Data sheet

Colibri® Electric expansion valves

Type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

ETS Colibri® is an electric stepper motor valve.

The valve has been designed for precise liquid

injection into evaporators for air conditioning

and refrigeration applications.

The valve in-line design includes balanced cage

and slider assembly operated by the direct driven

motor technology. This ensures solenoid tight

shut-off in both flow directions, thus providing

smooth operation of the system.

The valve incorporates a powerful bi-polar motor

which precisely controls flow regulation.

ETS Colibri® valves are compatible with electronic

control solutions from Danfoss and other

manufacturers.

Applications:

Air Conditioning

- Chillers, heat pumps

- Roof top and ducted split systems

- VRF and other split systems

- Close control cooling

Refrigeration

- Cold Rooms, Food retail and Transport

Features / Benefits

Precise control of liquid injection

• Optimum utilization of the evaporator

• Increased energy efficiency and COP

• Improved overall system performance

Linear Flow characteristic

• Repetitive operation of the valve at all

conditions

Balanced cage design

• Higher MOPD and MWP

• Easily fits in various application and operating

conditions

Direct driven valve motor technology

• Powerful motor that guarantees precise flow

control and increased energy efficiency of the

system

Supports variety of refrigerants, approved for

oil free applications

• Wide application scope

Fast opening/closing time of 2.5 seconds

• Quick reaction to the operating condition

• Minimizes the risk of liquid refrigerant flowing

into the compressor at shut down and low

pressure cut out at start up

Solenoid tight shut-off

• Prevents migration of the refrigerant during

stand-still

• Reduced complexity by reducing number of

components in the system

Sight glass / moisture indicator

• Fast troubleshooting during system

diagnostics

Compact, lightweight and in-line design

• Flexible and easy integration in any system

Bi-metal connectors

• Fast and improved brazing process - no wet

wrap needed

Stainless construction

• Internal and external corrosion resistant

Fully hermetic laser welded design

• Hermetic valve in accordance to EU F-gas

Regulation EU 517/2014

• No external leakage which saves cost on

maintenance and refrigerant loss

• Protecting the environment and climate

Manufactured according to ISO/TS16949

• Second – to – none quality and reliability

For more info

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.VD1.E7.02 | 1

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

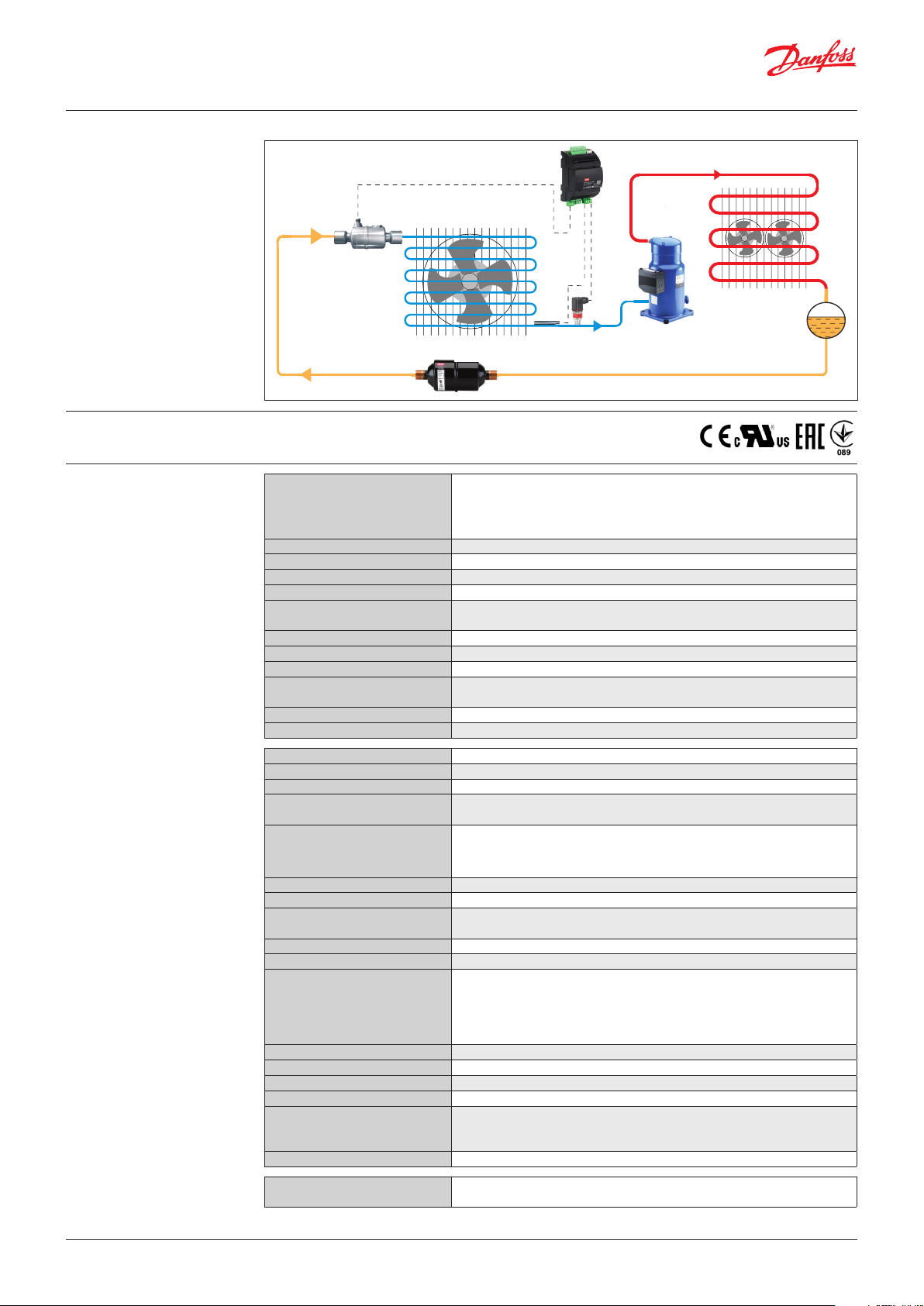

Application

Approvals: ETS Colibri®

Technical data

Electrical data

Electronic

controller/ driver

ETS Colibri®

Condenser

Receiver

Evaporator

AKS temp. sensors

and press. transmitters

Compressor

DML/DCL Filter drier

CE, REACH, UL, (Fluid Group l and ll , article 4 para 3), LLC CDC EURO TYSK, EAC

Applied for: ATEX II 3G Ex nA T6

Compatible refrigerants

R123zde, R1234yf, R1234ze(E), R1270, R134A, R152A, R22, R227, R23, R245fa, R290,

R32, R404A, R407A, R407B, R407C, R407F, R407H, R410A, R412A, R413A, R417A,

R422A, R422B, R422D, R427A, R438A, R442A, R444B, R447A, R448A, R449A, R449B,

R450A, R452A, R452B, R454A, R454B, R454C, R455A, R463A, R502, R507, R512A,

R513A, R513B, R515A, R515B, R516A, R600, R600A

Refrigerant oil POE, PVE, All mineral oils, ester oils and supports oil free

Complies with PED Yes, Fluid group 1 and 2, article 4 paragraph 3 for all ETS Colibri

