Page 1

Data Sheet

EM-PME375-T150

Electric machine, permanent magnet external

FEATURES

• Synchronous Reluctance assisted Permanent

Magnet (SRPM) technology

• Extremely compact and robust structure

• Highest efficiency throughout the operation range

on the market (~96 %)

• Liquid cooled with plain water or water/glycol

mixture

• Low coolant flow required

• Allowed coolant temperature up to +65°C

• Up to IP65 enclosure class to maximize reliability

• Multiple mounting possibilities

GENERATOR SPECIFIC FEATURES

• Standard SAE flange mounting to match the diesel

engine connection

• Wide

• Can be also used as starter motor for the ICE

selection of speed ratings allowing the

generator to be selected to customer specific

applications with various voltage requirements

MOTOR SPECIFIC FEATURES

• Extended speed and torque capabilities compared

to standard PM motors from Danfoss reluctance

assisted permanent magnet motor technology

• Motor structure is designed to be able to produce

high starting torque: EM-PME motor can produce

instantly full torque to a non-rotating shaft

• Optimized speed range to meet the most common

gear ratios used in heavy mobile machinery

GENERAL

The machine is developed especially for demanding

applications. The design of these machines makes them

smaller, lighter and more efficient than conventional

products on the market.

The machine is designed to be shorter than normal motors

for applications where axial length is crucial parameter. The

machine is designed to be connected directly to the ICE

flywheel housing with part of the motor being inside the

flywheel housing further shortening the length of the motor.

TYPICAL APPLICATIONS

• Generator for diesel-electric/serial hybrid

applications

• Traction/propulsion motor

• Generator/Motor for parallel hybrid applications

1 | © Danfoss | April 2020 AI312650743939en-000103

Page 2

Data Sheet

General electrical properties

Nominal voltage (line

to line)

500 VAC

Voltage stress

IEC 60034-25, Curve A: Without

filters for motors up to 500 VAC

Nominal efficiency

96 %

Pole pair number

10

Power supply

Inverter fed.

Minimum inverter

switching frequency

8 kHz

Basic information

Machine type

Synchronous reluctance assisted

permanent magnet

Mounting direction

Can be used in any direction, see

user guide for details.

Mounting

(IEC 60034-7)

IM 3001 (Flange)

Standard Flange D-end

(SAE J617)

SAE 3, transmission housing

Standard Flange N-end

SAE 3, flywheel housing

Standard rotation

direction

Clockwise (both directions

possible)

Protection class

(IEC 60034-5)

Up to IP65

Duty type

(IEC 60034-1)

S9

Standard color

Dark grey RAL7024 powder

coating

Mechanical

Total weight

75 kg (no options)

Moment of inertia

0.63 kgm²

Rotating mass

23 kg

Dimensions

Length (frame)

66 mm

Diameter (frame)

451 mm

Total length (frame +

195.6 mm

Cooling

Cooling liquid

Plain water with appropriate

corrosive inhibitor)

Cooling liquid

corrosive inhibitor type

Ethylene glycol Glysantin

G48 recommended

Cooling method

(IEC 60034-6)

IC 71 W

Minimum cooling

liquid flow

20 l/min

Pressure loss

0.3 bar with 20 l/min

(+25°C coolant)

Cooling liquid

temperature max

+65°C (Derating required if

exceeded)

Temperature rating

Insulation class

(IEC 60034-1)

H (180°C)

Temperature rise

(IEC 60034-1)

85°C

Maximum winding

temperature

150°C

Nominal ambient

(IEC 60034-1)

65°C

Min. ambient

temperature

-40°C

Nominal altitude

(IEC 60034-1)

1000 m

Connections

Coolant connection

2 x G1/2 bores

HV cables

3 x 50 mm2 max.

