Page 1

Data Sheet

vaporator and room control

E

Type EKE 400

For industrial refrigeration applications

1

ppendix A

See A

2

Pulse Width Modulating valves like Danfoss type AKV or AKVA.

The EKE 400 controller is a dedicated controller

or evaporators typically used in industrial

f

refrigeration applications. EKE 400 will be able

to manage the complete operation in cooling

and defrost mode.

Features:

• Approved and qualied b

refrigeration applications

• One product covering multiple valve

congurations

• HMI includes wizard for easy setup

• Multiple EKE 400 can be interconnected for

signal sharing via integrated CANBUS.

(defrost coordination

etc.)

• Easy to connect to third party equipment like

PL

C via integrated MODBUS

• EKE 400 can be connected to AK-SM 800

series

• EKE 400 is available without HMI to save cost

• One remote HMI can interface multiple EKE

400

• One EKE 400 cover both 24 V AC and 24 V DC

• One EKE 400 cover wide voltage and

frequency range; 85 – 265 V AC, 50/60 Hz

• Flexible Analog input. Cover both

Pt-1000/NTC temperature sensor and 4 – 20

mA / 1 – 5 V Pressure transmitter

• 2 Digital output out of 8 Digital output is solid

state for PWM

• EKE 400 with HMI includes multilanguage

suppor

Spanish)

• International units supported. Metric and

Imperial

• HMI will during setup, lter out irrelevant

parameters or conversely, show parameters

that are relevant based on earlier selection

(2)

(puls) valves

t (English, Chinese, Portuguese,

y Danfoss for

(1)

, temperature sharing

AI306444073210en-000801

Page 2

Evaporator and room control, type EKE 400

Application

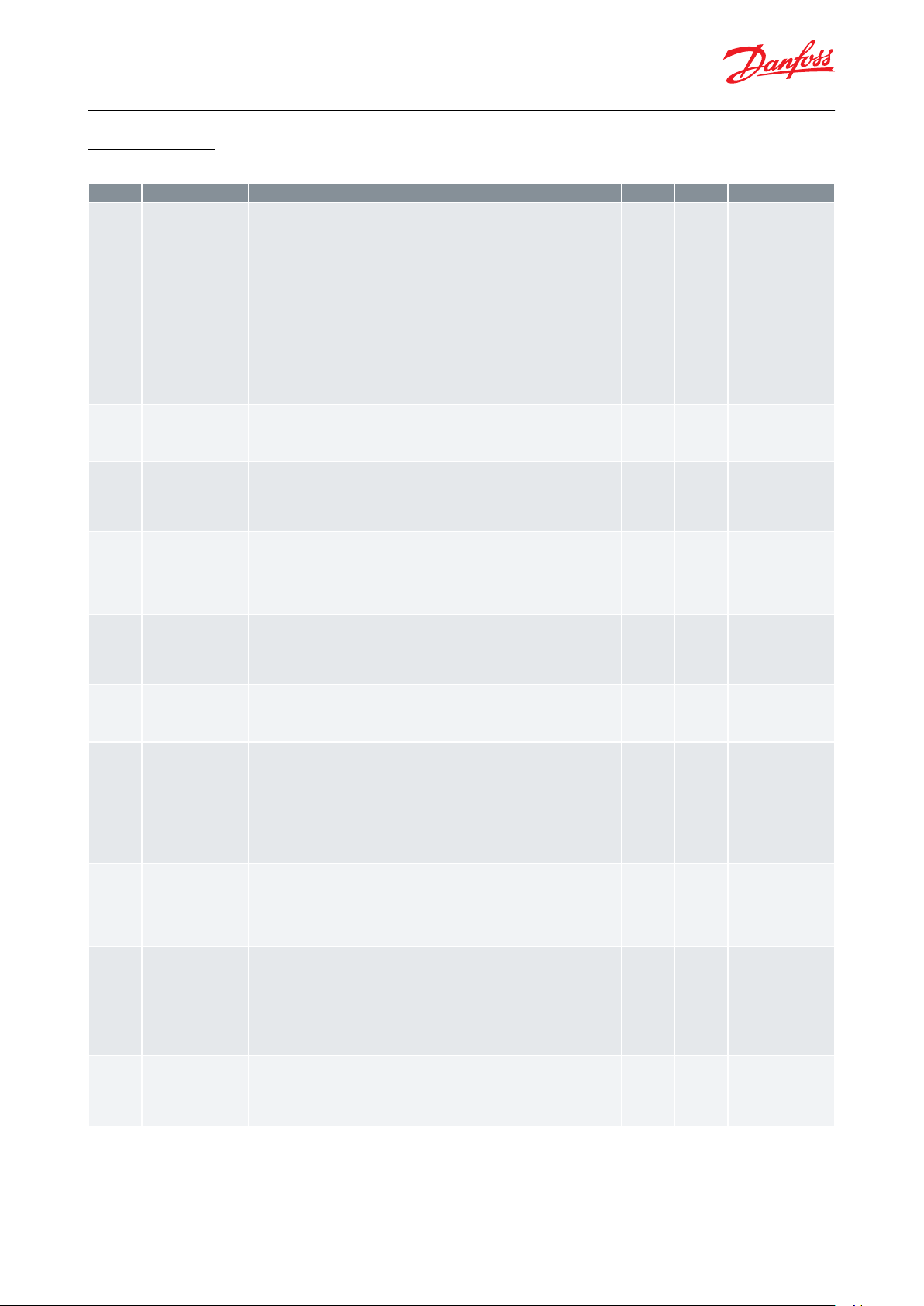

igure 1: EKE 400 without/with HMI

F

For industrial refrigeration applications the Danfoss EKE 400 can control the operation of the valves and the fans for

ev

aporators to achieve optimal cooling mode and defrost sequence for an ecient, safe and trouble-free operation

of the evaporators, complying with IIAR

This means:

• Controls operation of the valves and the fans for each evaporator

• Controlling and optimizing defrost sequence and performance

• Applicable for defrosting ooded ev

• Supports various defrost methods: Hot gas defrost by pressure control or liquid drain, water/brine defrost, and

electrical defrost.

• EKE 400 is using industry terminology in both the HMI

feed line etc.)

(3)

safety recommendations for hot gas defrost.

aporators, including Ammonia and CO

(4)

in

terface and associated literature (wet return line, liquid

2

EKE 400 is available both with and without HMI. The HMI contains a graphical display and a six push button to

operate and navigate through the menu system. A menu wizard will guide the user through basic conguration

questions. Based on parameter selections, irrelevant parameters will be ltered out and minimize time at

commissioning the EKE 400

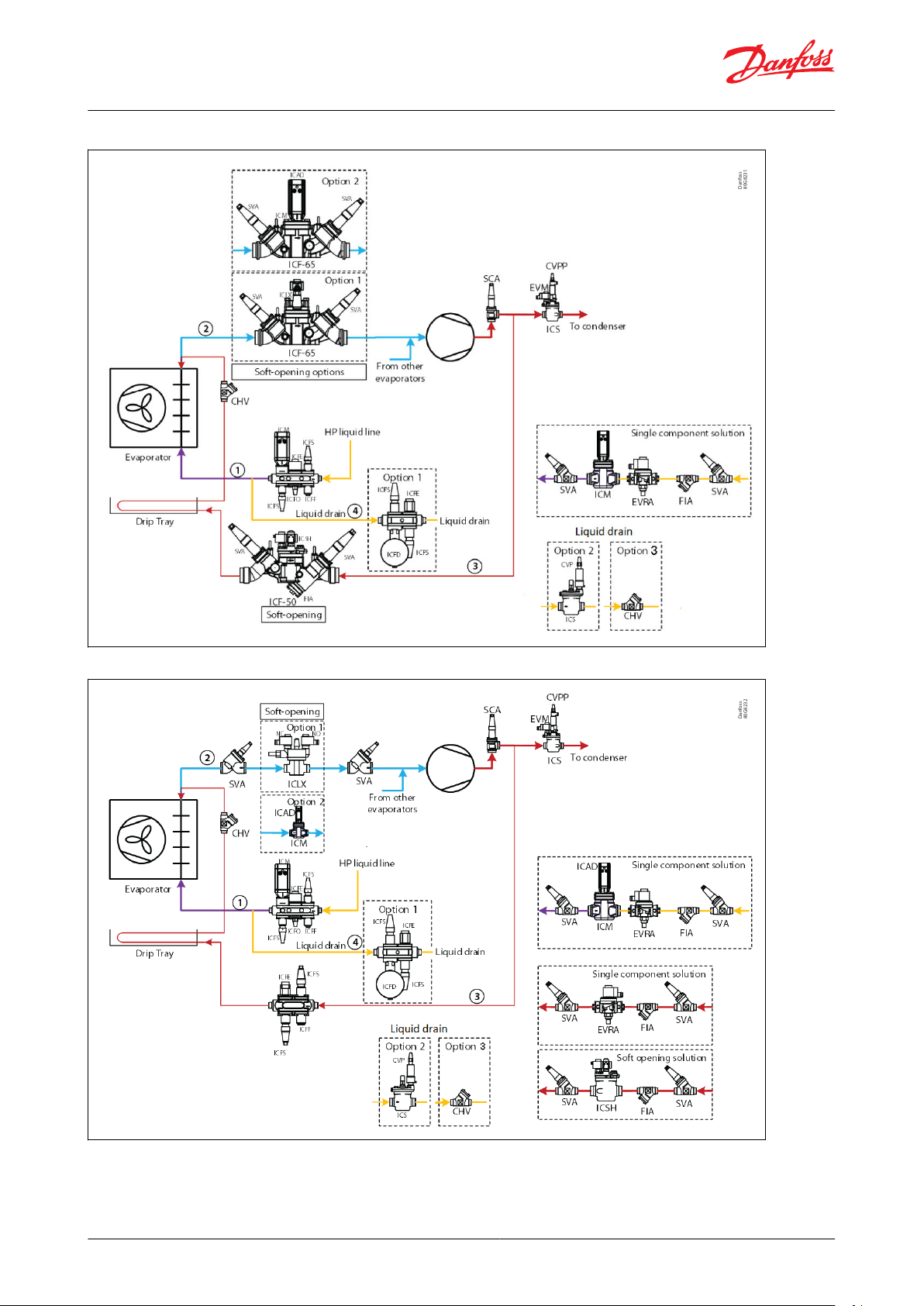

As EKE 400 is a dedicated controller for industrial refrigeration it will have full support of Danfoss industrial

refrigeration valves

(5)

:

• ICF valve station

• ICM motorized valve

(6)

• ICS servo valve with constant pressure control pilots like CVP

• OFV o

verow valve

• ICLX 2-step gas powered solenoid valve

• ICSH dual position solenoid valve

• ICFD Defrost module

• Various solenoid valves; EVRA, EVRAT, EVRS, EVRST, ICS with EVM, ICF with ICFE

Product function features

roduct function features

P

Examples of applications supported by EKE 400:

• Flooded ammonia/CO2/HCFC/HFC

• Direct expansion (DX) ammonia/CO2/ HCFC/HFC

• Superheat Control by

◦ Fixed Superheat reference

◦ Load dened r

◦ Minimum Stable Superheat (MSS)

eference (LoadAP)

3

International Institute of Ammonia Refrigeration

4

Human Machine Interface (HMI) is the interface between the EKE 400 controller and the user.

5

Competitors valves may be used with EKE 400.

6

EKE 400 can support: ETS 6, ETS, KVS, ETS Colibri®, KVS Colibri®, CTR, CCMT valves. See A

© Danfoss | Climate Solutions | 2021.03

ppendix B

AI306444073210en-000801 | 2

Page 3

Evaporator and room control, type EKE 400

• Modulating Thermostat (MTR) or simple ON/OFF

• Media temperature control of suction line valve with motorized valve (Danfoss type ICM/ICAD or similar)

• Media temperature control of suction line valve with servo valve (Danfoss type ICS/CVE/ICAD or similar)

• Pressure control of suction line valve with motorized valve (Danfoss type ICM/ICAD or similar)

• Pressure control of suction line valve with servo valve (Danfoss type ICS/CVE/ICAD or similar)

• Modulating Thermostat (MTR) by modulating the valve (Danfoss type AKV/AKVA) or similar in the liquid line

• Defrost

• Support of Multiple Defrost methods

◦ Hot Gas defrost by pressure

◦ Hot Gas defrost by liquid drain

◦ Defrost by water or brine

◦ Individual defrost schedules by single weekdays, Saturdays and Sundays

• Defrost start

◦ Defrost start by PLC via MODBUS or Digital Input

◦ Defrost start by time interval (time since last defrost start)

◦ Defrost start according to accumulated cooling time

◦ Defrost start via defrost schedules and Real Time Clock (RTC)

◦ Forced manual defrost via HMI or by PLC via MODBUS

• Defrost stop

◦ Defrost stop on time duration

◦ Defrost stop on temperature

• Separate Drip tray control (separate from main Hot Gas valve)

