Data sheet

Solenoid valve

Type EVR 2 - EVR 40 Version 2

EVR is a direct or servo operated solenoid valve

suitable for liquid, suction, and hot gas lines with

most refrigerants, including flammable refrigerants.

EVR valves and coils are sold separately.

Features

Approvals • Pressure Equipment Directive (PED) 2014/68/EU

© Danfoss | DCS (az) | 2017.12

• Complete range of solenoid valves for

refrigeration, freezing and air conditioning plant

• Supplied in versions normally closed (NC) and

normally open (NO) with de-energized coil

• Wide choice of coils for AC and DC

• Suitable for most refrigerants, including

flammable refrigerants

• Designed for media temperatures up to 221 °F

• Low Voltage Directive (LVD) 2014/35/EU

• UL429 General Purpose Valve

• EAC

• UA

• Flare connections up to 5⁄8 in

• Solder connections up to 2 1⁄8 in

• Extended ends on solder versions make the

installation easy, eliminating the need to

dismantle the valve when soldering in

• Available in flare, solder and flange

connection versions

• ATEX zone 2

• CQC

• RoHS II

• For Marine approvals: Contact Danfoss for latest

updates

DKRCC.PD.BB0.F2.22 | 1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Table of contents

Technical data ............................................................................................................................................................................. 3

Rated capacity [TR] ................................................................................................................................................................... 4

Ordering ....................................................................................................................................................................................... 5

EVR solder connection (NC) ........................................................................................................................................... 5

EVR solder connection (NO) ........................................................................................................................................... 6

EVR flare connection (NC) ............................................................................................................................................... 6

EVR flare connection (NO) .............................................................................................................................................. 6

EVR flange connection (NC) ........................................................................................................................................... 7

EVRC solder connection (NC) ........................................................................................................................................ 7

BJ and BX coils .................................................................................................................................................................... 8

BG coils .................................................................................................................................................................................. 9

Function ......................................................................................................................................................................................10

Design and material specifications ...................................................................................................................................11

EVR 2 - EVR 3 solder and flare connection ..............................................................................................................11

EVR 4 - EVR 6 - EVR 8 solder and flare connection ...............................................................................................12

EVR 10 solder and flare connection ..........................................................................................................................13

EVR 15 - EVR 18 solder, flare and flange connection ...........................................................................................14

EVR 20 - EVR 22 solder and flange connection .....................................................................................................15

EVR 25 solder connection .............................................................................................................................................16

EVR 32 - EVR 40 solder connection ............................................................................................................................17

EVRC solder connection ................................................................................................................................................18

Dimensions and weights ......................................................................................................................................................19

EVR 2 - EVR 3 solder connection .................................................................................................................................19

EVR 4 - EVR 6 - EVR 8 solder connection ..................................................................................................................20

EVR 10 solder conncetion .............................................................................................................................................21

EVR 15 - EVR 18 solder connection ............................................................................................................................22

EVR 20 - EVR 22 solder connection ............................................................................................................................23

EVR 25 solder connection .............................................................................................................................................24

EVR 32 - EVR 40 solder conncetion ............................................................................................................................25

EVRC 15 solder connection ..........................................................................................................................................26

EVRC 20 solder connection ..........................................................................................................................................27

EVR 2 - EVR 3 flare connection ....................................................................................................................................28

EVR 6 flare connection ..................................................................................................................................................29

EVR 10 flare connection.................................................................................................................................................30

EVR 15 flare connection.................................................................................................................................................31

EVR 15 flange connection .............................................................................................................................................32

EVR 20 flange connection .............................................................................................................................................33

Extended capacity, Liquid ....................................................................................................................................................34

Extended capacity, Suction .................................................................................................................................................37

Extended capacity, Hot gas .................................................................................................................................................49

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 2

psi

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

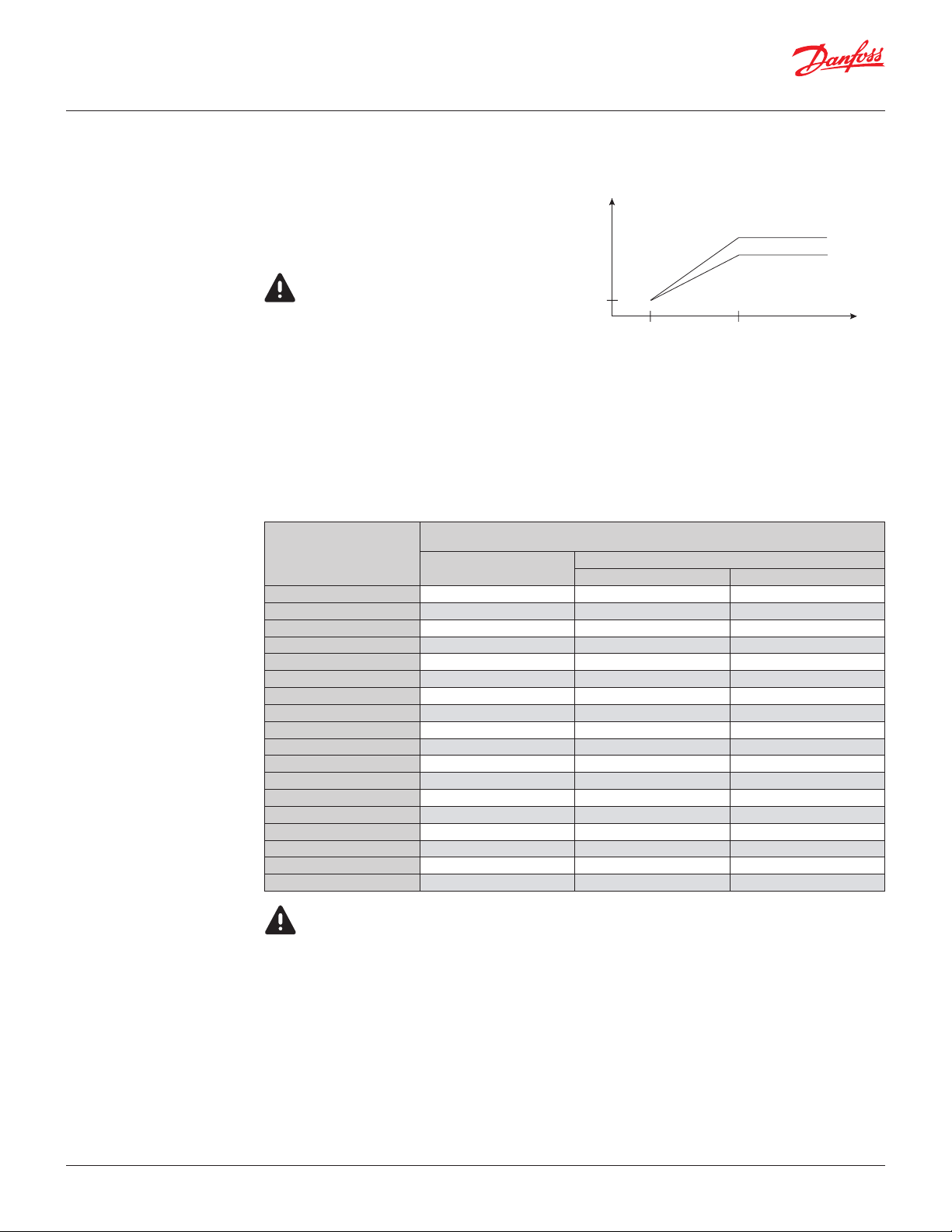

Technical data

Refrigerants

R22/R407C, R134a, R404A/R507, R410A, R407A,

R32, R290, R600, R600a, R1234yf, R1234ze, R407F,

Max. working pressure

EVR solder and flare connections: 655 psi.

EVR flange connections: 460 psi.

R125, R152A, R448A, R449A, R452A, and R450A.

For a complete list of approved refrigerants, visit

www.products.danfoss.com and search for individual

code numbers, where refrigerants are listed as part

of technical data.

Special note for R152A, R32, R290, R600, R600a,

R1234yf, and R1234ze:

This product is validated in accordance to ATEX, ISO

5149, IEC 60335, and UL. Ignition risk is evaluated in

43.5

-40 32

Max. working pressure in bar in relation to media

temperature in °F.

accordance to ISO 5149 and IEC 60335.

See safety note at the bottom of this page.

Capacity

See extended capacity tables later in this data

Media temperature

sheet.

-40 – 221 °F

Max. 266 °F during defrosting

Ambient temperature and enclosure for coil

See separate data sheet for solenoid and ATEX coils.

Opening differential pressure

Type

Min.

EVR 2 NC 0 550 478

EVR 3 NC 0 550 261

EVR 4 NC 0.44 550 406

EVR 6 NC 0.44 550 406

EVR 6 NO 0.44 305 305

EVR 8 NC 0.44 550 406

EVR 10 NC 0.44 550 290

EVR 10 NO 0.44 305 305

EVR 15 NC 0.44 550 290

EVR 15 NO 0.44 305 305

EVR 18 NC 0.44 550 290

EVR 20 NC 0.44 550 290

EVR 20 NO 0.44 276 276

EVR 22 NC 0.44 550 290

EVR 22 NO 0.44 276 276

EVR 25 NC 2.9 450 246

EVR 32 NC 2.9 450 246

EVR 40 NC 2.9 450 246

with standard coil ∆p [psi]

Max. (= MOPD) liquid

AC coil [14-17 W] DC coil [20 W]

655 psi

460 psi

°F

The EVR 2 - EVR 22 with solder connections and

without manual stem can be applied on systems

with R152A, R32, R290, R600, R600a, R1234yf, and

R1234ze as the working fluid.

For countries where safety standards are not an

indispensable part of the safety system Danfoss

recommends the installer gets a third party

approval of any system containing flammable

refrigerant.

Note: please follow specific selection criteria stated

in the datasheet for these particular refrigerants.

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 3

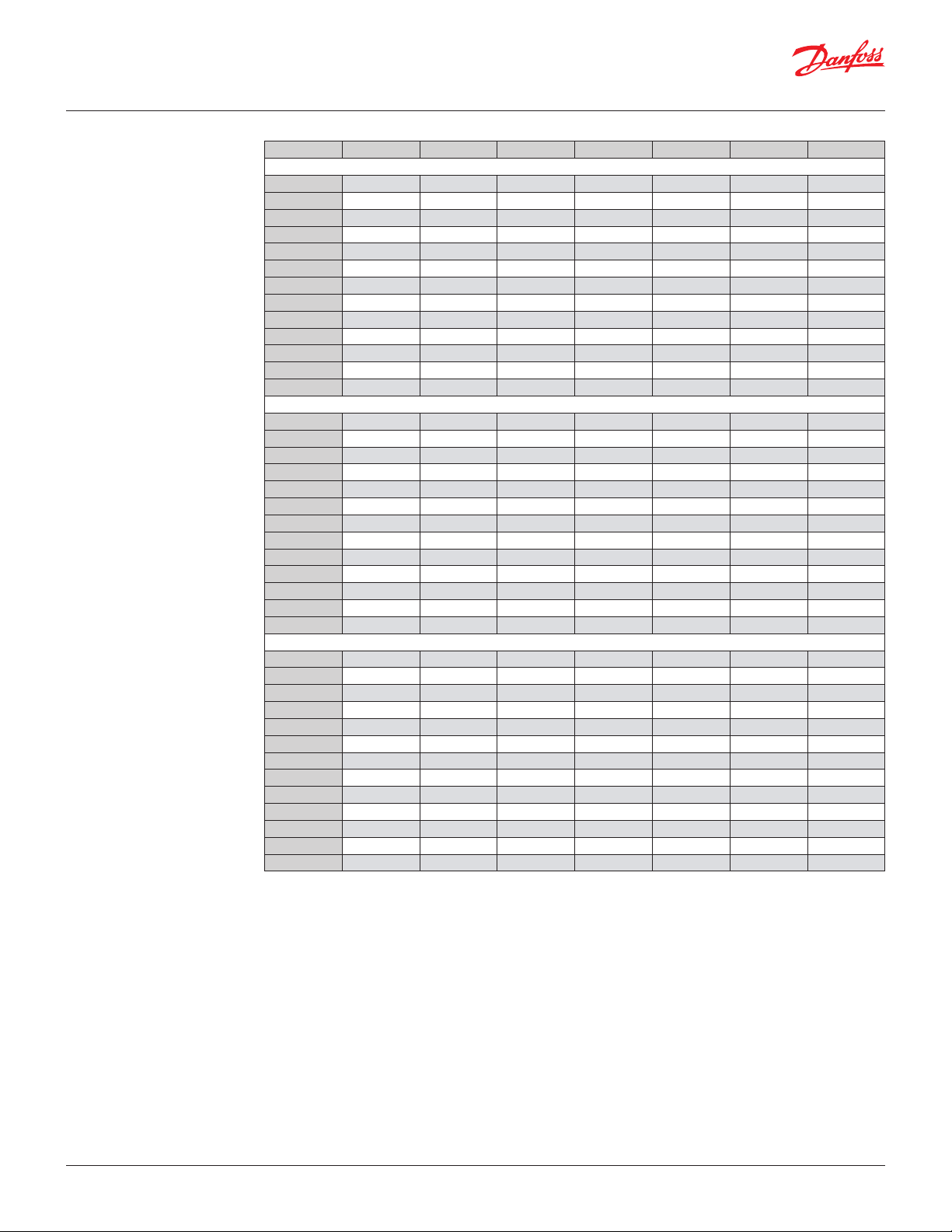

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Rated capacity [TR]

For other refrigerants, refer

to Coolselector®2

Capacities are based on:

Pressure drop across valve: 3.00 psi

Liquid temperature: 100.0 °F

Subcooling: 10.0 °F

Evaporating temperature: 40.0 °F

Superheat: 0 °F

Capacities are based on:

Pressure drop across valve: 1.00 psi

EVR 25, EVR 32, EVR 40: 2.00 psi

Liquid temperature: 100.0 °F

Subcooling: 10.0 °F

Evaporating temperature: 40.0 °F

Superheat: 0 °F

Capacities are based on:

