Data Sheet

Liquid level controller

Type EKE 347

An intuitive and easy to navigate controller with

Modbus network capability

The EKE 347 controller is used for regulation of

the liquid level in:

• Pump reservoirs

• Separators

• Intermediate coolers

• Economisers

• Condensers

• Receivers

The controller is communicating with a

transmitter that continuously measures the

liquid level in the actual reservoir.

By comparing the measured value with the

level setpoint entered by the customer, the

controller dictates the valve to increase or

decrease the liquid ow to or from the

reservoir.

AI190286434038en-000501

Liquid level controller, Type EKE 347

Features

• Liquid level control

• Alarm if the set alarm limits are exceeded

• Relay outputs for upper and lower level limits and for alarm level

• User friendly and easy setup Wizard for rst time conguration

• PI control

• Low or High side control

• When AKV/A is selected, a MASTER/SLAVE system can run up to 3 AKV/A with distributed Opening Degree

• Manual control of output

• Limitation of Opening degree possible

• ON/OFF operation with hysteresis

• Programming menu with 3 access levels and separate passwords

• Connection to other EKE 347 controllers possible

• Wired remote display possible

• BUS communication:

◦ CAN Bus (Danfoss internal only)

◦ MODBUS RTU RS485 for communication with e.g. PLC

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 2

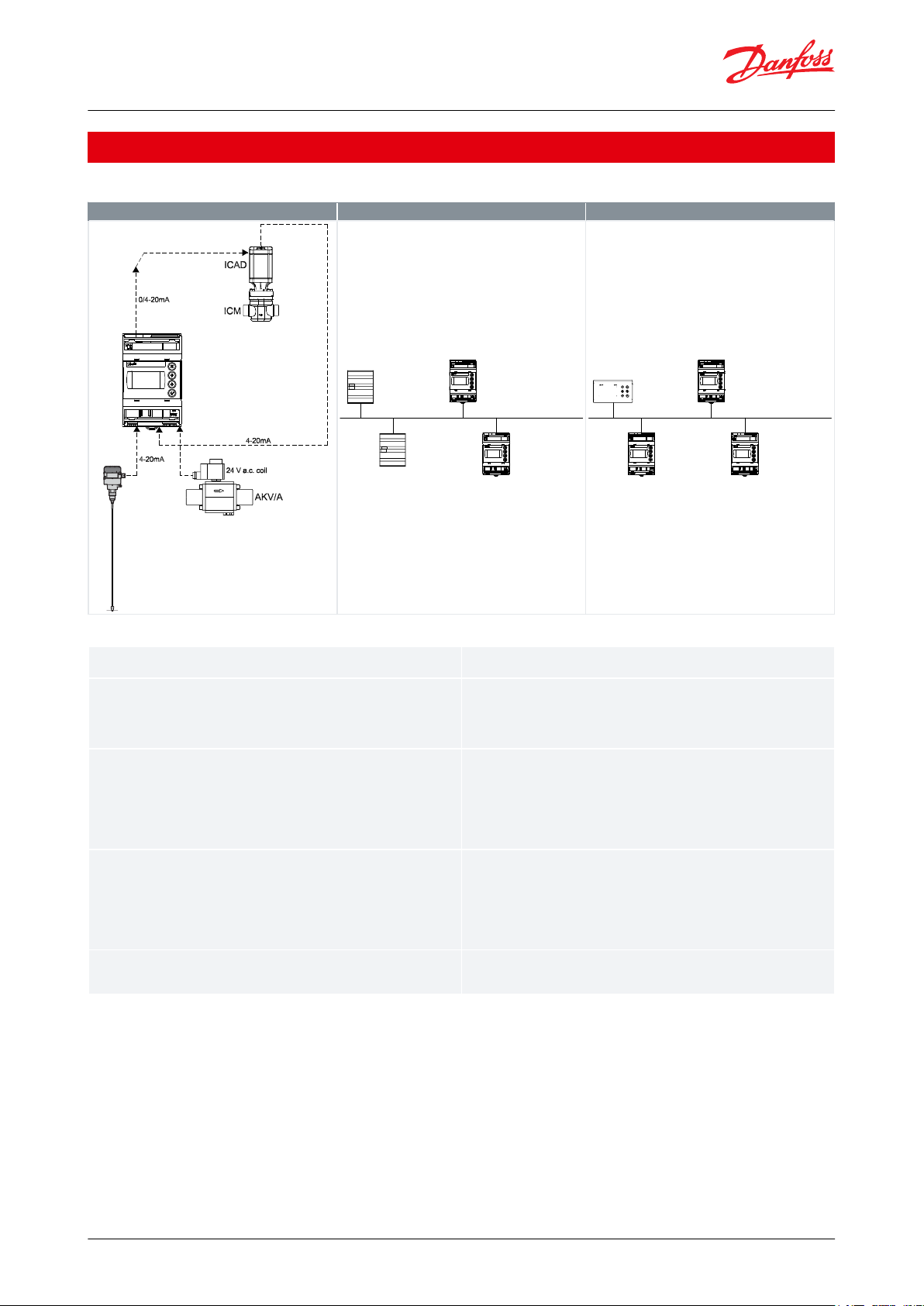

EKE 347 assembly

MODBUS communication

Remote Display - option

Danfoss

M84H0081_1

AKS 4100/

AKS 4100U

EKE 347

Danfoss

M84H0086_1

PLC

Master

PLC

Slave

EKE 347

Slave

EKE 347

Slave

MODBUS-RTU network

Danfoss

M84H0087_1

Remote

display

EKE 347

EKE 347

Danfoss CAN bus

EKE 347

Signaltransmitter

With the guided micro wave rod AKS 4100/4100U it is possible to set the refrigerant level within a wide range.

EKE 347

The controller receive a signal which enable it to contol low or high side applications (see page 3).

EKE 347 does support 2 types of Danfoss expansion valves. (see below) One

analog input is available as feed back from ICM in order to indicate opening

degree of the ICM.

Expansion valves

Two types of Danfoss expansion valves can be used

ICM

ICM are direct operated motorized valves

driven by digital stepper motor type ICAD

AKV/A

AKVA or AKV are pulse-width modulating

expansion valves.

