User Guide

Interface

EKC 366

The controller is used for regulating a valve in

a refrigerating system - for example in

connection with:

• Long-term storage of fruits and vegetables

• Refrigerating plant

• Brewery systems

• Processing plant

Application Here the controller has been specially

designed for the following functions:

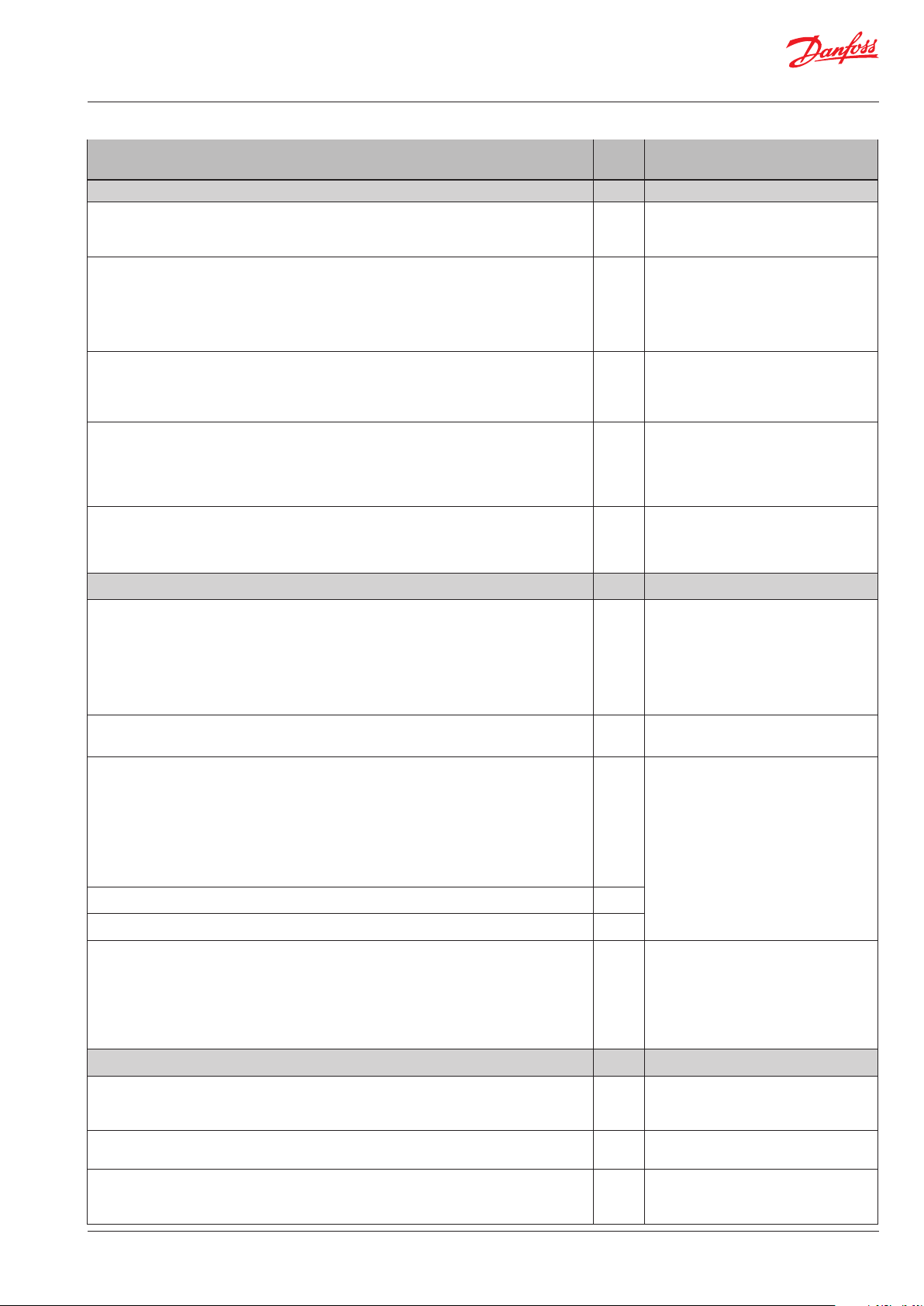

Maintenance of a constant

evaporating pressure

A temperature sensor in the valve’s actuator will

regulate its temperature. This temperature is

an indication of the pressure in the valve, and

the interface module will keep this temperature

constant.

