Page 1

Data Sheet

Electric expansion valve

Type ETS 175L - 250L - 400L

For liquid injection into evaporators

ETS 175L - 250L - 400L is a series of electric

expansion valves for precise liquid injection in

to evaporators for air conditioning and

refrigeration applications. The valve comes with

two piston options, a linear and a S-shaped

characteristics. The design is fully balanced,

providing bi-ow feature as well as tight shut-

o function in both ow directions. The valve

design uses bi-polar drive providing very

precise ow regulation.

ETS 175L - 250L - 400L valves are compatible

with electronic control solutions from Danfoss

and other manufacturers.

Features

• Precise positioning for optimal control of

liquid injection.

• Wide range for all common refrigerants

including A2L.

• ETS can be operated with ow in both

directions.

• Balanced design allows to minimised the step

loss.

• Designed with built-in sight glass with

moisture indicator.

• Easy to service.

• Cable and connector assemblies as

accessories.

• Danfoss EKE series, EKF series, MCX are

examples of Danfoss controllers with drivers

matching the ETS needs.

• For manual operation and service of ETS 175L

- 250L - 400L valves an AST-g service driver is

available.

AI374946650883en-000202

Page 2

EKF 1A/2A Stepper Valve Driver

EKE 1 series superheat controllers

(EKE 1B is shown)

EKF series is an economical stepper valve driver that translates analog signal

provided by master controller to valve driving sequence .

EKE superheat controllers are for DIN rail mounting, and comes in three versions

with dierent combinations of inputs and output relays and dierent

functionality.

Figure 3: Pressure transmitter

(DST P110 shown)

Figure 4: Temperature sensor

(AKS 12 shown)

Backup power module

EKE 2U

DST P110 is a digital ratiometric pressure transmitter.

Depending on controller type, other ratiometric

pressure transmitters can be used as well (e.g. AKS

32R).

AKS is a PT1000 temperature sensor. Depending on

controller type, other temperature sensors can be

used as well.

EKE 2U Backup power module ensures sucient

power in case of power failures to the controller to

ensure closure of the electronic valves

.

Electric expansion valve, Type ETS 175L - 250L - 400L

Portfolio overview

ETS 175L - 250L - 400L is an electric expansion valve series whose function is controlled though a Danfoss electronic

controller, or a third party electronic controller that is compatible with the ETS 175L - 250L - 400L as to control

functionality and connections.

Danfoss recommends the use of the EKE 1 series Superheat controllers or EKF driver units together with ETS 175L 250L - 400L. With EKE1 series controllers a super heat accuracy better than 0.5K can be obtained.

The electronic controller requires precise temperature input from a temperature sensor (refrigerant temperature)

and precise pressure inputs (evaporator pressure) from a pressure transmitter.

