Page 1

Data sheet

Electric expansion valves

Type ETS 6

The range of Electric expansion valves are based

on many years of experience.

ETS 6 secure reliability and provide a precise

solutions for ex pansion and flow control in a

wide range of refrigeration and air conditioning

systems.

Compact and lightweight. The current range is

available with a wide capacity range, and can be

used with all common fluorinated refrigerants.

Bi-flow operation is also possible for heat pump

systems.

The valve operation is by means of a uni-polar

motor, which can be controlled by a number of

controllers from Danfoss or third party vendors.

With an EKE 1V and EIM 336 (current drivers) and

an AKS sensor, an accuracy better than

± 0.5 K can be obtained.

Please contact Danfoss for more details.

Features • Optimized energy efficiency of the system.

• Precision flow control with high resolution.

• Compact and lightweight.

• Energy saving design.

• Proven know-how and high reliability.

• Wide range for all common refrigerants.

• Bi-flow for heat pump applications.

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 1

Page 2

Data sheet | Electric expansion valves, type ETS 6

Approvals

Technical data

Complies with:

EC PED 97/23/EC a3P3, RoHS, REACH

UL (Danfoss UL file no. is MH 7648.) and CQC

Valve data

Flow characteristic Bi-flow.

Maximum working pressure 47 bar / 681 psig.

Compatible refrigerants

Refrigerant oil All mineral oils and ester oils (to lubricate ETS 6 valve).

Ambient temperature

Fluid Temperature

(measured at the inlet of the

valve like the image below)

Durability

Ambient humidity 95 % RH or less.

Capacity control range 10 % – 100 %

Electrical data

Modulation Permanent magnet type direct operating stepper motor.

Excitation method 1-2 phase.

Electrical connection JST XHP-6, JST XHP-5 and AMP connection.

Excitation speed min. 30 pps (pulses per second) to max. 90 pps, recommended 31 pps.

Operating range

Full motion transit time e.g. 16 sec @ 30 pps, 6 sec @ 80 pps

Installation position

Liquid line solenoid valve

Max. coil winding temperature 115 °C / 239 ° F

Compatible Danfoss controller EKE 1A, EKE 1B, EKE 1C, EIM 336 (for OEM only).

RoHS

R22, R32, R134a, R290, R404A, R407C, R407H, R410A, R448, R449A, R452A,

R452B, R454C, R463A, R513A, R1234yf (for flammable refrigerants follow EN 378

standard)

-30 – 70°C / -22 – 158 °F

-30 – 70°C / -22 – 158 °F

Tested for 60 Million total pulses supplies to the valve during partially open

valve, which is comparable to 150,000 cycles if the valve is operated between

100 to 300 pulses open.

Tested for 30,000 full stroke cycles including 20 pulse overdrive at each closing.

0 to 480 pulses, no holding power required (NOTE: do not apply more than

520 pulses).

With coil on the upper side and the valve/coil assembly within ±15˚of the

vertical axis

If using a liquid line solenoid valve, it must be installed in such a way that it

does not create liquid hammering this ETS 6 valve.

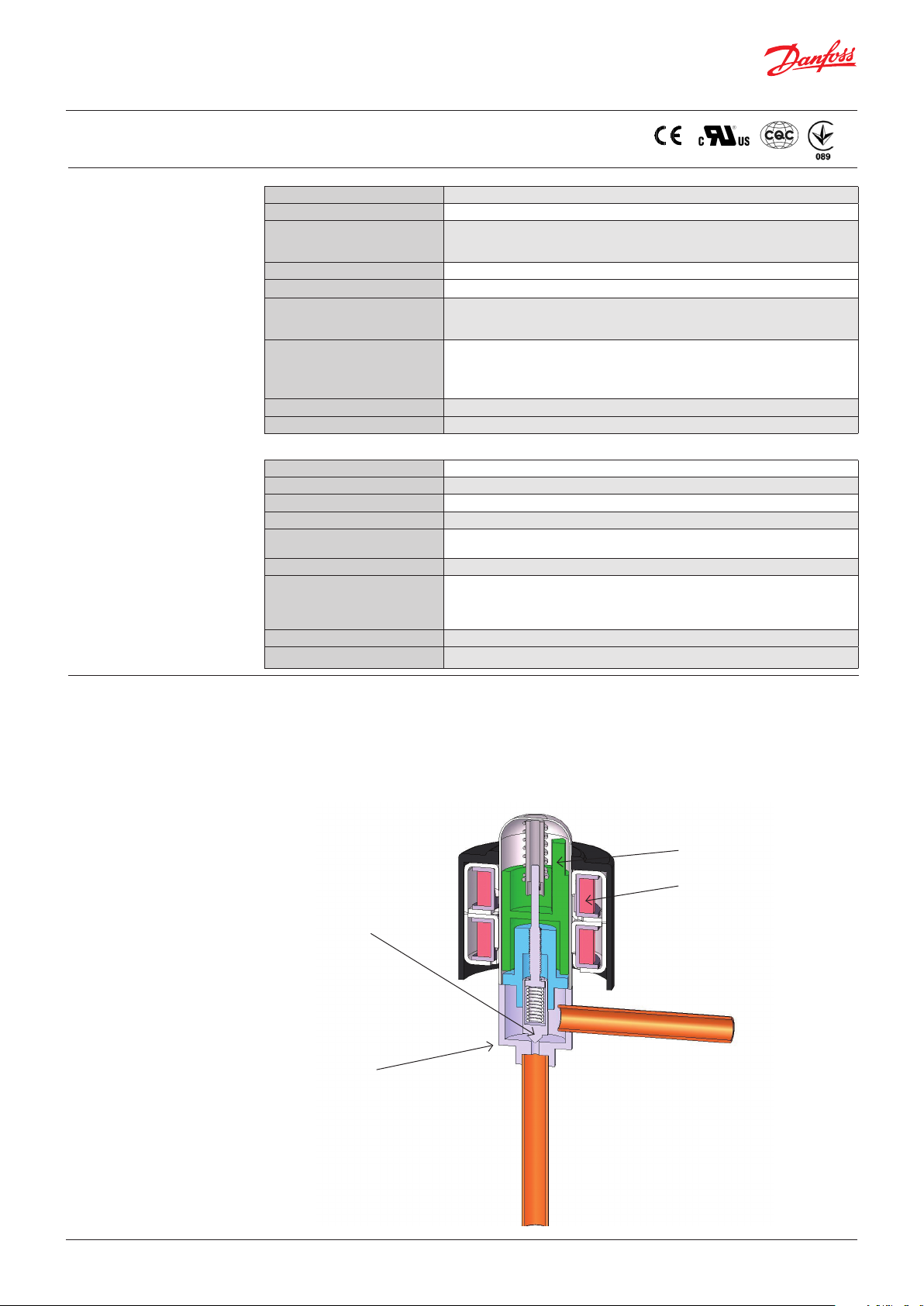

Design/function

The ETS 6 Electric expansion valves open and

close to regulate refrigerant flow by means of

a screw, whose rotating motion is transformed

into linear motion. This occurs by the rotation

of a magnet-needle valve assembly which

moves when electrical signals are applied to the

surrounding coil.

Within the coil structure, there are different

winding configurations, and the

Needle valve

Valve body

polarities are changed by the electrical signals

applied. By application of the appropriate

combination of signals, in the form of pulses,

the coil forces the rotor of the valve to move in a

stepwise fashion.

Application of multiple pulses will make the valve

mechanism to move through a series of steps

in the chosen direction, in order to set the valve

with the required opening degree.

Permanent magnet motor

Coil

Inlet (B*)

Outlet (A*)

© Danfoss | DCS (rm) | 2019.08

Bi-flow

Cross section diagram of ETS 6 series

* Refers to refrigerant flow in cooling mode

AI227986437323en-000901 | 2

Page 3

Data sheet | Electric expansion valves, type ETS 6

Valve ordering

Nominal Capacity kW

Orifice Nominal Capacity [kW]

Type

[mm] R22 R134a R404A R407C R410A

Connec-

tion

(solder)

A / B

[mm]

Valve

tube

confi-

guration

MWP MOPD

Reverse

Pressure

[bar] [bar] [bar]

Max.

1)

KV

[m3/h]

SI units

Code No.

Single pack

ETS 6 - 08 0.8 1.5 1.2 1.1 1.6 1.8 6.35 90° 47 35 20 0.011 034G5095

ETS 6 - 10 1 2.6 2 1.8 2.7 3.1 7.94 90° 47 35 35 0.030 034G5005

ETS 6 - 14 1.4 5.8 4.5 4.1 5.9 6.8 7.94 90° 47 35 20 0.052 034G5015

ETS 6 - 18 2) 1.8 10.3 8.1 7.3 10.6 12.1 6.35 90° 47 35 28 0.082 034G5026

ETS 6 - 25 2.5 19.6 15.3 13.8 20.1 23 7.94 90° 47 35 22 0.164 034G5035

ETS 6 - 32 3.2 28.8 22.5 20.3 29.6 33.9 7.94 90° 47 28 12* 0.242 034G5055

ETS 6 - 40 4 39.1 30.6 27.6 40.2 46 7.94 90° 47 21 7 0.329 034G5065

I-pack (100 units per box)

ETS 6 - 08 0.8 1.5 1.2 1.1 1.6 1.8 6.35 90° 47 35 20 0.011 034G5090

ETS 6 - 10 1 2.6 2 1.8 2.7 3.1 7.94 90° 47 35 35 0.030 034G5000

ETS 6 - 14 1.4 5.8 4.5 4.1 5.9 6.8 7.94 90° 47 35 20 0.052 034G5010

ETS 6 - 18 2) 1.8 10.3 8.1 7.3 10.6 12.1 6.35 90° 47 35 28 0.082 034G5024

ETS 6 - 25 2.5 19.6 15.3 13.8 20.1 23 7.94 90° 47 35 22 0.164 034G5030

ETS 6 - 32 3.2 28.8 22.5 20.3 29.6 33.9 7.94 90° 47 28 12* 0.242 034G5050

ETS 6 - 40 4 39.1 30.6 27.6 40.2 46 7.94 90° 47 21 7 0.329 034G5060

Nominal Capacity based on:

tC = 38 °C, te = 5 °C, SC = 0 °C, SH = 0 °C

* Please contact Danfoss if higher maximum reverse pressure valve is required.

1)

Max. Reverse Pressure = Pressure as which the valve can still close tightly in reverse direction (from A to B see fig. 1).

2

) For other connection size, please contact Danfoss.

Nominal Capacity [TR]

Orifice Nominal Capacity [TR]

Type

[in.] R22 R134a R404A R407C R410A

Connec-

tion

(solder)

A / B

[in.]

Valve

tube

confi-

guration

MWP MOPD

Reverse

Pressure

[psi] [psi] [psi]

Max.

1)

C

V

[gpm]

US units

Code No.

Single pack

ETS 6 - 08

ETS 6 - 10

ETS 6 - 14

ETS 6 - 18 2)

ETS 6 - 25

ETS 6 - 32

ETS 6 - 40

1

0.426 0.341 0.312 0.454 0.511

32

0

/

3

0.739 0.568 0.512 0.767 0.881

64

0

/

1

1.649 1.279 1.165 1.677 1.933

16

0

/

5

2.928 2.303 2.075 3.014 3.440

64

0

/

3

5.573 4.350 3.923 5.715 6.539

32

0

/

1

8.189 6.397 5.772 8.416 9.639

8

0

/

5

11.117 8.700 7.847 11.430 13.079

32

0

/

1

90° 681 507 290 0.013 034G5095

4

/

5

5

5

5

5

90° 681 507 507 0.035 034G5005

16

/

90° 681 507 290 0.060 034G5015

16

/

1

90° 681 507 406 0.099 034G5026

4

/

90° 681 507 319 0.190 034G5035

16

/

90° 681 406 174 0.280 034G5055

16

/

90° 681 304 101 0.380 034G5065

16

/

I-pack (100 units per box)

ETS 6 - 08

ETS 6 - 10

ETS 6 - 14

ETS 6 - 18 2)

ETS 6 - 25

ETS 6 - 32

ETS 6 - 40

1

0.426 0.341 0.312 0.454 0.511

32

0

/

3

0.739 0.568 0.512 0.767 0.881

64

0

/

1

1.649 1.279 1.165 1.677 1.933

16

0

/

5

2.928 2.303 2.075 3.014 3.440

64

0

/

3

5.573 4.350 3.923 5.715 6.539

32

0

/

1

8.189 6.397 5.772 8.416 9.639

8

0

/

5

11.117 8.700 7.847 11.430 13.079

32

0

/

1

90° 681 507 290 0.013 034G5090

4

/

5

5

5

5

5

90° 681 507 507 0.035 034G5000

16

/

90° 681 507 290 0.060 034G5010

16

/

1

90° 681 507 406 0.099 034G5024

4

/

90° 681 507 319 0.190 034G5030

16

/

90° 681 406 174 0.280 034G5050

16

/

90° 681 304 101 0.380 034G5060

16

/

Nominal Capacity based on:

tC = 100 °F, te = 41 °F, SC = 32 °F, SH = 32 °F

* Please contact Danfoss if higher maximum reverse pressure valve is required.

1)

Max. Reverse Pressure = Pressure as which the valve can still close tightly in reverse direction (from A to B see fig. 1).

2

) For other connection size, please contact Danfoss.

Product identification

© Danfoss | DCS (rm) | 2019.08

034G5xxx

7061

Valve

Danfoss code no.

Manufactoring no.

Coil

Manufacturing

no.

7061

Electric Expansion Valve

ETS 6

034G5xxx

Coil 12VDC / 3W

Product designation

Type

Danfoss code no.

Technical data

Contry of origin

AI227986437323en-000901 | 3

Made in YYY

Page 4

Data sheet | Electric expansion valves, type ETS 6

1

2

3

Coil ordering

Accessories

Single pack

Model

No.

Voltage

(current)

Enclosure

Insulation Cable length

class [m] [in.]

Connector

Units per

box

Single pack

Code No.

0.7 27.5 JST XHP-6 1 034G5105

0.7 27.5 JST XHP-5 1 034G5115

ETS 6 Coil

12 V DC

(0.26A/phase)

IP 66

Class “E”

(UL Class 105

(A))

1.5 59.0 JST XHP 5

2.0 78.7 JST XHP 5

3.0 118.0 JST XHP 5

0.6 23.6 AMP UPC- 6

1

1

1

1

034G5145

034G5185

034G5135

034G5175

I-pack

0.7 27.5 JST XHP-6 100 034G5100

0.7 27.5 JST XHP-5 100 034G5110

1.5 59.0 JST XHP 5 100 034G5140

2.0 78.7 JST XHP 5 100 034G5180

3.0 118.0 JST XHP 5 40 034G5130

ETS 6 Coil

12 V DC

(0.26A/phase)

IP 66

Class “E”

(UL Class 105

(A))

3.0 118.0 JST XHP 6 40 034G5150

0.6 23.6 AMP UPC- 6 100 034G5170

For the Danfoss controller select a ETS 6 coil with JST XHP-5 connector.

