Page 1

ENGINEERING

R64-3002.11

R

64-3002.1

a

o

30

.

0

TOMORROW

Installation guide

Electronic superheat controller - Modbus version

Type EKD 316C (Colibri®)

Introduction

EKD 316 is a superheat controller that can be used where there are requirements for accurate control of superheat.

Typically it will operate in Commercial air conditioning, heat pumps, commercial refrigeration, food retail and

084R8 047

industrial application. Compatible valve - Danfoss ETS / ETS C, K VS / KVS C and CCM / CCMT valves.

English

084R8 047

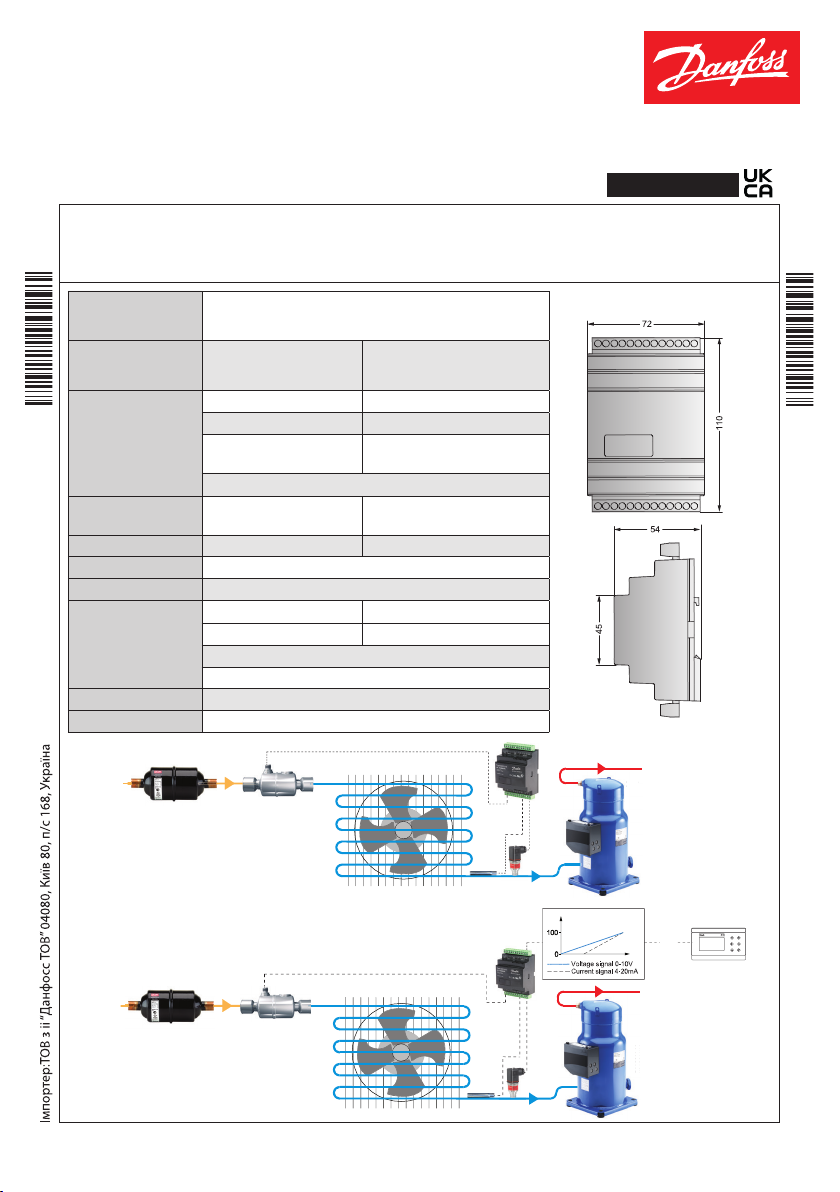

Supply voltage

Power consumption

24 V AC / DC ±15%, 50/60 Hz, 22 VA / 15 Watt

(the supply voltage is not galvanically

separated from the input and output signals)

Controller

ETS C / KVS C

ETS, KVS, CCM, CCMT

5 VA

7.2 VA

1.3 VA

Current signal * 4 - 20 mA or 0 - 20 mA

Input signal

*)Ri: mA: 400 Ohm

V: 50 kOhm

Voltage signal * 0 - 10 V or 1 - 5 V

Pressure transmitter

e.g. AKS 32R

0.5 - 4.5V DC ratiometric type

(10% - 90% of supply voltage)

