Page 1

MAKING MODERN LIVING POSSIBLE

Electronic Controls

Fitter’s Notes

www.danfoss.com

Page 2

Fitter notes – Electronic Controls

2 DKRCC.PF.000.G2.02 / 520H8626

Page 3

Fitter notes – Electronic Controls

Contents

Measuring 4

Measuring a temperature 4

Temperature sensor type EKS 111 5

Temperature sensor type EKS 211 5

Positioning sensors 6

Evaporator positions 6

S1 and S2 sensors 7

How to mount S2 sensor on a vertical pipe 7

How to mount S2 sensor on a horizontal pipe 7

Measuring a pressure 8

Positioning sensors 11

Pressure transmitter in liquid line with pulse snubber 12

Electrical connections 13

Pulse width modulation electronically operated expansion valve type AKV 13

Stepper motor electronically operated expansion valve type ETS 13

Digital Input (DI) / Digital Output (DO) 14

No power 14

Split sensors and AKV 14

External Start/Stop of regulation 14

Controlling 15

Input and output 15

Op eratio n 15

Evaporator controls 16

Parameters 16

What is the controller doing...? 17

Quick start 17

What is wrong....? 18

Communication 19

Why...? 19

How…? 19

Cable selection / termination 20

Requirement to installation 20

Cable 21

Addressing 24

Trouble shooting 24

DKRCC.PF.000.G2.02 / 520H8626 3

Page 4

Fitter notes – Electronic Controls

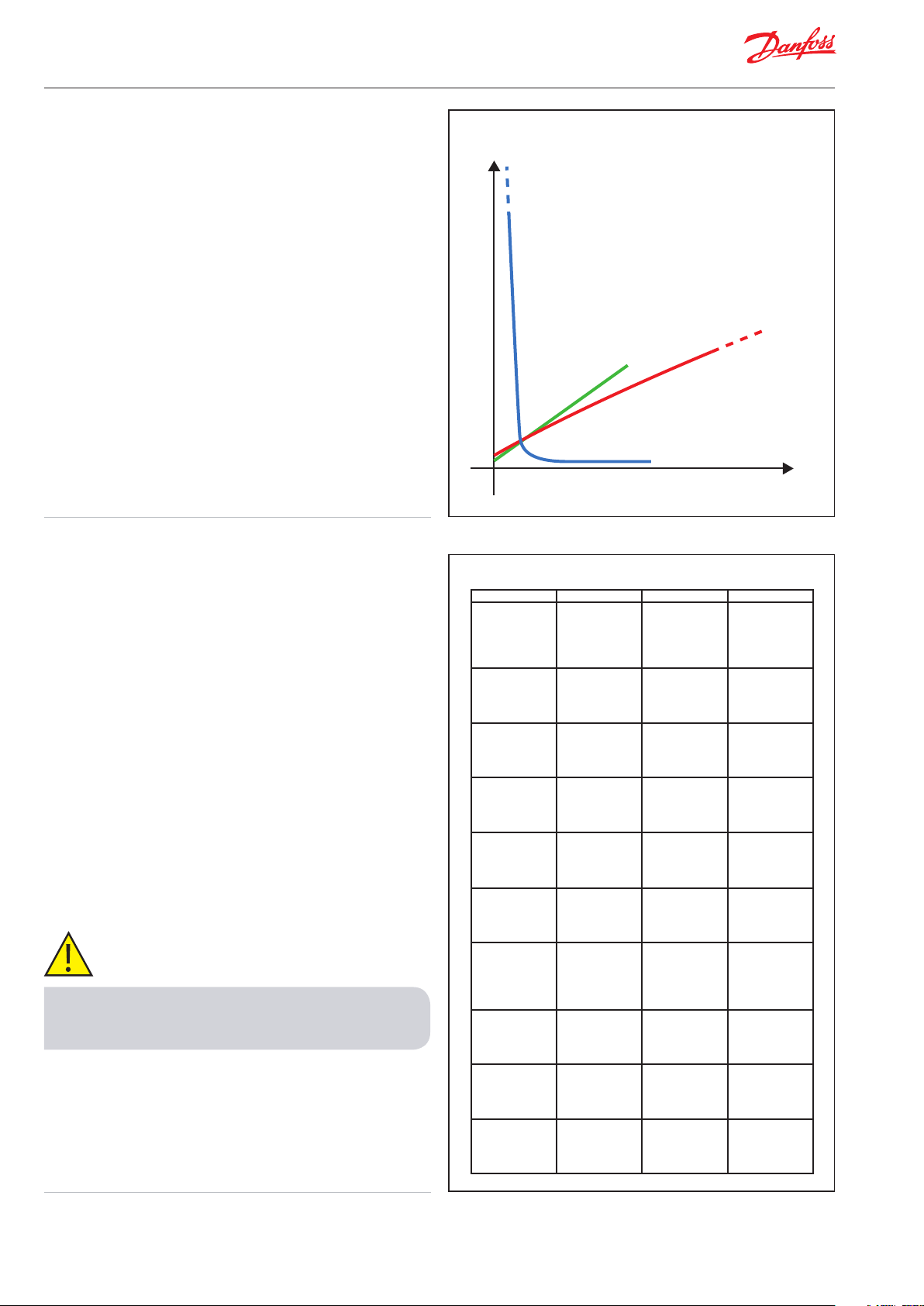

R

NTC

PTC

Pt

T

Measuring

Measuring a temperature

Pressure temperature inputs

With the use of electronic controllers such as

Danfoss ADAP-KOOL® products the installation requirements must

be followed to ensure the electrical connections, pressure and

temperature sensors and any communication network

connections are correct so that the unit operates as intended.

The following are some general guidelines:

y Pressure temperature inputs

It is very important that the correct type of temperature sensor

is used for the temperature range, sensing application, and the

temperature sensor signal is compatible with the electronic

refrigeration controller, (please see the technical manual for the

controller to ensure the correct temperature sensor is used).

y Sensor types

The product programme of temperature sensors for

refrigeration consists of two main families: AKS and EKS.

These sensor elements are based on the three technologies:

Pt, PTC and NTC.

Temperature sensor type:

AKS11, AKS12, AKS21, AK-HS 1000

Pt sensor

These sensors are also known as RTD´s, Resistance Temperature

Detectors. The sensing elements is made of platinum, example

PT1000, where the number describes the nominal resistance at

0°C, here 1.000Ω. The resistance increases 4Ω per 1°C. The sensor

characteristic is linear. In Danfoss these sensors are the type AKS.

The tolerance of a Pt1000 sensor is less than ± (0.3 + 0.005 T).

This translates into a temperature error of less than 0.5 degree for

refrigeration control.

The Pt1000 sensor must be used for food safety logs and

regulation of superheat as they conform to the tolerance

requirements of EN 60751 Class B and therefore satisfy the HACCP

requirements of EN 12830, EN 13485.

Extension of sensor cables

When extending a sensor cable, the new resistance value of the

longer cable may give rise to indication error. It is recommended

that the total cable resistance should not exceed 2Ω

corresponding to an indication error of 0.5°C (Pt1000Ω).

Note

Up to 50m use 0.75mm²

Up to 100m use 1.5mm²

Up to 150m use 2.5mm²

The typical resistance values for cables are:

y -2.4Ω/100m for core cross-sectional area of 0.75mm².

y -1.2Ω/100m for core cross-sectional area of 1.5mm².

y -0.7Ω/100m for core cross-sectional area of 2.5mm² .