MODBUS communication

EKE 347 include as standard RS 485 based MODBUSRTU bus communication interface to third

party equipment like PLC.

Via the MODBUS it is possible to read and write

parameters to the EKE 347

Operation, monitoring and data collection can

then be performed via PLC from a SCADA system.

Remote Display - option

A remote display for panel mounting is available. From the remote display a full

overview and access is possible to all individual EKE 347 controllers connected to

the internal Danfoss CAN bus.

Liquid level controller, Type EKE 347

Functions

Table 1: Functions

Table 2: Functions

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 3

ICM with

ICAD mo tor

EKE 347

AKS 4100/

AKS 4100U

AKS 4100/

AKS 4100U

EKE 347

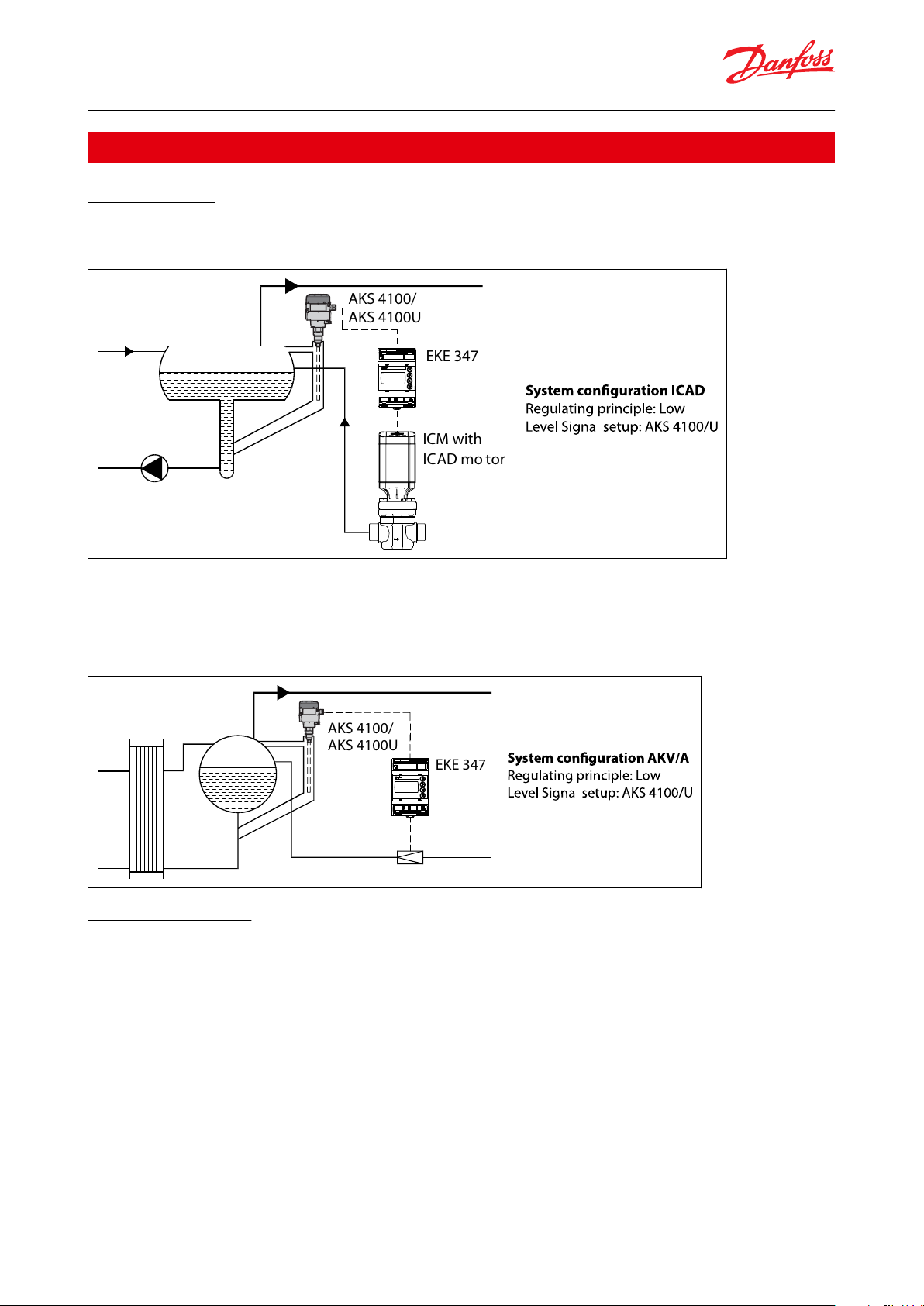

Liquid level controller, Type EKE 347

Applications

Pump reservoir

Modulating control of injection for a more stable liquid level and suction pressure.

Figure 1: System conguration ICAD

Separator on ooded evaporator

Modulating control and the valve’s large capacity range ensure a stable level - even under conditions of quickly

changing loads.

