Page 1

Installation Guide

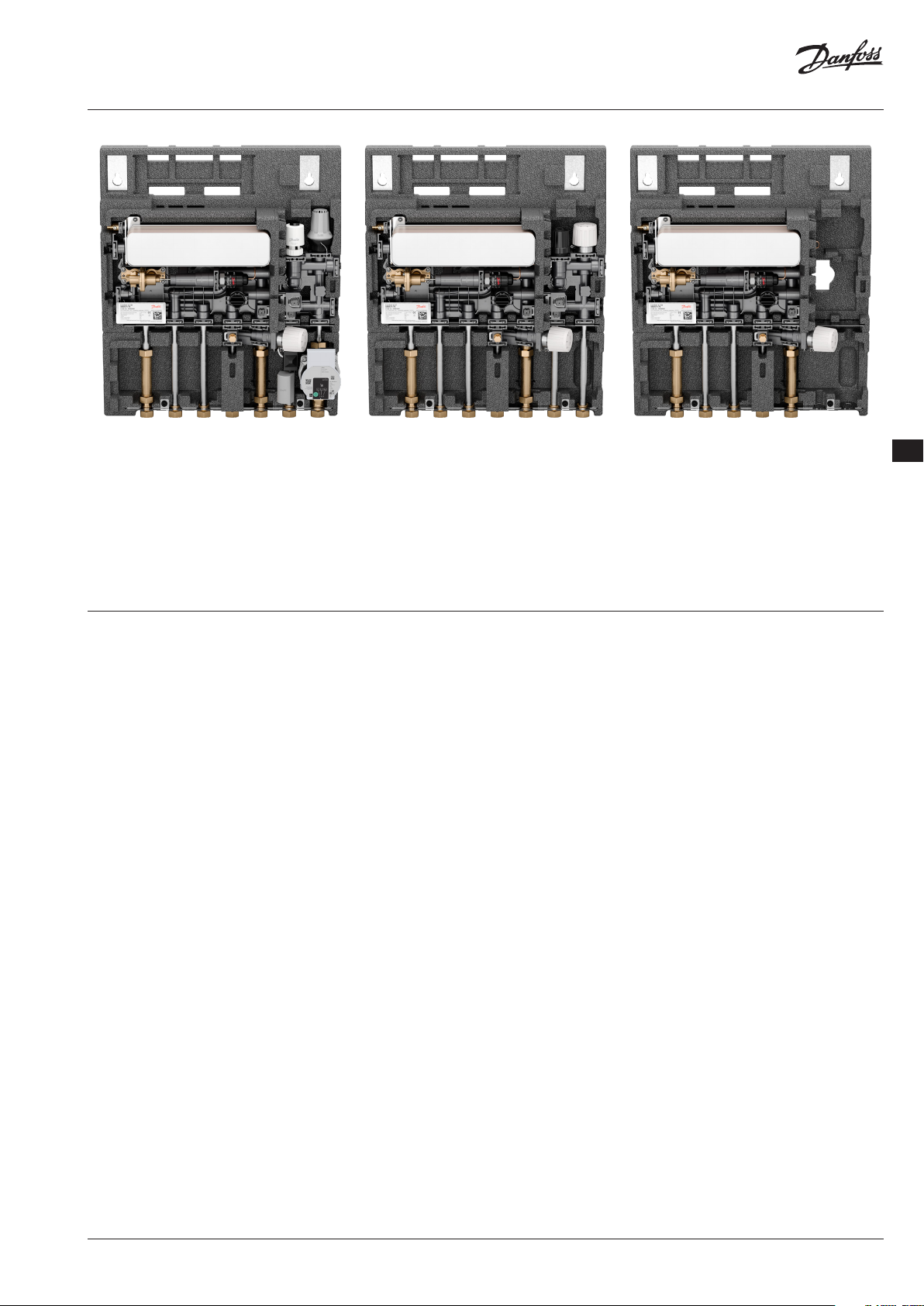

EvoFlat 4.0

Flat Stations for apartments, single- and multi-family houses

Complete heat-insulated flat stations for direct heating and instantaneous domestic hot water

EN

DE

FR

Page 2

Page 3

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

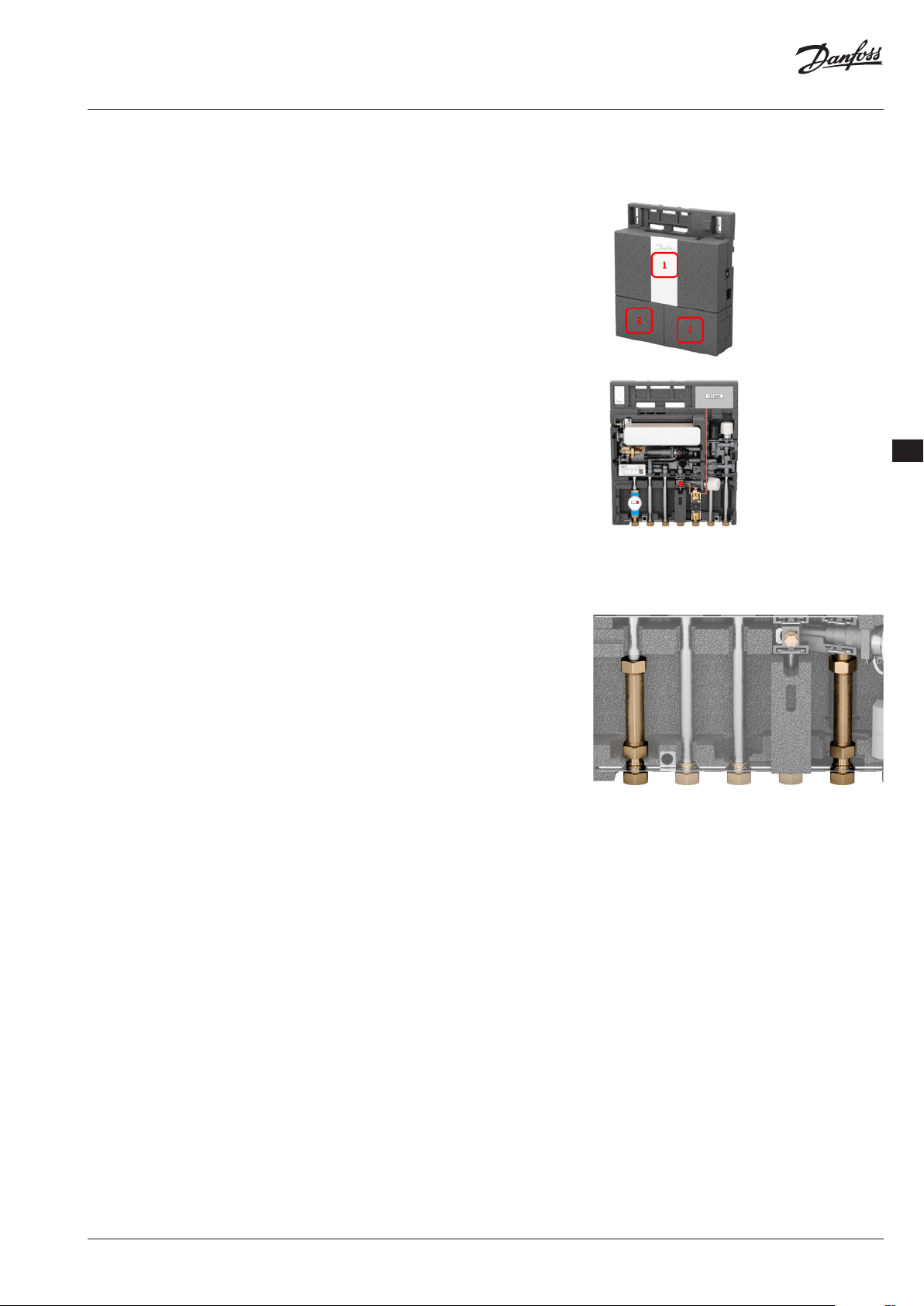

EvoFlat 4.0 M EvoFlat 4.0 F EvoFlat 4.0 W

1. CONTENT

2. SAFETY NOTES ...............................................................................4

2.1 Safety Notes — general ......................................................................................4

3. MOUNTING ..................................................................................5

3.1 Mounting ....................................................................................................5

3.2 Start-up ......................................................................................................6

3.3 Electrical connections ........................................................................................6

4. MAIN COMPONENTS & DIMENSIONAL SKETCHES .............................................7

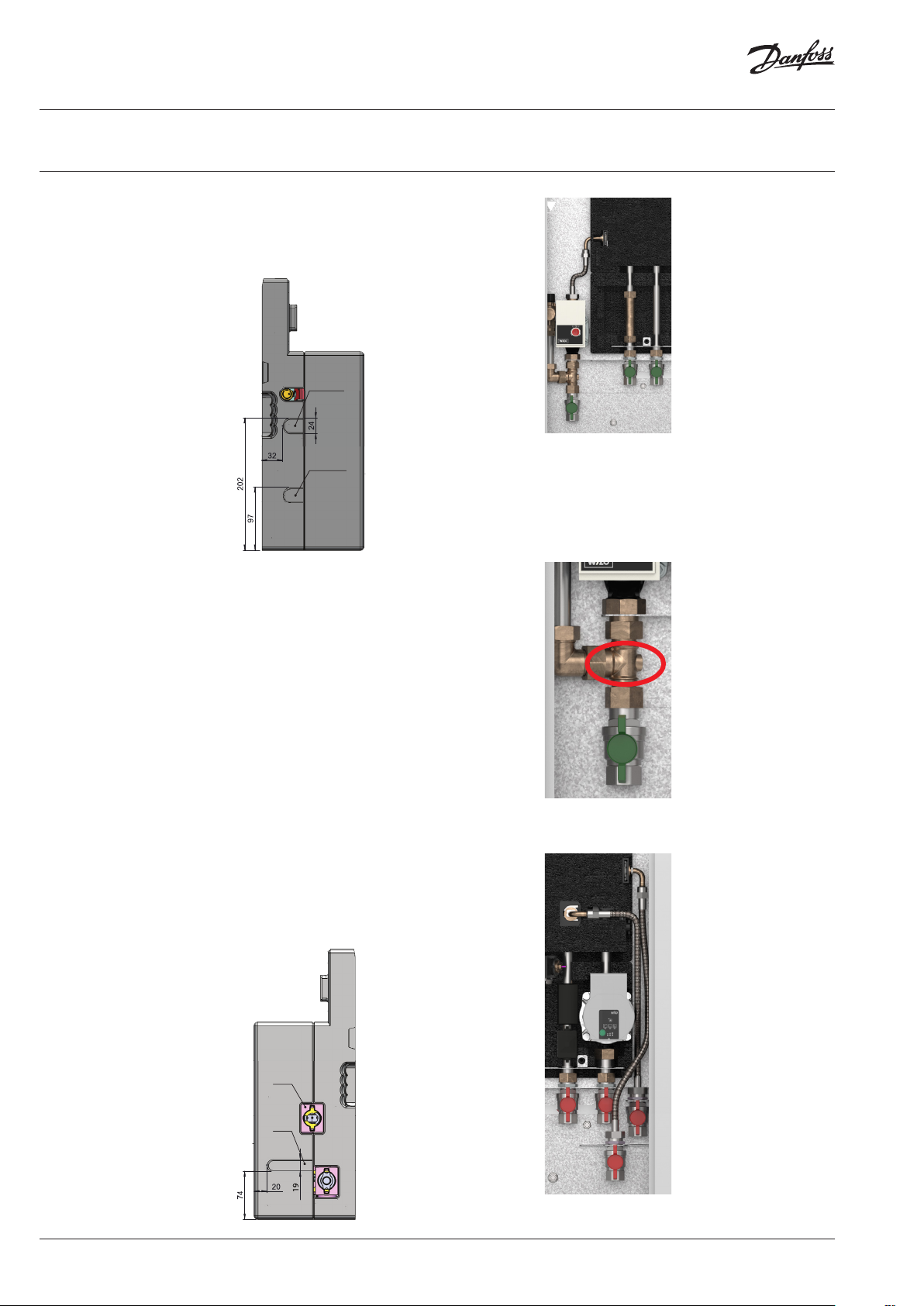

4.1 EvoFlat 4.0 M. Construction and Diagrams. ....................................................................7

4.2 EvoFlat 4.0 F. Construction and Diagrams. .....................................................................8

4.3 EvoFlat 4.0 W. Construction and Diagrams. ....................................................................9

EN

5. CONTROLS .................................................................................10

6. CIRCULATION ...............................................................................12

7. MAINTENANCE ..............................................................................13

8. TROUBLESHOOTING ........................................................................14

8.1 Troubleshooting in general ..................................................................................14

8.2 Troubleshooting: DHW ......................................................................................14

8.3 Troubleshooting HE .........................................................................................15

8.4 Disposal .....................................................................................................15

9. DECLARATION ..............................................................................16

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 3

Page 4

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

2. SAFETY NOTES

2.1 Safety Notes — general

The following instructions refer to the standard design of flat stations.

It is not allowed to work with any kind of tool on the composite block — however only

when working HTC and circulation set — for mounting these.

This operating manual should be read carefully before installation and start-up of the

flat station. The manufacturer accepts no liability for damage or faults that result from

non-compliance with the operating manual. Please read and follow all the instructions

carefully to prevent accidents, injury and damage to property.

Assembly, start-up and maintenance work must be performed by qualified and au

thorized personnel only. Please comply with the instructions issued by the system

manufacturer or system operator.

Corrosion protection.

All pipes and components are made of stainless steel and brass.

The maximum chloride compounds of the flow medium should not be higher than

150 mg/l. The risk of equipment corrosion increases considerably if the recommended

level of permissible chloride compounds is exceeded.

Energy source.

The flat station is designed to be connected to decentralized heating installations with

various energy sources, such as district heating, central boiler (gas, oil, biomass, etc.),

solar, heat pump or a combination between them if the operating conditions allow it.