• Emergency cooling - failsafe operation

• Safe startup after power failure

• Product temperature alarm option

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 3

Page 4

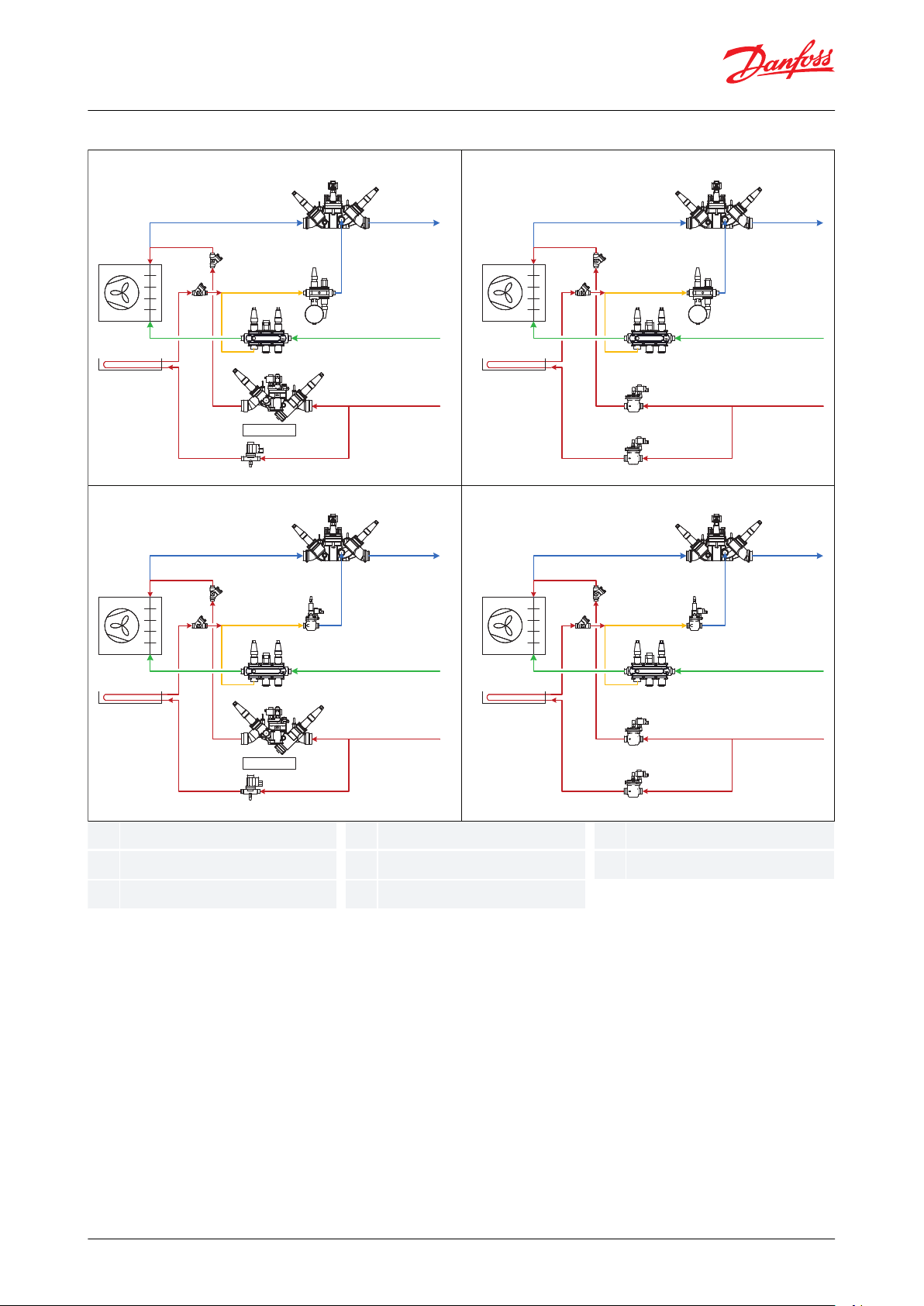

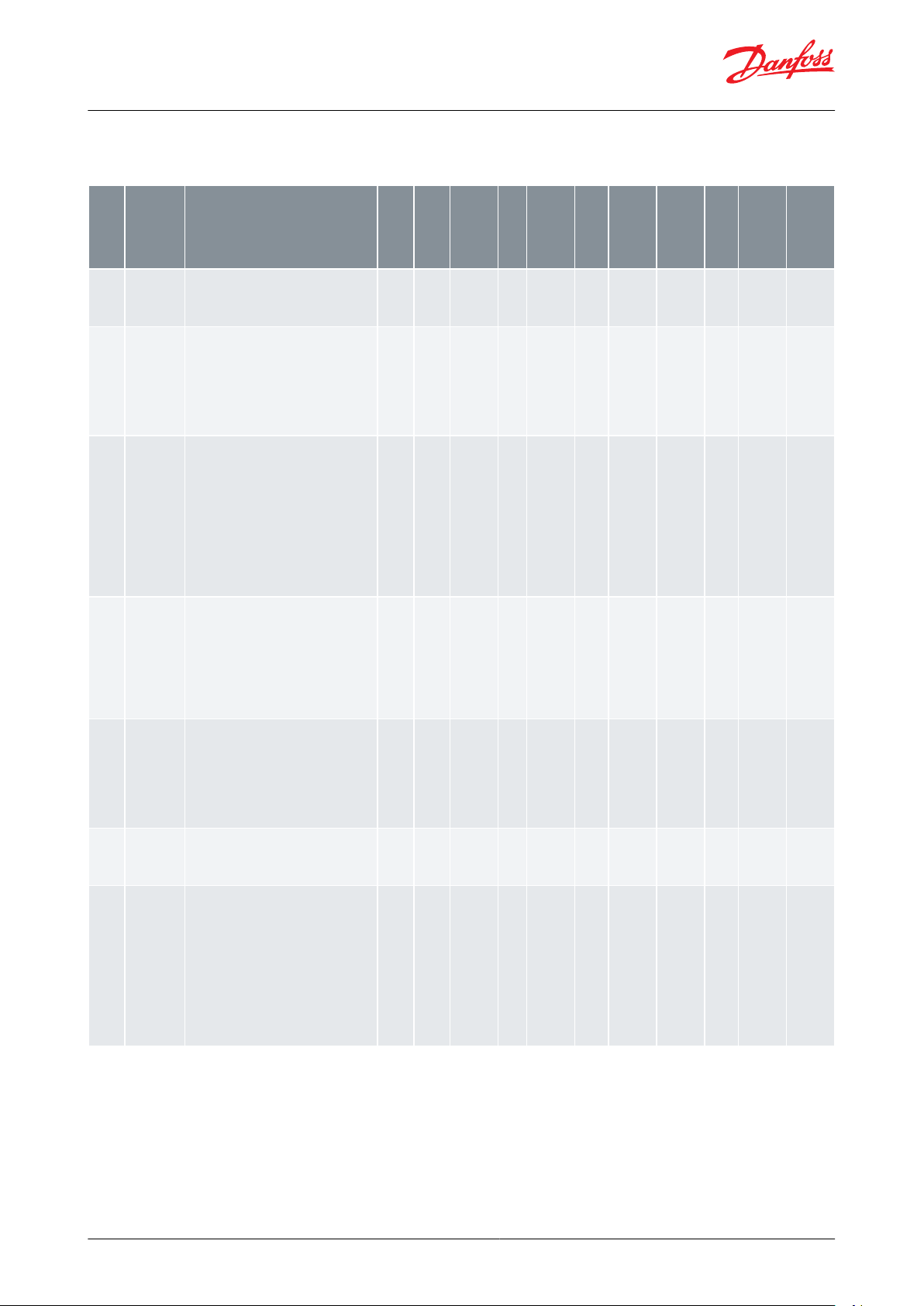

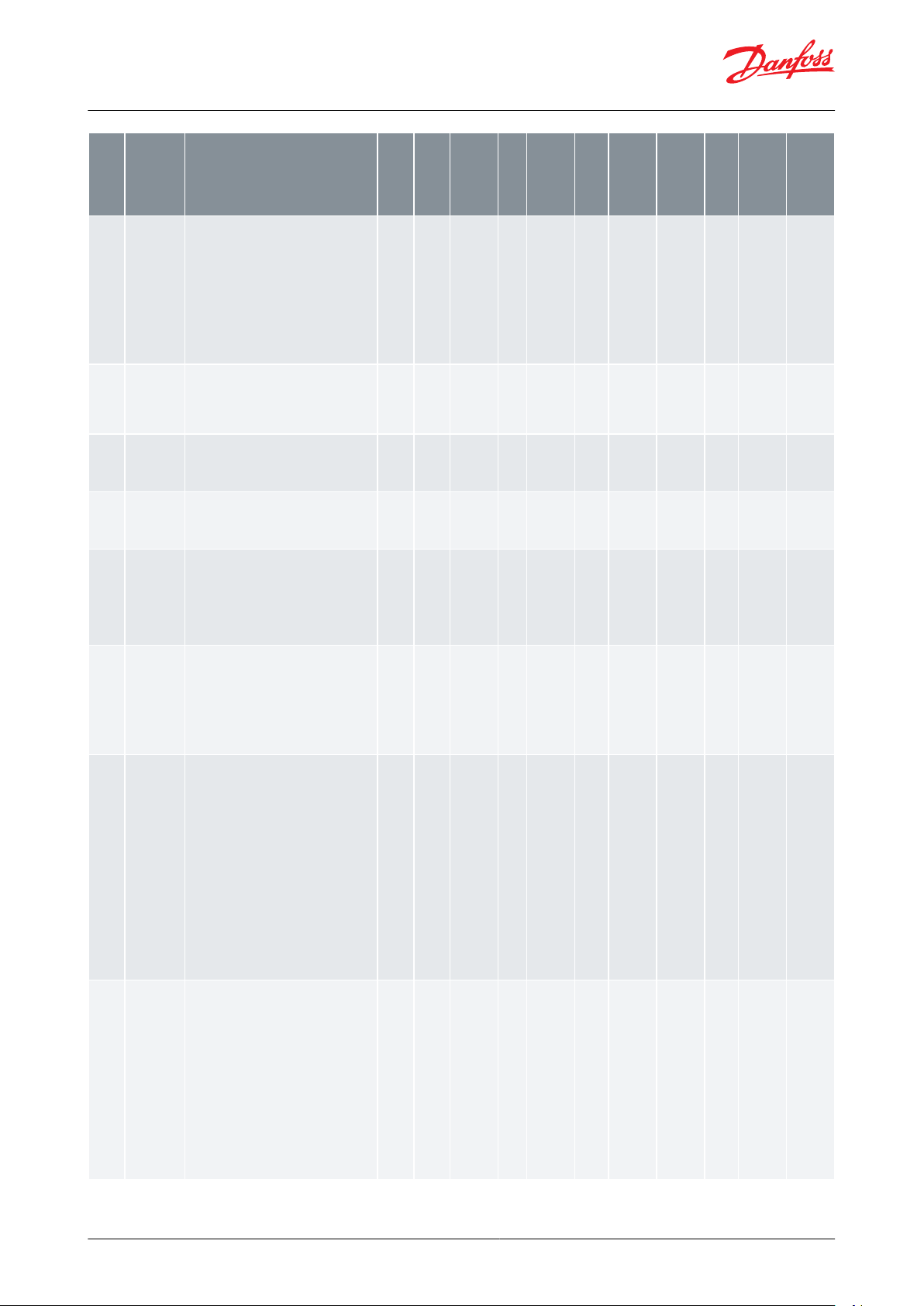

ABCDEFG

H

Soft-opening

CHV

CHV

EVRST

ICSH

ICLX

ICF

ICFE

ICFSICFR

ICFF

ICFC

ICFW

ICFD

ICF

ICFS

ICFE

ICFS

CHV

CHV

ICS

ICLX

EVM

ICF

ICFE

ICFSICFR

ICFF

ICFC

ICFW

ICF

ICFS

ICFS

ICFE

ICFD

ICS

EVM

Soft-opening

CHV

CHV

EVRST

ICSH

ICLX

EVM

CVP

ICS

ICF

ICFE

ICFSICFR

ICFF

ICFC

ICFW

CHV

CHV

ICS

ICLX

EVM

ICF

I

CFE

ICFSICFR

ICFF

ICFC

ICFW

EVM

CVP

ICS

ICS

EVM

A

B B

B B

C C

C C

A

D D

D D

A A

E E

E E

F F

F F

G G

G G

H H

H H

Danfoss

80G8136

Soft opening

Evaporator

Drip tray

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

Drip tray line

Evaporator and room control, type EKE 400

Figure 2: Flowchart

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 4

Page 5

Danfoss

80G8231

Evaporator and room control, type EKE 400

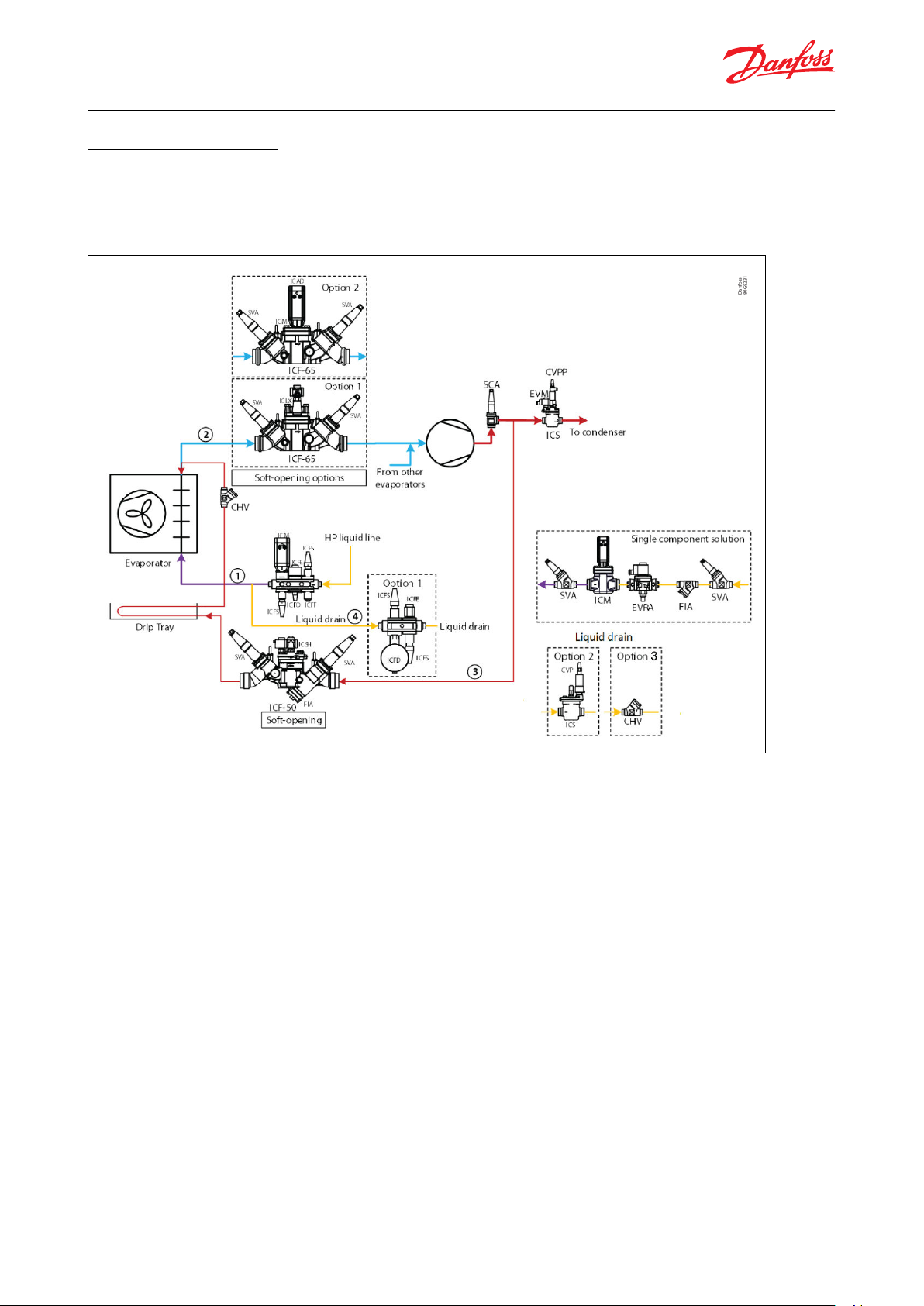

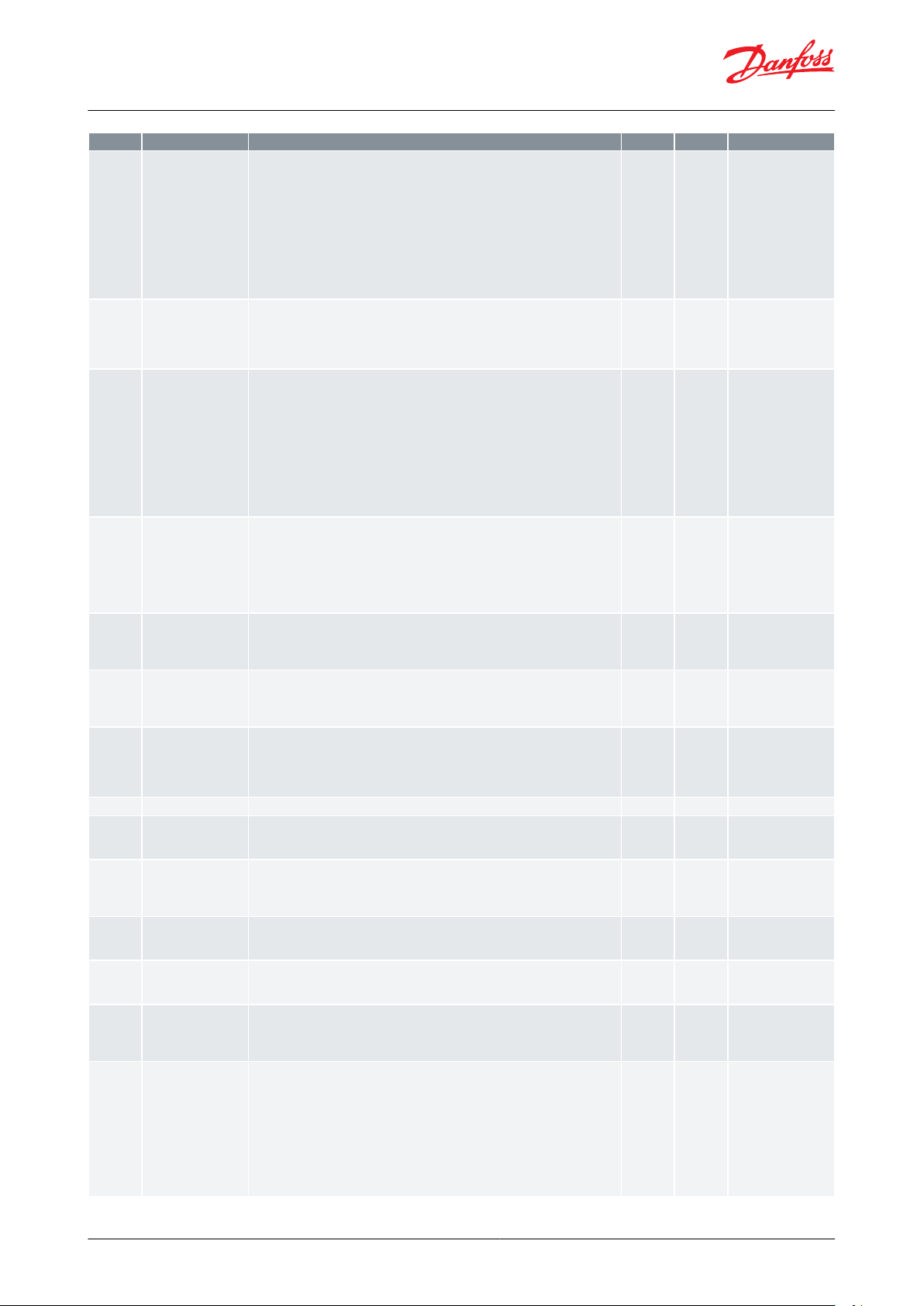

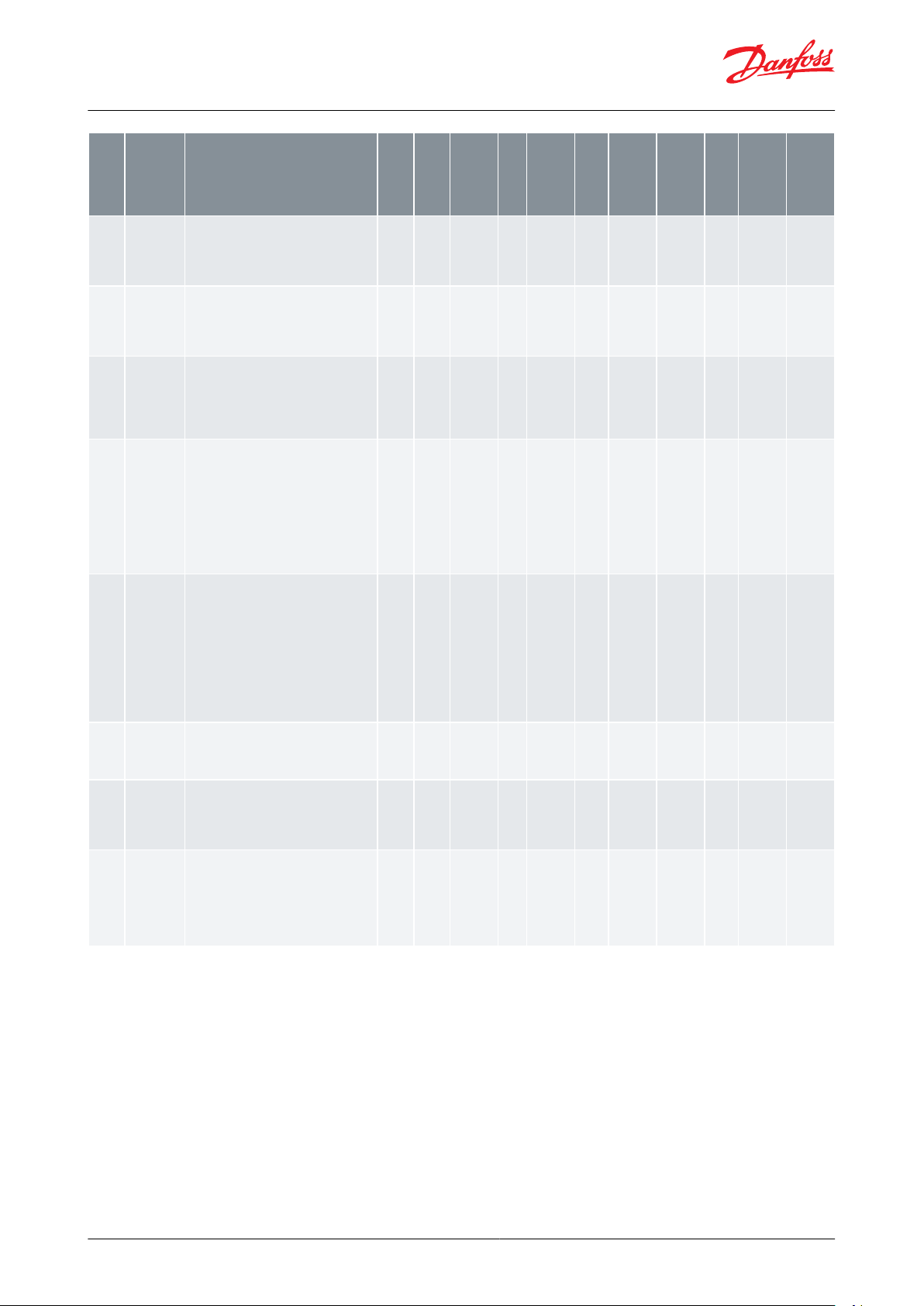

DX and Hot gas defrost

X and Hot gas defrost

D

EKE 400 oers the possibility to control DX applications and combine with Hot gas defrost across all the possible

valves available. E.g. EKE 400 can support DX and CO2, combined with Hot gas defrost with ICF valve stations.