Type Description Code no.

ETS 6 manual coil Manual coil for service 034G5199

Stepper motor

switch sequence

Electrical wiring

Type Description Code no.

AST-G service driver Driver for service of the valve 034G0013

Coil I Coil II Common

Orange Yellow Red Black Gray

on off off off 0

on off on off 0

↓ OPENING ↓

off off on off 0

off on on off 0

↑ CLOSING ↑

off on off off 0

off on off on 0

off off off on 0

on off off on 0

4

6

© Danfoss | DCS (rm) | 2019.08

1

2

4

AMP UPC-6

Danfoss

80G322.10

3

5

6

JST XHP-5

JST XHP-6

Controller

The illustration shows the JST XHP-6 connetor. The coil with JST XHP-5 is identical except that it does not have an unused pin.

AI227986437323en-000901 | 4

Page 5

Data sheet | Electric expansion valves, type ETS 6

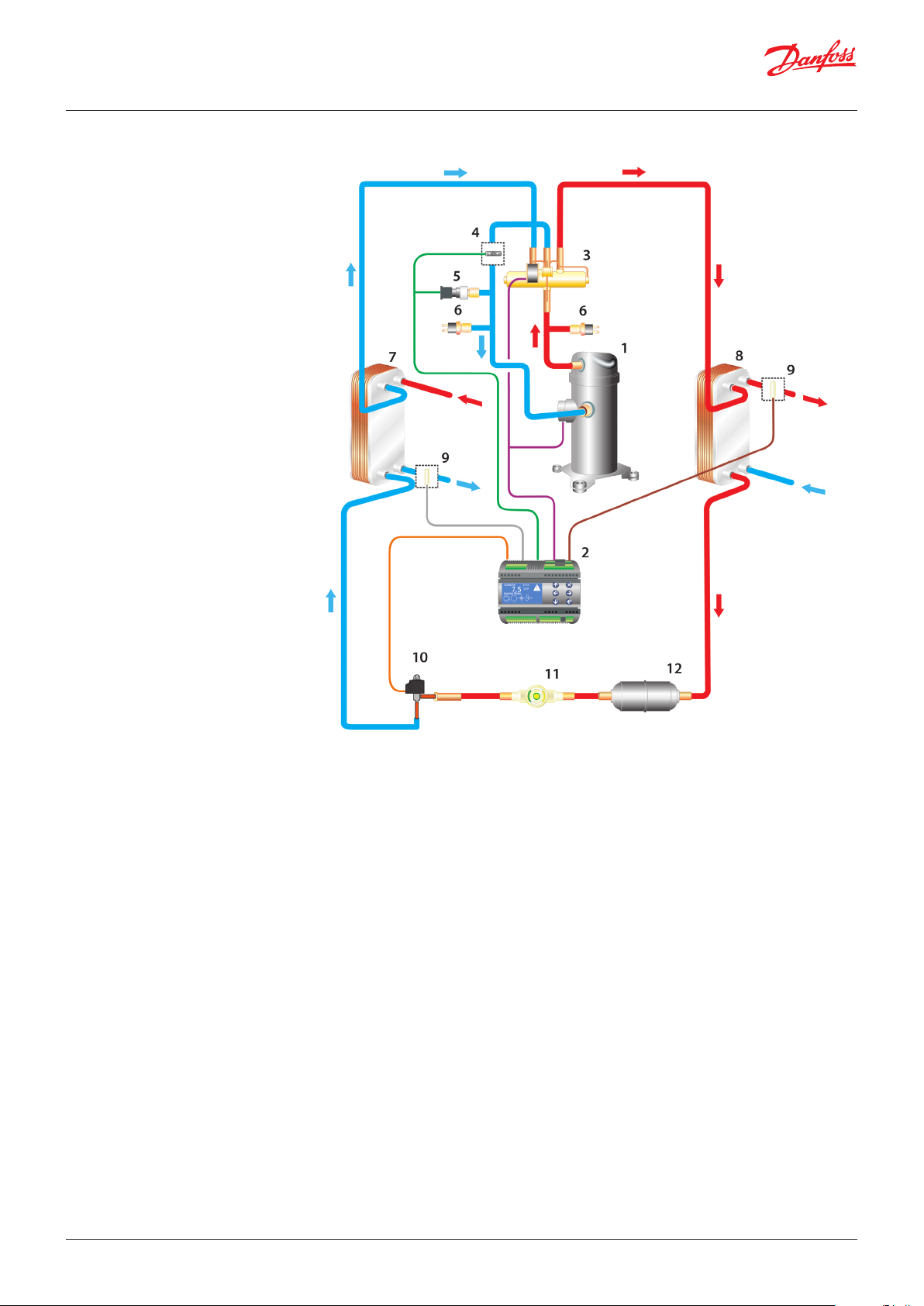

Application example

Heat pump components in typical system.

1. Compressor.

2. Controller.

3. Four-way valve.

4. Temperature sensor.

5. Pressure transmitter.

6. Cartridge pressure control.

7. Evaporator.

8. Condenser.

9. Temperature sensor.

10. Electric expansion valve.

11. Sight glass.

12. Liquid line filter drier.

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 5

Page 6

Data sheet | Electric expansion valves, type ETS 6

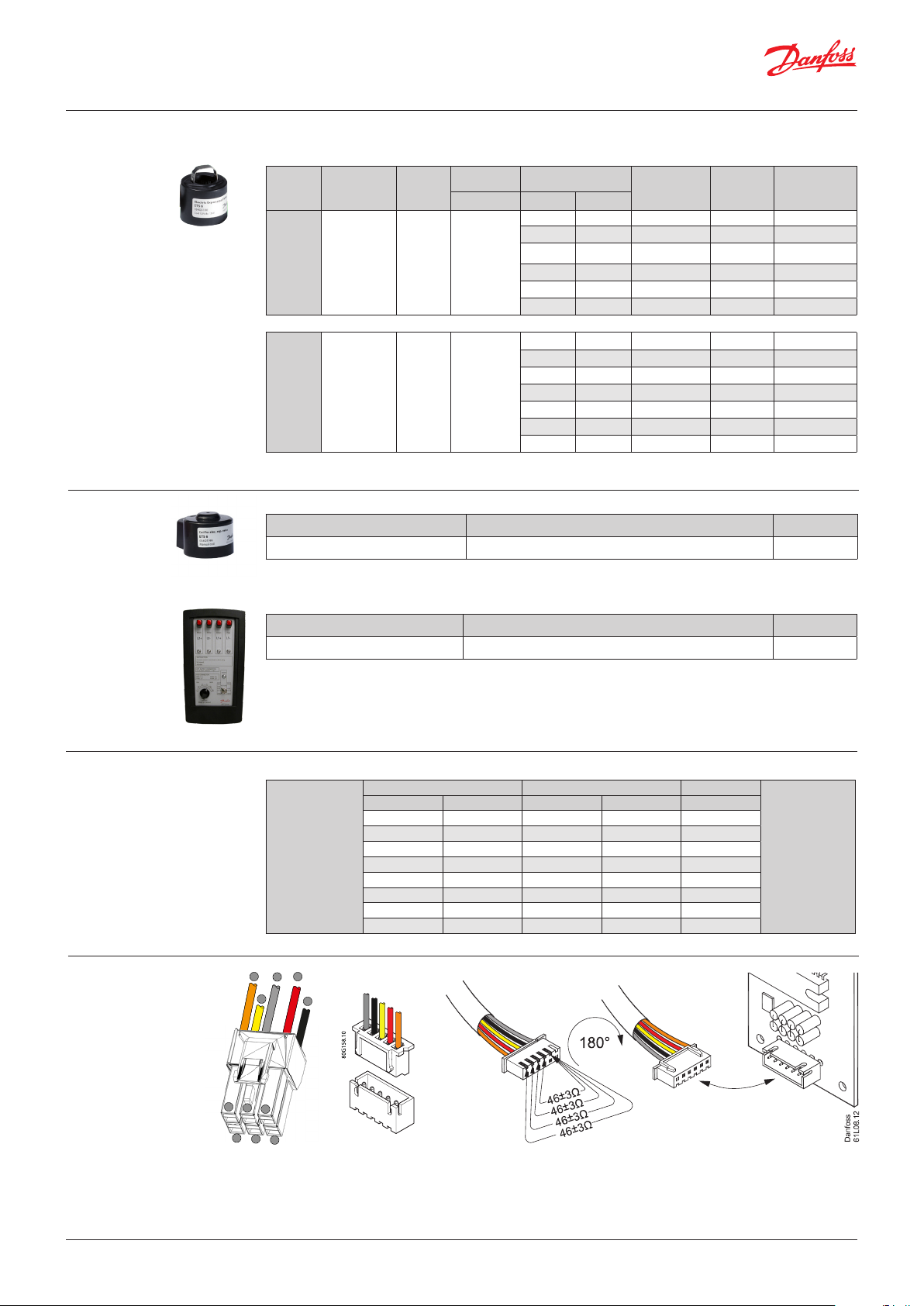

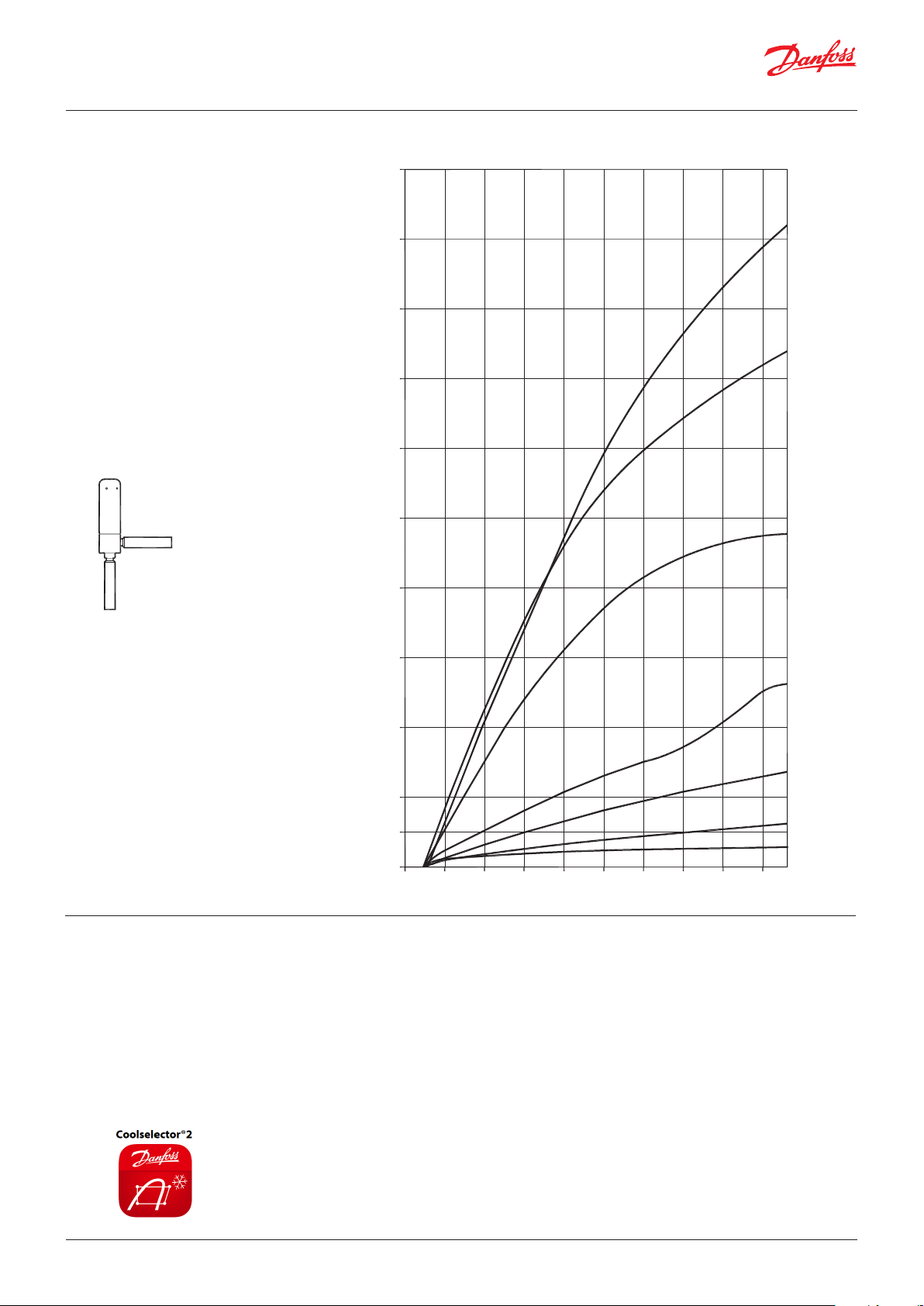

Pulse [PS]

Flow characteristics

Conditions R410 A

Te: 5 °C / 41 °F)

Tc: 38 °C / 100.4 °F)

Subcooling: 0 °C / 32 °F)

Superheat: 0 °C / 32 °F)

Flow B to A

B inlet

Refrigeration capacity in kW (TR)

50.0

(14.2)

45.0

(12.8)

40.0

(11.4)

35.0

(10.0)

30.0

(8.5)

25.0

(7.1)

20.0

(5.7)

Danfoss

34G165.10

ETS 6 - 40

ETS 6 - 32

ETS 6 - 25

A outlet

Valve Selection

15.0

(4.3)

ETS 6 - 18

10.0

(2.8)

ETS 6 - 14

5.0

(1.4)

2.5

(0.7)

0.0

050 100 150 200 250 300 350 400 450

ETS 6 - 10

ETS 6 - 08

Example

For optimum performance, it is important to

correct the evaporator capacity. In order to

select the correct size of ETS 6 you will need the

following information:

When selecting the valve it may be necessary to

apply a correction factor to the actual evaporator

capacity. This correction factor is required when

system conditions are different than table

conditions. Selection also depends on having an

Refrigerant: HCFC / HFC

Evaporator capacity Qe in kW or TR

Evaporating temperature te in °C / °F

Condenser temperature tc in °C / °F

Subcooling Δt

in K / °F

sub

acceptable pressure drop across the valve. In the

selection table, the pressure drop in the liquid

line is assumed to be zero. The following example

illustrates correct selection of the valve.

