Page 1

User Guide

Stepper valve driver

Type EKF 1A, EKF 2A

Driver for stepper motor valves SW V1.24

Page 2

Stepper valve driver, type EKF 1A, EKF 2A

Introduction

Stepper valve driver EKF series is used where stepper valves must be accurately controlled typically in commercial

air conditioning, heat pumps, commercial refrigeration and food retail applications.

Features

• Support both Bipolar and Unipolar stepper motor valves

• Driven by analog input signal

• Fast installation and setup

• Lost step prevention

• Open circuit detection

• LED indication for valve movement and alarm/warnings

• On board DIP switch for quick selection

• Plug and play

• 4 pole terminal block and JST-XHP 5 pin connections

• Phoenix connector terminals

• Digital output for alarm signal

• 1 and 2 valve driver version available

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 2

Page 3

Features

EKF 1A

EKF 2A

Code number

080G5030

080G5035

Power supply

24 V AC/DC

24 V AC/DC

Number of valves

1 stepper motor valve

2 stepper motor valves

Valve type

Unipolar/Bipolar

Unipolar/Bipolar

Analog inputs

1

2

Digital outputs

1

1

Dip switch

1

2

Battery backup support

Yes

Yes

Mounting

35 mm, 4 DIN

35 mm, 4 DIN

Dimension (H x W)(mm)

110 x 70

110 x 70

EKE 2U Backup power module

Power supply

EKE 2U Backup power module ensures sucient power in case of power failures

to the controller / driver to ensure closure of the electronic valves.

AK-PS

Input: 100 - 240 V AC/45 - 65 Hz

Output: 24 V DC: available with 18 VA, 36 VA and 60 VA

ACCTRD

Input: 230 V AC, 50 - 60 Hz

Output: 24 V AC, available with 12 VA, 22 VA and 35 VA

Stepper valve driver, type EKF 1A, EKF 2A

Portfolio overview

Table 1: Portfolio overview

Table 2: Related Products

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 3

Page 4

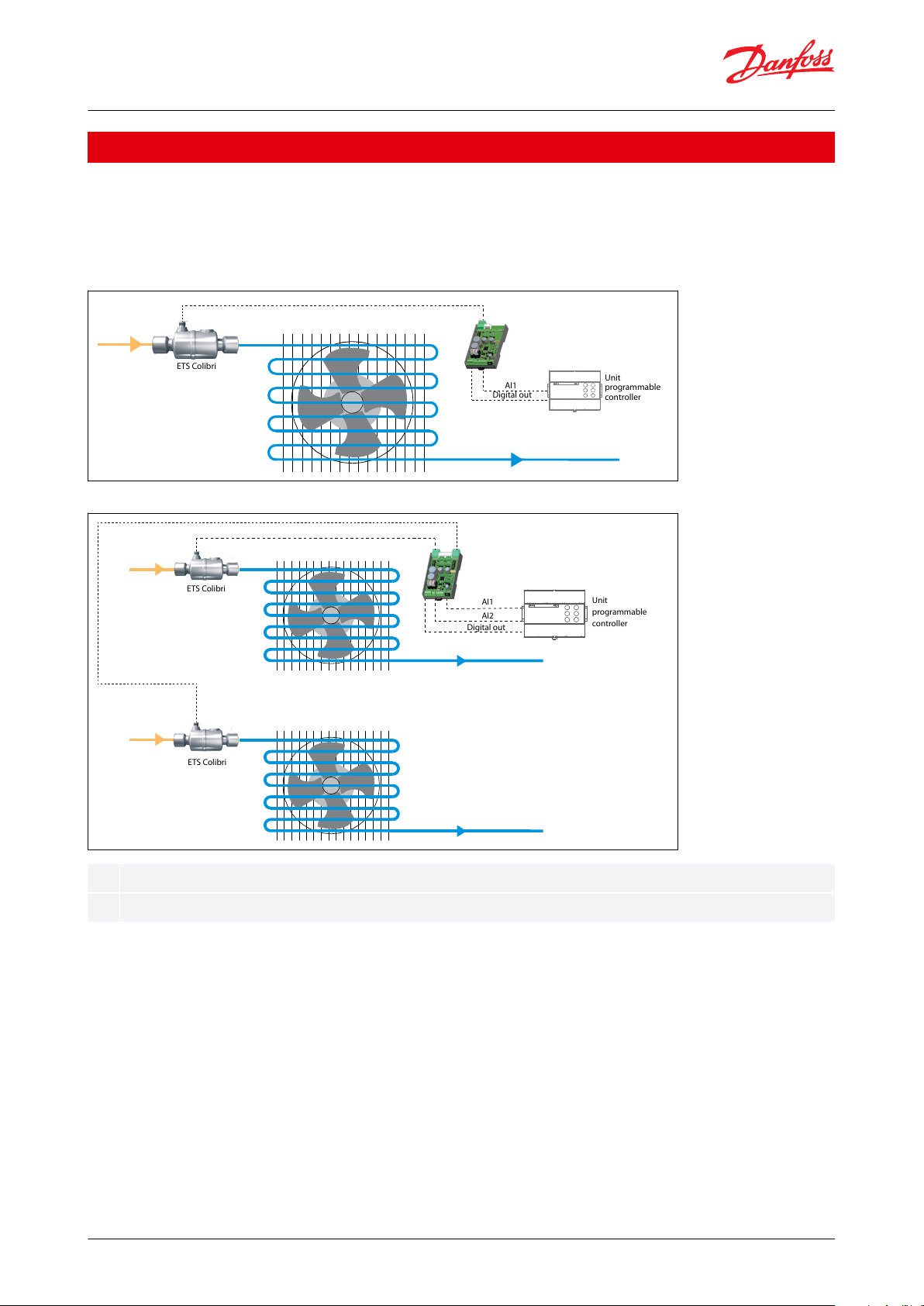

AI1

AI2

Unit

programmable

controller

ETS Colibri

AI1

Digital out

ETS Colibri

AI1

AI2

ETS Colibri

Digital out

Unit

programmable

controller

Analog input signal 1

Analog input signal 2

Stepper valve driver, type EKF 1A, EKF 2A

Applications

EKF series stepper valve drivers can be used in application where accurate control of stepper motor valves are

needed using analog input signals (0-10V, 0-5V, 4-20 mA, 0-20 mA) from unit programmable controllers. The

product can be used for both Bipolar and Unipolar type valves. General applications include use in commercial air

conditioning, heat pumps, commercial refrigeration and food retail application

Figure 1: EKF 1A

Figure 2: EKF 2A

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 4

Page 5

Either JST or 4

pin should be

used

JST XHP 5

pin for ETS

5m & ETS 6

M12 cable from

stepper motor

to 4 pin

terminal

For stepper Valve 1

output

stepper Valve 1 DIP

SWITCH

EKE 2U Battery Backup

Koolkey

24V ± 20%

AC/DC

supply

source

Battery connection

KoollProg PC tool

Digital Output (DO) -> Relay/PLC

Analog Input (Al1), [0-5V, 0-10V, 0-20mA, 4-20mA

M12 cable from

stepper motor

to 4 pin

terminal

Either JST or 4

pin should be

used

JST XHP 5 pin

for ETS 5m &

ETS 6

For stepper Valve 1

output

stepper Valve 1 DIP

SWITCH

24V ± 20%

AC/DC

supply

source

Battery connection

KoollProg PC tool

Koolkey

Digital Output (DO) -> Relay/PLC

Analog Input (Al1), [0-5V, 0-10V, 0-20mA, 4-20mA

Analog Input (Al2), [0-5V, 0-10V, 0-20mA, 4-20mA

For stepper Valve 2

output

stepper Valve 2 DIP

SWITCH

Stepper valve driver, type EKF 1A, EKF 2A

Installation

Wiring terminals

Figure 3: EKF 1A

Figure 4: EKF 2A

NOTE:

There are both 4 pin terminal and JST 5 pin terminal available on the board per stepper drive output.

Only one of the terminals should be used per valve.

Do not connect valves to both 4 pin terminal and JST terminal of the same stepper driver output.

Power sharing

EKF can share power from the same source with a battery backup or unit controller only if battery backup/unit

controller ports are galvanically isolated.

Danfoss recommends to use EKE 2U as the preferred battery backup device.

NOTE:

EKE 2U can only support 2 valves for emergency closing, thus EKE 2U should not be shared with more than one EKF

2A or more than two EKF 1A.

