

•

Parameter 8-33 Parity / Stop Bits

•

Parameter 8-35 Minimum Response Delay

•

Parameter 8-36 Maximum Response Delay

•

Parameter 8-37 Maximum Inter-char delay

•

Parameter 8-70 BACnet Device Instance

•

Parameter 8-72 MS/TP Max Masters

•

Parameter 8-73 MS/TP Max Info Frames

•

Parameter 8-74 "I am" Service

•

Parameter 8-75 Intialisation Password

•

Parameter 15-00 Operating hours to parameter 15-05 Over Volt's

•

Parameter 15-03 Power Up's

•

Parameter 15-04 Over Temp's

•

Parameter 15-05 Over Volt's

•

Parameter 15-30 Alarm Log: Error Code

•

Parameter group 15-4* Drive identification

•

Parameter 18-10 FireMode Log:Event

3.5.2 Two-finger Initialization

Procedure

Power off the drive.

1.

Press [OK] and [Menu].

2.

Power up the drive while still pressing the keys for 10 s.

3.

AU363928304090en-000101 / 130R0982 | 27Danfoss A/S © 2021.07

VLT® Flow Drive FC 111

Programming Guide

4.

The drive is now reset, except for the following parameters.

•

Parameter 1-06 Clockwise Direction

•

Parameter 15-00 Operating hours

•

Parameter 15-03 Power Up's

•

Parameter 15-04 Over Temp's

•

Parameter 15-05 Over Volt's

•

Parameter group 15-4* Drive identification

•

Parameter 18-10 FireMode Log:Event

Programming

AU363928304090en-000101 / 130R098228 | Danfoss A/S © 2021.07

0-** Operation/Display

0-0* Basic Settings

0-01 Language

0-03 Regional Settings

0-04 Operating State at Pow-

er-up

0-06 GridType

0-07 Auto DC Braking

0-1* Set-up Operations

0-10 Active Set-up

0-11 Programming Set-up

0-12 Link Setups

0-16 Application Selection

0-3* LCP Custom Readout

0-30 Custom Readout Unit

0-31 Custom Readout Min

Value

0-32 Custom Readout Max

Value

0-37 Display Text 1

0-38 Display Text 2

0-39 Display Text 3

0-4* LCP Keypad

0-40 [Hand on] Key on LCP

0-42 [Auto on] Key on LCP

0-44 [Off/Reset] Key on LCP

0-5* Copy/Save

0-50 LCP Copy

0-51 Set-up Copy

0-6* Password

0-60 Main Menu Password

0-61 Access to Main Menu

w/o Password

1-** Load and Motor

1-0* General Settings

1-00 Configuration Mode

1-01 Motor Control Principle

1-03 Torque Characteristics

1-06 Clockwise Direction

1-08 Motor Control Band-

width

1-1* Motor Selection

1-10 Motor Construction

1-14 Damping Gain

1-15 Low Speed Filter Time

Const.

1-16 High Speed Filter Time

Const.

1-17 Voltage time const.

1-2* Motor Data

1-20 Motor Power

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Tor-

que

1-29 Automatic Motor Adap-

tion (AMA)

1-3* Adv. Motor Data

1-30 Stator Resistance (Rs)

1-31 Rotor Resistance (Rr)

1-33 Stator Leakage Reac-

tance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-38 q-axis Inductance (Lq)

1-39 Motor Poles

1-4* Adv. Motor Data II

1-40 Back EMF at 1000 RPM

1-42 Motor Cable Length

1-43 Motor Cable Length Feet

1-44 d-axis Inductance Sat.

(LdSat)

1-45 q-axis Inductance Sat.

(LqSat)

1-46 Position Detection Gain

1-48 Current at Min Induc-

tance for d-axis

1-49 Current at Min Induc-

tance for q-axis

1-5* Load Indep. Setting

1-50 Motor Magnetisation at

Zero Speed

1-52 Min Speed Normal Mag-

netising [Hz]

1-55 U/f Characteristic - U

1-56 U/f Characteristic - F

1-6* Load Depen. Setting

1-62 Slip Compensation

1-63 Slip Compensation Time

Constant

1-64 Resonance Dampening

1-65 Resonance Dampening

Time Constant

1-66 Min. Current at Low

Speed

1-7* Start Adjustments

1-70 Start Mode

1-71 Start Delay

1-72 Start Function

1-73 Flying Start

1-8* Stop Adjustments

1-80 Function at Stop

1-82 Min Speed for Function

at Stop [Hz]

1-88 AC Brake Gain

1-9* Motor Temperature

1-90 Motor Thermal Protec-

tion

1-93 Thermistor Source

2-** Brakes

2-0* DC-Brake

2-00 DC Hold/Motor Preheat

Current

2-01 DC Brake Current

2-02 DC Braking Time

2-04 DC Brake Cut In Speed

2-06 Parking Current

2-07 Parking Time

2-1* Brake Energy Funct.

