Page 1

Installation guide

Stepper Valve Driver

Type EKF 1A, EKF 2A

Introduction

Stepper Valve Driver EKF series is for use where stepper motor valves must be accurately controlled,

typically in commercial air conditioning, heat pumps, commercial refrigeration and food retailing

080R0435

applications.

Technical Specificatons

Supply voltage EKF 1A: 24 V AC / DC 50 / 60 Hz

EKF 2A: 24 V AC / DC, 50 / 60 Hz

Power consumption Idle operating: < 1 W (without valve)

Power consumption for using 1 valve.

CCMT 16 – CCMT 42: 25 VA / 15 W

ETS 5M, ETS 6: 20 VA / 10 W

ETS 12C – ETS 100C, KVS C: 30 VA /15 W

ETS 12.5 – 400: 10 VA / 5 W

ETS 500P, 800P: 28 VA / 20 W

CCMT 2- CCMT 8: 10 VA / 5 W

CTR 20: 14 VA / 10 W

CCMT L: 20 VA / 10 W

When using two valves sum the power consumption of each valve.

Analog inputs

EKF 1A: 1 input AI1 0-5 V, 0-10 V, 4-20 mA, 0-20 mA

080R0435

EKF 2A: 2 inputs AI1 and AI2 0-5 V, 0-10 V, 4-20 mA, 0-20 mA

Max. 15 V Analog input voltage. Do not connect voltage sources to unpowered units

without limiting the current to analog inputs (overall 40 mA per input).

Input Impedance: >50 kΩ (Voltage Input) 120 Ω ± 2% (Current Input)

Digital outputs 1 output for EKF1A / EKF 2A: D01 (open collector), sink current max 10 mA

Valve support EKF 1A: 1 stepper motor valve output, EKF 2A: 2 stepper motor valve output

STEPPER 1: A1, A2, B1, B2

STEPPER 2: A1, A2, B1, B2

Bipolar and unipolar stepper motor output:

- Danfoss ETS/ ETS L/ KVS/ ETS C/ KVS C/ CCMT 2 – CCMT 42/ CTR/ CCM/ CCMT L Valves

- ETS 6/ ETS 5M Valves

Open circuit HW diagnostics is present.

Battery backup 1 input for EKF 1A / EKF2A: Vbat

BAT, GND: Nominal 18 – 24 V DC, Min 16 V DC - Max 28 V DC (EKE 2U

recommended)

Max. battery current: 2 A at 18 V (valve depended)

Battery alarm/warning will be activated below 16 V DC.

