Page 1

Data sheet

Electric expansion valve

Type ETS 12.5 - ETS 400

ETS is a series of electric expansion valves for

precise liquid injection in evaporators for air

conditioning and refrigeration applications.

The valve piston and linear positioning design is

fully balanced, providing bi-flow feature as well

as solenoid tight shut-off function in both flow

directions.

The valve design uses bi-polar drive providing

very precise flow regulation.

ETS valves are compatible with electronic control

solutions from Danfoss and other manufacturers.

Features • Precise positioning for optimal control of

liquid injection.

• Wide range for all common refrigerants.

• ETS 250, ETS 400 provides 34 bar / 493 psig.

• All ETS can be operated with flow in both

directions and are solenoid tight.

• ETS 50 to ETS 400 have a balanced design.

• ETS 50 and ETS 100 feature improved process

and productivity due to waterless brazing i.e

soldering without wet cloth for cooling.

• Special ETS 250 and ETS 400 available for oil

free applications.

• ETS 50 – ETS 400 are all designed with built-in

sight glass with moisture indicator.

• Internal and external corrosion resistant

design.

• Low power consumption.

• Cable and connector assemblies as

accessories.

• Danfoss EKE 1A, EKE 1B, EKE 1C, MCX061V,

MCX152V are examples of Danfoss controllers

with drivers matching the ETS needs.

• For manual operation and service of ETS valves

an AST-g service driver is available.

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 1

Page 2

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Approvals

Approvals

089

Technical data

NOTE:

Technical data also applicable for ETS 250

and ETS 400 oil free version.

Electrical data

Wide range for all common refrigerants R1234ze, R134A, R22, R404A, R407A, R407C,

R407F, R410A, R422B, R422D, R438A, R448A, R449A, R450A, R452A, R507, R513A and other

Compatible refrigerants

Refrigerant oil All mineral oils and ester oils and special ETS 250 and ETS 400 support oil free applications

Comply with P.E.D. Yes

Max. opening pressure

differential (MOPD) normal flow

Max. opening pressure

differential (MOPD) reverse flow

Max. working pressure (PS/MWP)

Inlet fluid temperature -40 °C – 65 °C (-40 °F – 149 °F). For higher temperature valve, please contact Danfoss.

Ambient temperature -40 °C – 60 °C (-40 °F – 140 °F)

Material of Construction

Motor enclosure IP67

Stepper motor type Bi-polar - permanent magnet.

Step mode 2 phase full step.

Phase resistance 52 Ω ±10%

Phase inductance 85 mH

Step angle

Nominal voltage

Phase current Using chopper drive: 100 mA RMS -4% – 15%

Holding current

Max. total power Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2)

Step rate

Total steps

Full travel time

Lifting height

Reference position Overdriving against the full close position

Electrical connection M12 connector

refrigerants.

Special valves for R744 (CO2) are available.

For other refrigerants, please contact your local Danfoss representative.

33 bar (478.6 psi)

ETS 12.5, ETS 25, ETS 50, ETS 100: 33 bar (478.6 psi)

ETS 250, ETS 400: 10 bar (145 psi)

ETS 12.5, ETS 25, ETS 50, ETS 100: 45.5 bar (660 psig)

ETS 250, ETS 400: 34 bar (493 psig)

ETS 50, ETS 100: Body and AST enclosure in brass, connections in bi-metal

(stainless steel/copper).

ETS 12.5, ETS 25, ETS 250, ETS 400: Body and AST enclosure in brass, connections in copper.

7.5° (motor),

0.9° (lead screw),

Gearing ration 8.5:1. (38/13)2:1

Constant voltage drive: 12 V dc -4% – 15%,

150 steps/sec.

Constant voltage drive: Depends on application.

Chopper drive: full current allowed (100% duty cycle)

Constant voltage drive: 150 steps/sec.

Chopper current drive: 0 – 300 steps/sec. 300 recommended

ETS 12.5, ETS 25, ETS 50: 2625 [160 / -0] steps

ETS 100: 3530 [160 / -0] steps

ETS 250, ETS 400: 3810 [160 / -0] steps

ETS 12.5, ETS 25, ETS 50: 17 / 8.5 sec. (voltage / current)

ETS 100: 23 / 11.5 sec. (voltage / current)

ETS 250, ETS 400: 25.4 / 12.7 sec. (voltage / current)

ETS 12.5, ETS 25, ETS 50: 13 mm (0.5 in.)

ETS 100: 16 mm (0.6 in.)

ETS 250, ETS 400: 17.2 mm (0.7 in.)

© Danfoss | DCS (rm) | 2019.02

Compatible Danfoss controllers Danfoss EKE 1A, EKE 1B, EKE 1C, MCX061V, MCX152V and more

NOTE:

Full life time of standard ETS can only be ensured if oil is present in the system.

Oil free applications: Special ETS 250 and ETS 400 are available for higher capacity and use ETS Colibri for smaller capacity.

DKRCC.PD.VD1.3C.02 | 2

Page 3

A

A

A

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

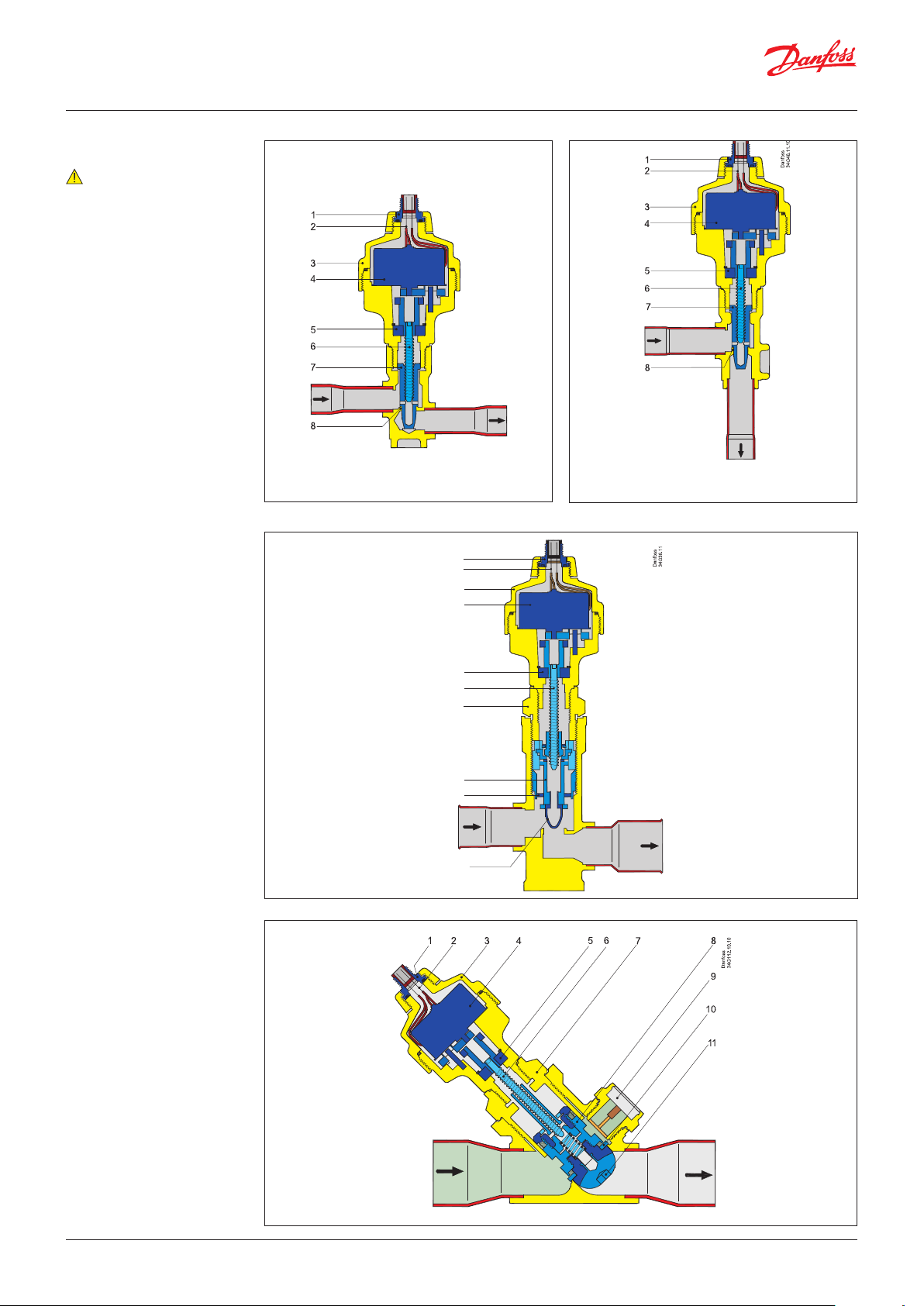

Design

Note:

Flow direction from A to B

refers to the normal flow

Danfoss

34G45.12.10

1. M12 connection

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Cone and lead nut

8. Valve seat

1. M12 connector

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Top Nut

8. Valve piston

9. Valve seat

10. Valve cone

ETS 12.5, ETS 25 - straight

ETS 50 & 100

B

B

ETS 12.5, ETS 25 - angleway

1

2

3

4

5

6

7

8

9

10

.10

B

1. M12 connector

2. Glass seal

3. AST motor housing

4. Stepper motor

5. Bearing

6. Spindle

7. Top Nut

8. Valve piston

A

B

9. Sight glass with indicator

10. Valve seat

11. Valve cone

© Danfoss | DCS (rm) | 2019.02

ETS 250 & 400

DKRCC.PD.VD1.3C.02 | 3

Page 4

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

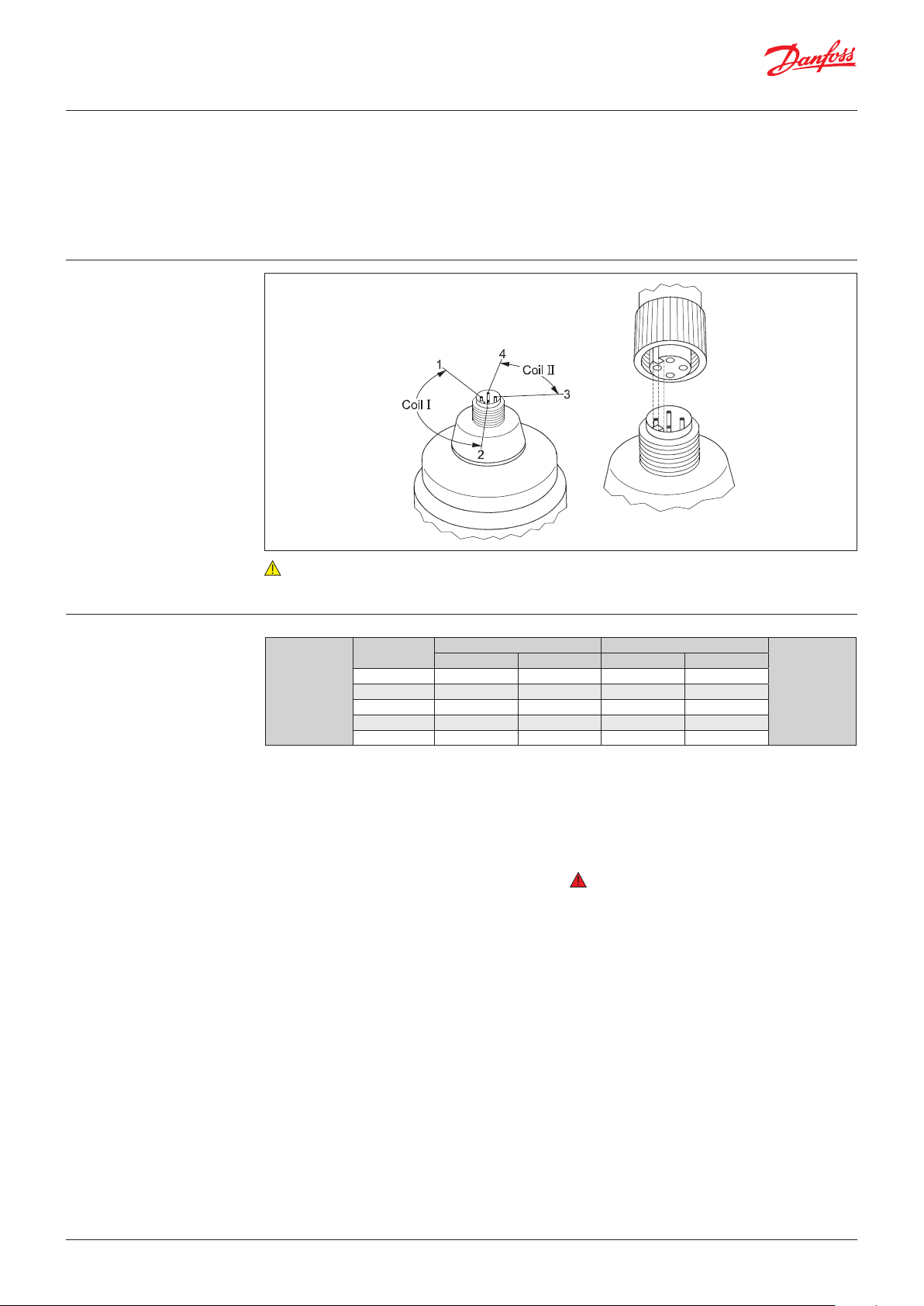

Sight glass and indicator

Electrical wiring

ETS 50, ETS 100, ETS 250 and ETS 400 are

equipped with sight glass with moisture

indicator. The physical position of the piston in

the valve can be checked through the sight glass.

It also helps to determine the flow direction of

Insufficient sub cooling can produce flash gas

which is visible through the sight glass. The

moisture indicator in the sight glass indicates

dry or wet state of the refrigerant by changing its

colour.

the refrigerant in the system (ETS 50 and

ETS 100).

Danfoss

34G212.10

Note:

Electrical check of stepper motor and wiring: Coil I = 52 ohm, coil II = 52 ohm

Stepper motor

switch sequence

Coil I Coil II

Red Green White Black

↑ CLOSING ↑

STEP

1 + - + 2 + - - +

3 - + - +

4 - + + 1 + - + -

If the controller driving the ETS valve is from

another manufacturer than Danfoss or a custom

design, the following points must be considered

in order to overcome potential step loss.

a. To ensure total closing of the valve, the

controller should have a function to overdrive

the valve in the closing direction. It is

recommended to overdrive ten percent of the

full step range at appropriate intervals.

↓ OPENING ↓

b. The amount of lost steps may increase as a

function of the amount of changes of the

opening degree. Such designed controller

should be able to compensate the lost steps

after a defined number of changes in opening

degree.

Warning:

At power failure the ETS valve will remain in

the opening position it has at the moment

of power failure, unless a safety device in the

form of a battery backup is installed.

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 4

Page 5

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

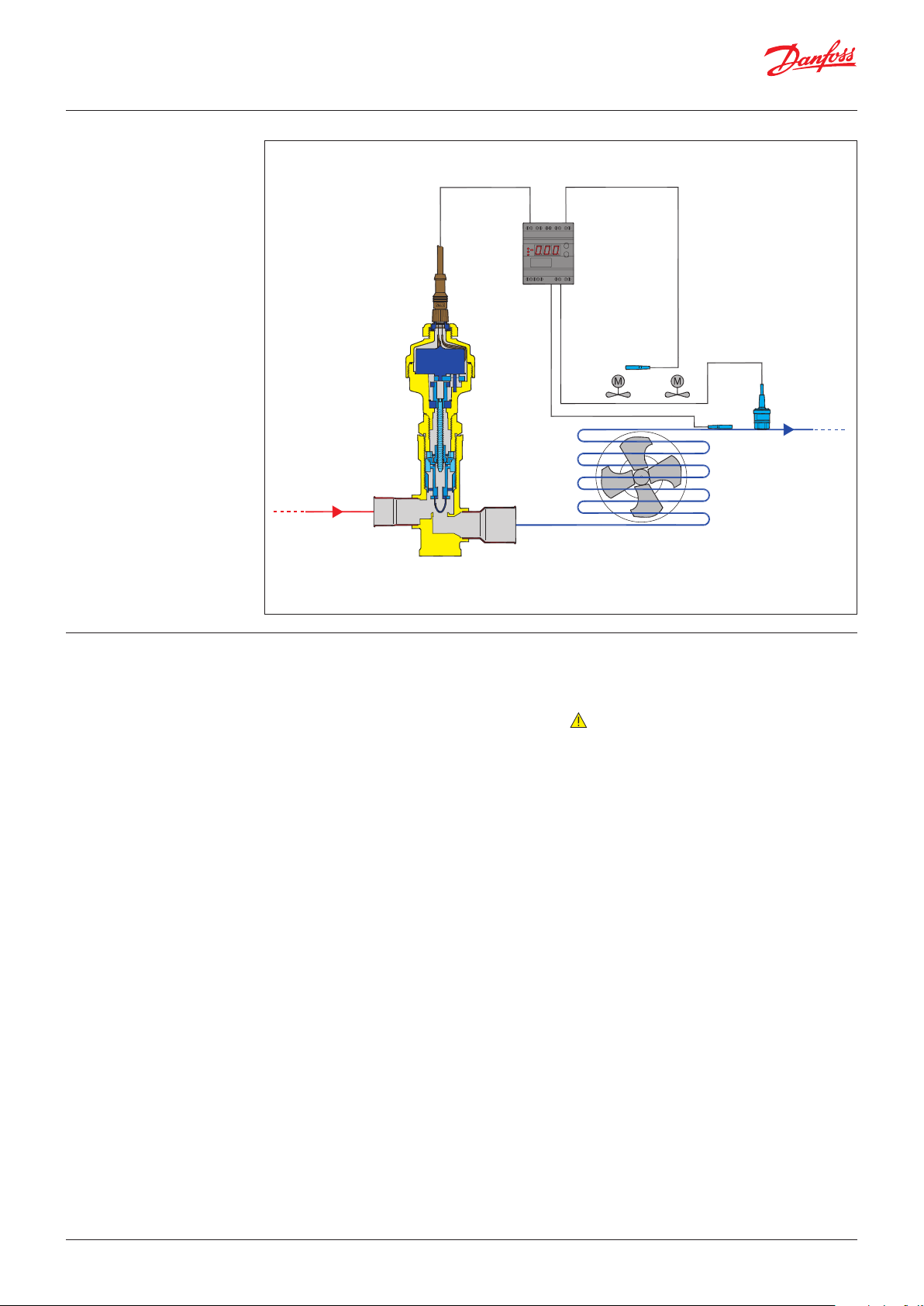

Valve application

Controller/Driver

Temperature sensor

Danfoss

93G18.14

ETS

Valve operation The ETS valves operate modulating by

electronically controlled activation of the AST

stepper motor. The motor is a type 2-phase

bi-polar, which stays in position, unless power

pulses from a driver initiate the two discrete sets

of motor stator windings for rotation in either

directions.

