Page 1

Data Sheet

Superheat controller

Type EKE 1A, 1B, 1C, 1D (PV04)

For commercial air conditioning and refrigeration applications

The exible pre-programmed EKE superheat

controller from Danfoss provides ultimate

software control, allowing you to tailor the

performance of your system to your exact

requirements. EKE is ideal for controlling a wide

range of commercial air conditioning and

refrigeration applications, such control helps

you to achieve the highest eciency in the

system reducing the operational cost by up to

20% with minimal eort. EKE is generally used

where there is a requirement for accurate

control of superheat or temperature control in

connection with air conditioning and

refrigeration. The superheat is regulated to the

lowest possible value within a short period of

time. It regulates the superheat of the

evaporator by charging optimally even when

there are great variations of load resulting in

reduction of energy consumption and

operational cost

Typical Applications:

• Chillers

• Processing plant / Cabinet cooling

• Cold store (air coolers)

• A/C plant / Air conditioning

• Heat pumps. Residential Heat Pump

• Transport cooling

• Stepper Motor Driver

AI197986442906en-000501

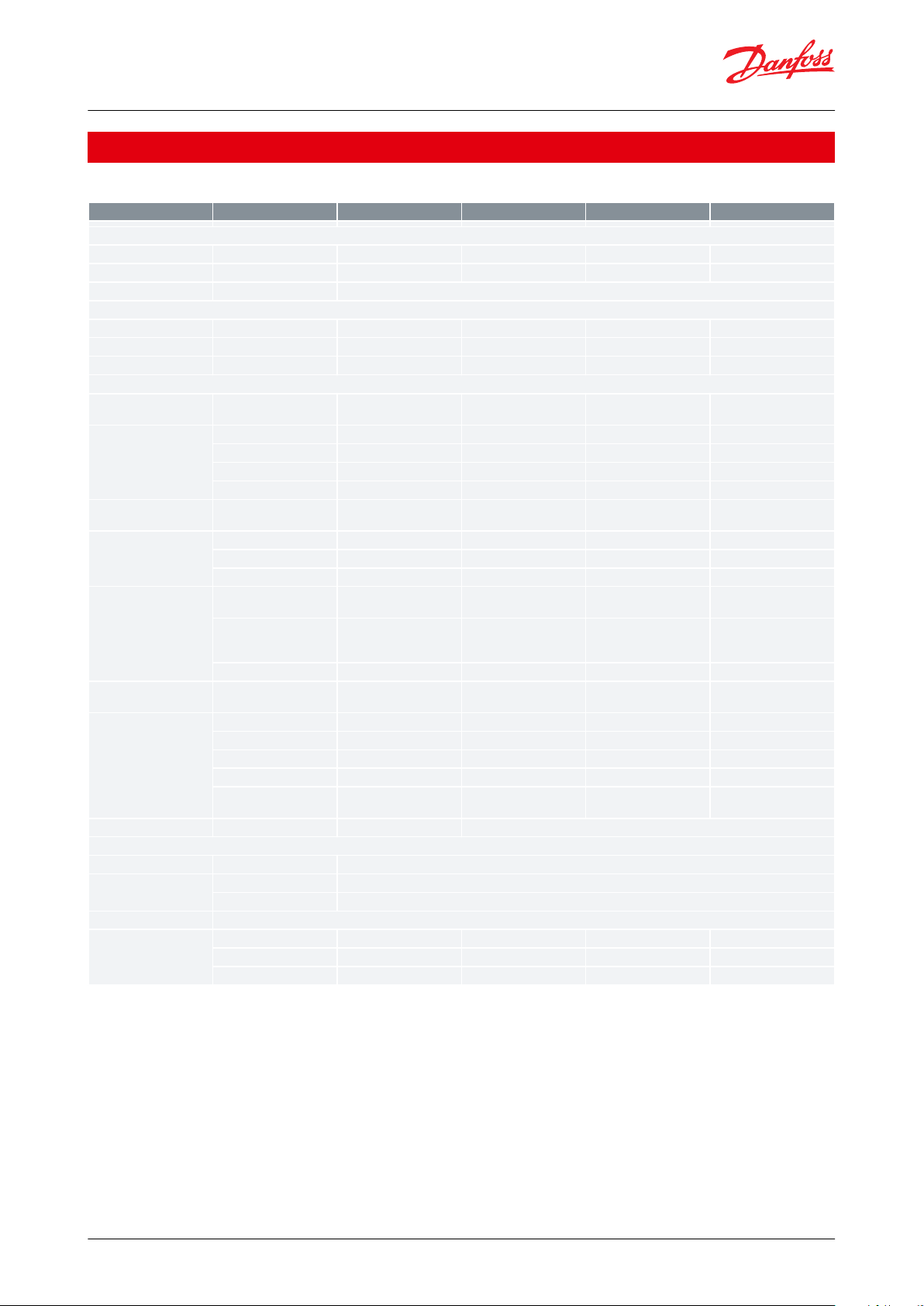

Page 2

Features

EKE 1A

EKE 1B

EKE 1C

EKE 1D

Power supply:

Power Supply Type

24 V AC / DC ± 20%••••

Battery Backup input

18-24 V DC••••

Class of insulation

Class II

Data communication

MODBus

RS 485 RTU••

Wired CANbus

(4 wires)

(3 wires)

CANbus RJ 12

Danfoss MMI service port

•••

•

Inputs::

Number of temperature

sensors

123

2

Temperature sensor types

PT1000

•

NTC 10K, type EKS••••

NTC 10K, type ACCPBT

•••

•

NTC 10K, type Sensata

•••

•

Number of Pressure sensor

112*

1

Pressure Transmitter

types

Ratiometric 0.5 - 4.5 V

•••

•

Voltage signal 0 – 10 V

•••

•

Current signal 0 – 20 mA

•

Share Pressure Signal

Hardware (Up to 5 devices)

•••

Via wired CANbus (not

possible to share ratiometric sensor)

•

•

Via MODbus••

Number of external references

111

1

External reference

0-20mA

•

User dened current

•

0-10V

•••

•

0- 5V

•••

•

User dened voltage( max

10V)

•••

•

Digital input Dry contact

3

2

Outputs

Digital output

1

Relay

Normally Open

3A General purpose, 250V ac, 100k

Normally closed

2A General purpose, 250V ac, 100k

Relay Function

Alarm relay or LLSV (Liquid Line Solenoid Valve)

