Page 1

Data sheet

ELIMINATOR® Hermetic burn-out filter drier

Type DAS

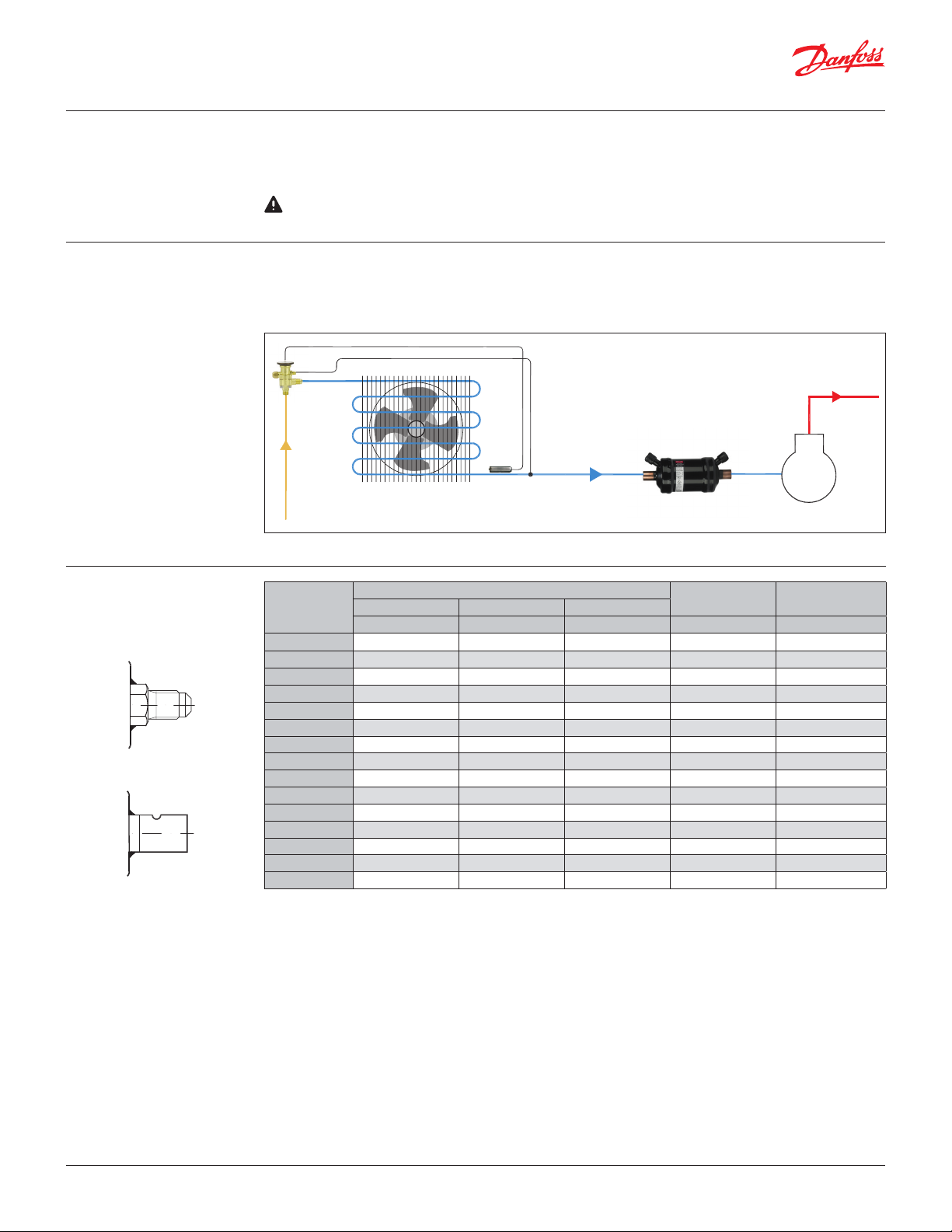

ELIMINATOR® Hermetic burn-out filter driers

type DAS are used in the suction line to clean up

refrigeration and air conditioning systems after a

compressor motor burn-out.

The solid core, which is composed of 70% activated

alumina and 30% Molecular Sieve, adsorbs harmful

acids as well as moisture.

Available with flare and solder (pure copper)

connections.