2-10 Brake Function

2-16 AC Brake, Max current

2-17 Over-voltage Control

2-19 Over-voltage Gain

3-** Reference / Ramps

3-0* Reference Limits

3-02 Minimum Reference

3-03 Maximum Reference

3-1* References

3-10 Preset Reference

3-11 Jog Speed [Hz]

3-14 Preset Relative Reference

3-15 Reference 1 Source

3-16 Reference 2 Source

3-17 Reference 3 Source

3-4* Ramp 1

3-41 Ramp 1 Ramp Up Time

3-42 Ramp 1 Ramp Down

Time

3-5* Ramp 2

3-51 Ramp 2 Ramp Up Time

3-52 Ramp 2 Ramp Down

Time

3-8* Other Ramps

3-80 Jog Ramp Time

3-81 Quick Stop Ramp Time

4-** Limits / Warnings

4-1* Motor Limits

4-10 Motor Speed Direction

4-12 Motor Speed Low Limit

[Hz]

4-14 Motor Speed High Limit

[Hz]

4-18 Current Limit

4-19 Max Output Frequency

4-4* Adj. Warnings 2

4-40 Warning Freq. Low

4-41 Warning Freq. High

4-5* Adj. Warnings

4-50 Warning Current Low

4-51 Warning Current High

4-54 Warning Reference Low

4-55 Warning Reference High

4-56 Warning Feedback Low

4-57 Warning Feedback High

4-58 Missing Motor Phase

Function

4-6* Speed Bypass

4-61 Bypass Speed From [Hz]

4-63 Bypass Speed To [Hz]

4-64 Semi-Auto Bypass Set-up

5-** Digital In/Out

5-0* Digital I/O mode

5-00 Digital Input Mode

5-01 Terminal 27 Mode

5-02 Terminal 29 Mode

5-03 Digital Input 29 Mode

5-1* Digital Inputs

5-10 Terminal 18 Digital Input

5-11 Terminal 19 Digital Input

5-12 Terminal 27 Digital Input

5-13 Terminal 29 Digital Input

5-3* Digital Outputs

5-30 Terminal 27 Digital Out-

put

5-31 Terminal 29 Digital Out-

put

5-34 On Delay, Digital Output

VLT® Flow Drive FC 111

Programming Guide

4 Parameters

4.1 Parameter List

Table 9: Parameter List

Parameters

AU363928304090en-000101 / 130R0982 | 29Danfoss A/S © 2021.07

5-35 Off Delay, Digital Output

5-4* Relays

5-40 Function Relay

5-41 On Delay, Relay

5-42 Off Delay, Relay

5-5* Pulse Input

5-50 Term. 29 Low Frequency

5-51 Term. 29 High Frequency

5-52 Term. 29 Low Ref./Feedb.

