Page 1

Data sheet

Data sheet

Solenoid valve

Solenoid valve

Type EVO 100 - EVO 103

Type EVO 100 - EVO 103

EVO solenoid valves are packed with coil

BB230AS 230V/50Hz plus DIN plug and EVO

direct or servo operated solenoid valve suitable

for liquid, suction, and hot gas lines with most

refrigerants, including flammable refrigerants.

Features

Approvals

y Complete range of solenoid valves for

refrigeration, freezing and air conditioning

plant

y Supplied in versions normally closed (NC) with

de-energized coil

y Supplied with coil type BB230AS 230V/50Hz

and DIN plug according to DIN 43650-A PG 11,

enabling protection IP65 with mounted cable

plug

y Pressure Equipment Directive

(PED) 2014/68/EU

y Low Voltage Directive (LVD) 2014/35/EU

y EAC

y Suitable for most refrigerants, including

flammable refrigerants

y Designed for media temperatures up to 105 °C

y Solder connections up to 16 mm and 5⁄8 in

y Extended ends on solder versions make the

installation easy, eliminating the need to

dismantle the valve when soldering in

y UA

y CQC

y RoHS II

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 1

Page 2

Data sheet | Solenoid valve, types EVO 100 - EVO 103

Technical data

Refrigerants

R22/R407C, R134a, R404A/R507, R410A, R407A,

R32, R290, R600, R600a, R1234yf, R1234ze, R404A,

R407F, R407H, R125, R152A, R448A, R449A,

R452A, and R450A.

For a complete list of approved refrigerants,

visit www.products.danfoss.com and search for

individual code numbers, where refrigerants are

listed as part of technical data.

Special note for R152A, R32, R290, R600,

R600a, R1234yf, and R1234ze:

This product is validated in accordance to

ISO 5149, IEC 60335. Ignition risk is evaluated in

accordance to ISO 5149 and IEC 60335.

See safety note at the bottom of this page.

Media temperature

-40 – 105 °C

Max. 130 °C during defrosting

Ambient temperature and enclosure for coil

80 °C IP65 with DIN plug mounted.