MOPD 40 bar / 580 psi

Max. working pressure PS/MWP 50 bar(g) / 725 psi(g)

Refrigerant temperature range

(measured at the inlet of the valve)

-40 – 70 °C / -40 – 158 °F

Ambient temperature -40 – 70 °C / -40 – 158 °F

Capacity control range 10% - 100% of total opening degree

Initial opening

Environmental transport/storage

temperature and humidity

5% = 30 full steps

Max. +75 °C / +167 °F, Humidity: <100% RH

Material of construction Body: Stainless Steel / Connector: Bimetal (stainless steel and copper)

Sightglass / moisture indicator Type N moisture indicator

Motor enclosure IP67

Stepper motor type Bi-polar - permanent magnet

Step mode Microstepping (recommended), 2 phase full step or half step

Phase current

800 mA peak / 600 mA RMS. For more details on 3rd party controllers and

lower phase current see section: Driving Colibri valve.

No permanent holding current needed. Max. 20% permanent holding current

Holding current

allowed with refrigerant flow through valve

For optimal performance, driver should keep 100% current on coils 10ms

after last step

Phase resistance 10 Ω ±10% at +20 °C / +68 °F

Inductance 14 mH ±25%

Duty cycle

100% possible, requiring refrigerant flow through valve

Less than 50% over 120 sec period recommended

Nominal Power consumption 7.44 W RMS at 20 °C (total, both coils)

Total number of full steps 600

Step rate Current control driver:

a. Step type: Microstep (1⁄4 th or higher): 240 full steps/sec. recommended

b. Step type: Full step or Half steps: 240 full steps/sec. recommended

Emergency close : 240 full steps/sec.

OEMs with 3rd party controller, please contact Danfoss

Step translation 0.0167 mm / step

Full travel time 2.5 at 240 steps / sec

Opening stroke 10 mm / 0.4 in.

