Page 1

Data sheet

Electric expansion valve

Type ETS 500P, ETS 800P

ETS 500P, ETS 800P are extension to current

electric expansion valves ETS program by

integrate dual ETS 250 or dual ETS 400 in parallel.

They can be used for precise liquid injection in

evaporators for air conditioning and

refrigeration applications with high capacity.

The valve piston and linear positioning design is

fully balanced, providing bi-flow feature as well

as solenoid tight shut-off function in both flow

directions.

The valve design uses bi-polar drive providing

very precise flow regulation.

ETS 500P and ETS 800P are compatible with

electronic control solutions from Danfoss and

other manufacturers.

Features • Refrigerants: R134a, R513A, R1234ze,

other refrigerants are on request.

• Rated capacity for R134a:

ETS 500P: 471 TR / 1652 kW

ETS 800P: 640 TR / 2245 kW

• Maximum working pressure: 25 bar / 363 psig.

• Compatible with oil free applications.

• Precise positioning for optimal control

of liquid injection.

• Balanced design.

• Built-in sight glass with moisture indicator.

• Can be operated with flow in both

directions and are solenoid tight.

• Low power consumption.

• Danfoss controller type EKE 1 series can be used

to drive ETS 500P and ETS 800P.

• For manual operation and service of ETS

valves an AST-G service driver is available.

© Danfoss | DCS (rm) | 2020.06

AI330734333508EN-000201 | 1

Page 2

Data sheet | Electric expansion valve, type ETS 500P, ETS 800P

Approvals

Technical data

Electrical data

RoHS

Compatible refrigerants

Refrigerant oil All mineral oils and ester oils and also support oil free applications.

Comply with P.E.D. Yes

Max. opening pressure

differential (MOPD) normal flow

Max. opening pressure

differential (MOPD) reverse flow

Max. working pressure (PS/MWP) 25 bar (363 psig)

Inlet fluid temperature -40 °C – 65 °C (-40 °F – 149 °F). For higher temperature valve, please contact Danfoss.

Ambient temperature -40 °C – 60 °C (-40 °F – 140 °F)

Material of Construction Body and AST enclosure in brass, connections in copper.

Motor enclosure IP67

Stepper motor type Bi-polar - permanent magnet

Step mode 2 phase full step

Phase resistance 52 Ω ±10%

Phase inductance 85 mH

Step angle

Nominal voltage Constant voltage drive: 12 V dc -4% – 15%

Phase current Using chopper drive: 100 mA RMS -4% – 15%

Holding current

Max. total power Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2)

Step rate

Total steps For each ETS 250 or ETS 400: 3810 [160 / -0] steps

Full travel time For each ETS 250 or ETS 400: 25.4 / 12.7 sec. (voltage / current)

Lifting height For each ETS 250 or ETS 400: 17.2 mm (0.7 in.)

Reference position Overdriving against the full close position

Electrical connection M12 connector

R134a, R513A, R1234ze.

For other refrigerants, please contact your local Danfoss representative.

25 bar (363 psig)

10 bar (145 psig)

7.5° (motor)

0.9° (lead screw)

Gearing ration 8.5:1. (38/13)2:1

Constant voltage drive: Depends on application

Chopper drive: full current allowed (100% duty cycle)

