Page 1

ENGINEERING

R

0

o

s

130

TOMORROW

Installation guide

Electronic superheat controller

Type EKE 1D

Introduction

Superheat controller EKE 1D is for use where superheat must be accurately controlled,

typically in commercial air conditioning, heat pumps, commercial refrigeration, food retailing

080R9345

and industrial applications.

Compatible valves: Danfoss ETS 6 / ETS / ETS Colibri®, KVS / KVS Colibri® and CCM / CCMT /

CTR valves.

Reference: For details please see EKE data sheet.

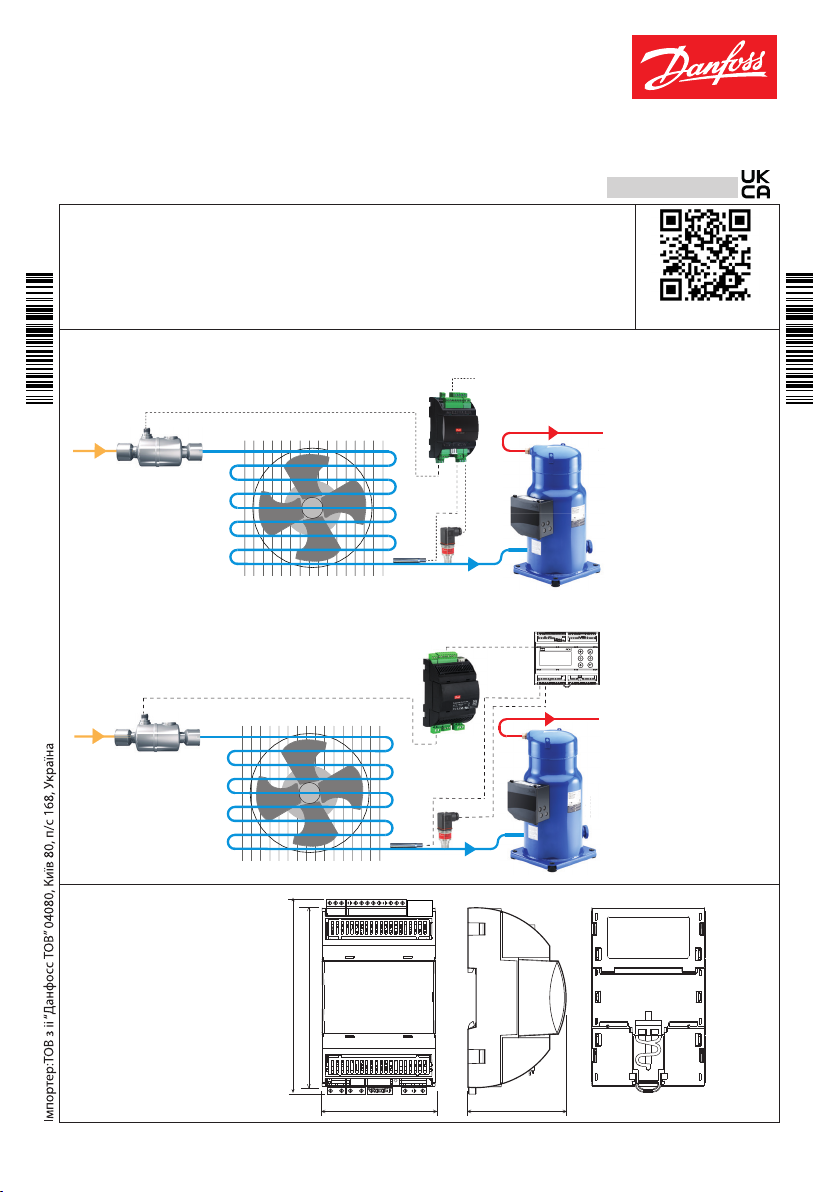

Applications

1. Superheat controller: standalone / network

ETS Colibri®

S2 Pe

Communication

Danfoss

Danfoss

64-3033.1

R64-3033.10

English

080R9345

More info

2. Valve driver

ETS Colibri®

Dimensions in mm

EKE 1D

Weight: 152 gram

© Danfoss | Climate Solutions | 2021.09

110

Reference signal

Reference signal

S2 Pe

CAN RJ

70 60

s

nf

64-3041.10

Danfoss

R64-3041.10

Danfoss

80G8215.11

AN325741271542en-000403 | 1

Info for UK customers only: Danfoss Ltd., 22 Wycombe End, HP9 1NB, GB

Page 2

Technical specications

POWER SUPPLY

EKE has galvanic isolation by switch-mode power supply.

24 V AC ± 20 %, 50/60 Hz. Maximum power consumption: 18 VA.

Input voltage rating (DC): 24 V DC ± 20%, 15 W.

I/O TYPE NUMBER SPECIFICATION

Max. 15 V input voltage

Do not connect voltage sources to unpowered units without limiting the

current to analog inputs (overall 80 mA).