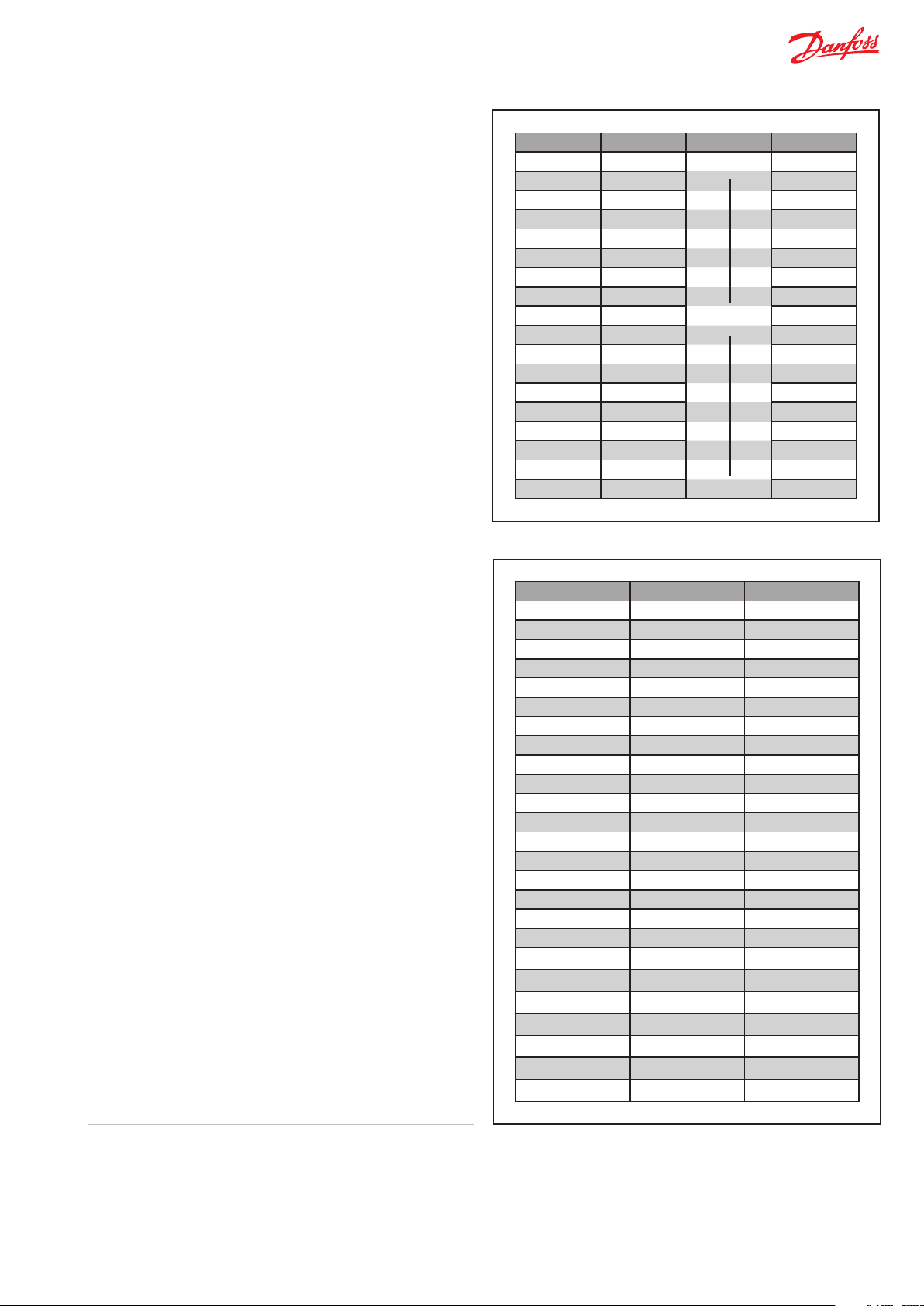

AKS 11, AKS 12, AKS 21, AK-HS 1000

°C ohm °C ohma

0 1000.0 1000.0

1 1003.9 -1 996.1

2 1007.8 -2 992.2

3 1011.7 -3 988.3

4 1015.6 -4 984.4

5 1019.5 -5 980.4

6 1023.4 -6 976.5

7 1027.3 -7 972.6

8 1031.2 -8 968.7

9 10.35.1 -9 964.8

10 1039.0 -10 960.9

11 1042.9 -11 956.9

12 1046.8 -12 953.0

13 1050.7 -13 949.1

14 1054.6 -14 945.2

15 1058.5 -15 941.2

16 1062.4 -16 937.3

17 1066.3 -17 933.4

18 1070.2 -18 929.5

19 1074.0 -19 925.5

20 1077.9 -20 921.6

21 1081.8 -21 917.7

22 1085.7 -22 913.7

23 1089.6 -23 909.8

24 1093.5 -24 905.9

25 1097.3 -25 901.9

26 1101.2 -26 898.0

27 1105.1 -27 894.0

28 1109.0 -28 890.1

29 1112.8 -29 886.2

30 1116.7 -30 882.2

31 1120.6 -31 878.3

32 1124.5 -32 874.3

33 1128.3 -33 870.4

34 1132 -34 866.4

34 1132.2 -34 866.4

35 1136.1 -35 862.5

36 1139 -36 858.5

37 1143.8 -37 854.6

38 1147.7 -38 850.6

39 1151.5 -39 846.7

40 1155.4 -40 842.7

41 1159.3 -41 838.8

42 1163.1 -42 835.0

43 1167.0 -43 830.8

44 1170.8 -44 826.9

45 1174.7 -45 822.9

46 1178.5 -46 818.9

47 1182.4 -47 815.0

48 1186.3 -48 811.0

49 1190.1 -49 807.0

50 1194.0 -50 803.1

approx 3.9 ohm/K

4 DKRCC.PF.000.G2.02 / 520H8626

Page 5

Fitter notes – Electronic Controls

Temperature sensor type EKS 111

PTC sensor

The PTC sensor got their name as the sensing element has a

positive temperature coecient.

The sensing element is a semi conductor, example PTC1000

where the number describes the nominal resistance at 25°C.

The sensor characteristic is almost linear but is not standardized,

the manufacturer can dene their own characteristics.

In Danfoss the EKS111 is a PTC1000 type.

The PTC temperature sensor type EKS111 must not be used for

food safety logs as they do not conform to the requirements

EN 12830, EN 13485 or regulation of superheat because they do

not have the needed accuracy of +/- 0.5K.

R (typ.) Ohm Tem p. °C Error K Te mp ° F

1679 100 +/-3.5 212

1575 90 194

1475 80 176

1378 70 15 8

128 6 60 14 0

119 6 50 12 2

1111 40 104

1029 30 86

990 25 +/-1.3 77

951 20 68

877 10 50

807 0 32

740 -10 14

677 -20 -4

617 -30 -2 2

562 -40 -40

510 -50 -58

485 -55 +/-3.0 - 67

Temperature sensor type EKS 211

NTC sensor

The sensing element in NTC´s is a thermistor having a

negative temperature coecient.

The sensor characteristic is described by a number, that as with

PTC´s, indicates the nominal resistance at 25°C, and by a β-value

which denes the curve characteristic.

Due to the variety of characteristics it is not possible to develop a

standard NTC sensor that can be used for all controller types.

Hence, when making service you must install an “original” NTC

sensor to ensure the controller to work properly.

Temperature sensor type EKS 211

NTC characteristic matches controllers type EKC and AK-CC.

The NTC temperature sensor type EKS211 must not be used for

food safety logs as they do not conform to the requirements

EN 12830, EN 13485 or regulation of superheat because they do

not have the needed accuracy of +/- 0.5K.

