Page 1

Technical Information

Passive Force Feedback Electric Steering Wheel Bas

e

powersolutions.danfoss.com

Page 2

Technical Information

e-Wheel 100

Revision history Table of re

Date Changed Rev

January 2020 Second Edition : Corrected RPM operating speed

September 2019

visions

Fir

st Edition

0102

0101

© 2019 Danfoss A/S. All rights reserved

All trademarks in this material are properties of their respective owners.

PLUS+1, GUIDE and Sauer-Danfoss are trademarks of Danfoss A/S.

2 | © Danfoss | September 2019 BC318774147046en-000101

Page 3

Technical Information

e-Wheel 100

Table of Contents

iterature References ...................................................................................................................................................................... 4

L

OEM responsibility ........................................................................................................................................................................... 5

Introduction ..................................................................................................................................................................................... 6

e-Wheel 100 ...................................................................................................................................................................................................................................... 6

Features of e-Wheel ....................................................................................................................................................................................................................... 6

Benefits of e-Wheel ........................................................................................................................................................................................................................ 7

e-Wheel Safety Functions ............................................................................................................................................................................................................ 7

Application Example ...................................................................................................................................................................................................................... 7

Different steering wheel sizes .................................................................................................................................................................................................... 9

e-Wheel Torque Control Algorithms ............................................................................................................................................ 10

Information Flow Block Diagram .............................................................................................................................................................................................10

Graphical Representation of Torque featuring various control algorithms ............................................................................................................11

End-Stop Torque Control ...........................................................................................................................................................................................................12

Base Torque Control .....................................................................................................................................................................................................................12

RPM Torque Control .....................................................................................................................................................................................................................12

Warning Control Torque .............................................................................................................................................................................................................14

Vehicle Speed Torque Control .................................................................................................................................................................................................15

Technical Data ................................................................................................................................................................................ 16

Mechanical characteristics .........................................................................................................................................................................................................16

Electrical characteristics ..............................................................................................................................................................................................................16

CAN (Controller Area Network) ................................................................................................................................................................................................16

Connector type and Pin Configuration .................................................................................................................................................................................16

Environmental characteristics ..................................................................................................................................................................................................17

F

unctional Safety ...........................................................................................................................................................................................................................17

Communication Protocol .............................................................................................................................................................. 18

Messages from e-Wheel to steering controller [AUX_STW_P and AUX

Messages from Vehicle speed sensor to steering controller and to e-Wheel [VSP_P and VSP_R] ..................................................................20

Messages from steering controller to e-Wheel ..................................................................................................................................................................21

Installations .................................................................................................................................................................................... 25

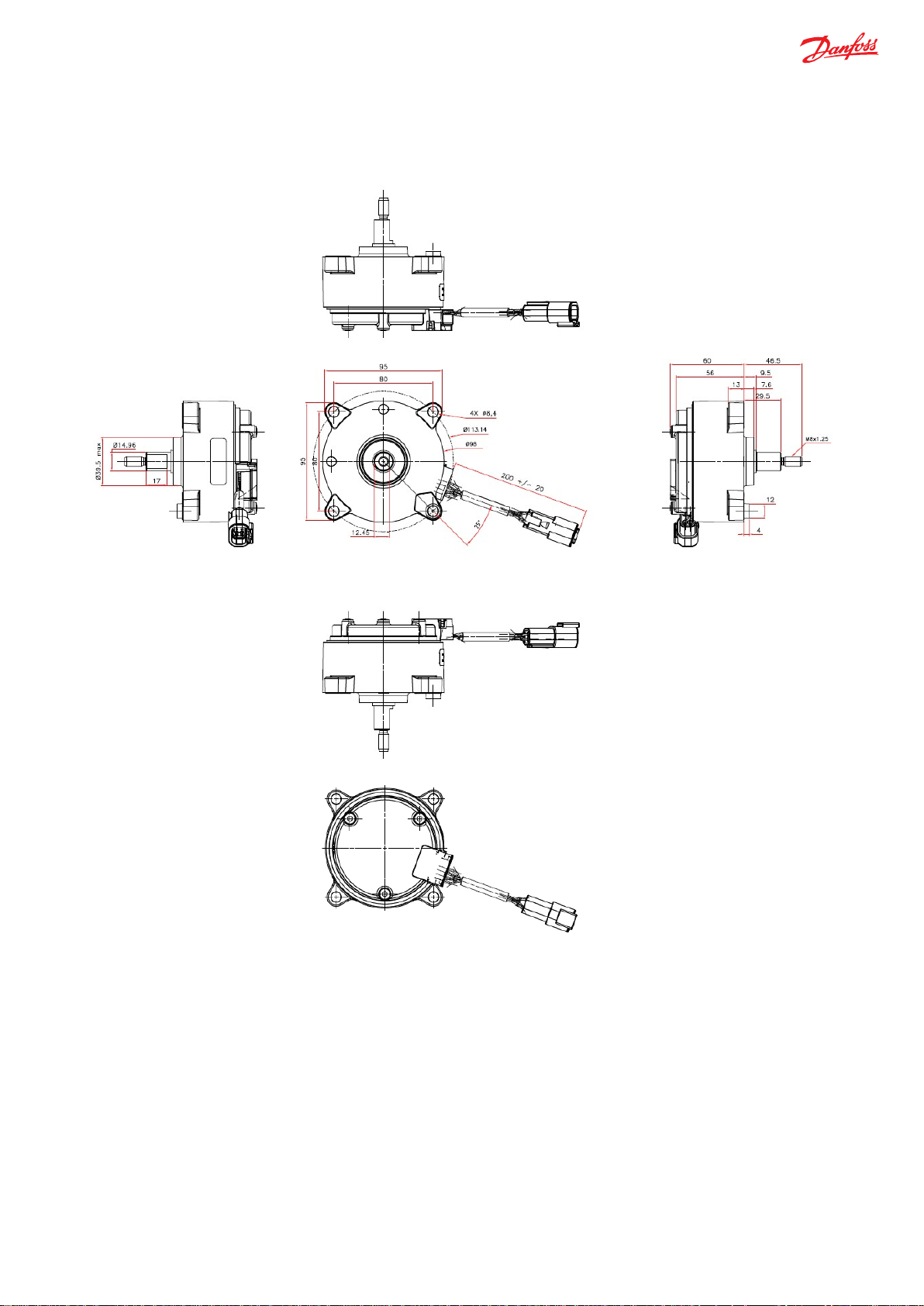

Dimensions ......................................................................................................................................................................................................................................25

Instructions ......................................................................................................................................................................................................................................25

Variant and ordering specifications ............................................................................................................................................. 26

e-Wheel MMC .................................................................................................................................................................................................................................26

Code Numbers ...............................................................................................................................................................................................................................26

Variants codes for e-Wheel MMC ............................................................................................................................................................................................27

STW_R] ...................................................................................................19

_

3 | © Danfoss | September 2019 BC318774147046en-000101

Page 4

PVED-CLS

User Manual

L1525062

Technical Information

e-Wheel 100

Literature References

Purpose of the document

References

Definitions and Abbreviations

This document describes the technical specifications and features’ information of the e-Wheel,

applied with Danfoss electro-hydraulic steering valves and steering controller.

Literature Type Reference number

PVED-CLS Communication Protocol L1425546

PVED-CLS Safety Manual BC00000331

OSPE Steering valve, SASA

Sensor

EHi Steering Valve Technical Information BC00000379

Technical Information 11068682

e-Wheel

SbW

AgPL

SIL

CAN

PL

PVED-CLS

OSPE

EHi

Fail Safe

Fail Operational

PAE

Electric Steering Wheel Base

Steer-by-Wire

Agricultural Performance Level

Safety Integrity Level

Controller Area Network

Performance Level

Proportional Valve Digital – Closed Loop - Safety (steering valve controller)

Orbital Steering Product – Electro-hydraulic steering valve

Electro-hydraulic in-line steering valve

To detect fault, indicate fault to safe state system and revert to a safe

condition in the event of a breakdown or malfunction

To detect fault, indicate fault to safe state system and continue full

operation with enough redundancy level

Product Application Engineering

4 | © Danfoss | September 2019 BC318774147046en-000101

Page 5

Technical Information

e-Wheel 100

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all consequences that

might occur. Danfoss has no responsibility for any consequences, direct or indirect, caused by failures or malfunctions.

•

The OEM shall perform a hazard and risk analysis for the target system to analyze if the relevant risks are

sufficiently reduced by the safety functions. The safety functions are provided by the involved functional safety

elements.

•

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained equipment.

•

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the system being

programmed in a manner that jeopardizes safety.