Reference position Overdriving against the full close position

1% (6 full steps) Overdrive is recommended for optimum performance

Overdriving performance

628 steps in closing direction recommended for initialisation

Overdriving in open position not recommended

Electrical connection according to EN 61076-2-101

Compatible controllers / driver Danfoss EKE 1A, EKE 1B, EKE 1C, MCX061V, MCX152V

Certain third party controllers / drivers. Contact Danfoss for details

Danfoss

R64-3010.11

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.VD1.E7.02 | 2

34G230.10

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

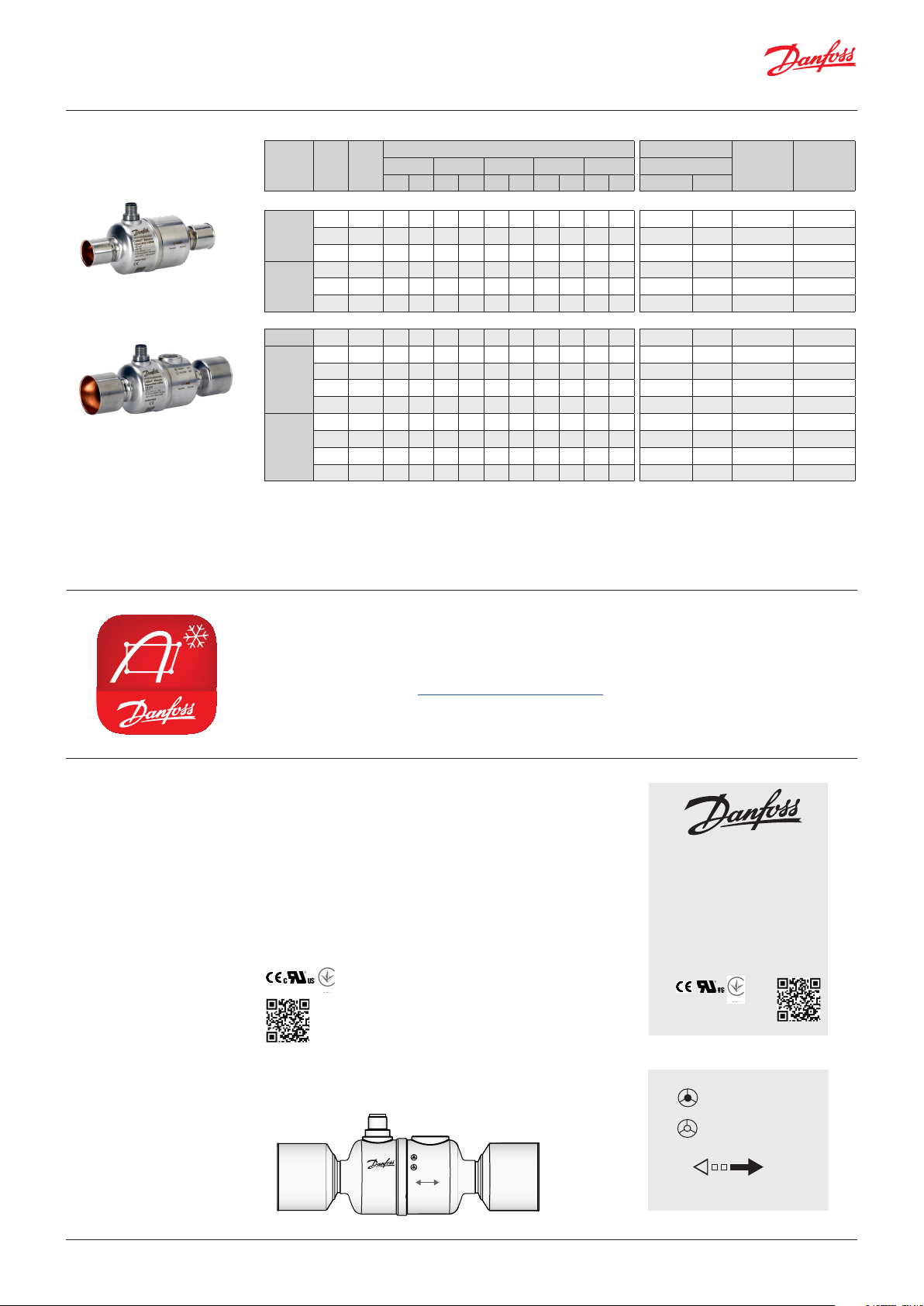

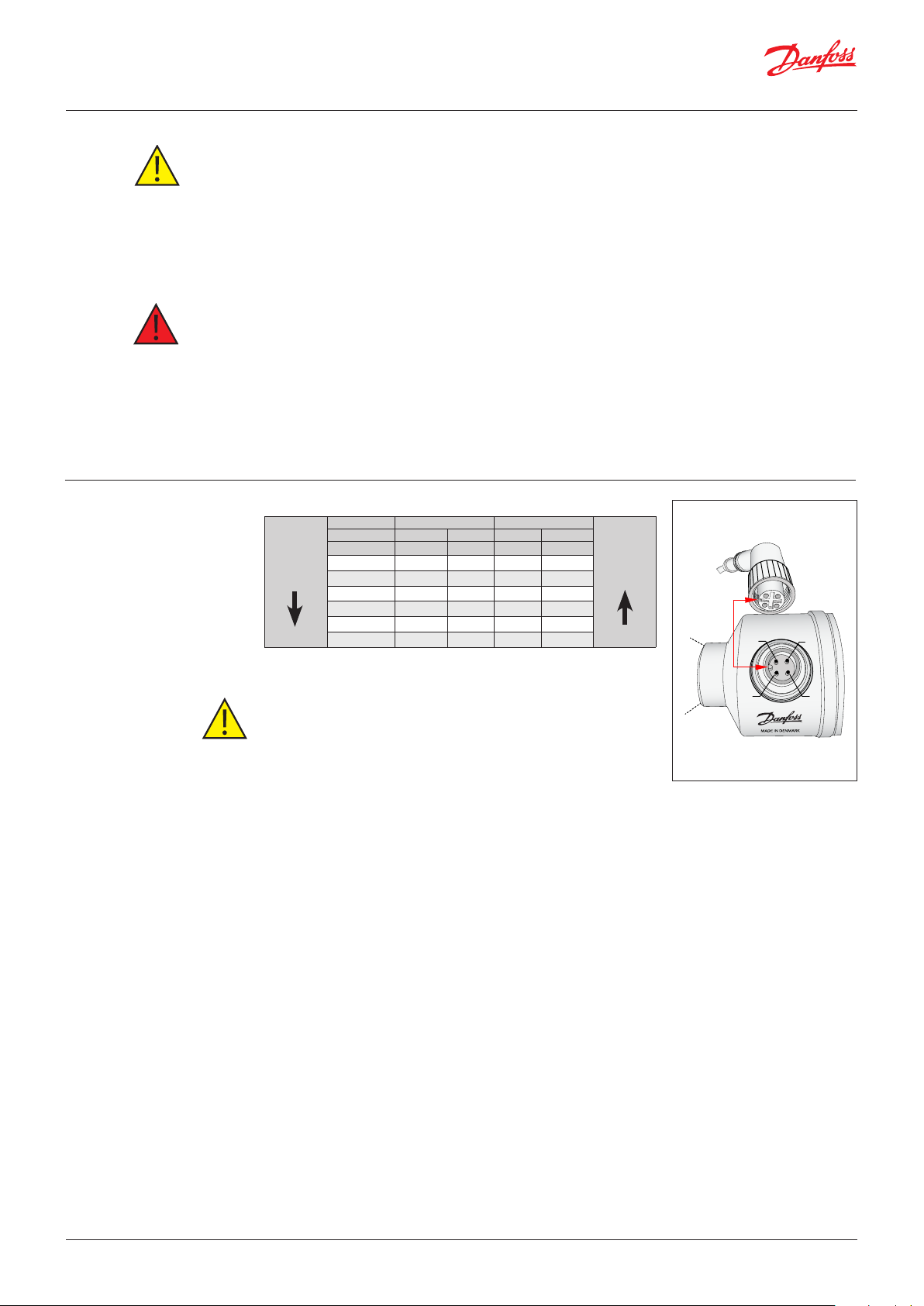

Ordering

Type

KV

value

[m3/h]

CV

R410A R407C R1234ze R134a R290 ODF × ODF (A × B)

value

[gpm]

[kW] [TR] [kW] [ TR] [kW] [TR] [kW] [ TR] [kW] [TR] [in] [mm]

Rated capacity1) Connection

Code no.

single pack

Code no.

I-pack

12 pcs.

