Page 1

MAKING M ODERN LIVING POS SIBLE

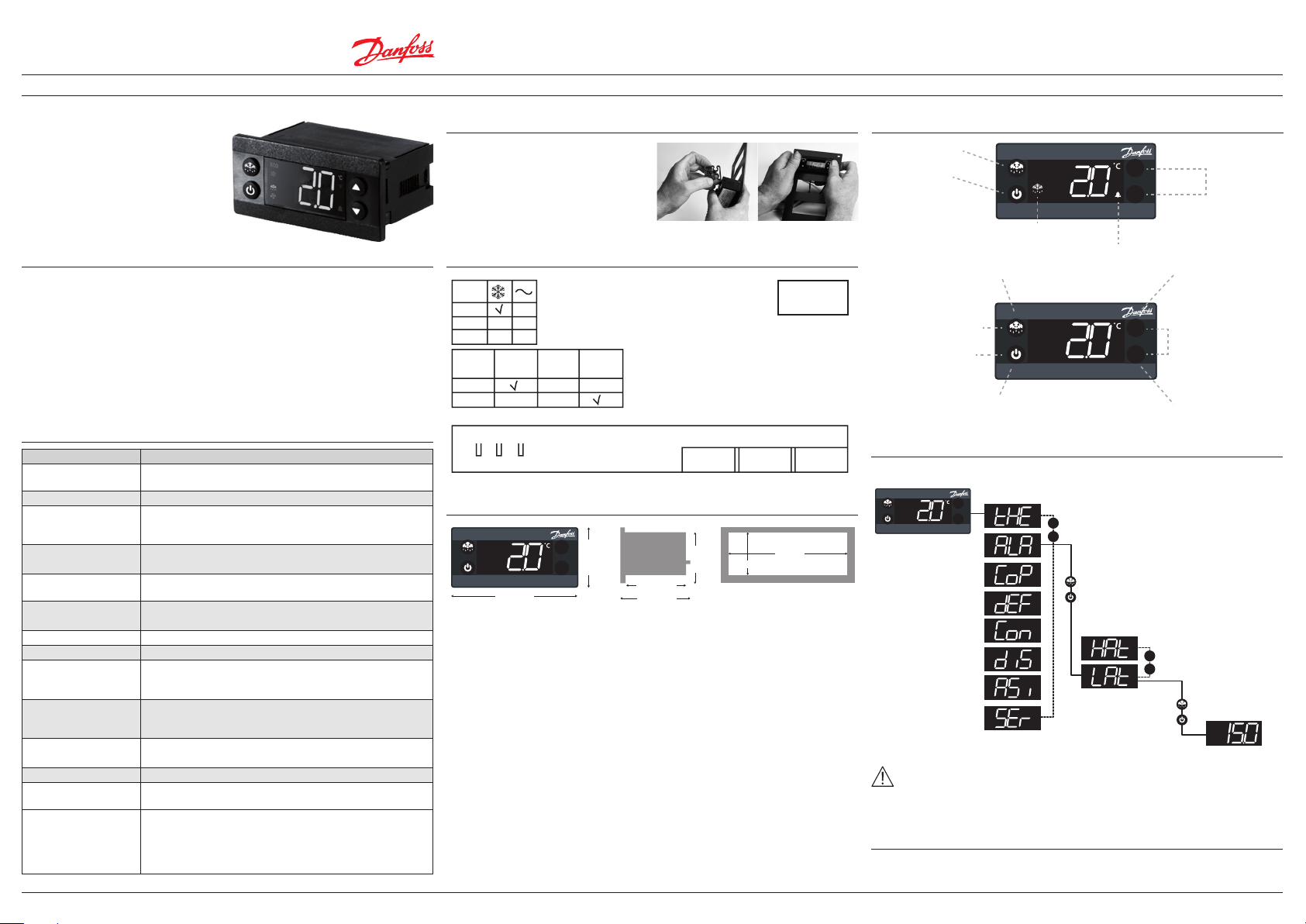

51.25 mm

EN-Instruction sheet ERC 101 kit

Technical highlights

y Pre-programmed - ready to use

y Compressor protection against instable voltage

y High condensing temperature protection

y Compact design - total depth is only 46 mm

y Real 16A power relay - up to 2.5 HP compressors

y Automatically controlled brightness of large-size LED display

y Fully compatible with ammable refrigerants (R290)

y Moisture protection (housing & coating)

y Advanced defrost algorithms

Technical specications

FEATURES DESCRIPTION

Power supply

100 VAC - 240 VAC 50-60 Hertz, automatic switch mode

power supply

Rated power Less than 0.5 W

Danfoss NTC Air temperature probes

2 analogue inputs

Danfoss NTC Condenser

temperature probes (optional)