Digital input from external contact function

Sensor input 2 pcs. Pt 1000 ohm

DI : < 800 Ohm = ON

DI : > 30 kOhm = OFF

Alarm relay 1 pcs. SPDT Max 24V, 1A resistive - Class II

Step motor output Pulsating 30 - 300 mA

Data communication RS 485 Modbus data communication

Operations 0 – 55 °C / 32 – 131 °F

Environments

Transportation -40 – 70 °C / -40 – 158 °F

Humidity 20 - 80 % Rh, none condensing

No shock influence/vibrations

Enclosure IP 20

Compatible valves Bipolar stepper motor valves

Standalone controller

ETS Colibri®

Danfoss

84B3177.10

Danfoss

Danfoss

Valve driver

© Danfoss | Climate Solutions | 2021.03

ETS Colibri®

OD

Danfoss

I/V

ss

nf

Danfoss

D

84B2707.10

1

11

4R64-3011.10

I/V

AN220086430005en-000502 | 1

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

Page 2

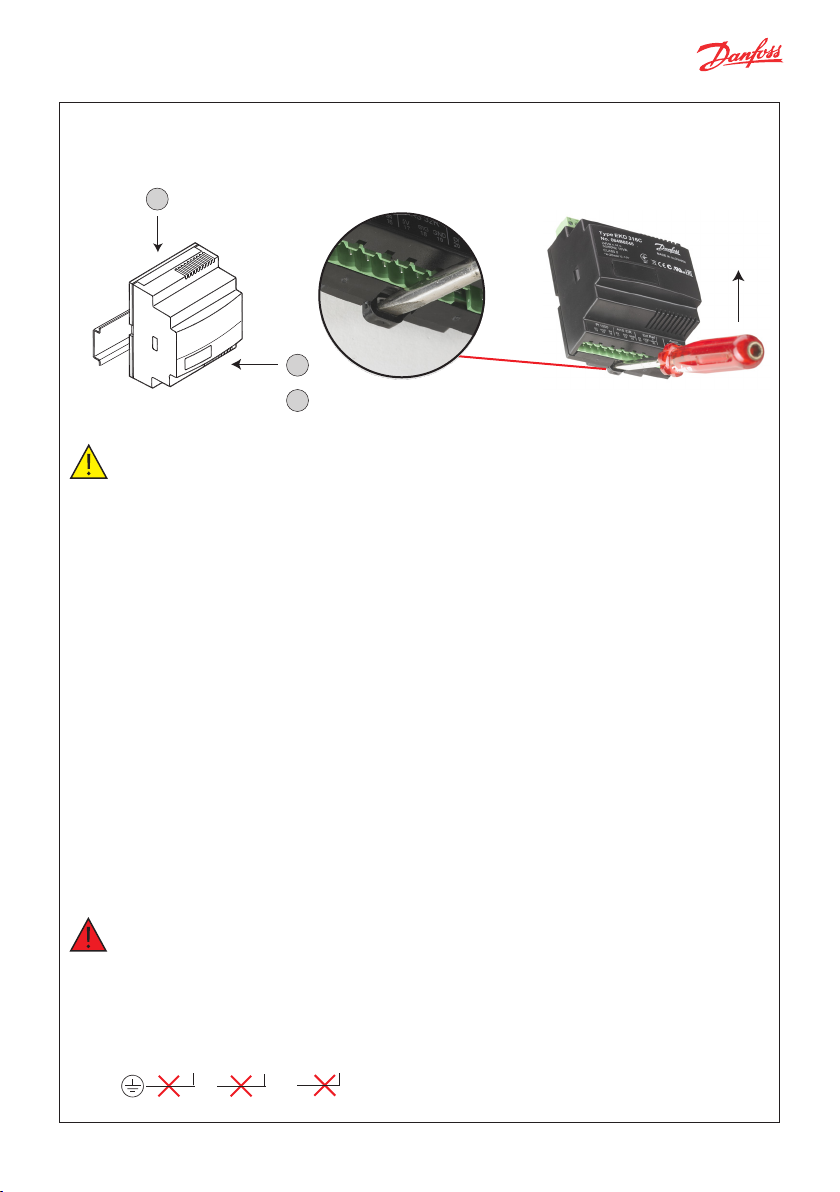

DIN rail mounting / dismounting

The unit can be mounted onto a 35 mm DIN rail (in accordance with EN 5022) simply by snapping it into place

and securing it with a stopper to prevent sliding. It is dismounted by gently pulling the stirrup located in the

base of the housing.

