Page 1

Data Sheet

Electric expansion valve

Type ETS 8M

ETS 8M is a stepper motor driven electric

expansion valve with a high level of reliability,

and it provides a precise solution for expansion

and ow control in a wide range of

refrigeration and air conditioning system. The

valve comes with two ow curve options, a

linear and a S-shaped characteristic.

ETS 8M can be applied for applications i.e.

Modular Chiller and Low Ambient Temp Heat

Pump in single/bi-ow operations.

Valve operation is by means of a uni-polar

motor, and as such it is compatible with a

number of electronic controllers from Danfoss

or third-party vendors.

Features:

• High MOPD to comply with compressor

operating envelope

• Low internal leakage

• Long lifetime and durability

• Optimized valve ow characteristic

• Stable ow control at low opening degree

• Dedicated ow control curve for heat pump

• Compatible with existing valve drivers

• Bi-ow, with good performance in both ow

directions

• Flexible installation: vertical orientation

±90°C

• Coil enclosure up to IP67

• In accordance with

◦ JB/T 10212

◦ RoHS (China and EU)

◦ REACH

◦ PED

AI395332395118en-000102

Page 2

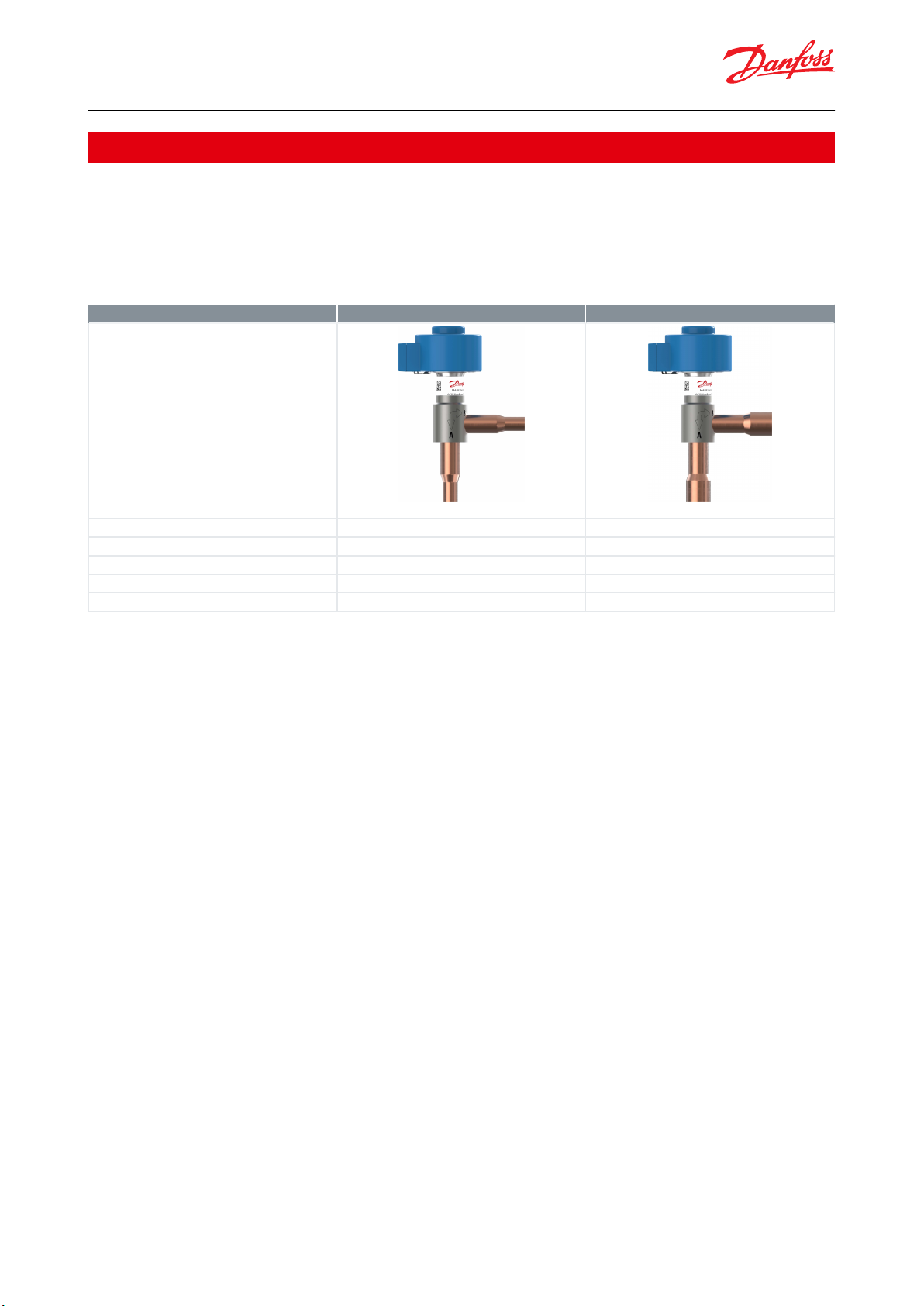

Features

ETS 8M

ETS 8M

Solder connection

Copper

Copper

Size [mm]

4.0 – 4.5

4.0 – 6.5

Connection size

ODM 3/8”

ODM 5/8”

Max. working pressure [bar]4949

Brazing connector conguration

Angle way

Angle way

Electric expansion valve, type ETS 8M

Portfolio overview

ETS 8M is a system product whose function is controlled through a Danfoss electronic controller or a third-party

vendor electronic controller that is compatible with the ETS 8M as to control functionality and connections.

The electronic controller requires precise temperature input from a temperature sensor (refrigerant temperature)

and precise pressure inputs (evaporator pressure) from a pressure transmitter.

