Page 1

Data sheet

Superheat Controller

Type EKD 316 and EKD 316C

EKD 316 / EKD 316C is a superheat controller for

the stepper motor valve that can be used where

there are requirements for accurate control of

superheat in connection with refrigeration.

The controller and valve can be used where

there are requirements for accurate control of

superheat in connection with refrigeration.

Applications:

• Processing plant (water chillers)

• Cold store (air coolers)

• A/C plant

• Heat pumps

• Air conditioning

Benets • The superheat is regulated to the lowest

possible value.

• The evaporator is charged optimally – even

when there are great variations of load and

suction pressure.

Main features

• Regulation of superheat

• MOP function

• ON/OFF input for start/stop of regulation

• Relay output to alarm

• Energy savings – the adaptive regulation of

the refrigerant injection ensures optimum

utilisation of the evaporator and thus a high

suction pressure.

• MOD bus communication

• Safety features and

• Alarm indications

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 1

Page 2

Data sheet | Superheat controller type EKD 316, EKD 316C

Contents Pages

Applications..................................................................................................................................................3

Function overview ..........................................................................................................................................3

Data ...........................................................................................................................................................4

Ordering ......................................................................................................................................................4

Dimensions ..................................................................................................................................................4

Accessories ...................................................................................................................................................4

Related products ............................................................................................................................................4

Connections .................................................................................................................................................5

Conguration ................................................................................................................................................6

Parallel Evaporators with common suction line .........................................................................................................7

Data communication .......................................................................................................................................8

Installation ...................................................................................................................................................9

Installation sensors ........................................................................................................................................ 10

Start of controller.......................................................................................................................................... 11

Settings and checks to be made before start .......................................................................................................... 11

Stepper motor valve type ................................................................................................................................ 12

Operation .................................................................................................................................................. 13

Types of regulation ........................................................................................................................................ 14

Manually operating the valve ............................................................................................................................ 15

Finding the optimum settings ........................................................................................................................... 16

If the superheat uctuates ............................................................................................................................... 16

Troubleshooting ........................................................................................................................................... 17

Alarms ...................................................................................................................................................... 17

Appendix I.................................................................................................................................................. 18

- Menu survey EKD 316 ............................................................................................................................ 18 - 19

- Survey of functions .......................................................................................................................... 20 - 21 - 22

Appendix II ................................................................................................................................................. 23

- General information to MODBUS communication via a PLC etc. ................................................................................ 23

- EKD 316 – Parameter identication (modbus) ..................................................................................................... 24

- EKD 316C – Parameter identication (modbus) .............................................................................................. 25 - 26

- Installation considerations ............................................................................................................................ 27

List of literature ............................................................................................................................................ 27

Acronyms and abbreviations used in this manual:

LOC Loss of charge indication

SH Superheat

MOP Maximum operating pressure

MSS Minimum stable superheat

PNU Parameter number

Te Saturated suction temperature

Pe Evaporator pressure

S2 Evaporator temperature

S4 Evaporator outlet temperature

OD Opening degree

EEV Electronic expansion valve

∆Tm Temperature dierence between media temperature and evaporating temperature

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 2

Page 3

Data sheet | Superheat controller type EKD 316, EKD 316C

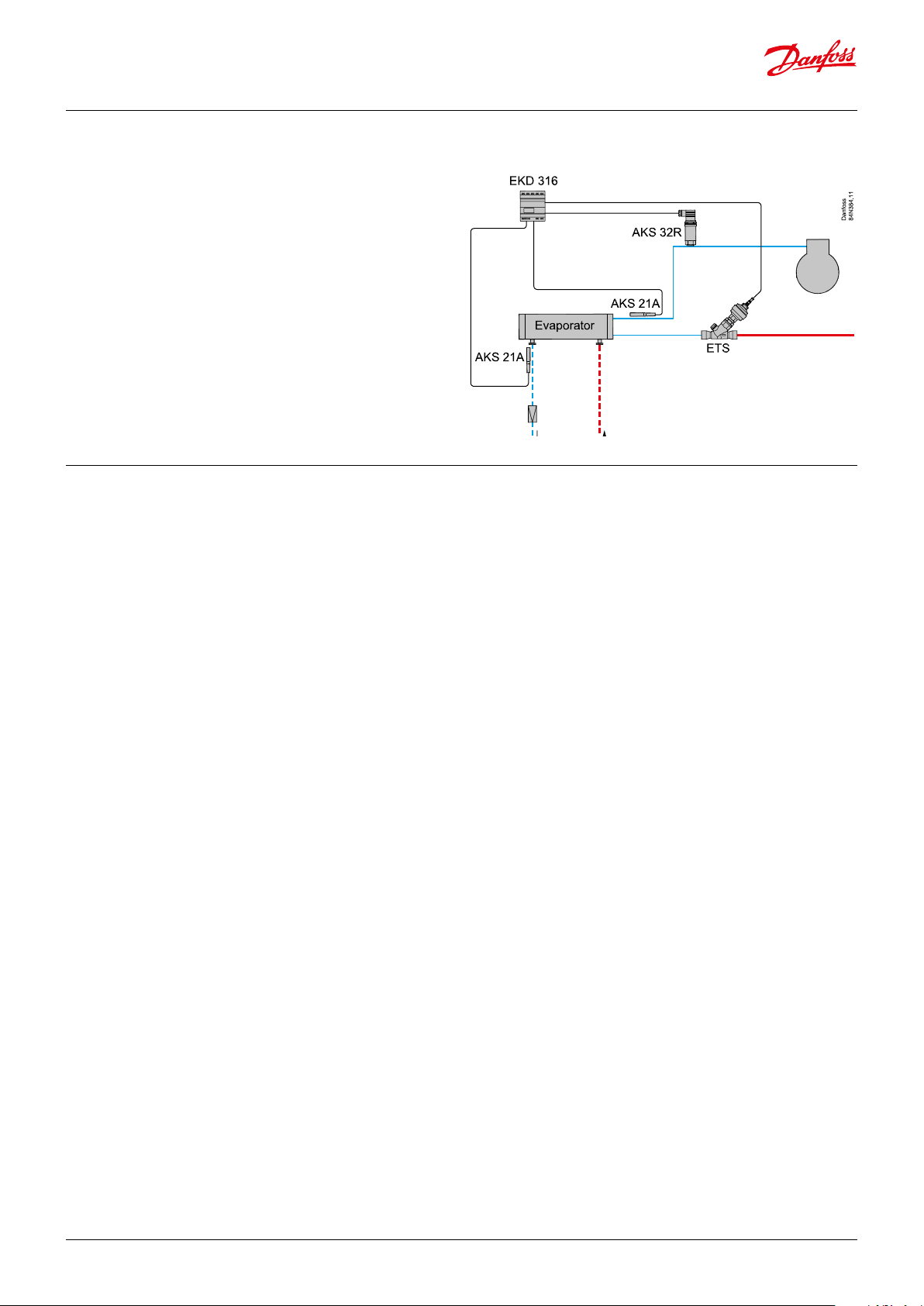

Applications

The following gives an idea of the application scope of the

EKD 316 / EKD 316C controller.

Water chiller using direct expansion

The most common application is water chillers using direct

expansion. The regulation can be single loop using an AKS 32R

pressure transmitter to measure evaporator pressure and an S2

sensor to measure superheated gas. If double loop regulation is

used, the S4 sensor should be located at the water outlet pipe to

measure the leaving water temperature. It is recommended to

start with factory settings.

The application diagram shows the use of EKD 316 as a superheat

controller, where temperature sensor AKS 21A and pressure

transmitter AKS 32R have been shown as an example.

Function overview

Minimum Stable Superheat (MSS)

The controller will search for the minimum stable superheat

between an upper and lower boundry. If the superheat has been

stable for a period, the superheat reference is decreased. If the

superheat becomes unstable, the reference is raised again. This

process continues as long as the superheat is within the bounds

set by the user. The purpose of this is to search for the lowest

possible superheat that can be obtained while still maintaining a

stable system. The superheat reference can also be xed, in which

case this function is disabled.

Maximum Operating Pressure (MOP)

In order to reduce the strain of the compressor, a maximum

operating pressure can be set. If the pressure comes above this

limit, the controller will control the valve to provide a lower

pressure instead of a low superheat. The limit for this function

is usually a xed pressure, but it is possible to oset the limit

temporarily.

Stand-alone function

EKD 316 / EKD 316C is designed to operate in conjunction with a

system master controller, which will control the EKD 316 /

EKD 316C via MODBUS or analog signal. It is however possible

to use it in a standalone mode using one temperature and one

pressure transducer.

Manual Control as a valve driver

The valve can be controlled manually by setting the desired

operating degree using MODBUS. Alternatively, the controller may

also be started and stopped externally using the analog signal 4 to

20 mA/0 to 10 V DC, /1 to 5 V DC.

Forced opening during startup

In some applications it is necessary to open the valve quickly when

the compressor turns on to prevent suction pressure becoming

too low. This is ensured by setting a xed opening degree and

a startup time for the controller. Note that this will give a xed

opening degree for the duration of the start time, regardless of the

superheat value.