1

Danfoss

84B2714.11

2

“Click”

General warnings

• Every use that is not described in this manual is considered incorrect and is not authorised by the

manufacturer.

• Verify that the installation and operating conditions of the device respect the ones specified in the manual,

specially concerning the supply voltage and environmental conditions.

• This device contains live electrical components therefore all the service and maintenance operations

must be performed by qualified personnel.

• The device cannot be used as a safet y device.

• Liabilit y for injury or damage caused by the incorrect use of the device lies solely with the user.

Installation warnings

- The installation must be executed according the local standards and legislation of the country.

- Always operate on the electrical connections with the device disconnected from the main power supply.

- Before carrying out any maintenance operations on the device, disconnect all the electrical connections.

- For safet y reasons the appliance must be fitted inside an electrical panel with no live parts accessible.

- Don’t expose the device to continuous water sprays or to relative humidity greater than 80%.

- Avoid exposure to corrosive or pollutant gases, natural elements, environments where explosives or mixes of

flammable gases are present, dust, strong vibrations or chock, large and rapid fluctuations in ambient temperature

that in combination with high humidity can condensate, strong magnetic and/or radio interference

(e.g. transmitting antennae).

- When connecting loads beware of the maximum current for each relay and connector.

- Use cable ends suitable for the corresponding connectors. After tightening the screws of connectors, slightly tug

the cables to check their tightness.

- Use appropriate data communication cables. Refer to the Fieldbus Installation Guide for the kind of cable to be

used and setup recommendations.

- Reduce the path of the probe and digital inputs cables as much as possible, and avoid spiral paths enclosing power

devices. Separate from inductive loads and power cables to avoid possible electromagnetic noises.

- Avoid touching or nearly touching the electronic components fitted on the board to avoid electrostatic discharges.

Warnings

• Use a class II category transformer for 24 V AC power supply.

• Do not ground the 24 V AC wires.

• By connecting any EKD 316C inputs to mains voltage will permanently damage the controller.

• Do not apply voltage to the controller before the wiring is completed.

3

Dismounting

Pull down the stirrup to dismount unit from din rail

Connection of the terminals to earth will destroy the controller.

