Page 1

Quick Start Guide

ogramming key – EKA 183B (080G9741)

(according to the product code number)

ERC 213

Overview

The ERC 213 is designed to be an easy, universal replacement control. We encourage users to employ one of five predefined applications that meet the

needs of most systems. If users need to modify specific parameters, it should be done after installing the predefined application that most closely meets

system needs.

For more information, including detailed instructions, error codes, parameters, and more,

visit www.danfoss.com/erc or download the Koolcode app from iTunes or Google Play.

For a video guide of the quick set-up, visit http://bit.ly/ERC213 or use the QR code located to the right.

Quick Set-up

STEP Action Screen Display

STEP 1 Wire control, to include power and sensors

Power up control

STEP 2

Energize control

Enter Quick Configuration Menu and Select app

Press ”<” for more than three seconds within one minute of power up to enter Quick Configuration Menu. o61 appears on screen

STEP 3

Press “set” while o61 is on screen AP0 flashes on screen

Select appropriate app using App Selection section below by pressing “ ” or “ ”, then press “set”. o06 appears on screen

Select Sensor

Press “set” while o06 is on screen n10 flashes on screen

STEP 4

If using included sensor, leave default value “n10”. If using another sensor, select using Sensor Resistance

section on opposing page or cycle through steps 2 – 4 changing the sensor type until the temperature reading

on the main screen is accurate. As above, cycle between options by pressing “ ” or “ ” and press “set” to save.

Set Temperature

STEP 5

From main screen, quickly press “set” (1 second). Current temp. setting appears on screen

Cycle to intended temperature by pressing “ ” or “ ” and press “set” to save. Screen returns to main screen

Control turns on, goes through start up,

then shows the current temperature reading

o06 appears on screen, then control resets

App Selection

Select application based on application and wiring configuration (i.e., refrigeration vs. freezing, and number of temperature sensors). The Typical Wiring

Configurations diagram on the reverse side of this document may be used to assist with selection. All parameters can be modified using the full menu.

Some parameters have min and max set points which may need to be changed for less common configurations.

Control

Application

Code

Application

Defrost

Type*

Defrost

Termination

Sensors

Default

Temp. [°F]

[r00]

Temp. Range

min. / max.

[r02/r03]

AP0 (Default) No preset application - full menu 2 36 -31 / 22 4 6 30 43

AP1 Refrigeration Natural Time 1 39 36 / 43 4 4 30 –

AP2 Refrigeration Electric Time 1 36 32 / 39 4 6 15 –

AP3 Freezing Electric Time 1 -11 -15 / -4 4 6 15 –

AP4 Refrigeration Electric Temp. 2 36 32 / 39 4 6 30 43

AP5 Freezing Electric Temp. 2 -11 -15 / -4 4 6 30 43

AP6 No preset application - simplified menu 2 36 -31 – 122 4 6 30 43

* Hot gas defrost is an option available in full menu (d01).