Output compressor

relay

Display

Operating

conditions

16 (16A) EN60730; 16 (16A) CQC;

16A (16A FLA/72A LRA) UL60730

LED display, 3 digits, decimal point and

multi functionality icons, °C scale

0 °C to 55 °C, 93% rH

Storage conditions -40 °C to 85 °C, 93% rH

Measurement range -40 °C to 85 °C

Front: IP65/Rear: water and dust protection

Protection

corresponds to IP31, accessibility of connectors limit

rear part rating to IP00

Pollution degree III

Environmental

(can be mounted inside a refrigerated cabinet),

Installation

y Insert the ERC 101 in to the cabinet

y Attach the clips to each side of the

ERC 101

Input/output

DO

1(o1)

2

3

Input/

Sensors

Cabinet

Sensors

DO1:

L

UL: 16FLA 72LRA,

N

IEC: 16(16)A

Evapor.

Sensors

Conden.

Sensors

S1

S2

1 2 3

DO & Input/Sensors

Dimensions mm

36.5 mm

^

^

78.25 mm

100-240VAc +/-10% 50/60Hz

OT 55

S1 S2

28 mm

47.25 mm

30 mm

ERC 101

controller

71 mm

rear mounting

Display/operation

Press BRIEFLY to defrost

Press the button

5 seconds to ON/OFF

The green def symbol is list

when in defrost mode

Press: variable direct function defrost

Sub function: BACK

Press: upper left button BACK

to return to parameter group

To select: press the lower

left button (OK)

Press: variable direct functionON/OFF

Sub function: OK

Operation menu

Press 5 sec both right buttons

to access the menu

1) Parameter groups

^

^

^

^

Flasching

Press any button to acknowlege

^

^

^

Scroll through the

^

menu group

Higher left button to exit

Lower left button to conrm

2) Parameter name

Higher left button to exit

Lower left button to conrm

Press UP/DOWN to

adjust setpoint

Press: tempearture setpoint

sub function: UP

Press and hold for 5 seconds

to enter the menu

Press: UP/DOWN to scroll

through the menu

Press: tempearture setpoint

sub function: DOWN

^

Scroll through the

^

parameters group

3) Parameter value

non-condensing

Resistance to heat

& re

EMC category Category I

Operating cycles

Approvals

Produce d by Danfoss A/S (EL-MSSM/AZ ) | March 2014 DKRCC.EI. RL0.A3.02/520H8599 1

Category D (UL94-V0)

Compressor relay:

more than 175,000 at full load ((16A) 16A)

R290/R600a: EN/IEC 60079-15:2005,

Glow wire according to EN/IEC 60335-1,

IEC/EN 60730, UL60730, NSF, CQC, GOST R 60730

Note: These approvals are only valid when using the

accessories listed in this document

IMPORTANT NOTE

The inputs are not galvanic separated and are connected directly to

the mains supply! For that reason, door-switches, sensors as well as the cables must full the reinforced

insulation requirements.

Safety info

Risk of electrocution!

For mounting: do not connect mains power until the controller is correctly mounted.