User interfaces

Koolprog Software tool

•••

•

MMIGRS2 screen••••

Master controller••

•

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Portfolio overview

Table 1: Portfolio overview

*The 2nd pressure sensor is mounted on AI4

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 2

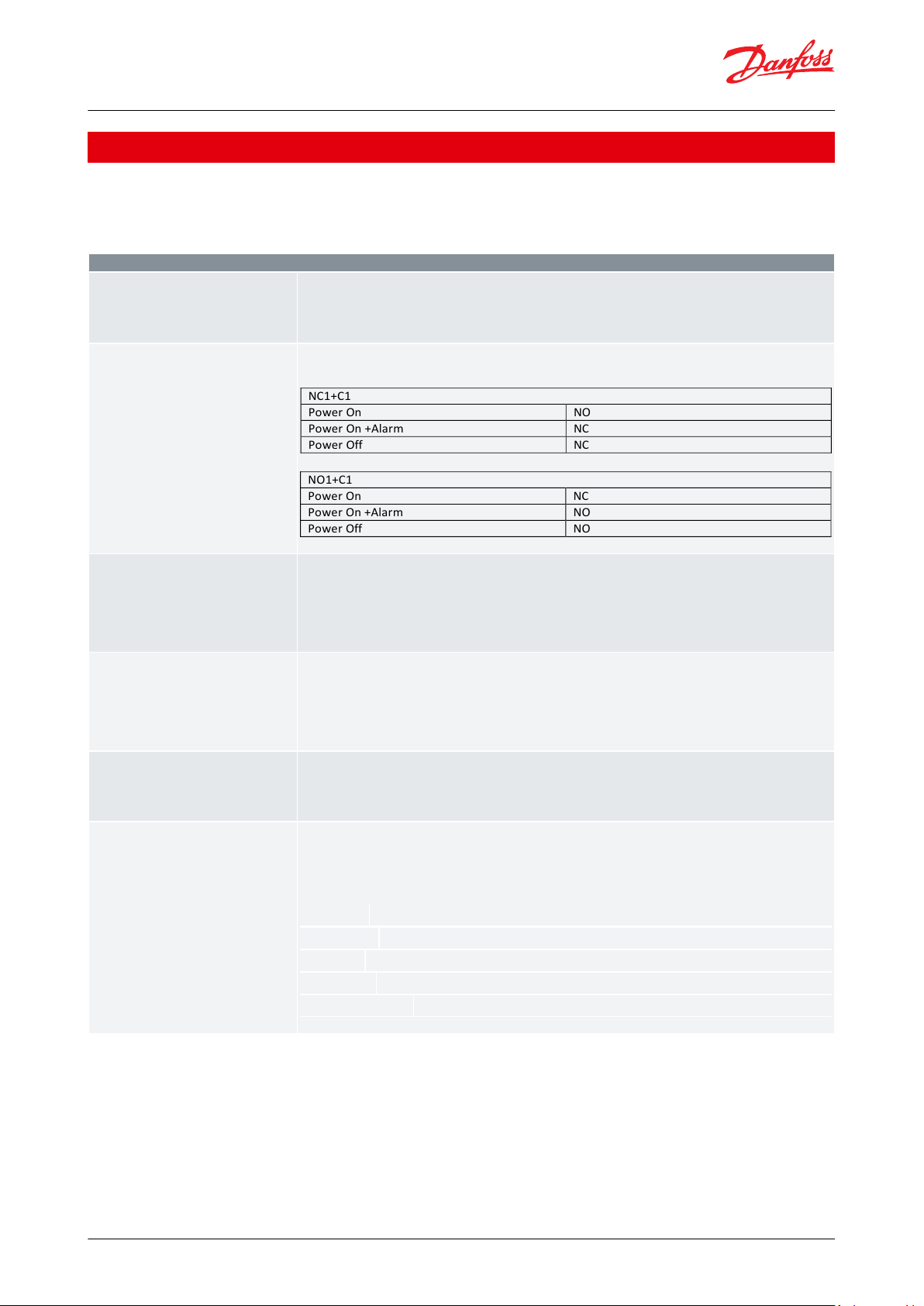

Page 3

Red constant

Green constant

Flashing red

Flashing green

Flashing red and green

Hardware functions

Digital inputs

Used to interact with the EKE for systems where the EKE is not connected to a system controller via data communication.

The available digital inputs DI can be used for the following functions:

a. Injection control ON/OFF(DI1). b. Defrost sequence (DI2). c. Heating and cooling selection mode (DI2) d. Preset OD

(DI2)

Digital Output (Relay)

• The relay for the liquid line solenoid valve will operate when refrigeration is required

• The contact of the relay is closed in alarm situations and when the controller is de-energized.

• The digital output DO1 O013 can be congured for solenoid valve, max capacity or for alarm function.

NC1+C1

Power On

NO

Power On +Alarm

NC

Power Off

NC

NO1+C1

Power On

NC

Power On +Alarm

NO

Power Off

NO

Handling power failure

For safety reasons the liquid ow to the evaporator must be cut o in case of power failure. The valve’s stepper Motor

will remain open in power failure situation

There are two ways of coping with this situation

One of the following two solutions can be applied in the system

• Mounting of a solenoid valve in front of EEV (using LLSV relay signal from EKE)

• Mounting of a battery backup for EEV valve (Use Danfoss EKE 2U)

Analog Inputs

External Reference Signal:

Used for:

• Driving the stepper motor valve to a desired opening degree (Driver Mode)

• Displacing temperature reference, superheat reference or max OD

The voltage signal e.g., 0 – 10 V can be used in all EKE controllers whereas current signal e.g 0 – 20 mA signal is only

available in EKE 1C

Communication: RS485 Modbus / CANbus

The controller can be provided with data communication for connecting to other devices in the systems.

In this case, monitoring and data collection can be performed from one device i.e., PLC – which will be benecial for

the diagnostic or during the installation processes.

For example, it is possible to substitute the physical sensors of the EKE controller by writing sensor values via Bus. The

frequency of update should be according to the Modbus maximum update interval G004 (Refer to parameter list)

Light-emitting diodes (LEDs)

Two sets of light-emitting diodes make it possible to follow the operation status of the valve and the controller. They

indicate the following

• Power/data transmission and Alarm/Error indication

• Stepper valve operational status

LED status:

valve is closed

valve is fully open

valve is moving in close direction

valve is moving in open direction

Error

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Functions

The EKE 1x products supports a wide range of functionalities illustrated in table 3 and 4. Check the user guide for

more detail about congurations and other detailed options.

Table 2: Hardware functions

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 3

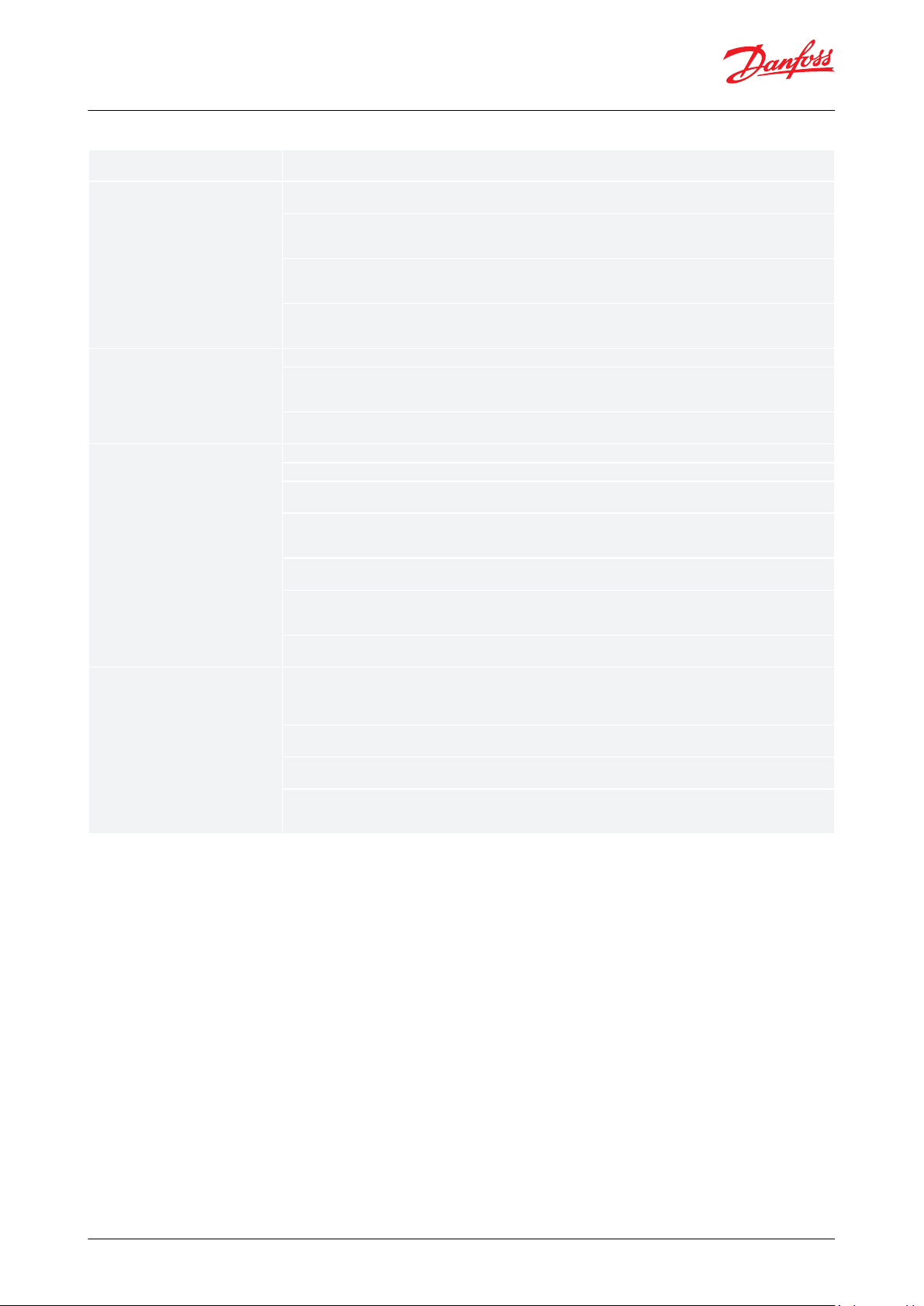

Page 4

Valve Driver

The EKE controls the opening degree of the valve, the control signal can be an analog signal or a value via communication bus