Relay

The relay for the alarm function is an alternating relay. In the event

of an alarm, the relay will close, which may, for instance, be used

for an alarm buzzer.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 3

Page 4

Data sheet | Superheat controller type EKD 316, EKD 316C

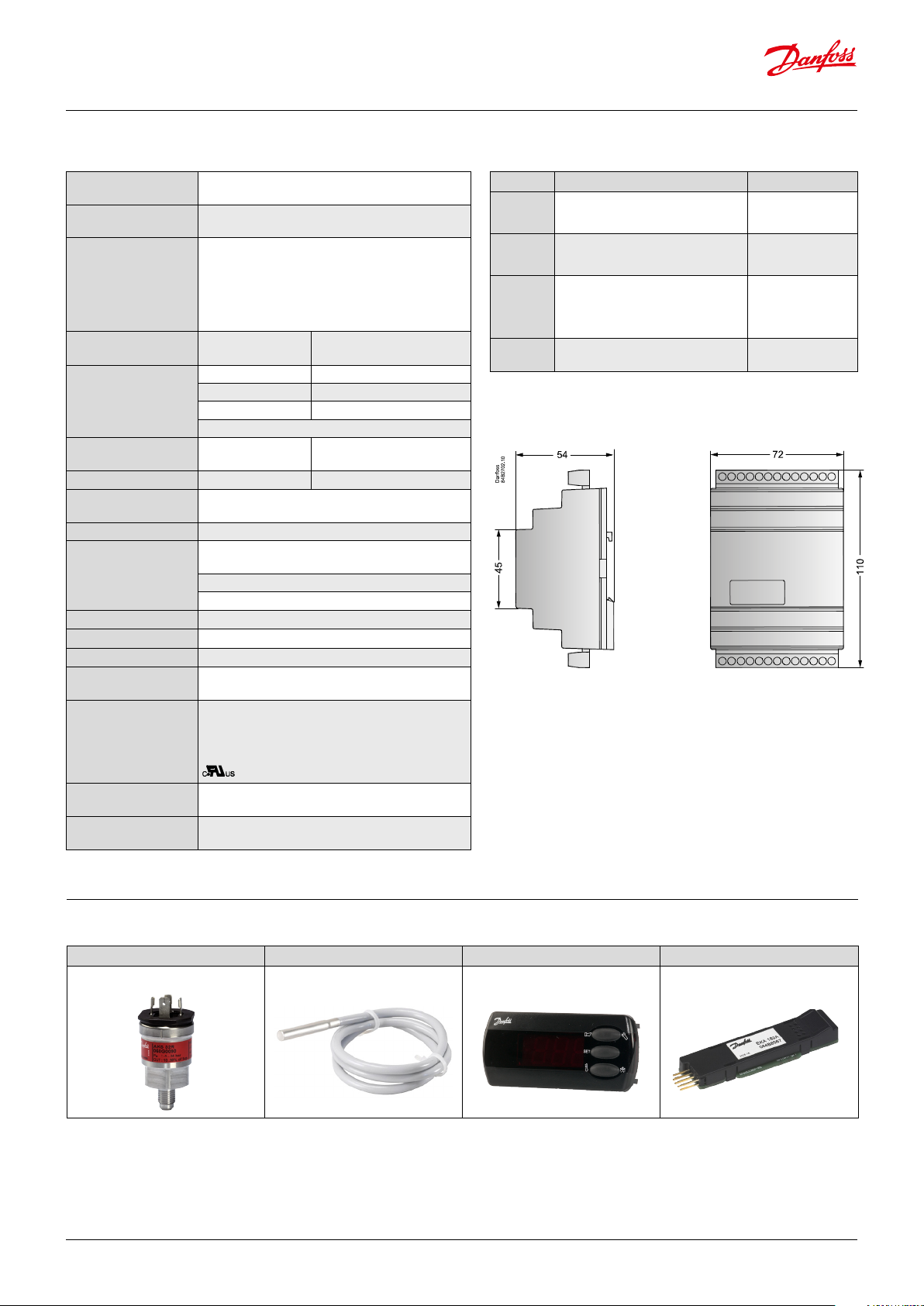

Data

Compatible valves

EKD 316 C

Compatible valves

EKD 316

Supply voltage

Power consumption

Input signal

*)Ri: mA: 400 ohm

V: 50 kohm

Sensor input 2 pcs. Pt 1000 ohm

Alarm relay 1 pcs. SPDT, Max 24V, 1A resistive - Class II

Step motor output

Data communication RS 485 Modbus data communication

Environments

Enclosure IP 20

Weight 300 g

Montage DIN rail

Operation

Approvals

ETS / CCM / CCMT 0 - 42 / CTR / ETS 6 /

ETS C / KVS C

ETS / CCM / CCMT 0 - 42 / CTR / ETS 6

ETS / KVS / CCM / CCMT 2 - CCMT 8

24 V AC / DC ±15% 50/60 Hz, 10 VA / 5 Watt

ETS 6 / CCMT 16 - CCMT 42:

24 V AC / DC ±15% 50/60 Hz, 15 VA / 8 Watt

(the supply voltage is not galvanically

separated from the input and output signals)

Controller

ETS step motor

Current signal * 4 - 20 mA or 0 - 20 mA

Voltage signal * 0 - 10 V or 1 - 5 V

Pressure transmitter AKS 32R

Digital input from external contact function

EKD 316 : Switching 30 - 300 mA RMS

EKD 316C : Switching 30 - 600 mA RMS

0 to +55°C, during operations

-40 to +70°C, during transport

20 - 80% Rh, not condensed

No shock inuence/vibrations

External display type EKA 164A or AK-ST via data

communication and system unit

EU Low Voltage Directive and EMC demands re. CEmarking complied with.

LVD-tested acc. to EN 60730-1 and EN 60730-2-9

EMC-tested acc. to EN50081-1 and EN 50082-2

5 VA

1.3 VA

DI : < 800 ohm = ON

DI : > 30 kohm = OFF

Ordering

Type Function Code no.

EKD 316C

EKD 316

EKA 164A

EKA 183A Programming key 084B8582

Superheat controller

(with terminals)

Superheat controller

(with terminals)

External display

(with MODBUS communication)

For technical details please see

literature reference on last page.

084B8045

084B8040

084B8563

Dimensions [mm]

Battery backup

Max. distance between

controller and valve

If battery backup is used, the requirements for the

battery are: 18 - 24 V DC See also page 12.

30 m

Related products

Pressure transducer Temperature sensor External display Programming key

AKS 32R, NSK AKS 21, AKS 11 EKA 164A EKA 183A

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 4

Page 5

Data sheet | Superheat controller type EKD 316, EKD 316C

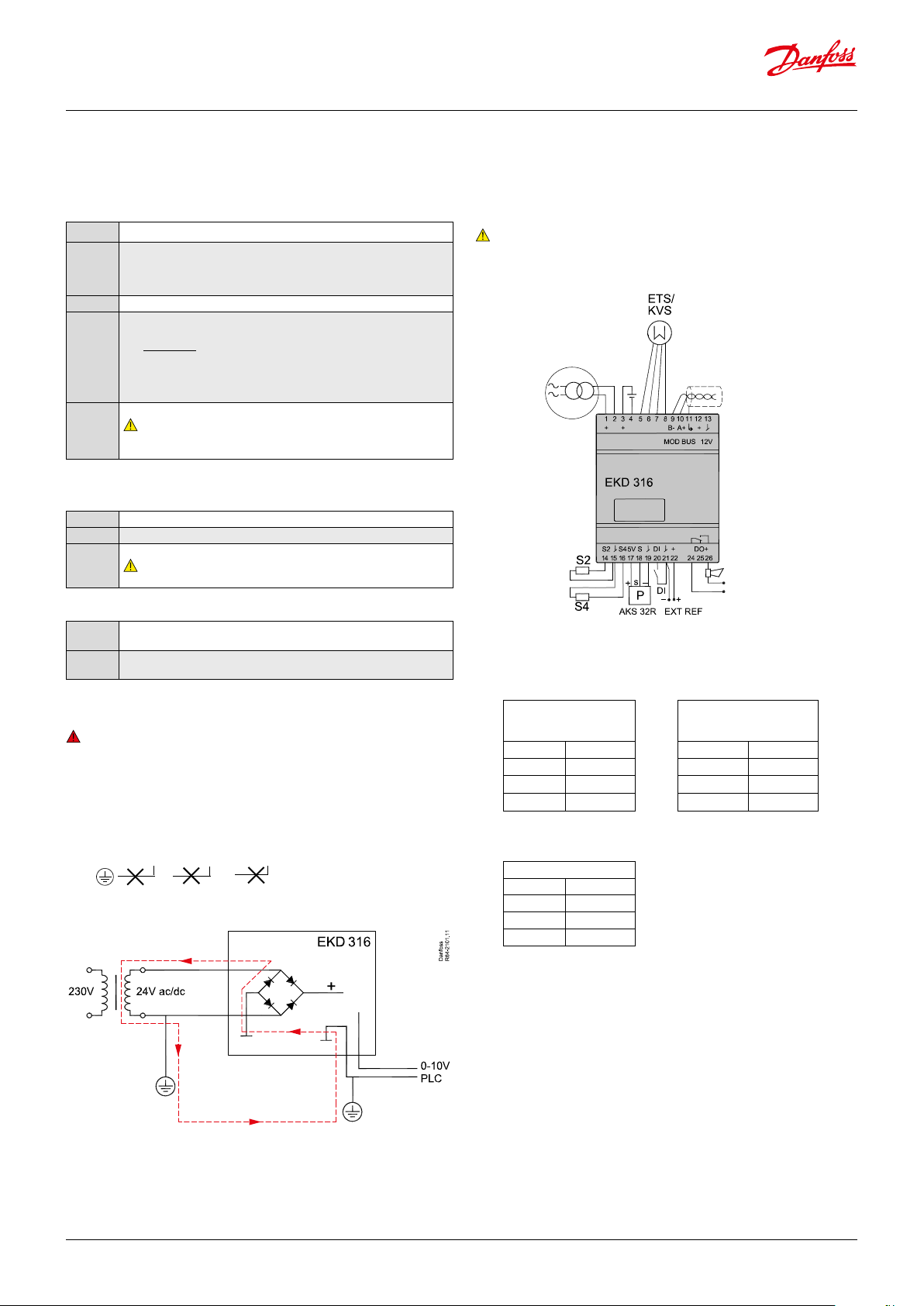

Connections

Necessary connections

Terminals:

1-2

3-4 Battery (the voltage will close the ETS valve if the

5-8 Supply to stepper motor

9-13 Operation via data communication

20-21 Switch function for start/stop of regulation.

Application-dependent connections

Superheat control

Supply voltage 24 V AC / DC

controller losses its supply voltage).

The battery voltage must not be connected from terminals 1

and 2.

EITHER EKA 164A OR System unit + software.

It is important that the installation of the data communication

cable be done correctly.

For further information on data communication: see literature

list page 23

Note:

If a switch is not connected, terminals 20 and 21 must be short

circuited.

14-15 Pt 1000 sensor at evaporator outlet (S2)

15-16 Pt 1000 sensor for measuring air temperature (S4)

17-19 Pressure transmitter type AKS 32R

Note:

The signal can not be shared with other controllers

A dedicated transformer must be used.

24V 18V

Class II

Danfoss

84B3201.10

Control of the valves opening degree with analog signal

21-22 Current signal or voltage signal from other regulation

(Ext. Ref.)

24-26 Alarm relay

There is connection between 24 and 26 in alarm situa tions.

Warning

Any external connection with grounding could create a ground

loop through a diode in the rectier bridge which could destroy

the power supply in EKD 316 / EKD 316C.