R_nom Ohm Tem p. °C Temp °F

631.0 80 176

743.2 75 167

878.9 70 158

104 4 65 149

1247 60 14 0

1495 55 131

1803 50 12 2

2186 45 113

2665 40 104

3266 35 95

4029 30 86

5000 25 77

6246 20 68

7855 15 59

9951 10 50

12696 5 41

16330 0 32

21166 -5 23

27681 -10 14

36503 -15 5

48 614 -20 -4

65333 -25 -13

88766 -30 -22

12179 5 -35 - 31

16915 7 -40 -40

DKRCC.PF.000.G2.02 / 520H8626 5

Page 6

Fitter notes – Electronic Controls

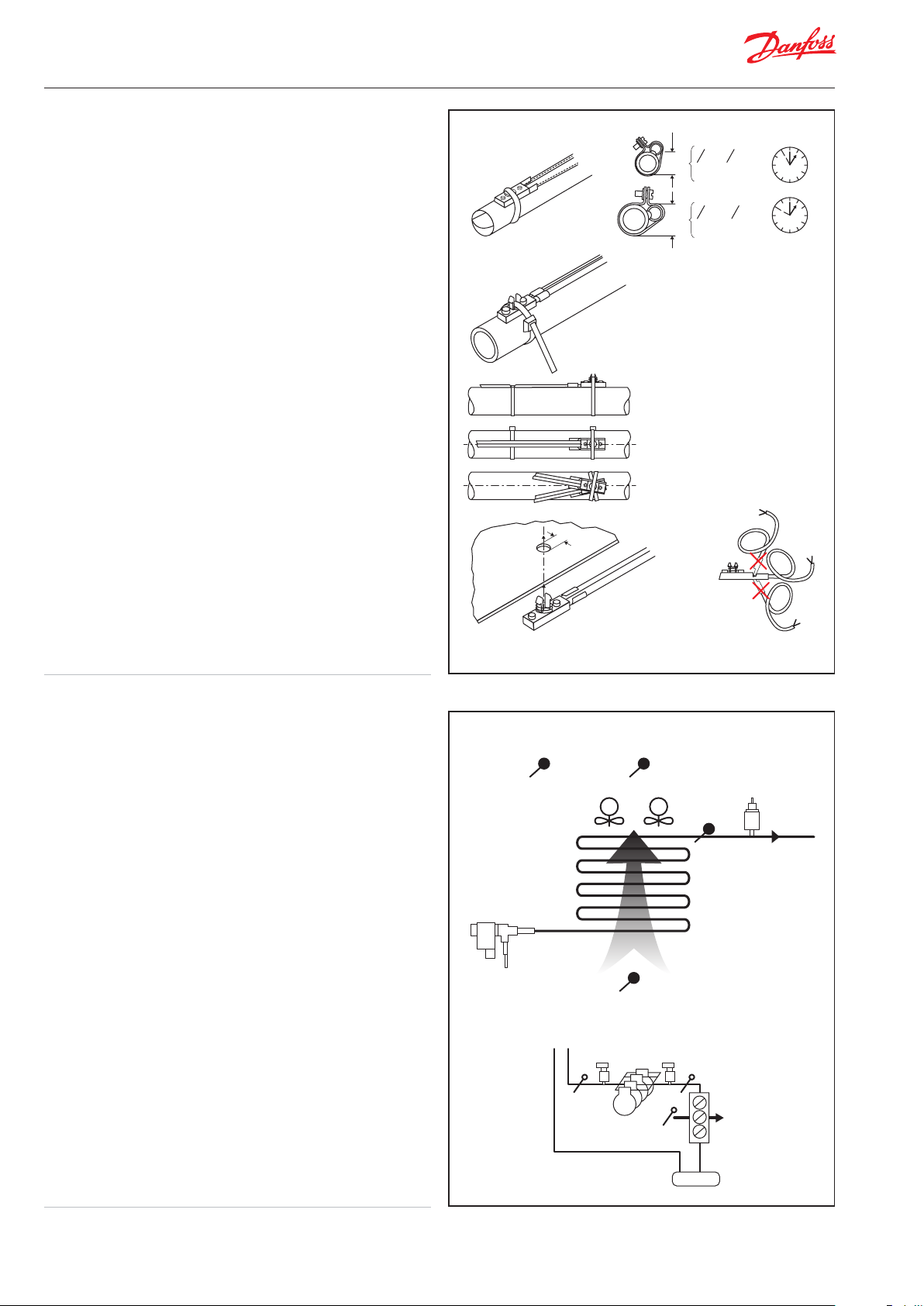

Positioning sensors

It is very important that during the installation process and also

during maintenance schedules the correct position and mounting

of all temperature sensors is in line with the recommendations.

Incorrect mounting can cause faulty temperature signals to be

used by the controller which will result in, in-correct operation of

the refrigeration application.

Ø=

Ø=

125

in.

8

12 - 16mm

341

1

8

18 - 26mm

in.

12

1

2

3

4

12

1

2

3

4

Evaporator positions

Nomenclature of temperature tensors & pressure

transmitters in Danfoss controllers

y S1: Temperature sensor measuring evaporating temperature

(Can be used as a less accurate measurement of

evaporating temperature without the need for a pressure

transmitter)

y Pe: Pressure transmitter measuring true evaporating pressure

(preferred method)

y S2: Suction temperature outlet of the evaporator

y S3: Air entering the evaporator

y S4: Air leaving the evaporator

y S5: Defrost termination temperature sensor when defrost is

being used

y S6: Is used as a product sensor (type AK-HS1000,HACCP

compliance for food safety)

Pack positions

y Po: Pressure transmitter - Suction pressure

y Pc: Pressure transmitter - Discharge pressure

y Ss: Temperature sensor - Suction temperature to work out

suction superheat in connection with suction pressure Po

y Sd: Temperature sensor - Discharge temperature

y Sc3: Temperature sensor - Ambient temperature of the air

entering the condenser

Ø=6.5

S6 S4

M M

S3

Po Pc

S

S

NB!

Pe

S2

S5

Sd

S

CS

6 DKRCC.PF.000.G2.02 / 520H8626

Page 7

Fitter notes – Electronic Controls

S1 and S2 sensors

S1 and S2 sensors measuring saturation temperature and

temperature of superheat gasses.

y S1: This sensor is measuring the evaporating temperature of

the evaporator and therefore must be mounted on the

coldest point on the evaporator, normally the rst return

bend.

The reading should be checked against the suction gauge

pressure to conrm that the pressure and temperature

relationship is correct otherwise the control of superheat

will be incorrect.

Where and how to mount the S1 sensor

S1

S1S1A

S1

B

B

y S2: Sensor function is to measure the temperature of the

refrigerant exiting at the evaporator’s pipe outlet and, has

thus, the same goal as a thermostatic expansion valve’s

bulb and should be placed exactly according to the same

rules.

Only a Pt1000 AKS11 type sensor must be used, as it is the

only type providing the necessary accuracy needed for

this purpose.