Figure 3: Application sketch

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 5

Page 6

Evaporator and room control, type EKE 400

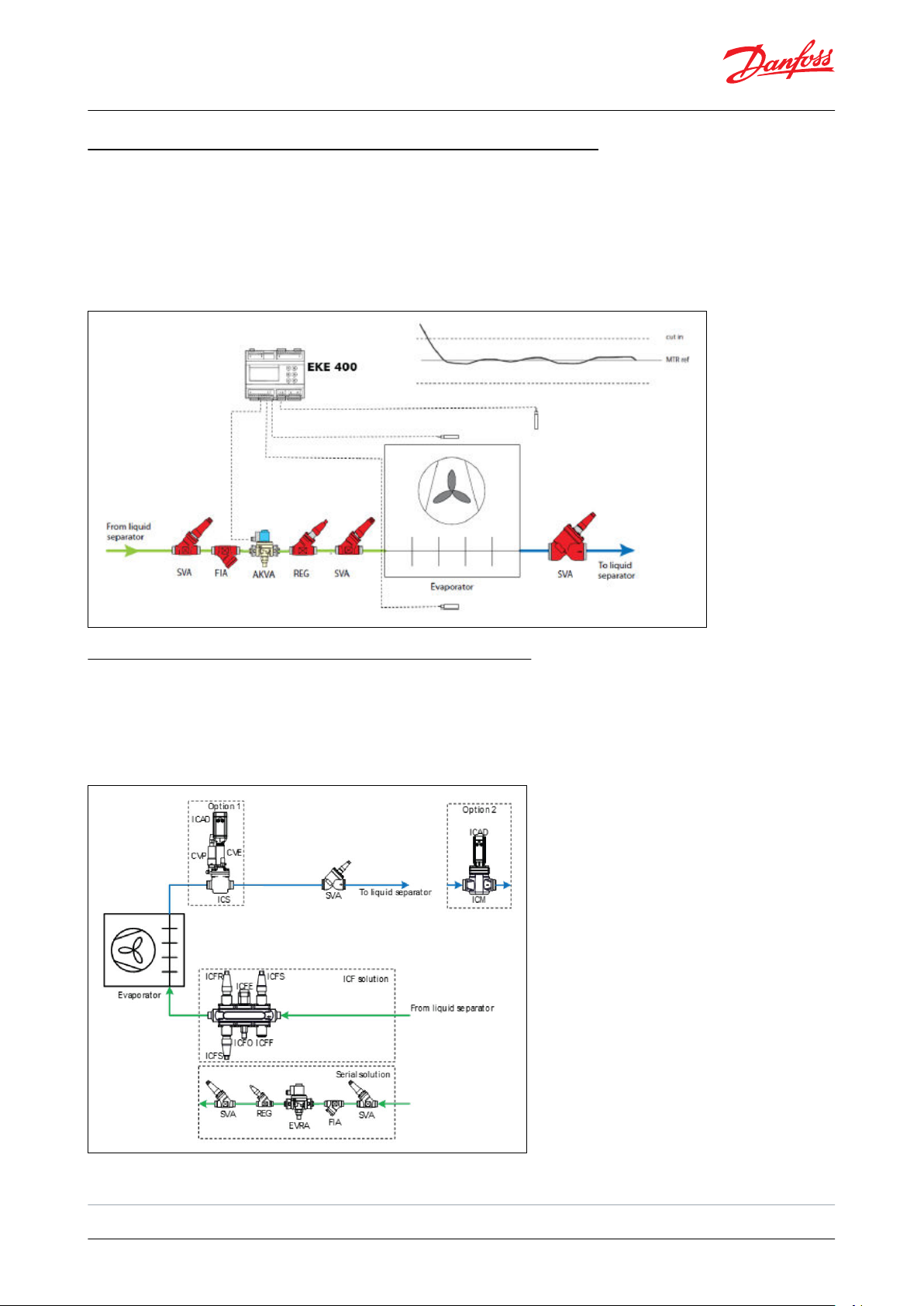

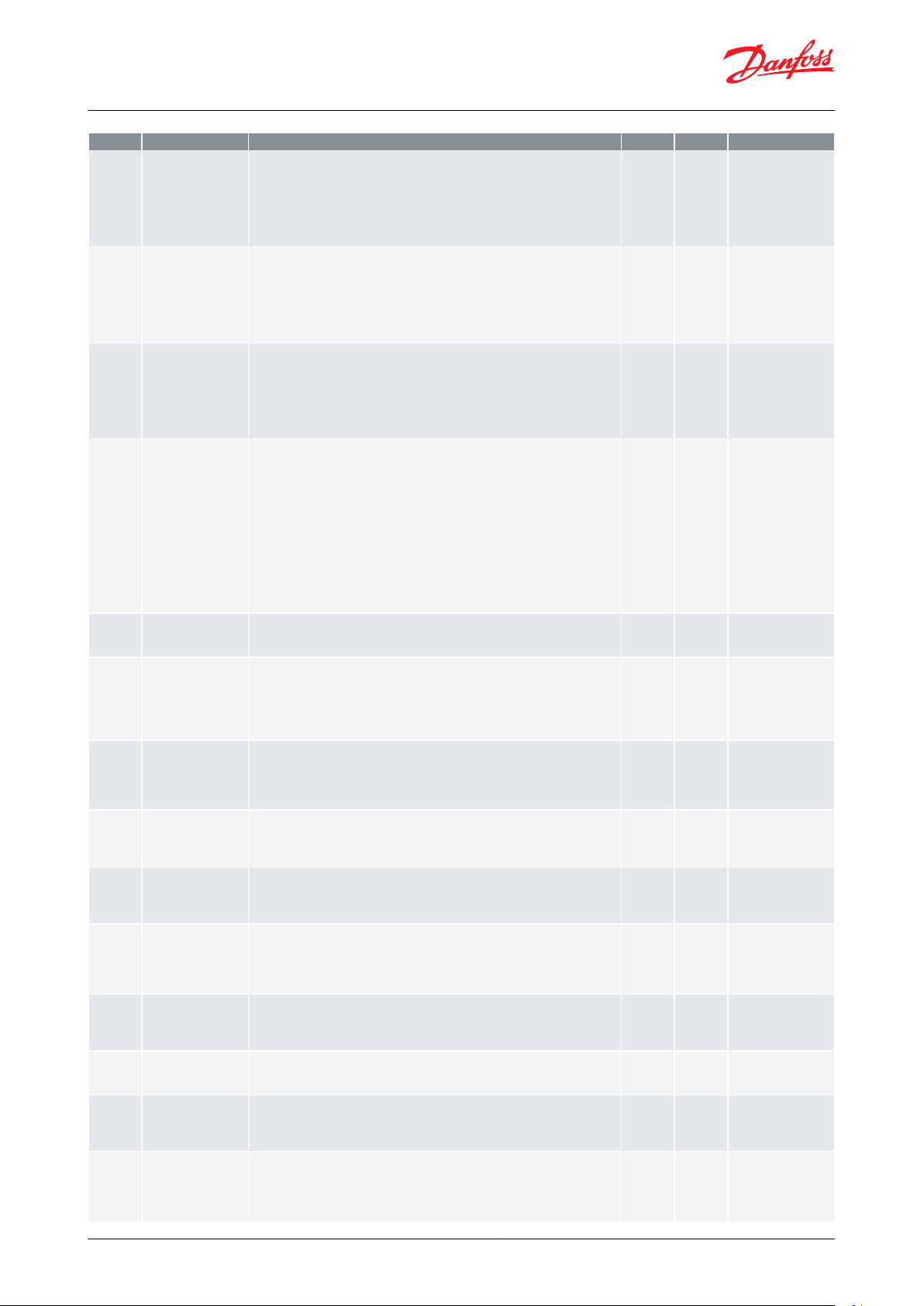

MTR (Modulating TheRmostat) in Liquid Line Flooded systems

TR (Modulating TheRmostat) in Liquid Line Flooded systems

M

As for DX systems, EKE 400 has an adapted function of MTR also for ooded systems. Selecting this function, EKE 400

wil be able to control the room temperature much more accurate than a traditional ON/OFF temperature control.

EKE 400 will also equalize the load on the system to get better operating conditions. MTR requires PWM (Pulse

Width Modulating) valves like Danfoss type AKV or AKVA in the liquid line. Typical industrial applications with the

refrigerant Ammonia or CO2 is in scope.

Figure 4: MTR in Liquid line ooded systems

Media temperature and pressure control - suction line

M

edia temperature and pressure control - suction line

EKE 400 will be able to control valves in the wet suction return line. The control mode can be either temperature or

pressure. Support of Danfoss Industrial Refrigeration Valves like ICM with ICAD and ICS/CVE/ICAD can be combined

with multiple defrost methods, including Hot Gas.

Figure 5: Media temperature and pressure control - suction line

(7)

7

Same basic media temperature functions as in EKC 361, but with updated and optimized algorithm. See A

© Danfoss | Climate Solutions | 2021.03

ppendix C

AI306444073210en-000801 | 6

Page 7

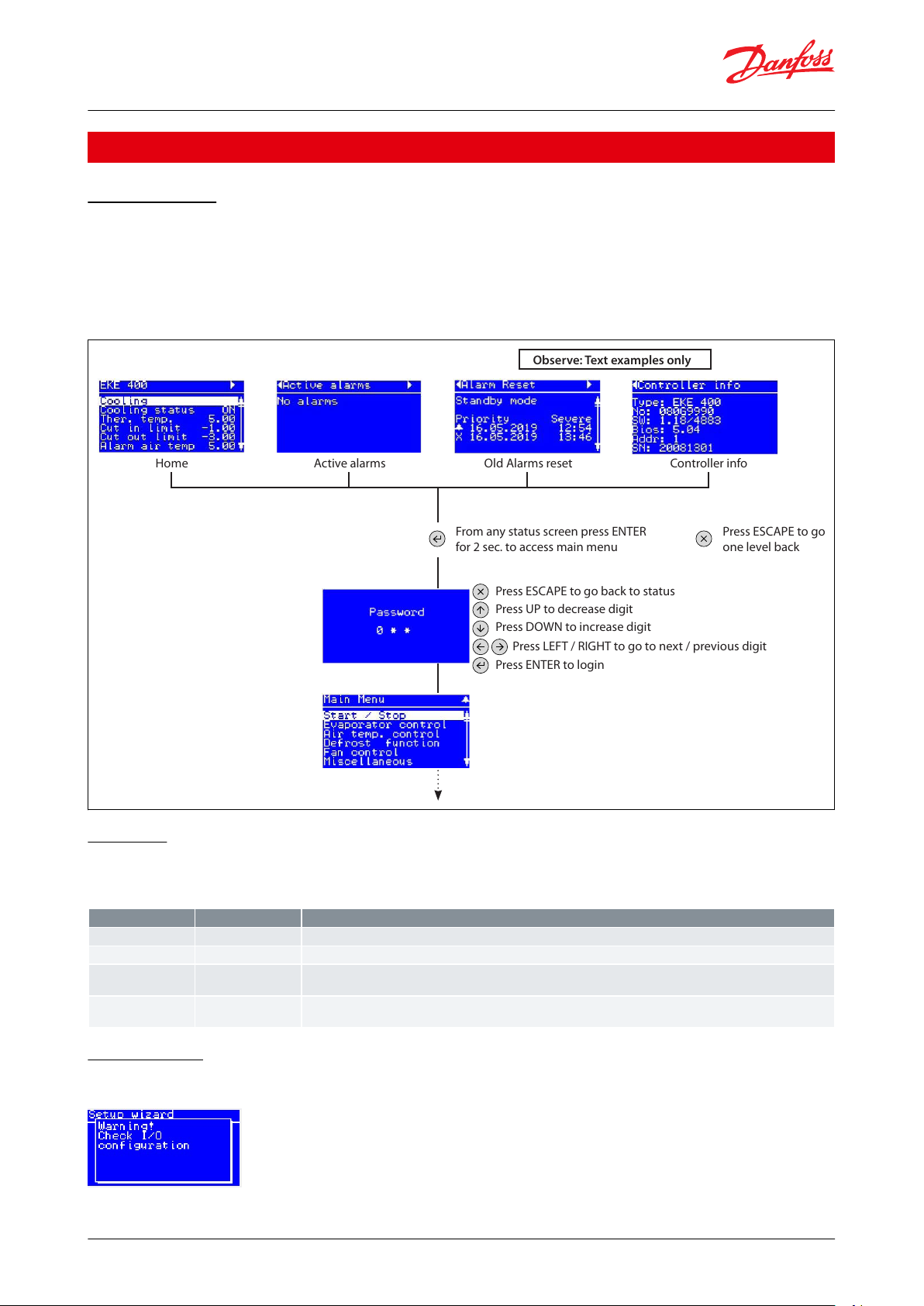

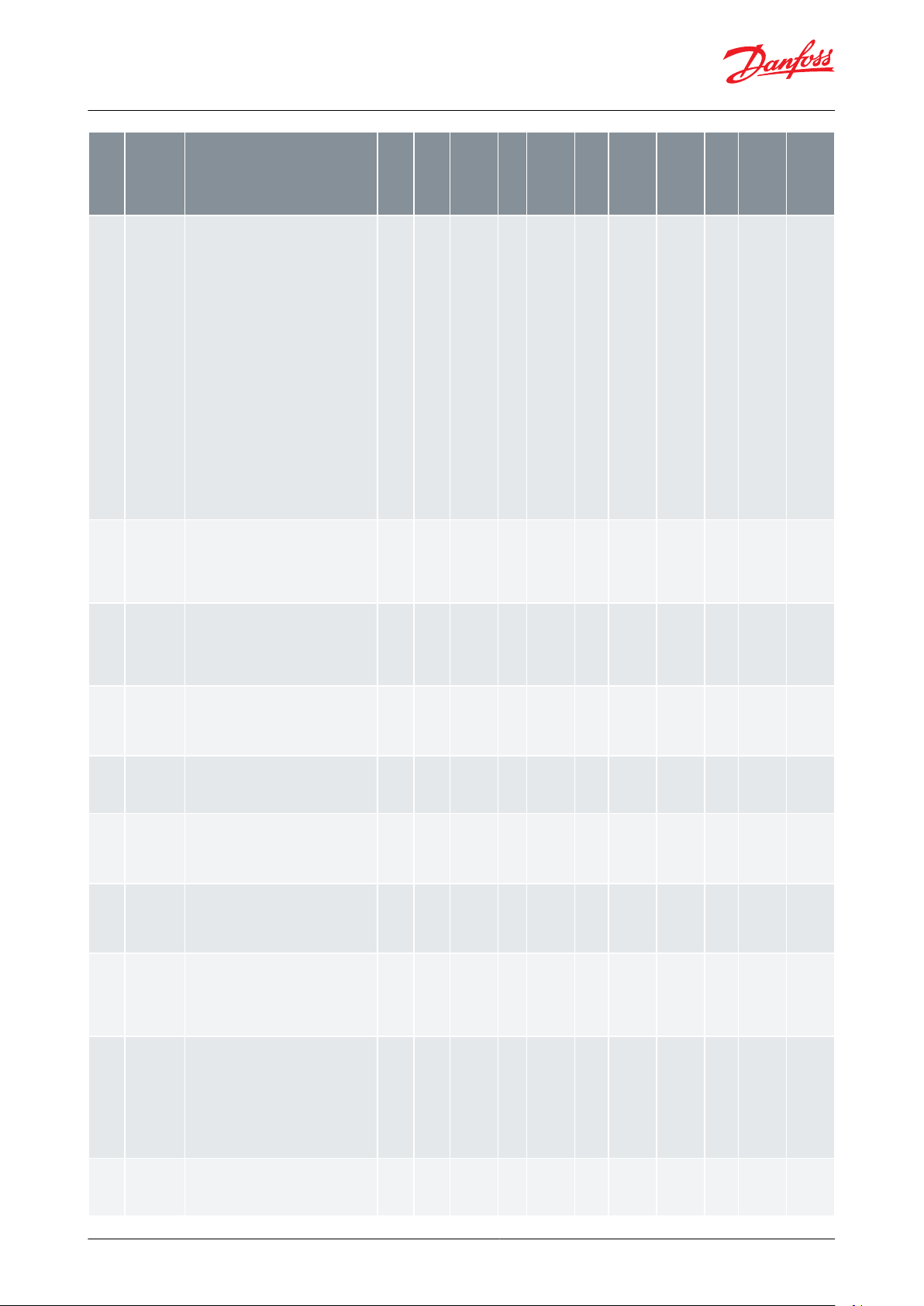

Home Active alarms Old Alarms reset

Observe: Text examples only

Controller info

From any status screen press ENTER

f

or 2 sec. to access main menu

Press ESCAPE to go back to status

Press UP to decrease digit

Press DOWN to increase digit

Press ENTER to login

Press LEFT / RIGHT to go to next / previous digit

Press ESCAPE to go

one lev

el back

Parameter

Password level

Functions

Password level 0

Level 0 will only allow to see the screens: "Status screen 1", "Active alarms", "Alarm Reset" and "Controller info"

G07

Password level 1

Level 1 will give access to see all parameters and sub menus, but no settings can be changed.

G08

Password level 2

Enter password for level 2 access. Level 1 will give access to see all parameters and sub menus. Some settings can

changed

.

G09

Password level 3

Enter password for level 3 access. Level 1 will give access to see all parameters and sub menus. All settings can

changed

.