Open circuit HW diagnostics available for voltage input on : AI4

AI3 (Pe)

Analog

inputs

Digital

inputs

Voltage 2

NTC 2

Auxiliary

Supplies

Voltage free

contacts

0 – 5 V ratiometric,

AI4

0 – 5 V , 0 – 10 V

AI1 (S3, S4), AI2 (S2)

NTC temperature probes, 10 kΩ at 25 °C

5 V +

1

Sensor supply: 5 V DC / 15 mA, overload protection approximately 150 mA

DI1, DI2

Steady current minimum 1mA

2

Cleaning current 100 mA at 15 V DC

On: RIL < = 300 Ω

O: RIH > = 3.5 k Ω

Digital

output

Stepper

motor

Battery

backup

Communication

© Danfoss | Climate Solutions | 2021.09

Relay 1

Bipolar /

unipolar

CAN

C1-NO1

Normally Open: 3 A General purpose, 250 V AC, 100 k cycle

Normally Open: 3 A Inductive (AC-15), 250 V AC, 100 k cycle

Normally Closed: 2 A General purpose, 250 V AC, 100 k cycle

Stepper valves: A1, A2, A3, A4

Bipolar and unipolar stepper motor output:

- Danfoss ETS / KVS / ETS C / KVS C / CCMT 2 – CCMT 42 / CTR Valves

(green, red, black, white)

1

1

1

1

- ETS6 / CCMT 0 / CCMT 1 (black, red, yellow, orange)

Other Valves:

- speed 10 – 400 pps

- drive mode 1/8 microstep

- max. peak phase current: 1.2 A (848 mA RMS)

- max. drive voltage 40 V

- max. output power 12 W

VB ATT : 18 – 24 V DC (24 V DC recommended):

– max. battery current: 850 mA at 18 V

– battery alarm will be activated below 16 V DC.

CAN - 3 way screw plug-in connector

No Built-in termination

CAN - RJ

RJ connector to directly connect and supply a MMI

No built in termination

AN325741271542en-000403 | 2

Page 3

Danfoss

n

fo

ss

G

General features and warnings

Plastic housing features

- DIN rail mounting complying with EN 50022

- Self-extinguishing V0 according to IEC 60695-11-10 and glowing/hot wire test at 960 °C according to IEC 60695-2-12

- Ball test: 125 °C according to IEC 60730-1. Leakage current: ≥ 250 V according to IEC 60112

Other features

- Operating conditions CE: -20T60, 90% RH non-condensing

- Storage conditions: -30T80, 90% RH non-condensing

- To be integrated in Class I and/or II appliances

- Index of protection: IP 20 on product and IP40 only on the front cover

- Period of electric stress across insulating parts: long

- Suitable for using in a normal pollution environment

- Category of resistance to heat and re: D

- Immunity against voltage surges: category II

- Software class and structure: class A

Ce compliance

This product is designed to comply with the following EU standards:

- Low voltage guideline: 2014/35/EU

- Electromagnetic compatibility EMC: 2014/30/EU and with the following norms:

- EN61000-6-1, EN61000-6-3 (immunity for residential, commercial and light-industrial environments)

- EN61000-6-2, EN61000-6-4 (immunity and emission standard for industrial environments)

- EN60730 (Automatic electrical controls for household and similar use)

General warnings

- Every use that is not described in this manual is considered incorrect and is not authorized by the manufacturer

- Verify that the installation and operating conditions of the device respect those specied in the

manual, especially concerning the supply voltage and environmental conditions

- This device contains live electrical components. All service and maintenance operations must therefore be

performed by qualied personnel

- The device must not be used as a safety device

- Liability for injury or damage caused by the incorrect use of the device lies solely with the user

Installation warnings

- Recommended mounting position: vertical

- Installation must comply with local standards and legislation

- Before working on the electrical connections, disconnect the device from the main power supply

- Before carrying out any maintenance operations on the device, disconnect all electrical connections

- For safety reasons the appliance must be tted inside an electrical panel with no live parts accessible

- Do not expose the device to continuous water sprays or to a relative humidity greater than 90%.

- Avoid exposure to corrosive or pollutant gases, natural elements, environments where explosives or mixes of

ammable gases are present, dust, strong vibrations or shock, large and rapid uctuations in ambient temperature

that might cause condensation in combination with high humidity, strong magnetic and/or radio interference

(e.g. transmitting antennae)

- When connecting loads be aware of the maximum current for each relay and connector

- Use cable ends suitable for the corresponding connectors. After tightening connector screws, tug the cables gently

to check their tightness

- Use appropriate data communication cables. Refer to the EKE data sheet for the kind of cable to be used and setup

recommendations

- Minimize the length of probe and digital input cables as much as possible, and avoid spiral routes around power

devices. Separate from inductive loads and power cables to avoid possible electromagnetic noises

- Avoid touching or nearly touching the electronic components tted on the board to avoid electrostatic discharges

Product warnings

• Use a class II category transformer for 24 V AC power supply.

• Connecting any EKE inputs to mains voltage will permanently damage the controller.

• Battery Backup terminals does not generate power to recharge a device connected.

• Batter y backup - the voltage will close the stepper motor valves if the controller loses its supply

voltage.

• Do not connect an external power supply to the digital input DI terminals to avoid damaging the

controller.