Without sight glass

0.8 0.9 91.4 26.4 83.0 23.9 46.8 13.5 59.4 17.1 79.7 23.0 ½ × ½ - 034G7500 034G7510

ETS 12C

0.8 0.9 98.1 28.3 89.1 25.6 50.3 14.5 63.7 18.4 85.6 24.75/8 × 5/816 × 16 034G7501 034G7511

0.8 0.9 105 30.2 95.1 27.3 53.6 15.4 68.0 19.6 91.3 26.37/8 × 7/822 × 22 034G7502 034G7512

1.3 1.5 129 37.3 117 33.7 66.2 19.1 83.9 24.2 113 32.5 ½ × ½ – 034G7900 034G7910

ETS 24C

1.3 1.5 138 39.7 125 35.9 70.4 20.3 89.3 25.7 120 34.65/8 × 5/816 × 16 034G7901 034G7911

1.3 1.5 170 49.2 155 44.5 87.3 25.1 111 31.9 149 42.87/8 × 7/822 × 22 034G7902 034G7912

With sight glass

ETS 25C 1.3 1.5 170 49.2 155 44.5 87.3 25.1 111 31.9 149 42.87/8 × 7/822 × 22 034G7602 034G7612

2.4 2.8 323 93.3 294 84.5 166 47.7 210 60.5 282 81.37/8 × 7/822 × 22 034G7700 034G7710

ETS 50C

2.4 2.8 323 93.3 294 84.5 166 47.7 210 60.5 282 81.37/8 × 11/822 × 28 034G7701 034G7711

2.4 2.8 323 93.3 294 84.5 166 47.7 210 60.5 282 81.3 11/8 × 11/828 × 28 034G7702 034G7712

2.4 2.8 323 93.3 294 84.5 166 47.7 210 60.5 282 81.3 11/8 × 13/828 × 35 034G7703 034G7713

5.0 5.8 635 183 577 166 325 93.7 413 119 554 160 11/8 × 11/828 × 28 034G7800 034G7810

ETS 100C

5.0 5.8 635 183 577 166 325 93.7 413 119 554 160 11/8 × 13/828 × 35 034G7801 034G7811

5.0 5.8 635 183 577 166 325 93.7 413 119 554 160 1 3/8 × 1 3/835 × 35 034G7802 034G7812

5.0 5.8 635 183 577 166 325 93.7 413 119 554 160 1 5/8 × 1 5/8- 034G7803 034G7813

1

) The above estimated capacities, are based on the following conditions:

Evaporating temperature te : 5 °C / 40 °F

Liquid temperature tl : 28 °C / 82 °F

Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal flow direction

Capacity is ± 10% in full open state in reverse flow direction

Identification

(laser engraved data)

Coolselector®2

is a Danfoss calculation and selection software, designed to make selection processes for all

refrigeration projects easier and less time consuming.

For fast and precise selection of valve, use Danfoss’ CoolSelector2® software.

You can download it from http://coolselector.danfoss.com

Made in Denmark : Country of origin

Colibri® Electric Expansion valve : Valve name

ETS XXXC : Valve type

N0317A (Manufacturing no.) : N = Nordborg, Denmark

03 = week

17 = 2017

A = Monday

10 Ω, 800 mA peak : Motor resistense, current

PS 50 bar / MWP 725 psig : Max. working pressure

-40/+70 °C / -40/+158 °F : Refrigerant temperature

034GXXXX : Code number

: Approvals

089

: QR code

(with traceable serial no.)

Danfoss, 6430 Nordborg,

Denmark : Manufacturer address

MADE IN DENMARK

Colibri® Electric

Expansion valve

ETS XXXC

N0317A

10 Ω, 800mA peak

PS 50bar / MWP 725psig

-40/+70°C / -40/+158°F

034GXXXX

089

Danfoss, 6430 Nordborg,

Denmark

GREEN: DRY

© Danfoss | DCS (rm) | 2019.09

MADE IN DENMARK

Colibri® Electric

Expansion valve

ETS XXXC

N0317A

10 Ω, 800mA peak

PS 50bar / MWP 735psig

-40/+70°C / -40/+158°F

034GXXXX

GREEN: DRY

YELLOW: WET

YELLOW: WET

NormalReverse

Danfoss

Reverse Normal

Valid for ETS 25C, ETS 50C, ETS 100C

DKRCC.PD.VD1.E7.02 | 3

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

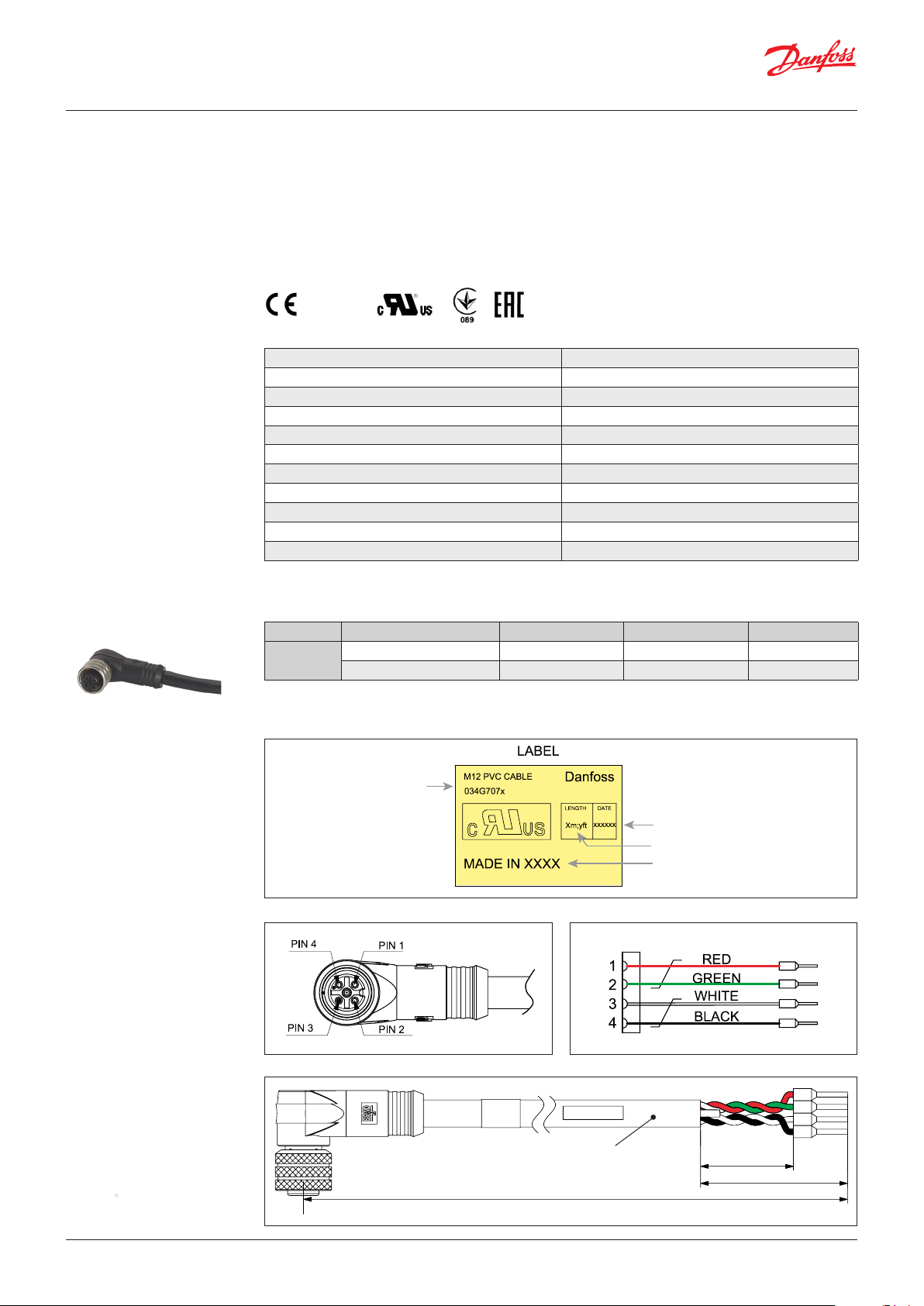

Accessories:

M12 angle cable

Approvals for cable

Specification

M12 angle female connector is intended for use with a standard M12 male connector, available on

stepper motor valves.