5 | © Danfoss | September 2019 BC318774147046en-000101

Page 6

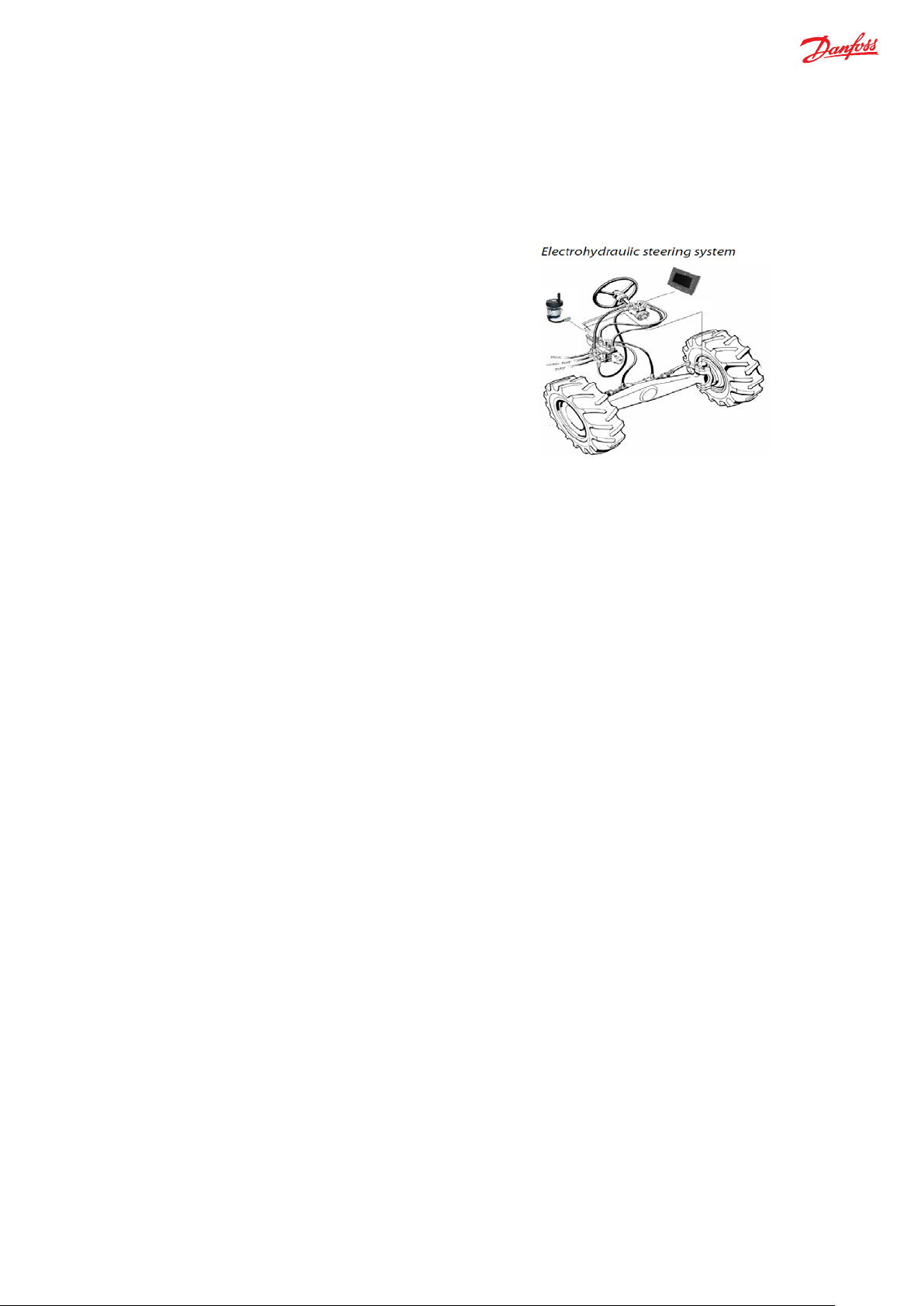

With the introduction of electro-hydraulic steering systems and

‘e-Wheel 100’ stands for Electric Steering Wheel Base, ‘100’ represents first of the series of Danfoss electric steering input devices.

Technical Information

e-Wheel 100

Introduction

eel 100

e-Wh

Danfoss steering products are used in vehicles where the driver must control high steering forces, reliably, comfortably and with

maximum safety.

Steer-by-Wire steering systems, applying electric steering wheel

advanced steering features like variable lock to lock ratio, softstop, anti-drift are possible, as easy integration in new vehicles

as well as retrofit to upgrade the existing vehicles. Primarily,

the objective of electric steering wheel is to offer high quality

steering feel, providing better operator comfort and reduce

operator fatigue. To meet this objective, Danfoss is now

offering electric steering input device ‘e-Wheel 100’.

‘e-Wheel 100’ is a haptic steering input device with passive force-feedback torque. ‘e-Wheel 100’ is referred to as ‘e-Wheel’

further in this document. The measured input steering angular position and the rate of change of steering angle from e-Wheel

are transmitted to steering valve controller, which determines the preferred steering response.

• e-Wheel is a ‘Plug and Play solution’ when interfaced directly to steering valve controller - PVED-CLS (for details refer

PVED-CLS User Manual), together with electro-hydraulic steering units OSPE / EHi.

• The communication protocol between e-Wheel and steering valve controller is based on the Danfoss proprietary safety

CAN protocol (refer PVED-CLS Communication Protocol).

• e-Wheel sub-system with PVED-CLS, supports realizing safe steering solutions designed to meet SIL 2/ PL d/ AgPL d by

designing the sub-system to a category 3 architecture (refer mini-steering wheel sub-system in PVED-CLS Safety

Manual).

In applications where e-Wheel is used as a primary steering input device or auxiliary steering input device, force-feedback is

necessary as the steering is expected not only to replicate same functions of conventional mechanically linked steering systems

(such as hydro-static enforced feedback) but also to provide advanced steering functions like:

• Directional control and wheel synchronization

• Variable steering ratio

• Smooth steering feel

The absence of hydro-static enforced feedback makes operator disconnected with the vehicle steering feedback which may

cause over or under steering. So, e-Wheel haptic passive force-feedback, mimics the feel of conventional steering systems, which

makes it a special attribute.