Table 1: Portfolio overview

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 2

Page 3

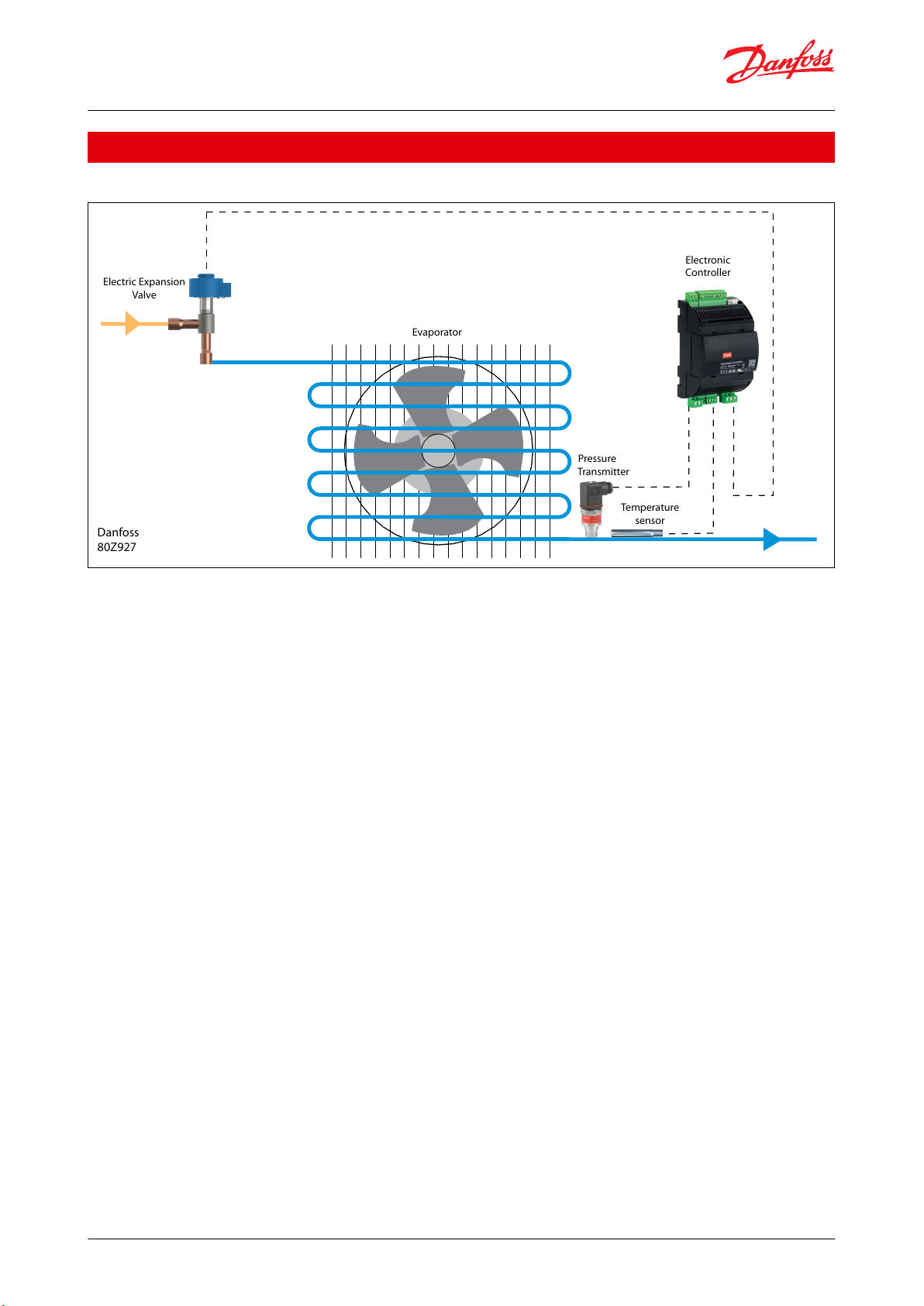

Danfoss

80Z927

Electric Expansion

Valve

Electronic

Controller

Pressure

Transmitter

Temperature

sensor

Evaporator

Electric expansion valve, type ETS 8M

Application

Figure 1: Typical application of ETS 8M

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 3

Page 4

Refrigerants

R410A, R32, R407C, R290, R454B, R452B, R454C, R513A, R449B, R404A,R448A,

R449A, R515B, R452A, R134a, R1234ze

Oil

POE, PVE

Electric expansion valve, type ETS 8M

Media

ETS 8M is designed for use with uorinated refrigerants with suitable lubricants.

Table 2: ETS 8M media data

NOTE:

For ammable refrigerants (R454C, R290, R32, R452B, R454B):

• This product is validated in accordance to ATEX, EN 378, ISO 5149, ASHRAE 15, IEC 60335-2-x or equivalent

standards.

• Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335.

• See safety note below.

NOTE:

• The product can be applied on systems with R454C, R290, R32, R452B, R454B as the working uid.

• For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing ammable refrigerant.

•

Note, please follow specic selection criteria stated in the datasheet for these particular refrigerants.

• The valve must only be used in closed circuit refrigeration system, where no oxygen is present acc. EN 378, ISO

5149 ASHRAE 15 or IEC 60335-2-x or equivalent standards.

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 4

Page 5

B

A

Data

Value [SI units]

Value [IMP. Units]

Max. working pressure (MWP)

