Page 1

User Guide

Bottle cooler controller

ERC 111

This reference manual is intended to be used primarily by OEMs for the purposes

of programming ERC 111. It may also be useful for technicians. It is not intended as

a user guide for end users.

www.danfoss.com/erc

Page 2

User Guide | ERC 111 Refrigeration Controller

Introduction

Application

Advantages

Approvals

Temperature control for refrigeration appliances.

Front panel mounting.

The latest generation CPU, plenty of memory

and high-end electronic components allow for

a uniquely versatile software. Three separate

password-protected user levels can be used to

control more than 300 different parameters to fit

all individual requirements.

R290/R600a end-use applications employing in

accordance to EN/IEC 60335-2-24, annex CC and

EN/IEC 60335-2-89, annex BB

Glow wire according to EN/IEC 60335-1;

IEC/EN 60730;

UL60730;

NSF,

CQC;

GOST R 60730.

Password protected

The access level can be set separately for each

parameter using "KoolProg Software".

There are three levels of access 1, 2, 3:

- level 1 is for shop access;

- level 2 for technicians;

- level 3 for OEMs.

The access levels cannot be set using the buttons.

Passwords for the different levels can however be

altered for the level of access you have,

e.g. a level 2 user can change the password for

level 1 and level 2 but not level 3.