1,2 3,4 21,22

Connection to earth will destroy the controller

Connections EKD 316 Connections EKD 316 C

ETS / KVS / CCMT2 CCMT42 / CCM / CTR

White 5 White 5

Black 6 Black 6

Red 7 Red 7

Green 8 Green 8

Connections EKD 316 /

Connections EKD 316 C

ETS 6 / CCMT 0 - CCMT 1

Orange 5

Yellow 6

Red 7

Black 8

ETS C / KVD C / ETS / KVS

/ CCMT2 - CCMT42 / CCM

/ CTR

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 5

Page 6

OD

Data sheet | Superheat controller type EKD 316, EKD 316C

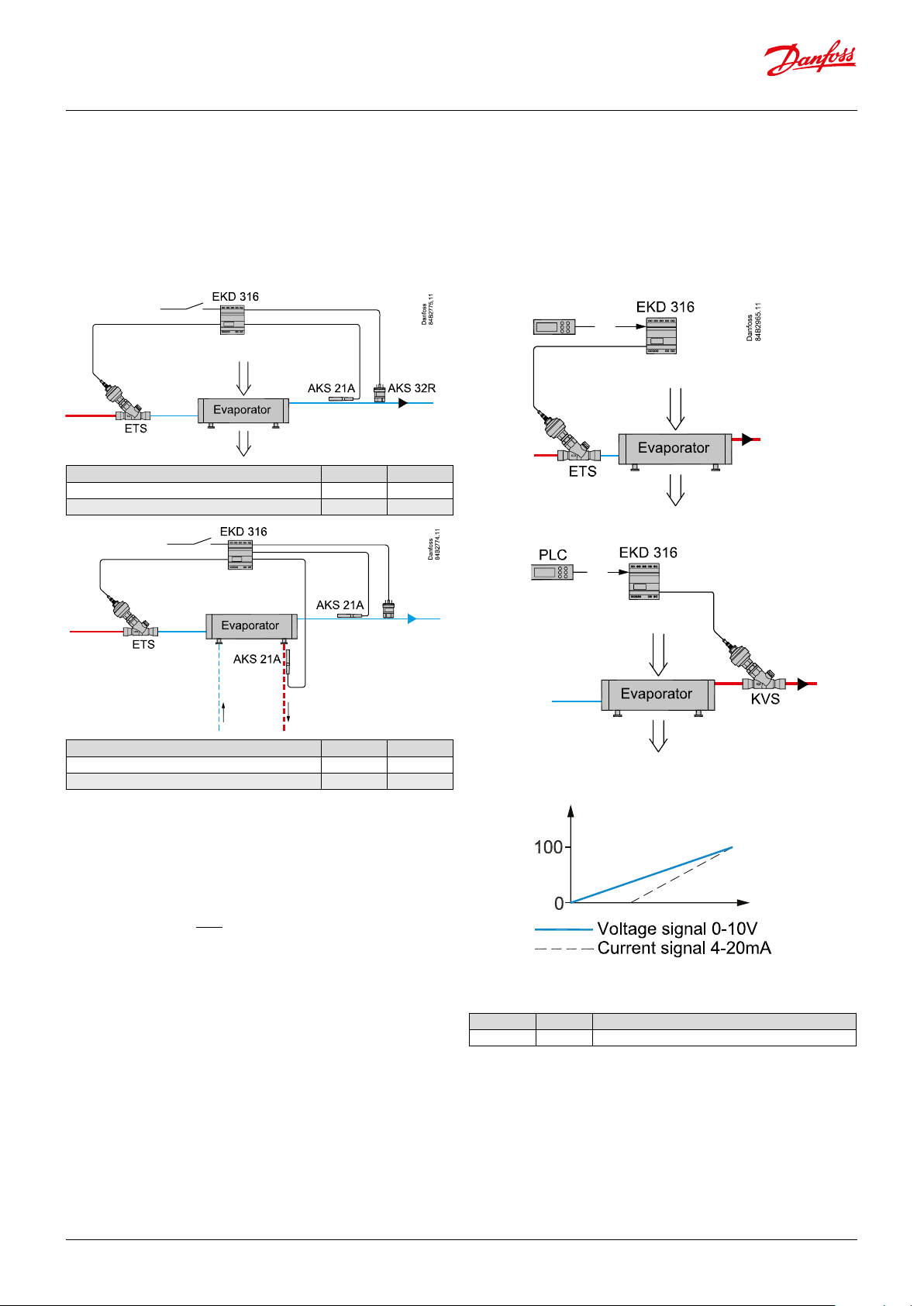

Conguration

Independent superheat regulation

The superheat in the evaporator is controlled by one pressure

transmitter P and one temperature sensor S2. This can be done

setting o61 = 2.

Fitting the "S4" temperature sensor is optional, but the regulation

is improved by an "inner loop control" when the sensor is tted.

Function Parameter Value

Application Mode – superheat regulation o61 2

Selection of normal control mode 056 1

Valve driver (Via Analog Signal)

This is where the controller receives signals from another

controller, after which it controls the valve’s opening degree.

The signal can either be a current signal or a voltage signal.

The valve can be any of the stepper motor valves listed on “valve

overview”.

Details can be found on the section “valve overview”.

I/V

Function Parameter Value

Application Mode – superheat regulation o61 2

Selection of inner loop control mode 056 2

We recommend this inner loop control application mode setting, if

the superheating is to be regulated with precision. Here the S4 and

T0 temperature are part of an inner loop control.

The regulation algorithms require that a temperature sensor be

tted in the chilled medium.

The temperature sensor is connected to input "S4" and mounted

in the chilled medium after the evaporator. (Danfoss calls a sensor

S4 when it is mounted in the refrigerant after the evaporator).

External start/stop of regulation

The controller can be started and stopped externally via a contact

function connected to input terminals 20 and 21. Regulation is

stopped when the connection is interrupted. The function must

be used when the compressor is stopped. The controller then

closes the ETS valve so that the evaporator is not charged with

refrigerant.

Battery

For safety reasons the liquid ow to the evaporator must be cut

o if there is a power failure to the controller. As the ETS valve

is provided with a stepper motor, it will remain open in such a

situation. When mounting the battery backup, the valve will close

in the event of a power cut.

I/V

Danoss

84B2966.12

Danfoss

84B2707.10

I/V

Parameter Value Function

o61 1 Application Mode - control via analog signal

Relays

The relay for the alarm function is an alternating relay.

In the event of an alarm the relay will close to connect terminals 24

and 26. This can, for instance, be used for an alarm buzzer. When

there is no alarm or the controller is o, terminals 24 and 25 are

connected.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 6

Page 7

Data sheet | Superheat controller type EKD 316, EKD 316C

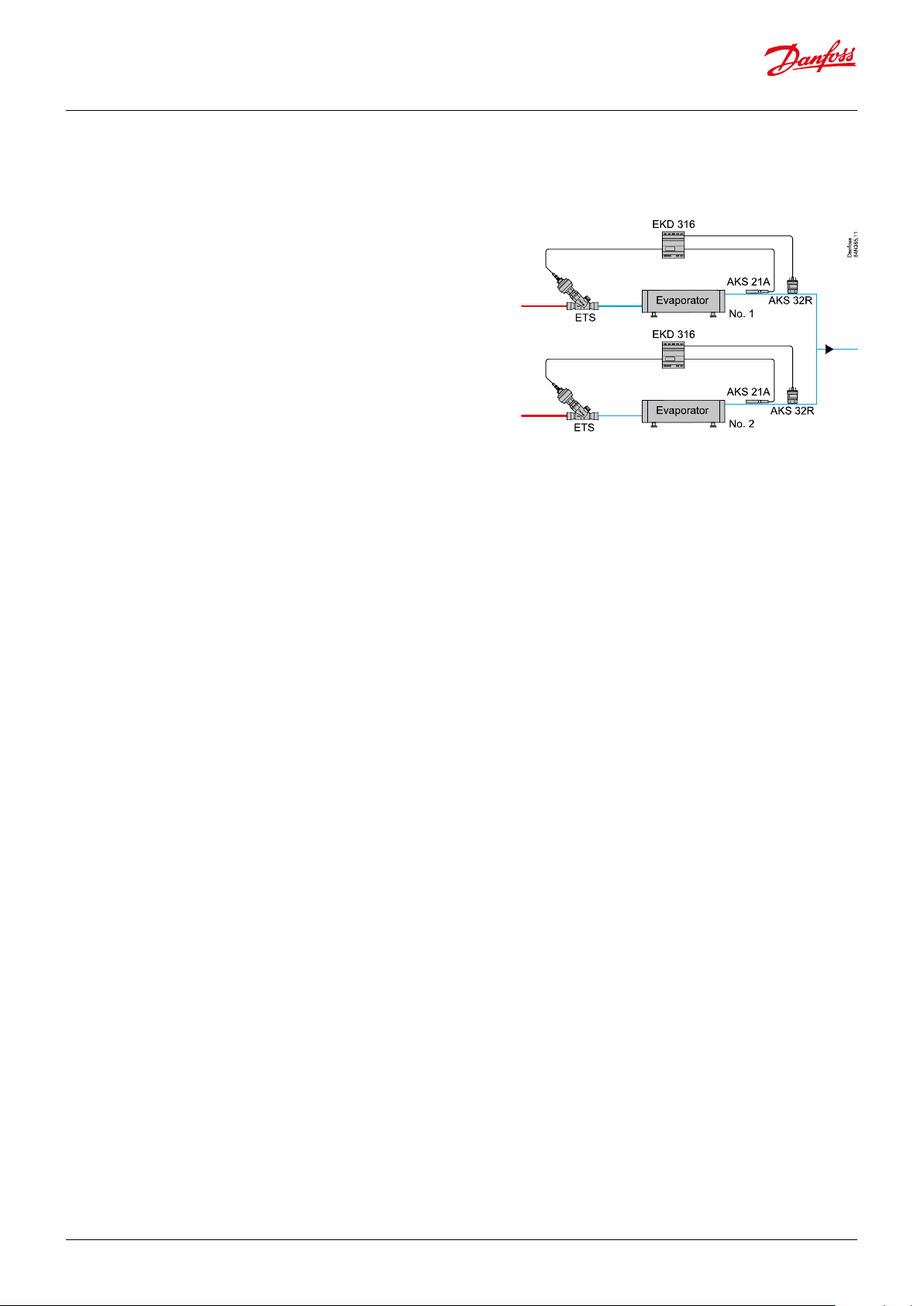

Parallel Evaporators with common suction line

Since the introduction of EEV, it has been observed the

phenomena the so-called Sleeping Evaporators phenomena have

been observed. This happens when the outlet of the evaporators

has a common suction line.

This is seen when using the Adaptive superheat Mode in some of

the controllers. What happens is that by controlling using the same

superheat reference in both controllers, evaporator No. 1 might be

controlling in the correct manner, but the EEV for evaporator No. 2

might be closed.

However, the measured superheat of controller No. 2 will be the

same as No. 1 because both S2 sensors will measure the same

temperature.

In other words, the open degree of the EEV integrates down to 0%

but, the measured superheat complies with the reference valve.

One solution is to use the Load-dened superheat Mode in the

controller because the measured superheat governs the opening

degree of the connected EEV.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 7