Features The Core type DAS

• Solid core with 70% activated alumina and

30% Molecular Sieve for adsorption of acid and

moisture

• Recommended for use with HFO, HC, HFC and

HCFC refrigerants

The Shell

• UL approved for MWP 500 psig

• Available with flare and solder (pure copper)

connections

• Corrosion resistant powder-painted finish

• Allows installation with any orientation provided

the flow is in the arrow direction

• 2 Schrader access valves to measure pressure

drop across the drier

• Available in sizes 8 – 60 cubic inches

© Danfoss | DCS (az) | 2016.04

The Filter

• 120 mesh wire mesh provides solid particle

retention with minimal pressure drop

DKRCC.PD.EH0.B4.22 | 520H10979 | 1

Page 2

Data sheet | ELIMINATOR® Hermetic burn-out filter drier, type DAS

TE

DAS

Danfoss

R64-2113.10

Approvals UL file no. SA 6398

PED 97/23/EC - a3p3

Compliant with ATEX hazard zone 2

Note: Only solder versions (cu-plated / pure copper) and

connection sizes below 25 mm are approved for flammable

refrigerants now.

Introduction

Technical data and capacities

Flare connection

Solder connection (pure copper)

ELIMINATOR® Hermetic filter driers protect

refrigeration and air-conditioning systems from

moisture, acids, and solid particles.

By adsorbing harmful acids after a compressor

motor damage, the DAS hermetic burn-out filter

drier protects the new compressor against

premature failure.

Rated capacity, Qn 1)

Type

DAS 083

DAS 084 2.9 1.6 2.3 0.13 500

DAS 085 4.1 2.6 3.6 0.13 500

DAS 086 5.4 3.3 4.7 0.13 500

DAS 164 6.3 1.7 2.4 0.30 500

DAS 165 4.3 2.7 3.7 0.30 500

DAS 166 5.7 3.4 4.9 0.30 500

DAS 167 6.3 3.9 5.4 0.30 500

DAS 305 5.1 3.1 4.3 0.64 500

DAS 306 6.3 4.0 5.4 0.64 500

DAS 307 7.4 4.6 6.3 0.64 500

DAS 309 8.9 5.7 7.7 0.64 500

DAS 417 8.6 5.1 7.1 0.86 500

DAS 419 10.0 6.3 8.6 0.86 500

DAS 607 5.7 3.4 4.9 1.29 500

1

) Rated capacity is stated at:

evaporating temperature te = 39.2 °F

pressure drop Δp = 3.04 psig

2

) Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number)

Temperature range:

-40 – 160 °F

R22/R407C/R410A R134a R404A/R507

[TR] [TR] [TR] [oz.] [psig]

1.7 1.0 1.3 0.13 500

Acid capacity 2)

Max. Working

Pressure MWP

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EH0.B4.22 | 520H10979 | 2

Page 3

Data sheet | ELIMINATOR® Hermetic burn-out filter drier, type DAS

Selection

Ordering

Flare connection

Solder connection

Capacities for other temperatures than 39.2 °F

are calculated by use of correction factors.

Look up the capacity table for the necessary rated

capacity.

Divide your actual evaporator capacity with the

correction factor given for your actual evaporating

temperature.

Qe/Fe = Qn

Qe = Actual evaporator capacity

Qn = Nominal capacity

Fe = Correction factor

Correction factors. Fe evaporating temperatures [°F]

[°F] 39.2 32 23 14 5 -4 -13 -22 -31 -40

F

e

1 0.9 0.75 0.6 0.5 0.4 0.35 0.25 0.2 0.15

Example

To select a hermetic burn-out filter drier for a R22 plant with an evaporator capacity at 2.41 TR at -4 °F you may use a burn-out filter drier

with a rated capacity of 8.5/0.4 = 6.02 TR or bigger.

For example DAS 306.

Flare

Type

DAS 083VV

DAS 084VV

DAS 164VV

DAS 165VV

Connection Multi pack

[in.] Qt y. Code no.

3

⁄8 24 023Z1001

1

⁄2 24 023Z1002

1

⁄2 12 023Z1007

5

⁄8 12 023Z1008

Solder

Type

DAS 083sVV

DAS 084sVV

DAS 085sVV

DAS 086sVV

DAS 164sVV

DAS 165sVV

DAS 166sVV

DAS 167sVV

DAS 305sVV

DAS 306sVV

DAS 307sVV

DAS 309sVV 11⁄8 8 023Z1016

DAS 417sVV

DAS 419sVV 11⁄8 8 023Z1018

DAS 607sVV

DAS 609sVV 11⁄8 12 023Z1020

Connection Multi pack

[in.] Qt y. Code no.

