Page 1

IMPORTANT!

DO NOT CROSS OR CUT THE RED CABLE

REMEMBER TO MEASURE, VERIFY AND

RECORD THE RESISTANCE

Danfoss

BRINGING WARMTH TO LIFE

LX

TM

Installation Manual

Electric Heating Mats

Manuel d'installation

Tapis chauffants électriques

Manual de instalación

Mallas calefactoras eléctricas

Page 2

Page 3

Table of Contents

LX Floor Heating System....................................... .......................................................................................................................................... 2

Typical Installations and Cautions ................................................................................................................................................................ 3

General Installation Guidelines ..................................................................................................................................................................... 4

Warranty................................................................................................................................................................................................................. 9

APPENDIX A: Typical Electrical Wiring

Spécifications techniques des tapis chauffants Danfoss LX .................................................................................................................... 10

Installations typiques et mises en garde......................................................................................................................................................... 11

Instructions d'installation d’ordre général ..................................................................................................................................................... 12

.

.......................................................................................................................................................... 26

Garantie ...................................................................................................................................................................................................................... 17

ANNEXE A: Câblage Électrique Typique........................................................................................................................................................... 26

Sistema de calefacción por suelo radiante DanfossLX ............................................................................................ 18

Instalaciones y precauciones típicas. ........................................................................................................................................................... 19

Pautas generales de instalació ....................................................................................................................................................................... 20

Garantía .................................................................................................................................................................................................................. 25

APÉNDICE A: Cableado Eléctrico Típico

....................................................................................................................................................... 26

...............................

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

1

Page 4

Page 5

Danfoss LX Floor Heating System

CAUTION!

It is important that this equipment is installed only by qualified electricians who are familiar with the proper sizing,

installation, construction and operation of floor warming system and the hazards involved. The heating mat is designed for

under floor heating purposes only.

Note!

The installation shall be in accordance with the manufacturer’s instructions and national and local codes.

The installation shall be in accordance with Part 424-J, American National Standard Institute / National Fire

Protection Association (ANSI/NFPA70), National Electrical Code (NEC) and Canadian Electrical Code (CEC),

Part 1. Danfoss recommends GFCI for heating cable in normally wet areas (i.e. bathrooms, showers, kitchens).

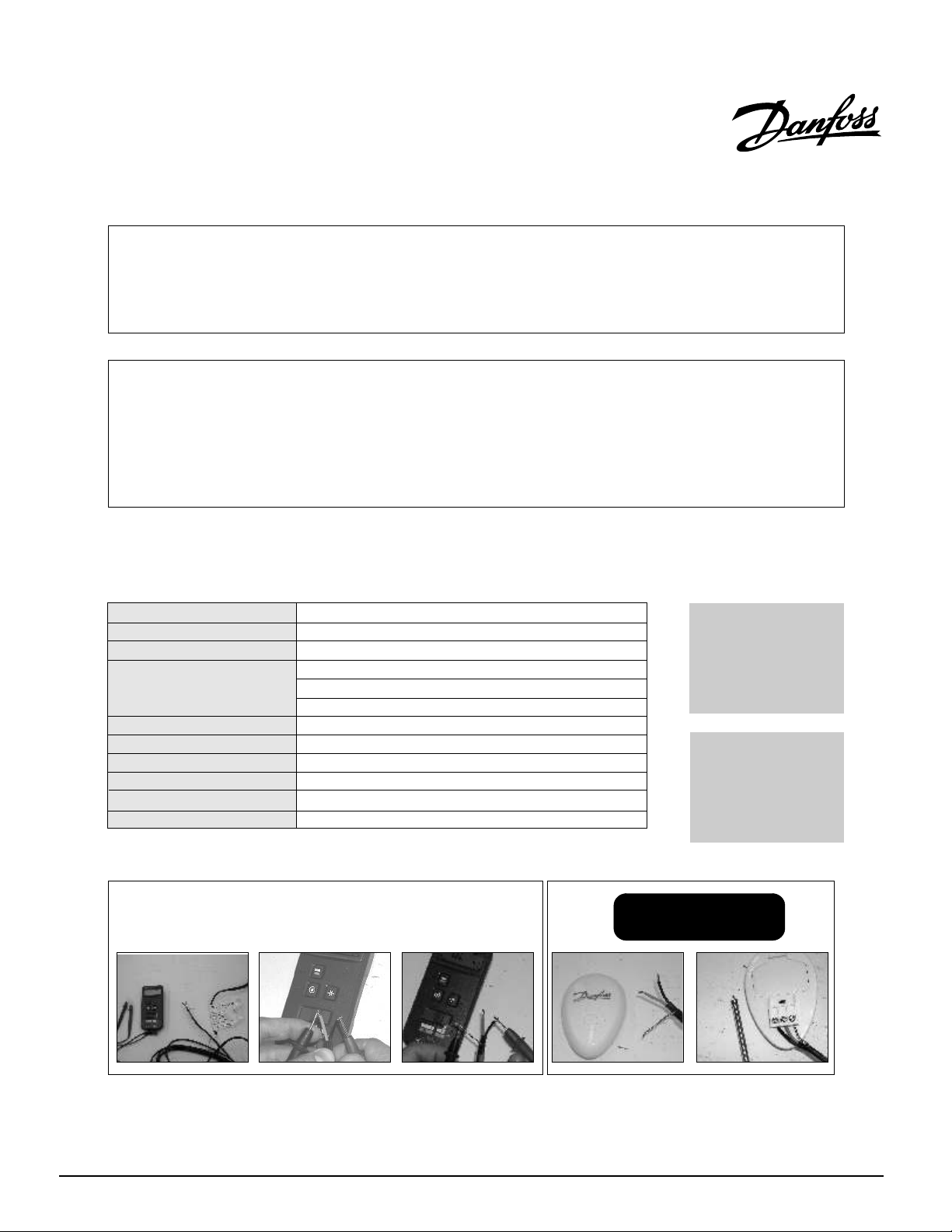

LX Mat Specifications

Type:

Voltage:

Output:

Heating Element Size:

Twin conductor

120V, 240V

12W/sq.ft. (130 W/m )

Width: 2’

2

Length: Refer to product label

Height: approx 1/8” (4 mm)

Cold Lead

Bending radius:

Wire insulation:

Casing:

Max. Allowable Temp.:

Min. Installation Temp.:

Note: Operating the 240V mat at 208V reduces power output to approximately 9W/sq.ft.

(25% reduction)

10’ (3.0 m)

Minimum 3/4” (19 mm)

FEP, Teflon

TM

PVDF

212°F (100°C)

40°F (5°C)

WARNING:

Remember to measure resistance.

Little Buzzer

Connection 120V

Phase - Black

Neutral - Blue

Ground - Shield

Connection 240V

Phase - Black

Phase - Blue

Ground - Shield

MONITOR YOUR INSTALLATION!

USE THE LITTLE BUZZER CONTINUITY

ALARM (PART#088L0028)

The resistance should be measured between the two conductors, blue and black. Compare the measured resistance to the resistance listed on

the product label (on the power lead).

Record the resistance on your warranty card.

infinity.

Copyright 2009 Danfoss Inc.

Also, measure the resistance between the blue, black and shielding/ground wire. Both should read

