Page 1

Data Sheet

Electric expansion valve

Type ETS 5M

For liquid injection into evaporators

ETS 5M is a compact and lightweight stepper

motor driven electric expansion valve with a

high level of reliability, and it provides a precise

solution for expansion and ow control in a

wide range of refrigeration and air conditioning

systems.

The portfolio is available with a wide capacity

range and is designed for use with uorinated

refrigerants.

ETS 5M can be applied for applications i.e VRF,

IT cooling, Heatpump, Mini Chiller, Bus /

Transport application in single/biow

operation.

Valve operation is by means of a uni-polar

motor, and as such it is compatible with a

number of electronic controllers from Danfoss

or third-party vendors. With an EKE1 series/EIM

336 superheat controlleres and AKS sensor, a

superheat accuracy better than ± 0.5 K can be

obtained.

Features

• Low ow noise and operation noise.

• Optimized valve ow characteristic.

• Accurate valve control, also at low opening

degrees.

• Bi-ow, with full performance in both ow

directions.

• Higher degree of freedom of installation

orientation.

• Future-proof regarding refrigerants.

• Compatible with existing valve drivers.

• Largest nominal capacity, R410A : 20.6 kW, 5.8

TR.

AI357347789371en-000202

Page 2

EIM 336 Superheat controller

EKE 1 series superheat controllers (EKE 1B is shown)

EIM 336 is designed as a controller on a pcb, i.e. must be built into a suitable

cabinet before use.

EKE superheat controllers are for DIN rail mounting, and comes in three versions

with dierent combinations of inputs and output relays and dierent

functionality.

Pressure transmitter (DST P110 shown)

EKF 1A/2A Stepper Valve Driver

EKE 2U Backup power module

DST P110 is a digital ratiometric pressure transmitter.

Depending on controller type, other ratiometric

pressure transmitters can be used as

well (e.g. AKS 32R).

EKF series is an economical stepper valve driver that

translates analog signal provided by master controller

to valve driving sequence .

EKE 2U Backup power module ensures sucient

power in case of power failures to the controller

to ensure closure of the electronic valves.

Electric expansion valve, Type ETS 5M

Portfolio overview

ETS 5M is a system product whose function is controlled through a Danfoss electronic controller, or a third party

vendor electronic controller that is compatible with the ETS 5M as to control functionality and connections.

Danfoss recommends the use of the EKE1 series / EIM 336 superheat controller together with ETS 5M. (See separate

data sheet on EIM 336 for details). with EKE1 series / EIM 336 or similar Danfoss electronic controllers, a superheat

accuracy better than 0.5 K can be obtained.

The electronic controller requires precise temperature input from a temperature sensor (refrigerant temperature)

and precise pressure inputs (evaporator pressure) from a pressure transmitter.