The direction of the rotation of the spindle

depends on the phase relationship of the power

pulses. This is decisive for the travel of the piston.

The motor is operating the spindle, whose

rotating movements are transformed into linear

motion by the transmission in the cage assembly.

The AST motor housing has a glass sealed M12

connection as standard, which can be connected

with customized cable and plug/socket

combinations.

Temperature sensor

Evaporator

Pressure transmitter

Operating the ETS series requires a controller

with either 12 V DC voltage drive (5.5 W) or using

chopper current drive (100 mA RMS).

Note:

Depending on the type of controller or driver,

there will be limitations in cable length between

valve actuator and driver.

Both the actual cable length, the level of EMC

emission on the location and driver circuit has an

impact on the actual distortion of the current to

the actuator motor.

In order to increase max. cable length

considerably, install a 10 mH filter type Danfoss

AKA 211 on the four power terminals.

Please contact Danfoss for further information

how and when to apply this countermeasure in

cases with questionable cable length.

© Danfoss | DCS (rm) | 2019.02

The piston design inside the ETS valve is pressure

balanced, giving identical bi-flow performance

capabilities and nearby identical maximum

capacities.

Closing the valve by overdriving, ensures that the

reference number in steps is always correct.

DKRCC.PD.VD1.3C.02 | 5

Page 6

34G181.10

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

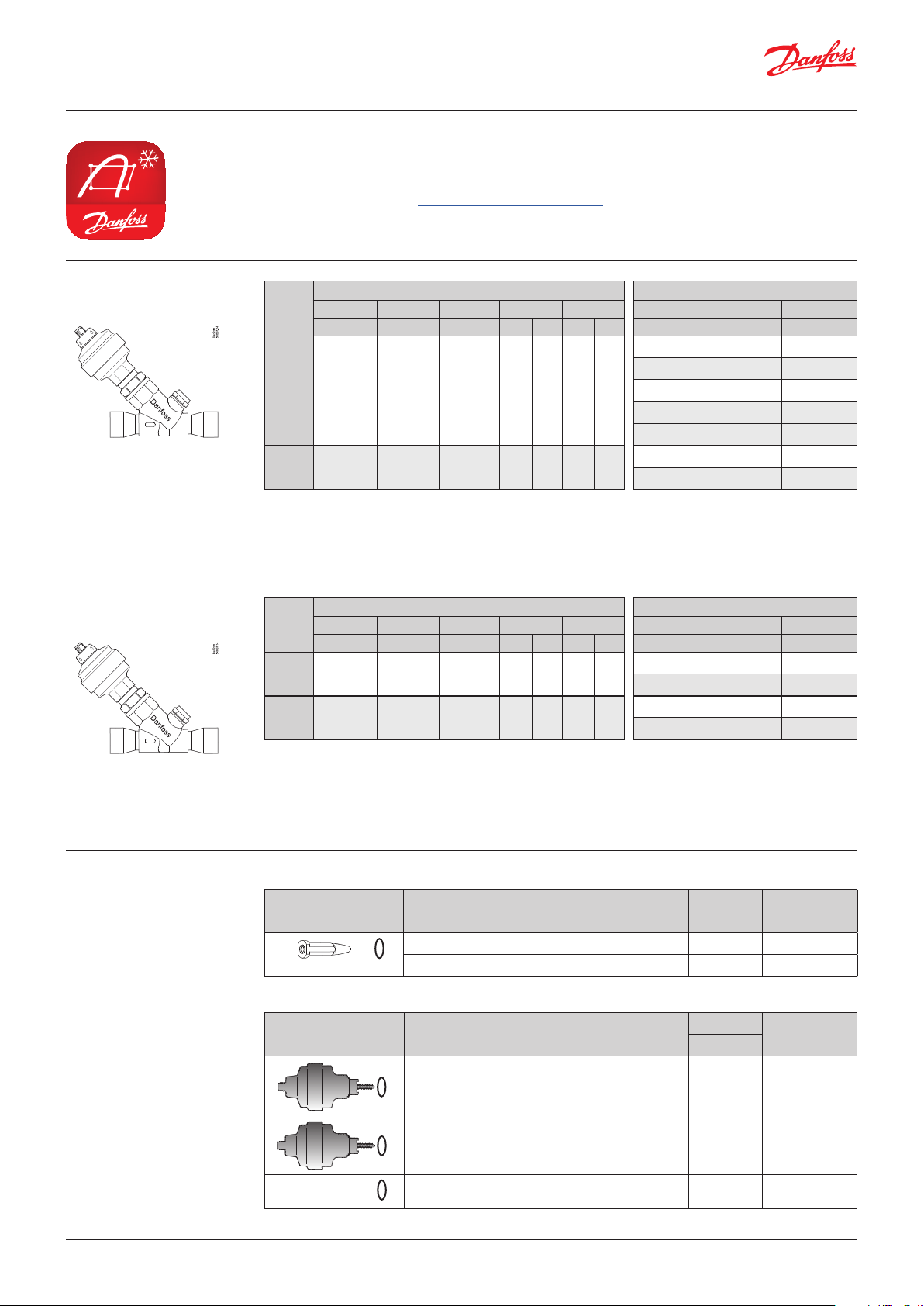

Coolselector2®

For easy and precise selection of valve, use Danfoss’ CoolSelector2® software. You can find the ETS

valves on the group, “Electronic expansion valves”.

You can download it from http://coolselector.danfoss.com

ETS 250, ETS 400

Valve incl. actuator

A B

ETS for oil free applications

Valve incl. actuator

A B

Rated capacity1 Connection

Type

R410A R407C R22 R134a R404A ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [in.] [mm] Single pack

ETS 250 – – 1212 349 1106 319 874 252 828 239

ETS 400 – – 1933 556 1764 509 1394 402 1320 381

1

) The Rated capacity is based on:

Evaporating temperature te : 5 °C / 40 °F

Liquid temperature tl : 28 °C / 82 °F

Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal flow direction

Rated capacity1 Connection

Type

R410A R407C R22 R134a R404A ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [in.] [mm] Single pack

Oil free

ETS 250

Oil free

ETS 400

1

) The Rated capacity is based on:

Evaporating temperature te : 5 °C / 40 °F

Liquid temperature tl : 28 °C / 82 °F

Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal flow direction

– – 1212 349 1106 319 874 252 828 239

– – 1933 556 1764 509 1394 402 1320 381

1 1/8 × 1 1/

1 3/8 × 1 3/

1 5/8 × 1 5/

28 × 28 034G2600

8

35 × 35 034G2601

8

8

– 034G2602

– 42 × 42 034G2611*

2 1/8 × 2 1/

1 5/8 × 1 5/

2 1/8 × 2 1/

8

8

8

– 034G2624

– 034G3500

54 × 54 034G3501

ETS 250 and ETS 400 have integrated sight glass

except 034G2611.

1 3/8 × 1 3/

1 5/8 × 1 5/

1 5/8 × 1 5/

2 1/8 × 2 1/

35 × 35 034G2625

8

8

8

8

– 034G2626

– 034G3514

54 × 54 034G3515

ETS 250 and ETS 400 have integrated sight glass

Spare parts

© Danfoss | DCS (rm) | 2019.02

For smaller capacities of ETS oil free valves see ETS Colibri

Cone/piston for ETS 12.5 / ETS 25

Items Description

Danfoss

Cone/piston for ETS 12.5 + metal gasket 1 034G2345

Cone/piston for ETS 25 + metal gasket 1 034G2346

Actuator with integrated M12 connection

Items Description

34G179.10

Danfoss

34G179.10

Danfoss

*For oil free spare parts of ETS 250 and ETS 400. Please contact Danfoss.