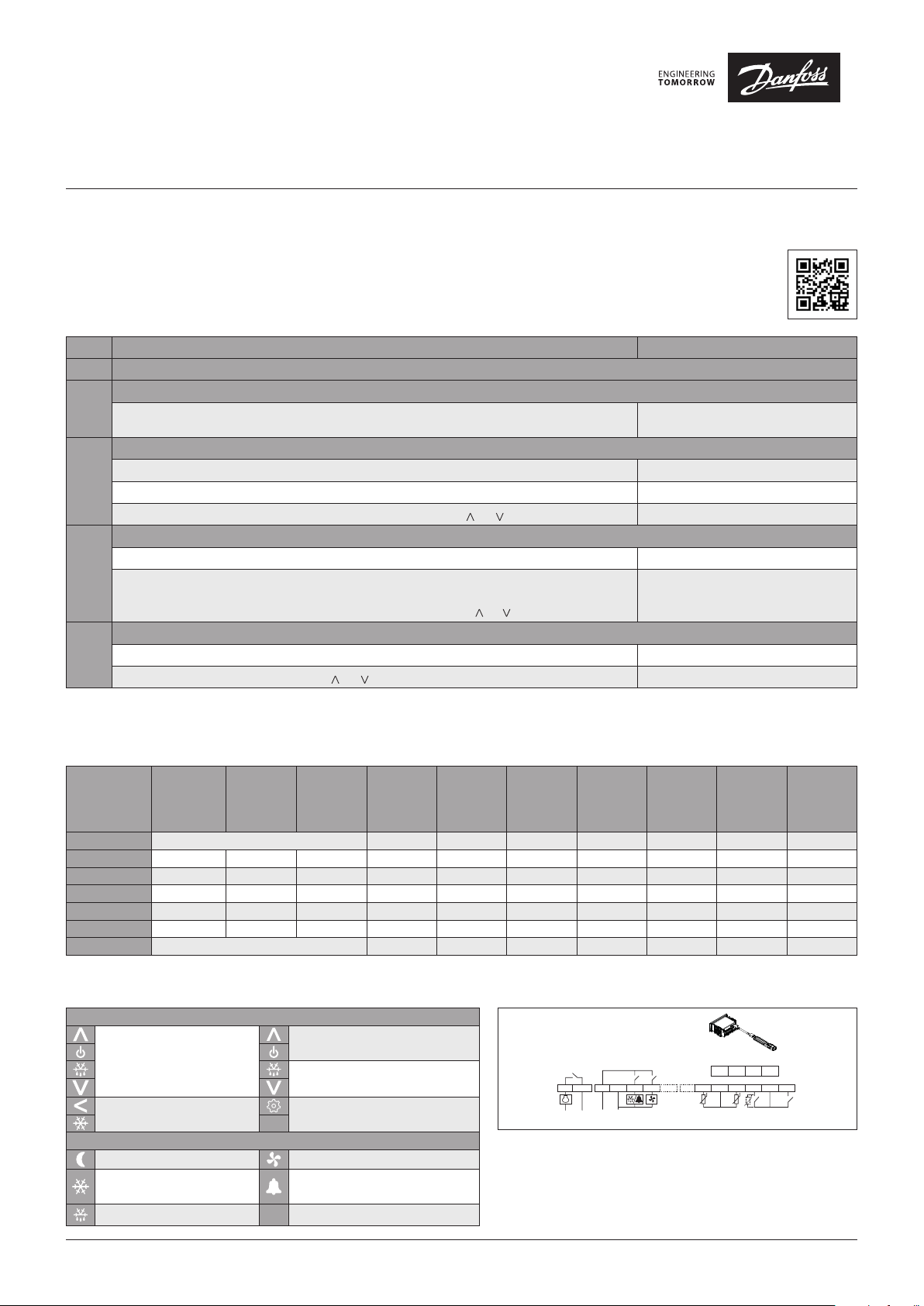

Key Functions and Display Icons

Key Functions

Press and hold at power up:

FACTORY RESET (“FAC” is

displayed)

Press for one second: BACK

Press and hold: PULL-DOWN

Display Icons

Night mode (Energy saving) Fan running

Compressor running (Flashes

in pull-down mode)

Defrost °C Unit (°C or °F)

SET

Press for one second: UP

Press and hold: ON / OFF

Press for one second: DOWN

Press and hold: DEFROST

Press for one second: TEMP. SETPOINT / OK

Press and hold: MENU

Active alarm

Connection Diagram

– Sair Control sensor

– S5 Defrost (evaporator) sensor

– SC Condenser sensor

– DI1 Digital input – configurable to the functions listed under

menu code o02

– DI2 Digital input – configurable to the functions listed under

menu code o37

© Danfoss | DCS (ADAP-KOOL®) | 2018-11

[°F]

Default Dif.

[°F] [r01]

