Page 1

User Guide

Motor / Generator

EM-PMI540-1500

danfoss.com

Page 2

4

4

4

5

6

6

7

7

8

8

8

9

9

10

12

13

14

15

17

18

19

19

19

20

20

21

24

24

24

26

26

27

28

28

28

29

32

32

32

32

1. General information

1.1. Copyright .........................................................................................................................................................................................

1.2. Intended use of the manual .....................................................................................................................................................

1.3. Product naming convention ....................................................................................................................................................

1.4. Conformity according to standards .......................................................................................................................................

1.5. Warranty ..........................................................................................................................................................................................

1.6. Terms and abbreviations ...........................................................................................................................................................

1.7. Trademarks .....................................................................................................................................................................................

1.8. Responsibility of the manufacturer .......................................................................................................................................

2. Safety information

2.1. General safety statement ..........................................................................................................................................................

2.2. Safety message signal words ...................................................................................................................................................

2.3. Safety symbols ..............................................................................................................................................................................

2.4. Personal protective equipment ..............................................................................................................................................

2.5. Security features ...........................................................................................................................................................................

2.6. Electromagnetic compatibility (EMC) .................................................................................................................................

3. Product overview

3.1. Intended use of the electric machine .................................................................................................................................

3.2. Used technology ........................................................................................................................................................................

3.3. System introduction .................................................................................................................................................................

3.4. Connections and interfaces ...................................................................................................................................................

3.5. Rating plate ..................................................................................................................................................................................

3.6. Tightening torques ....................................................................................................................................................................

4. Design principles

4.1. System design .............................................................................................................................................................................

4.1.1. Cooling and temperature measurement ..................................................................................................................

4.1.2. Inverter ..................................................................................................................................................................................

4.2. Mounting structure ...................................................................................................................................................................

4.2.1. Supporting structure requirements ............................................................................................................................

4.2.2. Shaft alignment and load ...............................................................................................................................................

5. Transportation and storage

5.1. Transportation ............................................................................................................................................................................

5.2. Receiving and unpacking .......................................................................................................................................................

5.3. Lifting .............................................................................................................................................................................................

5.4. Storage ...........................................................................................................................................................................................

5.4.1. Extended storage ..............................................................................................................................................................

6. Installation

6.1. Required tools .............................................................................................................................................................................

6.2. Insulation resistance test .........................................................................................................................................................

6.3. Mechanical installation ............................................................................................................................................................

6.3.1. Allowed mounting positions .........................................................................................................................................

6.3.2. Mounting the electric machine ....................................................................................................................................

6.3.3. Cooling connections ........................................................................................................................................................

6.4. Electrical installation .................................................................................................................................................................

6.4.1. Power connections ...........................................................................................................................................................

6.4.1.1. High voltage connection ........................................................................................................................................

EM-PMI540-T1500

Table of Contents

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 1

Page 3

34

35

40

42

45

46

47

47

48

48

49

50

50

53

57

57

6.4.1.2. Connection diagram ................................................................................................................................................

6.4.1.3. Cable gland assembly and power line connection .......................................................................................

6.4.2. Low voltageconnections ................................................................................................................................................

6.4.3. Grounding connections ..................................................................................................................................................

6.4.4. Anti-condensation heater connections .....................................................................................................................

7. Operation

7.1. Operation conditions ...............................................................................................................................................................

7.2. Condition monitoring during operation ...........................................................................................................................

7.3. Recommended lubricants ......................................................................................................................................................

7.4. Recommended coolants .........................................................................................................................................................

7.5. Emergency operation ...............................................................................................................................................................

8. Maintenance

8.1. Regular maintenance ...............................................................................................................................................................

8.2. Cleaning ........................................................................................................................................................................................

8.3. Bearings and lubrication .........................................................................................................................................................

8.4. Cooling system maintenance ................................................................................................................................................

9. Dismounting

10. Troubleshooting

11. Aftersales

11.1. Service policy ............................................................................................................................................................................

11.2. Service parts ..............................................................................................................................................................................

12. Disposal

13. Storage, installation and maintenance checklists

EM-PMI540-T1500

Table of Contents

2 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 4

Revision Information

6

EM-PMI540-T1500

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 3

Page 5

This manual is the installation, operation and maintenance manual for the EM-PMI540-

T1500electric machine.

Copyright

Danfoss Oy. All rights reserved.

No parts of this manual may be reproduced or transmitted in any form or by any means, electrical

or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

All specications and contents of this manual are subject to change without notice.

Intended use of the manual

This manual contains instructions necessary to safely and properly handle, install, operate and

maintain the electric machine. They should be brought to the attention of anyone who installs,

operates or maintains the machine or associated equipment.

All of the safety warnings and instructions in this book must be followed to prevent injury to

personnel or damage to property . Only qualied and authorized personnel, familiar with health

and safety requirements and national legislation, shall be permitted to handle, install, operate and

maintain the device.

This manual must be kept for future reference during installation, operation and maintenance.

This manual uses illustrations as examples only. Illustrations in this manual may not necessarily

reect all system features.

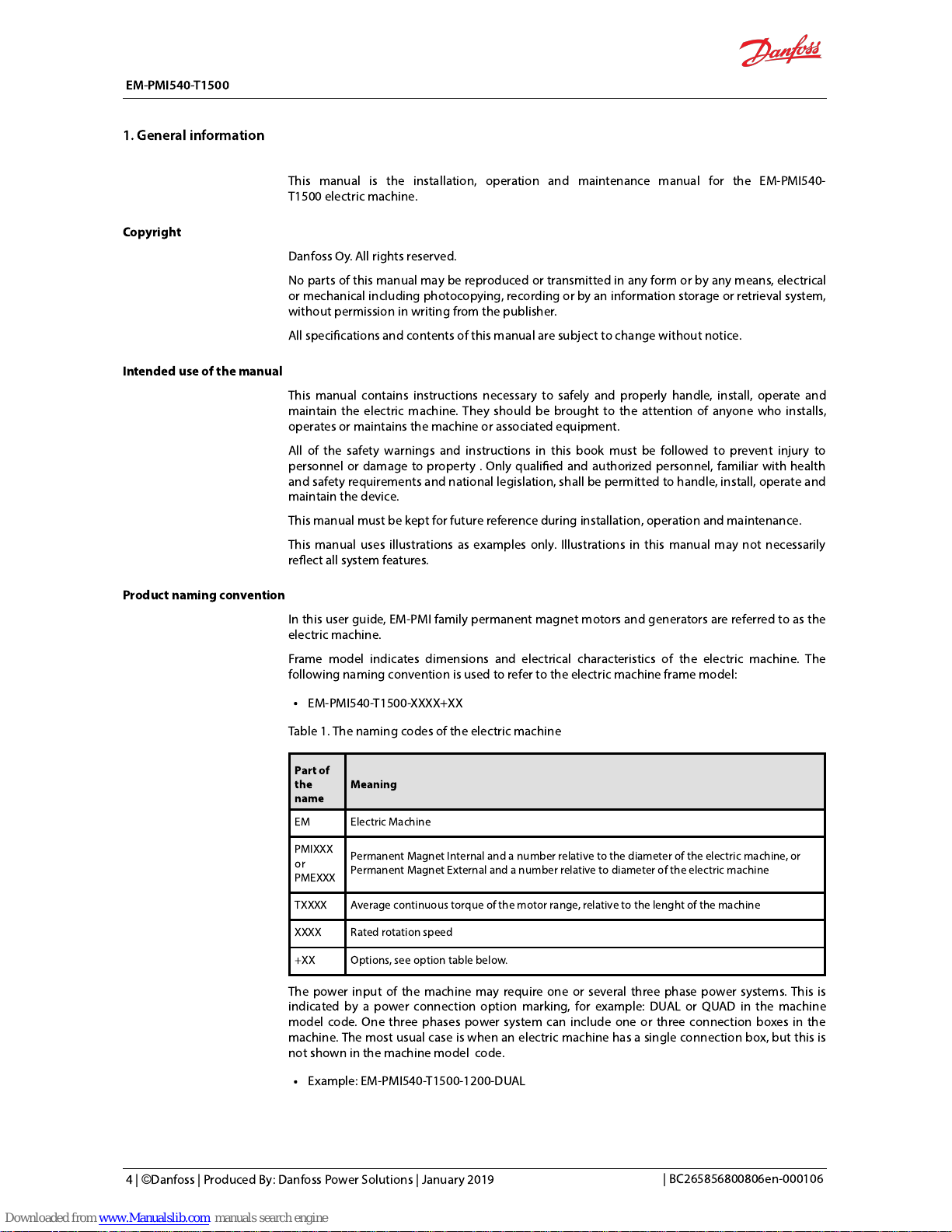

Product naming convention

In this user guide, EM-PMIfamily permanent magnet motors and generators are referred to as the

electric machine.

Frame model indicates dimensions and electrical characteristics of the electric machine. The

following naming convention is used to refer to the electric machine frame model:

EM-PMI540-T1500-XXXX+XX

Table 1. The namingcodes of the electric machine

Part of

the

name

Meaning

EM Electric Machine

PMIXXX

or

PMEXXX

Permanent Magnet Internal and a number relative to thediameterof the electric machine, or

Permanent Magnet External and a number relative todiameter of the electric machine

TXXXX Average continuous torque of the motor range, relative to the lenght of the machine

XXXX Rated rotation speed

+XX Options, see option tablebelow.

The power input of the machine may require one or several three phase power systems. This is

indicated by a power connection option marking, for example:DUAL or QUAD in the machine

model code. One three phases power system can include one or three connection boxes in the

machine. The most usual case is when an electric machine has a single connection box, but this is

not shown in the machine modelcode.

Example: EM-PMI540-T1500-1200-DUAL

EM-PMI540-T1500

1. General information

4 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 6

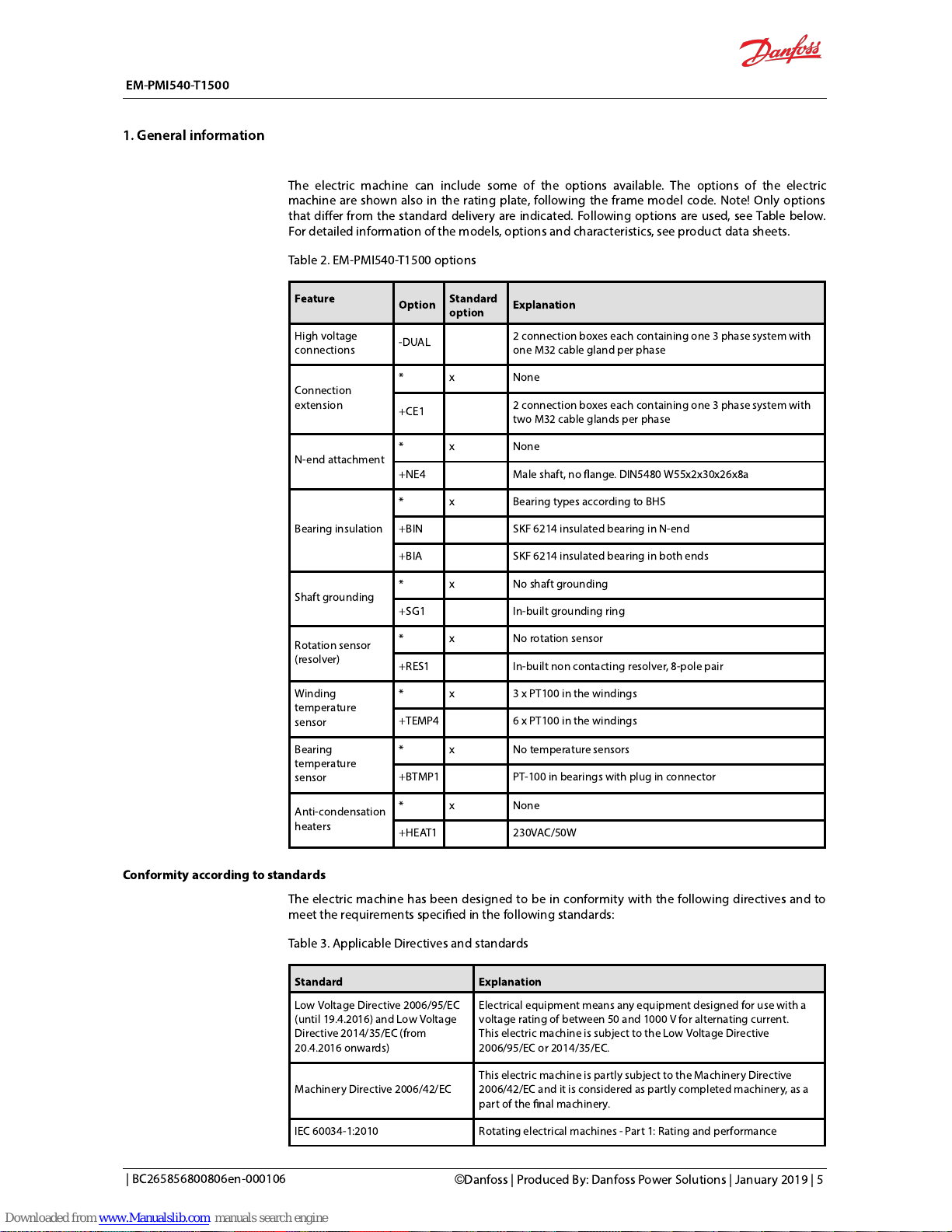

The electric machine can include some of the options available. The options of the electric

machine are shown alsoin the rating plate, following the frame model code. Note! Only options

that differ from the standard delivery are indicated. Following options are used, see Tablebelow.

For detailed information of the models, options and characteristics, see product data sheets.

