Page 1

Data Sheet

Pressure transmitter

Type EMP 2

For monitoring and control in marine and industial applications

The high accuracy pressure transmitter EMP 2 is

designed for monitoring and control in marine

and industial applications and oers a reliable

pressure measurement, even under harsh

environmental conditions.

The exible pressure transmitter programme

covers absolute or gauge (relative) versions

with zero and span adjustment with a 4 – 20

mA output signal.

It has all the necessary marine approvals.

Special versions with integrated pulse-snubber

available, designed for use in hydraulic

applications with severe medium inuences

like cavitation, liquid hammer or pressure

peaks.

Features

• For use in Zone 2 explosive atmosphere

AI175686432328en-000901

Page 2

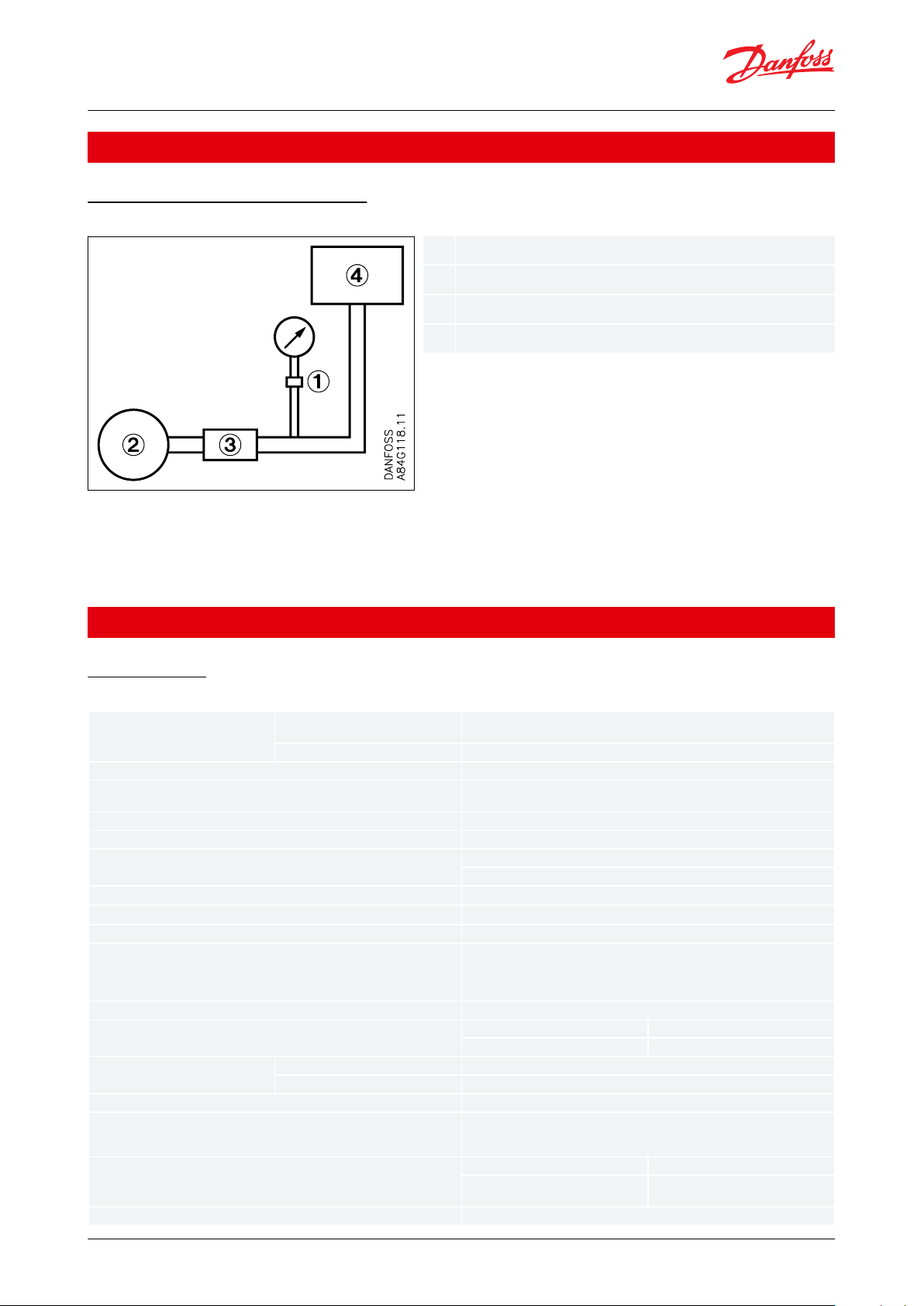

1234Surge damper

Pump

Valve

Tank

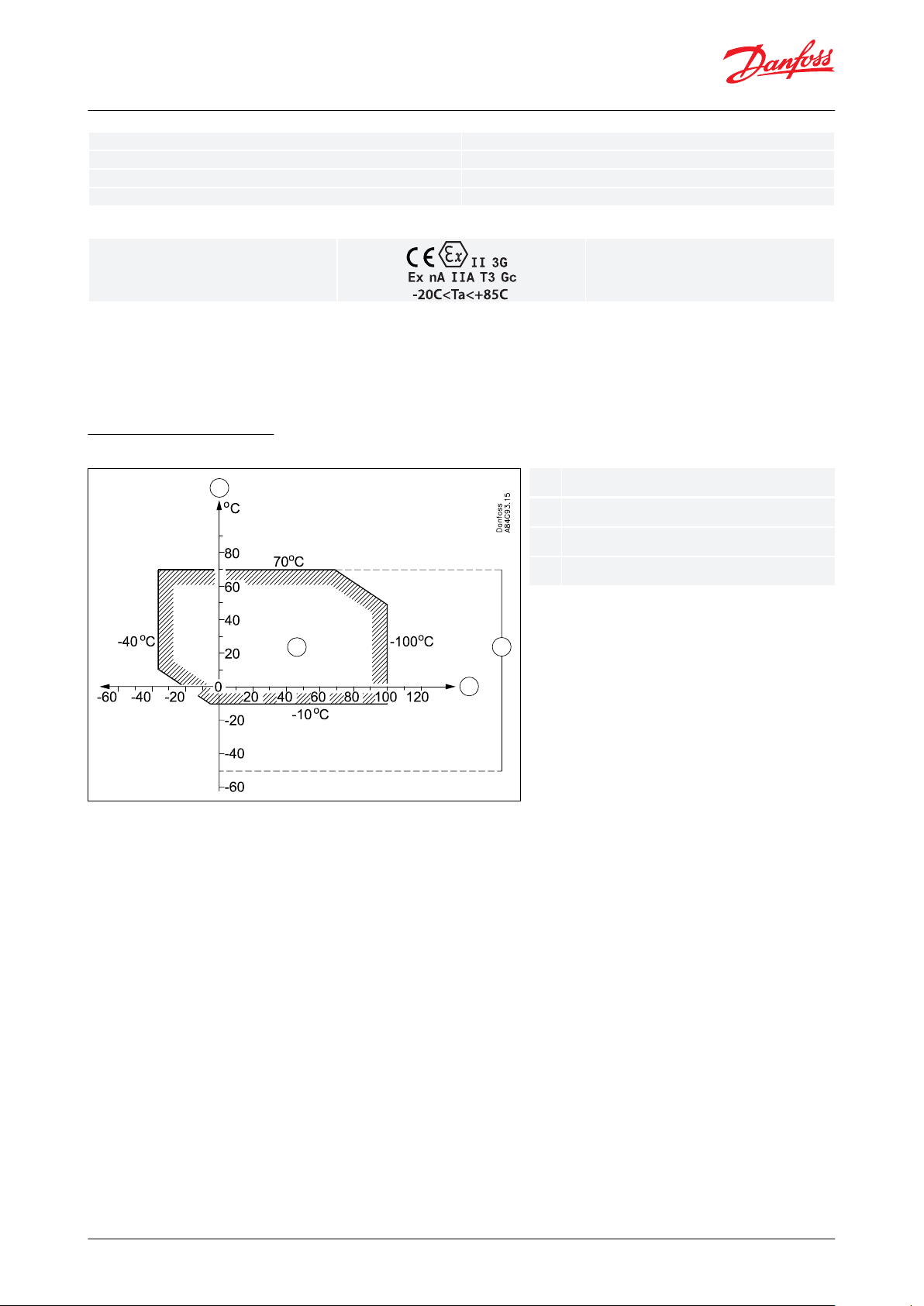

Sensor temperature range

Normal

-10 – 70 °C, (Ref.