1,2 3,4 21,22

© Danfoss | Climate Solutions | 2021.03

AN220086430005en-000502 | 2

Page 3

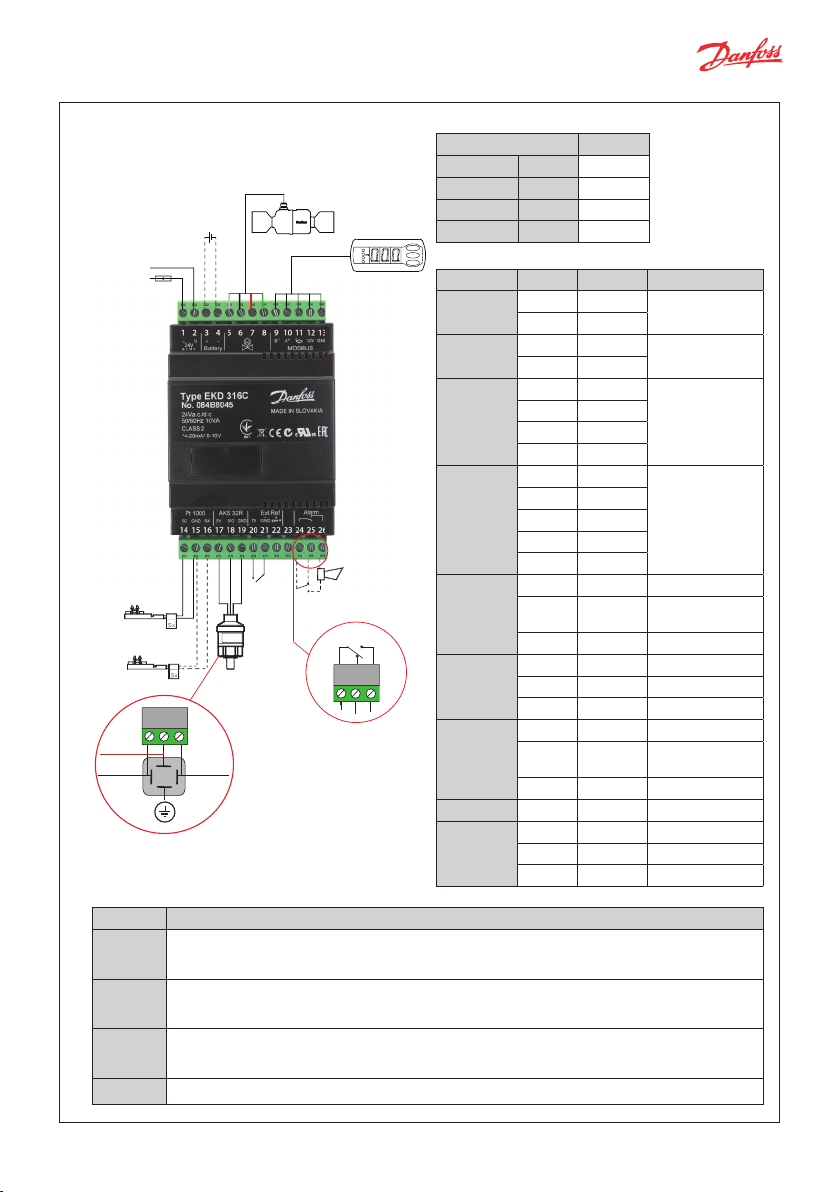

Po

24

EKA 164A

ETS C valve

Connection overview

Connections

ETS Colibri® EKD 316C

White A1 5

Black A2 6

Red B1 7

Green B2 8

Connection overview table

Function Position Pin name Description

Power

supply

Batter y

backup

1 24V L /+

2 24V N/ -

3 Bat+

4 BAT-

wer supply

V AC / DC

Fuse 2 A

Battery

or similar

back-up

–

+

1

Modbus

5 A1

Stepper

motor

driver

6 A2

7 B1

8 B2

9 RS485 B -

10 RS485 A+

11 Shield

12 12 V

13 GND

14 S2 Pt 1000

15 GND

16 S4 Pt 1000 sensor

17 5 V Supply +

18 sig Output +

19 GND Common -

20 DI Switch

21 GND (-)

22 Sig (+) Analog signal

Temperature

sensor S2

Temperature

sensor S4

+ output

+ supply

Danfoss

84B3186.10

17

18

3

12

14 15

19

- common

DI

switch

Pressure

transmitter P0

AKS 32R

Alarm

relay

Data

communication

Temperature sensor

NC

Com

NO

Pressure

transmitter

External

reference

Not in use 23 – –

24 Com Common

Alarm

25 NC Normal closed

26 NO Normal open

Important notes

Terminals

3 - 4 Batter y backup (the voltage will close the ETS valve if the controller looses its supply voltage).

9 - 13 Operation via modbus communication either EKA 164A or system unit + software.

20 - 21 Switch function for start / stop of regulation.

The battery voltage must not be connected from terminals 1 and 2. Power of the battery lower

than 16.5 V will trigger the low batter y alarm.

It is important that the installation of the data communication cable is done correctly.

For detail refer to our EKD 316 manual.

Note: If a switch is not connected, terminals 20 and 21 must be short circuited. Do not connect

external power supply to these terminals, else it will damage the controller.

24 - 26 Alarm relay: There is connection between 24 and 26 in alarm situations.

Power supply

24 V DC

Battery backup

Stepper motor

RS485 Modbus/

external display

EK A 164A

Common ground

for S2 / S4

Common ground

for 20 /22

© Danfoss | Climate Solutions | 2021.03

AN220086430005en-000502 | 3

Page 4

Application dependent /optional Connections

Po

24

ETS C valve

e

D

E

64

0

+

ETS C valve

Po

24

C controller

ETS C valve

Po

24

P

t

s

u

s

A. Connection for standalone controller.

DI

I

switch

or similar

Modbus

Alarm relay

EKA 164A

KA 1

wer supply

V AC / DC

–

+

Fuse 2 A

Temperature

mperatur

sensor S2

Temperature

sensor S4

Danfoss

Danfoss

84B3183.10

84B3183.1

Battery

back-up

Pressure

transmitter P0

B. Connection for Valve Driver

using analog signal.

