Page 1

Electronically controlled PTC Starting Device

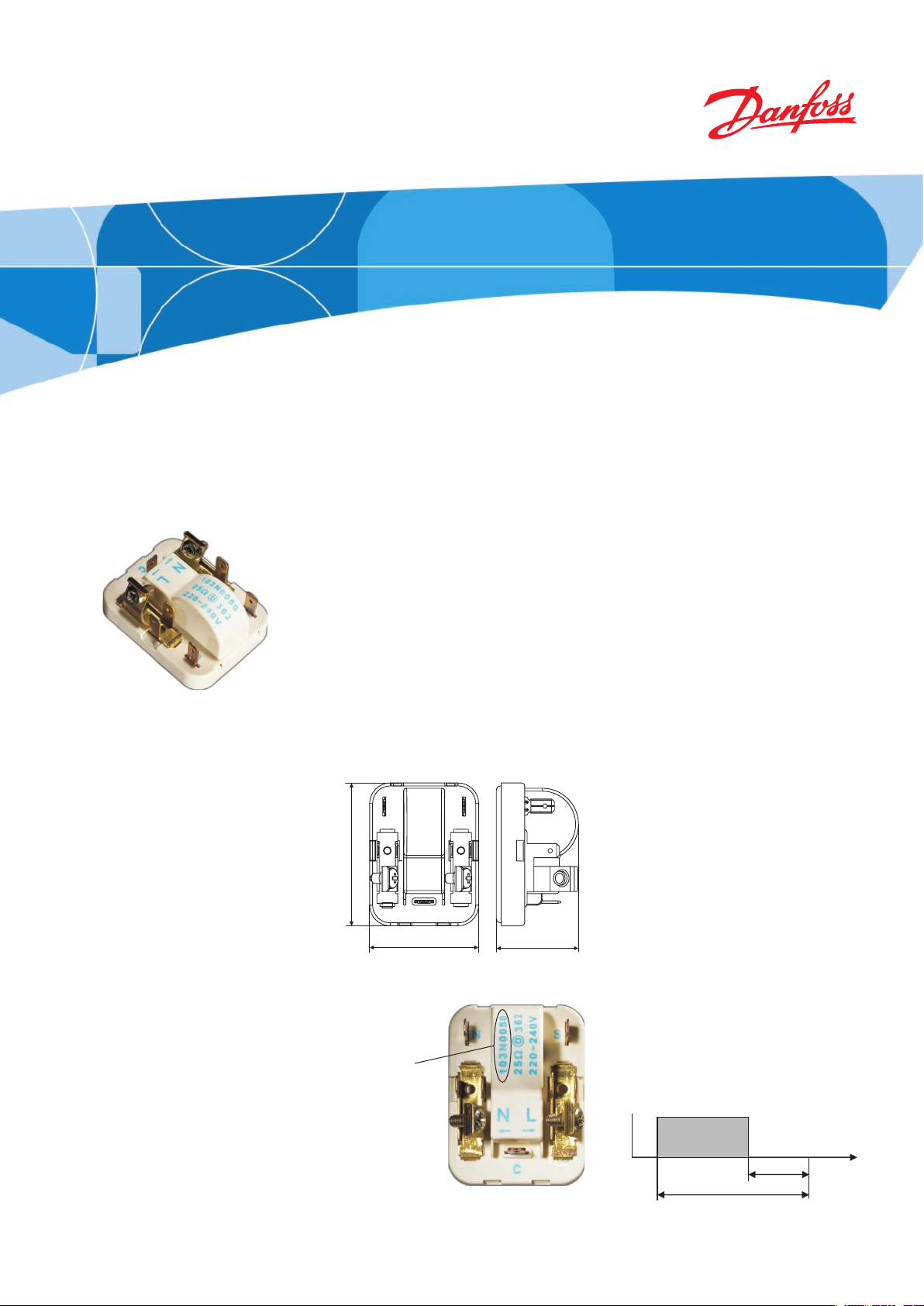

Approx. 6 s

Minimum 120

s

ON

OFF

27.9

48.5

37

8556

ePTC - Product Description

Technical Info

Introduction

The asynchronous motor of a single

phase AC powered compressor

has two windings, a main and an

auxiliary winding. The auxiliary

winding is powered high at start

by means of a starting device, then

powered down, often still utilized

continuously by means of a run

capacitor. The starting device of our

standard PTC-starters is a “Positive

Temperature Coefficient” resistor,

PTC. When heated up during the

start phase, the PTC almost cuts

off the current to the auxiliary winding, leaving only enough current

to keep itself heated to this closing

level. The heat loss for this amount

to approximately 2.5 W. With the

ePTC this loss can be reduced

to approximately 0.4 W by an extra

electronic circuit.