Page 8

EKD 316

Danfoss

84B3082.10

Data sheet | Superheat controller type EKD 316, EKD 316C

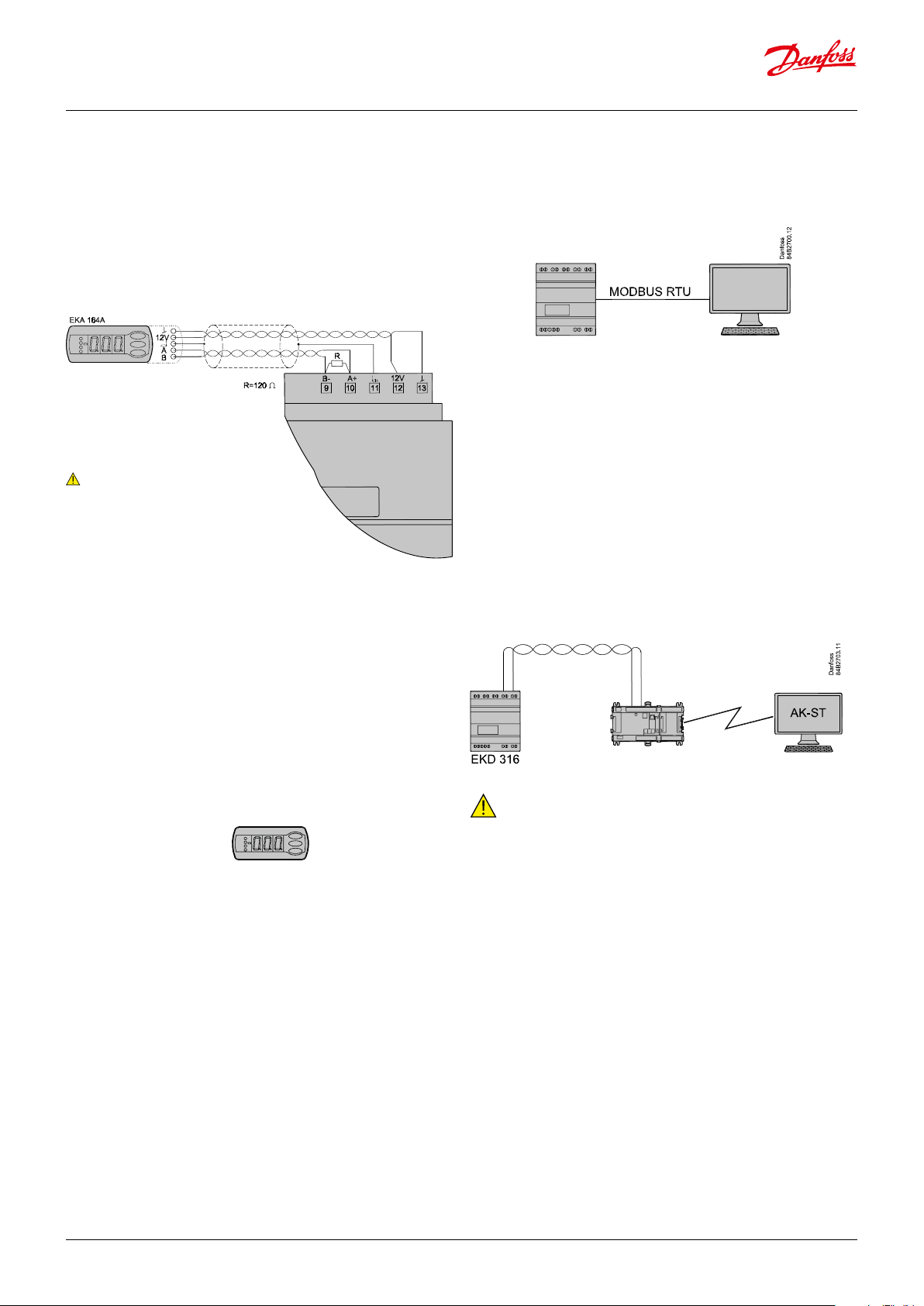

Data communication

Data communication with the EKD 316 is possible using one of the

following two ways:

• 1. Via External display (EKA 164A)

• 2. Via standard MODBUS Device

Via external display (EKA 164A)

Use an external display to operate the controller. This must be

done as follows:

Note:

Max. distance between controller and

display is 30 m.

The supply voltage to the display must be

maintained at 12 V +/- 15%.

The values are shown in three digits, and with a setting you

can determine whether the temperature is shown in °C or in °F.

(Pressure in bar or psig.)

In order to change a setting, the upper and lower buttons will

give you a higher or lower value depending on the button you

are pushing. But before you change the value, you must have

access to the menu. You obtain this by pushing the upper button

for a couple of seconds – you will then enter the column with

parameter codes. Find the parameter code you want to change

and push the middle button until the value for the parameter is

shown. When you have changed the value, save the new value by

pushing once more on the middle button.

By pushing the middle button you go directly to the Main Switch

setting (r12).

Example

Set a menu

1. Push the upper button until a parameter is shown

2. Push the upper or the lower button and nd the parameter you

want to change

3. Push the middle button and the value is shown

4. Push the upper or the lower button and select the new value

5. Push the middle button again to conclude the setting

Via standard MODBUS device

Communication direct to MODBUS RTU protocol.

There are 3 dierent MODBUS baud rates available, which are

9,600 baud, 19,200 baud and 38,400 baud.

The default MODBUS baud rate is 19,200 baud.

A scan is performed once the EKD 316 / EKD 316C controller is

connected to the network. This will auto detect the baud rate

used by the master and will automatically adjust to its setting. This

process usually take a few seconds.

The only available xed communication settings are 8 data bit,

EVEN parity and 1 stop bit.

The default unit address is 240 which, can be changed using

parameter "03 unit address".

EKD 316 can be operated from a PC that has AK-ST software

loaded.

System unit

Communication from a third party controller or monitoring

system

Settings and values can be read from the EKD 316 / EKD 316C via

MODBUS. However, the sensor values are from the local sensors

and software has not been developed to receive values from

another source.

A data list of EKD 316 parameters is provided in Appendix II and

the data for EKD 316C you can nd it in the installation guide

DKRCC.PI.RR0.A1.02

Please note that it is not possible to connect the EKA 164A

universal display in this conguration.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 8

Page 9

Data sheet | Superheat controller type EKD 316, EKD 316C

Installation

The EKD 316 / EKD 316C is normally mounted on a DIN rail, and

the necessary connections are shown in the diagram. If the sensor

S4 is not used to measure air temperature in connection with

thermostat function or as part of the controlling loop, then it is

not necessary to connect the S4 sensor. The 18-24 V battery input

at terminals 15 and 16 is not required if battery back-up is not

needed.

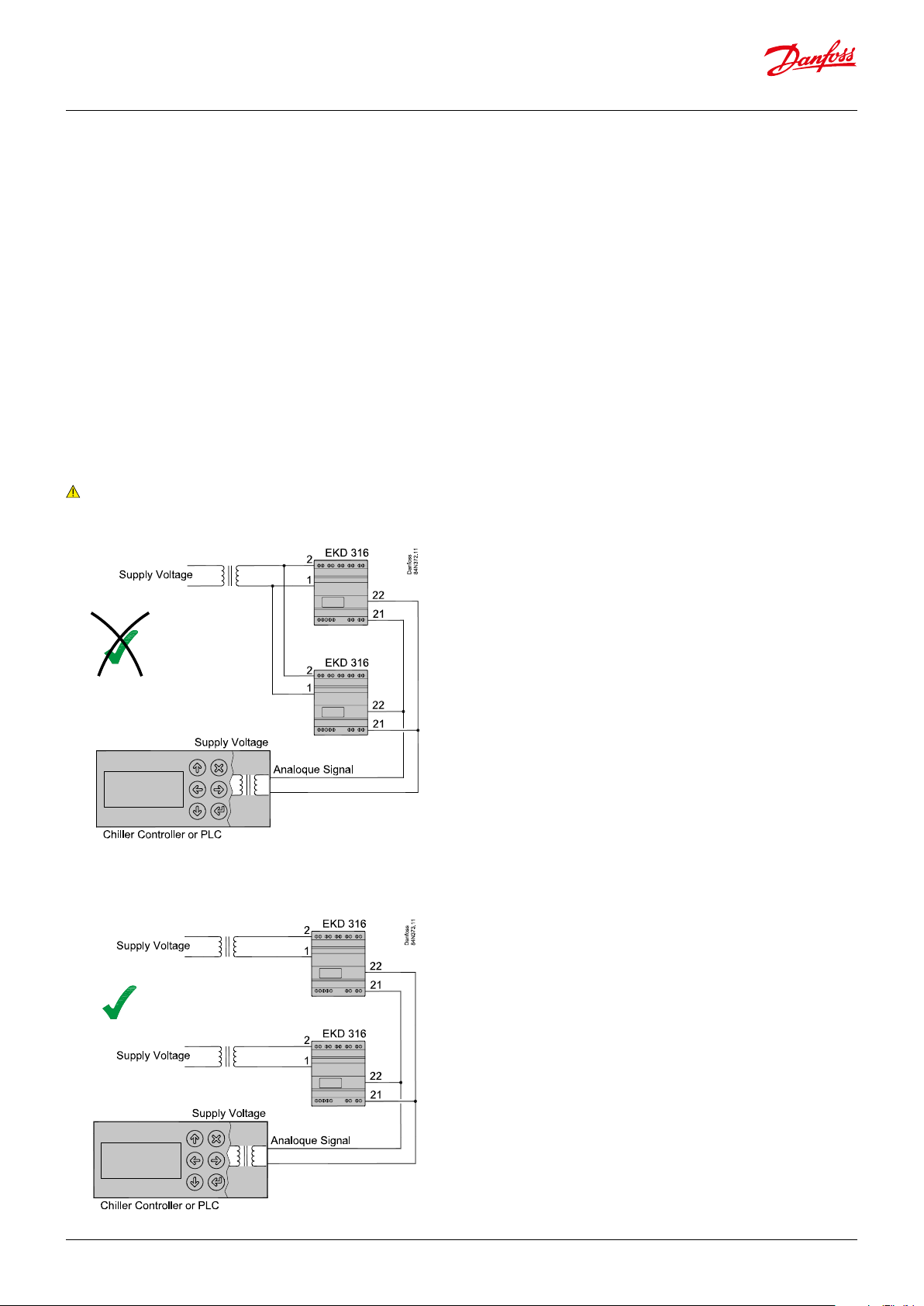

Power supply considerations

The terminals 1 and 2 for the voltage supply are not isolated

from the rest of the controller terminals. This means care should

be taken when connecting two or more controllers to the same

voltage supply. In the example below, the two controllers are

connected to the same voltage supply and on the input side,

terminals 21 (Analogue Input) are connected to each controller

and similarly terminals 22 (GND).

This way of connecting the controllers can cause damage and

should be avoided.

Note:

The same applies to other signal inputs e.g. terminals 2 and 4.

See warning page 5.

Stepper motor output

After installation the following checks can be made to the

connection between the EKD 316 controller and the stepper

motor of the ETS 6 / ETS valve.

With the power o, check that resistance between terminals 5 and

6 and terminals 7 and 8 is approximately:

ETS 6 / CCMT 0 : 46 Ohm

CCMT 1 : 31 Ohm

ETS / KVS / CCMT 2 - CCMT 8 / CCM : 53 Ohm

CCMT 16 - CCMT 42: 29 Ohm

ETS C / KVS C : 10 Ohm.

Make slight allowances for cable resistance.

If resistance values dier from above, ensure that the cable is

properly connected to the actuator of the stepper motor valve.

1. With the power on and parameter o18 set to 1, measure the

phase current from terminal 5 (or 6) and terminal 7 (or 8 ) with

a true RMS multimeter when the valve is operating. The valve

can be driven from 0% to 100% and vice versa by changing

the valve opening percentage in parameter o45. The phase

current should be 100 mA rms (for ETS) when operating.

2. If this not the case and the cable connections are correct, then

the stepper motor driver in the EKD 316 might be damaged.

Remember to set o18 back to 0 after checks. If checks 1) and

2) are not correct, ensure that motor cable corrections are

correct and the cable length is less than 30 meters.

If the controllers are operated by a common analogue signal as

above, the voltage supply should be separate as shown below.

Output relay contact

The contact of the alarm relay will be made when there is an alarm.

Battery back-up

A battery back-up can be connected to terminals 3 (+) and 4 (-).

It is recommended to use 24 V DC 100 mAh UPS. The voltage

should be at least 18 V and this can be achieved by using two 9 V

100 mAh batteries in series, if temporary solution is to be used.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 9

Page 10

Data sheet | Superheat controller type EKD 316, EKD 316C

Installation sensors

S2 sensor positioning in the suction line

The position of the S2 sensor is crucial for an optimal control of the

liquid injection.

The main purpose is to measure temperature of the superheated

gas leaving the evaporator. In addition to this, the S2 sensor plays

an important role detecting fast changes of superheat. Suction

pressure is on the whole stable whereas the leaving gas condition

is dependent on the temporary mixture of gas, liquid refrigerant

and oil.

The sensor is also there to react quickly on liquid passing the

evaporator, to avoid damage to the compressor.

An S2 sensor placed two-thirds of the way up a riser after an oil

trap is where conditions are at their optimum, i.e. good mixture of

gas, oil and liquid droplets, provided this is not more than 0.5 m

from the evaporator.