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

2

Page 6

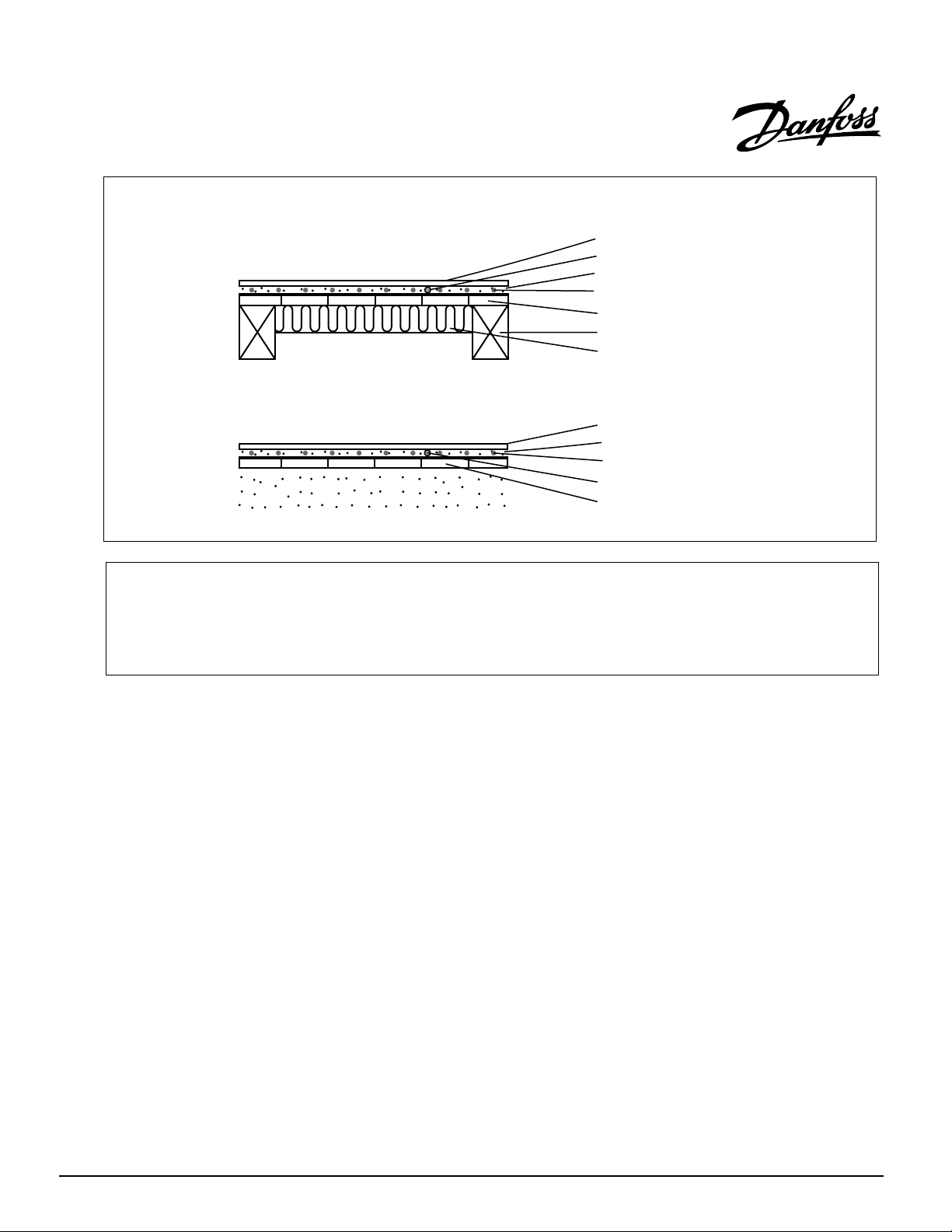

Danfoss LX typical installations and applications

Directly on plywood:

Directly on concrete.

Alternative method: self-leveling cement is

recommended for large surfaces and the

following floor materials: engineered wood,

laminate, floating floors, vinyl, linoleum and

carpet.

Ceramic tiles

Thermostat sensor

Thinset cement adhesive

fanD oss LX

Plywood on joists

Joists

Insulation (optional)

Ceramic tiles

Thin set cement adhesive

Danfoss LX

Thermosta

Concrete

t sensor

Warning:

Consult the manufacturer for information on special

installation requirements for wood, laminate and

vinyl or linoleum flooring.

Caution!

=Read the instructions carefully before installing

LX mat

=Do not install LX mat in walls or ceilings;

=The mat must be embedded in mortar,

thinset, concrete or similar material;

=The minimum installation temperature is

40°F (5°C);

=Never cut the red heating wire;

=It is recommended to use AWG 16 or greater

copper wire only if you need to extend the cold

lead

=Never install the LX mat such that two red

heating wires touch, cross or overlap;

=Measure the resistance between the blue,

black and shielding/ground wire. Both should

read infinity.

lRe memb er to al ways me asur e, ver ify and

record the actual resistance throughout the

install ation process (out of the box, af ter

installation, before thin set cement or self-leveler

application and after installation of floor tiles) and

compare all reading to the ratings on the product

label.

lRemember to check that the supply voltage

matches the voltage of the Danfoss LX mat;

lRemember to place the labels as written in

this instruction;

lOnly for indoor installation;

lMetal struct u res or materials used for the

support of or on which the Danfoss LX mat is

insta lled m ust be gro u nded in a ccorda n ce

with CSA Standard C22.1, section 10 and the NEC.

Please consult the factory for any other

questions or advice;

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

3

Page 7

General Installation Guidelines

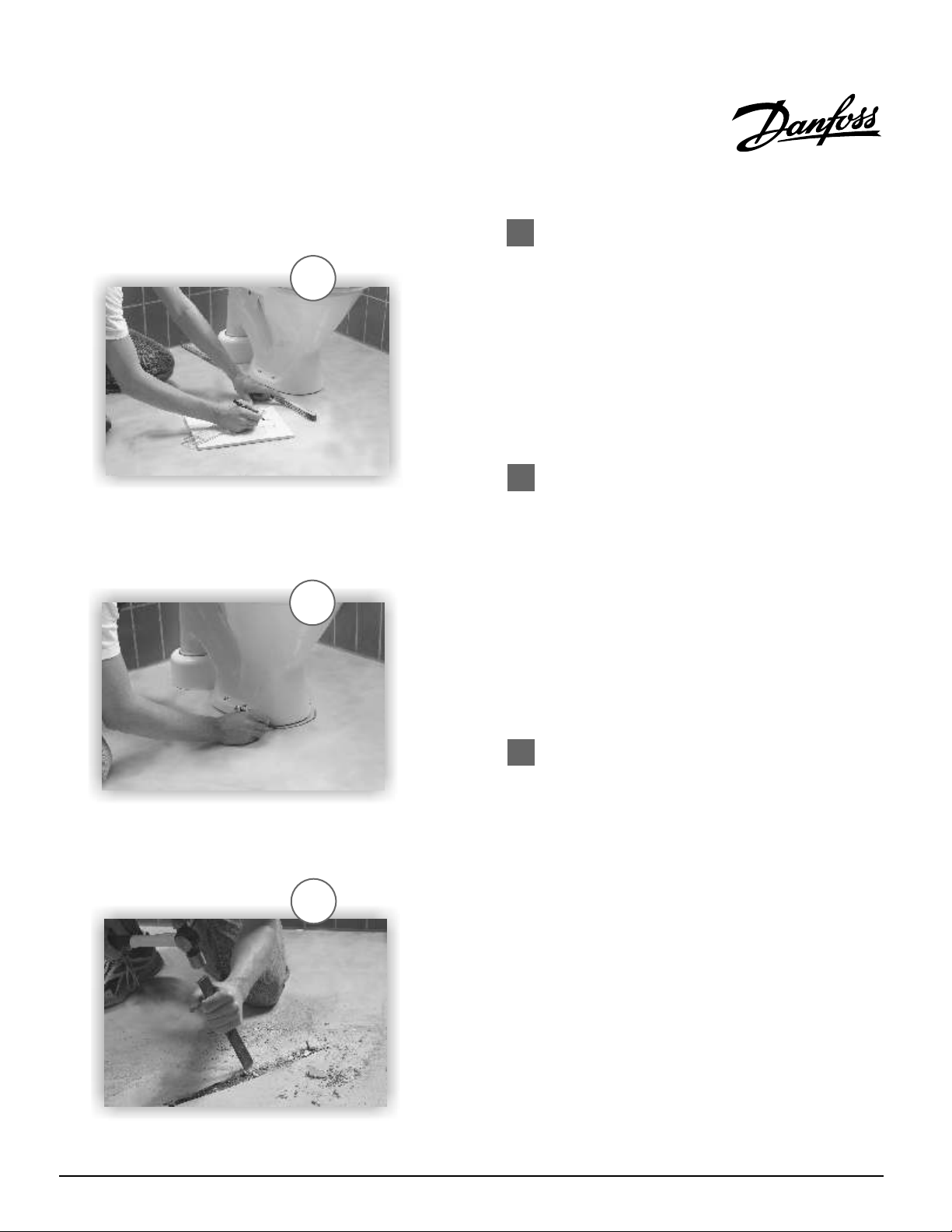

1

2

Step 1. PLAN LAYOUT

Make a sketch layout or a floor plan of the room;

include all permanent furnishings such as toilets,

bathtubs, appliances, cabinetry, etc. Indicate all

dimensions required to determine the available floor

are a and the position of th e LX thermo s t at.

TIP: Danfoss recommends installation is documented

with photos to note the location of connections and

the sensor.

Step 2. TRANSFER LAYOUT TO FLOOR

Draw an outline of the layout on the room floor including

a foot print of all furnishings that are not yet

installed. Unroll the first few feet of the LX mat. The

starting point of the cable must be placed within 10 ft.

from the thermostat. Mark the position of the connection

point between the power lead and the red LX heating

cable. This connection must be concealed in thinset or

self-leveling cement. When using a floor temperature

sensing thermostat, mark the sensor position in the

middle of 2 heating cables, about 10 in. (25cm) away from

the wall (within the heated area), as close as possible to

the thermostat.

Copyright 2009 Danfoss Inc.

3A

088L3380 - 06/09

Step 3. INSTALL SENSOR

(recommended in conduit, part#19809099 included)

If using a floor temperature sensing thermostat, install

the sensor now, either in conduit tube, or directly to

the subfloor. It is recommended that the sensor be

installed in conduit tube. This will allow the sensor

to be easily replaced in the unlikely event of failure.

The sensor and/or tube needs to be installed between

the thermostat wall box and the sensor position.

The conduit tube must be partially countersunk into the

subfloor. Cut a channel 5/16” deep by 5/16” wide in the

floor and wall up to the thermostat large enough to

accommodate the sensor conduit. The conduit has to go

from the thermostat and minimum of 10 “ away from the

wall towards the middle of the floor.

