Page 1

Instructions

Electronic module on

SH/SY/SZ compressors

Introduction

Large scroll compressors are delivered with

a pre-installed electronic module located in

the terminal box. This procedure describes

electronic module’s functions, fault diagnosis

and how to replace an electronic module on

SH/SY/SZ compressors.

These operations must be performed by

qualied personnel in compliance with all

pertinent practices and safety procedures.

Functional description

The electronic module device provides

ecient and reliable protection against motor

overheating and overloading as well as phase

loss and phase reversal detection.

1.Motor overheating and overloading

The motor protector comprises a control

module and PTC sensors embedded in the

motor winding. The close contact between

thermistors and windings ensures a very low

level of thermal inertia.

The motor temperature is constantly measured

by a PTC thermistor loop connected on

S1-S2. If the thermistor exceeds its response

temperature, its resistance increases above the

trip level (4,500 Ω ) and the output relay then

trips, i.e. contacts M1-M2 are open. After cooling

to below the response temperature (resistance

< 2,750 Ω), a 5-minute time delay is activated.

After this delay has elapsed, the relay is once

again pulled in, i.e. contacts M1-M2 are closed.

The time delay may be cancelled by means

of resetting the mains (L-N-disconnect) for

approximately 5 seconds.

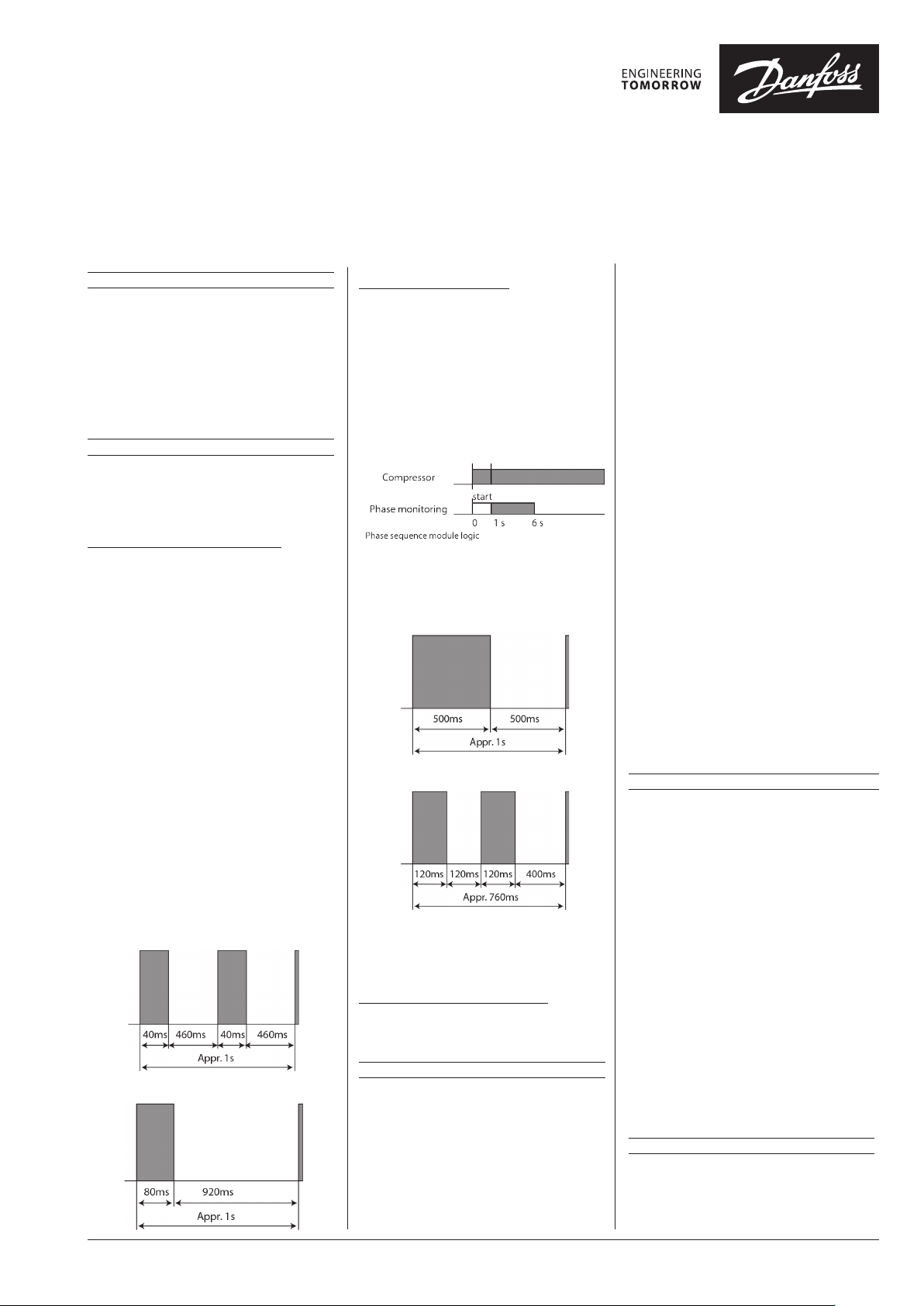

A red/green twin LED is visible on the

module. A solid green LED denotes a fault

free condition. A blinking red LED indicates an

identiable fault condition:

PTC overheat

PTC reset delay active (after PTC over temp.)

2.Phase loss, phase sequence

The electronic module provides protection

against phase reversal and phase loss at start-up.

The circuit should be thoroughly checked in

order to determine the cause of the phase

problem before re-energizing the control circuit.

The phase sequencing and phase loss

monitoring functions are active during a 5-sec

window 1 second after the compressor start-up

(power on L1-L2-L3).

Should one of these parameters be incorrect,

the relay would lock out (contact M1-M2 (or 11-

14) open). The red LED on the module will show

the following blink code:

In case of phase loss error

In case of phase reverse error

The lockout may be cancelled by resetting

the power mains (disconnect L-N) for

approximately 5 seconds.

3. Internal module failure protection:

An internal microprocessor fault leads to trip;

relay contact M1-M2 open.

Fault diagnosis