Application.

The flat station is designed to be connected to the house installation in a frost-free

room, where the temperature does not exceed 50 °C and the humidity does not exceed

80 %. Do not cover or wall up the flat station or in any other way block the entrance

to the station.

Choice of material.

Choice of materials always in compliance with local legislation.

Safety valve(s).

We recommend mounting of safety valve(s), however, always in compliance with local

regulations.

Noise level. ≤ 29,8 dB

Connection.

The flat station must be equipped with features that ensure that the flat station can be

separated from all energy sources (also power supply).

Emergency.

In case of danger or accidents — fire, leaks or other dangerous circumstances — interrupt

all energy sources to the station if possible, and seek expert help.

In case of discoloured or bad-smelling domestic hot water, close all shut-off valves on

the flat station, inform the operating personnel and call for expert help immediately.

Storage.

Any storage of the flat station which may be necessary prior to installation should be in

conditions which are dry and heated.

Reach.

All products of the EvoFlat series comply with the provisions of the REACH regulation.

We are therefore obliged to inform our customers about the presence of substances according to the SVHC candidate list, if they are present. We hereby inform you: This product

contains brass parts containing lead (CAS 7439-92-1) in a concentration above 1% (w/w).

Potential equalization / grounding.

Equipotential bonding is understood as all measures for eliminating electrical potential

differences (contact voltages), which can occur between eg two pipelines. Equipotential

bonding is an important measure for protection against electric shock. Equipotential

bonding reduces corrosion in the heat exchanger, instantaneous water heaters, district

heating stations and plumbing installations. Equipotential bonding should be in ac-

cordance with the provisions 60364-4-41: 2007 and IEC 60364-5-54: 2011.

Binding point is marked with a grounding symbol on the bottom right corner of the

mounting plate and there is a hole in the mounting plate and a label with grounding

symbol.

Disposal.

The station consists of materials that must not be disposed of with household waste.

Disconnect the entire energy supply and disassemble the product for disassembly and

dispose of it in accordance with local regulations.

Authorized personnel only

Assembly, start-up and maintenance work must

be performed by qualified and authorized personnel only.

-

Please observe instructions carefully

To avoid injury to persons and damage to the

device, it is absolutely necessary to read and observe these instructions carefully.

Warning of high pressure and temperature

Be aware of the installation’s permissible system

pressure and temperature.

The maximum temperature of the flow medium

in the flat station is 95 °C.

The maximum operating pressure of the flat station is 10 bar.

The risk of persons being injured and equipment damaged increases considerably if the recommended permissible operating parameters

are exceeded.

The flat station installation must be equipped

with safety.

Warning of hot surface

The flat station has got hot surfaces, which can

cause skin burns.

Please be extremely cautious in close proximity to

the flat station.

Power failure can result in the motor valves being

stuck in open position. The surfaces of the flat station can get hot, which can cause skin burns. The

ball valves on district heating supply and return

should be closed.

Warning of transport damage

Before flat station installation, please make sure

that the flat station has not been damaged during transport.

IMPORTANT — Tightening of connections

Due to vibrations during transport all flange connections, screw joints and electrical clamp and

screw connections must be checked and tightened before water is added to the system. After

water has been added to the system and the system has been put into operation, re-tighten ALL

connections. Check that all hairpins in click connections are completely pushed in.

Please notice

Interventions and reworking of our components

lead to the loss of warranty.

4 | © Danfoss | DCS-SGDPT/PL | 2022.01

AN40274706699301-010101

Page 5

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

3. MOUNTING

3.1 Mounting

Installation must be in compliance with local standards and regulations.

Heat Source (HS) — In the following sections, HS refers to the heat source which supplies the flat stations. A variety of energy sources, such as oil, gas or solar power, could

be used as the primary supply to Danfoss substations. For the sake of simplicity, HS

can be taken to mean the primary supply.

Mounting:

Adequate space

Please allow adequate space around the flat station for mounting and maintenance

purposes.

Orientation

The station must be mounted so that components, keyholes and labels are placed

correctly. If you wish to mount the station differently please contact your supplier.

Drillings

Where substations are to be wall-mounted, drillings are provided in the back mounting plate.

Labelling

Each connection on the substation is labelled.

Before installation:

Clean and rinse

Prior to installation, all substation pipes and connections should be cleaned and rinsed.

Thightening

Due to vibration during transport, all substation connections must be checked and

tightened before installation. Check that all hairpins in click connections are completely

pushed in.

Authorized personnel only

Assembly, start-up and maintenance work must

be performed by qualified and authorized personnel only.

EN

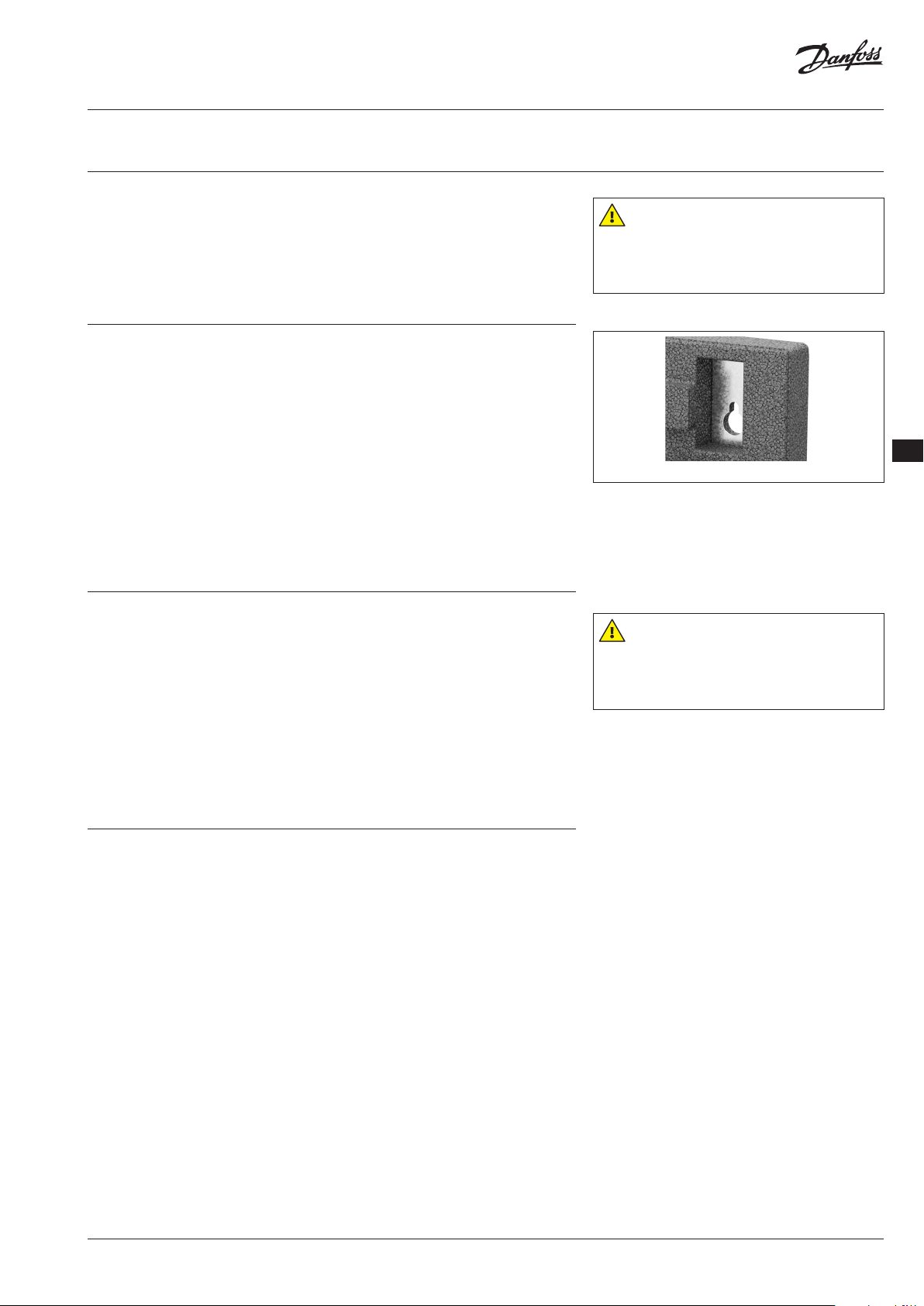

Keyhole for mounting.

Please notice

Use of packaging types other than that with which

the device is delivered will void the warranty.

Unused connections

Unused connections and shut-off valves must be sealed with a plug.

Should the plugs require removal, this must only be done by an authorized service

technician.

Installation:

Strainer

If a strainer is supplied with the station it must be fitted according to schematic diagram.

Please note that the strainer may be supplied loose.

Connections

Connection to the household installation and district heating pipes connections must

be made using threaded, flanged or welded connections.

The internal connections of the flat station are made by click-fit connections.

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 5

Page 6

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

3.2 Start-up

Start-up, Direct heating

The shut-off valves should b e opened and the unit observed as it enters service. Visual

checking should confirm temperatures, pressures, acceptable thermal expansion and

absence of leakage.

If the heat exchanger operates in accordance with design, it can be put to regular use.

After water has been added to the system and the system has been put into operation,

re-tighten ALL connec tions. Check that all hairpins in click connections are completely

pushed in.

Start-up, Heating with mixing loop (on the EvoFlat 4.0 M version)

Start-up:

1: Pump speed

Set the pump to its highest speed of rotation before start-up. On radiator systems,

the selector switch is normally set in “Variable curve / Proportional curve” setting, in

“max. pos.”. For floor heating systems, the selector switch is normally set in “Constant

curve” setting, in “max. pos.”.

2: Start pump

Start the pump and heat through the system.

3: Open shut-off valves

The shut-off valves should then be opened and the unit observed as it enters service.

Visual checking should confirm temperatures, pressures, acceptable thermal expansion and absence of leakage.

If the system operates in accordance with design, it can be put to regular use, — always

taking into account the conditions in the building.

4: Vent system

Switch off the pump and vent the installation after the system has been warmed up.

Please note that some pump types feature a built-in venting function. For others the

installation can be vented by using a vent valve in the flat station or on the radiators,

or, if appropriate, the air valve at the highest point of the system — For additional

information, please refers to the enclosed pump and manual.

Re-thighten connections

After water has been added to the system and

the system has been put into operation, re-tighten ALL connections.

Check that all hairpins in click connections are

completely pushed in.

5: Adjust pump speed

Set the pump to the lowest possible position, depending on the heating requirement

for the building — tak ing into account aspec ts such as cooling and power consumption.

If the heating requirement increases the pump setting can be changed by means

of the selector switch. Please refer to the enclosed instruction manual for detailed

information about setting ranges.

In the summer, you can switch off the power to the pump at the mains if you want to

save electricit y by not heating your home. It should be ensured that no inappropriate

hydraulic situation will occur, when the power to your pump is turned off.

For start-up and venting — see above and the enclosed pump manual.

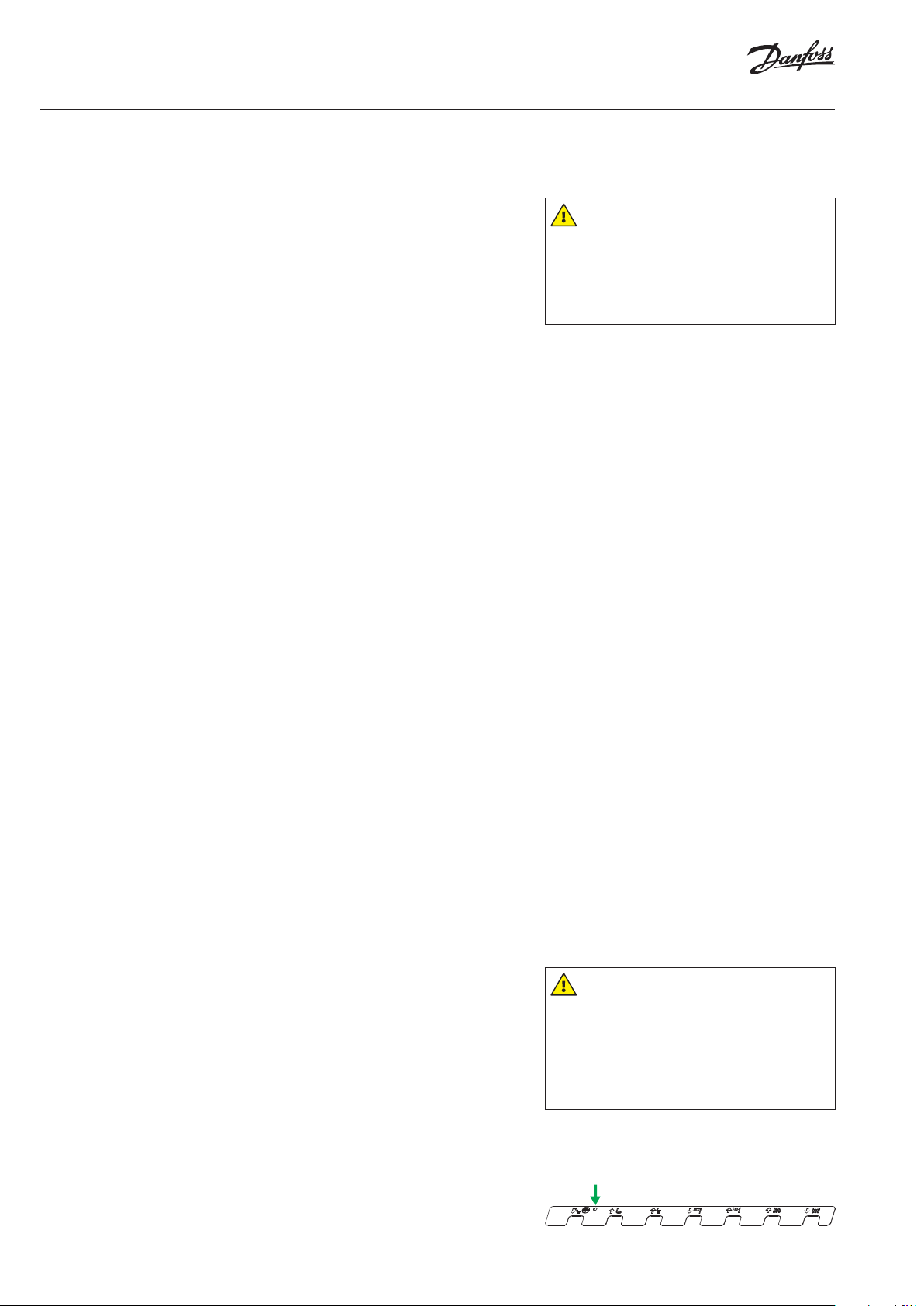

3.3 Electrical connections

Before making electrical connections, please note the following:

Safety notes

Please read the relevant parts of the safety notes.