Refrigerant: R407C

Evaporator capacity: Qe = 10 kW / 2.84 TR

Condensing temperature: tc = 40 °C / 104 °F

Evaporating temperature: te = +10 °C / 50 °F

Subcooling Δt

= 10 K / 18 °F

sub

Note!

Coolselector®2 is a Danfoss calculation and selection software designed to make selection processes for all refrigeration

projects easier and less time consuming. For details refer http://coolselector.danfoss.com

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 6

Page 7

Data sheet | Electric expansion valves, type ETS 6

Valve Selection

(continued)

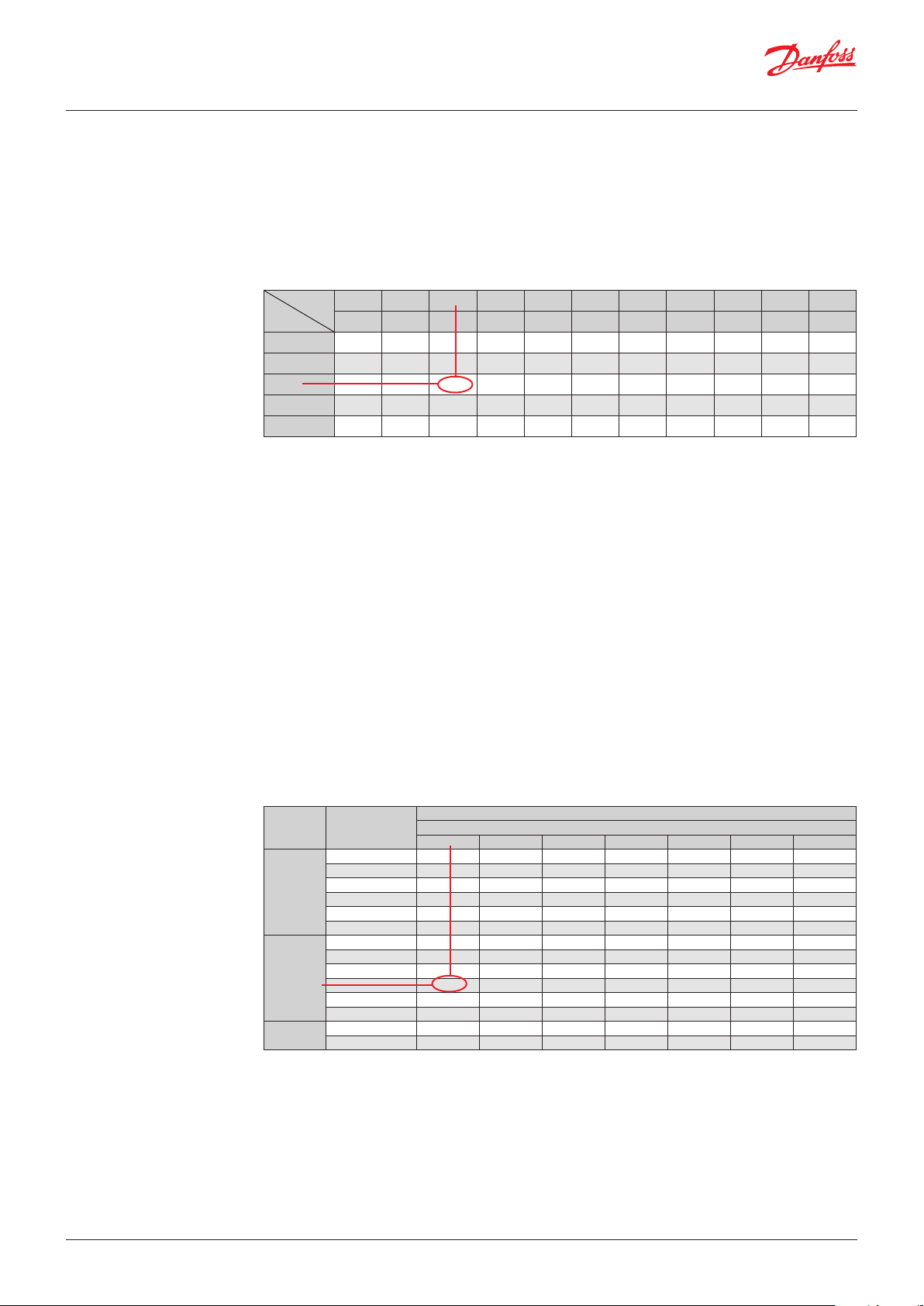

Step 1

Determine the correction factor for subcooling

Δt

. From the correction factor table (see below)

sub

a subcooling of 10 K, R407C corresponds to a

factor of 1.14.

Correction factors for subcooling Δt

R22 1.00 1.04 1.10 1.16 1.20 1.25 1.30 1.35 1.41 1.45 1.50

R410A 1.00 1.06 1.14 1.21 1.28 1.34 1.40 1.47 1.53 1.58 1.65

R407C 1.00 1.06 1.14 1.20 1.28 1.34 1.40 1.47 1.53 1.60 1.66

R134a 1.00 1.06 1.14 1.19 1.26 1.32 1.38 1.45 1.50 1.56 1.63

R404A 1.00 1.07 1.18 1.29 1.38 1.47 1.56 1.65 1.75 1.82 1.91

0°F 7.2°F 18°F 27°F 36°F 45°F 54°F 63°F 72°F 81°F 90°F

0K 4K 10K 15K 20K 25K 30K 35K 40K 45K 50K

ΔTsc

Step 2

Corrected evaporator capacity is

.

sub

Step 4

Choose ETS 6 -18:

• Single pack code no. 034G5026

Qe (Corrected) = 10 kW /1.14 = 8.8 kW / 2.5 TR

• I-pack code no. 034G5024

Step 3

Select the appropriate capacity table, R407C, and

choose the column for condensing temperature

of tc = 40°C / 104 °F and evaporating temperature

of te = 10°C / 50 °F which will provide an

equivalent or greater capacity of 8.8 kW / 2.5 TR.

ETS 6 - 18 provides 10.35 kW / 2.94 TR, which is

the proper selection for this example.

Rated Capacity (kW)

Condensing

temperature

(°C)

30 10.35 11.21 11.88 12.41 12.81 13.31 13.52

35 11.15 11.84 12.38 12.79 13.10 13.47 13.58

R410A

R407C

R22

38 11.51 12.11 12.58 12.94 13.20 13.50 13.55

40 11.70 12.25 12.67 13.00 13.23 13.48 13.50

45 12.00 12.44 12.77 13.02 13.19 13.33 13.27

50 12.07 12.41 12.66 12.84 12.95 13.00 12.86

30 8.95 9.61 10.11 10.48 10.74 11.02 11.06

35 9.75 10.26 10.65 10.92 11.11 11.27 11.22

38 10.13 10.57 10.90 11.13 11.28 11.38 11.28

40 10.35 10.75 11.04 11.24 11.36 11.42 11.30

45 10.79 11.09 11.30 11.43 11.50 11.47 11.27

50 11.06 11.28 11.42 11.49 11.50 11.39 11.13

30 8.59 9.27 9.80 10.22 10.53 10.92 11.07

35 9.41 9.96 10.38 10.71 10.96 11.24 11.33

Evaporation temperature (°C)

ETS 6 -18

10 5 0 -5 -10 -20 -30

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 7

Page 8

Data sheet | Electric expansion valves, type ETS 6

Correction factors for

subcooling Δt

sub

The evaporator capacities used must be

corrected if subcooling deviates from 0 K.

The corrected capacity can be obtained by

Δt

R22 1.00 1.04 1.10 1.16 1.20 1.25 1.30 1.35 1.41 1.45 1.50

R410A 1.00 1.06 1.14 1.21 1.28 1.34 1.40 1.47 1.53 1.58 1.65

R407C 1.00 1.06 1.14 1.20 1.28 1.34 1.40 1.47 1.53 1.60 1.66

R134a 1.00 1.06 1.14 1.19 1.26 1.32 1.38 1.45 1.50 1.56 1.63

R404A/R507 1.00 1.07 1.18 1.29 1.38 1.47 1.56 1.65 1.75 1.82 1.91

Δt

R32 1.00 1.03 1.08 1.12 1.16 1.20 1.23 1.27 1.31 1.34 1.37

R290 1.00 1.04 1.10 1.15 1.20 1.25 1.29 1.34 1.38 1.43 1.47

R448A 1.00 1.06 1.13 1.20 1.26 1.33 1.39 1.46 1.52 1.59 1.65

R449A 1.00 1.03 1.11 1.17 1.23 1.29 1.35 1.41 1.47 1.53 1.59

R452A 1.00 1.06 1.14 1.21 1.25 1.34 1.40 1.46 1.52 1.58 1.64

0K 4K 10K 15K 20K 25K 30K 35K 40K 45K 50K

sub

0°F 7.2°F 18°F 27°F 36°F 45°F 54°F 63°F 72°F 81°F 90°F

0K 4K 10K 15K 20K 25K 30K 35K 40K 45K 50K

sub

0°F 7.2°F 18°F 27°F 36°F 45°F 54°F 63°F 72°F 81°F 90°F

dividing the required evaporator capacity by the

correction factor below. Selections can then be

made from the tables above.

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 8

Page 9

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°C)

30 1.27 1.37 1.45 1.51 1.56 1.62 1.64

35 1.39 1.47 1.54 1.59 1.62 1.66 1.68

38 1.45 1.52 1.58 1.62 1.65 1.69 1.69

40 1.49 1.55 1.61 1.64 1.67 1.70 1.70

45 1.56 1.62 1.66 1.69 1.71 1.72 1.72

50 1.62 1.66 1.69 1.72 1.73 1.73 1.72

30 1.01 1.08 1.13 1.16 1.19 1.20 1.20

35 1.10 1.15 1.19 1.22 1.23 1.23 1.22

38 1.15 1.19 1.22 1.24 1.25 1.25 1.22

40 1.17 1.21 1.24 1.25 1.26 1.25 1.23

45 1.23 1.26 1.27 1.28 1.28 1.26 1.22

50 1.27 1.28 1.29 1.29 1.28 1.26 1.21

30 0.95 1.01 1.06 1.10 1.12 1.14 1.12

35 1.01 1.06 1.10 1.12 1.13 1.13 1.11

38 1.03 1.07 1.10 1.12 1.13 1.12 1.09

40 1.04 1.08 1.10 1.11 1.12 1.11 1.07

45 1.05 1.08 1.09 1.09 1.09 1.07 1.02

50 1.04 1.05 1.05 1.05 1.04 1.01 0.96

30 1.32 1.42 1.50 1.55 1.59 1.63 1.64

35 1.44 1.52 1.58 1.62 1.64 1.67 1.66

38 1.50 1.56 1.61 1.65 1.67 1.68 1.67

40 1.53 1.59 1.63 1.66 1.68 1.69 1.67

45 1.60 1.64 1.67 1.69 1.70 1.70 1.67

50 1.64 1.67 1.69 1.70 1.70 1.69 1.65

30 1.53 1.66 1.76 1.84 1.90 1.97 2.00

35 1.65 1.75 1.83 1.89 1.94 1.99 2.01

38 1.70 1.79 1.86 1.91 1.95 2.00 2.01

40 1.73 1.81 1.88 1.92 1.96 2.00 2.00

45 1.78 1.84 1.89 1.93 1.95 1.97 1.96

50 1.79 1.84 1.87 1.90 1.92 1.92 1.90

10 5 0 -5 -10 -20 -30

Evaporation temperature [°C]

ETS 6 - 08

SI units

Capacity (kW)

R32

R290

R448A

R449A

R452A

Condensing

temperature

(°C)

30 2.19 2.39 2.54 2.67 2.77 2.91 2.99

35 2.40 2.56 2.69 2.79 2.88 2.99 3.05

38 2.49 2.64 2.76 2.85 2.93 3.03 3.08

40 2.55 2.69 2.80 2.88 2.95 3.05 3.10

45 2.66 2.78 2.87 2.94 3.00 3.08 3.11

50 2.74 2.83 2.91 2.97 3.02 3.08 3.10

30 1.36 1.45 1.53 1.58 1.62 1.66 1.66

35 1.47 1.54 1.60 1.64 1.66 1.68 1.67

38 1.52 1.59 1.63 1.66 1.68 1.69 1.67

40 1.55 1.61 1.65 1.68 1.69 1.69 1.67

45 1.61 1.65 1.68 1.69 1.70 1.69 1.65

50 1.65 1.67 1.69 1.70 1.69 1.66 1.61

30 1.37 1.48 1.50 1.59 1.56 1.58 1.58

35 1.47 1.56 1.56 1.64 1.60 1.61 1.58

38 1.48 1.56 1.56 1.63 1.60 1.59 1.57

40 1.50 1.57 1.57 1.63 1.60 1.59 1.56

45 1.53 1.59 1.58 1.63 1.59 1.57 1.53

50 1.53 1.58 1.56 1.61 1.56 1.53 1.48

30 1.35 1.42 1.47 1.51 1.54 1.56 1.55

35 1.42 1.48 1.52 1.55 1.56 1.57 1.55

38 1.46 1.50 1.54 1.56 1.57 1.57 1.54

40 1.47 1.52 1.54 1.56 1.57 1.56 1.53

45 1.50 1.53 1.55 1.56 1.56 1.54 1.50

50 1.51 1.53 1.54 1.54 1.53 1.50 1.46

30 1.06 1.12 1.15 1.18 1.20 1.20 1.18

35 1.11 1.15 1.18 1.19 1.20 1.19 1.16

38 1.13 1.16 1.18 1.19 1.19 1.17 1.14

40 1.13 1.16 1.18 1.18 1.18 1.16 1.12

45 1.14 1.15 1.16 1.16 1.15 1.12 1.07

50 1.11 1.12 1.12 1.11 1.10 1.06 1.00

10 5 0 -5 -10 -20 -30

Evaporation temperature [°C]

ETS 6 - 08

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 9

Page 10

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°C)