Pressure drop across valve: 3.00 psi

Condensing temperature: 100.0 °F

Subcooling: 10.0 °F

Hot gas temperature = tc +: 40.0 °F

Evaporating temperature: 40.0 °F

Superheat: 0 °F

Type R22/R407C R134a R404A/R507 R410A R32 R290 R600a

Liquid

EVR 2 0.92 0.85 0.59 0.86 1.25 1.03 1.06

EVR 3 1.66 1.54 1.07 1.55 2.26 1.85 1.91

EVR 4 4.18 3.87 2.68 3.9 5.69 4.65 4.81

EVR 6 5.47 5.07 3.51 5.11 7.44 6.08 6.3

EVR 8 6.52 6.03 4.18 6.08 8.87 7.25 7.5

EVR 10 11.5 10.64 7.38 10.73 15.64 12.78 13.24

EVR 15 17.71 16.39 11.37 16.53 24.09 19.68 20.39

EVR 18 23.18 21.46 14.88 21.64 31.53 25.77 26.69

EVR 20 36.76 34.04 23.6 34.32 50.01 40.87 42.33

EVR 22 41.93 38.82 26.92 39.14 57.04 46.61 48.28

EVR 25 60.19 55.72 38.64 56.18 – – –

EVR 32 102.85 95.23 66.03 96.01 – – –

EVR 40 148.77 137.75 95.51 138.88 – – –

Suction vapour

EVR 2 0.08 0.06 0.06 0.09 0.12 0.09 0.06

EVR 3 0.14 0.11 0.12 0.17 0.22 0.17 0.1

EVR 4 0.35 0.27 0.29 0.42 0.55 0.42 0.26

EVR 6 0.46 0.35 0.38 0.55 0.72 0.55 0.34

EVR 8 0.55 0.41 0.46 0.66 0.86 0.66 0.4

EVR 10 0.96 0.73 0.8 1.16 1.51 1.16 0.71

EVR 15 1.48 1.13 1.24 1.79 2.32 1.79 1.1

EVR 18 1.94 1.47 1.62 2.34 3.04 2.34 1.44

EVR 20 3.08 2.34 2.57 3.71 4.82 3.71 2.28

EVR 22 3.51 2.67 2.93 4.23 5.5 4.24 2.61

EVR 25 4.67 3.5 3.9 5.65 – – –

EVR 32 7.97 5.99 6.66 9.65 – – –

EVR 40 11.53 8.66 9.63 13.96 – – –

Hot gas

EVR 2 0.21 0.17 0.18 0.25 0.33 0.25 0.16

EVR 3 0.37 0.30 0.32 0.46 0.59 0.44 0.29

EVR 4 0.94 0.76 0.82 1.16 1.48 1.12 0.73

EVR 6 1.23 0.99 1.07 1.51 1.94 1.46 0.95

EVR 8 1.47 1.18 1.27 1.80 2.31 1.74 1.13

EVR 10 2.59 2.09 2.25 3.18 4.07 3.07 2.00

EVR 15 4.00 3.22 3.46 4.89 6.26 4.73 3.08

EVR 18 5.23 4.21 4.53 6.40 8.20 6.19 4.03

EVR 20 8.30 6.69 7.18 10.16 13.01 9.81 6.40

EVR 22 9.46 7.62 8.19 11.59 14.83 11.19 7.30

EVR 25 13.58 10.94 11.76 16.63 – – –

EVR 32 23.21 18.70 20.09 28.42 – – –

EVR 40 33.58 27.05 29.06 41.11 – – –

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 4

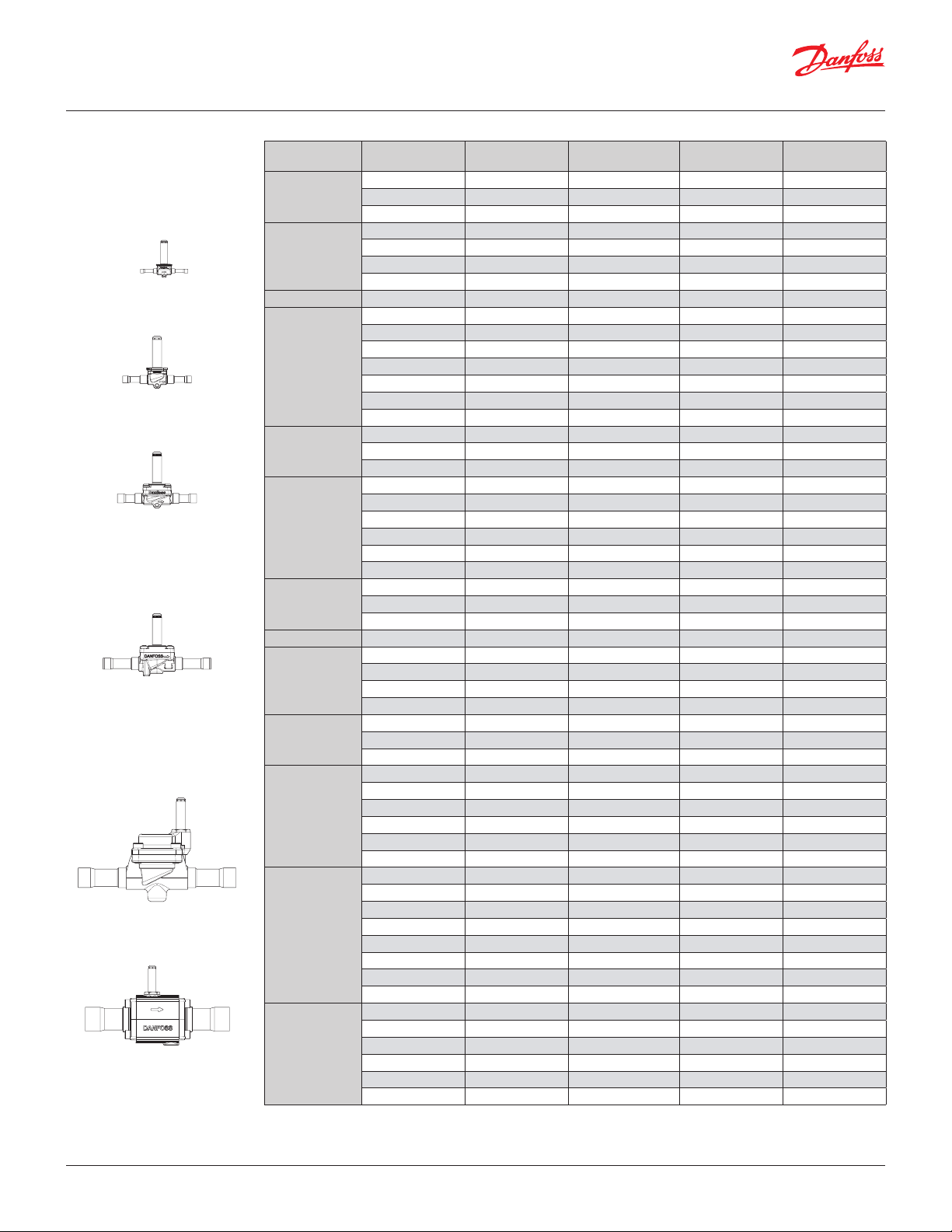

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Ordering

EVR solder connection,

Normally Closed (NC)

- separate valve bodies

EVR 2 / EVR 3

EVR 4 / EVR 6 / EVR 8

EVR 10

EVR 15 / EVR 18 / EVR 20 / EVR 22

EVR 25

EVR 32 / EVR 40

Type Coil voltage

AC / DC

EVR 2

AC / DC

AC / DC – 6 No 032F1202

AC / DC

EVR 3

AC / DC

AC / DC – 6 No 032F1207

AC / DC – 10 No 032F1208

EVR 4 AC / DC

AC / DC

AC / DC

AC / DC – 10 No 032L1213

EVR 6

AC / DC – 12 No 032L1236

AC / DC

AC / DC

AC / DC

AC /DC

EVR 8

AC / DC

AC / DC

AC / DC

AC / DC – 12 No 032L1218

EVR 10

AC / DC

AC / DC

AC / DC

AC / DC

AC / DC

EVR 15

AC / DC

AC / DC

EVR 18 AC / DC

AC / DC

EVR 20

AC / DC

AC / DC 1 1⁄8 – No 032L1244

AC / DC – 28 No 032L1245

AC / DC 1 1⁄8 – No 032L7145

EVR 22

AC / DC 1 1⁄8 – Ye s 032L7137

AC / DC 1 3⁄8 – No 032L3267

AC / DC 1 1⁄8 – Ye s 032L2200

AC / DC 1 1⁄8 – No 032L2201

EVR 25

AC / DC – 28 Ye s 032L2205

AC / DC – 28 No 032L2206

AC / DC 1 3⁄8 – Ye s 032L2207

AC / DC 1 3⁄8 – No 032L2208

AC / DC 1 3⁄8 35 Yes 032L1105

AC / DC 1 3⁄8 35 No 032L1106

AC / DC 1 5⁄8 – Ye s 032L1103

EVR 32

AC / DC 1 5⁄8 – No 032L1104

AC / DC – 42 Ye s 032L1107

AC / DC – 42 No 032L1108

AC / DC 2 1⁄8 – No 032L1180

AC / DC 2 1⁄8 – Ye s 032L1181

AC / DC 1 5⁄8 – Ye s 032L1109

AC / DC 1 5⁄8 – No 032L1110

EVR 40

AC / DC – 42 Ye s 032L1113

AC / DC – 42 No 032L1114

AC / DC 2 1⁄8 – Ye s 032L1111

AC / DC 2 1⁄8 – No 032L1112

See separate data sheet for coils

Connection size

[in]

1

⁄4 – No 032F1201

1

⁄4 – No 032F7100

1

⁄4 – No 032F1206

3

⁄8 – No 032F1204

3

⁄8 – No 032L7110

3

⁄8 – No 032L1212

3

⁄8 – Yes 032L7116

1

⁄2 – No 032L1209

1

⁄2 – Yes 032L7144

5

⁄8 – No 032L7117

1

⁄2 – No 032L7121

1

⁄2 – Yes 032L7148

5

⁄8 – No 032L7122

3

⁄8 – No 032L7125

1

⁄2 – No 032L1217

1

⁄2 – Yes 032L1188

5

⁄8 16 No 032L1214

5

⁄8 – Ye s 032L7149

5

⁄8 16 No 032L1228

5

⁄8 16 Ye s 032L1227

7

⁄8 22 No 032L1225

7

⁄8 – Ye s 032L1004

7

⁄8 – No 032L1240

7

⁄8 – Ye s 032L1254

Connection size

[mm]

Manual operation Code no.

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 5

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Ordering

EVR solder connection,

Normally Open (NO)

- separate valve bodies

Note:

tube design

EVR 6

Ordering

EVR flare connection,

Normally Closed (NC)

- separate valve bodies

EVR 6

Type Coil voltage

EVR 6

EVR 10

EVR 15

EVR 20

EVR 22 AC 1 3⁄8 – No 032L3268

AC / DC

AC / DC – 10 No 032L1295

AC / DC

AC / DC – 12 No 032L1296

AC / DC

AC / DC

AC / DC

AC / DC 1 1⁄8 – No 032L1269

AC / DC – 28 No 032L1279

Connection size

[in]

3

⁄8 – No 032L1290

1

⁄2 – No 032L1291

5

⁄8 16 No 032L1299

7

⁄8 – No 032L3270

7

⁄8 – No 032L1260

Connection size

[mm]

Manual operation Code no.

See separate data sheet for coils

The normal range of coils can be used for the NO valves, with the exception of the double frequency versions of

110 V, 50/60 Hz and 220 V, 50/60 Hz.

Type Coil voltage

EVR 2 AC / DC

EVR 3

EVR 6

EVR 10

EVR 15

AC / DC

AC / DC

AC / DC

AC / DC

AC / DC

AC / DC

AC / DC

AC / DC

Connection size

[in]

1

⁄4 6 No 032F8056

1

⁄4 6 No 032F8107

3

⁄8 10 No 032F8116

3

⁄8 10 No 032L8072

1

⁄2 12 No 032L8079

1

⁄2 12 No 032L8095

5

⁄8 16 No 032L8098

5

⁄8 16 Yes 032L8100

5

⁄8 16 No 032L8101

Connection size

[mm]

Manual operation Code no.

See separate data sheet for coils

Ordering

EVR flare connection,

Normally Open (NO)

- separate valve bodies

Note:

tube design

Type Coil voltage

EVR 6 AC / DC

EVR 10 AC / DC

Connection size

[in]

3

⁄8 10 No 032L8085

1

⁄2 12 No 032L8090

Connection size

[mm]

Manual operation Code no.

See separate data sheet for coils

The normal range of coils can be used for the NO valves, with the exception of the double frequency versions of

110 V, 50/60 Hz and 220 V, 50/60 Hz.

Valve bodies are supplied without flare nuts.

Separate flare nuts:

– 1⁄4 in or 6 mm, code no. 011L1101

– 3⁄8 in or 10 mm, code no. 011L1135

– 1⁄2 in or 12 mm, code no. 011L1103

– 5⁄8 in or 16 mm, code no. 011L1167

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 6

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

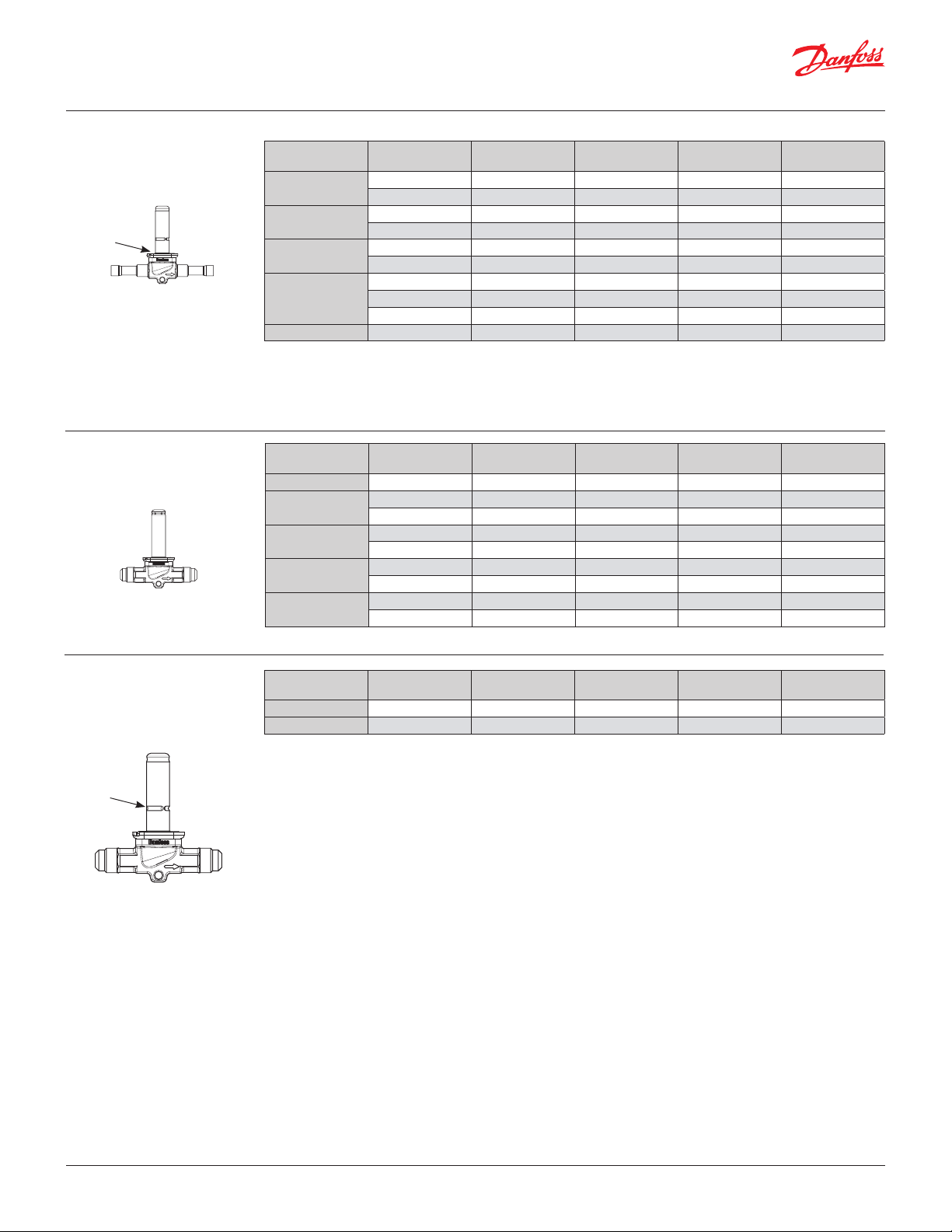

Ordering

EVR flange connection,

Normally Closed (NC)

- separate valve bodies

EVR 15

Type Coil voltage Connection Manual operation Code no.

EVR 15

EVR 20

AC / DC Flanges No 032L1224

AC / DC Flanges Ye s 032L1234

AC / DC Flanges No 032L1243

AC / DC Flanges Ye s 032L1253

See separate data sheet for coils

Flange sets

Type

EVR 15

EVR 20

Connection size Connection type

[in] [mm] Solder [in] Solder [mm] Weld [in]

1

⁄2 – – – Yes 027N1115

5

⁄8 – Yes – – 027L1117

– 16 – Yes – 027L1116

3

⁄4 – – – Yes 027N1120

7

⁄8 – Yes – – 027L1123

– 22 – Yes – 027L1122

3

⁄4 – – – Yes 027N1220

7

⁄8 – Yes – – 027L1223

– 22 – Yes – 027L1222

1 – – – Yes 027N1225

11

⁄8 – Yes – – 027L1229

– 28 – Yes – 027L1228

Code no.

See separate data sheet for coils

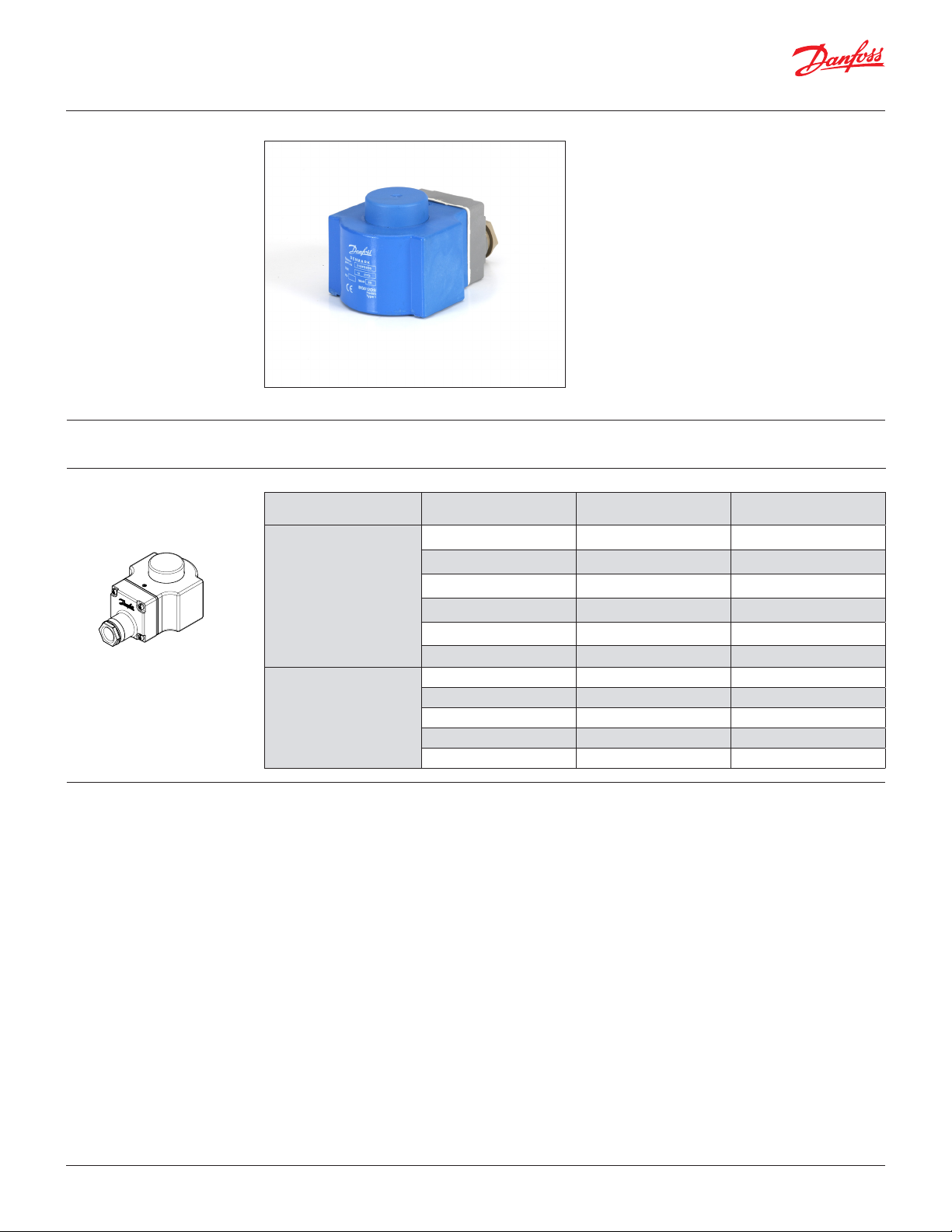

Ordering

EVRC solder connection,

Normally Closed (NC)

- separate valve bodies

Example

EVR 15 without manual operation,

code no. 032L1224

1

⁄2 in weld flange set,

code no. 027N1115

+ coil with terminal box, 220 V, 50 Hz,

code no. 018F6701

Type Coil voltage

EVRC 15 AC / DC

EVRC 20 AC / DC

See separate data sheet for coils

Connection size

[in]

5

⁄8 16 No 032L1255

7

⁄8 22 No 032L1258

Connection size

[mm]

Manual operation Code no.