© Danfoss | Climate Solutions | 2021.09

320.10

80G320.10

80

AN325741271542en-000403 | 3

Page 4

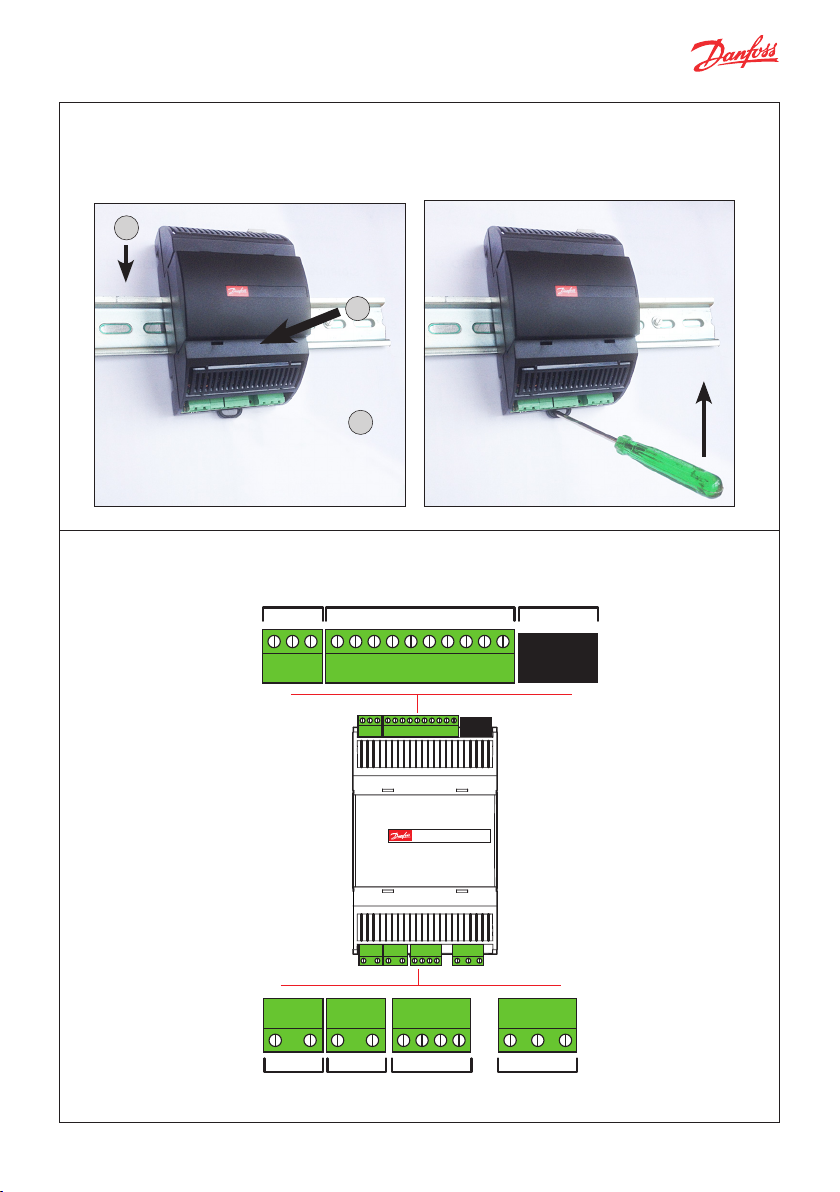

DIN rail mounting / demounting

The unit ca n be mounted onto a 35 mm DIN rail s imply by snapping it into p lace and securing it wi th a stopper to prevent

sliding.

It is demounted by gently p ulling the stirrup lo cated in the base of the h ousing.

1

2

Connection overview: EKE 1D

“Click”