TEL: 866-676-8062. FAX: 905-285-2055

4

Page 8

4

IMPORTANT: the sensor conduit must be centered in

the cable loop (between two red heating wires).

Seal the end of the conduit that is placed in the floor with a

piece of duct tape. This will prevent thinset from penetrating

the conduit.

Use duct tape to hold the sensor conduit into the groove to

prevent it from floating up when the mortar or thinset is

poured.

If the sensor is installed directly in the mortar bed, use duct

tape to secure to subfloor.

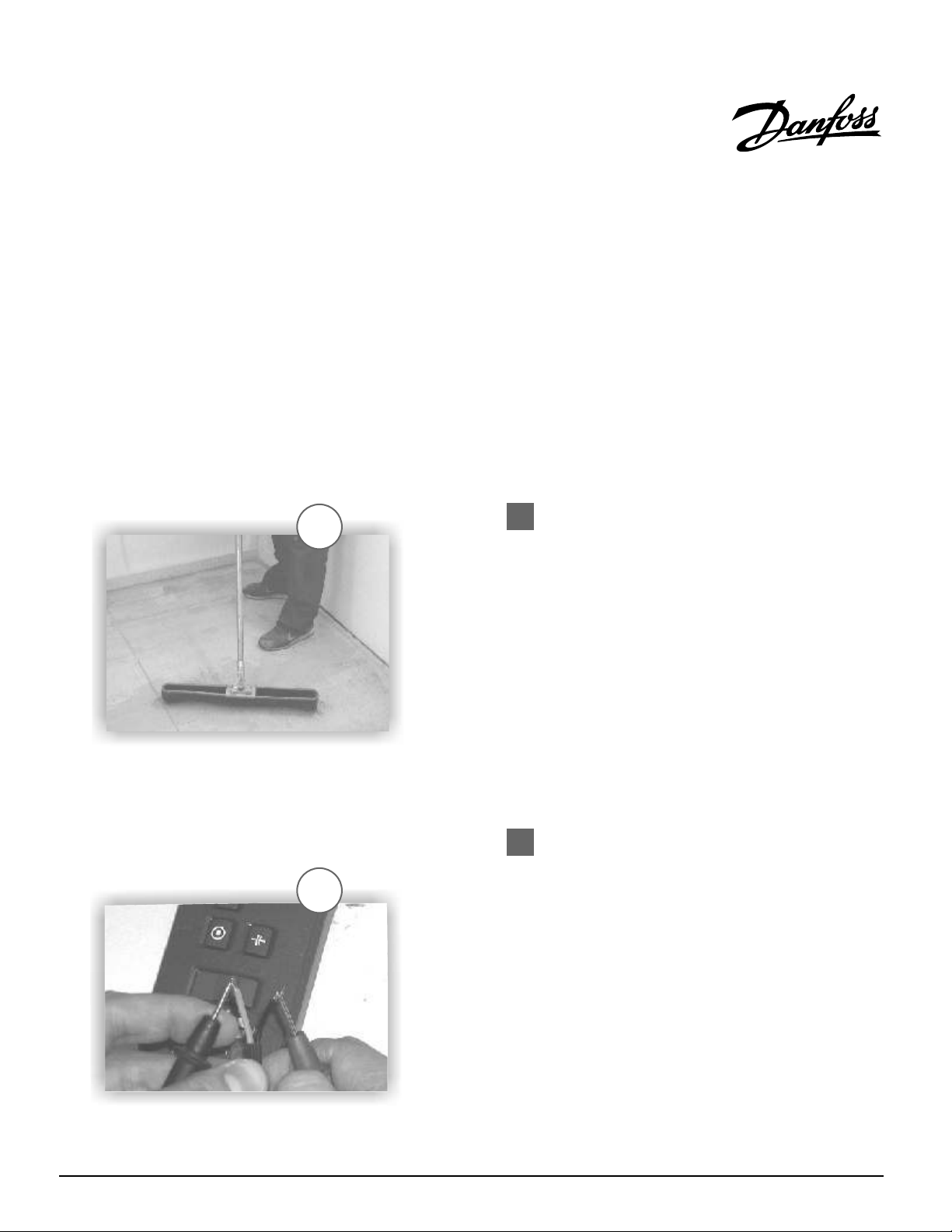

Step 4. PREPARE SUBFLOOR SURFACE

Clean and vacuum the floor thoroughly and remove dust

and debris from the floor that may damage the heating

cable or reduce adhesion.

Ensure that the subfloor is secure and stable. Carefully fill

in all cracks to prevent any potential damage to the new

tiles resulting from shifts in the subfloor.

5A

(Optional) To ensure maximum adhesion, apply a primer

or sealer as recommended by the thinset or self-leveling

cement manufacturer. If using a primer, ensure that the

entire floor is covered. Allow the primer to dry thoroughly

before proceeding to the next steps.

Step 5A. MEASURE THE RESISTANCE

Use a digital ohm meter to measure the resistance of

the Danfoss LX mat and compare it to the resistance listed

on the product label. The resistance should be measured

between the two conductors, blue and black. Compare

the measured resistance to the resistance on the product

label, located 3 inches from the splice, on the cold lead.

Also, measure the resistance between the blue, black and

shielding/ground wire. Both should read infinity.

Record the measured resistance on the warranty

card. Documenting the resistance at each stage of

in stallatio n is req uired for warra nty purpose s.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

5

Page 9

5B

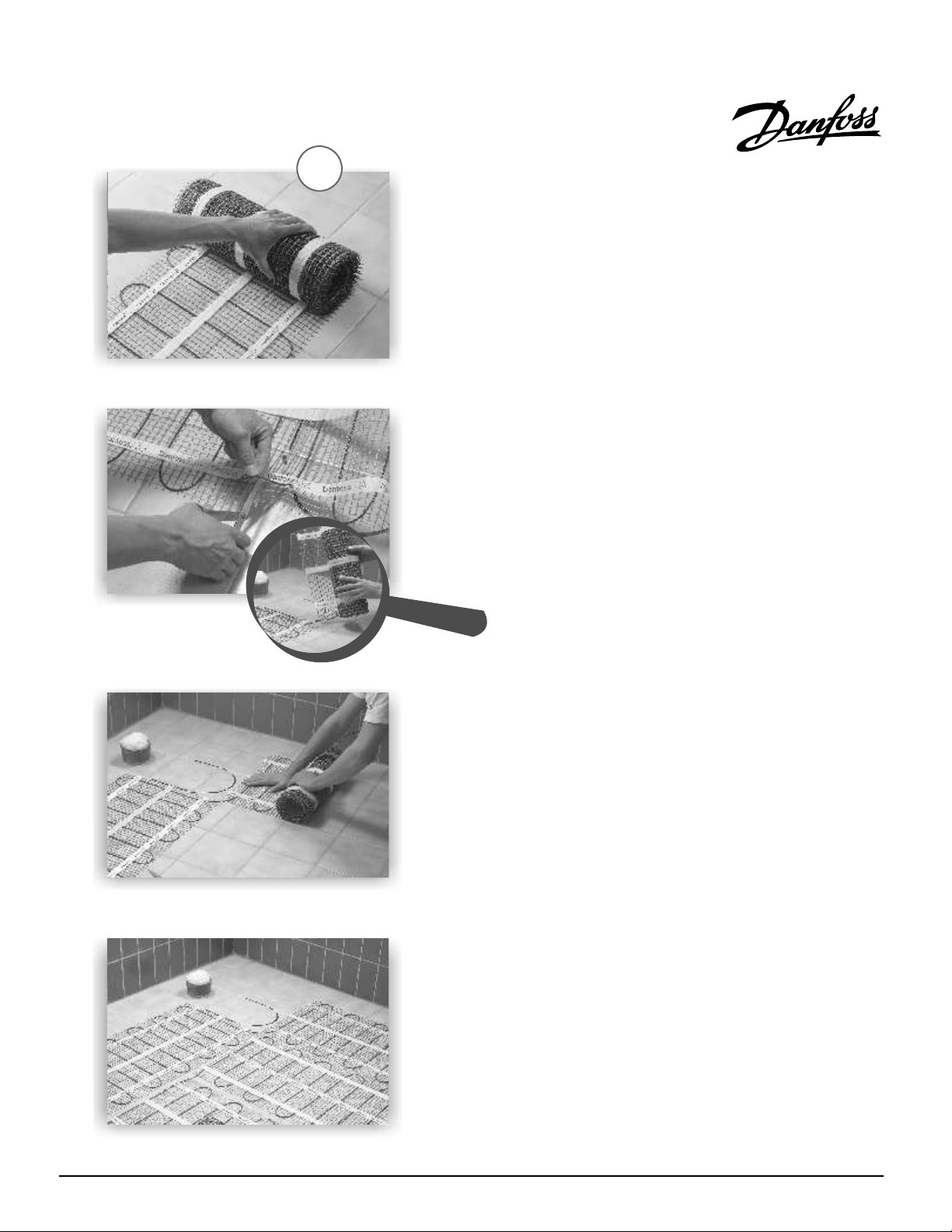

Step 5B. INSTALL THE LX MAT

An adhesive has been added to the bottom of the mat

which will prevent the mat from moving during

installation. Start by placing the mat such that the

connection point and the temperature sensor are in their

intended positions and bring the power cable to the

thermostat or connection box.