Constant voltage drive: 150 steps/sec

Chopper current drive: 0 – 300 steps/sec. 300 recommended

Compatible Danfoss controllers Danfoss EKE 1 series

© Danfoss | DCS (rm) | 2020.06

AI330734333508EN-000201 | 2

Page 3

Data sheet | Electric expansion valve, type ETS 500P, ETS 800P

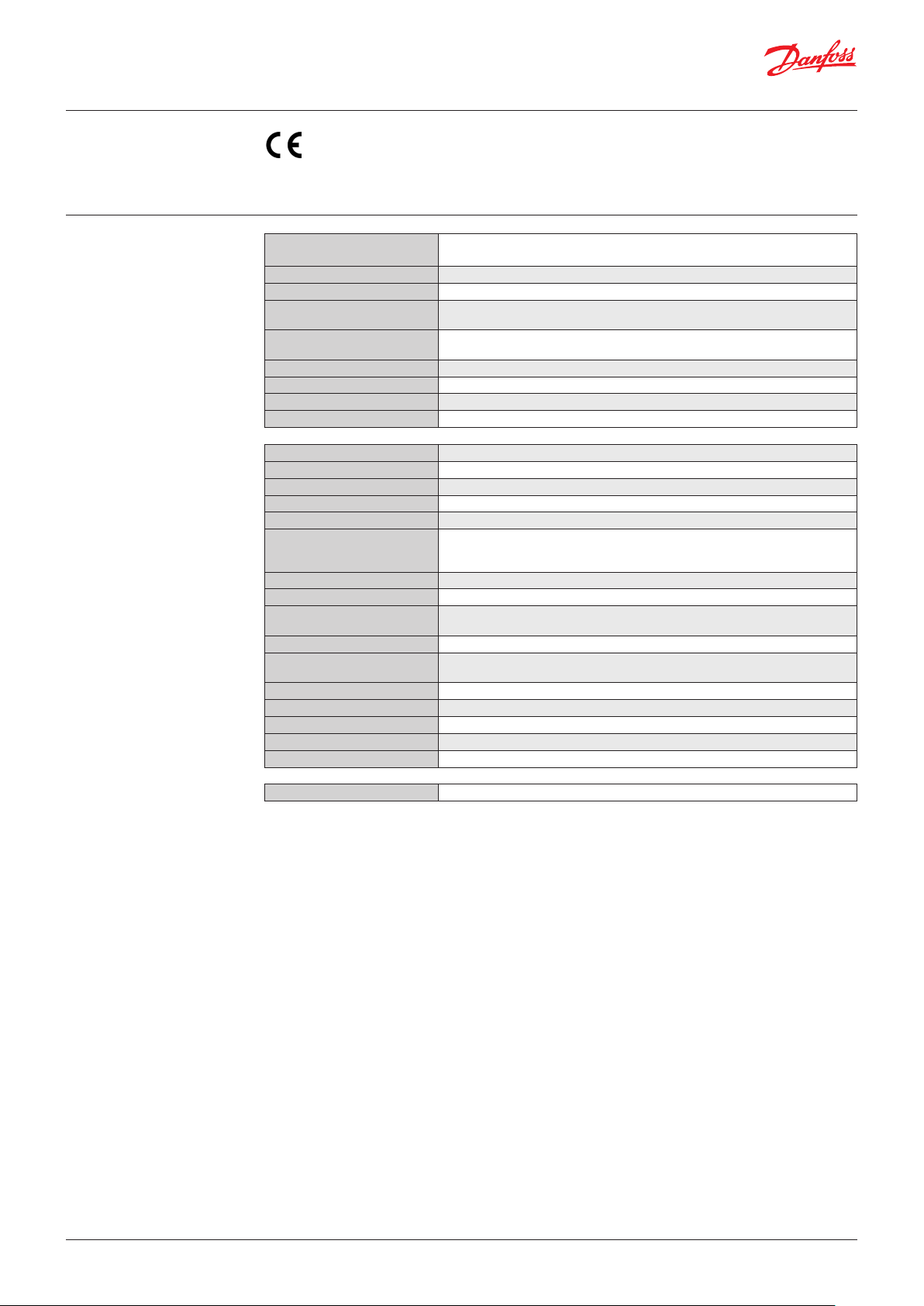

Design

Note:

Flow direction from A to B

refers to the normal flow

1. M12 connector

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Top Nut

8. Valve piston

9. Sight glass with indicator

10. Valve seat

11. Valve cone

Sight glass and indicator

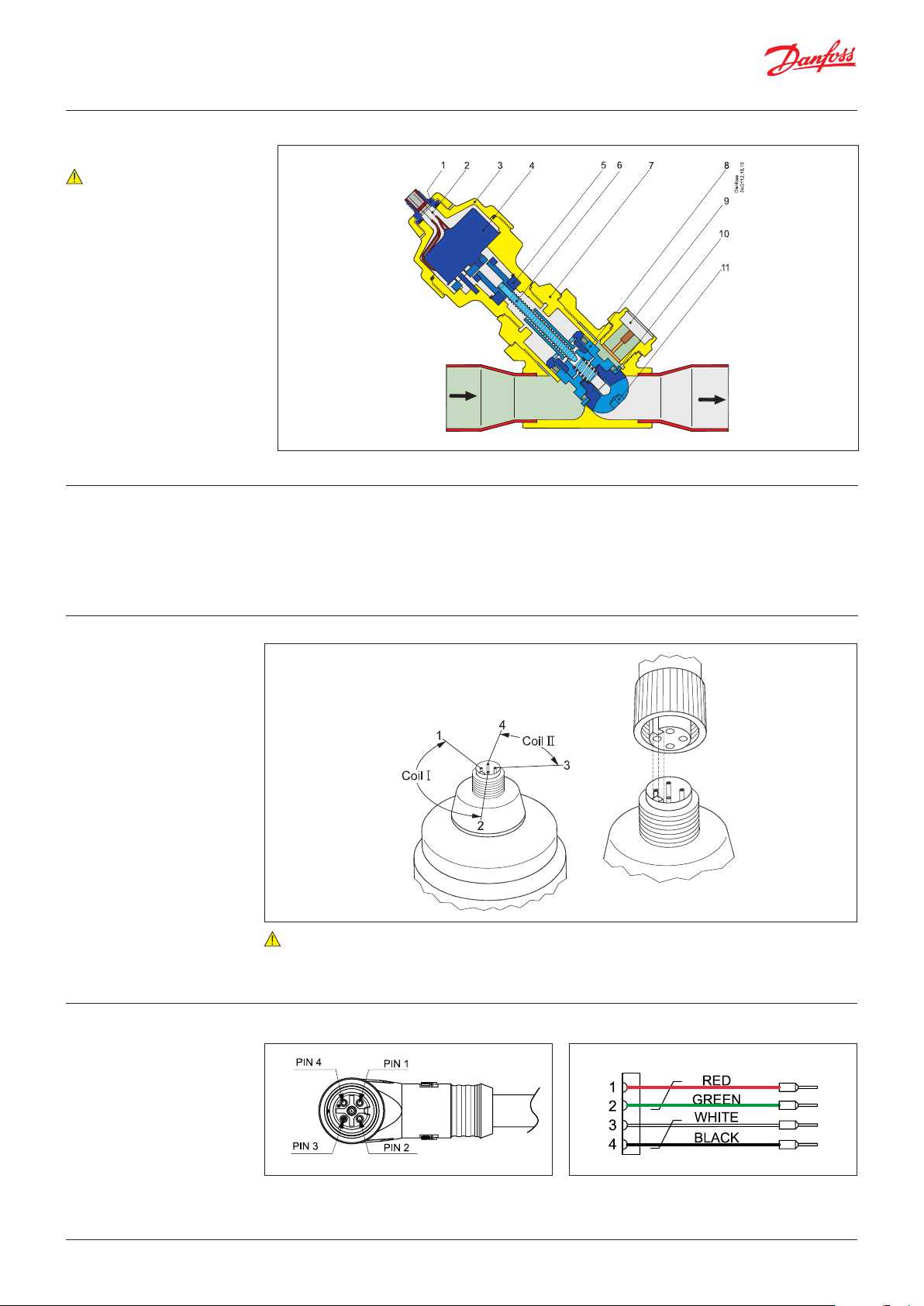

Electrical wiring

Section view of single

A

ETS 250 / ETS 400 on

ETS 500P / ETS 800P

ETS 500P and ETS 800P are equipped with sight

glass with moisture indicator. The physical

position of the piston in the valve can be

checked through the sight glass.