2 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 3

User Guide | ERC 111 Refrigeration Controller

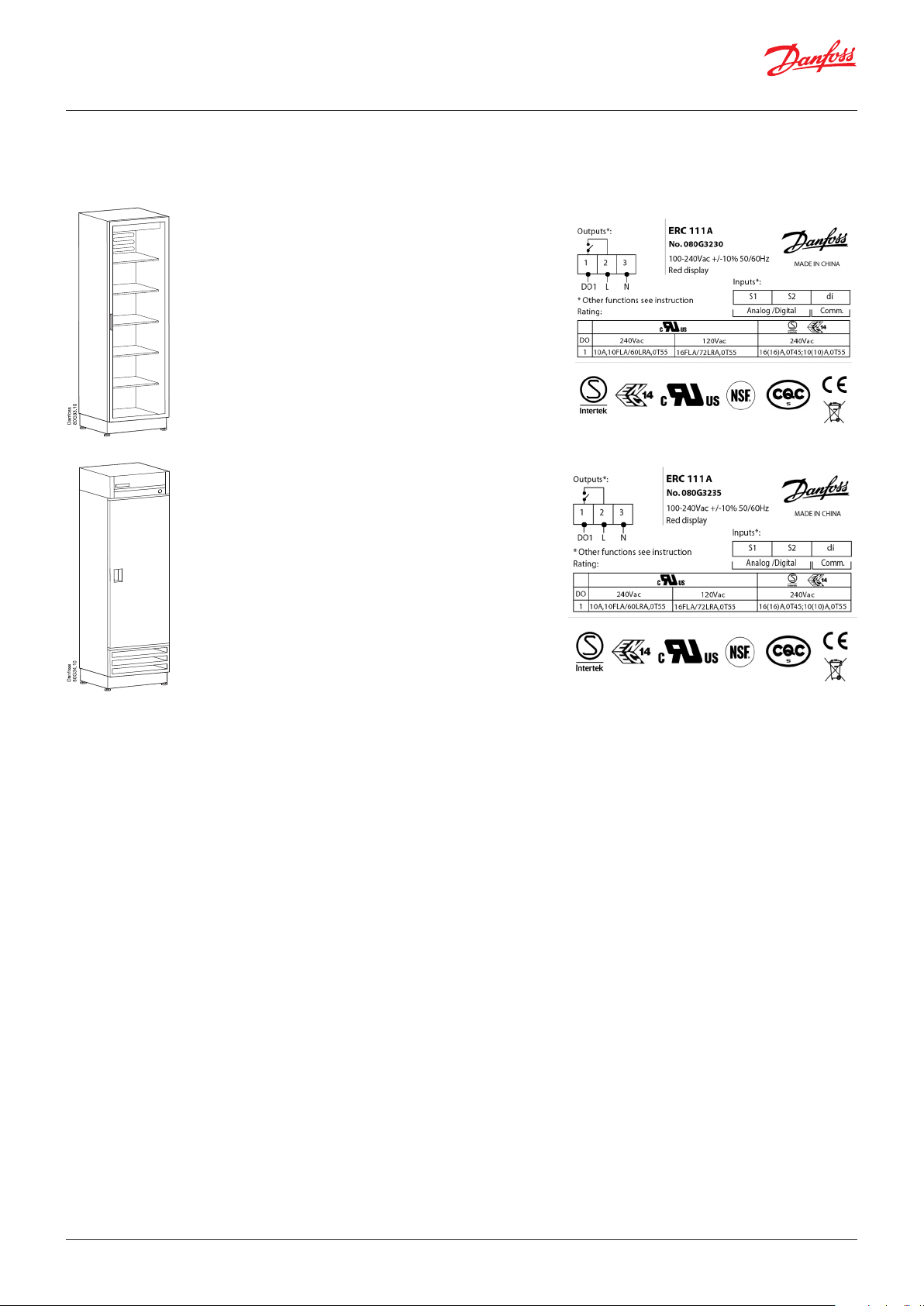

Typical application

Glass Door Merchandiser

Gastro cooler

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 3

Page 4

User Guide | ERC 111 Refrigeration Controller

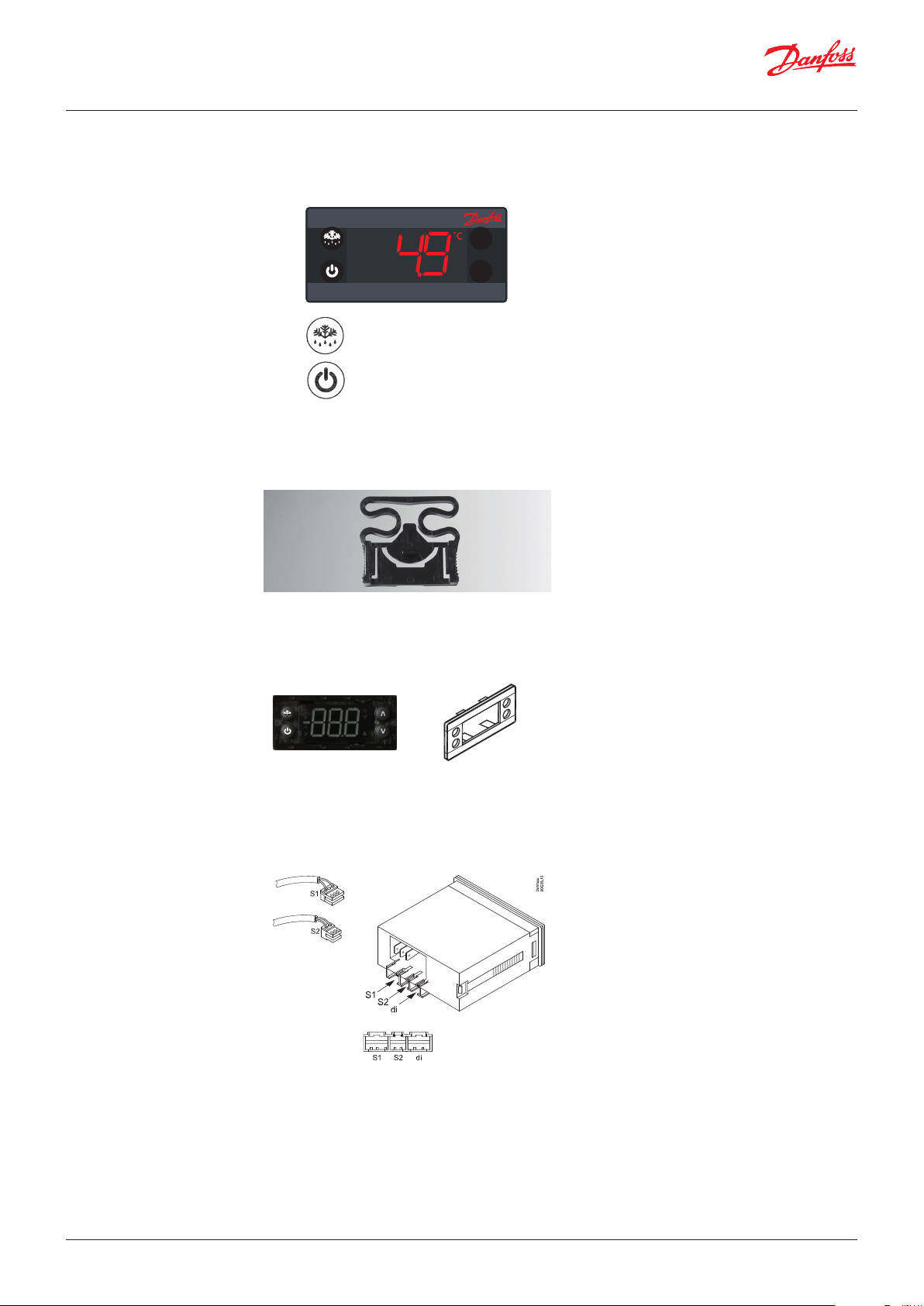

Product overview

Display

^

^

Buttons

Clips Are used to secure the controller in place in the

The ERC 111 is an electronic refrigeration

controller with an LED display especially

developed for bottle coolers and commercial

fridges and freezers. It is particularly suited for

OEM customers where time, easy and reliable

installation and high quality need to go hand in

hand with flexibility.

The display can be ordered in red or blue.

The controller is available with the upper left

button as "Defrost".

The lower left-button can be supplied with

"Stand by".

case of rear mounting. They are not used with

front mounting.

There are two identical clips, one placed on

either side of the controller.

Front frame

"S1"

Temperature sensor for

cabinet

"S2"

Temperature sensor for

defrost

At front mounting place the wired controller in

the hole. Then press the front frame in position.

The plastic lugs locks hereby the controller.

Controller without front frame Front fra me

Control temperature sensor

There are different lengths.

Defrost temperature sensor

Should be mounted on the evaporator.

The function of an input can be reprogrammed,

but the connector can not be moved.

The connector is designed to only one location.

"S1" to "S1", " S2" to "S2", etc.

4 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 5

User Guide | ERC 111 Refrigeration Controller

Quick programming

Software for PC

USB gateway

USB programming key

KoolProg

Software from Danfoss for programming the

ERC-controller via a PC rather than with the front

panel buttons.

https://www.danfoss.com/en/service-andsupport/downloads/dcs/koolprog/

USB gateway

The USB Gateway is a laboratory tool, offering

fast and easy programming of any ERC

controller connected directly to the PC.

"KoolProg Software" installation kit is provided

for the PC. The gateway is standard inventory

for OEM labs.

Programming an individual unit in a

laboratory

The USB key requires "KoolProg Software"

running on a PC. It enables parameters to be set

in real time and an array of status information to

be read (bidirectional connection).

Once the desired settings have been