Actuator with integrated M12 with Ceramic bearing

(incl. metal gasket) for ETS 12.5, ETS 25

Actuator with integrated M12 with ceramic bearing

(incl. metal gasket) for ETS 25B, ETS 50, ETS 100, ETS

250, ETS 400

Metal Gasket 1 034G2344

Quantity

[pcs]

Quantity

[pcs]

1 034G2088

1 034G2087*

DKRCC.PD.VD1.3C.02 | 6

Code no.

Code no.

Page 7

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Note:

ETS valve type ETS 12.5, ETS 25, ETS 50 and ETS 100 are currently in process of being

phased-out, Please select ETS Colibri sizes 12C-100C as a replacement.

For further information see: Colibri.danfoss.com

Ordering

ETS 12.5, ETS 25

Valve incl. actuator

A

Phasing out

B

Type

ETS 12.5

ETS 25

Type

ETS 12.5

ETS 25

Rated capacity1 Connection

R410A R407C R22 R134a R404A ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW ] [TR] [kW] [TR] [kW] [TR] [in.] [mm]

Straight way

Single Pack

½ × ½ – 034G4209

70 20 63 18 57 16 45 13 43 12

– 12 × 12 034G4208

5

/8 × 5/

7

/8 × 7/

16 × 16 034G4210

8

22 × 22 034G4211

8

½ × ½ – 034G4201

144 41 129 37 117 34 93 27 88 25

– 12 × 12 034G4200

5

/8 × 5/

7

/8 × 7/

16 × 16 034G4202

8

22 × 22 034G4203

8

ETS 12.5 and ETS 25 do not feature sight glass

Rated capacity1 Connection

R410A R407C R22 R134a R404A ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [in.] [mm]

Angle way

Single Pack

½ × ½ – 034G4213

70 20 63 18 57 16 45 13 43 12

– 12 × 12 034G4212

5

/8 × 5/

7

/8 × 7/

16 × 16 034G4214

8

22 × 22 034G4215

8

½ × ½ – 034G4205

144 41 129 37 117 34 93 27 88 25

5

/8 × 5/

7

/8 × 7/

–

12 × 12 034G4204

16 × 16 034G4206

8

22 × 22 034G4207

8

ETS 12.5 and ETS 25 do not feature sight glass

ETS 50, ETS 100

Valve incl. actuator

A

Phasing out

B

ETS for R744 Applications

Phasing out

A

Rated capacity1 Connection

Type

R410A R407C R22 R134a R404A ODF × ODF (A × B) Code no.

[kW] [TR] [kW] [TR] [kW] [TR] [kW] [TR] [kW ] [TR] [in.] [mm] Single pack

ETS 50 262.3 75.7 240.5 69.1 215 62 170 48.9 161.4 46.3

ETS 100 488.4 140.9 447.8 128.7 400.4 115.4 316.5 91.2 300.5 86.6

ETS for R744 can be use as loading/unloading valve

ETS for R744 Applications (PS/MWP = 45.5 bar /

660 psig)

For capacities, please contact Danfoss.

Type

ETS 12.5

ETS 25

Connection

ODF × ODF (A × B)

[in.]

7

/8 × 7/8 in 034G4220

7

/8 × 7/8 in 034G4219

Code no.

Single pack

ETS 50 1 / × 1 / in 034G1714

ETS 100 1 / × 1 / in 034G0515

ETS 50 and ETS 100 have integrated sight glass

7

/8 × 7/

7

/8 × 11/

11/8 × 11/

11/8 × 13/

11/8 × 11/

11/8 × 13/

13/8 × 13/

15/8 × 15/

22 × 22 034G1708

8

22 × 28 034G1705

8

28 × 28 034G1706

8

28 × 35 034G1704

8

28 × 28 034G0507

8

28 × 35 034G0501

8

35 × 35 034G0508

8

8

– 034G0505

ETS 50 and ETS 100 have integrated sight glass

B

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 7

Page 8

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Accessories:

M12 angle cable

Approvals

Specification

M12 angle female connector is intended for use with a standard M12 male connector,

available on stepper motor valves.

This cable is designed to offer high flexibility and small outer diameters with tensile strength.

The angle way M12 cable consist of paired, twisted wires, which decreases mutual influence between

signals transmitted along the cable and reduces influence of external sources of interference.

The cables thus provides a higher degree of protection against lost steps compared to other cables.

RoHS

Jacket PVC - black

Cable outer sheath Oil - resistant

Water proof rating IP 67

Operating temperature range -40 – +80 °C

Wire type Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter 7.0 mm

Minimum bending radius 10 x cable diameter

Cable combustibility / test Flame retardant / VW-1 / CSA FT - 1

M12 standard EN 61076-2-101

Reference standard UL style 2464 and DIN VDE 0812

LVD directive 2014/35/EU

Ordering

Identification

Connections

Cable Cable length (L) Insulation Packing format Code no.

PVC - black

A2 black

A1 white

2 + 0.089 m / 6.6 + 0.3 ft SR-PVC Single pack 034G7073

8 + 0.3 m / 26.2 +1 ft SR-PVC Single pack 034G7074

Product type

Code no

Manufacturing date

Meters / Feets

Country

B1 red

B2 green

34G210.10

34G211.10

Dimensions

© Danfoss | DCS (rm) | 2019.02

Ø 63 mm / 1/4 inch

8 + 0.3 meters / 26.2 +1 feet

34G209.10

35 mm / 1.4 inch2 + 0.089 meters / 6.6 + 0.3 feet

49 mm / 1.9 inch

DKRCC.PD.VD1.3C.02 | 8

Page 9

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Valve sizing

Valve selection

Step 1

For optimum performance, it is important to

correct the evaporator capacity. Selection is

also dependent on an acceptable pressure drop

across the valve. The evaporator capacity must be

corrected if sub cooling deviates from 4K / 7.2 °F.

In order to select the correct size of ETS you will

need the following information:

Refrigerant: R410A, R407C, R404A, R507, R134a,

R22, R1234ze

• Evaporator capacity Qe in [kW] or [TR]

• Evaporating temperature te in [°C] or [°F]

• Condensing temperature tc in [°C] or [°F]

• Max. acceptable pressure drop in the ETS

valve in [bar] or [psi] ∆p

• Sub cooling ∆t

sub

• Connection size

Example

When selecting the valve it may be necessary to

apply a correction factor to the actual evaporator

capacity. This correction factor is required when

system conditions are different from table

conditions. Selection also depends on having an

acceptable pressure drop across the valve. The

following example illustrates correct selection of

the valve.

Refrigerant: R410A

• Evaporator capacity: Qe = 500 kW / 143 TR

• Condensing temperature: tc = 25 °C / 77 °F

• Condensing pressure: pc = 23 bar / 330 psig

• Evaporating temperature: te = +10 °C / 50 °F

• Evaporating pressure: pe = 9.8 bar / 142 psig

• Liquid Line Loss: pl = 0.5 bar (estimate)

• Max. Pressure drop in the valve:

∆p = pc - pl - pe = 23 - 0.5 - 9.8 = 12.7 bar / 184 psi

• Connection size: 1/ × 1/ in.

Determine the correction factor for sub cooling

∆t

.

sub

From the correction factors table (see below) a

sub cooling of 15K / 27 °F, R410A corresponds to

a factor of 1.15.

Correction factors for sub cooling ∆t

Connection

factor

R22 1.00 1.06 1.11 1.15 1.20 1.25 1.30 1.35 1.39 1.44

R410A 1.00 1.08 1.15 1.21 1.27 1.33 1.39 1.45 1.50 1.56

R407C 1.00 1.08 1.14 1.21 1.27 1.33 1.39 1.45 1.51 1.57

R134a 1.00 1.08 1.13 1.19 1.25 1.31 1.37 1.42 1.48 1.54

R404A/R507 1.00 1.10 1.20 1.29 1.37 1.46 1.54 1.63 1.70 1.78

4 K 10 K 15 K 20 K 25 K 30 K 35 K 40 K 45 K 50 K

7.2 °F 18 °F 27 °F 36 °F 45 °F 54 °F 63 °F 72 °F 81 °F 90 °F

.

sub

Δt

sub

Step 2

Step 3

R410A

Step 4

Corrected evaporator capacity is

Qe (Corrected) = 500 kW/1.15 = 435 kW (124 TR)

Now select the appropriate capacity table, R410A,

and choose the column for an evaporating

temperature of te = 10 °C / 50 °F.

Using the corrected evaporator capacity, select

a valve that provides an equivalent or greater

ETS 100 delivers 503.8 kW / 143 TR at 14 bar

which is slightly higher than 12.7 bar / 184 psi

pressure drop across the valve. Based on the

required connection size of 1

1

/

in., the ETS 100 is

8

the proper selection for this example.

capacity at an acceptable pressure drop across

the valve of 12.7 bar / 184 psi.