Table 1: System product

Table 2: Sensors and other products for ETS 175L - 250L - 400L

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 2

Page 3

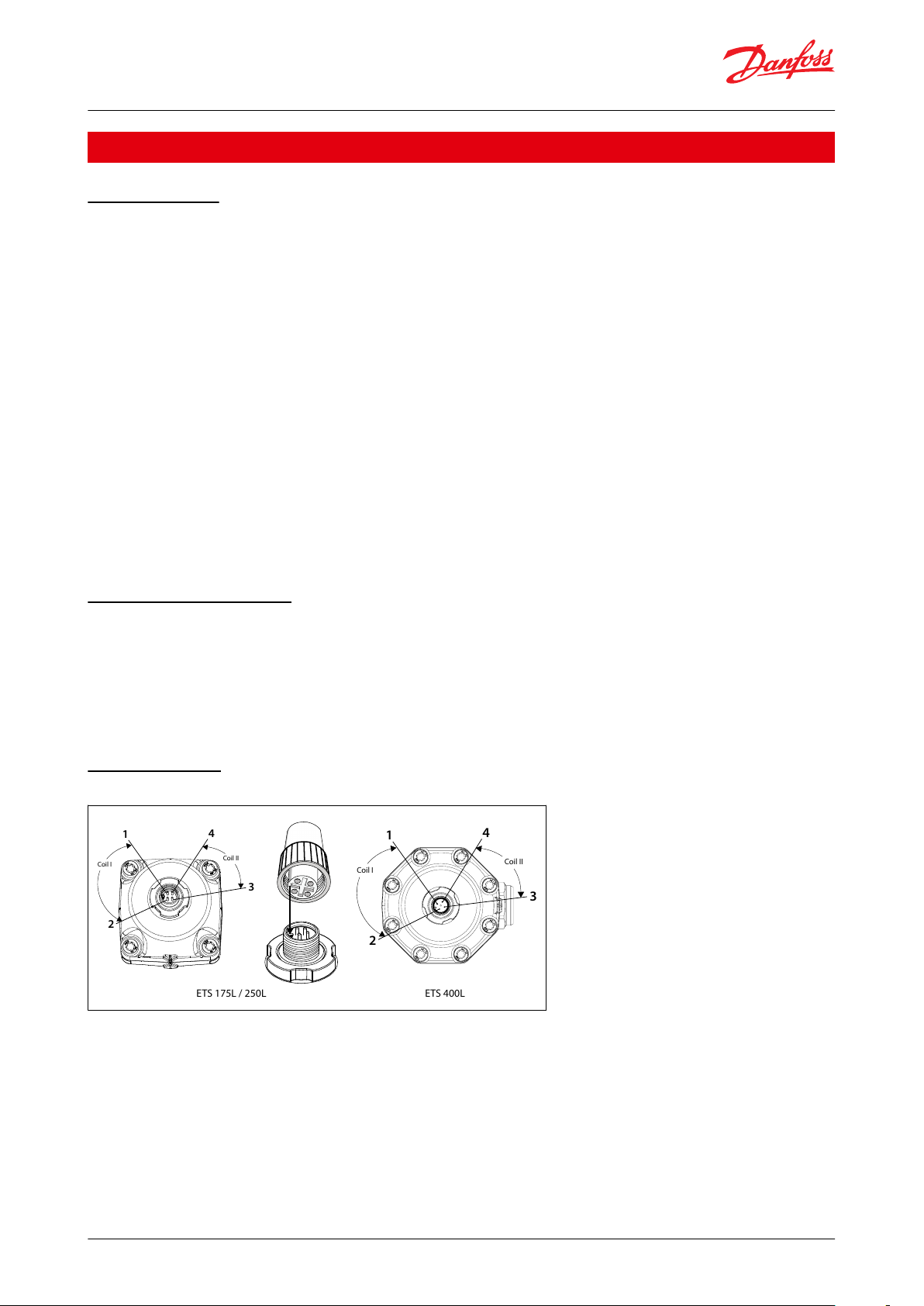

Coil I

Coil II

1

2

3

4

ETS 175L / 250L ETS 400L

Coil II

3

4

Coil I

1

2

Electric expansion valve, Type ETS 175L - 250L - 400L

Functions

Valve operation

The ETS 175L - 250L - 400L valves operate modulating by electronically controlled activation of the stepper motor.

The motor is a type 2-phase bi-polar, which stays in position, unless power pulses from a driver initiate the two

discrete sets of motor stator windings for rotation in either directions. The direction of the rotation of the spindle

depends on the phase relationship of the power pulses. This is decisive for the travel of the piston.

The motor is operating the spindle, whose rotating movements are transformed into linear motion by the

transmission in the cage assembly. The motor housing has a glass sealed M12 connection as standard, which can be

connected with a M12 A code 4-pin connector.

The piston design inside the ETS 175L - 250L - 400L valve is pressure balanced, giving identical bi-ow performance

capabilities and nearby identical maximum capacities. Closing the valve by overdriving, ensures that the reference

number in steps is always correct.

NOTE:

Depending on the type of controller or driver, there will be limitations in cable length between valve actuator and

driver. Both the actual cable length, the level of EMC emission on the location and driver circuit has an impact on

the actual distortion of the current to the actuator motor.

Do not overdrive the valve in open position. Please contact Danfoss for further information how and when to apply

this counter measure in cases with questionable cable length.

Sight glass and indicator

ETS 175L - 250L - 400L are equipped with sight glass with moisture indicator. The physical position of the valve can

be checked through the sight glass.

Insucient sub cooling can produce ash gas which is visible through the sight glass. The moisture indicator in the

sight glass indicates dry or wet state of the refrigerant by changing its colour.

Some variants comes without sight-glass and indicator, check section ordering for details.

Electrical wiring

Figure 1: Electrical wiring

NOTE:

Electrical check of stepper motor and wiring coil I = 52 ohm, coil II = 52 ohm

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 3

Page 4

Opening

↓↓

Coil I

Coil II

Closing

↑↑

123

4

1

+12V

GRD

+12V

GRD2GRD

+12V

+12V

GRD3GRD

+12V

GRD

+12V4+12V

GRD

GRD

+12V

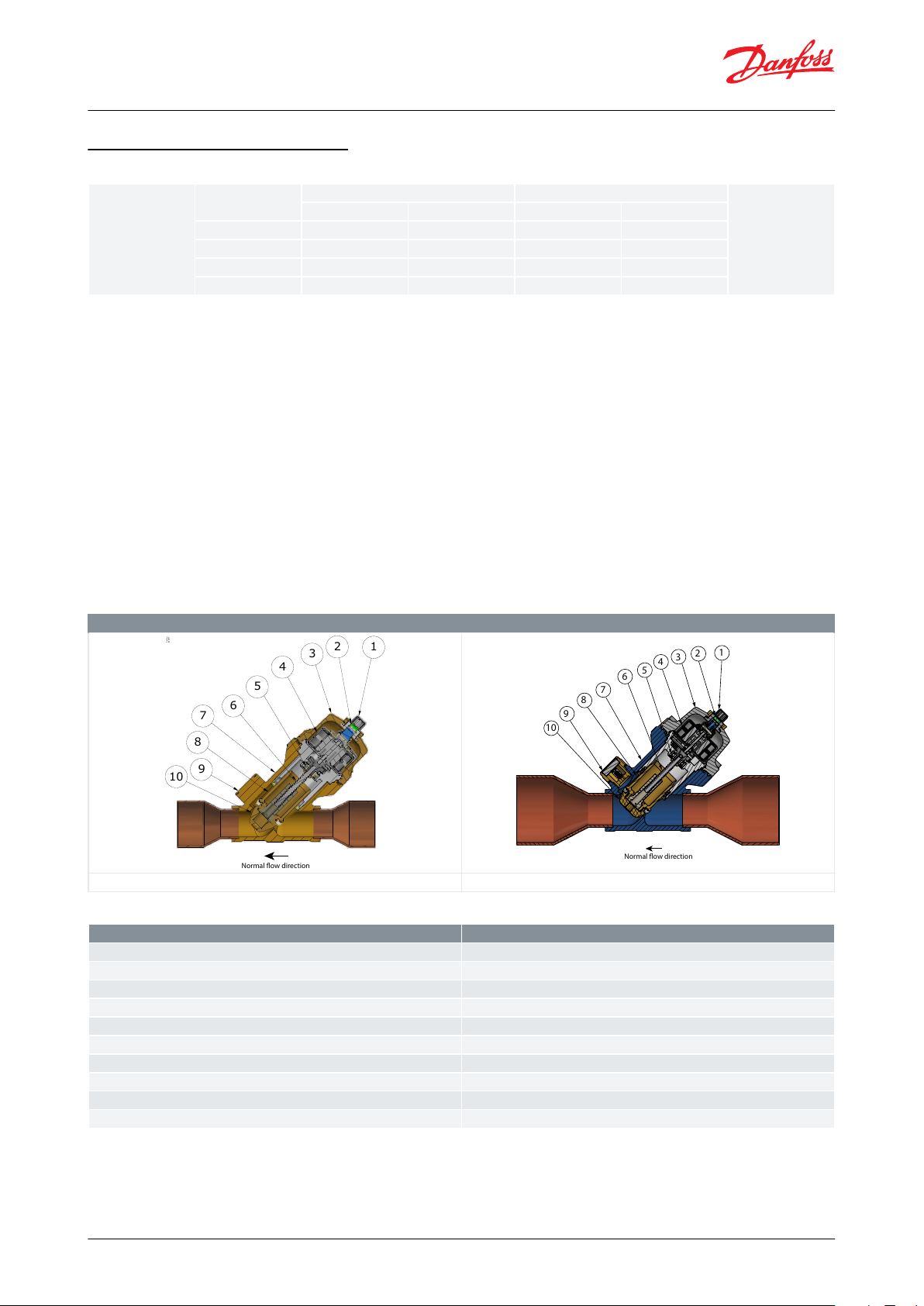

ETS 175L - 250L - 400L with / without sight glass

1

2

3

4

5

6

7

8

9

10

Danfoss

80Z874

Normal flow direction

1

2

3

4

6

5

7

8

9

10

Normal flow direction

ETS 175L - 250L

ETS 400L

Pos. no.

ETS 175L - 250L - 400L

1

M12 connector

2

Glass seal

3

Cover4Stepper motor

5

Bearing

6

Spindle

7

Valvehousing

8

Piston9Sight glass

10

Cone

Electric expansion valve, Type ETS 175L - 250L - 400L

Stepper motor switch sequence

Table 3: Stepper motor switch sequence

If the controller driving the ETS 175L - 250L - 400L valves is from another manufacturer than Danfoss or a custom

design,

the following points must be considered in order to overcome potential step loss.

1.

To ensure total closing of the valve, the controller should have a function to overdrive the valve in the closed

direction. It is recommended to overdrive 5% of the full step range at appropriate intervals. Overdrive should not

be performed in open direction of the valve.

2.

The amount of lost steps may increase as a function of the amount of changes of the opening degree. Such

designed controller should be able to compensate the lost step after a dened number of changes in opening

degree.

WARNING:

At power failure the ETS 175L - 250L - 400L valves will remain in the opening position it has at the moment of power

failure, unless a safety device in the form of a battery backup is installed. Danfoss recommends to use EKE 2U

backup power module.