Figure 2: System conguration AKV/A

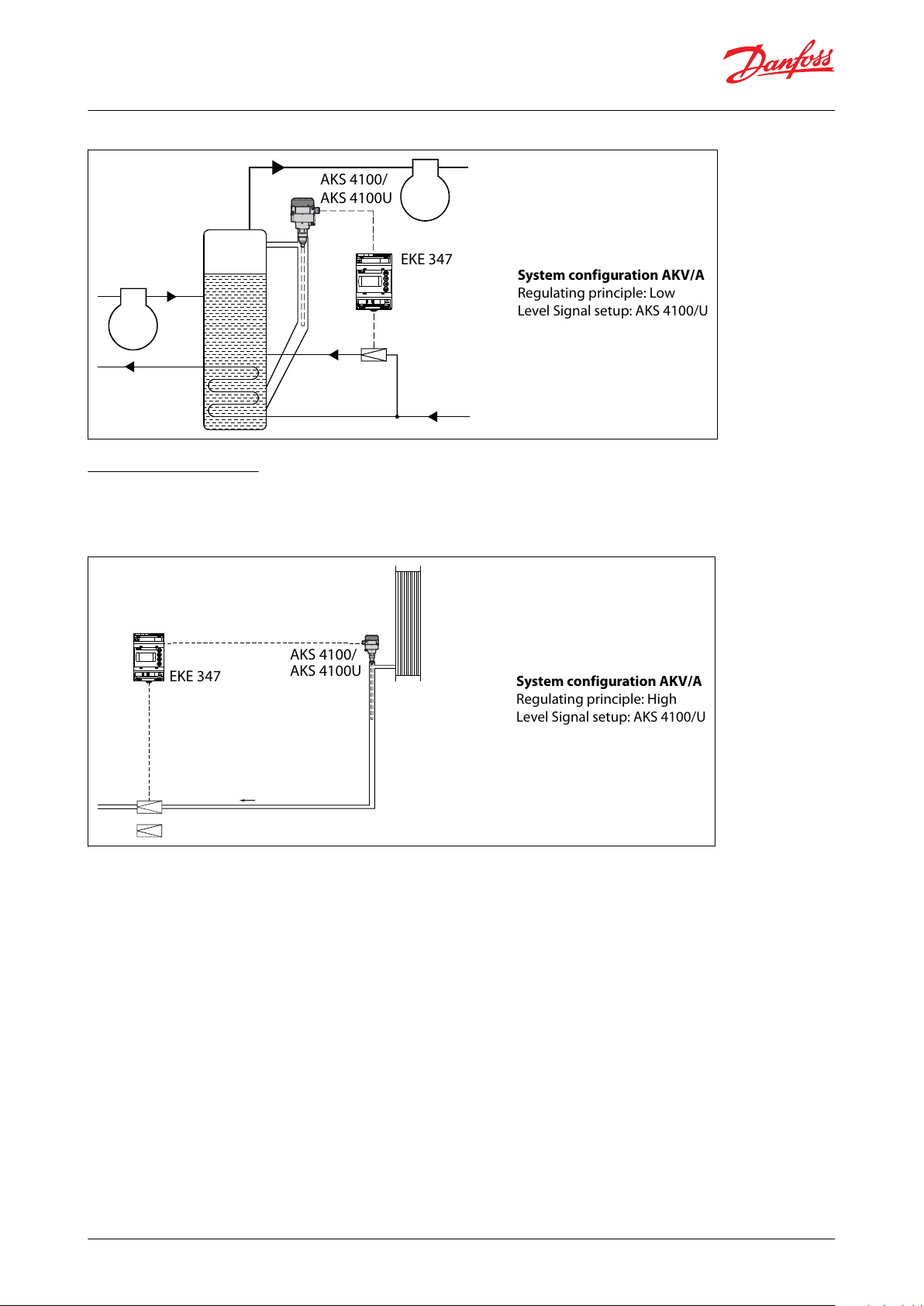

Intermediate cooler

The level transmitter’s wide measuring range enables it to monitor the liquid at all levels of the reservoir - and hence

to use the signal for safety functions in connection with the max. permissible level.

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 4

EKE 347

AKS 4100/

AKS 4100U

System configuration AKV/A

Regulating principle: Low

Level Signal setup: AKS 4100/U

EKE 347

AKS 4100/

AKS 4100U

System configuration AKV/A

Regulating principle: High

Level Signal setup: AKS 4100/U

Liquid level controller, Type EKE 347

Figure 3: System conguration AKV/A

Receiver / condenser

The control system’s short reaction time makes it very suited for high-pressure oat systems with small refrigerant

charges.

Figure 4: System conguration AKV/A

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 5

Supply voltage

24 V AC ±20% 50 / 60 Hz or 24 V DC ±20% (the supply voltage is galvanically separated from the input and

output signals. Input/output are not individual galvanic isolated)

Power consumption

Controller

20 W coil for AKV or AKVA

15 VA / 10W

55 VA

Input signal

* Ri =

0(4) – 20mA: 33 ohm

0(2) – 10 V: 100 kohm

Level signal *

4 – 20 mA or 0 – 10 V

ICM valve feedback signal *

From ICAD 0/4 – 20 mA

Contact function start / stop of regulation

Relay output

3 pcs. SPDT (Lower level alarm, Upper level alarm,

Common alarm / NC Solenoid)

Normally Open:

3 A GP*, 2.2 FLA / 13.2 LRA, 1/6 hp, PD 220 VA, 250 V

AC 100 k

3 FLA / 18 LRA, 1/10 hp, PD 150 VA, 125 V AC 100 k

Normally Closed:

3 A GP*, 250 V AC 100 k

(*GP = General purpose)

Max 240 V AC or 24 V AC / DC can be used, but same

voltage type must be used on DO3 and DO2

Current output

0 – 20 mA or 4 – 20 mA

Max. load: 500 ohm

Valve connection

ICM - via current output

AKV/A- via 24 AC Pulse-Width Modulating output

Data communication

MODBUS RTU: Communication to system controller,

MODBUS on RS485: galvanic isolation (500 V DC)

CAN: Communication to other EKE controllers

Supported Modbus Commands

Supported commands with max of 50 ms response

time

03 (0x03) Read Holding Registers

04 (0x04) Read Input Registers

06 (0x06) Write Single Register

Supported commands without

dened max response

time

08 (0x08) Diagnostics

16 (0x10) Write Multiple Registers (up to 20 registers)

43 (0x2b) Read Device

Identication

Environments

-20 °C – 55 °C, during operation

-30 °C – 80 °C, during storage

90% Rh, not condensed

No shock

inuence / vibrations

Enclosure

IP20 / IP40 for the front mounted into a panel

Weight

193 g

Mounting

DIN rail

Display

Graphical LCD display

Terminals

plugs 1.5 or 2.5 mm2 multicore

Terminals

28-29

Supply voltage 24 V a.c. or d.c.

1-7

Signal from level transmitter type AKS 4100/4100U

7-10

Signal from level transmitter type AKS 41

36-37

Expansion valve type AKV or AKVA

23-24

Expansion valve type: ICM with ICAD

13-14

Switch function for start/stop of controller. If a switch is not connected, terminals 13 and 14 must be shortcircuited

Liquid level controller, Type EKE 347

Product specication

Electrical connection

Table 3: Electrical connection

Material specication

Table 4: Material specication

Connection

Table 5: Necessary connections

NOTE:

See the gures on the next pages.