30 2.15 2.32 2.45 2.55 2.63 2.73 2.77

35 2.35 2.49 2.60 2.68 2.74 2.81 2.83

38 2.45 2.58 2.67 2.74 2.79 2.85 2.86

40 2.52 2.63 2.71 2.78 2.82 2.87 2.88

45 2.64 2.73 2.80 2.85 2.88 2.91 2.90

50 2.74 2.81 2.86 2.90 2.92 2.93 2.90

30 1.71 1.82 1.91 1.97 2.01 2.04 2.02

35 1.86 1.95 2.01 2.05 2.08 2.09 2.05

38 1.94 2.01 2.06 2.09 2.11 2.11 2.07

40 1.98 2.05 2.09 2.12 2.13 2.12 2.07

45 2.08 2.12 2.15 2.16 2.16 2.13 2.07

50 2.14 2.17 2.18 2.18 2.17 2.12 2.05

30 1.60 1.71 1.80 1.85 1.89 1.92 1.90

35 1.71 1.79 1.85 1.89 1.91 1.91 1.88

38 1.75 1.82 1.86 1.89 1.90 1.89 1.84

40 1.76 1.82 1.86 1.88 1.89 1.87 1.81

45 1.78 1.82 1.84 1.85 1.84 1.80 1.73

50 1.75 1.77 1.78 1.77 1.76 1.70 1.61

30 2.24 2.40 2.53 2.62 2.69 2.76 2.76

35 2.44 2.57 2.66 2.73 2.78 2.82 2.81

38 2.53 2.64 2.72 2.78 2.82 2.84 2.82

40 2.59 2.69 2.76 2.81 2.84 2.86 2.82

45 2.70 2.77 2.82 2.86 2.87 2.87 2.82

50 2.77 2.82 2.85 2.87 2.88 2.85 2.78

30 2.59 2.80 2.97 3.10 3.20 3.33 3.38

35 2.79 2.96 3.09 3.20 3.28 3.37 3.39

38 2.88 3.03 3.14 3.23 3.30 3.37 3.39

40 2.92 3.06 3.17 3.25 3.31 3.37 3.37

45 3.00 3.11 3.19 3.25 3.30 3.33 3.32

50 3.02 3.10 3.17 3.21 3.24 3.25 3.21

10 5 0 -5 -10 -20 -30

Evaporation temperature [°C]

ETS 6 -10

SI units

Capacity (kW)

R32

R290

R448A

R449A

R452A

Condensing

temperature

(°C)

30 2.15 2.32 2.45 2.55 2.63 2.73 2.77

35 2.35 2.49 2.60 2.68 2.74 2.81 2.83

38 2.45 2.58 2.67 2.74 2.79 2.85 2.86

40 2.52 2.63 2.71 2.78 2.82 2.87 2.88

45 2.64 2.73 2.80 2.85 2.88 2.91 2.90

50 2.74 2.81 2.86 2.90 2.92 2.93 2.90

30 1.71 1.82 1.91 1.97 2.01 2.04 2.02

35 1.86 1.95 2.01 2.05 2.08 2.09 2.05

38 1.94 2.01 2.06 2.09 2.11 2.11 2.07

40 1.98 2.05 2.09 2.12 2.13 2.12 2.07

45 2.08 2.12 2.15 2.16 2.16 2.13 2.07

50 2.14 2.17 2.18 2.18 2.17 2.12 2.05

30 1.60 1.71 1.80 1.85 1.89 1.92 1.90

35 1.71 1.79 1.85 1.89 1.91 1.91 1.88

38 1.75 1.82 1.86 1.89 1.90 1.89 1.84

40 1.76 1.82 1.86 1.88 1.89 1.87 1.81

45 1.78 1.82 1.84 1.85 1.84 1.80 1.73

50 1.75 1.77 1.78 1.77 1.76 1.70 1.61

30 2.24 2.40 2.53 2.62 2.69 2.76 2.76

35 2.44 2.57 2.66 2.73 2.78 2.82 2.81

38 2.53 2.64 2.72 2.78 2.82 2.84 2.82

40 2.59 2.69 2.76 2.81 2.84 2.86 2.82

45 2.70 2.77 2.82 2.86 2.87 2.87 2.82

50 2.77 2.82 2.85 2.87 2.88 2.85 2.78

30 2.59 2.80 2.97 3.10 3.20 3.33 3.38

35 2.79 2.96 3.09 3.20 3.28 3.37 3.39

38 2.88 3.03 3.14 3.23 3.30 3.37 3.39

40 2.92 3.06 3.17 3.25 3.31 3.37 3.37

45 3.00 3.11 3.19 3.25 3.30 3.33 3.32

50 3.02 3.10 3.17 3.21 3.24 3.25 3.21

10 5 0 -5 -10 -20 -30

Evaporation temperature [°C]

ETS 6 -10

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 10

Page 11

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

temperature (°C)

R22

R134a

R404A

R407C

R410A

Condensing

10 5 0 -5 -10 -20 -30

30 4.81 5.19 5.49 5.72 5.89 6.11 6.20

35 5.27 5.58 5.82 6.00 6.14 6.30 6.34

38 5.50 5.77 5.98 6.14 6.26 6.39 6.41

40 5.63 5.88 6.07 6.22 6.32 6.43 6.44

45 5.92 6.12 6.27 6.38 6.46 6.52 6.50

50 6.14 6.29 6.41 6.49 6.54 6.56 6.51

30 3.82 4.08 4.27 4.40 4.49 4.56 4.53

35 4.17 4.37 4.51 4.60 4.65 4.67 4.60

38 4.35 4.51 4.62 4.69 4.73 4.72 4.63

40 4.45 4.59 4.69 4.74 4.77 4.74 4.64

45 4.65 4.75 4.81 4.84 4.84 4.77 4.63

50 4.79 4.85 4.88 4.88 4.86 4.75 4.59

30 3.58 3.84 4.02 4.15 4.24 4.30 4.25

35 3.83 4.01 4.15 4.23 4.28 4.29 4.20

38 3.91 4.07 4.17 4.23 4.26 4.24 4.13

40 3.94 4.08 4.16 4.21 4.23 4.19 4.06

45 3.98 4.07 4.12 4.13 4.12 4.04 3.88

50 3.92 3.97 3.98 3.97 3.93 3.81 3.61

30 5.01 5.38 5.66 5.87 6.02 6.17 6.19

35 5.46 5.75 5.96 6.12 6.22 6.31 6.29

38 5.67 5.92 6.10 6.23 6.31 6.37 6.32

40 5.80 6.02 6.18 6.29 6.36 6.40 6.33

45 6.04 6.21 6.33 6.40 6.44 6.42 6.31

50 6.19 6.32 6.39 6.43 6.44 6.38 6.23

30 5.80 6.28 6.66 6.95 7.17 7.46 7.57

35 6.25 6.63 6.93 7.16 7.34 7.55 7.60

38 6.44 6.78 7.04 7.24 7.39 7.56 7.59

40 6.55 6.86 7.10 7.28 7.41 7.55 7.56

45 6.72 6.97 7.15 7.29 7.39 7.47 7.43

50 6.76 6.95 7.09 7.19 7.25 7.28 7.20

Evaporation temperature [°C]

ETS 6 - 14

SI units

Capacity (kW)

temperature (°C)

R32

R290

R448A

R449A

R452A

Condensing

10 5 0 -5 -10 -20 -30

30 8.30 9.04 9.63 10.10 10.48 11.02 11.32

35 9.06 9.67 10.16 10.56 10.88 11.32 11.56

38 9.44 9.98 10.43 10.78 11.07 11.46 11.66

40 9.65 10.16 10.58 10.91 11.18 11.54 11.71

45 10.08 10.51 10.86 11.14 11.36 11.65 11.77

50 10.36 10.72 11.02 11.25 11.43 11.65 11.72

30 5.13 5.50 5.78 5.98 6.13 6.27 6.27

35 5.56 5.84 6.05 6.20 6.30 6.37 6.31

38 5.76 6.00 6.18 6.29 6.36 6.40 6.31

40 5.88 6.09 6.24 6.34 6.40 6.40 6.30

45 6.10 6.25 6.36 6.41 6.43 6.38 6.23

50 6.23 6.34 6.39 6.41 6.40 6.29 6.10

30 5.19 5.61 5.67 6.02 5.91 5.99 5.96

35 5.56 5.89 5.90 6.19 6.06 6.08 6.00

38 5.60 5.91 5.91 6.17 6.04 6.03 5.94

40 5.67 5.96 5.94 6.18 6.04 6.02 5.91

45 5.80 6.02 5.97 6.16 6.00 5.93 5.78

50 5.80 5.98 5.91 6.07 5.90 5.80 5.62

30 5.11 5.38 5.58 5.73 5.82 5.90 5.87

35 5.39 5.60 5.75 5.86 5.92 5.94 5.87

38 5.52 5.69 5.82 5.90 5.94 5.94 5.84

40 5.58 5.74 5.84 5.91 5.94 5.92 5.81

45 5.68 5.80 5.86 5.90 5.90 5.84 5.69

50 5.70 5.77 5.81 5.82 5.80 5.69 5.51

30 4.01 4.22 4.37 4.47 4.52 4.54 4.46

35 4.20 4.35 4.45 4.51 4.53 4.50 4.38

38 4.26 4.38 4.46 4.50 4.51 4.44 4.30

40 4.29 4.39 4.45 4.48 4.48 4.40 4.24

45 4.30 4.36 4.39 4.38 4.35 4.23 4.04

50 4.22 4.24 4.24 4.21 4.16 4.00 3.78

Evaporation temperature [°C]

ETS 6 - 14

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 11

Page 12

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

temperature (°C)

R22

R134a

R404A

R407C

R410A

Condensing

10 5 0 -5 -10 -20 -30

30 8.59 9.27 9.80 10.22 10.53 10.92 11.07

35 9.41 9.96 10.38 10.71 10.96 11.24 11.33

38 9.82 10.30 10.68 10.96 11.17 11.40 11.44

40 10.06 10.50 10.85 11.11 11.29 11.49 11.50

45 10.57 10.93 11.20 11.40 11.53 11.65 11.60

50 10.96 11.24 11.45 11.59 11.68 11.72 11.62

30 6.83 7.29 7.63 7.87 8.02 8.14 8.08

35 7.45 7.80 8.05 8.21 8.31 8.34 8.21

38 7.76 8.05 8.25 8.38 8.44 8.42 8.26

40 7.94 8.20 8.37 8.47 8.52 8.46 8.28

45 8.31 8.49 8.59 8.64 8.64 8.52 8.27

50 8.56 8.67 8.72 8.72 8.68 8.49 8.19

30 6.40 6.85 7.18 7.41 7.56 7.67 7.60

35 6.83 7.17 7.41 7.56 7.65 7.66 7.51

38 6.99 7.26 7.45 7.56 7.61 7.57 7.38

40 7.04 7.28 7.43 7.52 7.55 7.47 7.25

45 7.11 7.27 7.35 7.38 7.36 7.21 6.92

50 7.00 7.08 7.11 7.09 7.03 6.80 6.45

30 8.95 9.61 10.11 10.48 10.74 11.02 11.06

35 9.75 10.26 10.65 10.92 11.11 11.27 11.22

38 10.13 10.57 10.90 11.13 11.28 11.38 11.28

40 10.35 10.75 11.04 11.24 11.36 11.42 11.30

45 10.79 11.09 11.30 11.43 11.50 11.47 11.27

50 11.06 11.28 11.42 11.49 11.50 11.39 11.13

30 10.35 11.21 11.88 12.41 12.81 13.31 13.52

35 11.15 11.84 12.38 12.79 13.10 13.47 13.58

38 11.51 12.11 12.58 12.94 13.20 13.50 13.55

40 11.70 12.25 12.67 13.00 13.23 13.48 13.50

45 12.00 12.44 12.77 13.02 13.19 13.33 13.27

50 12.07 12.41 12.66 12.84 12.95 13.00 12.86

Evaporation temperature [°C]

ETS 6 -18

SI units

Capacity (kW)

temperature (°C)

R32

R290

R448A

R449A

R452A

Condensing

10 5 0 -5 -10 -20 -30

30 14.83 16.14 17.19 18.04 18.72 19.67 20.21

35 16.18 17.27 18.15 18.86 19.43 20.22 20.64

38 16.85 17.82 18.62 19.26 19.77 20.47 20.82

40 17.24 18.14 18.89 19.48 19.96 20.60 20.91

45 18.01 18.77 19.40 19.90 20.29 20.80 21.02

50 18.50 19.15 19.67 20.09 20.41 20.80 20.93

30 9.16 9.83 10.32 10.69 10.94 11.20 11.20

35 9.92 10.43 10.81 11.07 11.24 11.37 11.27

38 10.29 10.72 11.03 11.24 11.37 11.42 11.27

40 10.50 10.88 11.15 11.33 11.42 11.43 11.25

45 10.89 11.17 11.35 11.45 11.49 11.39 11.13

50 11.10 11.31 11.42 11.45 11.43 11.24 10.90

30 9.26 10.02 10.12 10.75 10.56 10.70 10.64

35 9.92 10.53 10.54 11.05 10.82 10.85 10.71

38 10.00 10.56 10.55 11.02 10.78 10.78 10.60

40 10.13 10.64 10.61 11.04 10.79 10.75 10.55

45 10.35 10.75 10.66 11.00 10.72 10.59 10.32

50 10.35 10.69 10.56 10.85 10.54 10.35 10.03

30 9.12 9.61 9.96 10.23 10.39 10.54 10.48

35 9.63 10.00 10.27 10.46 10.57 10.61 10.47

38 9.85 10.17 10.39 10.53 10.61 10.60 10.42

40 9.96 10.25 10.44 10.56 10.61 10.57 10.37

45 10.15 10.35 10.47 10.54 10.54 10.42 10.15

50 10.17 10.31 10.37 10.39 10.35 10.16 9.83

30 7.16 7.54 7.80 7.98 8.08 8.11 7.97

35 7.49 7.76 7.94 8.05 8.09 8.03 7.82

38 7.61 7.83 7.97 8.03 8.05 7.94 7.68

40 7.66 7.85 7.96 8.00 7.99 7.85 7.57

45 7.67 7.79 7.83 7.83 7.77 7.55 7.22

50 7.53 7.58 7.57 7.52 7.42 7.14 6.75

Evaporation temperature [°C]

ETS 6 -18

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 12

Page 13

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

temperature (°C)

R22

R134a

R404A

R407C

R410A

Condensing

10 5 0 -5 -10 -20 -30

30 16.36 17.67 18.69 19.47 20.06 20.81 21.11

35 17.93 18.98 19.79 20.42 20.88 21.43 21.59

38 18.71 19.63 20.35 20.89 21.29 21.73 21.81

40 19.17 20.02 20.67 21.17 21.52 21.89 21.92

45 20.15 20.83 21.35 21.72 21.98 22.20 22.11

50 20.88 21.42 21.81 22.09 22.26 22.34 22.14

30 13.01 13.90 14.55 14.99 15.29 15.52 15.40

35 14.21 14.87 15.35 15.66 15.84 15.90 15.65

38 14.79 15.35 15.73 15.97 16.09 16.05 15.74

40 15.13 15.62 15.95 16.14 16.23 16.13 15.78

45 15.83 16.17 16.38 16.47 16.47 16.23 15.77

50 16.31 16.52 16.62 16.62 16.54 16.18 15.61

30 12.20 13.06 13.69 14.13 14.42 14.63 14.48

35 13.03 13.66 14.11 14.41 14.57 14.59 14.30

38 13.32 13.84 14.20 14.41 14.51 14.43 14.06

40 13.42 13.87 14.17 14.33 14.39 14.24 13.82

45 13.55 13.85 14.01 14.07 14.04 13.74 13.19

50 13.33 13.50 13.55 13.51 13.39 12.95 12.30

30 17.05 18.32 19.28 19.98 20.48 21.01 21.07

35 18.58 19.56 20.29 20.82 21.18 21.49 21.39

38 19.31 20.15 20.77 21.21 21.49 21.69 21.50

40 19.73 20.49 21.04 21.42 21.66 21.78 21.54

45 20.57 21.14 21.54 21.79 21.91 21.86 21.48

50 21.08 21.50 21.76 21.90 21.93 21.71 21.21

30 19.73 21.37 22.65 23.64 24.41 25.37 25.76

35 21.26 22.56 23.59 24.38 24.97 25.68 25.88

38 21.93 23.08 23.97 24.65 25.16 25.72 25.82

40 22.29 23.34 24.15 24.77 25.22 25.70 25.73

45 22.88 23.71 24.35 24.81 25.13 25.41 25.28

50 23.00 23.65 24.13 24.47 24.68 24.77 24.50

Evaporation temperature [°C]