Enviroment

DIN Mounting 4 DIN

Storage -30 – 80 °C / -22 – 176 °F

Operating -20 – 60 °C / -4 – 140 °F

Humidity < 90% RH, non-condensing

Імпортер:ТОВ з іі "Данфосс ТОВ" 04080, Київ 80, п/с 168, Україна

© Danfoss | Climate Solutions | 2022.01

Info for UK customers only: Danfoss Ltd., 22 Wycombe End, HP9 1NB, GB

AN375548103097en-000204 | 1

Page 2

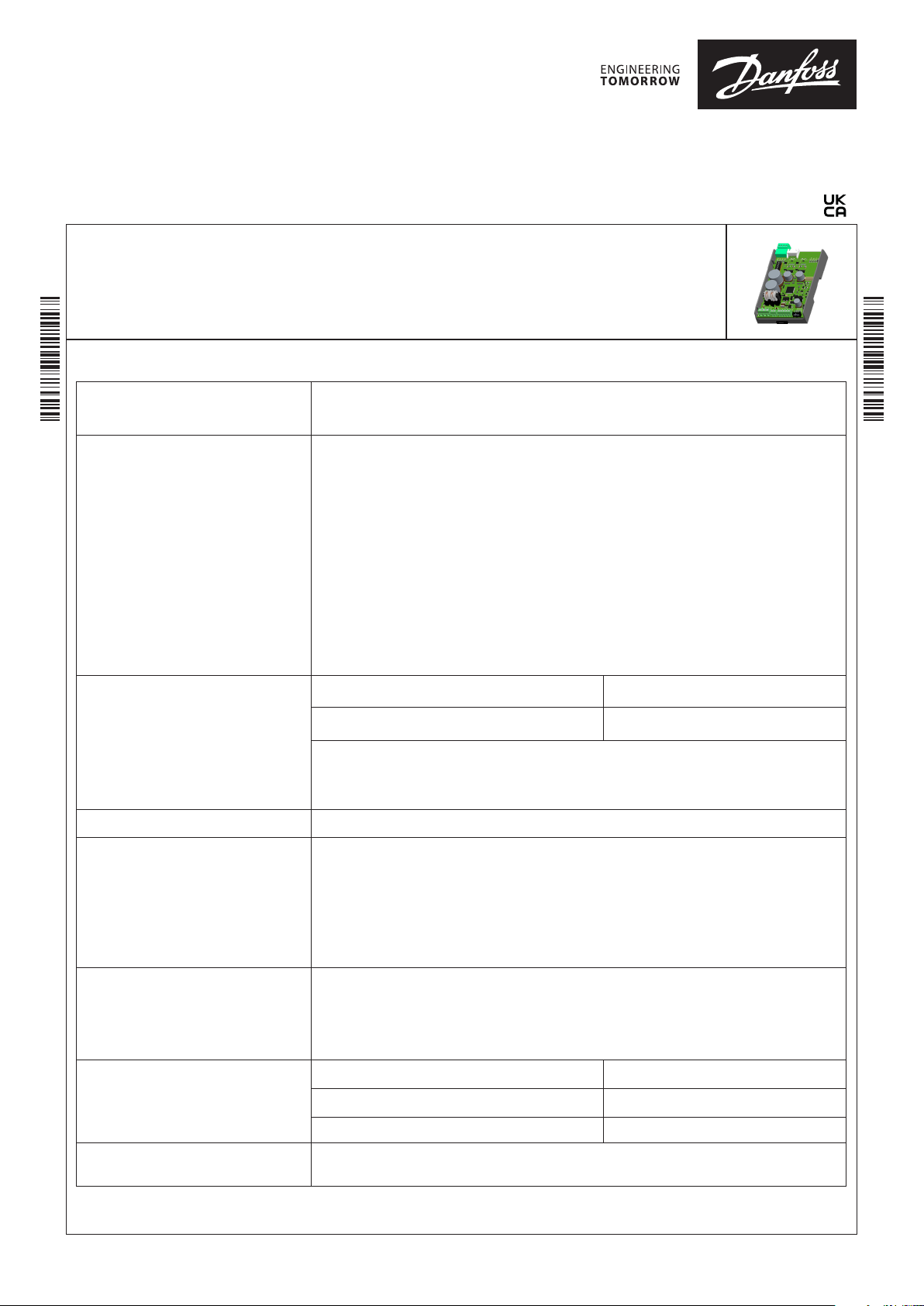

Application

Valve Driver

EKF 1A

ETS Colibri

Connection overview

EKF 1A

1 2 3 4

Analog signal AI1

Digital out

Wire Color scheme

1Green

2 Red

3 Black

4 White

EKF 2A

EKF 2A

ETS Colibri

ETS Colibri

1 2 3 4

1 2 3 4

AI 1

AI 2

Digital out

Dip Switch

Dip Switch1

Dip Switch2

AI1 Analog input 1

COM Common

Koolkey

AI2 Analog input 2 for EKF2A only

Koolkey

COM Common

Koolprog pc tool

DO1 Digital output 1

Koolprog pc tool

• Supports both Bipolar and Unipolar motor.

• Only one connection can be used, either 4 pole terminal block or JST XHP-5 pin connector.

• It is possible to share power supply with 2 EKF and battery backup if battery backup is galvanic isolated and the polarity of power

supply is maintained correct. The same should be observed while sharing power supply with EKF and master controller (AI signal)•

• Connect PE either to the or of power connector. If grounding is done in the transformer do not use EKF grounding connector.