This cable is designed to offer high flexibility and small outer diameters with tensile strength.

The angle way M12 cable consist of paired, twisted wires, which decreases mutual influence between

signals transmitted along the cable and reduces influence of external sources of interference. The

cables thus provides a higher degree of protection against lost steps compared to other cables.

RoHS

Jacket PVC - black

Cable outer sheath Oil - resistant

Water proof rating IP 67

Operating temperature range -40 – 80 °C

Wire type Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter 7.0 mm

Minimum bending radius 10 x cable diameter

Cable combustibility / test Flame retardant / VW-1 / CSA FT - 1

M12 standard EN 61076-2-101

Reference standard UL style 2464 and DIN VDE 0812

LVD directive 2014/35/EU

Ordering

Identification

Connections

Cable Cable length (L) Insulation Packing format Code no.

PVC - black

A2 black

A1 white

2 + 0.089 m / 6.6 + 0.3 ft SR-PVC Single pack 034G7073

8 + 0.3 m / 26.2 +1 ft SR-PVC Single pack 034G7074

Product type

Code no

Manufacturing date

Meters / Feets

Country

B1 red

B2 green

34G210.10

34G211.10

Dimensions

© Danfoss | DCS (rm) | 2019.09

34G209.10

Ø 63 mm / 1/4 inch

2 + 0.089 meters / 6.6 + 0.3 feet

8 + 0.3 meters / 26.2 +1 feet

35 mm / 1.4 inch

49 mm / 1.9 inch

DKRCC.PD.VD1.E7.02 | 4

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

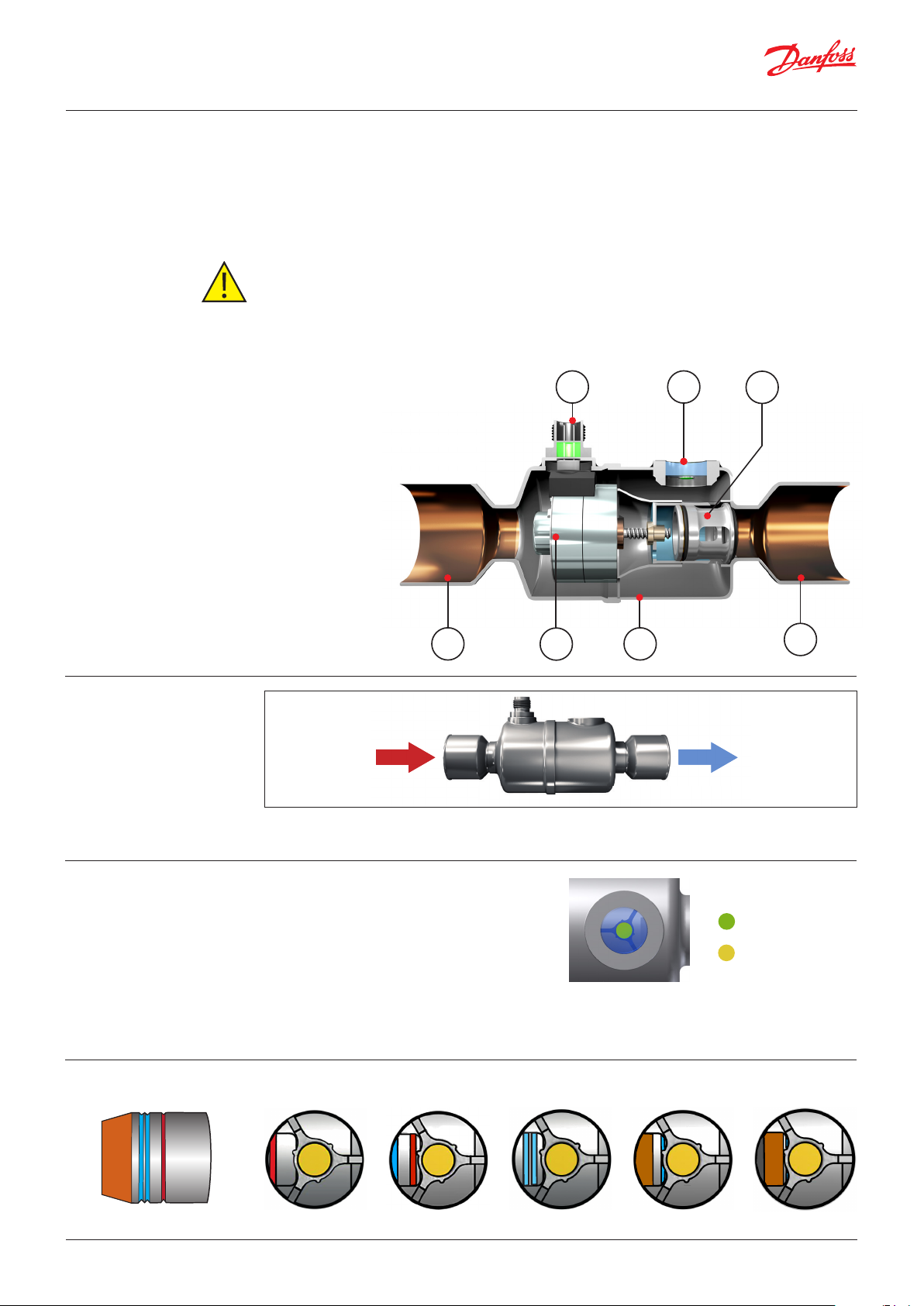

Design and function

The ETS Colibri® in-line electronic expansion valve

regulates refrigerant flow by means of an internal cage

slider which moves in a linear motion. This occurs by

the rotation of a spindle assembly which moves when

electrical pulses are applied to the motor.

The direction of the rotation of the spindle depends on

the phase relationship of the power pulses.

Cable length

Depending on the type of controller or driver, there will be limitations in cable length between the

controller / driver and the valve.