B

Insufficient sub cooling can produce flash gas

which is visible through the sight glass. The

moisture indicator in the sight glass indicates

dry or wet state of the refrigerant by changing its

colour.

Connections

© Danfoss | DCS (rm) | 2020.06

Danfoss

34G212.10

Note:

Electrical check of stepper motor and wiring: Coil I = 52 ohm, coil II = 52 ohm

A2 black

A1 white

B1 red

B2 green

34G210.10

34G211.10

AI330734333508EN-000201 | 3

Page 4

0

200

400

600

800

1000

1200

1400

1600

1800

0 20 40 60 80 100

ETS 500P

0

500

1000

1500

2000

2500

0 20 40 60 80 100

ETS 800P

Data sheet | Electric expansion valve, type ETS 500P, ETS 800P

The dual ETS 250 on ETS 500P and dual ETS 400 on ETS 800P are supposed to open/close

simultaneously, thus they should be connected to one common EKE 1 series controller.

To make one controller drives dual ETS 250 / ETS 400, follow next additional steps to set the

controller correctly prior to commissioning :

1. Go to “Valve selection“ in “Valve configuration”.

2. Select “ETS 250” (for ETS 500P) or “ETS 400” (for ETS 800P)

3. Change valve type to “User defined valve”.

4. Change valve drive current to 282 mA. (Single ETS 250 / ETS 400 requires 141 mA peak

current. ETS 500P / ETS 800P requires 2 times of the current as of the single valve. )

5. Done.

Stepper motor

switch sequence

Capacity

Normal flow direction

STEP

↑ CLOSING ↑

1 + - + 2 + - - +

3 - + - +

4 - + + 1 + - + -

If the controller driving the ETS valve is from

another manufacturer than Danfoss or a custom

design, the following points must be considered

in order to overcome potential step loss.

Coil I Coil II

Red Green White Black

↓ OPENING ↓

b. The amount of lost steps may increase as a

function of the amount of changes of the

opening degree. Such designed controller

should be able to compensate the lost steps

after a defined number of changes in opening

a. To ensure total closing of the valve, the

degree.

controller should have a function to overdrive

the valve in the closing direction. It is

recommended to overdrive ten percent of the

full step range at appropriate intervals.

Warning:

At power failure the ETS valve will remain in

the opening position it has at the moment

of power failure, unless a safety device in the

form of a battery backup is installed.

ETS 500P ETS 800P

[kW]

0

Q

[kW]

0

Q

Capacity based on: R134a

Te = 5 °C / 41 °F

T

= 32 °C / 89.6 °F

c

Tl = 28 °C / 82.4 °F

© Danfoss | DCS (rm) | 2020.06

Coolselector2®

For easy and precise selection of valve, use Danfoss’ CoolSelector2® software. You can find the ETS

valves on the group, “Electronic expansion valves”.

You can download it from http://coolselector.danfoss.com

Opening [%] Opening [%]

AI330734333508EN-000201 | 4

Page 5

Data sheet | Electric expansion valve, type ETS 500P, ETS 800P

Ordering

ETS 500P / ETS 800P

A

Ordering

EKE 1 series controllers

M12 angle cable

Note:

The cable will be

supplied seperately.

Rated capacity1 Connection

Type

ETS 500P 1652 471 1518 433 1289 367 2 5/8 × 3 1/

ETS 800P 2245 640 2060 587 1760 501 3 1/8 × 3 1/

ETS 800P 2245 640 2060 587 1760 501 2 5/8 × 2 5/

B

1

) The rated capacity is based on:

Evaporating temperature te : 5 °C / 40 °F

Liquid temperature tl : 28 °C / 82 °F

Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal flow direction

Type Pack format Code no.