Application dependent connections

A. Superheat control

Terminals Necessary connections

14 - 15

15 - 16

Pt 1000 sensor at eavaporator outlet

(S2) for measuring superheat.

Pt 1000 sensor for measuring air

temperature (S4).

Pressure transmitter t ype AKS 32R.

17 - 19

Note:

The signal cannot be shared with

other controllers.

B. Control of the valve ope ning degree with analog

signal

21 - 22

Current signal or voltage signal from

other regulation (Ex t. Ref.)

C. Control of the valve with Mo dbus signal

9 - 10

Operation via RS 485

data communication

C. Connection for valve driver using

Modbus signal.

wer supply

V AC / DC

–

+

Fuse 2 A

PLC controller

© Danfoss | Climate Solutions | 2021.03

Danfoss

84B3184.10

Battery

back-up

–

+

Analog signal

or similar

Modbus

Alarm relay

EKA 164A

wer supply

V AC / DC

–

+

e 2A

Fuse 2 A

anfos

Danfoss

Battery

back-up

or similar

Modbus

4B3185.10

84B3185.10

Alarm relay

DI

switch

AN220086430005en-000502 | 4

LC con

PL

Page 5

84N401.10

evaporator

Sensor mounting: Temperature sensor

1 2 3

Danfoss

60G496.10

OD

OD

1

/2 - 5/8 in.

12 - 16 mm

3

/4 - 7/8 in.

18 - 22 mm

Conductive

paste

Evaporator outlet

Danfoss

84N366.11

1 - 1

OD

25 - 35 mm

3

1

OD

35 mm and higher

3

/8 in.

/8 in. and higher

Important Note

• Mount sensor on a clean

surface without any paints.

Danfoss

84N403.10

• Remember to put on heat

conducting paste and

insulate the sensor.

• Sensor mounting max. 5 cm

from the outlet of the

evaporatorto get the precise

measurements.

Evaporator

Close to the

Pressure transmitter

Installation of the pressure transmitter is less critical, but mounting of pressure transmitter should be closer to

the temperature sensor, right after the evaporator and with its head in upright position"

Power supply

• Grounding of secondary (output) of transformer is not recommended.

• Do not reverse the polarity of the power connection cables and avoid ground loops (i.e. avoid connecting one

field device to several controllers as this may result in short circuits and can damage your device.

• Use individual transformers for EKD 316C controller to avoid possible interference or grounding problems in

the power supply.

EKD 316C

Danfoss

EKD 316C

Danfoss

84N402.10

EKD 316C

EKD 316C

Relay Outputs

EKD 316C has 1 relay outputs:

• SPDT relay, connected to terminals 24 - 26 can be used either to connect solenoid valve or to connect alarm.

• Relay is designed for switching max. 24 V, 1A resistive - Class II.

© Danfoss | Climate Solutions | 2021.03

AN220086430005en-000502 | 5

Page 6

Cable and wiring

Danf

84N404.10

• The cable distance between the controller and the valve depends on many factors like shielded/unshielded cable,

the wire size used in the cable, the output power for the controller and EMC. In g eneral, for the cab le distance upto

10 m, it is recomm ended to use cable wi th wire size 22AWG or lower. For ca ble distance up to 30 m, wi re diameter

of 20 AWG or lower is recommended.

• In case o f electrical no ises in the system, us e cable filter AK 211.

• Keep controller and sensor wiring well separated from mains wiring. Minimum recommended distance 30mm.

• Connecting sensors by wires more than 6 m long may decrease the accuracy of measured values.

• Sensors and secondary (output) of transformer may not be grounded simultaneously.

Warning

Separate the sensor and digital input cables as much as possible (at least 3 cm) from the power cables to

the loads to avoid possible electromagnetic disturbance. Never lay power cables and probe cables in the

same conduits (including those in the electrical panels).

Connecting external display EKA 164A

To setup the EKD 316C an EKA 164A display is needed. The display can be used not only for setting up the

necessar y parameter but also to use as an external display during operating to show the impor tant

parameters i.e. opening degree of the valve, superheat etc.