Superheat Reference Calculation

• Fixed Superheat The controller keep the superheat at a xed reference value determined by the user. SH xed setpoint

can be varied according to the need of application.

• Minimum Stable Superheat (MSS): The superheat control algorithm will attempt to regulate the superheat down to

the lowest stable value between the minimum superheat setting, “Min SH” and the maximum superheat setting, “Max.

SH”.

• LoadAP Superheat LoadAP is a kind of preprogrammed MSS curve. In Load ap application, SH reference follows a

dened curve as shown in the diagram. This two-point curve is dened by SH max and SH min, this method will give a

robust SH reference and can in many cases be the best t for systems.

• Delta temp. superheat SH reference is calculated as a ratio between the media temperature and evaporator temperature. This reference mode is only possible if media temperature (S3) sensor is available and if the system uses n and tube

evaporator.

Temperature Control *

EKE has a feature to regulate the temperature control. This can be done with either

• Thermostat cut in/cut out function: if temperature is above the set point + dierential, cooling is started with maximum cooling capacity. In maximum capacity superheat is controlled to be on superheat set point. Cooling is active until

the temperature is below set point.

• Modulating Thermostat (MTR): When temperature is getting close to the MTR reference the cooling capacity gradually

reduce so that the temperature can be stable on the MTR reference and the superheat will be oating.

Protection Functions

• Failsafe operation: During operation if sensors error occurs, the valve position can be set to full close, xed

opening degree or average calculated OD as required.

• Superheat close: When the superheat is below a set minimum value, the valve will close faster to protect the compressor from the risk of getting liquid in the suction line and bring the superheat back to superheat reference.

• Maximum Operating Pressure (MOP): To reduce the strain on the compressor, a maximum operating pressure is set. If

the pressure comes above this limit the controller will control the valve to provide a lower pressure instead of a low superheat.

• Low Operating Pressure (LOP): known as Cold start feature, it allows applications such as heat pumps to operate at

lower ambient conditions to prevent compressor from stopping due to low suction pressure in the startup phase.

• High Condensing temperature protection (HCTP)**: High condensing temperature protection will make sure that

the load on the condenser is reduced in case a too high condensing temperature is reached. This is done by limiting the

valve opening degree.

• Minimum S4/leaving media (freeze protection) *: Lowers the ow in the expansion valve if temperature of leaving

media out of the evaporator is below a minimum value set by the user.

Other Functions

• Fast Start up: Quickly open an EEV valve when compressor turns ON to prevent too low suction pressure as well as for

faster stabilization of superheat or temperature set point. This can be ensured by setting either P-control, Start opening

degree with protection or Fixed opening degree without protection. This start up condition is kept until the start time

expire or superheat reaches at setpoint.

• Defrost sequence: The controller does not itself handle defrost of the evaporator. It is however possible to enter a special defrost sequence which will overrule the normal control of the valve.

• Manual control: The valve can be controlled manually by setting the desired opening degree via Analog signal or communication bus used for commissioning purpose. A special service mode is also available for service and testing purpose.

• Service mode: Service mode is designed to provide a very simple way of operating the valve for diagnostic and service

purpose. There is neither application nor protection in this mode. The user can open and close the valve using simple

button presses on MMIGRS2.