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 6

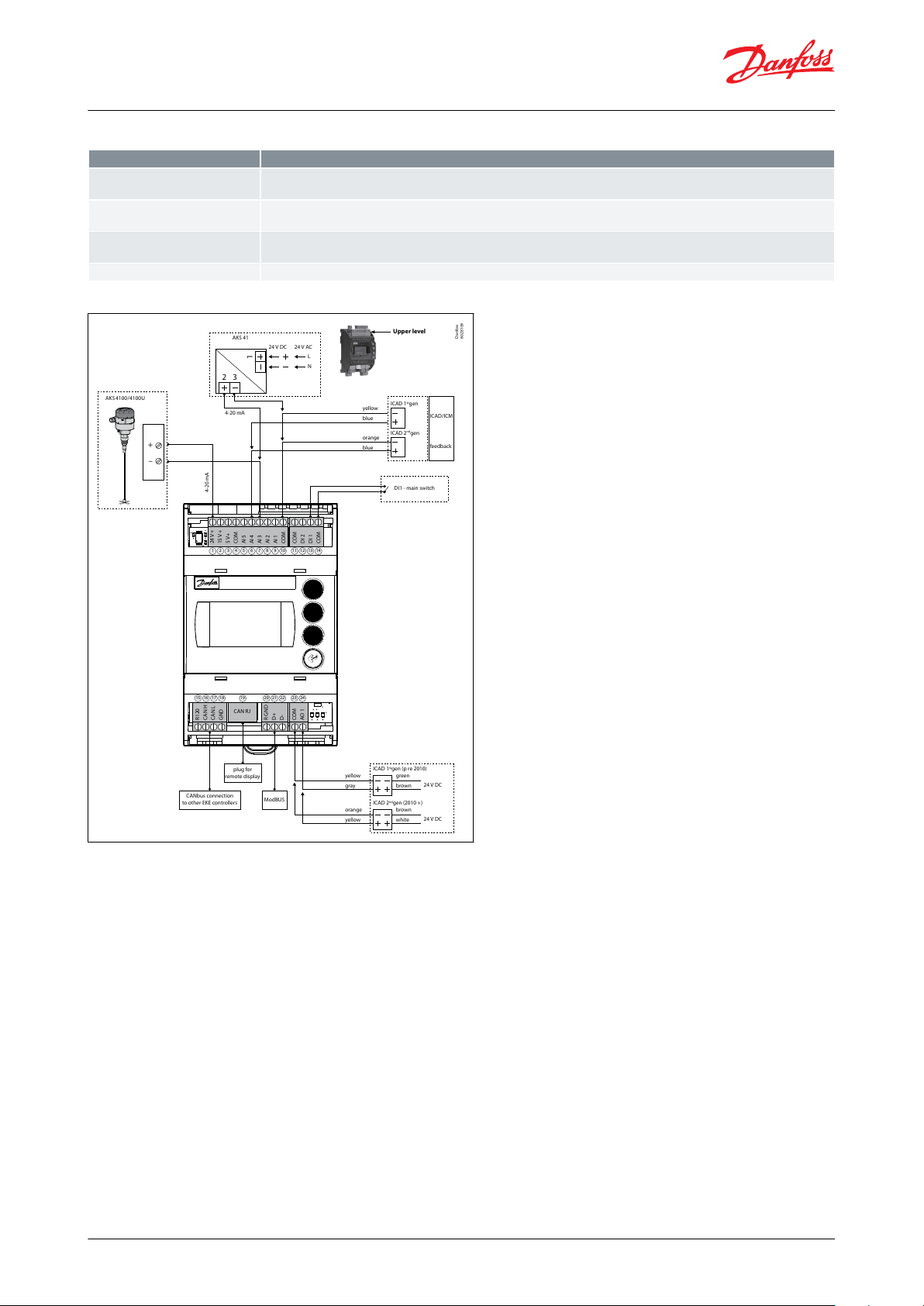

AKS4100 /4100U

AKS 41

DI1 - main switch

4-20 mA

CANbus connection

to other EKE controllers

plug for

remote display

ModBUS

4-20 mA

24V DC

yellow

blue

orange

ICAD 1stgen

ICAD/ICM

feedback

ICAD 2ndgen

blue

24V AC

L

N

+

–

1

2 3

yellow

gray

orange

ICAD 1stgen (p re 2010)

ICAD 2ndgen (2010 +)

yellow

green

brown

brown

white

24V+

15V+

5V+

COM

AI 5

AI 4

AI 3

AI 2

AI 1

COM

COM

DI 2

DI 1

COM

R120

CAN H

CAN L

GND

R GNDD+D-

COM

AO 1

CAN RJ

24V DC

24V DC

1

15 16 17 18 19 20 21 22 23 24

2 3 4 5 6 7 8 9 10 11 12 13 14

Upper level

Danfoss

80Z8109

Terminals

33-35

Relay for common alarm. Installer can choose between Normally Open (33-34) or Normally Closed (34-35) circuits. The relay

will switch according to the programmed setting

25-27

Relay for low level limit. Installer can choose between Normally Open (26-27) or Normally Closed (25-26) circuits. The relay will

switch when the set value is passed.

30-32

Relay for upper level limit. Installer can choose between Normally Open (30-31) or Normally Closed (31-32) circuits. The relay

will switch when the set value is passed.

6-10

ICM valve feedback signal from ICAD 0/4 – 20 mA

Liquid level controller, Type EKE 347

Table 6: Application dependent connections

Figure 5: Connections - Upper level

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 7

–/~

NO 4

NC 3

C 3

NO 3

NC 2

C 2

NO 2

-/~

+/~

NO 1

C 1

NC 1

POWER

SUPPLY

AKV/AKVA

24V AC

+/- 20% 15VA

24V DC

+/- 20% 10W

–

Common

Normally Open or

Normally Closed

Low Level Alarm

Normally Open or

Normally Closed

High Level Alarm

Normally Open or

Normally Closed

+

37

29

28 27 26 25

36 35 34 33 32 31 30

NC 2

C 2

NO 2

NC 3

C 3

NO 3

NO 1

C 1

NC 1

Lower level

Note:

AKV(A) Coil voltage must be the same

as controller supply voltage AC or DC

Danfoss

80Z8110

–/~

NO 4

NC 3

C 3

NO 3

NC 2

C 2

NO 2

–

+

NO 1

C 1

NC 1

POWER

SUPPLY

Voltage:

24 - 230 V a.c.