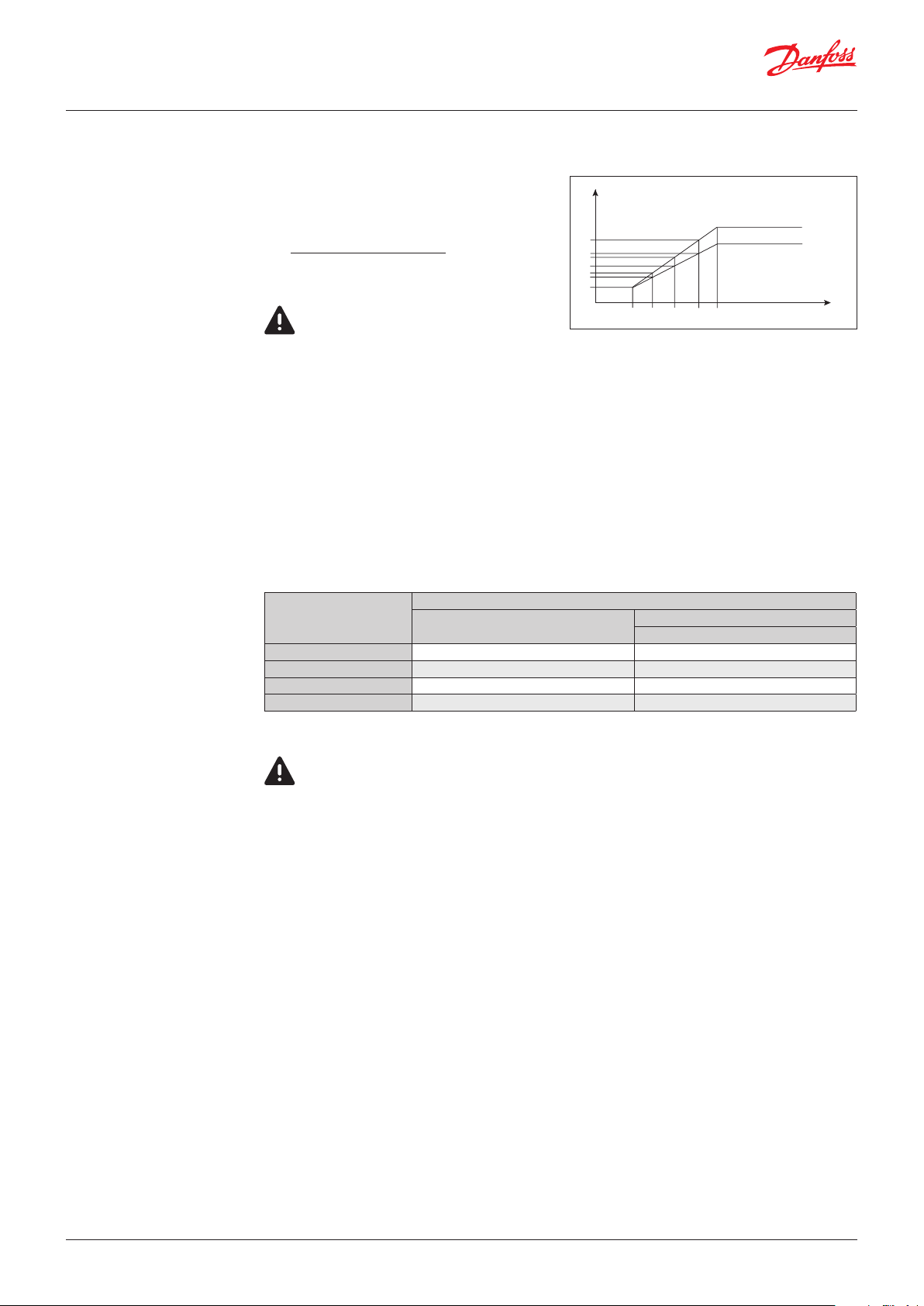

Max. working pressure

EVO solder connections: 45.2 bar.

Bar

34.65

24.75

24.1

17.5

13.55

10.25

3

-40

Max. working pressure in bar in relation to media temperature

in °C

0-10-20-30

45.2 bar

32 bar

°C

Capacity

See Kv values from the table.

The Kv value is the water flow in [m3/h] at a

pressure drop across valve of 1 bar,

ρ = 1000 kg/m3.

See extended capacity tables later in this data

sheet.

Opening differential pressure with standard coil Δp [bar]

Type

EVO 100 0.00 38

EVO 101 0.00 38

EVO 102 0.03 38

EVO 103 0.03 38

The EVO 100 - EVO 103 with solder connections

can be applied on systems with R152A, R32,

R290, R600, R600a, R1234yf, and R1234ze as the

working fluid.

Min.

For countries where safety standards are not an

indispensable part of the safety system Danfoss

recommends the installer gets a third party

approval of any system containing flammable

Max. (= MOPD) liquid

AC coil [10 W]

refrigerant.

Note: please follow specific selection criteria

stated in the datasheet for these particular

refrigerants.

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 2

Page 3

Data sheet | Solenoid valve, types EVO 100 - EVO 103

Rated capacity [kW]

For other refrigerants, refer

to Coolselector®2

Ordering

EVO solder connection,

Normally Closed (NC)

- separate valve bodies

EVO 100/EVO 101

EVO 101 R22/R407C R134a R404A/R507 R410A R32 R290 R600a

Liquid

EVO 100 3.02 2.79 2.04 2.96 4.23 3.36 3.38

EVO 101 5.43 5.02 3.68 5.32 7.61 6.05 6.09

EVO 102 17.90 16.56 12.12 17.55 25.09 19.93 20.07

EVO 103 37.62 34.80 25.47 36.88 52.71 41.88 42.17

Suction vapour

EVO 100 0.33 0.24 0.29 0.42 0.54 0.41 0.23

EVO 101 0.60 0.44 0.52 0.75 0.96 0.73 0.41

EVO 102 1.98 1.44 1.72 2.48 3.18 2.42 1.35

EVO 103 4.15 3.02 3.62 5.22 6.67 5.09 2.83

Hot gas

EVO 100 1.35 1.04 1.10 1.65 2.18 1.54 0.94

EVO 101 2.42 1.87 1.99 2.98 3.92 2.76 1.70

EVO 102 7.99 6.16 6.56 9.81 12.91 9.11 5.61

EVO 103 16.78 12.94 13.78 20.61 27.12 19.14 11.78

Rated liquid and suction vapor capacity is based on evaporating temperature te = -10 °C,

liquid temperature ahead of valve tl = 25 °C, pressure drop in valve Δp = 0.15 bar.