Table 2. EM-PMI540-T1500 options

Feature

Option

Standard

option

Explanation

High voltage

connections

-DUAL

2 connection boxes each containing one 3 phase system with

one M32 cable gland per phase

Connection

extension

* x None

+CE1

2 connection boxes each containing one 3 phase system with

two M32 cable glands per phase

N-end attachment

* x None

+NE4 Male shaft, no ange. DIN5480 W55x2x30x26x8a

Bearing insulation

* x Bearing types according to BHS

+BIN SKF 6214 insulated bearing in N-end

+BIA SKF 6214 insulated bearing in both ends

Shaft grounding

* x No shaft grounding

+SG1 In-built grounding ring

Rotation sensor

(resolver)

* x No rotation sensor

+RES1 In-built non contacting resolver, 8-pole pair

Winding

temperature

sensor

* x 3 x PT100 in the windings

+TEMP4 6 xPT100 in the windings

Bearing

temperature

sensor

* x No temperature sensors

+BTMP1 PT-100 in bearings with plug in connector

Anti-condensation

heaters

* x None

+HEAT1 230VAC/50W

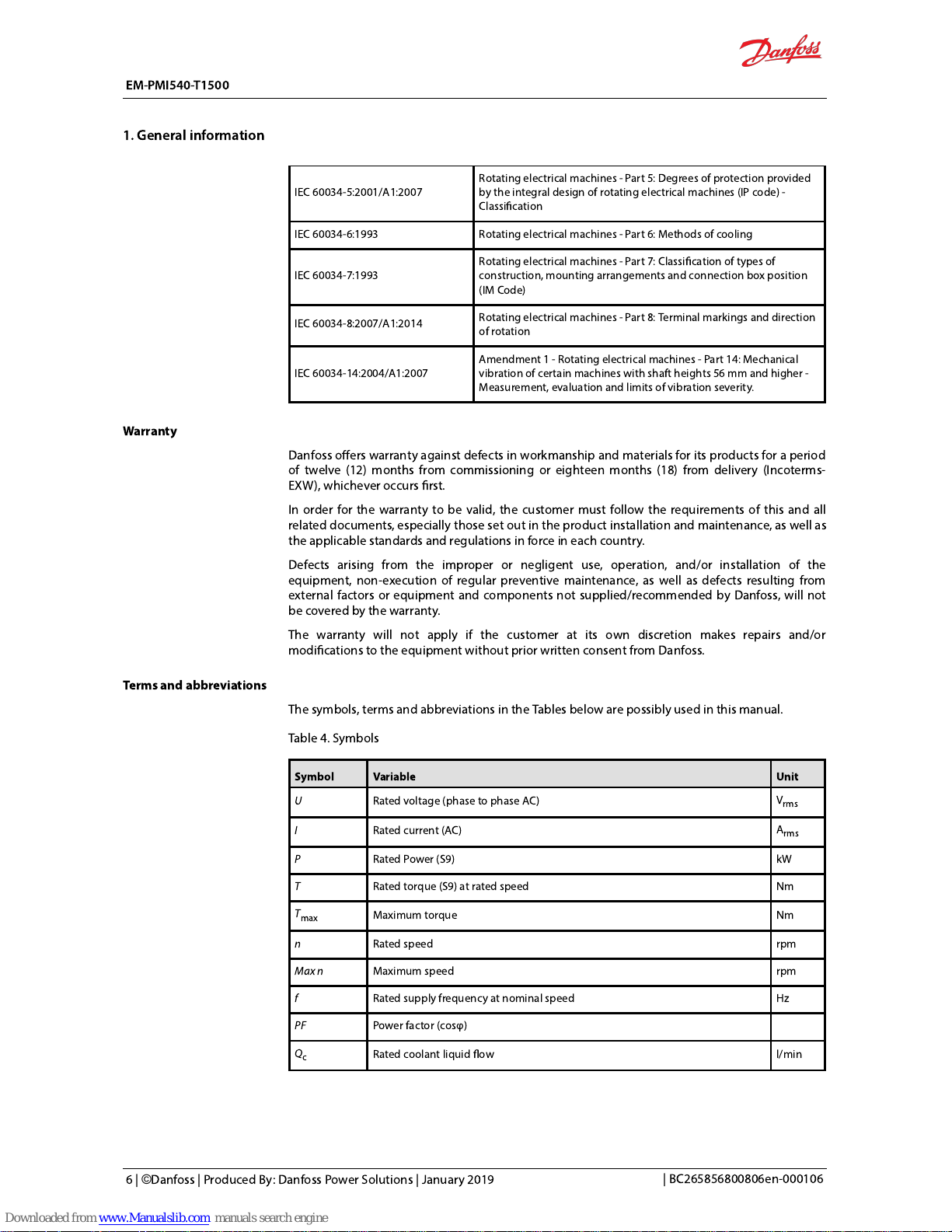

Conformity according to standards

The electric machinehas beendesigned to be in conformity with thefollowing directives and to

meet the requirements specied in the following standards:

Table 3. Applicable Directives and standards

Standard Explanation

Low Voltage Directive 2006/95/EC

(until 19.4.2016) andLow Voltage

Directive 2014/35/EC (from

20.4.2016 onwards)

Electrical equipment means any equipment designed for use with a

voltage rating of between 50 and 1000 V for alternating current.

Thiselectric machineissubject to the Low Voltage Directive

2006/95/EC or 2014/35/EC.

Machinery Directive 2006/42/EC

This electric machine is partly subject to the Machinery Directive

2006/42/EC and it is considered as partly completed machinery, as a

part of the nal machinery.

IEC 60034-1:2010 Rotating electrical machines - Part 1: Rating and performance

EM-PMI540-T1500

1. General information

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 5

Page 7

IEC 60034-5:2001/A1:2007

Rotating electrical machines - Part 5: Degrees of protection provided

by the integral design of rotating electrical machines (IP code) -

Classication

IEC 60034-6:1993 Rotating electrical machines - Part 6: Methods of cooling

IEC 60034-7:1993

Rotating electrical machines - Part 7: Classication of types of

construction, mounting arrangements and connection box position

(IM Code)

IEC 60034-8:2007/A1:2014

Rotating electrical machines - Part 8: Terminal markings and direction

of rotation

IEC 60034-14:2004/A1:2007

Amendment 1 - Rotating electrical machines - Part 14: Mechanical

vibration of certain machines with shaft heights 56 mm and higher -

Measurement, evaluation and limits of vibration severity.

Warranty

Danfoss offers warranty against defects in workmanship and materials for its products for a period

of twelve (12) months from commissioning or eighteen months (18) from delivery (Incoterms-

EXW), whichever occurs rst.

In order for the warranty to be valid, the customer must follow the requirements of this and all

related documents, especially those set out in the product installation and maintenance, as well as

the applicable standards and regulations in force in each country.

Defects arising from the improper or negligent use, operation, and/or installation of the

equipment, non-execution of regular preventive maintenance, as well as defects resulting from

external factors or equipment and components not supplied/recommended by Danfoss, will not

be covered by the warranty.

The warranty will not apply if the customer at its own discretion makes repairs and/or

modications to the equipment without prior written consent from Danfoss.

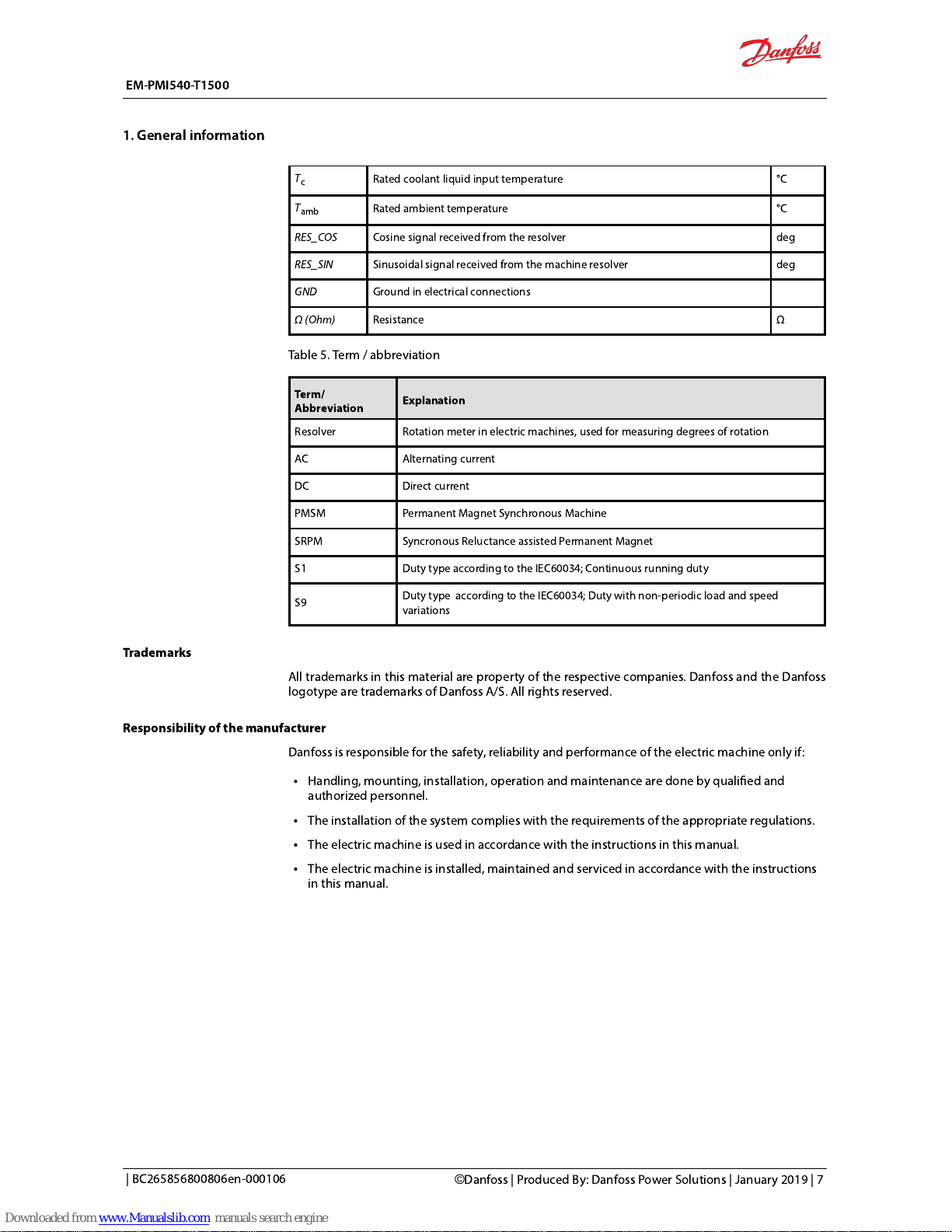

Terms and abbreviations

Thesymbols, terms and abbreviations in the Tables below are possibly used in this manual.

Table 4. Symbols

Symbol Variable Unit

U

Rated voltage (phase to phase AC)

V

rms

I

Rated current (AC)

A

rms

P

Rated Power (S9) kW

T

Rated torque (S9) at rated speed Nm

T

max

Maximum torque Nm

n

Rated speed rpm

Max n

Maximum speed rpm

f

Rated supply frequency at nominal speed Hz

PF

Power factor (cosφ)

Qc

Rated coolant liquid ow l/min

EM-PMI540-T1500

1. General information

6 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 8

Tc

Rated coolant liquid input temperature °C

T

amb

Rated ambient temperature °C

RES_COS

Cosine signal received from the resolver deg

RES_SIN

Sinusoidal signal received from the machine resolver deg

GND

Ground in electrical connections

Ω

(Ohm)

Resistance

Ω

Table 5. Term / abbreviation

Term/

Abbreviation

Explanation

Resolver Rotation meter in electric machines, used for measuring degrees of rotation

AC Alternating current

DC Direct current

PMSM Permanent Magnet Synchronous Machine

SRPM Syncronous Reluctance assisted Permanent Magnet

S1 Duty type according to the IEC60034;Continuous running duty

S9

Duty type according to the IEC60034; Duty with non-periodic load and speed

variations

Trademarks

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss

logotype are trademarks of Danfoss A/S. All rights reserved.

Responsibility of the manufacturer

Danfossis responsible for the safety, reliability and performance of the electric machineonly if:

Handling, mounting, installation, operation and maintenance are done by qualied and

authorizedpersonnel.

The installation of the system complies with the requirements of the appropriate regulations.

The electric machineis used in accordance with the instructions in this manual.

The electric machineis installed, maintained and serviced in accordance with the instructions

in this manual.

EM-PMI540-T1500

1. General information

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 7

Page 9

General safety statement

The electric machineis intended for use as a component for industrial and commercial

installations. The end product containing the electric machinemust conform with all related

regulations.

The use of the electric machineis prohibited in hazardous areas unless it is expressly designed

for such use.

The electric machineis intended for installation, use and maintenance by qualied personnel,

familiar with health and safety requirements and national legislation. Ignoring these

instructions may invalidate all applicable warranties.

These instructions must be followed to make sure of safe and correctinstallation, operation

and maintenance of the electric machine. They should be brought to the attention of anyone

who installs, operates or maintains the electric machineor associated equipment.

High voltage and rotating parts can cause serious or fatal injuries. For electric machinecovered

by this manual, it is important to observe safety precautions to protect personnel from

possible injury.

Safety message signal words

Safety message signal words indicate the severity of a potential hazard.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury. CAUTION may also alert against unsafe practices.

NOTICE

Indicates a potentially hazardous situation which, if not avoided, could result in property

damage.

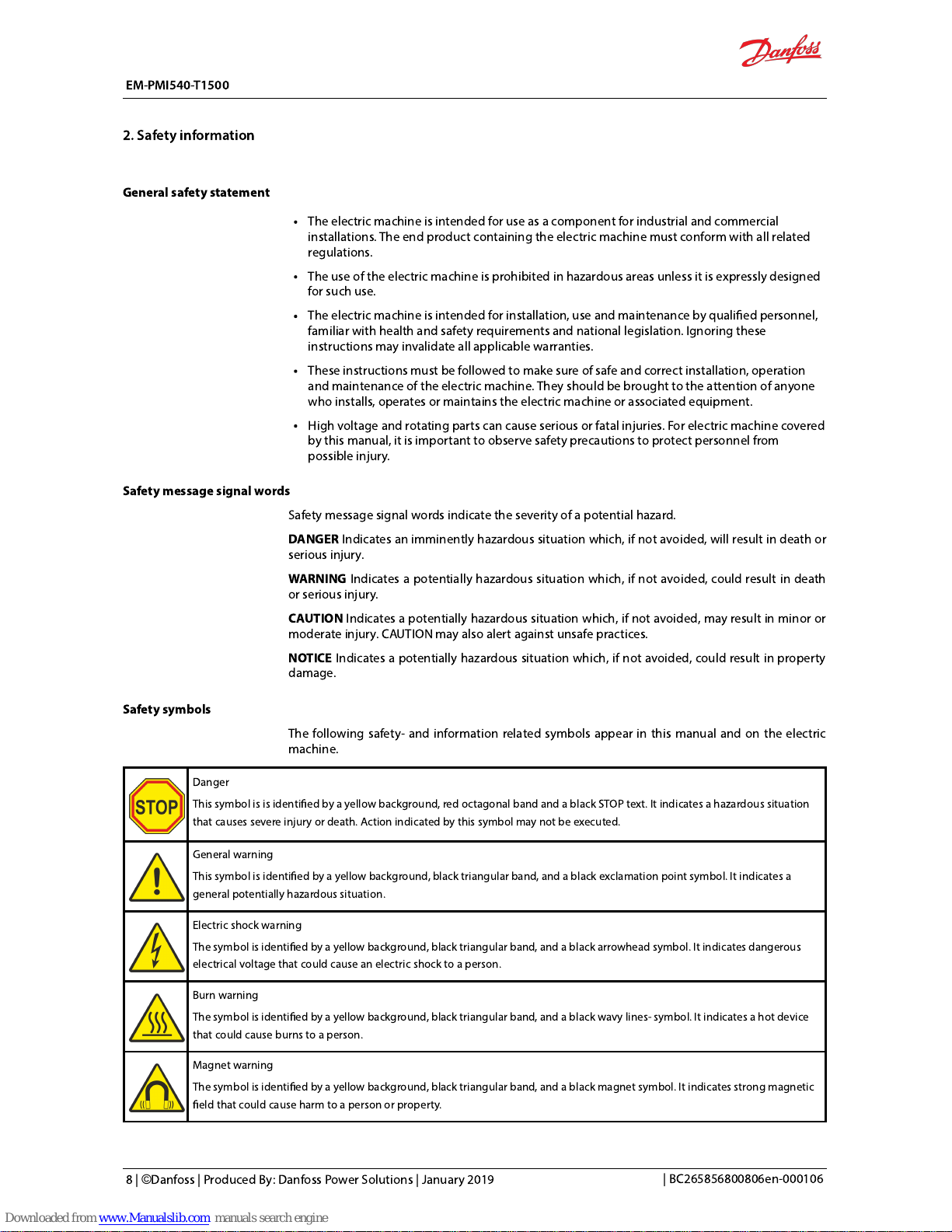

Safety symbols

The following safety- and information related symbols appear in this manual and on the electric

machine.

Danger

This symbol is is identied by a yellow background, red octagonal band and a black STOP text. It indicates a hazardous situation

that causes severe injury or death. Action indicated by this symbol may not be executed.

General warning

This symbol is identied by a yellow background, black triangular band, and a black exclamation point symbol. It indicates a

general potentially hazardous situation.

Electric shock warning

The symbol is identied by a yellow background, black triangular band, and a black arrowhead symbol. It indicates dangerous

electrical voltage that could cause an electric shock to a person.