determined, a specific parameter file is saved to

the USB key for later mass programming through

the docking station.

Docking station

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 5

Mass programming on an assembly line:

The docking station is used for high volume

programming of ERC controllers, for example on

an assembly line. The docking station is a

write-only device.

The USB key, is to be inserted into the docking

station. The settings are then loaded into each

successive controller in a matter of seconds.

"KoolProg Software" is not required for mass

programming.

Page 6

User Guide | ERC 111 Refrigeration Controller

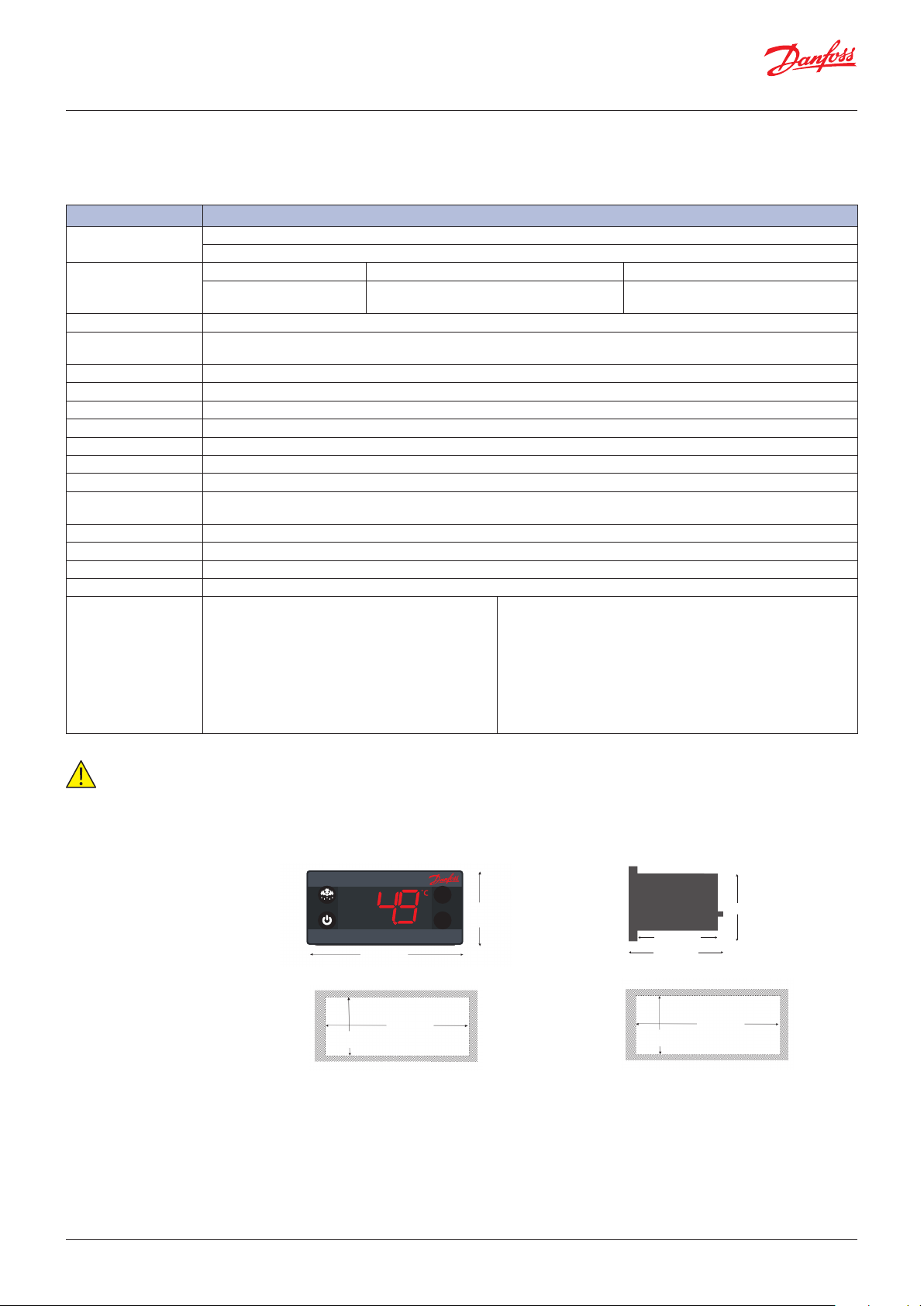

Technical specs

Power Supply 100 - 240 V AC Switch mode power supply. Average 0.7 W

Input

Output

Probes Danfoss NTC sensors and Danfoss ERC accessories

Connectors

Programming Programming with Danfoss KoolProg PC software, Docking station and Programming key

Assembly Front mounting; brackets; fully integrated solution (requires OEM specific design of mounting hole)

Display LED display, 3 digit, decimal point and multi functionality icons; °C/°F scale

Keypad 4 buttons (integrated IP65 design), 2 left, 2 right; user programmable

Operating Conditions 0 °C to 55 °C, 93% rH

Storage Conditions -40 °C to 85 °C, 93% rH

Range of Measurement -40 °C to 85 °C

Protection

Environmental Pollution degree II, non-condensing

Resistance to heat & fire Category D (UL94-V0)

EMC category Category I

Operating Cycles Compressor relay: more than 175,000 at full load (16A(16A))

Approvals

3 inputs: 2 analogue (digital), 1 digital; user specific assignment

• Air/evaporator/condenser

UL60730 EN60730

"DO1" (Compressor relay)

120 V AC: 16 A resistive/FLA16/LRA72

240 V AC: 10 A resistive/FLA10/LRA60

16(16) A

Modular connector system for OEM customers, with optional output screw terminal adapter;

Input connector type: Rast2 5 Edge connectors; output connector type: RAST 5 standard

Front: IP65

Rear: water and dust protection corresponds to IP31, accessibility of connectors limit rear part rating to IP00

R290/R600a end-use applications employing in

accordance to EN/IEC 60335-2-24, annex CC and EN/

These approvals are only valid when using the accessories listed in

this document

IEC 60335-2-89, annex BBGlow wire according to EN/

IEC 60335-1

IEC/EN 60730

UL60730

NSF

CQC

GOST R 60730

IMPORTANT NOTE

The inputs are not galvanic separated and are connected directly to the mains supply!