EKA 164A EKD 316 C

EK A 164A

L = max. 30 m

R

R = 120 Ohm, min. 0.25 Watt

R

A+B-

9

10 121113

Danfoss

12 V

EKD 316C

Important Note:

• Max. distance bet ween controller and display is 30 m.

• The supply voltage to the display must be maintained at 12 V ± 15%.

• Terminal resistor of 120 Ohm is recomanded at both sides of the wire for

• length longer than 1 m to prevent elec trical noice.

84B3192.11

Connecting Modbus

• For the modbus cable, it is best to use 24 AWG shielded twisted-pair cable with a shunt capacitance of

16 pF/ft and 100Ω impedance.

• The controller provides an insulated RS485 communication interface which is connected to terminals 9 to 11

(see connection overview).

• The max. permissible number of devices simultaneously connec ted to RS485 output is 32. The RS485 cable is

of impedance 120 Ohm with maximum length of 1000 m.

• Terminal resistors 120 Ohm for terminal devices are recommended for length > 1 m.

In EKD 316C communication frequency (baudrate) can be one of the following:

9600 baud, 19200 baud and 384 00 baud.

• The only available fixed comm unication setti ngs in EKD 316C are 8 data bit, EVEN parity and 1 stop bit.

The def ault unit address is 240 which, can be changed using param eter “03 unit address ”.

Detail explanation on Modbus installation and sof tware parameter setting can be found on

Installation guide RC8AC602 and manual DKRCC.PS.RI0.F1.02.

© Danfoss | Climate Solutions | 2021.03

Modbus

A+

BNot in use

oss

Gnd

AN220086430005en-000502 | 6

Page 7

Stepper Motor Output

• All Valves are driven in a bipolar mode with a 24V supply that is chopped to control the current (Current driver).

• The stepper motor is connected to terminals 5 to 8 (see terminal assignment) with M12 motor cable.

• To configure stepper motor valves other than Danfoss stepper motor valve, it is necessary to set the right

valve parameters as described on section Valve configuration. The default valve setting in EKD 316C is

16 (i.e. ‘non’)

• It is neccesary to define correct valve in ‘Valve type’ i,e parameter n03. The overview of the valve types has

been defined in section “valve overview”.

Valve overview

n03 EKA 164A Danfoss valve type n37 n38

0 ETS 12.5, ETS 25, KVS 15 262 300

1 ETS 50, CCM 10, CCM 20, CCM30 262 300

2 ETS 100, CCM 40 353 300

3 ETS 250, KVS 42 381 300

4 ETS 400 381 300

5 User defined - -

6 UKV, SKV, VKV, PKV 24 16

7 ETS 6 24 16

8 CCMT 2, CCMT 4, CCMT 8 110 220

9 CTM16 80 200

10

11

12

13

14

15

16

17

CCMT 24

CCMT 30

CCMT 42

CTR

CCMT 0

CCMT 1

No valve se lected

ETS 12C, ETS 24C , ETS 25C, ETS 50C , ETS 100C, KVS 2C , KVS 3C, KVS 5C

140 200

230 200

220 200

660 75

24 16

24 16

10 160

60 160

© Danfoss | Climate Solutions | 2021.03

AN220086430005en-000502 | 7

Page 8

84B3193.10

For detail parameter list and explanation, please check the EKD 316C Manual.

Application specific setup

A. Supe rheat control

Use as cont roller (SH).

B. Valve drive r

Using analog signal.

Parameter Name PNU Value Value

o10 Ai type 2027 No signal 0 - 20 mA / 4 - 20 mA / 0 - 10 V / 1 - 5 V

o18 Manual control 2075 No override No override

o30 Refrigerant 2551 See EKD instruc tion for

refrigerant setting.

See EKD instruction for

refrigerant setting.

o61 App. mode 2077 2 = Superheat 1= Valve driver using analog signal

o20 Min. trans. press. 2034 Min. value on transmitter -

021 Max. trans. press 2033 Max. value on transmitter -

r12 Main switch 117 On

On

Valve configuration

Parameter Name PNU Description

n03 Valve type 3002 Define the proper valve type, check Valve over view for detail.

n37 Max. steps x 10 3032 Total number of full steps. on using EKA display, 800 step is

display as 80.

n38 Max. step / second (PPS) 3033 Define the require/recommended steps per sec.

n39 Start backlash (% of FS) 3034 (extra closing steps at 0 % opening (in % of n37))

n40 Backlash (steps) 3035 Compensation for spindle play.

n56 Motor current (mA) 30 51 Define the require current in mA RMS.

