Page 1

Data Sheet

Electronic Foot Pedal

Over Center Rocker Type/Bi-directional

The rocker type Electronic Foot Pedal is used to drive

off-highway vehicles equipped with hydrostatic

transmissions and/or electronically controlled

engines. The foot pedal typically provides speed

commands to the electronic transmission or the

engine controller, where the output signal of the foot

pedal is proportional to the angle of the foot pedal

actuation. The rocker type foot pedal is commonly

used on vehicle applications that have a high duty

cycle of direction changes (forward/neutral/reverse).

For example: warehouse trucks, piggy-back fork

trucks, and other material handling equipment.

The electronic foot pedal features a specially

designed sensor for heavy equipment applications

which uses Hall effect technology. This special sensor

offers two different types of redundant signals to fit a

variety of control strategies. In addition, the

redundant sensors have independent isolated circuits

and protection against electrical misconnection.

Features

•

Robust over-center rocker pedal

•

14 +/- 2 degrees angular rotation fore

and aft

•

3 million full actuation cycle life

•

Non-contact ratiometric Hall effect

sensors

•

Independent isolated redundant

sensors

•

Protected against electrical

misconnection

•

IP 66 sealed electronics

•

Wide operating temperature

•

Withstands high static loads

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | Aug 2016 L1024042 | AI00000110en-US0302 | 1