For unmounting: disconnect the power supply before unmounting

Page 2

MAKING M ODERN LIVING POS SIBLE

EN-Instruction sheet ERC 101 kit

Parameters

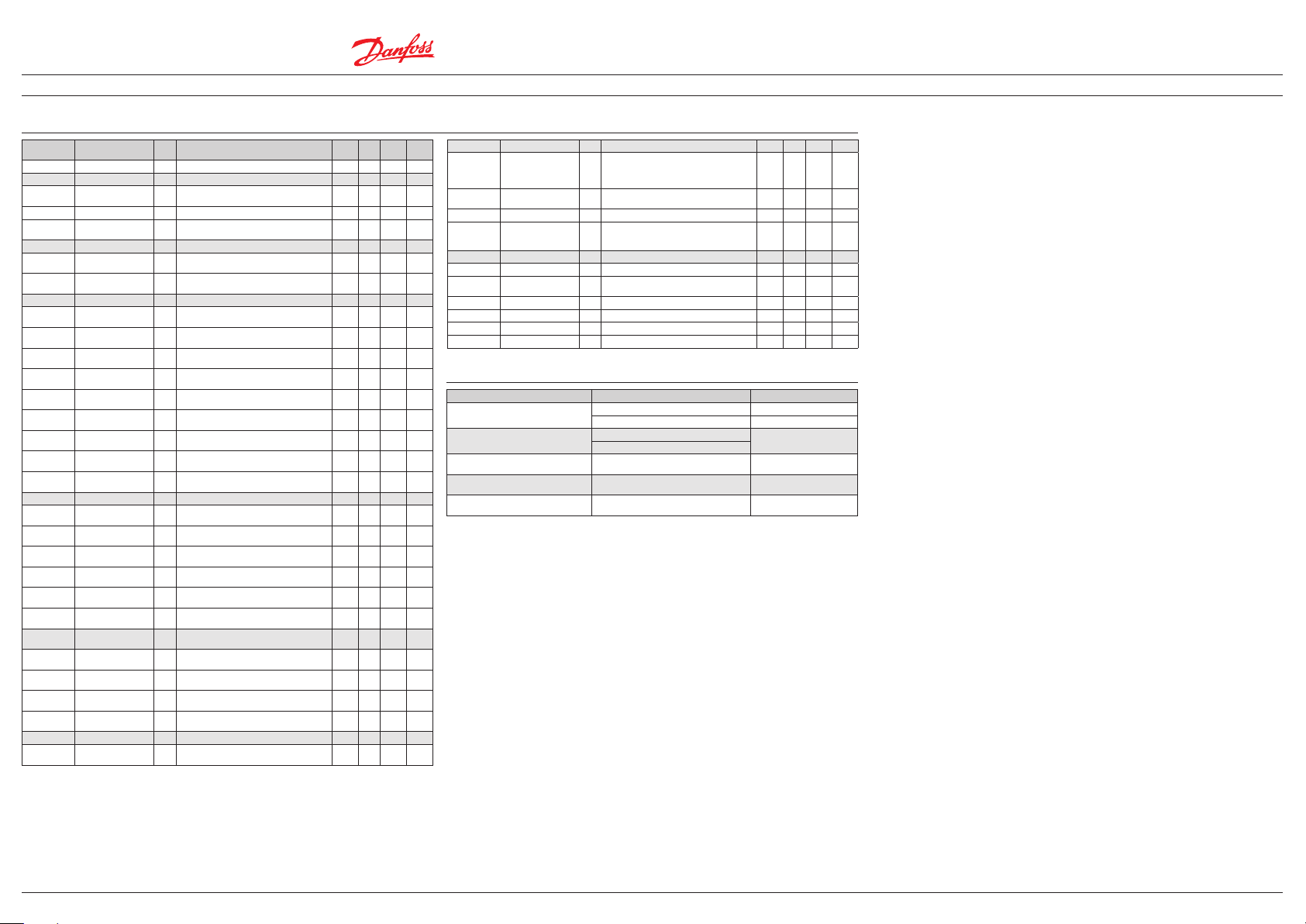

Menu Parameters Cod Description Min Max Unit

Thermostat tHE Thermostat settings

Alarm ALA Alarm setting

Compressor CoP Compressor Setting

Defrost dEF Defrost Setting

Condenser

Protection

Display diS Display setting

Setpoint Stp Setpoint -50 80 C 2

Setpoint adjustment

ratio

Dierential diF Thermostat dierential 0.0 20.0 K 2.0

Air temperature

adjust

High temperature

alarm

Low temperature

alarm

Min run time Crt

Min Stop time CSt

Max OFF time Cot

Error run time Ert

Error stop time ESt

Minimum cut-in

voltage

Minimum cut-out

voltage

Maximum voltage uHi

Power ON delay Pod

Defrost type dFt

Terminating temp dtt

Def Min Interval dii

Def Max Interval dAi

Def Min time dit

Def Max time dAt

Condenser Alarm

Limit

Condens er Block

Lim it

Condenser OK limit CoL

Condenser Low Temp CLL

Lock-time After

defrost

SPr Current setpoint adjustment value diF * SPr 0.0 1.0 - 0.0

tAD Air Temp Adjust 0.0 20.0 K 0

Alarm is activated above this temperature

HAt

(Celsius )