Rated capacity [kW] in the normal flow direction

t

e

[°C]

2 4 6 8 10 12 14 16 2 4 6 8 10 12 14 16

-40 173.7 224.6 255.1 275.5 289.5 299.2 305.7 309.6 323.5 418.1 475.0 512.9 539.1 557.2 569.2 576.4

-30 169.3 220.8 252.3 273.5 288.3 298.6 305.7 310.1 315.2 411.2 469.7 509.2 536.8 556.1 569.2 577.5

-20 163.3 214.9 246.8 268.6 284.1 295.0 302.5 307.4 304.0 400.1 459.6 500.2 528.9 549.2 563.3 572.4

-10 155.9 206.8 238.8 260.9 276.6 287.9 295.8 301.0 290.3 385.0 444.6 485.7 515.1 536.1 550.8 560.5

-5 151.7 202.0 233.7 255.8 271.6 283.0 291.0 296.4 282.5 376.0 435.2 476.3 505.8 527.0 541.9 551.8

10 137.5 184.5 214.8 236.1 251.5 262.7 270.6 275.8 256.0 343.5 399.9 439.6 468.3 489.1 503.8 513.6

ETS 100, 1

ETS 50 ETS 100

Pressure drop p [bar]

1

1

/

x 1

/

in. connection size:

8

8

Single pack code no. 034G0507.

Note:

For easy and precise selection of valve, use Danfoss’ CoolSelector software. You can download it from

http://www.danfoss.com/businessareas/refrigerationandairconditioning/

product+selection+tools+details/coolselector.htm

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 9

Page 10

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Correction for subcooling

t

sub

Rated Capacity [kW]

t

e

[°C]

2 4 6 8 10 12 14 16 2 4 6 8 10 12 14 16

-40 46.4 60.0 68.1 73.5 77.3 79.9 81.6 82.6 95.3 123.2 140.0 151.1 158.8 164.1 167.7 169.8

-30 45.2 59.0 67.3 73.0 76.9 79.7 81.6 82.7 92.9 121.2 138.4 150.0 158.1 163.8 167.7 170.1

R410A

R407C

R22

R134a

R404A

-20 43.6 57.4 65.9 71.7 75.8 78.7 80.7 82.0 89.6 117.9 135.4 147.4 155.8 161.8 165.9 168.6

-10 41.6 55.2 63.7 69.6 73.8 76.8 78.9 80.3 85.5 113.5 131.0 143.1 151.7 157.9 162.2 165.0

-5 40.5 53.9 62.4 68.3 72.5 75.5 77.6 79.0 83.3 110.8 128.2 140.3 149.0 155.2 159.6 162.5

10 36.7 49.2 57.3 63.0 67.1 70.1 72.2 73.5 75.4 101.2 117.8 129.5 137.9 144.0 148.3 151.2

-40 42.1 52.8 58.6 62.0 63.9 64.9 65.0 64.6 86.5 108.5 120.5 127.5 131.4 133.3 133.6 132.7

-30 41.9 53.0 59.2 63.0 65.2 66.3 66.7 66.4 86.0 109.0 121.7 129.4 133.9 136.3 137.1 136.6

-20 41.2 52.8 59.3 63.4 65.8 67.2 67.8 67.8 84.7 108.5 121.9 130.2 135.3 138.2 139.4 139.3

-10 40.2 52.0 58.8 63.1 65.9 67.5 68.3 68.4 82.6 106.9 120.9 129.8 135.4 138.7 140.3 140.6

-5 39.6 51.4 58.4 62.8 65.6 67.3 68.2 68.4 81.3 105.7 120.0 129.0 134.9 138.4 140.2 140.6

10 37.1 48.9 56.0 60.6 63.7 65.5 66.7 67.1 76.3 100.5 115.0 124.6 130.9 134.8 137.1 138.0

-40 40.2 51.3 57.9 62.1 65.0 66.9 68.0 68.6 82.6 105.5 118.9 127.7 133.6 137.5 139.8 141.1

-30 39.8 51.3 58.1 62.6 65.7 67.7 69.1 69.8 81.8 105.4 119.4 128.7 135.0 139.2 142.0 143.5

-20 39.1 50.8 57.9 62.6 65.9 68.1 69.6 70.4 80.3 104.4 118.9 128.7 135.4 140.0 143.0 144.8

-10 38.0 49.9 57.1 62.1 65.5 67.9 69.5 70.5 78.1 102.5 117.4 127.5 134.6 139.5 142.8 144.9

-5 37.4 49.3 56.6 61.6 65.1 67.5 69.2 70.2 76.9 101.2 116.3 126.5 133.7 138.8 142.2 144.4

10 35.2 46.8 54.1 59.2 62.9 65.4 67.2 68.4 72.3 96.2 111.3 121.7 129.2 134.5 138.2 140.6

-40 35.6 43.2 46.8 48.5 49.0 48.6 47.7 46.3 73.1 88.8 96.3 99.7 100.7 100.0 98.0 95.1

-30 35.8 44.0 48.0 50.0 50.7 50.6 49.9 48.6 73.5 90.4 98.6 102.7 104.2 104.0 102.5 99.9

-20 35.6 44.3 48.8 51.1 52.1 52.2 51.7 50.6 73.3 91.1 100.2 105.0 107.0 107.3 106.2 104.0

-10 35.2 44.3 49.1 51.7 53.0 53.3 53.0 52.1 72.3 91.0 100.9 106.2 108.8 109.6 108.9 107.1

-5 34.8 44.1 49.0 51.8 53.2 53.7 53.4 52.6 71.6 90.6 100.8 106.4 109.3 110.3 109.8 108.2

10 33.3 42.8 48.1 51.2 53.0 53.7 53.8 53.2 68.3 88.0 98.9 105.3 108.9 110.4 110.5 109.4

-40 31.9 39.6 43.4 45.2 45.9 45.8 45.0 43.8 65.7 81.4 89.2 93.0 94.3 94.0 92.5 90.0

-30 31.5 39.5 43.6 45.8 46.7 46.7 46.2 45.1 64.7 81.2 89.7 94.0 95.9 96.1 94.9 92.8

-20 30.7 39.0 43.3 45.7 46.9 47.1 46.8 45.9 63.0 80.1 89.1 94.0 96.3 96.9 96.1 94.3

-10 29.5 37.9 42.5 45.1 46.4 46.9 46.7 45.9 60.7 78.0 87.4 92.7 95.4 96.3 95.9 94.4

-5 28.9 37.3 41.9 44.6 46.0 46.5 46.3 45.6 59.4 76.6 86.1 91.6 94.5 95.5 95.2 93.8

10 26.5 34.6 39.2 41.9 43.5 44.1 44.1 43.5 54.4 71.0 80.5 86.2 89.3 90.6 90.6 89.4

The evaporator capacities used must be corrected

if subcooling deviates from 4 K / 7.2 °F.

The corrected capacity can be obtained by

dividing the required evaporator capacity by the

correction factor. Selections can then be made

from the tables below.

t

sub

Correction factor

R22 1.00 1.06 1.11 1.15 1.20 1.25 1.30 1.35 1.39 1.44

R410A 1.00 1.08 1.15 1.21 1.27 1.33 1.39 1.45 1.50 1.56

R407C 1.00 1.08 1.14 1.21 1.27 1.33 1.39 1.45 1.51 1.57

R134a 1.00 1.08 1.13 1.19 1.25 1.31 1.37 1.42 1.48 1.54

R404A / R507 1.00 1.10 1.20 1.29 1.37 1.46 1.54 1.63 1.70 1.78

4 K 10 K 15 K 20 K 25 K 30 K 35 K 40 K 45 K 50 K

7.2 °F 18 °F 27 °F 36 °F 45 °F 54 °F 63 °F 72 °F 81 °F 90 °F

Note:

Insufficient subcooling can produce flash gas.

SI units

Rated capacity [kW] in the normal flow direction

ETS 12.5 ETS 25

Pressure drop p [bar]

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 10

Page 11

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Rated Capacity [kW]

SI units

t

e

[°C]

2 4 6 8 10 12 14 16 2 4 6 8 10 12 14 16

-40 173.7 224.6 255.1 275.5 289.5 299.2 305.7 309.6 323.5 418.1 475.0 512.9 539.1 557.2 569.2 576.4

-30 169.3 220.8 252.3 273.5 288.3 298.6 305.7 310.1 315.2 411.2 469.7 509.2 536.8 556.1 569.2 577.5

R410A

R407C

R22

R134a

R404A

The capacities stated in the tables are for the normal flow direction. For ETS 50 and 100 specifically, the capacity in reverse flow direction varies between 90% and 125% of the

capacity in normal flow direction.