Evaporator and room control, type EKE 400

Product specication

Basic operation

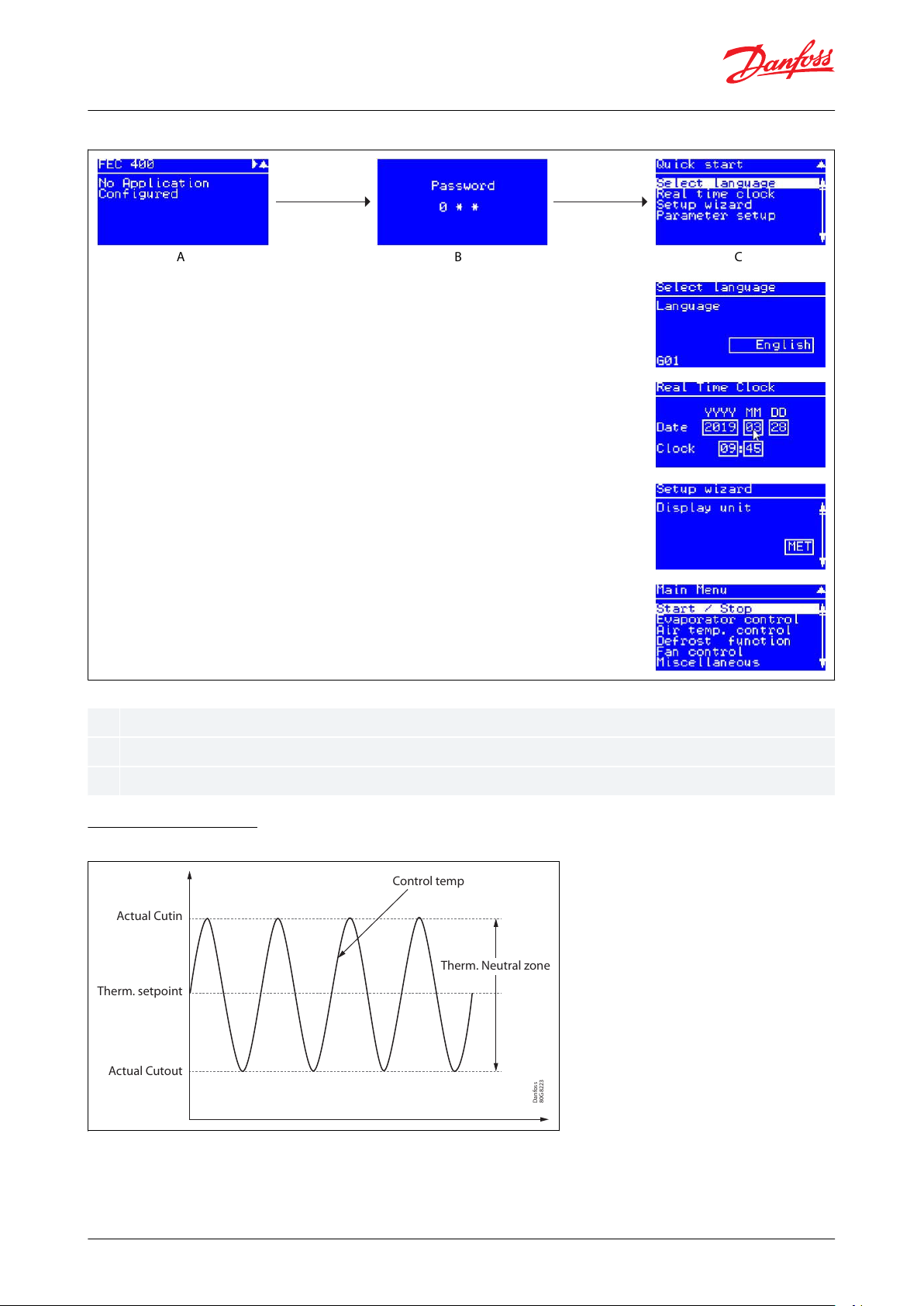

asic operation: Conguration and daily operation of EKE 400 is done via the built-in HMI or via a remote

B

connected HMI. The display supports multiple languages and engineering units.

Status screens: Get an overview of how the system is running in the status screens. Use the LEFT / RIGHT buttons to

view the status screens.

Figure 6: Status screen

Password

ee EKE 400 Wizard, Parameterlist, for further details further details on Password levels and user rights

S

Table 1: Password level

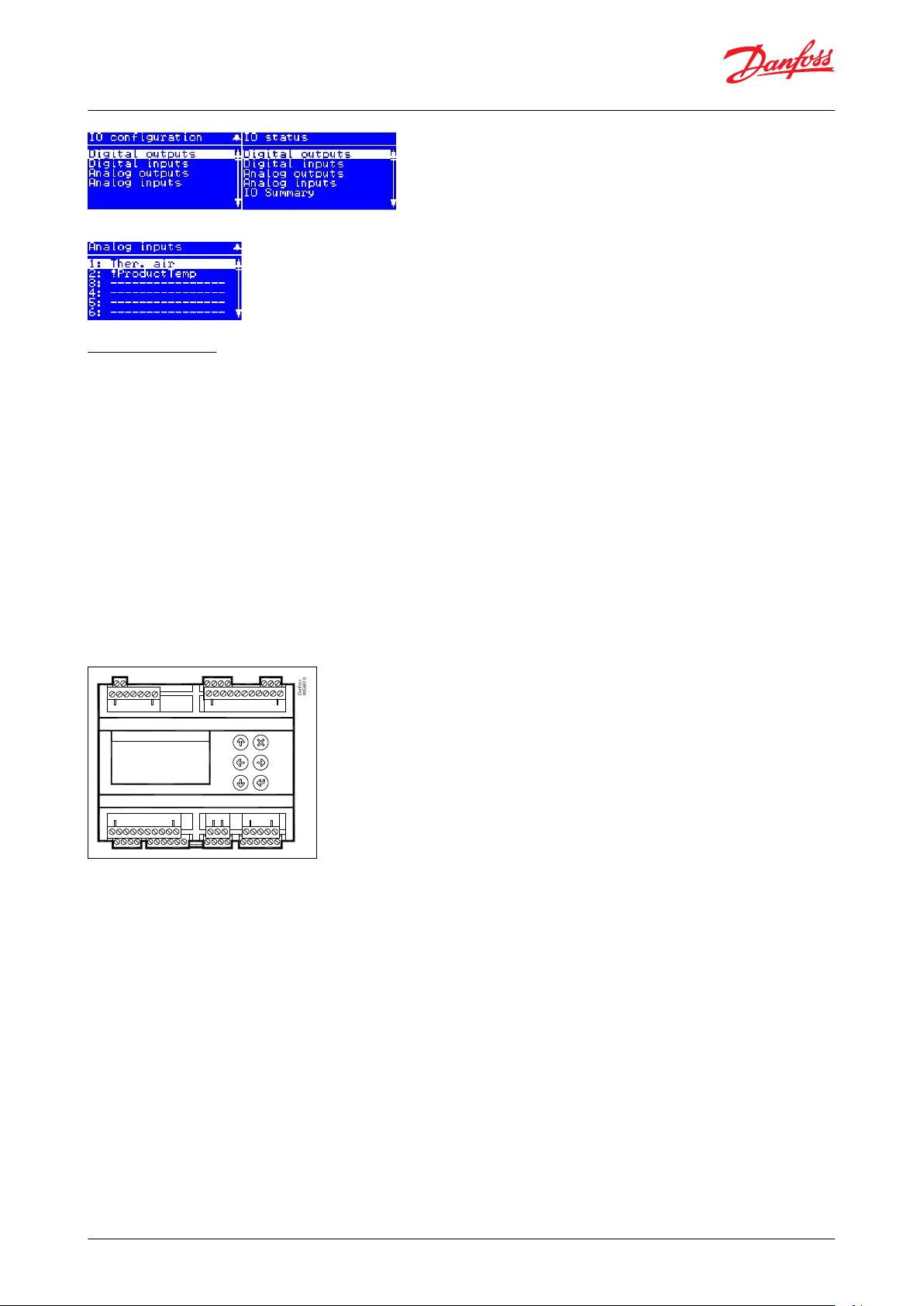

Conguration

f the I/O conguration can not be met, after the Wizard is completed, a warning will be displayed

I

Go to IO c

onguration or IO status and go through Digital output/input and Analog output/input

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 7

Page 8

Danfoss

80G8010

Evaporator and room control, type EKE 400

Identify the IO with and exclamation mark “!” and recongure it.

Setup overview

T

here are two ways in which the controller can be set up:

Wizard

• Here you will be led through a series of selected parameters that are commonly needed to be c

start up. This will also mean faster setup for many applications.

• Please observe, that some parameters not included in the Wizard may still need to be congured. this must then

be done from the complete Parameter list

Parameter list

• Here a complete list of all parameters can be found

ongured at every

perating principles:

O

1.

Select position using arrow keys

2.

Select using “Enter”

3.

Use the “X” to return

Figure 7: EKE 400

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 8

Page 9

ABC

A B C

Hold “Enter” down for 2 seconds to come to password entry

The default password upon delivery is 300. Use the arrow keys to set the password. End by pressing “Enter”

Select a set-up method. End by pressing “Enter”

Danfoss

80G8223

Actual Cutout

Therm. setpoint

Actual Cutin

Control temp

Therm. Neutral zone

Evaporator and room control, type EKE 400

Figure 8: Start screen upon delivery

Temperature control

F

igure 9: Temperature control

For ON/OFF thermostat and F

looded and DX application

One, two or three temperatures sensors, normally located in the cool room, can be connected to EKE 400. The

number of sensors depends normally on the size of the room.

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 9

Page 10

Temperature

Valve OD

SH

Time

Time

Temp setpoint

(T04)

SH ref

Danfoss

80G8224

Evaporator and room control, type EKE 400

If more than one temperature sensor have been selected, then the thermostat function can be selected to control

emperature from the average or the highest temperature from the temperature sensors.

t

A Temperature setpoint (T04) and a Neutral zone(T05) are entered in EKE 400. Neutral zone divided by 2 will give

Cut-in and Cut-out temperature of the thermostat, normally the liquid line valve ON/OFF.

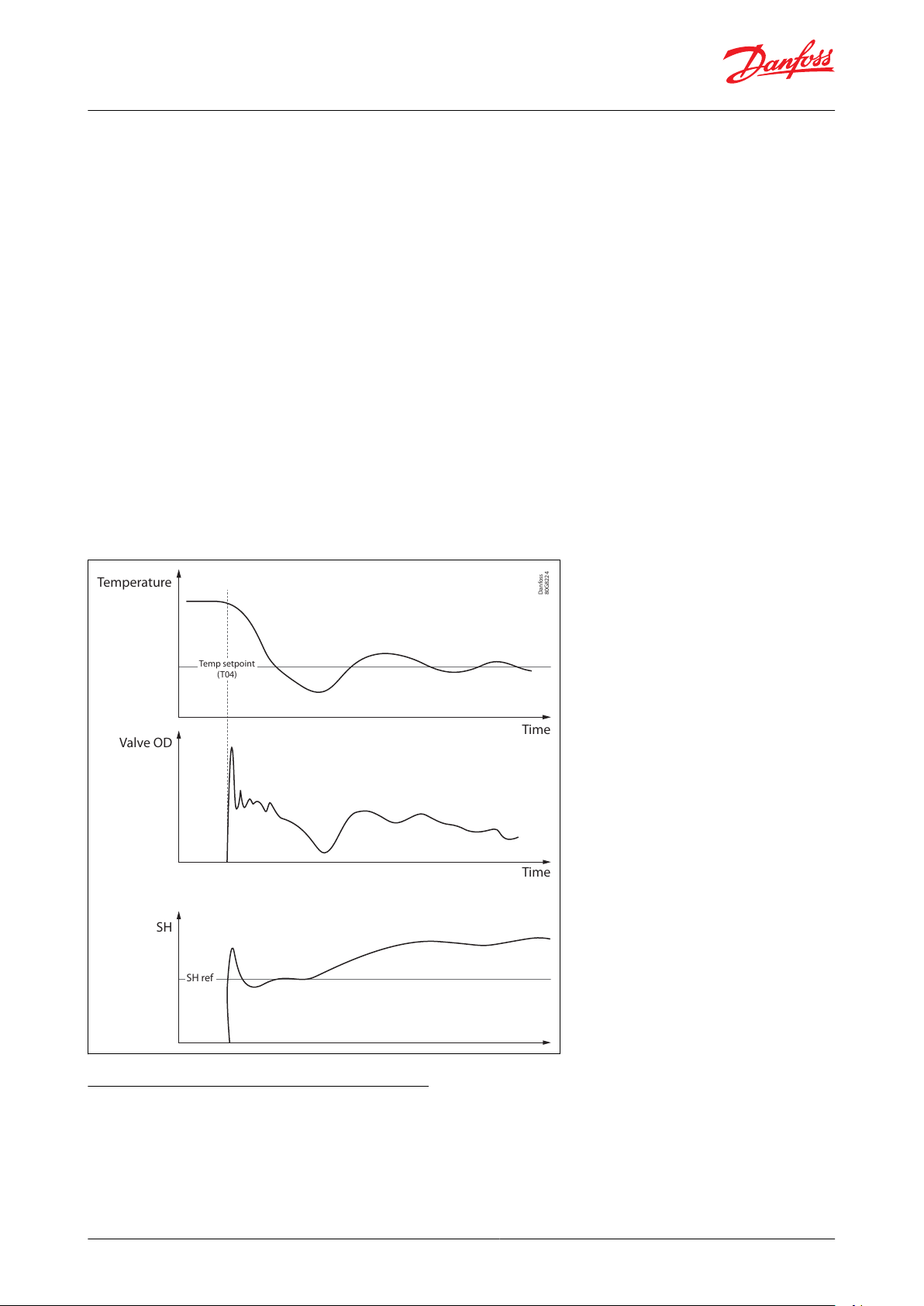

Modulating thermostat (MTR)

DX only

Observe: The MTR function must not be enabled in a system containing only 1 evaporator

Modulating thermostat (MTR regulation maintains a more constant temperature and also equalize the load on the

system to get better operating conditions:

• Each of the individual evaporator sections is controlled individually using a modulating thermostat function.

• A Temperature setpoint (T04) and a Neutral zone(T05) must be set as with an ON/OFF thermostat.

TR is modulating the cooling capacity to match the cooling demand.

M

In the pull-down phase then the temperature is well above the MTR set point cooling capacity is at maximum and

superheat is controlled to be on superheat reference. When temperature is getting close to the MTR reference

(typical 4 K) the cooling capacity gradually reduce so that the temperature can be stable on the MTR reference.

The MTR reference is dened by Temperature setpoint (T04).

Figure 10: Modulating thermostat

Superheat reference calculation methods

n superheat mode the controller will control the superheat to be stable and closer to the superheat reference. This

I

will give the optimal utilization of heat exchanger and thereby maximum cooling capacity. If superheat is too low,

the ow in the expansion is decreased and superheat will be higher.

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 10

Page 11

Danfoss

80G8225

TT

P

S2

TT, S2

P

Pt1000 temperature sensor

Pressure transmitter

Danfoss

80G8226

EKE

oper

ating

envelope

Pressure (P)

Enthalpy (H)

Superheat

r

eference

Evaporator and room control, type EKE 400

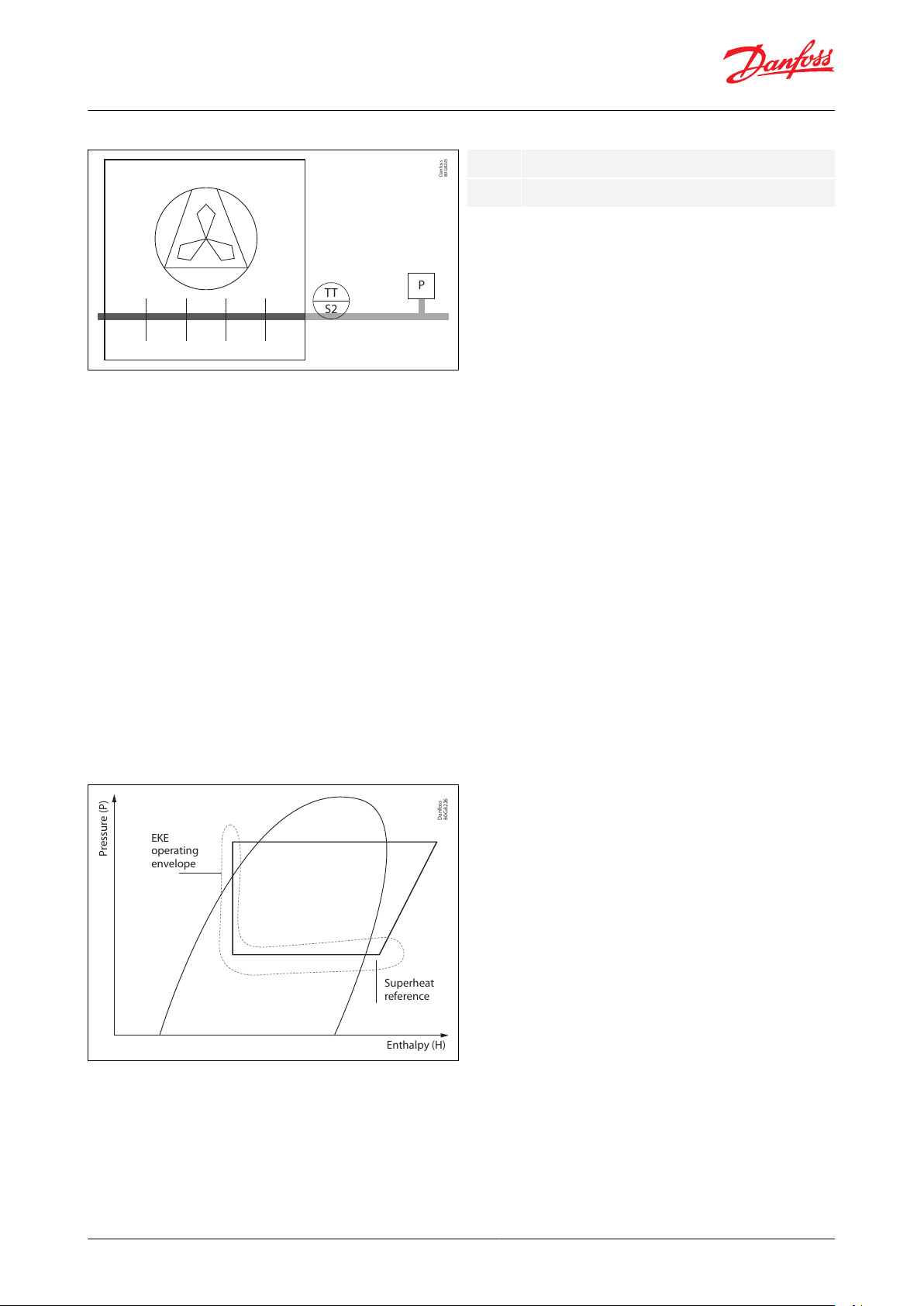

Figure 11: Actual superheat = S2 - T0

P can be display

ed in [Bar] or [psi].

It a refrigerant has been entered in parameter “r20,Refrigerant“ then the calculated evaporating temperature,

converted from the pressure transmitter, is called T0 (or Te).

Superheat reference can be calculated based on following 3 dierent methods:

MSS (Minimum Stable Superheat)

The superheat control algorithm will attempt to regulate the superheat down to the lowest stable value between

the minimum superheat setting, “Min SH” and the maximum superheat setting, “Max. SH”.

LoadAP Superheat

LoadAP is an abbreviation of “load dened reference”. LoadAP will adjust reference to be higher if load is higher.