Value

5-53 Term. 29 High Ref./

Feedb. Value

5-8* I/O Options

5-80 AHF Cap Reconnect De-

lay

5-9* Bus Controlled

5-90 Digital & Relay Bus Con-

trol

6-** Analog In/Out

6-0* Analog I/O Mode

6-00 Live Zero Timeout Time

6-01 Live Zero Timeout Func-

tion

6-02 Fire Mode Live Zero

Timeout Function

6-1* Analog Input 53

6-10 Terminal 53 Low Voltage

6-11 Terminal 53 High Volt-

age

6-12 Terminal 53 Low Current

6-13 Terminal 53 High Current

6-14 Terminal 53 Low Ref./

Feedb. Value

6-15 Terminal 53 High Ref./

Feedb. Value

6-16 Terminal 53 Filter Time

Constant

6-19 Terminal 53 mode

6-2* Analog Input 54

6-20 Terminal 54 Low Voltage

6-21 Terminal 54 High Volt-

age

6-22 Terminal 54 Low Current

6-23 Terminal 54 High Current

6-24 Terminal 54 Low Ref./

Feedb. Value

6-25 Terminal 54 High Ref./

Feedb. Value

6-26 Terminal 54 Filter Time

Constant

6-29 Terminal 54 mode

6-7* Analog/Digital Output 45

6-70 Terminal 45 Mode

6-71 Terminal 45 Analog Output

6-72 Terminal 45 Digital Output

6-73 Terminal 45 Output Min

Scale

6-74 Terminal 45 Output Max

Scale

6-76 Terminal 45 Output Bus

Control

6-9* Analog/Digital Output 42

6-90 Terminal 42 Mode

6-91 Terminal 42 Analog Out-

put

6-92 Terminal 42 Digital Out-

put

6-93 Terminal 42 Output Min

Scale

6-94 Terminal 42 Output Max

Scale

6-96 Terminal 42 Output Bus

Control

6-98 Drive Type

8-** Comm. and Options

8-0* General Settings

8-01 Control Site

8-02 Control Source

8-03 Control Timeout Time

8-04 Control Timeout Func-

tion

8-3* FC Port Settings

8-30 Protocol

8-31 Address

8-32 Baud Rate

8-33 Parity/Stop Bits

8-35 Minimum Response De-

lay

8-36 Maximum Response De-

lay

8-37 Maximum Inter-char de-

lay

8-4* FC MC protocol set

8-42 PCD Write Configuration

8-43 PCD Read Configuration

8-5* Digital/Bus

8-50 Coasting Select

8-51 Quick Stop Select

8-52 DC Brake Select

8-53 Start Select

8-54 Reversing Select

8-55 Set-up Select

8-56 Preset Reference Select

8-7* BACnet

8-70 BACnet Device Instance

8-72 MS/TP Max Masters

8-73 MS/TP Max Info Frames

8-74 "I am" Service

8-75 Intialisation Password

8-79 Protocol Firmware ver-

sion

8-8* FC Port Diagnostics

8-80 Bus Message Count

8-81 Bus Error Count

8-82 Slave Messages Rcvd

8-83 Slave Error Count

8-84 Slave Messages Sent

8-85 Slave Timeout Errors

8-88 Reset FC port Diagnos-

tics

8-9* Bus Feedback

8-94 Bus Feedback 1

8-95 Bus Feedback 2

13-** Smart Logic

13-0* SLC Settings

13-00 SL Controller Mode

13-01 Start Event

13-02 Stop Event

13-03 Reset SLC

13-1* Comparators

13-10 Comparator Operand

13-11 Comparator Operator

13-12 Comparator Value

13-2* Timers

13-20 SL Controller Timer

13-4* Logic Rules

13-40 Logic Rule Boolean 1

13-41 Logic Rule Operator 1

13-42 Logic Rule Boolean 2

13-43 Logic Rule Operator 2

13-44 Logic Rule Boolean 3

13-5* States

13-51 SL Controller Event

13-52 SL Controller Action

14-** Special Functions

14-0* Inverter Switching

14-01 Switching Frequency

14-03 Overmodulation

14-07 Dead Time Compensa-

tion Level

14-08 Damping Gain Factor

14-09 Dead Time Bias Current

Level

14-1* Mains Failure

14-10 Mains Failure

14-11 Mains Fault Voltage

Level

14-12 Response to Mains Imbalance

14-15 Kin. Back-up Trip Recovery Level

14-2* Reset Functions

14-20 Reset Mode

14-21 Automatic Restart Time

14-22 Operation Mode

14-23 Typecode Setting

14-27 Action At Inverter Fault

14-28 Production Settings

14-29 Service Code

14-3* Current Limit Ctrl.