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 5

Page 6

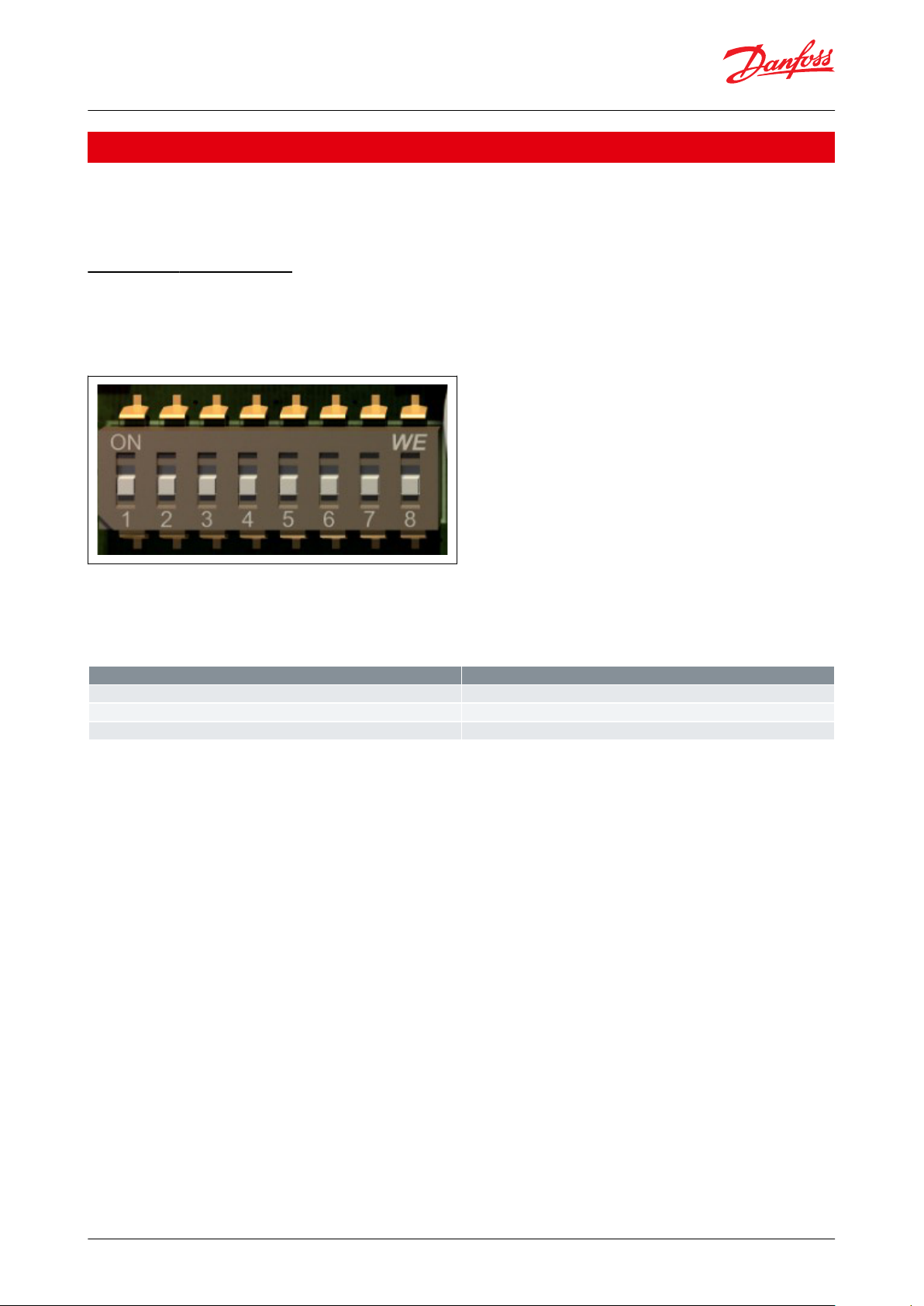

Switch numbers

Selection

Switch 1-5

Valve selection

Switch 6

Analog sharing selection

Switch 7 & 8

Analog signal selection

Stepper valve driver, type EKF 1A, EKF 2A

Conguration

EKF can be congured using

1.

DIP switch

2.

Koolkey & KoolProg PC tool

DIP Switch conguration

The basic product conguration can be done through DIP switch present on the hardware.

EKF 1A supports 1 stepper drive output and 1 Dip switch for settings.

EKF 2A supports 2 stepper drive output and 2 Dip switch for settings.

Figure 5: DIP switch

The image above shows a schematic of a dip switch

Each DIP switch consists of 8 switches.

The below table shows what each Dip switch section represents.

Table 3: Dip switch section

Steps to follow to congure EKF using Dip switch:

1.

Disconnect the EKF from power supply.

2.

Connect the valves and AI inputs to EKF.

3.

Make the needed settings on the EKF dip switch.

4.

Turn the power back on to EKF.

5.

EKF is ready to use with the new settings

NOTE:

Any changes made to EKF dip switch while EKF is powered ON will result in warning and the new settings are not

active. In case of the above error switch the power OFF and then ON the EKF. The newly made settings will now be

active.

The tables below can be used to help select dip switch positions.

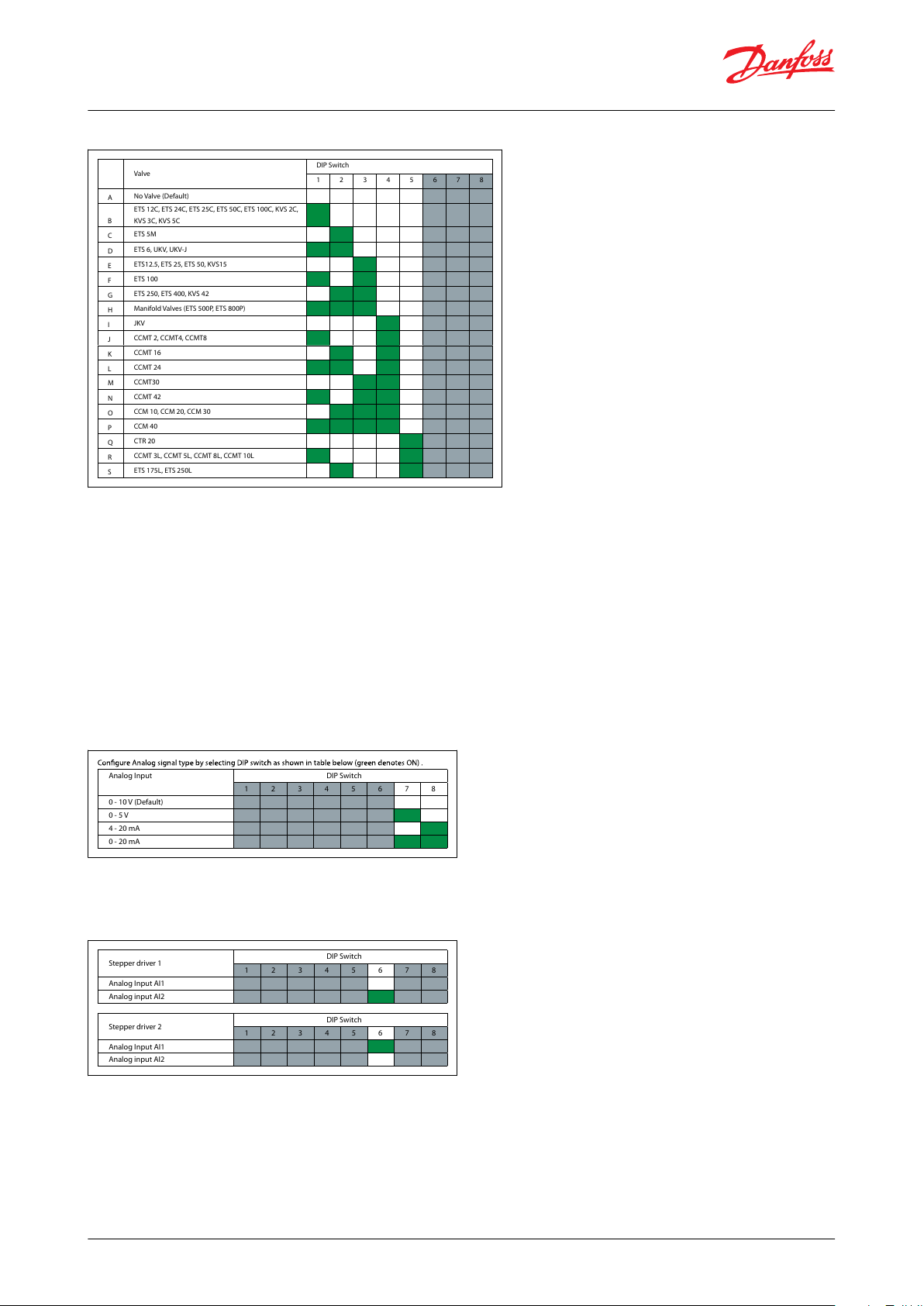

Valve selection (Switch 1-5)