Note: Please refer to Danfoss EKD 316 manual for details.

Parameter setup

AA.. Setting controller in Superheat control mode.

Make sure that r12 = 0 (OFF) and change the settings

The setting will depends on the system requirement.

Selec t Refrigerant

o30 = 1-42 (default non selected)

Select val ve type

n03 = 0 - 9 (default is “non” i.e non valve selec ted).

On using EKA 164A display, check the valve

overview chart.

Define pressure sensor range in gauge bar

o20 = Min. Transducer pressure

o21 = Max. Transducer pressure

Set the application mode

BB.. Setting controller in valve driver m ode

using analog signal

Make sure that r12 = 0 (OFF) and change the

settings so they fit to their application:

Select Appication mode

o61 = 1 (remote/AI control)

Selec t Analog signal type

o10 = 2 (4-20mA)

(for other analog signal check the parameter list)

Select valve t ype

n03 = 17 (valve type, E TS C = 17)

for other valve types refer to valve overview table.

To s tar t the controlle r in Valve driver mode

Set r12 = ON

For MSS control n21 = 1 (de fault)

For Load define control n21 = 2

Define min/max superheat

n10 = min. superheat reference

n09 = max. superheat reference

For fixed superheat define n09 = n10

Define MOP (optional)

n11 = maximum operating pressure

(default is 20 bar, max. 200 = MOP off)

Set force opening of the valve ( opti onal)

Start OD% (n17 )

StartUp time (n15 )

To s tart the supeheat control

Set r12= ON

© Danfoss | Climate Solutions | 2021.03

Danfoss

AN220086430005en-000502 | 8

Page 9

EKD 316C – Parameter identification (Modbus)

Lock - the value can only be changed when the main switch is off

PNU - equivalent to to the modbus register no. (modbus adress + 1).

Actual value

Values are read/written as 16 bit integer values without decimals. This is the default value as read via modbus.

Scale

This shows the scaling factor of the value. *1 means that there is no scaling. *10 means that the read value

is 10 times larger than the actual value.

Parameter PNU R/W Lock Min. Max. Default

Actual

value

Scale

Regulation

Control

r12 Main switch (Off = 0 /

On = 1)

o10 AI type (0: no signal

1: 0-20 mA, 2: 4-20 mA

3: 0-10 V, 4: 1-5 V)

o61 should be set to 1 in

order to use this feature

o18 Manual control 2075

o45 Manual OD%

o56 Reg. type

1= Normal

2 = With inner loop

o61 Appl.mode

1: Valve driver mode using

analogue signal

2: Superheat regulation

Valve n03 Valve type

Ref. valve overview

n32 ETS OD% Max

n37 Max. steps [Stp]

n38 Max. Stp/Sec (Hz)

n39 Start backlash [%]

n40 Backlash [Stp]

n56 Motor current (mA RMS)

h22 Holding current [%]

Refrigerant

Refrigerant

o30

(Ref. appendix 1)

---

Rfg.Fac.A1 2548 R/W - 8000 - 10428 10428 *1

---

Rfg.Fac.A2 2549 R/W - -4000 - -2255 -2255 *1

---

Rfg.Fac.A3 2550 R/W - 1000 3000 2557 2557 *1

117 R/W - 0 1 0 0 *1

2027 R/W - 0 4 0 0 *1

R/W - 0 3 0 0 *1

2064 R/W - 0 100 0 0 *1

2076 R/W x 1 2 1 1 *1

2077 R/W x 1 2 2 2 *1

3002 R/W x 0 17 16 1 *1

3023 R/W - 0 100 100 100 *1

3032 R/W x 10 999 60 60 *1

3033 R/W x 5 300 160 160 *1

3034 R/W x 0 100 10 3 *1

3035 R/W x 0 100 0 0 *1

3051 R/W x 0 600 0 0 *1

2198 R/W x 0 100 0 0 *1

2551 R/W x 0 42 0 0 *1

Sensors r05

Temp.unit 105 R/W - 0 1 0 0 *1

r09

Adjust S2 [K] 113 R/W - -1 10 0 0 x10

r10

Adjust S4 [K] 114 R/W - -1 10 0 0 x10

Min. Trans. Pres.