Burn warning

The symbol is identied by a yellow background, black triangular band, and a black wavy lines- symbol. It indicates a hot device

that could cause burns to a person.

Magnet warning

The symbol is identied by a yellow background, black triangular band, and a black magnet symbol. It indicates strong magnetic

eld that could cause harm to a person or property.

EM-PMI540-T1500

2. Safety information

8 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 10

Rotating shaft warning

The symbol is identied by a yellow background, black triangular band, and a black rotating shaft symbol. It indicates strong

rotating shaft that could cause harm to a person or property.

General Information

Read the instructions in the manual

Personal protective equipment

Personal protective equipment shall be used when necessary during handling, installation and

maintenance of the electric machine to avoid injury.

Use eye protective equipment like safety goggles or mask when you workwith the electric device.Permanent damage to the eye

could be caused if bearing grease, melted nitrile rubber (radial lip seal), glycol or other uids splash.

Use hearing protective equipment when you workon the electric machine.Hearing injuries canbe caused by too loud noise

(noise in excess of 85 dBA).

Use head protective equipment like helmet when you liftthe electric machine! Head injuries canbe caused by object impact.

Use cut resistant gloves when youhandleand maintainthe electric machine.There is a risk of cut injuries.

Use protective footwear when you liftor movethe electric machine! Foot injuries could be caused if lifting system or lifting

brackets fail.

Security features

The electric machinehasat least one PT100 temperature sensor in the windings. The amount of

the sensors depend on the options chosen. The temperature signal(s) can be read out from the

measurement connector of the machine. You can connect the temperature signal to the

temperature surveillance pin in the inverter (EC-C) and make sure that the inverter has the

machine temperature protection feature activated.

Theelectric machinecan be ordered with bearing temperature measurement. This option includes

one PT100 temperature sensor at both D-end and N-end bearings. The signal can be read out

using a separate connector at both ends.

The electric machine hasleakage sensors (2pcs) at the lower part of the electric machine. This

feature is usefulin moist conditions to detect possible excessive water in contact with the electric

machine. Separate connectors for both leakage signals exist.

EM-PMI540-T1500

2. Safety information

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 9

Page 11

Electromagnetic compatibility (EMC)

When interfacing other equipment, connect only equipment that are specied as part of the system and that

arecompatible.

Magnetic and electromagnetic elds generated near the current-carrying conductors and permanent magnets in electric

machines represent a health danger to persons with heart pacemakers, metal implants and hearing aids. Persons with a

heart pacemaker, metal implants or hearing aids must consult a doctor before they enter the following areas:

Areas in which electric equipment and parts are operated

Areas in which electric equipment with permanent magnets are stored, mounted, operated or repaired

If necessary, perform a special electromagnetic compatibility (EMC) test on the installation

.

EMC stands for Electromagnetic compatibility. It is the ability of electric equipment to operate

without problems within an electromagnetic environment. Likewise, the equipment must not

disturb or interfere with any other product or system within its locality. This is a legal requirement

for all equipment taken into service within the European Economic Area (EEA).

Our products are designed with high standards of EMC in mind. Connect the power lines and

groundings along the instructions in this manual to achieve the required level of EMIprotection.

It is the responsibility of the installer to ensure that the equipment or system into which the

product is incorporated complies with the EMC legislation of the country of use. Within the

European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC.

EM-PMI540-T1500

2. Safety information

10 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 12

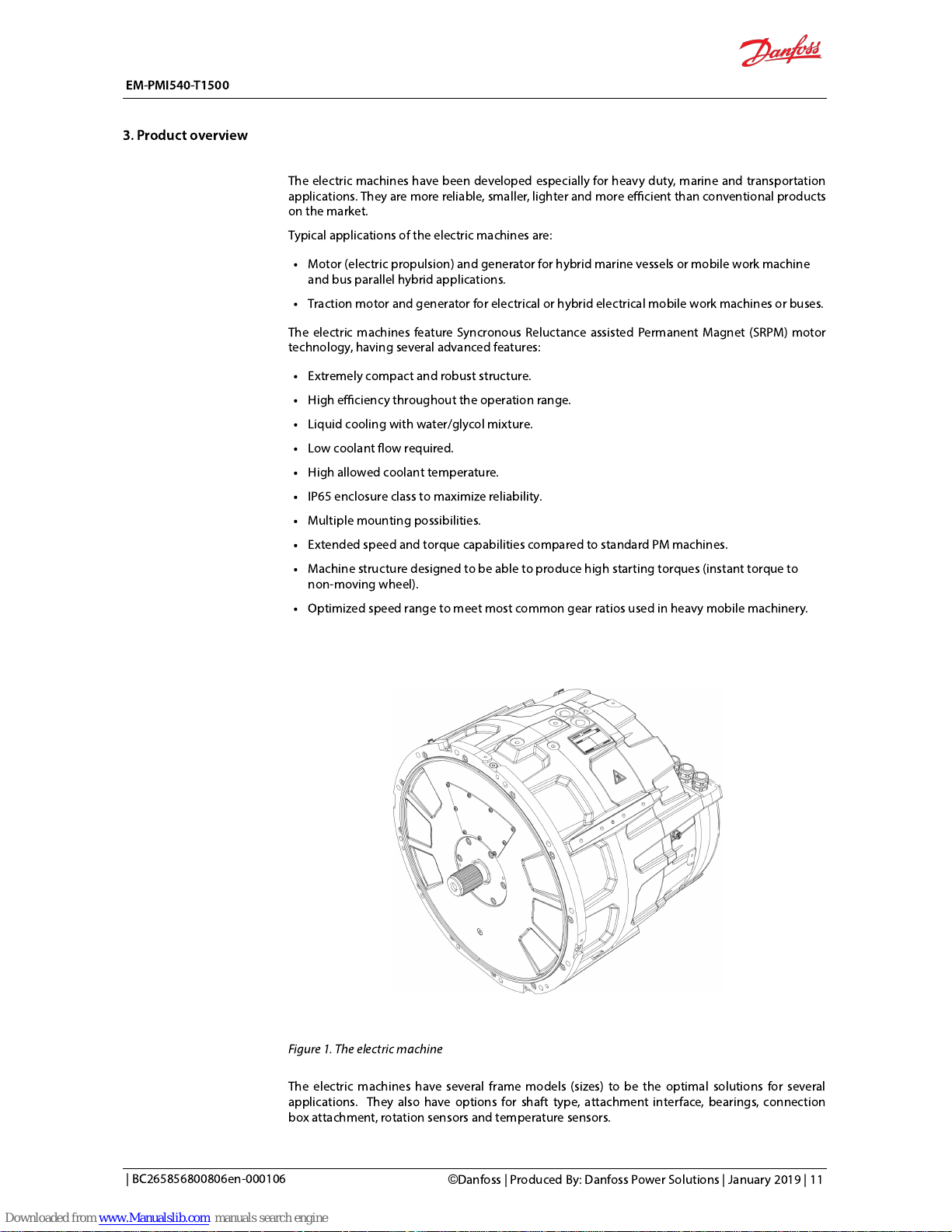

Theelectric machineshavebeen developed especially for heavy duty, marine and transportation

applications. They aremore reliable, smaller, lighter and moreefficientthan conventional products

on the market.

Typical applications ofthe electric machines are:

Motor (electric propulsion) and generator for hybrid marine vessels or mobile work machine

and bus parallel hybrid applications.

Traction motor and generator for electrical or hybrid electrical mobile work machines or buses.

The electric machines feature Syncronous Reluctance assisted Permanent Magnet (SRPM) motor

technology, having several advanced features:

Extremely compact and robust structure.

High efficiency throughout the operation range.

Liquid cooling with water/glycol mixture.

Low coolant ow required.

High allowed coolant temperature.

IP65 enclosure class to maximize reliability.

Multiple mounting possibilities.

Extended speed and torque capabilities compared to standard PM machines.

Machine structure designed to be able to produce high starting torques (instant torque to

non-moving wheel).

Optimized speed range to meet most common gear ratios used in heavy mobile machinery.

Figure 1. The electric machine

Theelectric machines have several frame models (sizes) to be the optimal solutions for several

applications. Theyalso haveoptions for shaft type, attachment interface, bearings, connection

box attachment, rotation sensors and temperature sensors.

EM-PMI540-T1500

3. Product overview

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 11

Page 13

Intended use of the electric machine

This electric machineisintended to be used as a motor or generator and as a part of a machinery,

for examplein:

Power train of a marine vessel, transportation vehicle or a heavy duty work machine.

Power generation equipment.

Theelectric machineisintended to be powered and controlled with an inverter or inverters

capable of supplying three-phase alternating current and that is capable of controlling the

electricmachine. The electric machineisnot suitable for direct online use.

In a power generation equipment theelectric machines are intended to be powered by a prime

mover, for example,an internal combustion engine and controlled by the above mentioned

electric power inverter.

The electricmachineissolely intended for professional use, and may be operated only by trained

professionals. The maintenance of the electric machine may be doneonly by trained professionals.

Not-allowed use of theelectric machine

It is forbidden to use, handle and maintain the machine in following ways (including but not

limited to):

Using the electric machinefor other purposes than dened in thismanual.

Disregarding the obligation to comply with the manual, safety signs and rating plate of the

electric machine.

Using the electric machine, making adjustments and maintenance without rst reading

thismanual.

Exceeding the designed limits during the electric machine operation.

Using non-original service parts of wrong material causing corrosion problems and mechanical

failures in time.

Operating and performing maintenance for the electric machinewithout appropriate personal

protective equipment.

Using electric machine parts like frame, shaft end or terminal box for climbing or for support

for other structures.

Causing any kind of impact forces to the electric machine (for examplehitting or hammering

or dropping objects).

Operating the electric machinewith electric connections other than dened in the manual

and/or other documents.

Operating the electric machinewith insufficiently tightened connections or cable glands.

Operating the electric machinewith power cables routed against the instructions.

Operating the electric machinewithout properly dimensioned and operating cooling system.

Operating theelectric machinewithout following the bearing lubrication instructions.

Accessing the connection box(es) of the electric machine, doingmaintenance or adjustment

operations on the electric machine withthe electricity connected.

Accessing the connection box(es) ifthe shaft canbe turned by an external prime mover.

Lifting the electric machinefrom wrong lifting points and without correctlifting equipment.

EM-PMI540-T1500

3. Product overview

12 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 14

Lifting additional load with the machine.

Storing the electric machineoutdoors in wet or dusty conditions.

Storing the electric machinewithout correctsupport to prevent rolling or falling of the

machines.

Using the electric machinein potentially explosive environment.

Allowing dirt or liquid to enter into the electric machine or connection box.

Using cables that can't withstand the maximum currents of the electric machine.

Used technology

The electric machineis aSyncronous Reluctance assisted Permanent Magnet (SRPM) machine. This

technology has several benets compared to standard permanent magnet (PM) technology and

traditional induction machine (IM) technology. The SRPM technology combines the benets of PM

and Syncronous Reluctance technology, having increased torque capability over wide speed range

and ability to produce torque to higher speeds. The electric machine efficiency at lower speeds is

also good.

The supply current to the machine stator windings create rotating magnetic eld, which in turn

rotates the rotor containing permanent magnets. In the syncronous permanent magnet machine,

the rotation of the rotor (shaft) is syncronized with the frequency of the power supply current. The

reluctance technology maximizes the pull-out torque of the machine.

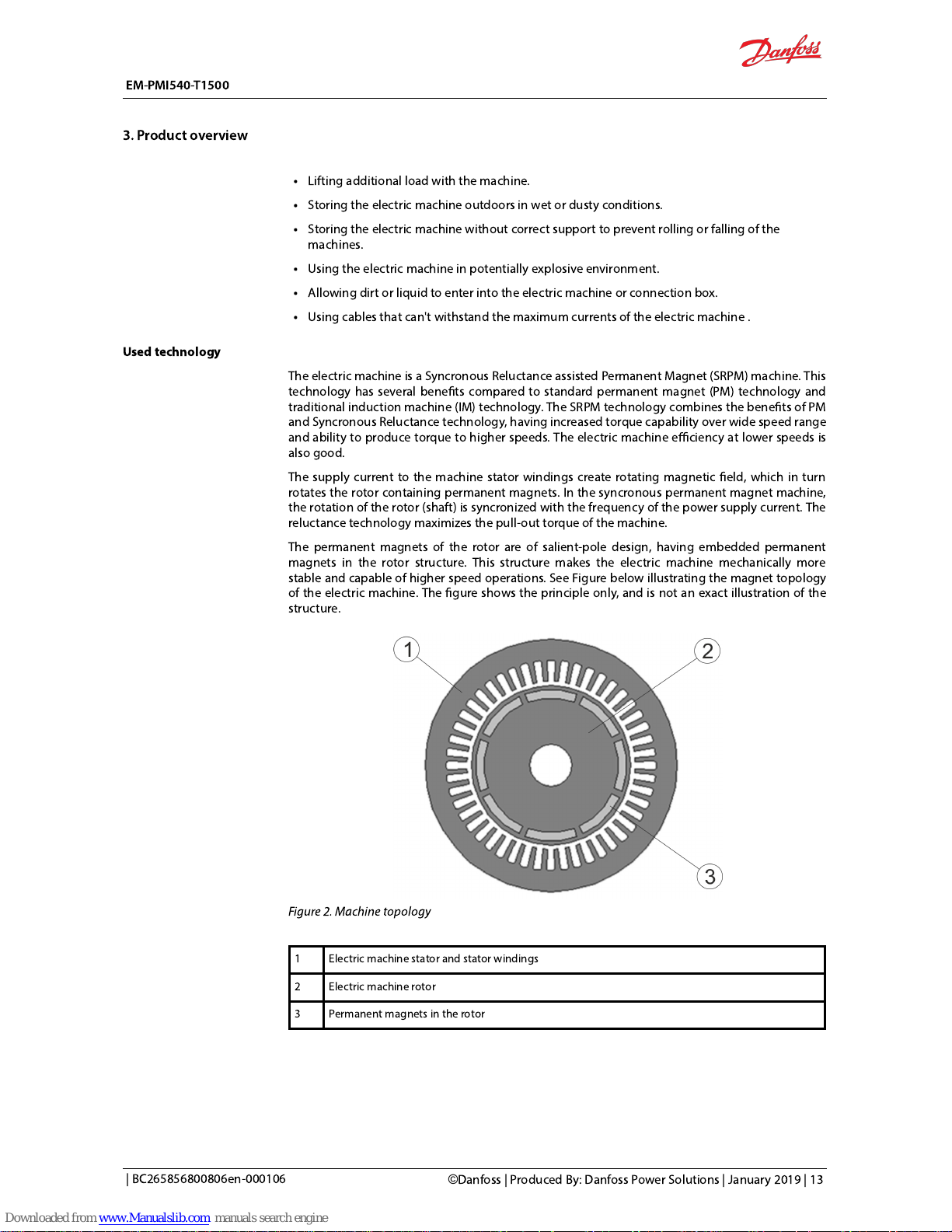

The permanent magnets ofthe rotor are of salient-pole design, having embedded permanent

magnets in the rotor structure. This structure makes theelectric machine mechanically more

stable and capable of higher speed operations. See Figure below illustrating the magnet topology

of the electric machine. The gure shows the principle only, and is not an exact illustration of the

structure.