Green denotes ON position of DIP switch

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 6

Page 7

Valve

DIP Switch

1 2 3 4 5 6 7 8

A

No Valve (Default)

B

ETS 12C, ETS 24C, ETS 25C, ETS 50C, ETS 100C, KVS 2C,

KVS 3C, KVS 5C

C

ETS 5M

D

ETS 6, UKV, UKV-J

E

ETS12.5, ETS 25, ETS 50, KVS15

F

ETS 100

G

ETS 250, ETS 400, KVS 42

H

Manifold Valves (ETS 500P, E TS 800P)

I

JKV

J

CCMT 2, CCMT4, CCMT8

K

CCMT 16

L

CCMT 24

M

CCMT30

N

CCMT 42

O

CCM 10, CCM 20, CCM 30

P

CCM 40

Q

CTR 20

R

CCMT 3L, CCMT 5L, CCMT 8L, CCMT 10L

S

ETS 175L, ETS 250L

Analog Input DIP Switch

1 2 3 4 5 6 7 8

0 - 10 V (Default)

0 - 5 V

4 - 20 mA

0 - 20 mA

Stepper driver 1

DIP Switch

1 2 3 4 5 6 7 8

Analog Input AI1

Analog input AI2

Stepper driver 2

DIP Switch

1 2 3 4 5 6 7 8

Analog Input AI1

Analog input AI2

Stepper valve driver, type EKF 1A, EKF 2A

Figure 6: DIP valve section

NOTE:

Only applicable for EKF 2A When using Manifold valves.

Dip switch 1 for stepper driver 1 should be selected to base valve type.

Eg: ETS C should be selected in Dip switch 1 if ETS Colibri is used in manifold operation.

ETS 250/400 should be selected if using ETS 500P/ETS 800P.

Dip switch 2 for stepper driver 2 should be selected as manifold valve (Group H).

While setting Dip switch 2 as manifold valve EKF automatically recognize that it is using only 1 Analog input to

control both valves and by default AI1 is used as the analog input. Analog sharing function is automatically

activated.

Analog input selection (Switch 7 & 8)

Green denotes ON position of DIP switch

Figure 7: DIP analog input selection

Analog sharing selection (Switch 6)

Green denotes ON position of DIP switch

Figure 8: DIP analog sharing selection

NOTE:

Analog sharing is used only in EKF 2A.

Analog sharing can be done to run 2 valves using the same analog input.

If stepper driver 1 should use analog input from AI2 (AI2 is meant for stepper driver 2 analog input).

Then Dip switch 1 should have switch 6 at position ON.

EKF 2A will then use AI2 signal to control stepper valve 1.

If stepper driver 2 should use analog input from AI1 (AI1 is meant for stepper driver 1 analog input).

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 7

Page 8

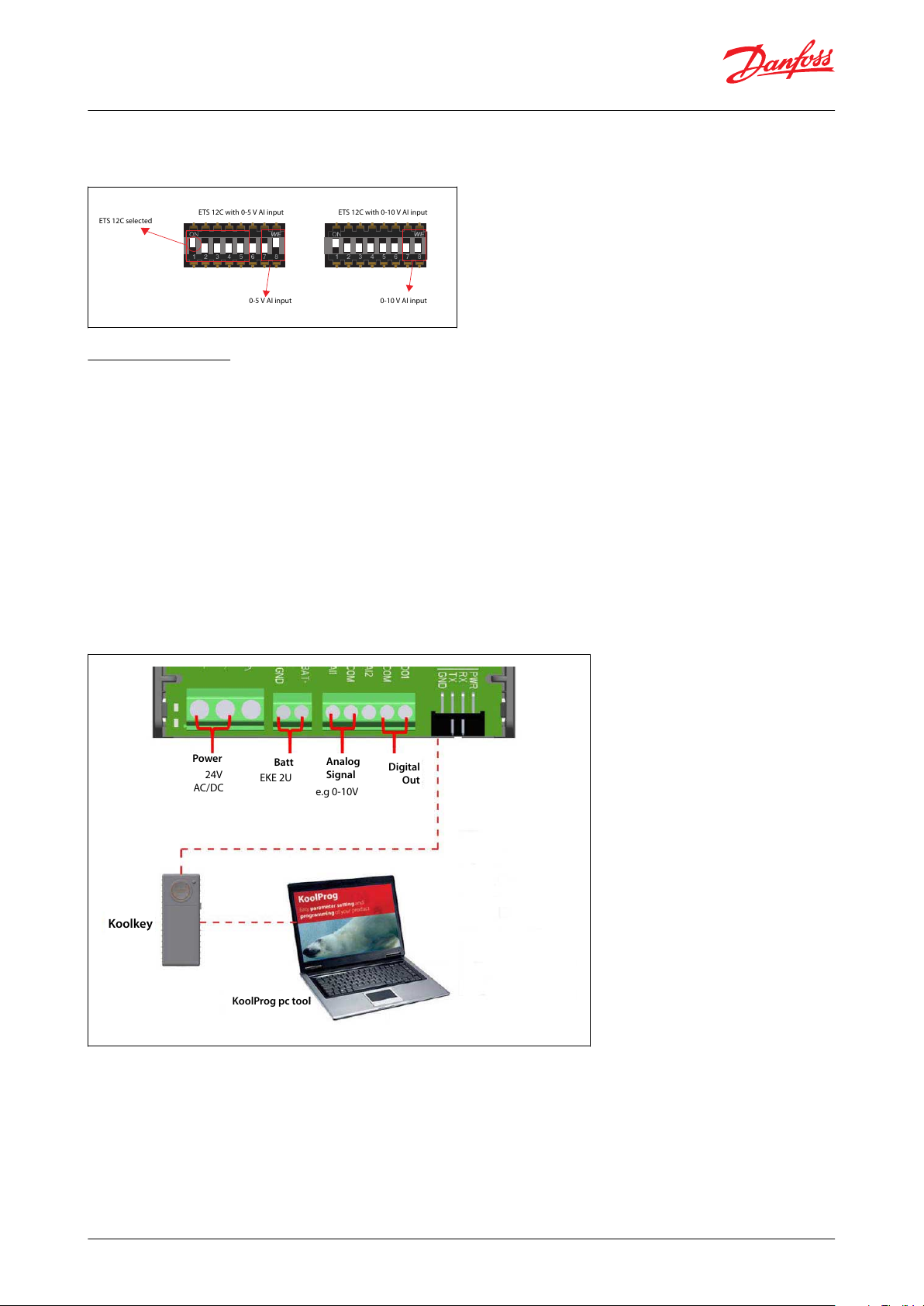

ETS 12C with 0-5 V AI input

ETS 12C selected

ETS 12C with 0-10 V AI input

0-5 V AI input

0-10 V AI input

Power

Batt

Analog

Signal

Digital

Out

KoolProg pc tool

Koolkey

24V

AC/DC

EKE 2U

e.g 0-10V

Stepper valve driver, type EKF 1A, EKF 2A

Then Dip switch 2 should have switch 6 at position ON.

EKF 2A will then use AI1 signal to control stepper valve 2.

Figure 9: DIP switch setting

Connecting to PC

EKF Series stepper drivers can be connected to PC for

1.

Accessing and changing advanced settings

2.

Accessing alarm/warning and diagnostic readouts

3.

Performing service

If the advanced parameter settings are not needed, the product can be set using Dip switch only.

While using the Dip switch option a connection to PC is not required.

To connect EKF to pc the below tools are needed

1.

KoolProg PC software (Check KoolProg website if the version supports EKF)

2.

Koolkey

3.

Cables to connect Koolkey to PC and EKF(available as Koolkey accessory)

The schematic below shows how to connect EKF with Koolkey and PC

Figure 10: EKF with Koolkey and PC

Steps to follow while connecting EKF to KoolProg:

1.

Connect EKF to power, make sure power is ON

2.

Connect Valve and input signals to EKF.

3.

Connect Koolkey to EKF and PC

4.

Select On-line service option in Koolprog.

5.

Select SW Main switch to OFF

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 8

Page 9

Stepper valve driver, type EKF 1A, EKF 2A

6.

Make necessary changes to parameters from drop down lists.

7.

After completing all changes set SW Main switch to ON.

8.

EKF is ready to use with the new settings.

Figure 11: On-line service

NOTE:

To make changes to the settings of EKF using Koolkey/KooProg software, the SW main switch should be OFF.