Both the actual cable length, the level of EMC emission on the location and the driver circuit have an impact on the

actual distortion of the current to the motor. On using 3rd party longer cable, make sure that the valve receives the

exact current as defined in the specification.

1. Valve body in stainless steel

2. Connections in bi-metal

3. Sight glass with moisture indicator

4. M12 electrical connection

5. Stepper motor

6. Cage and slider

The valve design is pressure balanced, giving identical

bi-flow performance capabilities and nearly identical

maximum capacities.

Operating the ETS Colibri® series requires a controller

that can provide 800mA peak/ 600mA RMS current per

phase in order to achieve the operational temperature

and MOPD envelope of the valve.

4 3

6

Flow direction

Valve design

Valve opening position

(Valid for ETS 25C - ETS 100C)

2

5

1

A

Flow direction from A to B refers the normal flow.

Sightglass for flash gas detection can only be used in normal flow direction.

Sight glass and indicator

ETS 25C, ETS 50C and ETS 100C have integrated

sight glass with moisture indicator. The presence

of the sight glass provides the availability to

check the physical position of the slider in

the valve. It also helps to determine the flow

direction of the refrigerant in the system.

Insufficient sub cooling can produce flash gas

which is visible through the sight glass. The

moisture indicator in the sight glass indicates dry

or wet state of the refrigerant by changing colour.

0% open 25% open 50% open 100% open75% open

2

B

Moisture indicator

Green = dry

Yellow = wet

© Danfoss | DCS (rm) | 2019.09

The colors of the grooves are only for illustration purposes

DKRCC.PD.VD1.E7.02 | 5

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

Flow curve

ETS Colibri. Capacity Vs Opening %

ETS Colibri Capacity Vs Opening %

450

400

Fully open

Partially open

Partially open

Fully closed

350

300

250

200

Capacity [KW]

150

100

50

0

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Opening Degree [%]

Danfoss

34G161.20

For R134a

The above estimated capacities, are based on the following conditions:

- Evaporating temperature te : 5 °C / 40 °F

- Liquid temperature tl : 28 °C / 82 °F

- Condensing temperature tc : 32 °C / 90 °F

Full stroke opening in normal flow direction. Capacity is ± 10% in full open state in reverse flow direction.

ETS 12C ETS 24C, ETS 25C ETS 50C ETS 100C

7/8 x 7/8 in 7/8 x 7/8 in

Opening degree [%]

Driving Colibri® valve

with 3rd party controller

ETS Colibri valves use a bipolar, 2-phase, permanent magnet stepper motor.

ETS valves can be driven using various electronic control techniques i.e: Full step excitation mode, half

step excitation mode, micro stepping mode (recommended).

On selecting controller from other manufacturer than Danfoss, it is necessary to set the following

correct valve data into the controller setting. The wrong settings may impair the performance of the

valve.

a. Total no. of steps - 600 full steps (or equivalent steps based on excitation mode, e.g 1 full step = 2

half steps)

b. Step rate

For current control driver:

Step type: Microstep (1⁄4 th or higher): 240 full steps/sec. recommended

Step type: Full step or Half steps: 240 full steps/sec. recommended Emergency close : 240

full steps/sec.

c. Phase current

Always use full current of 600 mA RMS (800mA Peak) for driving ETS Colibri when possible. For

application that requires lower MOPD or moderate operating temperatures, it is possible to drive

ETS Colibri with low driving current . See below guideline for details.

d. Overdriving against closing position

1% (i.e 6 full steps) Overdrive is recommended for optimum performance initialization during

startup, 628 steps in closing direction recommended for initialization

Overdriving in open position is not allowed.

e. Holding current

No permanent holding current needed. Max. 20% permanent holding current allowed with

refrigerant flow through valve

For optimal performance, driver should keep 100% current on coils 10ms after last step

For controllers with limited driving current, it will be good to have some holding current.

© Danfoss | DCS (rm) | 2019.09

ETS Colibri guideline for using low current in 3rd party controllers, for low operating conditions.

MOPD

Evaporting

temperature

Bar Psig (°C) (°F) (°C) (°F)

Condensing

temperature

Current rating

RMS

(mA)

Peak

(mA)

AC (Cooling only) 30 435 0 32 60 140 250 353

Reversible Chiller 30 435 -20 -4 50 122 300 423

Heat Pump 40 580 -30 -22 65 149 375 530

Refrigeration 30 435 -30 -22 60 140 300 423

* Operating conditions stated above are evaluated on refrigerants like R32/R410A for Chiller/Heat pump and R448A/R449A for

Refrigeration.

DKRCC.PD.VD1.E7.02 | 6

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

Important notes:

1. It is always best to use the highest possible current achievable in the controller while going below

standard phase current.

2. Use lower speed rates to achieve higher torque while lowering the Phase current.

3. Customer must evaluate the performance of the system while using ETS Colibri with lower phase current and

with 3rd party controllers.

4. All qualification testing of performance, robustness and reliability of Colibri has been conducted on 600mA RMS

capable current drivers.

If the controller driving the ETS Colibri valve is from another manufacturer than Danfoss or a custom

design, the following points must be considered in order to overcome potential step loss.

To ensure total closing of the valve, and to compensate the lost steps after a defined number of

changes in opening degree the controller should have a function to overdrive the valve in the

closing direction. It is recommended to overdrive the valve at appropriate intervals as specified in the

specification table.

At power failure the ETS valve will remain in the actual opening position it has at the moment of

power failure, unless a device in the form of a battery backup to the controller is installed.

Stepper motor

switch sequence

The following table shows the full step excitation switching sequence

Pin A 1 A 2 B 1 B 2

Wire color

STEP

CLOSING

Color code is only valid for Danfoss M12 cable

1 + - + 2 + - - +

3 - + - +

4 - + + 1 + - + -

Coil A Coil B

White Black Red Green

OPENING

Electrical check of stepper motor and wiring:

coil A and coil B = 10 Ω at 20 °C / 68 °F

M12 connector

B1

B2

Danfoss

34G152.10

A2

A1

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.VD1.E7.02 | 7

A1 B1

excited excited excited excited

Stator

Plain view

Enlarged view

Rotor

Stepper motor

A1 B2 A2 B2 A2 B1

A2

A1

B1

B2

Danfoss

R64-2110.11

A1

Rotor

S

N

N

N

N

N

N

N

N

N

N

N

N

N

N

S

S

S

S

S

S

S

S

S

S

S

S

N

S

S

S

S

S

N

N

N

N

N

A1

A1

A2

A2

B2

B2

B1

B1

B1

B2

B1

A1

A2

N

N

N

S

N

N

S

S

B1

B2

B1

A1

A2

N

N

N

S

N

N

S

S

B1

B2

B1

A1

A2

N

N

N

S

N

N

S

S

B1

B2

B1

A1

A2

N

N

N

S

N

N

S

S

Opening

Closing

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

Operation principle

This section explains the operation of the two phase full step excitation method in a bipolar stepper

motor. Fig. 1 shows the simplified diagram of a rotor and a stator. The Full stepping operation is

summarized below.