-20 163.3 214.9 246.8 268.6 284.1 295.0 302.5 307.4 304.0 400.1 459.6 500.2 528.9 549.2 563.3 572.4

-10 155.9 206.8 238.8 260.9 276.6 287.9 295.8 301.0 290.3 385.0 444.6 485.7 515.1 536.1 550.8 560.5

-5 151.7 202.0 233.7 255.8 271.6 283.0 291.0 296.4 282.5 376.0 435.2 476.3 505.8 527.0 541.9 551.8

10 137.5 184.5 214.8 236.1 251.5 262.7 270.6 275.8 256.0 343.5 399.9 439.6 468.3 489.1 503.8 513. 6

-40 158.5 199.3 222.0 235.6 243.8 248.1 249.7 249.1 295.1 371.2 413.3 438.7 453.9 462.0 464.9 463.8

-30 157.6 200.3 224.4 239.3 248.5 253.7 256.1 256.2 293.5 373.0 417.8 445.5 462.6 472.5 476.9 477.1

-20 155.3 199.5 224.9 241.0 251.2 257.3 260.5 261.3 289.2 371.5 418.8 448.7 467.7 479.2 485.1 486.6

-10 151.7 196.8 223.3 240.4 251.5 258.5 262.5 263.9 282.4 366.4 415.9 447.6 468.4 481.4 488.7 491.4

-5 149.4 194.7 221.7 239.2 250.8 258.1 262.4 264.2 278.1 362.6 412.8 445.4 466.9 480.6 488.6 491.9

10 140.7 185.7 213.2 231.6 244.0 252.3 257.4 259.9 261.9 345.7 397.0 431.2 454.4 469.8 479.2 483.9

-40 151.5 193.5 218.1 234.2 245.1 252.2 256.6 258.8 282.1 360.2 406.2 436.2 456.3 469.6 477.7 481.9

-30 149.9 193.2 218.9 236.0 247.6 255.4 260.4 263.1 279.1 359.7 407.6 439.4 460.9 475.5 484.8 489.9

-20 147.1 191.3 218.0 235.9 248.2 256.6 262.2 265.5 273.9 356.2 405.9 439.2 462.1 477.9 488.2 494.3

-10 143.2 187.8 215.2 233.8 246.7 255.7 261.8 265.6 266.6 349.7 400.8 435.3 459.4 476.2 487.5 494.5

-5 140.8 185.5 213.1 231.9 245.1 254.4 260.7 264.6 262.3 345.4 396.8 431.8 456.4 473.7 485.4 492.8

10 132.4 176.2 203.9 223.0 236.7 246.5 253.2 257.6 246.5 328.1 379.6 415.3 440.8 458.9 471.5 479.7

-40 133.1 161.8 175.4 181.6 183.4 182.1 178.6 173.3 247.8 301.3 326.6 338.2 341.5 339.1 332.5 322.6

-30 133.9 164.7 179.7 187.1 189.9 189.5 186.7 182.1 249.3 306.6 334.6 348.5 353.6 352.8 347.6 339.0

-20 133.4 166.1 182.6 191.2 195.0 195.4 193.4 189.5 248.4 309.2 340.0 356.0 363.1 363.9 360.1 352.8

-10 131.7 165.9 183.7 193.5 198.3 199.6 198.3 195.1 245.2 308.8 342.1 360.3 369.2 371.6 369.3 363.3

-5 130.3 165.1 183.6 193.9 199.2 200.9 200.0 197.1 242.6 307.4 341.9 361.1 370.8 374.1 372.4 367.0

10 124.5 160.3 180.2 191.9 198.3 201.2 201.3 199.3 231.8 298.5 335.5 357.2 369.3 374.6 374.8 371.1

-40 119.8 148.6 162.8 169.8 172.3 171.9 169.2 164.7 223.0 276.6 303.1 316.1 320.9 320.0 315.0 306.7

-30 118.0 148.2 163.7 171.7 175.2 175.6 173.6 169.8 219.7 276.0 304.7 319.7 326.2 326.9 323.2 316.1

-20 115.0 146.1 162.6 171.6 176.0 177.1 175.7 172.5 214.0 272.1 302.8 319.6 327.6 329.7 327.2 321.3

-10 110.8 142.3 159.5 169.3 174.4 176.1 175.4 172.7 206.3 265.0 297.1 315.2 324.6 327.9 326.6 321.5

-5 108.3 139.8 157.2 167.3 172.6 174.6 174.1 171.7 201.7 260.3 292.7 311.4 321.4 325.1 324.2 319.7

10 99.4 129.7 147.1 157.5 163.3 165.8 165.8 163.7 185.0 241.6 273.9 293.2 304.0 308.7 308.6 304.8

ETS 50 ETS 100

Rated capacity [kW] in the normal flow direction

Pressure drop p [bar]

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 11

Page 12

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Rated Capacity [kW]

Rated capacity [kW] in the normal flow direction

ETS 250 ETS 400

R407C

R22

R134a

R404A

t

e

[°C]

2 4 6 8 10 12 14 16 2 4 6 8 10 12 14 16

-40 811 1017 1129 1195 1232 1249 1252 1244 1294 1622 1801 1905 1964 1992 1997 1984

-30 806 1022 1141 1213 1255 1277 1284 1280 1286 1629 1820 1934 2002 2037 2049 2041

-20 794 1017 1143 1220 1268 1295 1306 1305 1266 1621 1823 1947 2023 2065 2083 2082

-10 774 1002 1133 1216 1269 1300 1315 1317 1235 1598 1808 1940 2024 2073 2097 2101

-5 762 990 1124 1209 1264 1297 1314 1318 1215 1580 1793 1929 2016 2068 2095 2102

10 715 941 1078 1167 1226 1264 1285 1293 1141 1502 1719 1862 1956 2016 2049 2062

-40 779 995 1122 1205 1261 1297 1320 1331 1243 1587 1790 1922 2011 2069 2105 2123

-30 771 994 1126 1214 1273 1314 1339 1353 1230 1585 1796 1936 2031 2095 2136 2159

-20 757 984 1121 1213 1277 1320 1349 1366 1207 1569 1789 1935 2036 2106 2151 2178

-10 737 966 1107 1202 1269 1315 1347 1366 1175 1541 1766 1918 2024 2098 2148 2179

-5 724 954 1096 1193 1261 1309 1341 1361 1156 1522 1748 1903 2011 2087 2139 2171

10 681 906 1049 1147 1218 1268 1303 1325 1086 1446 1673 1830 1942 2022 2078 2114

-40 684 832 902 934 943 937 919 891 1092 1328 1439 1490 1505 1494 1465 1422

-30 688 847 924 963 977 975 960 937 1098 1351 1474 1535 1558 1555 1532 1494

-20 686 854 939 983 1003 1005 995 975 1094 1362 1498 1569 1600 1603 1587 1555

-10 677 853 945 995 1020 1027 1020 1003 1080 1360 1507 1587 1627 1637 1627 1600

-5 670 849 944 997 1024 1033 1029 1014 1069 1354 1506 1591 1634 1648 1641 1617

10 640 824 927 987 1020 1035 1035 1025 1021 1315 1478 1574 1627 1650 1651 1635

-40 615 763 836 871 884 881 867 844 981 1217 1333 1390 1410 1406 1383 1346

-30 606 761 840 881 899 900 890 870 967 1214 1340 1406 1434 1436 1419 1387

-20 591 750 835 881 903 908 901 884 942 1197 1332 1405 1440 1448 1437 1410

-10 569 731 819 869 894 903 899 884 908 1166 1306 1386 1426 1440 1433 1411

-5 556 718 807 858 885 895 892 879 887 1145 1287 1369 1412 1428 1423 1402

10 510 666 755 807 837 849 849 838 814 1062 1204 1288 1335 1355 1354 1336

SI units

Pressure drop p [bar]

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 12

Page 13

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Rated Capacity [TR]

(TR = ton of refrigeration)

Rated capacity [TR] in the normal flow direction

ETS 12.5 ETS 25

R410A

R407C

R22

R134a

R404A

t

e

[°F]

40 60 80 100 125 150 175 200 40 60 80 100 125 150 175 200

-40 14.9 17.2 18.9 20.1 21.3 22.1 22.7 23.2 30.7 35.5 38.8 41.4 43.7 45.5 46.7 47.6

-20 14.6 16.9 18.6 19.9 21.1 22.0 22.7 23.1 29.9 34.8 38.3 40.9 43.4 45.2 46.6 47.6

0 14.0 16.4 18.1 19.4 20.7 21.6 22.3 22.8 28.8 33.7 37.2 39.9 42.5 44.4 45.9 46.9

20 13.3 15.7 17.4 18.7 20.0 20.9 21.6 22.2 27.4 32.2 35.7 38.4 41.0 43.0 44.5 45.5

40 12.5 14.7 16.4 17.7 18.9 19.9 20.6 21.1 25.7 30.3 33.7 36.4 38.9 40.9 42.3 43.4

50 12.0 14.2 15.8 17.1 18.3 19.2 19.9 20.5 24.7 29.2 32.5 35.1 37.6 39.6 41.0 42.1

-40 13.4 15.2 16.3 17.2 17.8 18.2 18.4 18.5 27.5 31.2 33.6 35.3 36.7 37.5 37.9 38.0

-20 13.4 15.2 16.5 17.4 18.2 18.6 18.9 19.0 27.5 31.3 33.9 35.8 37.3 38.3 38.8 39.1