By default EKF looks at DIP switch for the settings. If settings are altered to use values for Koolprog then EKF will look

at Koolprog settings only and not follow changes in DIP switch. To use DIP switch again, EKF should be changed

back to use DIP switch settings using Koolprog

EKF can be congured using PC with the use of Koolkey and Koolprog PC tool.

The KoolProg tool should be used for making advanced selection and setting of EKF.

There are 2 main sections in Koolprog for EKF conguration:

1.

Basic setting

2.

Valve driver setting

Basic setting

Figure 12: Basic setting

Basic setting – Generic

Main Switch - Main

Main switch should be OFF while making changes to parameters and must be turned back ON to have the settings

made active.

Battery alarm enable – B000

This parameter should be used to set battery alarm ON/OFF.

Turning it on will enable alarm through DO(Digital output) when battery voltage is low.

Factory reset – B001

This parameter should be used to factory reset EKF, When full reset of all parameters are required

Relay position – B002

This parameter should be kept at position Auto.

There is an option to force open and close the alarm.

This parameter should be used as service test to see if alarm activates and communicates through DO (Digital

output).

Basic setting – Driver

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 9

Page 10

Stepper valve driver, type EKF 1A, EKF 2A

Driver enabling – B100

This parameter should be used to turn ON/OFF driver output.

When OFF is selected EKF will not drive valve connected to corresponding stepper output.

Valve selection – B101

This parameter is used to select which valve the stepper output is connected to and which setting

(DIP switch or KoolProg) that EKF has to follow.

When set to Dip switch EKF reads the setting made on DIP switch.

When set to User dened, Additional parameters will be visible in valve driver setting.

This should be used when conguring valves that are not preset into EKF.

When set to groups, EKF will recognize the valves according to the group naming

Valve position mode – B102

This parameter is used to select which input EKF should use to position the valve.

When selecting from AI, EKF will read the AI input and move valve accordingly.

When selecting from register, an additional parameter valve position will be visible.

According to the valve position % (OD%) EKF will move the valve.

Figure 13: Basic setting - Driver1

NOTE:

Valve position mode: From register is only used for service and check purpose.

Basic setting – Valve analog input

AI selection -B104

This parameter is used to set if EKF has to use Dip switch for AI selection or from Koolprog.

When selected to Dip switch EKF will read the dip switch setting.

When selected to other inputs from drop down list EKF will not read from Dip switch instead will use setting

selected here.

AI calibration oset V - B105

This parameter is used to oset 0 - 10 V, 0 - 5 V AI input signal

AI calibration oset mA – B106

This parameter is used to oset 4 - 20 mA, 0 - 20 mA AI input signal

Figure 14: Valve driver setting

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 10

Page 11

Opening

Degree

(OD)

Overdrive

Overdrive

Time

Overdrive block time (V117)

Overdrive enable OD (V116)

V116 criteria fulfilled

V117 criteria not fulfilled

Valve OD <1 % not fulfilled

No overdrive

V116 criteria fulfilled

V117 criteria not fulfilled

Valve OD <1 % not fulfilled

Execute overdrive

Stepper valve driver, type EKF 1A, EKF 2A

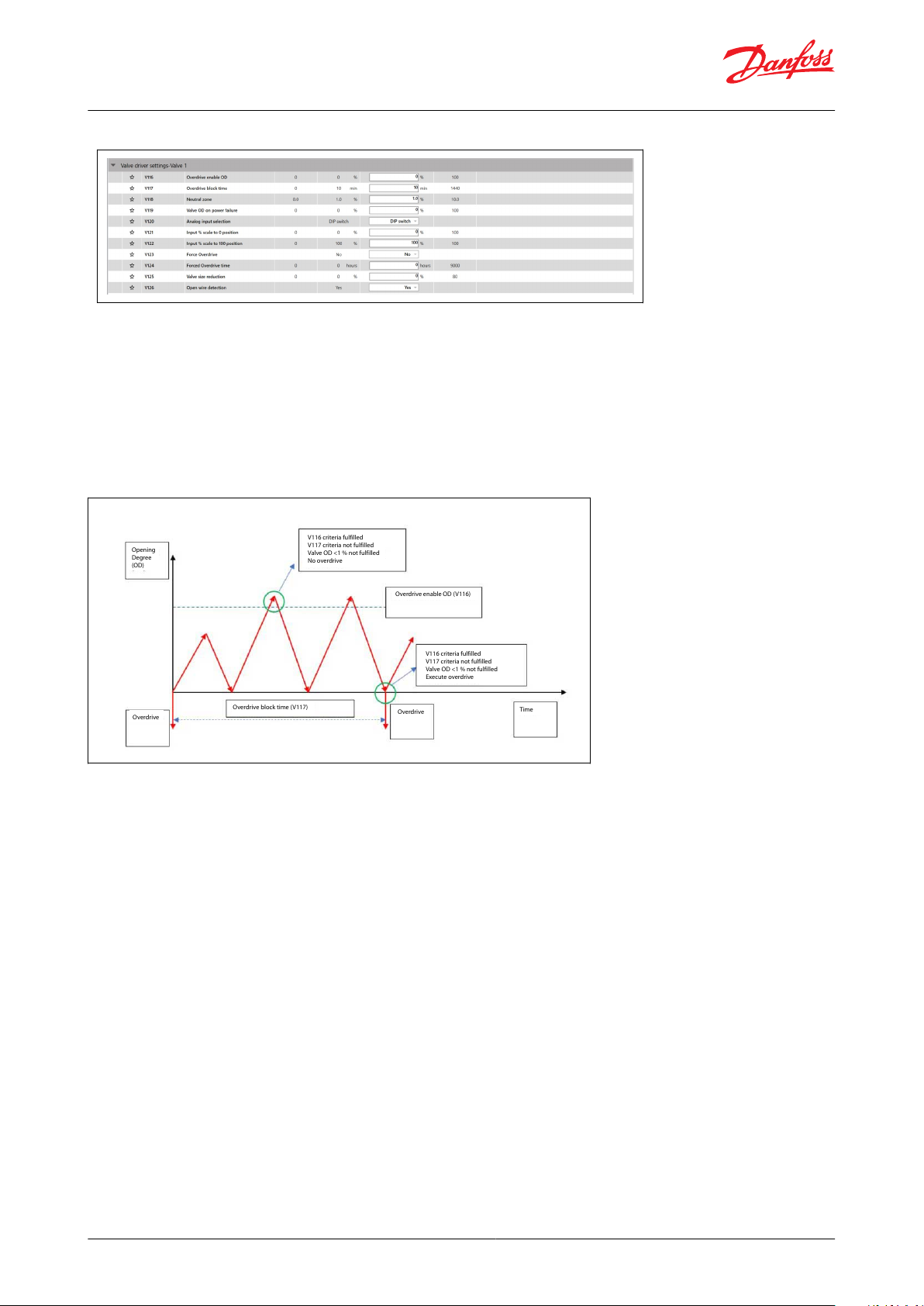

Figure 15: Valve driver setting - valve 1

Overdrive

Overdrive features are necessary to help driver calibrate the valve position and prevents accumulation of loss of

step.

Overdrive will close the valve with extra number of steps towards closing direction.

The number of additional steps for overdrive is valve depended. While using Danfoss valves from

valve selection list number of steps for overdrive is automatically set.

For third party products this should be set as a parameter inside user dened valve.

Excess overdrive will increase valve wear rate.

Figure 16: EKF overdrive

Overdrive enable OD – V116

This parameter denes the opening degree that triggers an overdrive. If the actual opening degree of the valve

crosses the overdrive enable OD then the driver will be ready for an overdrive the next time the valve actual

opening degree reaches below 1% opening degree

Overdrive block time - V117

This parameter denes the time block between 2 consecutive overdrives

Neutral zone – V118

Valve neutral zone limits the driver from moving the valve from its position if the dierential between the current

valve position to the new position of the valve is within this percentage. This limits the valve from changing position

for small variations in incoming analog signals

By defualt Neutral zone is 1% that is any change in valve opening degree from reference of +0.5% will not move the

valve. Any change above this band will move the valve to the new position.

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 11

Page 12

Opening

Degree

(OD)

Overdrive

Forced overdrive time V124

Overdrive

Time

Valve position back as per

AI signal

V123 = Yes

V124 criteria fulfilled

Execute overdrive

Stepper valve driver, type EKF 1A, EKF 2A

Figure 17: Forced overdrive

Forced Overdrive – V123

Forced overdrive is use to trigger an overdrive purely based on time. The driver will move the valve to 0 position

with overdrive and immediately come back to the requested position from analog signal

Forced overdrive time – V124

Forced overdrive time is a timer for forced overdrive.