When a current in a form of a pulse flows to a given phase, that phase of the stator is excited as shown

in Fig. 2.

1. On exciting Phases B1 and A1 simultaneously, the permanent magnets on the rotor are moved in

the intermediate position between phase B1 and phase A1

2. When phases A1 and B2 are excited simultaneously, the rotor is then positioned between phases

A1 and B2

3. Next, by exciting the successive adjacent pairs of phases sequentially i.e phases B2 and A2, phases

A2 and B1, and phases B1 and A1, the rotor rotates through two phase excitations

4. By completely reversing the cycle in the following sequence phases B1 and A1 to phases A2 and

B1 to phases B2 and A2 to phases A1 and B2, the stepper motor then reverses its rotation

5. The stepper motor is stopped by holding the phase excitation for a specified period at the last

phase of forward or reverse rotation

Fig. 1.

Fig. 2.

Two phase full step excitation

ETS Colibri valves can also be driven by micro stepping excitation method (preferred) in addition to

the one explained above.

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.VD1.E7.02 | 8

Data sheet | Colibri® Electric expansion valves, type ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C

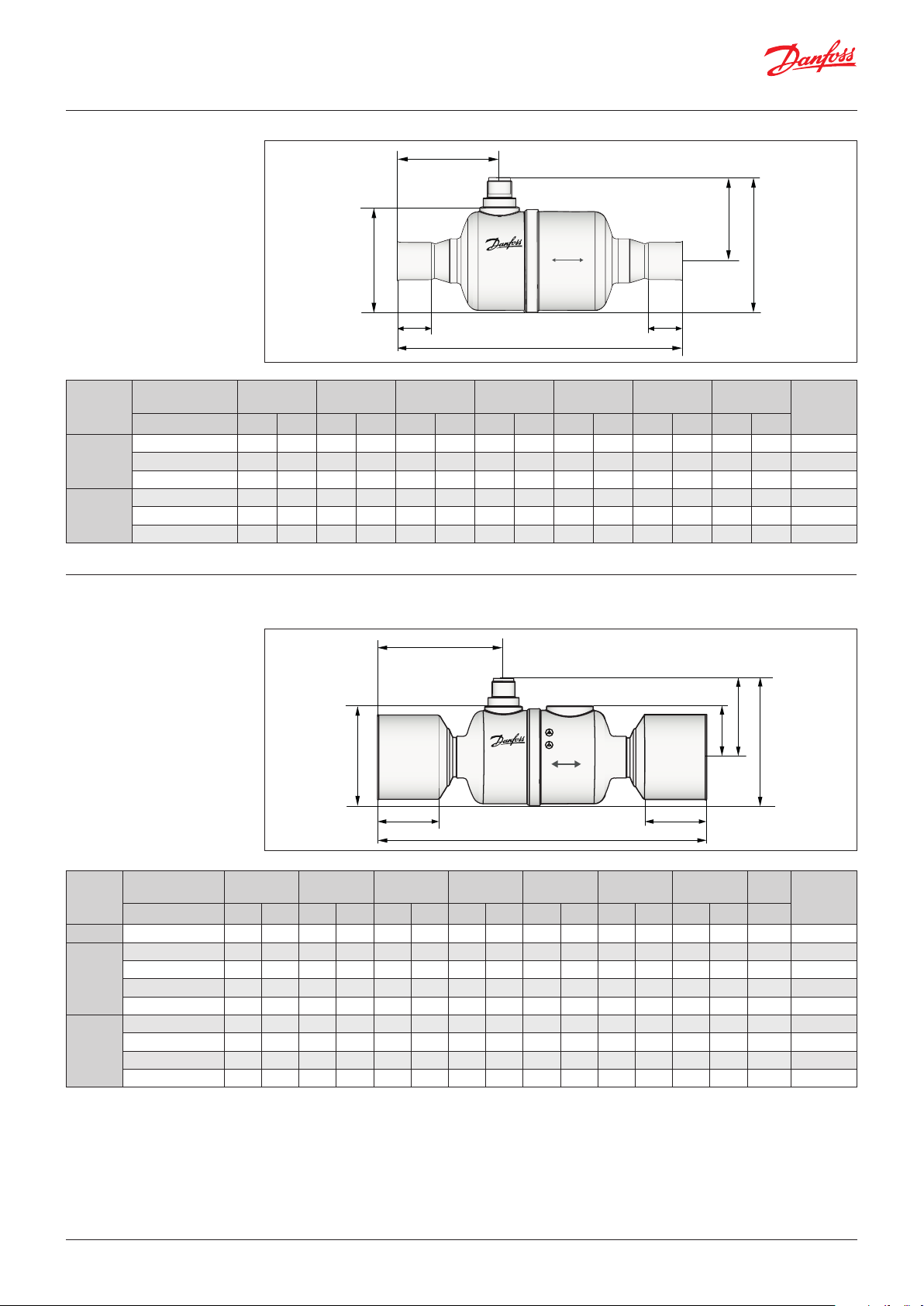

Dimensions

ETS 12C / ETS 24C

Connections

Typ e

ODF x ODF (A x B)

[in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in]

