Page 1

Data Sheet

Engine Information Center Software

PLUS+1

Mobile Machine Management

The Engine Information Center (EIC) software for PLUS

+1® DP200 and DP250 engine interface through

J1939 CAN provides run time monitoring fault

recording and retrieval.

Product Highlights

Navigate through diagnostic information and

configurations screens using front panel soft keys.

Choose from more than 50 preconfigured parameter

profiles and display up to 4 signals per screen.

User-programmable

EIC application software allow machine specific

tailoring, which is accomplished by using Danfoss PC

based PLUS+1® GUIDE (Graphic User Integrated

Development Environment) tool set. This

environment allows the developer to configure

Danfoss PLUS+1® display hardware, select application

options, integrate the applications with other subsystem applications, and enhance the application

with additional features.

®

Features

Standard

•

Multi-lingual Support

•

Graphic Image Support for more than

50 icon

•

Color or Grey Scale Models with

Brightness and Contrast Adjustment

•

More than 50 pre-configured

parameters

•

Configurable Display Screens, Alarms

and Warnings Pop-up

•

Fault Logging

•

Tier III and Tier IV Engine Compatibility

•

Tier IV Emissions Implementation

©

Danfoss | Jul 2016 L1229134 | AI00000152en-US0201 | 1

Customizable

•

Configure proprietary engine and

transmission messages

•

Create custom machine service and

diagnostic screens

Comprehensive technical literature online

at powersolutions.danfoss.com

Page 2

-

-

-

-

-

-

d

F

N

R

Data Sheet

EIC software DP2XX

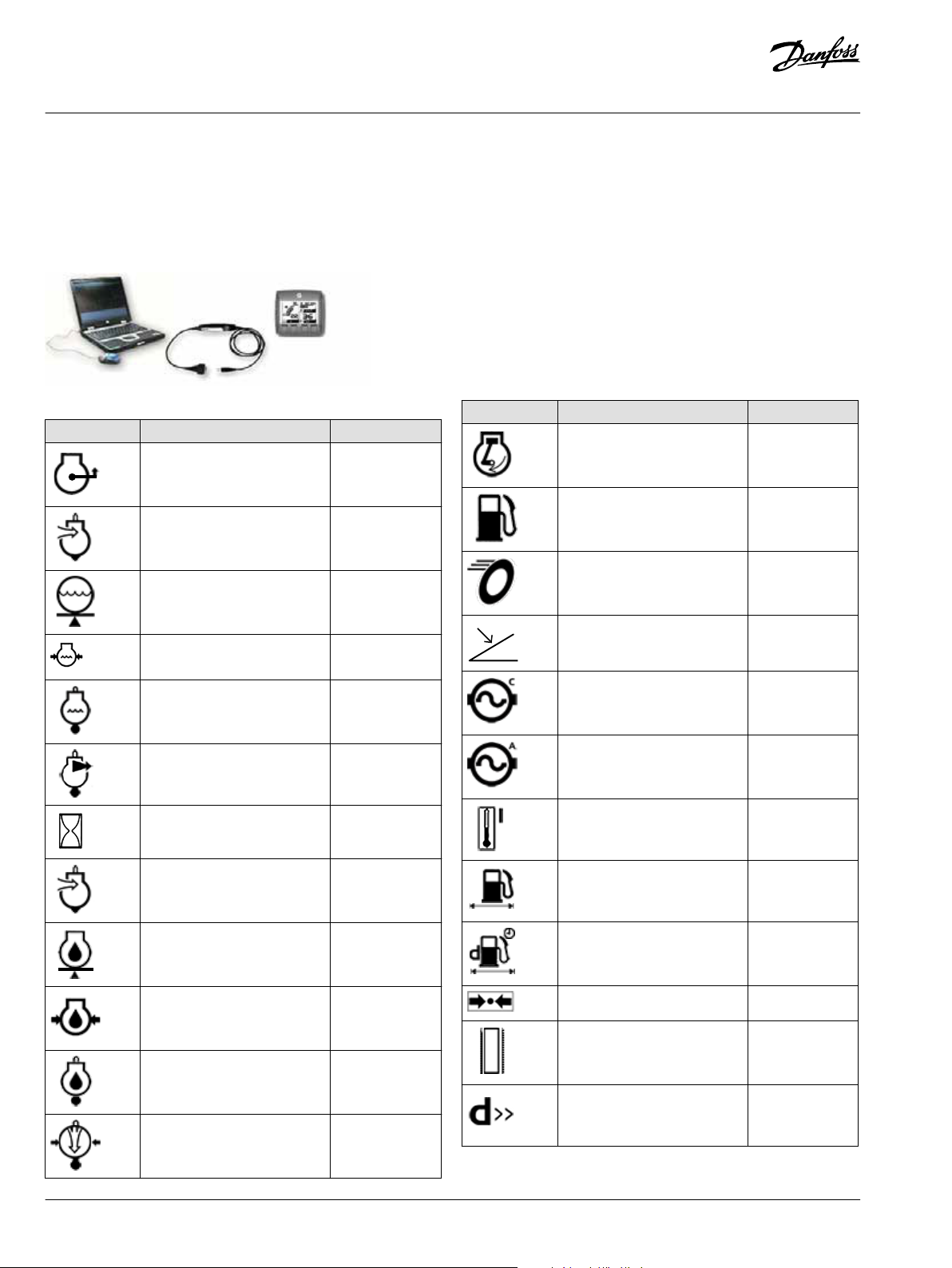

GUIDE Programmable Subsystem Application Service Tool

The PLUS+1® GUIDE Service Tool screens provide the ability to monitor and tune the operation of devices on the PLUS+1® network.

Standard features include: bar graph display, oscilloscope display for trending and tuning, data record, and export feature. All required

user modifiable service screens are provided with this product.

PC with Danfoss PLUS+1® GUIDE. Gateway supported by Service Tool program. PLUS+1® compliant display.