2 | AN375548103097en-000204

© Danfoss | Climate Solutions | 2022.01

Page 3

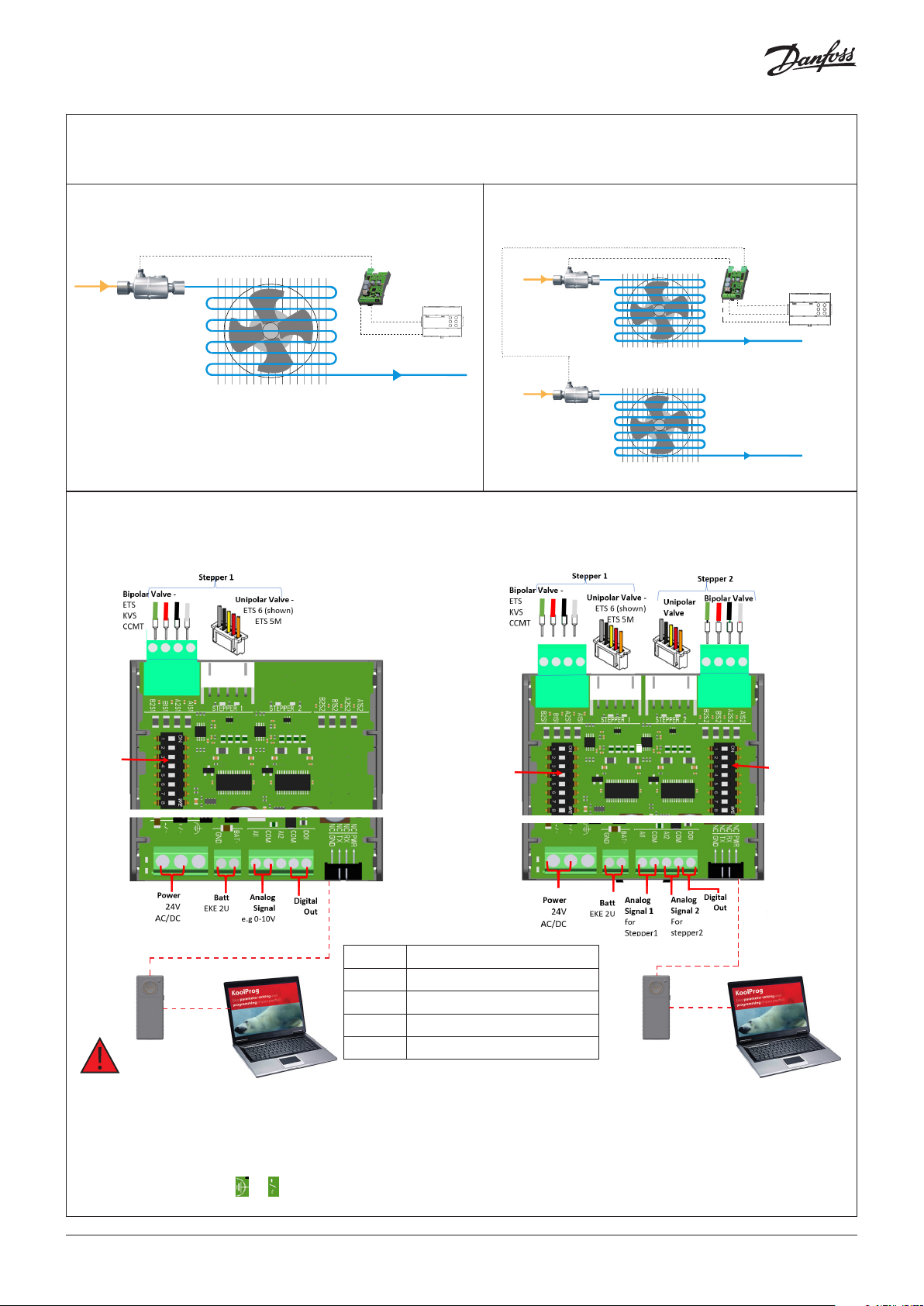

Quick set up guide

1. Disconnect power to EKF.

2. Connect Valve and Analog signal to the dedicated terminals. Select the Valve via DIP switch 1 to 5.

3. Select the required Analog signal input via DIP switch 7 and 8. For EKF 2A, perform 3 and 4 for both DIP switches.

4. Connect EKF to power and the device is ready to use

LED indication

Valve

LED for Error/Alarm

LED for Stepper 1

Valve

Two status LED per valve output

Each stepper drive has a set of Red and Green LED

as shown in image. The change in LED light with

the LED indication table can help determine the

valve movement.