Forced overdrive has highest priority and will overrule overdrive block time V117.

Overdrive block time V117 will be reset after forced overdrive is made.

After forced overdrive valve will return back to last position.

Valve OD on power failure – V119

This parameter sets the opening degree to which the driver should position the valve during an emergency closing

has been done due to power failure

Analog input selection – V120

This parameter is used to select which analog input signal EKF should use to position the valve. If Dip switch is

selected then EKF will read the settings made at dip switch else it will use as per the selection made in software.

Valve scaling

EKF has parameter that can scale valve opening degree to the input analog signal.

Input % scale to 0 position – V121

In normal operation EKF will linearly control valve from 0 – 100 % opening degree corresponding to 0 – 10 V analog

signal.

When input scaling is done from 0 position the Analog input is scaled towards this range.

Eg: If V121 is 0 then valve will move 0 – 100% opening degree with 0 – 10 V.

If V121 is 10 then valve will move 10 – 100% opening degree with 0 – 10 V

Input % scale to 100 position – V122

In a normal operation EKF will linearly control valve from 0 – 100 % opening degree corresponding to 0 – 10 V

analog signal.

When input scaling is done from 100 position the Analog input is scaled towards this range.

Eg: If V122 is 100 then valve will move 0 – 100% opening degree with 0 – 10 V.

If V121 is 90 then valve will move 0 – 90% opening degree with 0 – 10 V

Valve size reduction - V125

This parameter can help reduce oversized valves in application.

If V125 is 0 then valve size is 0 – 100% of opening degree

If V125 is 10 then valve size is 0 – 90% of opening degree

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 12

Page 13

V125 - Valve Size reduction

V121 - Input % scale to 0 position

V122 - Input % scale to 100 position

V120 - Analog input selection

B105 AI calibration offset V

B106 AI calibration offset mA

AI = 0-100%

OD% = scaled by Ai

(limit: 0-100%)

Step = OD% * steps *

size%

Valve steps

0-10V / 0-20mA

V122 - Scale 100 pos.

100

0

0

100

V121 - Scale 100 pos.

10-0V for 0-100% valveOD

Valve 1: 0-6V for 0-100%

Default: 0-10 for 0-100% valveOD

Valve 2: 5,5V - 10V for 0-100%

OD%

AI %

Stepper valve driver, type EKF 1A, EKF 2A

Figure 18: EKF valve

Open wire detection – V126

This parameter is used to switch on and o the open wire detection. This helps detect if there is any open wire or

discontinuity in stepper coil connection

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 13

Page 14

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

DRIVER 1

B100

Driver enabling

1 = On

0=O;1=On

0:Parameter conguration allowed for update; 1:Normal operation

B101

Valve selection

0 = DIP Switch

DIP switch, User dened,

Group B, Group C, Group D,

Group E, Group F, Group G,

Group H, Group I, Group J,

Group K, Group L, Group M,

Group N, Group O, Group P,

Group Q, Group R, Group S

0:Valve selection by DIP switch;

1 – 19:DIP switch set by parameter

B102

Valve positioning mode

0 = From AI

0=From AI;1=From register

0:Analog input; 1:parameter

B103

B103

Valve position

0

1000%

Manual opening degree set by

parameter (B102 = AI)

ANALOG INPUT 1

B104

AI selection

0 = DIP switch

0=DIP switch;1=0 – 10 V; 2=0

– 5 V; 3=4 – 20 mA; 4=0 – 20

mA

0:Type selection by DIP switch; 1

– 4: Type selection by parameter

B105

AI calibration oset V

-110

V

Oset added to measured signal

B106

AI calibration oset mA

-220

mA

Oset added to measured signal

DRIVER 2

B200

Driver enabling

1 = On

0=O;1=On

0:Parameter conguration allowed for update; 1:Normal operation

B201

Valve selection

0 = DIP Switch

DIP switch, User dened,

Group B, Group C, Group D,

Group E, Group F, Group G,

Group H, Group I, Group J,

Group K, Group L, Group M,

Group N, Group O, Group P,

Group Q, Group R, Group S

0:Valve selection by DIP switch;

1 – 31:DIP switch set by parameter

B202

Valve positioning mode

0 = From AI

0=From AI;1=From register

0:Analog input; 1:parameter

B203

B203

Valve position

0

1000%

Manual opening degree set by

parameter (B202 = AI)

ANALOG INPUT 2

B204

AI selection

0 = DIP switch

0=DIP switch; 1=0 – 10 V;

2=0 – 5 V; 3=4 – 20 mA; 4=0

– 20 mA

0:Type selection by DIP switch; 1

– 4: Type selection by parameter

B205

AI calibration oset V

-110

V

Oset added to measured signal

B206

AI calibration oset mA

-220

mA

Oset added to measured signal

GENERIC

B000

Battery alarms enable

0 = O

0=O;1=On

0:No Alarm; 1:Alarm based on

battery voltage

B001

Factory reset

0 = No

0=No;1=Yes

0:No; 1:Yes,Reset all parameters

to factory settings

B002

Relay position

0 = Auto

0=Auto;1=Open;2=Close

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

VALVE 1

V100

User dened Motor type

0 = Unipolar

0=Unipolar; 1=Bipolar

Type of motor used in the stepper valve (Unipolar/Bipolar).

V101

User dened Decay mode

0 = Fast

0=Fast; 1=Slow; 2=Mixed

Fast decay mode causes a rapid

reduction in inductive current

and allows the motor to coast

toward zero velocity. Slow decay mode leads to a slower reduction in inductive current but

produces rapid deceleration.