For that reason, door-switches, sensors as well as the cables must fulfil the reinforced insulation requirements.

Dimensions

^

36,5 mm

^

47,25 mm

78,25 mm

71 mm

28,5 mm

Front mounting

(Lock with frame)

51,25 mm

30 mm

Rear mounting

(Lock with clips)

28 mm

71 mm

6 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 7

User Guide | ERC 111 Refrigeration Controller

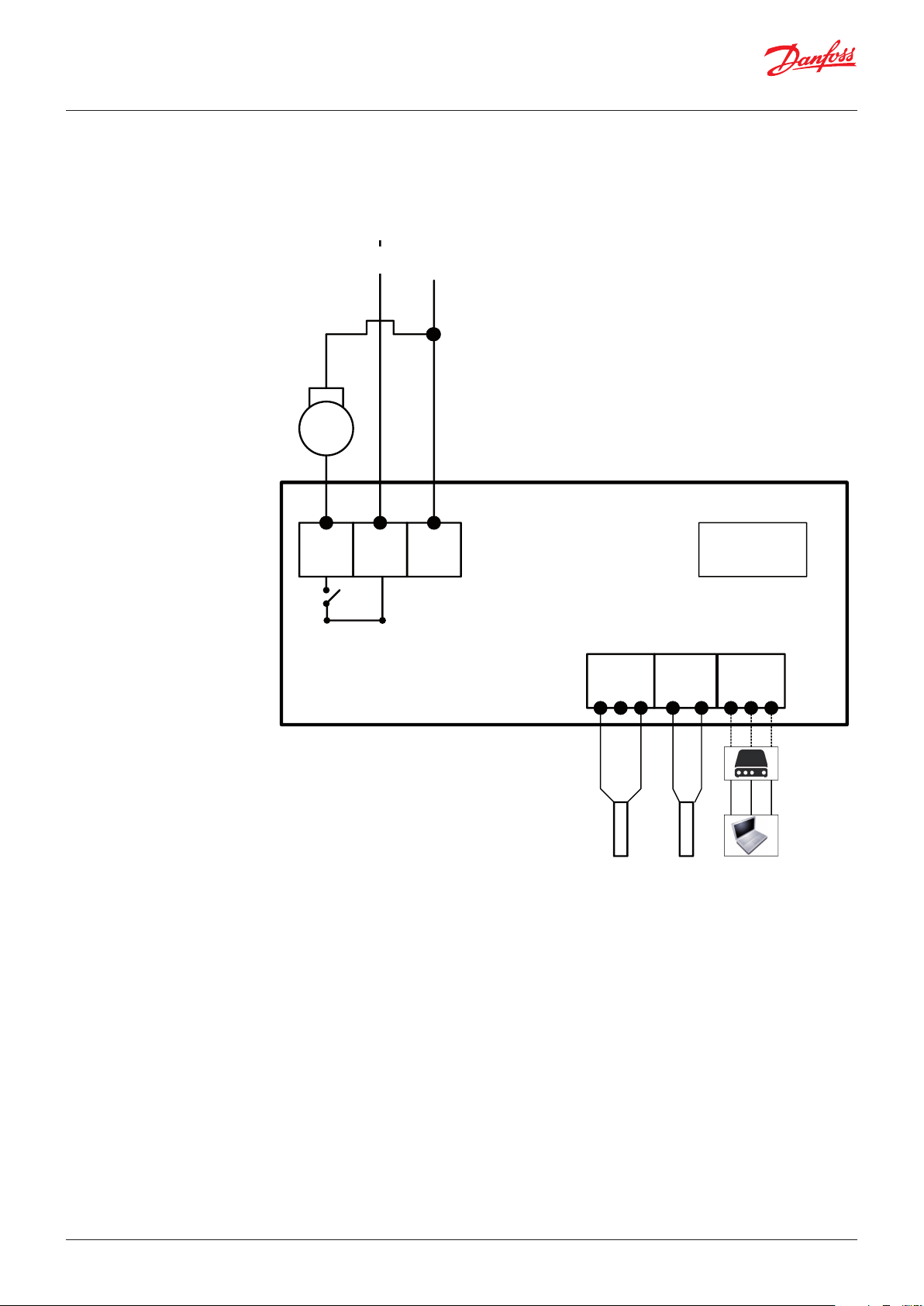

Connections

100 –240 VAC SMPS

Compressor

1 32

DO1

L

N

DO’s

ERC111A

Controller

diS1 S2AI/DI’s

Cabinet temp. sensor

Evaporator or condenser

temp. sensor

Gateway

Optional PC

communicaton

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 7

Page 8

User Guide | ERC 111 Refrigeration Controller

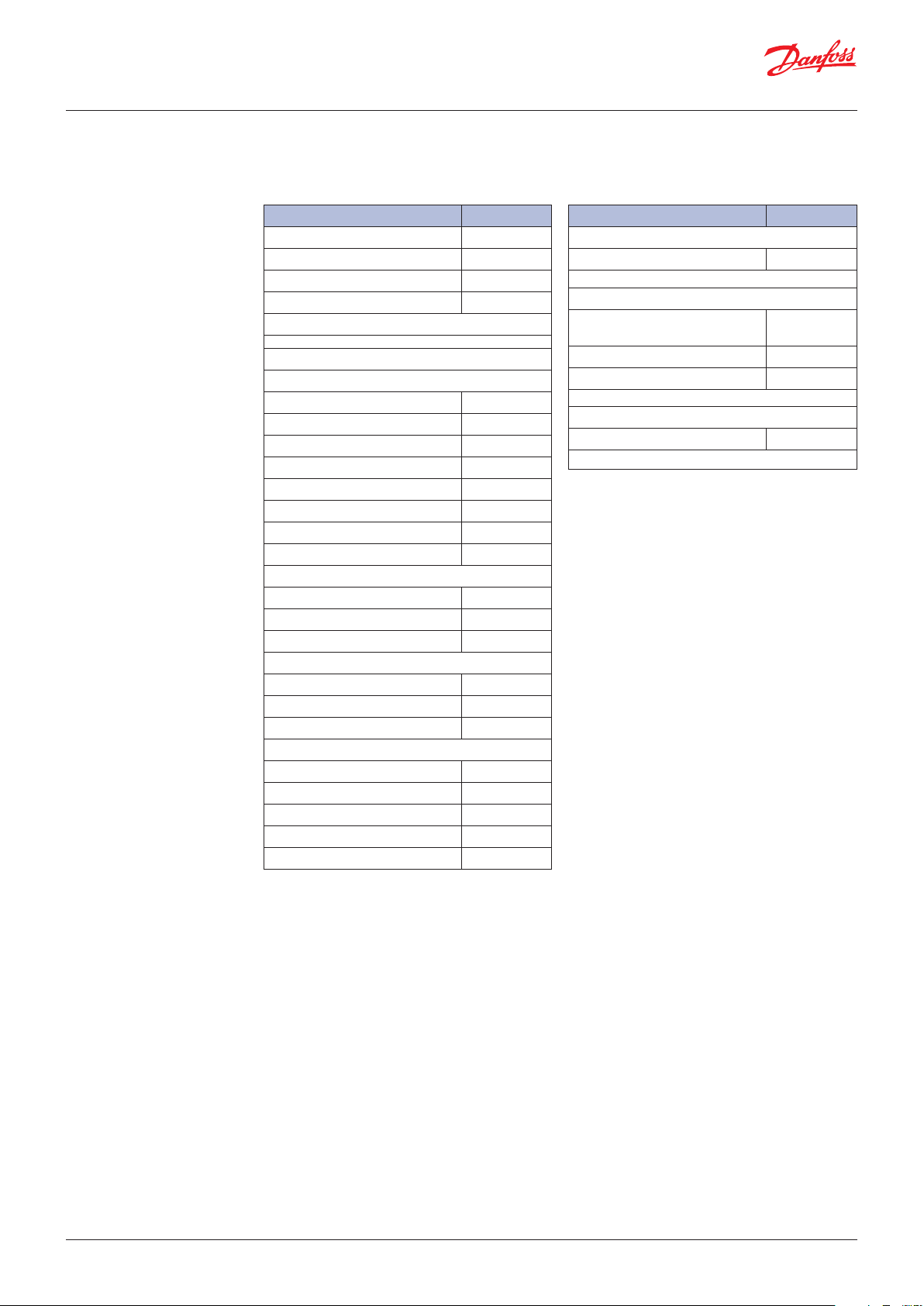

Code numbers

Type Code no. I-Pack

ERC 111, Red LED, without buzzer 080G3230

ERC 111, Blue LED, without buzzer 080G3231

ERC 111, Red LED, with buzzer 080G3235

ERC 111, Blue LED, with buzzer 080G3236

Version with buzzer is available only on demand

Temperature sensors

-40 – 85 °C, PVC Standard, NTC 5 K

S1, 470 mm, 3-pole 077F8751

S1, 1000 mm, 3-pole 077F8757

S1, 1500 mm, 3-pole 077F8761

S1, 2000 mm, 3-pole 077F8765

S1, 2200 mm, 3-pole 077F8767

S1, 3000 mm, 3-pole 077F8769

S1, 3500 mm, 3-pole 077F8723

S1, 6000 mm, 3-pole 080G2019

-40 – 120 °C, TPE precision NTC 5 K, Santroprene

S1, 1500 mm, 3-pole 077F8726

S1, 2000 mm, 3-pole 077F8727

S1, 3000 mm, 3-pole 077F8729

-20 – 175 °C, Silicone rubber cable, NTC 100 K

S1/S3, 1000 mm, 3-pole 080G2041

S1/S3, 2000 mm, 3-pole 080G2043

S1/S3, 3000 mm, 3-pole 080G2045

-40 – 85 °C, PVC Standard, NTC 5 K

S2, 1000 mm, 2-pole 077F8786

S2, 1500 mm, 2-pole 077F8790

S2, 2000 mm, 2-pole 077F8794

S2, 3000 mm, 2-pole 077F8798

S2, 6000 mm, 2-pole 080G2029

Type Code no. I-Pack

Clips

Black (2 needed per controller) 080G3308

Programming

OEM Docking station, production

line

Programming key EKA183A 080G9740

Gateway incl USB Cable for R&D 080G9711

Power Plug*

3-pole with screw 080G3356

*available optional plugs with screw connection are limited to 16A

080G9701

NOTE: For more information about temperature sensor

Sx (di)= connector position.

Inputs are configurable.

types and connectors, please refer to Danfoss’ technical

brochure "NTC type temperature sensors for ETC & ERC

controllers".

8 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 9

User Guide | ERC 111 Refrigeration Controller

Operation

KoolProg Software/Gateway

Docking station

Manual operation with

buttons (Direct Access)

Examples

The controller can be controlled in three ways:

Using "KoolProg Software", the Danfoss Docking

Station or manually by means of the buttons on

the front panel.

"KoolProg Software" is licenced Danfoss software

offering easy parameter set up via a USB gateway.

This software is supplied separately;

for technical literature and further information,

please contact your local Danfoss representative.

Docking station is supplied separately.

For further information, please contact your local

Danfoss representative.

1 Press: variable direct

function, e.g. defrost

Sub function: “back”

1 Press: variable direct

function, e.g. ON/OFF

Sub function: “OK”

Changing the Desired Temperature Set point:

1. The display shows the current temperature.

2. Press "up/down" to access set point.

3. Press "up/down" to adjust set point.

After 30 seconds, the display automatically

reverts to showing the current temperature

Acknowledging Alarms:

1. Display Flashing the alarm message.

2. Press any button to acknowlege.

Password protection:

1. Press "up/down" and hold 5 seconds to access

the menu.

2. The display shows "PAS".

3. Press "OK".

4. Press "Up/Down" to the code.

5. Press "OK".

Password protection on three levels:

1. Level 1: "shop" (daily use by shop personnel).

2. Level 2: "ser" (service technician).

3. Level 3: "OEM" (OEM programming).

1 Press: temperature set point

Sub function: “up”

^

^

1 Press: temperature set point

Sub function: “down”

Changing a Parameter

Some parameters may be hidden to you.

When scrolling through menus, the parameters

available will have been pre-determined using

"KoolProg Software".

Your access level will determine which

parameters you can view and edit:

1. Press "up/down" and hold 5 seconds to access

the menu.

2. First parameter group is shown "tHE".

3. Press "up/down" to find the desired group.

4. Press "OK".

5. First parameter is shown.

6. Press "up/down" to find the desired

parameter.

7. Press "OK".

8. Press "up/down" to find the desired setting.

9. Press "OK".

After 30 seconds, the display automatically

reverts to showing the current temperature.

Or Press 2 x "Back".

NOTE:

Incorrect parameter settings can lead

to inadequate cooling, excessive energy

consumption, unnecessary alarms and in the

case of temperature-sensitive food storage,

breaches in food hygiene principles and

regulations.

Only a trained operator should make changes to

parameters.

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 9

Page 10

User Guide | ERC 111 Refrigeration Controller

Menu/functions

ERC menu code Description

"tHE Thermostat settings

"SEt"

Min. -100.0°C

Max. 200.0°C

Default 2.0°C

"SPr"

Min. 0.0

Max. 1.0

Default 0.5

"diF"

Min. 0.0 K

Max. 20.0 K

Default 2.0 K

"HSE"

Min. -100.0°C

Max. 200.0°C

Default 50.0°C

"LSE"

Min. -100.0°C

Max. 200°C

Default -35.0°C

"iCi"

Min. no

Max. yes

Default no

Pud Pull Down settings

"PCy"

Min. 0 min

Max. 360 min

Default 30 min

"Pdi"

Min. 0 hour

Max. 48 hour

Default 15 hour

"Pdd"

Min. 0 hour

Max. 48 hour

Default 24 hour

"PLt"

Min. -55.0°C

Max. 55.0°C

Default 0.0°C

Set point

This parameter defines the desired temperature (set point)

In standard operation the set point is changed by simply pressing the

"temperature up/down" buttons on ERC 111; for laboratory and

assembly line you may opt for software controlled set point adjustment

(speed improvement)

Current set point adjustment value diF * SPr

The default value is set to 0.5 and the parameter is hidden by default.

"Spr" defines the position of the set point in relation to cut-in and cut-out

"Spr=0,5" sets the set point mid between cut-in and cut-out.

"Spr=0" sets the set point at the cutout. "Spr=1" sets the set point at cut-in

Thermostat differential

This defines the difference between the cut-out and the cut-in

The desired temperature is determined by "SPr" and "diF"

Upper limit of thermostat set point

Define the temperature range limit of the controller

Once set, the desired temperatue (set point) can not go above "HSE" or below "LSE"

Lower limit of thermostat set point

Define the temperature range limit of the controller

Once set, the desired temperatue (set point) can not go below "LSE"

Initial cut in

Comp relay action when Tair is between cut-in and cut-out at power-up:

"yES": cut in the compressor

"no": cut out the compressor

Pull down (sometimes known as Super Cool) is a procedure for improving

cooling performance, accelerating the time used to reach the desired

temperature. Pull down settings overrule all other settings.