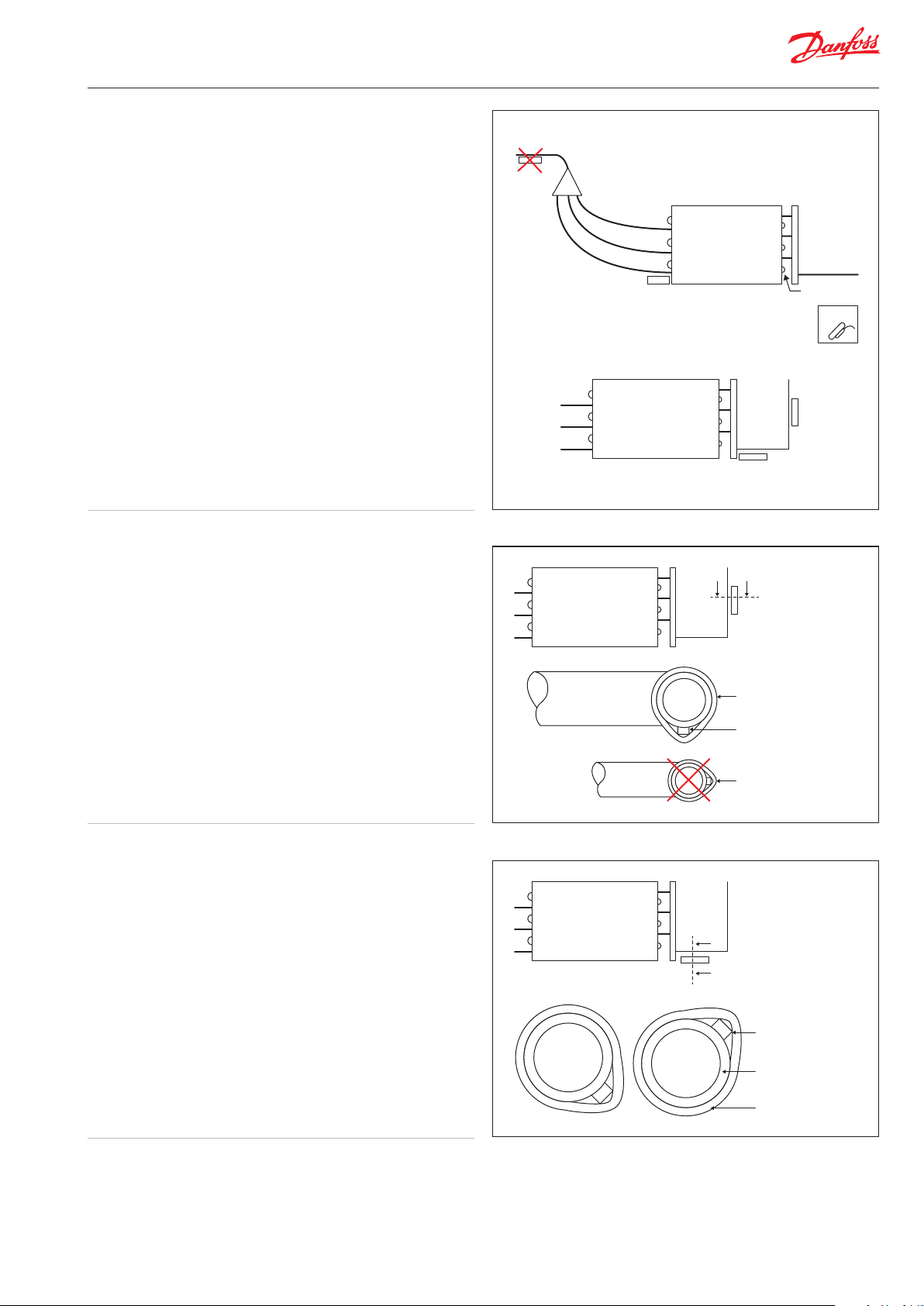

How to mount S2 sensor on a vertical pipe

Steel pipes

If steel pipes are used on the evaporator outlet the superheat

signal it must be measured using a pocket sensor “S2” to get a

correct signal. This is absolutely necessary to get a good injection

control.

Copper pipes (exceeding 50mm)

When pipe dimensions go up so does the material thickness.

Bigger thickness also means greater temperature dierence

between inner and outer temperatures. You should use

immersion pocket sensors here also.

Where and how to mount the S2 sensor

Mount on vertical pipe if possible not too close to bend

and not to far from evaporator outlet

AA

Cut A-A

Cut A-A

A

S2

S2 B

The sensor should be

mounted rmly on the

pipe using heat-conducting

paste and the sensor

should be insulated

S2

Pipe isolation

S2 sensor

Oil splash can disturb the signal

How to mount S2 sensor on a horizontal pipe

The sensor should be

When mounted on horizontal pipe the position depends on the

size of the pipe.

y Mount at 1 o’clock when diameter is between 1/2 and 5/8inch

(12-16mm).

y Mount at 2 o’clock when diameter is between 3/4 and

1- 1/8inch (18-26mm).

y Mount at 4 o’clock when diameter is over 1- 1/2inch (38mm).

y Use immerse pocket sensor if you want to measure on steel

pipe.

B

B

Cut B-B

mounted rmly on the

pipe using heat-conducting

paste and the sensor

should be insulated

S2

S2 sensor

Pipe

Isolation

DKRCC.PF.000.G2.02 / 520H8626 7

Page 8

Fitter notes – Electronic Controls

Measuring a pressure

It is very important that the correct type of pressure transmitter is

used for the pressure range, sensing application, and the pressure

transmitter signal is compatible with the electronic refrigeration

controller, (please see the technical manual for the controller to

ensure correct pressure transmitter is used).

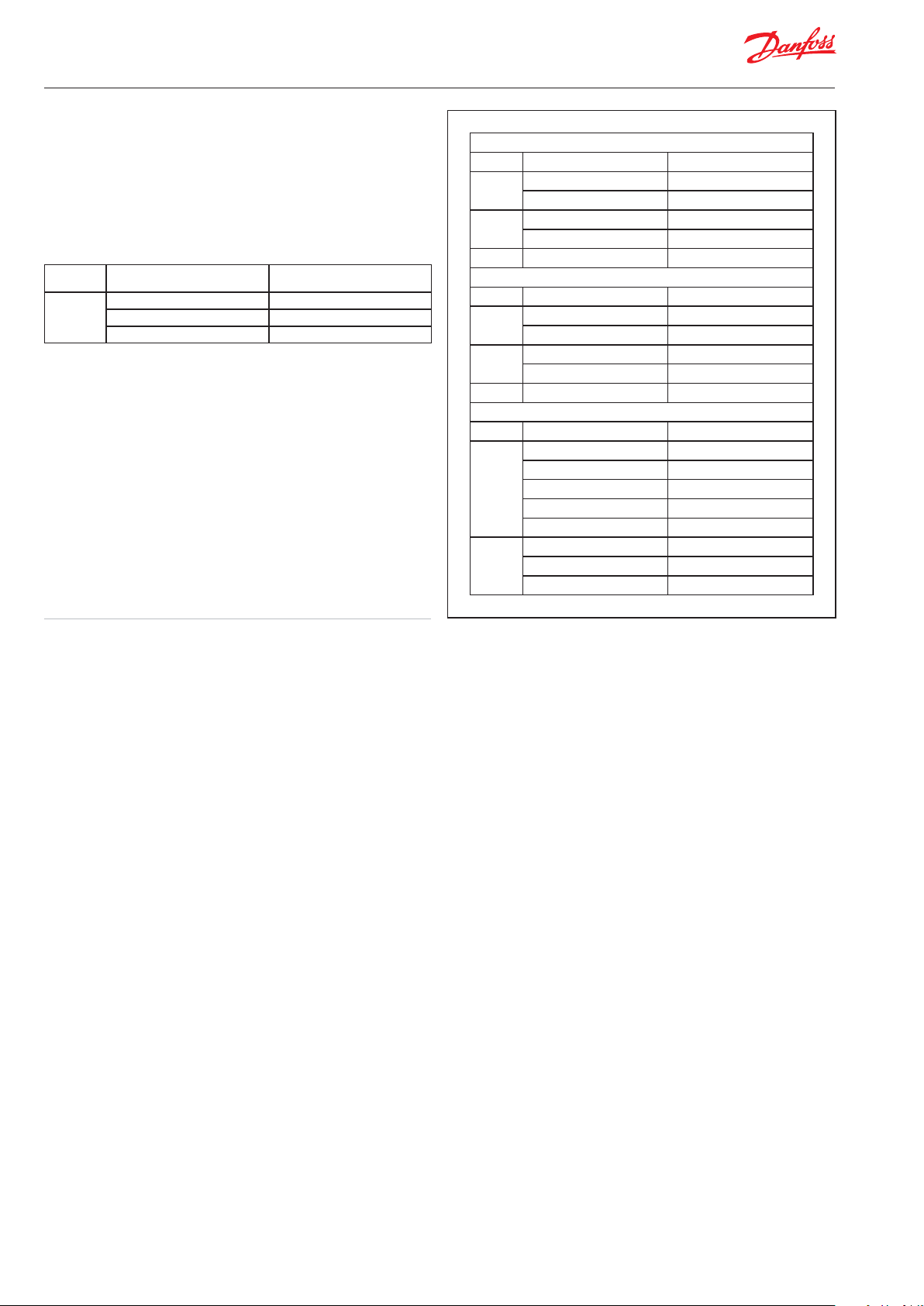

AKS ratiometric

Typ e Operating range [bar] Permissible working pressure

AKS 2050 -1 to 59 100

-1 to 99 150

-1 to 159 250

PB [b ar]

AKS 32, ver sion 1-5V

Operating range Max working pressure PB

LP

HP

AKS 32, ver sion 0-10V

LP

HP

AKS 33, version 4-20mA

LP

HP

-1 --> 6 [bar] 33 [bar]

-1 --> 12 [bar] 33 [bar]

-1 --> 20 [bar] 40 [bar]

-1 --> 34 [bar] 55 [bar]

Operating range Max working pressure PB

-1 --> 5 [bar] 33 [bar]

-1 --> 9 [bar] 33 [bar]

-1 --> 21 [bar] 10 [b ar]

-1 --> 39 [bar] 60 [bar]

Operating range Max working pressure PB

-1 --> 5 [bar] 33 [bar]

-1 --> 6 [bar] 33 [bar]

-1 --> 9 [bar] 33 [bar]

-1 --> 12 [bar] 33 [bar]

-1 --> 20 [bar] 40 [bar]

-1 --> 34 [bar] 55 [bar]

0 --> 16 [bar] 40 [bar]

0 --> 25 [bar] 4 0 [bar]

8 DKRCC.PF.000.G2.02 / 520H8626

Page 9

Fitter notes – Electronic Controls

Pressure transmitter

Range and types of signals

A pressure transmitter will measure the pressure and this

measurement will be conditioned in the form of a dened

electrical signal that will allow it to be “transmitted” on a further

distance.