If a horizontal pipe is the only option, the S2 sensor must be

placed at least half a meter away from the evaporator.

S1 (Po pressure) is less critical but must be close to the actual

suction pressure right after the evaporator.

If the measured value is 1-2 K lower than the actual value of Po

right after the evaporator, it may cause the evaporator to ood.

This is the case when the pressure transmitter is located in the

machine room away from the evaporator. If the measured value

is higher than the actual value of Po, the evaporator might be

starved of liquid.

Choice of S2 sensor type

Surface sensor S2 *

Suction pipe of copper or on thin (≤ 3mm) steel pipe.

Remember to put on heat conducting paste and insulate the

sensor.

Pocket sensor S2 **

Suction pipe of steel ≥ 3mm

*) Pt1000 Ω Type AKS21 or AKS10

**) Pt1000 Ω Type AKS21W

AKS 21W

Heat compound

S2 sensor xing on the suction pipe:

When the S2 sensor is xed to the surface of the suction pipe, the

angle of the sensor position will depend on the diameter of the

pipe, as given in the following diagram:

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 10

Page 11

Data sheet | Superheat controller type EKD 316, EKD 316C

Start of controller

When the electric wires have been connected to the controller, the

following points have to be attended to before the regulation starts:

1. Switch o the external ON/OFF switch that starts and stops the

regulation.

2. Follow the menu survey in Appendix I, and set the various

parameters to the required values.

3. Switch on the external switch, and regulation will start.

4. Follow the actual superheat on the display.

Settings and checks to be made before

shown on the following table:

start

Basic settings

Before using the controller, there are settings that have to be made

for each individual application. These are the refrigerant type, the

pressure transducer range and the total number of steps for the

ETS valve.

It is good practice and in some cases necessary to set the Main

Switch r12 to OFF when making these changes.

If terminal 20-21 has been used as a start/stop regulation, then the

interaction between internal and external start/stop function is, as

Refrigerant type

It is possible to choose from a list of 42 dierent refrigerants in the

controller.

Refrigerant setting

Before refrigeration can be started, the refrigerant must be dened.

You can select the following refrigerants:

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User-dened

14 = R32

15 = R227

16 = R401

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

For EKD 316C the default factory setting for parameter o30 is 0 = none refrigerant selected

Internal

Start/stop

External

start/stop (DI)

O O => O No Yes

O On => O No Yes

On O => O Yes No

On On => Ye s Yes No

If the refrigerant is not found on the list, it is possible to enter the

Antione constants for the unlisted refrigerant using MODBUS

communication and setting o30 to 13.

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = 427A

35 = R438A

36 = Opteon XP10

37 = R407F

38 = R1234ze

39 = R1234yf

40 = R448A

Regulation Sensor

monitoring

41 = R449A

42 = R452A

Conguration

settings

o30

( Warning: Wrong selection of refrigerant may cause damage to the compressor).

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 11

Page 12

Data sheet | Superheat controller type EKD 316, EKD 316C

Stepper motor valve type

It is important to select the right valve type as listed under Valve

denition. On using external display EKA 164A, the valve selection

will be displayed as shown in table below.

In practise, the EKD 316 / EKD 316C external display can only

manage three digits. Therefore the set value at address n37 is

always 10 times greater, i.e. if n37 is set to 263 then the true value

is 2630. The same applies to the n37 address in the MODBUS

The number of steps and steps/sec can also be set in the controller

communication system.

at addresses n37 and n38 respectively:

Valve overview EKD 316

n03 EKA 164A Danfoss valve type n37 n38

0 ETS 12.5, ETS 25, KVS 15 262 300

1 ETS 50, CCM 10, CCM 20, CCM30 262 300

2 ETS 100, CCM 40 353 300

3 ETS 250, KVS 42 381 300

4 ETS 400 381 300

5 User dened - -

6 UKV/SKV/VKV/PKV 24 16

7 ETS 6 24 16

8 CCMT 2, CCMT 4, CCMT 8 110 220

9 CCMT 16 80 200

10 CCMT 24 140 200

11 CCMT 30 230 200

12 CCMT 42 220 200

13 CTR 660 75

14 CCMT 0 24 16

15 CCMT 1 24 16

Valve overview EKD 316C

n03 EKA 164A Danfoss valve type n37 n38

0 ETS 12.5, ETS 25, KVS 15 262 300

1 ETS 50, CCM 10, CCM 20, CCM30 262 300

2 ETS 100, CCM 40 353 300

3 ETS 250, KVS 42 381 300

4 ETS 400 381 300

5 User dened - -

6 UKV/SKV/VKV/PKV 24 16

7 ETS 6 24 16

8 CCMT 2, CCMT 4, CCMT 8 110 220

9 CCMT 16 80 200

10

11

12

13

14

15

16

17

CCMT 24

CCMT 30

CCMT 42

CTR

CCMT 0

CCMT 1

No valve se lected

ETS 12C, ETS 24C , ETS 25C, ETS 50C , ETS 100C, KVS 2C , KVS 3C, KVS 5C

140 200

230 200

220 200

660 75

24 16

24 16

10 160

60 160

Pressure transmitter

The range of the pressure transmitter can be set by entering the

transmitter’s minimum value at address o20 and maximum value

at address o21. The pressure sensor input is set up by default to

accept an AKS 32R pressure transducer. If another sensor is to be

The default range for the typical pressure transducer is 0 to 16 bar.

This can be changed by setting the minimum transducer pressure,

"o20 MinTransPres", and the maximum transducer pressure, "o21

MaxTransPres", to the new values.

used, it is important to note that it needs to be a 5 V ratiometric

type (10% - 90% of supply voltage).

Working range for pressure transmitter

Depending on the application a pressure transmitter with a given working range is used.

For the range of (-1 to 12 bar), the min. value is set to -1 bar o20 MinTransPres.

For the range of (-1 to 12 bar), the max. value is set to 12 bar o21 MaxTransPres.

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 12

Page 13

Data sheet | Superheat controller type EKD 316, EKD 316C

Operation

Superheat function

You may choose between two kinds of superheat regulation,

either:

• Minimum stable superheat (MSS)

• Load-dened superheat

The regulation modes for controlling superheat

There are two dierent ways of controlling superheat, i.e.

controlling according to the minimum stable superheat (MSS) and

Load Dened superheat.

The parameter SH mode selects the controlling form where it can

be set to MSS when set to 1, or Load Dened superheat when set

to 2.

Minimum stable superheat (MSS)

The superheat control algorithm will attempt to regulate the

superheat down to the lowest stable value between the minimum

superheat setting, "Min SH" and the maximum superheat setting,

"Max SH".

The reference follows a dened curve. This curve is dened by

three values: the closing value, the min. value and the max. value.

These three values must be selected in such a way that the curve

is situated between the MSS curve and the curve for average

temperature dierence ∆Tm (temperature dierence between

media temperature and evaporating temperature.

Setting example = n22 = 4, n10 = 6 and n09 =10 K).

Function Parameter Value

Superheat control mode -2

= Load dene

n21 2

Min. Superheat Reference n10 1K - 100K

Max. Superheat Reference n09 1K - 100K

Value of min. SH ref for loads

under 10%

n22

Must be below

Min. SH (n10)

The superheat reference SH ref is adaptive and adjusted.

When using this form of control, there are three settings that have

major aect on this mode of control.

Max. SH – The maximum limit of SH ref.

Min. SH – The minimum limit of SH ref. Care should be taken not

to set this value too low in order to avoid ooding back into the

compressor.

Stability – This factor determines how much instability can be

accepted. Small values will cause the SH ref to increase if the

slightest instability in SH is detected. Higher values will accept a

higher degree of instability.

Function Parameter Default value

Superheat control -MSS n21 1

Min Superheat Reference n10 1K - 100K

Max Superheat Reference n09 1K - 100K

Load dene application

SH ref follows a dened curve as shown below. This curve is

dened by three values: SH close SH max and SH min.

This form of regulation is similar to the thermostatic valve where

the spring force can be adjusted to keep the SH (superheat) in the

stable region to the right of the curve.

The advantage over the thermostatic valve is that there are three

settings to dene the operating curve.

Using the MOP

In order to reduce the current to the compressor it is possible to

control the maximum operating pressure of the evaporator.

Evaporator pressure exceeds the "MOP" limit, the valve opening

degree is controlled by the MOP function which will keep the

pressure below the "MOP" limit. This function takes precedence

over the superheat control, so during MOP control the superheat is

not controlled.

The MOP function (address n11) is active when it is set to values

less than the maximum range of the pressure transmitter. Setting

it above the maximum range of the pressure transmitter or at 200

Bar will deactivate the MOP.. The pressure value is converted to

the corresponding temperature value and when the MOP is active,

the controller will prevent the evaporating temperature T1 from

exceeding this value.

If Maximum Operating suction Pressure MOP parameter n11 is

reset from factory setting 20 to 1 bar (gauge) From the MOP i.e 1

bar point the OD increases slower and slower until the pressure

reaches MOP + 0.5 i.e 1.5 bar. Subsequently the OD decreases

rapidly as the pressure increases.

OD

At this pressure the OD

no longer increases.

Beyond it the OD

decreases.

+ 0.5

MOP

At this pressure the OD

increases slower and

slower.

Pressure Pe

© Danfoss | DCS (sw) | 2016.11

Function Parameter Value

Maximum operating pressure

MOP

n11 0-200 bar

DKRCC.PD.RR0.B2.02 | 13

Page 14

Data sheet | Superheat controller type EKD 316, EKD 316C

Types of regulation

As a general rule, do not use mode 2 (Load dene application)

if the eect is not evaluated by e.g. an OEM chiller

manufacturer in a laboratory.

An incorrect setting will only make regulation poorer than the

factory setting of mode 1.

Instability caused by too much Proportional Gain can be corrected

by reducing to the value of the Kp factor.

This should be done by gradually reducing and observing the

results before making further reductions.

Single Loop (address o56 Reg.type = 1)

The EKD 316 / EKD 316C has the traditional PI controlling function

with the Kp factor for Proportional Gain and Tn for Integration

Time in seconds. This is also known as the Single loop control with

only one PI block, as shown in the diagram below.

Double Loop (address o56 Reg.type = 2)

The controller can regulate the superheat using a double loop

system. The so-called outer loop is really the same as in the single

loop system except that the output of PI block is the reference for

the inner loop.

The inner loop also has a PI block where the Proportional Gain

factor is KpT0 and the Integration Time is TnT0.

The feedback of the inner loop is the temperature dierence

between media temperature S4 and S1. This value represents the

load on the evaporator and large values will tend to increase the

opening degree OD% of the valve.

When to use Single or Double Loop

In most applications and especially air coolers, the single loop is

the best option due to its simplicity and being easier to tune.

In water chillers where the S4 sensor is located at the leaving water

outlet, the double loop gives some advantage in terms of being

less susceptible to compressor or fan step changes. In addition, it

opens the valve quicker during startup. However, the double loop

is less advantageous on air coolers because of the slower response

to the media temperature changes.

If the superheat response is slow to change, it can be increased by

reducing the value of the Integration Time Tn.

When tuning the superheat stability, it is good practice to have a

xed superheat reference by making SH max the same as SH min.

The tuning of the double loop is more complicated than the single

loop and it is advisable not to change too many parameters at

the same time. The starting point should be to use the following

settings.