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 7

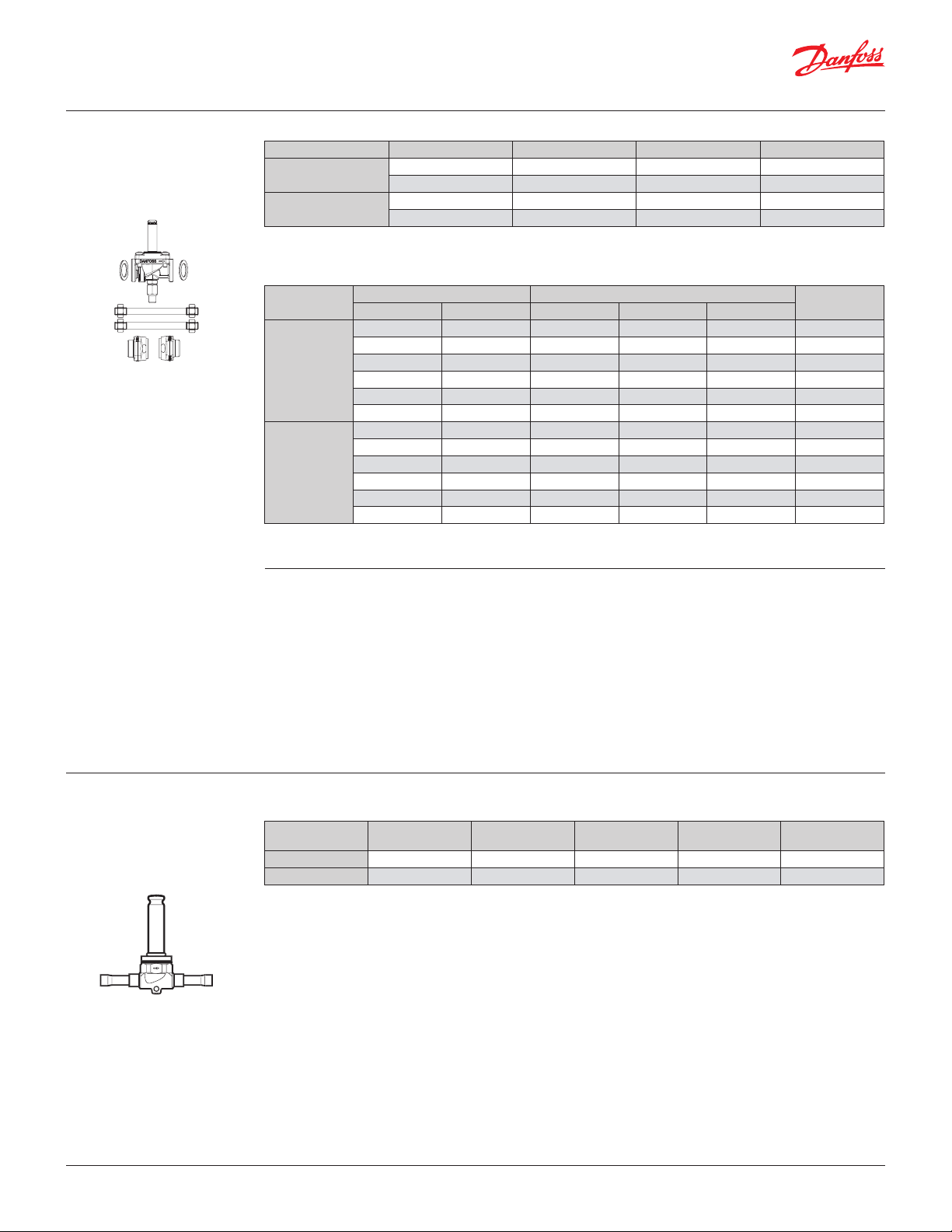

Danfoss

18F66.10

Danfoss

18F67.10

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

BJ and BX coils

Approvals

Ordering

Listed

Coil type

Junction box NEMA 2

BJ024CS 7 18 24 50 / 60 14 018F4100

BJ120CS

BJ240CS

BJ120BS 7 18 120 60 16 018F4130

BJ208BS 7 18 208 60 16 018F4132

BJ240BS 7 18 240 60 16 018F4134

Conduit boss NEMA 4

BX024CS 18 46 24 50 / 60 14 018F4102

BX024CS 71 180 24 50 / 60 14 018F4103

BX024CS 98 250 24 50 / 60 14 018F4104

BX120CS 18 46

BX120CS 36 91 018F4113

BX120CS 71 180 018F4114

BX120CS 98 250 018F4115

BX240CS 18 46

BX240CS 98 250 018F4123

BX120BS 98 250 120 60 16 018F4131

BX208BS 98 250 208 60 16 018F4133

BX240BS 98 250 240 60 16 018F4135

Wire length

[in] [cm]

7 18 110-120 60 15

7 18 110 50 16

7 18 208 – 240 60 14

7 18 230 50 17

Voltage

[V ] AC

110-120

110

208 – 240

230

Frequency

[Hz]

60

50

60

50

Power

consumption

[W]

15

16

14

17

Code no.

018F4110

018F4120

018F4112

018F4122

Technical data

© Danfoss | DCS (az) | 2017.12

Design

In accordance with UL 429

Power supply

Alternating current (AC)

Permissible voltage variation

Alternating current (AC):

50 Hz and 60 Hz: -10% – +15%

50/60 Hz: +/- 10%

Power consumption

Alternating current (AC): Inrush: 49 VA;

Holding: 28 VA. 14-17 W

Insulation of coil wire

Class H according to IEC 85

Connection

Junction box or Conduit boss

Enclosure. IEC 60529

Junction box NEMA 2 ~ IP 12–32

Conduit boss NEMA 4 ~ IP 54

Ambient temperature

-40 °F – 122 °F (-40 °C – 50 °C)

DKRCC.PD.BB0.F2.22 | 8

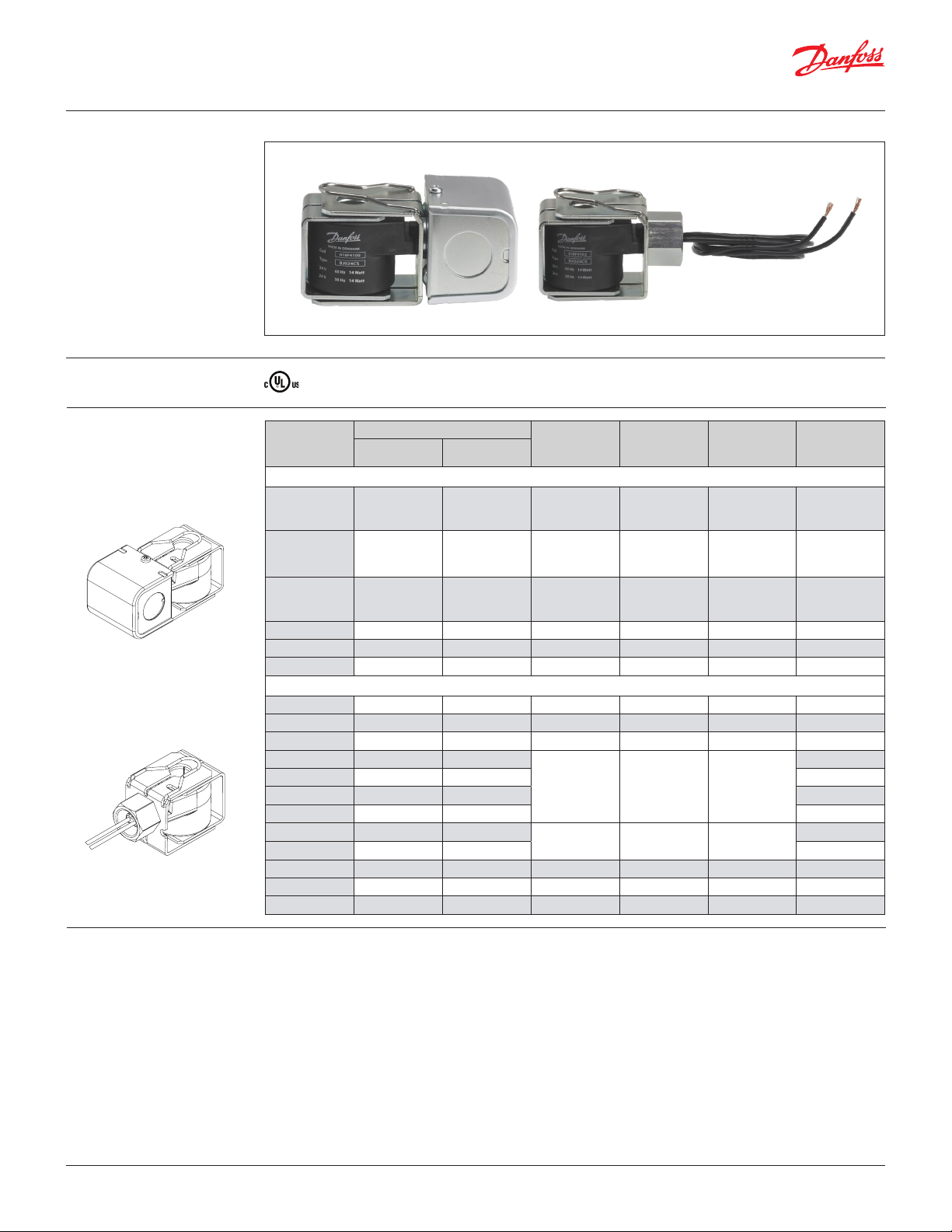

Danfoss

18F61

BG coils

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

BG coils

Approvals

Ordering

Low Voltage Directive (LVD) 2014/35/EU

Valve type

EVR 2 to 8 (NC)

EVR 25 to 40 (NC/NO)

EVR 6 to 8 (NO)

EVR 10 to 22 (NC/NO)

EVRC 15 to 20

Voltage

[V] DC

y For high temperatures – class H insulated wire

y Encapsulated coils with long life time

y Wide range of coils

− from 12 V – 220 V DC

− with terminal box IP67 ~ NEMA 6

Power consumption

[W]

12 20 018F6856

24 16 018F6857

48 19 018F6859

110 16 018F6860

115 19 018F6861

220 20 018F6851

12 20 018F6886

24 20 018F6887

48 20 018F6889

110 20 018F6890

220 20 018F6881

Code no.

Technical data

© Danfoss | DCS (az) | 2017.12

Design

In accordance with VDE 0580

Power supply

Direct current (DC)

Permissible voltage variation

±10%

Power consumption

16-20 W

Insulation of coil wire

Class H according to IEC 85

Connection

Terminal box

Enclosure. IEC 529

IP 67 NEMA 6

Ambient temperature

-40 °F – 122 °F (-40 °C – 50 °C)

DKRCC.PD.BB0.F2.22 | 9

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Function

See Design and material

drawings for additional details

on the following pages

EVR solenoid valves are designed on two different

principles:

1. Direct operation

2. Servo operation

1. Direct operation (NC)

EVR 2 – EVR 3 are direct operated. The valves open

directly for full flow when the armature (3) moves

up into the magnetic field of the coil.

This means that the valves operate with a minimum

differential pressure of 0 bar.

The seat plate is fitted directly on the armature (3).

Inlet pressure acts from above on the armature and

the valve plate. Thus, the inlet pressure and spring

force act to close the valve when there is no current

in the coil.

2. Servo operation (NC)

EVR 4 – EVR 22 are servo operated with a "floating"

diaphragm (4). The pilot orifice of stainless steel

is placed in the center of the diaphragm. The seat

plate is fitted directly to the armature (3). When

there is no current in the coil, the main orifice and

pilot orifice are closed. The pilot orifice and main

orifice are held closed by the armature spring force

and the differential pressure between inlet and

outlet sides.

When current is applied to the coil, the armature

is drawn up into the magnetic field and opens the

pilot orifice. This relieves the pressure above the

diaphragm, i.e. the space above the diaphragm

becomes connected to the outlet side of the valve.

The differential pressure between inlet and outlet

sides then presses the diaphragm away from the

main orifice and opens it for full flow. Therefore a

certain minimum differential pressure is necessary

to open the valve and keep it open. For EVR 4 – EVR

22 valves the minimum differential pressure for

safe operation is 0.03 bar.

When the current is switched off, the pilot orifice is

closed. Via the equalization holes in the

diaphragm, the pressure above the diaphragm

rises to the same value as the inlet pressure and the

diaphragm closes the main orifice.

EVR 25, EVR 32 and EVR 40 are servo operated

piston valves. The servo piston (16) with sealing

face closes against the valve seat by means of the

differential pressure between inlet and

outlet side of the valve and the force of the

compression spring. When the coil is switched on,

the pilot orifice opens. This relieves the pressure on

the piston spring side of the valve. The differential

pressure will then open the valve. The minimum

differential pressure for safe operation is 0.2 bar.

EVR (NO) has the opposite function to EVR (NC), i.e.

it is open with de-energized coil.

EVR (NO) is available with servo operation only.

3. Bi-flow operation with EVRC

EVRC is a servo operated solenoid valve with a

special diaphragm with built-in non-return valve.

The valve is for use in liquid lines in refrigeration

plants.

EVRC allows flow in both directions and can be

used in liquid lines in refrigeration plants with hot

gas or gas defrost.

During the refrigeration period EVRC works as

a normal solenoid valve, while during defrost it

allows the condensed liquid to return to the liquid

manifold.

During the defrosting period the coil for EVRC must

be energized.

4. Manual stem operation for EVR 6 - EVR 25 NC

EVR 6 - EVR 25 NC are available with optional

manual stem operation to manually force the

NC valve open when the coil is de-energized.

The protective cap should be removed and the

manual stem (12) should be rotated until the valve

is fully open. It takes approx. 6 cycles from fully

closed, to reach the fully open position.

After manual operation is completed, the valve

should manually be closed again and the protective

cap mounted.

Alternatively, all EVR NC and NO valves can be

manually operated by removing the coil and force

the valve open or closed by using a solenoid valve

tester (permanent magnet) code no. 018F0091.