Cable direction

Cable direction radial with straight

standard angle connector

HV cable connector

3x AMPHENOL

HVBI005R10AMHARD

HV cable mating

3 x AMPHENOL HVBI-7-05R10-XFC-

connector manufacturer)

HV cable

Recommended H+S Radox

screened cable

LV connector

12 pin TE HDSCS

LV connector type

TE 1-1564520-1

LV connector pin type

Gold plated

LV mating connector

type

TE 1-1703639-1

LV mating connector

pin type

TE 1241380-2 (Gold plated)

LV connector pin

configuration

See Table below

EM-PME375-T150

SPECIFICATIONS

temperature

shaft)

2 | © Danfoss | April 2020 AI312650743939en-000103

corrosive inhibitor (max. 50 %

connector and towards N-end with

connector

XXXX-FG/PC (straight plug)

3x AMPHENOL HVBI-9-05R10-XFCXXXX-FG/PC (right angle plug)

(check the exact codes form

Page 3

Data Sheet

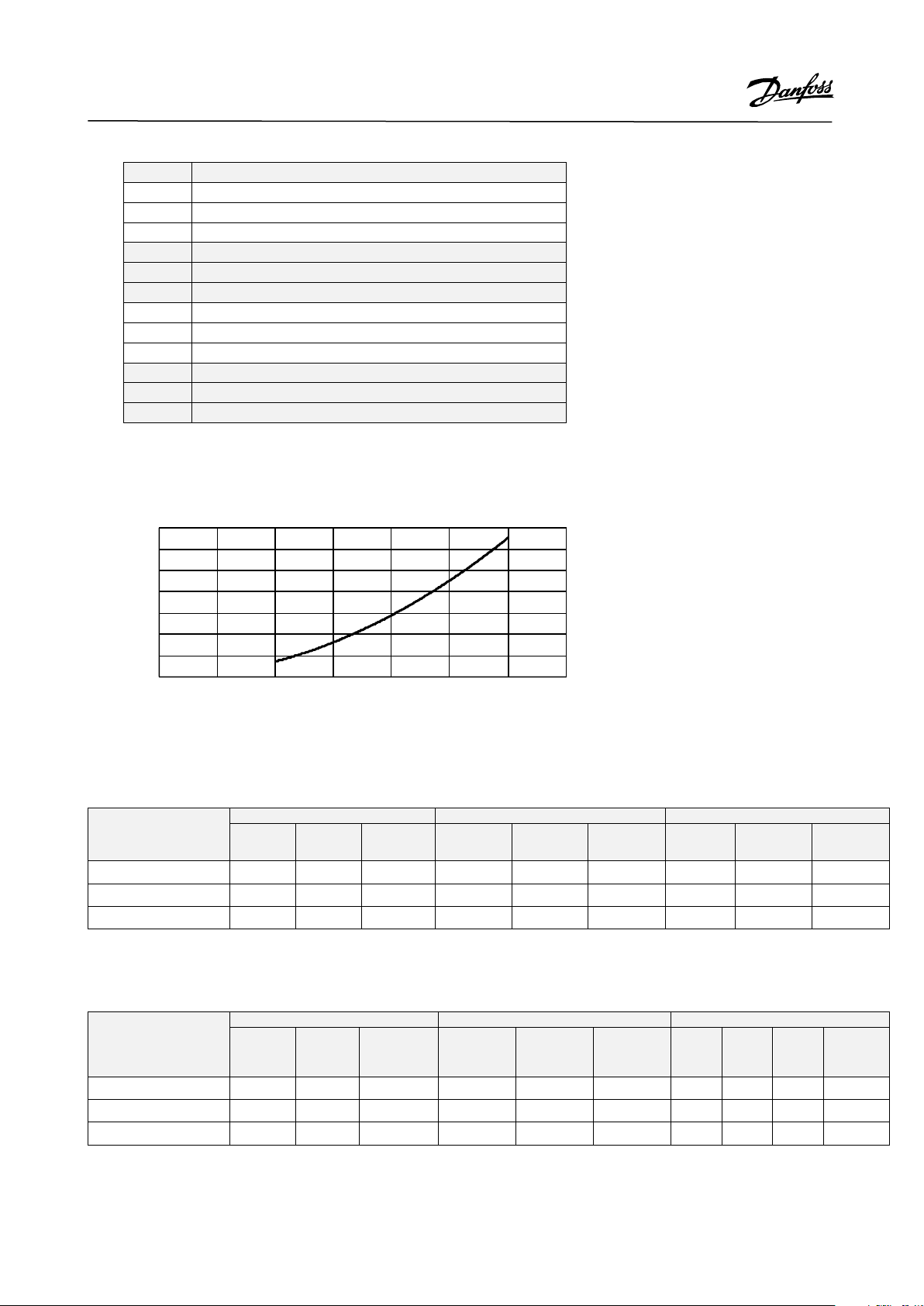

PIN

Description

1

Resolver, RES_COSN

2

Resolver, RES_SINN

3

Resolver, EXCN

4

Temperature, PT100, windings

5

Temperature, PT100, windings

6

Temperature, PT100, windings

7

Resolver, RES_COSP

8

Resolver, RES_SINP

9

Resolver, EXCP

10

Temperature, PT100, windings GND

11

Temperature, PT100, windings GND

12

Temperature, PT100, windings GND

Coolant temperature +65°C

Coolant temperature +40°C