Table 4: Design

Table 5: Design

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 4

Page 5

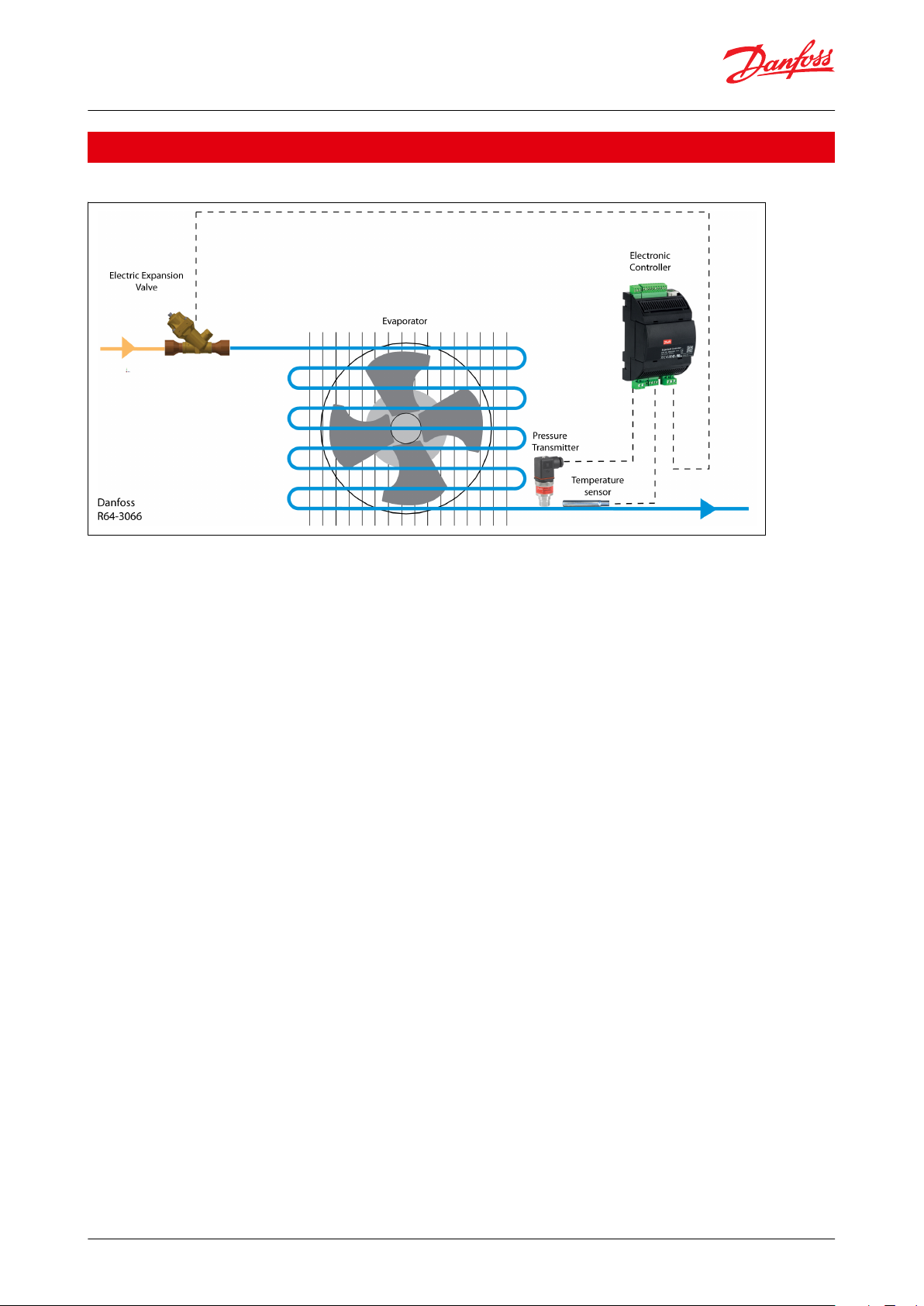

Electric expansion valve, Type ETS 175L - 250L - 400L

Applications

Figure 2: Applications

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 5

Page 6

Media Data

Value

Refrigerants

R22, R134a, R404A, R407A, R407C, R407F, R407H, R422B, R422D, R438A, R410A,

R417A, R422A, R438A, R442A, R448A, R449A, R449B, R450A, R452A, R463A,

R507A, R513A, R513B, R515A, R515B, R1234ze

Refrigerant oil

POE, PVE, mineral oil

Oil free application

No

Media temperature range

-40 °C to +70 °C

Electric expansion valve, Type ETS 175L - 250L - 400L

Media

ETS L series is designed to be used with the below shown refrigerants and lubricants.

Table 6: Refrigerants and lubricants

Refrigerant safety class (ASHRAE Standard 34/1S0 817)

NOTE:

For ammable refrigerants R1234ze :

• This product is validated in accordance to EN 378, ISO 5149, ASHRAE 15 or equivalent standards.