Rated hot gas capacity is based on condensing temperature tc = 40 °C,

pressure drop across valve Δp = 0.8 bar, hot gas temperature th = 65 °C,

and subcooling of refrigerant Δtsub = 4 K.

Type

EVO 100 6 0.15 24

EVO 100 1/4 0.15 24

EVO 101 6 0.26 24

EVO 101 10 0.26 24

EVO 101 1/4 0.26 24

EVO 102 10 1.0 12

EVO 102 12 1.0 12

EVO 103 12 2.2 12

EVO 103 16 5/8 2.2 12

All valves equipped with coil type BB230AS 230V/50 Hz code No. 018F7351 + DIN plug 042N0156

Solder connections

[mm] [inch]

Kv value

[m3/h]

Multipack quantity

EVO code no.

(complete valves)

032L2010

032L2011

032L2030

032L2031

032L2032

032L2060

032L2061

032L2070

032L2071

EVO 102

EVO 103

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 3

Page 4

Data sheet | Solenoid valve, types EVO 100 - EVO 103

Function

See Design drawings for

additional details

on the following pages

EVO solenoid valves are designed on two

different principles:

1. Direct operation

2. Servo operation

1. Direct operation (NC)

EVO 100 - EVO 101 are direct operated. The valves

open directly for full flow when the armature (3)

moves up into the magnetic field of the coil.

This means that the valves operate with a

minimum differential pressure of 0 bar.

The seat plate is fitted directly on the

armature (3).

Inlet pressure acts from above on the armature

and the valve plate. Thus, the inlet pressure and

spring force act to close the valve when there is

no current in the coil.

2. Servo operation (NC)

EVO 102 - EVO 103 are servo operated with a

“floating” diaphragm (4). The pilot orifice of

stainless steel is placed in the center of the

diaphragm. The seat plate is fitted directly to the

armature (3). When there is no current in the coil,

the main orifice and pilot orifice are closed.

The pilot orifice and main orifice are held closed

by the armature spring force and the differential

pressure between inlet and outlet sides.

When current is applied to the coil, the armature

is drawn up into the magnetic field and opens

the pilot orifice. This relieves the pressure

above the diaphragm, i.e. the space above the

diaphragm becomes connected to the outlet side

of the valve.

The differential pressure between inlet and

outlet sides then presses the diaphragm away

from the main orifice and opens it for full flow.

Therefore a certain minimum differential pressure

is necessary to open the valve and keep it

open. EVO 102 - EVO 103 valves the minimum

differential pressure for safe operation is 0.03 bar.

When the current is switched off, the pilot

orifice is closed. Via the equalization holes in the

diaphragm, the pressure above the diaphragm

rises to the same value as the inlet pressure and

the diaphragm closes the main orifice.

Alternatively, all EVO valves can be manually

operated by removing the coil and force the valve

open or closed by using a solenoid valve tester

(permanent magnet) code no. 018F0091.

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 4

Page 5

Data sheet | Solenoid valve, types EVO 100 - EVO 103

EVO 100 - EVO 101

Solder connection

Dimensions [mm]

A

B

L1

Type

EVO 100 6 mm

EVO 100

EVO 101 6 mm

EVO 101 10 mm

EVO 101

A B L1 [mm] L2 [mm]

1

⁄4 in

1

⁄4 in

L2

Connection Length

8 mm

8 mm 101 115 032L2011

8 mm

12 mm

8 mm 101 115 032L2032

101 115 032L2010

101 115 032L2030

117 123 032L2031

EVO code no.

(complete valves)

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 5

Page 6

EVO 102 - EVO 103 Solder connection - Dimensions [mm]

EVO 102 solder connection 10 mm (code no. 032L2060)

EVO 103 solder connection 12 mm (code no. 032L2070)

EVO 102 solder connection 12 mm (code no. 032L2061)

EVO 103 solder connection 16 mm / 5⁄8 in (code no. 032L2071)

© Danfoss | DCS (az) | 2018.07

DKRCC.PD.B00.X1.02 | 6

Loading...

Loading...