Software Overview of Signal Monitoring

Symbol Name/Function Units

Actual Engine Torque %

Engine Air Inlet Temperature °C, °F

Engine Coolant Level %

Engine Coolant Pressure psi, bar, Pa x 1000

Engine Coolant Temperature °C, °F

Engine Exhaust Gas Temperature °C, °F

Engine Hours Hours

Symbol Name/Function Units

Engine RPM RPM

Fuel Level %

Wheel-based Vehicle Speed km/h, mph

Accelerator Pedal Position %

Alternator Current

Alternator Voltage

Auxiliary Temperature

Engine Intake Manifold

°C, °F

Average Fuel Economy

Temperature

Engine Oil Level %

Engine Oil Pressure psi, bar, Pa x 1000

Trip Average Fuel Rate

Barometric Pressure

Current Gear

Engine Oil Temperature °C, °F

Distance Remaining

Engine Turbocharger Boost

psi, bar, Pa x 1000

Pressure

2 | © Danfoss | Jul 2016 L1229134 | AI00000152en-US0201

Page 3

-

--

-

-

-

1

2

F

N

R

>

Data Sheet

EIC software DP2XX

Symbol Name/Function Units

Engine Air Filter Differential

psi, bar, Pa x 1000

Pressure

Engine Air Inlet Temperature °C, °F

Engine Injector Metering Rail 1

psi, bar, Pa x 1000

Pressure

Engine Injector Metering Rail 2

psi, bar, Pa x 1000

Pressure

Engine Intercooler Temperature °C, °F

Engine Turbocharger Oil

°C, °F

Temperature

Fan Speed %

Engine Fuel Delivery Pressure psi, bar, Pa x 1000

Symbol Name/Function Units