0 13.2 15.1 16.5 17.4 18.3 18.8 19.2 19.3 27.1 31.1 33.9 35.9 37.6 38.7 39.4 39.7

20 12.8 14.8 16.3 17.3 18.2 18.8 19.2 19.4 26.4 30.5 33.4 35.5 37.4 38.6 39.4 39.9

40 12.4 14.4 15.8 16.9 17.8 18.5 18.9 19.2 25.4 29.5 32.5 34.7 36.6 38.0 38.9 39.4

50 12.1 14.1 15.5 16.6 17.5 18.2 18.7 18.9 24.8 28.9 31.9 34.1 36.1 37.4 38.4 38.9

-40 12.9 14.8 16.1 17.1 18.0 18.6 19.0 19.3 26.5 30.3 33.1 35.1 36.9 38.2 39.1 39.7

-20 12.8 14.7 16.1 17.2 18.1 18.8 19.3 19.6 26.3 30.3 33.1 35.3 37.2 38.7 39.7 40.4

0 12.6 14.6 16.0 17.1 18.1 18.8 19.4 19.8 25.8 29.9 32.9 35.1 37.2 38.7 39.8 40.6

20 12.2 14.2 15.7 16.8 17.9 18.7 19.3 19.7 25.1 29.3 32.3 34.6 36.8 38.4 39.6 40.4

40 11.7 13.8 15.3 16.4 17.5 18.3 18.9 19.3 24.1 38.3 31.4 33.7 35.9 37.6 38.9 39.7

50 11.5 13.5 15.0 16.1 17.2 18.0 18.6 19.1 23.6 27.7 30.8 33.1 35.4 37.4 38.3 39.2

-40 11.2 12.4 13.1 13.6 13.9 13.9 13.8 13.6

-20 11.3 12.6 13.5 14.0 14.3 14.5 14.5 14.3

0 11.3 12.7 13.7 14.3 14.7 14.9 14.9 14.8

20 11.2 12.7 13.7 14.4 14.9 15.1 15.2 15.2

40 10.9 12.5 13.5 14.3 14.8 15.2 15.3 15.3

50 10.7 12.3 13.4 14.1 14.8 15.3 15.1 15.3

-40 10.1 11.4 12.1 12.6 12.9 13.1 13.0 12.8 20.8 23.4 25.0 25.9 26.6 26.8 26.7 26.4

-20 10.0 11.3 12.2 12.7 13.1 13.3 13.3 13.2 20.6 23.3 25.0 26.2 27.0 27.3 27.4 27.1

0 9.8 11.1 12.0 12.6 13.1 13.4 13.4 13.3 20.0 22.9 24.8 26.0 27.0 27.4 27.5 27.4

20 9.4 10.8 11.7 12.4 12.9 13.2 13.3 13.2 19.3 22.2 24.1 25.4 26.5 27.0 27.3 27.2

40 8.9 10.3 11.2 11.9 12.4 12.7 12.9 12.8 18.2 21.1 23.0 24.4 25.5 26.1 26.4 26.4

50 8.6 9.9 10.9 11.5 12.1 12.4 12.5 12.5 17.6 20.4 22.4 23.7 24.9 25.5 25.8 25.8

US units

Pressure drop p [psi]

22.9 25.5 27.0 27.9 28.5 28.6 28.4 27.9

23.2 26.0 27.7 28.8 29.5 29.8 29.7 29.3

23.2 26.2 28.1 29.3 30.2 30.6 30.7 30.4

22.9 26.1 28.1 29.5 30.6 31.1 31.3 31.2

22.4 25.6 27.8 29.3 30.5 31.2 31.5 31.5

22.0 25.3 27.5 29.1 30.3 31.1 31.4 31.4

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 13

Page 14

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Rated Capacity [TR]

(TR = ton of refrigeration)

US units

Rated capacity [TR] in the normal flow direction

t

e

[°F]

40 60 80 100 125 150 175 200 40 60 80 100 125 150 175 200

-40 55.9 64.6 70.8 75.4 79.7 82.9 85.2 86.8 104.2 120.3 131.8 140.4 148.5 154.4 158.6 161.6

-20 54.6 63.4 69.8 74.6 79.1 82.5 85.0 86.7 101.6 118.0 129.9 138.9 147.4 153.6 158.2 161.5

R410A

R407C

R22

R134a

R404A

The capacities stated in the tables are for the normal flow direction. For ETS 50 and 100 specifically, the capacity in reverse flow direction varies between 90% and 125% of the

capacity in normal flow direction.

0 52.6 61.4 67.9 72.8 77.5 81.0 83.6 85.5 97.8 114.3 126.4 135.6 144.3 150.9 155.7 159.2

20 49.9 58.7 65.1 70.1 74.8 78.4 81.1 83.1 93.0 109.2 121.2 130.4 139.3 146.0 151.0 154.6

40 46.8 55.2 61.4 66.3 71.0 74.6 77.2 79.2 87.1 102.7 114.4 123.5 132.2 138.8 143.8 147.5

50 45.0 53.2 59.3 64.1 68.7 72.2 74.8 76.8 83.8 99.0 110.4 119.3 127.8 134.4 139.3 142.9

-40 50.4 57.3 61.9 65.1 67.9 69.6 70.6 71.0 93.9 106.6 115.2 121.2 126.4 129.6 131.5 132.2

-20 50.4 57.6 62.5 66.0 69.1 71.1 72.4 73.0 93.8 107.2 116.4 122.9 128.7 132.4 134.7 135.9

0 49.7 57.2 62.5 66.3 69.6 71.9 73.4 74.2 92.6 106.6 116.3 123.4 129.6 133.9 136.6 138.2

20 48.5 56.2 61.7 65.7 69.3 71.8 73.5 74.6 90.4 104.7 114.9 122.3 129.1 133.8 136.9 138.8

40 46.8 54.6 60.1 64.3 68.1 70.8 72.7 73.9 87.1 101.6 111.9 119.7 126.8 131.8 135.3 137.5

50 45.7 53.5 59.0 63.2 67.1 69.9 71.8 73.1 85.2 99.5 109.9 117.7 125.0 130.1 133.7 136.1

-40 48.5 55.6 60.6 64.3 67.7 70.1 71.8 72.9 90.3 103.6 112.9 119.8 126.1 130.5 133.7 135.7

-20 48.1 55.5 60.8 64.7 68.3 70.9 72.8 74.0 89.6 103.4 113.1 120.4 127.2 132.0 135.5 137.8

0 47.3 54.9 60.3 64.4 68.2 71.0 73.1 74.5 88.1 102.2 112.3 119.9 127.1 132.3 136.0 138.7

20 46.0 53.6 59.2 63.5 67.5 70.4 72.6 74.1 85.6 99.9 110.3 118.1 125.6 131.1 135.1 138.0

40 44.2 51.9 57.5 61.8 65.9 68.9 71.2 72.9 82.3 96.6 107.0 115.0 122.7 128.4 132.6 135.7

50 43.2 50.8 56.4 60.7 64.8 67.9 70.2 71.9 80.4 94.5 104.9 112.9 120.6 126.4 130.7 133.8

-40 41.8 46.4 49.2 50.9 51.9 52.2 51.8 50.9

-20 42.3 47.3 50.4 52.4 53.8 54.2 54.1 53.4

0 42.3 47.7 51.1 53.4 55.1 55.8 55.9 55.5

20 41.8 47.5 51.3 53.8 55.7 56.7 57.0 56.8

40 40.8 46.7 50.7 53.4 55.6 56.9 57.4 57.4

50 40.1 46.1 50.1 53.0 55.3 56.6 57.2 57.3

-40 37.9 42.6 45.6 47.4 48.6 49.0 48.9 48.2 70.6 79.4 84.8 88.2 90.5 91.3 91.0 89.8

–20 37.5 42.5 45.7 47.8 49.3 50.0 50.0 49.6 69.9 79.2 85.1 89.0 91.8 93.0 93.1 92.3

0 36.6 41.8 45.2 47.5 49.2 50.1 50.4 50.1 68.1 77.8 84.2 88.4 91.7 93.3 93.8 93.3

20 35.2 40.5 44.0 46.4 48.4 49.4 49.8 49.7 65.5 75.3 81.9 86.4 90.1 92.0 92.8 92.6

40 33.3 38.5 42.1 44.6 46.6 47.8 48.3 48.3 62.0 71.7 78.4 83.0 86.8 89.0 90.0 89.9

50 32.2 37.3 40.9 43.4 45.4 46.6 47.2 47.2 59.9 69.5 76.1 80.7 84.6 86.8 87.8 87.8

ETS 50 ETS 100

Pressure drop p [psi]

77.7 86.4 91.6 94.7 96.7 97.1 96.4 94.8

78.7 88.1 93.9 97.6 100.1 101.0 100.7 99.5

78.7 88.8 95.2 99.4 102.5 103.9 104.1 103.3

77.8 88.5 95.4 100.1 103.7 105.6 106.2 105.8

75.9 87.0 94.4 99.5 103.6 105.9 106.9 106.8

74.6 85.8 93.4 98.6 102.9 105.4 106.6 106.7

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 14

Page 15

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Rated Capacity [TR]