Features of e-Wheel

•

‘Plug and Play’ solution with PVED-CLS as steering controller

•

SIL Claim limit : 2

•

Dual channel redundant CAN bus interface

•

High quality steering feel

• Smooth steering torque control

• Absence of traditional steering wheel backlash and drift

• End-Stop feeling when vehicle wheels steered to extreme end-locks

• RPM torque for better controllability during Quick Steer

• Warning or event signal via steering wheel vibration

6 | © Danfoss | September 2019 BC318774147046en-000101

Page 7

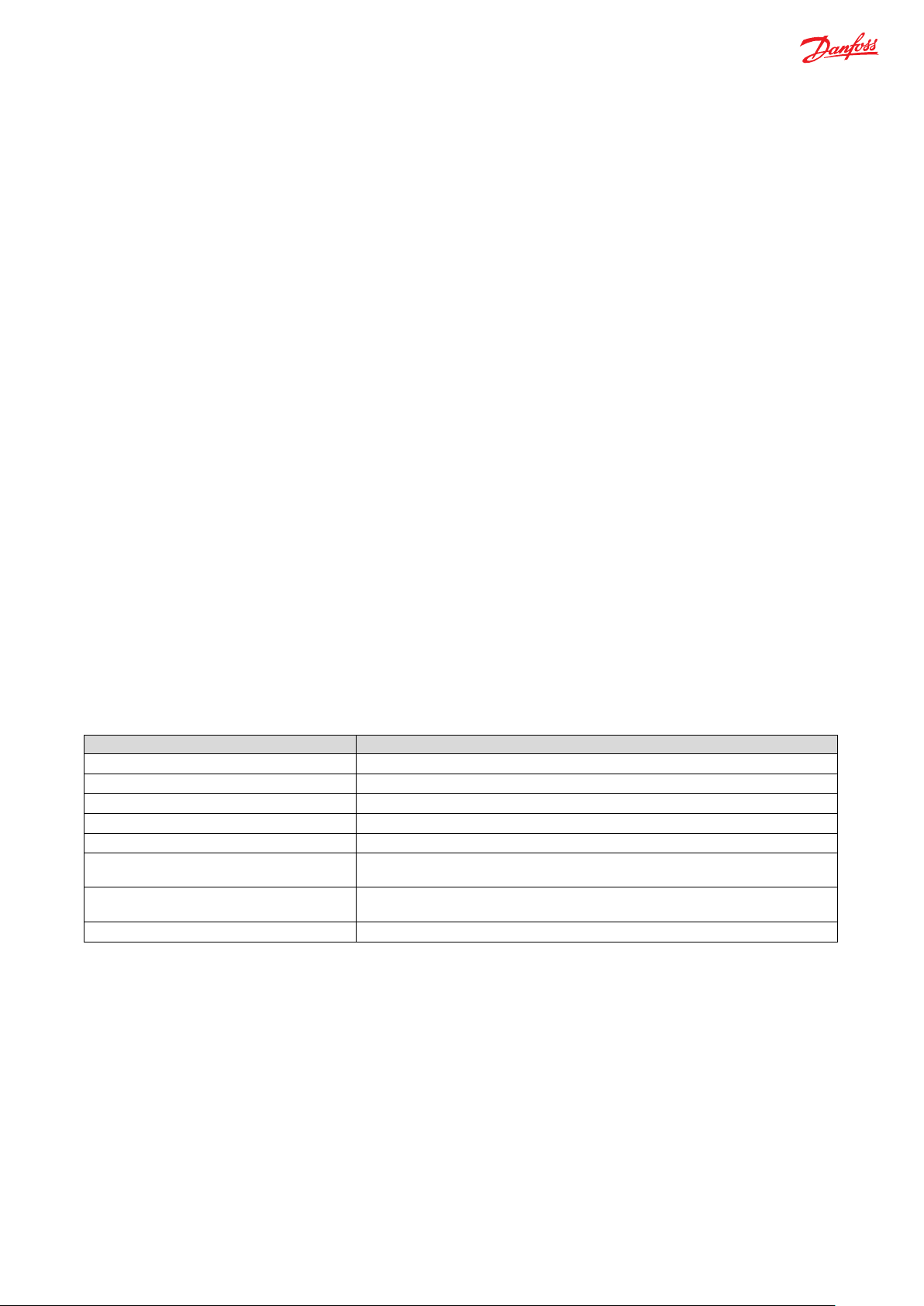

Components

Description

e-Wheel 100

Primary steering input device

EHi (configuration type 7)

Electro-hydraulic steering unit

PVED-CLS

Steering valve Controller

WAS

Dual Analogue Wheel Angle sensor

VSP

CAN Vehicle Speed Sensor (Dual Channel)

MMI

Man-Machine Interface as well as a Gateway for primary vehicle speed message

(Dual Channel)

MC012

External Controller (as a redundant controller) for secondary vehicle speed

message

Vehicle ECU

OEM controller for braking function during any malfunction or events of failure

Technical Information

e-Wheel 100

Benefits of e-W

•

•

•

•

•

e-Wheel Safety Functions

1. Safe Steering Angular Position and Safe Steering Speed:

2. Safe Force-Feedback Brake Torque:

heel

Reduced operator fatigues due to improved ergonomics

Benefits for different steering solutions

• Electro-hydraulic steering solutions

• e-Wheel applied as auxiliary steering input device

• In case of failures, reliable fallback to the primary manual steering wheel

• Fail-Safe SbW solutions

• Eliminates steering column

• Cabin design freedom for OEMs

• Better accessibility for operator, flexibility in seat movements and orientation

Low power consumption

Compact and robust design

Easy to install

Two Channels of e-Wheel (each channel provides sub-system elements as the hall effect angle sensors, microprocessor

logic blocks, power supply conditioning and protection , CAN transceivers) independently measure angular positions,

calculate steering speeds and transmit both steering angular positions and steering speeds onto CAN bus (safety

protocol as per PVED-CLS communication protocol)

Applying force-feedback torque by e-Wheel as response to the data received via CAN bus (safety protocol as per PVEDCLS communication protocol). Software in the microprocessors will run various torque algorithms in response to the

system inputs, defining the required current for force feedback brake torque of e-Wheel. Both microprocessors within eWheel will also carry out independent monitoring of sub-systems elements to identify and react to subsystem faults.

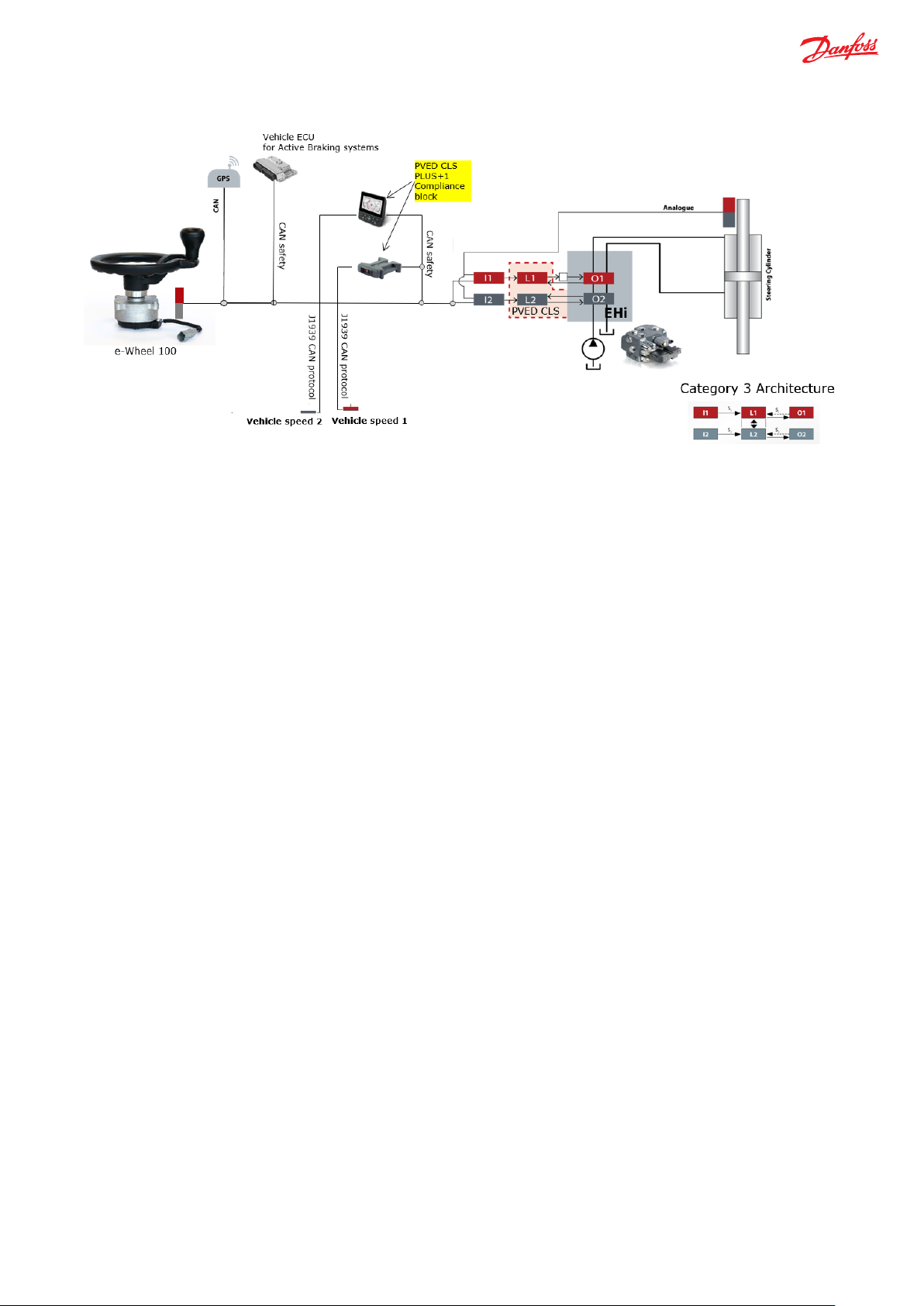

Application Example

e-Wheel supports category 3 architecture and can be integrated in a Danfoss CAT 3 Fail-Safe Steering System with Danfoss EHi /

OSPE and PVED-CLS as steering valve controller (refer to EHi / OSPE Technical Information Document). In below example shown in

figure 1, we consider a Fail-Safe steering solution with Steer-by-Wire (SbW) system:

7 | © Danfoss | September 2019 BC318774147046en-000101

Page 8

Technical Information

e-Wheel 100

Figure 1 Fail-Safe Steer-by-Wire steering sub-system with e-Wheel

Here, e-Wheel is the primary steering input device in the vehicle with Fail-Safe steering system, which transmits the steering

angular positions and the rate of change of steering angle, via CAN bus, to the steering valve controller. The steering valve

controller uses the dual redundant analogue wheel angle sensor inputs, dual redundant vehicle speed messages and dual MMI

(display) message, as per PVED-CLS communication protocol. In this example, vehicle speed (VSP) message is as per standard CAN

J1939 protocol. So, the VSP messages further needs to be converted from standard CAN protocol to PVED-CLS communication

protocol using PLUS+1 functional block in the two redundant external controllers (Danfoss Display and Danfoss MC- 012

Controller). With above messages along-with the e-Wheel inputs, steering valve controller determines the appropriate steering

response.