• Ignition risk is evaluated in accordance to ISO 5149.

• See safety note below.

NOTE:

• The product can be applied on systems with R1234ze as the working uid.

• For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing ammable refrigerant.

• Note, please follow specic selection criteria stated in the datasheet for these particular refrigerants.

• The valve must only be used in closed circuit refrigeration system, where no oxygen is present acc. EN 378, ISO

5149 ASHRAE 15 or equivalent standards.

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 6

Page 7

Valve technical specication

Value

Motor type

Bi-Polar

Coil resistance @ 25C

52.4 ohm +- 10%

Nominal voltage

Constant Voltage drive: 12V -4/+15%

Phase current

Chopper drive: 200 mA recommended, max 250 mA RMS.

Phase inductance

70 mH +- 20%

Power consumption

Voltage / current drive: 5.5 / 6.5 W (UL: NEC class 2)

Holding current

Recommended holding current 0-25%. For optimal performance, driver should

keep 100% current on coils 10ms after last step.

Excitation methods

Full step, Half step and micro stepping

Number of steps

3810 -0/+400 Full steps

Nominal step rate

Constant voltage drive: 100pps recommended

Chopper drive: 200 pps recommended, max 300 pps

Travel time

<15 sec @ 300pps

Max duty cycle

100% possible, requiring refrigerant ow through valve.

Dielectric strength

>100MΩ at 500VDC after 4 seconds

Minimum stable control opening degree

10% of opening degree

Reference position

Overdriving against the full close position

Valve conguration

Inline, Straightway

Electrical connections

M12 A-code 4 pin

Compatible Danfoss controllers

Danfoss EKE 1 series superheat controllers, EKF drivers, AK-XM 208C, MCX series

Data

Value (SI units)

Value (IMP units)

Max working pressure (MWP)

37 barg

537 Psig

Maximum operating pressure dierential

(MOPD, measured at initial opening)

normal

ow: 26 barg

normal

ow: 377 psig

reverse ow:

175L: 26 bar g both Voltage and current driven

250L: 12 barg voltage driven

250L: 17 barg current driven

400L: 10 barg both Voltage and current driven

reverse ow:

175L: 377 psig both Voltage and current driven

250L: 174 psig voltage driven

250L: 246.5 psig current driven

400L: 145 psig both Voltage and current driven

Ambient temperature

-40 °C to 70 °C

-40 °F to 158 °F

Ambient relative humidity

Max 95% RH

Max 95% RH

Inlet

uid temperature range

-40 °C to 70 °C

-40 °F to 158 °F

Flow direction

Bi-Flow

Sightglass / moisture indicator

Type N moisture indicator

Electric expansion valve, Type ETS 175L - 250L - 400L

Product specication

Valve technical specication

Table 7: Electrical specication

Pressure and temperature data

Table 8: Valve Specication

Identication

Figure 3: Identication (example)

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 7

Page 8

0

1

2

3

4

5

6

7

8

9

10

11

0 10 20 30 40 50 60 70 80 90 100

Kv [m3/h]

Openning Degree [%]

ETS 175L

ETS 175L - S-curve flow

ETS 175L - Linear flow

Danfoss

80Z8135

ETS 250L - S-curve flow

ETS 250L - Linear flow

Danfoss

80Z8136

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

0 10 20 30 40 50 60 70 80 90 100

Kv [m3/h]

Openning Degree [%]

ETS 250 L

Electric expansion valve, Type ETS 175L - 250L - 400L

Flow characteristics

Figure 4: ETS 175L ow curve

Figure 5: ETS 250L ow curve

• Measured at 1 barg dierential pressure

• Kv ow provided in m3/hour (Y axis)

• Valve position provided by pulses in full steps

• Flow direction: Normal ow

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 8

Page 9

0

2

4

6

8

10

12

14

16

18

20

22

0 10 20 30 40 50 60 70 80 90 100

Kv

[m3/h]

Opening Degree [%]

ETS 400L

ETS 400L L curve

ETS 400L S curve

Environmental conditions

Value

Max, external leakage @37bar @20C with 100% helium

1.56*10-5 mbarL/s

Enclosure rating IP

IP67

Insulation resistance

>100 MΩ

Storage temperature range (C)

-30 °C to 70 °C

Shipping and Shelf life

EC 60068-2-30 (damp heat, cyclic), at 25/55 °C. valve in packaging

Relative humidity

Max 95% RH

Installation

Value

Installation orientation

Vertical +-90 °C

Ex-factory delivery position

90% open position

Bi

ow application

Yes

Electric expansion valve, Type ETS 175L - 250L - 400L

Figure 6: ETS 400L ow curve

Performance and enviroment conditions

Table 9: Environmental condition data

Mounting

Table 10: Mounting

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 9

Page 10

B

1

L

3

L

4

H

1

L

2

L

1

A

B

H

2

Danfoss

80Z872

L

3

L

4

B

1

H

1

H

2

L

1

L

2

Type

Sight

glass

Connections

B1H1H2L1L2L3L

4

ODF x ODF (A x

B)

