Data sheet

Servo-operated 2/2-way solenoid valves

Type EV220B 65 - EV220B 100

EV220B 65 - EV220B 100 is a 2/2-way solenoid

valve program for use in robust industrial

applications, demanding high flow rates.

The valve is designed with cast iron valve

body and flanged connection.

Water-hammer damped design and built-in pilot

filter ensures a reliable operation.

Features y For water and similar neutral media

y Flow range for water KV: 50 - 130 m³/h

y Ambient temperature: Up to 80 °C

y Differential pressure: Up to 10 bar

y Viscosity: Up to 50 cSt

y Coil enclosure: Up to IP67

y Flange connections: 2 ½, 3 and 4”

y Water hammer damped

y Built-in filter for protection of pilot system

y Seal material: EPDM and NBR

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 1

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

ON

OFF

24h

EV220B 65-100

Valve body with flange

connection

Technical data

Connection

ISO 228/1

Seal

mate rial

Orifice

size

[mm]

kv - value

[m³/ h]

Differential pressure,

min. to max.

[bar]

Media

temperature

min. to max.

[°C]

Code number

2 ½ EPDM 65 50 0.25 – 10 -25 – 90 016D6065

2 ½ NBR 65 50 0.25 – 10 -25 – 90 016D3330

3 EPDM 80 75 0.25 – 10 -25 – 90 016D6080

3 NBR 80 75 0.25 – 10 -25 – 90 016D3331

4 EPDM 100 130 0.25 – 10 -25 – 90 016D6100

1

) It is recommended to use filter in front of the valve. Recommended filter 50 mesh (297 microns).

2

) In water applications, exercise the valves at least once every 24 hours, meaning change the state of the valve. The valve exercise

will minimize the risk of the valve sticking due to calcium carbonate, zinc or iron oxide build-up.

3

)

To minimize scaling, and corrosion attack it is recommended that the water passing the valve have the following values:

- Hardness 6-18 °dH to avoid scaling (chalk / lime stone build up)

- Conductivity 50 – 800 µS/cm to avoid brass dezincification and corrosion.

- Above 25°C media temperature avoid stagnant water inside the valve to avoid dezincification and corrosion attack.

Main type EV220B 65 EV220B 80 EV220B 100

Time to open [s] 1)

Time to close [s] 1)

1)

The times are indicative and apply to water.

5 5 5

7 15 29

Type EV220B 65 - EV220B 100

Installation Vertical solenoid system is required (see page 5, mounting angle)