Begin unrolling the LX mat evenly across the floor

outside the areas that you marked previously.

The adhesive on the mat is made such that the mat may

be mo ved s ever al t i mes b e fore i t l ose s i ts

adhesiveness. When you reach the next wall, cut

the grey mesh, turn the mat, and begin rolling

in the desired direction.

NEVER CUT OR SHORTEN THE RED HEATING CABLE!

Ensure that the LX mat is in full contact with the

subfloor at all times. Avoid walking on the heating

mat. If this is not possible, use shoes with soft soles.

When approaching obstacles (toilets, cabinets, etc.),

carefully remove some of the red heating cable

f r o m t h e m a t a n d l e a d t h e c a b l e

around the obstacle. In some cases pieces of the

grey mesh will be cut away entirely. Remember to never

cut the red cable. Use hot melt glue or a thin strip of tape

to secure the loose cable to the floor.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

6

Page 10

6

Step 6. INSTALL FLOOR COVERING

Measure the resistance in the mat and record it on the

warranty certificate. It is highly recommend to take

photographs of the installed LX mat before installing

the flooring.

ENSURE THAT THE SENSOR CONDUIT HAS BEEN

PROPERLY INSTALLED BEFORE PROCEEDING (see Step 3).

In the case of tiles, proceed with the installation of the tiles

by covering the heating cables with a layer of thin-set

cement as directed by the tile manufacturer. Ensure that the

thin-set mortar covers the entire height of the heating

cable as the tiles are installed. In the case of a wood,

engineered or laminate floor covering, it is recommended

that the flooring manufacturer be contacted. For wooden

floors, a minimum of 3/16 in. of self-leveling cement over

the heating cable is recommended. Ensure that all

moisture in the self-leveling cement has been fully

eliminated in accordance with the drying times

recommended by the manufacturer (consult the

manufacturer for exact drying time).

Once the thin-set cement has dried, measure the

resistance in the mat and record it on the warranty

certificate. The LX mat must not be turned on until the thin-

set cement has fully dried. A minimum of seven (7) days is

recommended.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

Step 7. CONNECT POWER SUPPLY AND

THERMOSTAT

(See Appendix A)

The connection of the power supply and the LXstat GFCI

thermostat must be done by a qualified electrician in

accordance with the National Electrical Code (NEC) and

the Canadian Electrical Code (CEC). The electrician

should also feed the sensor cable into the installed conduit

and connect it to the thermostat.

TEL: 866-676-8062. FAX: 905-285-2055

7

Page 11

8

Step 8. RECORD INFORMATION AND AFFIX

LABELS

A final resistance reading must be taken and recorded on the

warranty certificate. Compare the resistance values with values

listed on the cold lead. Also, measure the resistance between the

blue, black and shielding/ground wire. Both should read infinity. It

is important for the homeowner to mail in the certificate

immediately after installing the LX mat and thermostat.

Failure to do so could void the manufacturer's warranty. The

warranty is subject to the guarantee conditions listed on the

warranty certificate.

Label 1: Product identification label

The eight digit product code provided on the LX mat label must be

recorded on the warranty certificate.

Label 2: Electric panel label

This label is to be placed inside the electric panel. On this label

record the name of the room where the heating cable has been

installed.

Label 3: The warning label

The warning label must be placed in the room where the

heating cable has been installed, preferably on the floor.

The label should be kept in the room at least for the

duration of the construction or renovation of the floor.

Copyright 2009 Danfoss Inc.

9

088L3380 - 06/09

Step 9. ENJOY THE COMFORT OF DANFOSS LX

The LX floor heating system is now ready to use. Increase the

floor temperature gradually and adjust it until it reaches a

comfortable level depending on the type of room and your

personal preferences.

TEL: 866-676-8062. FAX: 905-285-2055

8

Page 12

EXTENDED WARRANTY

For a period of ten (10) years from the date of purchase Danfoss warrants that the Danfoss LX mat is free from

defects in material, design and workmanship. The extended warranty is only valid if the warranty certificate has

been properly completed and mailed, and the installation is in accordance with the installation instructions.

The defective Danfoss LX cable has to be inspected by or submitted to Danfoss or an authorized Danfoss LX dealer.

Failure to comply with all of the foregoing will void this extended warranty. Danfoss will, when the customer has

documented that a defect in the Danfoss LX was present at the date of delivery, repair or supply a new Danfoss LX

at Danfoss’ option. All claims shall be made within the extended warranty period. Danfoss shall not be liable for any

claims made later than ten years from date of purchase.

Danfoss shall not be liable for any consequential and secondary costs or damages linked to the defect or

replacement of the Danfoss LX. Danfoss will be liable for any costs related to the dismantling of defective product

and the installation of a new product; however such liability is limited to the amount of five (5) times the initial

product costs for each damage/case.

THE FOREGOING WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ON THE PART OF

DANFOSS. DANFOSS DISCLAIMS ANY WARRANTY, EXPRESS OR IMPLIED, OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. DANFOSS NEITHER ASSUMES NOR AUTHORIZES ANY OTHER PERSON, FIRM OR CORPORATION TO

ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH SALE OR PRODUCT. DANFOSS SHALL NOT BE HELD

RESPONSIBLE FOR DAMAGE TO PERSON OR PROPERTY, CONSEQUENTIAL LOSS, LOSS OF PROFIT, LOSSES ON GOODS IN

STORE, OR THE LIKE WHICH MIGHT ARISE OUT OF THE FAILURE OF THE EQUIPMENT DELIVERED, IRRESPECTIVE OF THE CAUSE

(INCLUDING FAULTY MANUFACTURE).

How to claim this warranty

Contact the company's Customer Service

depar t ment and provide t h e following

information:

1) Nature of the manufacturing defect

2) Date of purchase and, if already

installed, date of installation

3) If installed, name of electrician and

flooring installer

4) Resistance readings taken by installer

5) Proof of purchase and serial number

from product label

Our Customer Service department will provide

you with an authorization number and advise you

on the next steps to complete your warranty

claim.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

Disclaimer:

This warranty gives you specific legal rights and you may

also have some legal rights which may vary from state to

state or province to province. Danfoss hereby disclaims,

and it is as a condition of the sale, that there are no implied

warranties. Some states and provinces do not allow

limitations on an implied warranty so the above limitation

may not apply to you.

Manufacturer:

Mail: Danfoss Inc.

6711 Mississauga Rd.,

Suite 410

Toronto, ON

L5N 2W3

Phone: 905-285-2050

1-866-676-8062

Fax: 905-285-2055

TEL: 866-676-8062. FAX: 905-285-2055

9

Page 13

Dispositif de chauffage de plancher DanfossLX

ATTENTION!

Il est important que ce tapis chauffant soit installé uniquement par un électricien agréé qui connaît le calibrage, le mode

d'installation, la construction et le fonctionnement des systèmes de chauffage de plancher ainsi que les risques associés.

Le tapis chauffant a été conçu à des fins de chauffage seulement par-dessous le plancher.

REMARQUE

L'installation doit se faire conformément aux instructions du fabricant et aux codes nationaux et locaux. Elle doit respecter

la section 424-J, American National Standards Institute / National Fire Protection Association (ANSI / NFPA70), le National

Electrical Code et la Première partie du Code canadien de l'électricité. Vous devez vous servir d'un dispositif de protection

contre les défauts de terre ou d'un dispositif de courant résiduel dans les salles de bains et autres pièces.

Spécifications techniques des tapis chauffant Danfoss LX

Type:

Tension:

Puissance:

Dimension de l’élément

chauffant:

Liaison froide:

Rayon de pliage

Isolation de fil

Enveloppe:

Température admissible max.:

Temp. min. d’installation:

:

:

Faisceau double

120V, 240V

pied carré

12W/ (130 W/m )

Largeur

: 2’

Longueur : Référez-vous à l'étiquette du produit

taille

: approx 1/8” (4 mm)

10’ (3.0 m)

Mín.

3/4” (19 mm)

FEP, Teflon

PVC

212°F (100°C)

40°F (5°C)

MC

2

Note: Si le tapis chauffant de 240V est alimenté par une tension de 208V, la puissance émise par le

tapis est de 9W/pied carré (une réduction d’environ 25%).

AVERTISSEMENT :

Pensez à mesurer la résistance

Little Buzzer

SURVEILLER L’INSTALLATION GRÂCE

AU PETIT AVERTISSEUR SONORE DE

CONTINUITÉ ( # 088L0028).

Connexion 120 V

Phase Noir

Neutre Bleu

Terre Blindage

Connexion 0 V

24

Phase Noir

Phase Bleu

Terre Blindage

La résistance doit être mesurée entre les deux conducteurs, le bleu et le noir. Comparer la résistance mesurée à

celle mentionnée sur l'étiquette du produit (sur le fil d'alimentation). Noter la résistance sur la fiche de garantie.