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Table 3: Control Functions

*Not available in EKE 1A

**Only Available EKE 1C

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 4

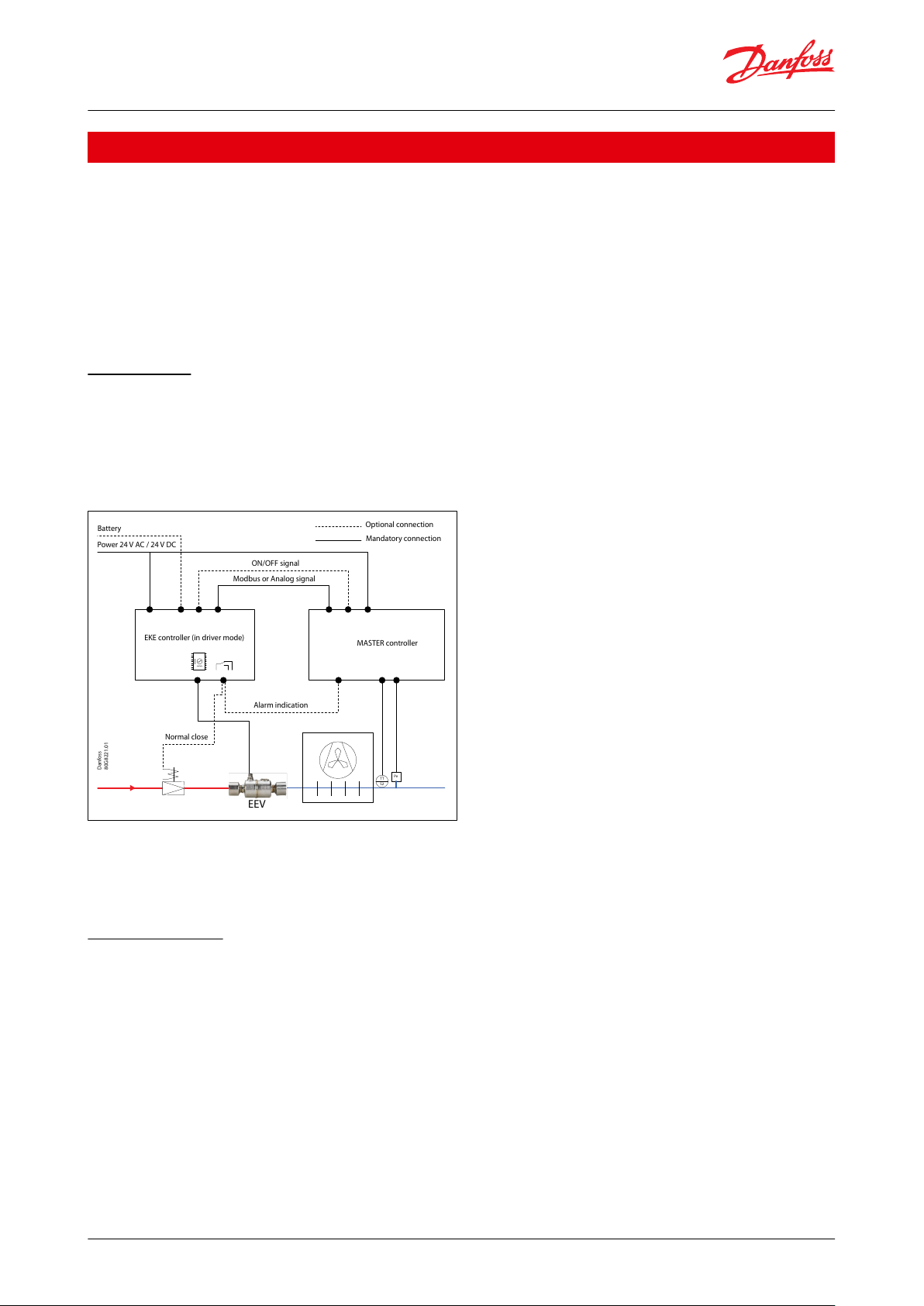

Page 5

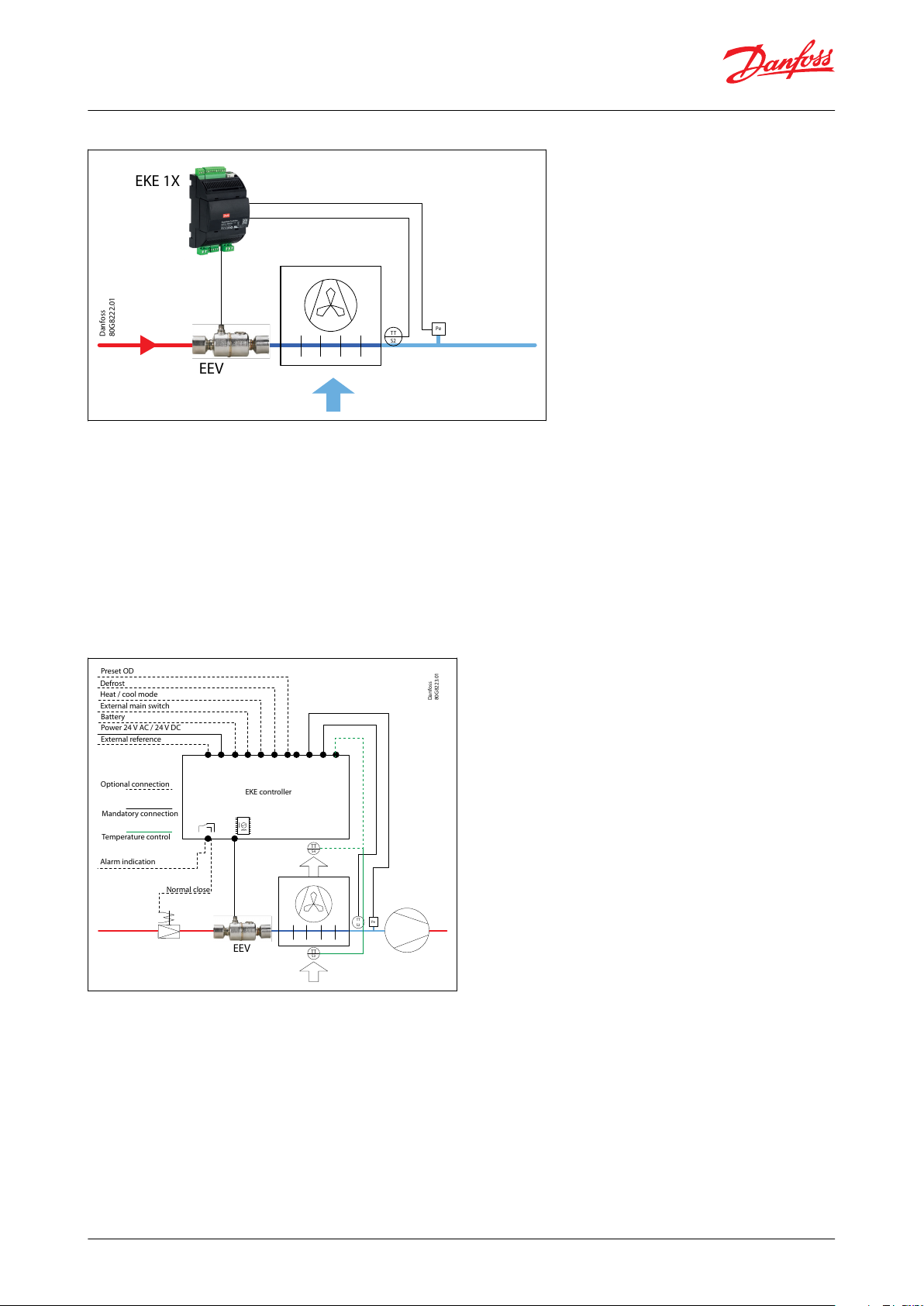

Danfoss

80G8221.01

EEV

TT

Pe

S2

Battery

Optional connection

Alarm indication

Normal close

Mandatory connection

ON/OFF signal

Modbus or Analog signal

Power 24 V AC / 24 V DC

EKE controller (in driver mode)

MASTER controller

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Applications

EKE series devices are used where precise control of superheat in air conditioning system is needed. It helps

achieving high energy eciency and reliable operation

EKE serves 2 main applications:

• Driver Mode

• Controller Mode

1.

Superheat controller

2.

Temperature controller

Driver mode

Driver Mode:A master is commanding the valve open degree to the EKE controller. The control signal can be fed for

example by:

• Analog signal e.g., 0 – 10 V, a 4 – 20 mA

• Bus communication via RS485 (Modbus RTU).

Figure 1: EKE as Driver Mode

NOTE:

'Normal closed' valve in front of EEV is optional alternative to a battery backup solution which closes the EEV in case

of power fail. The Digital output can also be used as alarm indication to the master controller. The Master can send a

start signal to EKE DI terminals

Controller Mode

Controller Mode:

Superheat Control: EKE can serve as a PI controller that controls the superheat of the evaporator based on a

pressure Pe and temperature (S2) sensors. In superheat mode the controller will control the superheat to be stable

and close to the superheat reference. If superheat is too low the ow in the expansion is decreased and superheat