49 barg

710 psig

Burst pressure

5 x MWP

5 x MWP

Max. operating pressure

dierential (MOPD)

B->A, 39 barg

A->B, 32 barg

B->A, 565 psig

A->B, 464 psig

Ambient temperature

-30 - 70

〫°C

-22 - 158

〫°F

Ambient relative humidity

Max 95%RH

Max 95%RH

Fluid temperature range

-30 - 70

〫〫〫°C

-22 - 158

〫〫°F

Data

Value

Max. internal leakage @10 bar

< 800 cm

3

/min

Mechanical noise

Normal operating <60 dB(A) 15 cm away, Overdriving <70 dB(A) @ 15 cm away

Enclosure rating IP (Valve and coil combined)

IP67

Insulation class

Class B

Insulation resistance

>100MΩ

Storage temperature

-30°C to 60°C

Electric expansion valve, type ETS 8M

Product specication

Design

The ETS 8M Electric expansion valves open and close to regulate refrigerant ow by means of a screw whose

rotating motion is transformed into linear motion. This occurs by the rotation of a magnet needle valve assembly

which moves when electrical signals are applied to the surrounding coil. Within the coil structure, there are dierent

winding congurations, and the polarities are changed by the electrical signals applied.

By application of the appropriate combination of signals, in the form of pulses, the coil forces the rotor of the valve

to move in a stepwise fashion. Application of multiple pulses will make the valve mechanism move through a series

of steps in the chosen direction, in order to set the valve with the required opening degree.

Flow direction

Figure 2: Flow direction

ETS 8M is designed for normal and reverse ow direction, above image from B to A refers the normal ow.