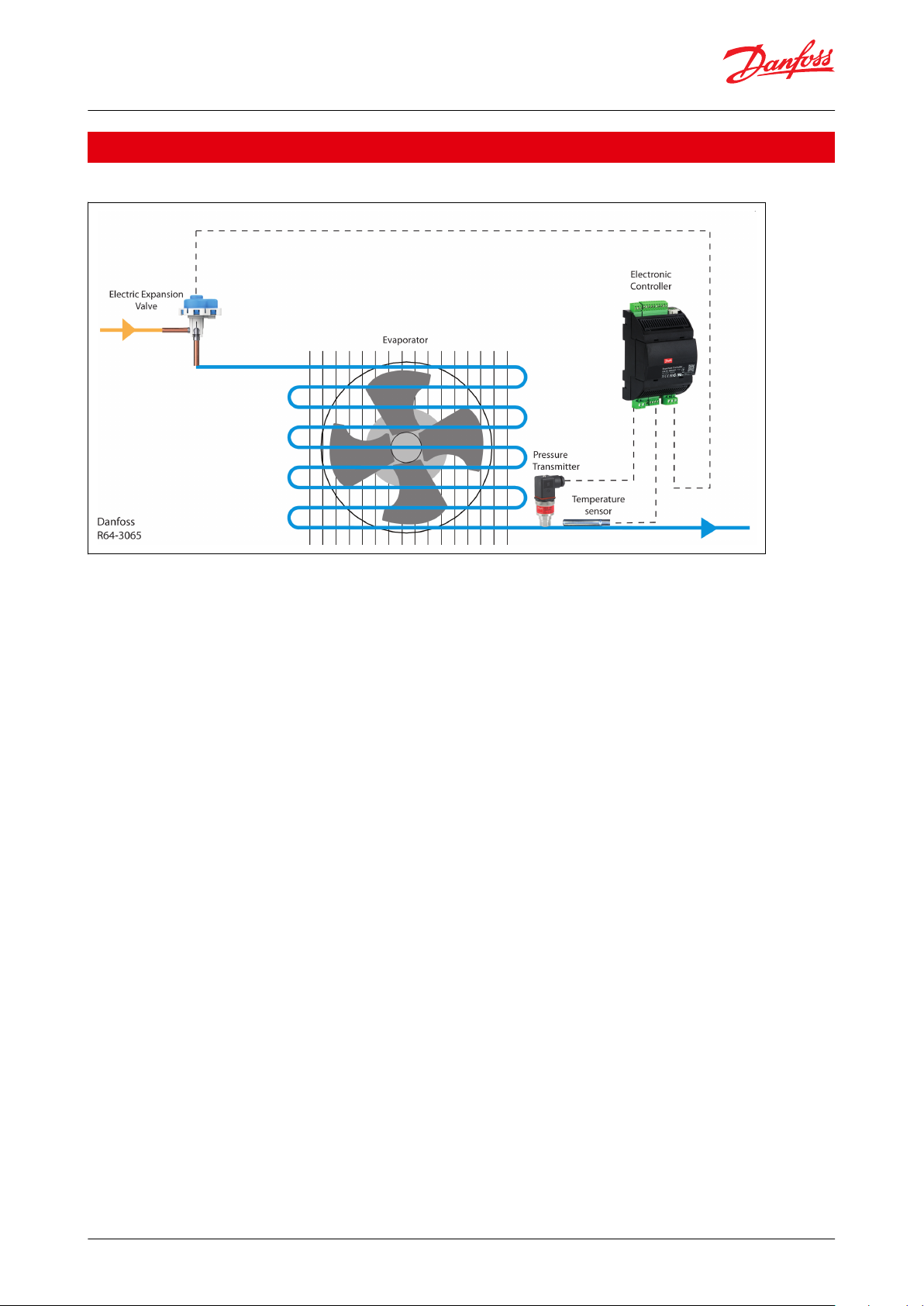

System product

Table 1: Electronic controllers for ETS 5M

Table 2: Sensors and other products for ETS 5M

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 2

Page 3

Electric expansion valve, Type ETS 5M

Applications

Figure 1: Typical application of ETS 5M

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 3

Page 4

Media data

Value

Refrigerants

R410A, R32 R290, R22, R454C, R515B, R1234ze, R452B, R1234yf, R452A, R454B, R454A, R455A, R449A, R407C,

R134a, R407H, R513A, R449B, R404A, R448A, R463A

Refrigerants oil

POE, MO

Electric expansion valve, Type ETS 5M

Media

ETS 5M is designed for use with uorinated refrigerants with suitable lubricants.

Table 3: ETS 5M media data

NOTE:

For ammable refrigerants (R454C, R454A, R1234ze, R290, R32, R452B, R454B, R455A,

R1234yf):

• This product is validated in accordance to ATEX, EN 378, ISO 5149, ASHRAE 15, IEC 60335-2-x or equivalent

standards.

• Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335.

• See safety note below.

NOTE:

• The product can be applied on systems with R454C, R454A, R1234ze, R290, R32, R452B, R454B, R455A, R1234yf as

the working uid.

• For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing ammable refrigerant.

• Note, please follow specic selection criteria stated in the datasheet for these particular refrigerants.