Pull Down Cycling

This is the duration in minutes of the compressor cycling at the reduced

set point temperature. Once the desired pull down limit temperature

"PLt" has been reached during pull down, the compressor will continue to

cycle ON/OFF for the duration of "PCy". At the end of the period defined by

"PCy", the set point temperature will return to normal and pull down will

cease.

Pull Down Defrost Interval

Even though most applications do not need Defrost during pull down, an

extended defrost during pull down can be applied. This is the time

between defrost cycles during pull down. It is measured in hours and can

be up to 48 hours. During pull down, this setting overrides the defrost

interval and defrost time settings (see the defrost section).

Pull Down Duration

You can choose to limit the maximum pull down time. Once this time

value (max. 48 hours) is reached, pull down will stop regardless of

whether the desired pull-down temperature has been reached.

Pull Down Limit Temperature

This parameter sets the minimum allowed temperature during pull-down.

In order to protect valuable contents you must always specify the absolute

minimum temperature allowed in your application.

For glass door merchandisers 0°C/32°F protects bottles from freezing;

for commercial fridges you may opt for a slightly higher temperature

(e.g. 2°C)

10 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 11

ON ON

User Guide | ERC 111 Refrigeration Controller

dEF Defrost settings

"dFt"

Default no

Defrost Type

"no": defrost function is disabled.

"nat": OFF-cycle defrost (natural defrost).

"Add"

Min. no

Max. yes

Default no

"dtt"

Min. 0.0°C

Max. 25.0°C

Default 6.0°C

"drt"

Min. 0.0°C

Max. 200.0°C

Default 5.0°C

"dii"

Min. 1 hour

Max. 96 hour

Default 6 hour

"dAi"

Min. 1 hour

Max. 96 hour

Default 7 hour

"dit"

Min. 0 min

Max. 240 min

Default 5 min

"dAt"

Min. 0 min

Max. 480 min

Default 30 min

"dCt"

Min. no

Max. yes

Default no

"doC"

Min. 0 hour

Max. 24 hour

Default 0 hour

"dEt"

Min. -50.0°C

Max. 0.0°C

Default -50.0°C

Adaptive defrost

"no": defrost controlled by time.

"yES": automatic defrost control activated.

Terminate Temperature

This parameter defines at what temperature the defrost cycle will stop.

The temperature is given by the evaporator sensor or by the cabinet

temperature sensor if no evaporator sensor is used.

Defrost reset temperature

The defrost counter is saved and restored at power-up, but if the

temperature sensor, used for defrost, is higher than this value at

power-up, it is assumed that the evaporator is free of ice and the

defrost counter will be cleared.

Defrost minimum Interval/dii

Defines the minimum time period between the start of two defrost cycles.

Once the minimum interval has expired, the defrost cycle will start at

the following cut-out or once the maximum interval "dAi" has been

reached.

Maximum Interval

Defines the maximum time period between the start of two defrost cycles.

Minimum Time

Defines the minimum duration of a defrost cycle. During this period, the

controller will not check the temperature. Once the minimum time has

expired, the temperature will be checked and if the terminate temperature

"dtt" has been reached, the defrost cycle will end. If dtt has not been

reached, defrost will continue until either dtt is reached or the

maximum time "dAt" reached, whichever occurs first.

Maximum Time

Defines the maximum duration of a defrost cycle.

The controller will not allow a maximum time to be entered which is

less than the minimum time, or a minimum time which is more than the

maximum time.

Defrost ON Compressor Time

If this parameter is set to "yES", then defrost cycles are based on the total

time the compressor has been running.

If this parameter is set to no, then defrost cycles are related to elapsed

time, regardless of how long and how often the compressor has been on.

Defrost by Comp. running time

Continuous compressor running can cause defrost.

"0" = deactived

Defrost start evaporator temp

Defrost start trigger for adaptive defrost.

DEFROST CYCLE

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 11

Page 12

User Guide | ERC 111 Refrigeration Controller

"ddt"

Min. 0.0 K

Max. 30.0 K

Default 5.0 K

"idi"

Min. 0 hour

Max. 96 hour

Default 3 hour

Defrost Δt

Defrost Δt compare with evaporator temperature of first cut out after defrost

to trigger defrost start.

The defrost start if evaporator temperature has decreased

Initial Defrost Interval

The initial defrost interval determines the time for first defrost after

power-up. The initial defrost is mainly intended for factory testing of the

defrost functionality and can be set to expire after a number compressor

cycles according to the setting of parameter idd. During normal operation,

the defrost counter will be saved in memory and restored after power loss,

making the initial defrost unnecessary.

"idd"

Min. 0

Max. 999

Default 100

Initial Defrost Duration

The initial defrost duration is the number of compressor cycles before

the initial defrost is deactivated.

"0": "idi" No initial defrost.

"1-998": number of compressor cycles before deactivation.

"999": initial defrost always active.

CoP Compressor settings

"uPt"

Voltage protection

"no": no voltage protection.

Min. no

Max. yes

Default no

"uLi"

Min. 0 V AC

Max. 270 V AC

Default 0 V

"uLo"

Min. 0 V AC

Max. 270 V AC

Default 0 V

"uHi"

Min. 0 V AC

Max. 270 V AC

Default 270 V

"yES": voltage protection activated based on voltage related settings.

Minimum cut-in voltage/uLi. Minimum cut-out voltage/uLo.

Maximum voltage/uHi

These three parameters provide voltage protection to the compressor.

Start by setting "uHi", followed by "uLo" and "uLi".

"uLi": when the compressor is due to start, the voltage of the power

supply will be checked and the compressor will only be allowed to

start if it is at least the value given in this parameter.

"uLo": when the compressor is running, it will be switched

OFF if the voltage goes below that given in this

parameter.

"uHi": when the compressor is running, it will be switched

OFF if the voltage exceeds that given in this parameter.

If the compressor is already stopped, it will remain

switched OFF.

"EHd"

Default no

Sensor Error Type

"no": no sensor error handling.

"SEt": in case of control sensor error, follow error run/stop time.

"Aut": automatical sensor error handling.

"Ert"

Min. 0 min

Max. 60 min

Default 0 min

Error Run Time

The parameter only become active in the unlikely event of a broken

temperature sensor. It is used to run the application in safety mode.

At the same time the sensor error will be shown in the display.

"Ert" define the duration the compressor will run.

Example: "Ert=4" [min] and "ESt=16" [min] will provide an average cooling

system activity of 20%. Ert and "ESt" values are based on OEM experience

and are by default inactive.

"ESt"

Min. 0 min

Max. 60 min

Default 1 min

Error Stop Time

The parameter only become active in the unlikely event of a broken

temperature sensor. It is used to run the application in safety mode.

At the same time the sensor error will be shown in the display.

"ESt" define the duration the compressor will be "idle".

12 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 13

User Guide | ERC 111 Refrigeration Controller

"CSt"

Min. 0 min

Max. 30 min

Default 2 min

Minimum Stop Time

It determines the minimum number of minutes the compressor must

remain idle before a Temperature cut-in can take effect. For example,

if the temperature sensor indicates that the cut-in temperature has been

reached, but the number of minutes set in this parameter have not elapsed

since the compressor last stopped, then the compressor will stay OFF.

It will only start once the duration given by "CSt" has been reached

provided the temperature is still high enough. "CSt" thus overrides the cut-in.

"Crt"

Min. 0 min

Max. 30 min

Default 0 min

Minimum Run Time

It determines the minimum number of minutes the compressor must run

before a Temperature cut-out can take effect. For example, if the

temperature sensor indicated that the cut-out temperature has been

reached, but the number of minutes set in this parameter have not

elapsed since the compressor last started, then the compressor will

continue. It will only stop once the duration given by "Crt" has been

reached – provided the temperature is still low enough.

"Crt" thus overrides the cut-out.

"Cot"

Min. 0 min

Max. 480 min

Default 0 min

Maximum OFF Time

This is the maximum time in minutes the compressor is allowed to

"idle" – up to 480 minutes. Cot is set to zero by default (inactive).

If the controller is used on a draft beer (ice bank) application, this

parameter can be used to control the ice thickness.