Coolant temperature +40 / +65°C

Cont.

[Nm]

Cont.

[kW]

Nom.

[A]

Nom.

[A]

Nom.

[rpm]

Coolant temperature +65°C

Coolant temperature +40°C

Coolant temperature +40 / +65°C

Volt/

[V/rpm]

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0 5 10 15 20 25 30 35

Pressure loss [bar]

Volume flow [l/min]

EM-PME375-T150

Table 1 Pin configuration of LV-connector

PRESSURE LOSS VS COOLANT FLOW

Picture 1 Pressure loss vs coolant flow

MOTORS

Type

EM-PME375-T150-1500 160 25 33 191 30 40 1500 3000 600

EM-PME375-T150-1800 167 31 40 179 33 45 1800 3600 600

EM-PME375-T150-2600 147 40 50 164 45 60 2600 4000 600

Torque

Power

Current

(* Peak torque achieved with one (350A) inverter

(** Peak torque achieved with two (350A) inverter

Cont. Torque

[Nm]

Cont. Power

[kW]

Current

speed

Max. speed

[rpm]

Peak torque

GENERATORS

[Nm]

Type

EM-PME375-T150-1500 27 26 32 33 32 39 1575 263 0.99 0.319

EM-PME375-T150-1800 34 33 39 38 36 44 1890 315 0.97 0.273

EM-PME375-T150-2600 42 41 49 50 48 59 2730 455 0.99 0.182

(*** Back EMF for cold (20°C) generator

3 | © Danfoss | April 2020 AI312650743939en-000103

Apparent

power

[kVA]

Cont.

power

[kW]

Nom.

Current

[A]

Apparent

power

[kVA]

Cont. Power

[kW]

Nom.

Current

[A]

Nom.

speed

[rpm]

Nom.

Freq.

[Hz]