Point with picture of how the earth connection is to be mounted (the rail).

230 V

The flat station must be connected to 230 V AC and earth. Only valid for the M version

or F version when using room thermostat and TWA (as an option).

Disconnection

The substation must be electrically connected so that it can be disconnected for repairs.

Grounding / potential compensation

The station should be connected to a grounding point.

Authorized electrician

Electrical connections must be made by an authorized electrician only.

Local standards

Electrical connections must be made in accordance with current regulations and local standards.

6 | © Danfoss | DCS-SGDPT/PL | 2022.01

AN40274706699301-010101

Page 7

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

4. MAIN COMPONENTS & DIMENSIONAL SKETCHES

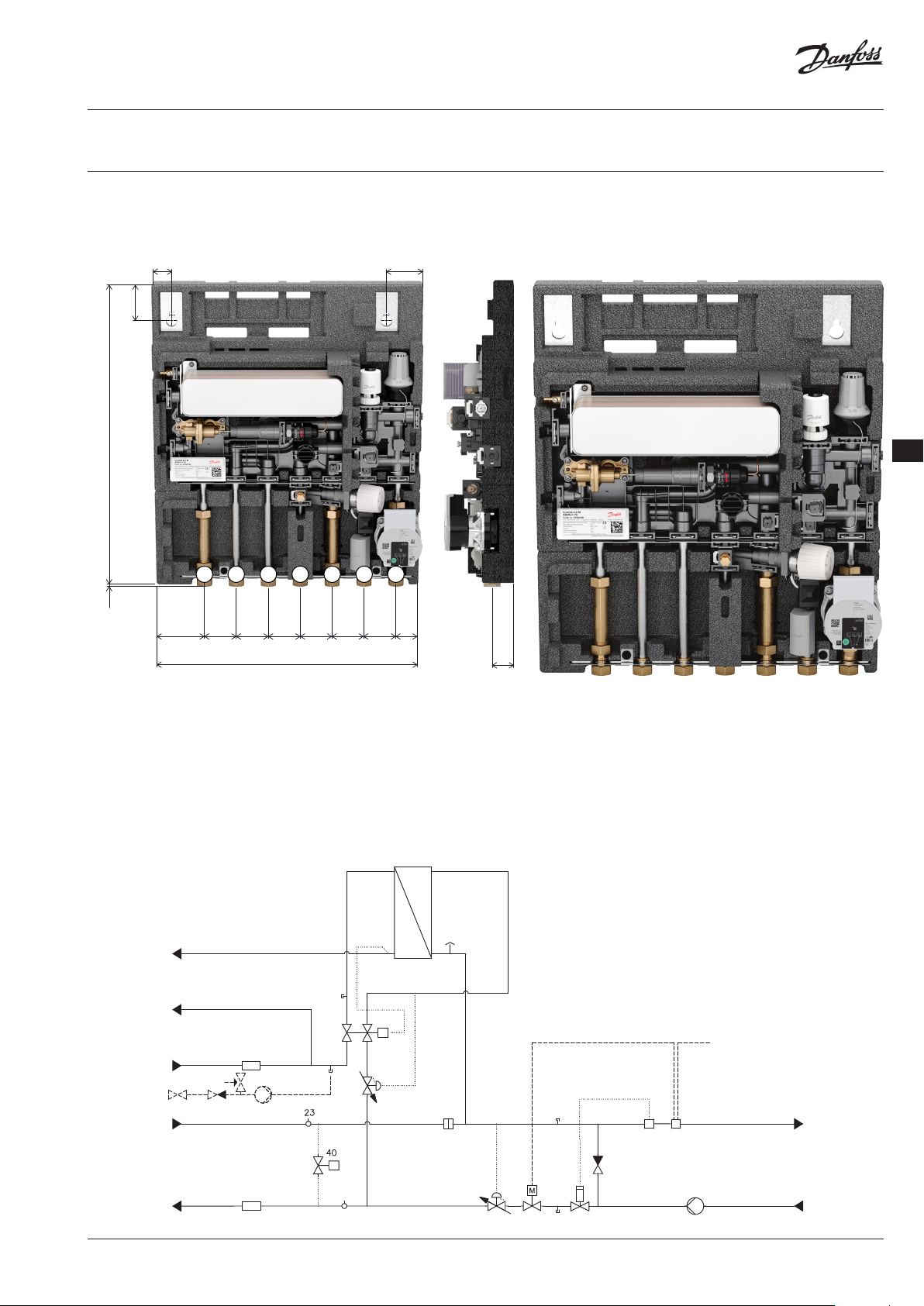

4.1 EvoFlat 4.0 M. Construction and Diagrams.

36 69

64

613

8

1 2 3 4 5 6 7

65 65 65 65 65 65 4496

530

Connections:

1. Domestic cold water (DCW) inlet

2. Domestic hot water (DHW)

3. Domestic cold water (DCW) outlet

4. District heating (DH) supply

5. District heating (DH) return

6. Heating (HE) supply

7. Heating (HE) return

Options:

• HTC (183H0501)

• PWH- Circulation set (183H0500)

• Actuator TWA-Q NO 230V (082F1601)

DHW

DCW

DCW

DHW-C

DH

Supply

59

12

97

17

52A

30

2

52

4

EN

4 38

33

5

40

12

59 24

10

54

44

2 Plate heat exchanger DHW

4 Differential pressure controller

5 Stainer

6 Check valve

7 Ball valve

9 DHW circulation set with safety valve

(Wilo yonos Para Z)

10 Heating pump mixing cirquit

12 Safety valve

2

17

33

38

33

4

33

5

17 Air vent

23 Sensor pocket

24 Fitting piece for energy meter 3/4” × 110 mm

29 Sensor

30 Valve HE

33 Plug for heating cirquit

38 Hot Water Controller

40 Summer by-pass

52 Zone valve

54 Safety thermostat with TWA

59 Fitting piece for water meter 3/4” × 110 mm

~ 230 V

HE

54

Supply

DH

Return

© Danfoss | DCS-SGDPT | 2022.01

24

6

23

4 52 33 30

29

10

HE

Return

AN40274706699301-010101 | 7

Page 8

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

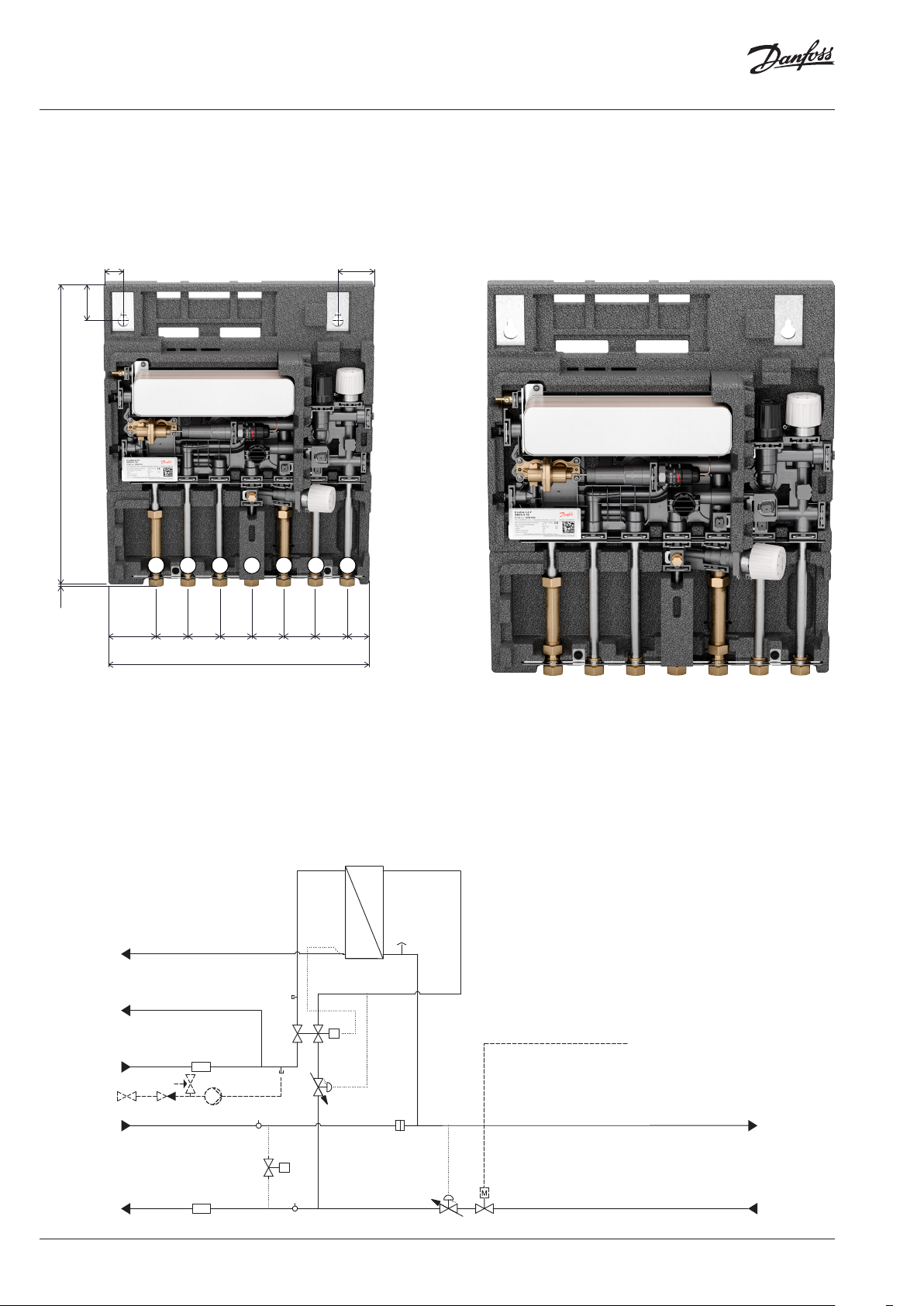

4.2 EvoFlat 4.0 F. Construction and Diagrams.

36 69

64

52

613

1 2 3 4 5 6 7

8

65 65 65 65 65 65 4496

Connections:

1. Domestic cold water (DCW) inlet

2. Domestic hot water (DHW)

3. Domestic cold water (DCW) outlet

4. District heating (DH) supply

5. District heating (DH) return

6. Heating (HE) supply

7. Heating (HE) return

Options:

• PWH- Circulation set (183H0500)

• Actuator TWA-Q NO 230V (082F1601)

DHW

530

2

52A

4

4 38

5

40

59 24

2 Plate heat exchanger DHW

4 Differential pressure controller

5 Stainer

7 Ball valve

9 DHW circulation set with safety valve

12 Safety valve

17 Air vent

23 Sensor pocket

24 Fitting piece for energy meter 3/4” × 110 mm

2

17

38 Hot Water Controller

40 Summer By-pass

52 Zone valve

52A TWA Q-NO 230V for zone valve (optional)