Electronic controller EKE 1A Single pack 080G5300

Electronic controller EKE 1B Single pack 080G5350

Electronic controller EKE 1C Single pack 080G5400

R134a R513A R1234ze ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW] [TR] [in.] Single pack

8

8

8

Note:

The controller will be supplied seperately.

M12 angle female connector is intended for use with a standard M12 male connector,

available on stepper motor valves.

This cable is designed to offer high flexibility and small outer diameters with tensile

strength. The angle way M12 cable consist of paired, twisted wires, which decreases mutual

influence between signals transmitted along the cable and reduces influence of external

sources of interference.

The cables thus provides a higher degree of protection against lost steps compared to other

cables.

034Z1017

034Z1018

034Z1019

Approvals

Specification

Ordering

Dimensions

RoHS

Jacket PVC - black

Cable outer sheath Oil - resistant

Water proof rating IP 67

Operating temperature range -40 – +80 °C

Wire type Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter 7.0 mm

Minimum bending radius 10 x cable diameter

Cable combustibility / test Flame retardant / VW-1 / CSA FT - 1

M12 standard EN 61076-2-101

Reference standard UL style 2464 and DIN VDE 0812

LVD directive 2014/35/EU

Cable Cable length (L) Insulation Packing format Code no.

PVC - black

2 + 0.089 m / 6.6 + 0.3 ft SR-PVC Single pack 034G7073

8 + 0.3 m / 26.2 +1 ft SR-PVC Single pack 034G7074

34G209.10

© Danfoss | DCS (rm) | 2020.06

Ø 63 mm / 1/4 inch

8 + 0.3 meters / 26.2 +1 feet

35 mm / 1.4 inch2 + 0.089 meters / 6.6 + 0.3 feet

49 mm / 1.9 inch

AI330734333508EN-000201 | 5

Page 6

Dimensions and weights

ETS 500P

195 mm

[7.68 in]

4.6 kg / 10.1 lb.

ETS 800P

[4.80 in]

122 mm

[4.80 in]

122 mm

[4.80 in]

122 mm

38 mm

[1.50 in]

[Ø2 5/8 in]

Ø66.68 mm

38 mm

[1.50 in]

204 mm

[8.01 in]

85 mm

[3.35 in]

375 mm

[14.74 in]

89 mm

[3.48 in]

65 mm

[2.54 in]

84 mm

[3.29 in]

86 mm

Ø79.38 mm

5.4 kg / 11.9 lb.

[3.39 in]

[Ø3 1/8 in]

[6.44 in]

164 mm

86 mm

[3.39 in]

Code no. A B C

034Z1018

034Z1019

Ø79.38 mm/

Ø 3 1/8 in.

Ø66.68 mm/

Ø 2 5/8 in.

Ø79.38 mm/

Ø 3 1/8 in.

Ø66.68 mm/

Ø 2 5/8 in.

164 mm/

6.46 in.

158 mm/

6.21 in.

Related products

EKE 1 series EKS 221, ACCPBT, AKS 11/AKS 12 AKS 32R, AKS 33, NSK AST-G

[4.80 in]

122 mm

C

A

402 mm

[15.83 in]

B

Code no. 034G0013

Superheat controller Temperature sensor Pressure transmitter Service driver

All Danfoss products fulfill the requirements in REACH.

One of the obligations in REACH is to inform customers about presence of Candidate list substances if any, we hereby inform you about one substance on the candidate list:

A moist indicator in the sight glass contains a paper which is impregnated with Cobalt Dichloride (CAS no: 7646-79-9) in a concentration above 0.1% w/w.

- Avoid skin contact with the paper - Do not inhale the dust from the paper - The paper must be disposed as hazardous waste.

© Danfoss | DCS (rm) | 2020.06

AI330734333508EN-000201 | 6

Loading...

Loading...