Function Parameter Value

Kp factor n04 0.7

Tn sec n05 120

KpT0 n20 3

TnT0 sec n44 30

If the superheat is unstable, the KpT0 parameter should be slightly

reduced. The value parameter Kp factor is not large so little is

gained by reducing this parameter.

For details refer to the "Finding the optimum setting” section.

Note:

The S4 sensor has to be connected when Reg. type = 2, otherwise

an alarm sounds.

Note:

After o56 is changed, the controller must be switched o and

powered up again.

Recommended control loop type and settings for some

applicatiions

From the experience of using single loop and double regulation,

the following recommendations are given. These are only

recommendations and the nal choice is made by the end user.

Application Reg. type

address

o56

Air cooler

Water chiller2(Double

1

(Single loop)

loop)

Kp

factor

address

n04

3.0 120 0.4 -

0.7 120 2.0 30

Tn sec KpT0 TnT0 sec

address

n05

address

n20

address

n44

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 14

Page 15

Data sheet | Superheat controller type EKD 316, EKD 316C

Manually operating the valve

There are two modes for operating the valve manually, and these

are described in the following sections.

Operating the valve manually from the external display (or via

MODBUS)

The opening degree of the ETS can be operated manually by

setting parameter o18 to 1 and then setting parameter o45 to the

required opening degree between 0% and 100%. Relay outputs

can also be checked using parameter o18.

Manual control of outputs

For service purposes the valve output and alarm relay outputs can be forced.

OFF: No override

1: Manual control via o45 is enabled

2: The alarm relay releases so that there is a connection between 24 and 25 (= alarm)

3: The alarm relay picks up so that there is a connection between 25 and 26 (= no alarm)

Manual control of the valve’s opening degree 045 0 - 100% valve OD

Operating the valve manually using an external analogue

signal

The opening degree of the stepper motor valve can be operated

manually with 0 - 20 mA or 4 - 20 mA or 0 - 10 V or 1 - 5 V external

analogue signal connected to terminals 21 (-) and 22 (+) of the

controller.

018 Manual ctrl

Controlling a valve with an analogue signal 061 Application mode 061=1

Input signal for external control of the valve's opening degree

Only used if o61 is set to 1.

Denition of the signal's range:

0: No signal

1: 0 - 20 mA

2: 4 - 20 mA

3: 0 - 10 V

4: 1 - 5 V

(At the lower value the valve will be closed. At the upper value the value will be fully open.

There is a linear relationship between the signal and the opening degree. The height of the

valve is not taken into account.)

o10

AI type

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 15

Page 16

Data sheet | Superheat controller type EKD 316, EKD 316C

Finding the optimum settings

Details on the controller algorithm and settings

Kp factor (n04) and Kp min (n19)

The Proportional Gain is dependent on the value of the measured

superheat SH relative to Reference superheat SH ref. The

Proportional Gain has the following values relative to superheat SH:

If SH is more than 2.5K greater than SH ref, then Gain equals Kp

factor.

If SH is within the range -0.5 and 2.5K from SH ref, then Gain equals

Kp factor times Kp min.

The reason for this variable Gain is to provide stable superheat for

values near the superheat reference.

Note:

The value of Gain does not change suddenly but gradually when

SH gets close to SH ref.

Proportional Gain

Kp factor

Danfoss

84N375.11

Problems with startup

Sometimes in one-to-one applications, the valve does not open

suciently on startup, and troublesome low pressure trips may

occur. This problem is typical when using the single loop control

where only the SH controls the opening of the valve.

The force opening of valve function has been implemented in

the EKD 316 / EKD 316C controller. After startup, this function

will provide a constant, set minimum opening degree during a

set time period, regardless of the superheat value. The setting

parameters are called Start OD% (n17) and StartUp time (n15).

Please observe that the Start OD% is a minimum value after

startup and if the measured superheat (u21) produces a value

greater than Start OD% then the value will be valve opening

degree (u24) – see the diagram.

OD%

Valve OD%

Start OD%

Reg.OD%

Danfoss

84N378.11

Kp factor multiplied Kp min.

-0.5

2.5

SH ref

SH

Initial "Kick start" startup

In general the valve opening degree is controlled by the measured

value of the superheat SH. This means that during certain

situations during startup, the valve will be slow to open due to

the built-up of superheat from a small value. To prevent this from

happening, the valve is given an initial opening degree dependent

on the Kp factor, the measured superheat SH and SH close, as

given in the following relationship:

Initial OD% = kp factor*(SH – SH close)

This procedure is not to be confused with the force opening of the

valve given in the “Problems with startup” section.

OD%

Kp factor* (SH - SH Close)

When Kp factor = 3, SH = 12, Close = 2

Initial OD % = 30%

Start

Time

Danfoss

84N376.11

Forced OD%

Normal Reg.

Start Up time*

Start

Time from start

If the superheat uctuates

When the refrigerating system has been made to work steadily,

the controller’s factory-set control parameters should in most

cases provide a stable and relatively fast regulating system.

If the system, however, uctuates this may be due to the fact that

superheat parameters that are too low have been selected. Before

starting any adjustment of the factory settings check the S2 sensor

location – see section “Installation sensors”.

If adaptive superheat has been selected (n21 = 1):

Adjust: n09, n10 and n18.

If load-dened superheat MSS has been selected (n21 = 2):

Adjust: n09, n10 and n22.

Alternatively it may be due to the fact that the set regulation

parameters are not optimal.

If the time of oscillation is longer than the integration time:

(Tp > Tn (Tn is e.g. 240 seconds))

1. Increase Tn to 1.2 times T

2. Wait until the system is in balance again

3. If there is still oscillation, reduce Kp by e.g. 20%

4. Wait until the system is in balance

5. If it continues to oscillate, repeat 3 and 4

If the time of oscillation is shorter than the integration time:

(Tp < Tn (Tn is e.g. 240 seconds))

1. Reduce Kp by e.g. 20% of the scale reading

2. Wait until the system is in balance

3. If it continues to oscillate, repeat 1 and 2.

p

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 16

Page 17

Data sheet | Superheat controller type EKD 316, EKD 316C

Troubleshooting

Symptom Possible Cause Remedy

Pressure drop across the evaporator too high

Lack of subcooling ahead of expansion valve

Evaporator superheat too high

Suction pressure too low

Pressure drop across the expansion valve less than valve is

sized for

Expansion valve too small

Expansion valve block with foreign material Remove valve and examine the orice.

Evaporator wholly or partly iced up De-ice evaporator

Superheat of expansion valve too low Increase the values of SH close and SH min.

Liquid hammer

in compressor

Superheat reference set too low Increase the value of SH min

The S2 sensor not in good contact with the suction line

Alarms

Check refrigerant ahead of expansion valve.

If the valve is placed much higher than condenser outlet,

check pressure dierence.

1. Check superheat performance, the settings

SH min and SH max.

2. Check valve capacity.

3. Check that the maximum number of steps of

valve is same as parameter n37.

Check pressure drop across expansion valve. Replace with

larger valve.

Check refrigeration system capacity and compare with

expansion valve capacity. Replace with larger valve if

necessary.

Ensure that S2 sensor is secured on suction line. Insulate

sensor.

Symptom Possible Cause Fault Message Remedy

E1 Fault in controller

E24 S2 Sensor error

Error message

The controller can give the

following messages

Alarm message

Status codes

E25 S4 Sensor error

E19 The input signal on terminals 21 - 22 is outside the range.

E20

A11 No refrigerant has been selected

A44 Battery alarm (no voltage or too low voltage)

S5 MOP

S10 Refrigeration stopped r12=o

non Regulation, no fault

Note:

1. Only one alarm is displayed at a time in the controller display and are shown in

the order given above. All alarms are displayed in the AKM system.

2. The alarm E19 will only be active if address o10 is set to 1 or more.

3. EKD 316 / EKD 316C with change over relay ( 3 terminals 24-25-26)

4. The battery alarm A44 is only active when battery alarm address A34 is set to ON.

The input signal on terminals 17 - 19 is below

minumum limit (P0 signal)

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 17

Page 18

Data sheet | Superheat controller type EKD 316, EKD 316C

Appendix I

Menu survey for EKD 316

(For EKD 316C default parameter setting see Parameter identication table)

262

Application

choice

menu = o61

Function

The menus from either column 1 or column 2 are shown 1 2

Normal display

During regulation the actual level of superheating is displayed.

(If you would like to see the expansion valve’s actual opening degree, press the bottom button for approx. one second.)

During control with an analogue signal the opening degree is displayed. - % -

Reference

Units (0 = °C +bar / 1 = °F + psig) r05 0 1 0

Correction of signal from S2 r09 -10.0 K 10.0 K 0.0

Correction of signal from S4 r10 -10.0 K 10.0 K 0.0

Start/stop of refrigeration r12 O/0 On/1 O/0

Alarm

Battery monitoring A34 O/0 On/1 O/0

Regulating parameters

Valve denition:

0 = ETS 12.5, ETS 25, KVS 15

1 = ETS 50, CCM 10 – CCM 30

2 = ETS 100, CCM 40

3 = ETS 250, KVS 42

4 = ETS 400

5 = user-dened

On using external display EKA 164A, please check section valve overview

P: Amplication factor Kp

o56 = 1; n04 = 2.0

o56 = 2; n04 = 0.7

( Warning: Changes to n04 are lost when changing o56)

I: Integration time T n05 30 s 600 s 120

D: Dierentiation time Td (0 = o)

Max. value of superheat reference n09 1 K 100 K 10

Min. value of superheat reference n10 1 K 100 K 6

MOP (max = o) n11 0.0 bar 200 bar 20

Signal reliability during startup. Safety time period.

Should only be changed by trained sta

Signal reliability during startup – opening degree’s start value. Should only be changed by trained sta. n17 0% 100% 0

Stability factor for superheat control.

Changes should only be made by trained sta

Damping of amplication around reference value

Changes should only be made by trained sta

Amplication factor for superheat

Changes should only be made by trained sta

o56 = 1; n20 = 0.4

o56 = 2; n20 = 3.0

( Warning: Changes to n20 are lost when changing o56)

Denition of superheat control mode

1 = MSS,

2 = LOADAP

Value of min. superheat reference for loads under 10% n22 1 K 15 K 4

Max. opening degree

Changes should only be made by trained sta

Number of steps from 0 - 100% opening degree (only if n03 = 5 (User-dened))

Note: The display can only show three digits, but the setting value is four digits.

Only the three most important are shown, i.e. a reading of e.g. 250 means a setting of 2500.

(Automatic setting when valve is selected in n03).

Number of steps per second n38 5 stp/s 300 stp/s 300

Start backlash (extra closing steps at 0% opening (in % of n37)) n39 0% 100% 10

Integration time for inner loop (TnT0) n44 10 s 120 s 30

Compensation for spindle play n40 0 stp 100 stp 23 stp

6 = UKV/SKV/VKV/PKV

7 = ETS 6

8 = CCMT 2 – CCMT 8

9 = CCMT 16

10 = CCMT 24

11 = CCMT 30

12 = CCMT 42

13 = CTR

14 = CCMT 0

15 = CCMT 1

Para-

meter

n03 0 15 1

n04 0.5 20 2.0/0.7

n06 0 s 90 s 0

n15 0 sec. 90 sec. 0

n18 0 10 5

n19 0.0 1.0 0.3

n20 0.0 10.0 0.4/3.0

n21 1 2 1

n32 0 % 100 % 100

n37

Min. Max.