The media temperature is regulated

by a PLC or similar device

Here the interface module receives a variable

signal from the PLC and will subsequently

regulate the valve, so that the refrigeration will

be as accurate as possible.

PLC

© Danfoss | DCS (ADAP-KOOL®) |2015-11

DKRCI.PS.RP0.C1.02 | 1

User Guide | Interface, EKC 366

System

The controller must always be used in conjunction with a pilot

valve of the types shown here.

The most commonly used one is pilot valve CVQ in conjunction

with main valve PM3 (sketched out above).

Valve types:

- CVQ + PM

- KVQ

- TQ

- PHTQ

- TEAQ

- CVMQ

Function

The valve constantly receives feedback of the pressure in the

evaporator. Whatever the variations in the suction pressure from

the compressor, this feedback will produce the result that the

evaporating pressure is kept constant.

In conjunction with the controller, an electronic constant-pressure

valve is thus obtained.

Inserted between the controller and the actuator is a so-called

inner regulating loop. This loop will - via an NTC resistance - constantly control the temperature in the actuator.

In an application where a PLC or similar device is used for regulating a media temperature, the regulating system will in this way be

supplied with an outer regulating loop - which will result in great

regulating accuracy.

"Q valve"

PLC

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 2

User Guide | Interface, EKC 366

Survey of functions

Function Para-

meter

Temperature regulation Actuator temperature

Display of valve temperature

The display constantly shows the valve's temperature.

The display is ltered over a period of approx. 10 seconds

Valve’s basic temperature reference

This temperature setting is the valve’s basic setting. At this value no signal must be

received from an external regulation.

The setting value is taken from one of the curves shown and may be ne-adjusted later when the valve has reached the temperature (read the manometer in the system).

(Push both buttons simultaneously to set the menu)

Temperature unit

Set here whether the controller is to show the temperature values in °C or in °F. If indication in °F is selected, other temperature settings will also change over to Fahrenheit, either as absolute values or as delta values.

Input signal’s temperature inuence

This setting determines how much the input signal has to raise the temperature in

the valve. You should aim at selecting the value, so that the valve can close at the

highest occurring evaporating pressure when the input signal is maximum (value to

be set in Kelvin)

Reference

The valve’s temperature is regulated on the basis of the basic setting plus the signal

from the external regulation. (Reference = SP Temp + percentage of "r06".)

The reference can be seen when you push the lower of the two buttons

Sundry congurations Miscellaneous

Parameter by operation via data

communication

- Actuator temp.

- SP Temp.

r05 Temp. unit (°C=0, °F=1)

(In AKM only °C is displayed, whatever

the setting).

r06 Ext.Ref.oset K

- Actuator Ref.

External signal

Here you set the signal that is to be connected to the controller.

0: no signal

1: 4-20 mA

2: 0-20 mA

3: 0-10 V

4: 2-10 V

Frequency

Set network frequency

Data communication

If the controller is built into a network with data communication, it must have an

address, and the master gateway of the data communication must then know this

address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

been completed.

This installation is mentioned in a separate document “RC.8A.C”.

The address is set between 1 and 60 o03

The address is sent to the gateway when the menu is set in pos. ON o04

Language

This setting is only required when data communication is connected to the controller.

Settings: 0=English, 1=German, 2=French, 3=Danish, 4=Spanish, and 6= Swedish

When the controller is operated via data communication, the texts in the right-hand

column will be shown in the selected language.

When you change the setting to an other language you must activate o04 before "the

new language" can be visible from the AKM program.

Service

o10 AI Type

o12 50 / 60 Hz

o11 Language

(50=0, 60=1)

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigeration controls.