3

⁄8 24 023Z1003

1

⁄2 24 023Z1004

5

⁄8 24 023Z1005

3

⁄4 24 023Z1006

1

⁄2 12 023Z1009

5

⁄8 12 023Z1010

3

⁄4 12 023Z1011

7

⁄8 12 023Z1012

5

⁄8 8 023Z1013

3

⁄4 8 023Z1014

7

⁄8 8 023Z1015

7

⁄8

7

⁄8 12 023Z1019

8 023Z1017

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EH0.B4.22 | 520H10979 | 3

Page 4

Data sheet | ELIMINATOR® Hermetic burn-out filter drier, type DAS

Identification

Type codes

Type Codes Description

Filter drier D Drier

Solid core A Burn-out, 70% activated alumina / 30% Molecular Sieves

Application S Suction line

3

3

3

3

3

3

⁄8 in. / 10 mm

1

⁄2 in. / 12 mm

5

⁄8 in. / 16 mm

3

⁄4 in. / 18 (19) mm

7

⁄8 in. / 22 mm

Size (volume)

Connection (filter connection

in 1/8 of an inch increments)

08 8 in

16 16 in

30 30 in

41 41 in

60 60 in

3

4

5

6

7

9 11⁄8 in. / 28 mm

Connection type

(blank) Flare connection

s Solder connection (pure copper)

Inlet: Outlet:

Access valves

(blank) No access valves No access valves

V Schrader valve No access valves

VV Schrader valve Schrader valve

Example for type codes

D A S 08 3 s vv

Solid core

Filter drier

Application

Size (volume)

Access valves

Connection type

⁄8 of an inch increments)

1

in

Connection (filter connection

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EH0.B4.22 | 520H10979 | 4

Page 5

Data sheet | ELIMINATOR® Hermetic burn-out filter drier, type DAS

Danfoss

23Z18.13

72 3 45 6 7 1

Design / function

1. Inlet

2. Spring

3. Solid core

4. Polyester mat

5. Metal mesh

6. Perforated plate

7. Schrader valve

The large diameter of the hermetic burn-out filter

drier means that flow velocity is suitably low and

the pressure drop minimal.

Dimensions and weights Solder connections

Type

DAS 083sVV 4.0 4.7 5.5 2.3 2.1 1.6 1.00

DAS 084sVV 4.0 4.8 5.6 2.3 2.1 1.6 1.10

DAS 085sVV 4.0 4.9 5.9 2.3 2.1 1.6 1.10

DAS 086sVV 4.0 5.2 6.3 2.3 2.1 1.6 1.10

DAS 164sVV 4.3 5.2 6.0 3.1 3.0 2.0 2.03

DAS 165sVV 4.3 5.3 6.2 3.1 3.0 2.0 1.90

DAS 166sVV 4.3 5.5 6.7 3.1 3.0 2.0 1.90

DAS 167sVV 4.3 5.6 6.8 3.1 3.0 2.0 1.90

DAS 169sVV 4.3 5.6 6.8 3.1 3.0 2.0 0.84

DAS 305sVV 7.3 8.3 9.2 3.1 3.0 2.0 2.90

DAS 306sVV 7.3 8.5 9.7 3.1 3.0 2.0 2.90

DAS 307sVV 7.3 8.5 9.8 3.1 3.0 2.0 2.90

DAS 309sVV 7.3 8.5 9.8 3.1 3.0 2.0 3.00

DAS 417sVV 7.4 8.6 9.8 3.7 3.5 2.2 4.60

DAS 419sVV 7.4 8.6 9.8 3.7 3.5 2.2 4.60

DAS 607sVV 13.3 14.3 15.7 3.1 3.0 2.0 5.30

DAS 609sVV 13.3 14.1 15.7 3.1 3.0 2.0 5.30

Powder formation is eliminated because the solid

core grains are bonded and cannot move against

each other.

A B L D

[in.] [in.] [in.] [in.] [in.] [in.] [lbs]

1

2

D

F Net weight

© Danfoss | DCS (az) | 2016.04

DKRCC.PD.EH0.B4.22 | 520H10979 | 5

Page 6

Danf

already on order pro

All trademarks in this material are property of the respec

Dimensions and weights

(continued)

Flare connections

Type

A L D

1

[in.] [in.] [in.] [in.] [in.] [lbs]

2

D

F Net weight

DAS 083VV 4.0 6.2 2.3 2.1 1.6 1.12

DAS 084VV 4.0 6.5 2.3 2.1 1.6 1.37

DAS 164VV 4.3 6.9 3.1 3.0 1.6 2.01

DAS 165VV 4.3 7.2 3.1 3.0 1.6 2.09

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (az) | 2016.04

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PD.EH0.B4.22 | 520H10979 | 6

Loading...

Loading...