L

H

3

ANALOG / DIGITAL INPUT

ANALOG / DIGITAL INPUT

COM

5V+

DI2

Danfoss

80G8287A.01

L

–/~

DI1

COM

5V+

DI2

DI1

H

GND

Superheat controller

Superheat controller

EKE 1D - 080G5360

+/~

GND

Bat+A1A2B1B2

GND

CAN - RJCAN

CAN RJ

COM

AI4

AI3

AI2

AI1

COM

CAN RJ

COM

AI4

AI3

AI2

AI1

COM

NO1C1NC1

© Danfoss | Climate Solutions | 2021.09

–/~

+/~

GND

Bat+A1A2B1B2

PWR 24V Vbat STEPPER VALVE DIGITAL OUTPUT

NO1C1NC1

DIGITAL OUTPUTSTEPPER VALVE

AN325741271542en-000403 | 4

Page 5

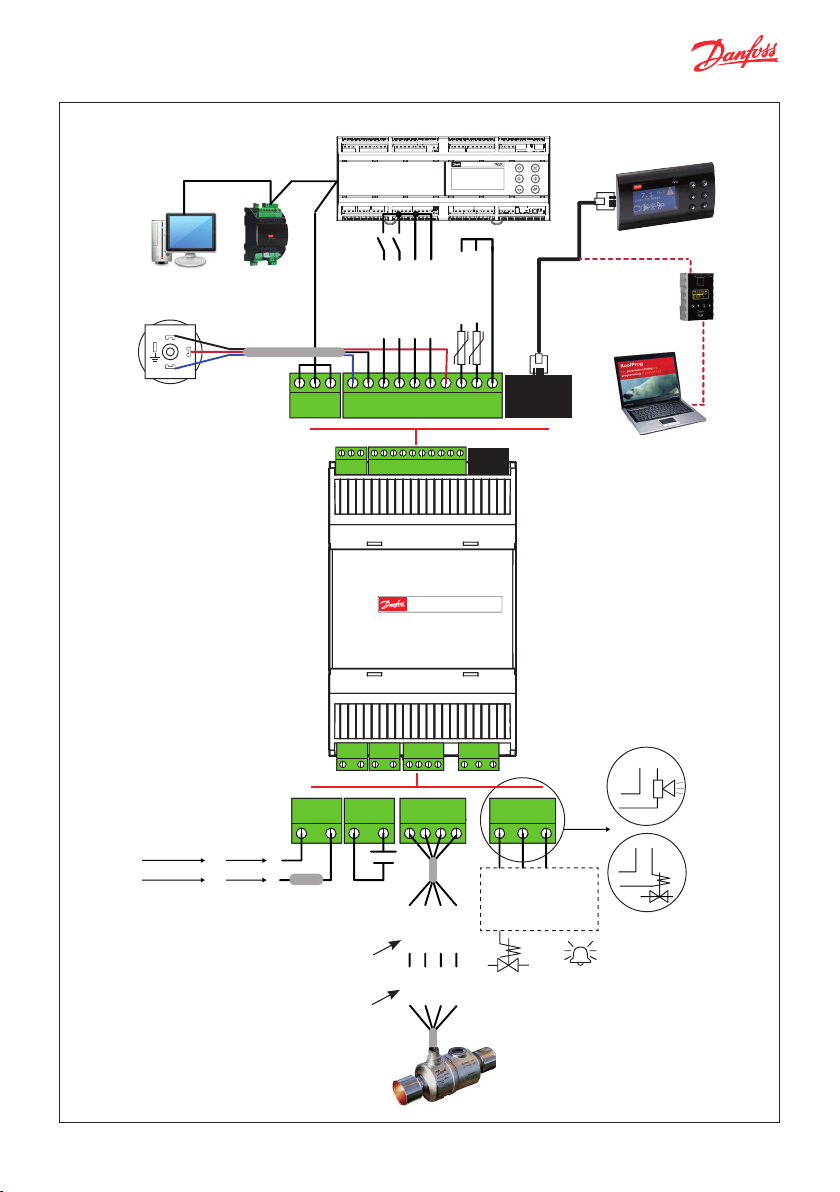

Connection overview, EKE 1D

CANBus

Master controller

MMIGRS2 Display

CAN RJ

080G0294 (optional)

Supervisor

network

1

3

2

Pressure transmitter

e.g. AKS 32R

Power supply

24 V AC

± 20%

–

+

EKE

AKS Cable

connection

060G1034

24 V DC

± 20%

LHGND

Danfoss

80G318.10

–/~

–/~

2.5 A

T fuse

(optional)

ETS6 valve

ETS / KVS

Colibri®

CCMT/CTR valves

CANBus

LHGND

–/~

–/~

+/~

+/~

backup

(optional)

COM

COM

GND

GND

+

18 V

Batt

5V+

5V+

Superheat controller

+/~

+/~

DI2

DI1 (ON/OFF)*

DI2

DI1

DI2

DI1

COM

5V+

DI2

COM

5V+

DI2

Superheat controller

EKE 1D - 080G5360

GND

Bat+A1A2B1B2

GND

Bat+A1A2B1B2

Bat+A1A2B1B2

Bat+A1A2B1B2

NTC (S2)

COM

AI4 (0 / 10 V)

COM

AI4

AI3

AI2

COM

AI4

AI3

AI2

DI1

COM

AI4

AI3

AI2

DI3

COM

DI1

COM

AI4

AI3

AI2

AI1

COM

NO1C1NC1

NO1C1NC1

red

black

yellow

orange

red

black

white

green

Optional

NTC (S3/S4)

CANBus

CAN RJ

CAN RJ

DI3

COM

AI1

COM

CAN RJ

CAN RJ

* Note: If Dl1(On/O) switch is not

used it must be short circuited

NO1C1NC1

NO1C1NC1

Relay

Normally open or

normally closed

(optional)

ON/OFF

solenoid

valve

080G0075 (opt.)

Alarm

MMIMYK

Gateway

Power

Power

KoolProg

PC tool

C1 NC1

C1 NO1

© Danfoss | Climate Solutions | 2021.09

AN325741271542en-000403 | 5

Page 6

Sensor mounting: Temperature sensor

1

1

Danfoss

60G496.11

Conductive

paste

Important Note

• Mount the sensor on a clean

paint-free surface.

• Remember to use heat

conducting paste and insulate

the sensor.

• For precise measurements,

mount the sensor max. 5 cm

from the outlet of the evaporator.

Evaporator outlet

Danfoss

84N365.11

Danfoss

84N403.10

3

Evaporator

Danfoss

84N366.12

Close to the

Close to the

evaporator

evaporator

2

/2 - 5/8 in.

OD

12 - 16 mm

3

/4 - 7/8 in.

OD

18 - 22 mm

1 - 1

OD

25 - 35 mm

1

OD

35 mm and higher

3

/8 in.

3

/8 in. and higher

Pressure transmitter

• Installation of the pressure transmitter is less critical. However, the pressure transmitter should be closer to

the temperature sensor, right after the evaporator and with its head upright. It is a good practice to select

a pressure transmitter with an average load of 40 - 60% of full scale.