- K -

10

(100 stp)

Factory

setting

999

(9990

stp)

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 18

Page 19

Data sheet | Superheat controller type EKD 316, EKD 316C

Menu survey for EKD 316 continued

Function

The menus from either column 1 or column 2 are shown

Parameter

Min. Max.

Miscellaneous

Controller’s address o03 0 240 240

If the valve’s opening degree should be controlled with an external signal, the signal is dened as:

0: no

signal

1: 0 - 20 mA 2: 4 - 20 mA 3: 0 - 10 V 4: 1 - 5 V

o10 0 4 0

Manual control of outputs:

OFF: no manual control

1: Manual control with "o45" enabled

o18 o/0 3 O /0

2: Simulate Alarm o : connection between 24 and 25

3: Simulate Alarm on : connection between 24 and 26

Working range for pressure transmitter – min. value

o20 -1 bar 0 bar -1.0

Working range for pressure transmitter – max. value o21 1 bar

Refrigerant setting

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User def.

14 = R32

15 = R227

16 = R401A

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = 427A

35 = R438A

36 = R513A

37 = R407F

38 = R1234ze

39 = R1234yf

40 = R448A

41 = R449A

42 = R452A

o30 0 42 0

For EKD 316C the default factory setting for parameter o30 is 0 = none refrigerant selected

Manual control of the valve’s opening degree. The function can only be operated if o18 has been set

to "1".

o45 0 % 100 % 0

This function is only for manual operation. It must not be used for as a regulation function.

Selection of control mode:

1= Normal

o56 1 2 1

2 = With inner loop (S media temperature less T0)

Application mode. Menus blanked out so only the shaded menus are seen. See the two columns to

the right.

1: Controlling a valve with an analogue signal

o61 1 2 2 1 2

2: Superheat regulation

Holding current h22 0 % 100 % 20 %

High pressure alarm o99 0 1 0

Overdrive

Open hysteresis is the minimum requested opening degree required before the valve will open. This value cannot

be lower than the Close hysteresis.

Close hysteresis: if the requested opening degree is below this value, the valve will close to 0%. This value cannot

be set higher than the Open hysteresis.

Overdrive enable level. The opening degree needs to be above this value, before the overdrive will become enabled. When the overdrive is enabled the valve will overdrive once it is closed to 0%

Overdrive protection time. The valve will not overdrive until this time has elapsed after the last overdrive. This

prevents too frequent overdrives. The default is 0 meaning that it is o and doesn’t limit overdrives.

Forced overdrive time. The valve is forced to close and overdrive after this time has elapsed. The valve will then

open again to the desired opening degree. The default is 0 meaning it is o and doesn’t force close.

P67 0% 100% 1%

P68 0% 100% 1%

P69 0% 100% 10%

P70 0 hours

P71 0 hours

Service

Analog input (21 - 22) u06 mA (V)

Read status of input DI (20 - 21) u10 on/o

Temperature at S2 sensor u20 °C

Superheat u21 K

Superheat reference u22 K

Read valve’s opening degree u24 %

Read evaporating pressure u25 bar

Read evaporating temperature u26 °C

Temperature at S4 sensor u27 °C

Conguration settings (n03, n37, n38, n39, n40, o03, o30, o56 and o61) available only when regulation is stopped (r12=o).

Factory settings are indicated for standard unit (see code number, page 1). Other code number have customised settings.

200

bar

999

hours

999

hours

Factory

setting

12.0

0

0

Application

choice

menu = o61

1 2

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 19

Page 20

Data sheet | Superheat controller type EKD 316, EKD 316C

Survey of functions

Function Para-

meter

Normal display

The superheat is normally shown.

The opening degree is displayed during manual operation or if the valve is under

analogue control.

Reference

Unit

Here you select whether the controller is to indicate the temperature values in °C or in

°F and pressure values in bar or psig.

If indication in °F is selected, other temperature settings will also switch to Fahrenheit,

either as absolute values or as delta.

The combination of temperature unit and pressure unit is depicted to the right.

Correction of signal from S2

(Compensation possibility through long sensor cable).

Correction of signal from S4

(Compensation possibility through long sensor cable).

Start/stop of refrigeration

With this setting, refrigeration can be started and stopped. Start/stop of refrigeration

can also be accomplished with the external switch function. See also appendix 1.

Alarm

If there is an alarm, the LEDs on the front of the external display will ash if it is connected. The alarm relay in the controller is closed.

Battery alarm

Here it is dened whether the controller is to monitor the voltage from the battery

backup. If there is low voltage, or no voltage, an alarm will be given

Parameter by operation via

data communication

SH/OD%

Units (Menu = Misc.)

r05

0: °C + bar

1: °F + psig

r09 Adjust S2

r10 Adjust S4

r12 Main Switch

Alarm setting

A34 Batt. alarm

Control parameters Injection control

Valve denition for EKD 316.

For EKD 316C refer to section “Stepper motor valve type”

0 = ETS 12½, ETS 25, KVS 15

1 = ETS 50, CCM 10 – CCM 30

2 = ETS 100, CCM 40

3 = ETS 250, KVS 42

4 = ETS 400

5 = user-dened

On using external display EKA 164A, please check page 9 section ETS valve

6 = UKV/SKV/VKV/PKV

7 = ETS 6

8 = CCMT 2 – CCMT 8

9 = CCMT 16

10 = CCMT 24

11 = CCMT 30

12= CCMT 42

13= CTR

14= CCMT 0

15= CCMT 1

P: Amplication factor Kp

If the Kp value is reduced the regulation becomes slower.

I: Integration time Tn

If the Tn value is increased the regulation becomes slower.

D: Dierentiation time Td

The D-setting can be cancelled by setting the value to min. (0).

Max. value for the superheat reference

Min. value for the superheat reference

Warning:

Due to the risk of liquid ow, the setting should not be lower than approx. 2-4 K.

MOP Note:

If no MOP function is required, select pos. O. (A value of 200 corresponds to O)

Startup time for safety signal

If the controller does not obtain a reliable signal within this period of time the controller will try to establish a stable signal in other ways. (A value that is too high may

result in a ooded evaporator).

The value should only be changed by specially-trained sta .

Signal safety during startup

The control function uses the value as a start value for the valve’s opening degree at

each thermostat cut-in. By adaptive control the controller continuously calculates a

new value.

The value should only be changed by specially-trained sta.

Stability factor for regulation of superheat

With a higher value, the control function will allow a greater uctuation of the superheat before the reference is changed. The value should only be changed by speciallytrained sta.

n03 Valve type

n04 Kp factor

n05 Tn sec.

n06 Td sec.

n09 Max SH

n10 Min SH

n11 MOP (bar)

n15 StartUp time

n17 Start OD%

n18 Stability

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 20

Page 21

Data sheet | Superheat controller type EKD 316, EKD 316C

Survey and function (continued)

Function Para-

Damping of amplication near reference value

This setting damps the normal amplication Kp, but only just around the reference

value. A setting of 0.5 will reduce the KP value by half.

The value should only be changed by specially-trained sta.

Amplication factor for the superheat

This setting determines the valve’s opening degree as a function of the change in

evaporating pressure. An increase of the evaporating pressure will result in a reduced

opening degree. When there is a drop-out on the low-pressure thermostat during

startup, the value must be raised slightly. If there is pendling during start-up, the

value must be reduced slightly.

The value should only be changed by specially-trained sta.

Denition of superheat regulation (Ref. section "Operation")

1: Lowest permissible superheat (MSS). Adaptive regulation.

2: Load-dened superheat. The reference is established based on the line formed by

the three points: n09, n10 and n22.

Value of min. superheat reference for loads under 10%

(The value must be smaller than "n10").

Max. opening degree

The valve’s opening degree can be limited. The value is set in %.

Number of steps from 0% to 100% open (User-dened valve, n03 =5)

(Automatic setting when valve is selected in n03).

Spindle stroke speed (number of steps per second)

(Automatic setting when valve is selected in n03).

Integration time for the inner loop gain

Used only when o56 = 2

The value should only be changed by specially-trained sta.

meter

n19 Kp Min

n20 Kp T0

n21 SH mode

n22 SH Close

n32 ETS OD% Max

n37 Max. steps (100 to 9990 step)

n38 Steps/sec (5 to 300 step/sec)

n44 TnT0 sec

Parameter by operation via

data communication

Miscellaneous

Address/data communication

The controller must always have an address. The factory-set address is 240.

When an external display is connected, the display itself will nd the address of the

controller so that communication can take place.

Note:

A display and a system unit must not be connected at the same time.

The display will not be able to communicate in this situation.

If the controller is to be part of a network with other controllers and a system unit, the

controller‘s address must be within the range 1 to 200.

This address must EITHER be set via a display before it is connected to the data communication and a scan of the network is performed

OR the network is connected and a scan is performed. The address is then set afterwards. A new scan is performed so that the new address is known.

Requirements for the installation and data communication cable are discussed in the

separate document no. "RC8AC".

Application mode

1: The controller receives signals from another controller and must control the valve’s

opening degree.

2: Superheat regulation.

Input signal for external control of the valve‘s opening degree

Only used if o61 is set to 1.

Denition of the signal's range.

0: No signal

1: 0-20 mA / 2: 4-20 mA / 3: 0-10 V / 4: 1-5 V

(At the lower value the valve will be closed. At the upper value the value will be fully

open. There is a linear relationship between the signal and the opening degree. The

height of the valve is not taken into account.)

The controller can be operated via the

system unit and AK service tool.

It cannot be operated via AKM type

system software.

o03 Unit addr.

The address is set between 0 and 200.

(When the address is set, the system

the system unit’s scan function should

be activated)

o61 Appl. mode

o10 AI type

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 21

Page 22

Data sheet | Superheat controller type EKD 316, EKD 316C

Survey and function (continued)

Function Para-

meter

Manual control of outputs

For service purposes the ETS-output and alarm relay outputs can be forced

However, only when regulation has been stopped.

OFF: No override

1: Manual control via o45 is enabled

2: The alarm relay releases so that there is a connection between 24 and 25 (= alarm)

3: The alarm relay picks up so that there is a connection between 25 and 26 (= no alarm)

Manual control of the ETS valve

The valve‘s opening degree can be set manually.

However, it does require "o18" to be set to "1", "2" or "3".

This function must only be used for manual operation. It must not be used for external

control.

Working range for pressure transmitter

Depending on the application, a pressure transmitter with a given working range is

used.

For the range of (-1 to 12 bar), the min. value is set to -1 bar.

For the range of (-1 to 12 bar), the max. value is set to 12 bar. o21 MaxTransPres.

Selection of control algorithm

Depending on the application, control can be carried out based on dierent parameters.

The two possibilities are shown in section "Type of regulation".

1=normal control (single loop)

2=with inner loop regulation and S4 temperature less T0 (double loop)

Note:

* After o56 is changed, the controller must be switched o and powered up again.

Refrigerant setting

Before refrigeration can be started, the refrigerant must be dened. You can select

the following refrigerants:

1 = R12

2 = R22

3 = R134a

4 = R502

5 = R717

6 = R13

7 = R13b1

8 = R23

9 = R500

10 = R503

11 = R114

12 = R142b

13 = User def.