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

ETS

175L

Yes

1 1/8 X

1 1/8

29 X 29

0.9

24.0

3.9

98.8

1.8

46.4

6.6

167.5

2.5

62.5

3.2

82.5

3.3

85.0

Yes

1 1/8 X

1 1/8

29 X 29

0.9

24.0

3.9

98.8

1.8

46.4

6.6

167.5

2.5

62.5

3.2

82.5

3.3

85.0

No

1 1/8 X

1 1/8

29 X 29

0.9

24.0

3.9

98.8

1.5

38.1

6.6

167.5

2.5

62.5

3.2

82.5

3.3

85.0

Yes

1 3/8 X

1 3/8

35 X 35

0.9

24.0

3.9

98.8

1.8

46.4

7.0

177.5

2.5

62.5

3.4

87.7

3.5

90.0

Yes

1 3/8 X

1 3/8

35 X 35

0.9

24.0

3.9

98.8

1.8

46.4

7.0

177.5

2.5

62.5

3.4

87.5

3.5

90.0

Yes

1 5/8 X

1 5/8

41 X 41

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 5/8 X

1 5/8

41 X 41

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Electric expansion valve, Type ETS 175L - 250L - 400L

Dimensions

Figure 7: Dimensions ETS 175L - 250L

Table 11: Dimensions

Figure 8: Dimensions ETS 400L

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 10

Page 11

Type

Sight

glass

Connections

B1H1H2L1L2L3L

4

ODF x ODF (A x

B)

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

[in.]

[mm]

ETS

250L

Yes

1 1/8 X

1 1/8

29 X 29

0.9

24.0

3.9

98.8

1.8

46.4

6.6

167.5

2.5

62.5

3.2

82.5

3.3

85.0

Yes

1 1/8 X

1 1/8

29 X 29

0.9

24.0

3.9

98.8

1.8

46.4

6.6

167.5

2.5

62.5

3.2

82.5

3.3

85.0

Yes

1 3/8 X

1 3/8

35 X 35

0.9

24.0

3.9

98.8

1.8

46.4

7.0

177.5

2.5

62.5

3.4

87.7

3.5

90.0

Yes

1 3/8 X

1 3/8

35 X 35

0.9

24.0

3.9

98.8

1.8

46.4

7.0

177.5

2.5

62.5

3.4

87.5

3.5

90.0

Yes

1 5/8 X

1 5/8

41 X 41

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 5/8 X

1 5/8

41 X 41

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 5/8 X

2 1/8

41 X 54

0.9

24.0

3.9

98.8

1.8

46.4

8.0

202.0

2.5

62.5

8.0

107.0

3.7

95.0

Yes

1 5/8 X

2 1/8

41 X 54

0.9

24.0

3.9

98.8

1.8

46.4

8.0

202.0

2.5

62.5

8.0

107.0

3.7

95.0

Yes

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

Yes

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.8

46.4

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

No

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.5

38.1

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

No

1 21/32

X 1

21/32

42 X 42

0.9

24.0

3.9

98.8

1.5

38.1

7.4

187.5

2.5

62.5

3.6

92.5

3.7

95.0

ETS

400L

YES

1 5/8 X

1 5/8

41 X 41

0.9

24.0

4.0

101

1.9477.9

202

3.0763.8984.1

104

YES

1 5/8 X

1 5/8

41 X 41

0.9

24.0

4.0

101

1.9477.9

202

3.0763.8984.1

104

YES

2 1/8 X

2 1/8

54 X 54

0.9

24.0

4.0

101

1.9479.5

242

3.0764.6

118

4.9

124

YES

2 1/8 X

2 1/8

54 X 54

0.9

24.0

4.0

101

1.9479.5

242

3.0764.6

118

4.9

124

YES

2 5/8 X

2 5/8

67 X 67

0.9

24.0

4.0

101

1.94710.7

272

3.0765.2

132

5.5

139

Electric expansion valve, Type ETS 175L - 250L - 400L

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 11

Page 12

Type

Linear/S-

shape

Built-in

sight glass

Rated capacity

Connections

Code no.