• 5 EKEs at maximum are allowed to share the output signal of a ratiometric pressure transmitter.

In order to get a correct acquisition on all the units all the three wires (GND, 5 V and transmitter signal

output) must be routed to every unit.

Power supply

• Power sharing is allowed in EKE controller.

• It is a good practice not to reverse the polarity of the power connection cables.

Selection of the common power supply depends on the total number of sharings and the valve in use.

EKE EKE EKE

CAN RJ

D–D+RGND

COM

5V+

COM

5V+

CAN RJ

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

D–D+RGND

COM

5V+

COM

5V+

CAN RJ

CAN RJ

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

D–D+RGND

COM

5V+

COM

5V+

CAN RJ

CAN RJ

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

Danfoss

80G295.10

–/~

–/~

+/~

+/~

Superheat controller Superheat controller

Superheat controller

EKE 1x - 080G5xxx

–/~

+/~

GND

Bat+A1A2B1B2

–/~

+/~

GND

Bat+A1A2B1B2

Power supply

© Danfoss | Climate Solutions | 2021.09

NO1C1NC1

NO1C1NC1

Superheat controller

Superheat controller

EKE 1x - 080G5xxx

–/~

+/~

GND

Bat+A1A2B1B2

GND

Bat+A1A2B1B2

NO1C1NC1

NO1C1NC1

–/~

+/~

Superheat controller

EKE 1x - 080G5xxx

–/~

+/~

GND

Bat+A1A2B1B2

GND

Bat+A1A2B1B2

NO1C1NC1

NO1C1NC1

–/~

+/~

AN325741271542en-000403 | 6

Page 7

Danf

84N404.10

Relay Outputs

EKE 1D has 1 relay output:

• Ty pe SP DT relay. Digital Output can be used to connect either a solenoid valve or an alarm.

• The relays cannot be used for the direct connection of capacitive loads such as LEDs and ON/OFF control of

EC motors. All loads with a switch-mode power supply must be connected with a suitable contactor or similar.

Cable length

EKE controller supports the following max. cable length.

Cable length Wire size min. / max.

[m] [m2]

Analog inputs (Current/Voltage) max. 10 0.14 / 1.5

Temperature sensor max. 10 *) –

Stepper valve connection max. 30 0.14 / 1.5

Power supply max. 5 0.2 / 2.5

Digital input max. 10 0.14 / 1.5

Digital output – 0.2 / 2.5

Digital MMI max. 3 over CAN RJ –

Communication bus max. 1000 0.14 / 1.5

Cable and wiring *)

• The max. cable distance between the controller and the valve depends on many factors like shielded/

unshielded cable, the wire size used in the cable, the output power for the controller and EMC.

• Keep controller and sensor wiring well separated from mains wiring.

• Connecting sensors by wires more than the specied length may decrease the accuracy of measured values.

Warning

Separate the sensor and digital input cables as much as possible (at least 10 cm) from the power cables to the

loads to avoid possible electromagnetic disturbance. Never lay power cables and probe cables in the same

conduits (including those in the electrical panels).

Connecting CANbus

• For the CANbus cable, it is best to use 24 AWG shielded twisted-pair cable with a shunt capacitance

of 16 pF/ft and 100 Ω impedance.

• The controller provides a communication interface which is connected to the RJ and CAN terminals

(see connection overview).

• Terminal resistors 120 Ω for terminal devices are recommended at both ends of the bus, Terminal

resistance between H and L terminals.

• The default unit address is 1, which can be changed using parameter “G001 Controller adr".

© Danfoss | Climate Solutions | 2021.09

CANbus

H

L

Not in use

oss

Gnd

AN325741271542en-000403 | 7

Page 8

Stepper Motor Output

• All valves are driven in a bipolar mode with a 24 V supply chopped to control the current (Current driver).

• The stepper motor is connected to the “Stepper Valve” terminals (see terminal assignment) with a standard M12

connection cable.

• To congure stepper motor valves other than Danfoss stepper motor valves, the correct valve parameters must

be set as described in the Valve conguration section (see manual for details).

• The default valve setting in EKE 1D is: none.

• The correct valve must be dened in “Valve conguration”, i.e. parameter I067. An overview of valve types is

given in the “Parameter identication” section.

Valve Cable Connec tion

ETS Colibri / KVS Colibri/ ETS / KVS / CCM / CCMT / CTR

Danfoss M12 Cable White Black Red Green

ETS / KVS / CCM Pins 3 4 1 2

ETS Colibri® / KVS Colibri / CCMT / CTR / Pins A1 A2 B1 B2

EKE terminals A1 A2 B1 B2

Pin designation used in above table are shown in the product data sheet.

ETS 6

Wire color Orange Yel low Red Black Gray

EKE terminals A1 A2 B1 B2 Not connected

Guideline for long M12 cables on Danfoss stepper motor valves

• Long cables will lead to degradation of performance.

• You can overcome this degradation by changing the settings for the valve driver. This guideline is based on

the cable t ype being the same t ype as the standard Danfoss stepper motor cable.