14-30 Current Lim Ctrl, Pro-

portional Gain

14-31 Current Lim Ctrl, Inte-

gration Time

14-32 Current Lim Ctrl, Filter

Time

14-4* Energy Optimising

14-40 VT Level

14-41 AEO Minimum Magnet-

isation

14-44 d-axis current optimiza-

tion for IPM

14-5* Environment

14-50 RFI Filter

14-51 DC-Link Voltage Com-

pensation

14-52 Fan Control

14-53 Fan Monitor

14-55 Output Filter

14-6* Auto Derate

14-61 Function at Inverter

Overload

14-63 Min Switch Frequency

14-64 Dead Time Compensa-

tion Zero Current Level

14-65 Speed Derate Dead

Time Compensation

14-9* Fault Settings

14-90 Fault Level

15-** Drive Information

15-0* Operating Data

15-00 Operating hours

15-01 Running Hours

15-02 kWh Counter

15-03 Power Up's

15-04 Over Temp's

15-05 Over Volt's

VLT® Flow Drive FC 111

Programming Guide

Table 10: Parameter List

Parameters

AU363928304090en-000101 / 130R098230 | Danfoss A/S © 2021.07

15-06 Reset kWh Counter

15-07 Reset Running Hours

Counter

15-3* Alarm Log

15-30 Alarm Log: Error Code

15-31 InternalFaultReason

15-32 Alarm Log: Time

15-4* Drive Identification

15-40 FC Type

15-41 Power Section

15-42 Voltage

15-43 Software Version

15-44 Ordered TypeCode

15-45 Actual Typecode String

15-46 Drive Ordering No

15-48 LCP Id No

15-49 SW ID Control Card

15-50 SW ID Power Card

15-51 Drive Serial Number

15-52 OEM Information

15-53 Power Card Serial Num-

ber

15-57 File Version

15-59 Filename

15-9* Parameter Info

15-92 Defined Parameters

15-97 Application Type

15-98 Drive Identification

16-** Data Readouts

16-0* General Status

16-00 Control Word

16-01 Reference [Unit]

16-02 Reference [%]

16-03 Status Word

16-05 Main Actual Value [%]

16-09 Custom Readout

16-1* Motor Status

16-10 Power [kW]

16-11 Power [hp]

16-12 Motor Voltage

16-13 Frequency

16-14 Motor current

16-15 Frequency [%]

16-16 Torque [Nm]

16-17 Speed [RPM]

16-18 Motor Thermal

16-22 Torque [%]

16-26 Power Filtered [kW]

16-27 Power Filtered [hp]

16-3* Drive Status

16-30 DC Link Voltage

16-34 Heatsink Temp.

16-35 Inverter Thermal

16-36 Inv. Nom. Current

16-37 Inv. Max. Current

16-38 SL Controller State

16-5* Ref. & Feedb.

16-50 External Reference

16-52 Feedback[Unit]

16-54 Feedback 1 [Unit]

16-55 Feedback 2 [Unit]

16-56 Feedback 3 [Unit]

16-6* Inputs & Outputs

16-60 Digital Input

16-61 Terminal 53 Setting

16-62 Analog input 53

16-63 Terminal 54 Setting

16-64 Analog input 54

16-65 Analog output 42 [mA]

16-66 Digital Output

16-67 Pulse input 29 [Hz]

16-71 Relay output

16-72 Counter A

16-73 Counter B

16-79 Analog output 45 [mA]

16-8* Fieldbus & FC Port

16-86 FC Port REF 1

16-9* Diagnosis Readouts

16-90 Alarm Word

16-91 Alarm Word 2

16-92 Warning Word

16-93 Warning Word 2

16-94 Ext. Status Word

16-95 Ext. Status Word 2

16-97 Alarm Word 3

16-98 Warning Word 3

18-** Info & Readouts

18-1* Fire Mode Log

18-10 FireMode Log:Event

18-5* Ref. & Feedb.

18-50 Sensorless Readout

[unit]

18-8* Compatibility

18-87 Inv. Max. Current

18-88 Motor current

18-9* PID Readouts

18-90 Process PID Error

18-91 Process PID Output

18-92 Process PID Clamped

Output

18-93 Process PID Gain Scaled

Output

20-** Drive Closed Loop

20-0* Feedback

20-00 Feedback 1 Source

20-01 Feedback 1 Conversion

20-03 Feedback 2 Source

20-04 Feedback 2 Conversion

20-06 Feedback 3 Source

20-07 Feedback 3 Conversion

20-12 Reference/Feedback

Unit

20-2* Feedback/Setpoint

20-20 Feedback Function

20-21 Setpoint 1

20-6* Sensorless

20-60 Sensorless Unit

20-69 Sensorless Information

20-7* PI Autotuning

20-70 Closed Loop Type

20-71 PI Performance

20-72 PI Output Change

20-73 Minimum Feedback

Level

20-74 Maximum Feedback

Level

20-79 PI Autotuning

20-8* PI Basic Settings

20-81 PI Normal/ Inverse Con-

trol

20-83 PI Start Speed [Hz]

20-84 On Reference Band-

width

20-9* PI Controller

20-91 PI Anti Windup

20-93 PI Proportional Gain

20-94 PI Integral Time

20-97 PI Feed Forward Factor

22-** Appl. Functions

22-0* Miscellaneous

22-01 Power Filter Time

22-02 Sleepmode CL Control

Mode

22-04 Check Valve Monitor

22-2* No-Flow Detection

22-23 No-Flow Function

22-24 No-Flow Delay

22-26 Dry Pump Function