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 10

11

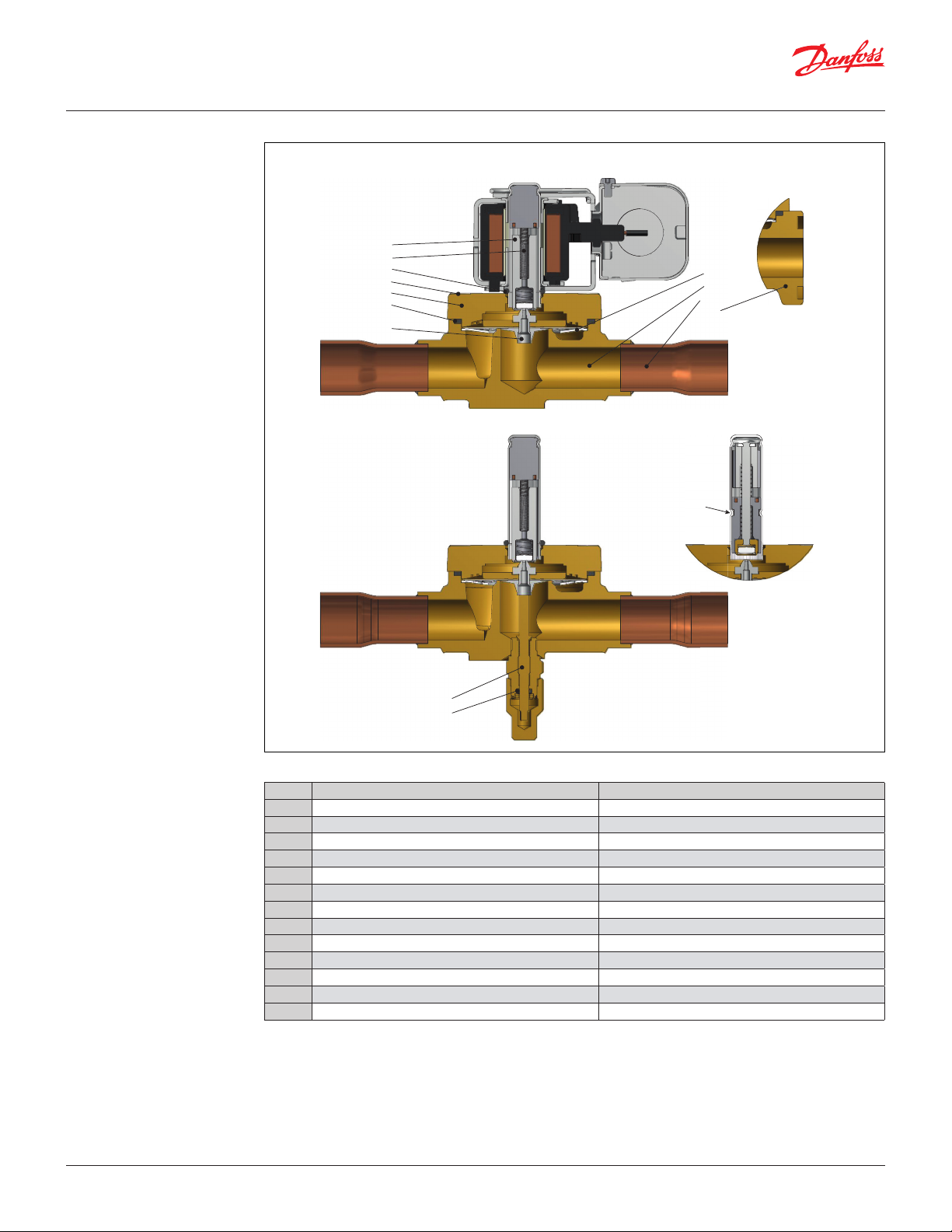

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

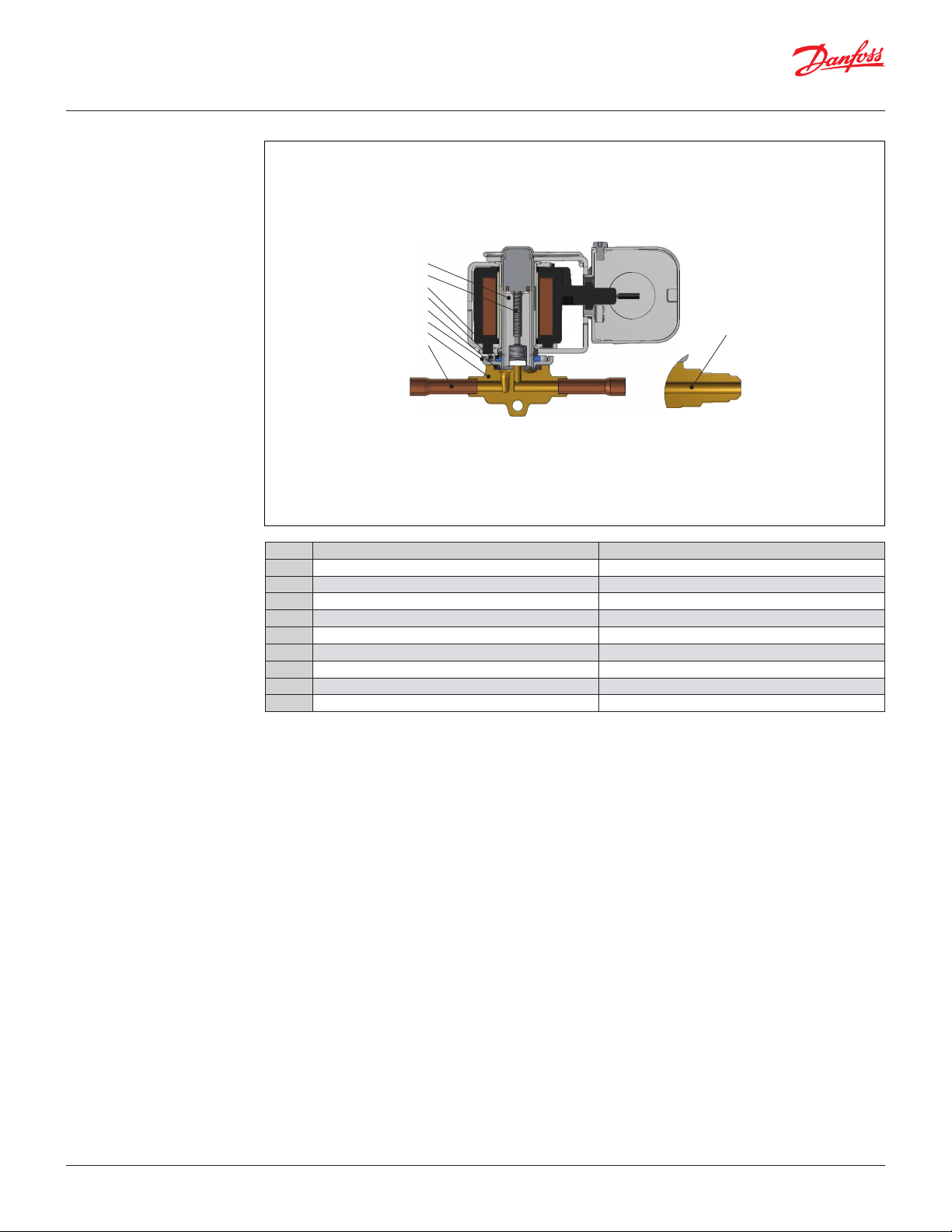

EVR 2 - EVR 3

Solder and flare connection

3

6

9

8

7

2

1

10

Pos. no. Description Material

1 Valve assembly housing Brass, copper

2 Cover assembly Stainless steel

3 Armature assembly Stainless steel/PTFE

6 Armature spring Stainless steel

7 Seal Chloroprene rubber

8 Screw Stainless steel

9 O-ring EPDM Rubber

10 Solder connection Copper

11 Flare connection Brass

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 11

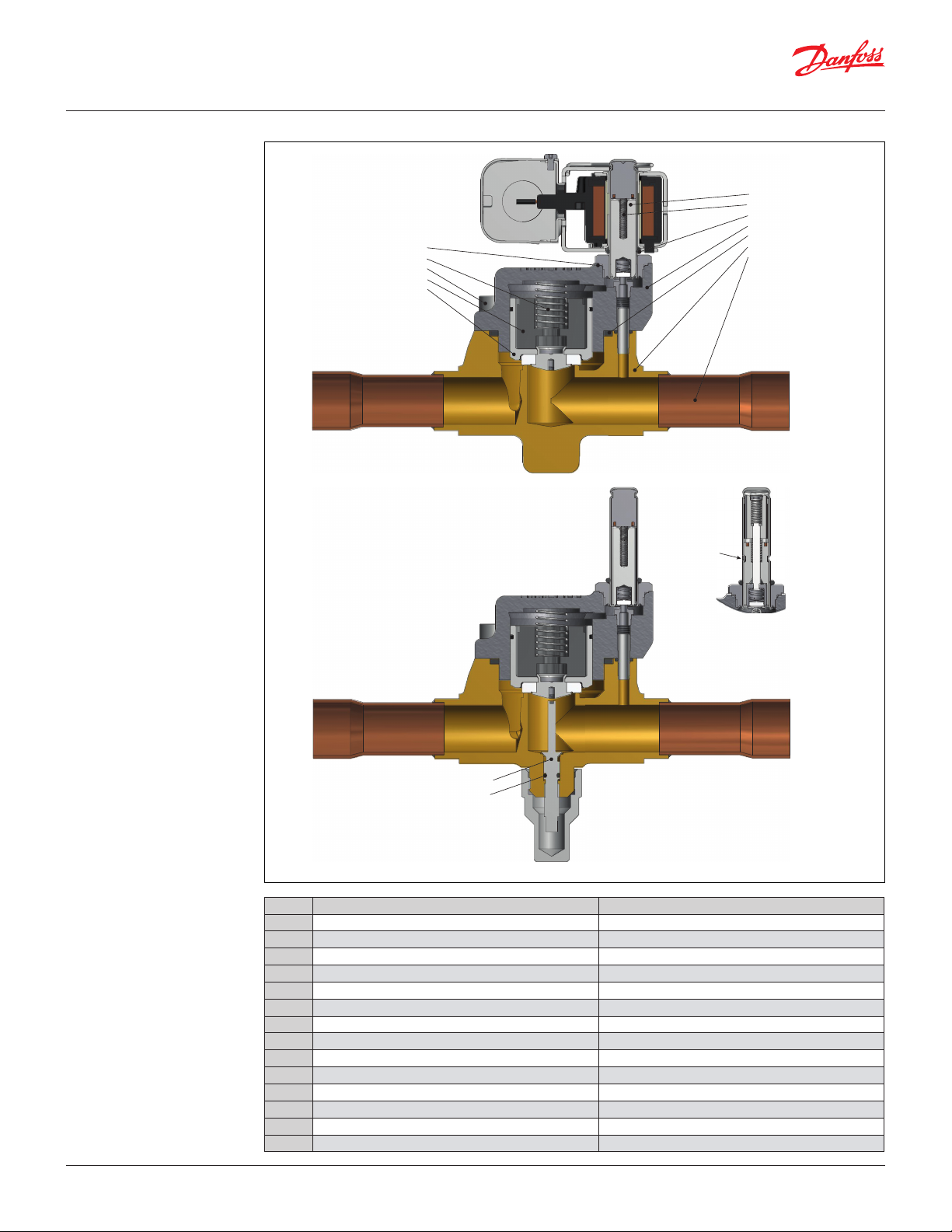

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

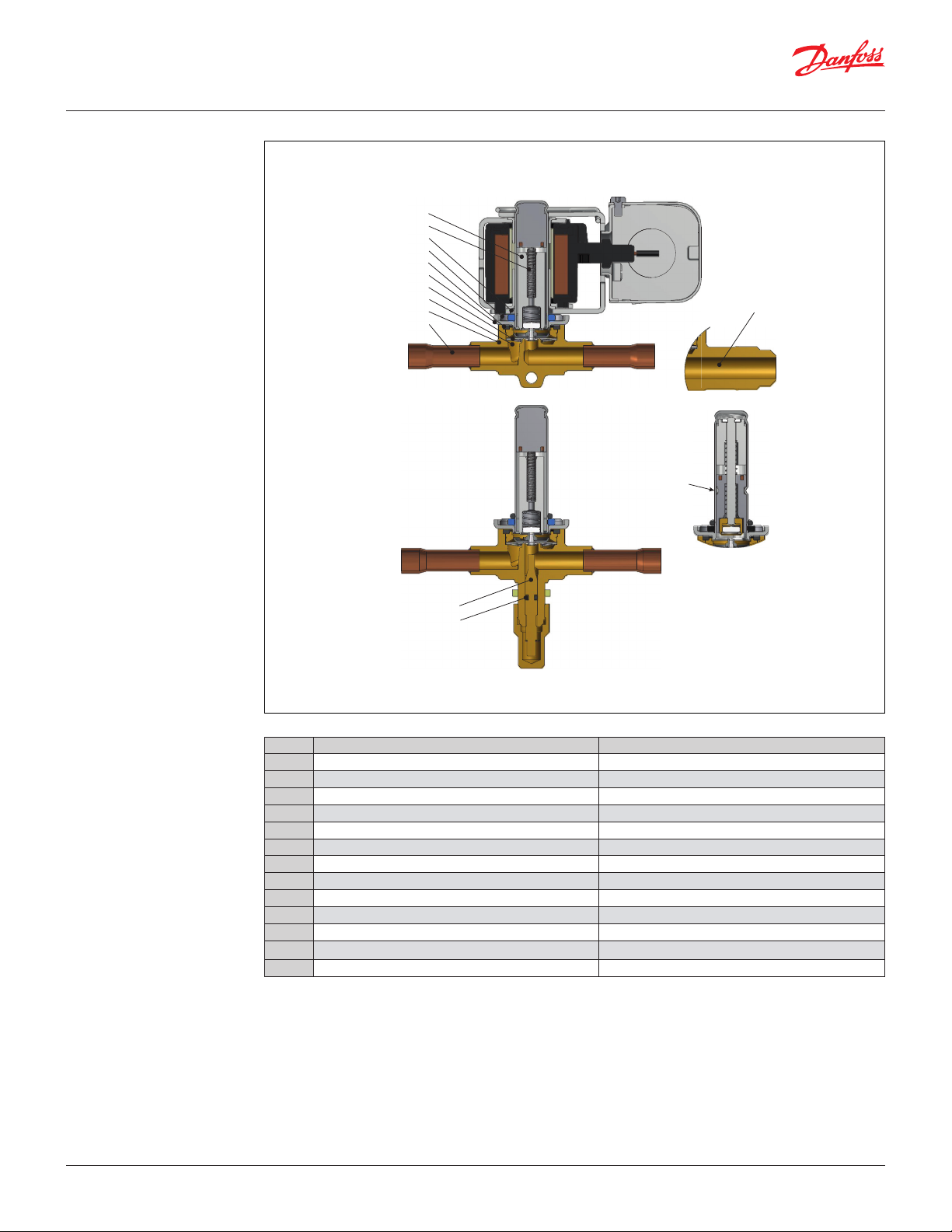

EVR 4 - EVR 6 - EVR 8

Solder and flare connection

3

6

9

8

7

2

1

10

4

5

11

NO tube design

12

13

© Danfoss | DCS (az) | 2017.12

Pos. no. Description Material

1 Valve housing assembly Brass

2 Cover Stainless steel

3 Armature assembly Stainless steel/PTFE

4 Diaphragm assembly Stainless steel/PTFE

5 Suppor t washer Stainless steel

6 Armature spring Stainless steel

7 Seal Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

11 Flare connection Brass

12

13 O-ring Chloroprene rubber

1)