Pressure and temperature data

Table 3: Pressure and temperature data in SI and Imperial units

Environmental conditions

Table 4: Environmental conditions

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 5

Page 6

0

20

40

60

80

100

120

0 100 200 300 400 500 600

Capacity (kw)

Step

Linear capacity - Normal flow directi on B->A

Orifice 4.0 Orifice 4.5 Orifice 5.5 Orifice 6.5

0

20

40

60

80

100

120

0 100 200 300 400 500 600

Capacity (kw)

Step

Linear capacity - Reverse flow directi on A->B

Orifice 4.0 Orifice 4.5 Orifice 5.5 Orifice 6.5

Electric expansion valve, type ETS 8M

Flow characteristics

Figure 3: Linear capacity - Normal ow direction B → A

Figure 4: Linear capacity - Reverse ow direction A → B

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 6

Page 7

0

20

40

60

80

100

120

140

0 100 200 300 400 500 600

Capacity (kw)

Step

S-shape capacity - Normal flow direc�on B->A

Orifice 4.0 Orifice 4.5 Orifice 5.5 Orifice 6.5

0

20

40

60

80

100

120

0 100 200 300 400 500 600

Capacity (kw)

Step

S-shape capacity - Reserve flow direc�on A->B

Orifice 4.0 Orifice 4.5 Orifice 5.5 Orifice 6.5

Electric expansion valve, type ETS 8M

Figure 5: S-shaped capacity - Normal ow direction B → A

Figure 6: S-shaped capacity - Reverse ow direction A → B

NOTE:

The rated capacity is based on:

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 7

Page 8

Electrical and motor

specications

Value

Motor type

Uni-polar input from controller

Nominal voltage

12V -15% / +10% DC

Coil resistance @ 20°C

46 ± 3 Ω

Rated current

261 mA

Permanent holding current

No holding current

Open pulses

Max. 52 steps

Number of pulses

500 half-step pulses

pulse rate

30 - 90 pps

Maximum duty cycle (30s)

50%

Insulation resistance

>100 MΩ

Dielectric strength

< 5 mA

Ex-factory delivery valve position

Packed in 300 steps open valve position

Cable Color

Excitation Sequence

-> Valve opening

<- Valve closing

1234567

8

OrangeONON

OFF

OFF

OFF

OFF

OFF

ON

Red

OFFONONONOFF

OFF

OFF

OFF

Yellow

OFF

OFF

OFFONONONOFF

OFF

Black

OFF

OFF

OFF

OFF

OFFONON

ON

GreyONONONONONONONON

Electric expansion valve, type ETS 8M

• Refrigerant: R410A

• Evaporating temperature: Te = 5°C

• Condensing temperature: Tc = 38°C

• Refrigerant temperature ahead of valve: T

liquid

= 34°C

• Subcooling = 4k

• Superheat = 0K

• Driving steps = 500steps

NOTE:

The reverse ow capacity of Orice 4.0 and 4.5 with 3/8" connection is slightly lower than the 5/8" connection,

please contact Danfoss for more details.

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector

®

Rated and extended capacities are calculated with Coolselector®2 calculation engine to ARI standards with the

ASEREP equations based on laboratory measurements of selected valves.

Electrical connection

Electrical connection is via a xed cable in a number of lengths from the coil to the controller. Cables up to 6 m

length are available with a JST XHP-5 / JST XHP-6 connector. See ETS 8M ordering for details.

Electrical and motor specications

Valve operation is by means of a Uni-polar motor, designed as a separate coil that clicks onto the valve body.

Table 5: Electrical and motor specications

Stepper motor switch sequence

The stepper motor opens and closes as outlined in the table, opening moving to the right of the table, closing

moving the opposite direction.

Table 6: Stepper motor switch sequence

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 8

Page 9

ETS 8M 3/8” ODM

ETS 8M 5/8” ODM

48.1

3

mm

1.89

0.12

in

[

]

5

0

.

2

3

m

m

1

.

9

8

0

.

1

2

i

n

[

]

9

,

5

2

0

,

0

4

O

D

M

3

/

8

i

n

(

m

m

)

9,52

0,04

ODM 3/8 in ( mm)

22.5 mm

[ 0.89 in]

1

1

4

.

4

m

m

[

4

.

5

1

i

n

]

(

)

43.1 mm

[ 1.70 in]

( )

53.9 mm

[2.12 in]

( )

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

±

±

±

±

± ±

1

5

,

8

8

0

,

0

4

O

D

M

5

/

8

i

n

(

m

m

)

15,88

0,04

ODM 5/8 in ( mm)

22.5 mm

[ 0.89 in]

1

1

4

.

4

m

m

[

4

.