Figure 2: Max. ambient temperature as a function of

temperature)

ATEX Zone 2

-10 – 85 °C

Transport / storage temperature

-50 – 70 °C

Media temperature

-40 – 100 °C, (Ref.

Figure 2: Max. ambient temperature as a function of

temperature)

Media

Water, fuel, oil, lubricating oil, refrigerants, ammonia, gas etc.

Voltage supply

Max. 32 V and min. 12 V DC between terminals N and P

Load resistance

A. max. 410 Ω at 24 V DC 50% / -20%

B. max. 650 Ω at 24 V DC 50% / 0%

Zero point adjustment

- 5 – 20% range span; but max. -1–1.5 bar (kp/cm

2

)

Span adjustment

± 5% of range span; max. ± 5 bar (kp/cm

2

)

Combination of span and zero point adjustments

- 5 – 20% of range span

Noise – immunity

Complies with the standard for industrial apparatus EN 61000-6-2. The standard

contains tests for the following: HF elds, mains transmitted HF, voltage transients, electrostatic immunity, supply voltage variations, low-frequency radiation

and transient protection in accordance with Germanischer Lloyd

Noise – emission

Complies with standard EN 61000-6-3

Accuracy

< 0.3 % of FS

In vacuum (below 0 bar)

< 2.3 % of FS

Temperature dependence

Thermal zero point shift

≤ ± 0.06 % FS / °C

Thermal sensitivity (span) shift

≤ ± 0.06 % FS / °C

Voltage dependence

≤ ± 0.1% FS / 10 V

Vibration stability

3 – 30 Hz amplitude 1.13 mm and 30 – 300 Hz acceleration 4G according to IEC

60068-2-6. The requirements of the ship classication societies are up to 100 Hz,

acceleration 4G. Extended specications by prior arrangement

Time constant

Liquids with viscosity < 100 cSt

< 4 ms

Air and gas in combination with pulse

snubber:

< 35 ms

Shock stability

500 g for 1 ms to IEC 60068-2-27

Pressure transmitter, Type EMP 2

Applications

Application and media conditions

Figure 1: Pressure range

In cases where valves are closed momentarily, surges of a value in excess of that for which the pressure element is

designed can occur. To avoid damage to the pressure element, a damper should be tted.

The device can consist of a exible pipe, a throttle, a shock valve, or a combination of these items. The amplitude of

surges should never exceed the maximum pressure range of the pressure transmitter.

Product specication

Technical data

Table 1: Performance (EN 60770)

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 2

Page 3

A

D

B

C

ABCDAmbient temperature

Temperature and medium

Operating range

Transport and storage temperature

Enclosure

IP65, Housings are made of enamelled pressure-die-cast aluminium (GD-AISI 12)

Pressure connection

G ¼, G ½ A standard, G ⅜ A mano

Net weight

approx. 1 kg

Cable entry

Pg 13.5 for cable diameters 5 – 14 mm

Zone 2 applications

(1)

EN60079-0; EN60079-15

Pressure transmitter, Type EMP 2

Table 2: Explosive atmospheres

(1)

(1)

When used in ATEX Zone 2 areas at temperatures <-10 °C the cable and plug must be protected against impact

When used in ATEX Zone 2 areas at temperatures <-10 °C the cable and plug must be protected against impact

Identication

The type designation and code number of the transmitter is embossed on the side of the housing at the bottom

close to the pressure connector.

Installation conditions

Figure 2: Max. ambient temperature as a function of temperature

Mounting

Type EMP 2 is equipped with a 3 mm stell bracket for mounting.

Pressure connection

Connector with outside cylindrical thread G ½, some types available with G ⅜ A mano, and inside cylindrical thread

G ¼, to ISO 228.