will be higher

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 5

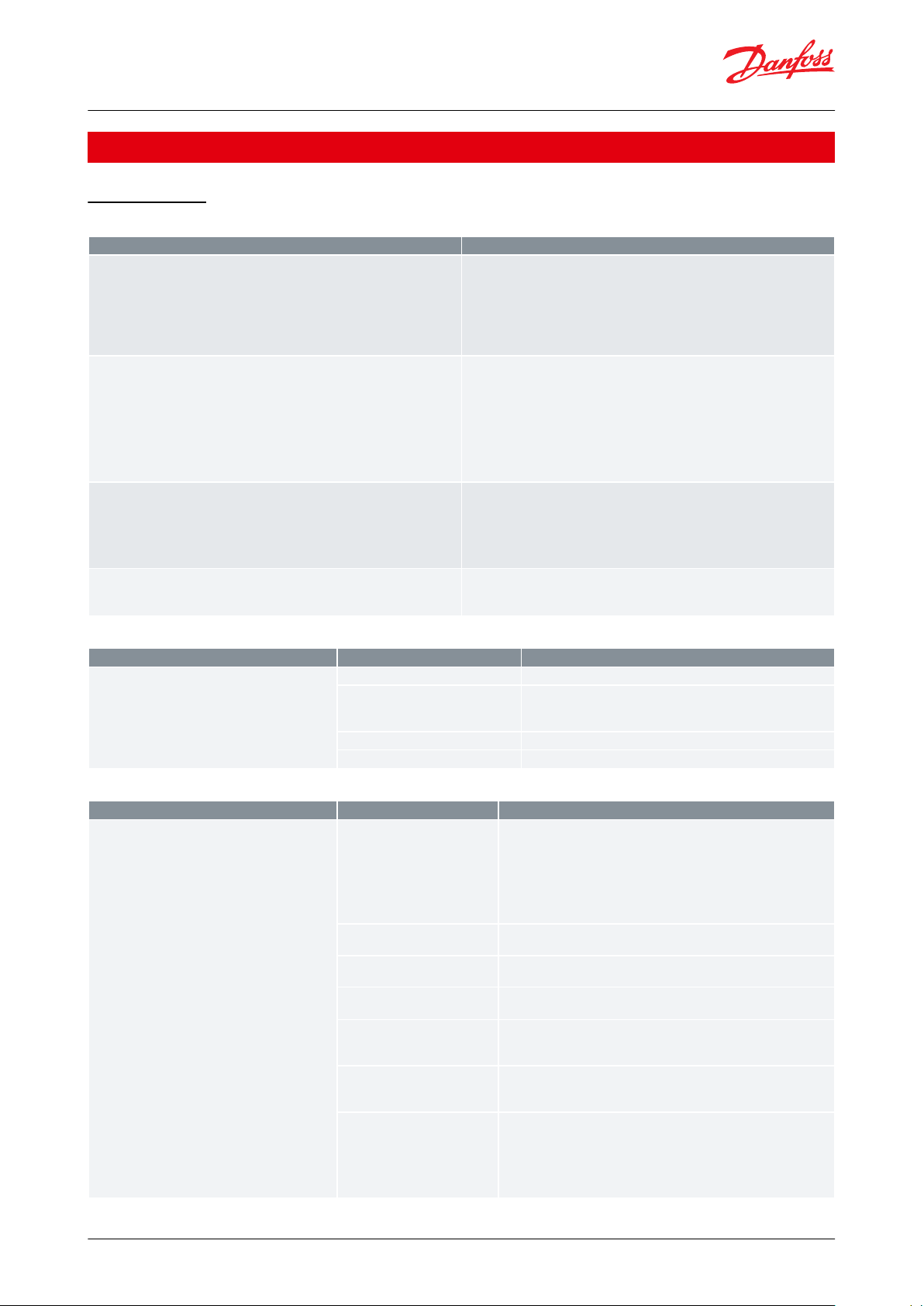

Page 6

Danfoss

80G8222.01

TT

S2

EEV

EKE 1X

Pe

Danfoss

80G8223.01

EEV

EKE controller

Preset OD

Defrost

Heat / cool mode

Battery

Power 24 V AC / 24 V DC

External reference

Optional connection

Mandatory connection

Temperature control

Alarm indication

Normal close

External main switch

TT

S4

Pe

TT

S2

TT

S3

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 2: Superheat control application

Temperature controller The temperature control is an ON/OFF thermostat that opens/closes the stepper valve or

modulating thermostat that regulates temperature more smoothly following a temperature reference point. The

temperature control can be accomplished via a signal from temperature sensor S3 placed in the air ow before the

evaporator or S4 placed in the air ow after the evaporator.

EKE has 2 methods of controlling temperature:

• ON/OFF thermostat

• Modulating thermostat (MTR)

The need for cooling can either be dened by the incoming media (S3) or the outgoing media (S4) temperature

Figure 3: Temperature control application

NOTE:

EKE1A can only work in the driver mode or superheat control mode as it supports only one temperature sensor

input

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 6

Page 7

Feature

Description

Power supply

Galvanic isolation by switch mode power supply

Input voltage rating (AC): 24 V AC ± 20 % (min.19.2 V AC - max. 28.8 V AC

Input frequency (AC): 50 / 60 Hz

Input voltage rating (DC): 24 V DC (min. 20 - max. 40 V DC)

Provides 5 W at 5 V and 15 V outputs isolated from the 24 V input

Insulation between power supply and the extra-low voltage.

Class of insulation Class II

Power Consumption

Total Power consumption with following valve in operation and MMIGRS2 connected to the controller:

CCMT 16 - CCMT 42: 15VA/10W

ETS 6: 11 VA / 7.5W

ETS 12C - ETS 100C: 20VA / 14W

KVS C: 20VA / 14W

ETS 12.5 - ETS 400 7 VA / 5W

CCMT 2 - CCMT 8 7 VA / 5W

CTR 20: 7 VA / 5W

Plastic Housing

• DIN rail mounting complying with EN 50022

• Self-extinguishing V0 according to IEC 60695-11-10 and glowing / hot wire

test at 960 °C according to IEC 60695-2-12

• Material used for Enclosure are UL94-V0 and RoHS compliant

• Ball test: 125 °C according to IEC 60730-1

• Leakage current: ≥ 250 V according to IEC 60112

Connectors

• Plug able Screw connector Pitch 3.5 mm, relay and power connector Pitch 5

mm, CAN MMI: Modular Jack 6P4C

• Material used for connectors are RoHS and UL approved

Feature

Type

Description

Protection

Short circuit

Motor driver: dissipative over current protection

Over voltage

Analog input: current limit and internal clamp diode

Digital input: current limit and internal clamp diode

Communication: transceiver IC

Over Temperature

Motor driver: thermal shutdown at 150 °C

Unstable Digital Input

Continuous variation of the digital input state

I/O

Type

Specications

Analog inputs

• Max. 15 V input voltage

• Open circuit HW diagnostics available for voltage input on: AI3, AI4

(EKE 1C) AI4 (EKE 1A and EKE 1B).

WARNING:

Do not connect voltage sources without current limitation (overall 80

mA) to analog inputs while unit is not powered.

0 – 5 V

EKE 1C (AI3, AI4) and EKE1A/1B/1D AI3 | Accuracy ± 40 mV, resolution 1.2

mV.

0 – 10 V

EKE 1C (AI3, AI4) and EKE1A/1B/1D AI3 | Accuracy ± 50 mV, resolution 2.5

mV.

0 – 20 mA (EKE 1C only)

Accuracy ± 100 μA, resolution 10 μA.

Input resistance: <100 Ω

NTC Sensor

NTC temperature probes: 10 kΩ at 25 °C range: 300 kΩ to 100 Ω

Accuracy: 50 – 120 °C: 1.5 K, -40 – 50 °C: 0.4 K, 0 °C: 0.2 K

Resolution: ≤ 0.1 K, ≤ 0.3 K (EKC 1C, AI5)

Pt1000 sensor

Range: 723 Ω to 1684 Ω

Accuracy: ≤ 0.5 K

Resolution: ≤ 0.1K

Pressure Sensor

Type: Ratiometric

• Accuracy: 1.6 %

• Range: 0.5 – 4.5 V

• Resolution: 1.2 mV

• Supply voltage: 5 V DC / 15 mA, overload protection approximately

150 mA

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Product specication

Technical data

Table 4: General specication

Table 5: Electrical specication

Table 6: Input/Output

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 7

Page 8

I/O

Type

Specications

Digital Input DI

Voltage free contacts

Steady current of 1 mA (EKE 1C only). A cut-in input will activate a function.

Cleaning current of 100 mA at 15 V DC.

On: RIL <= 300 Ω . O: RIH >= 3.5kΩ.

No destructive if Vbat + is connected to DI (only for DI on bottom pcb).

Min. pulse time 64 ms.

Digital output (D01)

Relay

Normally Open: 3 A General purpose, 250 V AC, 100 k cycle

Normally Open: 3 A Inductive (AC-15), 250 V AC, 100 k cycle

Normally Closed: 2 A General purpose, 250 V AC, 100 k cycle

Stepper motor

Bipolar and unipolar stepper Motor Output

Danfoss ETS / KVS / ETS C / KVS C / CCMT 2 – CCMT 42 / CTR / CCMTL

Valves (green, red, black, white)

ETS 6 / CCMT 0 / CCMT 1 (black, red, yellow, orange)

Other Valves:

• speed 10 - 400 pps

• drive mode full step, half step, 1/8 microstep

•

max. peak phase current: 1.2 A (848 mA RMS)

• max. output power 12 W

Battery backup

VBATT: 18 – 24 V DC:

Leakage: <15 μA @30 V DC

Optional: critical low alarm below 12V

Optional: low alarm at 17 V, high voltage alarm at 27 V

The valve will not close at power fail if voltage is higher than 27 V

Required power to do 1 closing of stepper valve:

ETS 6: 110 J / 30 VmAh

ETS 12.5 - ETS 400: 60 J / 17 VmAh

KVS 15 / KVS 42: 60 J / 17 VmAh

ETS 12C - ETS 100C: 55 J / 15 VmAh

KVS 2C / KVS 5C: 55 J / 15 VmAh

CCMT 2 - CCMT 8: 60 J / 17 VmAh

CCMT 16 - CCMT 42: 175 J / 49 VmAh

CTR 20: 60 J / 17 VmAh

NOTE:

Danfoss recommends using EKE 2U as a battery backup

Communication

RS-485 RTU (only for EKE 1B and

1C)

Galvanic isolation. No Built-in termination.