DO1

12

3L 4N 5678

~~~~

Power supply

DO2 DO3

Defrost

Interval

[hrs]

[d03]

910

SairS5Sc/DI1 DI2

Max.

Defrost

Time [mins]

[d04]

Pr

GND TX RX +5V

15 16 17 18

GND GND

11 12 13 14

Defrost

Termination

Temp. [°F]

[d02]

DKRCE.PD.RL0.A3.02 | 1

Page 2

Quick Start Guide, ERC 213

(Control

Sensor)

115 V AC

230 V AC

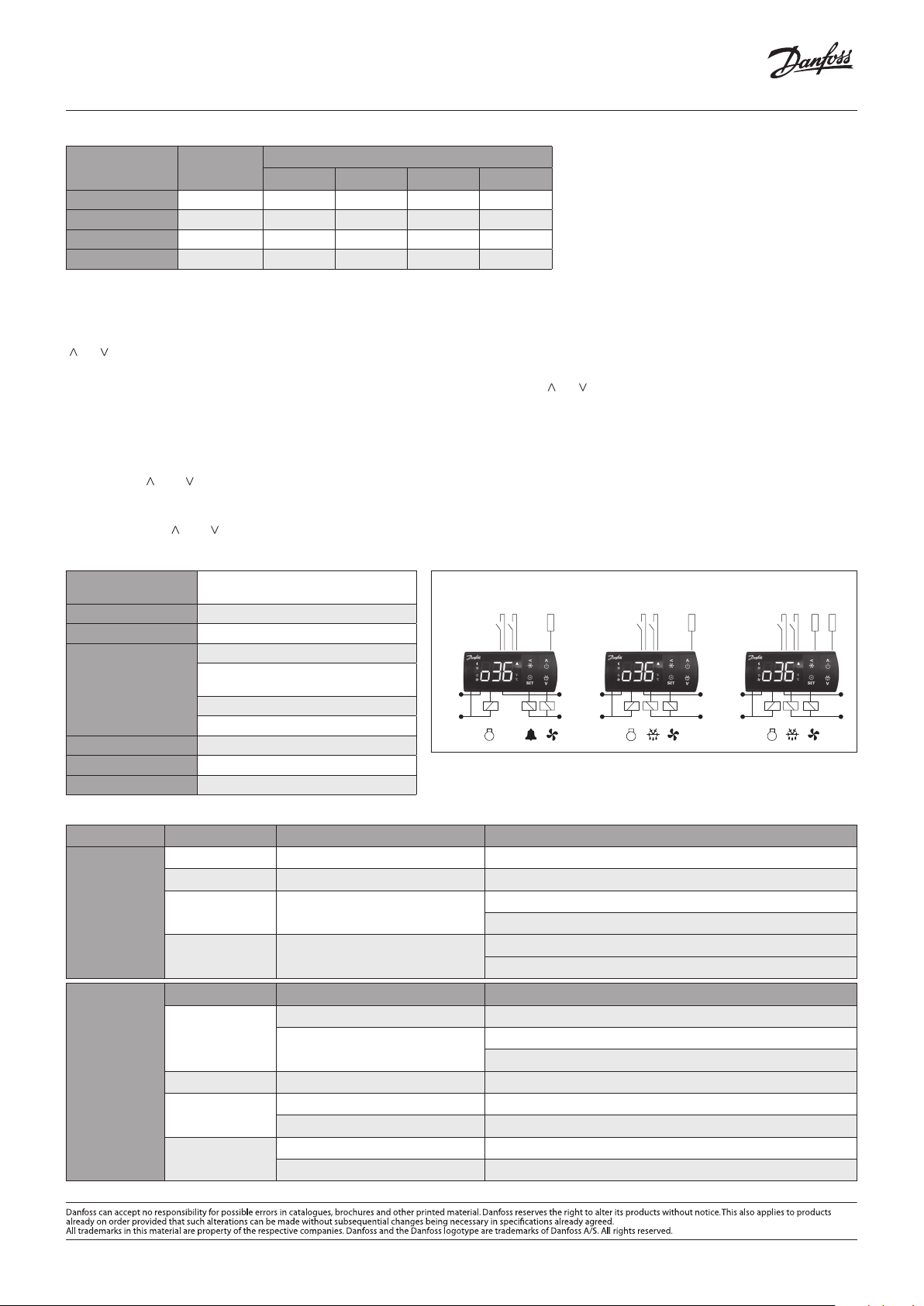

ERC 213 - APP 1 ERC 213 - APP 2-3 ERC 213 - APP 4-5

Sensor Resistance: Using an ohmmeter, you can measure resistance of a sensor to identify sensor type or to troubleshoot a potentially faulty sensor.

Sensor Type Code

PTC Ptc 690 761 807 980

PTC 1000 Pt1 931 974 1000 1093

NTC 10000 * n10 70317 40411 29481 10459

NTC 5000 n5 42664 23110 16325 5251

* Included in kit

Resistance [ohm] at Temperature [°F]

0 20 32 75

Common Functions

Adjust Temperature Set Point

From main screen, quickly press “set” (one second). The current temperature setting will appear on screen. Cycle to intended temperature by pressing

“^” or “^” and press “set” to save. The display will return to the main screen.

Adjust Differential

From main screen, press “set” for more than three seconds. Cycle to “r--” submenu by pressing “ ” or “ ” and press “set.” Cycle to “r01” and press “set.” Cycle to

preferred differential setting, and press “set” to save. “r01” will appear on screen. Press “<” twice to return to main screen.

Manual Defrost

From main screen, press defrost for more than three seconds to initiate defrost. The DEFROST icon is shown during defrost. Press defrost key for at least

three seconds to stop manual defrost.

Factory Reset

Press and hold “ ” and “ ” simultaneously at power up.

Unlock Keypad

After 5 minutes of no activity, the keypad will lock if P76 = yes (by default it is set to no). When the keypad is locked any key press shows “LoC”

in the display. Press “ ” and “ ” simultaneously for three seconds to unlock the keyboard. “unl” is displayed for three seconds.

Technical Specifications

Power Supply

Inputs 4 total; 2 analog, 1 analog / digital, 1 digital

080G3411 115V AC 50/60 HZ;

080G3412 230V AC 50/60 Hz

Typical Wiring Configurations

Sair

(Control Sensor)

DI1DI2

DI1DI2

Sair

(Control Sensor)

Sensor Included in Kit NTC 10000

D01 Compressor Relay

115 V (080G3268): 16 FLA / 72 LRA

Output

230 V (080G3269): 10 FLA / 60 LRA

D02 Defrost Relay and / D03 Fan Relay

8A, 2 FLA, 12 LRA

DO1

DO2 DO3 DO1 DO3DO2

115 V AC

230 V AC

Operating Conditions 14 – 131 °F

Storage Conditions -40 – 158 °F

Approvals UL Recognized / NSF

Troubleshooting

Power Supply Code Description Remedy (applicable parameter code in parenthesis)