Load is indicated by the OD of valve. LoadAP is a kind of preprogrammed MSS curve. This method will give a robust

SH reference and can in many cases be the best t for systems.

Fixed Superheat

This feature is used in a system where a stable xed superheat is required.

• MSS - Parameter N01, SH ref. mode is set to: Adaptive SH ctrl

• LoadAP - Parameter N01, SH ref. mode is set to: Load dened c

trl

• Fixed Superheat - Parameter N01, SH ref. mode is set to: Fixed SH ref.

Figure 12: Superheat reference

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 11

Page 12

Danfoss

84B1488

100 %

Qo

Unstable r

e

g

ion

(wet)

10 %

Superheat

Danfoss MSS

Danfoss LoadAP

Fixed SH, 3rd party SH control

Danfoss

84B1487

100 %

10 %

40 %

Superheat

Q o

Un

stable r

egion

(wet)

Stable

r

egion (dry)

Min. SH Max. SH

Danfoss MSS

Evaporator and room control, type EKE 400

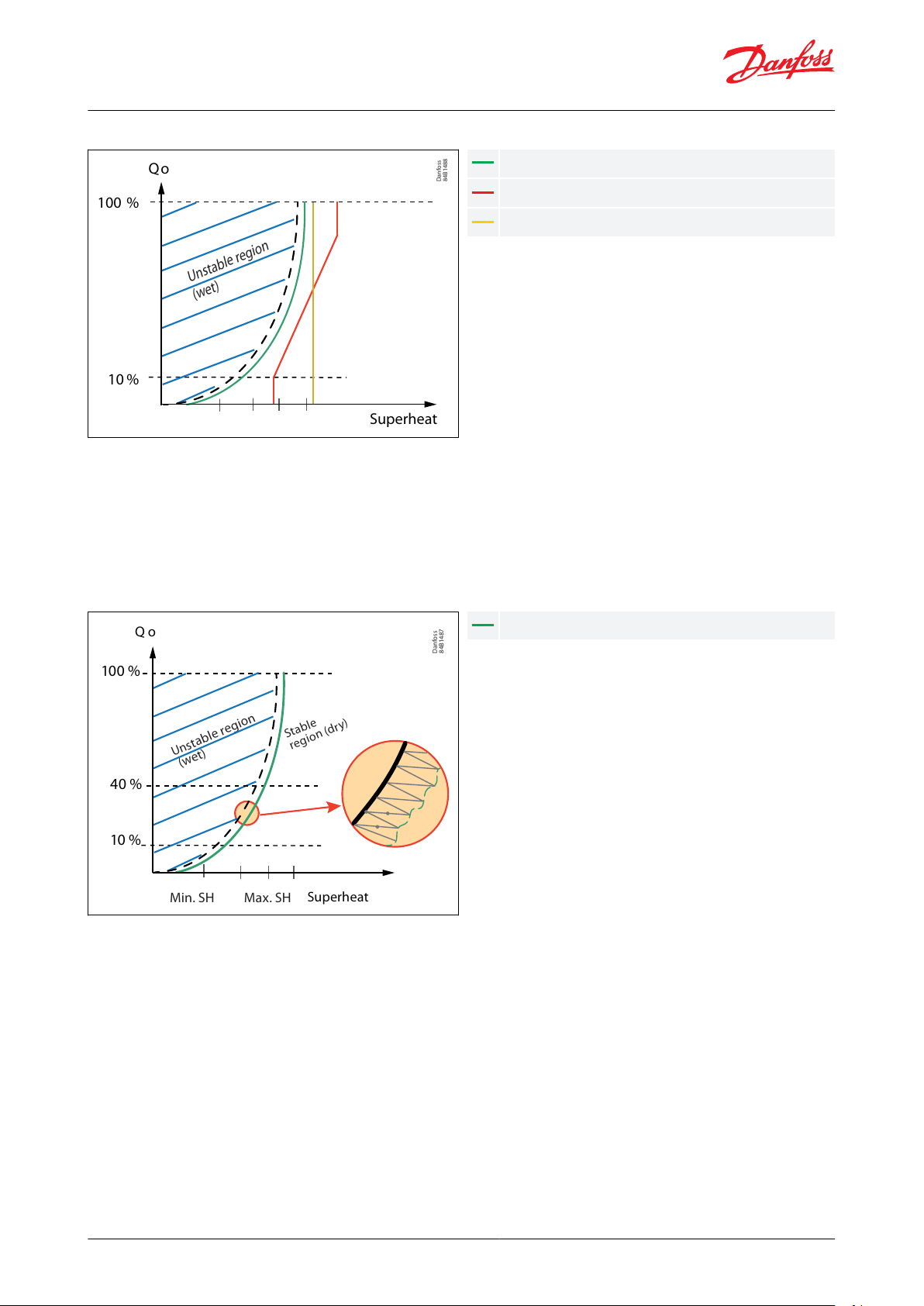

Figure 13: Comparison between SH reference

MSS

he controller will search for the minimum stable superheat between an upper and lower boundary. If the

T

superheat has been stable for a period, the superheat reference is decreased. If the superheat becomes unstable.

the reference is raised again. This process continues as long as the superheat is within the bounds set by the user.

The purpose of this is to search for the lowest possible superheat that can be obtained while still maintaining a

stable system.

Figure 14: MSS

MSS PI controller is made up of 3 parts:

• a stability set point

• the variant from the Te signal

• actual superheat reference

T

he stability set point is given from the “user”. The variants from the T0 signal is used to allow for increased

instability if the T0 signal is unstable. Finally the part from the actual superheat allows for more instability at higher

superheat references than at lower references.

The superheat reference SH ref is adaptive and adjusted. When using this form of control, there are three settings

that have major eect on this mode of control. These are Min. SH, Max. SH and SH close parameters.

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 12

Page 13

Danfoss

80G8227

Start time

Min start

time

The Pctrl is active in

the min star

t time and

until SH cross the

reference

SH

SH ref

Danfoss

80G8228

Start time

Min start

time

The Pctrl is active until

the star

t time if SH

does not get below

reference

SH

SH ref

Parameter

Function

Description

R01

Evaparator control mode

2 = DX control

N01

SH reference mode

2 = Adaptive SH ctrl.

N03

SH max. value

Max. allowed SH reference

N04

SH min. value

Min. allowed SH reference Note: SH min. value must be >0.5K higher than SH close value, if N09 =

1

N18

MSS stability

Stablility factor for regulation of superheat, only relevant for MSS. With a higher value the control

func

tion will allow a greater uctuation of the superheat before the reference is changed.

N19

MSS T0 stability factor

Only relevant for MSS. T0 stability factor denes if v

ariation in suction pressure will inuence superheat reference. The SH reference change can be adjusted by setting the value 0 to 1 (1 = max

T0 inuence and S2, 0 = S2 only). With often change in suction pressure due to compressor start/

stop, some T0 (and S2) inuence on MSS is recommended.

N09

SH close function

0 = O

| 1 = On, default = 1

N10

SH close setpoint

Default value = 2 K (recommended)

Evaporator and room control, type EKE 400

Where to use:

MSS is a benet f

or systems with a long runtime and slow changing conditions like cold rooms, display cases and

chillers. Short cycling and system with fast changing operation condition will not benet from MSS as this feature

will take time to nd the optimal reference. Adaption to a new set point is approx. 15 min.

Table 2: Functions

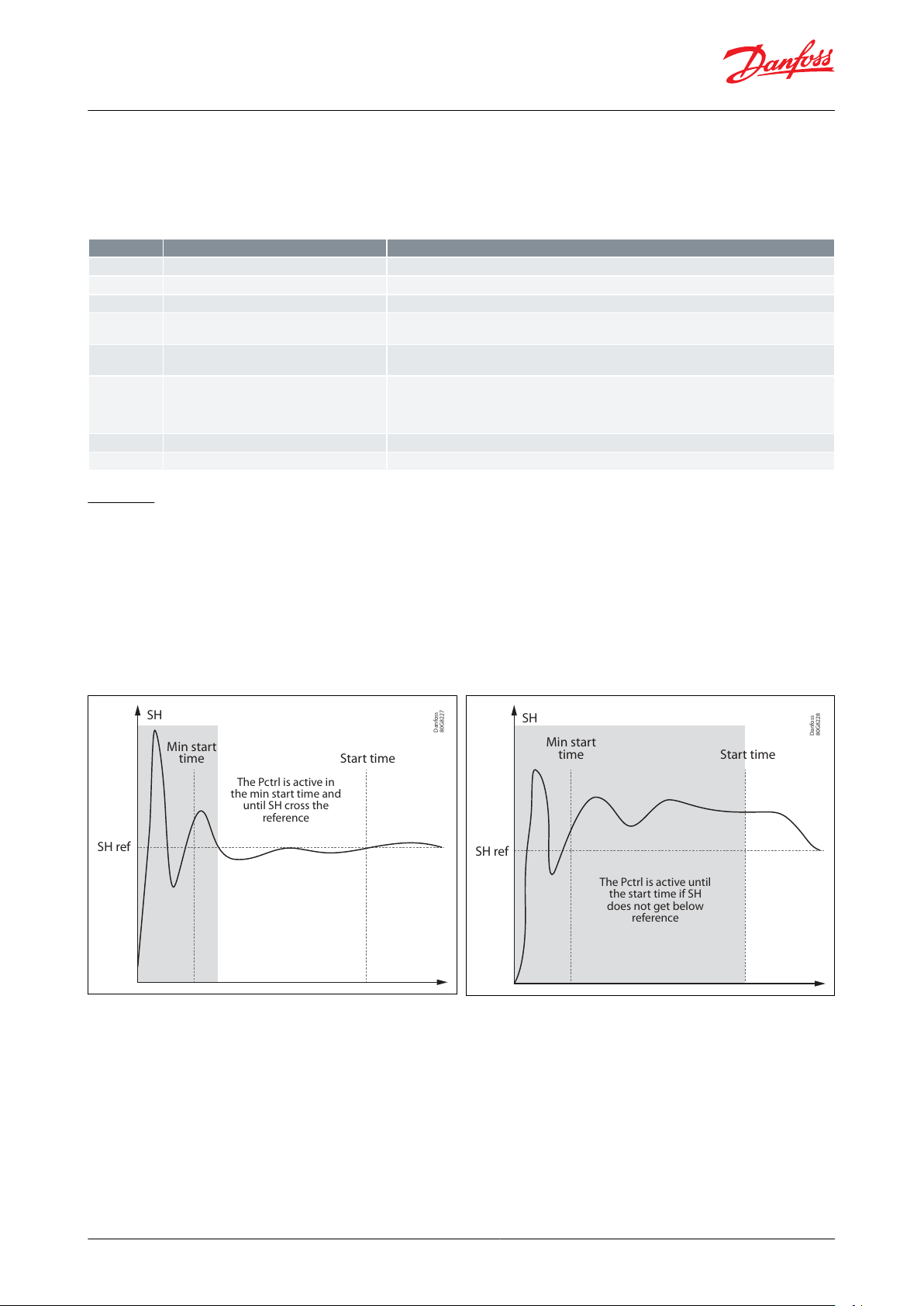

Start up

ometimes in one to one applications. the valve does not open suciently on start-up and troublesome low-

S

pressure trips happen. The following features allows the valve to open faster as well as to reach the optimal

operating conditions quickly.

Proportional (P) control N20, Startup Mode=0

P-control function quickly stabilize the system's superheat by reaching optimal operating conditions in shorter

period of time. The controller is programmed for auto proportional control that will quickly change the opening

degree based on evaporating temperature and superheat of the system.

Figure 15: SH reference

Figure 16: SH reference

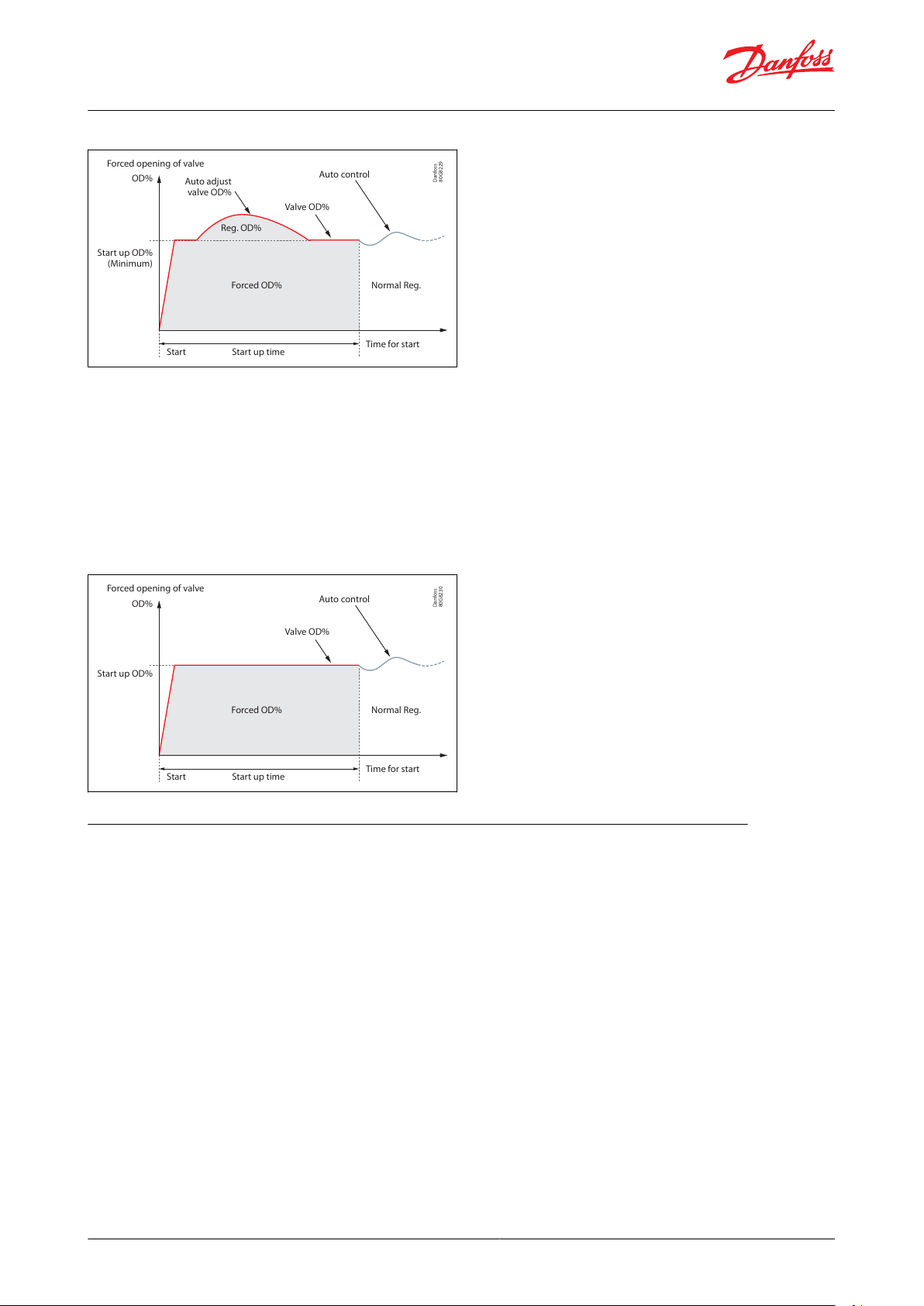

Predened OD with protection N20, Startup Mode=1

After startup, this function will provide a start opening degree during a set time period. If the limiters, the valve will

do the auto adjustment based on the operating conditions and the set limitations.

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 13

Page 14

Danfoss

80G8229

Auto control

Forced opening of valve

Auto adjust

v

alve OD%

Valve OD%

Reg. OD%

Forced OD% Normal Reg.

Time for start

Start up time

Start up OD%

(M

inimum)

OD%

Start

Danfoss

80G8230

Auto control

Forced opening of valve

Valve OD%

Forced OD% Normal Reg.

Time for start

Start up time

Start up OD%

OD%

Start

Evaporator and room control, type EKE 400

Figure 17: P

redened OD with protection N20

NOTE:

A

t start up. if the valve is opened too much, it could result in ow of liquid in the compressor or could trigger the HP

switch which will stop the system. Whereas if you start the system with too low opening degree. it could also stop

the system because of the low-pressure switch cut in. It will be safe to start the system with approximately 50% OD

of the valve at start up, if P-control is not being used.

Predened OD without protection N20, Startup Mode=2

After startup, this function will provide a constant opening degree during a set time period regardless of the

superheat value. No limiters are taken in consideration during this time.

Figure 18: Predened OD without protection N20

DX with defrost by Hot Gas, and the Defrost Drain Line connected to the receiver

n a DX application, with Hot Gas defrost and the Defrost Drain Line connected to the receiver, the EKE 400 can

I

provide a function to manage the valve in the main Hot Gas line. See Figure 19 and Figure 20.

If the Defrost Drain Line is connected to the Liquid receiver it is possible to control the valve in the main HG line

from EKE 400. The purpose of the valve in the main Hot Gas line (e.g. Danfoss type ICS with EVM (SI-port) and a CVPP

(P-port)) is to build up pressure in the Hot Gas line to the receiver during defrost. I.e. once the EVM is energized then

pressure is built up in the Hot Gas line to the receiver via the CVPP.

The EVM can be controlled from the EKE 400. See sketch below: The parameter: D08, Def. seq. status on DO, must be

set to: Yes The assigned DO (DO1 to DO8) must be connected to the EVM on the ICS with CVPP in the main Hot Gas

line.