Les résistances entre la terre (nu) et les conducteurs bleu et noir devraient aussi être mesurées, et devraient être

infinies.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

10

Page 14

Installations et applications typiques de Danfoss LX

Directement sur du contreplaqué

Directement sur du b toné

Autre façon : il est recommandé d'utiliser du

ciment autonivelant pour les grandes surfaces

ainsi que pour les matériaux de recouvrement

suivants : bois d'ingénierie, parquet lamellaire,

parquet flottant, vinyle, linoléum et tapis.

Tuiles de céramique

Sonde de thermostat

Mortier ciment-colle

fanD oss LX

Contreplaqu sur poutrelles é

Poutrelles

Isolation (facultatif)

Tuiles de céramique

Mortier ciment-colle

Danfoss LX

Sonde de thermostat

B toné

Mise en garde

Pour obtenir de l'information sur les exigences d'installation

particulières des revêtements en bois, en parquet lamellaire,

en vinyle ou en linoléum, consulter le fabricant.

ŸAttention!

Ÿ Avant d'installer LXmat, lisez avec soin les

instructions d'installation.

Ÿ

Ÿ N'installez pas LXmat dans le mur ou le plafond.

Ÿ Le tapis doit être encastré dans du mortier, un

mélange de mortier, du béton ou autre matériau

semblable.

Ÿ La température minimale d'installation est de 5 °C

(40 °F).

Ÿ Ne coupez pas le fil de chauffage rouge.

Ÿ Il est recommandé d'utiliser uniquement du fil de

cuivre.

Ÿ N'installez pas LXmat de façon à ce que les deux

fils de chauffage rouges se touchent, se croisent

ou se chevauchent.

Ÿ N'oubliez pas de continuellement mesurer, vérifier

et inscrire la résistance tout au long du processus

d'installation (au moment de l'ouverture de la boîte,

après l'installation, avant la pose de ciment à pose

simplifiée ou du produit autonivelant, et après

l'installation de tuiles), et comparez toutes les

résistances mesurées à celles indiquées sur

l ’ é t i q u e t t e d e l a l i a i s o n f r o i d e .

Ÿ N'oubliez pas de vérifier si la tension d'alimentation

correspond à la tension du tapis Danfoss LX.

Ÿ N'oubliez pas d'apposer les étiquettes tel qu’indiqué

dans les instructions.

Ÿ Po ur u ti li sa t io n à l 'i nt ér ie ur s eu le m en t.

Po u r toute autre question ou tout co n s eil,

communiquez avec l'usine. Les structures métalliques

ou matériaux servant au soutien ou à l'installation de

LXmat Danfoss doi ve n t être mis à l a te r re

conformément à la norme C22.1, article 10, de la CSA, et

conformément au National Electrical Code.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

11

Page 15

Instructions d'installation d'ordre général

1

Étape 1. SCHÉMA D’INSTALLATION

Tracez un plan ou un croquis de la pièce, en y incluant tout

accessoire permanent comme la toilette, la baignoire, les

appareils ménagers, les armoires, etc. Indiquez toutes les

dimensions afin d'établir la superficie de plancher

disponible et l'emplacement du thermostat LX.

CO NSEIL : Da nfoss conseille de documenter

l'installation avec des ph otos afin de noter

l'emplacement des branchements et de la sonde.

2

Étape 2. TRANSFERT DU PLAN AU PLANCHER

3A

Dessinez le plan sur le faux plancher de la pièce. Dessinez la

place occupée par tous les meubles qui y seront installés.

Déroulez les quelques premiers pieds de tapis Danfoss LX.

Marquez l'emplacement de la connexion entre le câble

d'alimentation (liaison froide) et le câble de chauffage rouge.

Cette connexion doit se trouver à l'intérieur du ciment à

pose simplifiée ou du ciment autonivelant. Si vous avez une

sonde de température au plancher (p. ex., LXstat 430), marquez

l'emplacement de la sonde. Elle devrait se trouver au milieu de

deux câbles de chauffage et à environ 25 cm (10 po) à l'intérieur

du tapis, aussi près que possible du thermostat.

Étape 3. POSE DU CONDUIT ET DE LA SONDE

conduit recommandé , # de pièce 19809099 - inclus

( )

Il faut installer le conduit flexible pour la sonde entre la boîte

électrique du thermostat et la sonde, au cas où il serait

nécessaire de changer la sonde. Ce conduit doit être fraisé dans

le faux plancher.

Taillez un canal d'environ 5/16 po de profond et 5/16 po de

large dans le plancher et dans le mur jusqu'au thermostat, en

vue d'y insérer le conduit du capteur. Ce conduit doit aller du

thermostat vers le milieu du plancher, se terminant à au moins

10 po du mur.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

12

Page 16

4

IMPORTANT : le conduit de sonde doit être centré dans la

boucle de câble (entre deux fils chauffants rouges).

Utiliser du ruban adhésif en toile pour fermer l'extrémité du

conduit et ainsi empêcher toute introduction de mortier

ciment-colle dans le conduit.

Utiliser ce même adhésif pour fixer le conduit de sonde dans

la rigole et l'empêcher de flotter lors de l'application du

mortier ou du mortier ciment-colle.

Si la sonde est posée directement dans le bain de mortier,

utiliser du ruban adhésif en toile pour la fixer au sousplancher.

Étape 4. PRÉPARATION DE LA SURFACE DU

FAUX PLANCHER

Assurez-vous que le faux plancher est solidement fixé et

qu'il ne bougera pas. Remplissez les fissures afin de

prévenir tout dommage ultérieur aux tuiles en raison d'un

déplacement du plancher.

5A

Nettoyez le faux plancher, passez soigneusement

l'aspirateur pour enlevez toute poussière et tous les débris

qui pourraient endommager le câble de chauffage ou

réduire l'adhésion.

(En option) Afin d'assurer une adhésion maximale,

ap pli quez un apprê t ou un sce llan t selon les

recommandations du fabricant du ciment (pose simplifiée

ou autonivelant). Si vous utilisez un apprêt, assurez-vous

de couvrir tout le plancher. Laissez l'apprêt sécher

complètement avant de passer aux étapes suivantes.

Étape 5 : MESURE DE LA RÉSISTANCE

À l'aide d'un ohmmètre numérique, mesurer la résistance

du câble LX et la comparer à celle mentionnée sur

l'étiquette du produit. Noter la résistance mesurée sur la

fiche de garantie. Les informations relatives à la résistance

à chaque phase de l'installation sont nécessaires à des fins

de garantie.

Les résistances entre la terre (nu) et les conducteurs bleu

et noir devraient aussi être mesurées, et devraient être

infinies.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

13

Page 17

5B

Étape 5B. INSTALLATION DE LX MAT

Le dessous du tapis est adhésif afin de l'empêcher de

bouger pendant l'installation. Commencez en plaçant le

tapis de façon à ce que le point de connexion et la sonde de

température se trouvent au bon endroit et amenez le câble

d'alimentation vers le thermostat ou la boîte de

connexion.

Commencez à dérouler tapis Danfoss LX uniformément

sur le plancher, en dépassant les démarcations déjà

tracées. L'adhésif du tapis est conçu de façon à permettre

de déplacer le tapis plusieurs fois avant qu'il perde de son

efficacité. Lorsque vous arrivez au mur opposé, coupez la

maille grise, tournez le tapis et commencez à le dérouler

dans le sens contraire.

NE JAMAIS COUPEZ NI RACCOURCIR LE CÂBLE DE

CHAUFFAGE ROUGE!

Assurez-vous que LX mat est toujours en plein contact

avec le faux plancher. Évitez de marcher sur le tapis

chauffant. Si cela n'est pas possible, portez des chaussures

à semelle souple.

Lorsque vous approchez d'obstacles (toilette, armoire,

etc.), enlevez soigneusement une partie du câble de

chauffage rouge de la maille grise et acheminez le câble

autour de l'obstacle. Dans certains cas, le maille grise sera

complètement enlevée. N'oubliez pas : le câble rouge ne

doit jamais être coupé. Fixez le câble libre au plancher au

moyen de colle thermofusible ou d'un mince ruban

adhésif.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

14

Page 18

6

Étape 6. INSTALLATION DU RECOUVREMENT

DE PLANCHER

Mesurez la résistance du tapis et inscrivez-la dans le tableau

figurant sur le certificat de garantie. Il est fortement

recommandé de prendre des photos de LXmat, une fois

celui-ci installé, avant de poser le recouvrement.

AVANT DE CONTINUER, ASSUREZ-VOUS QUE LE CONDUIT DE

LA SONDE EST BIEN INSTALLÉ (Voir l'étape 3).

Si vous posez des tuiles, couvrez les câbles de chauffage d'une

couche de ciment à pose simplifiée en suivant les directives

du fabricant des tuiles. Assurez-vous que le mortier à pose

simplifiée couvre toute la hauteur du câble de chauffage lors

de la pose des tuiles.

Si vous posez un plancher de bois, de bois d'ingénierie ou du

parquet lamellaire, il est recommandé de communiquer avec

le fabricant du recouvrement.