A01 High temperature alarm Bring down temperature or increase high limit alarm limit (A13)

A02 Low temperature alarm Increase temperature or low temperature alarm limit (A14)

Common Alarm /

Error Codes

E27 Defrost sensor error

E29 Air temperature sensor error

Problem Likely Cause Remedy (applicable parameter number in parenthesis)

Waiting for compressor delay timer

Compressor does

not start

Defrost in progress

Common

Problems /

Resolution

Need additional help with programming, parameters, or error codes? Download Danfoss’ Koolcode app.

Defrost does not start

Wrong temperature

is displayed

Evaporator icing

Controller in pull down mode Check pull-down duration (r96)

Wrong type of sensor selected Verify that correct sensor type is selected (o06)

Sensor installed into incorrect terminals Verify that control sensor is wired into terminals 9 and 10 – 8 is not used

Defrost interval too long Reduce defrost interval (d03)

Defrost time too short Increase max. defrost time (d04)

Verify that defrost sensor is wired into terminals 10 and 11

Verify that correct sensor type is selected (o06)

Verify that control sensor is wired into terminals 9 and 10 – 8 is not used

Verify that correct sensor type is selected

Check compressor minimum off time (

CO2)

Check defrost interval (d03)

Check defrost on demand (temp. initiated defrost) (d19)

115 V AC

230 V AC

DI1DI2

DO1DO3DO2

S5

(Defrost)

Sair

2 | DKRCE.PD.RL0.A3.02

© Danfoss | DCS (ADAP-KOOL®) | 2018-11

Page 3

Quick Start Guide, ERC 213

Parameter sheet

Parameter Name Menu Code Unit Min. Value Max. Value Default Value Value

Predefined applications o61 – – – App0 App0

Sensor type o06 – – – n10 n10

Temperature Setpoint r00 °C -100 200 2 2

Differential r01 K 0.1 20 2 2.7

Min. set point limit r02 °C -100 200 -35 -35

Max. set point limit r03 °C -100 200 50 50

Display offset r04 K -10 10 0 0

Display Unit r05 – – – °C °F

Calibration of Sair r09 K -20 20 0 0

Night Set back r13 K -50 50 0 0

Offset reference displacement r40 °C -50 20 0 0

Pull down duration r96 min.. 0 960 0 0

Pull down temp limit r97 °C -100 200 0 0

Alarm delay - Normal conditions A03 min. 0 240 30 30

Alarm delay - pulldown / startup / def

High temp alarm A13 °C -100 200 8 8

Low temp alarm A14 °C -100 200 -30 -30

DI1 delay A27 min. 0 240 30 30

DI2 delay A28 min. 0 240 30 30

Condenser High temp alarm A37 °C 0 200 80 80

Condenser High block limit A54 °C 0 200 85 85

Voltage protection A72 – – – No No

Min. cut-in voltage A73 V 0 270 0 0

Min. cut-out voltage A74 V 0 270 0 0

Max. voltage A75 V 0 270 270 270