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 14

Page 15

Danfoss

80G8231

Danfoss

80G8232

Evaporator and room control, type EKE 400

Figure 19: Application sketch

Figure 20: Application sketch

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 15

Page 16

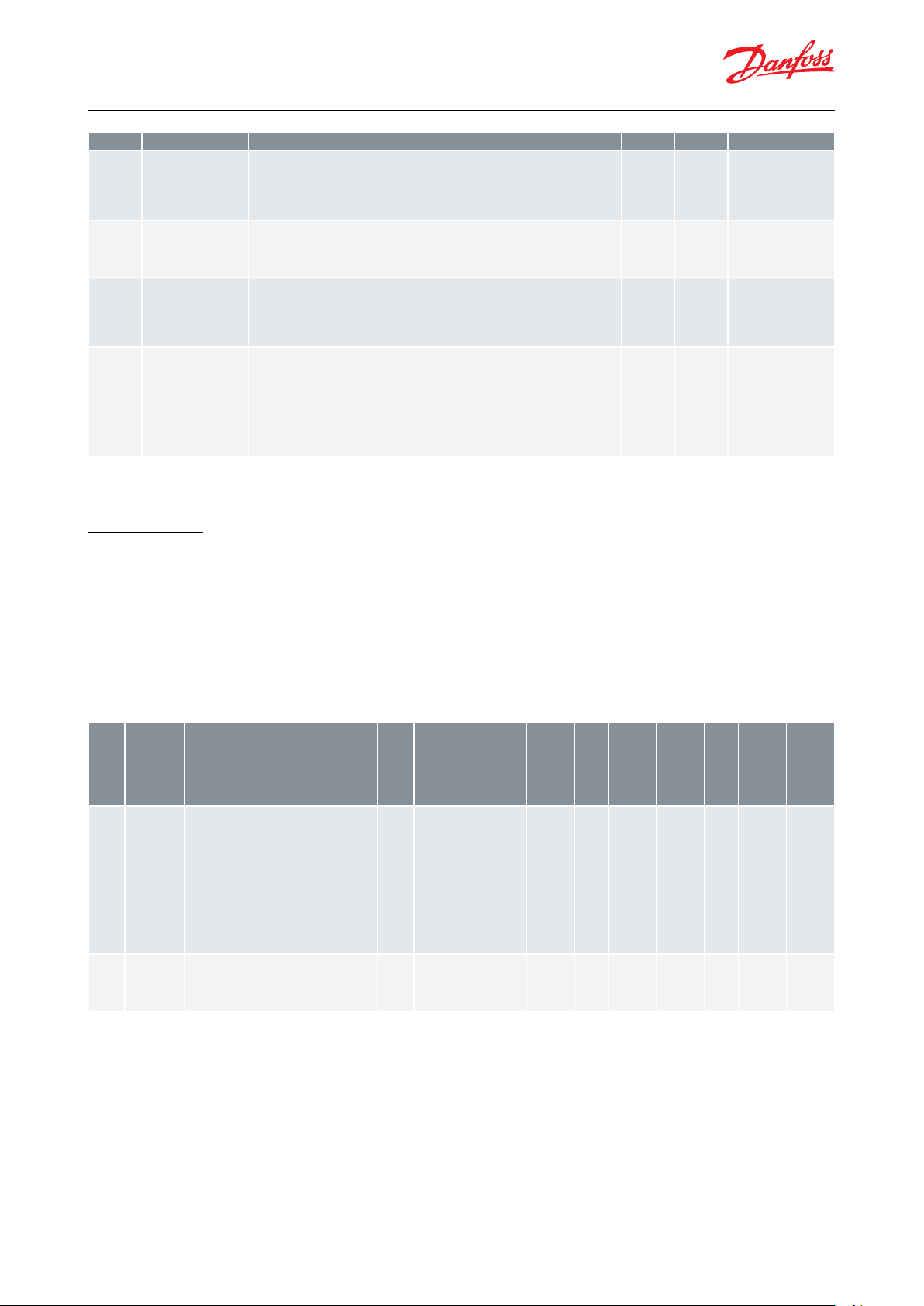

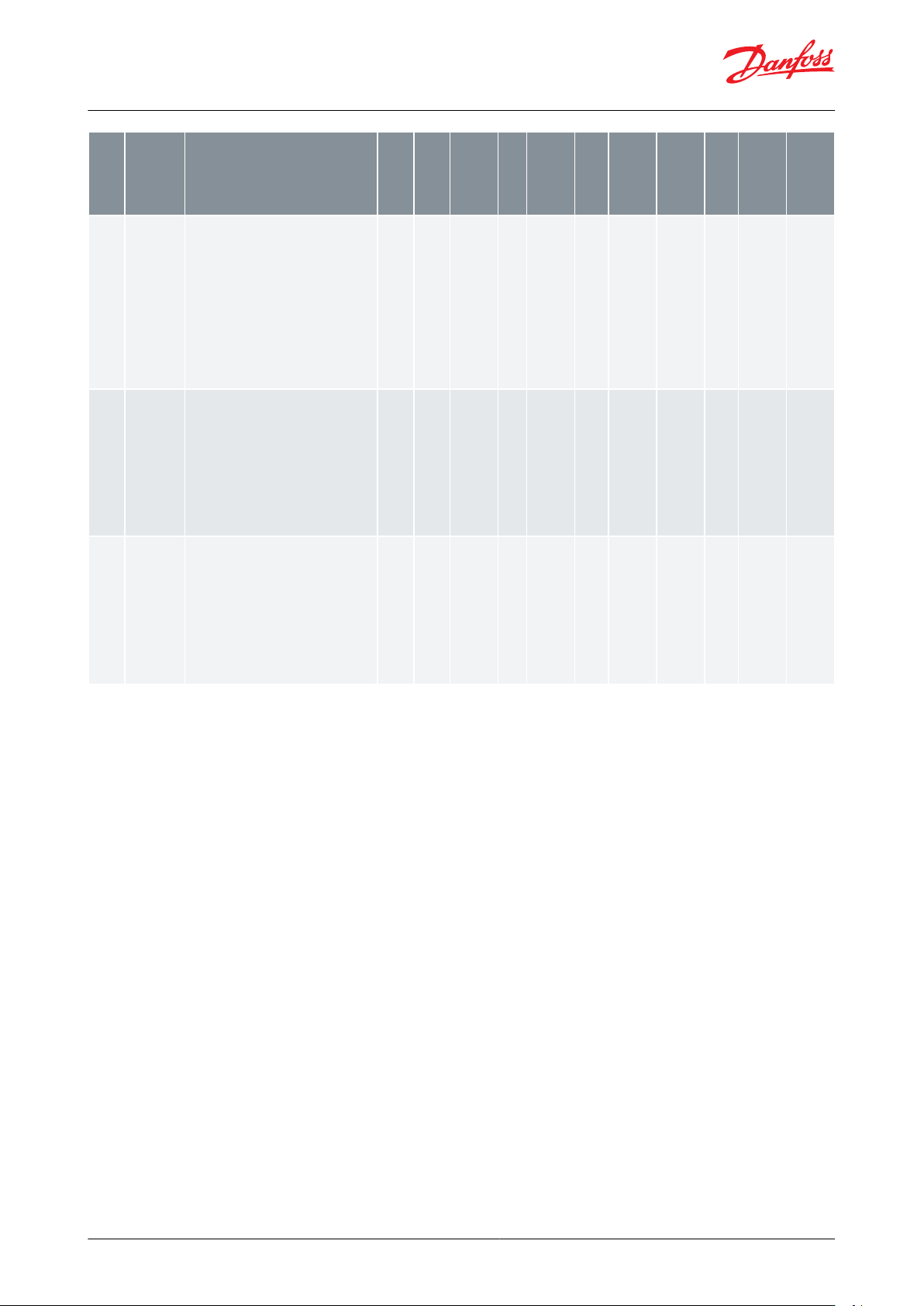

Label ID

(1)

Parameter name

Description and selection options

Min.

Max.

Factory setting

QS

Select quick setting

Select most common type of applications

S

electing one of below application will then preselect valves the actual appliction

in question. See Table 2

1: Flooded On/O: Flooded, Thermostat ON/FF with Hotgas Defrost by pressure

or Liquid drain

2: Dx On/O: DX with Hotgas Defrost by pressure or Liquid drain

3: Flooded Mod WR ctrl: Flooded, Wet Return line control (pressure) Defrost by

pressure or Liquid drain

5: PWM mod.ood: PWM Modulating Thermostat (MTR) in Liquid Line. Flooded

systems

6: EKC315A replace: Retrot/upgrade from EKC 315A to EKE 400

7: EKC361 replace: Retrot/upgrade from EKC 361 to EKE 400

0: User dened; Means that if none of the applications 1 to 7, match - then select

User dened and continue to complete the wizard

070

P01

Display unit

Display unit

0:ME

T: Metric units - Celsius (°C) and Kelvin (°K)

1:IMP: Imperial units - Fahrenheit (°F) and Rankine (°R)

010=MET

R01

Evap. ctrl mode

Evaporator control mode:

-1:None

0:F

lood. evap. On/O

2: DX control

-120=Flood. evap. On/O

D1A

Defrost method

Select the defrost method

0: No defr

ost: No defrost function

1: Hot gas: Defrost done by Hot gas

2:Electrical, water or air defrost (air defrost in rooms with temperature higher

than 0 °C (32 °F))

021=Hot gas

T01

Ther. mode

Select thermostat control mode

1: I

ndividual On/O

3: Mod WR ctrl: MTC (Media Temperature Control) in Wet Return line

5: Pwm mod.ood.: Modulating Thermostat (MTR) in Liquid Line. Flooded systems

151=Individual On/O

R04

Mod WR ctrl. Mode

Select the mode for MTC (Media Temperature Control) in Wet Return line

0: T

emp room const.: Temperature control

1: Press.evap const. evap.: Pressure control

010=Temp room cons

R20

Refrigerant

Select Refrigerant

0: not used;1: R12;2: R22;3: R134a;4: R502;5: R717;6: R13;7: R13B1;8: R23;9:

R500;10: R503;11: R114;12: R142b;13: U

ser;14:R32;15:R227ea;16: R401A;17:

R507A;18: R402A;19: R404A;20: R407C;21: R407A;22: R407B;23: R410A;24: R170;25:

R290;26: R600;27: R600a;28: R744;29: R1270;30: R417A;31: R422A;32: R413A;33:

R422D;34: R427A;35: R438A;36: R513A;37: R407F;38: R1234zeE;39: R1234yf;40:

R448A;41: R449A;42: R452A;43: R450A;44: R452B;45: R454B;46:R1233zdE;47:

R1234zeZ;48: R449B;49: R407H;

0490=Not used

R2A

Liq. feed line valve

Select type of valves in Liquid feed line

1: S

olenoid (ICFE): ON/OFF Solenoid ICF 20 Valve station

2: Solenoid (ICS): ON/OFF Solenoid ICS with EVM pilot

3: Solenoid (ICM): Motorized ICM, as slow opening/closing ON/OF valve. Occupy 1

DO

131=Solenoid (ICFE)

R2B

Liq. feed line valve DX

Select Liquid feed line valve for DX

4: AK

V: AKV or AKVA. Occupy 1 DO. DO5 or DO6 must be assigned

5: AKV + Solenoid: AKV or AKVA (Occupy 1 DO. DO5 or DO6 must be assigned) +

Solenoid (Occupy 1 DO)

6: Mod ICM; Modulating motorized ICM. Occupy 1 AO

7: Mod ICM + solenoid: Modulating motorized ICM (Occupy 1 AO) + Solenoid

(Occupy 1 DO)

474=AKV

R2C

Liq. feed line valve

PWM

Select Liquid feed line valve for Modulating Thermostat (MTR) Flooded

sy

stems

4: AKV: AKV or AKVA. Occupy 1 DO. DO5 or DO6 must be assigned

5: AKV + Solenoid: AKV or AKVA (Occupy 1 DO. DO5 or DO6 must be assigned) +

Solenoid (Occupy 1 DO)

454=AKV

Evaporator and room control, type EKE 400

EKE 400 Wizard

Table 3: EKE 400 Wizard

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 16

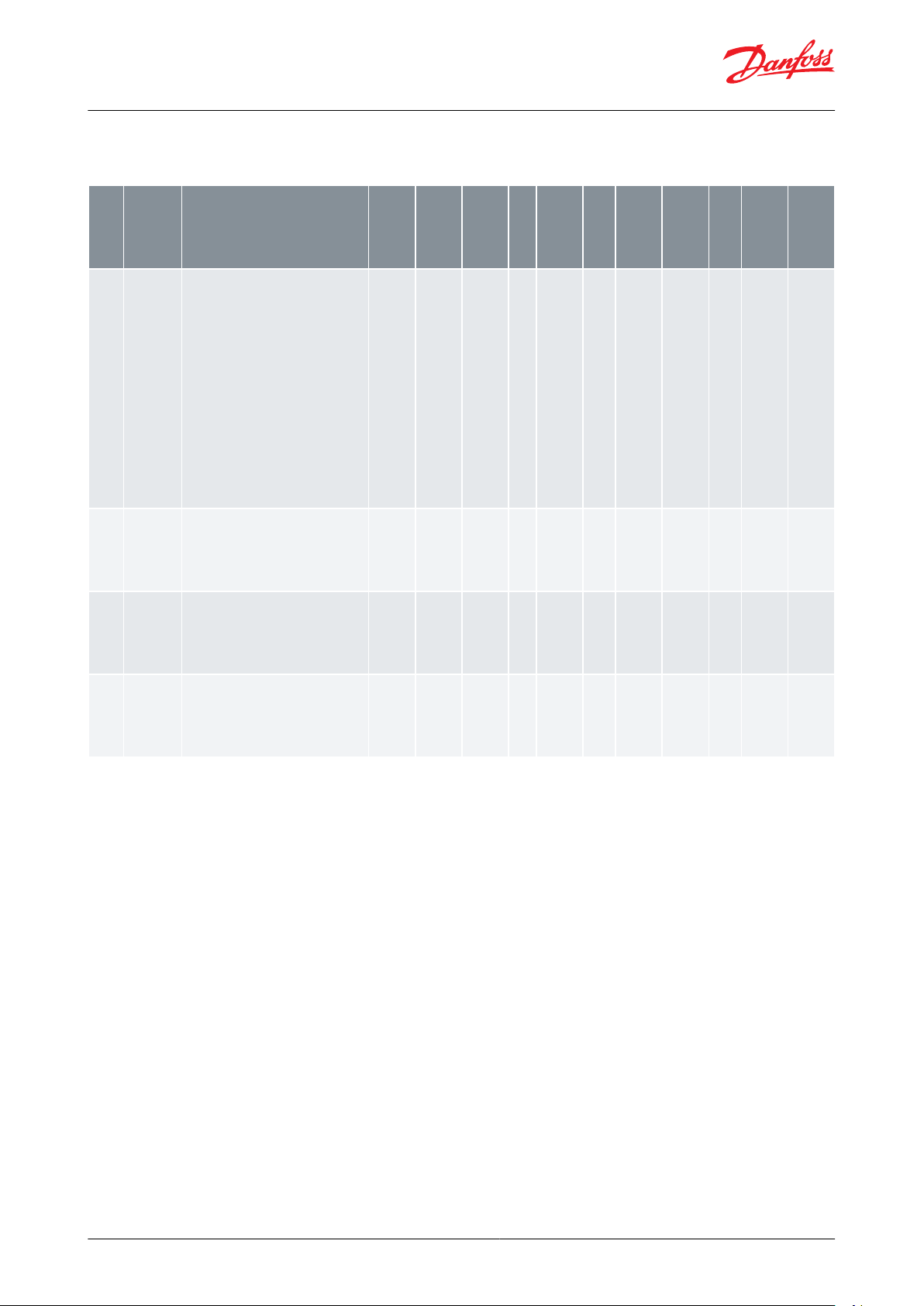

Page 17

Label ID

(1)

Parameter name

Description and selection options

Min.

Max.

Factory setting

D3A

Wet return line val.

Select type of valves in Wet return suction line

0: No V

alve

1: Soft (ICS+EVRST): Dual position individual solenoid valves. Occupy 2 DO

2: Soft (ICSH): Dual position solenoid valve. Occupy 2 DO

3: Soft (ICLX): 2-step gas powered solenoid valve. Occupy 1 DO

4: Solenoid (ICS):ON/OFF Solenoid ICS with EVM pilot

5: Solenoid (ICM):Motorized ICM, as slow opening/closing ON/OF valve. Occupy 1

DO

6: Slow (ICM): Motorized ICM, as slow opening/closing modulating valve. Occupy

1 AO

063=Soft (ICLX)

D3C

Wet return line val.

Select type of valves in Wet return line

7: M

od (ICM): Modulating Motorized ICM

8: Mod+PE (ICM+EVRST): Modulating Motorized ICM with pressure Equalization

valve EVRA/EVRAT/EVRST

787=Mod (ICM)

D2A

Hot gas line valve

Select type of valves in Hot gas defrost line

0: No V

alve

1: Soft (ICS+EVRST): Dual position individual solenoid valves. Occupy 2 DO

2: Soft (ICSH): Dual position solenoid valve. Occupy 2 DO

3: Solenoid (ICFE): ON/OFF Solenoid ICF 20 Valve station

4: Solenoid (ICS):ON/OFF Solenoid ICS with EVM pilot

5: Solenoid (ICM):Motorized ICM, as slow opening/closing ON/OF valve. Occupy 1

DO

6: Slow (ICM): Motorized ICM, as slow opening/closing modulating valve. Occupy

1 AO

062=Soft (ICSH)

D1B

HG Drain valve

Select type of valves in defrost drain line

0: P

ressure (ICS+CVP): Pressure control valve during hot gas defrost. CVP pilot

have adjustable pressure setting

1: Pressure (OFV): Pressure control valve during hot gas defrost. OFV have

adjustable pressure setting

2: Liquid drain (ICFD): Liquid drain during defrost

021=Pressure (ICS+CVP)

D2B

HG Drip tray DO

Select possible DO hot gas valve for drip tray line

No: No Dr

ip tray valve/function

Yes: Drip tray valve and function active

0=No

Yes=1

0=No

D4A

Drain solenoid?

Decide if drain solenoid in defrost drain line is installed

No

Y

es

0=No

1=Yes

1=Yes

D4B

Quick Drain?

Decide if drain valve is installed to drain liquid quikly out before hot gas

en

ter evaporator

No

Yes

0=No

1=Yes

0=No

T04

Ther. setpoint

Thermostat set point temperature

-50.0

50.0

2.0

T05

Ther. neutral zone

Thermostat neutral zone

S

tart/Stop limit around the "T03 Ther. Setpoint"

0.1

20.0

2.0

T17

Suc.Pres. SP To

Evaporator pressure Setpoint in [C] / [F]

T

emperature Setpoint in [C]/[F] compared measured pressure value (calulated

into [C]/[F]

-50.0

50.0

0.0

B02

High alarm limit

High alarm limit

H

igh alarm for the room temperature alarm function. Entered as absolute value

-50.0

50.0

6.0

B03

Low alarm limit

Low alarm limit

L

ow alarm for the room temperature alarm function. Entered as absolute value

-50.0

50.0

-30.0

B04

Alarm delay

Alarm delay

A

larm delay time during normal control used for both high- and low temperature

alarms

0

240

120

D11

Def. time interval

Defrost start by time interval

F

ail safe function if another congured defrost start, has failed.

A defrost will be started when the interval counter (real time) exceeds the

‘Defrost time interval’ setting.

The interval counter is start counting from zero when the defrost is started.