59 Fitting piece for water meter 3/4” × 110 mm

DCW

59

DCW

12

DHW-C

DH

Supply

DH

Return

8 | © Danfoss | DCS-SGDPT/PL | 2022.01

7

9

24

33

38

33

4

23

5

40

23

52A

524

~ 230 V

HE

Supply

HE

Return

AN40274706699301-010101

Page 9

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

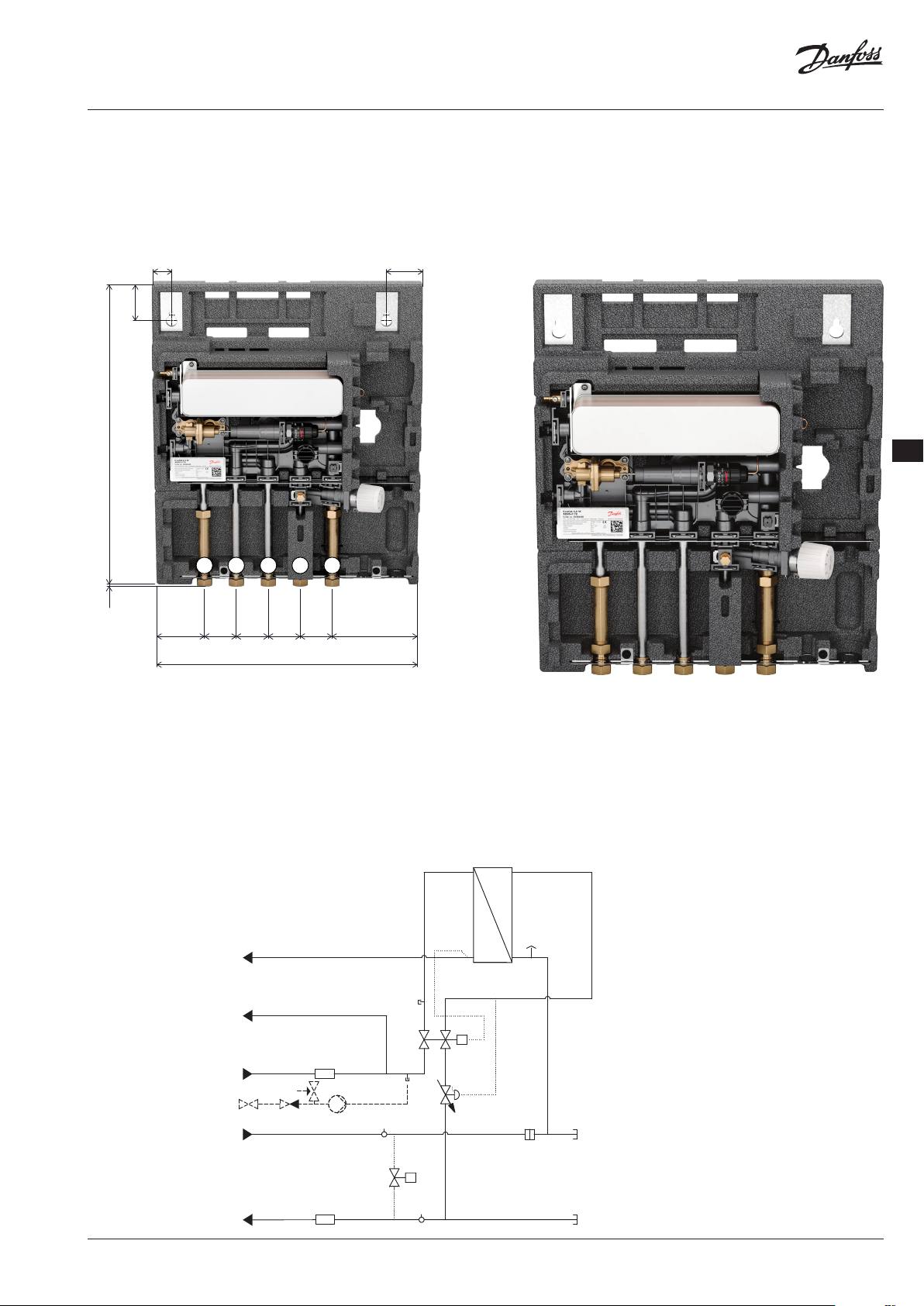

4.3 EvoFlat 4.0 W. Construction and Diagrams.

36 69

64

17

613

1 2 3 4 5

8

65 65 65 65 17496

530

Connections:

1. Domestic cold water (DCW) inlet

2. Domestic hot water (DHW)

3. Domestic cold water (DCW) outlet

4. Heating (HE) supply

5. Heating (HE) return

2

EN

4 38

33

5

40

59 24

2 Plate heat exchanger DHW

4 Differential pressure controller

5 Stainer

7 Ball valve

9 DHW circulation set with safety valve

12 Safety valve

17 Air vent

23 Sensor pocket

24 Fitting piece for energy meter 3/4” × 110 mm

2

38 Hot Water Controller

40 Summer By-pass

59 Fitting piece for water meter 3/4” × 110 mm

DHW

DCW

DCW

DHW-C

DH

Supply

DH

Return

© Danfoss | DCS-SGDPT | 2022.01

17

33

59

33

9127

23

40

24

38

4

33

5

23

33

AN40274706699301-010101 | 9

Page 10

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

5. CONTROLS

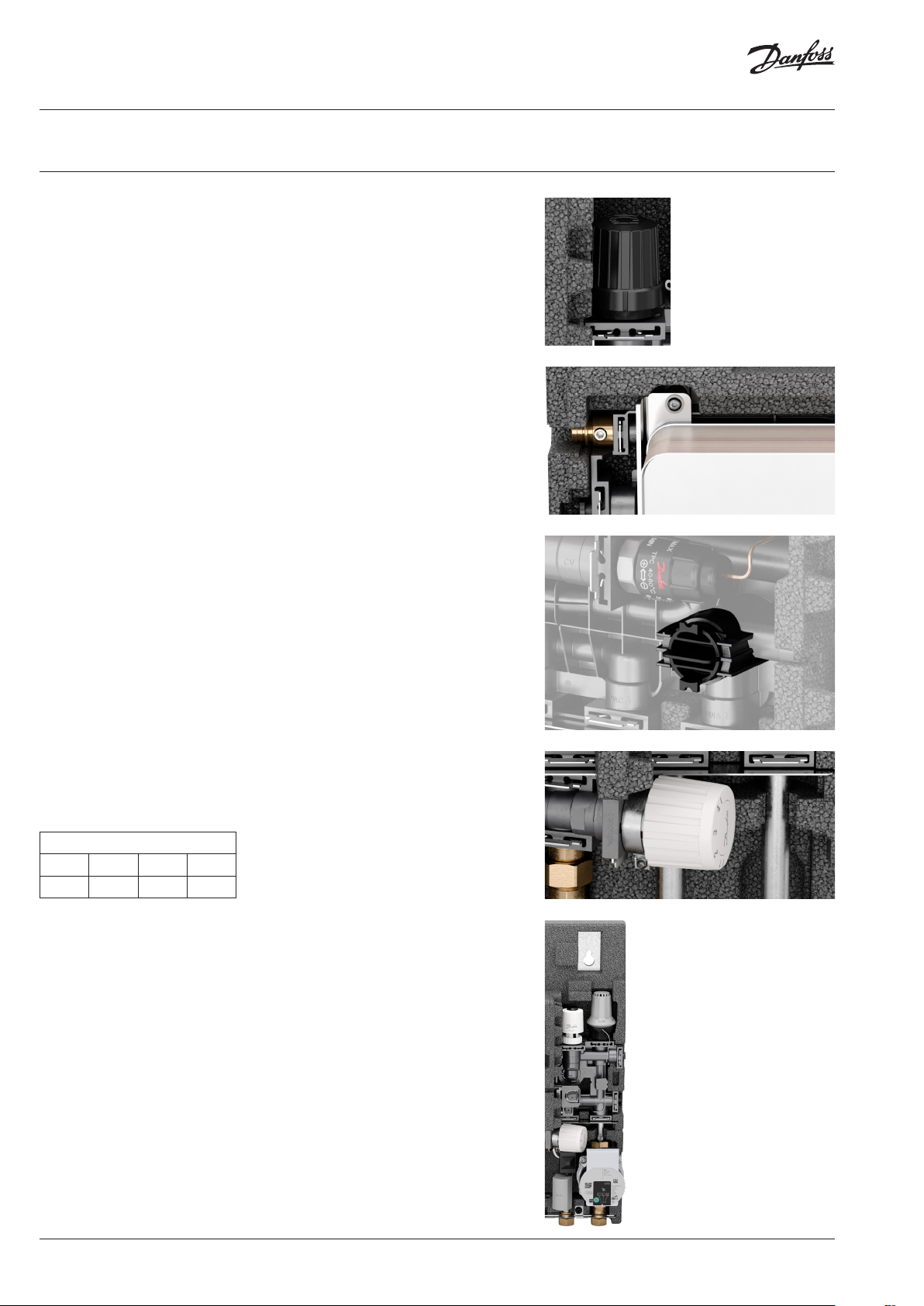

5.1 Zone valve

Heating block contains a zone valve. For F version without TWA. If a plastic cap is to

be fitted, the zone valve is closed.

5.2 Air vent

The station should be vented during start up.

5.3 Strainer

Strainers should be cleaned regularly by authorized personnel. The frequency of

cleaning would depend on operating conditions.

Note! Do not use tool to open the filter.

5.4 Summer bypass

The bypass thermostat is designed to keep the supply line warm.

Setting range: from 10 °C to 50 °C.

Scale setting (indicative).

Factory setting 3.

Scale setting

1 2 3 4

20 30 40 45

5.5

Mixing loop

The mixing loop creates a suitable temperature level e.g. for floor heating.

Setting range: Can be done by the FTC termostat.

FTC control

The FTC controls the mixing loop HE supply temperature.

Setting range from 15 °C to 50 °C.

The setting values may vary depending on the operating conditions.

It is important to set the supply temperature to the radiators as low possible.

NB! For houses that are heated exclusively with floor heating.

ALWAYS refer to the instructions from the floor supplier.

Factory setting: 50 °C.

Safety thermostat

The safety thermostat will shut the zone valve if the HE supply temperature is

above 55 °C.

If the temperature is lower, the safety thermostat will open the zone valve.

10 | © Danfoss | DCS-SGDPT/PL | 2022.01

AN40274706699301-010101

Page 11

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

5.6 Mount EPP cover

To install heat and water meters, the insulation must be removed in the order 1, 2 and

3 and reassembled in the reverse order.

After both meters have been installed, the wiring of the heat meter to the calculator

must be laid (clamped) in the cable bar provided for this purpose. It is important to

ensure that no cables cross the insulating bars. Otherwise, there will be an uncontrolled

leakage of heat and the room may heat up unnecessarily.

EN

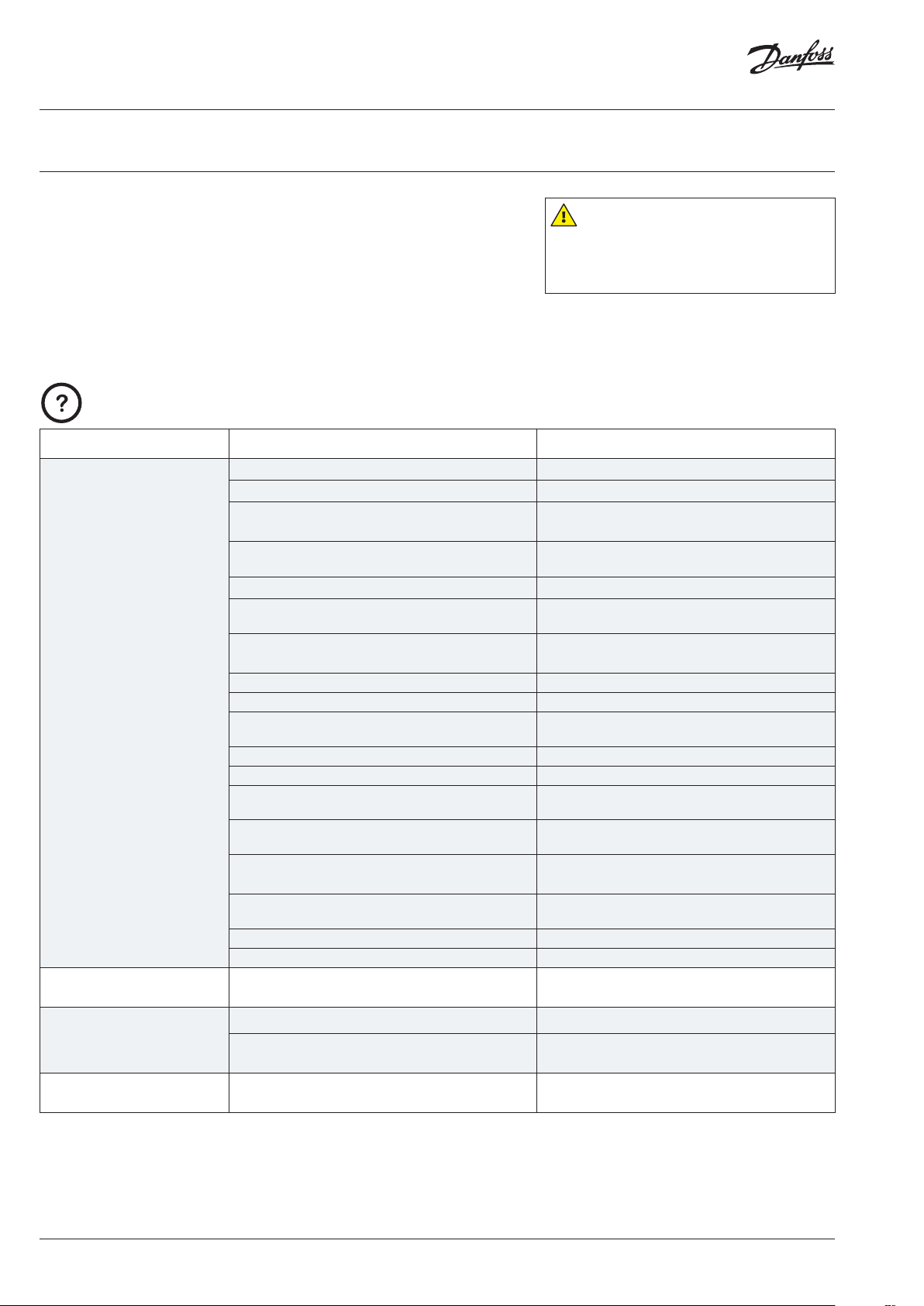

5.7 Fitting piece

The flatstation is equipped with a steel fit ting piece for energy meter and braz z fitting

piece for cold wather meter.

Mounting of energy meters:

1: Close ball valves

Close the ball valves on DH Supply and DH Return, if there is water on the system.

2: Loosen nuts (see pictures)

Loosen the nuts on the fitting piece.

3: Remove fitting piece

Remove the fitting piece and replace it with the energy meter. Do not forget the

gaskets.

4: Tighten connections

After mounting of the energy meter remember to check and tighten all threaded

connections.

5: Torques for connections at the Flatstation

Union nuts G 3/4” 45 Nm

Union nuts G 1” 45 Nm

Screw connections for fitting pieces 35 Nm

Piping of the heating circuit distributor 30 Nm

Note: When installing a heat and / or water meter, the respective manufacturer’s instructions must be observed.