14 = R32

15 = R227

16 = R401A

17 = R507

18 = R402A

19 = R404A

20 = R407C

21 = R407A

22 = R407B

23 = R410A

24 = R170

25 = R290

26 = R600

27 = R600a

28 = R744

29 = R1270

30 = R417A

31 = R422A

32 = R413A

33 = R422D

34 = 427A

35 = R438A

36 = R513A

37 = R407F

38 = R1234ze

39 = R1234yf

40 = R448A

41 = R449A

42 = R452A

For EKD 316C the default factory setting for parameter o30 is 0 = none refrigerant selected

( Warning: Incorrect selection of refrigerant may cause damage to the compressor).

Parameter by operation via

data communication

o18 Manual ctrl

o45 Manual ETS OD%

o20 MinTransPres.

o56 Reg. type *

o30 Refrigerant

Service Service

A number of controller values can be printed for use in a service situation

Read value of external current signal/voltage signal (Ext.Ref.) u06 Analogue input

Read status of input DI (start/stop input) u10 DI

Read the temperature at the S2 sensor u20 S2 temp.

Read superheat u21 SH

Read the control’s actual superheat reference u22 SH ref.

Read the valve’s opening degree u24 OD%

Read evaporating pressure u25 Evap. pres. P

Read evaporating temperature u26 Evap.Press.T

e

e

Read the temperature at the S4 sensor u27 S4 temp.

-- DO1 Alarm

Read status of alarm relay

Operating status

The controller’s operating status can be called forth by a brief (1s) activation of the

upper button. If a status code exists, it will be shown. (Status codes have lower prior-

EKC State

(0 = regulation)

ity than alarm codes. This means that status codes cannot be seen if there is an active

alarm code.

The individual status codes have the following meanings:

S10: Refrigeration stopped by the internal or external start/stop. 10

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 22

Page 23

Data sheet | Superheat controller type EKD 316, EKD 316C

Appendix II

General information to MODBUS

communication via a PLC etc.

* Baudrate : 19200

* EKD Address : 240

* Polarity A-A and B-B

* Termination with 120 ohm resistor

Some parameters have what is called a "cong lock". This means

that they can only be changed when the main switch of the EKD

is set to OFF (r12 = 0). This applies for instance to the type of

refrigerant (o30). So if you want to change the refrigerant, the

main switch (r12) must rst be set to 0, then the refrigerant type

(o30) can be changed.

The following parameters require the main switch to be OFF:

n03 Valve type

n37 Max steps

n38 Max steps/sec

o03 Unit address

o30 Refrigerant

o56 Regulation type

o61 Application mode

Please refer to the manual for descriptions of these parameters.

It should be possible to change all other parameters while the unit

is running (regulation parameters etc.).

Example:

EKD 316 / EKD 316C as simple ETS valve driver function with the

following settings:

• PNU 117 [0] r12 Main switch = 0

• PNU 2075 [1] o18 Manual mode

• PNU 2064 [OD% ] o45 Manual ETS OD% (replace 0-10V signal)

• PNU 3032 [262] n37 Max. steps 2620

• PNU 3033 [250] n38 Steps pr. sec 250

• EKD 316 / EKD 316C address : 240

• PNU 2064 will go back to 0% at power o as the only one

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 23

Page 24

Data sheet | Superheat controller type EKD 316, EKD 316C

EKD 316 – Parameter identication (modbus)

Explanations: Parameter – The parameter name and abbreviation

Parameter PNU R/W Cong lock Min Max Default Actual value Scale

Injection control (1)

n04 Kp factor 3003 R/W 0.5 20.0 2.0 20 *10

n05 Tn seconds 3004 R/W 30 600 120 120 *1

n06 Td seconds 3005 R/W 0 90 0 0 *1

n09 Max SH 3015 R/W 1.0 100 10.0 100 *10

n10 Min SH 3021 R/W 1.0 100 6.0 60 *10

n11 MOP 3013 R/W 0.0 200.0 20.0 200 *10

n15 Start time 3017 R/W 1 90 0 0 *1

n17 MinOdAtStart 3012 R/W 0 100 0 0 *1

n18 Stability 3014 R/W 0 10 5 5 *1

n19 Kp min. 3024 R/W 0.0 1.0 0.3 3 *10

n20 Kp T0 3025 R/W 0.0 10.0 0.4 4 *10

n21 SH mode 3026 R/W 1 2 1 1 *1

n22 SH close 3027 R/W 1.0 15.0 4.0 40 *10

n32 ETS OD% Max 3023 R/W 0 100 100 100 *1

n44 TnT0 sec. 3039 R/W 10 120 30 30 *1

o56 Reg. type 2076 R/W x 1 2 1 1 *1

Motor(2)

n37 Max steps 3032 R/W x 10 999 262 262 *1

n38 Max StepsSec 3033 R/W x 5 300 300 300 *1

n39 Start backlash 3034 R/W x 0 100 10 10 *1

n40 Backlash 3035 R/W x 0 100 23 23 *1

n03 Valve type 3002 R/W x 0 15 1 1 *1

N56 Motor current 3051 R/W 0 600 0 0 *1

h22 Holding current 2198 R/W x 0 100 0 0 *1

Alarm settings (3)

A34 Battery low 10035 R/W 0 1 0 0 *1

Miscellaneous (11)

r05 Temp.unit 105 R/W 0 1 0 0 *1

r09 Adjust S2 113 R/W -10.0 10.0 0.0 0 x10

r10 Adjust S3 114 R/W -10.0 10.0 0.0 0 x10

o20 MinTransPres 2034 R/W -1.0 0.0 0.0 0 *10

o21 MaxTransPres 2033 R/W 1.0 200.0 12.0 120 *10

o30 Refrigerant 2551 R/W x 0 42 0 0 *1

o18 Manual ctrl. 2075 R/W 0 3 0 0 *1

o45 Manual OD% 2064 R/W 0 100 0 0 *1

o99 Enable high press. alarm 2199 R/W 0 1 0 0 *1

Service (12)

o61 Appl.mode 2077 R/W x 1 2 2 2 *1

u10 DI1 status 2002 R 0 1 0 0 *1

o10 AI type 2027 R/W 0 4 0 0 *1

u06 Analog input 2504 R 0.0 30.0 0.0 0.0 *10

--- AL/Light rel 2509 R 0 1 0 0 *1

--- Reset alarm 2046 R/W 0 1 0 0 *1

--- Rfg.Fac.A1 2548 R/W 8000 12000 10428 10428 *1

--- Rfg.Fac.A2 2549 R/W -4000 -1000 -2255 -2255 *1

--- Rfg.Fac.A3 2550 R/W 2000 3000 2557 2557 *1

Alarms (13)

--- Standby 20000 R 0 1 0 0 *1

--- EKC Error 20001 R 0 1 0 0 *1

--- S2 Error 20002 R 0 1 0 0 *1

--- S3 Error 20003 R 0 1 0 0 *1

--- Pe inp.error 20004 R 0 1 0 0 *1

--- AI inp.error 20005 R 0 1 0 0 *1

--- No Rfg. Sel. 20006 R 0 1 0 0 *1

--- Battery low 20008 R 0 1 0 0 *1

Danfoss only (14)

o03 Unit addr. 2008 R/W x 1 240 240 240 *1

No text (15)

r12 Main switch 117 R/W 0 1 0 0 *1

u20 S2 temp. 2537 R -200.0 200.0 0.0 0.0 *10

u21 Superheat 2536 R 0.0 100.0 0.0 0.0 *10

u22 SuperheatRef 2535 R 0.0 100.0 0.0 0.0 *10

u24 Opening % 2542 R 0 100 0 0 *1

u25 EvapPress P

u26 EvapTemp T

u27 Temp. S3 2545 R -200.0 200.0 0.0 0.0 *10

--- EKC State 2007 R 0 100 0 0 *1

e

e

PNU – The Parameter Number. Note: This is equivalent to the modbus register number (modbus address + 1)

R/W – R means read only, RW means it can be changed

Cong lock – If the parameter is cong locked it means that the value can only be changed when the main switch is o

Min. – The minimum value of the parameter

Max. – The maximum value of the parameter

Default – The default value of the parameter (factory setting)

Actual value – Values are read/written as 16 bit integer values without decimals. This is the default value as read via modbus

Scale – This shows the scaling factor of the value. *1 means that there is no scaling. *10 means that the read value is

10 times larger than the actual value.

2543 R -200.0 200.0 0.0 0.0 *10

2544 R -200.0 200.0 0.0 0.0 *10

© Danfoss | DCS (sw) | 2016.11

DKRCC.PD.RR0.B2.02 | 24

Page 25

Data sheet | Superheat controller type EKD 316, EKD 316C

EKD 316C – Parameter identication (Modbus)

Lock - the value can only be changed when the main switch is o

PNU - equivalent to to the modbus register no. (modbus adress + 1).

Actual value

Values are read/written as 16 bit integer values without decimals. This is the default value as read via modbus.

Scale

This shows the scaling factor of the value. *1 means that there is no scaling. *10 means that the read value

is 10 times larger thanthe actual value.

Parameter PNU R/W Lock Min. Max. Default

Regulation Control

r12 Main switch (O = 0 / On = 1)

o10 AI type (0: no signal

1: 0-20 mA, 2: 4-20 mA

3: 0-10 V, 4: 1-5 V)

o61 should be set to 1 in order to

use this feature

o18 Manual control 2075

o45 Manual OD%

o56 Reg. type

1= Normal

2 = With inner loop

o61 Appl.mode

1: Valve driver mode using

analogue signal

2: Superheat regulation

117 R/W - 0 1 0 0 *1

2027 R/W - 0 4 0 0 *1

R/W - 0 3 0 0 *1

2064 R/W - 0 100 0 0 *1

2076 R/W x 1 2 1 1 *1

2077 R/W x 1 2 2 2 *1

Actual

value

Scale

Valve

n03 Valve type

Ref. valve overview

n32 ETS OD% Max

n37 Max. steps [Stp]

n38 Max. Stp/Sec (Hz)

n39 Start backlash [%]

n40 Backlash [Stp]

n56 Motor current (mA RMS)

h22 Holding current [%]

3002 R/W x 0 17 16 1 *1

3023 R/W - 0 100 100 100 *1

3032 R/W x 10 999 60 60 *1

3033 R/W x 5 300 160 160 *1

3034 R/W x 0 100 10 3 *1

3035 R/W x 0 100 0 0 *1

3051 R/W x 0 600 0 0 *1

2198 R/W x 0 100 0 0 *1

Refrigerant

o30 Refrigerant

(Ref. appendix 1)

---

Rfg.Fac.A1 2548 R/W - 8000 - 10428 10428 *1

---

Rfg.Fac.A2 2549 R/W - -4000 - -2255 -2255 *1

---

Rfg.Fac.A3 2550 R/W - 1000 3000 2557 2557 *1

2551 R/W x 0 42 0 0 *1

Sensors

r05

Temp.unit 105 R/W - 0 1 0 0 *1

r09

Adjust S2 [K] 113 R/W - -1 10 0 0 x10

r10

Adjust S4 [K] 114 R/W - -1 10 0 0 x10

o20 Min. Trans. Pres.

(bar relative)

o21 Max. Trans. Pres.

(bar relative)

o99

Enable high pressure alarm 2199 R/W - 0 1 0 0 *1

2034 R/W - -1 0 -1 -10 *10