Selected Gear F, N, R

Torque Convertor Lock-up

Engd, Dis

Engaged

Total Distance km, m

Engine Total Fuel Used l, gal, igal

Transmission Input Shaft Speed RPM

Transmission Oil Pressure psi, bar, Pa x 1000

Transmission Oil Temperature °C, °F

Fuel Rate l/h, g/h, ig/h

% Soot Soot level percent %

% Ash Ash level percent %

Fuel Remaining l, gal, igal

Engine Fuel Temperature 1 °C, °F

Instantaneous Fuel Economy 1/100km, mpg,

Internal Voltage Volts

Net Battery Current Amps

Transmission Output Shaft Speed RPM

Trip Distance km, m

Trip Engine Hours hrs

Trip Fuel l, gal, igal

impg

©

Danfoss | Jul 2016 L1229134 | AI00000152en-US0201 | 3

Page 4

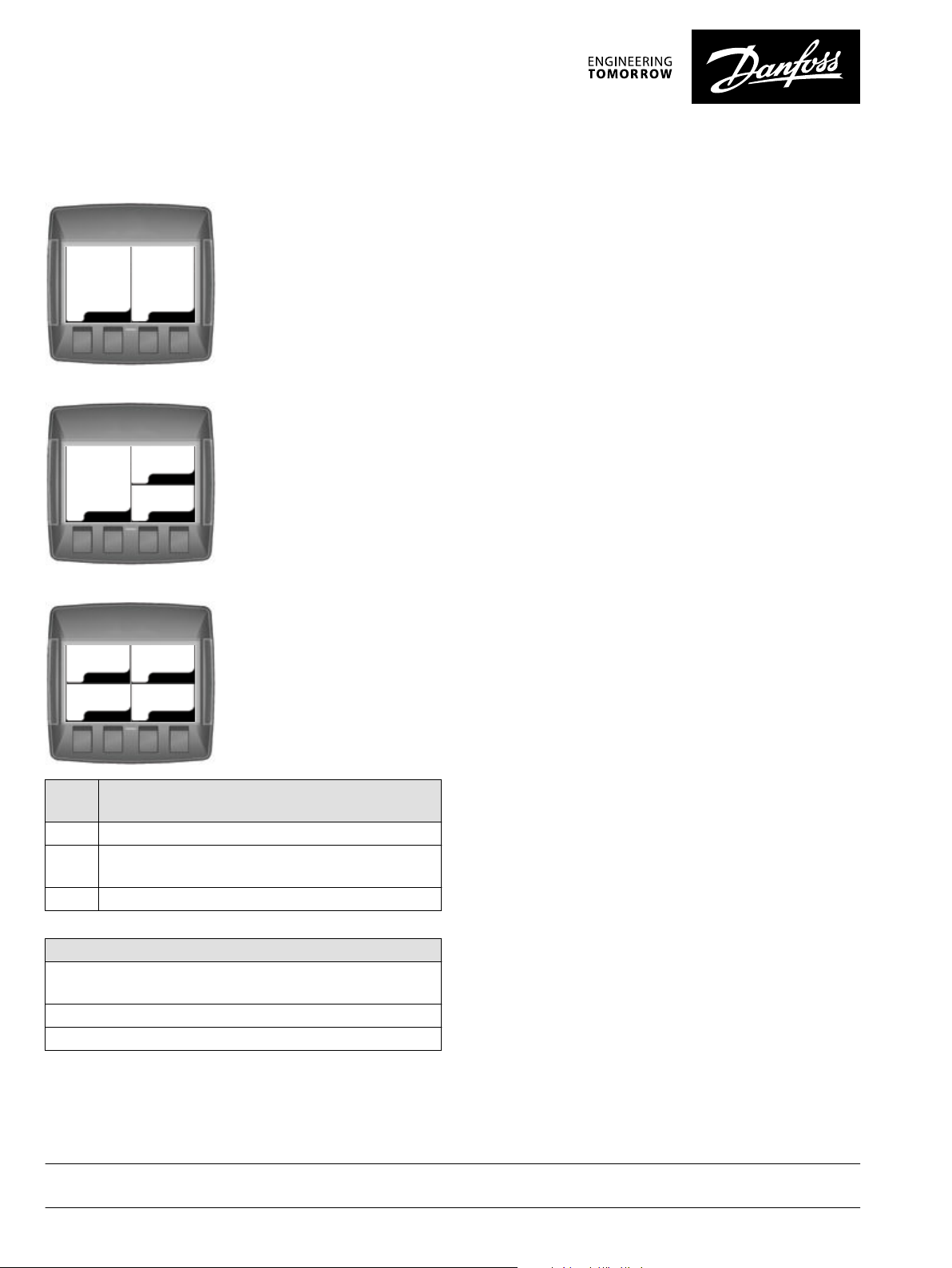

Screen Views

Type 1

Type 2

Type 3

Screen

View

Type 1 Two-up screen view with two signal capacity.

Type 2 Three-up screen view with one large and two small signal

Type 3 Four-up screen view with four small signal capacity.

Description

capacity.

Minimum Requirements

Related product

Danfoss PLUS+1® application hardware microcontroller with 256K

internal flash memory (Key #10106603)

PC with Danfoss GUIDE program, version 4.1 or later

Gateway supported by the PLUS+1® Service Tool

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | Jul 2016 L1229134 | AI00000152en-US0201

Loading...

Loading...