ETS 6 - 25

SI units

Capacity (kW)

temperature (°C)

R32

R290

R448A

R449A

R452A

Condensing

10 5 0 -5 -10 -20 -30

30 28.26 30.75 32.76 34.38 35.67 37.50 38.53

35 30.84 32.90 34.59 35.95 37.03 38.54 39.34

38 32.11 33.97 35.48 36.70 37.68 39.01 39.69

40 32.85 34.58 35.99 37.13 38.04 39.26 39.86

45 34.32 35.78 36.97 37.92 38.67 39.64 40.05

50 35.27 36.50 37.49 38.28 38.89 39.64 39.89

30 17.40 18.67 19.62 20.31 20.79 21.27 21.27

35 18.85 19.82 20.53 21.03 21.36 21.60 21.41

38 19.55 20.37 20.95 21.35 21.60 21.70 21.42

40 19.94 20.67 21.18 21.52 21.71 21.73 21.38

45 20.70 21.22 21.57 21.76 21.83 21.65 21.14

50 21.15 21.50 21.69 21.76 21.72 21.36 20.71

30 17.65 19.11 19.28 20.48 20.12 20.40 20.29

35 18.91 20.26 20.09 21.06 20.62 20.68 20.41

38 19.06 20.12 20.11 21.00 20.54 20.54 20.20

40 19.30 20.28 20.22 21.05 20.57 20.49 20.11

45 19.73 20.49 20.32 20.97 20.43 20.18 19.66

50 19.73 20.37 20.13 20.67 20.09 19.73 19.11

30 17.38 18.31 18.99 19.49 19.81 20.09 19.96

35 18.35 19.07 19.58 19.93 20.14 20.23 19.96

38 18.77 19.38 19.79 20.08 20.22 20.20 19.86

40 18.99 19.53 19.89 20.13 20.23 20.15 19.76

45 19.34 19.73 19.96 20.09 20.09 19.86 19.35

50 19.39 19.65 19.77 19.80 19.73 19.36 18.74

30 13.65 14.36 14.87 15.20 15.39 15.45 15.18

35 14.28 14.79 15.14 15.34 15.42 15.31 14.90

38 14.51 14.92 15.18 15.31 15.34 15.12 14.64

40 14.60 14.95 15.16 15.25 15.23 14.96 14.43

45 14.63 14.84 14.93 14.92 14.82 14.40 13.76

50 14.35 14.44 14.43 14.33 14.15 13.60 12.86

Evaporation temperature [°C]

ETS 6 - 25

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 13

Page 14

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

temperature (°C)

R22

R134a

R404A

R407C

R410A

Condensing

10 5 0 -5 -10 -20 -30

30 24.0 26.0 27.5 28.6 29.5 30.6 31.0

35 26.3 27.9 29.1 30.0 30.7 31.5 31.7

38 27.5 28.8 29.9 30.7 31.3 31.9 32.0

40 28.2 29.4 30.4 31.1 31.6 32.2 32.2

45 29.6 30.6 31.4 31.9 32.3 32.6 32.5

50 30.7 31.5 32.0 32.5 32.7 32.8 32.5

30 19.1 20.4 21.4 22.0 22.5 22.8 22.6

35 20.9 21.9 22.5 23.0 23.3 23.4 23.0

38 21.7 22.5 23.1 23.5 23.6 23.6 23.1

40 22.2 22.9 23.4 23.7 23.8 23.7 23.2

45 23.3 23.8 24.1 24.2 24.2 23.8 23.2

50 24.0 24.3 24.4 24.4 24.3 23.8 22.9

30 17.9 19.2 20.1 20.8 21.2 21.5 21.3

35 19.1 20.1 20.7 21.2 21.4 21.4 21.0

38 19.6 20.3 20.9 21.2 21.3 21.2 20.7

40 19.7 20.4 20.8 21.1 21.1 20.9 20.3

45 19.9 20.3 20.6 20.7 20.6 20.2 19.4

50 19.6 19.8 19.9 19.8 19.7 19.0 18.1

30 25.0 26.9 28.3 29.3 30.0 30.8 30.9

35 27.3 28.7 29.8 30.5 31.1 31.5 31.4

38 28.3 29.6 30.5 31.1 31.5 31.8 31.5

40 28.9 30.1 30.9 31.4 31.8 31.9 31.6

45 30.2 31.0 31.6 32.0 32.1 32.1 31.5

50 30.9 31.5 31.9 32.1 32.2 31.8 31.1

30 29.0 31.4 33.3 34.7 35.9 37.3 37.8

35 31.2 33.1 34.7 35.8 36.7 37.7 38.0

38 32.2 33.9 35.2 36.2 37.0 37.8 37.9

40 32.8 34.3 35.5 36.4 37.1 37.8 37.8

45 33.6 34.8 35.8 36.5 36.9 37.3 37.1

50 33.8 34.7 35.5 35.9 36.3 36.4 36.0

Evaporation temperature [°C]

ETS 6 - 32

SI units

Capacity (kW)

temperature (°C)

R32

R290

R448A

R449A

R452A

Condensing

10 5 0 -5 -10 -20 -30

30 41.52 45.18 48.13 50.50 52.41 55.09 56.60

35 45.32 48.35 50.82 52.81 54.40 56.62 57.79

38 47.18 49.91 52.13 53.92 55.36 57.31 58.30

40 48.26 50.80 52.88 54.55 55.88 57.68 58.56

45 50.42 52.56 54.31 55.71 56.81 58.24 58.84

50 51.81 53.62 55.08 56.24 57.14 58.24 58.60

30 25.64 27.51 28.91 29.92 30.64 31.35 31.35

35 27.79 29.21 30.26 31.00 31.48 31.83 31.56

38 28.81 30.01 30.88 31.47 31.82 31.98 31.56

40 29.39 30.46 31.21 31.71 31.99 32.02 31.50

45 30.50 31.27 31.78 32.07 32.17 31.90 31.16

50 31.16 31.68 31.97 32.07 32.01 31.47 30.52

30 25.93 28.07 28.33 30.09 29.56 29.97 29.80

35 27.78 29.47 29.52 30.94 30.30 30.39 29.98

38 28.01 29.56 29.54 30.86 30.18 30.17 29.68

40 28.36 29.79 29.71 30.92 30.22 30.11 29.55

45 28.99 30.11 29.86 30.81 30.02 29.65 28.89

50 28.99 29.92 29.57 30.37 29.52 28.98 28.08

30 25.53 26.90 27.90 28.63 29.11 29.51 29.33

35 29.69 28.01 28.76 29.28 29.58 29.71 29.33

38 27.58 28.47 29.08 29.50 29.70 29.68 29.18

40 27.90 28.69 29.22 29.57 29.71 29.60 29.03

45 28.41 28.98 29.32 29.51 29.52 29.18 28.43

50 28.49 28.87 29.05 29.10 28.98 28.44 27.53

30 20.05 21.10 21.84 22.33 22.62 22.70 22.30

35 20.98 21.73 22.24 22.54 22.66 22.49 21.89

38 21.31 21.92 22.30 22.50 22.53 22.22 21.51

40 21.45 21.97 22.27 22.40 22.38 21.98 21.20

45 21.49 21.80 21.93 21.91 21.77 21.15 20.21

50 21.09 21.22 21.20 21.05 20.79 19.98 18.89

Evaporation temperature [°C]

ETS 6 - 32

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 14

Page 15

Data sheet | Electric expansion valves, type ETS 6

Capacity (kW)

temperature (°C)

R22

R134a

R404A

R410A

Condensing

10 5 0 -10 -20 -30 -40

30 32.6 35.2 37.3 40.0 41.5 42.1 42.0

35 35.7 37.8 39.5 41.6 42.7 43.0 42.8

38 37.3 39.1 40.6 42.4 43.3 43.5 43.1

40 38.2 39.9 41.2 42.9 43.7 43.7 43.2

45 40.2 41.5 42.6 43.8 44.3 44.1 43.4

50 41.6 42.7 43.5 44.4 44.5 44.1 43.3

30 25.9 27.7 29.0 30.5 30.9 30.7 35 28.3 29.7 30.6 31.6 31.7 31.2 38 29.5 30.6 31.4 32.1 32.0 31.4 40 30.2 31.1 31.8 32.4 32.2 31.5 45 31.6 32.2 32.7 32.8 32.4 31.4 50 32.5 32.9 33.1 33.0 32.3 31.1 30 24.3 26.0 27.3 28.7 29.2 28.9 28.1

35 26.0 27.2 28.1 29.1 29.1 28.5 27.5

38 26.6 27.6 28.3 28.9 28.8 28.0 26.9

40 26.8 27.7 28.2 28.7 28.4 27.6 26.3

45 27.0 27.6 27.9 28.0 27.4 26.3 24.9

50 26.6 26.9 27.0 26.7 25.8 24.5 22.9

30 39.3 42.6 45.2 48.7 50.6 51.4 51.3

35 42.4 45.0 47.0 49.8 51.2 51.6 51.2

38 43.7 46.0 47.8 50.2 51.3 51.5 51.0

40 44.5 46.5 48.2 50.3 51.2 51.3 50.7

45 45.6 47.3 48.5 50.1 50.7 50.4 49.6

50 45.9 47.2 48.1 49.2 49.4 48.9 47.8

Evaporation temperature [°C]

ETS 6 - 40

SI units

Capacity (kW)

temperature (°C)

R32

R290

R448A

R449A

R452A

Condensing

10 5 0 -10 -20 -30 -40

30 59.48 64.74 68.96 72.36 75.09 78.93 81.09

35 64.93 69.28 72.81 75.66 77.95 81.12 82.80

38 67.60 71.50 74.69 77.26 79.31 82.12 83.53

40 69.14 72.79 75.76 78.16 80.07 82.64 83.90

45 72.24 75.31 77.81 79.82 81.39 83.45 84.31

50 74.23 76.82 78.92 80.58 81.86 83.45 83.96

30 34.79 37.34 39.23 40.61 41.58 42.55 42.55

35 37.71 39.65 41.06 42.06 42.72 43.19 42.83

38 39.10 40.73 41.91 42.71 43.19 43.40 42.83

40 39.89 41.34 42.36 43.04 43.41 43.45 42.75

45 41.40 42.44 43.13 43.52 43.65 43.29 42.29

50 42.29 42.99 43.39 43.52 43.44 42.71 41.42

30 37.15 40.22 40.59 43.12 42.35 42.94 42.70

35 39.81 42.23 42.29 44.33 43.41 43.54 42.95

38 40.13 42.36 42.33 44.21 43.24 43.23 42.53

40 40.63 42.68 42.57 44.30 43.29 43.14 42.33

45 41.53 43.14 42.78 44.15 43.01 42.48 41.39

50 41.53 42.87 42.37 43.51 42.29 41.52 40.23

30 36.58 38.54 39.98 41.02 41.70 42.28 42.02

35 38.62 40.13 41.20 41.96 42.38 42.57 42.02

38 39.51 40.79 41.67 42.26 42.55 42.53 41.81

40 39.97 41.11 41.87 42.37 42.57 42.41 41.59

45 40.70 41.52 42.01 42.28 42.29 41.81 40.74

50 40.82 41.36 41.62 41.69 41.52 40.75 39.44

30 28.73 30.23 31.29 31.00 32.40 32.53 31.96

35 30.05 31.14 31.86 32.29 32.47 32.22 31.37

38 30.54 31.41 31.96 32.23 32.28 31.83 30.82

40 30.74 31.48 31.91 32.10 32.07 31.49 30.38

45 30.79 31.24 31.43 31.40 31.18 30.31 28.96

50 30.21 30.40 30.38 30.16 29.78 28.63 27.06

Evaporation temperature [°C]

ETS 6 - 40

SI units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 15

Page 16

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°F)

75 0.452 0.452 0.45 0.446 0.439 0.414 0.394 0.367 0.385 0.28

85 0.464 0.465 0.465 0.463 0.458 0.439 0.423 0.402 0.437 0.336

95 0.474 0.475 0.477 0.476 0.474 0.46 0.448 0.431 0.482 0.38

115 0.481 0.484 0.488 0.491 0.492 0.487 0.481 0.471 0.547 0.44

125 0.478 0.481 0.487 0.491 0.493 0.492 0.488 0.481 0.569 0.458

135 0.472 0.475 0.482 0.487 0.491 0.493 0.491 0.487 0.584 0.469

75 0.325 0.327 0.329 0.33 0.329 0.317 0.305 0.287 0.262 0.225

85 0.331 0.334 0.338 0.341 0.341 0.335 0.327 0.314 0.296 0.269

95 0.336 0.339 0.344 0.348 0.351 0.349 0.344 0.336 0.323 0.303

115 0.333 0.338 0.345 0.352 0.358 0.365 0.365 0.362 0.357 0.347

125 0.326 0.331 0.34 0.348 0.355 0.365 0.367 0.367 0.365 0.359

135 0.316 0.321 0.331 0.34 0.349 0.362 0.366 0.368 0.368 0.365

75 0.317 0.319 0.322 0.324 0.322 0.311 0.299 0.281 0.257 0.221

85 0.312 0.315 0.32 0.323 0.324 0.319 0.311 0.299 0.281 0.255

95 0.304 0.307 0.314 0.319 0.322 0.321 0.317 0.309 0.297 0.279

115 0.27 0.275 0.284 0.292 0.298 0.307 0.308 0.307 0.302 0.294

125 0.244 0.249 0.259 0.268 0.276 0.288 0.292 0.293 0.292 0.287

135 0.211 0.217 0.228 0.238 0.248 0.263 0.268 0.272 0.273 0.272

75 0.459 0.461 0.464 0.464 0.463 0.449 0.435 0.416 0.389 0.351

85 0.463 0.466 0.47 0.473 0.473 0.465 0.456 0.441 0.421 0.392

95 0.465 0.468 0.474 0.478 0.481 0.478 0.472 0.461 0.446 0.424

115 0.452 0.456 0.465 0.472 0.478 0.484 0.483 0.479 0.472 0.46

125 0.436 0.442 0.451 0.46 0.467 0.477 0.479 0.477 0.473 0.465

135 0.416 0.422 0.433 0.443 0.451 0.464 0.468 0.469 0.468 0.463

75 0.561 0.561 0.559 0.553 0.544 0.511 0.486 0.459 0.406 0.343

85 0.566 0.567 0.567 0.564 0.558 0.534 0.514 0.493 0.452 0.404

95 0.567 0.568 0.57 0.57 0.567 0.549 0.534 0.518 0.486 0.449

115 0.544 0.548 0.553 0.556 0.558 0.552 0.544 0.536 0.516 0.494

125 0.519 0.523 0.53 0.535 0.538 0.537 0.533 0.527 0.512 0.496

135 0.484 0.489 0.497 0.504 0.509 0.512 0.51 0.508 0.497 0.485

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 08

US units

Capacity (TR)