A pressure transmitter needs a power supply, most of the time this

is going to be provided from the controller it is connected to.

Don’t forget that sensors, in general, are the “eyes” of a controller.

The better they are selected and positioned, the better the controller is

able to do its job!

Two main data will be needed to dene a pressure transmitter:

1. The pressure range, depending on the application where the

pressure transmitter is needed.

In traditional refrigeration system, mostly two dierent ranges

of pressures will be found, the evaporating pressure (LP) and

the condensing pressure (HP).

This is happening at rather dierent pressure levels so the

pressure range of the pressure transmitter for the low pressure

side will be dierent than the one for the high pressure side.

Typically, a range from -1 to 12bar is used for the low pressure

side and a range of -1 to 34bar is used on the high pressure

side. It is important, for the accuracy of the signal, that the

range is properly selected according to the application.

Example:

If you need to measure a pressure of 5bar, a pressure

transmitter of -1 to 12bar will give you a much better accuracy

than one of -1 to 34bar.

2. The type of electrical signal, can be either in current [mA] or

voltage [V]. The two rst types mentioned, the electrical signal

issued is directly proportional to the pressure only.

How to nd the value of the expected signal for a known

pressure?

Example:

A pressure transmitter with a range -1 to 12bar is used.

The pressure in the system is 5bar. The total pressure range is

thus from -1 to 12bar making a total of 13bar (+12-(-1)).

For a 4-20mA transmitter, a signal of 4mA will be issued for a

pressure of -1bar and 20mA will be for 12bar.

The current output range is from 4 to 20mA making a total

range of 16mA (20-4). We divide the 16mA by 13bar, and this

will give us 1,23mA/bar. We multiply now by the number of bar

starting from -1bar, thus 1+5 = 6bar by 1,23. Results = 7.38mA

and we nally add the starting point of 4mA (not “0” !!) to give

us the nal answer of 11,38mA for a pressure of 5bar.

This value can be easily controlled by using a ammeter in series

with the sensor’s wires.

For a 0-10V transmitter, a signal of 0V will be issued for a

pressure of -1bar and 10V will be for 12bar. The total pressure

range is thus from -1 to 12bar making a total of 13bar (+12-(-1)).

The voltage output range is from 0 to 10V making a total range

of 10V.

We divide the 10V by 13bar, and this will give us 0.77V/bar.

We multiply now by the number of bar starting from -1bar, thus

1+5 = 6bar by 0.77. Results = 4.62V for a pressure of 5bar.

This value can be easily controlled by using a voltmeter on the

sensor’s wires.

1

3

R

2

L

4-20mA output, 2 wires (+,-)

1

3

R

2

L

0-10V or 1-5V output, 3 wires (+, s, -)

U

B

U

B

DKRCC.PF.000.G2.02 / 520H8626 9

Page 10

Fitter notes – Electronic Controls

For ratiometric transmitter, the ratio metric transmitter, the

output signal is not only proportional to the pressure but is also

directly depending of the voltage on the power supply.

This is the type that is commonly used on most of the

controllers. The output signal of the transmitter will be

presented as a percentage of the voltage of the power supply

Example: 10….90% of [V] supply.

For a ratiometric transmitter, let’s take an example:

a pressure transmitter with a range -1 to 12bar is used.

The pressure in the system is 5bar and the power supply is of

5VDC. The lowest signal will be for -1bar and will correspond to

10% of the power supply, thus 0.5V.

The highest signal will be for 12bar and will correspond to 90%

of the power supply, thus 4.5V.

A signal of 0.5V will be issued for a pressure of -1bar and 4.5V

will be for 12bar. The total pressure range is thus from -1 to

12bar making a total of 13bar (+12-(-1)). The voltage output

range is from 0.5V to 4.5V making a total range of 4V (4.5-0.5).

We divide the 4V by 13 (bar), and this will give us 0.3V/bar.

We multiply now by the number of bar starting from

-1 bar, thus 1+5 = 6bar by 0.3. Results = 1.8V and we nally add

the starting point of 0.5V (not “0” !!) to give us the nal answer

of 2.3V for a pressure of 5bar.

This value can be easily controlled by using a voltmeter on the

sensor’s wires but you need to measure not only the signal but

also the value of the power supply to ensure a correct answer

1

3

R

2

L

Ratio metric [V] output, 3 wires (+, s, -)

U

B

10 DKRCC.PF.000.G2.02 / 520H8626

Page 11

Fitter notes – Electronic Controls

Positioning sensors

Sensor mounting

It is very important that during the installation process and also

during maintenance schedules the correct position and mounting

of all pressure transmitters is in line with the recommendations.

Incorrect mounting can cause faulty pressure signals to be used

by the controller which will result in, in-correct operation of the

refrigeration application.

Cable version

The pressure transmitter must be mounted before the cable is

fastened to avoid twisting the cable.

Orientation

Can be mounted horizontal or vertical but with the pressure

connection facing downwards, example not on the bottom of the

pipe to avoid oil or dirt contamination. Plug cable facing

downwards prevents water collection in the cable entry.

Hot gas pipe

Use a distance sleeve to reduce the temperature inuence on hot

gas lines to avoid overheating the pressure transmitter.

DKRCC.PF.000.G2.02 / 520H8626 11

Page 12

Fitter notes – Electronic Controls

Pressure transmitter in liquid line with pulse

snubber

y Cavitation, liquid hammer and pressure peaks may occur in

liquid lled systems with changes in ow velocity, example fast

closing of a valve or pump starts and stops. The problem may

occur on the inlet and outlet side, even at rather low operating

pressures.

y Pressure pulsations do not normally limit the pressure sensor

lifetime, however for the sake of the controller or the pressure

display equipment it may be expedient to dampen or lter the

signal from the pressure sensor.

y Dampening can be performed by electronics in the controller

equipment, or by means of connecting the sensor to the plant

through normal damping coils (capillary tubes).

y It is also possible to order specic pressure transmitters which

have a damping orice tted.

If a control valve is mounted on an evaporator, a separate pressure

measurement will have to be made for the other controllers on

the common suction if the evaporator controllers are of course

using a pressure transmitter to measure the evaporating

temperature.

Damping orice

AKS 32R

AKS 32R

AKS 32R

12 DKRCC.PF.000.G2.02 / 520H8626

Page 13

Fitter notes – Electronic Controls

Electrical connections

Pulse width modulation electronically

operated expansion valve type AKV

Using AC coil (alternating current)

On present controllers (AK-CC) you nd the electronic contact

which switches the power to the AC coil.

Note

Do not use a switch between the output and AKV coil.

Using DC coil (direct current)

In previous controllers (AKC or EKC) the supply came directly from

the controller to the DC coil.

56

~

230V a.c.

~

230V a.c. coil

15

230V d.c.

14

Stepper motor electronically operated

expansion valve type ETS

On some controllers the length between the controller and the

valve ETS have to be max 5m.

If the cable distance is greater than 5m a lter need to be used on

some controllers to extend the cabling up to 50m.

Find more information in the Instruction or Manual of the specic

controller.

Filter

The lter has to placed beside the controller.