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 11

Page 12

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

6. CIRCULATION

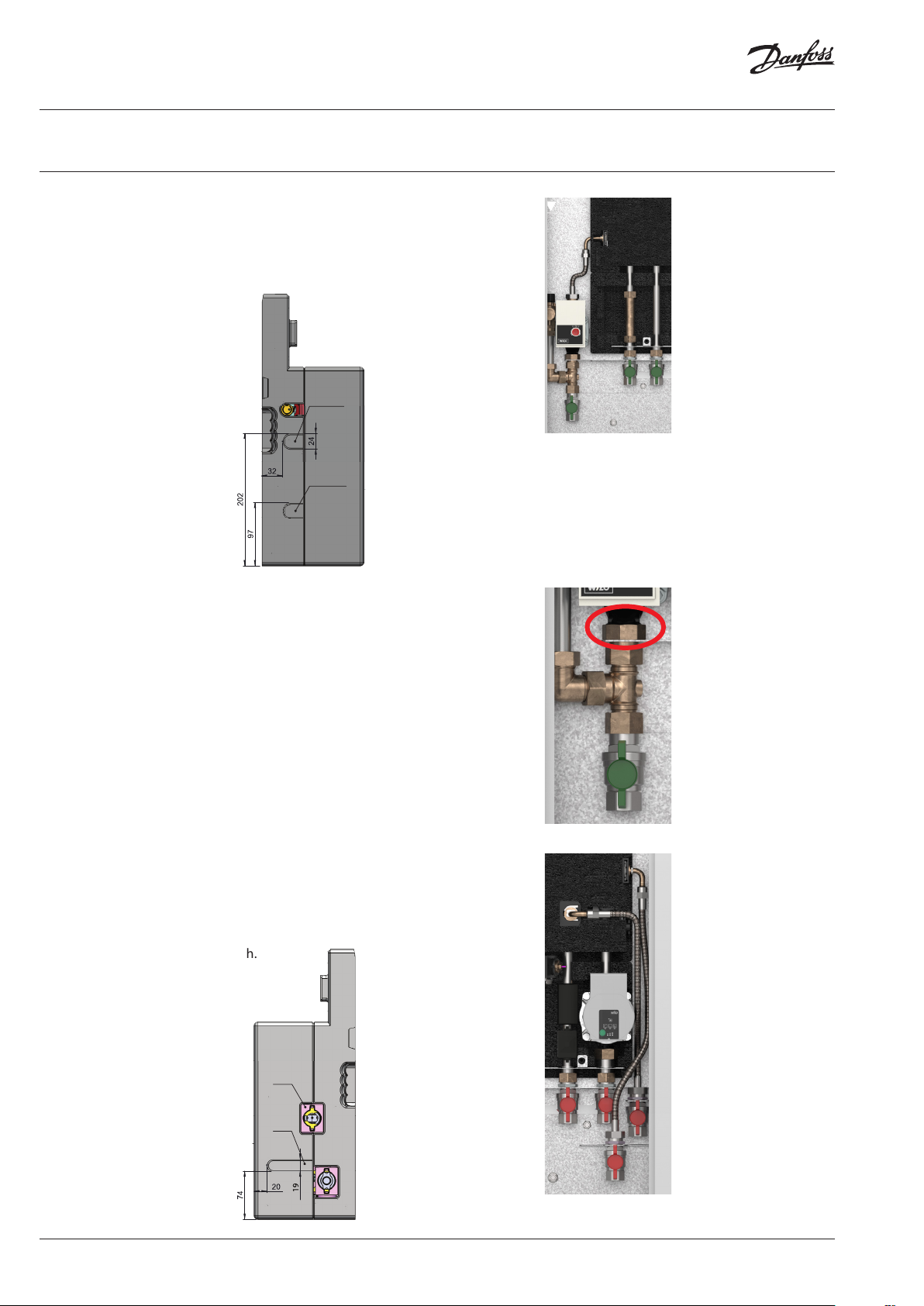

6.1 Circulation

The pump must be mounted on the metal plate which must be mounted on the existing mounting rail.

Remove the plug on the side of the station (remove hair pin).

Mount the connection from the flex hose and secure it with the hair pin.

Electronic

For cutout for circulation, please

see instructional drawing.

Self acting

Note: A non-return valve must be fitted between the connection from the safety valve and

the ball valve.

6.2 HTC

Remove the plug on the side of the station (remove hair pin).

Mount the connection from the flex hose and secure it with the hair pin.

For cutout for HTC, please see

instructional drawing.

12 | © Danfoss | DCS-SGDPT/PL | 2022.01

HWR

HWS

AN40274706699301-010101

Page 13

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

7. MAINTENANCE

The flat station requires little monitoring, apart from routine checks. It is recommended to

read the energy meter at regular intervals, and to write down the meter readings.

Regular inspections of the flat station according to this Instruction are recommended, which

should include:

Strainers

Cleaning of strainers.

Meters

Checking of all operating parameters such as meter readings.

Temperatures

Checking of all temperatures, such as HS supply temperature and PWH temperature.

Connections

Checking all connections for leakages.

Safety valves (for the circulation)

The operation of the safety valves should be checked by turning the valve head in the

indicated direction.

Venting

Checking that the system is thoroughly vented.

Authorized personnel only

Assembly, start-up and maintenance work

must be performed by qualified and authorized

personnel only.

EN

Inspections should be carried out minimum every two years.

Spare parts can be ordered from Danfoss.

Please ensure that any enquiry includes the flat station serial number.

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 13

Page 14

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

8. TROUBLESHOOTING

8.1 Troubleshooting in general

In the event of operating disturbances, the following basic features

should be checked before carrying out actual troubleshooting:

• the flat station is connected to electricity,

• the strainer on the HS supply pipe is clean,

• the supply temperature of the HS is at the normal level,

• the differential pressure is equal to or higher than the normal (local) differential

pressure in the HS network – if in doubt, ask the HS plant supervisor.

8.2 Troubleshooting: DHW

Problem Possible cause Solution

Authorized personnel only

Assembly, start-up and maintenance work

must be performed by qualified and authorized

personnel only.

Too little or no domestic hot

water

DHW is available only at some

draw-off points.

DHW temperature too high DHW controller Adjust controller

Supply flow insufficient Collect data from the heat meter

Check the network pump — constant pressure

If necessary, close the bypass in the tap block on

the bathroom radiator

Check the function of the ball valves and open

if necessary

Vent the system throughly — see the instruction

Change the summer bypass setting if

necessary

Low temperature / variations in temperature at the

draw-off points

Strainer in the cold water supply line clogged. Clean strainer

Circulation pump out of operation , set at too low

speed of rotation (if DHW circulation is established)

Non-return valve defective or clogged

(if DHW circulation is established)

Defective DHW thermostat

Defective TPC-M controller Check the functions of the controller,

Calified heat exchanger Replace heat exchanger

Lack of cold water pressure Increase pressure

Defective thermostatic mixing valve Replace thermostatic mixing valve

Collect data from the heat meter

Change the positioning time of the mixer actuator

Change the heating curve if necessary

Position the switch-on sensor correctly on the

buffer line

Change cleaning periods for biomass boilers

Check the function of the circulation pump and

replace if required

Check the functioning of the non-return valve and

replace if required

Check the functioning of the DHW thermostat

and repace if necessary

and replace if required

DHW controller defective Check the functions of the controller,

Temperature drop during

tapping.

14 | © Danfoss | DCS-SGDPT/PL | 2022.01

Larger DHW flow than the flat station has been

designed for.

and replace if required

Reduce DHW flow

AN40274706699301-010101

Page 15

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

8.3 Troubleshooting HE

Problem Possible cause Solution

Too little or no heat. Strainer in supply line clogged. Clean strainer(s)

The filter in the energy meter clogged. Clean the filter

Defective differential pressure controller. Replace main controller, TPC

Defective temperature sensors. Replace thermostat

Automatic controls, if any, wrongly set or defective

— possibly power failure.

Pump out of operation. Check if the pump is receiving power and that it

The pump is set at too low speed of rotation. Set the pump at higher speed of rotation.

Air pockets in the system. Vent the system throughly — see the instruction

Defective radiator valves. Check — replace

HS supply temperature

too high.

Noise in system. Pump pressure too high.

Too high HS return

temperature.

Defective TPC-M controller, alternatively differential

pressure controller. The controller does not reac t as

it should according to the instructions.

Noice from radiator valves.

Mass flow below the control range

Too small heating surface/too small radiators

compared to the total heating requirement of the

building.

Poor utilization of existing heating surface.

Defective sensor on self-acting thermostat.

The system is single pipe loop. The system should be equipped with electronic

Pump pressure too high. Set the pump at a lower speed of rotation.

Air in system. Vent the system throughly — see the instruction

Defective or incorrectly set radiator valve(s).

Single pipe loop systems require special one-pipe

radiator valves.

Dirt in the differential pressure controller. Check — clean out.

Defective motorized valve, sensor or automatic

controller.

Check if the setting of the controller is correct —

set coorectly or replace

turns. Check if there is air trapped in the pump

housing. See pump manual

See pump manual.

Replace TPC-M controller

Adjust pump to a lower level.

Check flow direction.

Reduce the spread and thereby increase the mass

flow

Increase total heating surface.

Make sure the heat is distributed evenly across

the full heating surface — open all radiators and

keep the radiators in the system from heating up

at the bottom. It is extremely important to keep

the supply temperature to the radiators as low

as possible, while maintaining a reasonable level

of comfort.

controls and return sensors.

See pump manual.

Check — set/replace.

Check — replace.

EN

8.4 Disposal

© Danfoss | DCS-SGDPT | 2022.01

Disposal

This product should be dismantled and its compo

nents sorted, if possible, in various groups before

recycling or disposal.

Always follow the local disposal regulations.

-

AN40274706699301-010101 | 15

Page 16

Installation Guide EvoFlat 4.0 Flat Stations for apartments, single- and multi-family houses

9. DECLARATION

9.1 Declaration of conformity

Category 0 with electrical equipment

EU DECLARATION OF CONFORMITY

Danfoss Redan A/S

Hårupvænget 11

DK-8600 Silkeborg

Denmark

declares on our sole responsibility that the product(s)

EvoFlat

Covered by this declaration is in conformity with the following directive(s), standard(s) or other normative document(s), provided that the product is used in accordance with our instructions.

EMC – Directive – 2004/108/EC

EN 61000-6-1 2007. Electromagnetic compatibility –

General standard:

Immunity for residential, commercial and light industry

Machinery Directive 2006/42/EC

EN 14121-1. Safety of machinery – Risk assessment

EN 60204-1. Safety of machinery – Electricalequipment

of machines – Part 1:

General requirements.

EN 61000-6-3 2007. Electromagnetic compatibility –

Generic standard:

Emission for residential, commercial & light industry.

Pressure Equipment Directive – 97/23/EC

Equipment category: 0 (article 3.3).

Silkeborg - 08-10.2014

Place and date of issue

Henrik Daugaard Thomas Bruun Hansen

16 | © Danfoss | DCS-SGDPT/PL | 2022.01

AN40274706699301-010101

Page 17

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

EvoFlat 4.0 M EvoFlat 4.0 F EvoFlat 4.0 W

DE

1. INHALT

2. SICHERHEITSHINWEISE ......................................................................18

2.1 Allgemeine Sicherheitshinweise ..............................................................................18

3. MON TAGE ..................................................................................19

3.1 Montage ....................................................................................................19

3.2 Inbetribnahme ............................................................................................. 20

3.3 Elektrische Anschlüsse ...................................................................................... 20

4. AUFBAU & MASSSKIZZEN ....................................................................21

4.1 EvoFlat 4.0 M. Darstellungen und Diagramme. ................................................................21

4.2 EvoFlat 4.0 F. Darstellungen und Diagramme.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 EvoFlat 4.0 W. Darstellungen und Diagramme. ..............................................................23

5. REGELKOMPONENTE ........................................................................24

6. ZIRKUL ATION ...............................................................................26

7. WA RTU NG ..................................................................................27

8. FEHLERSUCHE ..............................................................................28

8.1 Allgemeine Fehlersuche ....................................................................................28

8.2 Fehlersuche: PWH-Versorgung .............................................................................. 28

8.3 Problemlösung Heizung .................................................................................... 29

8.4 Entsorgung ................................................................................................ 29

9. ERKLÄRUNG ................................................................................30

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 17

Page 18

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

2. SICHERHEITSHINWEISE

2.1 Allgemeine Sicherheitshinweise

Die folgende Anleitung bezieht sich auf das Standarddesign der Station.

Es ist nicht zulässig, mit Werkzeugen jedlicher Art am Composit-Block zu arbeiten –

Auch nicht zur Montage des Hochtemperaturkreis- und/oder Zirkulationsanschlusses.

Vor der Installation und Inbetriebnahme der Station sollte diese Betriebsanleitung

aufmerksam durchgelesen werden. Der Hersteller übernimmt keine Haftung für

Schäden oder Defekte, die aus der Missachtung der Betriebsanleitung resultieren.

Bitte lesen und befolgen Sie sämtliche Hinweise, um Unfälle, Verletzungen und Sachschäden zu vermeiden.

Aufbau, Inbetriebnahme und Wartungsarbeiten dürfen nur von qualifizierten und

autorisierten Fachleuten durchgeführt werden.

Beachten Sie bitte die Vorgaben des Systemherstellersund des Anlagenbetreibers.

Korrosionsschutz.

Alle Rohre und Komponenten bestehen aus Edelstahl und Messing.

Der maximale Chloridgehalt des Mediums sollte 150 mg/l NICHT übersteigen.

Das Risiko von Korrosionsschäden steigt beträchtlich an, wenn der empfohlene Chloridgehalt in Abhängigkeit von der Temperatur überschritten wird.

Wärmeversorgung.

Die Wohnungsstationen können an Fernwärme oder Heizsystemen mit unterschiedli

chen Energiequellen (zentraler Kessel mit Gas, Öl oder Biomasse befeuert), Solarenergie,

Wärmepumpe, KWK-Anlagen oder eine Kombination aus diesen angeschlossen werden.

Die Betriebsbedingungen der Wohnungsstationen müssen eingehalten werden.

Anwendung.