Recommended wire size and cable distance bet ween EKE controller and stepper motor valve

Cable length 1 m – 15 m 15 m – 30 m 30 m – 50 m

Wire diameter

0.52 / 0.33 mm

(20 / 22 AWG)

2

0.33 mm

(20 AWG)

2

0.82 mm

2

(18 AWG)

Parameter setting for long M12 cable

Product

ETS 12C - ETS 100C

KVS 2C - KVS 5C

0 m – 15 m cable 15 m – 30 m cable 30 m – 50 m cable

Use default values

ETS 12.5 - ETS 400

KVS 15 - KVS 42

CTR 20

Use default values

CCMT 2 - CCMT 8

CCM 10 - CCMT 40

ETS 6 Use default values

CCMT 0 Use default values

CCMT 1 Use default values

CCMT 16 - CCMT 42 Use default values

© Danfoss | Climate Solutions | 2021.09

Update following parameter

I028 Valve drive current=

925 mA peak

I028 Valve drive current=

200 mA peak

I028 Valve drive current=

270 mA peak

I028 Valve drive current=

270 mA peak

I028 Valve drive current=

400 mA peak

I028 Valve drive current=

450 mA peak

I028 Valve drive current = 1000 mA peak

I065 Valve duty cycle = 90%

I028 Valve drive current= 300 mA peak

I028 Valve drive current= 350 mA peak

I028 Valve drive current= 350mA peak

I028 Valve drive current= 500 mA peak

I028 Valve drive current= 500 mA peak

AN325741271542en-000403 | 8

Page 9

LED indication

(A) Two status LEDs to indicate operational status

• Steady green = power ON

• Flashing green = data transmission / initialization

• Flashing red = alarm / error condition

(B) Two status LEDs to indicate valve operation

• Flashing red = valve closing

• Steady red = valve fully closed

(A)

(B)

• Flashing green = valve opening

• Steady green = valve fully open

• Both green and red ashing = valve-related alarm

User interface

EKE 1D can be setup using one of the following user interfaces:

1. Danfoss KoolProg soft ware

2. Danfoss MMIGRS2 external display

3. Communication bus: CANbus

KoolProg

KoolProg is a software tool for quickly and easily conguring EKE controllers. It enables you

to make online changes to parameter conguration, copy settings to multiple controllers,

monitor the live status of input/outputs, and quickly analyze controller behavior and

program patterns with a graphical trending tool.

KoolProg Software is available for download free of charge at http://koolprog.danfoss.com.

KoolProg requires a Gateway (code 080G0073) to connect to the PC.

CANRJ

EKE

Power supply

Danfoss

80G296B.10

Gateway

Cable holder

USB

Important note!

To guarantee a reliable USB connection to a host device (e.g. industrial PC), you must:

• Connect terminals R and H on MMIMYK CAN port using a termination wire.

• Place cable holder close to MMIMYK to keep USB connector rmly in place.

• Keep USB cable length < 1 m.

• Place MMIMYK and route USB cable far from noise sources (inver ter, motors, contactors etc.)

© Danfoss | Climate Solutions | 2021.09

AN325741271542en-000403 | 9

Page 10

ACCCBI080G0075

Danfoss MMIGRS2 display

Connecting external MMIGRS2 display

MMIGRS2 display can be used to set up EKE 1D. The display

can be used not only for setting up the necessary parameters, but also as an ex ternal display during operation to

show impor tant parameters, e.g. degree of opening of

valve, superheat, etc.

Important note:

• Max. distance bet ween controller and display is

3 m over CAN RJ.

• CANbus requires termination in both ends of the cable

by a 120 Ohm resistor to ensure reliable communication.

On EKE 1D terminate L and H with resistor and on

MMIGRS2 terminate R and H with jumper.

• External power for MMIGRS2 is not needed while using

CAN RJ connector. In case of connecting via 3 way screw

plug-in connector external power supply is required for

MMIGRS2.

MMIGRS2 (Back view)

COM

–/~

+/~

GND

–/~

+/~

GND

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

Superheat controller

Superheat controller

EKE 1D - 080G5360

Bat+A1A2B1B2

Bat+A1A2B1B2

CAN RJCAN RJ

NO1C1NC1

NO1C1NC1

CAN RJ

MMIGRS2

Danfoss

80G319.10

For cable <3 meter

RJ CAN connector

Termination Jumper

between R and H

Danfoss

34G306.11

For cable >3 meter (only EKE 1C and EKE 1D)

2-way screen connector for power supply

4-way screen connector for CANbus network

MMIGRS2 (Front view)

Controller name

Primary readout

Operating status

Evap. temperature

Evap. pressure

Valve OD

Note: Setup and ser vice menu requires login with the default password 100 ( daily use),

200 (service use) or 300 (commissioning use). Long press Enter key to access login menu.

© Danfoss | Climate Solutions | 2021.09

Homescreen

UP

Escape/cancel

Right

Left

Enter

Down

Navigation help

Alarm indicator

Reference point

S2 – S4

Media

Temperature

AN325741271542en-000403 | 10

Page 11

Setup wizard via MMIGRS2 display

When all connections to the controller have been made, af ter the power is switched on, the Danfoss logo will appear

for 5 seconds, then the Home screen will be displayed.

To access the Wizard: press and hold enter to access the Login screen, the commissioning password is 300, scroll down

the Setup and service menu and select “Setup wizard”.