Manual stem is not available for EVR 4

Manual stem

1

Brass

DKRCC.PD.BB0.F2.22 | 12

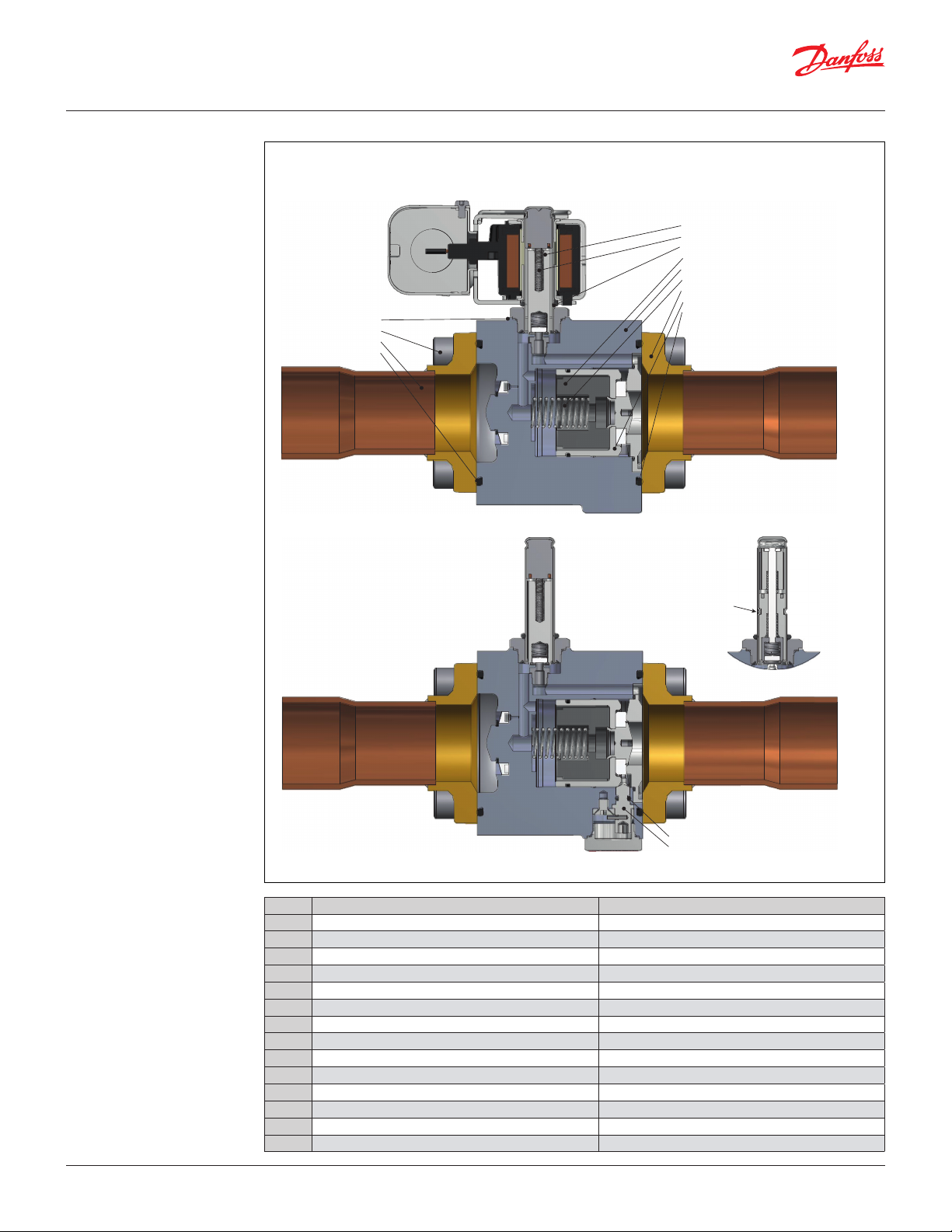

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

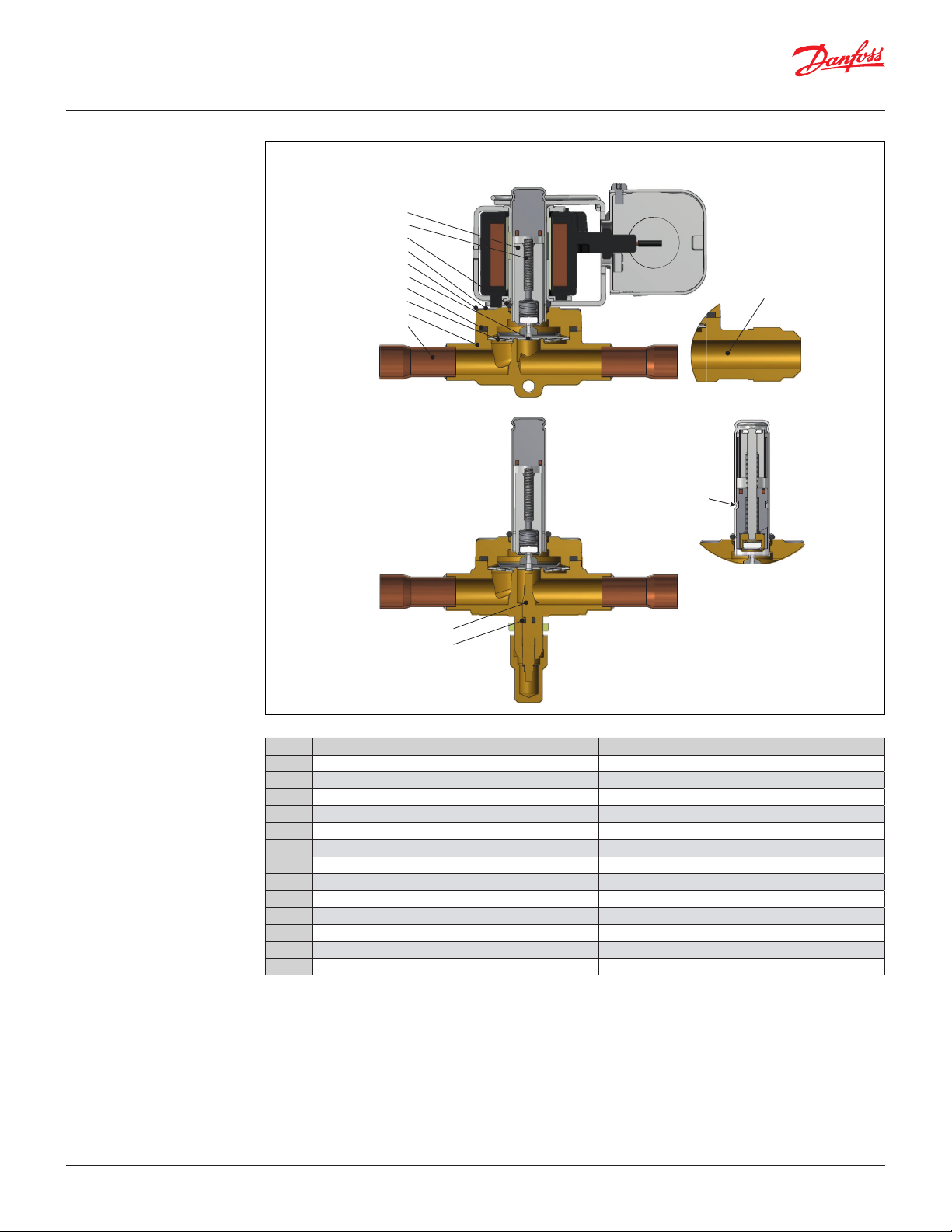

EVR 10

Solder and flare connection

3

6

9

8

2

7

5

10

4

11

1

NO tube design

12

13

© Danfoss | DCS (az) | 2017.12

Pos. no. Description Material

1 Valve body Brass

2 Cover Brass

3 Armature assembly Stainless steel/PTFE

4 Diaphragm assembly Stainless steel/PTFE

5 Support washer Stainless steel

6 Armature spring Stainless steel

7 Seal Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

11 Flare connection Brass

12 Manual stem Brass

13 O-ring Chloroprene rubber

DKRCC.PD.BB0.F2.22 | 13

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

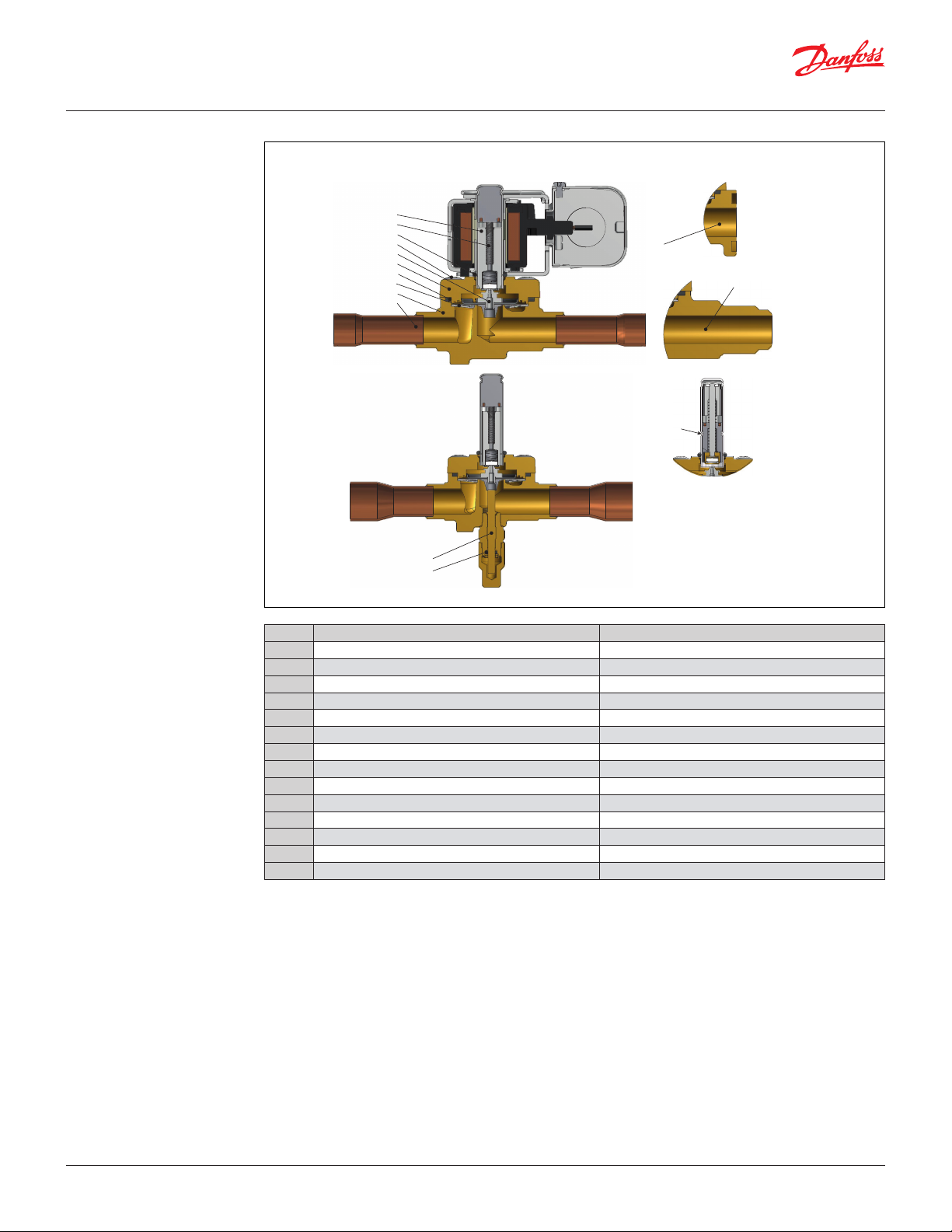

Design and

material specifications

EVR 15 - EVR 18

Solder, flare, and flange

connection

3

6

5

9

8

4

2

7

1

10

14

11

NO tube design

12

13

Pos. no. Description Material

1 Valve body Brass

2 Cover Brass

3 Armature assembly Stainless steel/PTFE

4 Diaphragm assembly Stainless steel/PTFE

5 Support washer Stainless steel

6 Armature spring Stainless steel

7 Seal Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

11 Flare connection Brass

12 Manual stem Brass

13 O-ring Chloroprene rubber

14 Flange connection Brass

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 14

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

EVR 20 - EVR 22

Solder and flange

connection

3

6

9

8

2

7

4

5

1

10

14

NO tube design

12

13

Pos. no. Description Material

1 Valve body Brass

2 Cover Brass

3 Armature assembly Stainless steel/PTFE

4 Diaphragm assembly Stainless steel/PTFE

5 Support washer Stainless steel

6 Armature spring Stainless steel

7 Seal Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

12 Manual stem Brass

13 O-ring Chloroprene rubber

14 Flange connection Brass

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 15

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

EVR 25

Solder connection

15

17

16

18

3

6

9

2

7

1

8

10

NO tube design

© Danfoss | DCS (az) | 2017.12

12

13

Pos. no. Description Material

1 Valve body Brass

2 Cover Cast iron

3 Armature assembly Stainless steel/PTFE

6 Armature spring Stainless steel

7 Gasket Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

12 Manual stem Brass

13 O-ring Chloroprene rubber

15 Gasket Aluminum

16 Insert Nylon

17 Piston spring Stainless steel

18 Piston Stainless steel

DKRCC.PD.BB0.F2.22 | 16

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

EVR 32 - EVR 40

Solder connection

15

8

10

7

3

6

9

16

1

17

2

18

7

NO tube design

13

12

Pos. no. Description Material

1 Valve body Cast iron

2 Cover Brass

3 Armature assembly Stainless steel

6 Armature spring Stainless steel

7 Gasket Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

12 Manual stem Brass

13 O-ring Chloroprene rubber

15 Gasket Aluminum

16 Insert Nylon

17 Piston spring Stainless steel

18 Piston Stainless steel

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 17

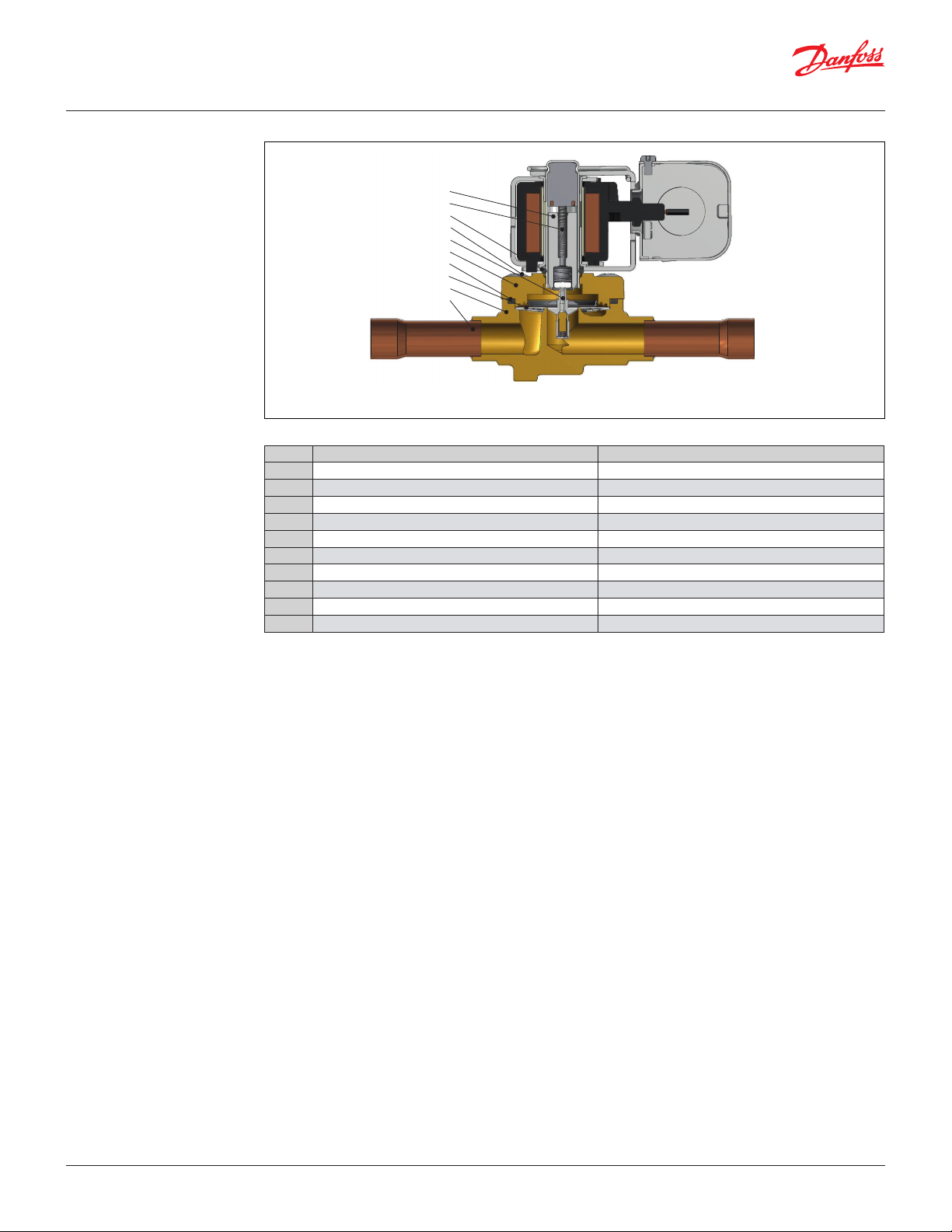

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Design and

material specifications

EVRC

Solder connection

Pos. no. Description Material

1 Valve body Brass

2 Cover Brass

3 Armature assembly Stainless steel/PTFE

4 Diaphram assembly Stainless steel/PTFE

5 Support washer Stainless steel

6 Armature spring Stainless steel

7 Gasket Chloroprene rubber

8 Screws Stainless steel

9 O-ring EPDM rubber

10 Solder connection Copper

3

6

9

8

4

7

5

10

2

1

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 18

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

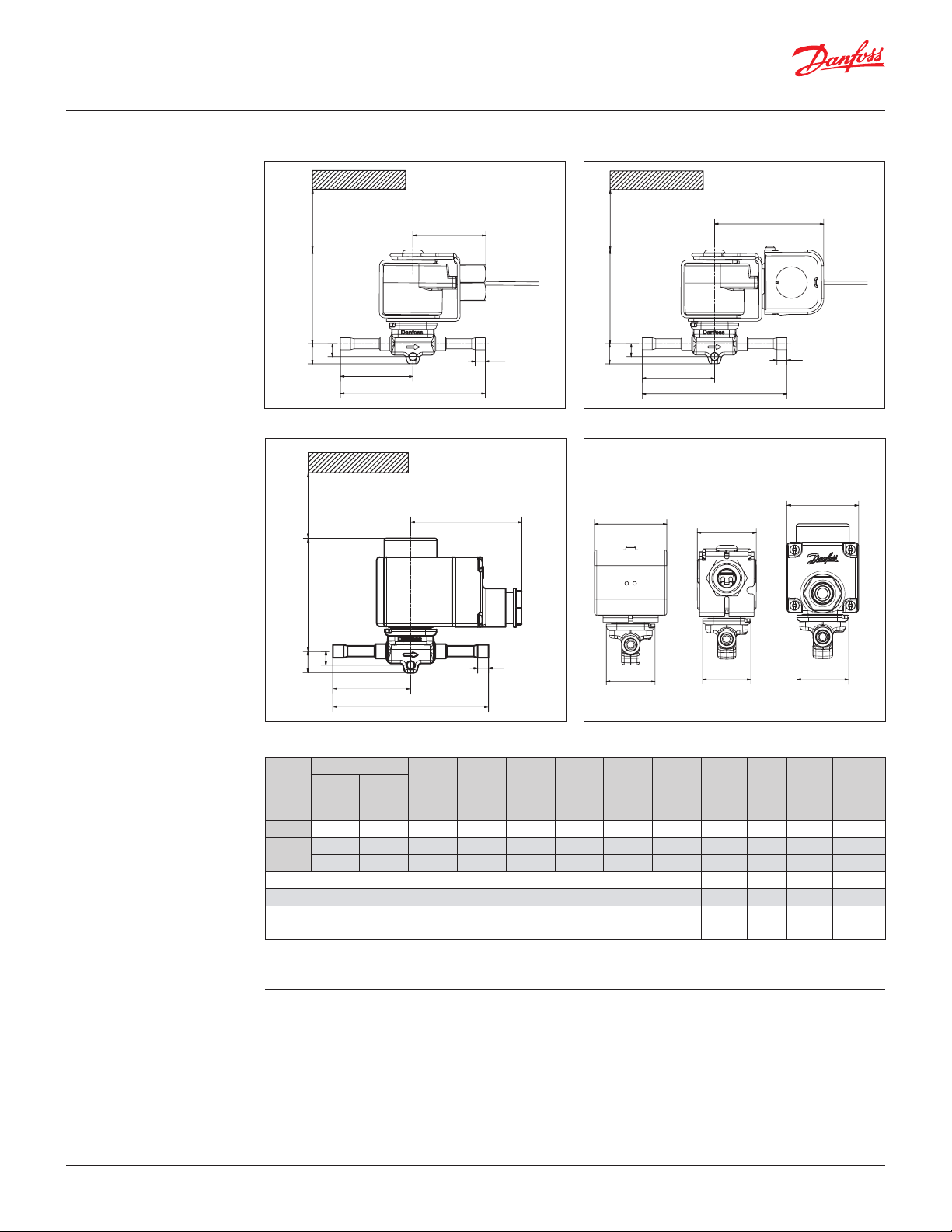

Dimensions and weights

EVR 2 - EVR 3

Solder connection

Conduit hub 1)

H3

Terminal box 3)

Min. 65 mm

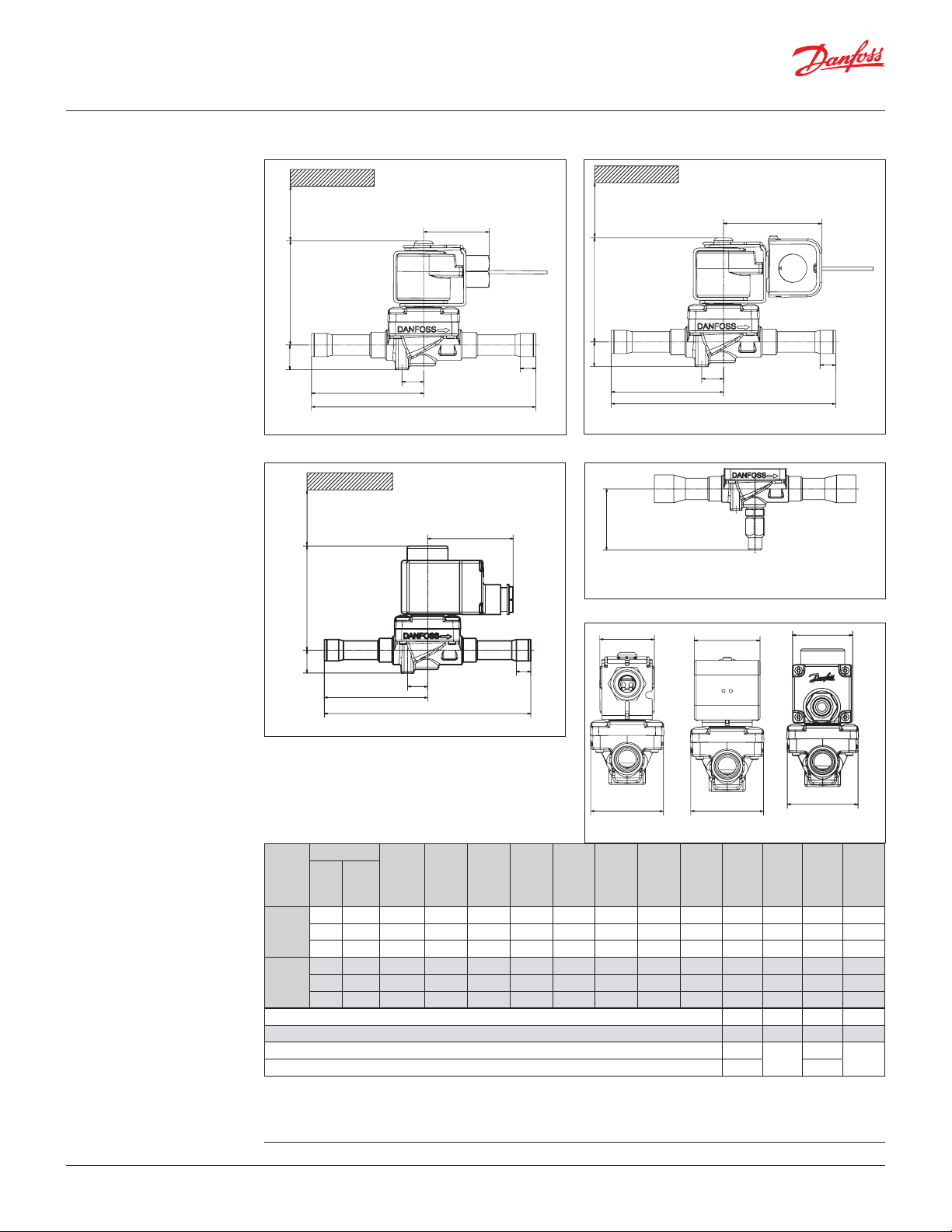

Lc

L2

L1

L

Junction box 2)

Lc

H3

L1

L

L2

End view

Lc

H2

Type

EVR 2

EVR 3

H3

H1

L1

L

Connection

H

1

[in] [mm]

1

⁄4 6 0.55 2.87 0.35 3.98 1.99 0.28 – 1.34 – 0.35

1

⁄4 6 0.55 73 0.35 3.98 1.99 0.28 – 1.34 – 0.35

3

⁄8 10 0.55 73 0.35 4.61 2.30 0.31 – 1.34 – 0.37

[in]

H

[in]

L2

W

Conduit hub 1)

W

Junction box 2)

W

Terminal box 3)

Net

weight

H

2

[in]

L

3

[in]

[in]

L

L

1

[in]

2

L

C

[in]W[in]

W1 max.