Die Wohnungsstation ist ausschließlich für die Erwärmung von Trinkwasser konzipiert. Die Wohnungsstation muss in einem frostfreien Raum installiert werden, wo die

Raumtemperatur nicht über 50 °C steigt und die Luftfeuchtigkeit 80% nicht überschreitet. Die Station darf weder zugestellt noch eingemauert werden, und der freie Zugang

zur Station muss stets gewährleistet sein.

Materialwahl.

Die verwendeten Materialien müssen den geltenden örtlichen Vorschriften entsprechen.

Sicherheitsventil(e).

Es sind stets die geltenden örtlichen Vorschriften einzuhalten.

Geräuschpegel. ≤ 29,8 dB

Anschlussart.

Die Station muss bauseits mit Vorrichtungen versehen sein, die sicherstellen, dass die

Station vom Heizungs- und Trinkwassernetz einschließlich der Spannungsversorgung

getrennt werden kann.

Notfälle.

Bei Gefahr oder Unfällen (wie z. B. durch Feuer, Leckagen oder sonstige gefährliche

Umstände) sollten – sofern möglich – sämtliche Energiequellen von der Station getrennt

werden. Außerdem sollten Fachleute hinzugezogen werden.

Bei verfärbtem oder übel riechendem Trinkwarmwasser sollten sämtliche Kugelhähne

an der Station geschlossen werden.

Informieren Sie zudem den zuständigen Betreiber / Fachhandwerker.

Lagerung und Handhabung.

Muss die Station vor der Installation gelagert werden, so hat dies unter trockenen und

frostfreien Bedingungen zu erfolgen.

Reach.

Sämtliche Produkte der EvoFlat 4.0 Serie erfüllen die Bestimmungen der REACH-Verordnung.

Wir sind dem gemäß verpflichtet unsere Kunden über das Vorhandensein von Stoffen

laut SVHC Kandidatenliste zu informieren so diese vorhanden sind.

Hiermit informieren wir Sie: Dieses Produkt enthält Messingteile die Blei (CAS 7439-92-1)

in einer Konzentration über 0,1% Massenprozent enthalten.

Potentialausgleich / Erdung.

Unter Potentialausgleich versteht man alle Maßnahmen zum Beseitigen elektrischer Potentialunterschiede (Kontaktspannungen), die zwischen z.B zwei Rohrleitungen auftreten

können. Der Potentialausgleich ist eine wichtige Maßnahme zum Schutz gegen elektrischen Schlag.

Potentialausgleich reduziert Korrosion im Wärmetauscher, Durchlauferhitzer, Wohnungsstationen und Sanitärinstallationen. Potentialausgleich sollte nach den Bestimmungen 60364-4-41: 2007 und IEC 60364-5-54: 2011 erfolgen.

Nur autorisierte Fachkräfte

Aufbau, Inbetriebnahme und Wartungsarbeiten

dürfen nur von qualifi zierten und autorisierten

Fachleuten durchgeführt werden.

Bitte beachten Sie Hinweise in dieser Anleitung.

Um Personenschäden und eine Beschädigung

des Geräts zu verhindern, muss diese Anleitung

genau beachtet werden.

Warnung vor hohem Druck und hohen Temperaturen

Beachten Sie den erlaubten Systemdruck und die

Systemtemperatur der Installation.

Die Höchsttemperatur in der Station beträgt 95 °C.

Der maximale Betriebsdruck der Station beträgt

10 bar.

Das Risiko von Personenschäden und beschädigter Einbauteile nimmt beträchtlich zu, wenn

die empfohlenen zulässigen Betriebsparameter

überschritten werden.

Die Installation ist mit Sicherheitsventilen

auszustatten, wenn dies die landesspezifi

schen Vorschriften vorsehen.

Warnung vor heißen Oberfl ächen

Die Station hat heiße Ober fl ächen, die zu Verbrennungen der Haut führen können. Seien Sie bitte in

der Nähe der Station sehr vorsichtig.

Bei einem Stromausfall kann es passieren, dass die

Motorventile geöff net bleiben. Die Oberfl ächen

der Station können sehr heiß werden und dann

bei Berührung zu Hautverbrennungen führen. Die

Kugelhähne an Versorgungsvor- und -rücklauf sollten geschlossen werden.

Warnung vor Transportschäden

Stellen Sie bitte vor der Installation der Station

sicher, dass die Station beim Transport nicht beschädigt wurde.

WICHTIGER HINWEIS: Anschlüsse nachziehen

Wegen der Erschütterungen während des

Transports müssen alle Schraubverbindungen sowie sämtliche elektrischen Klemm- und

Schraubanschlüsse überprüft und ggf. nachgezogen werden, bevor die Anlage mit Wasser

befüllt wird.

Nachdem die Anlage mit Wasser befüllt und

in Betrieb genommen wurde, ist ein erneutes

Nachziehen ALLER Verschraubungen erforderlich. Überprüfen Sie, dass alle Stifte der Click-FitAnschlüsse vollständig eingesteckt sind.

Bitte bemerken

Eingriffe und Nacharbeiten an unseren Komponenten führen zum Verlust der Gewährleistung.

18 | © Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101

Page 19

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

Verbindungsstelle ist mit einem Erdungssymbol auf der rechten unteren Ecke der Montageplatte markiert und es gibt ein Loch in der Montageplatte und ein Etikett mit Erdungssymbol.

Entsorgung.

Die Station besteht aus Materialien, die nicht zusammen mit dem Hausmüll entsorgt

werden dürfen. Die gesammte Energieversorgung unterbrechen und zerlegen Sie das

Produkt zur entsorgung in Einzelteile und führen Sie sie gemäß den geltenden örtlichen

Vorschriften sortenrein der Entsorgung zu.

3. MONTAGE

3.1 Montage

Die Installation muss den landesspezifi schen Normen und Richtlinien und dem neusten

anerkannten Regeln der Technik entsprechen.

Wärmequelle: In den folgenden Abschnitten bezeichnet WQ die Wärmequelle, die die

Wohnungsstationen versorgt. Eine Vielzahl von Energiequellen, wie z. B. Öl, Gas oder

Solarenergie,kann als Hauptenergiequelle für die Wohnungsstationen von Danfoss

verwendet werden.

Montage:

Ausreichende Abstände

Lassen Sie um die Station herum ausreichende Abstände für Installations- und Wartungsarbeiten.

Ausrichtung

Die Station muss so montiert werden, dass alle Bauteile, Bohrlöcher und Typenschilder

ordnungsgemäß positioniert sind. Falls Sie die Station auf andere Weise montieren

möchten, wenden Sie sich an Ihren Händler.

Bohrlöcher

Zur Montage der Station nutzen Sie bitte die in der Rückenplatte vorgesehenen Bohrlöcher.

Beschriftung

Jeder Anschluss der Station ist beschriftet.

Vor dem Einbau:

Reinigen und spülen

Vor der Montage der Wohnungsstation muss das Rohrnetz gemäß den gültigen landesspezifischen Vorgaben gereinigt bzw. gespült werden.

Nachziehen

Aufgrund von Erschütterungen während des Transports müssen alle Anschlüsse der

Station vor der Installation kontrolliert und nachgezogen werden. Überprüfen Sie, dass

alle Stifte der Click-Fit-Anschlüsse vollständig eingesteckt sind.

Nur autorisierte Fachkräfte

Aufbau, Inbetriebnahme und Wartungsarbeiten

dürfen nur von qualifi zierten und autorisierten

Fachleuten durchgeführt werden.

DE

Bohrloch für die Wandmontage.

Bitte bemerken

Verwendung anderer Verpackungsarten, als die,

mit denen das Gerät geliefert wird, führen zum Verlust der Gewährleistung.

Nicht verwendete Anschlüsse

Nicht verwendete Anschlüsse und Absperrventile müssen mit einem Stopfen verschlossen werden. Müssen die Stopfen entfernt werden, darf dies nur durch einen

autorisierten Fachleuten geschehen. Landesspezifi schen Vorschriften sind einzuhalten.

Einbau:

Schmutzfänger

Im Lieferumfang der Station ist ein Schmutzfänger enthalten. Dieser muss gemäß der

schematischen Darstellung eingebaut und regelmäßig gereinigt werden.

Anschlüsse

Die Anschlüsse an die Hausinstallation sind mit Gewinde und/oder Pressverbindungen

auszuführen.

Die internen Anschlüsse der Wohnungsstation sind Click-Fit-Anschlüsse.

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 19

Page 20

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

3.2 Inbetribnahme

Inbetriebnahme, direktes Heizen

Während der Inbetriebnahme müssen die Absperrventile geöffnet sein und das Gerät

überwacht werden. Prüfen Sie die Temperaturen, Drücke, thermische Ausdehnung und

die Dichtigkeit. Sobald der Wärmeübertrager ordnungsgemäß arbeitet, kann das Gerät

seinen bestimmungsgemäßen Betrieb aufnehmen.

Das Befüllen der Anlage und der Station(en) muss über den Vorlauf erfolgen.

Ist die Anlage befüllt, ist der Filter zu prüfen und ggf. zu reinigen.

Nachdem die Anlage mit Wasser befüllt und in Betrieb genommen wurde, kann ein

erneutes Nachziehen erforderlich sein. Überprüfen Sie, dass alle Stifte der Click-FitAnschlüsse vollständig eingesteckt sind.

Inbetriebnahme, Heizung mit Mischkreis (bei allen EvoFlat 4.0 M Versionen)

Inbetriebnahme:

1: Pumpendrehzahl

Die Pumpe ist nach dem Einschalten auf die der Anzahl der Heizkreise entsprechenden Drehzahl einzustellen.

Die Einbau- und Betriebsanleitung des Herstellers der Umwälzpumpe ist zu beachten.

2: Pumpe starten

Pumpe starten und System durchheizen.

Hinweise, die bei Montage, Betrieb und Wartung beachtet werden müssen, sind der beigelegten Einbau- und Betriebsanleitung der Hersteller zu entnehmen.

3: Absperrventile öffnen

Jetzt müssen die Absperrventile geöffnet und die Station überwacht werden. Prüfen Sie die Temperaturen, Volumenströme und die Dichtigkeit.

Wenn das System ordnungsgemäß funktioniert kann die Station in Betrieb genommen werden.

4: System entlüften

Pumpe ausschalten und die Station entlüften, nachdem das System aufgewärmt wurde. Bitte beachten Sie, dass einige Pumpentypen über

eine eingebaute Entlüftungsfunktion verfügen. Andere Installationen können unter Verwendung eines manuellen Entlüfters in der Wohnungsstation oder an den Heizkörpern / Heizkreisverteilern oder, wenn möglich, über das Lüftungsventil am obersten Punkt des Systems,

entlüftet werden. Für weitere Informationen lesen Sie bitte die Einbau- und Betriebsanleitung des Herstellers der Umwälzpumpe.

Anschlüsse erneut festziehen

Nachdem die Anlage mit Wasser befüllt und in Betrieb genommen wurde, ist ein erneutes Nachziehen ALLER Verschraubungen erforderlich. Überprüfen Sie, dass alle Stifte der Click-Fit-Anschlüsse

vollständig eingesteckt sind.

5: Pumpendrehzahl anpassen

Stellen Sie die Pumpe je nach Anzahl der Heizkreise bzw. nach Wärmebedarf des Gebäudes auf die niedrigste Position ein.

Bei zu geringer Leistung kann die Pumpendrehzahl mit dem Wahlschalter verändert werden. Bitte beachten Sie die beiliegende Anleitung.

Im Handbuch finden Sie weitere detaillierte Informationen zu den Einstellbereichen.

Im Sommer können Sie die Pumpe am Stromnetz ausschalten. Es sollte sicher gestellt sein, dass keine unangemessenen hydraulischen

Situationen auftreten, wenn die Stromversorgung Ihrer Pumpe unterbrochen wird.

Inbetriebnahme und Entlüftung — siehe oben und beiliegende Unterlagen.

(Bei Einzelraumregelungen mit integrierter Pumpensteuerung ist die manuelle Abschaltung nicht erforderlich).

3.3 Elektrische Anschlüsse

Vor dem Herstellen der elektrischen Anschlüsse ist folgendes zu beachten:

Sicherheitshinweise

Die landesspezifischen Sicherheitsrichtlinien sind zu beachten.

230 V

Die Station muss an einen 230 V AC-Anschluss und an die Erdung angeschlossen

werden. Der elekrische Anschluß ist bei dem Stationstyp M, dem Typ F — bei Verwendung eines Raumthermostates in Kombination mit einem Stellantrieb oder bei

allen EvoFlat Typen, wenn eine Zirkulationspumpe bei der Trinkwassererwärmung

vorhanden ist, notwendig.

Trennung

Der elektrische Anschluss der Station muss so erfolgen, dass sie für Reparaturen vom

Stromnetz getrennt werden kann.

Autorisierter Elektriker

Elektrische Anschlüsse dürfen nur durch einen

autorisierten Elektriker hergestellt werden.

Landestypische Vorschriften

Elektrische Anschlüsse müssen nach den aktuellen Richtlienien und landestypischen Vorschriften

erfolgen.

Die Station muss mit einem Kupferkabel (min. 6 mm²) an einer Potentialausgleichsschiene geerdet werden. (DIN VDE 0100-540 ist zu beachten).