Stepper valve driver, type EKF 1A, EKF 2A

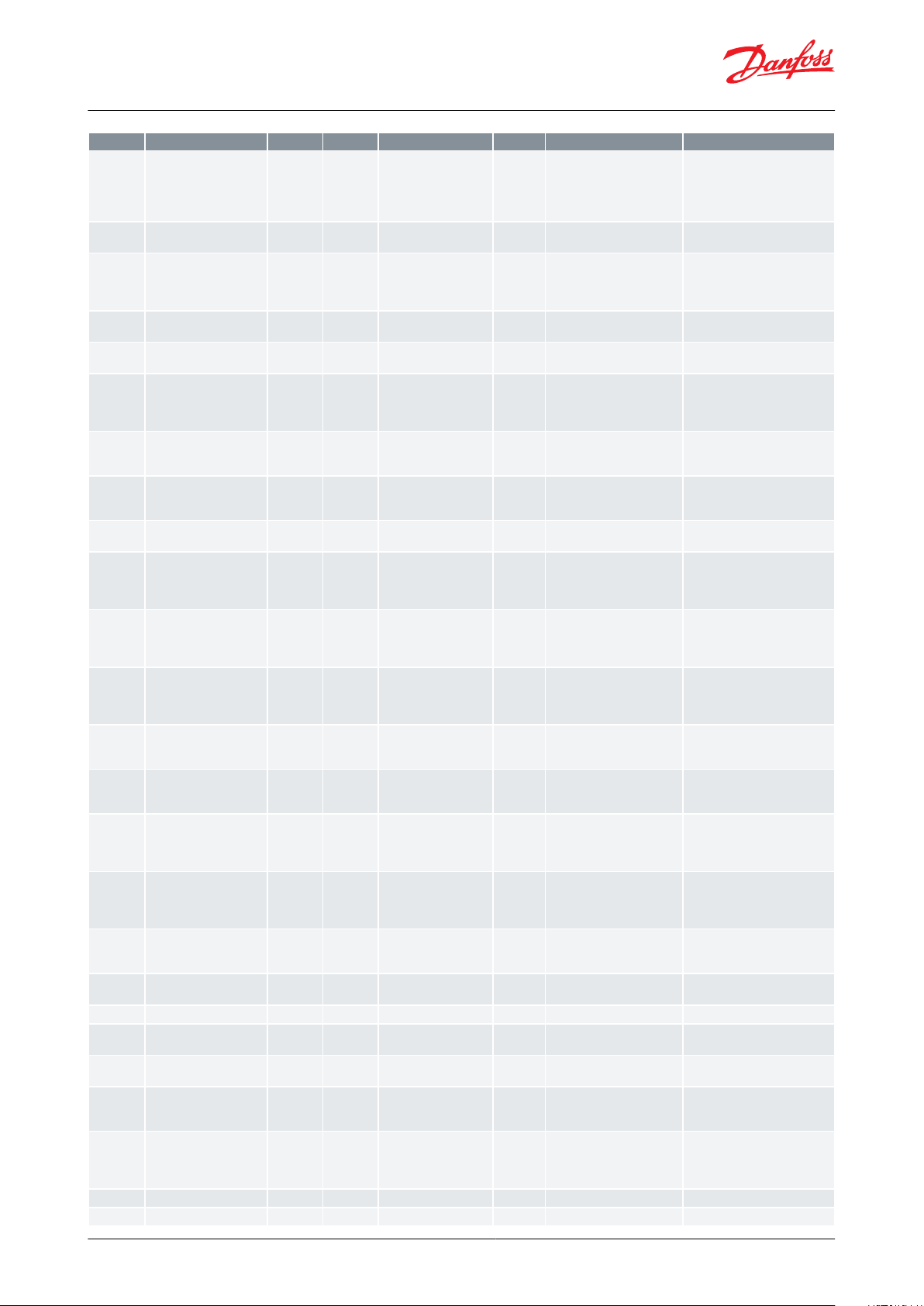

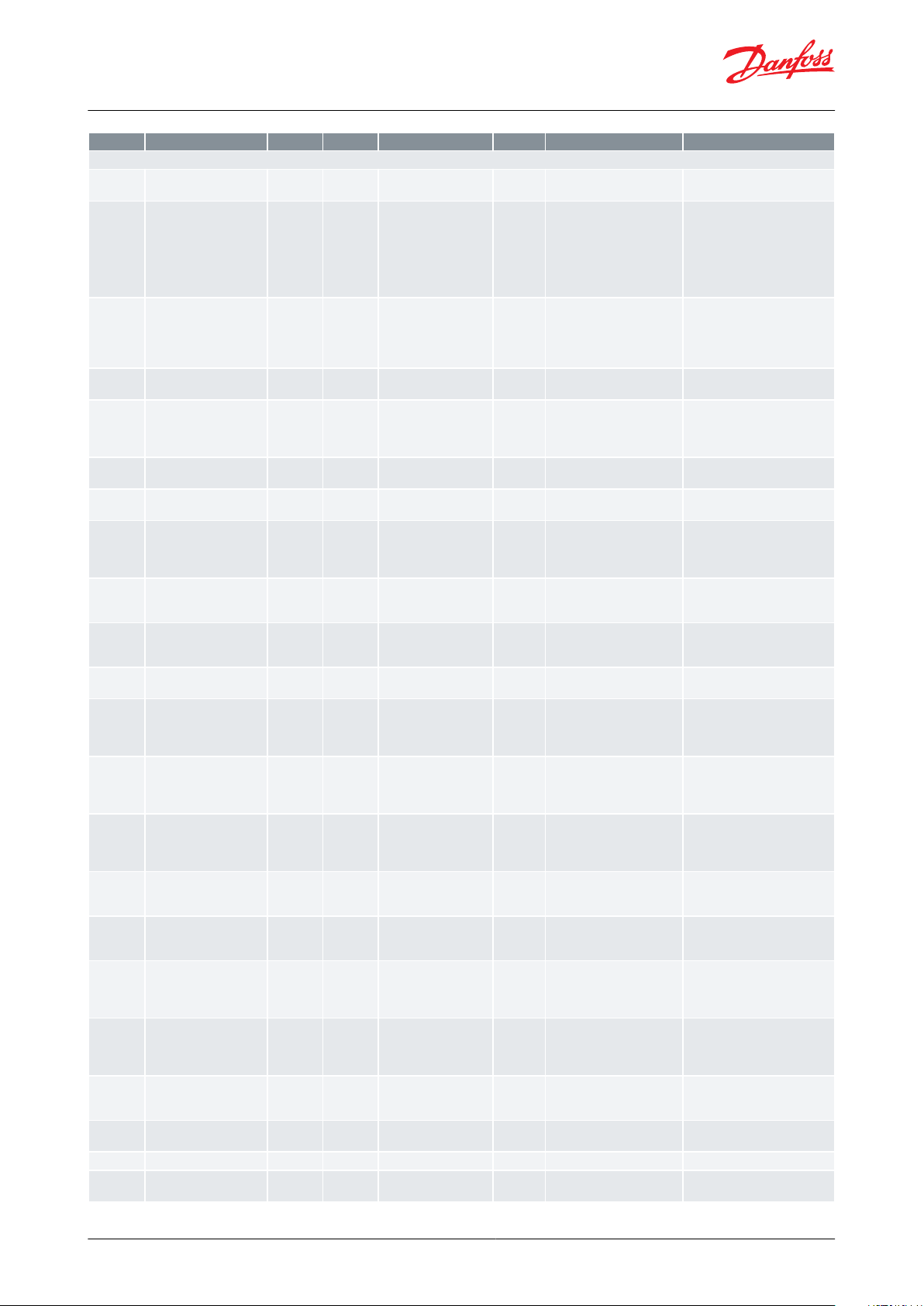

Parameters

Table 4: BASIC SETTING

Table 5: VALVE DRIVER SETTINGS

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 14

Page 15

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

V102

User dened Step mode

0 = Full

0=Full; 1=Half; 2=1/4; 3=1/8;

4=1/16

Danfoss recommends using 1/8

stepping mode as this provides

a good balance between torque

and speed and ensures smooth

operation.

V103

User dened Step positioning

2 = Auto

0=Fullstep;1=Halfstep;2=Auto

V104

User dened Total steps

0

100000stp

The total no of steps will vary

according to the selected valve

motor type, always referring to

full steps.

V105

User dened Speed

10

30010pps

Desired valve speed drive rate

in steps per second.

V106

User dened Start speed

100

100

100

%

Valve Start Speed (1 – 100% of

Valve speed)

V107

User dened Emengency

speed

50

200

100

%

Emergency close is in use when

the main power is lost, and the

valve is closed using the battery

backup

V108

User dened Drive current

10

100010mA

Current applied to each phase

of the stepper motor during actual valve movement.

V109

User dened Acceleration

current

100

100

100

%

Current supplied to the coils under acceleration of the stepper

motor

V110

User dened Acceleration

time

101010

ms

Time used to get from min

speed to normal speed

V111

User dened Holding current

0

1000%

Percent of Max Phase Current

that should be applied to each

phase of the stepper output

when the valve is stationary.

V112

User dened Valve excitation time after stop

0

100010ms

Time that the drive current is

continued after the motor has

stopped movement. Next state

is holding current.

V113

User dened Compensation backlash

0100

%

Number of steps needed to correct for mechanical hysteresis

when a reduction gear is part of

the valve design

V114

User dened Valve thermal protection

0

100

100

%

For Danfoss valves don't

changemaximum - allowed dutycycle

V115

User dened Overdrive

0205

%

Extra steps for zerocalibrating

valve possition, scaled as a percentage of the full opening.

V116

Overdrive enable OD

0

1000%

Denes how much the valve

must have been open before

overdrive is allowed at next

close position

V117

Overdrive block time

0

144010min

Denes the minimum time between two overdrive actions.

Overdrive calibrations within

this time frame will be ignored.

V118

Neutral zone

0101

%

Dene how much the requested

OD must change before a new

OD is set.

V119

Valve OD on power failure

0

1000%

Move the valve to a predened

position during power failure

V120

Analog input selection

0 = DIP switch

0=DIP switch; 1=AI 1; 2=AI 2

0:DIP switch; 1:AI 1; 2: AI 2

V121

Input % scale to 0 position

0

1000%

Signal type is dened by “B104”

“AI selection”

V122

Input % scale to 100 position

0

100

100

%

Signal type is dened by “B104”

“AI selection”

V123

Force Overdrive

0 = No

0=No;1=Yes

Manually initiate an overdrive.

NOTE this will close the valve for

some tome

V124

Forced Overdrive time

0

90000hours

Timer based overdrive. If no

overdrive has been performed

within this period, then a valve

close is done (forced overdrive)

V125

Valve size reduction

0800

%

V126

Open wire detection

1 = Yes

0=No; 1=Yes

Stepper valve driver, type EKF 1A, EKF 2A

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 15

Page 16

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

VALVE 2

V200

User dened Motor type

0 = Unipolar

0=Unipolar; 1=Bipolar

Type of motor used in the stepper valve (Unipolar/Bipolar).

V201

User dened Decay mode

0 = Fast

0=Fast; 1=Slow; 2=Mixed

Fast decay mode causes a rapid

reduction in inductive current

and allows the motor to coast

toward zero velocity. Slow decay mode leads to a slower reduction in inductive current but

produces rapid deceleration.

V202

User dened Step mode

0 = Full

0=Full; 1=Half; 2=1/4; 3=1/8;

4=1/16

Danfoss recommends using 1/8

stepping mode as this provides

a good balance between torque

and speed and ensures smooth

operation.