Figure 2. Machinetopology

1 Electric machine stator and stator windings

2 Electric machine rotor

3 Permanent magnets in the rotor

EM-PMI540-T1500

3. Product overview

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 13

Page 15

System introduction

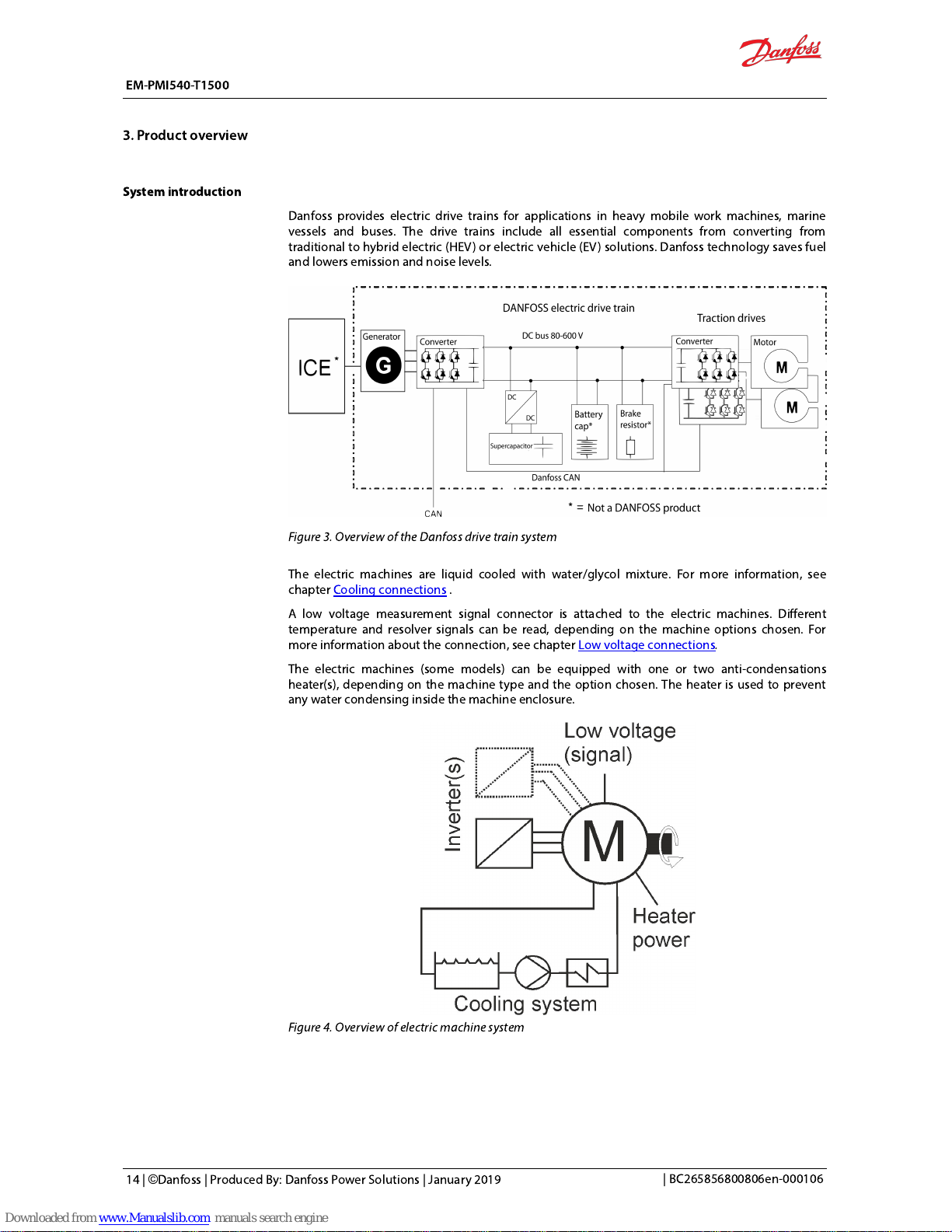

Danfoss provides electric drive trains for applications in heavy mobile work machines, marine

vessels and buses. The drive trains include all essential components from converting from

traditional to hybrid electric (HEV) or electric vehicle (EV) solutions. Danfosstechnology saves fuel

and lowers emission and noise levels.

Figure 3. Overview of the Danfoss drive train system

The electric machines are liquid cooled with water/glycol mixture. For more information, see

chapterCooling connections.

A low voltage measurement signal connector is attached to the electric machines. Different

temperature and resolver signals can be read, depending on the machine options chosen. For

more information about the connection, see chapterLow voltageconnections

.

Theelectric machines (some models) can be equipped with one or two anti-condensations

heater(s), depending on the machine type and the option chosen. The heater is used to prevent

any water condensing inside the machine enclosure.

Figure 4. Overview of electric machine system

EM-PMI540-T1500

3. Product overview

14 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 16

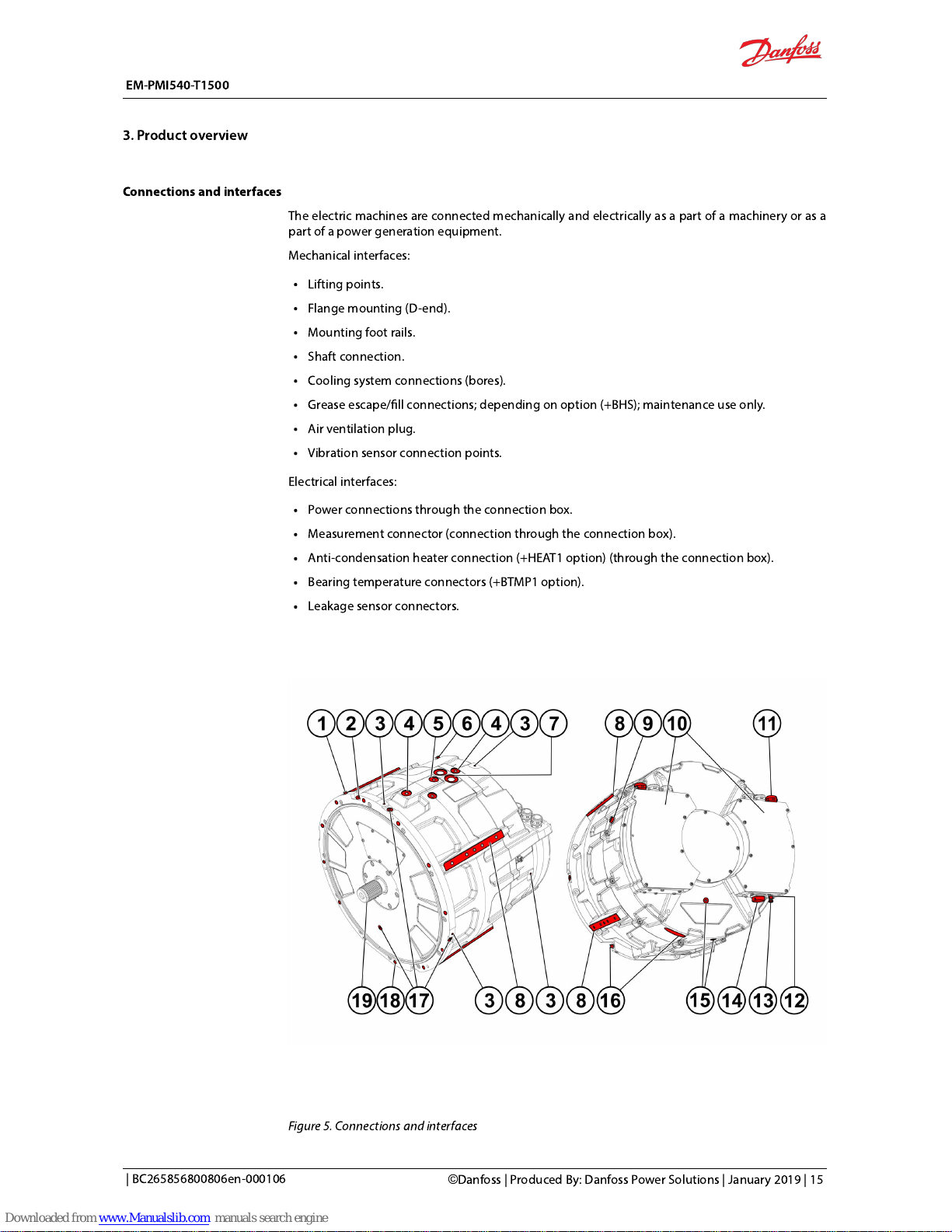

Connections and interfaces

The electric machines are connected mechanically and electrically as a part of a machinery or as a

part of a power generation equipment.

Mechanical interfaces:

Lifting points.

Flange mounting (D-end).

Mounting foot rails.

Shaft connection.

Cooling system connections (bores).

Grease escape/ll connections; depending on option (+BHS); maintenance use only.

Air ventilation plug.

Vibration sensor connection points.

Electrical interfaces:

Power connections through the connection box.

Measurement connector (connection through the connection box).

Anti-condensation heater connection (+HEAT1 option) (through the connection box).

Bearing temperature connectors (+BTMP1 option).

Leakage sensor connectors.

Figure 5. Connections and interfaces

EM-PMI540-T1500

3. Product overview

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 15

Page 17

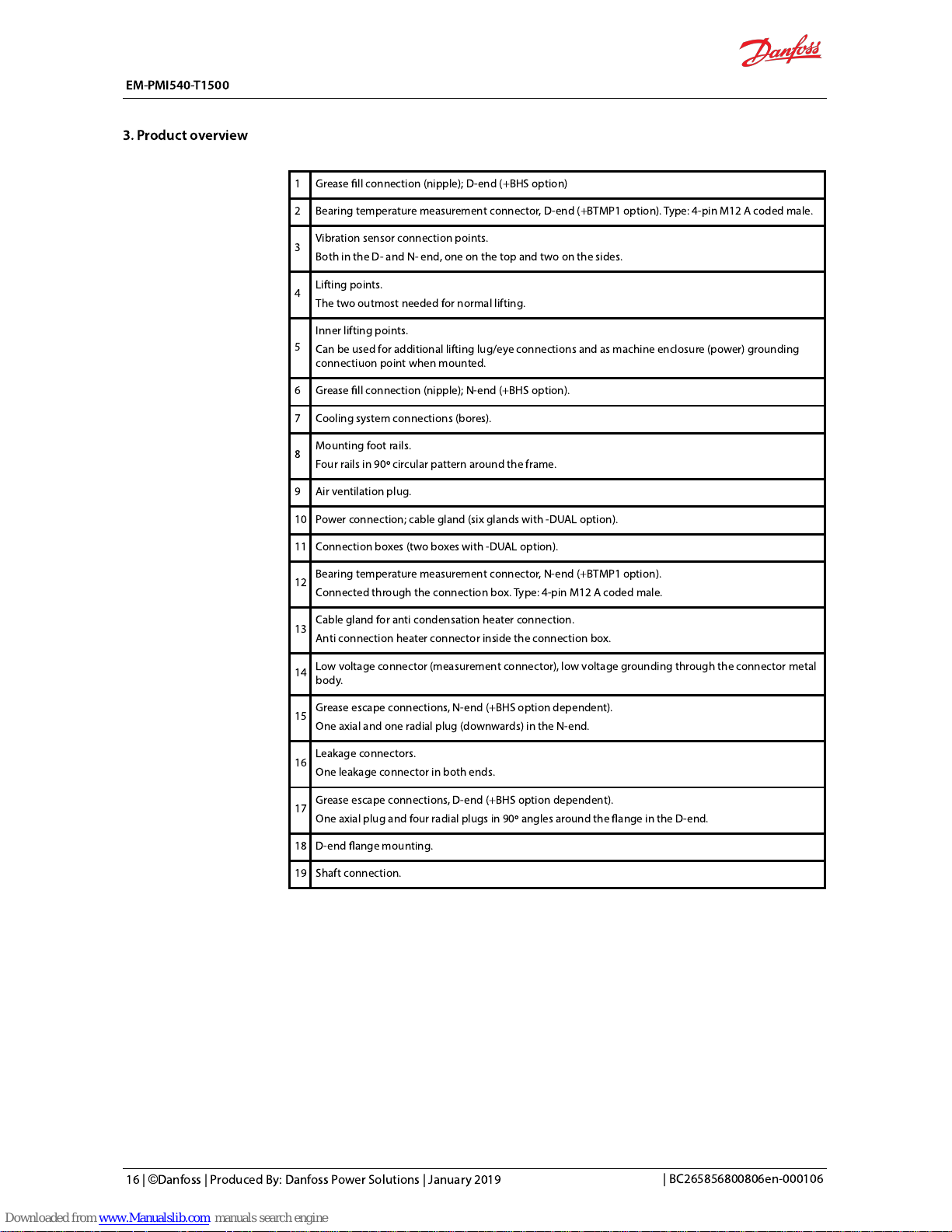

1 Grease ll connection (nipple); D-end (+BHS option)

2 Bearing temperature measurement connector, D-end (+BTMP1 option).Type:4-pin M12 A coded male.

3

Vibration sensor connection points.

Both in the D- and N- end, one on the top and two on the sides.

4

Lifting points.

The two outmost needed for normal lifting.

5

Inner lifting points.

Can be used for additional lifting lug/eye connections and as machine enclosure (power) grounding

connectiuon point when mounted.

6 Grease ll connection (nipple); N-end (+BHS option).

7 Cooling system connections (bores).

8

Mounting foot rails.

Four rails in 90º circular pattern around the frame.

9 Air ventilation plug.

10 Power connection; cable gland (six glands with -DUAL option).

11 Connection boxes (two boxes with -DUAL option).

12

Bearing temperature measurement connector, N-end (+BTMP1 option).

Connected through the connection box.Type:4-pin M12 A coded male.

13

Cable gland for anti condensation heater connection.

Anti connection heater connector inside the connection box.

14

Low voltage connector (measurement connector), low voltage grounding through the connector metal

body.

15

Grease escape connections, N-end (+BHS option dependent).

One axial and one radial plug (downwards) in the N-end.

16

Leakage connectors.

One leakage connector in both ends.

17

Grease escape connections, D-end (+BHS option dependent).

One axial plug and four radial plugs in 90º angles around the ange in the D-end.

18 D-end ange mounting.

19 Shaft connection.

EM-PMI540-T1500

3. Product overview

16 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 18

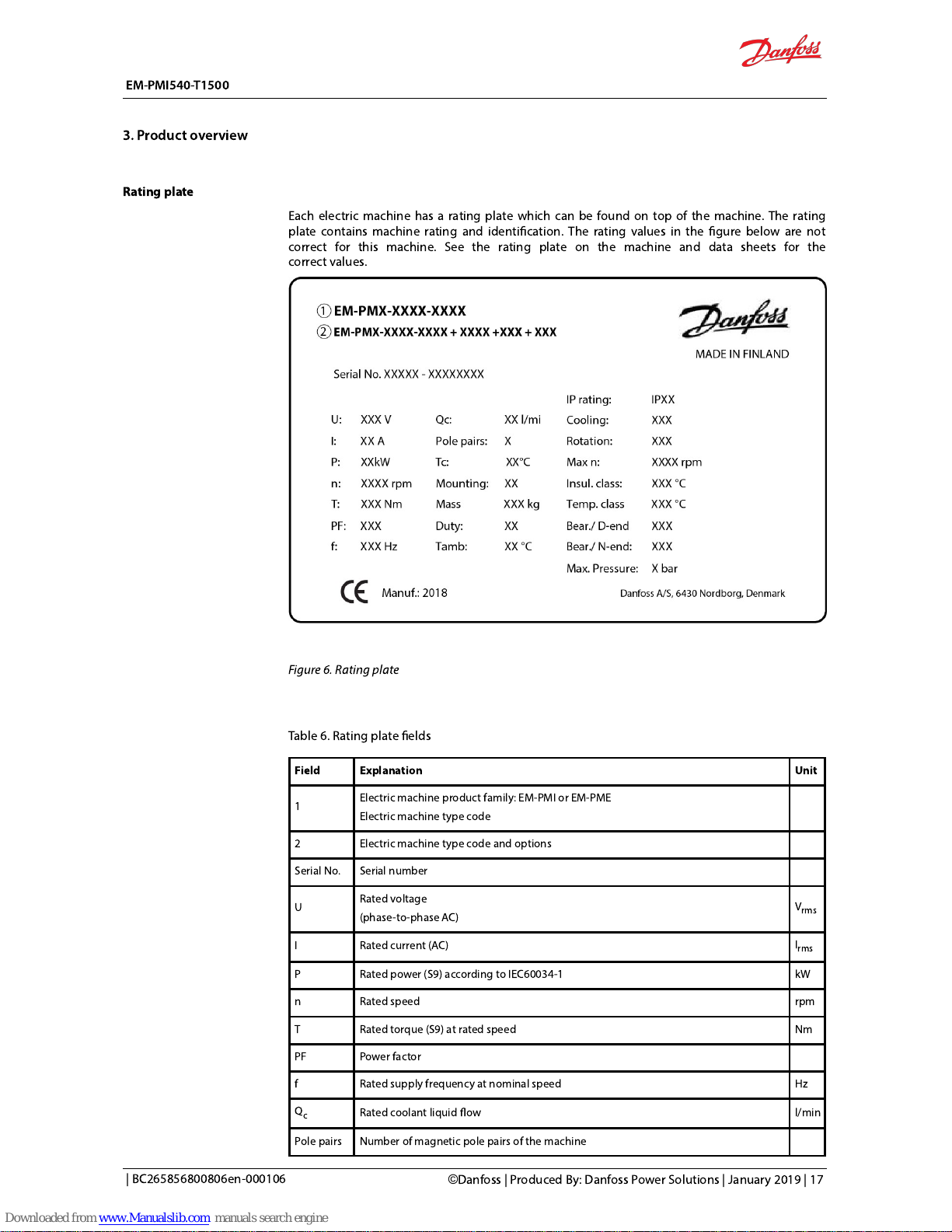

Rating plate

Each electric machine has a rating plate which can be found on top of the machine. The rating

plate contains machine rating and identication. The rating values in the gure below are not

correct for this machine. See the rating plate on the machine and data sheets for the

correctvalues.