20 | © Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101

Page 21

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

4. AUFBAU & MASSSKIZZEN

4.1 EvoFlat 4.0 M. Darstellungen und Diagramme.

36 69

64

613

8

1 2 3 4 5 6 7

65 65 65 65 65 65 4496

530

Verbindungen:

1. Kaltwasser (PWC) Eintritt

2. Warmwasser (PWH)

3. Kaltwasser (PWC) Austritt

4. Vorlauf Versorgungsnetz

5. Rücklauf Versorgungsnetz

6. Vorlauf Verbraucher

7. Rücklauf Verbraucher

Optionen:

• Hochtemperaturset (183H0501)

• PWH-Zirkulationsset (183H0500)

• Stellantrieb TWA-Q NO 230V (082F1601)

PWH

PWC

17

52A

30

2

4

52

4 38

33

5

DE

40

12

59 24

10

54

44

2 Plattenwärmübertrager

4 Differenzdruckregler

5 Schmutzfänger MW 0,6 mm

6 Rückschlagventil

7 Kugelhahn

9 Zirkulationspumpe Yonos Para Z 15/7

10 Umwälzpumpe Wilo Para R

12 Sicherheitsventil

17 Entlüftung

2

17

33

23 Fühlertauchhülse

24 Passstück für WMZ 3/4” × 110 mm

29 Sensor

30 Ventil (Heizung)

33 Stopfen

38 Warmwasser-Regler

40 Sommer-Bypass

52 Zonenventil

54 Sicherheitsthermostat

59 Passstück für WZ 3/4” × 110 mm

PWC

PWH-C

Versorgungnetz

Versorgungnetz Verbraucher

© Danfoss | DCS-SGDPT | 2022.01

59

12

24

33

97

38

4

33

5

6

23

4 52 33 30

29

54

~ 230 V

10

AN40274706699301-010101 | 21

Verbraucher

Page 22

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

4.2 EvoFlat 4.0 F. Darstellungen und Diagramme.

36 69

64

52

613

1 2 3 4 5 6 7

8

65 65 65 65 65 65 4496

530

Verbindungen:

1. Kaltwasser (PWC) Eintritt

2. Warmwasser (PWH)

3. Kaltwasser (PWC) Austritt

4. Vorlauf Versorgungsnetz

5. Rücklauf Versorgungsnetz

6. Vorlauf Verbraucher

7. Rücklauf Verbraucher

Optionen:

• PWH-Zirkulationsset (183H0500)

• Stellantrieb TWA-Q NO 230V (082F1601)

PWH

2

52A

4

4 38

5

40

59 24

2 Plattenwärmübertrager

4 Differenzdruckregler

5 Schmutzfänger MW 0,6 mm

7 Kugelhahn

9 Zirkulationspumpe Yonos Para Z 15/7

12 Sicherheitsventil

17 Entlüftung

23 Fühlertauchhülse

24 Passstück für WMZ 3/4” × 110 mm

2

17

38 Warmwasser-Regler

40 Sommer-Bypass

52 Zonenventil

52A TWA Q-NO 230V - für Zonenventil (optional)

59 Passstück für WZ 3/4” × 110 mm

PWC

59

PWC

12

PWH-C

Versorgungnetz

Versorgungnetz Verbraucher

22 | © Danfoss | DCS-SGDPT | 2022.01

7

9

24

33

38

33

4

23

5

40

23

52A

524

~ 230 V

AN40274706699301-010101

Verbraucher

Page 23

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

4.3 EvoFlat 4.0 W. Darstellungen und Diagramme.

36 69

64

17

613

1 2 3 4 5

8

65 65 65 65 17496

Verbindungen:

1. Kaltwasser (PWC) Eintritt

2. Warmwasser (PWH)

3. Kaltwasser (PWC) Austritt

4. Vorlauf Versorgungsnetz

5. Rücklauf Versorgungsnetz

530

2

4 38

33

5

DE

40

59 24

2 Plattenwärmübertrager

4 Differenzdruckregler

5 Schmutzfänger MW 0,6 mm

7 Kugelhahn

9 Zirkulationspumpe Yonos Para Z 15/7

12 Sicherheitsventil

17 Entlüftung

23 Fühlertauchhülse

24 Passstück für WMZ 3/4” × 110 mm

2

38 Warmwasser-Regler

40 Sommer-Bypass

59 Passstück für WZ 3/4” × 110 mm

PWH

PWC

PWC

PWH-C

Versorgungnetz

Versorgungnetz

© Danfoss | DCS-SGDPT | 2022.01

17

33

59

33

9127

23

40

24

38

4

33

5

23

33

AN40274706699301-010101 | 23

Page 24

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

5. REGELKOMPONENTE

5.1 Zonenventil

Das in der F-Station verbaute Zonenventil ist standatsmäßig mit einer Kappe versehen.

Achtung: Ist diese Kappe zugedreht, ist das Zonenventil geöffnet. Somit ist bei

geöffneter Kappe das Ventil geschlossen!

5.2 Entlüftung

Die Station sollte während der Inbetriebnahme entlüftet werden.

5.3 Schmutzfänger

Schmutzfänger sollten regelmäßig von autorisierten Fachkräften gereinigt werden.

Die Häufigkeit der Reinigung ist von den Betriebsbedingungen abhängig.

Achtung: Die Nutzung eines Werkzeuges zum öffnen d es Schmutzfängers ist nicht zulässig.

5.4 Sommer Bypass

Das Bypass-Thermostat hält die Vorlaufleitung warm.

Einstellbereich: von 10 °C bis 50 °C.

Skaleneinstellung (indikativ).

Werkseinstellung 3.

Skaleneinstellung

1 2 3 4

20 30 40 45

5.5

Mischkreis

Der Mischkreis liefert das geeignete Temperaturniveau (z.B. für die Fußbodenheizung).

Die gewünschte Vorlauftemperatur kann an dem FTC-Thermostat eingestellt werden.

FTC Regelung

FTC regelt die HE Vorlauftemperatur des Mischkreises.

Einstellbereich: von 15 °C bis 50 °C.

Die Einstellwerte können je nach Betriebsbedingungen abweichen.

Hinweis: Für Hauser die ausschliesslich mit Fussbodenheizung.

Beachten Sie die Anleitungen des Fussbodenherstellers.

Sicherheitsthermostat STW

Das in der EvoFlat Typ M verbaute Sicherheitsthermostat schließt das Zonenventil

mittels eines Stellantriebes, soball die Vorlauftemperatur 55 °C übersteigt.

Bei Unterschreitung um 5K öffnet das Zonenventil wieder.

24 | © Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101

Page 25

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

5.6 Montagereihenfolge der dreiteiligen Dämmhaube

Zum Einbau von Wärme- und Wasserz ählern muss die Dämmhaube in der Reihenfolge

1, 2 und 3 entfernt werden und in umgekehrter Reihenfolge wieder montiert werden.

Nachdem alle Zähler installiert wurden, erfolgt die Verkabelung des Wärmezählers

zum Rechenwerk.

Die Kabel müssen in die dafür vorgesehene Kabelschiene gelegt (gek lemmt) werden.

Achten Sie darauf, dass keine Kabel die Isolierstege kreuzen. Andernfalls kommt es

zu unkontrollierten Wärmeverlust und die Umgebung kann sich unnötig aufheizen.

DE

5.7 Passstück

Die Wohnungsstation ist mit zwei Passstücken 3/4”x110mm ausgestattet.

Auf der linken Seite kann der Kaltwasserzähler und rechts der Wärmezähler montiert

werden.

Einbau von Wärmezählern:

1: Kugelhähne schließen

Kugelhähne an FW Vorlauf und FW Rücklauf schließen, falls sich Wasser in der Anlage

befindet.

2: Überwurfmuttern lösen

Muttern an den Passstücken lösen.

3: Passstücke entfernen

Passstücke entfernen und durch Wärmezähler und/oder Kaltwasserzähler ersetzen.

Dichtungen nicht vergessen.

4: Verbindungen festziehen

Nach dem Einbau der beiden Zähler müssen unbedingt sämtliche Gewindeanschlüsse

überprüft und festgezogen werden.

5: Maximale Drehmoment der Schraubverbindungen innerhalb der Wohnungsstation

Überwurfmutter G 3/4” 45 Nm

Überwurfmutter G 1” 45 Nm

Verschraubungen für Passstücke 35 Nm

Verrohrung des Heizkreisverteilers 30 Nm

Hinweis: Beim Einbau eines Wärme- und/oder Wasserzählers sind die jeweiligen Herstellerhinweise zu beachten.

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 25

Page 26

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

6. ZIRKULATION

6.1 Zirkulation

Die Pumpe muss auf dem Metallwinkel montiert werden. Der Metallwinkel muss

wiederum mit der Kugelhahnschiene verschraubt werden.

Entfernen Sie den unteren Stopfen an der linken Seite der Station. (Klammer nach

vorne ziehen).

Montieren Sie den Anschluss vom Flexschlauch und sichern Sie ihn mit der Klammer.

Electronic

Die Position und Größe des

Ausschnittes für den Cirkulation entnehmen Sie bitte der

Montageanleitung.

Self acting

Hinweis: Zwischen dem T-Stück vom Sicherheitsventil und dem Kugelhahn muss das beiliegende Rückschlagventil eingebaut werden. Auf die Flussrichtung ist zu achten!

6.2 Hochtemperaturkreisanschluss

Öffnen Sie die beiden Klammern an der Station (seitlich und vorne die Klammern

lösen und die Stopfen entfernen).

Montieren Sie den Anschluss vom Flexschlauch und sichern Sie ihn wieder mit den

Klammern.

Vorlauf — unterer Anschluss vorne.

Rücklauf — oberer Anschluss seitlich.

Die Position und Größe des Ausschnittes für den Hochtemperaturkreisanschluss entnehmen

Sie bitte der Montageanleitung.

26 | © Danfoss | DCS-SGDPT | 2022.01

Rücklauf

Vorlauf

AN40274706699301-010101

Page 27

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

7. WARTUNG

Die Station erfordert, abgesehen von Routineüberprüfungen, nur einen geringen

Wartungs-aufwand.

Wartungs- und Überprüfungsarbeiten an der Station gemäß dieser Anleitung sind

gemäß EN 806-5 durchzuführen und sollten zusätzlich Folgendes umfassen:

Schmutzfänger

Reinigung der Schmutzfänger.

Wärmezähler

Überprüfung sämtlicher Betriebsparameter — bspw. der abgelesenen Messwerte.

Temperaturen

Überprüfung sämtlicher Temperaturen, z. B. der Temperatur der Wärmequelle und

der Trinkwarmwassertemperatur.

Anschlüsse

Überprüfung sämtlicher Anschlüsse auf Leckagen.

Nur autorisierte Fachkräfte

Aufbau, Inbetriebnahme und Wartungsarbeiten

dürfen nur von qualifizierten und autorisierten

Fachleuten durchgeführt werden.

Entlüftung

Überprüfen Sie, ob die Anlage gründlich entlüftet wurde.

Sicherheitsventile

Die Funktion der Sicherheitsventile sollte überprüft.

Die Sichtprüfung der zuvor aufgeführten Komponenten sollte mindestens alle zwei Jahre

durchgeführt werden.

Ersatzteile können bei Danfoss bestellt werden. Stellen Sie bitte sicher, dass Sie in

Ihrer Anfrage auch die Seriennummer der Station angeben.

DE

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 27

Page 28

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

8. FEHLERSUCHE

8.1 Allgemeine Fehlersuche

Bei Betriebsstörungen sollten vor dem Ergreifen von Massnahmen grundsätzlich

folgende Parameter überprüft werden:

• Ist die Station an die Spannungsversorgung angeschlossen?

• Ist der Filter in der Vorlaufleitung des Versorgungsnetzes sauber?

• Liegt eine geeignete Vorlauftemperatur an?

•

Ist der Pumpendruch im Netz höher als der Regeldruck des Differnzdruckreglers

(min. 350 mbar)?

8.2 Fehlersuche: PWH-Versorgung

Problem Mögliche Ursache Lösung

Nur autorisierte Fachkräfte

Aufbau, Inbetriebnahme und Wartungsarbeiten dürfen nur von qualifizierten und autorisiert Fachleuten durchegefürht werden.

Zu wenig oder kein Trink warmwasser.

Massenstrom Versorgungsnetz nicht ausreichend Daten aus dem Wärmezähler entnehmen

Netzpumpe kontrollieren — Konstantdruck

Am Badheizkörper ggf. Beipass im Hahnblock

schließen

Kugelhähne prüfen und ggf. öffnen

Station entlüften

Einstellung Sommerbypass ggf. ändern

Temperatur Vorlauf im Versorgungsnetz zu gering

oder schwankt

Schmutzfänger im Vorlauf verstopft Schmutzfänger reinigen

Zirkulationspumpe ausgefallen oder zu niedrig

eingestellt. (wenn PWH-Zirkulation installiert ist)

Rückschlagventil defekt oder verstopft (wenn PWH-

Zirkulation installiert ist)

Defektes PWH-Thermostat PWH-Thermostat prüfen oder austauschen

Defekter TPC-M Kombiregler Regler prüfen oder austauschen

Daten aus dem Wärmezähler entnehmen

Stellzeit des Mischermotors ändern

Heizkennlinie ggf. ändern

Einschaltfühler am Puffer richtig positionieren

Reinigungszeiten bei Biomassekesseln verändern

Zirkulationspumpe prüfen oder austauschen

Rückschlagventil prüfen oder austauschen

Ablagerungen auf dem Plattenwärmeübertrager Wärmeübertrager austauschen

Zu geringer Kaltwasserdruck Druckerhöhung

Warmwasser ist nur an einigen

Zapfstellen verfügbar.

PWH-Temperatur zu hoch. PWH-Regler zu hoch eingestellt Regler einstellen

Temperaturabfall bei PWHZapfung

28 | © Danfoss | DCS-SGDPT | 2022.01

Defektes Thermostatmischventil Mischventil austauschen

PWH-Regler defekt Regler austauschen

Zu hoher PWH-Durchfluss Armaturen eindrosseln

AN40274706699301-010101

Page 29

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

8.3 Problemlösung Heizung

Problem Mögliche Ursache Lösung

Zu wenig oder zu viel wärme. Schmutzfänger im Vorlauf verstopft Schmutzfänger reinigen

Filter im Wärmezähler verstopft Filter reinigen lassen

Differenzdruckregler defekt TPC-M Kombiregler austauschen

Anlegefühler des FTC defekt FTC-Anlegethermostat austauschen

Automatische Regelung def ekt oder falsch eingestellt

Pumpe ausser Betrieb Prüfen ob Spannung anliegt

Pumpenleistung nicht ausreichend Pumpeneinstellung ändern. Betriebsanleitung des

Luft in der Anlage Entlüften

Defektes Heizkörperventil Austauschen

WQ-Vorlauftemperatur zu

hoch.