Supported commands with max. of 50 ms response time: 0 x 03, 0 x 04, 0

x 06

Supported commands without dened max response time : 0x08, 0x10,

0x14, 0x15,0x2b

CAN

• EKE 1A/1B: CANOpen over RJ12 connector.

• EKE 1C: CANOpen over CAN 4pin terminal and RJ12 connector.

• EKE 1D: CANOpen over CAN 3pin terminal and RJ12 connector.

NOTE:

• For EKE EKE 1A/1B, RJ12 connector is used directly connect and supply a user interface MMI

• Refer to the user guide for information about type of connection cables

Feature

Description

Operating conditions

-20 – 60 °C, 90% RH non-condensing

Storage / Transport conditions

-30 – 80 °C, 90% RH non-condensing

Vibration and shock

According to IEC 60068-2-27 Ea

Integration

In Class I and / or II appliances

Index of protection

IP40 only on the front cover (General IP20 )

PCB protection

None (no conformal coating)

Period of electric stress across insulating parts

Long

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Environmental conditions:

Table 7: Environmental conditions

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 8

Page 9

1.

2.

3.

Feature

Description

Resistance to heat and re

Category D

Immunity against voltage surges Category II

Approvals

CE compliance:

This product is designed to comply with the following EU standards:

• Low voltage guideline: 2014/35/EU

• Electromagnetic compatibility EMC: 2014/30/EU and with the following norms

EN61000-6-1. EN61000-6-3, (immunity and emission standard for residential. commercial and lightindustrial environments)

EN61000-6-2. EN61000-6-4, (immunity and emission standard for industrial environments)

EN60730-1 and EN60730-2-9 (Automatic electrical controls for household and similar use)

•

RoHS compliance to 2011/65/EU and no components from negative list acc. to 500B0751

Product name

Product type - code no.

Electrical specification

Product version

Approvals

Product QR code

Country of origin

Manufacturer address

Example: EKE 1C

PV04 SW2.04

110

70 60

Danfoss

80G8215.11

CAN RJ

130

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Identication

Product label is positioned in the front of the product

Figure 4: Example EKE 1C

Dimensions and weights

Figure 5: EKE 1A, EKE 1B, EKE 1C, EKE 1D Dimensions

Net Weight:

• EKE 1C: 170 g

• EKE 1A / EKE 1B / EKE 1D: 130 g

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 9

Page 10

EKA 1A - 080G5300

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

CAN RJ

ANALOG / DIGITAL INPUT

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

PWR 24V Vbat STEPPER VALVE DIGITAL OUTPUT

CAN - RJ

Danfoss

80G8286

Danfoss

80G8286.01

EKA 1B - 080G5350

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

D –

D+

RGND

CAN RJ

ANALOG / DIGITAL INPUT

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

PWR 24V Vbat STEPPER VALVE DIGITAL OUTPUT

CAN - RJCAN

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Connections:

Figure 6: EKE 1A connectors

Figure 7: EKE 1B connectors

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 10

Page 11

Danfoss

80G8286.01

EKA 1D- 080G5360

Superheat controller

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

D –

D+

RGND

CAN RJ

ANALOG / DIGITAL INPUT

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

PWR 24V Vbat STEPPER VALVE DIGITAL OUTPUT

CAN - RJCAN

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 8: EKE 1D connectors

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 11

Page 12

Danfoss

80G8286.01

EKE 1C - 080G5400

R120

CANH

CANL

GND

RGNDD+D-

COM

AO1

CAN RJ

CAN CAN RJ

RS485 AO1

15V+

5V+

COM

AI5

AI4

AI3

AI2

AI1

COM

COM

DI2

DI1

COM

ANALOG INPUT 1-5

Not used

DIGITAL INPUT 1-2

Danfoss

80G8286.01

EKE 1C - 080G5400

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

PWR 24V Vbat STEPPER VALVE DIGITAL OUTPUT

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 9: EKE 1C connectors: Front

Figure 10: EKE 1C connectors: Back

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 12

Page 13

–/

~

+/

~

GND

Bat+A1A2

B1B2NO1

C1

NC1

–/~

+/~

GND

Bat+A1A2

B1

B2

NO1

C1

NC1

–

+

+

V

–/

~

+/~

GND

Bat+A1A2B1B2

NO1

C1

NC1

–/

~

+/~

GND

Bat+A1A2B1B2

NO1

C1

NC1

COM

5V+

DI2

DI1

CO

M

AI4

AI3

AI2

DI3

CO

M

CAN RJ

COM

5V+

DI2

DI1

CO

M

AI4

AI3

AI2

DI3

CO

M

CAN RJ

1

2

3

C

CAN RJCAN RJ

COM

5V+

DI2

DI1COM

AI4AI3AI2

DI3

COM

CAN RJ

COM

5V+

DI2

DI1COM

AI4AI3AI2

DI3

COM

C1 NC1

Power

C1 NO1

Power

fu

Master controller Optional

Pressure Transmitter

Ratiometric 0.5 – 4.5 V

AKS cable

connection

060G1034

e.g. AKS 32R

Power supply

24 V AC

± 20%

24 V DC

± 20%

2.5 A

T se

(optional)

Batt

backup

(optional)

ON/OFF

solenoid

valve

Alarm

orange

yellow

red

black

brown

black

orange

yellow

Relay

Normally open or

normally closed

(optional)

white

black

red

green

ETS 6 valve

ETS 5M

ETS / KVS

Colibri ®

CCMT / CTR valve

MMIGRS2 Display

MMIMYK

Gateway

080G0294 (optional)

CANbus

DI2

DI1 (ON/OFF)*

COM

AI4 (voltage)

NTC (S2)

DI3

CAN RJ

080G0075 (opt.)

KoolProg PC tool

Danf

oss

80G311.10

18

Superheat controller

EKE 1A - 080G5300

*Note; IF Dl1(ON/Off)

switch is not used it

must be turned off in

Dl1 parameter

configuration

COM

Common

DI3

Digital input 3

Software congurable DI

AI2

Analog input NTC 10K

S2

AI3

Analog inputs 0 – 5 V / Ratiometric pressure transmitterPeAI4

analog inputs 0 – 10 V

External Reference signal

COM

Common

DI1

Digital input 1

Main switch (hardware)

DI2/3

Digital input 2 and 3

Software congurable DI

5V+

Power output for Ratiometric pressure transmitter 0 –

5V

COM

Common

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Connection diagrams

Figure 11: EKE 1A connection overview

Table 8: EKE 1A pinout

NOTE:

If Dl1(On/O) switch is not used it must be short circuited

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 13

Page 14

Danfoss

80G318.10

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

LHGND

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–

+

+

18 V

1

2

3

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

LHGND

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

C1

NC1

Power

C1

NO1

Power

Superheat controller

EKE 1D - 080G5360

Master controller

Pressure transmitter

e.g. AKS 32R

Power supply

24 V AC

± 20%

24 V DC

± 20%

2.5 A

T fuse

(optional)

Batt

backup

(optional)

ON/OFF

solenoid

valve

Alarm

Relay

Normally open or

normally closed

(optional)

AKS Cable

connection

060G1034

* Note: If Dl1(On/Off) switch is not

used it must be short circuited

RS485 MODBus

RS485 RTU MODBus

Supervisor

network

EKE

MMIGRS2 Display

MMIMYK

Gateway

KoolProg

PC tool

080G0294

(optional)

CANBus

0

80G0075 (opt.)