1

/2 x 1/

2

ETS 12C

ETS 24C

*) For the equivalent industrial p acked code number see the ordering sec tion

5

/8 x 5/

7

/8 x 7/

1

/2 x 1/

5

/8 x 5/

7

/8 x 7/

8

8

2

8

8

ØD1 L1 L2 L3 min L4 min H1 H2

49.9 2 122 4.8 41.6 1.6 9.5 0.3 9.5 0.3 65.6 2.6 40.7 1.6 034G7500

49.9 2 132 5.2 46.6 1.8 14.7 0.6 14.7 0.6 65.6 2.6 40.7 1.6 034G7501

49.9 2 135 5.3 48.4 1.9 20.0 0.8 20.0 0.8 65.6 2.6 40.7 1.6 034G7502

49.9 2 122 4.8 41.6 1.6 9.5 0.3 9.5 0.3 65.6 2.6 40.7 1.6 034G7900

49.9 2 132 5.2 46.6 1.8 14.7 0.6 14.7 0.6 65.6 2.6 40.7 1.6 034G7901

49.9 2 135 5.3 48.4 1.9 20.0 0.8 20.0 0.8 65.6 2.6 40.7 1.6 034G7902

L2

MADE IN DENMARK

ØD1

A

Colibri® Electric

Expansion valve

ETS XXXC

N0317A

10 Ω, 800mA peak

PS 50bar / MWP 735psig

-40/+70°C / -40/+158°F

034GXXXX

NormalReverse

L3 L3

L1

Danfoss

34G156.12

H2

H1

B

Danfoss

34G223.20

Code no. *)

ETS 25C, ETS 50C and

ETS 100C

ØD1

Connections

Typ e

ODF x ODF (A x B)

[in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [mm] [in] [kg]

ETS 25C

ETS 50C

ETS 100C

*) For the equivalent industrial p acked code number see the ordering sec tion

7

/8 x 7/

7

/8 x 7/

7

/8 x 1 1/

1 1/8 x 1 1/

1 1/8 x 1 3/

1 1/8 x 1 1/

1 1/8 x 1 3/

1 3/8 x 1 3/

1 5/8 x 1 5/

8

8

8

8

8

8

8

8

8

ØD1 L1 L2 L3 min L4 min H1 H2

49.9 2 135 5.3 48.4 1.9 20 0.8 20 0.8 65.6 2.6 40.7 1.6 0.31 034G7602

49.9 2 135 5.3 48.4 1.9 20 0.8 20 0.8 65.6 2.6 40.7 1.6 0.31 034G7700

49.9 2 137 5.4 48.4 1.9 20 0.8 20 0.8 65.6 2.6 40.7 1.6 0.32 034G7701

49.9 2 139 5.5 50.4 2 20 0.8 20 0.8 65.6 2.6 40.7 1.6 0.32 034G7702

49.9 2 147 5.8 50.4 2 20 0.8 25 1.0 65.6 2.6 40.7 1.6 0.33 034G7703

49.9 2 139 5.5 50.4 2 20 0.8 20 0.8 65.6 2.6 40.7 1.6 0.32 034G7800

49.9 2 147 5.8 50.4 2 20 0.8 25 1.0 65.6 2.6 40.7 1.6 0.33 034G7801

49.9 2 155 6.1 58.4 2.3 25 1.0 25 1.0 65.6 2.6 40.7 1.6 0.35 034G7802

49.9 2 169 6.7 65.4 2.3 30 1.2 30 1.2 65.6 2.6 40.7 1.6 0.37 034G7803

L2

GREEN: DRY

A

MADE IN DENMARK

Colibri® Electric

Expansion valve

ETS XXXC

N0317A

10 Ω, 800mA peak

PS 50bar / MWP 735psig

-40/+70°C / -40/+158°F

034GXXXX

YELLOW: WET

NormalReverse

B

L3 L3

L1

H3

Danfoss

34G222.20

H2

H1

Net

weight

Code no. *)

© Danfoss | DCS (rm) | 2019.09

DKRCC.PD.VD1.E7.02 | 9

Troubleshooting

Symptom Possible Cause Remedy

Lack of proper electrical connection • Check the connection between valve and a controller

• Check valve settings in controller i.e pre-selected valves, no. of steps,

phase current, direction of valve rotation, steps per second

• Check the resistance between coil A and coil B. Resistance in each

coil should be 10 ohms @20°C. Details on page 4

• Replace a complete valve

• Separate the cable from high power lines

• Check the maximum cable length allowed between the controller

and the valve

• For longer cable distance, use cable with bigger wire diameter

• Use cable filter

• Controller should overdrive the valve to compensate the lost steps

after a number of changes in opening degree

• Check the current/voltage supply from controller to valve

• Check the supply power to controller

• Check refrigeration system capacity and compare with expansion

valve capacity. Replace with larger valve if necessary

• Check superheat performance, the settings SH min and SH max.

in the super heat controller

• Check valve capacity

• Check ‘total number of steps’ defined in the controller

• Also check section ‘High Superheat’

• Check refrigerant

• Also refer to section Insufficient capacity

• Check the controller superheat settings and sensors connected to it

• Tune PID parameters in the controller

• Check refrigerant for flash gas ahead of expansion valve / external

subcooler

• If the valve is placed much higher than condenser outlet,

check pressure difference

• Limit max opening degree of the valve setting in controller

• Check refrigeration system capacity and compare with expansion

valve capacity. Use proper valve size suitable for the system

No valve movement

Internal leakage

(due to ‘Step Loss’)

Insufficient capacity

High superheat

Flash gas

Wrong parameter setting in controller

Broken motor/ short circuit

Insufficient power supply to valve • Check the current/voltage supply from controller to valve

Control pulse to valve is influenced by high

external electrical noise

Longer cable length between valve and

controller

Accumulated backlash in valve

Insufficient power supply to the valve

Expansion valve too small

Suction pressure too low

Evaporator superheat too high

Expansion valve blocked with foreign material • Remove and examine the valve

Evaporator wholly or partly iced up • De-ice evaporator

Lack of sub-cooling

Controller is not setup/tuned properly

Lack of sub-cooling ahead of expansion valve

Oversized valve selected

Related products

Code no. 034G0013

EKE 1A, EKE 1B, EKE 1C

superheat controller

All Danfoss products fulfill the requirements in REACH.

One of the obligations in REACH is to inform customers about presence of Candidate list substances if any, we hereby inform you about one substance on the candidate list:

A moist indicator in the sight glass contains a paper which is impregnated with Cobalt Dichloride (CAS no: 7646-79-9) in a concentration above 0.1% w/w.

Avoid skin contact with the paper - Do not inhale the dust from the paper - The paper must be disposed as hazardous waste.

© Danfoss | DCS (rm) | 2019.09

EKS 221, ACCPBT, AKS 11 / AKS 12

temperature sensor

AKS 32R, AKS 32, AKS 33, NSK

pressure transmitter

AST-G service driver

DKRCC.PD.VD1.E7.02 | 10

Loading...

Loading...