Power

factor

speed

ratio

Page 4

Data Sheet

EM-PME375-T150

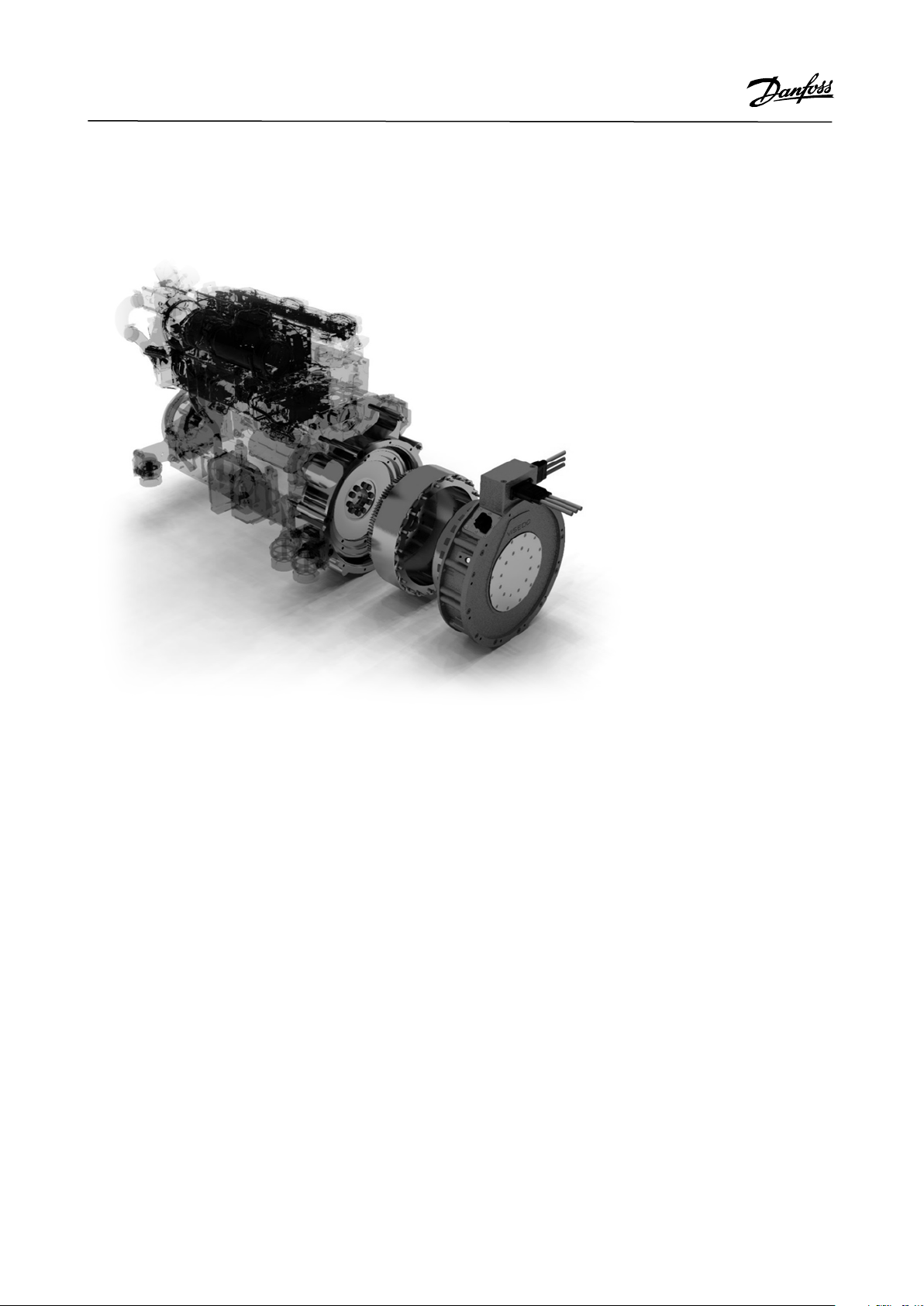

Integrated machine is commonly connected directly to the diesel engine flywheel housing. In such application, part of the motor is inside the diesel engine. Exploded view of this kind of application is shown below.

Picture 2 Integrated machine connected to diesel engine flywheel housing

4 | © Danfoss | April 2020 AI312650743939en-000103

Page 5

EM-PME375-T150-1500

EM-PME375-T150-1500+RES1

Data Sheet

EM-PME375-T150

PRODUCT CODE AND OPTIONS

Use product code including all needed options for ordering. Standard options do not need to be listed in the code as they are

selected by default if a non-standard option is not selected. Standard options are indicated by a star (*).

Product code Description

Standard unit with standard options

Standard unit otherwise but with resolver angle sensor

Table 2 Product code examples

Variant Code Description Additional information

High voltage connector * High voltage plug-in connectors

for 50 mm

+HVC1 High voltage plug-in connectors

for 35 mm

Rotation sensor * None No resolver

+RES1 Resolver In-built non contacting resolver, 5-pole pair

*Standard option

2

cables

2

cables

One plug-in connector per phase for 50 mm

cable

One plug-in connector per phase for 35 mm

cable

2

2

Table 3 Option list

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in

specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are

trademarks of Danfoss A/S. All rights reserved.

5 | © Danfoss | April 2020 AI312650743939en-000103

Loading...

Loading...