R32

R290

R448A

R449A

R452A

Condensing

temperature

(°F)

75 0.835 0.833 0.824 0.811 0.793 0.737 0.696 0.643 0.575 0.484

85 0.859 0.857 0.851 0.841 0.827 0.825 0.746 0.704 0.649 0.578

95 0.875 0.874 0.871 0.864 0.853 0.815 0.788 0.752 0.708 0.651

115 0.883 0.885 0.885 0.883 0.877 0.854 0.836 0.839 0.782 0.743

125 0.872 0.874 0.876 0.876 0.873 0.856 0.842 0.822 0.797 0.766

135 0.852 0.855 0.859 0.860 0.859 0.848 0.836 0.821 0.800 0.774

75 0.459 0.460 0.462 0.461 0.457 0.437 0.418 0.392 0.356 0.303

85 0.464 0.466 0.470 0.472 0.471 0.458 0.448 0.425 0.398 0.361

95 0.464 0.467 0.473 0.477 0.478 0.472 0.464 0.450 0.430 0.403

115 0.450 0.455 0.464 0.472 0.478 0.484 0.482 0.477 0.468 0.454

125 0.434 0.440 0.451 0.461 0.469 0.479 0.481 0.479 0.474 0.465

135 0.414 0.421 0.433 0.445 0.454 0.469 0.473 0.475 0.473 0.468

75 0.433 0.434 0.435 0.434 0.432 0.416 0.412 0.378 0.349 0.289

85 0.432 0.436 0.445 0.449 0.450 0.445 0.447 0.425 0.408 0.370

95 0.411 0.422 0.444 0.453 0.456 0.457 0.460 0.443 0.432 0.396

115 0.412 0.418 0.430 0.439 0.445 0.453 0.460 0.450 0.445 0.425

125 0.396 0.403 0.418 0.427 0.435 0.445 0.454 0.446 0.444 0.428

135 0.347 0.353 0.365 0.376 0.386 0.401 0.406 0.409 0.409 0.406

75 0.433 0.434 0.435 0.434 0.432 0.416 0.412 0.378 0.349 0.289

85 0.439 0.440 0.441 0.442 0.443 0.437 0.428 0.414 0.395 0.367

95 0.439 0.440 0.441 0.443 0.446 0.444 0.438 0.428 0.414 0.395

115 0.418 0.421 0.426 0.432 0.438 0.444 0.443 0.436 0.428 0.422

125 0.405 0.407 0.412 0.419 0.427 0.436 0.437 0.436 0.432 0.424

135 0.357 0.363 0.374 0.385 0.395 0.411 0.422 0.420 0.422 0.414

75 0.329 0.332 0.336 0.339 0.340 0.332 0.323 0.308 0.289 0.257

85 0.324 0.328 0.333 0.338 0.341 0.339 0.334 0.324 0.311 0.289

95 0.316 0.320 0.327 0.333 0.337 0.340 0.338 0.329 0.323 0.306

115 0.282 0.288 0.297 0.307 0.314 0.325 0.328 0.328 0.325 0.318

125 0.254 0.261 0.271 0.282 0.290 0.306 0.310 0.313 0.314 0.311

135 0.225 0.231 0.242 0.255 0.264 0.283 0.289 0.294 0.296 0.296

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 08

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 16

Page 17

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

temperature

R22

R134a

R404A

R407C

R410A

Condensing

(°F)

75 0.76 0.76 0.76 0.75 0.74 0.70 0.67 0.62 0.65 0.47

85 0.78 0.79 0.79 0.78 0.77 0.74 0.72 0.68 0.74 0.57

95 0.80 0.80 0.81 0.81 0.80 0.78 0.76 0.73 0.82 0.64

115 0.81 0.82 0.82 0.83 0.83 0.82 0.81 0.80 0.92 0.74

125 0.81 0.81 0.82 0.83 0.83 0.83 0.83 0.81 0.96 0.77

135 0.80 0.80 0.81 0.82 0.83 0.83 0.83 0.82 0.99 0.79

75 0.55 0.55 0.56 0.56 0.56 0.54 0.52 0.49 0.44 0.38

85 0.56 0.56 0.57 0.58 0.58 0.57 0.55 0.53 0.50 0.45

95 0.57 0.57 0.58 0.59 0.59 0.59 0.58 0.57 0.55 0.51

115 0.56 0.57 0.58 0.60 0.61 0.62 0.62 0.61 0.60 0.59

125 0.55 0.56 0.57 0.59 0.60 0.62 0.62 0.62 0.62 0.61

135 0.53 0.54 0.56 0.58 0.59 0.61 0.62 0.62 0.62 0.62

75 0.54 0.54 0.54 0.55 0.55 0.53 0.51 0.48 0.43 0.37

85 0.53 0.53 0.54 0.55 0.55 0.54 0.53 0.50 0.48 0.43

95 0.51 0.52 0.53 0.54 0.54 0.54 0.54 0.52 0.50 0.47

115 0.46 0.46 0.48 0.49 0.50 0.52 0.52 0.52 0.51 0.50

125 0.41 0.42 0.44 0.45 0.47 0.49 0.49 0.50 0.49 0.49

135 0.36 0.37 0.39 0.40 0.42 0.44 0.45 0.46 0.46 0.46

75 0.78 0.78 0.78 0.78 0.78 0.76 0.74 0.70 0.66 0.59

85 0.78 0.79 0.79 0.80 0.80 0.79 0.77 0.75 0.71 0.66

95 0.79 0.79 0.80 0.81 0.81 0.81 0.80 0.78 0.75 0.72

115 0.76 0.77 0.79 0.80 0.81 0.82 0.82 0.81 0.80 0.78

125 0.74 0.75 0.76 0.78 0.79 0.81 0.81 0.81 0.80 0.79

135 0.70 0.71 0.73 0.75 0.76 0.78 0.79 0.79 0.79 0.78

75 0.95 0.95 0.94 0.94 0.92 0.86 0.82 0.78 0.69 0.58

85 0.96 0.96 0.96 0.95 0.94 0.90 0.87 0.83 0.76 0.68

95 0.96 0.96 0.96 0.96 0.96 0.93 0.90 0.88 0.82 0.76

115 0.92 0.93 0.93 0.94 0.94 0.93 0.92 0.91 0.87 0.84

125 0.88 0.88 0.89 0.90 0.91 0.91 0.90 0.89 0.87 0.84

135 0.82 0.83 0.84 0.85 0.86 0.87 0.86 0.86 0.84 0.82

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -10

US units

Capacity (TR)

temperature

R32

R290

R448A

449A

R152A

Condensing

(°F)

75 1.411 1.406 1.392 1.370 1.340 1.244 1.176 1.086 0.972 0.817

85 1.451 1.448 1.438 1.421 1.397 1.394 1.260 1.189 1.095 0.976

95 1.477 1.476 1.471 1.459 1.440 1.377 1.331 1.271 1.196 1.100

115 1.492 1.494 1.495 1.491 1.482 1.443 1.413 1.417 1.321 1.256

125 1.473 1.476 1.480 1.480 1.475 1.446 1.422 1.389 1.347 1.293

135 1.439 1.444 1.450 1.453 1.451 1.432 1.413 1.386 1.352 1.308

75 0.775 0.777 0.780 0.779 0.772 0.737 0.706 0.662 0.601 0.512

85 0.783 0.788 0.794 0.797 0.795 0.773 0.757 0.718 0.673 0.609

95 0.783 0.789 0.799 0.806 0.808 0.798 0.784 0.760 0.727 0.680

115 0.760 0.768 0.784 0.798 0.808 0.817 0.814 0.806 0.790 0.766

125 0.734 0.744 0.762 0.778 0.792 0.809 0.812 0.809 0.801 0.785

135 0.700 0.711 0.732 0.751 0.768 0.793 0.799 0.802 0.800 0.791

75 0.731 0.733 0.736 0.734 0.729 0.703 0.696 0.639 0.590 0.488

85 0.730 0.737 0.752 0.758 0.761 0.752 0.754 0.717 0.689 0.626

95 0.695 0.713 0.750 0.765 0.771 0.771 0.778 0.749 0.729 0.669

115 0.695 0.706 0.727 0.741 0.752 0.765 0.777 0.760 0.752 0.718

125 0.669 0.681 0.706 0.722 0.734 0.752 0.767 0.754 0.749 0.722

135 0.587 0.597 0.617 0.635 0.651 0.677 0.685 0.690 0.691 0.686

75 0.731 0.733 0.736 0.734 0.729 0.703 0.696 0.639 0.590 0.488

85 0.742 0.743 0.744 0.747 0.749 0.738 0.723 0.700 0.668 0.621

95 0.742 0.742 0.744 0.749 0.754 0.750 0.741 0.724 0.700 0.668

115 0.707 0.711 0.719 0.729 0.740 0.749 0.748 0.737 0.722 0.712

125 0.683 0.688 0.696 0.708 0.721 0.736 0.739 0.737 0.730 0.717

135 0.603 0.613 0.632 0.650 0.667 0.694 0.713 0.709 0.712 0.700

75 0.556 0.561 0.568 0.573 0.574 0.560 0.546 0.520 0.488 0.434

85 0.547 0.554 0.563 0.572 0.576 0.573 0.565 0.548 0.526 0.488

95 0.533 0.541 0.552 0.563 0.570 0.575 0.571 0.555 0.545 0.517

115 0.477 0.486 0.501 0.518 0.530 0.550 0.553 0.553 0.549 0.538

125 0.429 0.440 0.457 0.476 0.490 0.517 0.524 0.529 0.530 0.525

135 0.379 0.391 0.409 0.430 0.446 0.478 0.488 0.496 0.500 0.500

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -10

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 17

Page 18

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°F)

75 1.71 1.71 1.70 1.69 1.66 1.57 1.49 1.39 1.46 1.06

85 1.76 1.76 1.76 1.75 1.73 1.66 1.60 1.52 1.66 1.27

95 1.79 1.80 1.80 1.80 1.79 1.74 1.70 1.63 1.82 1.44

115 1.82 1.83 1.85 1.86 1.86 1.84 1.82 1.78 2.07 1.66

125 1.81 1.82 1.84 1.86 1.87 1.86 1.85 1.82 2.15 1.73

135 1.78 1.80 1.82 1.84 1.86 1.87 1.86 1.84 2.21 1.77

75 1.23 1.24 1.25 1.25 1.24 1.20 1.15 1.09 0.99 0.85

85 1.25 1.26 1.28 1.29 1.29 1.27 1.24 1.19 1.12 1.02

95 1.27 1.28 1.30 1.32 1.33 1.32 1.30 1.27 1.22 1.15

115 1.26 1.28 1.31 1.33 1.35 1.38 1.38 1.37 1.35 1.31

125 1.23 1.25 1.29 1.32 1.34 1.38 1.39 1.39 1.38 1.36

135 1.19 1.21 1.25 1.29 1.32 1.37 1.38 1.39 1.39 1.38

75 1.20 1.21 1.22 1.22 1.22 1.18 1.13 1.06 0.97 0.83

85 1.18 1.19 1.21 1.22 1.23 1.21 1.18 1.13 1.06 0.97

95 1.15 1.16 1.19 1.21 1.22 1.22 1.20 1.17 1.12 1.05

115 1.02 1.04 1.07 1.10 1.13 1.16 1.17 1.16 1.14 1.11

125 0.92 0.94 0.98 1.02 1.05 1.09 1.10 1.11 1.10 1.09

135 0.80 0.82 0.86 0.90 0.94 1.00 1.02 1.03 1.03 1.03

75 1.74 1.74 1.75 1.76 1.75 1.70 1.65 1.57 1.47 1.33

85 1.75 1.76 1.78 1.79 1.79 1.76 1.72 1.67 1.59 1.48

95 1.76 1.77 1.79 1.81 1.82 1.81 1.78 1.74 1.69 1.60

115 1.71 1.73 1.76 1.79 1.81 1.83 1.83 1.81 1.79 1.74

125 1.65 1.67 1.71 1.74 1.77 1.80 1.81 1.81 1.79 1.76

135 1.57 1.60 1.64 1.68 1.71 1.76 1.77 1.78 1.77 1.75

75 2.12 2.12 2.11 2.09 2.06 1.93 1.84 1.74 1.54 1.30

85 2.14 2.15 2.15 2.13 2.11 2.02 1.94 1.87 1.71 1.53

95 2.14 2.15 2.16 2.16 2.14 2.08 2.02 1.96 1.84 1.70

115 2.06 2.07 2.09 2.11 2.11 2.09 2.06 2.03 1.95 1.87

125 1.96 1.98 2.00 2.02 2.04 2.03 2.01 2.00 1.94 1.88

135 1.83 1.85 1.88 1.91 1.92 1.94 1.93 1.92 1.88 1.83

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -14

US units

Capacity (TR)

temperature

R32

R290

R448A

R449A

R452A

Condensing

(°F)