The interval counter will be reset at every defrost start.

The interval counter shall be in standby (not counting) at "Main switch is OFF".

Can be seen in Status Sceen 1.

If "D11,Def. time interval" is 0 (zero) the function is disabled

0

240

0

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 17

Page 18

Label ID

(1)

Parameter name

Description and selection options

Min.

Max.

Factory setting

D12

Def. start acc. cool

time

Defrost start by accumulated cooling time

C

an also be used as a fail safe function if another congured defrost start, has

failed.

A defrost will be started when the accumulated cooling time exceeds "D12,Def.

start acc. cool time" setting.

The accumulated cooling time will be reset at every defrost start.

0

240

0

D14

Def. start by DI

Defrost start by DI

Option t

o start defrost via DI. Typical external dignal from PLC or a push bottom.

If function is enabled, a defrost is started when the DI changes from OFF to ON.

Successive change of the DI during the defrost period are ignored.

No: Function disable

Yes: Function enabled"

0=No

1=Yes

0=No

D15

Def. start schedule

Defrost start schedule

Option t

o run defrost according to local time scedules in EKE 400. Three

schcdules possible (weekdays, saturdays and sunday) with 6 defrost start time

each

No: Function disable

Yes:Function enabled"

0=No

1=Yes

0=No

D40

Defrost stop method

Defrost stop method

S

elect method for stop of defrost

1: Stop on time: When the time delay "D58,Max defrost time" expires, the defrost

is terminated

2: Stop on temp: When the defrost sensor temperature becomes greater than the

set point "D43,Def. stop temp. limit", then the defrost is terminated. If the defrost

time exceed "D58,Max defrost time", then the alarm ‘Max defrost time’ is send and

the defrost is terminated. In case of sensor error, and the time ‘Max defrost time’

expires, the alarm ‘Max defrost time’ is send and the defrost is terminated. The

alarm will automatically be reset after 5 minutes.

To assign defrost sensor temperature, go to I/O conguration in Main menu and

select an available AI"

121=Stop on time

D43

Def. stop temp. limit

Defrost stop temperature limit

S

ee description for "D40, Defrost stop method"

0.0

25.0

8.0

D50

Pump down delay

Pump down delay

Dr

aining the evaporator before defrosting.

Always active

The pump down state is used to empty the evaporator for liquid.

See Figure 21: Defrost sequence.

13010

D51

HG open delay

Hot Gas open delay

T

ime delay in minutes before opening the hot gas valve (delay for valve in the

wet return line to close)

See Figure 21: Defrost sequence.

1105

D5A

Drip tray pre-heat

Driptray pre-heat

P

re-heating time for hot gas to drip tray

See Figure 21: Defrost sequence

0205

D5B

Drip tray delay OFF

Drip tray delay OFF

C

ontinue drip tray heating some dened time

See Figure 21: Defrost sequence

0

120

30

D57

Quick drain time

Quick drain time

En

ter how long time the Quick Drain valve stays open. Quick Drain valve will start

opening together with Hot gas valve

See Figure 21: Defrost sequence

1

300

30

D53

HG soft time

Hot gas soft time

T

ime between step 1 and step 2 for opening the hot gas valve (2 DO used)

See Figure 21: Defrost sequence.

1303

D58

Max defrost time

Max defrost time

M

ax. allowed defrost duration in minutes

1

120

30

D59

Drip o time

Drip o time

A

llow water on the evaporator to drip o.

See Figure 21: Defrost sequence.

1155

D61

WR soft time

Wet return soft time

T

ime between step 1 and step 2 for opening the wet return valve ("Soft (ICS

+EVRST)" or "Soft (ICSH)

See Figure 21: Defrost sequence.

1302

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 18

Page 19

Label ID

(1)

Parameter name

Description and selection options

Min.

Max.

Factory setting

D6A

WR main time

Wet return main time

A

fter defrost and wet return valve has opened (main), enter delay before valve in

liquid line to open.

See Figure 21: Defrost sequence.

1302

D65

Fan start delay

Fan start delay

T

he fan will be started when the time has elapsed.

See Figure 21: Defrost sequence.

0302

D69

WR Pr. Equalising

WR Pressure Equalizing time

E

qualizing pressure in evaporator by soft opening wet return line valve. Carefully

emptying the evaporator for hot gas via a little drain valve (by-pass valve) in the

wet return line or soft opening of wet return valve.

1105

P03

Main switch via DI

Mainswitch via DI

R

elease EKE 400 for operation or force EKE 400 out of operation via external

equipment (e.g. PLC), via DI

OFF: EKE 400 is forced out of operation. Observe if "M01,Main switch" is ON, this

parameter will also when OFF, force EKE 400 out of operation

ON: EKE 400 released for operation. Observe if "M01,Main switch" is ON, this

parameter must also be ON, to release EKE 400 for operation

0=No

1=Yes

0=No

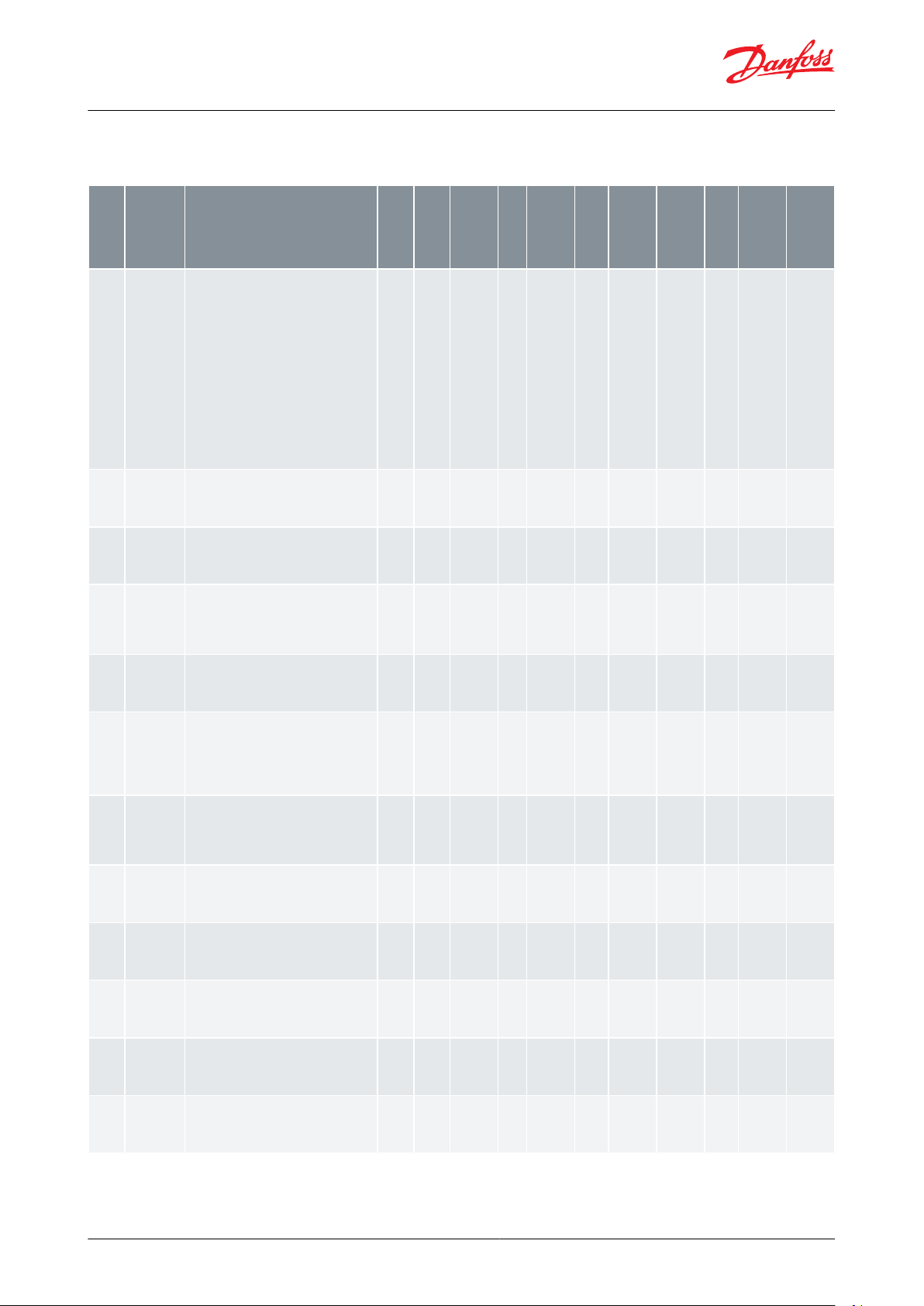

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

M01

Main switch

Release the controller for operation or

f

orce EKE 400 out of operation

OFF: the controller is forced out of

operation. Observe if "M02, Ext. Main

switch" is ON, this DI will also when OFF,

forced the controller out of operation

ON: the controller released for operation.

Observe if "M02, Ext. Main switch" is ON,

this DI must also be ON to release the

controller for operation

0=OFF

1=ON

0=OFF0No

Passw

ord

level

1,2,3

2

3001RWYes

3, 4 & 16

M02

Ext. Main

swit

ch

Status of the external main switch (DI)

0=OFF

1=ON-0

Yes

Passw

ord

level

1,2,3

Can nev-

er be

changed

3002ROYes

3

Evaporator and room control, type EKE 400

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET)

Parameter list

ve that many of the individual parameters listed below, will only be visible, if other parameters have been set.

Obser

Hereby irrelevant parameters are ltered out, during setup of EKE 400.

NOTE:

See Label ID, G07, G08, G09.

1.

All Modbus parameters is type: WORD (signed 16 bit).

2.

Start / Stop

Table 4: Start / Stop

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 19

Page 20

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

R01

Evap. ctrl

mode

Evaporator control mode:

-1: None

0: F

lood. evap. ON/OFF

-100=Flood.

ev

ap.

On/O;

0

Yes

Passw

ord

level

1,2,3

3

3020RWYes

3, 4 & 16

R2A

Liq. feed

line v

alve

Select Liquid feed line valve

1: S

olenoid (ICFE): ON/OFF Solenoid ICF

20 Valve station

2: Solenoid (ICS): ON/OFF Solenoid ICS

with EVM pilot

3: Solenoid (ICM): Motorized ICM, as

ON/OF valve. Occupy 1 DO

1310Yes

Passw

ord

level

1,2,3

3

3021RWYes

3, 4 & 16

R2B

Liq. feed

line v

alve

for DX

Select Liquid feed line valve for DX

4: AK

V: AKV or AKVA. Occupy 1 DO. DO5

or DO6 must be assigned

5: AKV + Solenoid: AKV or AKVA (Occupy

1 DO. DO5 or DO6 must be assigned) +

Solenoid (Occupy 1 DO)

6: Mod ICM; Modulating motorized ICM.

Occupy 1 AO

7: Mod ICM + solenoid: Modulating

motorized ICM (Occupy 1 AO) + Solenoid

(Occupy 1 DO)

4740Yes

3384RWYes

R2C

Liq. feed

line v

alve

PWM

Select Liquid feed line valve for

M

odulating Thermostat (MTR)

Flooded systems

4: AKV: AKV or AKVA. Occupy 1 DO. DO5

or DO6 must be assigned

5: AKV + Solenoid: AKV or AKVA (Occupy

1 DO. DO5 or DO6 must be assigned) +

Solenoid (Occupy 1 DO)

4540Yes

3380RWYes

R10

LL valve AI

f

eedback

Liquid Line feedback from ICAD on

ICM v

alve

In IO conguration \ Analog inputs the

Analog input type can be selected. 0-10

V;0-20 mA;4-20 mA;2-10 V

No: ICAD not connected to EKE 400

Yes: ICAD connected to EKE 400

No

YesNo0

Yes

Passw

ord

level

1,2,3

3

3446RWYes

3, 4 & 16

R05

Cool On/O

by DI

Cooling demand from external

equipmen

t (e.g. PLC) to EKE 400, via DI

0=No

1=Yes

0=No0Yes

Passw

ord

level

1,2,3

3

3024RWYes

3, 4 & 16

R06

Forced closing

Forced stop cooling via MODBUS (e.g.

PL

C) or local from EKE 400

If a PLC controls cooling ON/OFF,

"R06,Forced closing" can be used to stop

cooling

OFF: Function disabled

ON: Forced stop cooling, regardless of

cooling request. Observe. Will

automatically after 15 min go back to

OFF

0=OFF

1=ON

0=OFF0No

Passw

ord

level

1,2,3

2

3025RWNo

3, 4 & 16

Evaporator and room control, type EKE 400

Evaporator control \ Evaporator control mode

Table 5: Evaporator control \ Evaporator control mode

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 20

Page 21

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

R07

Forced

c

ooling

Forced cooling via MODBUS (e.g. PLC)

or lo

cal from EKE 400

The function is typical used to secure

enough hot gas to defrost other

evaporators If a PLC controls cooling ON/

OFF, "R07,Forced cooling" can be used to

start cooling

OFF: Function disabled

ON: Forced cooling, regardless of cooling

request. Observe. Will automatically after

15 min go back to OFF

0=OFF

1=ON

0=OFF0No

Passw

ord

level

1,2,3

2

3026RWNo

3, 4 & 16

R08

Forced

close b

y DI

Forced stop cooling via external

equipmen

t (e.g. PLC) to EKE 400, via DI

If a PLC controls cooling ON/OFF, DI can

be used to stop cooling

No: Function disabled

Yes: Forced stop cooling, regardless of

cooling request. To assign DI, go to I/O

conguration in Main menu and select

an available DI

0=No

1=Yes

0=No0Yes

Passw

ord

level

1,2,3

3

3027RWYes

3, 4 & 16

R09

Forced cool

b

y DI

Forced cooling via external equipment

(e

.g. PLC) to EKE 400, via DI

If a PLC controls cooling ON/OFF, DI can

be used to start cooling

No: Function disabled

Yes: Forced cooling, regardless of cooling

request. To assign DI, go to I/O

conguration in Main menu and select

an available DI

0=No

1=Yes

0=No0Yes

Passw

ord

level

1,2,3

3

3028RWYes

3, 4 & 16

Evaporator and room control, type EKE 400

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 21

Page 22

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func‐

tion

R20

Refrigerant

Select Refrigerant

0: not used;1: R12;2: R22;3: R134a;4: et

c.

0: not used;1: R12;2: R22;3: R134a;4:

R502;5: R717;6: R13;7: R13B1;8: R23;9:

R500;10: R503;11: R114;12: R142b;13:

User;14:R32;15:R227ea;16: R401A;17:

R507A;18: R402A;19: R404A;20:

R407C;21: R407A;22: R407B;23:

R410A;24: R170;25: R290;26: R600;27:

R600a;28: R744;29: R1270;30: R417A;31:

R422A;32: R413A;33: R422D;34:

R427A;35: R438A;36: R513A;37:

R407F;38: R1234zeE;39: R1234yf;40:

R448A;41: R449A;42: R452A;43:

R450A;44: R452B;45:

R454B;46:R1233zdE;47: R1234zeZ;48:

R449B;49: R407H

04900Yes

Passw

ord

level

1,2,3

3

3029RWYes

3, 4 & 16

R23

Refrig fact.

A1

User dened r

efrigerant

When R20=13 (User dened refrigerant)

Enter the Refrigerant factor A1

constants for the Antoine Equation for

the actual refrigerant

8000

13000

104003Yes

3032RWYes

R24

Refrig fact.

A2

User dened r

efrigerant

When R20=13 (User dened refrigerant)

Enter the Refrigerant factor A2

constants for the Antoine Equation for

the actual refrigerant

-3200.0

-1200.0

-2255.01Yes

3033RWYes

R25

Refrig fact.

A3

User dened r

efrigerant

When R20=13 (User dened refrigerant)

Enter the Refrigerant factor A3

constants for the Antoine Equation for

the actual refrigerant

220.0

320.0

254.21Yes

3034RWYes

Evaporator and room control, type EKE 400

Evaporator control \ Pressure c

onguration

Table 6: Evaporator control \ Pressure conguration

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 22

Page 23

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

N01

SH ref.

mode

Select Superheat reference mode:

0: F

ixed SH ref. Used when a stable xed

superheat is required

1: Load dened ctrl: LoadAp mode.

Reference set in dependence of actual

load (Opening Degree) Useful in

applications with rapidly changing load

conditions and at very short cut-in

perios.