"Pod"

Min. 0 s

Max. 30 0 s

Defaul t 300 s

"PF1"

Min. -90°

Max. 90°

Default 0°

Power ON Delay

This is the delay in seconds between power-on and the compressor being activated.

Depends on the power ON temperature setting.

Power Factor

"PF1": relay 1.

Power factor (phasic angle) is introduced in zero crossing function

which is used for cut-in/out compressor at the proper timing for

prolonging the lifespan of relay. (Can only be accessed by Danfoss).

"Pot"

Min. -100.0°C

Max. 200.0°C

Default -100.0°C

Power ON Temperature

This parameter is used to accelerate the first application test on the

OEM assembly line; if the cabinet temperature is higher than this

parameter the power ON Delay is overruled and the outputs are activated

without delay.

Con Condenser Protection settings

NOTE: A condensor temperature sensor is required to use these parameters.

Condenser protection is generally used in dusty environments where

the condenser may accumulate a layer of dust or dirt and therefore be

at risk of overheating.

"CAL"

Min. 0°C

Max. 200°C

Default 80°C

Condenser Alarm Limit/CAL

This parameter sets the temperature for the condenser at which an alarm

will be generated.

"CbL"

Min. 0°C

Max. 200°C

Default 85°C

"CoL"

Min. 0°C

Max. 200°C

Default 60°C

Condenser Block Limit/CbL

This parameter sets the temperature which if reached will cause the

compressor to switch OFF.

Condenser OK Limit/CoL

This parameter sets the temperature at which the compressor is

allowed to start again after the temperature set in "CbL" above has been

exceeded and the compressor stopped.

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 13

Page 14

User Guide | ERC 111 Refrigeration Controller

"CLL"

Min. -100°C

Max. 20°C

Default -5°C

Condenser Low Limit/CLL

This parameter sets the lowest (condenser) temperature at which the

compressor is allowed to start.

diS Display settings

NOTE: some display parameters can be set in such as way that they

may be illegal in some jurisdictions. Please check local legislation.

"din"

Min. 2

Max. 10

Default 10

Display Intensity

The controller can have its display intensity (brightness) set in one of

two ways:

A) With a Danfoss ambient light sensor attached, the brightness of the

display is adjusted automatically according to the ambient light level

(see the assignments section).

B) When no ambient light sensor is attached, the display intensity can

be set to a fixed intensity.

Both options are on a scale of 1 to 10, where 10 is the brightest.

"CFu"

Min. °C

Max. °F

Default °C

"trS"

Default SCo

Display Unit

This parameter sets the display to Fahrenheit or Celsius. Switching from

one to the other will cause all temperature settings to be automatically

updated accordingly.

Temp sensor to display

"SCo": temperature control.

"EuA": evaporator temperture.

"Con": condenser temperature (condenser cleaning).

"AuS": only for showing on display.

"rES"

Min. 0.1

Max. 1

Default 0.1

Display Resolution

This parameter can be set to 0.1, 0.5 or 1 and affects the way the

temperature is displayed. With the parameter set to 1, the display will

only ever show temperatures rounded to the nearest whole degree.

At 0.5, it will round the temperature to the nearest half degree for display.

For example, 3.3 degrees will be shown in the display as 3.5 degrees

and 3.9 as 4.0. With the parameter set to 0.1, no rounding occurs.

This parameter does not affect the temperature itself, merely the display.

"rLt"

Min. no

Max. yes

Default no

Display Range Limit

In some point of sales applications you may want to show the desired

instead of the real temperature. This parameter sets whether the

displayed temperature is the actual temperature or whether it is restricted

to the cut-in / cut-out limits. Set to "nO" means that the actual temperature

will de displayed. The parameter is set to "nO" by default.

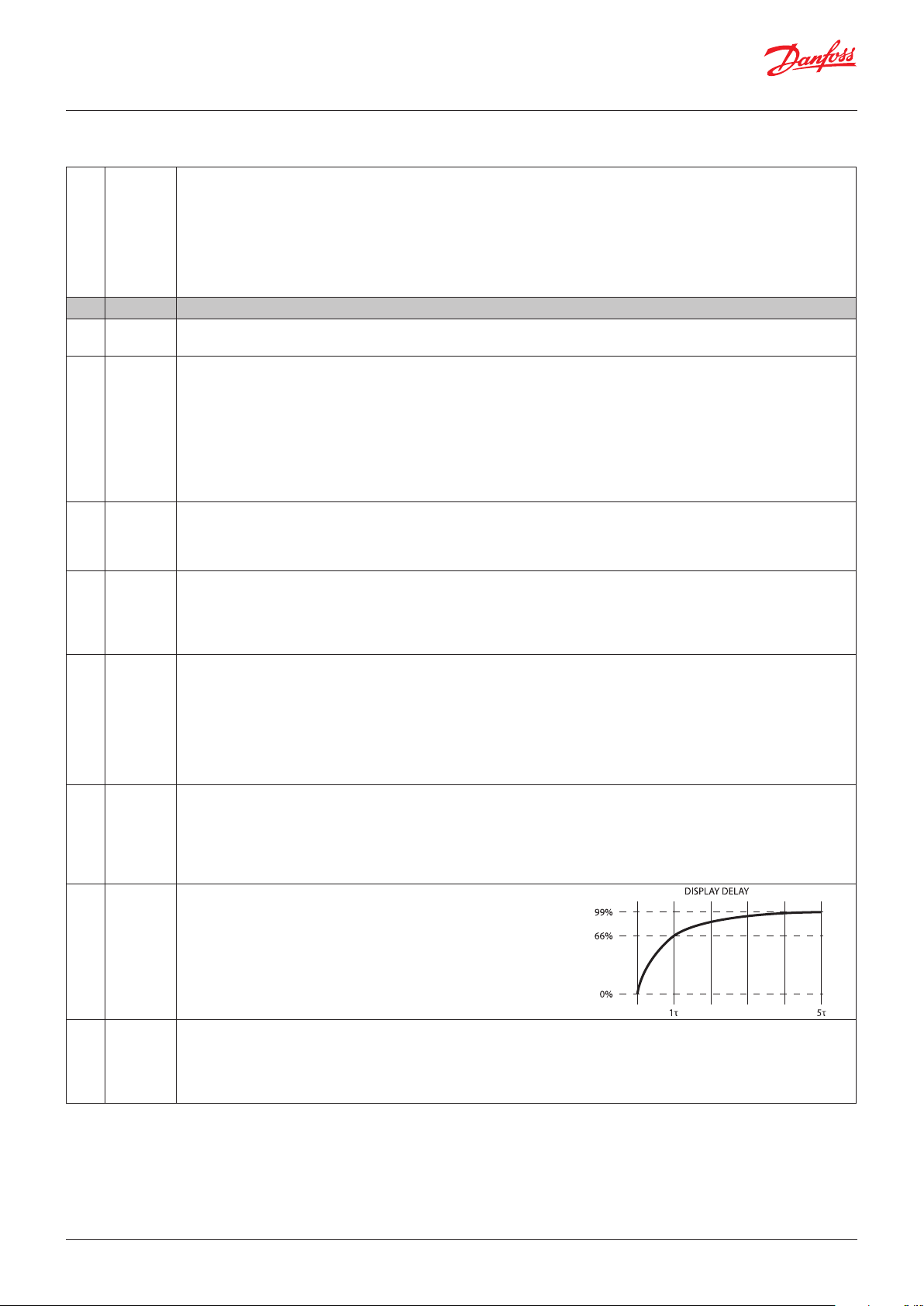

"ddL"

Min. 0 s

Max. 10 min

Default 0 min

Display Delay

In order to provide a realistic temperature appearance for an application,

a display delay can be set.

The parameter sets the time constant τ (tau) of the moving average filter

for the display.

Physically, one time constant represents the time it takes the system’s

step-response to reach 66% of its final value and five time-constants

the time it takes to reach 99% of its final value.

"doF"

Min. -10.0 K

Max. 10.0 K

Default 0.0 K

Display Offset

This parameter is a relative value and allows the temperature displayed

to be different to the temperature measured.