The signal will be constantly updated. If you wish to follow the signal beyond the

20 seconds, the time-out period, push one of the two buttons before the time-out

period expires

External current signal

Here you can read the value of the current signal received by the controller at its input

External voltage signal

Here you can read the value of the voltage signal received by the controller at its

input

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

u06 AI mA

u07 AI Volt

DKRCI.PS.RP0.C1.02 | 3

User Guide | Interface, EKC 366

Operation

Display

The values will be shown with three digits, and with a setting you

can determine whether they are to be shown in °C or in °F.

LED’s on the front panel

There is one LED on the front panel which will light up when

power is sent to the pilot valve.

There are furthermore three LED’s which will ash if there is an

error in the regulation. In this situation you can show the error

code on the display and cut out the alarm by giving the upper

button a brief push.

The controller can give the following messages:

E1 Errors in the controller

E11 Valve’s actuator temperature outside its range

E12 Input signal outside its range

The buttons

When you want to change a setting, the two buttons will give you

a higher or lower value depending on the button you are pushing. But before you change the value, you must have access to the

menu. You obtain this by pushing the upper button for a couple

of seconds - you will then enter the column with parameter codes.

Find the parameter code you want to change and push the two

buttons simultaneously. When you have changed the value, save

the new value by once more pushing the two buttons simultaneously.

Menu survey

Function

Read valve’s actual temperature (standard display) -

Set valve’s basic temperature reference - 40.0°C 140°C

Read valve’s regulation reference -

Select temperature unit (°C/°F) r05 °C °F

Input signal’s temperature inuence r06 -99.9 K 99.9 K

Controller’s address o03* 1 60

ON/OFF switch (service-pin message) o04* - -

Dene input signal

0: no signal

1: 4 - 20 mA

2: 0 - 20 mA

3: 0 - 10 V

4: 2 - 10 V

Language (0=English, 1=German, 2=french, 3=Danish,

4=Spanish, 6=Swedish). When you change this setting

you must also activate o04.

Set supply voltage frequency o12 50 Hz 60 Hz

Service information

Read value of external current signal u06

Read value of external voltage signal u07

*) This setting will only be possible if a data communication module has been

installed in the controller.

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep both buttons depressed at the same time as you recon nect the supply voltage

Parameter

o10 0 4

011* 0 6

SW =1.2x

Min. Max.

°C

°C

mA

V

Gives access to the menu

Gives access to changes

Saves a change

Examples of operations

Set the valve’s basic temperature reference

1. Push the two buttons simultaneously

2. Push one of the buttons and select the new value

3. Push both buttons again to conclude the setting

Read the valve’s regulating reference

1. Push the lower button

(After approx. 20 seconds the controller automatically returns

to its setting, and it again shows the valve’s actual temperature)

Set one of the other menus

1. Push the upper button until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push both buttons simultaneously until the parameter value is

shown

4. Push one of the buttons and select the new value

5. Push both buttons again to conclude the setting

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 4

User Guide | Interface, EKC 366

Valve’s working temperature

Without external signal

The working temperature must be set on the basis of one

of the following curves. Find the actuator temperature corresponding to the required evaporating temperature (push).

Set the value in the controller as mentioned under “Set the

valve’s basic temperature reference”.

With external signal

If the valve is to be operated with an external signal, two settings have to be made. One is as mentioned to the left, and the

other determines how much the signal must be able to raise the

temperature in the valve. This value is also read on one of the following curves.

Set the value in the r06 menu.

If the set value is too low, the valve will not be able to close/

open fully.

CVQ KVQ

TQ

All the curves shown are approximate.

Example

CVQ type = 0-6 bar

Refrigerant = R

A constant evaporating temperature or input pressure to the valve of -9°C (2 bar) is

required.

According to the CVQ curve this will require a temperature in the actuator of 80°C.

Set the valve’s basic temperature reference at 80°C.

When the valve has reached its working temperature, it may be necessary to neadjust the setting from the system’s manometer.