75 3.161 3.150 3.119 3.070 3.002 2.788 2.634 2.433 2.177 1.830

85 3.249 3.243 3.221 3.184 3.130 3.122 2.823 2.664 2.454 2.186

95 3.310 3.307 3.294 3.268 3.226 3.085 2.982 2.847 2.679 2.464

115 3.342 3.347 3.349 3.340 3.320 3.233 3.164 3.175 2.959 2.813

125 3.300 3.307 3.316 3.315 3.303 3.239 3.185 3.111 3.017 2.897

135 3.224 3.235 3.249 3.255 3.251 3.207 3.165 3.105 3.028 2.929

75 1.735 1.741 1.748 1.745 1.730 1.652 1.582 1.482 1.345 1.148

85 1.754 1.764 1.779 1.785 1.781 1.732 1.697 1.609 1.508 1.364

95 1.754 1.768 1.790 1.804 1.810 1.788 1.755 1.703 1.629 1.523

115 1.702 1.721 1.756 1.786 1.809 1.830 1.824 1.805 1.771 1.716

125 1.643 1.666 1.707 1.743 1.774 1.813 1.819 1.813 1.794 1.759

135 1.568 1.593 1.639 1.682 1.719 1.775 1.791 1.797 1.791 1.772

75 1.637 1.641 1.648 1.643 1.633 1.574 1.559 1.432 1.322 1.093

85 1.635 1.652 1.685 1.699 1.704 1.685 1.690 1.606 1.543 1.401

95 1.556 1.598 1.680 1.714 1.727 1.728 1.742 1.678 1.634 1.499

115 1.558 1.582 1.628 1.660 1.684 1.713 1.741 1.703 1.684 1.609

125 1.499 1.527 1.581 1.617 1.645 1.685 1.717 1.689 1.679 1.618

135 1.315 1.337 1.381 1.421 1.459 1.516 1.535 1.546 1.548 1.537

75 1.637 1.641 1.648 1.643 1.633 1.574 1.559 1.432 1.322 1.093

85 1.662 1.664 1.667 1.672 1.678 1.652 1.619 1.568 1.496 1.391

95 1.661 1.663 1.667 1.677 1.689 1.681 1.659 1.621 1.567 1.496

115 1.583 1.592 1.611 1.634 1.657 1.679 1.676 1.651 1.618 1.595

125 1.531 1.541 1.560 1.586 1.614 1.649 1.654 1.651 1.636 1.605

135 1.350 1.372 1.416 1.456 1.493 1.555 1.598 1.588 1.596 1.568

75 1.246 1.257 1.273 1.284 1.286 1.255 1.223 1.165 1.094 0.973

85 1.226 1.241 1.261 1.280 1.290 1.284 1.266 1.227 1.179 1.094

95 1.194 1.211 1.236 1.261 1.277 1.288 1.279 1.244 1.221 1.159

115 1.068 1.089 1.123 1.160 1.187 1.231 1.240 1.240 1.230 1.205

125 0.962 0.986 1.024 1.066 1.098 1.158 1.174 1.185 1.186 1.176

135 0.850 0.876 0.917 0.963 0.999 1.070 1.092 1.111 1.120 1.121

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -14

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 18

Page 19

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°F)

75 3.05 3.05 3.04 3.01 2.97 2.80 2.66 2.48 2.60 1.89

85 3.13 3.14 3.14 3.12 3.09 2.96 2.86 2.71 2.96 2.27

95 3.20 3.21 3.22 3.22 3.20 3.11 3.03 2.92 3.26 2.57

115 3.25 3.27 3.30 3.31 3.32 3.29 3.25 3.18 3.70 2.97

125 3.23 3.25 3.29 3.31 3.33 3.33 3.30 3.25 3.84 3.09

135 3.19 3.21 3.25 3.29 3.31 3.33 3.32 3.29 3.95 3.17

75 2.19 2.21 2.22 2.23 2.22 2.14 2.06 1.94 1.77 1.52

85 2.24 2.26 2.28 2.30 2.30 2.26 2.21 2.12 2.00 1.82

95 2.27 2.29 2.33 2.35 2.37 2.36 2.33 2.27 2.18 2.05

115 2.25 2.28 2.33 2.38 2.42 2.46 2.46 2.45 2.41 2.34

125 2.20 2.24 2.30 2.35 2.40 2.47 2.48 2.48 2.46 2.42

135 2.13 2.17 2.24 2.30 2.35 2.44 2.47 2.49 2.49 2.47

75 2.14 2.16 2.18 2.19 2.18 2.10 2.02 1.90 1.73 1.49

85 2.11 2.13 2.16 2.18 2.19 2.15 2.10 2.02 1.90 1.73

95 2.05 2.08 2.12 2.15 2.17 2.17 2.14 2.09 2.00 1.88

115 1.82 1.86 1.92 1.97 2.02 2.07 2.08 2.07 2.04 1.99

125 1.65 1.68 1.75 1.81 1.87 1.95 1.97 1.98 1.97 1.94

135 1.42 1.46 1.54 1.61 1.67 1.78 1.81 1.84 1.85 1.84

75 3.10 3.11 3.13 3.14 3.12 3.03 2.94 2.81 2.63 2.37

85 3.13 3.15 3.18 3.20 3.20 3.14 3.08 2.98 2.84 2.65

95 3.14 3.16 3.20 3.23 3.25 3.23 3.19 3.11 3.01 2.86

115 3.05 3.08 3.14 3.19 3.23 3.27 3.27 3.24 3.19 3.11

125 2.95 2.98 3.05 3.11 3.16 3.22 3.23 3.23 3.20 3.14

135 2.81 2.85 2.92 2.99 3.05 3.14 3.16 3.17 3.16 3.13

75 3.79 3.79 3.78 3.74 3.68 3.46 3.28 3.10 2.74 2.32

85 3.82 3.83 3.83 3.81 3.77 3.61 3.47 3.33 3.05 2.73

95 3.83 3.84 3.85 3.85 3.83 3.71 3.61 3.50 3.28 3.04

115 3.68 3.70 3.74 3.76 3.77 3.73 3.68 3.62 3.49 3.34

125 3.50 3.53 3.58 3.61 3.63 3.63 3.60 3.56 3.46 3.35

135 3.27 3.30 3.36 3.40 3.44 3.46 3.45 3.43 3.36 3.27

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -18

US units

Capacity (TR)

R32

R290

R448A

R449A

R452A

Condensing

temperature

(°F)

75 5.645 5.626 5.569 5.482 5.361 4.978 4.703 4.344 3.887 3.267

85 5.802 5.791 5.752 5.686 5.590 5.576 5.041 4.757 4.382 3.903

95 5.910 5.906 5.883 5.835 5.761 5.510 5.324 5.083 4.784 4.400

115 5.969 5.977 5.981 5.965 5.928 5.773 5.650 5.669 5.283 5.023

125 5.892 5.906 5.921 5.920 5.899 5.784 5.687 5.555 5.387 5.173

135 5.758 5.777 5.801 5.812 5.805 5.726 5.651 5.545 5.408 5.231

75 3.098 3.110 3.122 3.116 3.089 2.950 2.825 2.647 2.403 2.049

85 3.133 3.151 3.177 3.188 3.180 3.094 3.030 2.873 2.692 2.436

95 3.132 3.157 3.196 3.222 3.233 3.192 3.134 3.041 2.909 2.720

115 3.039 3.074 3.137 3.190 3.231 3.268 3.257 3.223 3.162 3.064

125 2.934 2.975 3.048 3.113 3.167 3.237 3.247 3.237 3.203 3.140

135 2.799 2.844 2.927 3.004 3.070 3.170 3.198 3.209 3.199 3.164

75 2.924 2.930 2.943 2.934 2.917 2.810 2.784 2.557 2.361 1.951

85 2.919 2.949 3.009 3.034 3.043 3.009 3.017 2.868 2.755 2.502

95 2.778 2.853 3.000 3.061 3.084 3.085 3.110 2.996 2.918 2.677

115 2.782 2.824 2.908 2.964 3.007 3.059 3.108 3.041 3.008 2.873

125 2.677 2.726 2.822 2.888 2.938 3.008 3.067 3.016 2.997 2.890

135 2.348 2.388 2.467 2.538 2.605 2.707 2.742 2.760 2.764 2.744

75 2.924 2.930 2.943 2.934 2.917 2.810 2.784 2.557 2.361 1.951

85 2.968 2.971 2.977 2.986 2.996 2.950 2.892 2.799 2.671 2.483

95 2.966 2.970 2.977 2.994 3.016 3.001 2.963 2.895 2.798 2.672

115 2.826 2.844 2.877 2.917 2.959 2.998 2.993 2.949 2.889 2.849

125 2.734 2.751 2.785 2.832 2.883 2.945 2.954 2.948 2.921 2.866

135 2.411 2.451 2.529 2.600 2.666 2.776 2.853 2.836 2.850 2.800

75 2.225 2.245 2.272 2.292 2.296 2.241 2.184 2.078 1.953 1.737

85 2.189 2.215 2.253 2.287 2.304 2.293 2.260 2.191 2.105 1.954

95 2.132 2.162 2.207 2.252 2.280 2.300 2.284 2.221 2.180 2.070

115 1.906 1.945 2.006 2.071 2.119 2.198 2.213 2.214 2.197 2.152

125 1.717 1.760 1.828 1.904 1.961 2.067 2.096 2.116 2.118 2.100

135 1.518 1.563 1.637 1.720 1.784 1.911 1.950 1.984 2.000 2.001

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 -18

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 19

Page 20

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°F)

75 5.80 5.80 5.78 5.73 5.64 5.31 5.05 4.70 4.94 3.60

85 5.96 5.96 5.96 5.94 5.88 5.63 5.43 5.16 5.62 4.31

95 6.08 6.10 6.12 6.11 6.08 5.91 5.75 5.54 6.19 4.88

115 6.18 6.21 6.26 6.30 6.31 6.25 6.17 6.05 7.02 5.64

125 6.14 6.18 6.25 6.30 6.33 6.32 6.27 6.18 7.30 5.87

135 6.05 6.10 6.18 6.25 6.30 6.33 6.31 6.25 7.50 6.02

75 4.17 4.19 4.23 4.24 4.22 4.07 3.92 3.69 3.37 2.89

85 4.25 4.29 4.34 4.37 4.38 4.30 4.20 4.03 3.79 3.45

95 4.31 4.35 4.42 4.47 4.50 4.48 4.42 4.31 4.14 3.89

115 4.28 4.33 4.43 4.52 4.60 4.68 4.68 4.65 4.58 4.45

125 4.19 4.25 4.36 4.47 4.56 4.69 4.72 4.72 4.68 4.61

135 4.05 4.12 4.25 4.37 4.47 4.64 4.70 4.73 4.72 4.69

75 4.07 4.10 4.14 4.15 4.14 3.99 3.84 3.61 3.30 2.83

85 4.01 4.05 4.11 4.15 4.16 4.09 3.99 3.83 3.61 3.28

95 3.90 3.95 4.03 4.09 4.13 4.13 4.07 3.97 3.81 3.58

115 3.47 3.53 3.64 3.75 3.83 3.94 3.95 3.94 3.88 3.78

125 3.13 3.20 3.33 3.44 3.55 3.70 3.75 3.76 3.75 3.69

135 2.71 2.78 2.93 3.06 3.18 3.38 3.45 3.49 3.51 3.50

75 5.89 5.91 5.95 5.96 5.94 5.76 5.59 5.33 4.99 4.50

85 5.95 5.98 6.04 6.07 6.08 5.97 5.85 5.66 5.40 5.03

95 5.96 6.01 6.08 6.14 6.17 6.13 6.05 5.92 5.72 5.44

115 5.80 5.86 5.97 6.06 6.14 6.21 6.20 6.15 6.06 5.91

125 5.60 5.67 5.79 5.91 6.00 6.12 6.14 6.13 6.07 5.97

135 5.34 5.41 5.55 5.68 5.79 5.96 6.01 6.02 6.01 5.95

75 7.20 7.20 7.17 7.10 6.99 6.56 6.24 5.89 5.21 4.40

85 7.27 7.28 7.28 7.24 7.17 6.85 6.59 6.33 5.80 5.19

95 7.27 7.30 7.32 7.32 7.27 7.05 6.86 6.66 6.24 5.77

115 6.99 7.03 7.10 7.14 7.16 7.09 6.99 6.88 6.63 6.34

125 6.66 6.71 6.80 6.86 6.91 6.90 6.84 6.77 6.58 6.36

135 6.21 6.27 6.38 6.47 6.53 6.57 6.55 6.52 6.38 6.22

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 25

US units

Capacity (TR)

temperature

R32

R290

R448A

R449A

R452A

Condensing

(°F)

75 10.758 10.722 10.614 10.447 10.217 9.487 8.963 8.279 7.409 6.227

85 11.059 11.037 10.963 10.836 10.653 10.627 9.607 9.067 8.351 7.439

95 11.264 11.256 11.212 11.121 10.981 10.501 10.147 9.688 9.118 8.386

115 11.375 11.391 11.398 11.369 11.298 11.003 10.769 10.805 10.069 9.574

125 11.230 11.256 11.285 11.280 11.242 11.024 10.839 10.586 10.267 9.859

135 10.974 11.010 11.057 11.077 11.064 10.914 10.770 10.568 10.307 9.969

75 5.89 5.91 5.93 5.92 5.87 5.60 5.37 5.03 4.56 3.89

85 5.95 5.99 6.04 6.06 6.04 5.88 5.76 5.46 5.12 4.63

95 5.95 6.00 6.07 6.12 6.14 6.07 5.95 5.78 5.53 5.17

115 5.77 5.84 5.96 6.06 6.14 6.21 6.19 6.12 6.01 5.82

125 5.58 5.65 5.79 5.92 6.02 6.15 6.17 6.15 6.09 5.97

135 5.32 5.40 5.56 5.71 5.83 6.02 6.08 6.10 6.08 6.01

75 5.572 5.584 5.608 5.592 5.559 5.356 5.306 4.873 4.500 3.719

85 5.563 5.621 5.734 5.782 5.800 5.734 5.751 5.467 5.251 4.769

95 5.295 5.438 5.717 5.834 5.878 5.880 5.928 5.711 5.561 5.102

115 5.302 5.383 5.542 5.649 5.731 5.830 5.924 5.796 5.732 5.476

125 5.102 5.195 5.379 5.504 5.599 5.733 5.845 5.747 5.713 5.508

135 4.475 4.551 4.701 4.838 4.965 5.160 5.225 5.261 5.269 5.229

75 5.572 5.584 5.608 5.592 5.559 5.356 5.306 4.873 4.500 3.719

85 5.656 5.662 5.674 5.691 5.710 5.623 5.511 5.335 5.091 4.732

95 5.654 5.660 5.674 5.707 5.748 5.720 5.646 5.518 5.333 5.092

115 5.387 5.419 5.484 5.560 5.640 5.714 5.705 5.620 5.505 5.430

125 5.210 5.243 5.309 5.398 5.494 5.612 5.630 5.619 5.568 5.463

135 4.595 4.671 4.820 4.956 5.082 5.292 5.438 5.406 5.432 5.337

75 4.241 4.279 4.331 4.368 4.375 4.272 4.163 3.963 3.723 3.311

85 4.173 4.222 4.293 4.358 4.391 4.370 4.307 4.177 4.011 3.724

95 4.063 4.121 4.207 4.292 4.345 4.384 4.354 4.233 4.155 3.945

115 3.633 3.707 3.823 3.948 4.038 4.190 4.219 4.219 4.187 4.101

125 3.273 3.355 3.484 3.628 3.737 3.940 3.995 4.033 4.037 4.002

135 2.892 2.980 3.120 3.278 3.400 3.642 3.717 3.782 3.812 3.815

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 25

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 20

Page 21

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

US units

Condensing

temperature

(°F)