RED

RED

GREEN

GREEN

RED

GREEN

RED

GREEN

0s

Power by Koolkey, no valve operation

1s

Valve movement

Valve open circuit

2s

Valve closed

Valve closing

Valve idle on target

Valve idle on target

Valve opening

Valve open

LED for Stepper 2

3 | AN375548103097en-000204

© Danfoss | Climate Solutions | 2022.01

Page 4

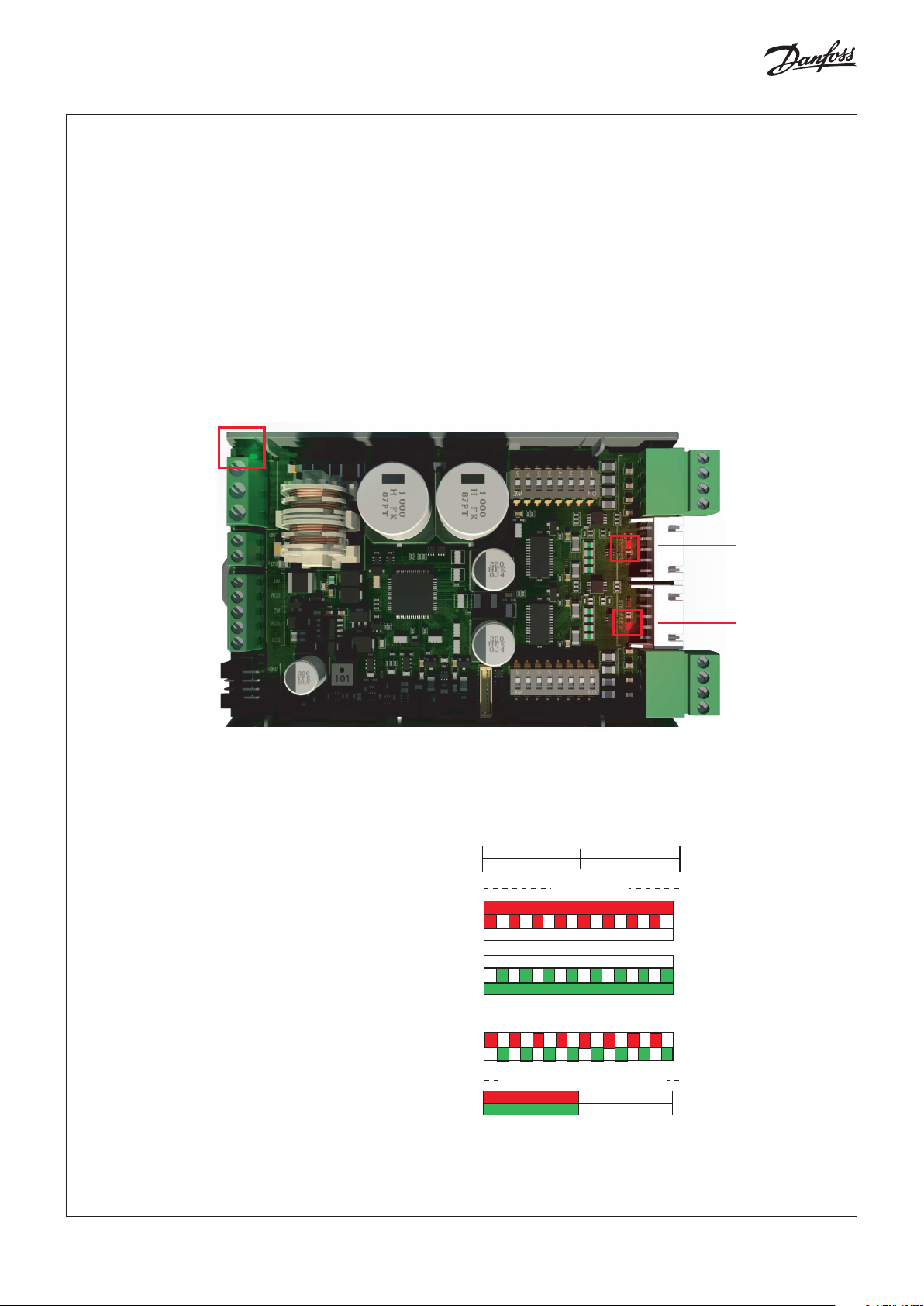

Alarm

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0s

1sec

2sec

RED

GREEN

RED

GREEN

RED

GREEN

RED

GREEN

RED

GREEN

RED

GREEN

RED

GREEN

0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 0

1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

0

1

1 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

1 0

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1

1 0

00

0

0

0

0

1

0

1

0

1 1 1

1

1

0

0

0 0

0

1

0

1

1 1 1 1

0

0

0

0

1 01

00

00

0 0

00 0

1 0

01

1 0

01 0

01

1 0101

01 0

0

0

0

11

1

11

1

1 1 1 1 1 1 1 1

0

0

1

1

0

00

10 1

0

0

01 001

0

10 1

0

0

1

10

0

10

0

0

0

0

0

0

0

0

0

00

1

0

0

0

0

No

Alarm/Warning

Alarm valve 1

Alarm valve 2

Alarm valve 1

+ valve 2

Warning valve 1

Warning valve 2

Warning valve 1

+ valve 2

Alarm/Warning LED

The image shows the position of the alarm/Warning LED.

Alarms has higher priority than warning

~/-

~/+

4 | AN375548103097en-000204

© Danfoss | Climate Solutions | 2022.01

Page 5

DIP switch

The driver has one 8-position DIP switch per stepper motor output.

Note: DIP switch must be changed during POWER OFF only, Any change during power on will not take effect until driver

switches off.