Figure 6. Rating plate

Table 6. Rating plate elds

Field Explanation Unit

1

Electric machine product family: EM-PMI or EM-PME

Electric machine type code

2 Electric machine type code and options

Serial No. Serial number

U

Rated voltage

(phase-to-phase AC)

V

rms

I Rated current (AC)

I

rms

P Rated power (S9) according to IEC60034-1 kW

n Rated speed rpm

T Rated torque (S9) at rated speed Nm

PF Power factor

f Rated supply frequency at nominal speed Hz

Qc

Rated coolant liquid ow l/min

Pole pairs Number of magnetic pole pairs of the machine

EM-PMI540-T1500

3. Product overview

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 17

Page 19

Tc

Rated coolant liquid input temperature °C

Mounting Allowed mounting position according to IEC60034-7

Mass Mass of the electric machine kg

Duty Dened rotating electric machine duty cycles by IEC60034-1 standard

T

amb

Rated ambient temperature °C

IP rating Enclosure class according to IEC60034-5

Cooling Cooling method according to IEC60034-6

Rotation Direction of rotorrotation with default phase order. Observed facing the D-end.

Max n Maximum rotation speed rpm

Insul. class Temperature rating (class) of insulation of the machine according to IEC60034-1

Temp. class

Temperature rating (class) of individual insulation materials of the insulation according

to IEC60034-1

Bear. / D-

end

Bearing type in the D-end of the machine

Bear. / N-

end

Bearing type in the N-end of the machine

Max.

pressure

Cooling liquid max pressure

Tightening torques

Connection Torque

Mounting bolts for D-end attachment 69 Nm

Connection box mounting screws 7 Nm

Connection box cover plate screws 4 Nm

Cable gland (tighten from the cap of the gland) 15 Nm

Cable lug 15Nm

EM-PMI540-T1500

3. Product overview

18 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 20

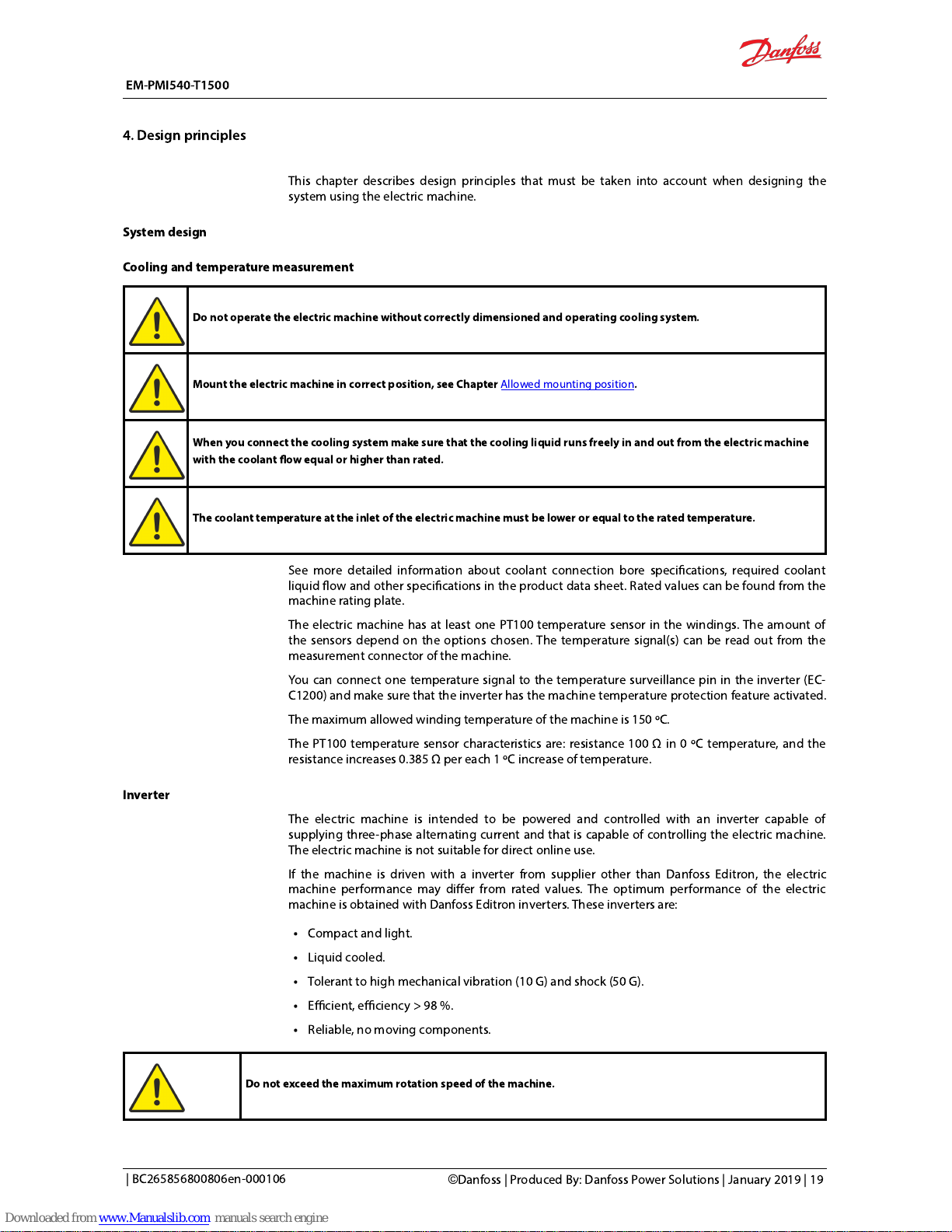

This chapter describes design principles that must be taken into account when designing the

system using theelectric machine.

System design

Cooling and temperature measurement

Do not operate the electric machine without correctlydimensioned and operating cooling system.

Mount the electric machine in correct position, see ChapterAllowed mounting position

.

When you connectthe cooling system make surethat the cooling liquid runs freely in and out from the electric machine

with the coolant ow equal or higher than rated.

The coolant temperature at the inlet of the electric machine must be lower or equal to the rated temperature.

See more detailed information about coolant connection bore specications, required coolant

liquid ow and other specications in the product data sheet. Rated values can be found from the

machine rating plate.

The electric machinehasat least one PT100 temperature sensor in the windings. The amount of

the sensors depend on the options chosen. The temperature signal(s) can be read out from the

measurement connector of the machine.

You can connect one temperature signal to the temperature surveillance pin in the inverter (EC-

C1200) and make sure that the inverter has the machine temperature protection feature activated.

The maximum allowed winding temperature of the machine is 150 ºC.

The PT100 temperature sensor characteristics are: resistance 100 Ω in 0 ºC temperature, and the

resistance increases 0.385 Ω per each 1 ºC increase of temperature.

Inverter

The electric machineisintended to be powered and controlled with an inverter capable of

supplying three-phase alternating current and that is capable of controlling the electricmachine.

The electric machineis not suitable for direct online use.

If the machine is driven with a inverter fromsupplier other than Danfoss Editron, the electric

machine performance may differ from rated values. The optimum performance of the electric

machine is obtained with Danfoss Editroninverters. These inverters are:

Compact and light.

Liquid cooled.

Tolerant to high mechanical vibration (10 G) and shock (50 G).

Efficient, efficiency > 98 %.

Reliable, no moving components.

Do not exceed the maximum rotation speed of the machine.

EM-PMI540-T1500

4. Design principles

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 19

Page 21

Figure 7. EC-C1200

Figure 8. Schematic of the inverter powerstage

The main machine power driving parameters are shown in the machine rating plate. For

moreinformation, please contact Danfossrepresentative.

You can connect one of the temperature signals (from the low voltage connector) to the

temperature surveillance pin in the inverterand make sure that the inverter has the machine

temperature protection feature activated.

Mounting structure

Supporting structure requirements

Do not install the electric machine near or in direct contact with easily ammable materials. The surface of the electric

machine can be hot.

The mating housing arrangement of the electric machine must be secure and sufficiently rigid to

prevent vibrations and mechanical failures. Necessary actions should be taken to avoid corrosion

on the mating housing arrangement.

EM-PMI540-T1500

4. Design principles

20 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 22

The supporting structure for the electric machine must be such that the machine can be mounted

using its allowed mounting positions, see chapterAllowed mounting positions.

Themounting space must be adequate for the machine mounting and possible auxiliary

components. See the length and the diameter data of the electric machine from the product

drawing. Main dimensions of the electric machine are shownin the Figure below(not an exact

illustration of the electric machine).

The electric machine has a SAE 1/2 D-end ange (IM 3001). A SAE 1/2 ywheel housing is required

as mating ange. The connection boxes are connected to N-end.

Figure 9. Main dimensions of the machine

Symbol Explanation

L

F

Length of the machine frame (including the connection box(es).

L

S

Length of the shaft (from the end of the shaft to the machine D-end mounting shoulder).

D

M

Diameter of the ange mounting bore circle.

D

S

Diameter of the mounting shoulder.

For all dimensions of the electric machine, see the product drawings.

Shaft alignment and load

Improper alignment (misalignment) may result in bearing overloads, premature bearing failures, vibrations and shaft

failures. Flexible coupling doesnot compensate for excessive misalignment.

The type of the electricmachine shaft is cylindrical shaft with diameter of 70 mm h7 and contact

length of 130 mm. The ange type is SAE 1/2 Transmission housing.

Alignment between the shaft and mating structure must be accurate.

The misalignment can be parallel or angular misalignment, or combination of those. With parallel

misalignment, the center lines of both shafts are parallel but they are offset. With angular

misalignment, the shafts are at an angle to each other. Figures below illustrate the parallel and

angular misalignment.

EM-PMI540-T1500

4. Design principles

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 21

Page 23

Figure 10. Parallel alignment of the shaft and mating structure

Figure 11. Angular alignment of the shaft and mating structure

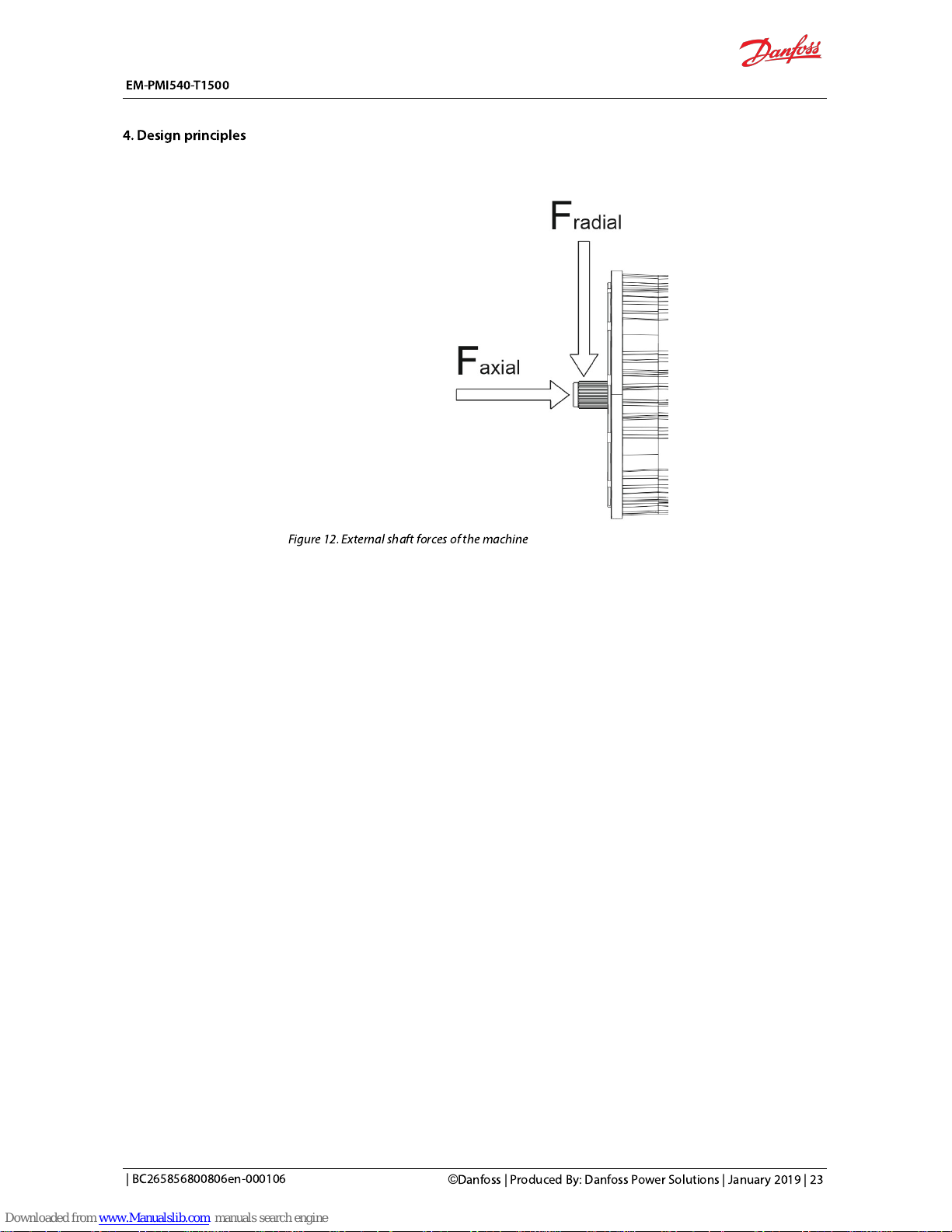

The maximum external force directed to the shaft axially and radially may not exceed machine specic values.Calculate

these values with the documentDOC-000454.

EM-PMI540-T1500

4. Design principles

22 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 24

Figure 12. External shaft forces of the machine

EM-PMI540-T1500

4. Design principles

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 23

Page 25

Transportation

Heavy equipment. Handle with care during transportation

.