[in]

without

coil

[lbs]

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

–

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For CAD models on individual code numbers, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 19

H1

H2

Min. 2 9/16

H4

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

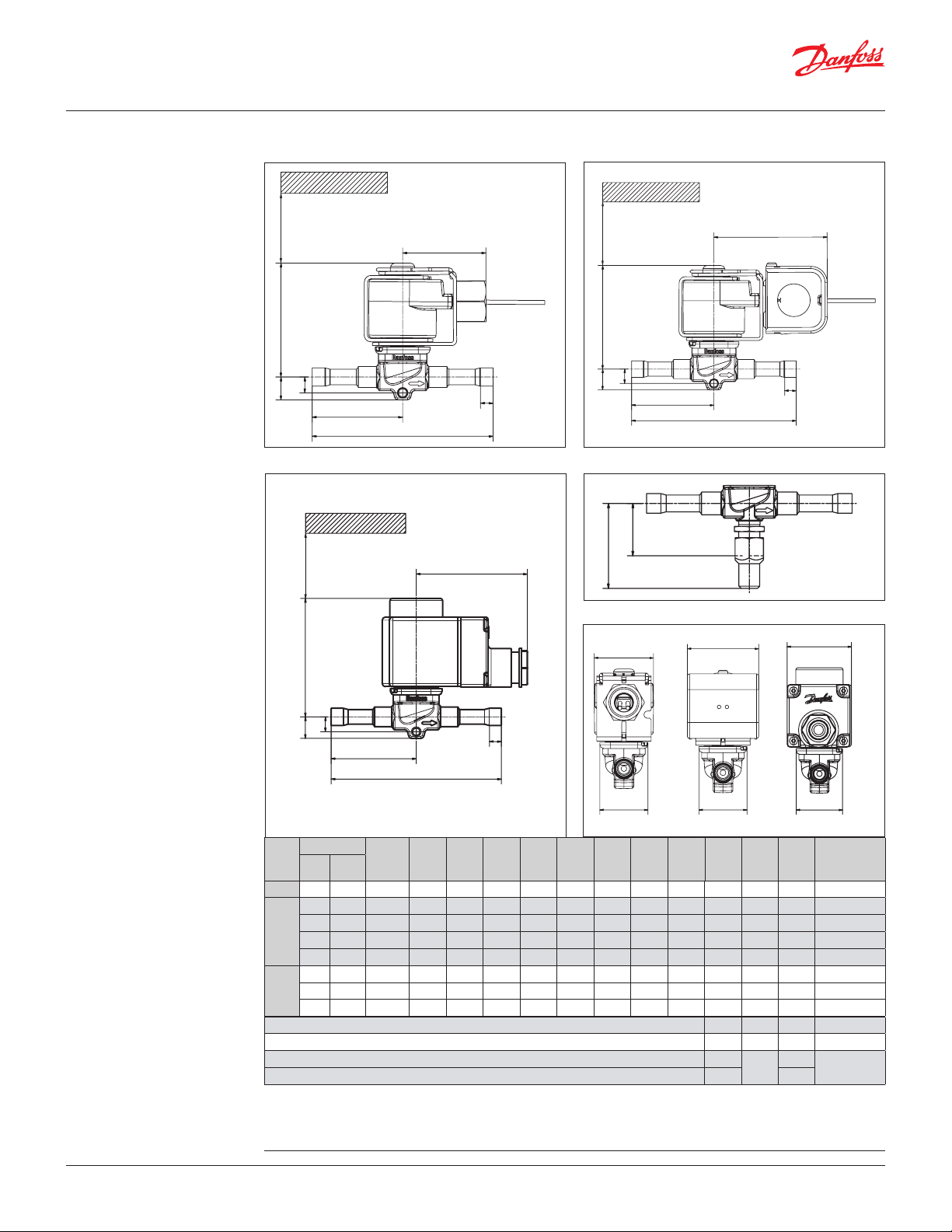

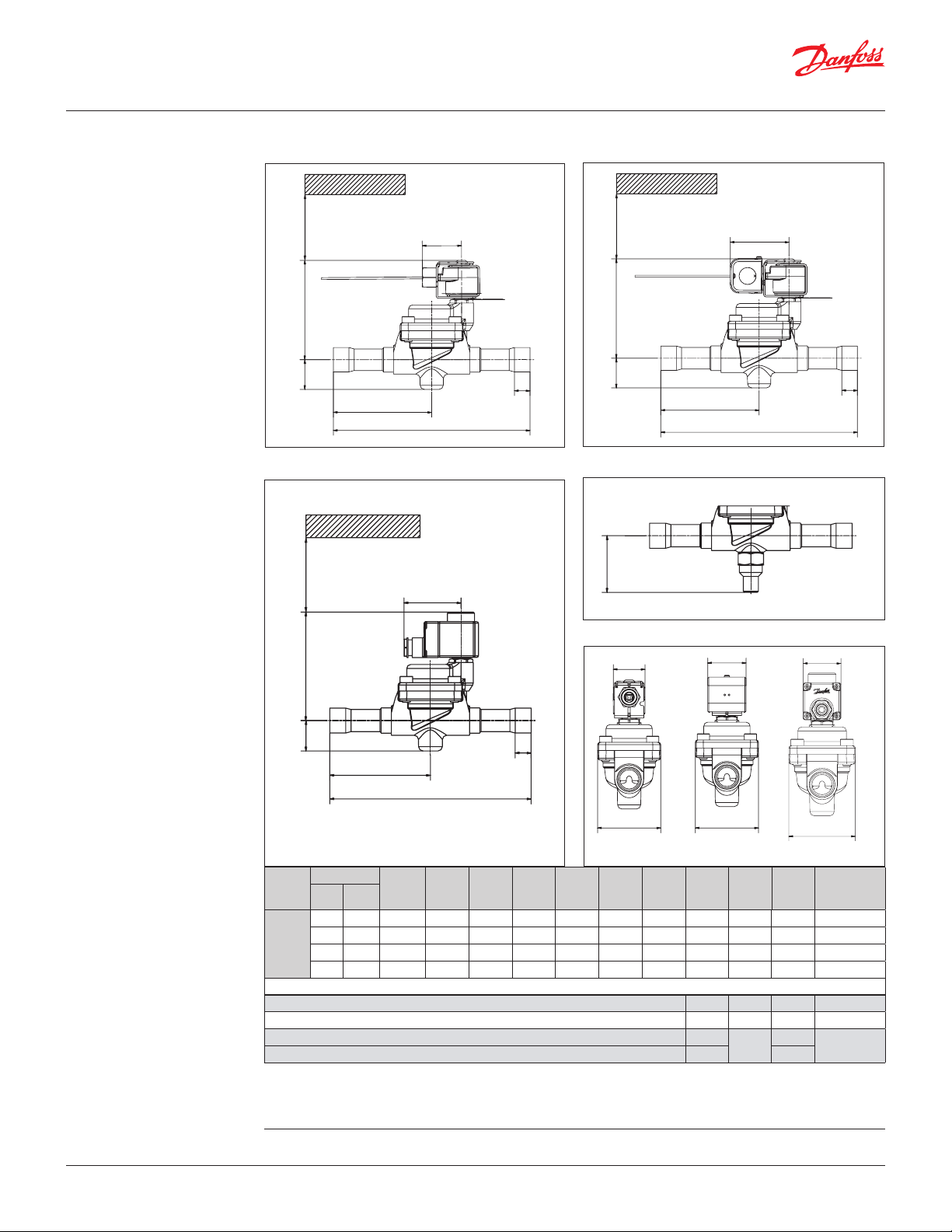

Dimensions and weights

EVR 4 - EVR 6 - EVR 8

Solder connection

Conduit hub 1)

H3

Terminal box 3)

Lc

L2

L1

L

Lc

Junction box 2)

H3

Manual stem

H5

Lc

L2

L1

L

© Danfoss | DCS (az) | 2017.12

End view

3

Connection Manual

Type

[in] [mm]

H

L1

L

opera-

tion

[in]

H

1

H

[in]

L2

W

L

[in]

1

Conduit hub 1)

H

H

2

3

[in]

[in]

4

H

5

[in]L[in]

W

Junction box 2)

L

L

2

C

[in]

[in]W[in]

Terminal box 3)

W1

max.

[in]

W

Net weight

without coil

[lbs]

EVR 43⁄8 10 No 0.55 3.07 0.39 — — 4.61 2.30 0.31 — 1.34 — 0.42

3

⁄8 10 Ye s 0.55 3.07 0.39 1.89 1.18 4.61 2.30 0.31 — 1.34 — 0.42

3

⁄8 10 No 0.55 3.07 0.39 — — 4.37 2.19 0.31 — 1.34 — 0.42

EVR 6

1

⁄2 12 Ye s 0.55 3.07 0.39 1.89 1.18 5 2.50 0.39 — 1.34 — 0.44

1

⁄2 12 No 0.55 3.07 0.39 — — 5 2.50 0.39 — 1.34 — 0.44

1

⁄2 12 Ye s 0.55 3.07 0.39 1.89 1.18 5 2.50 0.39 — 1.34 — 0.44

1

EVR 8

⁄2 12 No 0.55 3.07 0.39 — — 5 2.50 0.39 — 1.34 — 0.44

5

⁄8 16 No 0.55 3.07 0.39 — — 6.42 3.21 0.47 — 1.34 — 0.44

Cable coil 1) 1.93 — 1.81 —

DIN plug coil 2) 2.52 — 1.85 —

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

—

—

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 20

H1

H2

Min. 2 9/16

H4

H1

H2

Min. 2 9/16

W1

W1

W1

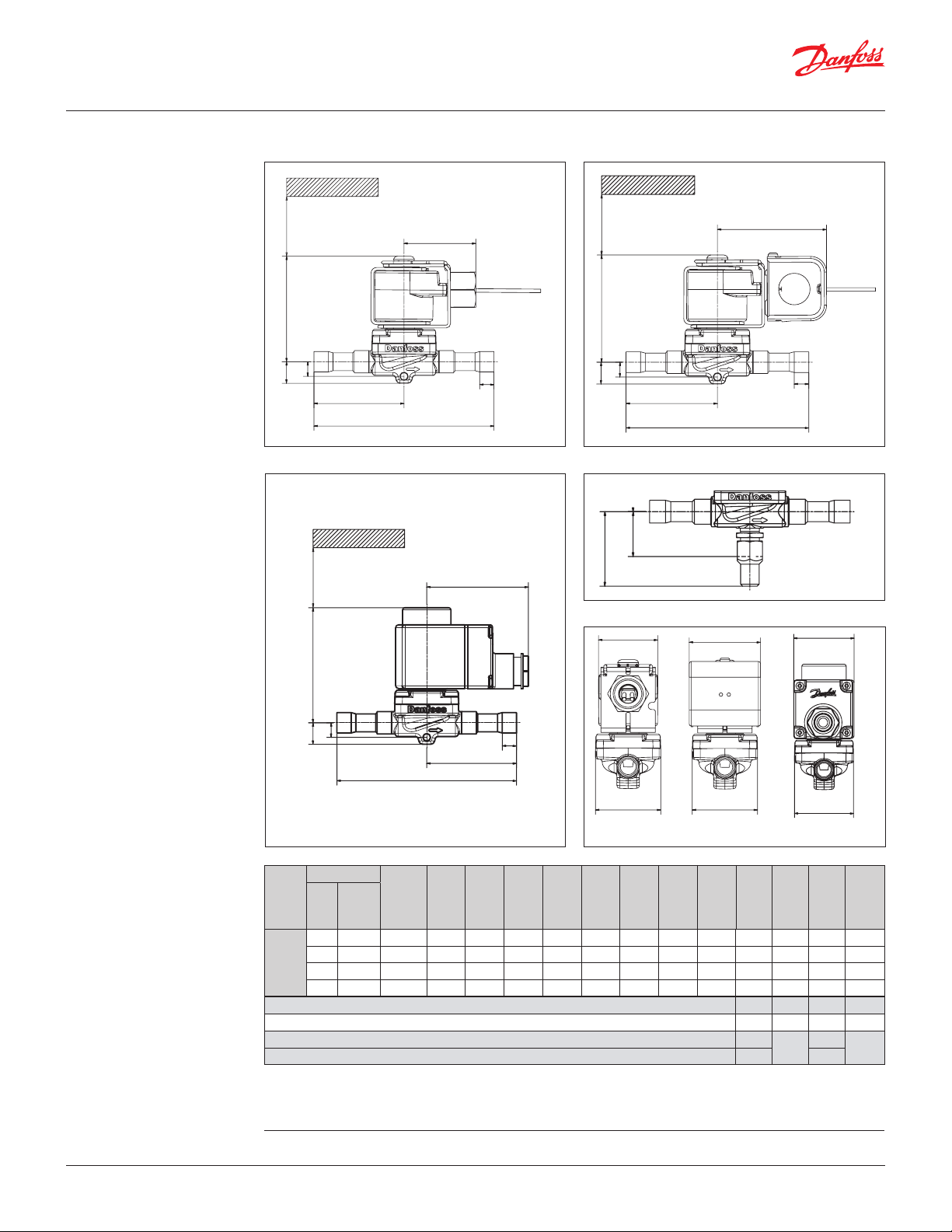

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 10

Solder connection

Conduit hub 1)

H3

Terminal box 3)

Min. 65 mm

Lc

L2

L1

L

Lc

Junction box 2)

H3

Manual stem

Lc

L2

L1

L

H5

End view

© Danfoss | DCS (az) | 2017.12

H2

H3

Type

EVR 10

H1

L

Connection

Manual

[in] [mm]

opera-

1

⁄2 12 Yes 0.59 3.23 0.39 1.89 1.14 5.04 2.52 0.39 – 1.81 – 0.86

3

⁄8 10 No 0.59 3.23 0.39 – – 4.65 2.32 – – 1.81 – 0.75

5

⁄8 16 No 0.59 3.23 0.39 – – 6.42 3.21 0.47 – 1.81 – 0.84

5

⁄8 16 Yes 0.59 3.23 0.39 1.89 1.14 6.42 3.21 0.47 – 1.81 – 0.88

tion

H

[in]

1

L2

L1

[in]

W

Conduit hub 1)

H

H

2

[in]

H

[in]

4

H

5

[in]L[in]

3

L

[in]

W

Junction box 2)

L

1

2

[in]

Terminal box 3)

L

C

[in]W[in]

W

W1

max.