The Wizard workow is: a. Language selection; b. Application selection; c. Input conguration; and d.

Output conguration.

When using the Setup Wizard, repeat the following sequence for all parameter settings:

a. From Setup wizard, select relevant parameters.

b. Press ENTER to highlight 1st option

c. Scroll with UP / DOWN to your desired option

d. If the selected default value is acceptable, press DOWN to get to the next settings. Other wise,

press ENTER to set your choice

e. Scroll with DOWN to the next parameter (repeat sequence a. to e.)

Note:

• If you do not have sucient information to complete the Wizard, leave settings on their default values. To generate

the requested info, you can use Danfoss Coolselector2 software to calculate operating conditions and valve OD for the

same operating point.

• Setup Wizard only covers the most important parameters. If other features are to be enabled

(e.g. Alarm settings, MOP/LOP, etc.), they must be congured separately once the Setup Wizard is done.

Setup Wizard is also available in KoolProg PC tool.

The workow process is the same as that described above for MMIGRS2 display.

For details, pl ease refer to EKE data sheet.

1

1

Power on

2

2

Press and

hold enter

Status menu

QR code

Controller info

Detailed status

SH trend 25 mi n

Display

Home menu

© Danfoss | Climate Solutions | 2021.09

3

3

Commissioning 300

Danfoss

Danfoss

80G294.20

80G294.20

Login

PW:

Service 200

Daily 100

5

5

Esc

Setup and service

Reference

Control

Defrost

Alarm conguration

IO cong

Display

Communication

Service

Setup wizard

Controller name

AN325741271542en-000403 | 11

4

4

Page 12

Quick guide for parameter selection

Apart from wizard setup, users can also use the following section which describes quick parameter settings for general

applications.

Driver Controller

Start : Main switch= O

Selec t valve type

Application mode

Driver- Controller

Analog signal type e.g

1 - 5 V / 0 - 10 V

EKE 1D Parameters

Driver reference

conguration

Ext .ref.

voltage,low

Ext .ref.

voltage,high

Ext .ref.

current,low

Ext .ref.

current,high

I091

I034

I035

–

–

Select Refrigerant

Select Temperature sensor

Select Pressure transmitter

Dene Min/Max Pressure

Select Superheat Control

Set Min/Max Ref value

Make sure that main switch is OFF before changin g

the settings. Th e setting will dep end on the system

requirement.

Parameter: R012 Main Switch

Selec t predened Danfoss valve type ETS, ETS C, K VS,

KVS C, CCM , CCMT, CTR, o r user dened.

Parameter: I067 Valve conguration

Selec t how you want to use EKE: dri ver or superheat

controller.

Parameter: R102 Operation mode

Select the predened refrigerant .

Parameter: O030 Refrigerant

Selec t Temperatur e sensor type: EK S, ACCPBT, MBT,

Sensata 112CP, Bus shared

Parameter: I081 - S2 sensor conguration.

Check parameter list for other sensors.

Selec t Pressure transmitter typ e –AKS 32R, Sensata

112CP, OEM Ratio, NSK, AKS 32 1 - 5 V,

OEM Voltage, Bus shared

Parameter: I085 - Pe transmitter conguration.

Check parameter list for other sensors.

Dene min and max Pressure transm itter in barg.

Parameter: O020 - Pe min., O 021 Pe max., Check

parameter list for other sensors.

Selec t application control type SH control. 1: MSS,

2: LoadAp, 3: Fixed, 4: Del ta SH.

Parameter: N021 SH reference mode.

Set the value for the selected control m in./max.

superheat reference.

Parameter N009 SH max., N 010 - SH min.

Selec t Other features

Finish: main switch = ON

© Danfoss | Climate Solutions | 2021.09

Dl1= ON

Optional – Force star t up, MOP, LOP, Alarm,

Thermostat function.

Check par ameter list for details.

Remember to turn on main switch to s tart ‘ON’ .

Parameter R012 Main switch.

ON=Regulation start

Parameter O002: 0 = Bus->Start /Stop | 1 = Main Switch

IF Dl1 is not use d make a short circuit w ith a wire

betwe en Dl1 and COM.

AN325741271542en-000403 | 12

Page 13

EKE 1D – Commonly used parameter identication

If the parameter value is outside the range, controller will not detect error.

Parameter CA N

R012 Main switch 550B B8 0 0 = regulati on O | 1 = regulation On

R102 Operation mode 550B B9 0 0 = Supe rheat control | 1 = Valve driver

O002 Dl1 conguration 550C 1C 1 0 = Bus->Start/Stop | 1 = Main Switch

I091 Driver reference

conguration

I034 Ex t ref. voltage low 550C 39 0 Ra nge 0 – 10 V. To be used with l 091

I035 Ex t ref. voltage high 550 C 38 10 Range 0 – 10 V. To be used with l0 91

I067 Valve conguration 550C 3B 0

O030 Refrigerant 550B C8 0

I081 S2 sensor

conguration

I083 S3 sens or

conguration

I084 S4 sensor

conguration

I085 Pe transmitter

conguration

O020 Pe transmitter min.

(in bar g)

O021 Pe transmitter max.