Danfoss

80Z8111

Liquid level controller, Type EKE 347

Figure 6: Connections - Lower level

Figure 7: EKE 347 - ON/OFF Application. Open/Close solenoid valve with coil 24 V - 230V

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 8

AKS 4100/

AKS 4100U

Danfoss

M84H0075_1

AKS 41/

AKS 41U

Danfoss

M84H0076_1

AKS 4100/

AKS 4100U

Danfoss

M84H0077_1

AKS 4100/

AKS 4100U

Danfoss

M84H0078_1

Back

Press and hold = Log Out

Scroll up

Scroll down

Enter

Press and hold = Log In

Home Image

Danfoss

80Z8104_MS

Controller name

Actual liquid le vel

Valve opening deg ree

Flashing bell = Activ e alarm

Controller mode

Lower level alarm of (pump on)

Upper level alarm of

Danfoss

80Z8105_MS

Liquid level controller, Type EKE 347

Table 7: Connection examples

Control Panel

Figure 8: Control Panel

The user interface of the control panel consists of a multiline display and 4 individual push buttons: Enter button,

Scroll up button, Scroll down button and Back button.

The gure shows the Home display image, which give the actual overview. This is the starting point for entering into

menus, and you will revert to this image by pushing 1 – 3 times (depending on actual position).

Display

Figure 9: Display

The display itself show the state of Liquid level, Controller Mode (controller On/O), Valve opening degree,

Lower level alarm (o = no alarm present) and Upper level alarm (o = no alarm present).

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 9

Options

Setpoint

Liquid level setpoint

0 – 100% *)

Active alarms

Example of alarm content. The list will be empty in normal operation as no alarm is active.

Level signal out of range

hours minutes **)

Standby mode

hours minutes **)

Detailed status

Controller state

Stop, Manual, Auto, Slave, IO **)

Actual level

0.0 – 100% **)

Actual reference

0.0 – 100% **)

Actual OD

0.0 – 100% **)

Digital input status

On /

O **)

Actual level signal current

mA **)

Oscillation amplitude

0.0 – 100% **)

Oscillation period

sec **)

Controller Info

Type

**)

Name (Controller name)

**)

SW (Software version)

**)

Bios (Bios version)

**)

Adr (Controller address)

**)

SN (Serial Number)

**)

PV (Product version)

**)

Site (Production site)

**)

QR code

Code

**)

Liquid level controller, Type EKE 347

Additional to the external connected alarm audio/video sources, a Bell symbol will ash in the upper right corner in

case of an alarm.

To see more details on system performance and setting of parameters, 2 dierent main menu levels can be reached

by operation of the push buttons.

From Home image the Status menu can be reached by 1 push on Enter. From Home image the Setup & service

menu can be reached by 1 push and hold on Enter. For entrance a Log In is required by the password given during

Commisioning.

Menus

Status menu

To enter Status menu from Home image: Push once.

Figure 10: Status menu

The Status menu is an open menu accessible for all. Therefore only 1 parameter can be changed from here. A

selection of other parameters can be seen from the status menu.

Table 8: Status menu ( Open menu )

NOTE:

*) Read & write

**) Write only

Setup & service menu (Requires log-in password assigned in Commisioning menu)

To enter Setup and service menu from Home image: Push and hold

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 10

Parameter

Options

Default values

Read & Write

Read only

Reference

Main switch

On, OO

Yes

_

Liquid level setpoint

0 – 100%

50.00%

_

Operation mode

Master, IO, Slave

Master

_

Alarm setup

Lower level limit

0 – 100%

15%

Yes

_

Upper level limit

0 – 100%

85%

_

Level alarm mode

Time, Hysteresis

Time

_

Lower delay

0 – 999 sec

10 sec

_

Upper delay

0 – 999 sec

50 sec

_

Lower level hysteresis

0 – 20%

3%

_

Upper level hysteresis

0 – 20%

5%

_

Function common alarm

Not follow; Follow up; Fol-

low low; Follow all

Not follow

_

Oscillation detect band

0 – 100%

100%

_

Oscillation detect timeout

2 – 30 min

20 min

_

Force pump OFF in stop mode

Yes / No

No

_

IO Lower level limit

0 – 100%

5%

_

IO Upper level limit

0 – 100%

95%

_

IO Lower level hysteresis

0 – 20%

3%

_

IO Upper level hysteresis

0 – 20%

3%

_

IO Lower delay

0 – 999 sec

10 sec

_

IO Upper delay

0 – 999 sec

50 sec

_

IO Level limit

0 – 100%

50%

_

IO Level delay

0 – 999 sec

10 sec

_

IO Level hysteresis

0 – 20%

3%

_

IO Level action

Falling,Rising

Falling

_

Liquid level controller, Type EKE 347

Maneuvering in the Status menu and the Setup and service menu’s are done by use of the 4 push buttons shown on

page 4.

Figure 11: Setup & service menu

The Setup & service menu is divided into 3 access levels, where personnel have individual authority.

Most advanced level is Commissioning, where you have access to change all allowable parameters, including

password issuing and re-run of Setup wizard.

Service level is for service personnel and has fewer rights than commissioning.

The lowest level is for Daily use, and allows only a few changes.

The table on the next page shows authority given to the Commisioning level.