Page 2

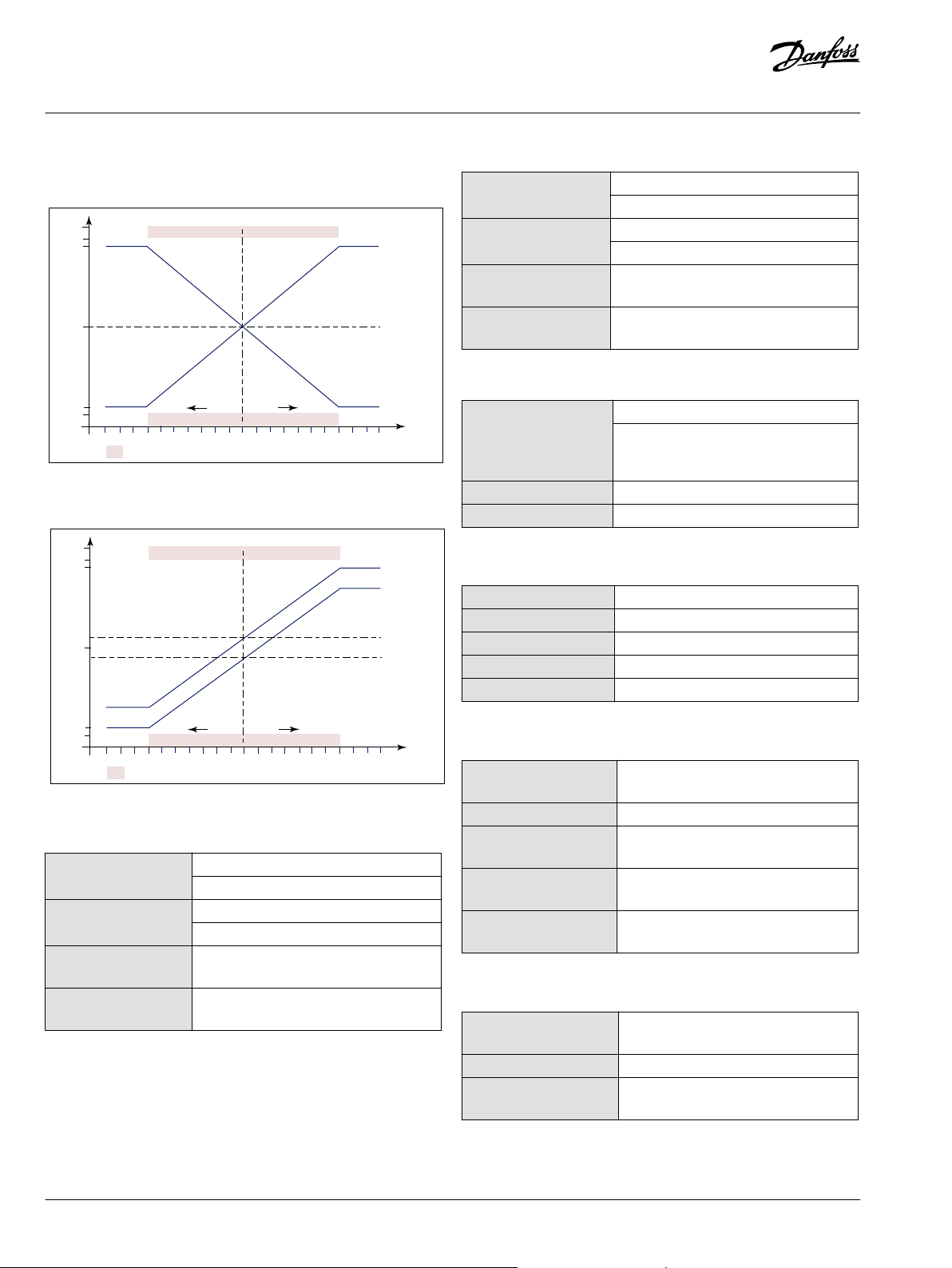

100%

Dir. A

Dir. B

50%

Sensor 2 output

(percent of

input voltage)

Sensor 1 output

(percent of

input voltage)

94%

90%

10%

5%

Neutral position

Pedal angle

-20°

-18°

-16°

-14°

-12°

-10°

-8°

-6°

-4°

-2°

-0°

2°

4°

6°

8°

10°

12°

14°

16° 18°

20°

Fault area

100%

50%

Sensor 2 output

(percent of input voltage)

Sensor 1 output

(percent of input voltage)

94%

90%

10%

5%

Neutral position

Pedal angle

-20°

-18°

-16°

-14°

-12°

-10°

-8°

-6°

-4°

-2°

-0°

2°

4°

6°

8°

10°

12°

14°

16° 18°

20°

Fault area

Neutral position

Dir. A

Dir. B

Data Sheet

Electronic Foot Pedal Bi-directional

Technical Data

Option 1: 10%-90% and 90%-10%

Option 2: 20%-90% and 10%-80%

Option 2: Signal Level

Signal 1 range nominal

(APS1)

Signal 2 range nominal

(APS2)

Neutral 1 range nominal

(APS1)

Neutral 2 range nominal

(APS2)

Minimum (Uout/Ucc): 20%, +4% and -2%

Maximum (Uout/Ucc): 90%, +2% and -4%

Minimum (Uout/Ucc): 10%, +4% and -2%

Maximum (Uout/Ucc): 80%, +2% and -4%

(Uout/Ucc): 45% ± 4%

(Uout/Ucc): 55% ± 4%

Specifications

Supply voltage (Ucc1,

Ucc2) Current

consumption (each Hall

element)

Operating temperature -40 to +85° C [-40 to +185° F]

Sealing of electronics IP 66

5 Vdc ± 0.5 Vdc

Maximum: 10 mA (for both Hall elements 20

mA)

Material

Casting Irridited aluminum

Hall element shaft Stainless steel

Base plate Zinc plated steel

Spring Stainless steel

Weight Typical: 2.6 Kg [5.6 lbs]

Mechanical Ratings

Pedal angle (toeboard

angle)

Activations (full stroke) Minimum: 3 million

Option 1: Signal Level

Signal 1 range nominal

(APS1)

Signal 2 range nominal

(APS2)

Neutral 1 range

Minimum (Uout/Ucc): 10%, +4% and -2%

Maximum (Uout/Ucc): 90%, +2% and -4%

Minimum (Uout/Ucc): 90%, +2% and -4%

Maximum (Uout/Ucc): 10%, +4% and -2%

50% ± 4%

Static load limit (forward

or reverse)

Side load limit Maximum: 500 N (measured 150mm from

Vertical load limit

(neutral)

nominal (APS1)

Neutral 2 range

nominal (APS2)

2 | © Danfoss | Aug 2016 L1024042 | AI00000110en-US0302

50% ± 4%

Signal Output

Signal current (APS1,

APS2)

Signal load Maximum: 10 K Ohms

Short circuit of signal

(APS1, APS2)

Maximum: 14° ± 2°

Maximum: 1500 N (measured 150mm from

pivot)

pivot)

Maximum: 1000 N (measured center of

treadle on pivot axis)

Maximum: 0.5 mA

Maximum: 20 minutes

Page 3

A

B

C D E F

Data Sheet

Electronic Foot Pedal Bi-directional

Sensor Connections

Pin Function Color

A Signal 1 = Us1 Black

B Ground 1 = GND1 White

C Supply 1 = Ucc1 Red

D Supply 2 = Ucc2 Green

E Ground 2 = GND2 Blue

F Signal 2 = Us2 Orange

Ordering Information

Part number Description

11065877 Option 1 Bi-directional

11065874 Option 2 Bi-directional

11065878 100 cm Cable

©

Danfoss | Aug 2016 L1024042 | AI00000110en-US0302 | 3

Page 4

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | Aug 2016 L1024042 | AI00000110en-US0302

Loading...

Loading...