down

Features

The electronic design of the staring

device offers some strong features

such as:

• Restart of compressor possible

after a few seconds. Only very

short cooling time necessary,

due to the electronic design.

• Operational wattage loss

reduced by 2 Watt.

Dimensions

Identification

Code number

103N0050

Functional Description

The main component of the ePTC is

the same PTC pill like in other 220240 V 103N…. Danfoss PTC starters.

Thus the start of the compressor

motor is performed in the same

way. In standard PTC starters the

>2 W energy loss to keep the PTC

heated during compressor operation are not avoidable. In the ePTC

a small electronic circuit cuts off

the current through the PTC short

time after start and thus reduces

the energy loss down to approx

0.4 W. The switch used is a Triac, an

electronic AC switch, controlled by

a timer circuit.

As the timer circuit has a short

reset time and the main PTC cools

down

during compressor operation

already, the full start torque will be

available after approx 6 s compressor off time. However, it is still a

LST starting device, needing full

pressure equalization before start.

Min. On/Off time

of compressor

REFRIGERATION AND

AIR CONDITIONING

Page 2

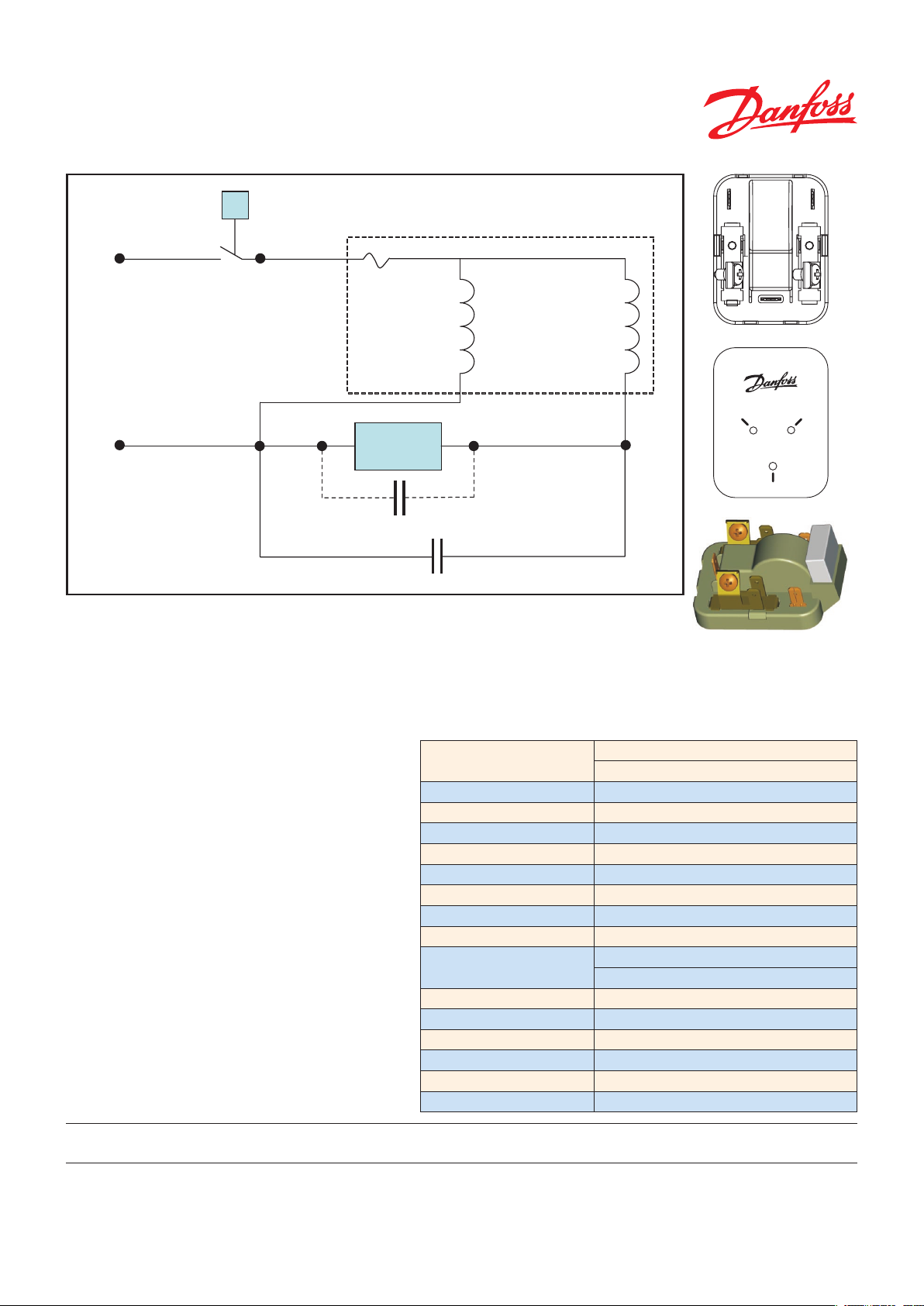

Wiring diagram

M

C

S

N L

C

SN

Front

Rear side

8558

Screw

terminal

Spade

terminal

Spade

terminal

Internal

protecto

r

Auxiliary

winding

Main

windin

g

Supply voltage

220-240 VAC

50 / 60 HZ

Compressor

Internal connection

T

ePTC

Electronic PC

B

L

N

C

N

S

Run capacitor (optional)

Thermostat

Spade

terminal

Spade

terminal

Internal

protecto

r

Auxiliary

winding

Main

windin

g

-240 VAC

Compressor

Internal connection

Screw

terminal

Spade

terminal

Spade

terminal

8557-2

with X2-Cap (optional)

Connections & Terminals

The wiring diagram shows how to make the

connections. The two screw terminals marked