L < 5m

ETS

L

5m < L < 50m

ETSAKA 211

L

ETS

AKA 211

4x10mH

DKRCC.PF.000.G2.02 / 520H8626 13

Page 14

Fitter notes – Electronic Controls

Digital Input (DI) / Digital Output (DO)

Digital Output NC/NO

You must be aware, which type of contact do you have.

3132 33 39 40 41 42 43 44 45 46 47 48 49 50

25 16 17 18 19

Digital Input powerless contacts

No power

Generally

The drawings ( especially the digital outputs ) of the electrical

connections are always shown without connected power supply.

~ ~

1

V/Ω

Ω

SIG GND

1

Relay or

AKV coil

110/230V

C24NO NC

1 2 3

DI1 DI2

24 25

24 25

Split sensors and AKV

Temperature sensor

Each controller needs its own temperature sensor input.

Pressure transmitter

The signal from one ratiometric pressure transmitter can be

received by up to 10 controllers. But only if there are no signicant

pressure dierence between the evaporators to be controlled.

AKV

Use only one AKV coil for one solid state output.

(“Pulse width modulation electronically operated

expansion valve type AKV“) on page 13.

External Start/Stop of regulation

Some controllers can be started and stopped externally via a

contact function connected to input terminals.

The function must be used when the compressor is stopped.

The controller then closes the solenoid valve so that the

evaporator is not charged with refrigerant.

AKS 32R info

AKS 32R info

+ - out

1 2 3

blue

black

30 31 32

+ s

The signal from one pressure transmitter

can be received by up to ten controllers

Solid State Output DO1 (for AKV co il) Max 240V a.c.

brown

30 31 32

+ s

MAx 0.5 A

Leak < 1mA

Max 1 pcs . AKV

Start/Stop

14 DKRCC.PF.000.G2.02 / 520H8626

Page 15

Fitter notes – Electronic Controls

Controlling

Input and output

Electronic controllers will have a number of inputs and outputs

that will allow the measurement and control of several tasks

related to refrigeration, mostly for evaporators and packs.

Inputs can roughly be divided in 2 types:

y Analog inputs that are typical for either temperature or

pressure sensors, readings being °C/°F or bar/psi,

(see MEASURING).

y Digital inputs that are typical for contact or voltage detection,

readings being an ON/OFF results, (see CONNECTION).

Outputs can be divided in several types like:

y Digital outputs that are typically electromechanical relays.

y Electronics outputs generating pulses signals typically for

controls of electronic expansion valves like AKV

(pulse width modulation) or ETS (stepper motor).

y Analog outputs generating mostly a 0 to 10VDC signal

available either as information or additional controls.

See the example beside

Operation

1

S2

S3

18 19 20 21 22 23 24 25 26

S2 S3

ETS

white

black

red

green

Display

The values will be shown with three digits, and with a setting you

can determine whether the temperature is to be shown in °C or

in ° F.

Light-Emitting Diodes (LED) on front panel

The LED’s on the front panel will light up when the relevant relay

is activated.

The light-emitting diodes will ash when there is an alarm.

In this situation you can download the error code to the display

and cancel/sign for the alarm by giving the top button a brief

push.

The buttons

When you want to change a setting, the upper and the lower

buttons will give you a higher or lower value depending on the

button you are pushing. But before you change the value, you

must have access to the menu. You obtain this by pushing the

upper button for a couple of seconds, you will then enter the

column with parameter codes. Find the parameter code you want

to change and push the middle buttons until value for the

parameter is shown. When you have changed the value, save the

new value by once more pushing the middle button.

Examples:

Set menu

1. Push the upper button until a parameter r01 is shown

2. Push the upper or the lower button and nd that parameter you

want to change

3. Push the middle button until the parameter value is shown

4. Push the upper or the lower button and select the new value

5. Push the middle button againt to freeze the value

Refrigeration

Defrost

Fan running

Cutout alarm relay/receipt alarm/see alarm code

y A short press of the upper button If there are several alarm codes

they are found in a rolling stack. Push the uppermost or lowermost

button to scan the rolling stack.

DKRCC.PF.000.G2.02 / 520H8626 15

Page 16

Fitter notes – Electronic Controls

Set temperature

1. Push the middle button until the temperature value is shown

2. Push the upper or the lower button and select the new value

3. Push the middle button again to conclude the setting

Reading the temperature at defrost sensor

(Or product sensor, if selected in “o92”)

y A short press of the lower button

Manuel start or stop of a defrost

(Or product sensor, if selected in “o92”)

y Push the lower button for four seconds

Evaporator controls

Controllers for evaporators have built in functionalities that allow

them to perform the necessary tasks for the control of the

application including evaporators like cold rooms, cases, etc.

Being electronic, allow them a large choice in the available

functionalities under a very compact format, this is giving a lot of

exibility in their use.

Access to the functionalities is easily made through the use of a

display and keys, allowing access to a list containing the dierent

parameters. Basically, no “programming” is necessary, just setting

of parameters values. An explanation on how to access

parameters via display and keys is shown beside.

Parameters

Parameters are placed in “groups” related to their functions.

Example:

Thermostat related functions are all placed in the group of

parameters starting with letter “r” followed by a number.

Access to the thermostat dierential is done via parameter “r01”

and the value is expressed in degree Kelvin (to show it’s a

dierence). In all available controllers, “r01” will be referring to the

dierential therefore making the use of dierent controllers much

easier. And so on for the others parameters.

y Group “r..” refers to thermostat related functions.

y Group “A..” refers to Alarms setting and functions.

y Group “C..” refers to Compressor management.

y Group “D..” refers to Defrost functions.

y Group “F..” refers to Fan functions.

y Group “h..” refers to HACCP temperature.

y Group “n..” refers to setting linked with the use of electronic

expansion valves.

y Group “t” refers to the real-time clock.

y Group “o..” refers to miscellaneous functions like addressing,

door functions, refrigerant, etc.

Beside parameters, readings are available in the “u..” group

allowing to access sensors readings and Input/output status

like opening degree of an electronic expansion valve or

superheat value. These are usefully indications for the service

technician, allowing him to see what the controller “sees” and

helping drawn a fast diagnostic in case of problems.

Continued Code 1 2 3 4 5 6 7 8 9 10

Service

Temperatur e measured with S5 se nsor u09 1 1 1 1 1 1 1 1 1 1

Status on DI1 inp ut. on/1=closed u10 1 1 1 1 1 1 1 1 1 1

Actual defrost time (minutes)

Temperatur e measured with S3 se nsor u12 1 1 1 1 1 1 1 1 1 1

Status on ni ght operation

(on or o) 1= on

Temperatur e measured with S4 s ensor u1 6 1 1 1 1 1 1 1 1 1 1

Thermostat temperature u17 1 1 1 1 1 1 1 1 1 1

Run time of t hermostat (cooli ng time)

in minutes

Temperatur e of evaporator ou tlet

temp.

Superheat across evaporator u 21 1 1 1 1 1 1 1 1 1 1

Reference of superheat control u22 1 1 1 1 1 1 1 1 1 1

Openin g degree of AKV va lve ** u23 1 1 1 1 1 1 1 1 1 1

Evaporating pressure Po (relative) u25 1 1 1 1 1 1 1 1 1 1

Evapor ator temperature To

(Calculated)

Temperatur e measured with S6 s ensor

(product temperature)

Status on DI2 o utput. on/1=clos ed u37 1 1 1 1 1 1 1 1 1 1

Air tempe rature . Weighted S3 an d S4 u56 1 1 1 1 1 1 1 1 1 1

Measured temperature for alarm

thermostat

Status on re lay for cooling ** u58 1 1 1 1

Status on re lay for fan ** u59 1 1 1 1 1 1 1 1 1 1

Status on re lay for defrost ** u 60 1 1 1 1 1 1 1 1 1

Status on re lay for rail heat ** u61 1 1 1 1 1 1 1

Status on relay for alarm

Status on re lay for light

Status on re lay for valve in suct ion line

u11

1 1 1 1 1 1 1 1 1 1

u13 1 1 1 1 1 1 1 1 1 1

u18 1 1 1 1 1 1 1 1 1 1

u20 1 1 1 1 1 1 1 1 1 1

u26 1 1 1 1 1 1 1 1 1 1

u36 1 1 1 1 1 1 1 1 1

u57 1 1 1 1 1 1 1 1 1 1

** u62

1 1 1 1 1

** u63

1 1 1 1 1 1 1 1

** u64

1

16 DKRCC.PF.000.G2.02 / 520H8626

Page 17

Fitter notes – Electronic Controls

What is the controller doing...?