For vehicles with Fail-Safe SbW steering systems only using EHi steering valve, manual activated emergency steering will not be

possible. Such steering systems must be set up with complete redundancy and limited only for off road usage. In case of failures,

vehicles must be brought to a defined safe state, for instance by stopping the vehicle or switching to a backup steering system. As

shown in figure 1, during the malfunction or events of failure, based on the operational status message from the steering

controller and the vehicle speed CAN safety message from the two plus+1 controllers, the vehicle ECU can signal the vehicle brake

systems for reduction of the speed and stopping the vehicle as a safe state response. Vehicle builder necessarily must perform

hazard and risk analysis, to have a “safe vehicle brake” safety function which the steering sub-system can demand. In order to

integrate with above steering system, suggested category is category 3. The steering controller will not monitor any status

message from the braking system and no action is intended to steering system related to the status of the braking system.

8 | © Danfoss | September 2019 BC318774147046en-000101

Page 9

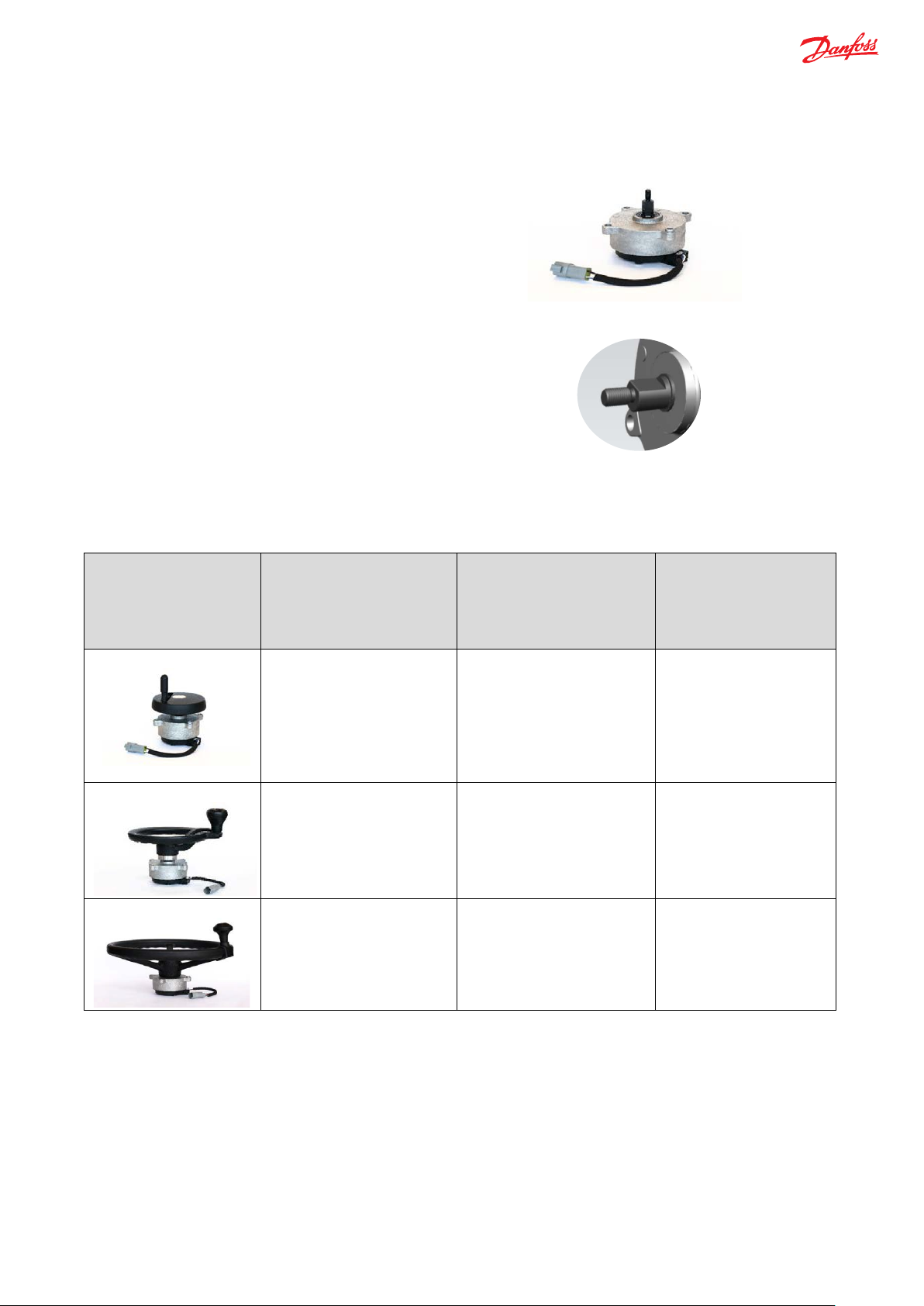

Danfoss offers e-Wheel – I without mounting any top steering

Figure 2

The steering wheels to be mounted on top, must be machined

Examples*

(* Danfoss does not offer the

possibilities with the

Steering wheel sizes to fit on

Recommended Torque for

Recommended Part

Mini-steering wheel

2 Nm

11224128 / 11198022

Medium size steering wheel

5 Nm

11224129 / 11243182

Larger size steering wheel

5 Nm

11224129 / 11243182

Technical Information

e-Wheel 100

Different steering wheel sizes

wheel, shown as per figure 2.

The shaft of e-Wheel is a ‘flat D-shaped’ shaft with:

• with a maximum axial force of 1500 N

• bending moment of 50 Nm

in a way that they accept the ‘flat D-shaped’ shaft of e-Wheel,

as shown in figure 3.

Figure 3

Below are few possibilities of different steering wheel sizes that can fit on shaft of the e-Wheel:

e-Wheel

steering wheels, below are

just the

e-Wheel)

corresponding steering

wheel size

Numbers

Recommendation:

• Danfoss offers e-Wheel with 5 Nm and 2 Nm as standard variants for maximum operating torque; choice of these

variants majorly depends on the type of application and the type of steering wheel size required in respective

application.

9 | © Danfoss | September 2019 BC318774147046en-000101

Page 10

Primary

Primary Primary

Primary

Prima ry

Steering Valve Controller

E-Wheel 100

Steering

Input Device

MMI Display

Analogue WAS

Vehicle Speed Sensor

MMI_P and MMI_R

AUX_STW_P and AUX_STW_R

STR_FB_MSG_X

VSP _P and V SP_R

Primary

Controller

Redundant

Controller

Primary

Controller

Redundant

Controller

Primary Redundant

Primary

Redundant

Primary

Redundant

Analog Input 1

Analog Input 2

STAT_MSG_OP_X

Cross check

Technical Information

e-Wheel 100

e-Wheel Torque Control Algorithms

The passive force- feedback torque is controlled by applying a proportional current, where the current is function of the below

mentioned control algorithms in e-Wheel. Force feedback torque will be based on, only one commanded control algorithm

offering maximum torque out of all available control algorithms in the configured variant of e-Wheel, at any instant applicable

during steering. Below is the list of e-Wheel Torque Control Algorithms:

• End Stop Torque

• Base Torque

• RPM Torque

• Vehicle Speed Dependent Torque

• Warning Control Torque

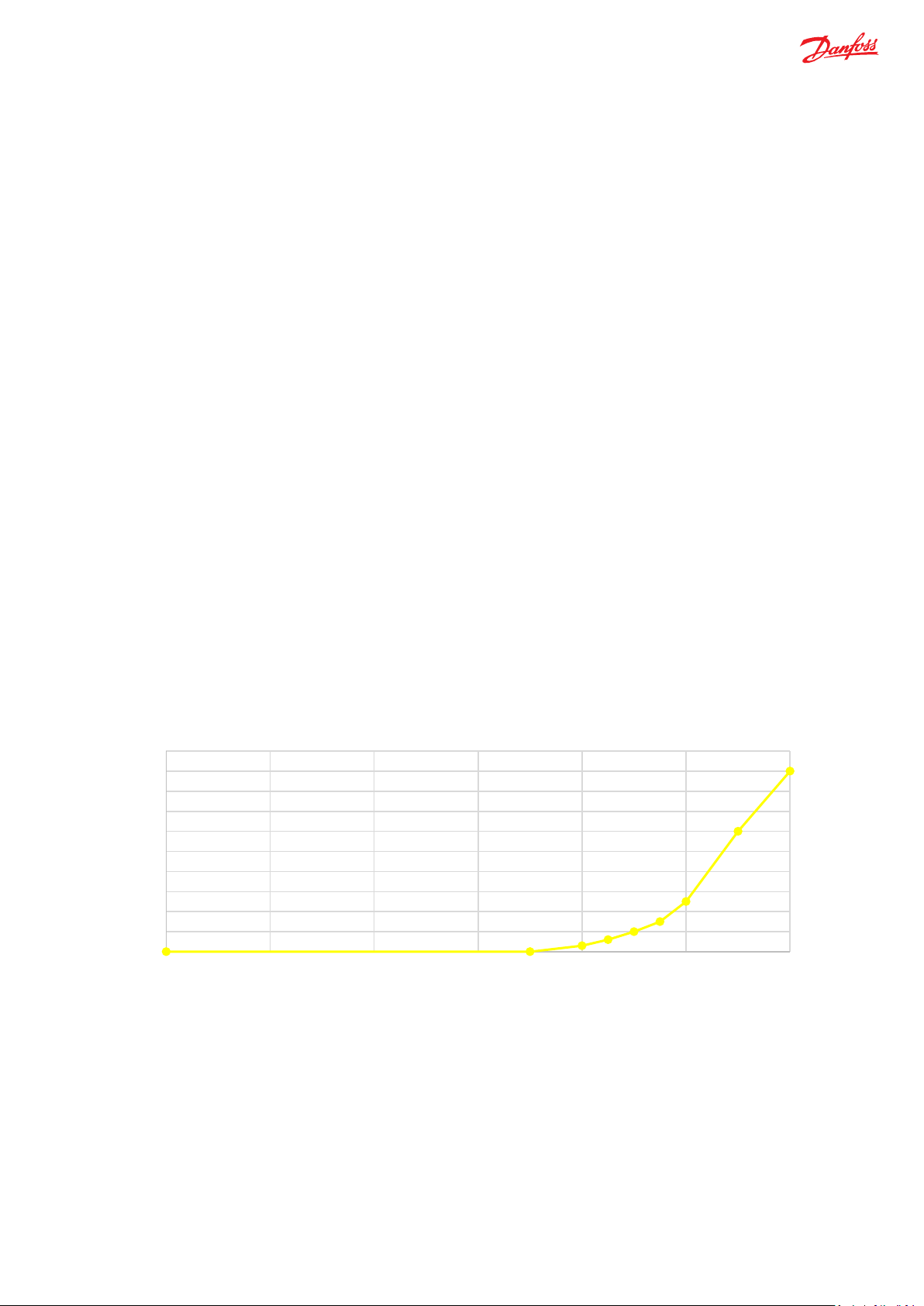

Information Flow Block Diagram

Figure 4 Block diagram for e-Wheel with steering valve controller

The operation between e-Wheel and steering controller in the steering system with relevant messages from each component is

simplified in figure 4. In terms of the primary purpose of e-Wheel, is giving steering inputs (steering angle and steering speed);

whereas the steering controller is defining the steering response based on the data available from all components in steering subsystem. The messages from each component in figure 4, are as per the PVED-CLS communication protocol, specified with the

respective annotations.

Recommendation:

• e-Wheel being a ‘Plug and Play solution’ with PVED -CLS, it is recommended to use PVED-CLS as steering valve controller.

• The Steering Primary and Redundant Controller must perform the cross checks to use e-Wheel in a safe way, refer PVED-

CLS Safety Manual.

• In Off Road Reaction/Non reaction mode, the controller detects AUX open loop device (e-Wheel 100) when, the steering

wheel velocity and the steering wheel angular position is above the threshold set in steering controller, along-with the

pre-condition that AUX device is set present and is allowed to steer (see flags in MMI message as per PVED CLS

communication protocol).

10 | © Danfoss | September 2019 BC318774147046en-000101

Page 11

Technical Information

e-Wheel 100

Graphical Representation of Torque featuring various control algorithms

The control algorithms in e-Wheel, are offered as standard variants with the torque values shown as per figure 5 and figure 6.

%End stop Torque %Base Torque %RPM Torque

100

90

80

70

60

50

40

% OF MAX. TORQUE

-100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100

30

20

10

0

% WHEEL ANGLE

Figure 5 Torque Control Algorithms for 5 Nm

%End stop Torque %Base Torque %RPM Torque

100

90

80

70

60

50

40

% OF MAX.TORQUE

-100 -90 -80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100

Figure 6 Torque Control Algorithms for 2 Nm

30

20

10

0

% WHEEL ANGLE

In above figures 5 and 6 respectively,

• ±100 % wheel angle shall correspond to maximum wheel angles on right and left end stop.

• Figure 5 represents for e-Wheel with 5 Nm as 100 % of the maximum operating torque and figure 6 represents for e-

Wheel with 2 Nm as 100 % of the maximum operating torque.

• RPM torque in both the above graph depicts that it can be experienced irrespective of the wheel angle position,

11 | © Danfoss | September 2019 BC318774147046en-000101

Page 12

Technical Information

e-Wheel 100

depending upon the allowable RPM, at corresponding steering lock to lock ratio from steering controller. Figure 5 shows,

the maximum RPM torque for 5Nm is defined for 90 % of the maximum operating torque; whereas figure 6 shows RPM

torque for 2Nm is defined for 60 % of the maximum operating torque.

End-Stop Torque Control

Wheel angle sensors close the feedback loop with the steering controller, ensuring the vehicle wheels’ match steering commands.

During the operation, steering controller transmits the estimated wheel angle values as a feedback message over CAN bus to the

e-Wheel, refer Figure 4. Based on this message, e-Wheel detects the wheel angle values and determines the torque force feedback.

As shown in figure 5 and figure 6, the End-Stop control algorithm increases linearly from 90 % to 100 % wheel angles and provides

maximum operating torque (torque of 5Nm or 2Nm based on the chosen e-Wheel variant) at 100 % wheel angle. Thus, operator

experiences the End- Stop torque feedback, on vehicle wheels reaching the maximum wheel angle limits. As soon as the operator

steers away from the end stop towards neutral, the torque drops to the base torque control, as explained below.

Base Torque Control

The background torque for normal steering, excluding end-stop conditions, is the base torque control. This torque is smooth and

persistent through-out steering at different wheel angles, as shown in figure 5 and figure 6, as 10 % of the maximum operating

torque.

RPM Torque Control

e-Wheel offers more-precise control at low speeds. In material handling applications, for instance, vehicles might require two or

three steering wheel turns lock to lock, for maneuvering at low speeds. Whereas in other applications, steering wheel turns lock to

lock needs to adjust the range to six or more turns for less sensitivity at high speeds. Regardless of how quickly the operator might

turn the steering wheel, e-Wheel limits steering speed, to not exceed the maximum allowable steering speed for a given lock to

lock configuration. The lock to lock configuration is provided in the feedback message from steering valve controller to e-Wheel.

This attribute of restricting higher steering speed than allowable steering speed is therefore called as RPM torque control.

Figure 7 shows the amount of torque requested (as a percentage of maximum allowable torque), as the operator approaches the

maximum allowable RPM (scaled to 1200 internal resolution) for the respective lock to lock ratio. The torque brake in e-Wheel is

applied by the algorithm to limit the actual steering speed so that the maximum steering speed is not exceeded highly. Figure 7

shows the maximum RPM torque is limited to 90 % of maximum operating torque of 5 Nm. This is applicable in case of medium to

larger steering wheel size application.

% RPM torque

100

90

80

70

60

50

40

30

% Max Torque

20

10

0

0 200 400 600 800 1000 1200

% of Maximum Allowable RPM (scaled to 1200 IR)

Figure 7 RPM torque for e-Wheel with 5 Nm

12 | © Danfoss | September 2019 BC318774147046en-000101

Page 13

Lock to Lock

Maximum Allowable steering speed (RPM)

1

25

2

50

3

75

4

100

5

125

6

150

7

175

8

200

Technical Information

e-Wheel 100

% RPM torque

70

60

50

40

30

%Max Torque

20

10

0

0 200 400 600 800 1000 1200

% of Maximum Allowable RPM (scaled to 1200 IR)

Figure 8 RPM control for e-Wheel with 2 Nm

Figure 8 shows maximum RPM torque is limited to 60 % of maximum operating torque of 2 Nm. This is applicable in case of ministeering wheel applications.