• The valve must only be used in closed circuit refrigeration system, where no oxygen is present acc. EN 378, ISO

5149 ASHRAE 15 or IEC 60335-2-x or equivalent standards.

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 4

Page 5

Data

Value [SI units]

Value [IMP. units]

Max working pressure (MWP)

45.5 barg

660 psig

Burst pressure

5 x MWP

5 x MWP

Maximum operating pressure dierential (MOPD)

(1)

A→B 35 barg

B→A 35 barg

A→B 508 Psig

B→A 508 Psig

Ambient temperature

-10 - 60 °C

-14 - 140 °F

Ambient relative humidity

Max. 95 % RH

Max. 95 % RH

Fluid temperature range, normal ow A→B

(1)

-8 - 70 deg C (on valve inlet)

-30 - 28 deg C (on valve outlet)

18 - 158 deg F (on valve inlet)

-22 - 82 deg F (on valve outlet)

Fluid temperature range, reverse ow B→A

(1)

20 - 50 deg C (on valve inlet and outlet)

68 - 122 deg F (on valve inlet and outlet)

Environmental conditions

Value

Max. Internal leakage @10 bar, A-> B and B->A

(1)

< 150 cm

3

/min

Mechanical noise

< 60 dB(A)

Enclosure rating IP (Valve and coil combined)

IP 66

Insulation class

B

Insulation resistance

>100 MΏ

Storage temperature range [°C]

-30 - 70 °C / -22 - 158 °F

Relative humidity

Max. 95 % RH

Electric expansion valve, Type ETS 5M

Product specication

Design

The ETS 5M Electric expansion valves open and close to regulate refrigerant ow by means of a screw, whose

rotating motion is transformed into linear motion. This occurs by the rotation of a magnetneedle valve assembly

which moves when electrical signals are applied to the surrounding coil. Within the coil structure, there are dierent

winding congurations, and the polarities are changed by the electrical signals applied.

By application of the appropriate combination of signals, in the form of pulses, the coil forces the rotor of the valve

to move in a stepwise fashion. Application of multiple pulses will make the valve mechanism move through a series

of steps in the chosen direction, in order to set the valve with the required opening degree.

Pressure and temperature data

Table 4: Pressure and temperature data in SI and Imperial units

(1)

(1)

A = Valve inlet

A = Valve inlet

B = Valve outlet

B = Valve outlet

Enviromental conditions

Table 5: Enviromental conditions

(1)

(1)

A = Valve inlet

A = Valve inlet

B = Valve outlet

B = Valve outlet

Flow characteristics

Air ow characteristics are provided for ETS 5M20 with normal and reverse ows.

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 5

Page 6

0

1

2

3

4

5

6

0

100

200 300

400

500

600

m^3/hr

Step

Air flow -Normal flow directi on

Model E TS24M

Model E TS20M

Model E TS17M

Model E TS13M

0

1

2

3

4

5

6

0 100

200

300

400

500

600

m^3/hr

Step

Air flow -Reverse flow directi on

Model E TS24M Revers e Flow

Model E TS20M Revers e Flow

Model E TS17M Revers e Flow

Model E TS13M Revers e Flow

Electric expansion valve, Type ETS 5M

Figure 2: Normal ow A -> B

Figure 3: Reverese ow B -> A

Flow characteristics

• Measured at 1 barg dierential pressure.

• Air ow provided in m3 /hour (Y axis).

• Valve position provided by pulses in half steps (X axis).

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 6

Page 7

A

B

Inlet

Outlet

Shape L

Shape L

Shape h

Shape h

Shape u

1⁄4 in

5⁄16 in

1⁄4 in

5⁄16 in

1⁄4 in

ODM

ODM

ODM

ODM

ODF

L Shape

ODF with straight connectors

L Shape

ODM with straight connectors

h Shape

ODF with elbow inlet and straight outlet

h Shape

ODM with elbow inlet and straight outlet

u Shape

ODF with straight inlet and elbow outlet

u Shape

ODM with straight inlet and elbow outlet

Electric expansion valve, Type ETS 5M

Mechanical conguration options

ETS 5M is an angleway valve designed with a valve body in steel and ODM or ODF solder connections in copper,

with inlet and outlet sizes

Figure 4: ETS SM inlet and outlet conguration

1

⁄4 in or 5⁄6 in.

The copper connections are highly congurable and can be produced with the following shapes.

Table 6: Connection conguration

NOTE:

Not all combinations of sizes and congurations are available. The table shows currently available congurations

Table 7: Mechanical conguration options

Electrical connection

Electrical connection is via a xed cable in a number of lengths from the coil to the controller. Cables up to 2.7 cm

length are available with a JST XHP-5 / JST-XHP6 connector. See ETS 5M coil Ordering for details.

Electrical and motor specications

Valve operation is by means of a uni-polar motor, designed as a separate coil that clicks onto the valve body.