Through status codes, the controller keeps you informed about his present behavior.

Example:

“S11” indicate that refrigeration has stopped after reaching thermostat cutout.

“S14” would indicate that a defrost is in progress.

S0 Normal regulation S23 Adaptive control S46

S1 Waiting for the end of the coord def. S24 Start up phase: signal reliability S47

S2 Comp. must run for at least x min S25 Manual control of outputs S48

S3 Comp. must remain stop for x min S26 No refrigerant selected S49

S4 Evaporator drips OFF S27 Forced cooling S50

S5 Renewed cuting of relay wait x min S28 Stopped regulation S51

S6 Day operation (Sout control) S29 Case cleanig procedure S52

S7 Night operation (sin control) S30 Forced cooling S53

S8 Next relay must not cutin until x min S31 Door is oper (DI open) S54

S9 Nerxt relay must not cutout until x min S32 Delay on outputs during start up S55

S10 Stopped by mainswitch “r12 ” or DI S33 Heat func tion “r36” is active S56

S11 Refrig. stopped by thermostat S34 Safety cutout S57

S12 Refrig. stopped due to low sair S35 Cooling ON section B S58

S13 Defrost KVQ valve is closing S36 Cooling OFF sec tion B S59

S14 Defrost in progress S37 Cooling ON section C S60

S15 Defrost sequence: fan delay S38 Cooling OFF section C S 61

S16 Refrig. stopped by ON input S39 Cooling ON section D S62

S17 Door is open. DI input is open S40 Cooling OFF section D S63

S18 Melt function S41 S64

S19 Modulating thermostat control S42 S65

S20 Emergency cool sensor error S43 S66

S21 Injection problems S44 S67

S22 Start up: evaporator beign charged S45 S68

Quick start

Before allowing the controller to start the regulation, it is

important to check if the controller readings are showing the right

measurements.

(“u”, see chapter “Parameters” at page 16).

Accessing the “u” readings in the service group, allow you to

check this.

Use the instruction sheet of the specic controller to locate the “u”

readings corresponding to the connected sensors and contacts.

y Begin with checking that parameter “r12 ” (main switch) is set to

OFF(0), that will stop the regulation.

y When done, ensure that the proper selection of the electrical

diagram for the outputs has be done via the parameter “o 61”.

y An easy way would then be to use preselected settings for your

application room/case/cooling/freezing via the parameter

“o62”.

y Setting parameter “r12 ” to ON(1) will then start the regulation

with immediate eect.

100% tight

The buttons and the seal are imbedded in the front.

A special moulding technique unites the hard front plastic, the

softer buttons and the seal, so that they become an integral

part of the front panel.

There are no openings that can receive moisture or dirt.

DKRCC.PF.000.G2.02 / 520H8626 17

Page 18

Fitter notes – Electronic Controls

What is wrong....?

In case of a default, Error and Alarm codes will be shown pointing directly to the problem.

Example:

“A1” will tell you that the alarm temperature has been reached.

“E8” shows that the “S4” temperature sensor wiring is short-circuited.

A1 High temperature alarm A24 Compressor 6 fault A47 Fan 6 fault

A2 Low temperature/P0 alarm A25 Compressor 7 fault A48 Fan 7 fault

A3 Alarm level limit reached A26 Compressor 8 fault A49 Fan 8 fault

A4 Door alarm A27 Housing temperature A50 Saux1 temperature

A5 Max hold time/Slv def time-out A28 Digital input 1 alarm A51 DO1 fault

A6 “S4” out high temperature A29 Digital input 2 alarm A52 DO2 fault

A7 “S4” out low temperature A30 Digital input 3 alarm A53 DO3 fault

A8 “S3 ” in high temperature A31 Digital input 4 alarm A54 DO4 fault

A9 “S3 ” in low temperature A32 Digital input 5 alarm A55 DO5 fault

A10 Injection problem A33 Conguration change A56 DO6 fault

A11 No refrigerant selected A34 Fan 1 fault A57 DO7 fault

A12 Digital input alarm A35 Fan 2 fault A58 DO8 fault

A13 High temperature “S6” A36 Fan 3 fault A59 Case cleaning (DI input)

A14 Low temperature “S6” A367 Fan 4 fault A60 HACCP alarm

A15 Digital input 1 alarm A38 Fan 5 fault A61 Condenser alarm

A16 Digital input 2 alarm A39 Fan 6 fault A62 High T1 alarm

A17 Pc high alarm A4 0 Fan 7 fault A63 Low T1 alarm

A18 Pc low alarm A41 Fan 8 fault A64 High T2 alarm

A19 Compressor 1 fault A42 Amb. mode A65 Low T2 alarm

A20 Compressor 2 fault A43 Stepper motor alarm A66 High T3 alarm

A21 Compressor 3 fault A44 Battery alarm A67 Low T3 alarm

A22 Compressor 4 fault A45 Standby mode (“r12 ” or DI) A68 High temperature B

A23 Compressor 5 fault A46 Fan 5 fault A69 Low temperature

A70 High temperature C E1 Faults in the controller E24 Sensor “S2” error

A71 Low temperature C E2 Air sensor open circuit E25 Sensor “S3” error

A72 High temperature D E3 Air sensor short circuit E26 Sensor “S4” error

A73 Low temperature D E4 Defrost sensor open circuit E27 Defrost sensor “S5” error

A74 Adaptive defrost fault E5 Defrost sensor short circuit E28 Product sensor “S6” error

A75 Adaptive defrost evaporator iced E6 Realtime clock error (battery) E29 Sensor Sair error

A76 Adaptive Defrost not defrosted E7 “S4” out sensor open circuit E30 Sensor Saux error

A77 Pump 1 fault E8 “S4” out sensor short circuit E31 T1 error

A78 Pump 2 fault E9 “S3” in sensor open circuit E32 T2 error

A79 Pump 1 & 2 fault E10 “S3” in sensor short circuit E33 T3 error

A80 Condensor blocked E11 Q-actuator error E34 Sensor “S3 ” error B

A81 “S3 ” in “S4” out switched E12 AI input signal outside range E35 Sensor “S3” error C

A82 E13 “S1” sensor open circuit E36 Sensor “S3” error D

A83 E14 “S1” sensor short circuit E37 Sensor “S5” error B

A84 E15 “S2” sensor open circuit E38 Sensor “S6” error B

A85 E16 “S2 ” sensor short circuit E39

A86 E17 “S3” sensor open circuit E40

A87 E18 “S3 ” sensor short circuit E41

A88 E19 Analog input error E42

A89 E20 Po pressure input error E43

A90 E21 Level signal outside the range E44

A91 E22 Signal AK S45 outside range E45

A92 E23 Sensor “S1” error E46

18 DKRCC.PF.000.G2.02 / 520H8626

Page 19

Fitter notes – Electronic Controls

Communication

Why...?

Although controllers have their own independent control,

communication between controllers and systems open up new

possibilities in terms of service, commissioning, monitoring,

alarming and optimization of energy on installations.

Some tasks can then be centralized in the system, allowing for

example scheduled defrosts, coordinated defrosts between

controllers, lighting control, scheduled stop of refrigeration and

optimization of the suction pressure for energy savings.

Access to any controller connected to the system can now be

done from a central point making set point and setting

adaptation faster and easier.

How…?

The interconnection between the controllers (and system) is done

by the mean of “bus”.

A ”bus” is physically a specic electrical cable containing twisted

wires in the form of a pair, with a shield.

The shield is protecting the signal transmitted on the pair from

external disturbances, it must only be connected to the proper

connection for shielding that is present on each controller.

Connection of the shied must never be done directly to the earth,

thus bypassing internal lters presents.