System ist zu laut. Pumpendruck ist zu hoch Leistung der Pumpe reduzieren

WQ-Rücklauftemperatur zu

hoch.

Schmutz im TPC-M Regler bz w. Differenzdruckegler

(Anlage wurde über den Rücklauf gefüllt)

Massenstrom unterhalb des Regelbereich Spreizung reduzieren und dadurch Massenstrom

Zu geringe Heizfläche/zu kleine Heizkörper im Vergleich zum Gesamtheizbedarf des Gebäudes.

Schlechte Nutzung der vorhandenen Heizfläche.

Fühler des selbsttätigen Thermostats ist defekt.

Das System ist ein Einrohrsystem. Das System sollte mit elektronischen Reglern und

Pumpendruck ist zu hoch. Pumpe niedriger einstellen.

Regelung einstellen oder austauschen

Herstellers der Umwälzpumpe ist zu beachten.

TPC-M Kombiregler austauschen

erhöhen.

Gesamtheizfläche erhöhen.

Sicherstellen, dass die Wärme gleichmässig über

die ganze Heizfläche verteilt wird - alle Heizkörper

aufdrehen und verhindern, dass die Heizkörper im

System unten zu heiss werden. Es ist sehr wichtig,

die Temperatur im Vorlauf der Heizkörper so gering wie möglich zu halten, um eine angenehme

Temperatur zu errichen.

Rücklauffühlern ausgestattet sein.

DE

8.4 Entsorgung

© Danfoss | DCS-SGDPT | 2022.01

Luft im System. System entlüften.

Defekte(s) oder falsch eingestellte(s) Heizkörperventil(e). Einrohrsysteme erfordern besondere Einrohrheizkörperventile.

Schmutz im Differenzdruckregler. Prüfen — reinigen.

Motorventil, Fühler oder automatischer Regler

defekt.

Entsorgung

Dieses Produkt sollte vor dem Recycling oder der

Entsorgung zerlegt und ggf. in unterschiedliche

Materialgruppen sortiert werden.

Beachten Sie stets die örtlichen Entsorgungsbestimmungen.

Prüfen — einstellen/austauschen.

Prüfen — austauschen.

AN40274706699301-010101 | 29

Page 30

Installationsanleitung EvoFlat 4.0 Wohnungsstation für Wohnungen, Ein- und Mehrfamilienhäuser

9. ERKLÄRUNG

9.1 Konformitätserklärung

Kategorie 0 mit elektrischen Geräten

EG-KONFORMITÄTSERKLÄRUNG

Danfoss Redan A/S

Hårupvænget 11

DK-8600 Silkeborg

Denmark

erklärt in alleiniger Verantwortung, dass das Produkt/die Produkte

EvoFlat,

auf das/die sich diese Erklärung bezieht, den folgenden Richtlinien, Standards oder sonstigen normativen Dokumenten entspricht/entsprechen, sofern das Produkt/die Produkte gemäß den Hinweisen in unseren Anleitungen

verwendet werden.

EMV-Richtlinie 2004/108/EG

DIN EN 61000-6-1 2007. Elektromagnetische

Verträglichkeit - Fachgrundnorm:

Störfestigkeit für Wohnbereich, Geschäftsund Gewerbebereiche sowie Kelinbetriebe

DIN EN 61000-6-3 2007. Elektromagnetische

Maschinenrichtlinie 2006/42/EG

DIN EN ISO 14121-1. Sicherheit von Maschinen-

Risikobeurteilung

DIN EN 60204-1. Sicherheit von Maschinen -

Elektrische Ausrüstung von Maschinen - Teil 1:

Allgemeine Anforderungen

Verträglichkeit - Fachgrundnorm:

Störaussendung für Wohnbereich, Geschäftsund

Gewerbebereiche sowie Kleinbetriebe

Druckgeräterichtlinie 97/23/EG

Gerätekategorie: 0 (Artikel 3.3)

Silkeborg — 08-10.2014

Ort und Datum der Ausstellung

Henrik Daugaard Thomas Bruun Hansen

30 | © Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101

Page 31

Guide d’installation EvoFlat 4.0 Modules d’alimentation pour appartements, maisons individuelles et immeubles d’habitations

EvoFlat 4.0 M EvoFlat 4.0 F EvoFlat 4.0 W

FR

1. TABLE DES MATIÈRES

2. REMARQUES DE SÉCURITÉ ..................................................................32

2.1 Remarques de sécurité – Généralités ........................................................................ 32

3. MON TAGE ..................................................................................33

3.1 Montage ................................................................................................... 33

3.2 Démarrage ................................................................................................. 34

3.3 Raccordements électriques ................................................................................. 34

4. PRINCIPAUX COMPOSANTS ET SCHÉMAS DIMENSIONNELS ...................................35

4.1 EvoFlat 4.0 M. Construction et diagrammes ................................................................. 35

4.2 EvoFlat 4.0 F. Construction et diagrammes .................................................................. 36

4.3 EvoFlat 4.0 W. Construction et diagrammes ................................................................. 37

5. RÉGULATEURS ..............................................................................38

6. BOUCLAGE ECS .............................................................................40

7. MAINTENANCE ..............................................................................41

8. DÉPANNAGE ................................................................................42

8.1 Dépannage en général ..................................................................................... 42

8.2 Résolution des problèmes ECS .............................................................................. 42

8.3 Dépannage EC .............................................................................................43

8.4 Mise au rebut ..............................................................................................43

9. DÉCLARATION ..............................................................................44

© Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101 | 31

Page 32

Guide d’installation EvoFlat 4.0 Modules d’alimentation pour appartements, maisons individuelles et immeubles d’habitations

2. REMARQUES DE SÉCURITÉ

2.1 Remarques de sécurité – Généralités

Les instructions suivantes se rapportent aux modules d’alimentation de conception

standard.

Il est interdit de travailler sur le bloc composite quel que soit l’outil, mais uniquement en cas

de montage d’un kit de bouclage ECS et de HTC.

Ce manuel d’utilisation doit être lu attentivement avant l’installation et le démarrage du

module d’alimentation. Le fabricant décline toute responsabilité en cas de dommages ou

de pannes résultant du non-respect du manuel d’utilisation. Lire et suivre attentivement

toutes les instructions afin d’éviter les accidents, les blessures et les dommages matériels.

Le travail d’assemblage, de démarrage et de maintenance doit être effectué uniquement

par un personnel qualifié et agréé. Suivre les instructions fournies par le fabricant ou

l’opérateur du système.

Protection contre la corrosion.

Tous les tubes et composants sont en acier inoxydable et en laiton.

La teneur maximale en composés chlorés du fluide ne doit pas dépasser 150 mg/l. Le risque

de corrosion de l’équipement augmente considérablement en cas de dépassement du niveau

recommandé de composés chlorés autorisés.

Source d’énergie.

Le module d’alimentation est conçu pour être raccordé à des installations de chauffage

décentralisé avec différentes sources d’énergie, telles que le chauffage urbain, une chaudière

centrale (gaz, fioul, biomasse, etc.), l’énergie solaire, une pompe à chaleur ou une combinaison

de ceux-ci si les conditions de fonctionnement le permettent.

Application.

Le module d’alimentation est conçu pour être raccordé à l’installation domestique dans

une pièce hors gel, où la température ne dépasse pas 50 °C et l’humidité ne dépasse pas

80 %. Ne pas couvrir ou emmurer le module d’alimentation ni bloquer d’une autre manière

l’accès au module.

Choix des matériaux.

Choix des matériaux toujours en conformité avec la législation locale.

Soupape(s) de sécurité.

Nous recommandons toutefois de toujours monter les soupapes de sécurité conformément

aux règlements locaux.

Niveau sonore. ≤ 29,8 dB

Raccordement.

Le module d’alimentation doit être équipé de fonctionnalités permettant de le séparer

de toutes les sources d’énergie (y compris l’alimentation).

Urgence.

En cas de danger ou d’accidents (incendie, fuites ou autres circonstances dangereuses),

interrompre si possible toutes les sources d’énergie vers le module et demander l’aide

d’un expert.

En cas d’eau chaude sanitaire colorée ou malodorante, fermer toutes les vannes d’arrêt

du module d’appartement, informer le personnel d’exploitation et appeler un expert

immédiatement.

Stockage.

Si le module d’alimentation doit être stocké avant l’installation, il doit l’être dans des conditions

sèches et chauffées.

REACH.

Tous les produits de la série EvoFlat sont conformes aux dispositions du règlement REACH.

Nous sommes donc tenus, le cas échéant, d’informer nos clients de la présence de substances

sur la liste des substances candidates SVHC. Nous vous informons que : ce produit contient

des pièces en laiton contenant du plomb (CAS 7439-92-1) à une concentration supérieure

à 1 % (m/m).

Équilibrage de potentiel / mise à la terre.

Par liaison équipotentielle, on entend toutes les mesures visant à éliminer les différences

de potentiel électrique (tensions de contact) qui peuvent se produire entre, par exemple,

deux canalisations. La liaison équipotentielle est une mesure importante de protection

contre les chocs électriques. La liaison équipotentielle réduit la corrosion dans l’échangeur

thermique, les chauffe-eau instantanés, les stations de chauffage urbain et les installations

de plomberie. La liaison équipotentielle doit être conforme aux dispositions 60364-4-41 :

2007 et CEI 60364-5-54 : 2011.

Le point de liaison est indiqué par un symbole de mise à la terre dans le coin inférieur droit

de la plaque de montage et il y a un trou dans la plaque de montage et une étiquette avec

un symbole de mise à la terre.

Recyclage.

Le module se compose de matériaux qui ne doivent pas être mis au rebut avec les autres

déchets ménagers. Débrancher toutes les alimentations en énergie, démonter et mettre

au rebut le produit conformément aux règlements locaux.

Personnel agréé uniquement

Le travail d’assemblage, de démarrage et de

maintenance doit être effectué uniquement par un

personnel qualifié et agréé.

Respecter scrupuleusement les instructions

Pour éviter qu’une personne ne se blesse et que le

dispositif ne soit endommagé, il est absolument

nécessaire de lire attentivement et de respecter ces

instructions.

Avertissement de pression et de température

élevées

Tenir compte de la pression et de la température

de système admissibles pour l’installation.

La température maximale du fluide dans le module

d’alimentation est de 95 °C.

La pression de service maximale du module d’alimentation est de 10 bar.

Le risque de blessures corporelles et d’endommagement de l’équipement augmente considérablement si les paramètres de fonctionnement autorisés

recommandés sont dépassés.

L’installation du module d’alimentation doit être

équipée d’un dispositif de sécurité.

Avertissement de surface chaude

Le module d’alimentation a des surfaces chaudes,

ce qui peut provoquer des brûlures cutanées.

La plus grande prudence est requise à proximité du

module d’alimentation.

Une panne de courant peut entraîner le blocage

des vannes motorisées en position ouverte. Les

surfaces du module d’appartement peuvent devenir

très chaudes, ce qui peut provoquer des brûlures

cutanées. Les vannes à boisseau sphérique sur

l’alimentation et le retour du chauffage côté primaire

doivent être fermées.

Avertissement de dommages résultant du

transport

Avant d’installer le module d’alimentation, assurezvous qu’il n’a pas été endom magé pendant le transp ort.

IMPORTANT – Serrage des raccords

En raison des vibrations pendant le transport, tous

les raccords à bride, les joints à vis, les raccords

électriques à collier et à vis doivent être contrôlés

et resserrés avant l’ajout d’eau dans le système. Une

fois que l’eau a été ajoutée au système et que le

système a été mis en marche, resserrez à nouveau

TOUS les raccords. Vérifi ez que toutes les goupilles des

raccords à encliqueter sont complètement enfoncées.

Attention

Les interventions et le réusinage de nos composants

invalident la garantie.

32 | © Danfoss | DCS-SGDPT | 2022.01

AN40274706699301-010101

Page 33

Guide d’installation EvoFlat 4.0 Modules d’alimentation pour appartements, maisons individuelles et immeubles d’habitations

3. MONTAGE

3.1 Montage

L’installation doit être conforme aux normes et réglementations locales.

Source de chaleur (HS) - Dans les sections suivantes, HS désigne la source de chaleur

qui alimente les modules d’alimentation. Différentes sources d’énergie, telles que

le fioul, le gaz ou l’énergie solaire, peuvent être utilisées comme alimentation

principale des sous-stations Danfoss. Dans un souci de simplicité, HS peut être considéré

comme l’alimentation primaire.

Montage :

Espace suffisant

Prévoir un espace suffisant autour du module d’appartement pour le montage et la

maintenance.

Orientation

La station doit être montée de manière à ce que les composants, les trous de serrure

et les étiquettes soient placés correctement. Si vous souhaitez monter la station

différemment, veuillez contacter votre fournisseur.

Perçages

Lorsque les sous-stations doivent être montées au mur, des perçages sont prévus

dans la plaque de montage arrière.

Étiquetage

Chaque raccordement de la sous-station est étiqueté.

Avant l’installation :

Nettoyage et rinçage

Avant l’installation, tous les tubes et raccordements de la sous-station doivent

être nettoyés et rincés.

Serrage

En raison des vibrations pendant le transport, tous les raccordements de la sous-station

doivent être contrôlés et resserrés avant l’installation. Vérifiez que toutes les goupilles

des raccords à encliqueter sont complètement enfoncées.

Personnel agréé uniquement

Le travail d’assemblage, de démarrage et de

maintenance doit être effectué uniquement par

un personnel qualifié et agréé.

Trou de serrure pour montage.

FR

Attention

L’utilisation de types d’emballage autres que