o20

(bar relative)

Max. Trans. Pres.

o21

(bar relative)

o99

Enable high pressure alarm 219 9

© Danfoss | Climate Solutions | 2021.03

2034 R/W - -1 0 -1 -10 *10

2033 R/W - 1 200 12 120 *10

R/W - 0 1 0 0 *1

AN220086430005en-000502 | 9

Page 10

Parameter PNU R/W Lock Min. Max. Default

Actual

value

Scale

Injection

control

Service ---

Alarms A34

Read ou t u06

n04

Kp factor 3003 R/W - 0.5 20 2

n05

Tn seconds 3004 R/W - 30 600 120

n06

Td seconds 3005 R/W - 0 90 0

n09

Max SH 3015 R/W - 1 100 10

n10

Min SH 3021 R/W - 1 100 6

n11

MOP [bar] (max = off) 3013 R/W - 0 200 20

n15

Start time [sec] 3017 R/W - 1 90 0

n17

MinOdAtStart [%] 3012 R/W - 0 100 0

n18

Stability 3014 R/W - 0 10 5

n19

Kp min. 3024 R/W - 0 1 0.3

n20

Kp T0 3025 R/W - 0 10 0.4

n21

SH mode

1= MSS, 2 = Load app.

n22

SH close [K] 3027 R/W - 1 15 4

n44

TnT0 sec. 3039 R/W - 10 120 30

3026 R/W - 1 2 1

AL/Light rel 2509 R - 0 1 0

---

Reset alarm 2046 R/W - 0 1 0

---

EKC State 2007 R - 0 100 0

A34 Battery low 10035 R/W - 0 1 0

---

Standby 20000 R - 0 1 0

---

EKC Error 20001 R - 0 1 0

---

S2 Error 20002 R - 0 1 0

---

S3 Error 20003 R - 0 1 0

--- Peinp. error

---

AI inp.error 20005 R - 0 1 0

---

No Rfg. Sel. 20006 R - 0 1 0

20004 R - 0 1 0

Analog input [mA] 2504 R - 0 30 0

u10

DI1 status 2002 R - 0 1 0

u20

S2 temp. [°C] 2537 R - -200 200 0

u21

Superheat [K] 2536 R - 0 100 0

u22

Superheat Ref [K] 2535 R - 0 100 0

o03

Unit addr. 2008 R/W x 1 240 240

20 *10

120 *1

0 *1

100 *10

60 *10

200 *10

0 *1

0 *1

5 *1

3 *10

4 *10

1 *1

40 *10

30 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *1

0 *10

0 *1

0 *10

0 *10

0 *10

240 *1

Appendix 1

1 = R12 7 = R13b1 13 = User-defined 19 = R404A 25 = R290 31 = R422A R36 = Opteon XP10 41 = R449A

2 = R22 8 = R23 14 = R32 20 = R407C 26 = R600 32 = R413A 37 = R407F 42 = R452A

3 = R134a 9 = R500 15 = R227 21 = R407A 27 = R600a 33 = R422D 38 = R1234ze

4 = R502 10 = R503 16 = R401 22 = R407B 28 = R744 34 = 427A 39 = R1234yf

5 = R717 11 = R114 17 = R507 23 = R410A 29 = R1270 35 = R438A 40 = R44 8A

6 = R13 12 = R142b 18 = R402A 24 = R170 30 = R417A

Installation considerations

Accidental damage, poor installation, or site conditions can give rice to malfunctions of the control system, and

lead to a plant breakdown. Every possible safeguard is incorporated into our products to prevent this. However, an

incorrec t installation, for example, could still present problems. Elec tronic controls are no substitute for normal,

good engineering practice. Danfoss will not be responsible for any goods, or plant components, damaged as a result

of the above defects. It is the installers responsibility to check the installation thoroughly, and to fit the necessary

safety devices. Particular attention is drawn to the need for a “force closing” signal to controllers in the event of

compressor stoppage and to the signal requirement for suction line accumulators.

Your local Danfoss agent will be pleased to assist with further advice, etc.

© Danfoss | Climate Solutions | 2021.03

AN220086430005en-000502 | 10

Loading...

Loading...