Table 9: Setup & service menu - COMMISSIONING

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 11

Parameter

Options

Default values

Read & Write

Read only

Control

Control Method

On/O ,P, PI

PI

Yes

_

Regulating principle

Low, High

Low

_

P-band

5 – 200%

30.00%

_

Integration time Tn

60 – 600 sec

400 sec

_

Neutral zone

0 – 25%

2.00%

_

Dierence

0,5 – 25%

2%

_

Period time for AKV/AKVA

3–15 sec

6 sec

_

Minimum OD

0 – 99%

0%

_

Maximum OD

1 – 100%

100%

_

Display

Language

EN,CN,PT,RU,SP,FR,IT, GER,

ARAB

EN

Yes

_

Output indication

level, OD

Level

_

Login timeout

1 – 120 min

10 min

_

Backlight timeout

0 – 120 min

2 min

_

Password daily

3 - digit, 0 – 999

100

_

Password service

3 - digit, 0 – 999

200

_

Password commission

3 - digit, 0 – 999

300

_

IO cong

System conguration

ICAD+NC, ICAD, AKV/A+NC,

AKV/A, NC only

ICAD + NC

Yes

_

Level signal setup

AKS 4100, AKS 41, Current,

Voltage

AKS4100

_

Voltage at low liquid level

0 – 10V

0 V

_

Voltage at high liquid level

0 – 10V

10 V

_

Current at low liquid level

0 – 20 mA

4 mA

_

Current at high liquid level

0 – 20 mA

20 mA

_

Valve position setup

Not used, Current, Voltage

Not used

_

Voltage at closed valve position

0 – 10V

0 V

_

Voltage at open valve position

0 – 10V

10 V

_

Current at closed valve position

0 – 20 mA

4 mA

_

Current at open valve position

0 – 20 mA

20 mA

_

Common alarm setup

D04, High alarm, D03, Disp

only

High alarm

_

Multiple valve setup

Not used, 2 same cap, 2 dif

cap, 3 same cap, 3 dif cap

Not used

_

Multiple valve pattern

Parallel,Sequence

Parallel

_

Valve A capacity

0 – 100%

50%

_

Valve B capacity

0 – 100%

50%

_

Valve C capacity

0 – 100%

30%

_

ICAD takeover OD

0 – 100%

80%

_

IO module setup

Used, Not used

Not used

_

Liquid level controller, Type EKE 347

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 12

Parameter

Options

Default values

Read & Write

Read only

Communication

CAN ID

1 – 127

1

Yes

_

CAN baudrate

20k, 50k, 125k, 250k, 500k,

1M

500k

_

Modbus ID

0 – 120

1

_

Modbus baudrate

0, 1200, 2400, 4800, 9600,

14400, 19200, 28800, 38400

19200

_

Modbus mode

8N1, 8E1, 8N2

8.00E+01

_

Modbus mapping

Operation, Setup

Operation

_

Valve B CAN ID

1 – 127

2

_

Valve C CAN ID

1 – 127

3

_

IO Mod. CAN ID

1 – 127

4

Yes

Service

Controller state–_

Actual level–_

Actual referrence–_

Actual OD–_

Actual valve position

_

Digital input status

–

_

Actual level signal voltage

_

Actual level signal current

–

_

Actual position signal voltage

_

Actual position signal current

_

Actual OD A

_

Actual OD B

_

Actual OD C

_

Manual Mode

On, O

O

Yes

_

Manual OD

0 – 100%

50.00%

_

Manual low alarm

O-OnO_

Manual high alarm

O-OnO_

Manual common alarm

O-OnOn_

Apply defaults

None, Factory

None

_

Setup wizard

Setup wizard

Re-run Setup wizard

–

Yes

_

I/O check

Main switch EKE act:

O

_

Yes

AKS 4100 EKE act:

–

_

ICAD EKE act:–_

Nor. Close (NC) EKE act:

–

_

Upper lvl (alarm) EKE act:

–

_

Lower lvl (alarm) EKE act:

–

_

Controller name

Controller name

Type in controller name

–

Yes

Upper level

Lower level

Standby mode

Valve B CAN ID

conict

Valve C CAN ID

conict

IO module CAN ID

conict

IO module communication

Communication to master lost

Min / max OD

conict

Common alarm HW

conict

Control method

conict

Multiple valve setup

conict

Liquid level controller, Type EKE 347

Alarm and error codes:

When detecting an alarm from external sources or the ashing bell in the display, the alarm description can be

found as a text message in the Status menu under Active alarms.

Both alarms and errors will be shown here. If more alarms/errors occur simultaneously, they will be shown as

subsequent text lines.

Table 10: Alarms:

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 13

Valve C alarm

Valve B alarm

Oscillation in level signal

Valve position

Multiple valve capacity

Valve C communication

Valve B communication

Internal error

Level signal out of range

Valve position signal out of range

Sensor supply overload

AKS 4100 error

Too much current AI3

Too much current AI4

DO4 overload

AKS 4100/

AKS 4100U

Danfoss

80Z8113

MASTER

SLAVE 1

SLAVE 2

AKVA

(ICAD)

AKVA

(ICAD)

AKVA

(ICAD)

R120

CAN H

CAN L

GND

15 16 17 18

R120

CAN H

CAN L

GND

15 16 17 18

R120

CAN H

CAN L

GND

15 16 17 18

Jumper

15-16

Jumper

15-16

When more controllers are

connected via CAN bus each

end of the bus must be

terminated with a jumper

between 15 and 16.

Liquid level controller, Type EKE 347

Table 11: Errors:

MASTER / SLAVE conguration

Figure 12: MASTER / SLAVE conguration

Multivalve

If the system capacity requires more than one control valve; up to three valves can be controlled simultaneously in a

Master/Slave conguration, where the master and each slave controls one valve respectively.

EKE 347 IO cong menu - Multiple valve setup - with one of these options:

• 2 valves with same capacity

• 2 valves with dierent capacity

• 3 valves with same capacity

• 3 valves with dierent capacity

Additionally the master must be programmed in IO cong menu - Multiple valve pattern - for either:

• Valves in parallel (valves regulate simultaneously) or

• Valves sequential (mainly one valve regulating at any time)

See principle below.

The slave EKE’s only need identication of Slave and valve CAN ID (communication menu).