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 7

Page 8

Electrical and motor specications

Value

Motor type

Uni-polar coil

Nominal voltage

12 V +10% / -15%

Coil resistance@ 20 °C

50 Ohm ± 10%

Rated current

0.26 A RMS

Power consumption

4.1 W

Holding current after each sequence of steps

Min. 30 ms, max. 1 s

Permanent holding current

Not allowed

Recommended excitation method Possible, but not recommended excitation method

1- 2

2- 2

Number of pulses

480 half-step pulse

Nominal pulse rate

31 pulses per second (PPS)

Maximum duty cycle (30s)

50 %

Insulation resistance

> 100 MΏ

Dielectric strength

< 5 mA

Yellow (A)

Orange (A1)

Black (B)

Brown (B1)

Red (Com)

Valve opening

↓↓

ON

OFF

OFF

OFF

0

Valve closing

↑↑

ON

OFFONOFF0OFF

OFFONOFF0OFFONON

OFF0OFFONOFF

OFF0OFFONOFFON0

OFF

OFF

OFFON0ONOFF

OFFON0

Danfoss

80Z881

41.1

83

Danfoss

80Z882

86.8

83

30

Danfoss

80Z883

41.1

44.5

33

Electric expansion valve, Type ETS 5M

Table 8: Electrical and motor specications

Stepper motor switch sequence

The stepper motor opens and closes as outlined in the table, opening moving down the table, closing moving the

opposite direction.

Table 9: Stepper motor open and close sequence

Dimensions (in mm)

Table 10: 1/4 inch male

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 8

Page 9

Danfoss

80Z884

80

38.1

84

30

80

Danfoss

80Z886

38.1

33

44.5

Danfoss

80Z887

80

38.1

Danfoss

80Z888

80

30

84

Danfoss

80Z889

38.1

33

44.5

40 mm

[1 5/8 in]

5

1

m

m

[

2

i

n

]

50 mm

[2 in]

25 mm

[1 in]

5 mm

[1/4 in]

L according to

product code

Danfoss

Dim034G3571

Electric expansion valve, Type ETS 5M

Table 11: 1/4 inch female

Table 12: 5/16 inch male

Figure 5: ETS 5M coil dimensions

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 9

Page 10

ETS 5M valve body, with L connection conguration

ETS 5M coil (stator)

Type

Design

cong.

shape

Orice size

Conn. type

Inlet x Out‐

let

Rated cap.

R410A

Rated cap.

R410A

Pack format

Qty/ pack

Code no

[mm]

[in]

[kW]

[TR]

ETS 5M13

L

1.3

Solder, ODM

1⁄4 x 1⁄4

8.9

2.52

Multi-pack

20 pc

034G6204

ETS 5M17

L

1.65

Solder, ODM

1⁄4 x 1⁄4

12.5

3.54

Multi-pack

20 pc

034G6207

ETS 5M20

L

2.0

Solder, ODM

1⁄4 x 1⁄4

16.7

4.74

Multi-pack

20 pc

034G6209

ETS 5M20

L

2.0

Solder, ODM

5⁄16 x 5⁄16

16.7

4.74

Industrial pack

40 pc

034G6210

ETS 5M20

L

2.0

Solder, ODM

5⁄16 x 5⁄16

16.7

4.74

Multi-pack

20 pc

034G6211

ETS 5M24

L

2.4

Solder, ODM

1⁄4 x 1⁄4

20.6

5.84

Multi-pack

20 pc

034G6212

ETS5M13

u

1.3

Solder, ODF

1⁄4 x 1⁄4

8.9

2.52

Industrial pack

40 pc

034G6205

ETS 5M13

u

1.3

Solder, ODF

1⁄4 x 1⁄4

8.9

2.52

Multi pack

20 pc

034G6206

ETS 5M17

h

1.65

Solder, ODM

1⁄4 x 1⁄4

12.5

3.54

Multi pack

20 pc

034G6208

ETS 5M20

h

2.0

Solder, ODM

1⁄4 x 1⁄4

16.7

4.74

Multi pack

20 pc

034G6202

ETS 5M24

h

2.4

Solder, ODM

1⁄4 x 1⁄4

20.6

5.84

Multi pack

20 pc

034G6203

ETS 5M24

h

2.4

Solder, ODM

5⁄16 x 5⁄16

20.6

5.84

Multi pack

20 pc

034G6213

Electric expansion valve, Type ETS 5M

Ordering

Being highly congurable, ETS 5M can be delivered with a number of dierent mechanical connections according to

requirements. This includes design conguration shape types L, h and u. See ordering details below.