5

1

i

n

]

(

)

53.9 mm

[2.12 in]

( )

43.1 mm

[ 1.70 in]

( )

48.1

3

mm

1.89

0.12

in

[

]

5

0

.

2

3

m

m

1

.

9

8

0

.

1

2

i

n

[

]

Ø

Ø

Ø

Ø

Ø

Ø

Ø

Ø

±

±

±

±

± ±

Electric expansion valve, type ETS 8M

Dimensions

Table 7: Dimensions

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 9

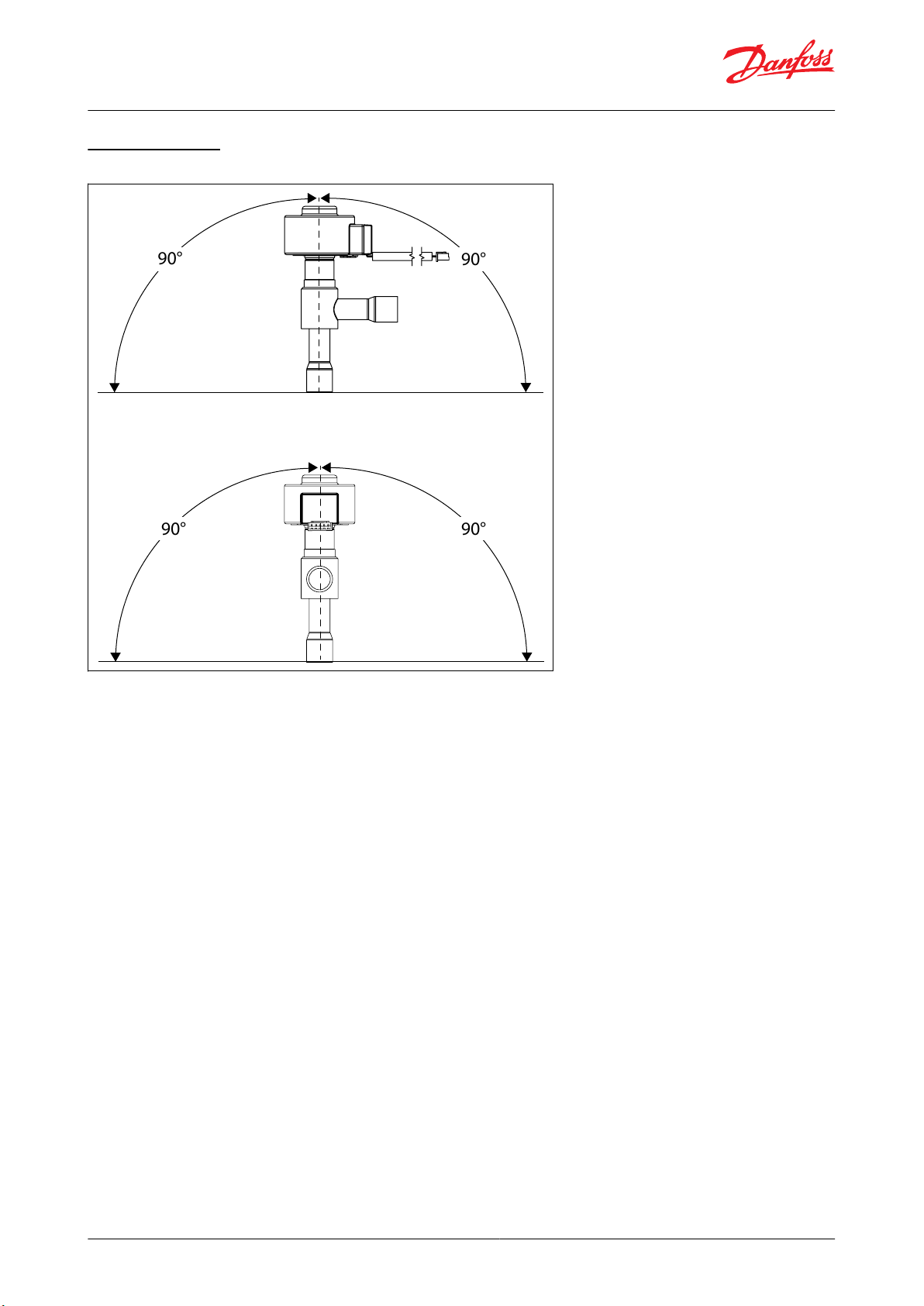

Page 10

90°

90°

90°

90°

Electric expansion valve, type ETS 8M

Mounting angle

Figure 7: Mounting angle

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 10

Page 11

ETS 8M valve body

ETS 5M coil

Orice

size

Connection size

Flow curve

Code no.