R513A

R134a

R407C

ODF x ODF

Single pack

Industrial

pack

(kW)

(TR)

(kW)

(TR)

(kW)

(TR)

(in)

(mm)

ETS 175L

Linear

Yes

703

200

822

233

1133

322

1-1/8 x 1-1/8

034G3602

S-shape

Yes

647

184

757

215

1042

296

1-1/8 x 1-1/8

034G3624

Linear

No

703

200

822

233

1133

322

1-1/8 x 1-1/8

034G3604

Linear

Yes

703

200

822

233

1133

322

1-3/8 x 1-3/8

034G3603

Linear

No

703

200

822

233

1133

322

1-3/8 x 1-3/8

034G3625

Linear

Yes

703

200

822

233

1133

322

1-3/8 x 1-3/8

034G3600

S-shape

Yes

647

184

757

215

1042

296

1-3/8 x 1-3/8

034G3601

Linear

Yes

703

200

822

233

1133

322

1-5/8 x 1-5/8

034G3626

S-shape

Yes

647

184

757

215

1042

296

1-5/8 x 1-5/8

034G3627

Linear

Yes

703

200

822

233

1133

322

42 x 42

034G3628

S-shape

Yes

647

184

757

215

1042

296

42 x 42

034G3629

ETS 250L

Linear

Yes

925

263

1081

307

1495

425

1-1/8 x 1-1/8

034G3616

S-shape

Yes

862

245

1007

286

1392

395

1-1/8 x 1-1/8

034G3617

Linear

Yes

925

263

1081

307

1495

425

1-3/8 x 1-3/8

034G3607

S-shape

Yes

862

245

1007

286

1392

395

1-3/8 x 1-3/8

034G3608

Linear

Yes

925

263

1081

307

1495

425

1-3/8 x 1-3/8

034G3610

Linear

Yes

925

263

1081

307

1495

425

1-5/8 x 1-5/8

034G3605

Linear

Yes

925

263

1081

307

1495

425

1-5/8 x 1-5/8

034G3609

Linear

No

925

263

1081

307

1495

425

1-5/8 x 1-5/8

034G3618

S-shape

Yes

862

245

1007

286

1392

395

1-5/8 x 1-5/8

034G3606

Linear

Yes

925

263

1081

307

1495

425

1-5/8 x 2-1/8

034G3619

S-shape

Yes

862

245

1007

286

1392

395

1-5/8 x 2-1/8

034G3620

Linear

Yes

925

263

1081

307

1495

425

42 x 42

034G3621

S-shape

Yes

862

245

1007

286

1392

395

42 x 42

034G3622

Linear

No

925

263

1081

307

1495

425

42 x 42

034G3611

S-shape

No

862

245

1007

286

1392

395

42 x 42

034G3623

Linear

Yes

925

263

1081

307

1495

425

2 1/8 x 2 1/8

034G3637

S-shape

Yes

862

245

1007

286

1392

395

2 1/8 x 2 1/8

034G3638

ETS 400L

S-shape

Yes

1053

300

1216

346

1723

491

1-5/8 x 1-5/8

034G3630

S-shape

Yes

1053

300

1216

346

1723

491

2-1/8 x 2-1/8

034G3631

Linear

Yes

1045

298

1196

341

1693

482

1-5/8 x 1-5/8

034G3632

Linear

Yes

1045

298

1196

341

1693

482

2-1/8 x 2-1/8

034G3633

Linear

Yes

1045

298

1196

341

1693

482

1-5/8 x 1-5/8

034G3634

Linear

Yes

1045

298

1196

341

1693

482

2-1/8 x 2-1/8

034G3635

Linear

Yes

1045

298

1196

341

1693

482

2-5/8 x 2-5/8

034G3636

Electric expansion valve, Type ETS 175L - 250L - 400L

Ordering

Table 12: Ordering

NOTE:

The Rated capacity is based on:

Evaporating temperature te : 5 °C / 40 °F

Liquid temperature tl : 28 °C / 82 °F

Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal ow direction

Valve sizing using calculation software

It is strongly recommended to use Coolselector®2 to nd the correct valve for your application. The software can be

downloaded from the Danfoss website. You can download it from http:// coolselector.danfoss.com

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 12

Page 13

2

1

Danfoss

34G1087

12Piston i.e Linear or S-curve

Position for Screw (x4)

Code no.

034G3612

034G3613

034G3614

034G3615

Item

ETS175L-linear-Actuator kit

ETS175L-SCurve-Actuator kit

ETS250L-linear-Actuator kit

ETS250L-SCurve-Actuator kit

Parts

1 pcs.

Actuator assembly

O-ring

Screw M6x25mm

1 pcs.

4 pcs.

1

2

Code no.

034G3641

034G3642

Item

ETS400L-linear-Actuator kit

ETS400L-SCurve-Actuator kit

1 pcs.

Actuator assembly

O-ring

Screw M6x25mm

1 pcs.

8 pcs.