Electric machineisshipped in rst class condition. It hasbeen inspected and packed correctlyto

prevent damage from ordinary handling during shipment. During transportation, shocks, fails and

humidity should be avoided. Protectthe cooling holes for transportation.

The weight of the electric machine can be found on the machine rating plate, and in the product

data sheet.

Receiving and unpacking

Do not touch the electric machine during the insulation resistance check. Discharge the electric machine afterwards.

Do not touchthe electrical terminals when the rotoris rotated. The electrical terminals have dangerous voltage during

rotation. Contact Danfoss representative if the rotorcan't be rotated.

Check upon arrival and unpacking

The electric machine and the package must be inspected immediately upon arrival. Make

surethat the rating plate data in the cover letter complieswith the purchase order. Any

external damage (in shaft-ends, anges, electrical interfacesand paint) must be photographed

and reported immediately.

It is recommended to measurethe insulation resistance of the machine upon arrival, or before

installing the electric machine.Reference value of150 MΩ

shall be exceeded in room

temperature, otherwise contact Danfoss representative.

Remove any shaft locks androtate theshaft by hand. It is normal for the rotation of the shaftto

be difficult.

Lifting

Use correct, adequately dimensioned lifting devices and inspect thembefore lifting.

Do not lift from the shaft of the electric machine!

Do not apply any excess weight on the electric machine when lifting.

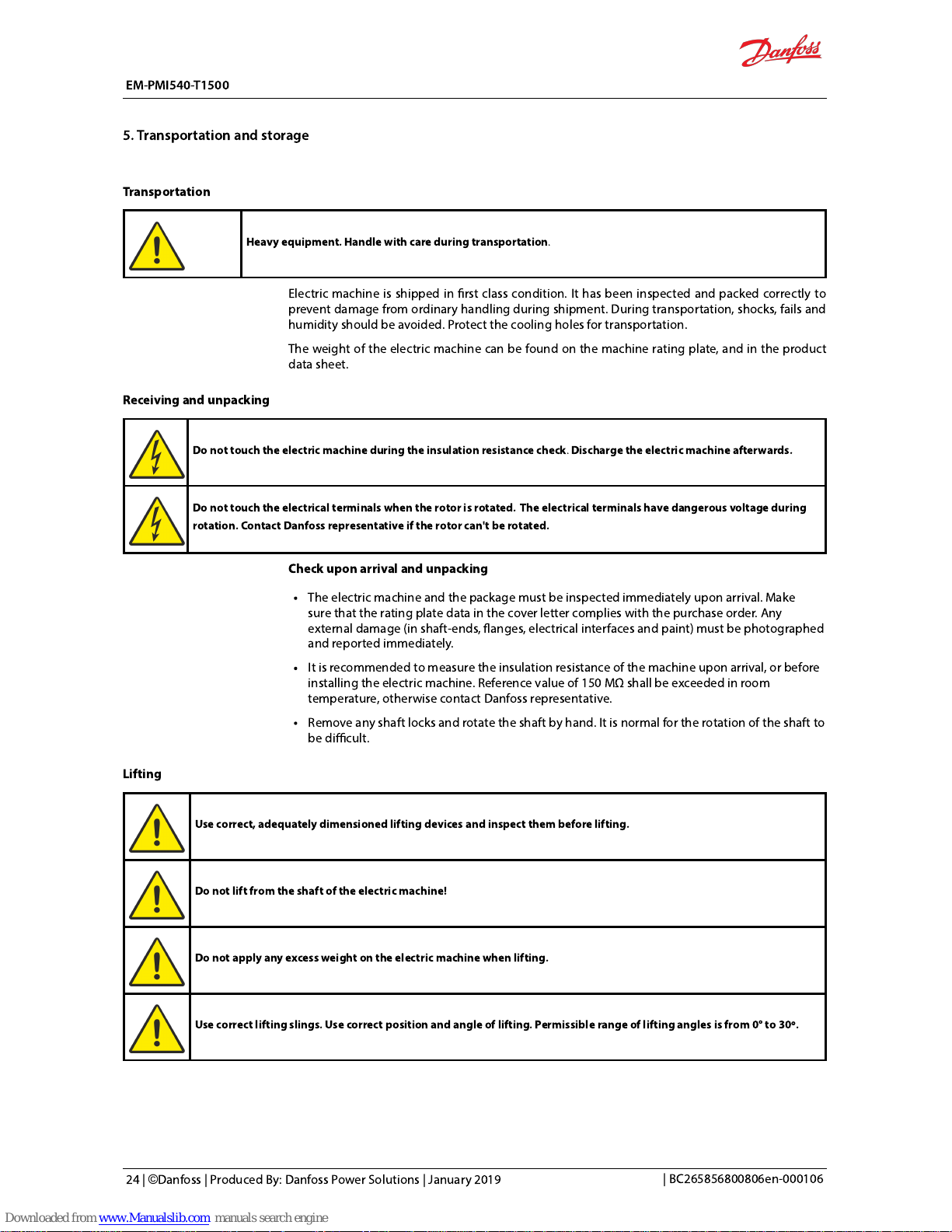

Use correct lifting slings. Use correct position and angle of lifting. Permissible range of lifting angles is from 0° to 30º.

EM-PMI540-T1500

5. Transportation and storage

24 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 26

See the electric machine rating plate and data sheets for weight information.

Lift the electric machine using the correct lifting lugs/eyes only.

Do not go under a lifted load.

Figure 13. Lifting lugs/eyes for lifting slings and lifting position of the electric machine

1

Lifting eye type of ANSI B18.15.1M M12x19 is recommended in M12 bores for horizontal and vertical

lifting. Not included in the delivery. Use the outmost lifting positions in horizontal lifting.

Horizontal lifting

Install 2 pieces of lifting eyes to the lifting bores in the electric machine frame. The lifting eyes

should be mounted with their full threaded length.

Vertical lifting

Install 4 pieces of lifting eyes to the lifting bores (M12x1,75) in the N-end bearing shield (non-shaft

end). Lifting eye should be mounted with its full threaded length.

EM-PMI540-T1500

5. Transportation and storage

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 25

Page 27

Storage

Do not touchthe electrical terminals when the shaft is rotated. The electrical terminals have dangerous voltage during

rotation.

Store the electric machine always indoors withthe storage temperature above -20 ºC and the

relative humidity less than 60 %.

The storage should be dry, dust free and vibration free.

Treat the unprotected electric machine surfaces such as the shaft-end and anges against

corrosion. Seal the cable exit holes and cooling bores for storage.

The electric machine must not be subject to any external vibrations during storage to avoid

damage to the bearings.

It is recommendedto use anti-condensation heaters, if tted, or direct winding heating to

avoid water condensing in the electric machine.

Rotate the shaft of the electric machine by hand monthly at least ten revolutions to prevent

grease migration.

Extended storage

Electric machines equipped with relubricable bearings (+BHS option): Apply grease before and

after long term storage.

It is recommendedto inspect the electric machine in storage at periodic intervals. Use attached

storage checklist.

EM-PMI540-T1500

5. Transportation and storage

26 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 28

Risk of electric shock when the connection box is open.When you workwith power connections make sure that electricity

is disconnected and rotorrotation is prevented.

Magnetic and electromagnetic elds generated near the current-carrying conductors and permanent magnets in electric

machines represent a health danger to persons with heart pacemakers, metal implants and hearing aids. Persons with a

heart pacemaker, metal implants or hearing aids must consult a doctor before they enter the following areas:

Areas in which electric equipment and parts are operated.

Areas in which electric equipment with permanent magnets are stored, mounted, operated or repaired.

Risk of electric shock when working with the electric machine. Use isolated electric tools.

Only trained and qualied personnel familiar with the relevant safety requirements canwork withthe electric machine.

Use correctpersonal protective equipment when you arenear the electric machine.

Read the instructions in thismanual before you installthe electric machine.

Required tools

Following tools are required to install the electric machine:

Grease pump.

Ratchet torque wrench.

Hex head wrench kit with different metric sizes.

Socket wrench kit with different metric sizes.

Cable gland tightening tool. Size according to cable glands.

Cable skinning knife.

Crimping tool for cable lugs. Consult cable lug manufacturer for correct size.

Lifting slings with sufficient rated capacity.

Lifting eyes. Size according to machine type. See Chapter

Lifting

.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 27

Page 29

Insulation resistance test

Do not touch the electric machine during theinsulation resistance check. Discharge the machine afterwards.

Measure the insulation resistance of the electric machine before the installation of the electric

machine. Because of the structure of the electric machine it is possible that the stator is damaged

during the installation.The reference value of150 MΩ

mustbe exceeded in room temperature.

Contact Danfossrepresentative if the reference value is not exceeded.

Mechanical installation

Allowed mounting positions

Theelectric machine with standard horizontal mounting optionmust be installedhorizontally. It

can be turned around its axis (shaft) for maximum of 45° to both directions from its default

assembly direction.See Figure below.

The electric machine canbe installedhorizontally or vertically (MHV option).See Figures below.

Figure 14. Allowed horizontal mounting position of the electric machine, mounting option 2

EM-PMI540-T1500

6. Installation

28 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 30

Figure 15. Allowed vertical mounting position of the electric machine, mounting option 3

Mounting the electric machine

Do not to exceed the maximum axial and radial forces calculated for the shaft with the documentDOC-000454.

Do not use the N-end of the electric machine for mounting the electric machine.

Refer to chapterAllowed mounting positionsfor the correct mounting positions of the electric machine.

Mount the electric machine on a correct supporting structure that is discussed in chapter

"Supporting structure requirements".

1. Lift the electric machine to the correct mounting position. See Chapter Liftingfor details

.

2. The electric machine is mounted from its D-end ange (SAE1/2 transmission housing ange).

SAE1/2 ywheel housing is required as a mating ange.The mounting foot rails in the side of the

electric machine (4 pieces) can also be used for mounting.

3. Align the electric machine with the mating housing alignment. See ChapterShaft alignment

and load.

4. Connect the shaft of the electric machine, make sure to use full spline engagement. Lubricate

the spline.

A recommended spline lubricant is a 50/50 compound of a high temperature greaseand a molybdenum disulphide

powder.When applied initially and re-applied atproper intervals, it will help preventfretting corrosion and premature

wear.This lubricant is not soluble in oil andshould be used accordingly. Furtherproducts which may be recommended

areMolycote, Metaux, Never Seeze, Optimoland similar.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 29

Page 31

5.Attach the mounting bolts. For steel housing the minimum lenght of the bolt is 40 mm and for

aluminium housing 45 mm.

Use tightening torque of 69 Nm for D-end bolts. The N-end of theelectric machine is not intended to be be used for

mounting.

Figure 16. Mechanical mounting connections of the electric machine (horizontal mounting)

EM-PMI540-T1500

6. Installation

30 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 32

1 Shaft of the electric machine; spline structure of the shaft (DIN5480 W55x2x30x26x8a).

2 D-end ange (SAE1/2) and bolt bores for mounting the machine (12 pieces).

3 Bores for the lifting eyes.

4 Mounting foot rails (see

Main dimension drawing

).

5 Mounting bolts (12 pcs of DIN912 M12 socket head). Not included in the delivery.

Vertical assembly

In vertical assembly, follow the steps givenin the previous chapter "Horizontal assembly".

Figure 17. Mechanical mounting connections of the electric machine (vertical mounting)

1 Mounting foot rails (4 rails in 90º circular pattern around the frame).

2 Bores for the lifting eyes, N-end.

3 D-end ange (SAE1/2) and bolt bores for mounting the machine (12 pieces).

4 Shaft of the machine; spline structure of the shaft (DIN5480 W55x2x30x26x8a).

5 Mounting bolts (12 pcs of DIN912 M12 socket head). Not included in the delivery.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 31

Page 33

Cooling connections

Make sure that cooling liquid runs freely into and out from the machine.

Connect the electric machine properly to the cooling circuit. Ensure that the coolant ow is equal

or higher than rated and the coolant temperature at the inlet of the machine cooling is lower or

equal to the rated temperature. For more information, see Chapter Recommended coolantsand

product data sheet. Rated values can be found in the electric machine rating plate.

It is recommendedto use coolant connector equipped with o-ring seal or to use sealing washer

(for exampleUsit or Bonded seals) in the connection. In addition, it is recommendedto use thread

sealant (Loctite 577 or similar) at the coolant connections to prevent loosening. Loosening can be

caused by vibration or temperature variations.

The electric machines are equipped with at least three PT100 temperature sensors in the windings.

The amount of the sensors depend on the options chosen. The temperature signal(s) can be read

out from the measurement connector of the machine.

You can connect the temperature signal to the temperature monitoring pin in the inverter (EC-C)

and make sure that the inverter has the machine temperature protection feature activated.

Electrical installation

Power connections

High voltage connection

Risk of electric shock when connection box is open. When you workwith power connections make sure that electricity is

disconnected and shaft rotation is prevented.

The high voltage cables of the electric machine are connected to the connection box, or

connection boxes of the machine. Figure belowshowsthe components of the high voltage

connection box assembly.

1. Remove the cover of the terminal box.

2. Install the power cables according to the wiring diagram.

3. Replacethe cover of the terminal box.

EM-PMI540-T1500

6. Installation

32 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 34

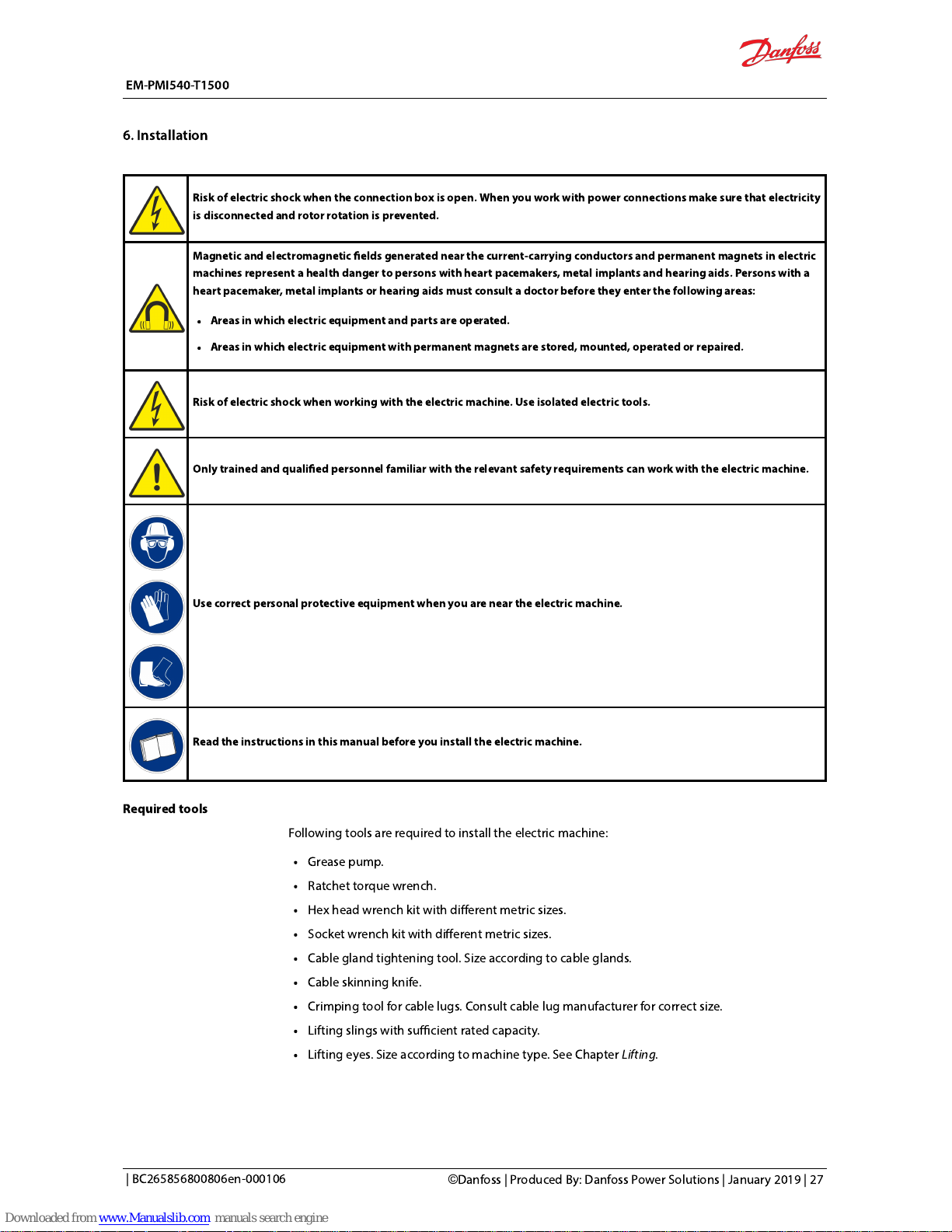

Figure 18. High voltage connection assembly structure

1 Mounting bolts (7 pcs) for coverplate

2 Connection box cover plate

3 Connection box cover plate gasket

4 Mounting bolts (4 pcs) for connection box

5 Connection box frame

6 Cable glands (3 pcs/ connection box)

7 Insulation sheet

8 Phase connection points (L1, L2, L3) for one phase

9

Low voltage (measurement) and anti condensation heater connection part (see Chapters Low voltage