(TR = ton of refrigeration)

Rated capacity [TR] in the normal flow direction

ETS 250 ETS 400

R407C

R22

R134a

R404A

t

e

[°F]

40 60 80 100 125 150 175 200 40 60 80 100 125 150 175 200

-40 258 292 315 331 344 351 355 356 411 466 502 527 548 561 567 568

-20 257 293 318 335 350 359 364 366 410 468 507 535 558 573 581 584

0 254 292 317 336 352 363 369 372 405 465 506 536 562 579 589 594

20 247 286 313 333 350 362 369 374 395 456 499 531 559 577 589 596

40 238 277 305 325 343 356 364 369 380 442 486 518 548 568 581 589

50 232 271 299 319 338 351 360 365 371 432 476 509 539 560 574 582

-40 250 286 312 331 348 361 369 375 398 456 497 528 556 575 589 598

-20 248 286 313 333 351 365 374 381 395 455 499 531 560 582 597 607

0 243 282 310 331 351 365 376 383 388 450 495 528 560 583 599 611

20 236 276 305 326 347 362 373 381 377 440 486 521 553 578 595 608

40 227 267 296 318 339 355 366 375 363 425 471 507 540 566 584 598

50 222 261 290 312 333 349 361 370 354 416 462 498 531 557 576 590

-40 215 239 253 262 267 268 266 262 342 381 404 417 426 428 425 418

-20 217 243 259 269 276 279 278 275 347 388 414 430 441 445 444 439

0 217 245 263 275 283 287 288 285 347 391 420 438 452 458 459 455

20 215 244 264 276 286 292 293 292 343 390 420 441 457 465 468 466

40 210 240 261 275 286 292 295 295 334 383 416 438 456 466 471 470

50 206 237 258 272 284 291 294 295 329 378 411 434 453 464 469 470

-40 195 219 234 243 249 252 251 247 311 349 373 388 398 401 400 394

-20 193 218 235 245 253 256 256 254 307 348 374 391 403 409 409 405

0 188 215 232 244 253 257 258 257 300 342 370 389 403 410 412 410

20 181 208 226 238 248 253 256 255 288 331 360 380 396 404 408 406

40 171 198 216 229 239 245 248 247 273 315 344 365 381 391 395 395

50 165 192 210 222 233 239 242 242 263 306 334 355 371 381 385 385

US units

Pressure drop p [psi]

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 15

Page 16

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Capacity

Normal flow direction

ETS 12.5

[kW]Q

0

Q

Opening [%]

[kW]Q

0

Q

ETS 50

[kW]Q

0

[kW]Q

0

ETS 25

Opening [%]

ETS 100

Opening [%]

ETS 250

[kW]

0

Opening [%]

Capacity based on: R407C

Te = 5 °C / 41 °F

T

= 32 °C / 89.6 °F

c

Tl = 28 °C / 82.4 °F

Opening [%]

ETS 400

[kW]

0

Opening [%]

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 16

Page 17

Data sheet | Electric expansion valve, type ETS 12.5 – ETS 400

Dimensions and weights for

ETS 12.5 and ETS 25

Connections H

Type

ODF × ODF (A × B)

[in.] [mm]

ETS 12.5

and 25

straight

ETS 12.5

and 25

angle

½ × ½ 12 × 12 1.2 30 0.5 13 2.5 64 5.9 150 – – 2.4 60 2.4 60 2.4 60 0.7 1.5

5

/8 × 5/816 × 16 1.2 30 0.5 13 2.5 64 5.9 150 – – 2.4 60 2.4 60 2.4 60 0.7 1.5

7

/8 × 7/822 × 22 1.2 30 0.5 13 2.5 64 5.9 150 – – 2.4 60 2.4 60 2.4 60 0.7 1.5

½ × ½ 12 × 12 1.2 30 – – 2.5 64 7.6 194 2.9 74 2.4 60 – – 2.4 60 0.7 1.5

5

/8 × 5/816 × 16 1.2 30 – – 2.5 64 7.6 194 2.9 74 2.4 60 – – 2.4 60 0.7 1.5

7

/8 × 7/822 × 22 1.2 30 – – 2.5 64 7.6 194 2.9 74 2.4 60 – – 2.4 60 0.7 1.5

Dimensions and weights for

ETS 50 and ETS 100

1

H

2

H

3

H

4

H

5

L

1

L

2

øD

1

Net weight

[in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [kg] [lb.]

B

Connections H

Type

ODF × ODF (A × B)

[in.] [mm]

7

ETS 50

ETS 100

/8 × 7/

7

/8 × 11/

11/8 × 11/

11/8 × 13/

11/8 × 11/

11/8 × 13/

13/8 × 13/

15/8 × 15/

22 × 22 1.0 26.2 0.5 13.0 4.7 118.0 8.1 205.0 2.2 56.0 2.2 56.0 2.4 60.0 1.5 3.3

8

22 × 28 1.0 26.2 0.5 13.0 4.7 118.0 8.1 205.0 2.2 56.0 2.5 63.0 2.4 60.0 1.5 3.3

8

28 × 28 1.0 26.2 0.5 13.0 4.7 118.0 8.1 205.0 2.5 63.0 2.5 63.0 2.4 60.0 1.5 3.3

8

28 × 35 1.0 26.2 0.5 13.0 4.7 118.0 8.1 205.0 2.5 63.0 2.9 74.0 2.4 60.0 1.5 3.3

8

28 × 28 1.2 30.0 0.7 17.0 5.0 127.0 8.4 214.0 2.6 66.0 2.6 66.0 2.4 60.0 1.7 3.7

8

28 × 35 1.2 30.0 0.7 17.0 5.0 127.0 8.4 214.0 2.6 66.0 3.0 76.0 2.4 60.0 1.7 3.7

8

35 × 35 1.2 30.0 0.7 17.0 5.0 127.0 8.4 214.0 3.0 76.0 3.0 76.0 2.4 60.0 1.7 3.7

8

8

– 1.2 30.0 0.7 17.0 5.0 127.0 8.4 214.0 3.3 84.0 3.3 84.0 2.4 60.0 1.7 3.7

© Danfoss | DCS (rm) | 2019.02

1

H

2

H

3

H

4

L

1

L

2

øD

Net weight

1

[in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [kg] [lb.]

DKRCC.PD.VD1.3C.02 | 17

Page 18

Dimensions and weights for

ETS 250 and ETS 400

Type

ETS 250

Connections H

ODF × ODF (A × B)

[in.] [mm]

11/8 × 11/

13/8 × 13/

15/8 × 15/

28 × 28 4.7 120.0 6.7 168.5 5.6 143.0 3.3 83.0 3.4 85.5 2.4 60.0 0.95 24.0 1.9 4.2

8

35 × 35 4.7 120.0 7.0 178.5 5.6 143.0 3.5 88.0 3.6 90.5 2.4 60.0 0.95 24.0 1.9 4.2

8

8

– 4.7 120.0 7.4 188.5 5.6 143.0 3.7 93.0 3.8 95.5 2.4 60.0 0.95 24.0 1.9 4.2

1

[in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [in.] [mm] [kg] [lb.]

L

1

L

2

L

3

L

4

øD

1

– 42 × 42 4.7 120.0 7.4 188.5 5.6 143.0 3.7 93.0 3.8 95.5 2.4 60.0 0.95 24.0 1.9 –

ETS 400

21/8 × 21/

15/8 × 15/

21/8 × 21/

8

8

8

– 4.7 120.0 8.1 204.0 5.6 143.0 4.0 101.0 4.1 103.0 2.4 60.0 0.95 24.0 1.9 4.2

– 4.8 121.0 8.0 203.0 5.7 144.5 3.9 99.0 4.1 104.0 2.4 60.0 0.95 24.0 2.2 4.9

54 × 54 4.8 121.0 9.6 243.0 5.7 144.5 4.7 119.0 4.9 124.0 2.4 60.0 0.95 24.0 2.2 4.9

Related products

EKE 1A, EKE 1B, EKE 1C EKS 221, ACCPBT, AKS 11/AKS 12 AKS 32R, AKS 33, NSK AST-G

Superheat controller Temperature sensor Pressure transmitter Service driver

B

Net weight

1

Code no. 034G0013

All Danfoss products fulfill the requirements in REACH.

One of the obligations in REACH is to inform customers about presence of Candidate list substances if any, we hereby inform you about one substance on the candidate list:

A moist indicator in the sight glass contains a paper which is impregnated with Cobalt Dichloride (CAS no: 7646-79-9) in a concentration above 0.1% w/w.

- Avoid skin contact with the paper - Do not inhale the dust from the paper - The paper must be disposed as hazardous waste.

© Danfoss | DCS (rm) | 2019.02

DKRCC.PD.VD1.3C.02 | 18

Loading...

Loading...