Capacity [R410A] *

Packing

ODM [in]

B->A

A->B

Orice Ø4.0

3/8

Linear

034G8800

60.0 kW

55.6 kW

Multi-pack 12 pcs

5/8

034G8801

62.8 kW

60.0 kW

Multi-pack 12 pcs

3/8

S-shape

034G8802

60.0 kW

55.6 kW

Multi-pack 12 pcs

5/8

034G8803

62.8 kW

60.0 kW

Multi-pack 12 pcs

Orice Ø4.5

3/8

Linear

034G8804

81.2 kW

72.8 kW

Multi-pack 12 pcs

5/8

034G8805

91.0 kW

83.6 kW

Multi-pack 12 pcs

3/8

S-shape

034G8806

81.2 kW

72.8 kW

Multi-pack 12 pcs

5/8

034G8807

91.0 kW

83.6 kW

Multi-pack 12 pcs

Orice Ø5.5

5/8

Linear

034G8808

102.0 kW

86.7 kW

Multi-pack 12 pcs

Multi-pack 12 pcs

5/8

S-shape

034G8809

Multi-pack 12 pcs

Multi-pack 12 pcs

Orice Ø6.5

5/8

Linear

034G8810

114.2 kW

103.2 kW

Multi-pack 12 pcs

Multi-pack 12 pcs

5/8

S-shape

034G8811

Multi-pack 12 pcs

Multi-pack 12 pcs

Valve type

Connection size

Electrical connector

Code no.

Packing

[m]

[in]

ETS 8M278.7

JST XHP-5

034G8300

Multi-pack 12 pcs

ETS 8M3118.1

JST XHP-5

034G8301

Multi-pack 12 pcs

ETS 8M6236.2

JST XHP-5

034G8302

Multi-pack 12 pcs

ETS 8M278.7

JST XHP-6

034G8303

Multi-pack 12 pcs

ETS 8M3118.1

JST XHP-6

034G8304

Multi-pack 12 pcs

ETS 8M6236.2

JST XHP-6

034G8305

Multi-pack 12 pcs

Electric expansion valve, type ETS 8M

Ordering

Parts program

ETS 8M is a parts program consisting of a valve body and a separate Uni-polar motor coil (ETS 8M coil). Each

component is purchased separately. See ordering details below.

Table 8: ETS 8M program

Besides using the ETS 8M coil as spare part, ETS 8M valve is hermetic and unserviceable, therefore is no other spare

parts.

Valve body, ordering codes

Table 9: ETS 8M valve body

Coil, ordering codes

Coils for ETS 8M are dedicated for the product

Table 10: Coils for ETS 8M

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 11

Page 12

Description

Explanation

Electric exp. Valve

Product name

034G8800

Code no.

ETS 8M40L

Product type

PS 49 bar/MWP 711 psig

Max. working pressure

-30/+70°C / -22/+158°F

Refrigerant temperature

MADE IN CHINA

Country of origin

6430 Nordborg, Denmark

Manufacturer address

Data matrix symbol

Machine readable data matrix

Coil for

ETS 8M

034G8300

12V DC

S/N: JS2121A12588

MADE IN CHINA

Danfoss A/S, 6430 Nordborg, Denmark

Description

Explanation

MADE IN CHINA

Country of origin

Coil for ETS 8M

Product type

034G8300

Code no.

12V DC

Rated voltage

S/N: JS2121A12588

Serial no.

Danfoss A/S, 6430 Nordborg, Denmark

Manufacturer address

Data matrix symbol

Machine readable data matrix

Electric expansion valve, type ETS 8M

Product identication

Relevant product data is available on the product label.

Figure 8: Product label, ETS 8M valve body

Table 11: Valve body, ETS 8M

Figure 9: Coil marking, ETS 8M

Table 12: Coil, ETS 8M

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 12

Page 13

Pressure Equipment Directive

Restriction of Hazardous Substances

Registration, Evaluation, Authorisation and Restriction of Chemicals

Electric expansion valve, type ETS 8M

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Approval

ETS 8M complies with:

Table 13: Compliance table ETS 8M

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 13

Page 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.03 AI395332395118en-000102 | 14

Loading...

Loading...