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 14

Capacity

Capacity

Opening degreeOpening degree

Valve B

Valve A

Valve B

Valve A

Two identical v alves (Parallel) Two identical v alves (Sequential)

Danfoss

80Z8114

AKS 4100/

AKS 4100U

Danfoss

M84H0084_1

MASTER

I/O

AKVA

(ICAD)

R120

CAN H

CAN L

GND

15 16 17 18

R120

CAN H

CAN L

GND

15 16 17 18

Jumper

15-16

Jumper

15-16

D02

D03

D01

NC 2

C 2

NO 2

NC 3

C 3

NO 3

NO 1

C 1

NC 1

Liquid level controller, Type EKE 347

Figure 13: Valves in parallel and Valves sequential

The default display of the master EKE will show the standard information together with a symbol of multiple valves

and the actual total opening degree (see below).

The default display of the slave EKE will show the actual liquid level (as the master), symbol of multiple valves, actual

total opening degree and the opening degree of the individual valves involved (see below).

I/O conguration

Figure 14: I/O conguration

Remote display

The daily operation can be set up directly on the controller or via an external display device.

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 15

Termination

Termination

Termination Termination

Termination Termination

Liquid level controller, Type EKE 347

Figure 15: Example 1

Figure 16: Example 2

Figure 17: Example 3

ERR31

Alarm on the external display - MMIGRS2

If the communication to the display is not carried out correctly, it will send an “ERR31” error notication. This may be

caused by the displayed terminations not being installed, or that there have been interruptions in data

communication during the time when the display retrieves the basic information from the controller. Once the

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 16

Label

Parameter name

Min value

Max val‐

ue

Default

Unit

Decimals

Modbus

PNU

Locked

by main

switch

EEPROM

Enumeration

r12

Main switch

01003001NOYES

0 =

O | 1 = On

R01

Liquid level setpoint

0

10050%13002NOYES

N07

Operation Mode

02003003

YES

YES

0 = Master | 1 = Slave | 2 =

IO

a02

Lower level limit

0

10015%03004NOYES

a01

Upper level limit

0

10085%03005NOYES

a07

Level alarm mode

01003006NOYES

0 = Time | 1 = Hysteresis

a04

Lower delay

0

99910s03007NOYES

a03

Upper delay

0

99950s03008NOYES

a06

Lower level hysteresis

0203%1

3009NOYES

a05

Upper level hysteresis

0205%1

3010NOYES

a08

Function common alarm

03003011NOYES

0 = Not follow | 1 = Follow

up | 2 = Follow low | 3 = Fol-

low all

a12

Oscillation detect band

0

100

100%0

3012NOYES

a13

Oscillation detect timeout

23020

min03013NOYES

a25

Force pump OFF in stopped

mode

01003117NOYES

0 = O | 1 = On

a14

IO Lower level limit

0

1005%03101NOYES

a15

IO Upper level limit

0

10095%03102NOYES

a16

IO Lower level hysteresis

0203%1

3103NOYES

a17

IO Upper level hysteresis

0203%1

3104NOYES

a18

IO Lower delay

0

99910s03105NOYES

a19

IO Upper delay

0

99950s03106NOYES

a20

IO Level limit

0

10050%03107NOYES

a21

IO Level delay

0

99910s03108NOYES

a22

IO Level hysteresis

020313109NOYES

a23

IO Level action

01003110NOYES

0 = Falling | 1 = Rising

N03

Control Method

02203014NOYES

0 = On /

o | 1 = P-ctrl | 2 =

PI-ctrl

n35

Regulating principle

01003015NOYES

0 = Low | 1 = High

Liquid level controller, Type EKE 347

terminations have been inspected, you should then check the software version of the external display. This is done

by holding down the Enter key and the X key for 5 seconds, until the Bios menu appears. Next, press the X key and

read o the software version in the bottom right corner. The software version must be 1.13 or newer.

Once the display’s software version has been checked, check the display’s settings as follows:

1.

Hold the Enter key and the X key down for 5 seconds, until the Bios menu appears

2.

Select the “MCX selection” menu

2.1.

Select the “Clear UI” line and press Enter

2.2.

Select the “Autodetect” line and press Enter

3.

Press the X key to return to the Bios menu

4.

Select the “COM selection” menu

4.1.

Select the “CAN” line and press Enter

5.

Press the X key to return to the Bios menu

6.

Select the “Start up mode” menu

6.1.

Select the “Remote application” line and press Enter

7.

Press the X key to return to the Bios menu

8.

Select the “CAN” menu

8.1.

Select the “Baudrate” line and then select the “Autobaud” setting and press Enter

8.2.

Select the “Node ID” line and set the value to 126 and press Enter

9.

Press the X key to return to the Bios menu

10.

Select the “Application” menu and press Enter

NOTE:

The display will once again retrieve data from the controller. This process will take about 5 minutes.