Pour les planchers de bois, il est recommandé de poser au

moins 3/16 po de ciment autonivelant sur le câble chauffant.

Assurez-vous que toute humidité que renferme le ciment

autonivelant s'est bien évaporée, conformément aux durées

de séchage recommandées par le fabricant (pour obtenir la

durée exacte du séchage, communiquez avec le fabricant).

Une fois que le ciment à pose simplifiée a séché, mesurez la

résistance du tapis et inscrivez-la sur le certificat de garantie.

LXmat ne doit pas être allumé avant le séchage complet du

ciment à pose simplifiée. On recommande une durée de

séchage d'au moins sept (7) jours.

Étape 7 . CONNEXION DE L'ALIMENTATION EN

COURANT ET DU THERMOSTAT

(Voir l’Annexe A)

La connexion de l'alimentation et du thermostat LXstat GFCI

doit être effectuée par un électricien agréé, conformément au

National Electrical Code et au Code canadien de l'électricité.

L'électricien doit aussi amener le câble de la sonde dans le

conduit et la connecter au thermostat.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

15

Page 19

8

Étape 8 . CONSIGNATION D'INFORMATION ET

APPOSITION DES ÉTIQUETTES

Prendre un relevé de la résistance et inscrire cette valeur sur le

certificat de garantie. Il est important que le propriétaire

conserve cette page en lieu sûr aux fins de consultation.

L'électricien doit également remplir le certificat, sinon la

garantie du fabricant pourrait être annulée. La garantie est

assujettie à toutes les conditions indiquées sur le certificat.

Étiquette 1: Identification du produit :

Le code du produit comportant huit chiffres et figurant

sur l'étiquette de LXmat doit être inscrit sur le certificat

de garantie.

Étiquette 2: Pour le panneau électrique:

Cette étiquette doit être apposée sur le panneau

électrique. Y inscrire le nom de la pièce où l'on a installé

le câble de chauffage.

Étiquette 3: Mise en garde:

L'étiquette de mise en garde doit être placée dans la

pièce où l'on a installé le câble de chauffage, de

préférence sur le plancher. Cette étiquette doit rester

dans la pièce pendant toute la durée de la construction

9

Étape 9. APPRÉCIEZ LE CONFORT DU TAPIS LX DE

DANFOSS

Vous pouvez maintenant utiliser le système de chauffage

de plancher LX. Augmentez la température graduellement

jusqu'à ce que vous atteigniez un niveau confortable selon

le type de pièce et vos préférences.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

16

Page 20

PROLONGATION DE GARANTIE

Pendant une période équivalant dix (10) ans à compter de la date d'achat, Danfoss garantit que le câble Danfoss LX

est exempt de défauts de matériau, conception et main d'œuvre. La prolongation de garantie est valable

uniquement si le certificat de garantie a été correctement rempli et envoyé, et si l'installation est conforme aux

instructions.

Le câble Danfoss LX défectueux doit être examiné par Danfoss ou soumis à l'expertise de ses services ou d'un

revendeur agréé de Danfoss LX. Le non-respect des instructions précédentes annulera la prolongation de

garantie. Danfoss, une fois que le client aura documenté la présence d'un défaut dans le câble Danfoss LX à la date

de livraison, s'engagera à son entière discrétion à réparer ou à fournir un câble Danfoss LX neuf. Toutes les

réclamations doivent être portées à la connaissance de Danfoss pendant la période de garantie. Danfoss ne pourra

être tenu responsable de toutes les réclamations postérieures aux dix années écoulées à compter de la date

d'achat.

Danfoss ne pourra être tenu responsable de tout dommage indirect et de tout frais ou dommage secondaire liés

au défaut ou au remplacement du tapis chauffant Danfoss LX. Danfoss sera responsable de tout frais associé au

démontage du produit défectueux et à l'installation d'un nouveau produit ; toutefois, cette responsabilité est

limitée à cinq (5) fois le montant des coûts initiaux du produit pour chaque dommage/cas.

LA GARANTIE SUSMENTIONNÉE REMPLACE EXPRESSÉMENT TOUTES LES AUTRES GARANTIES, EXPRESSES OU IMPLICITES, DE

DANFOSS. DANFOSS DÉCLINE TOUTE RESPONSABILITÉ QUANT À UNE GARANTIE EXPRESSE OU IMPLICITE, DE

COMMERCIALISATION OU D'ADÉQUATION À DES FINS SPÉCIFIQUES. DANFOSS DÉCLINE TOUTE RESPONSABILITÉ LIÉE À LA

VENTE OU AU PRODUIT, ET N'AUTORISE PAS DE TIERS, NI D'ENTREPRISE OU D'ORGANISATION À ASSUMER CETTE

RESPONSABILITÉ À SA PLACE. DANFOSS NE POURRA ÊTRE TENU POUR RESPONSABLE DES DOMMAGES OCCASIONNÉS AUX

PERSONNES OU AUX BIENS, DES PERTES INDIRECTES, DES PERTES DE PROFIT, DES PERTES DE MARCHANDISES STOCKÉES OU

SIMILAIRE SUSCEPTIBLES DE RÉSULTER D'UNE DÉFAILLANCE DE L'ÉQUIPEMENT LIVRÉ, ET CE, QUELLE QU'EN SOIT LA CAUSE, Y

COMPRIS UN VICE DE FABRICATION).

Réclamation de garantie

Contacter le service après-vente de la société et fournir

les informations suivantes :

1) Nature du défaut de fabrication

2) Date d'achat et, si l'installation a déjà été

réalisée, date de l'installation

3) Si l'installation a déjà été réalisée, nom de

l'électricien et du poseur de revêtement de

plancher

4) Relevés de résistance effectués par le

poseur

5) Preuve d'achat et numéro de série indiqué

sur l'étiquette du produit

Notre service après-vente vous fournira alors un

numéro d'autorisation et vous informera des étapes à

suivre pour la réclamation de garantie.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

Exclusion de garantie :

Cette garantie concède des droits légaux spécifiques et

certains droits peuvent également varier d'un état à un

autre. Danfoss décline par la présente toute responsabilité,

à titre de condition de vente, quant à l'absence de garanties

implicites. Certains états n'autorisent pas de limites sur une

gar an ti e i mp li ci t e, p ar c o ns éq ue nt , l a l im i te

susmentionnée peut ne pas s'appliquer.

Fabricant :

Adresse: Danfoss Inc.

6711 Mississauga Rd.,

Suite 410

Toronto, ON

L5N 2W3

Téléphone 905-285-2050

1-866-676-8062

Fax: 905-285-2055

TEL: 866-676-8062. FAX: 905-285-2055

17

Page 21

Sistema de calefacción por suelo radiante Danfoss LX

¡PRECAUCIÓN!

Es importante que la instalación de este equipo corra a cargo únicamente de electricistas cualificados que estén

familiarizados con las dimensiones, la instalación, la fabricación y el uso del sistema de calefacción por suelo radiante,

además de los peligros que conlleva. La malla calefactora se ha concebido solo a efectos de calefacción bajo el suelo.

Nota

La instalación se realizará de acuerdo con las instrucciones del fabricante y los códigos locales y nacionales: Parte 424-J,

Instituto estadounidense de estandarización / Asociación estadounidense antiincendios (ANSI/NFPA70), Código

eléctrico nacional (NEC) y Código eléctrico canadiense (CEC), Parte 1. Danfoss recomienda el cable de calefacción GFCl

en zonas normalmente húmedas (es decir, baños, duchas y cocinas).

Especificaciones de la malla LX

Tipo:

Tensión:

Salida:

Tamaño de componente

de calefacción:

Cable en frío

Radio de inclinación:

Aislamiento del hilo:

Carcasa:

Temp. máx. permitida:

Temp. mín. de instalación:

Nota: El uso de la malla de 240 V a 2O8 V reduce la potencia de salida a aproximadamente un 25 %.

Recuerde medir la resistencia

Dos conductores

120 V, 240 V

2

130 W/m

Anchura: 60,96 cm

Longitud: consulte la etiqueta del

producto.

Altura: aprox. 4 mm

3,0 m

Mínimo 19 mm

FEP, Teflón

PVDF

100 ºC

ADVERTENCIA:

TM

Little Buzzer

Conexión 120 V

Fase: negro

Neutro: azul

Masa: blindado

Conexión 240 V

Fase: negro

Fase: azul

Masa: blindado

SUPERVISE LA INSTALACIÓN.

USE LA ALARMA DE CONTINUIDAD

LITTLE BUZZER (PIEZA N.º 088L0028

Debe medirse la resistencia entre los dos conductores, azul y negro. Compare la medida de resistencia con la que figura en la etiqueta

del producto (en el cable de alimentación). Registre la resistencia en la tarjeta de la garantía.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

18

Page 22

Instalaciones y aplicaciones típicas de Danfoss LX

Directamente sobre contrachapado:.

Directamente sobre hormigón:.

Método alternativo: se recomienda cemento

autonivelante para grandes superficies y los

siguientes materiales para suelo: madera

prensada, laminado, suelos flotantes, vinilo,

linóleo y moqueta.