Electric expansion valve, Type ETS 175L - 250L - 400L

Spare parts for ETS valve

Figure 9: ETS 175L - ETS 250L

Table 13: Actuator kit

Figure 10: ETS 400L

Table 14: Actuator kit

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 13

Page 14

2000 mm / 78.7 inch

8000 mm / 314.9 inch

49 mm / 1.9 inch

Cable

Cable length (L)

Insulation

Packing

Code no.

Angle cable

2 m / 6.6 ft

SR-PVC

Single pack

034G7073

Angle cable

8 m / 26.2 ft

SR-PVC

Single pack

034G7074

Straight cable

12.2 m /40 ft

SR-PVC

Single pack

034G7078

Future

Description

Jacket

PVC - black

Cable outer sheat

Oil - resistant

Water proof rating

IP 67

Operating temperature range

-40 – 80 °C

Wire type

Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter

7.0 mm

Minimum bending radius

10 x cable diameter

Cable combustibility / test

Flame retardant / VW-1 / CSA FT - 1

M12 standard

EN 61076-2-101

Reference standard

UL style 2464 and DIN VDE 0812

LVD directive

2014/35/EU

A2

A1

B1

B2

1

2

3

4

Electric expansion valve, Type ETS 175L - 250L - 400L

Accessories

M12 cable

Figure 11: M12 angle cable dimensions

Figure 12: M12 Straight cable dimensions

Table 15: M12 cable

Table 16: Specication

Connections

Figure 13: Connections

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 14

Page 15

Electric expansion valve, Type ETS 175L - 250L - 400L

Service driver AST G code 034G0013

Figure 14: Service driver AST G

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 15

Page 16

Symptom

Possible Cause

Remedy

No valve movement

Lack of proper electrical connection

• Check the connection between valve and a controller

Wrong parameter setting in controller

• Check valve settings in controller i.e pre-selected

valves, no. of steps, phase current, direction of valve

rotation, steps per second

Broken motor/ short circuit

• Check the resistance between coil I and coil II. Resistance in each coil should be 52.4 ohms @20°C. Details

on Electrical wiring

• Replace a complete valve

Insucient power supply to valve

• Check the current/voltage supply from controller to

valve

Internal leakage (due to ‘Step Loss’)

Control pulse to valve is inuenced by high external

electrical noise

• Separate the cable from high power lines

Longer cable length between valve and controller

• Check the maximum cable length allowed between

the controller and the valve • For longer cable distance, use cable with bigger wire diameter • Use cable

lter

Accumulated backlash in valve

• Controller should overdrive the valve to compensate

the lost steps after a number of changes in opening

degree

Insucient power supply to the valve

• Check the current/voltage supply from controller to

valve • Check the supply power to controller

Insucient capacity

Expansion valve too small

• Check refrigeration system capacity and compare

with expansion valve capacity. Replace with larger

valve if necessary

Suction pressure too low Evaporator superheat too

high

• Check superheat performance, the settings SH min

and SH max. in the super heat controller • Check valve

capacity • Check ‘total number of steps’ dened in the

controller • Also check section ‘High Superheat’

Expansion valve blocked with foreign material

• Remove and examine the valve

Evaporator wholly or partly iced up

• De-ice evaporator

High superheat

Lack of sub-cooling

• Check refrigerant • Also refer to section Insucient

capacity

Controller is not setup/tuned properly

• Check the controller superheat settings and sensors

connected to it • Tune PID parameters in the controller

Flash gas

Lack of sub-cooling ahead of expansion valve

• Check refrigerant for ash gas ahead of expansion

valve / external subcooler • If the valve is placed much

higher than condenser outlet, check pressure dier-

ence

Oversized valve selected

• Limit max opening degree of the valve setting in

controller • Check refrigeration system capacity and

compare with expansion valve capacity. Use proper

valve size suitable for the system

Electric expansion valve, Type ETS 175L - 250L - 400L

Troubleshooting

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 16

Page 17

File name

Document type

Document topic

Approval authority

EAC RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

LLC CDC EURO-TYSK UA.089.D.00188-17

UA Declaration

PED

LLC CDC EURO TYSK

LLC CDC EURO-TYSK UA.TR-089.0993-17

Pressure - Safety Certicate

PED

LLC CDC EURO TYSK

EAC RU Д-DK.БЛ08.B.00189_18

EAC Declaration

EMC

EAC

EAC RU Д-DK.АИ30.В.04973

EAC Declaration

PED

EAC

EAC RU Д-DK.АИ30.В.04995

EAC Declaration

PED

EAC

Manufacturers Declaration Danfoss 034R9813.01

Manufacturers Declaration

Danfoss

EAC RU Д-DK.ГА02.В.08524

EAC Declaration

PED

EAC

Electric expansion valve, Type ETS 175L - 250L - 400L

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 17: Valid approvals

Table 18: Approvals

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 17

Page 18

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.01 AI374946650883en-000202 | 18

Loading...

Loading...