Max. test pressure 15 bar

Ambient temperature Up to 80 °C

Viscosity Max. 50 cSt

Materials

Valve body: Cast iron W.no. 0.6020

Armature: Stainless steel W.no. 1.4105/AISI 430L

Armature tube: Stainless steel W.no. 1.4306/AISI 304L

Springs: Stainless steel W.no. 1.4310/AISI 301

Pilot body Brass –

Ring Copper –

NBR, Cetellen WS3820,

PTFE, EPDM, CR

NBR, centellen WS3820,

PTFE

–

–

Media

EPDM version

NBR version

EPDM version Water, Brine, Glycol –

NBR version Air, Oil –

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 2

1

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

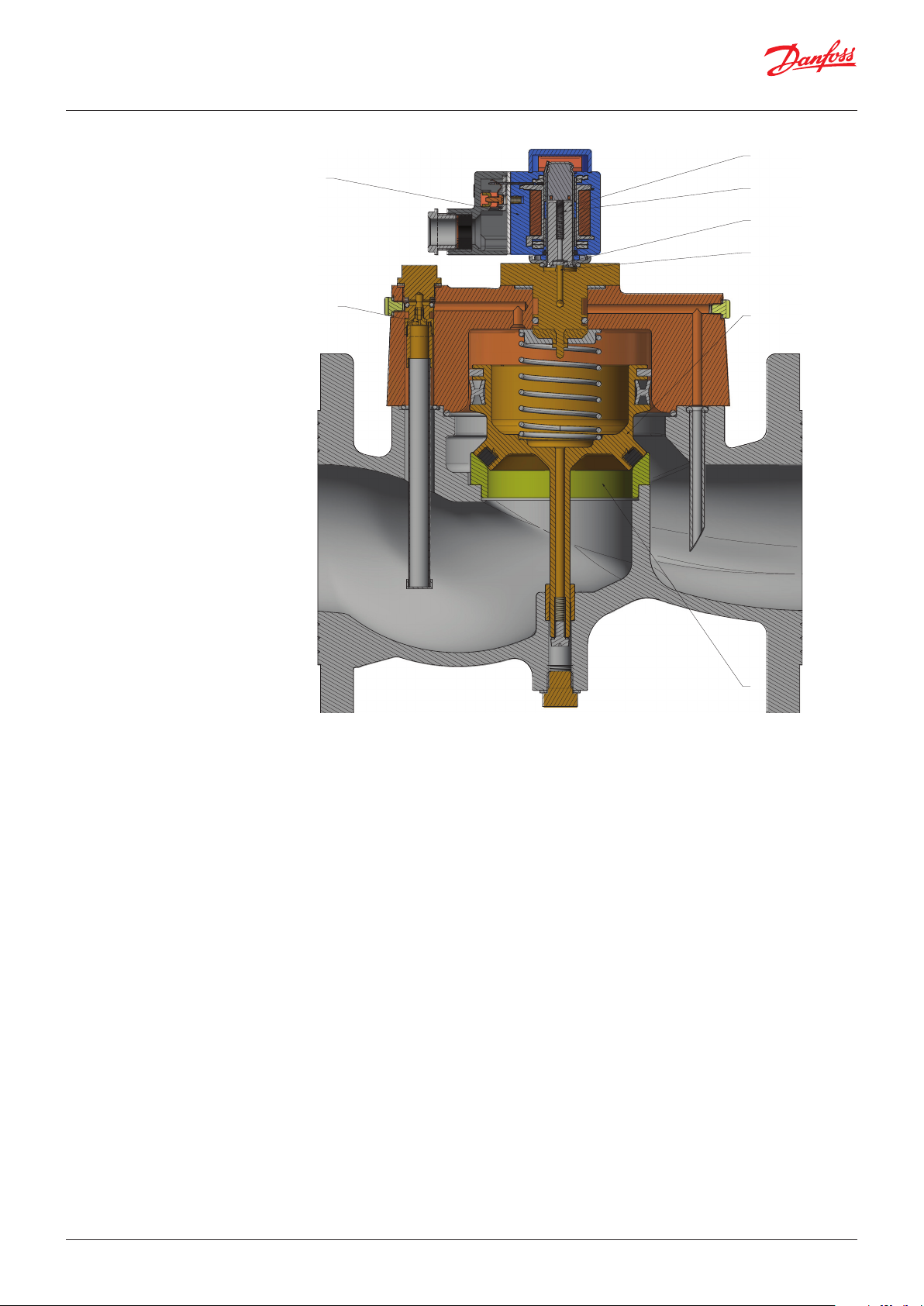

Function

7

2

3

4

1. Armature

2. Closing spring in pilot system

3. Valve plate

4. Pilot orifice

5. Servo piston

6. Main orifice

7. Coil

8. Equalizing orifice

8

Coil voltage disconnected (closed):

When the voltage is disconnected, the valve plate

(3) is pressed down against the pilot orifice (4) by

the pilot system’s closing spring (2).

The pressure across the servo piston (5) is built

up via the equalizing orifice (8). The servo piston

closes the main orifice (6) as soon as the

pressure across the piston is equivalent to the

inlet pressure.

The valve will be closed for as long as the voltage

to the coil is disconnected.

5

6

Coil voltage connected (open):

When voltage is applied to the coil (7), the

armature (1) and the valve plate (3) are lifted

clear of the pilot orifice (4). As the pilot orifice is

larger than the equalizing orifice (8), the pressure

across the servo piston (5) drops and therefore it

is lifted clear of the main orifice (6).

The valve will be open for as long as the

minimum differential pressure across the valve is

maintained, and for as long as there is voltage to

the coil.