DI2

DI1 (ON/OFF)*

COM

AI4 (0 / 10 V)

NTC (S2)

NTC (S3/S4)

Optional

CAN RJ

orange

yellow

red

black

brown

black

orange

yellow

white

black

red

green

ETS 6 valve

ETS 5M

ETS / KVS

Colibri ®

CCMT / CTR valve

COM

Common

AI

Analog inputs NTC 10K

S3/S4 selectable via software

AI2

Analog input NTC 10K

S2

AI3

Analog inputs 0 – 5 V / Ratiometric pressure transmitterPeAI4

analog inputs 0 – 10 V

External Reference signal

COM

Common

DI1

Digital input 1

Main switch (hardware)

DI2/3

Digital input 2 and 3

Software congurable DI

5V+

Power output for Ratiometric pressure transmitter 0 –

5V

COM

Common

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 12: EKE 1B connection overview

Table 9: EKE 1B pinout

NOTE:

If Dl1(On/O) switch is not used it must be short circuited

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 14

Page 15

R120

CANH

CANL

GND

RGNDD+D-

CAN RJ

COM

DI2

DI1

COM

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

15V+

5V+

COM

AI5

AI4

AI3

AI2

AI1

COM

1

2

3

C

CC

R120

CANH

CANL

GND

RGNDD+D-

CAN RJ

COM

DI2

DI1

COM

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

15V+

5V+

COM

AI5

AI4

AI3

AI2

AI1

COM

*

Superheat controller

*

Danfoss

80G315.10

Superheat controller

EKE 1C - 080G5400

NTC S3/S4

(optional)

Master controller

Pressure Transmitter

Ratiometric 0.5 – 4.5 V

AKS cable

connection

060G1034

NTC/PT 1000 (S2)

NTC/PT 1000 (S3/S4)

(Optional)

COM

DI2

DI1 (ON/OFF)

COM

AI4 (V/I)

e.g. AKS 32R

RS485 RTU MODBus

CANBus Local network

CANBus

MMIMYK

Gateway

EKE /

master

controller

MMIGRS display

080G0294 (optional)

supervisor

network

KoolProg

PC tool

CAN RJ

080G0075 (optional)

Note: If Dl1(On/Off) switch

is not used it must be short

circuited

COM

Common

AI1

Analog inputs temperature NTC 10K / PT1000

S3/S4 selectable via software

AI2

Analog inputs temperature NTC 10K / PT1000

S2

AI3

Analog inputs voltage / current

Pe

AI4

Analog inputs voltage / current

Ext. Ref. or Pc

AI5

Analog inputs NTC temperature

S3/S4 selectable via software

COM

Common

5V+

Power outputs for Ratiometeric pressure transmitter 0

– 5V

15V+

Power output for current signal pressure transmitter

DI1

Digital input 1

Main switch (hardware)

DI2

Digital input 2

Software congurable DI

24V+

Not used in EKE 1C

AO1

Not used in EKE 1C

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 13: EKE 1C - Front board connection overview

Table 10: EKE 1C pinout

NOTE:

If Dl1(On/O) switch is not used it must be short circuited

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 15

Page 16

Danfoss

80G316.10

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–

+

+

18 V

C1 NO1

Power

C1

NC1

Power

Superheat controller

EKE 1C - 080G5400

power supply

24 V AC

± 20%

24 V DC

± 20%

2.5 A

T fuse

(optional)

batt

backup

(optional)

ON/OFF

solenoid

valve

Alarm

Alarm Relay

Normally open or

normally closed

(optional)

Superheat controller

orange

yellow

red

black

brown

black

orange

yellow

white

black

red

green

ETS 6 valve

ETS 5M

ETS / KVS

Colibri ®

CCMT / CTR valve

User selection EKE connection

Signal

EKE Connection

Not

dened

--AKS 32R

Ratiometric 10-90%

5V supply from EKE

112CP (Sensata)

Ratiometric 10-90%

5V supply from EKE

OEM Ratio

Dened

by parameters

5V supply from EKE

NSK (Saginomiya)

Ratiometric 10-90%, 0.5 to 4.5V

5V supply from EKE

AKS 32 1-5V

1-5V

15V supply from EKE

OEM Voltage

Dened

by parameters

15V supply from EKE

Bus shared

Via RS485 Modbus

-

AKS 32 1-6V

1-6V

15V supply from EKE

AKS 32 0-10V

0-10v

15V supply from EKE

AKS 33

4-20mA

15V supply from EKE

XSK (Saginomiya)

4-20mA

15V supply from EKE

OEM Current

Dened

by parameters

15V supply from EKE

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 14: EKE 1C - Back board connection overview

Dierent types of 4 - 20 mA pressure Transmitters need dierent supply levels. Check the guide bellow

Table 11: EKE 1C pressure transmitters range

NOTE:

EKE 1A/1B/1D only support ratiometric 0.5 to 4.5V pressure transmitter

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 16

Page 17

Danfoss

80G318.10

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

LHGND

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

–

+

+

18 V

1

2

3

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

LHGND

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

AI1

COM

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

C1

NC1

Power

C1

NO1

Power

Superheat controller

EKE 1D - 080G5360

Master controller

Pressure transmitter

e.g. AKS 32R

Power supply

24 V AC

± 20%

24 V DC

± 20%

2.5 A

T fuse

(optional)

Batt

backup

(optional)

ON/OFF

solenoid

valve

Alarm

Relay

Normally open or

normally closed

(optional)

AKS Cable

connection

060G1034

used it must be short circuited

CANBus

CANBus

Supervisor

network

EKE

MMIGRS2 Display

MMIMYK

Gateway

KoolProg

PC tool

080G0294 (optional)

CANBus

0

80G0075 (opt.)

DI2

DI1 (ON/OFF)*

COM

AI4 (0 / 10 V)

NTC (S2)

NTC (S3/S4)

Optional

CAN RJ

orange

yellow

red

black

brown

black

orange

yellow

white

black

red

green

ETS 6 valve

ETS 5M

ETS / KVS

Colibri ®

CCMT / CTR valve

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 15: Connection for 4 - 20 mA

Figure 16: EKE 1D connection overview

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 17

Page 18

1

“Click”

3

2

COM

Common

AI

Analog inputs NTC 10K

S3/S4 selectable via software

AI2

Analog input NTC 10K

S2

AI3

Analog inputs 0 – 5 V / Ratiometric pressure transmitterPeAI4

analog inputs 0 – 10 V

External Reference signal

COM

Common

DI1

Digital input 1

Main switch (hardware)

DI2/3

Digital input 2 and 3

Software congurable DI

5V+

Power output for Ratiometric pressure transmitter 0 –

5V

COM

Common

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Table 12: EKE 1D pinout

Mounting

DIN rail mounting / demounting. The unit can be mounted onto a 35 mm DIN rail simply by snapping it into place

and securing it with a stopper to prevent sliding. It is demounted by gently pulling the stirrup located in the base of

the housing

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 18

Page 19

• Create your own

conguration les on your PC without

having to connect a controller

• Import a parameter conguration le to your PC from a

connected controller. Save the le and download it to

other controllers of the same model

• Select the most frequently used parameters as your favorites

•

Find all the technical documentation for each controller

model within one location

• Quickly program one. or multiple controllers

by using the progress and completion status

indicators

• Quickly analyze controller behavior and program

patterns by using the graphical trending tool

• Make Online changes to parameter congurations

• Monitor live status of inputs and outputs

Superheat controller, Type EKE 1A, 1B, 1C, 1D

User interface

Koolprog software tool

KoolProg is a software tool that can congure the EKE Controllers in fast and easy way

The main features of the KoolProg are listed as follows

• Make Online changes to parameter congurations

• Monitor live status of inputs and outputs

• Quickly analyze controller behavior. and program patterns by using the graphical trending tool. KoolProg

Software is available for download free of charge at http://koolprog.danfoss.com. The customer will rst be guided

through a registration process before download can commence

NOTE:

For updated EKE software versions it is required to install the latest KoolProg software versions to have the full

compatibility To guarantee a reliable USB connection to a host device (e.g. industrial PC), you must: keep USB cable

length < 1 m. Kool Prog software do not support multiple EKE controllers in a daisy chain network. EKE must be

powered up before starting programming

User interface Display MMIGRS2

MMIGRS2 is a remote interface that connects with EKE controller through the CAN RJ or CANbus network. All the

information about the user interface is loaded inside the EKE controller; that’s why there is no need of programming

the MMIGRS2 interface. MMIGRS2 is powered externally or from the controller which it is connected to and

automatically shows its user interface.