V203

User dened Step positioning

2 = Auto

0=Fullstep; 1=Halfstep;

2=Auto

V204

User dened Total steps

0

100000stp

The total no of steps will vary

according to the selected valve

motor type, always referring to

full steps.

V205

User dened Speed

10

30010pps

Desired valve speed drive rate

in steps per second.

V206

User dened Start speed

100

100

100

%

Valve Start Speed (1 – 100% of

Valve speed)

V207

User dened Emengency

speed

50

200

100

%

Emergency close is in use when

the main power is lost, and the

valve is closed using the battery

backup

V208

User dened Drive current

10

100010mA

Current applied to each phase

of the stepper motor during actual valve movement.

V209

User dened Acceleration

current

100

100

100

%

Current supplied to the coils under acceleration of the stepper

motor

V210

User dened Acceleration

time

101010

ms

Time used to get from min

speed to normal speed

V211

User dened Holding current

0

1000%

Percent of Max Phase Current

that should be applied to each

phase of the stepper output

when the valve is stationary.

V212

User dened Valve excitation time after stop

0

100010ms

Time that the drive current is

continued after the motor has

stopped movement. Next state

is holding current.

V213

User dened Compensation backlash

0100

%

Number of steps needed to correct for mechanical hysteresis

when a reduction gear is part of

the valve design

V214

User dened Valve thermal protection

0

100

100

%

For Danfoss valves don't

changemaximum - allowed dutycycle

V215

User dened Overdrive

0205

%

Extra steps for zerocalibrating

valve possition, scaled as a percentage of the full opening.

V216

Overdrive enable OD

0

1000%

Denes how much the valve

must have been open before

overdrive is allowed at next

close position

V217

Overdrive block time

0

144010min

Denes the minimum time between two overdrive actions.

Overdrive calibrations within

this time frame will be ignored.

V218

Neutral zone

0101

%

Dene how much the requested

OD must change before a new

OD is set.

V219

Valve OD on power failure

0

1000%

Move the valve to a predened

position during power failure

V220

Analog input selection

0 = DIP switch

0=DIP switch; 1=AI 2; 2=AI 1

0:DIP switch; 1:AI 2; 2: AI 1

V221

Input % scale to 0 position

0

1000%

Signal type is dened by “B204”

“AI selection”

Stepper valve driver, type EKF 1A, EKF 2A

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 16

Page 17

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

V222

Input % scale to 100 position

0

100

100

%

Signal type is dened by “B204”

“AI selection”

V223

Force Overdrive

0 = No

0=No; 1=Yes

Manually initiate an overdrive.

NOTE this will close the valve for

some tome

V224

Forced Overdrive time

0

90000hours

Timer based overdrive. If no

overdrive has been performed

within this period, then a valve

close is done (forced overdrive)

V225

Valve size reduction

0800

%

V226

Open wire detection

1 = Yes

0=No; 1=Yes

Label

Description

Min

Max

Value (Defualt)

Unit

Enumeration

Notes

DRIVER 1

R100

Valve position

0

1000%

Actual valve possition

R101

Analog input signal

0

200000uA/mV

Actual analog input signal

DRIVER 2

R200

Valve position

0

1000%

Actual valve possition

R201

Analog input signal

0

200000uA/mV

Actual analog input signal

GENERIC

R000

Battery voltage

0

300000mV

Measured battery voltage

R001

Software version high

0

65535

0

Software version high.low (the

integer part)

R002

Software version low

0

65535

0

Software version high.low (the

decimal part)

Stepper valve driver, type EKF 1A, EKF 2A

Table 6: READOUTS

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 17

Page 18

Function Data

Value

Supply Voltage

EKF 1A: 24 V AC / DC 50 / 60 Hz

EKF 2A: 24 V AC / DC, 50 / 60 Hz

Power consumption

Idle operating: < 1 W (without valve)

Power consumption for using 1 valve. CCMT 16 –

CCMT 42: 25 VA / 15 W

ETS 5M, ETS 6: 20 VA / 10 W

ETS 12C – ETS 100C, KVS C: 30 VA /15 W

ETS 12.5 – 400: 10 VA / 5 W

ETS 500P, 800P: 28 VA / 20 W

CCMT 2- CCMT 8: 10 VA / 5 W

CTR 20: 14 VA / 10 W

CCMT L: 20 VA / 10 W

When using two valves sum the power consumption of each valve

Number of analog inputs

EKF 1A: 1input (AI1)

EKF 2A: 2 inputs (AI1, AI2)

Analog signal supported

0-5 V, 0-10 V, 4-20 mA, 0-20 mA

Digital outputs

1 output for EKF1A / EKF 2A: D01 (open collector), max sink current 10 mA

Valve support

EKF 1A: 1 stepper motor valve output

EKF 2A: 2 stepper motor valve output

STEPPER 1: A1, A2, B1, B2

STEPPER 2: A1, A2, B1, B2

Bipolar and unipolar stepper motor output: - Danfoss ETS/ETS L / KVS / ETS C / KVS C / CCMT 2 – CCMT 42 / CTR / CCMT L

Valves

- ETS 6 / ETS 5M

Battery backup

1 input for EKF 1A / EKF2A: Vbat

Nominal 18 – 24 V DC, Min 16 V DC - Max 28 V DC (Danfoss EKE 2U recommended)

Storage temperature

-30 – 80 °C / -22 – 176 °F

Operating temperature

-20 – 60 °C / -4 – 140 °F

Humidity

<90% RH, non-condensing

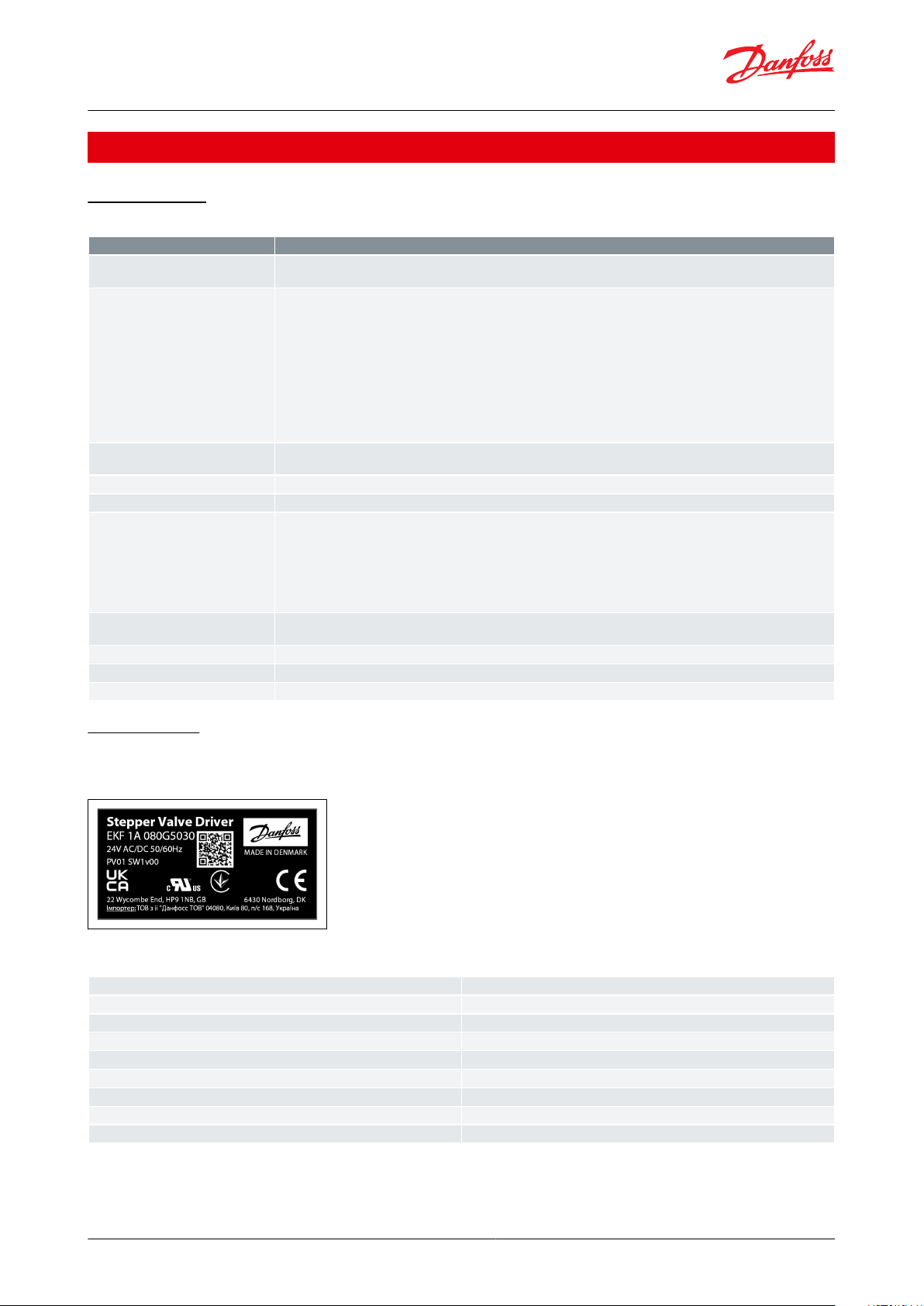

Stepper valve driver

Product description

EKF 2A

Product type designation

080G5035

Product code number

24V AC/DC 50/60 Hz

Input power rating

PV01

Product version

SW1v00

Software version

QR code

Danfoss product information website

Made in Denmark

Country of origin

Danfoss A/S, 6430 Nordborg, Denmark

Company address

Stepper valve driver, type EKF 1A, EKF 2A

Product specication

Technical data

Table 7: Valve settings

Identication

Product label and barcode label is positioned in the back of product

Figure 19: Product label

The product label above is an example (data might change from actual product label)