For different lock to lock shown in below table, the Max Allowable steering speed (RPM) is default in standard variants as:

13 | © Danfoss | September 2019 BC318774147046en-000101

Page 14

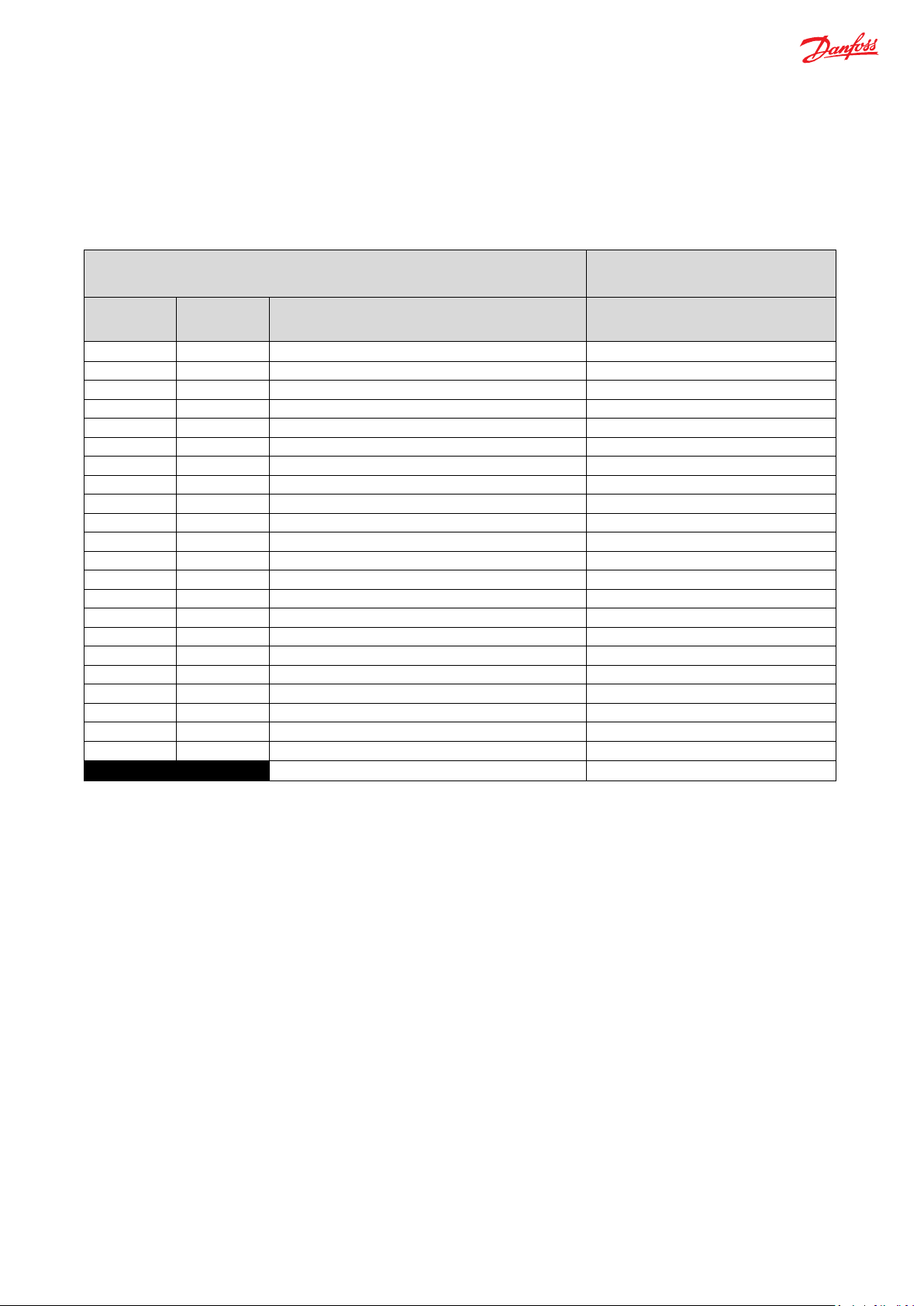

0

0x00

On-Road

Active through-out operation state

16

0x10

Off-Road Reaction

Active through-out operation state

17

0x11

Off-Road Non-reaction

Active through-out operation state

32

0x20

STW Program 1

Active through-out operation state

33

0x21

STW Program 2

Active through-out operation state

34

0x22

STW Program 3

Active through-out operation state

35

0x23

STW Program 4

Active through-out operation state

36

0x24

STW Program 5

Active through-out operation state

48

0x30

AUX Program 1

Active only if error occurs

49

0x31

AUX Program 2

Active only if error occurs

50

0x32

AUX Program 3

Active only if error occurs

51

0x33

AUX Program 4

Active only if error occurs

52

0x34

AUX Program 5

Active only if error occurs

64

0x40

GPS Steering

Active only if error occurs

65

0x41

GPS 2 Steering

Active only if error occurs

208

0xD0

Off-Road Safety-Check

Active through-out operation state

224

0xE0

Service mode – Direct Output Control

Active through-out operation state

225

0xE1

Service mode – Wheel angle sensor calibration

Active through-out operation state

226

0xE2

Service mode – Spool calibration

Active through-out operation state

227

0xE3

Service mode – Joystick calibration

Active through-out operation state

240

0xF0

Initialization

Active through-out operation state

255

0xFF

Safe State

Active through-out operation state

Powering up with no controller messages

Active through-out operation state

Technical Information

e-Wheel 100

Warning Control Torque

In case of missing messages or errors in CAN messages, steering valve controller goes to safe state and thus the e-Wheel provides

relevant error codes to steering valve controller which triggers the steering controller to a safe state mode. This makes e-Wheel to

send out warning to the operator by vibrational sensation via steering wheel. The vibrational feedback of e-Wheel also called as

Warning Control Torque, signals awareness to operator about the loss of steering control. In such events of failure, vehicles must

be defined with the necessary safe state conditions.

Steering Controller Outputs e-Wheel 100 Response

Value (Dec) Value (Hex) Current Operation state Warning Control Torque

14 | © Danfoss | September 2019 BC318774147046en-000101

Page 15

Technical Information

e-Wheel 100

Vehicle Speed Torque Control

This torque eliminates vehicle resonances entering e-Wheel by providing gradually increasing torque dependency on vehicle

speed.

% Vehicle Speed Torque

10

9

8

7

6

5

4

% of Max Torque

3

2

1

0

0 10 20 30 40 50

Vehicle speed (Kph)

Figure 9 Vehicle Speed Torque

15 | © Danfoss | September 2019 BC318774147046en-000101

Page 16

Description

Value

Rated Torque

5.5 Nm Nominal (100 % command)

Off-State Torque

<0.5 Nm (0% command)

Operating Speed

Max Axial Force

1500 N

Max Bending Moment

50 Nm

Shaft Type

D shaped

Rotating Angle

360 °, without mechanical stop

Weight

1.5kg

Description

Value

Supply Voltage

12 VDC or 24 VDC (9-36 V), single common power

Coil Resistance

10 Ω nominal

Maximum Power Dissipated

15 Watts

Cable

20 AWG x 4 conductors

Description

Value

Standard

CAN 2.0B

Channels

Two

Baud Rate

250k Baud

Connector

DEUTSCH DT 04-4P*

PIN

Wire Color

Function

1 White

CAN-H

2 Blue

CAN-L

3 Red

V+ 4

Black

V-

Technical Information

e-Wheel 100

Technical Data

echanical characteristics

M

Electrical characteristics

300 RPM maximum

CAN (Controller Area Network)

Connector type and Pin Configuration

*Mating part to be bought externally

(Sealed cable with single connector withstands cable pull load

maximum 100 N)

16 | © Danfoss | September 2019 BC318774147046en-000101

Page 17

Description

Value

Operating Temperature

-40 °C to 85 °C

Storage Temperature

-40 °C to 95 °C

Ingress Protection (IP) rating

IP66

Environmental Testing Std.

ISO 16750-4 §5.1 per IEC 60068-2

Description

e-Wheel Sensor Safety Specification

e-Wheel Brake Safety

Performance Level (EN 13849-1: 2015)

PLd

PLd

Hardware Fault Tolerance (HFT)

1

1

System

Fail Safe

Fail Safe

Safety Element Classification (IEC 62061)

Type B

Type B

Probability of Dangerous Failures

1.597 x 10-8

5.289 x 10-9

Safe Failure Fraction (SFF)

98.72%

99.25%

SIL Claim Limit (IEC 62061:2005)

2

2

Architecture (ISO 13849)

Category 3

Category 3

DC

High

High

Proof Test Interval / Mission Time

20 years

20 Years

MTTFd per channel (ISO 13849 Table K.1)

150 years

180 years

CCF factor (IEC 62061)

5 %

5 %

Technical Information

e-Wheel 100

Environmental characteristics

Functional Safety

(PFHDssD) (IEC 62061 : 2005)

Specification

(1)

(2)

Notes:

(1) The sensor sub-system is redundant. If one channel fails, the other channel continues transmitting data. However, the

steering controller can no longer perform diagnostics and a system safe state shall be reached. The system integrator

must ensure sufficient diagnostics, please refer Block Diagram.