Valve selection

Configure Valve type by selecting DIP switch as shown in table below (green denotes ON).

DIP Switch

Group

Valve

No Valve (Default)

A

1 2 3 4 5 6 7 8

ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C, KVS 2C,

B

KVS 3C, KVS 5C

ETS 5M

C

ETS 6, UKV, UKV-J

D

ETS12.5, ETS 25, ETS 50, KVS15

E

ETS 100

F

ETS 250, ETS 400, KVS 42

G

Manifold Valves (ETS 500P, ETS 800P)

H

JKV

I

CCMT 2, CCMT4, CCMT8

J

CCMT 16

K

CCMT 24

L

CCMT30

M

CCMT 42

N

CCM 10, CCM 20, CCM 30

O

CCM 40

P

CTR 20

Q

CCMT 3L, CCMT 5L, CCMT 8L, CCMT 10L

R

ETS 175L, ETS 250L, ETS 400L (including oil free

S

application)

Note:

When using Manifold Valves (ETS 500P ad ETS 800P).

Dip switch of driver 1 should be selected to ETS 250/ETS 400.

Dip switch of driver 2 should be selected to Manifold Valves (ETS 500P ad ETS 800P).

See example image of Dip Switch setting

ETS 12C selected

ETS 12C with 0-5 V AI input

0-5 V AI input 0-10 V AI input

5 | AN375548103097en-000204

ETS 12C with 0-10 V AI input

© Danfoss | Climate Solutions | 2022.01

Page 6

Analog input selection

Congure Analog signal type by selecting DIP switch as shown in below table (green denotes ON).

Analog Input DIP Switch

1 2 3 4 5 6 7 8

0 - 10 V (Default)

0 - 5 V

4 - 20 mA

0 - 20 mA

Analog input sharing

Congure analog input to be shared if needed as below (green denotes ON).

Stepper driver 1

Analog Input AI1

Analog input AI2

1 2 3 4 5 6 7 8

DIP Switch

Stepper driver 2

Analog Input AI1

Analog input AI2

Digital output signal

One digital output is present in EKF and only alarm activates the output.