(in bar g)

CAN

Index

Subindex

550C D1 0 0 = Voltage to OD | 1 = Bus to OD | 2 = Bus to steps

550C C1 0

550C BF 0

550C BD 0

550C C5 0

550C 2A

550C 2B

De-

Description

fault

0 = no valve, 1 = Use rDef

2 = ETS 12C, 3 = ETS 24C , 4 = ETS 25C, 5 = ETS 50C , 6 = ETC 100C

7 = ETS 6, 8 = ETS 12.5, 9 = ETS 25, 10 = ETS 50, 11 = ETS 100,

12 = ETS 2 50, 13 = ETS 400

14 = KVS 2C , 15 Імпорт ер:ТОВ з іі “Данфо сс ТОВ” 04080, Ки їв 80,

п/с 168, Україн а = KVS 3C, 16 = KVS 5C

17 = KV S 15, 18 = KVS 42

19 = CCMT 0, 20 = CCMT 1

21 = CCMT 2, 22 = CCMT 4, 23 = CCMT 8, 24 = CCMT 16, 25 = CCMT 24,

26 = CCMT 30, 27 = CCMT 42

28 = CCM 10, 29 = CCM 20, 30 = CCM 30, 31 = CCM 40

32 = CTR 20

0 = Undef 10 = R503 20 = R407C 30 = R417A 40 = 448A

1 = R12 11 = R114 21 = R407A 31 = R422A 41 = 449A

2 = R22 12 = R142b 22 = R407B 32 = R413A 42 = 452A

3 = R134A 13 = R User 23 = R410A 33 = R422D 43 = R450A

4 = R502 14 = R32 24 = R170 34 = 427A 44 = R452B

5 = R717 15 = R227 25 = R290 35 = R438A 45 = R454B

6 = R13 16 = R401A 26 = R600 36 = R513A 46 = R1233zdE

7 = R13b1 17 = R507 27 = R600a 37 = R407F 47 = R1234zeZ

8 = R23 18 = R402A 28 = R744 38 = R1234ze 48 = R449B

9 = R500 19 = R404A 29 = R1270 39 = R1234yf 49 = R407H

0 = Not dene d | 1 = EKS 221 | 2 = ACCPBT NTC10K | 3 = MBT 153 10K |

4 = 112CP | 5 = Bus Shared

0 = Not dene d | 1 = EKS 221 | 2 = ACCPBT NTC10K | 3 = MBT 153 10K |

4 = 112CP | 5 = Bus Shared

0 = Not dene d | 1 = EKS 221 | 2 = ACCPBT NTC10K | 3 = MBT 153 10K |

4 = 112CP | 5 = Bus Shared

0 = Not dene d | 1 = AKS 32R | 2 = ACCPBP Ratio | 3 = 112CP | 4 = OEM Ratio|

5 = NSK | 6 = AKS 32 1-5V | 7 = OEM Volt age | 8 = Bus shared

-1 Dene pressure range in bar gauge

12 Den e pressure range in bar g auge

N021 SH reference mode 550B D2 2 0 = Fixed SH | 1 = Loadap | 2 = MSS | 3 = Delta temp

N107 SH xed setpoint ( K) 550B D3 7 Ra nge 2 – 40 K

N009 SH max. ( K) 550B D4 9 Range 4 – 40 K

N010 SH mi n. ( K) 550B D5 4 Range 2 – 9 K

N116 SH ref. delta tem p.

factor ( %)

For a detailed p arameter list and expla nation, please check the EK E data sheet.

© Danfoss | Climate Solutions | 2021.09

550B DA 65 Range 20 – 100

AN325741271542en-000403 | 13

Page 14

For your own notes

© Danfoss | Climate Solutions | 2021.09

AN325741271542en-000403 | 14

Page 15

Related products

MMIGRS2 Display Power Supply MMIMYK Gateway

User interface module MMIGRS2 Display AK-PS

Pressure Transducer Temperature Sensor Backup power module

AKS Pressure Tranducer

Available with ratiometric and 4 – 20 mA.

NSK

Ratiometric pressure probe

XSK

Pressure probe 4 – 20 mA

ACCCBI Cable Stepper motor valves M12 cable

Input: 100 – 240 V AC, 45 – 65 Hz

Output: 24 V DC: available with 18 VA, 36

VA and 60 VA

ACCTRD

Input: 230 V AC, 50 – 60 Hz

Output: 24 V AC, available with 12 VA,

22 VA and 35 VA

PT 1000

AKS is a High precision temp. sensor

AKS 11 (preferred), AKS 12, AKS 21

ACCPBT PT1000

NTC sensors

EKS 221 ( NTC-10 Kohm) MBT 153

ACCPBT

NTC Temp probe (IP 67 /68)

MMIMYK device is used as a gateway

to connect EKEs and the PC tool i.e

KoolProg software for parameter

setting or data logging.

EKE 2U Backup power module can

provide enough energy during

power failure to the stepper

controller to ensure closure of the

electronic valves.

ACCCBI cables for MMI display and gateway. EKE is compatible with Danfoss stepper

motor valves i.e Danfoss ETS 6, ETS, KVS,

ETS Colibri®, KVS colibri®, CTR, CCMT

© Danfoss | Climate Solutions | 2021.09

M12 Angle cable to connect

Danfoss stepper motor valve and

EKE controller

AN325741271542en-000403 | 15

Loading...

Loading...