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 19

Page 20

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

CAN RJ

Danfoss

80G313.10

MMIGRS2

ACCCBI080G0075

CAN RJ

–/~

+/~

GND

Bat+A1A2B1B2

NO1C1NC1

COM

5V+

DI2

DI1

COM

AI4

AI3

AI2

DI3

COM

CAN RJ

Superheat controller

EKE 1A - 080G5300

2-way screw connector for

power supply

4-way screw connector for

CANbus network

RJ

Termination Jumper

between R and H

CAN connector

For cable >3m (only EKE 1C)

Danfoss

34G306.10

Right , Left : Navigate to alarm list, status,

controller info

UP and Down together: set actual step

position to 0 step

Up : Adjust requested step position upward

Escape: Leave service mode

Enter short press: start edit of requested

position/accept change

Enter press for 2 sec: change valve selection

Controller name

Primary readout

Operating status

Evap. temperature

Evap. pressure

Valve OD

Navigation help

S2 – S4

Media

temperature

Reference point

Homescreen

Alarm indicator

Master

Controller

PLC

Modbus RTU over RS485 wired

Danfoss

80G8212.10

KoolProg

PC Tool

EKE 1C

Connected

via CAN or

MODbus

EKE 1D

Connected

via CAN or

MODbus

EKE 1B

Connected

via MODbus

only

EKE 1A

No network

possible

Danfoss MMIMYK USB to

CAN converter connects to

the service port of EKE 1A,

EKE 1B and EKE 1C.

Service port CAN-RJ12 (point to point connection only).

Either MMIGRS2 or KoolProg PC Tool (via MMIMYK gateway)

can be connected to the RJ12 connector.

Analog signal (main switch, ext.

reference, alarm outputs etc.)

Danfoss

MMIGRS 2

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Figure 17: MMIGRS2 Display connection with EKE

Figure 18: MMIGRS2 Main screen

On the main screen the following data are displayed:

• the main analog inputs measurements or other information

• the icon indicating if unit is operating in superheat mode or temperature mode

• shows the status of the controller

• the alarm or service icon

NOTE:

When MMI is not connected to EKE via telephone cable the autodetection feature of the EKE CAN address will not

work. Therefore check the following MMIGRS2 setting: 1) enter BIOS menu pressing and holding X + Enter keys for 5

s 2) select “MCXselection”->” Manual Mode” and set the CAN address of the EKE you wish to connect to.

NOTE:

To use EKE 1x controllers with MMI using RJ 12 cable, The CAN R and H terminals behind MMI should be shorted. If

CAN wired connections are used, the rst and the last node in the CAN connection should be terminated using 120ohm resistor

Operation System Master

EKE 1x superheat controller can be interfaced with a System Master the over the network or via analog or digital

signals. The master could be e.g., a Danfoss MCX controller or a PLC system

Figure 19: EKE controller operation with system master

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 20

Page 21

Label

Alarm name

Modbus PNU

Bit number

Can Index

Can Subindex

Bit number

E100

Valve conguration

error

1901855076C0

E101

Conguration error

1901955076C1

E102

Sensor supply overload

19011055076C2

E024

S2 suction pipe sensor error

19011155076C3

E025

S3 media inlet sensor

error

19011255076C4

E026

S4 media outlet sensor error

19011355076C5

E020

Pe evaporator transmitter error

19011455076C6

E121

Pc condenser transmitter error

19011555076C7

E019

External reference signal alarm

1901055076C8

E011

No refrigerant selected

1901155076C9

E103

No valve congured

1901255076C10

E122

Shared signal timeout

1901355076C11

E128

Ext. ref. signal timeout

1901455076C12

A997

Battery critical low

voltage

1901555076C13

A996

Battery too high voltage

1901655076C14

W001

Battery low voltage

1901755076C15

A994

Low S4 media outlet

temperature

1902855076C16

A993

High temperature

1902955076C17

A992

Low temperature

19021055076C18

A991

High evaporation

pressure (MOP)

19021155076C19

A990

Low evaporation pressure (LOP)

19021255076C20

A989

High condensing temperature

19021355076C21

A988

High superheat

19021455076C22

A987

Low superheat

19021555076C23

A986

Lack of valve capacity

1902055076C24

W002

Standby mode

1902155076C25

W003

Manual control

1902255076C26

E104

SH reference too close

to SH close setpoint

1902355076C27

E105

LOP setpoint too close

to MOP setpoint

1902455076C28

E129

No sensor congured

for S4

1902555076C29

E106

No sensor congured

for S3

1902655076C30

E107

SH min higher than

SH max

1902755076C31

E108

OD min higher than

OD max

1903855076E0

E109

No transmitter cong-

ured for Pc

1903955076E1

E114

Check valve step

mode vs positioning

19031055076E2

E115

Valve speed too fast

19031155076E3

E116

Valve speed too slow

19031255076E4

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Alarms

Table 13: Alarms

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 21

Page 22

Label

Alarm name

Modbus PNU

Bit number

Can Index

Can Subindex

Bit number

E117

Valve emergency

speed too fast

19031355076E5

E118

Valve emergency

speed too slow

19031455076E6

E119

Valve start speed too

slow

19031555076E7

A999

DI1 unstable input

1903055076E8

A998

DI2 unstable input

1903155076E9

A983

DI3 unstable input

1903255076E10

E124

Open circuit on valve

1903355076E11

E125

AI5 cant operate with

AKS sensor

1903455076E12

E126

Valve short circuit or

driver too hot

1903555076E13

A982

Thermostatic signal

missing

1903655076E14

A981

SH control signal

missing

1903755076E15

E123

Low supply voltage

1904855076E16

E132

No sensor congured

for S2

1904955076E17

E133

No transmitter cong-

ured for Pe

19041055076E18

E134

Ext. ref conguration

error

19041155076E19

E135

DI H/C cant operate

with the thermostat

19041255076E20

A984

PWR Backup module

failure

19041355076E21

A985

Replace PWR Backup

module

19041455076E22

Superheat controller, Type EKE 1A, 1B, 1C, 1D

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 22

Page 23

Description

Pack format

CodeNo.

Electronic controller EKE 1A

Single pack

080G5300

Electronic controller EKE 1B

Single pack

080G5350

Electronic controller EKE 1C

Single pack

080G5400

Electronic controller EKE 1D

Single pack

080G5360

Description

Pack format

CodeNo.

MMIGRS2 Remote Display

Single pack

080G0294

MMIMYK gateway

Single pack

080G0073

ACCCBI telephone cable user interface connector 1.5

m

Single pack

080G0075

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Ordering

Table 14: Product part numbers

Table 15: Accessories part numbers

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 23

Page 24

File name

Document type

Document topic

Approval authority

080R4003.01

EU Declaration of conformity

EMC directive 2014/30/EU:

EN61000-6-3: 2007 +A1: 2011

EN61000-6-2: 2005

LVD directive 2014/35/EU:

EN60730-1: 2011

EN60730-2-9: 2010

RoHS directive 2011/65/EU

Danfoss

Superheat controller, Type EKE 1A, 1B, 1C, 1D

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 16: Valid approvals

Table 17: Approvals

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 24

Page 25

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.02 AI197986442906en-000501 | 25

Loading...

Loading...