Output type Similar to NPN, open collector

Load type Resistive only

Maximum allowed current 10 mA

Maximum Voltage 28 V (allow 24 V DC + 15%)

Stepper Motor Output

• The stepper motor is connected to the “Stepper Valve” terminals (see connection overview) with a standard M12

connection cable or JST XHP-5 connector.

• The default valve setting in EKF 1A/2A is: No Valve.

• The correct valve must be dened as per section DIP Switch – Valve

Valve Cable Connection

Danfoss recommends to use ETS 5M and ETS 6 valves to be connected to JST XHP-5 pin connectors instead of 4 pole terminal

block, but it is possible to connect to terminal block, follow color codes of wires of coil as shown in table below.

Stepper valve ETS/KVS/CCM/ CCMT/CTR/ CCMT L ETS 5M ETS 6

A1 White Brown Orange

A2 Black Black Yellow

B1 Red Orange Red

B2 Green Yellow Black

1 2 3 4 5 6 7 8

DIP Switch

While using JST 5pin, its plug and play for ETS 6 and ETS 5M valves.

Guideline for long M12 cables for Danfoss stepper motor valves

• Long cables will lead to degradation of performance.

• Cable length for stepper motor connection must be less than 30 m.

• Danfoss recommends to use 4-20 mA signal for long distances and use shorter cable between driver and valve.

6 | AN375548103097en-000204

© Danfoss | Climate Solutions | 2022.01

Page 7

General features and Warnings

Plastic housing:

• DIN rail mounting complying with EN 60715

• Self-extinguishing V0 according to IEC 60695-11-10 and glowing/hot wire test at 960 °C according to IEC 60695-2-12

CE COMPLIANCE

- Operating conditions CE: -20T60, 90% RH non-condensing

- Storage conditions: -30T80, 90% RH non-condensing

- Electromagnetic compatibility EMC: 2014/30/EU with the following norms,

- EN 61000-6-2:2005, Generic standards - Immunity for industrial environments (AC and DC voltage supply)

- EN 61000-6-3+A1:2011 and EN 61000-6-3:2007, Generic standards - Emission standard for residential, commercial and

light-industrial environments (DC voltage supply only)

- EN 61000-6-4:2019 and EN 61000-6-4:2007+A1, Generic standards – Emission standard for industrial environments

(AC and DC voltage supply)

GENERAL WARNINGS

- Every use that is not described in this manual is considered incorrect and is not authorized by the manufacturer

- Verify that the installation and operating conditions of the device respect those specied in the manual, especially concerning the

supply voltage and environmental conditions

- All service and maintenance operations must be performed by qualied personnel

- The device must not be used as a safety device

- Liability for injury or damage caused by the incorrect use of the device lies solely with the user

INSTALLATION WARNINGS

- Recommended mounting position: vertical

- Installation must comply with local standards and legislation

- Before working on the electrical connections, disconnect the device from the main power supply

- Before carrying out any maintenance operations on the device, disconnect all electrical connections

- For safety reasons the appliance must be tted inside an electrical panel with no live parts accessible

- Do not expose the device to water sprays or to a relative humidity greater than 90%.

- Avoid exposure to corrosive or pollutant gases, natural elements, environments where explosives or mixes of

ammable gases are present, dust, strong vibrations or shock, large and rapid uctuations in ambient temperature

that might cause condensation in combination with high humidity, strong magnetic and/or radio interference

(e.g. transmitting antennae)

- Use cable ends suitable for the corresponding connectors. After tightening connector screws, tug the cables gently to check their

tightness

- Minimize the length of probe and digital input cables as much as possible, and avoid spiral routes around power

devices. Separate from inductive loads and power cables to avoid possible electromagnetic noises

- Avoid touching or nearly touching the electronic components on the board to avoid electrostatic discharges

PRODUCT WARNINGS

• Use a class II power supply.

• Connecting any EKF ports to mains voltage will permanently damage the controller.

• Battery backup terminals do not generate power to recharge a device connected.

• Battery backup - the voltage will close the stepper motor valves if the controller loses its supply voltage.

7 | AN375548103097en-000204

© Danfoss | Climate Solutions | 2022.01

Loading...

Loading...