Modbus parameters

Table 12: Software version: 1.62.xx

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 17

Label

Parameter name

Min value

Max val‐

ue

Default

Unit

Decimals

Modbus

PNU

Locked

by main

switch

EEPROM

Enumeration

n04

P-band520030%13016NOYES

n05

Integration time Tn

60

600

400s0

3017NOYES

n34

Neutral zone

0252%1

3018NOYES

N06

Dierence

0,5252%1

3019NOYES

n13

Period time for AKV / AKVA

3156s1

3020NOYES

n33

Minimum OD

00%03021NOYES

n32

Maximum OD

1

100

100%0

3022NOYES

o11

Language0000

3023

YES

YES

0 = $ActiveLanguageList

o17

Output indication

01003024NOYES

0 = Level | 1 = OD

K04

Login timeout

1

12010min03025NOYES

K06

Backlight timeout

0

1202min03026NOYES

o05

Password daily

0

999

10003027NOYES

K02

Password service

0

999

20003028NOYES

K03

Password commission

0

999

30003029NOYES

K05

Contrast010040%03030NOYES

K01

Brightness

0

10080%03031NOYES

I09

System conguration

04003032

YES

YES

0 = ICAD+NC | 1 = ICAD | 2 =

AKV/A+NC | 3 = AKV/A | 4 =

NC only

o31

Level signal setup

03003033

YES

YES

0 = AKS4100 | 1 = AKS41 | 2

= Current | 3 = Voltage

o32

Voltage at low liquid level

00V13034NOYES

o33

Voltage at high liquid level

1010V13035NOYES

I06

Current at low liquid level

04mA13036NOYES

I07

Current at high liquid level

2020mA13037NOYES

o34

Valve position setup

02003038

YES

YES

0 = Not used | 1 = Current |

2 = Voltage

I02

Voltage at closed valve position

00V13039NOYES

I03

Voltage at open valve position

1010V13040NOYES

I04

Current at closed valve position

04mA13041NOYES

I05

Current at open valve position

2020mA13042NOYES

I18

Common alarm setup

03103043

YES

YES

0 = DO4 | 1 = High Alarm | 2

= DO3 | 3 = Disp only

I08

Multiple valve setup

04003044

YES

YES

0 = Not used | 1 = 2 same

cap | 2 = 2 dif cap | 3 = 3

same cap | 4 = 3 dif cap

I13

Multiple valve pattern

01003045NOYES

0 = Parallel | 1 = Sequence

I10

Valve A capacity

0

10050%03046

YES

YES

I11

Valve B capacity

0

10050%03047

YES

YES

I12

Valve C capacity

0

10033%03048

YES

YES

I17

ICAD takeover OD

0

10080%03052NOYES

I19

IO module setup

01003091

YES

YES

0 = Not used | 1 = Used

G01

CAN ID112710

4032NONO

G02

Can baudrate

05404033NONO

0 = 20k | 1 = 50k | 2 = 125k |

3 = 250k | 4 = 500k | 5 = 1M

G06

Modbus ID

0

12010

3055NOYES

G05

Modbus baudrate

08603056NOYES

0 = 0 | 1 = 1200 | 2 = 2400 | 3

= 4800 | 4 = 9600 | 5 =

14400 | 6 = 19200 | 7 =

28800 | 8 = 38400

G08

Modbus mode

02103057NOYES

0 = 8N1 | 1 = 8E1 | 2 = 8N2

G07

Modbus mapping

01003058NOYES

0 = Operation | 1 = Setup

G09

Valve B CAN ID

1

12720

3088

YES

YES

G10

Valve C CAN ID

1

12730

3089

YES

YES

G11

IO Mod. CAN ID

1

12740

3090

YES

YES

Liquid level controller, Type EKE 347

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 18

Label

Parameter name

Min value

Max val‐

ue

Default

Unit

Decimals

Modbus

PNU

Locked

by main

switch

EEPROM

Enumeration

B01

Controller state

06004001

YES

NO

0 = Powerup | 1 = Stop | 2 =

Auto | 3 = Manual | 4 = Slave

| 5 = IO | 6 = Safe

u01

Actual level

0

1000%14002NONO

u02

Actual reference

0

1000%14003

YES

NO

u24

Actual OD01000%14004NONO

u33

Actual valve position

0

1000%14005NONO

u10

Digital input status

01004006NONO

0 = O | 1 = On

u31

Actual level signal voltage

0

1000V14007NONO

u30

Actual level signal current

0240mA1

4008NONO

B02

Actual position signal voltage

0

1000V14009NONO

u32

Actual position signal current

0

1000mA14010NONO

B03

Actual OD A

0

1000%14011NONO

B04

Actual OD B

0

1000%14012NONO

B05

Actual OD C

0

1000%14013NONO

o18

Manual Mode

01004014NONO

0 = O | 1 = On

o45

Manual OD

0

10050%13059NONO

B08

Manual low alarm

01003060NONO

0 = O | 1 = On

B06

Manual high alarm

01003061NONO

0 = O | 1 = On

B07

Manual common alarm

01003062NONO

0 = O | 1 = On

B09

Apply defaults

01003063

YESNO0 = None | 1 = Factory

B11

Oscillation amplitude

0

1000%14028

YES

NO

B10

Oscillation period

0

36000s04029

YES

NO

Label

Alarm name

Modbus PNU

Bit number

A1

Upper level

1901

8

A2

Lower level

1901

9

A92

Oscillation in level signal

1901

10

A96

Valve position

1901

14

A97

Multiple valve capacity

1901

15

E1

Internal error

1901

0

E21

Level signal out of range

1901

1

E22

Valve position signal out of range

1901

2

E96

AKS 4100 error

1901

3

A45

Standby mode

1901

4

A99

Valve B communication

1901

5

A98

Valve C communication

1901

6

A85

Communication to master lost

1901

7

A91

Valve B alarm

1902

8

A90

Valve C alarm

1902

9

A88

Control method conict

1902

10

A87

Common alarm HW conict

1902

11

A86

Min / max OD conict

1902

12

E95

Sensor supply overload

1902

13

E99

DO4 overload

1902

14

E97

Too much current AI3

1902

15

E98

Too much current AI4

1902

0

A89

Multiple valve setup conict

1902

1

A80

Valve B CAN ID conict

1902

2

A81

Valve C CAN ID conict

1902

3

A82

IO module CAN ID conict

1902

4

A83

IO module communication

1902

5

Liquid level controller, Type EKE 347

Table 13: Alarms

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 19

110

5

70

60

63

Danfoss

80G74_}01-2014

Liquid level controller, Type EKE 347

Dimensions and weights

Figure 18: EKE 347

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 20

Type

Description

Code No.

EKE 347

Liquid level controller

080G5000

MMIGRS2

Remote display, Panel, S

080G0294

Wire for display unit, L = 1.5 m, 1 pcs.

080G0075

Wire for display unit, L = 3 m, 1 pcs.

080G0076

EKE / EKC accessory for panel mounting

027F0309

Liquid level controller, Type EKE 347

Ordering

Table 14: Ordering

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 21

File name

Document type

Document topic

Approval authority

UA.1O146.D.00070-19

UA Declaration

EMCD/LVD

LLC CDC EURO-TYSK

RU Д-DK.ГА02.В.05523

EAC Declaration

EMC

EAC

080R4002.01

China RoHS

CRN

Danfoss

080R4000.02

CRN

Danfoss

EU Low Voltage Directive and EMC demands re CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 60730-2-9

EMC-tested acc. to EN61000-6-3 and EN 61000-6-2

UL le E31024

Liquid level controller, Type EKE 347

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 15: Valid Approvals

Table 16: Conformity Approvals

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 22

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI190286434038en-000501 | 23

Loading...

Loading...