2: Adaptive SH ctrl: MSS (Minimum Stable

Superheat) The superheat control

algorithm will constantly lower the

superheat reference, until some

instability is registrated

021= Load

dened

c

trl

0xPass-

w

ord

level

1,2,3

3

3003RWYes

3, 4 & 16

N02

SH Fixed

setpoin

t

Superheat x

ed setpoint

The superheat reference is xed to this

set point under all operating conditions

0.5

40.0

8.01Pass-

w

ord

level

1,2,3

3

3004RWYes

3, 4 & 16

N03

SH max

Superheat maximum

M

aximum limitation of superheat

reference

0.5

40.0

10.01No

Passw

ord

level

1,2,3

2

3005RWYes

3, 4 & 16

N04

SH min

Superheat minimum

M

inimum limitation of superheat

reference

Unit: °C / °F

0.5

10.0

4.01No

Passw

ord

level

1,2,3

2

3006RWYes

3, 4 & 16

N05

SH Tn

Superheat Integration time

I

ntegration time (Tn) in PI controller

Unit: °C / °F

20

900900NoPass-

w

ord

level

1,2,3

3

3007RWYes

3, 4 & 16

N06

SH Kp min

Superheat minimum Proportional gain

c

onstant

Minimum proportional gain in Superheat

PI controller

Unit: °C / °F

0.1

1.0

0.61No

Passw

ord

level

1,2,3

3

3008RWYes

3, 4 & 16

N07

SH Kp

Superheat Proportional gain constant

P

roportional gain in Superheat PI

controller

Unit: sec

0.1

20.0

1.51No

Passw

ord

level

1,2,3

3

3009RWYes

3, 4 & 16

N08

SH KpTe

Superheat Pressure feedback gain

P

roportional gain constant on saturated

temperature

0

20.0

3.01No

Passw

ord

level

1,2,3

3

3010RWYes

3, 4 & 16

N09

SH close

func

tion

Superheat close function

No: F

untion Disabled

Yes: Function Enabled

0=No

1=Yes

1=Yes0Yes

Passw

ord

level

1,2,3

2

3011RWYes

3, 4 & 16

N10

SH close

setpoin

t

Superheat close limit

I

f the superheat is below this value the

valve in the liquid line is forced to close

-5.0

20.0

2.01No

Passw

ord

level

1,2,3

3

3012RWYes

3, 4 & 16

N11

SH close Tn

divide

Advanced parameter setting

F

or Danfoss only

1530No

Passw

ord

level

1,2,3

3

3013RWYes

3, 4 & 16

N12

SH close Kp

fac

tor

Advanced parameter setting

F

or Danfoss only

Unit: °C / °F

0.5101.50No

Passw

ord

level

1,2,3

3

3014RWYes

3, 4 & 16

Evaporator and room control, type EKE 400

Evaporator control mode \ Evaporator DX control

Table 7: Evaporator control mode \ Evaporator DX control

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 23

Page 24

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

N13

MOP function

Maximum Operating Pressure

MOPfunc

tion will limit the valve opening

degree such that the saturated

evaporation temperature Te is kept

below the "N14,MOP" set point. MOP

prevents overloading the compressor

during start-up, by reducing suction

pressure

No: Funtion Disabled

Yes: Function Enabled

No

Yes

0=No0Yes

Passw

ord

level

1,2,3

2

3015RWYes

3, 4 & 16

N14

MOP setpoin

t

Maximum Operating Pressure setpoint

A

ctive if "N13, MOP function" is set to Yes

The actual MOP Evaporator pressure

Setpoint in [C] / [F]

-70.0

50.0

0.01No

Passw

ord

level

1,2,3

2

3016RWYes

3, 4 & 16

N15

MTR Tn

Advanced parameter

I

ntegration time for the MTR algorithm

20

3600

18000No

Passw

ord

level

1,2,3

3

3017RWYes

3, 4 & 16

N16

MTR Kp

Advanced parameter

P

roportional factor for the MTR algorithm

Unit: °C / °F

20

3600

18000No

Passw

ord

level

1,2,3

3

3018RWYes

3, 4 & 16

N17

AKV period

AKV or AKVA period time

P

eriod time of AKV or AKVA

Example: "N17, AKV Period" is set to 6

sec., the Opening Degree is calculated to

40 %, then AKV or AKVA is open in 2,4

sec., and closed in 3, 6 sec

3660Yes

Passw

ord

level

1,2,3

2

3019RWYes

3, 4 & 16

N18

MSS stabilit

y

Minimum Stable Superheat stability

S

tability factor for regulation of

superheat, only relevant for MSS. With a

higher value the control function will

allow a greater uctuation of the

superheat before the reference is

changed.

0.0

10.0

5.01Yes

Passw

ord

level

1,2,3

3

3397RWYes

N19

MSS T0 stabilit

y factor

Minimum Stable Superheat stability

T0 fac

tor

Only relevant for MSS. T0 stability factor

denes if variation in suction pressure

will inuence superheat reference. The

SH reference change can be adjusted in

the range frome 0.0 to 1.0

A value of 1.0 will give max T0 inuence

and S2.

A value of 0.0 will give inuence on S2

only.

With often change in suction pressure

due to compressor start/stop, some T0

(and S2) inuence on MSS is

recommended.

0.0

1.0

0.01Yes

Passw

ord

level

1,2,3

3

3390RWYes

N20

Startup

M

ode

Startup Mode (See section Start Up)

A

fter startup, this function will provide a

constant opening degree during a set

time period regardless of the superheat

value. No limiters are taken in

consideration during this time.

0: Prop.Ctrl: Proprotional (P) control

1: Fix OD w prot: Predened OD

(parameter "N23, Startup OD") with

protection

2: Fix OD wo prot: Predened OD

(parameter "N23, Startup OD") without

protection

0200Yes

Passw

ord

level

1,2,3

3

3393RWYes

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 24

Page 25

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

N21

Startup

time

"Startup time (See section Start Up)

T

his parameter is related to "N20, Startup

Mode"

Unit: sec

1

600900

Yes

Passw

ord

level

1,2,3

3

3394RWYes

N22

Min.startup

time

Min.startup time (See section Start Up)

T

his parameter is related to "N20, Startup

Mode"

Unit: sec

1

240150

Yes

Passw

ord

level

1,2,3

3

3395RWYes

N23

Startup OD

Startup Opening Degree (See section

S

tart Up)

This parameter is related to "N20, Startup

Mode"

Unit: %

1

100320

Yes

Passw

ord

level

1,2,3

3

3396RWYes

N24

Minimum

OD

Minimum Opening Degree

W

hen required, the valve minimum OD

can be set to a required minimum

opening position, such feature is helpful

where the system always requires some

minimum ow.

The minimum OD limit has eect in

injection control mode only

Unit: %

0

10000

Yes

Passw

ord

level

1,2,3

3

3398RWYes

N25

Maximum

OD

Maximum Opening Degree

T

his is useful feature to limit the

maximum OD of a oversized valve used

in the system.

By default the maximum OD of a valve is

set at 100 OD%. This maximum OD % can

be set to lower value if required.

The maximum OD limit has eect in

injection control mode only

Unit: %

0

100

1000Yes

Passw

ord

level

1,2,3

3

3399RWYes

N26

Limit Kp

Limit Kp - Superheat c

onguration

Advance

Proportional gain

1.0

20.0

5.01Yes

Passw

ord

level

1,2,3

3

3400RWYes

N27

Limit Tn

Limit Tn - Superheat c

onguration

Advance

Integration time

Unit: sec

20

900450

Yes

Passw

ord

level

1,2,3

3

3401RWYes

N36

S3 air

in.t

emp.AI?

Air temperature sensor (S3) installed?

U

sed for MTR

0: No not installed

1: Yes installed

To assign AI, go to I/O conguration in

Main menu and select an available AI

0100Yes

Passw

ord

level

1,2,3

3

3405RWYes

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 25

Page 26

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

N28

Ext.Ref.DX

c

ong

External reference DX c

onguration

Select the signal used to change the

Superheat reference.

0: Not used

1: Displace by current: - dene the AI

input range via the following settings:

“N31,Ref.Current SH High”: 4 to 20 mA,

default = 20

“N32,Ref.Current SH Low”: 0 to 20 mA,

default = 4

To assign AI, go to I/O conguration in

Main menu and select an available AO

2: Displace by voltage: - dene the AI

input range via the following settings:

“N33,Ref.Voltage SH High”: 0 to10 Volt,

default = 10

“N34,Ref.Voltage SH Low”: 0 to 10 Volt,

default = 0

To assign AI, go to I/O conguration in

Main menu and select an available AI.

3: Displace by MODBUS

4: Displace by DI

0400Yes

Passw

ord

level

1,2,3

3

3402RWYes

N29

Ref.Oset

SH M

ax

Reference oset Sup

erheat maximum

Scaling of range for superheat

displacement - Maximum value.

See "N28, Ext.Ref.DX cong"

Unit: K

0.0

50.0

0.01No

Passw

ord

level

1,2,3

3

3410RWYes

N30

Ref.Oset

SH M

in

Reference oset Sup

erheat minimum

Scaling of range for temperature

displacement - Minimum value See "N28,

Ext.Ref.DX cong"

Unit: K

-50.0

0.0

0.01No

Passw

ord

level

1,2,3

3

3409RWYes

N31

Ref.Current

SH H

igh

Reference current Superheat high

S

caling of range for AI current - high

value See "N28, Ext.Ref.DX cong"

Unit: mA

N32

20.0

20.01No

Passw

ord

level

1,2,3

3

3354RWYes

N32

Ref.Current

SH L

ow

Reference current Superheat low Scaling

of r

ange for AI current - low value See

"N28, Ext.Ref.DX cong" Unit: mA

0.0

N31

4.01No

Passw

ord

level

1,2,3

3

3355RWYes

N33

Ref.Voltage

SH H

igh

Reference voltage Superheat high

S

caling of range for AI voltage - high

value See "N28, Ext.Ref.DX cong"

Unit: V

N34

10.0

10.01No

Passw

ord

level

1,2,3

3

3356RWYes

N34

Ref.Voltage

SH L

ow

Reference voltage Superheat low

S

caling of range for AI voltage - low value

See "N28, Ext.Ref.DX cong"

Unit: V

0.0

N33

0.01No

Passw

ord

level

1,2,3

3

3357RWYes

N35

Re.Oset

SH M

odbus

Reference oset Sup

erheat by

MODBUS

Oset value via MODBUS (e.g. PLC)

added to current SH reference.

Unit: K

-50.0

50.0

0.01No

Passw

ord

level

1,2,3

3

3358RWYes

N38

Ref. O

set

SH by DI

Reference O

set Superheat when DI is

open, 0 K if closed

If P10, Ext ref. cong.=Displace by DI,

then if the assigned DI:

OFF: No oset added

ON: Value entered here will be added to

SuperHeat reference

Unit: K

-70.0

50.0

0.01No

Passw

ord

level

1,2,3

3

3470RWYes

3, 4 & 16

N37

Tn SH tracking

Tn SH tracking

Unit: sec

3

600

2000No

Passw

ord

level

1,2,3

3

3413RWYes

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 26

Page 27

Label ID

(1)

Parameter name

Description and selection

options

Min.

Max

Factory

S

etting

Deci‐

mals

Locked

b

y

Main

switch

Yes/No

Read

Password

le

vel to

change/

write

Mod‐

bus ad‐

dr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Mod‐

bus

func‐

tion

R2A

Liq. feed line valve

Select type of valves in

Liquid f

eed line

1:Solenoid (ICFE): ON/OFF

Solenoid ICF 20 Valve

station

2:Solenoid (ICS): ON/OFF

Solenoid ICS with EVM pilot

3:Solenoid (ICM): Motorized

ICM, as slow opening/

closing ON/OF valve.

Occupy 1 DO

1310Yes

Passw

ord

level

1,2,3

3

3021RWYes

3, 4 &

16

R2B

Liq. feed line valve

f

or DX

Select Liquid feed line

v

alve for DX

4: AKV: AKV or AKVA.

Occupy 1 DO. DO5 or DO6

must be assigned

5: AKV + Solenoid: AKV or

AKVA (Occupy 1 DO. DO5 or

DO6 must be assigned) +

Solenoid (Occupy 1 DO)

6: Mod ICM; Modulating

motorized ICM. Occupy 1

AO

7: Mod ICM + solenoid:

Modulating motorized ICM

(Occupy 1 AO) + Solenoid

(Occupy 1 DO)

4740Yes

Passw

ord

level

1,2,3

3

3384RWYes

3, 4 &

16

R2C

Liq. feed line valve

PWM

Select Liquid feed line

v

alve for Modulating

Thermostat (MTR)

Flooded systems

4: AKV: AKV or AKVA.

Occupy 1 DO. DO5 or DO6

must be assigned

5: AKV + Solenoid: AKV or

AKVA (Occupy 1 DO. DO5 or

DO6 must be assigned) +

Solenoid (Occupy 1 DO)

4540Yes

Passw

ord

level

1,2,3

3

3380RWYes

3, 4 &

16

D3A

Wet Return line val.

Select type of valves in

W

et return suction line

0: No Valve

1: Soft (ICS+EVRST): Dual

position individual solenoid

valves. Occupy 2 DO

2: Soft (ICSH): Dual position

solenoid valve. Occupy 2

DO

3: Soft (ICLX): 2-step gas

powered solenoid valve.

Occupy 1 DO

4: Solenoid (ICS):ON/OFF

Solenoid ICS with EVM pilot

5: Solenoid (ICM):Motorized

ICM, as slow opening/

closing ON/OF valve.

Occupy 1 DO

6: Slow (ICM): Motorized

ICM, as slow opening/

closing modulating valve.

Occupy 1 AO

0630Yes

Passw

ord

level

1,2,3

3

3253RWYes

3, 4 &

16

Evaporator and room control, type EKE 400

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Evaporator control \ Valve c

onguration

Table 8: Evaporator control \ Valve conguration

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 27

Page 28

Label ID

(1)

Parameter name

Description and selection

options

Min.

Max

Factory

S

etting

Deci‐

mals

Locked

b

y

Main

switch

Yes/No

Read

Password

le

vel to

change/

write

Mod‐

bus ad‐

dr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Mod‐

bus

func‐

tion

D03

Wet Return line val.

Select type of valves in

W

et return suction line

7: Mod (ICM): Modulating

motorized ICM. Occupy 1

AO

8: Mod+PE (ICM+EVRST):

Modulating motorized ICM,

occupy 1 AO and Solenoid

for pressure pressure

equalization at opening,

occupy 1 DO

9: Mod (CVE): Electronic

pressure pilot. Occupy 1 AO

10: Mod+PE (CVE+ EVRST):

Electronic pressure pilot.

Occupy 1 AO and Solenoid

for pressure pressure

equalization at opening,

occupy 1 DO

11: Mod+PE(CVE+EVM

+EVRST): Electronic

pressure pilot. Occupy 1 AO

and two solenoid , occupy 2

DO. When installed in a ICS

3 topcover. SI port: EVM, to

secure valve closed during

defrost. SII port:CVE. P port:

Blocked. EVRST: For

pressure pressure

equalization at opening

71170Yes

Passw

ord

level

1,2,3

3

3388RWYes

3, 4 &

16

Evaporator and room control, type EKE 400

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 28

Page 29

Label ID

(1)

Parameter name

Description and selection

options

Min.

Max

Factory

S

etting

Deci‐

mals

Locked

b

y

Main

switch

Yes/No

Read

Password

le

vel to

change/

write

Mod‐

bus ad‐

dr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Mod‐

bus

func‐

tion

D2A

Hot gas line valve

Select type of valves in

H

ot gas defrost line

0: No Valve

1: Soft (ICS+EVRST): Dual

position individual solenoid

valves. Occupy 2 DO

2: Soft (ICSH): Dual position

solenoid valve. Occupy 2

DO

3: Solenoid (ICFE): ON/OFF

Solenoid ICF 20 Valve

station

4: Solenoid (ICS):ON/OFF

Solenoid ICS with EVM pilot

5: Solenoid (ICM):Motorized

ICM, as slow opening/

closing ON/OF valve.

Occupy 1 DO

6: Slow (ICM): Motorized

ICM, as slow opening/

closing modulating valve.

Occupy 1 AO

0620Yes

Passw

ord

level

1,2,3

3

3247RWYes

3, 4 &

16

D2C

HG valve AI feedback

Hotgas Line feedback

fr

om ICAD on ICM valve

In IO conguration \ Analog

inputs the Analog input

type can be selected. 0-10

V;0-20 mA;4-20 mA;2-10 V

No: ICAD not connected to

EKE 400

Yes: ICAD connected to EKE

400

No

YesNo0

Yes

Passw

ord

level

1,2,3

3

3451RWYes

3, 4 &

16

D1B

HG Drain valve

Select type of valves in

defr

ost drain line

0:Pressure (ICS+CVP):

Pressure control valve

during hot gas defrost. CVP

pilot have adjustable

pressure setting

1: Pressure (OFV): Pressure

control valve during hot gas

defrost. OFV have

adjustable pressure setting

2: Liquid drain (ICFD):

Liquid drain during defrost

0210Yes

Passw

ord

level

1,2,3

3

3245RWYes

3, 4 &

16

Evaporator and room control, type EKE 400

(1)

(1)

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

Visibility depends on other parameter settings. Numbers are displayed in Metric units ( P01, Temperature units=MET).

© Danfoss | Climate Solutions | 2021.03 AI306444073210en-000801 | 29

Page 30

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write

(RW)

Persis‐

t

ent

Yes/No

Modbus

func

tion

T1A

Ther. mode

Select thermostat control mode

0: None

1: I

ndividual On/O

2: Common On/O

3: Mod WR ctrl: MTC (Media Temperature

Control) in Wet Return line

5: Pwm mod.ood.: Modulating

Thermostat (MTR) in Liquid Line. Flooded

systems

0510Yes

Passw

ord

level

1,2,3

3

3037RWYes

3, 4 & 16

T1B

Ther. mode

Select thermostat control mode

0: None

1: I

ndividual On/O

2: Common On/O 4: MTR: Modulating

Thermostat (MTR) in Liquid Line. Flooded

systems

0410Yes

Passw

ord

level

1,2,3

2

3386RWYes

3, 4 & 16

R04

Mod WR

c

trl. Mode

Select the mode for MTC (Media

T

emperature Control) in Wet Return

line

0: Temp room const.: Temperature

control

1: Press.evap const. evap.:Pressure

control

010

Yes

Passw

ord

level

1,2,3

3

3022RWYes

3, 4 & 16

T02

No. of ther.

sensor

Number of temperature sensors

c

onnected to EKE 400

It is possible to connect up to 3 room

thermostat sensors to the same

controller. Typically, only one thermostat

sensor is connected, but sometimes

more sensors are connected to avoid

“hot spots” in a room.

0: No thermostat sensor connected

1: One thermostat sensor connected

2: Two thermostat sensors connected

3: Three thermostat sensors connected

0310Yes

Passw

ord

level

1,2,3

2

3038RWYes

3, 4 & 16

T03

Ctrl temp.

method

Control method

T

he control method shall be selected if

common thermostat is selected or if

more thermostat sensors are connected

to EKE 400. The temperatures used of

thermostat is selected by setting of “T03,

Ctrl temp. method”:

0:Ctrl highest temp:

1:Ctrl average temp.:

0100Pass-

w

ord

level

1,2,3

2

3039RWYes

3, 4 & 16

T04

Ther. setpoin

t

Thermostat set point temperature

Unit: °C / °F

-70.0

50.0

2.01Pass-

w

ord

level

1,2,3

2

3040RWYes

3, 4 & 16

T05

Ther. neutr

al zone

Thermostat neutral zone

S

tart/Stop limit around the "T03 Ther.

Setpoint"

Unit: K

0.1

20.0

2.01Pass-

w

ord

level

1,2,3

2

3041RWYes

3, 4 & 16

T06

Day/night

c

ontrol

Day/Night control

F

unction that allow to add an oset value

to "T03 Ther. Setpoint"

No: Function disabled

Yes: Function enabled. Night status

visible in Status Screen 1

See "T08,Night oset"

No

YesNo0

Passw

ord

level

1,2,3

3

3042RWYes

3, 4 & 16

Evaporator and room control, type EKE 400

Air temperature control \ Thermostat function

Table 9: Air temperature control \ Thermostat function

© Danfoss | Climate Solutions | 2021.03

AI306444073210en-000801 | 30

Page 31

Label

ID

(1)

Parameter

name

Description and selection options

Min.

Max

Factory

S

etting

Dec‐

im‐

als

Locked

b

y Main

switch

Yes/No

Read

Pass‐

w

ord

level to

change/

write

Modbus

addr

ess

Read

only

(R

O) /

Read

Write