For instance, at a measured temperature of 7°C and "doF" set to -2K, the

displayed temperature will be 5°C instead.

14 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 15

User Guide | ERC 111 Refrigeration Controller

"dLt"

Min. 0 min

Max. 60 min

Default 15 min

Lock Time After Defrost

In order not to show a rising temperature during defrosting, the displayed

temperature is locked at the temperature shown at the start of the defrost

cycle for the number of minutes set in this parameter.

"0": no lock.

"SSC"

Min. no

Max. yes

Default no

"SHo"

Min. no

Max. yes

Default no

"SdF"

Min. no

Max. yes

Default yes

"SCS"

Min. no

Max. yes

Default yes

"SdS"

Min. no

Max. yes

Default yes

"idp"

Min. 0

Max. 15

Default 15

Show Pull down state

If set to "yES", this parameter causes the display to show SC when the

system is in pull down mode.

If set to "nO", the temperature continues to be displayed.

Show Holiday

"no": display will show temperature or ECO mode during holiday mode.

"yES": display will show "HoL" during holiday mode.

Show Defrost

If set to "yES", this parameter causes the display to show DEF when the

system is in defrost mode. If set to "nO", the temperature continues to

be displayed.

Show compressor symbol

"no": compressor symbol will not show on display.

"yES": show compressor symbol on display.

Show Defrost symbol

"no": defrost symbol will not show on display.

"yES": show defrost symbol on display.

Info Menu Display Item

Switch of display items in Info menu. Visible on "KoolProg Software" O NLY.

Data structure:

0,0,0,0, (alarm item), (average item), (low temp), (high temp)".

ALA Alarm settings

"HAt"

Min. -100.0°C

Max. 200°C

Default 15.0°C

"LAt"

Min. -100.0°C

Max. 200°C

Default -50.0°C

"Htd"

Min. 0 min

Max. 240 min

Default 30 min

"Ltd"

Min. 0 min

Max. 240 min

Default 0 min

"Pdd"

Min. 0 min

Max. 960 min

Default 240 min

"uAL"

Min. no

Max. yes

Default no

"LEA"

Min. 0 hour

Max. 96 hour

Default 0 hour

High Temp Alarm

Absolute value.

By setting "HAt" to the maximum alarms will be deactivated.

Low Temp Alarm

Absolute value.

By setting "LAt" to the minimum value, alarms will be deactivated.

In most situations, the low alarm delay will be set to 0 to warn about

too low a temperature immediately.

Alarm delay on high temperature alarm

The number of minutes to wait before sounding an alarm once the

high temperature alarm temperature is reached.

Alarm delay on low temperature alarm

The number of minutes to wait before sounding an alarm once the

low temperature alarm temperature is reached.

Pull down delay

Normally, it is not necessary or desirable to sound an alarm during a pull

down (the initial phase of reaching the desired temperature). This

parameter prevents the high temperature alarm "HAt" sounding during pull down

and after a defrost for the number of minutes set for the parameter.

NOTE: it does not apply to the low temperature alarm "LAt".

Voltage alarm

"no": no voltage alarm.

"yES": voltage alarm activated.

Leakage alarm

Leakage detection for compressor protection.

"0": disable

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 15

Page 16

User Guide | ERC 111 Refrigeration Controller

"Abd"

Min. 0 min

Max. 999 min

Default 0 min

Alarm Buzzer Duration

The alarm sounds for 10 seconds, followed by silence for 50 seconds.

One alarm sequence therefore lasts 60 seconds. These values cannot be

changed. This parameter determines how long in minutes an audible

alarm will continue while there is still a reason to have an alarm.

If set to 999, the alarm will continue to sound until the reason for the

alarm is cleared – for example the temperature has dropped enough or

the door closed. In some cases, it may be necessary for a user or technician

to take action in order to clear the alarm. If set to 0, the alarm will never

sound.

"ACA"

Min. no

Max. yes

Default yes

Auto Clear of Alarm/Error/ACA

If this parameter is set to "nO":

The alarm status will not disappear automatically even if the condition

which caused the alarm is no longer valid or present.

If set to "yES":

As soon as the condition which caused the alarm is no longer valid or

present, the alarm status will automatically change back to inactive.

There will be no trace of the alarm having occurred.

In general, glass door merchandise applications will be set to "yES" and

commercial fridges and freezers set to "nO".

For example, if the temperature goes too high for a period there may

be food safety considerations in a freezer containing food but not in a

fridge with cold drinks.

ECS ECO strategy

"tto"

Min. 0 hour

Max. 168 hour

Default 0 hour

Time to pull down

Time which ERC stay in holiday mode to decide to enter pull

down or serving mode.

ECA ECO management

"Hto"

Min. -25.0 K

Max. 25.0 K

Default 6.0 K

Holiday Temperature Offset

Increase or decrease of temperature with respect to normal mode

during holiday mode.

ASi Assignments settings

"uSA"

Min. no

Max. yes

Default no

"t1A"

Min. -20.0 K

Max. 20.0 K

Default 0.0 K

"t2A"

MODBUS Safety

"on": MODBUS auto detection is enabled.

"yES": MODBUS communication is deactivaed.

Air Temperature Adjustment

(applies to non-Danfoss temperature sensors only)

This parameter is a relative value and allows adjustment of the control

sensor temperature.

For instance, at a measured temperature of 7*C and "tAd" set to -2 K,

the input from the control sensor will be 5*C instead.

Inputs and outputs are configurable

There are two steps:

1. Define the type of sensor attached to the input:

- temperature: light/digital.

2. Define the application for the sensor:

- temperature: control/condenser/evaporator.

- light: ECO/display/both.

- motion

- digital: door sensor.

Please contact your local Danfoss representative for information about

default settings.

NOTE: coded sensors will impact on the number of possible

configurations.

For instance: Danfoss supplies only 2-pole defrost sensors, so input "S3"

will most likely be used as a defrost/evaporator temperature sensor input.

16 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 17

23

User Guide | ERC 111 Refrigeration Controller

"S1C"

Default Stn

"S2C"

Default Stn

"S1A"

Default SCo

"S2A"

Default nC

"o1C"

Default CoP

"b1C"

Default noP

"b1L"

Default PoF

"b2C"

Default dEF

"b2L"

Default inF

"b3C"

Default tP

"b3L"

Default ECo

"b4C"

Default tn

"b4L"

Default Lig

"PS1"

Min. 0

Max. 999

Default 0

"PS2"

Min. 0

Max. 999

Default 0

"PS3"

Min. 0

Max. 999

Default 0

S1 Config/S1C

S2 Config/S2C

S3 Config/S3C

S4 Config/S4C

Available options are:

"Stn": for a standard temperature sensor NTC 5 K @ 25°C and TPE precision.

"Htn": for a high temperature sensor NTC 100 K @ 25°C.

S1 Application/S1A

S2 Application/S2A

S3 Application/S3A

S4 Application/S4A

Available options are:

"nC": not connected.

"SCo": temperature control.

"EuA": evaporator temperature.

"Con": condenser temperature (Condenser cleaning).

"AuS": only for showing temperature on display.

D01 Config

"CoP": direct compressor control.

"PiC": pilot Relay (no zero cross) – if using pilot relay to control a

compressor, this option must be used instead of "CoP".

"HEt": heating application, inverse output.

"PiH": pilot heat relay (no zero cross).

Lower left button:

Button 1 Config (short press)/b1C

Button 1 Config (long press)/b1L

Upper left button:

Button 2 Config (short press)/b2C

Button 2 Config (long press)/b2L

Upper right button:

Button 3 Config (short press)/b3C

The buttons can be programmed as follows:

Short press function Long press function

"noP": not operating

"tP": increase set point

"tn": decrease set point

"dEF": toggle defrost

"SuP": toggle super-cool/pull down

"diP" : increase display intensity

"din" : decrease display intensity

"CFA ": toggle °C and °F

Button 3 config (long press)/b3L

Lower right button:

Button 4 Config (short press)/b4C

Button 4 Config (long press)/b4L

NOTE: Your assignments may not be shown on the printed buttons. We advice to

use this functionality together with the fully integrated mounting model only.