Baldosas cerámicas

Sensor de termostato

Cemento adhesivo de capa delgada

Danfoss LX

Contrachapado sobre vigas

Vigas

Aislamiento (opcional) Directamente

Baldosas cerámicas

Cemento adhesivo de capa delgada

Danfoss LX

Sensor de termostato

Hormigón

Advertencia:

Solicite al fabricante información sobre requisitos

especiales de instalación para suelos de madera,

laminado y vinilo o linóleo.

¡Precaución!

Ÿ

Lea las instrucciones detenidamente antes de

montar la malla LX

Ÿ

No se recomienda montar la malla LX con un

termostato sin limitador de temperatura del suelo,

especialmente cuando haya otro calefactor

instalado en la sala.

Ÿ

No monte la malla LX en paredes o techos.

Ÿ

La malla debe estar embebida en mortero, una

capa delgada, hormigón o un material similar.

Ÿ

La temperatura mínima de instalación es de 5 °C.

Ÿ

No corte nunca el hilo rojo de calefacción.

Ÿ

Se recomienda usar solo hilo de cobre.

Ÿ

No instale nunca la malla LX de manera que se

toquen, crucen o solapen dos hilos rojos de

calefacción.

Ÿ

Recuerde siempre medir, verificar y registrar la

resistencia real en todo el proceso de instalación

(al desembalar el sistema, tras la instalación, antes

de aplicar el cemento de capa delgada o

autonivelante y tras el montaje de baldosas para

suelo) y compare todas las lecturas con los valores

nominales de la tabla del producto.

Recuerde comprobar que la tensión corresponda a la

Ÿ

de la malla LX.

Recuerde colocar las etiquetas tal como se especifica

Ÿ

en estas instrucciones.

Solo para la instalación en interiores

Ÿ

Las estructuras metálicas o los materiales utilizados

Ÿ

como soporte de la malla Danfoss LX o sobre los que

se extiende la malla deben tener conexión a tierra de

acuerdo con la norma CSA C22.1, apartado 10, y el

NEC.

Consulte con la fábrica cualquier otra pregunta o

consejo.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

19

Page 23

Pautas generales de instalación

1

Paso 1. PLANO DE MONTAJE

Realice un esbozo o un plano del suelo de la sala; incluya

todos los accesorios permanentes como son los

inodoros, las bañeras, los aparatos, la marquetería, etc.

Indique todas las dimensiones necesarias para

determinar la zona del suelo disponible y la posición del

termostato LX.

CONSEJO: Danfoss recomienda documentar la

instalación con fotos para que se vea la ubicación de

las conexiones y el sensor.

Paso 2. TRANSFERENCIA DEL PLANO AL

SUELO

2

Trace un contorno del plano en el suelo de la habitación,

incluido el de todos los accesorios que todavía no estén

instalados. Desenrrolle los primeros metros de malla LX. El

punto de partida del cable debe colocarse a 3,05 m del

termostato. Marque la posición del punto de conexión

entre el cable de alimentación y el cable rojo de

calefacción LX. Esta conexión debe ocultarse en una capa

delgada o un cemento autonivelante. Cuando use un

termostato detector de la temperatura del suelo, marque

la posición del sensor en medio de 2 cables de calefacción,

separados de la pared unos 25 cm (dentro de la zona

calefactada), lo más cerca posible del termostato.

Copyright 2009 Danfoss Inc.

3A

088L3380 - 06/09

Paso 3. INSTALACIÓN DEL SENSOR

(recomendada en conducto, pieza n.º 19809099- incluido)

Si se emplea un termostato detector de la temperatura del

suelo, instale el sensor ahora, en un conducto o

directamente bajo el suelo. Se recomienda instalar el

sensor en un conducto portacables. De este modo, el

sensor podrá sustituirse fácilmente en el caso improbable

de producirse un fallo.

El sensor o el tubo debe instalarse entre la caja del

termostato situada en la pared y la posición del sensor. El

tubo portacables debe estar parcialmente avellanado en el

suelo. Corte un canal (8mm x 8mm) en el suelo y en la pared

hasta el termostato que sea suficientemente grande para

alojar el tubo del sensor. El tubo debe ir desde el

termostato hacia la mitad del suelo, separado de la pared a

un mínimo de 25,4 cm.

TEL: 866-676-8062. FAX: 905-285-2055

20

Page 24

IMPORTANTE: El tubo del sensor debe centrarse

en el circuito cerrado del cable (entre dos hilos

rojos de calefacción).

Use cinta para conductos para cerrar el extremo del

conducto y que la capa delgada no pueda penetrar en él.

Use cinta para conductos para sujetar el conducto del sensor

en la ranura y evitar que flote cuando se vierta el mortero o la

capa delgada

.

Si el sensor se instala directamente en el lecho de mortero,

use cinta para conductos para fijarlo bajo el suelo.

4

5A

Paso 4. PREPARACIÓN DE LA SUPERFICIE

BAJO EL SUELO

Limpie y aspire el suelo concienzudamente para eliminar

el polvo y los residuos del suelo que puedan dañar el cable

de calefacción o reducir su adhesión.

Asegúrese de que la superficie bajo el suelo sea segura y

estable. Rellene cuidadosamente todas las grietas para

impedir que las baldosas nuevas puedan resultar dañadas

a causa de los movimientos que pueda experimentar la

capa del piso bajo el suelo.

(Opcional) Para garantizar la máxima adhesión, aplique

un imprimador o sellador recomendado por el fabricante

de capa delgada o de cemento autonivelante. Si usa un

imprimador, asegúrese de aplicarlo en todo el suelo. Deje

que se seque bien antes de realizar los pasos siguientes.

Paso 5A. MEDICIÓN DE LA RESISTENCIA

Use un ohmímetro digital para medir la resistencia de

la malla LX y compárela con la que figura en la etiqueta

del producto. Registre la medida de resistencia en la

tarjeta de garantía. A efectos de cobertura de la

garantía, la resistencia debe documentarse en cada

fase de la instalación..

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

21

Page 25

5B

Paso 5B. INSTALACIÓN DE LA MALLA LX

Se ha aplicado un adhesivo en la parte inferior de la malla

que impedirá que se mueva durante su montaje. Empiece

colocando la malla de manera que el punto de conexión y el

sensor de temperatura estén en sus debidas posiciones y

lleve el cable de alimentación al termostato o la caja de

conexiones

.Empiece a desenrollar la malla LX de manera homogénea

en el suelo fuera de las zonas que ha marcado

anteriormente. El adhesivo de la malla está fabricado para

que ésta pueda moverse varias veces antes de perder su

capacidad de adhesión. Cuando llegue a la siguiente pared,

corte el entramado gris, gire la malla y empiece a

desenrollarla en la dirección que desee.

¡NO CORTE NI ACORTE EL CABLE ROJO DE CALEFACCIÓN!!

Asegúrese de que la malla LX entre totalmente en

contacto con la superficie de debajo del suelo en todo

momento. Evite pisar la malla calefactora. Si no es posible,

utilice calzado con suela blanda.

Cuando se acerque a obstáculos (inodoros, armarios,

etc.), retire cuidadosamente parte del cable rojo de

calefacción del entramado gris y tienda el cable

rodeando el obstáculo. En algunos casos, algunas partes

del entramado gris quedarán totalmente cortadas.

Recuerde no cortar nunca el cable rojo. Use cola fundida

caliente o una tira fina de cinta para fijar el cable suelto

al suelo.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

22

Page 26

6

Paso 6. INSTALACIÓN DE LA CUBIERTA DEL

SUELO

Mida la resistencia de la malla y regístrela en el certificado

de garantía. Se recomienda especialmente sacar

fotografías de la malla LX montada antes de instalar el

suelo.

ASEGÚRESE DE QUE EL TUBO DEL SENSOR SE HAYA

INSTALADO DEBIDAMENTE ANTES DE CONTINUAR

(consulte el paso 3).

En el caso de las baldosas, continúe montándolas

cubriendo los cables de calefacción con una capa de

cemento de capa delgada según indique el fabricante de

baldosas. Asegúrese de que el mortero de capa delgada

cubra toda la altura del cable de calefacción al instalar las

baldosas. En el caso de las cubiertas de suelo de madera,

prensadas o laminadas, se recomienda ponerse en

contacto con el fabricante de suelos. En el caso de los suelos

de madera, se recomienda aplicar 4,8 mm de cemento

autonivelante sobre el cable de calefacción. Asegúrese de

que se haya eliminado toda la humedad del cemento

autonivelante de acuerdo con los tiempos de secado

recomendados por el fabricante del cemento (consulte al

fabricante el tiempo exacto de secado).