[in]

weight

with-

out coil

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models. visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 21

Net

[lbs]

–

H4

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 65 mm

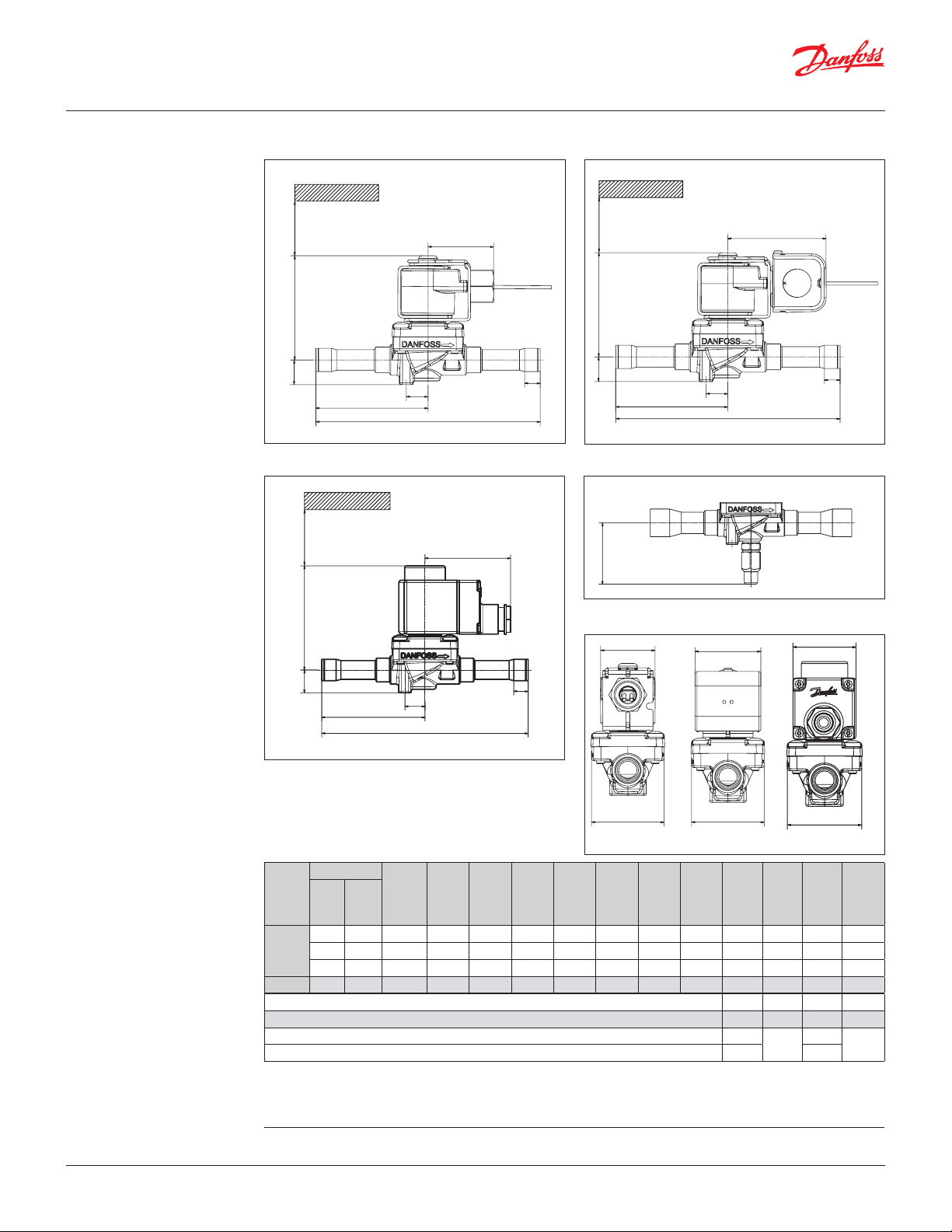

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 15 - EVR 18

Solder connection

Conduit hub 1)

Terminal box 3)

Junction box 2)

Lc

L3

L1

L

L2

L3

L1

L

Lc

L2

Manual stem

Lc

End view

W1

Type

EVR 15

L3

L1

L

Connection

Manual

[in] [mm]

5

⁄8 16 Yes 0.75 3.50 2.13 6.85 3.43 0.47 0.67 – 2.20 – 1.54

5

⁄8 16 No 0.75 3.50 – 6.85 3.43 0.47 0.67 – 2.20 – 1.54

7

⁄8 22 No 0.75 3.50 – 6.85 3.43 0.67 0.67 – 2.20 – 1.54

tion

opera-

H

[in]

1

H

[in]

2

L2

H

4

[in]L[in]

W

Conduit hub 1)

L

1

[in]

Junction box 2)

L

2

[in]

[in]

L

3

W

L

C

[in]W[in]

Terminal box 3)

W

W1

max.

[in]

Net

weight

without

coil

[lbs]

EVR 187⁄8 22 Yes 0.75 3.50 2.13 7.05 3.52 0.67 0.67 – 2.20 – 1.54

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 12 / 20 W 3) 3.15 2.68

Terminal box coil 10 W 3) 2.83

1.85

–

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 22

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

H4

Dimensions and weights

EVR 20 - EVR 22

Solder connection

Cable coil 1)

L1

Terminal box coil 3)

DIN plug coil 2)

Lc

L3

L2

L

L3

L1

L

Lc

L2

Manual stem

Lc

© Danfoss | DCS (az) | 2017.12

End view

H

[in]

2

L2

H

4

[in]L[in]

W

Conduit hub 1)

L

1

[in]

Junction box 2)

L

2

[in]

[in]

L

3

W

L

C

[in]W[in]

Terminal box 3)

–

W

W1

max.

[in]

1.85

weight

without

[lbs]

L3

L1

L

Connection

Manual

Type

EVR 20

opera-

[in] [mm]

7

⁄8 22 Yes 0.75 3.66 2.20 7.48 3.74 0.67 0.79 – 2.83 – 2.78

7

⁄8 22 No 0.75 3.66 – 7.48 3.74 0.67 0.79 – 2.83 – 2.78

tion

H

[in]

1

1 1⁄8 28 No 0.75 3.66 – 8.54 4.27 0.79 0.79 – 2.83 – 2.89

1 1⁄8 28 Yes 0.75 3.66 2.20 8.74 4.37 0.79 0.79 – 2.83 – 2.89

EVR 22

1 1⁄8 28 No 0.75 3.66 – 10.51 5.26 0.79 0.79 – 2.83 – 3.24

1 3⁄8 35 No 0.75 3.66 – 11.50 5.75 0.98 0.79 – 2.83 – 3.24

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 23

Net

coil

–

H4

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

H1

H2

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

W1

W1

Dimensions and weights

EVR 25

Solder connection

Conduit hub 1)

Terminal box 3)

Junction box 2)

Lc

L2

L1

L

L1

Lc

L2

L

Manual stem

Lc

© Danfoss | DCS (az) | 2017.12

End view

L2

L1

L

Type

Connection Manual

opera-

[in] [mm]

tion

H

[in]

W

Conduit hub 1)

H

[in]

2

H

4

[in]L[in]

[in]

1

L

L

1

2

[in]

W

Junction box 2)

L

C

[in]W[in]

Terminal box 3)

W1 max.

[in]

W

Net weight

without coil

1 1⁄8 28 Yes 1.54 5.43 2.80 10.04 5.02 0.79 – 3.23 – 5.89 *)

EVR 25

1 1⁄8 28 No 1.54 5.43 – 10.04 5.02 0.79 – 3.23 – 5.89 *)

1 3⁄8 35 Yes 1.54 5.43 2.80 11.06 5.53 0.98 – 3.23 – 6.17 *)

1 3⁄8 35 No 1.54 5.43 – 11.06 5.53 0.98 – 3.23 – 6.17 *)

*) Manual stem: +0.13 lbs

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 24

[lbs]

–

H4

H2

H1

Min. 2 9/16

H2

H1

Min. 2 9/16

W1

W1

H2

H1

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 32 - EVR 40

Solder connection

Conduit hub 1)

Terminal box 3)

Junction box 2)

Lc

L2

L1

L

Lc

L2

L1

L

Manual stem

Lc

© Danfoss | DCS (az) | 2017.12

End view

H

[in]

2

L2

H

4

[in]L[in]

W

Conduit hub 1)

L

1

[in]

Junction box 2)

L

2

[in]

W

L

C

[in]W[in]

W1 max.

–

W

Terminal box 3)

Net weight

without coil

[in]

1.85

[lbs]

L1

L

Connection Manual

Type

[in] [mm]

opera-

tion

H

[in]

1

1 3⁄8 35 Yes – 4.37 2.17 11.02 5.51 0.98 – 3.19 – 9.48

1 3⁄8 35 No 2.01 4.37 – 11.02 5.51 0.98 – 3.19 – 9.48

EVR 32

1 5⁄8 42 Yes – 4.37 2.17 11.02 5.51 1.14 – 3.19 – 9.70

1 5⁄8 42 No 2.01 4.37 – 11.02 5.51 1.14 – 3.19 – 9.70

2 1⁄8 – Ye s – 4.37 2.17 11.02 5.51 1.34 – 3.15 – 10.08

2 1⁄8 – No 2.01 4.37 – 11.02 5.51 1.34 – 3.15 – 10.08

1 5⁄8 42 Yes – 4.37 2.17 11.02 5.51 1.14 – 3.19 – 9.70

EVR 40

1 5⁄8 42 No 2.01 4.37 – 11.02 5.51 1.14 – 3.19 – 9.70

2 1⁄8 – Ye s – 4.37 2.17 11.02 5.51 1.34 – 3.15 – 10.08

2 1⁄8 – No 2.01 4.37 – 11.02 5.51 1.34 – 3.15 – 10.08

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

For 3D models. visit www.

danfoss.com/products/categories/

Terminal box: 1.10 lbs

DKRCC.PD.BB0.F2.22 | 25

–

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 65 mm

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions [mm]

and weights [kg]

EVRC 15

Solder connection

Conduit hub 1)

Lc

L3

L1

L

L2

Junction box 2)

Terminal box 3) End view

Lc

Lc

L3

L1

L

L2

W1

L3

L1

L

L2

W

Conduit hub 1)

W

Junction box 2)

W

Terminal box 3)

Connection

Type

[in] [mm]

Manual

opera-

tion

[in]

H

1

H

2

[in]L[in]

[in]

L

L

L

1

2

[in]

[in]

3

L

C

[in]W[in]

W1 max.

[in]

Net weight

without coil

[lbs]

EVRC 155⁄8 16 No 0.75 3.50 6.85 3.43 0.47 0.67 – 2.20 – 1.54

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 26

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVRC 20

Solder connection

Conduit hub 1)

Lc

L3

L1

L

L2

Junction box 2)

Terminal box 3) End view

Lc

Lc

L3

L1

L

L2

L3

L1

L

L2

W

Conduit hub 1)

W

Junction box 2)

W

Terminal box 3)

Connection

Type

[in] [mm]

Manual

opera-

tion

H

[in]

1

H

2

[in]L[in]

L

[in]

L

L

1

2

[in]

[in]

3

L

C

[in]W[in]

W1 max.

[in]

Net weight

without coil

[lbs]

EVRC 207⁄8 22 No 0.75 3.66 7.48 3.74 0.67 0.79 – 2.83 – 2.78

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 27

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

H1

H2

Min. 65 mm

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 2 - EVR 3

Flare connection

Conduit hub 1)

H3

H3

Terminal box 3)

Junction box 2)

c

c

L

L

H3

H3

L1

L1

L

L

L1

L1

L

L

c

c

L

L

End view

Lc

3

Type

EVR 2

EVR 3

H

L1

L

W

Conduit hub 1)

Junction box 2)

W

Connection

H

1

[in] [mm]

1

⁄4 6 0.55 2.87 0.35 2.95 1.48 – 1.34 – 0.40

1

⁄4 6 0.55 2.87 0.35 2.95 1.48 – 1.34 – 0.40

3

⁄8 10 0.55 2.87 0.35 2.95 1.48 – 1.34 – 0.40

[in]

H

[in]

H

2

[in]

3

[in]

L

[in]

L

L

1

[in]

W

C

[in]

W

Terminal box 3)

weight

[in]

without

[lbs]

W1 max.

Net

coil

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

–

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 28

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

Dimensions and weights

EVR 6

Flare connection

Conduit hub 1)

H3

Terminal box 3)

Min. 65 mm

Junction box 2)

Lc

H3

L1

L

L1

L

Lc

End view

Lc

H2

Type

EVR 6

H3

H1

L1

L

Connection

H

[in] [mm]

3

⁄8 10 0.55 3.03 0.39 3.23 1.61 – 1.34 – 0.46

1

⁄2 12 0.55 3.03 0.39 3.46 1.73 – 1.34 – 0.49

[in]

H

1

[in]

H

2

[in]

3

W

Conduit hub 1)

L

[in]

L

[in]

Junction box 2)

1

[in]

W

W

Terminal box 3)

Net

weight

L

W

C

W1 max.

[in]

[in]

without

coil

[lbs]

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

–

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 29

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

H1

H2

Min. 65 mm

W1

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 10

Flare connection

H3

Terminal box 3)

Junction box 2)Conduit hub 1)

Lc

H3

L1

L

L1

L

Lc

End view

W1

Lc

© Danfoss | DCS (az) | 2017.12

Type

EVR 10

H3

L1

L

Connection

H

1

[in] [mm]

1

⁄2 12 0.59 3.23 0.39 4.06 2.03 – 1.81 – 0.97

5

⁄8 16 0.59 3.23 0.39 4.33 2.17 – 1.81 – 0.99

[in]

H

[in]

H

2

[in]

3

W

Conduit hub 1)

L

[in]

L

[in]

Junction box 2)

1

[in]

W

W

Terminal box 3)

weight

L

W

C

W1 max.

[in]

[in]

without

[lbs]

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

–

1.85

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 30

Net

coil

–

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

H1

H2

Min. 65 mm

H4

W1

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 15

Flare connection

Conduit hub 1)

Lc

L3

L1

L

Junction box 2)

Terminal box 3) Manual stem

Lc

Lc

L3

L1

L

© Danfoss | DCS (az) | 2017.12

End view

W1

L3

L1

L

Type

EVR 15

W

Conduit hub 1)

Connection Manual

opera-

[in] [mm]

5

⁄8 16 Yes 0.75 3.50 2.09 5.16 2.58 0.67 – 2.20 – 1.72

5

⁄8 16 No 0.75 3.50 – 5.16 2.58 0.67 – 2.20 – 1.72

tion

H

[in]

H

[in]

2

H

4

[in]L[in]

1

[in]

L

L

1

3

[in]

W

Junction box 2)

L

C

[in]W[in]

Terminal box 3)

W1 max.

[in]

W

Net weight

without coil

Cable coil 1) 1.93 – 1.81 –

DIN plug coil

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

2)

2.52 – 1.85 –

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 31

[lbs]

–

H4

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

Min. 65 mm

H2

H1

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 15

Flange connection

Conduit hub 1)

Terminal box 3)

Junction box 2)

Lc

L3

L1

L

L3

L1

L

Lc

Manual stem

© Danfoss | DCS (az) | 2017.12

Lc

End view

L3

L1

L

W

Terminal box 3)

Net weight

without coil

Type

EVR 15

W

Conduit hub 1)

W

Junction box 2)

Manual

opera-

tion

H

[in]

1

[in]

H

H

2

[in]

L

4

[in]

[in]

L

L

1

[in]

L

3

[in]

W

[in]

W1 max.

[in]

C

Yes 0.75 3.50 2.09 4.96 1.33 0.67 – 3.15 – 1.41

No 0.75 3.50 – 4.96 1.33 0.67 – 3.15 – 1.41

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 32

[lbs]

–

H4

H1

H2

Min. 2 9/16

H1

H2

Min. 2 9/16

W1

W1

Min. 65 mm

H2

H1

W1

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Dimensions and weights

EVR 20

Flange connection

Conduit hub 1)

Lc

L3

L1

L

Junction box 2)

L1

Terminal box 3) Manual stem

Lc

L3

L

© Danfoss | DCS (az) | 2017.12

Lc

End view

L3

L1

L

W

Terminal box 3)

Net weight

without coil

Type

EVR 20

W

Conduit hub 1)

W

Junction box 2)

Manual

opera-

tion

H

[in]

1

[in]

H

H

2

[in]

L

4

[in]

[in]

L

L

1

[in]

L

3

[in]

W

[in]

W1 max.

[in]

C

Yes 0.75 3.66 2.20 6.14 1.67 0.79 – 3.78 – 2.65

No 0.75 3.66 – 6.14 1.67 0.79 – 3.78 – 2.65

Cable coil 1) 1.93 – 1.81 –

DIN plug coil 2) 2.52 – 1.85 –

Terminal box coil 10 W 3) 2.83

Terminal box coil 12 / 20 W 3) 3.15 2.68

1.85

–

Net weight of coil (approx.)

Conduit hub: 0.72 lbs

Junction box: 0.86 lbs

Terminal box: 1.10 lbs

For 3D models, visit www.danfoss.com/products/categories/

DKRCC.PD.BB0.F2.22 | 33

[lbs]

–

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Liquid

Typ e

1 2 3 4 5 6 7

Liquid capacity Qe [TR] at pressure drop across valve ∆p [psi]

R22/R407C

EVR 2 0.55 0.77 0.95 1.09 1.22 1. 34 1.44

EVR 3 0.98 1. 39 1.70 1.97 2.20 2. 41 2.60

EVR 4 2.48 3.50 4.29 4.95 5.54 6.06 6.55

EVR 6 3.24 4.58 5. 61 6.48 7.2 4 7.9 4 8.57

EVR 8 3.86 5.46 6.68 7.7 2 8.63 9. 45 10 .21

EVR 10 6. 81 9.63 11. 79 13. 61 15. 22 16.67 18. 01

EV R 15 10.48 14.83 18 .16 20 .97 23.4 4 25.68 27. 74

EVR 18 13.72 19.41 23.77 2 7.45 30.69 33. 62 36. 31

EVR 20 21. 77 30.79 37. 71 43.54 48.68 53.32 57. 60

EVR 22 24.83 3 5.11 43.00 49. 65 55. 52 60.81 65.69

EVR 25 0.27 33.4 4 61.73 71.28 79.69 8 7.3 0 94.29

EVR 32 0.46 57.13 105.49 121. 81 136 .18 149.18 161.13

EVR 40 0.65 82.62 152. 59 176.19 196.99 215. 79 233.08

R134a

EVR 2 0.51 0.72 0.88 1. 02 1.14 1. 25 1. 35

Capacities are based on:

Liquid temperature: 100.0 °F

Subcooling: 10.0 °F

Evaporating temperature:

40.0 °F

Superheat: 0 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

EVR 3 0.92 1. 30 1.59 1.84 2.05 2.25 2.43

EVR 4 2.31 3. 27 4.00 4.62 5.17 5.66 6.12

EVR 6 3.03 4.28 5.24 6.05 6.77 7. 41 8.00

EVR 8 3.60 5.10 6 .24 7.2 1 8.06 8.83 9.53

EVR 10 6.36 8.99 11. 01 12. 71 14.21 15. 57 16. 82

EV R 15 9.79 13 .85 16.96 19.58 21.89 23.98 25.90

EVR 18 12. 82 18.12 22.20 25.63 28.66 31. 39 33.91

EVR 20 20.33 28.75 35. 21 40.66 45.46 49.79 53.78

EVR 22 2 3.18 32.79 40.16 4 6. 37 51. 84 56.79 61.3 4

EVR 25 0.25 31.22 57. 64 66.56 74.42 81.52 88.05

EVR 32 0.43 53.35 98.50 113 .74 127.17 13 9. 31 15 0.47

EVR 40 0. 61 77.15 142.49 164.53 183 .95 201.51 2 17.65

Correction factors

When sizing valves, the plant capacity must be multiplied by a correction factor depending on liquid

temperature tl ahead of valve/evaporator.