(measurement signal) connections and Anti condensation heater connections)

10 Connection box gasket

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 33

Page 35

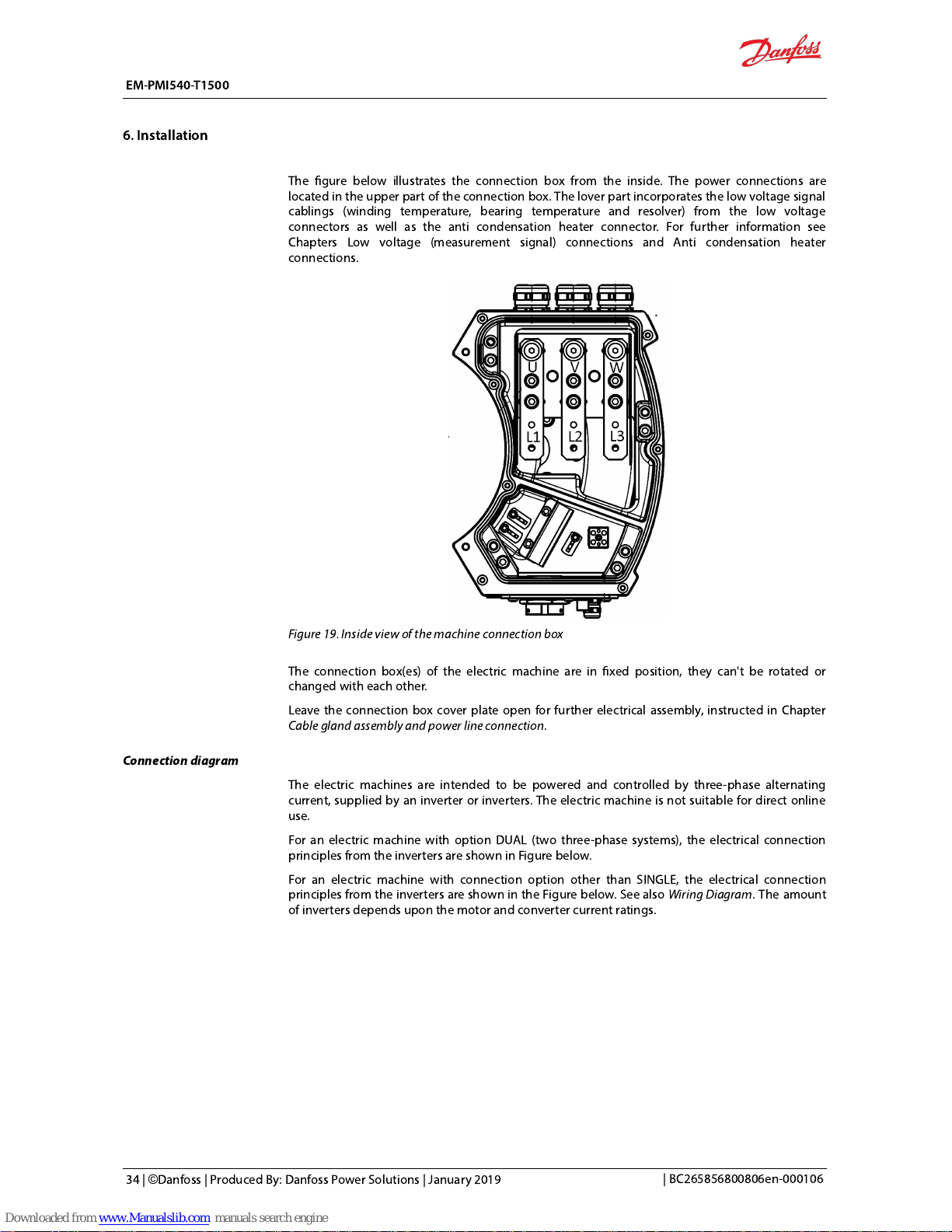

The gure below illustrates theconnection box from the inside. The power connections are

located in the upper part of the connection box. The lover part incorporates the low voltage signal

cablings (winding temperature, bearing temperature and resolver) from the low voltage

connectors as well as the anti condensation heater connector. For further information see

Chapters Low voltage (measurement signal) connections and Anti condensation heater

connections.

Figure 19. Inside view of the machine connection box

The connection box(es) of the electricmachine are in xed position, they can't be rotated or

changed with each other.

Leave the connection box cover plate open for further electrical assembly, instructed in Chapter

Cable gland assembly and power line connection

.

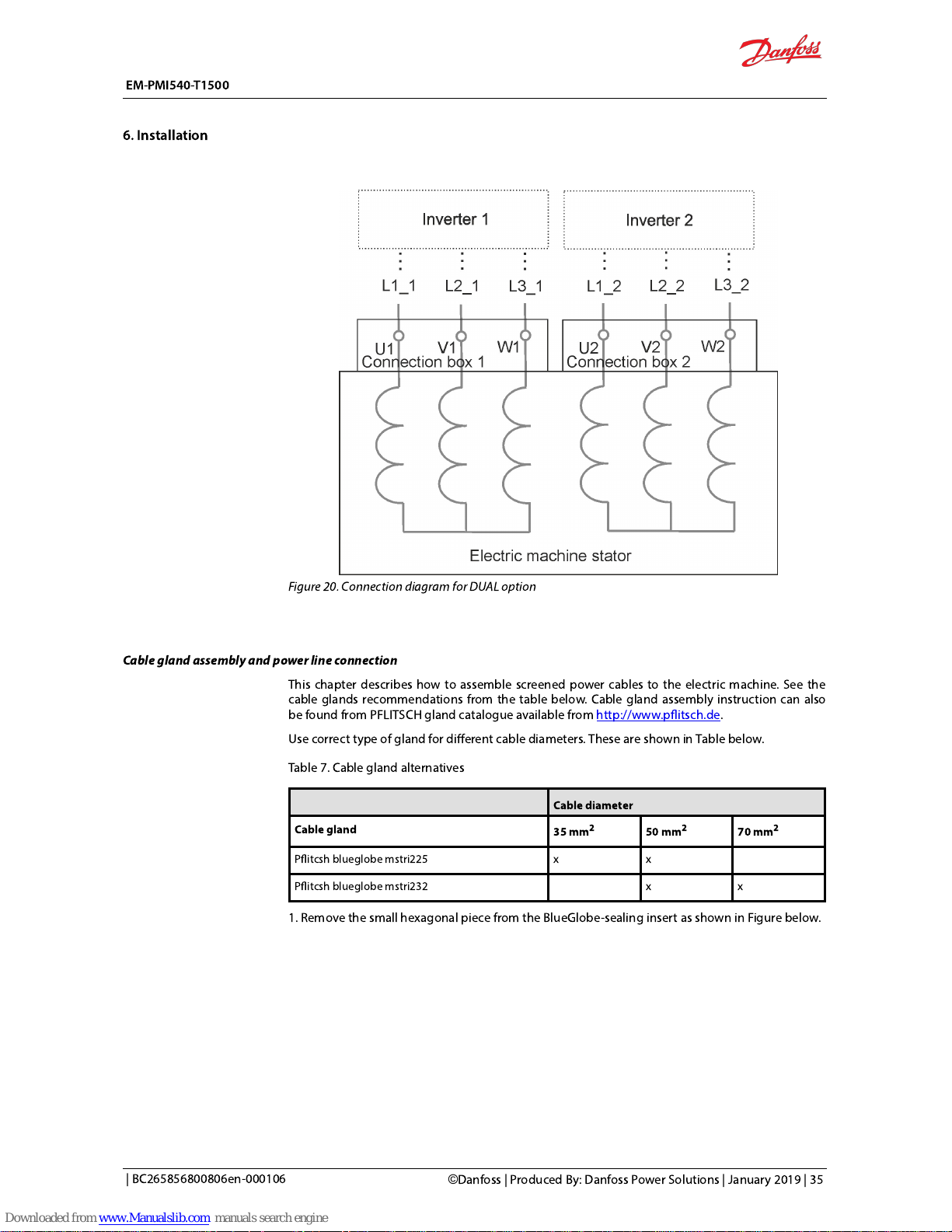

Connection diagram

The electric machines are intended to be powered and controlled by three-phase alternating

current, supplied by an inverter or inverters. The electric machineisnot suitable for direct online

use.

For an electric machine with option DUAL (two three-phase systems), the electrical connection

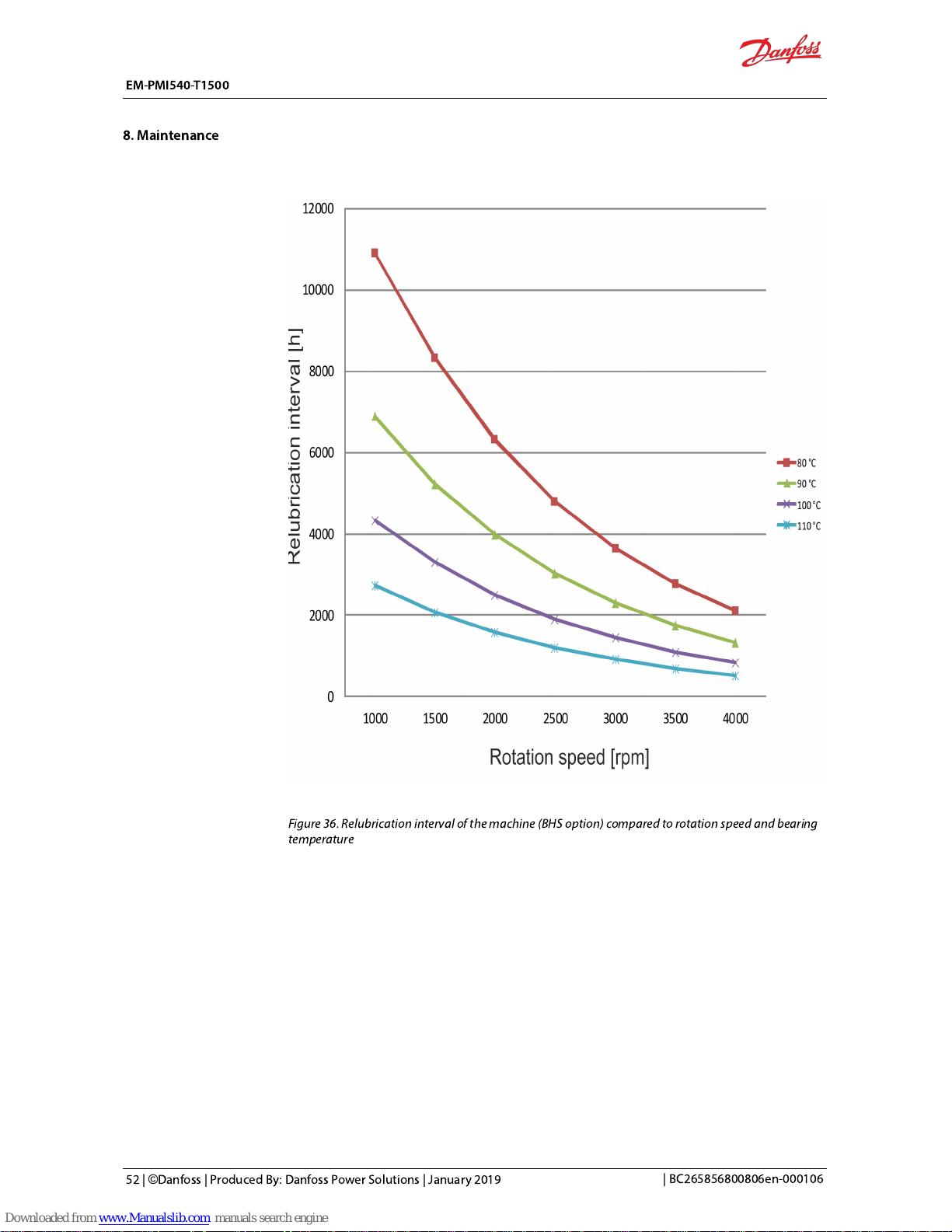

principles from the inverters are shown in Figure below.

For an electric machine with connection option other than SINGLE, the electrical connection

principles from the inverters are shown in the Figure below. See also

Wiring Diagram

. The amount

of inverters depends upon the motor and converter current ratings.