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 3

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

Below coils can be used with EV220B

Coil Type Power consumption Enclosure Features

Accessories:

Cable plug

BB, clip on

BE, clip on

BG, clip-on

Application Code number

GDM 2011 (grey) cable plug according to DIN 43650-A PG11 042N0156

10 W AC

18 W DC

10 W AC

18 W DC

12 W AC

20 W DC

IP00

with spade connector

IP67 With terminal box

IP67 With terminal box

IP20 with protective cap,

IP65 with cable plug

Ordering of flange set

Manuel override kit,

hand operated

© Danfoss | DCS (sb) | 2020.08

Connection Type Code number

2 ½ weld type 11 according to DIN EN 1092-1 EV220B 65 027N3065

3 weld type 11 according to DIN EN 1092-1 EV220B 80 027N3080

4 weld type 11 according to DIN EN 1092-1 EV220B 100 027N3100

Seal material Description Code number

EPDM

Manuel override kit. used for manuel overrride in event of power failure.]

Note: Valve height is increased by 16 mm

032U7390

AI243586443728en-000901| 4

H

D

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

Dimensions and weight

Dimensions

Type

L

[mm]

L

1

[mm]

Required

min. L2*

(mm)

B1 [mm]

Coil type

BB/

BE

BG

øD

[mm]

H1

[mm]

[mm]

H2

Weight

without

coil

[kg]

Required

min. inside

tube diameter

d** (mm)

EV220B 65 320 224 300 46 66 185 85 185 24 65

EV220B 80 370 265 350 46 66 200 93 215 34 80

EV220B 100 430 315 400 46 66 220 103 240 44 100

70

d

100

min. L2min. L2

1

H

L1

L

*Avoid closing problems caused by turbulent flow it is required to have a straight tube on both sides of the

valve.

** Required to keep same tube size for entire application, same or bigger inside diameter as valve orifice

65 / 80 / 100 mm

2

Mounting angle

5

X

°

A

M

°

5

M

A

X

°

5

5

°

X

A

M

M

A

X

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 5

n

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

Application diagram

Water

supply

1

2

Applicatio

N0. Part

1 Filter

2

3

4

Ball valve,

Water supply

Ball valve,

Test reservior

Ball valve,

Application

Capacity diagram for

EV220B 65 - 100

Example, water:

Capacity for EV220B 65 at differential

pressure of 4 bar: Approx. 100 m³/h

Recommended operating range:

Grey area 1-6 bar differential pressure.

A

A

4

3

Test

reservoir

x

∆

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 6

Data sheet | Solenoid valves, type EV220B 65 - EV220B 100

Periodic maintenance/inspection

Maintenance/Inspection every 6 to 12 months recommended.

Before starting maintenance/inspection be sure:

- Coil is not energized when removed from the armature tube.

- System/solenoid valve is not pressurerised. Eventually close ball valves on each side of the valve.

– Be sure any pumps one the upstream (inlet supply) will not be energized or a pressure sensor or switch will not start the pump.

- After cleaning and service, eventually with Danfoss spare part kit, it is recommended to lubricate piston and piston sealing with a

thin layer of lubrication included into the spare part kit.

Frequency and maintenance depend largely on the application and the medium used in the valve. Mechanical contaminants, iron,

excessive mineralization, through the valve or may cause problems with the operation of the valves. All maintenance and repair work

should be carried out by technically trained personnel who are familiar with the operation of the installation.

In case of large impurities visible on the filter, piston scale and cover, other impurities inside the valve, the frequency of inspections

should be increased.

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 7

Sparepart kits

1

13

DN65 - DN100

Type

Spare part

kit EPDM

Spare part

kit NBR

EV220B 65 016D0078 016D0095

EV220B 80 016D0079 016D0096

EV220B 100

016D0080 –

Seal kit

EPDM

Seal kit

NBR

016D0075 016D0084

016D0076 016D0085

016D0077

016D0086

2

3

4

5

6

7

8

9

10

11

12

14

1. Armature +Spring

2. 2x O-ring

3. O-ring

4. Piston

5. O-ring

1

2

4

5

1. Steam gasket

2. 2x Sealing

3. Sealing

4. O-ring

5. Rubber gasket

6. O-ring

7. O-ring

8. 2x Steam gasket

9. O-ring

10. O-ring

11. Filter holder

12. Orifice

13. Filter

14. Drain plug

For detailed guidance see installation guides for EV220B 65-100 valve, spare part kit and seal kit

© Danfoss | DCS (sb) | 2020.08

AI243586443728en-000901| 8

Loading...

Loading...