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 18

Page 19

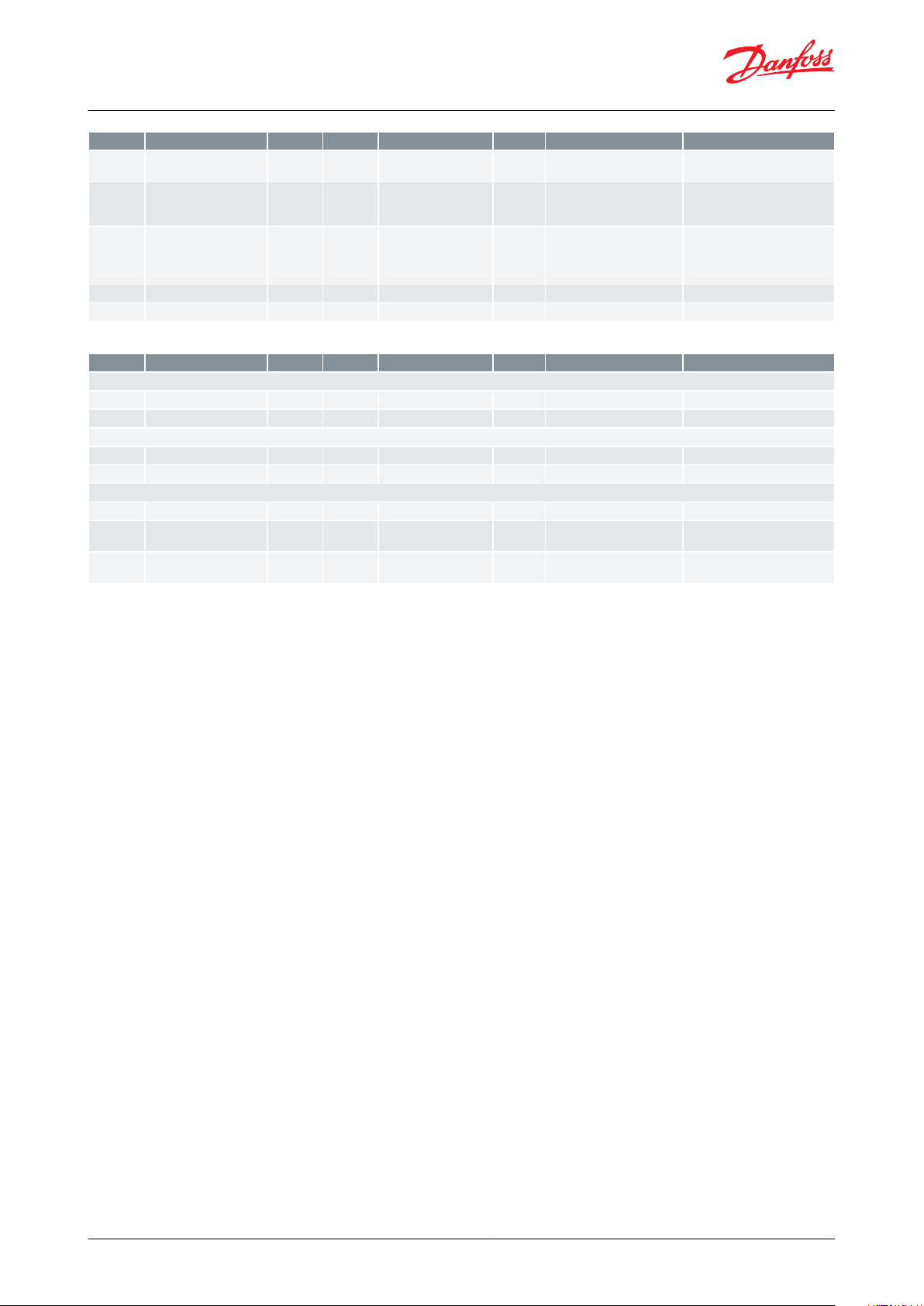

Label

Alarm/Warning

Description

Troubleshoot

A00

Overcurrent alarm driver 1

Analog signal has received higher current

than allowed in AI1 (detected while using

current signal selection)

Check Current signal source AI1 input.

Check DIP switch/ Software selection of AI1 setting (If wrong selection has

been made)

A01

Battery fault

Battery voltage alarm, Activated when Battery voltage <=12 V

Check battery connection

Change battery backup unit immediately.

W01

Battery warning

Battery voltage warning, Activated when

Battery voltage >12 V or <=16 V

Battery backup needs to be replaced soon

Check battery connection

A02

Stepper fault driver 1

Short circuit on the valve output (Stepper

driver 1) or over temperature of EKF driver

hardware

Check the valve connection in stepper driver 1

Check ambient temp conditions of hardware.

A03

Open circuit fault driver 1

Open circuit detection for valve connection (Stepper driver 1)

Check the valve connection (Stepper driver 1).

Broken wires (Stepper driver 1).

A04

Persistent memory fault

Memory error

Replace EKF driver.

W02

DIP Switch position

changed after boot driver

1

DIP switch position for stepper driver 1

has been changed while EKF is powered

on.

Only change DIP switch with EKF powered o. Reboot EKF

W06

Invalid conguration driver 1

Mistake in software or Dip switch congu-

ration of stepper driver 1.

Review conguration of stepper driver 1.

W03

Congured valve current

exceeds the maximum

supplied current driver 1

Alarm triggered when max current output

is above the limitation of 1A per driver.

Alarm detected on stepper driver 1

Max current output per driver is 1 A.

Adjust EKF valve parameters to limit current to 1A (if possible)

A06

Overcurrent alarm driver 2

Analog signal has received higher current

than allowed in AI2 (detected while using

current signal selection)

Check Current signal source AI2 input.

Check DIP switch/ Software selection of AI2 setting (If wrong selection has

been made)

A07

Stepper fault driver 2

Short circuit on the valve output (Stepper

driver 2) or over temperature of EKF driver

hardware

Check the valve connection in stepper driver 2

Check ambient temp conditions of hardware.

A08

Open circuit fault driver 2

Open circuit detection for valve connection (Stepper driver 2)

Check the valve connection (Stepper driver 2).

Broken wires (Stepper driver 2).

W04

DIP Switch position

changed after boot driver

2

DIP switch position for stepper driver 2

has been changed while EKF is powered

on.

Only change DIP switch with EKF powered o. Reboot EKF

W07

Invalid conguration driver 2

Mistake in software or Dip switch congu-

ration of stepper driver 2.

Review conguration of stepper driver 2.

W05

Congured valve current

exceeds the maximum

supplied current driver 2

Alarm triggered when max current output

is above the limitation of 1 A per driver.

Alarm detected on stepper driver 2.

Max current output per driver is 1 A.

Adjust EKF valve parameters to limit current to 1 A (if possible)

Stepper valve driver, type EKF 1A, EKF 2A

Troubleshooting

Table 8: Driver settings

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 19

Page 20

Description

CodeNo.

Stepper valve driver EKF 1A

080G5030

Stepper valve driver EKF 2A

080G5035

Stepper valve driver, type EKF 1A, EKF 2A

Ordering

Table 9: Productpart numbers

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 20

Page 21

Stepper valve driver, type EKF 1A, EKF 2A

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 10: Approvals

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 21

Page 22

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

© Danfoss | Climate Solutions | 2022.03 BC387326840736en-000102 | 22

Loading...

Loading...