Password level 1 / PS1

Password Level 2 / PS2

Password Level 3 / PS3

These assign passwords to the three levels of access. The password is a

three-digit number. Access levels are Shop, Service and OEM.

You may not therefore have access to change all the passwords.

Passwords are entered by using the up and down arrow buttons.

Danfoss advises against using passwords which are easy to remember

or enter, for example 111, 222, 123 etc.

NOTE: When accessing the controller with 3 wrong password in a sequence

ERC will automatically block access for 15 minutes.

"noP": not operating

"tP": increase set point

"tn": decrease set point

"dEF": toggle defrost

"SuP": toggle super-cool/pull down

"diP": increase display intensity

"din": decrease display intensity

"CFA ": toggle °C and °F

"PoF": ERC power ON/OFF

"HoL": enter holiday mode

"inF": enter info menu

1

4

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 17

Page 18

User Guide | ERC 111 Refrigeration Controller

Ser Service information settings

The parameters in the following section are READ ONLY and cannot be

changed by the user.

They provide information for technicians and OEM users.

NOTE: the only parameters that can be configured are: "oEL", " oEn", " oEH".

These parameters allow OEMs to enter their own product code.

"ACt" Accumulated Comp. run time

"AEt" Accumulated ERC up time

"uAC" Voltage value

Current main power supply voltage.

"ouS" DOs Status

Current relay open closed status.

"rL1" Relay 1 counter

Thousands of cycles of compressor relay since manufacture.

"int" Interval Counter

Compressor run time since last defrost.

"dnt" Defrost time counter

Duration of last defrost cycle [min].

"Snu" Serial number

Serial number given at manufacturing.

"Fir" SW version

Danfoss software version number.

"HAr" HW version

Danfoss hardware version number.

"onL" OrderNoLow

Danfoss order code number.

"onH" OrderNoHigh

Danfoss order code number.

"oEL" OEM code Low

"oEn" OEM code Middle

"oEH" OEM code High

"PAr " Parameter version

OEM parameter version number [requires EKA copy key update].

"CHd" Manufacturing date

Programme date WWY: week number and year number (2010-19).

"SFC" Set as Default

Resets all parameters to last good OEM settings.

"Ctt" Condenser Temp

Temperature of the condensor sensor.

"Et1" Evaporator1 Temp

Temperature of the evaporator sensor1.

"AuS" AUX Temp.

Temperature of the AUX sensor. invisible.

"att" Raw Sair Temp

18 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 19

User Guide | ERC 111 Refrigeration Controller

Display messages

"unP" Device is unprogrammed (relay output is lockt)

"Prg" Device has not finished programming (relay output is lockt)

"SC" Device is in pull-down mode (super-chill)

"dEF" Device is defrosting

Troubleshooting

Problem Probable cause Remedy

Compressor does not start Waiting for compressor delay timer

Defrost does not start Controller in pull down mode Defrost might be delayed during pull down

Alarm does not sound Alarm delayed Check ALA->Htd, Abd

Display alternates between condenser and

temperature

Display alternates between high and

temperature

Display alternates between low and

temperature

Display shows "dEf" Defrost in progress Check diS ->SdF

Defrost in progress

Line voltage to compressor too low

or too high

Condenser too hot Clean condenser

Temperature too high Check ALA->HAt

Temperature too low Check ALA -> LAt

Check CoP->CSt

Check CoP ->Pot /Pod

Check dEF ->dit, dot

Check CoP->uLi, uLo, uHi

Check parameter Pud->Pdi

Check Pud->Pdd

Check Con ->CAL, CbL

Alarm

code

"Hi" Air temperature is higher than

"Lo" Air temperature is lower than

"Con" Condenser temperature is too

"uHi" Line voltage is higher than

"uLi" Line voltage is lower than

"LEA" Compressor continuous

"E01" "S1" error Always Blink "E01". If configured: cut in alarm relay, beep the buzzer "S1" sensor failure

"E02" "S2" error Always Blink "E02". If configured: cut in alarm relay, beep the buzzer "S2" sensor failure

Trigg er Automatic

clearance

User configured Blink "Hi" with the highest temperature; If configured:

"AL A->H at " for "AL A->H td "

User configured Blink "Lo" with the lowest temperature. If configured:

"LAt" for "Ltd"

User configured Blink "Con". If configured: cut in alarm relay, beep the buzzer Condenser alarm

high or too low

Always Blink "uHi". If configured: cut in alarm relay, beep the buzzer High voltage alarm

"Cop->uHi"

Always Blink "uLo". If configured: cut in alarm relay, beep the buzzer. Low voltage alarm

"Cop->uLi"

Always Blink "LEA". If configured: cut in alarm relay, beep the buzzer Leakage alarm

running for more than

"AL A->L EA "

Outputs Comments

High temperature alarm

cut in alarm relay, beep the buzzer

Low temperature alarm

cut in alarm relay, beep the buzzer

(short or open)

(short or open)

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 19

Page 20

User Guide | ERC 111 Refrigeration Controller

Typical applications

Glass Door Merchandiser, No-frost freezer/sub-zero cooler

ERC 111

ERC 111, Red LED, without buzzer 080G3230

ERC 111, Blue LED, without buzzer 080G3231

Temperature Sensor for Cabinet

Temperature Control

PVC Standard Connector type

3-pole

470 mm 077F8751 1000 mm 077F8786

1000 mm 077F8757 1500 mm 077F8790

1500 mm 077F8761 2000 mm 077F8794

2000 mm 077F8765 3000 mm 077F8798

2200 mm 077F8767 6000 mm 077F2029

3000 mm 077F8769

3500 mm 077F8723

6000 mm 077F2019

Temperature Sensor for

Condenser Temperature Control

PVC Standard Connector type

2-pole

20 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 21

User Guide | ERC 111 Refrigeration Controller

Sensor placement

Control sensor

Control sensor

The control sensor must always be connected and is

used for controlling the cut-in and cut-out of the

compressor according to the set point.

The sensor is also used for the displayed temperature.

Vertical coolers with fan

Most common placement is in the return air to the

evaporator. The sensor can be placed close to the

fan – even when the fan is pulsed during compressor

OFF periods: the updating of the temperature is

blocked when the fan is stopped and only updated

when the fan has been running for a while, so that the

heat from the fan does not affect the temperature

reading.

For applications sensitive to sub-zero temperatures,

sensor placement in the evaporator outlet air can be

considered.

Vertical freezers with fan

Placement in the return air or in the freezer

compartment.

Coolers without fan

The best results are normally obtained when the

sensor is placed at the side-wall, 10 cm from the back

and approximately at 1/3 from the bottom or where

the evaporator ends.

The control sensor must always be connected and is

used for controlling the cut-in and cut-out of the

compressor according to the set point.

The sensor is also used for the displayed temperature.

Condenser sensor

The condenser sensor is used to protect the compressor

against high pressure when the condenser is blocked or

the condenser fan fails.

Placement of sensor

Place the sensor at the liquid side of the condenser.

Use a metal bracket or metal tape to ensure good

thermal conductivity. Be sure that the cable does not

pass hot spots at the compressor or condenser that

exceeds 80°C.

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 21

Page 22

User Guide | ERC 111 Refrigeration Controller

Application Matrix

ERC 111 Output Input

Application Type DO1 S1 S2 Di

Standard beverage cooler ERC 111 Comp Control Defrost or condenser -

Out-door beverage cooler ERC 111 Comp Control Defrost or condenser -

CFF refrigerator ERC 111 Comp Control Defrost or condenser -

CFF freezer static evaporator ERC 111 Comp Control Condenser -

NOTE:

• Select only one function per input, e.g. defrost or condenser sensor.

• Make sure that the accessory you select has a matching connector to the input, e.g. a sensor for input "S2" must have "S2" connector.

• Condenser sensor are optional and can be omitted.

22 | BC227086437558en-000702 © Danfoss | DCS (vt) | 2019.07

Page 23

User Guide | ERC 111 Refrigeration Controller

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 23

Page 24

© Danfoss | DCS (vt) | 2019.07 BC227086437558en-000702 | 24

ADAP-KOOL®

Loading...

Loading...