When the corrected capacity is known, the selection can be made from the table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 110 120

l

© Danfoss | DCS (az) | 2017.12

Factor 1.10 1.05 1.00 0.95 0.90

DKRCC.PD.BB0.F2.22 | 34

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Liquid

(continued)

Typ e

1 2 3 4 5 6 7

Liquid capacity Qe [TR] at pressure drop across valve ∆p [psi]

R404A/R507

EVR 2 0.36 0.51 0.62 0.72 0.80 0.88 0.95

EVR 3 0.65 0.91 1.12 1.29 1.45 1. 58 1.71

EVR 4 1.6 3 2.30 2.82 3.26 3.64 3.99 4. 31

EVR 6 2.13 3.01 3.69 4.26 4.77 5.22 5.64

EVR 8 2.54 3.59 4.40 5.08 5.68 6.22 6.72

EVR 10 4.4 8 6.33 7.76 8.96 10. 01 10.97 11. 85

EV R 15 6.9 0 9.75 11.9 4 13.79 15. 42 16. 89 18 .25

EVR 18 9.03 12.77 15 .64 18 .05 20.19 2 2.11 23.88

EVR 20 14.32 20. 25 24.80 28.64 32.02 35. 07 37.8 8

EVR 22 16. 33 23.09 28.29 32 .66 36.52 40.00 43. 21

EVR 25 0 .18 21.9 9 40.60 46.88 52.42 57. 42 62.02

EVR 32 0.30 37.5 8 69.39 80 .12 89.58 98.13 105.9 9

EVR 40 0.43 54.34 10 0.37 115 .8 9 129.57 141.9 4 15 3.31

R410A

EVR 2 0.52 0.73 0.89 1.03 1.15 1. 26 1.36

Capacities are based on:

Liquid temperature: 100.0 °F

Subcooling: 10.0 °F

Evaporating temperature:

40.0 °F

Superheat: 0 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

EVR 3 0 .93 1.31 1. 61 1.86 2.08 2. 27 2.46

EVR 4 2.34 3 .31 4.05 4.68 5.23 5.73 6.19

EVR 6 3.06 4.33 5.30 6 .12 6.84 7. 50 8 .10

EVR 8

EVR 10 6.43 9.09 11.14 12. 86 14.38 15.75 17. 01

EV R 15 9.9 0 14.00 17.15 19.8 0 22 .14 24.25 26.20

EVR 18 12 .96 18.33 22.45 25.92 28.98 31.75 34.29

EVR 20

EVR 22 23.45 33.16 40.61 46.90 52.43 57.4 4 62.04

EVR 25 0.25 31.58 58.30 67. 32 75.27 82.45 89. 06

EVR 32 0.43 53.96 99.63 11 5.0 4 12 8.6 2 140 .90 152.19

EVR 40

3.64 5 .15 6 .31 7. 29 8.15 8.93 9.64

20.56 29.08 35.61 41.12 45.97 50.36 54.40

0.62 78.03 14 4. 11 166.41 186.0 5 203. 81 220.14

Correction factors

When sizing valves, the plant capacity must be multiplied by a correction factor depending on liquid

temperature tl ahead of valve/evaporator.

When the corrected capacity is known, the selection can be made from the table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

l

© Danfoss | DCS (az) | 2017.12

Factor 1.10 1. 05 1.0 0 0.95 0.90

DKRCC.PD.BB0.F2.22 | 35

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Liquid

(continued)

Capacities are based on:

Liquid temperature tl= 100 °F

Evaporating

temperature te= 40 °F

Superheat

temperature (te+ 10 °F) = 50 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

EVR 2 0. 74 1.0 5 1.29 1.49 1.67 1.82 1.97

EVR 3 1. 34 1.90 2.32 2.68 3.00 3.28 3.55

EVR 4 3.38 4.78 5.85 6.75 7.55 8.27 8.93

EVR 6 4 .42 6.25 7.65 8.84 9.88 10. 83 11 .6 9

EVR 8 5.26 7. 44 9.12 10. 53 11. 77 12. 89 13.9 3

EVR 10 9.29 13.13 16 .0 8 18.57 20.76 22 .74 24. 57

EV R 15 14.3 0 20.22 24.77 28.60 31.9 8 35.03 37. 84

EVR 18 18. 72 26.47 32.42 3 7.4 4 41.8 6 45.85 49.53

EVR 20 29.69 41.99 51. 43 59. 39 66.40 72.74 78.56

EVR 22

1 2 3 4 5 6 7

33.87 47. 89 58.66 67. 73 75.72 82.95 89.60

Liquid capacity Qe [TR] at pressure drop across valve ∆p [psi]

R290

EVR 2 0. 61 0.87 1.06 1.23 1.37 1.50 1.62

EVR 3 1.11 1.56 1.91 2.21 2.47 2.71 2.92

EVR 4 2.78 3.94 4.82 5.57 6.22 6.82 7. 36

EVR 6 3.64 5.15 6.31 7. 29 8 .15 8.92 9.64

EVR 8 4.34 6.14 7. 52 8.68 9.70 10.63 11. 4 8

EVR 10 7.65 10. 83 13.26 15.31 17.12 18.75 20.25

EV R 15 11 .79 16.67 20.42 23.58 26.36 28. 88 31.19

EVR 18 15 .43 21. 82 26.73 30.87 34. 51 3 7. 80 40.83

EVR 20 24. 48 34.62 42.4 0 48.96 54.74 59.96 64.77

EVR 22

27. 92 39.4 8 48.36 55.8 4 62.43 68.38 73.86

R600a

EVR 2 0.63 0.90 1.10 1.27 1.42 1.55 1.68

EVR 3 1.14 1. 61 1.98 2.28 2.55 2.80 3.02

EVR 4 2. 87 4.06 4.98 5.75 6.43 7.0 4 7.60

EVR 6 3.76 5.32 6.52 7.5 2 8. 41 9. 21 9.95

EVR 8 4.48 6.34 7.76 8.96 10.02 10.97 11. 85

EVR 10 7.90 11.18 13 .69 15. 81 17. 67 19. 36 2 0.91

EV R 15 12.17 17. 21 21. 08 24.35 27. 22 29.82 32. 21

EVR 18 15.9 3 22.53 27. 60 31. 87 35. 63 39.03 42.16

EVR 20 25.27 35 .74 43.78 50.55 56.52 61.91 6 6.87

EVR 22

Correction factors

When sizing valves, the plant capacity must be multiplied by a correction factor depending on liquid

temperature tl ahead of valve/evaporator.

When the corrected capacity is known, the selection can be made from the table.

28.83 40.77 49.93 57. 65 64.46 70. 61 76.26

R32

© Danfoss | DCS (az) | 2017.12

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

l

DKRCC.PD.BB0.F2.22 | 36

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

EVR 2

EVR 3

EVR 4

EVR 6

EVR 8

EVR 10

EV R 15

EVR 18

Pressure

drop

∆p [psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R22/R407C

1 0.03 0.04 0.05 0.06 0.06 0.07 0.08 0.09

2 0.04 0.05 0.07 0.08 0.09 0.10 0 .11 0 .12

3 0.05 0.06 0.08 0.10 0 .11 0 .12 0.13 0.15

1 0.05 0.07 0.09 0.10 0 .11 0 .13 0 .14 0 .15

2 0. 07 0.10 0.13 0.14 0.16 0.18 0.20 0.22

3 0.09 0.12 0 .15 0.17 0 .19 0.22 0. 24 0.26

1 0.13 0.18 0.23 0. 26 0.29 0.32 0.35 0.39

2 0.18 0.25 0. 32 0.36 0.40 0.45 0.50 0.55

3 0.21 0. 29 0.38 0.43 0.49 0.54 0.60 0.66

1 0.18 0.23 0.30 0.34 0.38 0.42 0.46 0. 51

2 0.24 0 .32 0.42 0.47 0.53 0.59 0.65 0.72

3 0.28 0.38 0.50 0.57 0.64 0.71 0.79 0.87

1 0.21 0.28 0.36 0.40 0.45 0.50 0.55 0. 61

2 0.29 0.38 0.50 0.56 0.63 0.70 0.77 0.85

3 0.33 0.46 0.60 0.68 0.76 0.85 0.94 1.04

1 0.37 0.49 0.63 0.71 0.79 0.88 0.97 1.07

2 0.50 0.68 0.88 0.99 1. 11 1.2 3 1. 36 1.5 0

3 0.59 0.81 1.0 6 1.19 1. 34 1. 49 1. 66 1.83

1 0.57 0.76 0.97 1.0 9 1. 22 1.35 1.49 1.65

2 0.77 1.04 1.35 1.52 1.70 1.8 9 2.10 2 .31

3 0 .91 1.24 1.63 1. 84 2.06 2.30 2.55 2.82

1 0.75 0.99 1.27 1.43 1.59 1.77 1.9 6 2 .15

2 1.01 1.37 1.7 7 1.99 2.23 2.48 2.75 3.03

3 1.19 1.63 2 .13 2.41 2.70 3.01 3.34 3.69

© Danfoss | DCS (az) | 2017.12

Correction factors

When liquid temperature tl ahead of the expansion valve is other than 100 °F, adjust the table capacities

by multiplying them by the appropriate correction factor found in the following table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

l

DKRCC.PD.BB0.F2.22 | 37

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

(continued)

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

Pressure

drop ∆p

[psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R22/R407C (continued)

1 1.19 1.57 2.02 2.26 2.53 2 .81 3 .10 3.42

EVR 20

EVR 22

EVR 25 3 3.09 4.23 5. 53 6.25 7.0 1 7. 82 8.67 9. 57

EVR 32 3 5.27 7. 23 9.46 10.6 8 11 .98 13. 36 14.82 16. 36

EVR 40 3 7. 63 10 .46 13.6 8 15.45 17. 33 19.32 21.43 23.66

Correction factors

When liquid temperature tl ahead of the expansion valve is other than 100 °F, adjust the table capacities

by multiplying them by the appropriate correction factor found in the following table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

2 1.61 2.17 2. 81 3.16 3.53 3.93 4.36 4.80

3 1. 89 2.58 3.38 3.82 4.28 4.77 5.30 5.85

1 1. 35 1.79 2.30 2.58 2.88 3.20 3.54 3.90

2 1. 83 2.47 3.20 3.60 4.03 4.49 4.97 5.48

3 2.15 2.95 3.86 4.35 4.88 5.45 6.04 6.67

l

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 38

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

(continued)

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

Pressure

drop ∆p

[psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R134a

1 0. 02 0.03 0.04 0.04 0.05 0.05 0.06 0.07

EVR 2

EVR 3

EVR 4

EVR 6

EVR 8

EVR 10

EV R 15

EVR 18

Correction factors

When liquid temperature tl ahead of the expansion valve is other than 100 °F, adjust the table capacities

by multiplying them by the appropriate correction factor found in the following table.

2 0. 02 0.03 0.05 0.06 0.06 0.07 0.08 0.09

3 0.03 0.04 0.06 0. 07 0.08 0.09 0.10 0 .11

1 0.03 0.05 0.06 0.07 0.08 0.09 0 .11 0 .12

2 0.04 0.06 0.09 0.10 0.12 0.13 0 .15 0 .17

3 0.05 0. 07 0 .10 0 .12 0 .14 0.16 0.18 0.20

1 0.08 0 .12 0 .16 0.18 0.21 0. 24 0.27 0.30

2 0.11 0.16 0.22 0.25 0.29 0.33 0.38 0.42

3 0.12 0 .18 0.26 0.30 0 .35 0.40 0.45 0. 51

1 0.11 0.15 0 .21 0.24 0.28 0.31 0.35 0.40

2 0.14 0 .21 0.29 0.33 0.38 0.44 0.49 0. 55

3 0.15 0.24 0.34 0.40 0.46 0.52 0.60 0.67

1 0.13 0 .18 0.25 0.29 0.33 0. 37 0.42 0.47

2 0.16 0.25 0.34 0.40 0.45 0.52 0.59 0.66

3 0.18 0.28 0.40 0.47 0 .55 0. 62 0.71 0.80

1 0.23 0.32 0.44 0. 51 0.58 0.66 0.74 0.83

2 0.29 0.43 0.60 0.70 0.80 0.91 1.0 4 1.17

3 0. 32 0.50 0.71 0.83 0.96 1.10 1.25 1.41

1 0. 35 0.50 0.68 0.78 0.89 1.01 1.14 1. 28

2 0.45 0.67 0.93 1. 08 1.24 1.41 1.59 1.7 9

3 0.49 0.77 1.10 1.28 1.4 8 1.70 1.93 2.17

1 0.46 0.65 0.89 1.02 1.17 1. 32 1.50 1.6 8

2 0.58 0.87 1.2 2 1.41 1. 62 1. 84 2.09 2.35

3 0.64 1.01 1. 44 1.6 8 1.94 2.22 2.52 2.85

© Danfoss | DCS (az) | 2017.12

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

l

DKRCC.PD.BB0.F2.22 | 39

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

(continued)

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

Pressure

drop ∆p

[psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R134a (continued)

1 0.72 1. 03 1.41 1.62 1. 85 2.10 2.37 2.66

EVR 20

EVR 22

EVR 25 3 1.67 2.63 3 .74 4.36 5.04 5.77 6.55 7.39

EVR 32 3 2.85 4.49 6.39 7. 46 8 .61 9.85 11.19 12 .63

EVR 40 3 4 .12 6.49 9.24 10.79 12 .4 6 14. 25 16 .19 18. 27

Correction factors

When liquid temperature tl ahead of the expansion valve is other than 100 °F, adjust the table

capacities by multiplying them by the appropriate correction factor found in the following

table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

2 0.93 1.39 1.93 2.23 2.56 2.92 3 .31 3.73

3 1. 02 1.6 0 2.28 2.67 3.08 3.52 4.00 4 .51

1 0.83 1.18 1. 60 1.8 5 2 .11 2.40 2.70 3.04

2 1. 06 1.5 8 2.20 2. 55 2.93 3.33 3.77 4.25

3 1.16 1.83 2 .61 3.04 3.51 4.02 4.56 5.15

l

© Danfoss | DCS (az) | 2017.12

DKRCC.PD.BB0.F2.22 | 40

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

(continued)

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

EVR 2

EVR 3

EVR 4

EVR 6

EVR 8

EVR 10

EV R 15

EVR 18

Pressure

drop ∆p

[psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R404A/R507

1 0.02 0.03 0.04 0.05 0.05 0.06 0 .07 0.07

2 0. 03 0.04 0.06 0.06 0.07 0.08 0.09 0.10

3 0.04 0.05 0.07 0.08 0.09 0.10 0 .11 0 .13

1 0.04 0.06 0.07 0.08 0.09 0 .11 0 .12 0 .13

2 0.06 0.08 0 .10 0 .12 0 .13 0.15 0 .17 0.19

3 0.07 0.09 0 .12 0.14 0.16 0 .18 0.20 0.23

1 0.10 0.14 0.18 0 .21 0. 24 0.27 0.30 0.33

2 0.14 0.19 0.26 0.29 0.33 0.37 0.42 0. 47

3 0.16 0.23 0 .31 0.35 0.40 0.45 0 .51 0.57

1 0.13 0 .18 0.24 0.27 0. 31 0.35 0.39 0.44

2 0.18 0.25 0.34 0.38 0.43 0.49 0 .55 0. 61

3 0.22 0.30 0.41 0.46 0.53 0.60 0.67 0.75

1 0.16 0.22 0.29 0.33 0.37 0 .42 0 .47 0.52

2 0.22 0.30 0.40 0.46 0.52 0.58 0.65 0.73

3 0.26 0.36 0.48 0 .55 0.63 0.71 0.80 0.89

1 0.28 0.38 0.51 0.58 0.65 0.73 0. 82 0.92

2 0.38 0.53 0.71 0.80 0.91 1.03 1.15 1.29

3 0.45 0.63 0.85 0.97 1.11 1.2 5 1. 40 1.57

1 0.43 0.59 0.78 0.89 1.0 0 1.13 1.27 1.41

2 0.59 0. 82 1.0 9 1. 24 1. 41 1.5 8 1.78 1.9 8

3 0.70 0.98 1.31 1. 50 1.71 1. 93 2.16 2.42

1 0.56 0.77 1. 02 1.16 1.31 1. 48 1.6 6 1. 85

2 0.77 1. 07 1.42 1. 62 1.8 4 2. 07 2.33 2.60

3 0 .91 1. 28 1.7 2 1.97 2.23 2.52 2.83 3.16

© Danfoss | DCS (az) | 2017.12

Correction factors

When liquid temperature tl ahead of the expansion valve is other than 100 °F, adjust the table capacities

by multiplying them by the appropriate correction factor found in the following table.

Correction factors based on liquid temperature t

tl [°F] 80 90 100 11 0 120

Factor 1.10 1. 05 1.0 0 0.95 0.90

l

DKRCC.PD.BB0.F2.22 | 41

Data sheet | Solenoid valve, types EVR 2 - EVR 40 Version 2

Extended capacity

Suction

(continued)

The table values refer to the

evaporator capacity and

are given as a function of

evaporating temperature te

and pressure drop ∆p across

valve.

Capacities are based on:

Liquid temperature tl= 100 °F

Subcooling= 0 °F

Superheat = 7 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Typ e

Pressure

drop ∆p

[psi]

-40 -2 0 0 10 20 30 40 50

Suction vapour capacity Qe [TR] at evaporating temperature te [°F]

R404A/R507 (continued)

1 0.90 1.2 2 1. 62 1.8 4 2.08 2.34 2.63 2.93

EVR 20

EVR 22

EVR 25 3 2.37 3.32 4.46 5.10 5.80 6.55 7. 35 8.22

EVR 32 3 4.04 5.68 7. 62 8.72 9.91 11.19 12.5 7 14.0 4