N and L are for supply voltage. The spade on

the L terminal and the spade marked C are for

the thermostat. The spade marked S at the top

right position is internally connected to the

Start (or auxilary) fusite terminal. This spade

together with N is used for a run capacitor. The

spade marked N at the top left position is inter-

nally connected to the Neutral screw terminal.

The spade marked C at the bottom position

is internally connected to the Common fusite

terminal. On the rear side of the ePTC starter

there are three holes. The hole in the bottom

is for the Common fusite terminal on the compressor. The top left hole is for the Start fusite

terminal and the top right hole is for the Main

fusite terminal. The ePTC starter is mounted

with the C spade downwards.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already

on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

ePTC with X2-Cap

ePTC with X2-Cap for special Applications

For applications using a mechanical thermostat it can be neccessary to use the ePTC with integrated filter,type X2-Cap.

Technical data

Code number

Nominal supply voltage 220 - 240 V 50/60 Hz

Min. supply voltage 187 V

Max. supply voltage 254 V

Power consumption approx. 0.4 W (after 2 s)

Spade connectors

Cables Temperature resistant up to min. +60°C

Run Capacitor

Thermostats Mechanical or electronic

Ambient temperatures During operation from 0°C to 50°C

During transport from -20°C to 70°C

Enclosure

PTC protection screen Not needed (surface temp. < 82°C)

Approvals EN 60730-1, DEMKO

Radiation

EN 55014-1/EN 61000-3-2/EN 61000-3-3

Immunity EN 50014-2

Declarations

Standard: 103N0050

with X2-Cap:

103N0060

4.8 mm

Optional

IP 00

CE

DEHC.EI.200.B2.02/520N0192 Produced by Danfoss Compressors, DEHC6093, 08.2005

Danfoss Compressors GmbH

Mads-Clausen-Str. 7

D-24939 Flensburg / Germany

compressors.danfoss.com

Loading...

Loading...