Defrost Method d01 – – – Electric Electric

Defrost stop temperature d02 °C 0 50 6 6.5

Defrost Interval d03 hour 0 240 8 6

Max. defrost Time d04 min. 0 480 30 30

Defrost delay at power up d05 min. 0 240 0 0

Drip delay d06 min. 0 60 0 0

Fan delay after defrost d07 min. 0 60 0 0

Fan start temp after defrost d08 °C -50 0 -5 -5

Fan ON during defrost d09 – – – On On

Defrost stop sensor d10 – – – None None

Comp accumulated runtime d18 hour 0 96 0 0

Defrost on demand d19 K 0 20 20 20

Defrost delay after pulldown d30 min. 0 960 0 0

Fan at compressor cutout F01 – – – FFC FAo

Fan stop evaporator temp F04 °C -50 50 50 50

Fan ON time F07 min. 0 15 2 2

Fan OFF time F08 min. 0 15 2 2

A12 min. 0 240 60 60

© Danfoss | DCS (ADAP-KOOL®) | 2018-11

DKRCE.PD.RL0.A3.02 | 3

Page 4

Quick Start Guide, ERC 213

Parameter Name Menu Code Unit M in. Value Max. Value Default Value Value

Compressor min. ON time C01 min. 0 30 0 0

Compressor min. OFF time C02 min. 0 30 2 2

Comp OFF delay at open door C04 min. 0 15 0 0

Zero crossing C70 – – – yes yes

Delay of outputs at startup o01 sec 0 600 5 5

DI1 configuration o02 – – – Off Off

Serial address o03 – 0 247 0 0

Password o05 – 0 999 0 0

Display Resolution o15 – – – 0.1 1

Relay 1 counter o23 – – – – 0

Relay 2 counter o24 – – – – 0

Relay 3 counter o25 – – – – 0

DI2 configuration o37 – – – Off Off

Display during defrost o91 – – – -d- -d-

DO2 Config o71 – – – def def

DI1 polarity P73 – – – no no

DI2 polarity P74 – – – no no

Invert alarm relay P75 – – – Normal Normal

Keyboard lock P76 – – – No No

Main switch r12 – – – Off On

Controller status u00 – – – S25 S20

Air temperature (Sair) u01 °C – – – 321

Present regulation reference u02 – – – 0

Evaporator temperature (S5) u09 °C – – – 0

DI1 status u10 – – – Off Off

Night mode u13 – – – Off Off

DI2 status u37 – – – Off Off

Condenser temperature (Sc) U09 – – – 0

Compressor relay status u58 – – – Off Off

Fan relay status u59 – – – Off On

Defrost relay status u60 – – – Off Off

Firmware version u80 – – – – 4.16

Database version – – – – – 4.02

Order No Low – – – – – 3502

Air temperature sensor(Sair) error E29 – – – Off On

Defrost sensor (S5) error E27 – – – Off Off

Condensor sensor(Sc) error E30 – – – Off Off

High temperature alarm A01 – – – Off Off

Low temperature alarm A02 – – – Off Off

High voltage alarm A99 – – – Off Off

Low voltage alarm AA1 – – – Off Off

High condenser temperature alarm A61 0 – – Off Off

Door alarm A04 0 – – Off Off

DI external alarm A15 0 – – Off Off

4 | DKRCE.PD.RL0.A3.02

© Danfoss | DCS (ADAP-KOOL®) | 2018-11

Loading...

Loading...