If the relay contacts M1-M2 are open, carry out

following steps:

1. Check all electrical connections (wiring,

drawing conformity, connection tightness…)

2. Try to reset by interrupting mains supply to

the module for at least 5 seconds.

3. If after reset the relay contacts M1-M2 are

now closed, a fault in motor power supply or

high motor temperature had caused a trip

condition

(missing phase, wrong phase sequence,

operating outside of the compressor operating

envelope…).

4. If the relay contact M1-M2 remains open:

4.1 Disconnect the PTC thermistor leads and

measure the resistance value at this point (max

measurement voltage 3V).

• R=∞: PTC loop opened remove the

compressor.

• R>2750Ω: wait until compressor motor

winding temperature has cooled down,

reconnect PTC and try to reset check root

causes of motor over heating (operation outside

of working envelope…).

•

150Ω<R<1250Ω: normal resistance value for PTC

at ambient temperature continue with step 4.2.

• R=0Ω: PTC loop in short circuit replace the

compressor.

4.2 Following steps describe how to test the

module itself within the terminal box:

• Disconnect L-N.

• Disconnect S1-S2.

•Disconnect M1-M2.

• Reconnect mains supply L-N.

• Bridge S1-S2.

• Try to reset by interrupting mains supply to the

module for at least 5 seconds.

•

Check relay contacts M1-M2 with an ohmmeter.

• If the relay contacts M1-M2 are closed, module

is OK.

• If the relay contacts M1-M2 are still open

replace the module.

Replacement/Installation

1. Lock-out power supplies if compressor is

installed.

2. Remove electrical box cover.

3. Before removing wires, label the wires so they

can be connected to the correct connections

on the replacement module. Unplug wires

connected to the module.

4. Remove the two 3.5x25mm screws holding

the module and replace with required module.

5. If the change is to have a dierent module

supply voltage, please indicate the new electronic

module supply voltage close to the compressor

nameplate in case of compressor replacement.

6. Use two 3.5x25mm screws (torque: 0.5 to

2N.m), to mount the new module in place of the

existing one.

7. Connect thermistor wires and 3 phase wires

(when present) to the module. In case of the

installed compressor, connect safety circuit and

power supply wires to the module.

8. Snap the electrical box cover in place.

9. Reconnect power to compressor and module.

Handling and storage

• Handle the electronic module with care.

• In case of shock, the electronic module

should not be used.

• Store between -35°C and + 70°C.

• Don’t expose to rain or corrosive atmosphere.