Parts program

ETS 5M is a parts program consisting of a valve body and a separate uni-polar motor coil (ETS 5M coil). Each

component is purchased separately.

Table 13: 5/16 inch male

Besides using the ETS SM coil as spare part, ETS 5M valve is hermetic and cannot be taken apart, there are no other

spare parts.

Valve body, standard code

Valve body ordering data

Table 14: ETS 5M valve body

Valve sizing using calculation software

It is strongly recommended to use Coolselector®2 to nd the correct valve for your application. The software can be

downloaded from the Danfoss website. You can download it from http:// coolselector.danfoss.com

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 10

Page 11

Type

Cable length

Cable length

Electrical connector

Pack format

Qty/pack

Cade no.

[m]

[in]

ETS 5M

0.70 m

27.55

JST XHP-5

Industrial pack

40 pc

034G3805

ETS 5M

0.70 m

27.55

JST XHP-5

Multi pack

20 pc

034G3806

ETS 5M

1.00 m

39.37

JST XHP-6

Multi pack

20 pc

034G3804

ETS 5M

1.50 m

59.06

JST XHP-5

Multi pack

20 pc

034G3801

ETS 5M

2.70 m

106.30

JST XHP-5

Multi pack

20 pc

034G3802

ETS 5M

2.70 m

106.30

JST XHP-5

Industrial pack

24 pc

034G3807

ETS 5M

2.70 m

106.30

JST XHP-6

Multi pack

20 pc

034G3808

Image

Accessory

Description

Code no.

ETS 5M manual coil

Manual coil for service

034G3803

AST-G service driver

Driver for service of the valve

034G0013

Position

Inscription

Explanation

Box label

Electric exp. valve

Product title

Box label; Valve body

034G6204

Code no.

Box label; Valve body

12345N1219A

Internal production code

denoting time of production

Electric expansion valve, Type ETS 5M

ETS 5M coil

Coils for ETS 5M are dedicated for the product.

Table 15: Coils for ETS 5M

Accessories

Tools for servicing of ETS 5M

Table 16: Accessories for ETS 5M

Product identication

Valve body identication

Relevant product data is available on the box label and product label. On the product, information is laser engraved

in 4 dierent elds on the steel valve body (not shown).

Figure 6: Box label, ETS 5M valve body

Table 17: Valve body, ETS 5M

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 11

Page 12

Position

Inscription

Explanation

Valve body

ETS 5M

Product title

Box label; Valve body

ETS 5M17

Type and size

Box label

(Symbol drawing)

Conguration of code no.

Position

Inscription

Explanation

Product label

EEV coil ETS 5M

Product title and Type

Box label

Coil for elec. exp. valve ETS 5M

Product title and Type

Box label; Product label

STA 1234

Internal production code

denoting time of production

Product label

034G6204

Code no.

Product label

00001DA4119C

Serial no.

Product label

12 V

Rated voltage

Box label

Rated voltage: 12 V

Rated voltage

Box label

Cable: 1.Sm, JST XHP-5

Cable connection specications

Product label

(Data matrix symbol)

Machine readable data matrix

Product label

Made in Thailand

Manufacturing site acc. to EN standards

Box label

(Symbol drawing)

Conguration of code no.

Electric expansion valve, Type ETS 5M

ETS 5M Coil identication

Relevant product data is available on the box label and product label.

Figure 7: Box label Figure 8: Product label

Table 18: Product label, ETS 5M coil

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 12

Page 13

File name

Document type

Document topic

Approval Authority

CQC21002287020

Electrical - safety certicates

CQC

Pressure Equipment Directive

Restriction of Hazardous Substances

Registration, Evaluation, Authorisation and Restriction of Chemicals

CQC Approved

Electric expansion valve, Type ETS 5M

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 19: Certicates, declarations and approvals

Compliance

ETS 5M complies with:

Table 20: Compliance table ETS 5M

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 13

Page 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.05 AI357347789371en-000202 | 14

Loading...

Loading...