Cuando se haya secado el cemento de capa delgada, mida

la resistencia de la malla y regístrela en el certificado de

garantía. La malla LX no debe encenderse hasta que el

cemento de capa delgada no esté totalmente seco. Se

recomienda un mínimo de siete (7) días.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

Paso 7. CONEXIÓN DE LA FUENTE DE ALIMENTACIÓN Y

EL TERMOSTATO

(Véase el Apéndice A)

La conexión de la fuente de alimentación y el termostato

GFCI LXstat debe realizarla un electricista cualificado de

acuerdo con el Código eléctrico nacional (NEC) y el Código

eléctrico canadiense (CEC). El electricista también es quien

debe introducir el cable del sensor en el conducto instalado

y conectarlo al termostato.

Debe registrarse en el certificado de garantía una última

lectura de resistencia. Es importante que el propietario del

sistema envíe inmediatamente por correo el certificado tras

instalar la malla LX y el termostato. Si no lo hace, la garantía

del fabricante podría quedar invalidada. La garantía está

sujeta a las condiciones que figuran en el certificado de

garantía.

TEL: 866-676-8062. FAX: 905-285-2055

23

Page 27

8

Paso 8. REGISTRO DE LA INFORMACIÓN Y

ETIQUETADO

Mida la resistencia y regístrela en la tarjeta de garantía que se

suministra. Compare los valores de la resistencia con los que

figuran en el cable en frío.

Etiqueta 1:

Etiqueta de identificación del producto El código de producto de

ocho dígitos suministrado en la etiqueta de la malla LX debe

registrarse en el certificado de garantía.

Etiqueta 2:

Etiqueta del panel eléctricoEsta etiqueta debe ponerse en el

interior del panel eléctrico. Registre en ella el nombre de la

habitación en que se ha montado el cable de instalación

Etiqueta 3:

La etiqueta de advertencia debe colocarse en la habitación en

que se ha montado el cable de calefacción, preferentemente en

el suelo. La etiqueta debe dejarse en la habitación al menos

durante el período de construcción o renovación del suelo.

9

Step 9. EL CONFORT DE DANFOSS LX

El sistema de calefacción por suelo radiante LX está ahora listo

para su uso. Aumente la temperatura del suelo gradualmente y

regúlela hasta que alcance un nivel en que se esté cómodo según

el tipo de habitación y sus preferencias personales.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

24

Page 28

AMPLIACIÓN DE GARANTÍA

Danfoss ofrece cobertura de la malla Danfoss LX por defectos de material, diseño y fabricación durante un período

de diez (10) años a partir de la fecha de compra. La ampliación de garantía solo es válida si se ha cumplimentado el

certificado de garantía y se ha enviado por correo y si la instalación es conforme con las instrucciones de instalación.

Cualquier cable Danfoss LX defectuoso debe enviarse a Danfoss o a un distribuidor Danfoss LX autorizado para su

inspección. El incumplimiento de todo lo anterior anulará esta ampliación de garantía. En caso de que el cliente

documente un defecto presente en el Danfoss LX en la fecha de la entrega, Danfoss reparará el producto o suministrará

uno nuevo, según estime oportuno. Todas las reclamaciones se efectuarán dentro del plazo estipulado en la ampliación

de garantía. Danfoss no se responsabilizará de ninguna reclamación efectuada en un plazo de tiempo superior al de diez

años a partir de la fecha de compra.

Danfoss no se responsabilizará de ningún coste resultante o secundario ni de los daños relacionados con el defecto o la

sustitución del material Danfoss LX. Danfoss se responsabilizará de todo coste relativo al desmontaje del producto

defectuoso y la instalación de un producto nuevo; no obstante, dicha responsabilidad está limitada al coste del

producto inicial multiplicado por cinco (5) por cada daño / caso.

LA GARANTÍA ANTERIOR SUSTITUYE EXPLÍCITAMENTE CUALQUIER OTRA GARANTÍA, EXPLÍCITA O IMPLÍCITA, POR PARTE DE

DANFOSS. DANFOSS RECHAZA TODA GARANTÍA, EXPLÍCITA O IMPLÍCITA, DE COMERCIABILIDAD O ADECUACIÓN PARA UN FIN

DETERMINADO. DANFOSS NO PRESUPONE NI AUTORIZA A NINGUNA OTRA PERSONA, EMPRESA O SOCIEDAD A ASUMIR EN SU

LUGAR CUALQUIER OTRA RESPONSABILIDAD EN RELACIÓN CON LA VENTA O EL PRODUCTO. DANFOSS NO ASUMIRÁ LA

RESPONSABILIDAD DE DAÑOS INFRINGIDOS A PERSONAS O BIENES, PÉRDIDAS RESULTANTES, PÉRDIDA DE BENEFICIOS,

PÉRDIDAS DE PRODUCTOS EN ALMACÉN O SIMILARES QUE PUEDAN OCASIONARSE POR EL FALLO DEL EQUIPO

SUMINISTRADO, INDEPENDIENTEMENTE DE QUE LA CAUSA INCLUYA UNA FABRICACIÓN DEFECTUOSA.

Cómo reclamar esta garantía

Póngase en contacto con el departamento de Servicio de

atención al cliente y facilite la siguiente información:

1) Naturaleza del defecto de fabricación

2) Fecha de la compra del producto y, si ya está

instalado, fecha de la instalación

3) Si está instalado, nombre del electricisa e

instalador de suelos

4)Lecturas de resistencia tomadas por el

instalador

5) Comprobante de la compra y número de serie

de la etiqueta del producto

En nuestro departamento de Servicio de atención al cliente,

se le proporcionará un número de autorización y se le

informará de los pasos posteriores que debe seguir para

rellenar la reclamación de garantía.

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

Limitación de responsabilidad:

Esta garantía le ofrece unos derechos determinados; también

puede acogerse a los derechos que le garantiza la jurisdicción

estatal o provincial, que pueden variar en función del estado o la

provincia. Por la presente, Danfoss rechaza, como condición de la

venta, la ausencia de garantías implícitas. Algunos estados y

provincias no permiten restricciones de una garantía implícita, lo

cual implica que la restricción anterior puede no ser de

aplicación para usted.

Fabricante:

Dirección postal: Danfoss Inc.

6711 Mississauga Rd.,

Suite 410

Toronto, ON

L5N 2W3

Phone: 905-285-2050

1-866-676-8062

Fax: 905-285-2055

TEL: 866-676-8062. FAX: 905-285-2055

25

Page 29

APPENDIX A: Typical Electrical Wiring

ANNEXE A: Câblage Électrique Typique

APÉNDICE A: Cableado Eléctrico Típico

Thermostat Danfoss LX

Termostato Danfoss LX

Danfoss LX Thermostat

L1(L)

L2(N)

16A Max

Load/Charge/Carga

Bobine

Coil

> 16 Amps

L1 (L)

L2 (N)

240 (120) VAC

Sensor/Sonde/Sensor

L1 (L)

(No polarity/sans polarité/ninguna polaridad)

Cable en frío

Liaison Froide

Power lead

Bobina

Contactor

Contactor

Conjoncteur

Load greater than 16 Amps

Carga de más de 16 Amperios

Charge de plus de 16 Ampères

( No se incluye un GFCI en este diagrama)

( Un DDFT n’est pas inclus dans ce diagramme)

L2 (N)

240 (120) VAC

Cable en frío

Liaison Froide

Power lead

Danfoss LX Danfoss LX

( GFCI protection not provided in this wiring diagram)

≤ 16 Amps

Copyright 2009 Danfoss Inc.

Cable en frío

Liaison Froide

Power lead

Thermostat Danfoss LX

Termostato Danfoss LX

Danfoss LX Thermostat

Load/Charge/Carga

L1(L)

L2(N)

Max. load 16 Amps

L1 (L)

240 (120) VAC

16A Max

Max. load 16 Amps

L2 (N)

Sensor/Sonde/Sensor

(No polarity/sans polarité/ninguna polaridad)

088L3380 - 06/09

Danfoss LX Danfoss LX

Cable en frío

Liaison Froide

Power lead

TEL: 866-676-8062. FAX: 905-285-2055

Danfoss LX

26

Page 30

Wall Wiring Diagram

Diagramme de câblage du mur

Digrama eléctrico de la pared

Single or double gang box

Boîte simple ou double

Caja sola o doble

Power lead in conduit

Liaison Froide dans un conduit

Cable en frío en conducto

Power lead

Liaison Froide

Cable en frío

Sonsor in conduit

Sonde dans un conduit

Sensor en conducto

Cement

Ciment

Cemento

LX mats

Flooring / Plancher / Suelo

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

27

Page 31

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

Page 32

Danfoss can accept no responsibility for possible errors in catalogues, brochures, other printed materials, and website information. Danfoss reserves the right to alter its products without

notice. This also applies to products already on order provided that such alteration can be made without subsequent changes being necessary in specifications already agreed upon. All

trademarks in this material are propert y of the respective companies. Danfoss and the Danfoss logotype are registered trademarks of Danfoss A/S. All rights reserved.

Danfoss Inc.

Toronto

Toll Free: 866-676-8062

Phone: 905-285-2050

Fax: 905-285-2055

www.LX.Danfoss.com

Danfoss

LX

BRINGING WARMTH TO LIFE

Copyright 2009 Danfoss Inc.

088L3380 - 06/09

TEL: 866-676-8062. FAX: 905-285-2055

Loading...

Loading...