75 8.55 8.55 8.51 8.44 8.31 7.83 7.45 6.93 7.28 5.30

85 8.78 8.79 8.79 8.75 8.66 8.30 8.01 7.60 8.28 6.35

95 8.96 8.99 9.02 9.01 8.96 8.70 8.48 8.16 9.12 7.19

115 9.11 9.15 9.23 9.28 9.30 9.21 9.09 8.91 10.30 8.31

125 9.05 9.11 9.21 9.28 9.33 9.31 9.24 9.11 10.70 8.65

135 8.92 8.99 9.11 9.21 9.28 9.33 9.29 9.21 11.00 8.87

75 6.14 6.18 6.23 6.24 6.22 6.00 5.77 5.44 4.96 4.25

85 6.27 6.32 6.39 6.44 6.45 6.34 6.18 5.94 5.59 5.08

95 6.35 6.41 6.51 6.59 6.64 6.61 6.52 6.35 6.10 5.73

115 6.31 6.39 6.54 6.67 6.77 6.90 6.90 6.85 6.75 6.56

125 6.17 6.26 6.43 6.58 6.72 6.91 6.95 6.95 6.90 6.79

135 5.97 6.07 6.26 6.44 6.59 6.84 6.92 6.96 6.96 6.91

75 6.00 6.04 6.10 6.12 6.10 5.88 5.66 5.32 4.86 4.17

85 5.91 5.96 6.05 6.11 6.13 6.03 5.88 5.65 5.32 4.83

95 5.75 5.82 5.93 6.03 6.09 6.08 6.00 5.85 5.61 5.27

115 5.11 5.20 5.37 5.52 5.64 5.81 5.83 5.80 5.72 5.57

125 4.61 4.71 4.90 5.08 5.23 5.46 5.52 5.54 5.52 5.44

135 3.99 4.10 4.31 4.51 4.68 4.98 5.08 5.15 5.17 5.15

75 8.68 8.72 8.77 8.78 8.75 8.49 8.23 7.86 7.36 6.64

85 8.76 8.81 8.90 8.95 8.95 8.80 8.62 8.34 7.96 7.41

95 8.79 8.86 8.97 9.05 9.09 9.04 8.92 8.72 8.43 8.02

115 8.55 8.64 8.80 8.94 9.05 9.16 9.14 9.07 8.93 8.71

125 8.25 8.35 8.54 8.70 8.84 9.02 9.05 9.03 8.95 8.80

135 7.87 7.98 8.19 8.38 8.54 8.78 8.85 8.88 8.85 8.76

75 10.61 10.61 10.57 10.47 10.30 9.67 9.19 8.69 7.68 6.48

85 10.71 10.73 10.73 10.67 10.56 10.09 9.72 9.33 8.54 7.65

95 10.72 10.75 10.79 10.78 10.72 10.39 10.10 9.81 9.19 8.50

115 10.29 10.36 10.46 10.53 10.55 10.44 10.30 10.14 9.77 9.35

125 9.81 9.89 10.02 10.12 10.18 10.16 10.07 9.98 9.69 9.38

135 9.16 9.24 9.40 9.53 9.62 9.69 9.65 9.60 9.40 9.17

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 32

Capacity (TR)

temperature

R32

R290

R448A

R449A

R452A

US units

Condensing

(°F)

75 15.805 15.752 15.594 15.348 15.009 13.938 13.169 12.163 10.884 9.149

85 16.247 16.215 16.106 15.919 15.651 15.612 14.114 13.321 12.269 10.929

95 16.548 16.537 16.472 16.339 16.132 15.427 14.908 14.233 13.396 12.321

115 16.712 16.735 16.746 16.702 16.599 16.165 15.821 15.874 14.793 14.066

125 16.498 16.536 16.580 16.575 16.516 16.196 15.923 15.553 15.084 14.484

135 16.122 16.175 16.244 16.274 16.254 16.034 15.823 15.525 15.142 14.646

75 8.67 8.71 8.74 8.72 8.65 8.26 7.91 7.41 6.73 5.74

85 8.77 8.82 8.89 8.93 8.91 8.66 8.48 8.05 7.54 6.82

95 8.77 8.84 8.95 9.02 9.05 8.94 8.78 8.51 8.14 7.62

115 8.51 8.61 8.78 8.93 9.05 9.15 9.12 9.03 8.85 8.58

125 8.22 8.33 8.53 8.72 8.87 9.06 9.09 9.06 8.97 8.79

135 7.84 7.96 8.20 8.41 8.60 8.88 8.95 8.98 8.96 8.86

75 8.186 8.204 8.239 8.215 8.167 7.868 7.795 7.159 6.611 5.463

85 8.173 8.258 8.424 8.494 8.520 8.424 8.448 8.032 7.715 7.007

95 7.780 7.989 8.399 8.571 8.635 8.638 8.709 8.390 8.170 7.495

115 7.789 7.908 8.142 8.300 8.419 8.564 8.703 8.516 8.422 8.045

125 7.495 7.633 7.903 8.086 8.226 8.423 8.586 8.444 8.393 8.091

135 6.574 6.686 6.906 7.107 7.294 7.851 7.676 7.729 7.740 7.683

75 8.186 8.204 8.239 8.215 8.167 7.868 7.795 7.159 6.611 5.463

85 8.310 8.319 8.336 8.361 8.389 8.261 8.097 7.838 7.479 6.953

95 8.306 8.316 8.335 8.384 8.444 8.403 8.295 8.107 7.834 7.481

115 7.914 7.962 8.056 8.169 8.286 8.394 8.381 8.257 8.088 7.977

125 7.654 7.703 7.799 7.930 8.072 8.245 8.272 8.255 8.180 8.026

135 6.751 6.862 7.081 7.281 7.466 7.774 7.990 7.942 7.980 7.840

75 6.230 6.287 6.363 6.418 6.428 6.276 6.116 5.823 5.469 4.864

85 6.131 6.203 6.307 6.402 6.451 6.420 6.328 6.136 5.893 5.470

95 5.970 6.054 6.180 6.306 6.383 6.441 6.397 6.219 6.104 5.795

115 5.338 5.446 5.616 5.800 5.933 6.155 6.198 6.199 6.152 6.025

125 4.809 4.928 5.119 5.331 5.490 5.788 5.870 5.925 5.931 5.880

135 4.249 4.378 4.584 4.816 4.994 5.350 5.460 5.556 5.601 5.604

-40 -35 -25 -15 -5 15 25 35 45 55

Evaporation temperature [°F]

ETS 6 - 32

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 21

Page 22

Data sheet | Electric expansion valves, type ETS 6

Capacity (TR)

R22

R134a

R404A

R407C

R410A

Condensing

temperature

(°F)

75 11.60 11.60 11.60 11.50 11.30 10.60 10.10 9.41 9.87 7.19

85 11.90 11.90 11.90 11.90 11.80 11.30 10.90 10.30 11.20 8.63

95 12.20 12.20 12.20 12.20 12.20 11.80 11.50 11.10 12.40 9.76

115 12.40 12.40 12.50 12.60 12.60 12.50 12.30 12.10 14.00 11.30

125 12.30 12.40 12.50 12.60 12.70 12.60 12.50 12.40 14.60 11.70

135 12.10 12.20 12.40 12.50 12.60 12.70 12.60 12.50 15.00 12.00

75 8.34 8.39 8.45 8.47 8.44 8.14 7.84 7.38 6.73 5.77

85 8.51 8.57 8.68 8.74 8.76 8.60 8.39 8.06 7.59 6.90

95 8.62 8.70 8.84 8.94 9.01 8.97 8.84 8.62 8.28 7.78

115 8.56 8.67 8.87 9.05 9.19 9.36 9.36 9.30 9.15 8.91

125 8.37 8.50 8.73 8.94 9.12 9.37 9.43 9.43 9.37 9.21

135 8.10 8.24 8.49 8.73 8.95 9.29 9.39 9.45 9.45 9.38

75 8.14 8.20 8.28 8.31 8.28 7.98 7.68 7.22 6.59 5.66

85 8.02 8.09 8.22 8.30 8.32 8.18 7.98 7.67 7.21 6.56

95 7.80 7.89 8.05 8.18 8.26 8.25 8.14 7.93 7.62 7.15

115 6.93 7.06 7.29 7.49 7.66 7.88 7.91 7.87 7.76 7.55

125 6.25 6.39 6.65 6.89 7.09 7.41 7.49 7.52 7.49 7.38

135 5.41 5.56 5.85 6.12 6.36 6.75 6.89 6.98 7.02 6.99

75 11.80 11.80 11.90 11.90 11.90 11.50 11.20 10.70 9.99 9.01

85 11.90 12.00 12.10 12.10 12.20 11.90 11.70 11.30 10.80 10.10

95 11.90 12.00 12.20 12.30 12.30 12.30 12.10 11.80 11.40 10.90

115 11.60 11.70 11.90 12.10 12.30 12.40 12.40 12.30 12.10 11.80

125 11.20 11.30 11.60 11.80 12.00 12.20 12.30 12.30 12.10 11.90

135 10.70 10.80 11.10 11.40 11.60 11.90 12.00 12.00 12.00 11.90

75 14.40 14.40 14.30 14.20 14.00 13.10 12.50 11.80 10.40 8.80

85 14.50 14.60 14.60 14.50 14.30 13.70 13.20 12.70 11.60 10.40

95 14.50 14.60 14.60 14.60 14.50 14.10 13.70 13.30 12.50 11.50

115 14.00 14.10 14.20 14.30 14.30 14.20 14.00 13.80 13.30 12.70

125 13.30 13.40 13.60 13.70 13.80 13.80 13.70 13.50 13.20 12.70

135 12.40 12.50 12.80 12.90 13.10 13.10 13.10 13.00 12.80 12.40

-40 -35 -25 -15 -5 15 25 35 45 55

ETS 6 - 40

Evaporation temperature [°F]

US units

Capacity (TR)

temperature

R32

R290

R448A

R449A

R452A

Condensing

(°F)

75 22.645 22.569 22.342 21.991 21.505 19.970 18.868 17.427 15.595 13.108

85 23.278 23.233 23.076 22.809 22.424 22.369 20.222 19.085 17.579 15.658

95 23.709 23.693 23.600 23.409 23.114 22.103 21.359 20.392 19.193 17.653

115 23.944 23.978 23.993 23.930 23.782 23.161 22.668 22.744 21.195 20.153

125 23.637 23.693 23.755 23.748 23.663 23.205 22.815 22.283 21.612 20.753

135 23.099 23.174 23.274 23.317 23.288 22.973 22.670 22.244 21.695 20.984

75 11.77 11.82 11.86 11.84 11.74 11.21 10.74 10.06 9.13 7.79

85 11.90 11.97 12.07 12.11 12.09 11.76 11.51 10.92 10.23 9.26

95 11.90 12.00 12.14 12.24 12.28 12.13 11.91 11.56 11.05 10.34

115 11.55 11.68 11.92 12.12 12.28 12.42 12.38 12.25 12.01 11.65

125 11.15 11.30 11.58 11.83 12.04 12.30 12.34 12.30 12.17 11.93

135 10.64 10.81 11.12 11.41 11.67 12.05 12.15 12.19 12.15 12.02

75 11.729 11.755 11.805 11.771 11.701 11.273 11.169 10.257 9.472 7.828

85 11.710 11.831 12.070 12.170 12.208 12.069 12.104 11.507 11.054 10.039

95 11.146 11.446 12.034 12.281 12.372 12.376 12.479 12.021 11.706 10.739

115 11.160 11.330 11.666 11.891 12.063 12.271 12.470 12.201 12.067 11.526

125 10.739 10.936 11.323 11.585 11.786 12.069 12.302 12.098 12.025 11.593

135 9.419 9.580 9.895 10.183 10.451 10.862 10.998 11.074 11.090 11.007

75 11.729 11.755 11.805 11.771 11.701 11.273 11.169 10.257 9.472 7.828

85 11.906 11.919 11.944 11.980 12.020 11.836 11.601 11.230 10.716 9.961

95 11.901 11.915 11.942 12.012 12.098 12.040 11.885 11.615 11.225 10.719

115 11.339 11.408 11.543 11.704 11.871 12.027 12.008 11.830 11.589 11.429

125 10.967 11.037 11.175 11.362 11.565 11.814 11.851 11.827 11.720 11.499

135 9.672 9.832 10.146 10.432 10.697 11.139 11.448 11.379 11.433 11.233

75 8.927 9.008 9.116 9.195 9.210 8.992 8.763 8.343 7.830 6.970

85 8.784 8.887 9.037 9.173 9.243 9.199 9.066 8.792 8.443 7.838

95 8.553 8.674 8.855 9.035 9.146 9.228 9.165 8.910 8.746 8.303

115 7.648 7.803 8.047 8.310 8.501 8.819 8.880 8.882 8.814 8.632

125 6.890 7.061 7.335 7.638 7.865 8.293 8.410 8.490 8.498 8.425

135 6.088 6.272 6.567 6.900 7.156 7.665 7.823 7.961 8.024 8.029

-40 -35 -25 -15 -5 15 25 35 45 55

ETS 6 - 40

Evaporation temperature [°F]

US units

© Danfoss | DCS (rm) | 2019.08

AI227986437323en-000901 | 22

Page 23

Dimensions

47mm

47mm

43 mm

ETS 6 - 10

ETS 6 - 14

ETS 6 - 25

ETS 6 - 32

ETS 6 - 40

ETS 6 - 08

ETS 6 - 18

43 mm

[1.69 in.]

[1.85 in.]

7.94 mm

[0.31 in.]

47mm

[1.85 in.]

[0.31 in.]

7.94 mm

50 mm

[1.96 in.]

[1.69 in.]

99 mm

[3.90 in.]

Weight: 0.16 kg (0.35 lbs)

(complete)

[1.85 in.]

6.35 mm

[0.25 in.]

47mm

[1.85 in.]

[0.25 in.]

6.35 mm

50 mm

[1.96 in.]

99 mm

[3.90 in.]

Related Danfoss Products

AKS pressure transmitter and

temperature sensor

© Danfoss | DCS (rm) | 2019.08

EKE 1A, EKE 1B, EKE 1C

superheat controller

AI227986437323en-000901 | 23

Loading...

Loading...