The primary insertion length of the connector corresponds to EN 837. Connection to the transmitter is made

through a connector with a spanner at, 14 mm across ats.

When tting or removing pressure lines, the spanner ats on the pressure connector should be used to apply

counter-torque.

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 3

Page 4

A

B

C

D

E

F

ABCDEFmax. 70 °C

Condensed liquid

Reliable, good convection

Insulation against radiant heat

Steam 170 °C

Thin (=low heat conductivity)

uninsulated tube

Pressure transmitter, Type EMP 2

Figure 3: Insulation against radiant heat

Water systems

Water in the pressure element is not harmful, but in the event of frost a water-lled pressure element may burst. To

prevent this the transmitter should be allowed to operate on an air cushion.

Steam plant

To protect the pressure element against temperatures in excess of the maximum temperature for the medium (100

°C), the insertion of a water-lled loop is recommended. In the example, Figure 3: Insulation against radiant heat,

insulation against radiant heat is also shown.

Electrical connection

Figure 4: Wiring diagram

The transmitter has a wiring diagram, see above gure. Terminals P (positive) and N (negative) are connection

terminals for the supply voltage.

The same leads are used for supply voltage and output signal. A function test can be performed between terminals

N and T without cutting o the current loop.

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 4

Page 5

ABC

G ½ A (G 3/8 A mano)

Pg 13.5

G ¼

1

1

Pulse-snubber

Pressure transmitter, Type EMP 2

Pulse snubber

Figure 5: pulse snubber

EMP 2 with the pressure range 0 – 6 bar and 0 – 10 bar at extended test pressure is provided with an integrated

pulse snubber for protection of the sensor element against cavitations and air bubbles in the media due to extreme

pressure peaks and pulsations. Such conditions may be caused by pumps or fast operation valves in both high and

low pressure systems.

The integrated pulse snubber is designed as an 0.3 mm orice mounted in the pressure connection. The medium

should not contain particles which may clog up in the orice.

The viscosity has only little eect on the response time. Even at liquid viscosities up to 100 Cst the response time will

not exceed 4 ms.

Dimensions and weight

Net weight 1 kg

Figure 6: Dimensions diagram

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 5

Page 6

Operating pressure

Test pressure

Min. burst pressure

Code no. EMP 2

pe [bar]

pe [bar]

pe [bar]

G ½ A

G ⅜ A

-1 – 1.5

(1)

5

100

084G2100

-

-1 – 5

(1)

35

200

084G2101

-

0.2 – 1

3.2

100

084G2102

-

0 – 1.6

3.2

100

084G2104

-

0 – 2.55200

084G2105

-

0 – 48200

084G2106

084G2206

0 – 618400

084G2107

084G2207

0 – 6

60

(2)

400

084G2108

-

0 – 1020400

084G2109

084G2209

0 – 10

60

(2)

400

084G2110

-

0 – 1632400

084G2111

084G2211

0 – 2550400

084G2112

-

0 – 4080400

084G2113

084G2213

0 – 60

120

400

084G2114

-

0 – 100

200

400

084G2115

-

0 – 160

260

640

084G2116

-

0 – 250

375

1000

084G2117

-

-1 – 9

(1)

20

400

084G2120

-

Operating pressure

Test pressure

Min. burst pressure

Code no. EMP 2

pe [ kp/cm2]

pe [ kp/cm2]

pe [ kp/cm2]

G ½ A

G ⅜ A

-1 – 5

(1)

35

200

084G2131

-

0 – 48200

084G2136

084G2157

0 – 618400

084G2137

084G2158

0 – 1020400

-

084G2179

0 – 1532400

084G2141

084G2159

0 – 2550400

084G2142

-

0 – 4080400

084G2143

084G2169

0 – 50

120

400

084G2144

-

0 – 2050400

084G2154

-

Pressure transmitter, Type EMP 2

Ordering

Table 3: Pressure in bar

(1)

(1)

Sealed gauge

Sealed gauge

(2)

(2)

With pulse snubber

With pulse snubber

Table 4: Pressure in kp/cm

2

NOTE:

When ordering please state type and code number

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 6

Page 7

Part

Symbol

Description

Material

Code no.