© Copyright Danfoss | Commercial Compressors | 2015.03FRCC.PI.031.A2.02 - March 2015 - 8510268P01B

Page 2

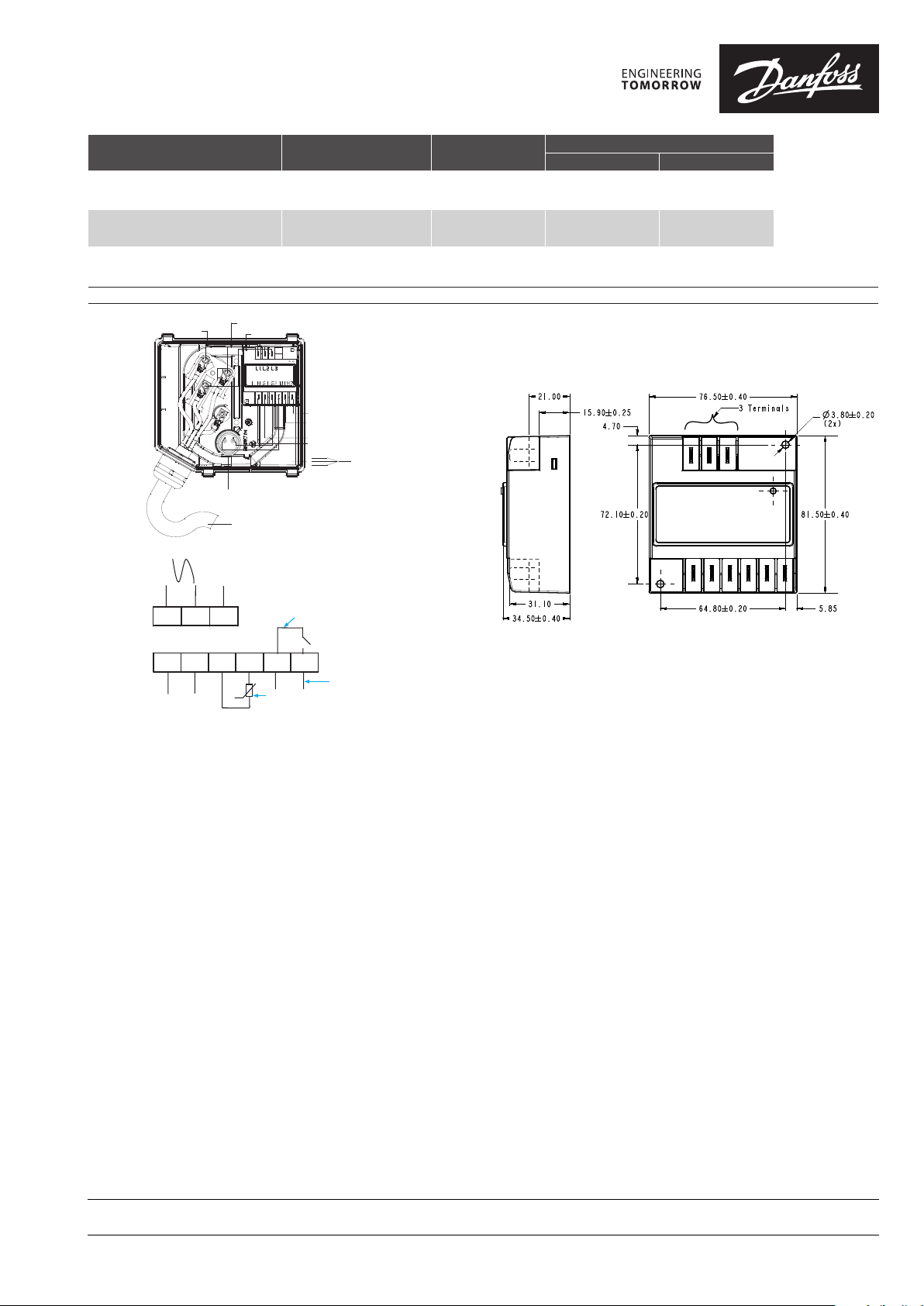

Blue

Compressor Model

SM/SY/SZ175 to 380

& SH180 - 240 to 485

SM/SY/SZ175 to 380

& SH180 - 240 to 485

Electronic Module Description

Electronic Module 24V AC

Electronic Module

115/240V AC

Electronic module overview

Danfoss Accessory

code

120Z0584

120Z0585

Codes marked on module nameplate

Module name Danfoss part number

DEP101A 6914009P01

DEP101B 6914010P01

Black

Phase sequence input

L1 L2 L3

Black Blue Brown

Brown

Faston 1/4” tabs

Power supply

Internal control contact

LNS1 S2 M1 M2

Thermistor

Module power

connection

M1 - M2

Control circuit

Module

}

power supply

}

Sump heater

Safety

circuit

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Copyright Danfoss | Commercial Compressors | 2015.03FRCC.PI.031.A2.02 - March 2015 - 8510268P01B

Loading...

Loading...