(2) Reaching a DC= High, depends on a correctly working diagnostic function in the steering controller. (Refer to the PVED-

CLS Safety Manual.)

17 | © Danfoss | September 2019 BC318774147046en-000101

Page 18

Messages from e-Wheel to Steering Controller

Sensor message

Default Message

Main Controller

Safety

Controller

Auxiliary Steering

0x0CFF144F

P3299 =0x4F

e-Wheel = Auxiliary

0x0CFF154F

P3299 = 0x4F

Messages from PVED-CLS Steering Controller to e-Wheel

Steering Feedback

0xCFF1813

P3297 = 0x13

P3297= 0x5A

Operation Status

0x18FF2013

P3297 = 0x13

P3297= 0x5A

Messages from Vehicle Speed Sensor to e-Wheel and to Steering Controller

Vehicle Speed -

0xCFF40FB

P3294 =0xFB

Vehicle Speed -

0xCFF41FB

P3294 = 0xFB

Sensor CAN Messages to Steering Controller

Wheel Angle Sensor-

0x0CFF12FA

P3298 = 0xFA

Wheel Angle Sensor-

0x0CFF13FA

P3298 = 0xFA

Man Machine

0x0CEF13FC

P3295 =0xFC

Man Machine Interface

0x0CEF5AFC

P3295 = 0xFC

Technical Information

e-Wheel 100

Communication Protocol

The below table shows how the steering controller shall be parameterized in order to correctly send main and redundant sensor

CAN messages. The auxiliary steering device ID’s will be used for fail-safe applications. (Refer PVED-CLS communication protocol

for further details)

Device (Mini STW) –

e-Wheel Primary

Steering Device

(Mini STW) – eWheel Redundant

Primary

Redundant

ID

Parameter

P3321 =0x14

P3318 =0x40

Parameter

P3321 = 0x15

P3318 = 0x41

Primary

Redundant

Interface – Primary

– Secondary

18 | © Danfoss | September 2019 BC318774147046en-000101

P3320 = 0x12

P3320 = 0x13

P3297 =0x13

P3297 = 0x5A

Page 19

Bytes

Encoding

Value/Range

Description

1..2

U16

4096..65535

Steering angle 1 relative to the 0-index point [AUX_STW_pos_P]:

Information not available

3..4

U16

Steering angle velocity

5 - All 1

Reserved

6

Bits 8..5

15

Error codes [AUX_STW_error_code_P]:

No Error

Bits 4..1

0..15

Sequence number [AUX_STW_Seq_P], incremented by 1 in each AUX

Rolls over from 15 to 0

7..8

U16

0..65535

CRC16 for data bytes 1..6 [AUX_STW_CRC_P]:

Polynomial: 0 x C86C

Technical Information

e-Wheel 100

Messages from e-Wheel to steering controller [AUX_STW_P and AUX_STW_R]

This message transmits angle, current, and fault information from the e-Wheel.

Priority: 3

Nominal Transmission: 50 ms

Sent by: e-Wheel

Send to: PVED-CLS Steering controller

0..4095

0..40960

40961..65535

0

1

2

3

4

5

6

7

8..13

14

Steering angle in [360 / 4096 degree] steps, where:

0 corresponds to 0 degrees,

4095 corresponds to 359.912 degrees

Note: the steering angle rolls over from 4095 to 0 for clockwise activation

and from 0 to 4095 for counter clockwise activation

[AUX_STW_velocity_P]:

Steering angle velocity (offset -20480) in [ 30 / 20480 RPM] steps, where

0 corresponds to -300 RPM (300 RPM counter clockwise)

20480 corresponds to 0 RPM

40960 corresponds to 300 RPM (300 RPM clockwise)

Information not available

Reserved

Sensor chip error

Steering angle failure

CAN input message failure

Power failure

CPU failure

Memory failure

Force feedback failure

Reserved

Temperature warning

Note:

• The above messages should be dual messages for both Primary and Redundant controllers.

19 | © Danfoss | September 2019 BC318774147046en-000101

primary message

Page 20

1

U8

All 1

Reserved

2

Bits 8..7

Direction Indication [ VSP_Dir_P]:

Bits 6..1

All 1

Reserved

3..4

U16

64256..65535

Vehicle speed [VSP_Speed_P]:

Information not available

5 - All 1

Reserved

6

Bits 8..5

All 1

Reserved

Bits 4..1

0..15

Sequence number [VSP_Seq_P], incremented by 1 in each VSP primary

Rolls over from 15 to 0

7..8

U16

0..65535

CRC16 for data bytes 1..6 [VSP_CRC_P]:

Polynomial: 0 x C86C

Technical Information

e-Wheel 100

Messages from Vehicle speed sensor to steering controller and to e-Wheel [VSP_P and VSP_R]

This message contains information from the steering controller to the e-wheel

Nominal Transmission: 100 ms

Priority: 3

Sent by: Vehicle Speed

Sensor Send to: e-Wheel

Bytes Encoding Value/Range Description

00

01

10

11

0..64255

Vehicle Speed

This parameter specifies the vehicle speed, measured in (1/256 kph).

Sequence number

This parameter is an internal counter that runs from 0 – 15 and then loops back. It could be used by the eWheel to check for validity of the incoming message.

Note:

• The above messages should be dual messages for both Primary and Redundant controllers.

Forward

Reverse

Error Condition

Information not available

Measured vehicle speed in [1/256 kmph]

message

20 | © Danfoss | September 2019 BC318774147046en-000101

Page 21

Technical Information

e-Wheel 100

Messages from steering controller to e-Wheel

Feedback Message [STR_FB_MSG_X]

This message contains information from the steering controller to the e-Wheel, including control commands and

relevant system level information.

Priority: 3

Nominal Transmission: 50 ms

Sent by: Steering controller

Send to: e-Wheel

Note:

• The above messages are dual messages from both Primary and Redundant controller.

21 | © Danfoss | September 2019 BC318774147046en-000101

Page 22

Bytes

Encoding

Value/Range

Description

0x00

On-Road

0x11

Off-Road Non-reaction

0x23

STW Program 4

0x30

AUX Program 1

0x34

AUX Program 5

0x41

GPS 2 Steering

0xE1

00

Steering device changes allowed

11

Information not available

[Lockout_program_change_X]:

00

Program changes allowed

01

Program changes prohibited

Technical Information

e-Wheel 100

Operation message [STAT_MSG_OP_X]

This message contains information from the steering controller to the e-Wheel.

Priority: 6

Nominal Transmission: 100 ms

Sent by: Steering controller

Send to: e-Wheel

1

U8

0x10 Off-Road Reaction

0x20 STW Program 1

0x21 STW Program 2

0x22 STW Program 3

Current Operation state [OperationState_X]:

2

Bits 8..7

0x24 STW Program 5

0x31 AUX Program 2

0x32 AUX Program 3

0x33 AUX Program 4

0x40 GPS Steering

0xD0 Off-Road Safety-Check

0xE0 Service mode – Direct Output Control

Service mode – Wheel angle sensor calibration

0xE2 Service mode – Spool calibration

0xE3 Service mode – Joystick calibration

0xF0 Initialization

0xFF Safe State

Lock-out status for steering device changes

[Lockout_device_change_X]:

01 Steering device changes prohibited

10 Error condition

Bits 6..5

22 | © Danfoss | September 2019 BC318774147046en-000101

Lock-out status for STW/AUX program changes

10 Error condition

11 Information not available

Page 23

00

EH-Steering functionality allowed

11

Information not available

prohibited)

01

GPS Steering selected

10

GPS 2 Steering selected

11

Reserved

Bits 6..1

Service mode state [Service_mode_state_X]:

0x02..0x0F

Reserved

0x11

WAS calibration in progress

0x1D

WAS calibration counter update

0x1F

WAS calibration complete

0x21

Spool calibration inactive

0x23

Spool calibration armed

0x25

Spool parameters plausibility check

0x27

Spool parameters update

0x2D

Spool calibration counter update

0x2F

Spool calibration complete

0x31

Joystick calibration in progress

Technical Information

e-Wheel 100

Bits 4..3

Bits 2..1

3

Bits 8..7

4

U8

Lock-out status for EH-steering functionality [Lockout_EH_steering_X]:

01

10 Error condition

11 Information not available

00 AUX device steering allowed

01 AUX device steering prohibited

10 Error condition

00 No GPS receiver selected (GPS steering

All 1 Reserved

0x00 Direct output control reset

0x01

EH-Steering functionality prohibited by an external switch

AUX Steering device lockout status [Lockout_AUX_X]:

GPS receiver selection and lockout status [Lockout_GPS_X]:

Direct output control active

0x10 WAS calibration Reset

0x12..0x1C Reserved

0x1E WAS calibration failure

0x20 Spool calibration reset

0x22 Spool calibration getting armed

0x24 Spool calibration in progress

0x26 Spool parameters ready to update

0x28..0x2C Reserved

0x2E Spool calibration failure

0x30 Joystick calibration Reset

23 | © Danfoss | September 2019 BC318774147046en-000101

Page 24

0x32..0x3C

Reserved

0x3D

Joystick calibration counter update

0x3E

Joystick calibration failure

0x3F

Joystick calibration complete

0x40..0xFC

Reserved

0xFD

No analog joystick configured

0xFE

No wheel angle sensor configured

mode)

Bits 8..5

All 1

Reserved

0xC86C

Technical Information

e-Wheel 100

0xFF

5

6

7..8 U16 0..65535

Note

• The above messages are dual messages from both Primary and Redundant controllers

• In Off Road Reaction/Non reaction mode, the controller detects AUX open loop device (e-Wheel 100) when, the steering

-

Bits 4..1 0..15 Sequence number [OperationState_Seq_X]: Incremented by 1 in

wheel velocity and the steering wheel angular position is above the threshold set in steering controller, along-with the

pre-condition that AUX device is set present and is allowed to steer (see flags in MMI message as per PVED CLS

communication protocol).

All 1 Reserved

Information not available (Operation state other than service

each Operation status message.

Rolls over from 15 to 0

CRC16 for data bytes 1..6

[OperationState_CRC_X]: Polynomial:

24 | © Danfoss | September 2019 BC318774147046en-000101

Page 25

Technical Information

e-Wheel 100

Installations

Dimensions

Instructions

-

To be installed such that shaft is between vertical axis and -10° from horizontal axis

-

Avoid misalignment that causes excessive load

25 | © Danfoss | September 2019 BC318774147046en-000101

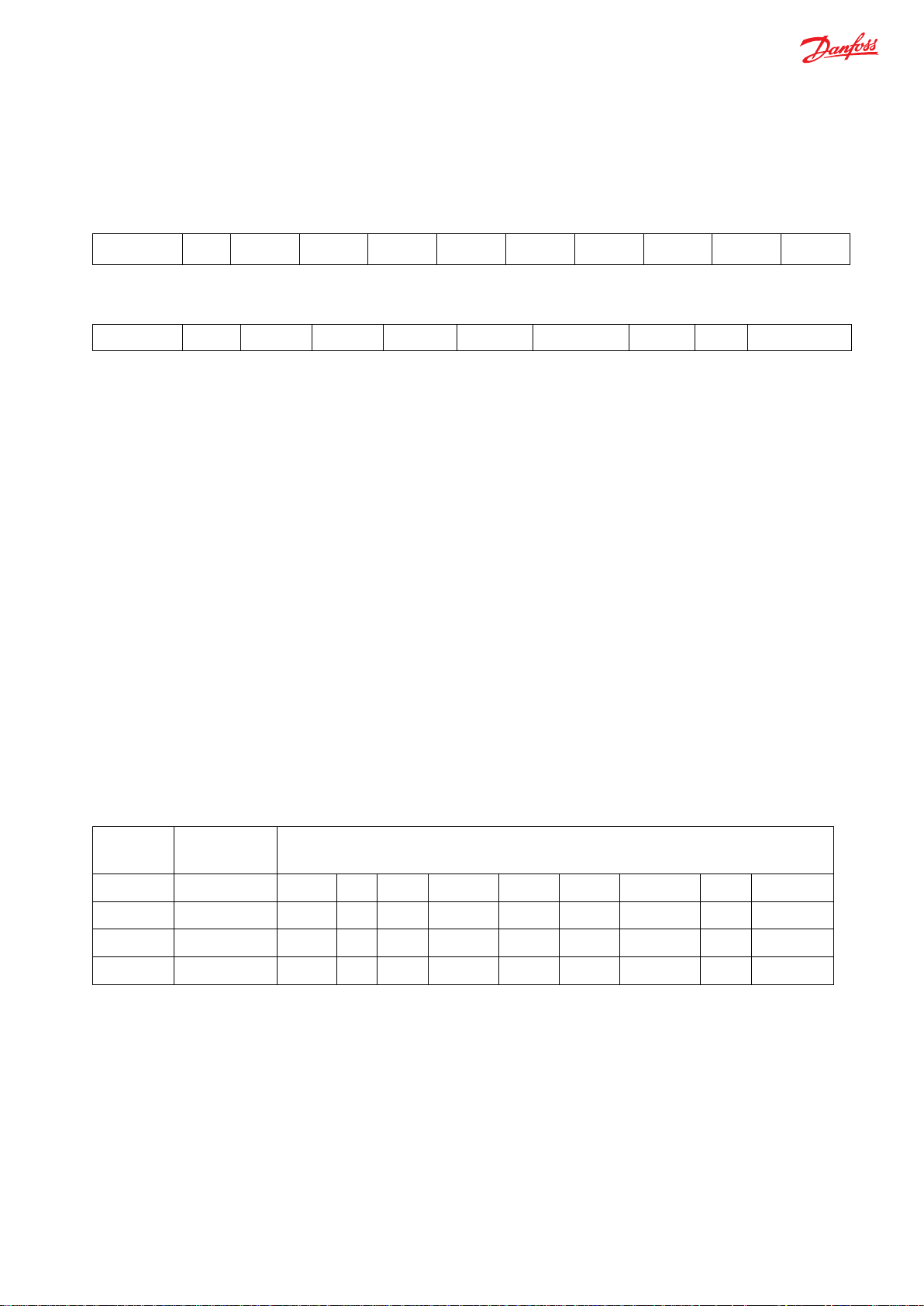

Page 26

e-Wheel 100

1

CAN2

53

ES4

BS5

RPM6

Reserved7

VSP8

D9

Package10

Code

Configuratio

MMC Specifications according to above description format

11224128

Type 1

CAN 2

ES

BS N - VSP D S

11224129

Type 2

CAN 5

ES

BS

RPM -

VSP D S

11198022

Type 3

CAN 2

ES

BS N - VSP D M

11243182

Type 4

CAN 5

ES

BS

RPM -

VSP D M

Technical Information

e-Wheel 100

Variant and ordering specifications

e-Wheel MMC

Determine Master Model Code (MMC). Fill in with codes from Variant codes for e-Wheel, to specify e-Wheel 100. MMC

values for e-Wheel

Example only

e-Wheel 100

1

e-Wheel 100 base

2

Communication channel

3

Maximum Operating Torque (Nm)

4

End Stop Torque (Nm)

5

Base Torque (Nm)

6

RPM Torque (Nm)

7

Reserved

8

Vehicle Speed Torque (Nm)

9

Connector Type

10

Package

Code Numbers

Configuration Numbers, in the following table, are referring to matrix description for e-Wheel standard configurations.

Code numbers for catalog versions with specifications:

No.

n No.

26 | © Danfoss | September 2019 BC318774147046en-000101

Page 27

e-Wheel

Electric Steering Wheel Base

Code

e-Wheel 100

Type

Digital

Code

CAN

Maximum Operating Torque

5 Nm

2 Nm

Code 5 2

EndStop Torque

Included

Not Included

Code

ES N

Base Torque

Included

Not Included

Code

BS N

Code

RPM N

VSP Torque

Included

Not Included

Code

VSP N

Technical Information

e-Wheel 100

Variants codes for e-Wheel MMC

1) e-Wheel 100 base

2) Communication Channel

3) Maximum Operating Torque (Nm)

4) End Stop Torque (Nm)

5) Base Torque (Nm)

6) RPM (Nm)

RPM Torque Included Not Included

7) Reserved

8) Vehicle Speed Torque (Nm)

27 | © Danfoss | September 2019 BC318774147046en-000101

Page 28

Type, Connector

Deutsch DT, one 4 pin

Code D

Package

Single

Multiple

Code S

M

Technical Information

e-Wheel 100

9) Connector Type

10) Package

28 | © Danfoss | September 2019 BC318774147046en-000101

Page 29

Technical Information

e-Wheel 100

Page 30

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss |

September 2019

BC318774147046en-000101

Loading...

Loading...