Alarm is activated below this temperature

LAt

(Celsius )

Minimum time compressor must run 0-30

minutes

Minimum time compressor must idle 0-30

minutes

Maximum time compressor must idle 0-480

minutes

Compressor run time if temperature sensor is

not working (0-60 minutes )

Compressor stop time if temperature sensor is

not working (0-60 minutes )

When compressor is OFF:

uLi

lowest compressor start voltage (0-270 V)

When compressor is ON:

uLo

lowest operation voltage (0-270 V)

When compressor is ON:

highest operation voltage (0-270 V)

Delay in seconds between power ON &

compressor being activated

No: defrost function is disabled,

nat: OFF-cycle defrost (natural defrost)

Temp at which defrost stop

(evap temperature or cabinet temperature)

The minimum time in hours between the start

of each defrost cycle

The maximum time in hours between the

start of each defrost cycle

The minimum duration of a defrost cycle

in minutes

The maximum duration of a defrost cycle

in minutes

Con Condenser protection settings

If condenser sensor exceeds this temperature,

CAL

alarm is activated

If this temperature is exceeded, compressor

CbL

will be stopped

Temperature at which compressor may start

after a stop due to exceeding CbL

Temperature below which the compressor is

not allowed to start

dLt Display lock time after defrost [0-60 min] 0 60 min 5

-50.0 80.0 C 15.0

-50.0 80.0 C -50.0

0 30 min 0

0 30 min 0

0 480 min 0

0 60 min 0

0 60 min 0

0 270 Vac 0

0 270 Vac 0

0 270 Vac 270

0 300 Sec 180

no nat - nat

0 25 C 7

0 96 hours 6

0 96 hours 7

0 240 min 10

0 480 min 30

0 85 C 75

0 85 C 85

0 85 C 60

-50 20 C -5

Default

Assignments Assignments of inputs and outputs

S2 Application S2A

DO1 conguration o1C

Password level1 PS1 Shop owner Most common parameters 0 999 - 0

Password level2 PS2

Service Service

Voltage value uAC Current main power supply voltage 0 270 Vac -

Relay 1 counter rL1

Interval counter int Compressor run time since last defrost 0 999 min -

Defrost time counter dnt Duration of last defrost cycle [min] 0 999 min -

Firmware version Fi r Danfoss software version number - - - -

Hardware version HAr Danfoss hardware version number - - - -

Application to be controlled with Sensor

C. (nC=Not Connected, Sco= Temp control,

EuA= Evap temp, Con=Cond temp {condenser

cleaning})

Relay output 1. compressor (CoP)

2. Heater HeT

Service technician all parameters with read

permission and possibility to change a

number of parameters

Thousands of cycles of compressor relay since

manufacture

nC Con - nc

CoP HeT - CoP

0 999 - 0

0 999 1000 -

Problem solving

Problem Probable cause Remedy

Compressor does not start

E01 or E02 is shown on display

Display alternates between "Con" and

temperature

Display alternates between "Hi" and

temperature

Display alternates between "Lo" and

temperature

Waiting for compressor delay timer Check CoP->CSt

Line voltage to compressor too low or too high Check CoP->uLi, uLo, uHi

E01: Sensor "S1" defective

E02: Sensor "S2" defective

Condenser temperature exceeds the

temperature set in condenser settings menu

Temperature too high Check ALA->HAt

Temperature too low Check ALA-> LAt

Replace sensor

Clean condenser,

Check Con->CAL, CbL

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Produce d by Danfoss A/S (EL-MSSM/AZ ) | March 2014 DKRCC.EI. RL0.A3.02/520H8599 2

Loading...

Loading...