EM-PMI540-T1500

6. Installation

34 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 36

Figure 20. Connection diagram for DUAL option

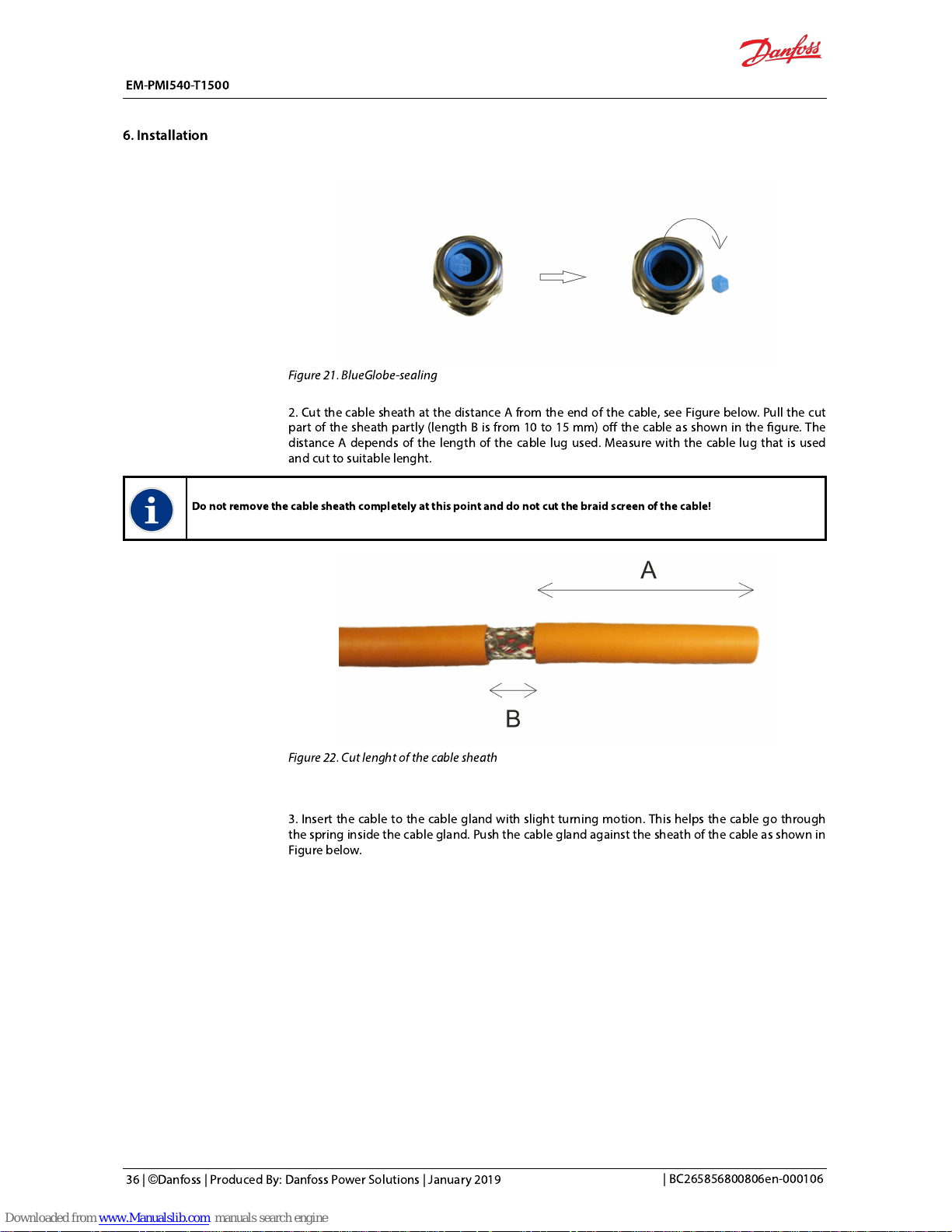

Cable gland assembly and power line connection

This chapter describes how to assemble screened power cables to theelectric machine. See the

cable glands recommendations from the table below. Cable gland assembly instruction can also

be found from PFLITSCH gland catalogue available from http://www.pitsch.de.

Use correct type of gland for different cable diameters. These are shown in Table below.

Table 7. Cable gland alternatives

Cable diameter

Cable gland

35 mm

2

50 mm

2

70 mm

2

Pitcsh blueglobe mstri225 x x

Pitcsh blueglobe mstri232 x x

1. Remove the small hexagonal piece from the BlueGlobe-sealing insert as shown in Figure below.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 35

Page 37

Figure 21. BlueGlobe-sealing

2. Cut the cable sheath at the distance A from the end of the cable, see Figure below. Pull the cut

part of the sheath partly (length B is from 10 to 15 mm) off the cable as shown in the gure. The

distance A depends of the length of the cable lugused.Measure with the cable lug that is used

and cut to suitable lenght.

Do not remove the cable sheath completely at this point and do not cut the braid screen of the cable!

Figure 22. Cut lenght of the cable sheath

3. Insert the cable to the cable gland with slight turning motion. This helps the cable go through

the spring inside the cable gland. Push the cable gland against the sheath of the cable as shown in

Figure below.

EM-PMI540-T1500

6. Installation

36 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 38

Figure 23. Cable to the gland assembly

4. After the cable gland is in place remove the length A piece of the sheath and cut the braid

screen (cover) from 10 mm (distance C) from the gland bottom as shown in Figure below.

Make sure that the cable gland spring is against the cable sheath before cutting the braid screen.

Figure 24. Cut the braid screen

5. Cut a piece of length D of the inner sheath shown in Figure Cutting the inner sheath. The length

D must equal to the length of the cable lug body.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 37

Page 39

Figure 25. Cutting the inner sheath

6. Place the cable inside the cable lug body, and crimp the cable lug twice in different places. See

Figure below.

Figure 26. Connecting cable lug

7. Cut piece of shrink tube and shrink it over the cable lug and braid screen as shown in Figure

below. This is done to keep the braid screen in place and for extra insulation.

The shrink tube must be specied for operating temperature range from -40 ºC to 150 ºC. Self gluing shrink tube is

recommended.

EM-PMI540-T1500

6. Installation

38 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 40

Figure 27. Shrink tube

8. Insert the cable through the corresponding hole in the connection box and connect the cable

lug to the connection point. Use spring washer between the cable lug and the connection screw

or nut. Example of the connection is shown in Figure below. Do not tighten the connection at this

point to ensure tting of the cable gland.

Make sure that there is at least 10 mm air gap between the cable lug and other metallic structures including the braid of

the cable. If the air gap is smaller, use extra insulation shrink tube to cover the lug.

Figure 28. Cable lug connection to the connection box (example only, the connection box may look

different)

9. Screw the cable gland to the connection box as shown in Figure below. Tighten the cable gland

from the cap of the gland. See Chapter Tightening torques.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 39

Page 41

Do not turn the body of the gland! By tightening from the cap of the gland the cable is sealed to the cable gland and at

the same time the cable gland is tightened to the connection box with correct torque.

10. Tighten the cable lug. Use tightening torque of 15 Nm.

11. Repeat the procedure to the other cables and connection box.

12. Check that the phase connections order in the connection box is correct, ie. corresponding

phases between the inverter and the machine are connected (U, V, W correspond to the L1, L2, L3

phases).

13. Close the connection box. Tighten the connection box cover screws. See chapter Tightening

torques.

Use thread locking compound that makes it possible to remove the screws. (For example

Loctite 221).

If you must connectthe anti condensation heater, you can leavethe connection box open. See

Chapter Anti condensation heater.

Check the power cable shield grounding, see ChapterGrounding connections.

Low voltageconnections

Plug the unused socket holes of the low voltage connectorwith suitable plugs:

DEUTSCH 0413-003-1605 (size 16)

DEUTSCH 0413-204-2005 (size 20)

The electric machine has aconnector which is used to read out in-built temperature and rotation

sensor (resolver) data from the machine. The temperature data comes from PT100 sensorsin the

stator windings and in some cases inthe bearings. The rating plate has the information about the

options ofthe machine: different options add sensors, and some machines do not have all the

sensors that are listed in the table below. For more information aboutthe options, refer to the data

sheet of the electric machine.

Figure 29. Location of the low voltage connectors in the connection box (N-end of the machine)

1

Low voltage (measurement signal) connector including winding temperature sensors (PT100) and

resolver connections

2 Bearing temperature measurement sensor (PT100) connector in the N-end of the machine

3 Inlet (cable gland) for anti condensation heater cable (see Chapter

Anti condensation heater connections

)

EM-PMI540-T1500

6. Installation

40 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 42

Figure 30. Pin conguration of the Deutch HD34-24-47PE connector

Table 8. Pin conguration of theDeutch HD34-24-47PE connector

Measurement Description PIN

Temperature 1

Temperature 1, PT100 (P), windings 47

Temperature 1, PT100 (N), windings 46

Temperature 2

Temperature 2, PT100 (P), windings 33

Temperature 2, PT100 (N), windings 32

Temperature 3

Temperature 3, PT100 (P), windings 45

Temperature 3, PT100 (N), windings 31

Temperature 4

Temperature 4, PT100 (P), windings, option TEMP4 30

Temperature 4, PT100 (N), windings, option TEMP4 29

Temperature 5

Temperature 5, PT100 (P), windings, option TEMP4 44

Temperature 5, PT100 (N), windings, option TEMP4 43

Temperature 6

Temperature 6, PT100 (P), windings, option TEMP4 28

Temperature 6, PT100 (N), windings, option TEMP4 16

Resolver COS_N Resolver, RES_COS_N, in-built non contacting 35

Resolver COS_P Resolver, RES_COS_P, in-built non contacting 20

Resolver SIN_N Resolver, RES_SIN_N , in-built non contacting 36

Resolver SIN_P Resolver, RES_SIN_P , in-built non contacting 21

Resolver EXCN Resolver, EXCN, in-built non contacting 22

Resolver EXCP Resolver, EXCP, in-built non contacting 10

Resolver shield Resolver, SHIELD/GROUND, in-built non contacting 34

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 41

Page 43

Figure 31. Bearing temperature measurement connector (optional)

1 PT-100 pin.

2 PT-100 pin.

3 PT-100 ground pin.

4 PT-100 ground pin.

Grounding connections

The grounding points on the frame of the electric machine are for safetygrounding, and signal cables and power cable

shields have their own grounding points.

For proper and safe operation, it is important to ensure proper grounding (earthing) of the

machine and cable shields connected to the machine. In the electric machine the middle lifting

bores can be used as a connection point for machine enclosure grounding. The low voltage

(measurement) signal cable is grounded through the ground/shield pins of the low voltage

connector, and the power cables through the cable glands in the connection box.

EM-PMI540-T1500

6. Installation

42 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 44

Figure 32. The machine enclosure grounding point, safety grounding

Figure 33. Low voltage cable grounding points

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 43

Page 45

Figure 34. Power cable grounding through the cable gland

Testing the power cable shield grounding(earthing)

The power cable shields are grounded (earthed) through the cable glands to the connection box

and further to the electric machine enclosure. After the cable gland assembly and power cable

installations, and any time when needed, make sure that the grounding (earthing) connections are

correct.

1. Connect one terminal of the measurement device to the cable shield of one power cable (in

the inverter end of the cable)

2. Connect the other terminal of the measurement device to the cable shield of an other power

cable. You can also use the machine enclosure grounding point for the measurement.

3. Measure the resistance between the two cable shields or between the cable shield and the

enclosure grounding point.

4. Change the measurement device terminal(s) to the shield of different power cable and repeat

the measurement until all cables have been measured.

Testing the low voltage (measurement signal) cable shield grounding (earthing)

The low voltage (measurement signal) cable shield connects to the ground through the connector

grounding/earthing pins, see Figure Low voltage cable shield grounding. After cable installation,

and any time when needed, make sure that the grounding (earthing) connection is valid.

1. Connect one terminal of the measurement device to the low voltage cable shield (in the non-

machine end of the cable).

2. Connect the other terminal of the measurement device to the machine enclosure grounding

point.

3. Measure the resistance between the cable shield and the enclosure grounding point.

EM-PMI540-T1500

6. Installation

44 | ©Danfoss | Produced By: Danfoss Power Solutions | January 2019

| BC265856800806en-000106

Page 46

Anti-condensation heater connections

Do not run the electric machine when the anti-condensation heater is in use.

Water condensing inside the electric machine enclosure can result in failure or corrosion ofthe

machine. This often happens in cooler temperatures or higher humidity areas typically in marine

environment, when the machine is not running.

The electric machinecan be equipped with anti-condensation heater to avoid condensation

issues. The heater (+HEAT1) or heaters (+HEAT2)arefactory assembled see Figure Heater

connector locations . The installed heater may not be used when the machine mains are switched

on, and the machine is running.

The installed anti condensation-heater must be supplied with 230 Vacpower. The heater

connector is inside the connection box, in the lower part if it. The anti-condensation heater cable

has an inlet (cable gland) next to the low voltage signal connector. See Figure below.

Figure 35. Anti-condensation heater connector

1 Anti-condensation heater connector (inside the connection box).

2 Inlet and cable gland for the anti condensation heater cable.

After installation of the machine, and any time when needed, the resistance of the warming

element can be measured. Connect the measurement device between the heater terminals. The

resistance shall be around1 kΩ. Measuring no value, or zero value indicates a possible failure in

the heater element.

If the electric machine has an anti-condensation heater and failure is suspected, contact

Danfossrepresentative.

EM-PMI540-T1500

6. Installation

| BC265856800806en-000106

©

Danfoss | Produced By: Danfoss Power Solutions | January 2019 | 45

Page 47

Only trained and qualied personnel familiar with the relevant safety requirements are allowed to operate the electric

machine.

Do not usethe electric machine without properly dimensioned and operating cooling system. Maximum operation

temperature, current and rotational speed of the electric machine must not be exceeded to avoid permanent damage.

The surface of the electric machine might be hot.Do not touch the electric machine during operation.

Entanglement hazard! Do not touch the electric machineduring operation.

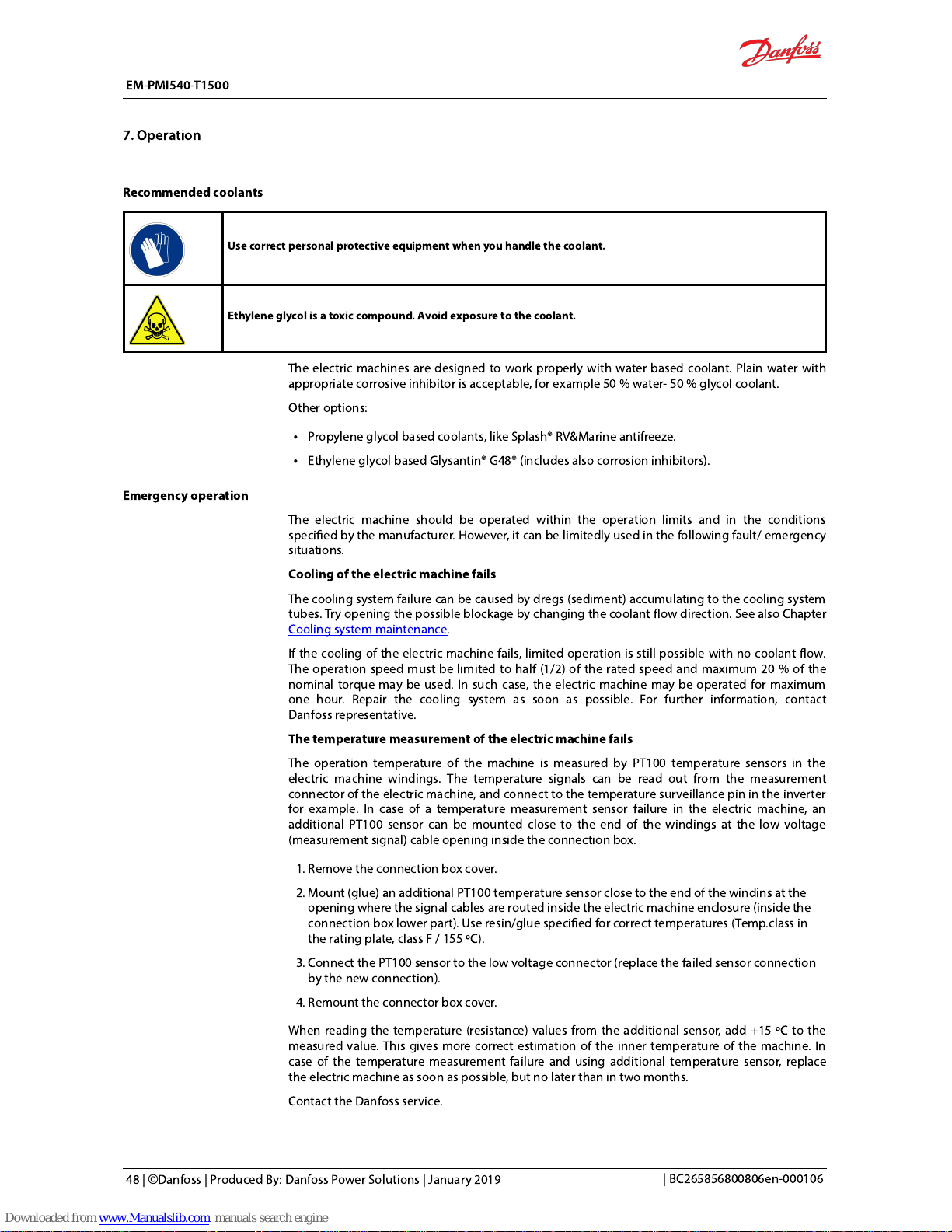

Do not run the electric machine when the heater is in use.