717

CVMQ

The two curves are shown with the valve’s spring setting equal-ling the factory

setting. If the spring setting is changed to a higher pressure, the curve will be

displaced correspondingly to a higher temperature.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 5

User Guide | Interface, EKC 366

Data

Supply voltage

Power consumption

Input signal

Actuator

Data communication

Ambient temperature

Enclosure IP 20

Weight 300 g

Mounting DIN rail

Display LED, 3 digits

Terminals max. 2.5 mm2 multicore

Approvals

24 V a.c. +/-15% 50/60 Hz, 80 VA

(the supply voltage is galvanically separated

from the input and output signals)

Controller

Valve

4-20 mA, 0-20 mA, 0-10V d.c. or

2-10 V d.c.

Input

Output

Possible to connect a data communication

module

During operation

During transport

EU Low Voltage Directive and EMC demands re

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 607302-9

EMC-tested acc. to EN 50081-1 and EN 50082-2

5 VA

75 VA

Temperature signal

from sensor in actuator

Pulsating 24 V a.c. to

actuator

-10 - 55°C

-40 - 70°C

Ordering

Type Function Code No.

EKC 366 Interface module 084B7076

EKA 173

EKA 174

Valves: Kindly refer to catalogue RK0YG

Data communication module (ac-

cessories), (FTT 10 module)

Data communication module (ac-

cessories), (RS 485 module)

with galvanic separation

084B7092

084B7124

Connections

Necessary connections

Terminals:

25-26 Supply voltage 24 V a.c. 80 VA

17-18 Signal from NTC sensor in valve

23-24 Supply to valve’s PTC resistance

Control signal, if applicable (see also o10)

Either terminals:

15-16 Voltage signal

or

18-19 Current signal

Data communication, if applicable

Terminals:

3-4 Mount only, if a data communication module has been

mounted.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC...

Data communication

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 6

User Guide | Interface, EKC 366

Data communication

This page contains a description of a few of the possibilities you

will have when the controller is provided with data communication.

Examples

Each controller is provided

with a plug-in module.

The controllers are then connected to a two-core cable.

Up to 60 controllers may be

connected to one cable.

This cable is also connected to

a gateway type AKA 243.

This gateway will now control

the communication to and

from the controllers.

It will collect temperature values and it will receive alarms.

When there is an alarm the

alarm relay will be activated for

two minutes

If you want to know more about operation of controllers via PC,

you may order additional literature.

The gateway can now be connected to a modem.

When an alarm occurs from

one of the controllers, the

gateway will - via the modem

- make a phone call to the

service company.

At the service company a

modem, gateway and PC

with system software type

AKM have been installed.

All the controllers’ functions

can now be operated from

the various menu displays.

The programme will for

example upload all the collected tempera ture values

once a day.

Example of menu display

Measurements are shown at

one side and settings at the

other.

You will also be able to see the

parameter names of the functions on page 3.

With a simple change-over the

values can also be shown in a

trend diagram.

If you prefer to see the earlier

temperature measurements,

you may upload a log collection.

Alarms

If the controller is extended

with data communication, it

will be possible to dene the

importance of the transmitted

alarms.

The importance is dened with

the setting: 1, 2, 3 or 0. When

the alarm then arises at some

time, it will result in one of the

following activities:

1 = Alarm

The alarm message is sent o

with alarm status 1. This means

that the gateway that is the

master in the system will have

its alarm relay output activated

for two minutes. Later, when

the alarm ceases, the alarm

text will be retransmitted, but

now with status value 0.

2 = Message

The alarm text is transmitted

with status value 2. Later, when

the “message” lapses, the alarm

text is retransmitted, but now

with status value 0.

3 = Alarm

As “1”, but the master gateway’s

relay output is not activated.

0 = Suppressed information

The alarm text is stopped at

the controller. It is transmitted

nowhere.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 7

User Guide | Interface, EKC 366

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DCS (ADAP-KOOL®) | 2015-11

DKRCI.PS.RP0.C1.02 | 8

Loading...

Loading...