Damping coil

Damping coil with G 3/8 unions and 1.5 m copper

capillary tube.

Copper

060-104766

Damping coil

Damping coil with G ½ unions and 1 m capillary

tube. Standard washers supplied

Stainless steel

060-016966

Damping coil, arm-

oured

Damping coil with G ³⁄8 unions and 1 m armoured

copper capillary tube. Standard washers supplied

Copper

060-333366

Nipple

G ¼ A × G 3/8A with copper washer

Brass

060-333266

G ¼ A × M10 ext. × 1 with copper washer

Brass

060-333866

Pascal (=

Newton per

square me‐

tre)

Newton per

square [mm]

[bar]

Kilopond

per square

metre [mm]

H2O

Meter water

gauge

Technical at‐

mosphere

[kp/cm2]

Physical at‐

mosphere

Torr [0 °C]

Inches Hg [0

°C]

Poundforce

per Square

inch

[N/m

2

] Pa

[N/mm

2

]

[kp/m

2

]

[m] H

2

O

[at]

[atm]

[mm] Hg

[in] Hg

[lbf/in

2

] psi

1 Pa

1

10-610

-5

0.1020

1.020 • 10

-4

1.020 • 10

-5

9.869 • 10

-5

7.500 • 10

-3

2.953 • 10

-4

1.450 • 10

-4

1 N/mm

2106

1

10

1.020 •10

5

10.20

10.20

9.869

7.5 • 10

3

295.3

145.0

1 bar

10

5

0.1

1

10.197 • 10

3

10.20

1.020

0.9869

750

29.53

14.50

1 kp/m

2

9.80665

9.807 • 10

-6

9.807 • 10

-5

1

10-310-40.9678 • 10

-4

0.07355

2.896 • 10

-3

1.422 • 10

-3

1 m H

2

O

9806.7

9.807 • 10

3

0.09807

100010.1

0.09678

73.55

2.896

1.422

1 at

98.066 • 10

3

0.09807

0.9807

104101

0.9678

735.5

28.96

14.22

1 atm

101.325 • 10

3

0.1013

1.013

10.333 • 10

3

10.33

1.0331760

29.92

14.70

1 mm Hg

133.32

1.333 • 10

-4

1.333 • 10

-3

13.60

0.01360

1.360 •10

-3

1.316 • 10

-3

1

0.03937

1.934 • 10

-2

1 in Hg

3387

3.387 •10

-3

0.03387

345.3

0.3453

0.03453

0.03342

25.410.4912

1 psi

6895

6.895 • 10

-3

0.06895

703.1

0.7031

0.07031

0.06804

51.71

2.036

1

Pressure transmitter, Type EMP 2

Accessories

Table 5: Accessories list

Conversion table

Table 6: Conversion values

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 7

Page 8

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.B.00302_18

EAC Declaration

EMC

EAC

DLN 34014-AE003

Marine - Safety Certicate

-KRELE071320XP

Marine - Safety Certicate

-

RINA

2002547TA

Marine - Safety Certicate

-LRTJ18T00028

Marine - Safety Certicate

-

CCS

TAA000012U

Marine - Safety Certicate

-

DNV GL

18.10316.266

Marine - Safety Certicate

-

RMRS

TA19494M

Marine - Safety Certicate

-

NKK

02280-H0 BV

Marine - Safety Certicate

-BV15-LD1339318-PDA

Marine - Safety Certicate

-

ABS

DK.C.30.018.A 31316

Measuring - Performance Certicate

-

GOST

064G9615.06

EU Declaration

ATEX/EMCD/RoHS

Danfoss

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

CRN.0F18477.5123467890YTN

Pressure - Safety Certicate

CRN

TSSA

064R9402.00

Manufacturers Declaration

PED

Danfoss

SMS.W.II-2179-B.0

Marine - Manufacturing Permission

-BVE494625

Electrical - Safety Certicate

-

UL

Pressure transmitter, Type EMP 2

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 7: Certicates and declarations

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI175686432328en-000901 | 9

Loading...

Loading...