This can cause serious communication problems.

Communication occurs by sending high frequency digital signals

on the cable. Twisted pair is then a must to carry this signal

without deforming it. Every cable has a capacitance and the eect

of a capacitance is to act as a short circuit at high frequency.

So if capacitance increase, so do the losses.

The capacitance of the cable is counter balanced by the coil eect

created by the twisted pair, ensuring the signal is kept in form

properly across the cable. Recommended cross section of the

wiring must be respected to avoid increasing the capacitance of

the cable by increasing is cross section.

The bigger doesn’t mean the better in this case.

The electrical signals sent over the cable can have an analogy in

the following form:

A length of pipe is lled with water and the pipe is closed at both

ends. If an hammer is used on one of the ends, a pressure wave

(signal) will travel through the pipe and bounce at the other end,

going back to where it came from and thus mixing with the

incoming wave. This deforms the signal. To avoid that, we should

put a damper on both ends. This is called termination of the bus,

and it’s done by means of connecting resistors of 120Ω on both

ends of the cable.

The resistors are supplied with the system.

=

Not OK

!

OK

Termination of the bus: 120Ω

DKRCC.PF.000.G2.02 / 520H8626 19

Page 20

Fitter notes – Electronic Controls

Cables selection / termination

When all cables have been mounted on the dierent units, the

cable must be terminated.

A section must be terminated at both ends.

The section must be terminated using a resistor.

A repeater will normally terminate two cable sections.

The termination should be made with 120Ω resistor

(the resistor can be in the range 100 to 130Ω).

Bus standards in use with the controllers are called:

LONbus RS-485, MODbus RS-485.

System

R

AB

R= 120Ω

Repeater

Requiements to installation

Cable type

Cables twisted in pairs must be used, and they may be provided

with a screen. Some types of communication require a cable with

a screen to be used.

The conductor’s cross section must be at least 0.60mm.

Examples of cable types:

y Belden 7703NH, single-thread 1 x 2 x 0.65mm, with screen.

y Belden 7704NH, single-thread 2 x 2 x 0.65mm, with screen.

y LAPP UNITRONIC Li2YCY (TP), multi-thread 2 x 2 x 0.65mm, with

screen.

y Dätwyler Uninet 3002 4P, single-thread 4 x 2 x 0.6mm, with screen.

Conductors

The wires in the cable that is connected to the controller must be

correct. Although there are four wires in the cable inside the

screen, you cannot simply choose colours freely. The wires are

twisted in pairs, example 2 and 2, and you must use a pair that is

twisted around each other.

If there are several “vacant” pairs in the cable, they must be used

for nothing else than data communication.

R

AB

R= 120Ω

Cable length

A cable length must not exceed 1200m (500m for Lon-FTT10.)

A repeater must be used for longer lengths.

See the additional requirements for the respective communication

forms.

20 DKRCC.PF.000.G2.02 / 520H8626

Page 21

Fitter notes – Electronic Controls

Cables

Note

Our experience indicates that problems can occur with

communication due to the following weaknesses:

Long wire ends

Do not strip more of the cable insulation than strictly necessary.

Max. 3-4cm. Continue the twisting of the cables right up to the

terminals.

Stubs

Avoid stubs on the cable. Feed the cable right to the end and then

back again.

Noise sources

Keep the cable away from electrical noise sources and power

cables (relays, contactors and especially electronic ballast for strip

lights are strong noise sources).

A distance of at least 10-15cm will be sucient.

Cable length extremities

Each section of data communication must be terminated

correctly.

Screen

See the respective communication forms. There should be a

continuity of the screening cable up to the last controller.

Cable tray

When the cable is ducted with other cables, there is a strong risk

that electrical noise will be transferred.

Keep away from live cables.

When the cable is ducted in a cable tray, the cable must be fed out

and right up to the controller. The fast solution where only wires

are fed out will cause problems.

Min 10-15cm

Max 10-15cm

DKRCC.PF.000.G2.02 / 520H8626 21

Page 22

Fitter notes – Electronic Controls

Cabinet mounting

When controllers are installed in a cabinet, internal cable ducting

must also comply with the relevant requirements.

Use this cable ducting when one or more controllers are installed

in a cabinet.

The short connections between controllers must also be of the

correct cable types.

Keep a distance to relays, their cables and other things emitting

electric noises.

Bus standards

in use with the controllers are called:

LONbus RS-485, MODbus RS-485.

Standards dene the kind of electrical signals and “language”

used on the bus.

Signals are at a voltage level of 5V and at a speed of several

thousand bits per second, but this cannot be measured by

common voltmeters.

An oscilloscope is needed to visualize the presence of the signal.

Min

10-15cm

Lon RS-485 bus & wiring

The cable must be with screen.

The cable is connected from controller to controller, and no

branches are allowed on the cable.

If the cable length exceeds 1.200m a repeater AKA223 must be

inserted.

If the data communication cable runs through an electrically noisy

environment which impairs the data signal, one ore more

repeaters must be added to stabilize the signal.

Every 60 controllers a repeater AKA223 needs to be placed.

Conductors

The two wires are looped from device. There are no polarisation

requirements.

On some controllers, the clamps are designated A and B.

On others there is no designation.

Otherwise the connections are identical.

If the screen used, it must be connected to the system device and

any repeaters.

A screen must always be looped from device to device.

The screen must not be connected to anything else.

Lon RS-485 bus

RS-485

System

Wiring

max 1.200m

Lon RS-485

OK

OK

OK

22 DKRCC.PF.000.G2.02 / 520H8626

Page 23

Fitter notes – Electronic Controls

MOD-bus

This data communication can be used in the series:

y EKC...

The system device must be:

y System manager type AK2-SM.

y Monitoring unit type AK2-AM.

Wiring

The cable must be with screen.

The cable is connected from controller to controller, and no

branches are allowed on the cable.

If the cable length exceeds 1.200m a repeater type AKA222 must

be inserted.

Every 32 controllers a repeater AKA222 is to be placed.

If the data communication cable runs through an electrically noisy

environment which impairs the data signal, one or more repeaters

must be added to stabilise the signal.

AK-SM

MOD

max 1.200m

32

32

Conductors

The wires are looked from device to device:

y A is connected to A.

y B is connected to B.

The screen must be connected to the system device, all

controllers and any repeaters.

A screen must always be looked from device to device.

The screen must not be connected to anything else.

The screen is earthed inside the system device and must not be

earthed in any other way.

MOD

A+ B- A+ B- A+ B-

DKRCC.PF.000.G2.02 / 520H8626 23

Page 24

Fitter notes – Electronic Controls

Addressing

Each controller need to have an unique address in the range of

1 to 120. This address can be set via parameter “o03” or by means

of rotary switch, depending of the type of controller.

If parameter “o03” and “o04” are not visible, it means that the

communication card is not seen as present by the controller.

Always power o the controller before inserting/extracting a

communication card.

A scan can be perform by the system to discover the connected

addresses. It is important that no address is used more than once!

Display EKA 163/164

L<15m

Max 15m

Displays communication

Some controllers allow remote placement of display, this can be

done in two ways:

y On short distances, less than 15m, connector type display can

be used.

y On long distance, up to 1.000m, Modbus display must be used

with communication cable.

Then, to activate the communication between the remote display

and the controller, an address must be set in parameter “o03”.

Trouble shooting

Trouble shooting communication without an oscilloscope can

prove dicult but there is some basic verication that can be

done:

y Are all controllers and systems properly earthed?

y Is the termination resistors in place, are they of the correct

value of 120Ohm?

y Is the shield not in contact with the earth somewhere?

That can be check with an ohmmeter, disconnect from the

system before measuring between the shield and the Earth.

y Is the used communication cards of the proper type?

y If Modbus is in use, is the polarity respected everywhere?

L>15m

EKA 163A/164A

12V

A

Max 1000m

Data com

B

RS MOD

54 55 56 57

A+

B-

58

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order

provided that such alternations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PF.000.G2.02 / 520H8626

© Danfoss A/S (EL-MSSM/AZ), 2014-March

Loading...

Loading...